Internal-swelling pipe beveling machine

A beveling machine and internal expansion technology, which is used in metal processing machinery parts, milling machine equipment details, metal processing equipment, etc., can solve problems such as unbalanced station installation, imprecise machine as a whole, and inaccurate automatic feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

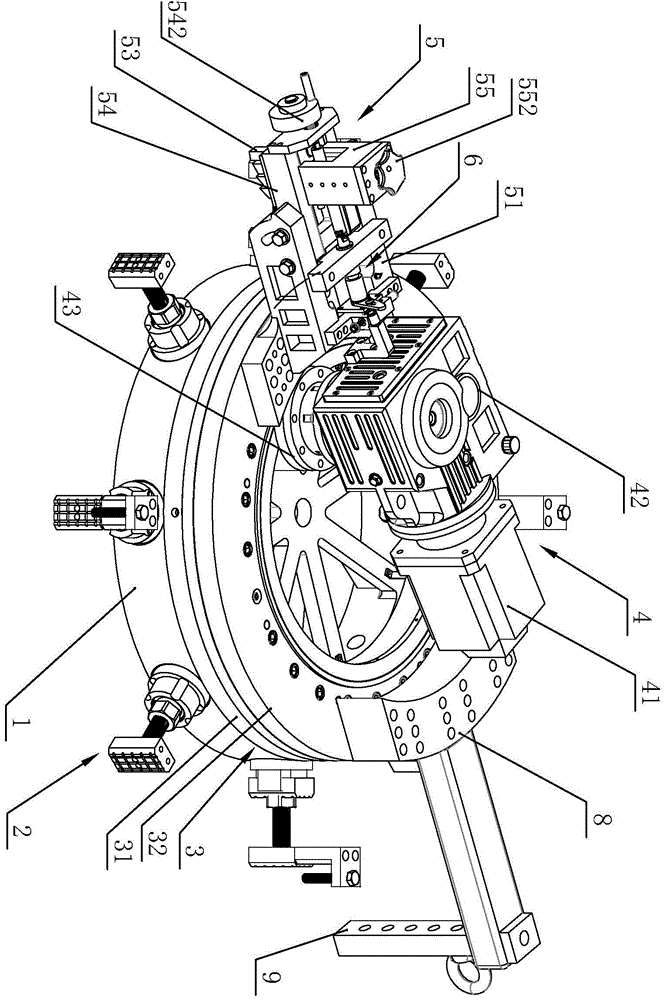

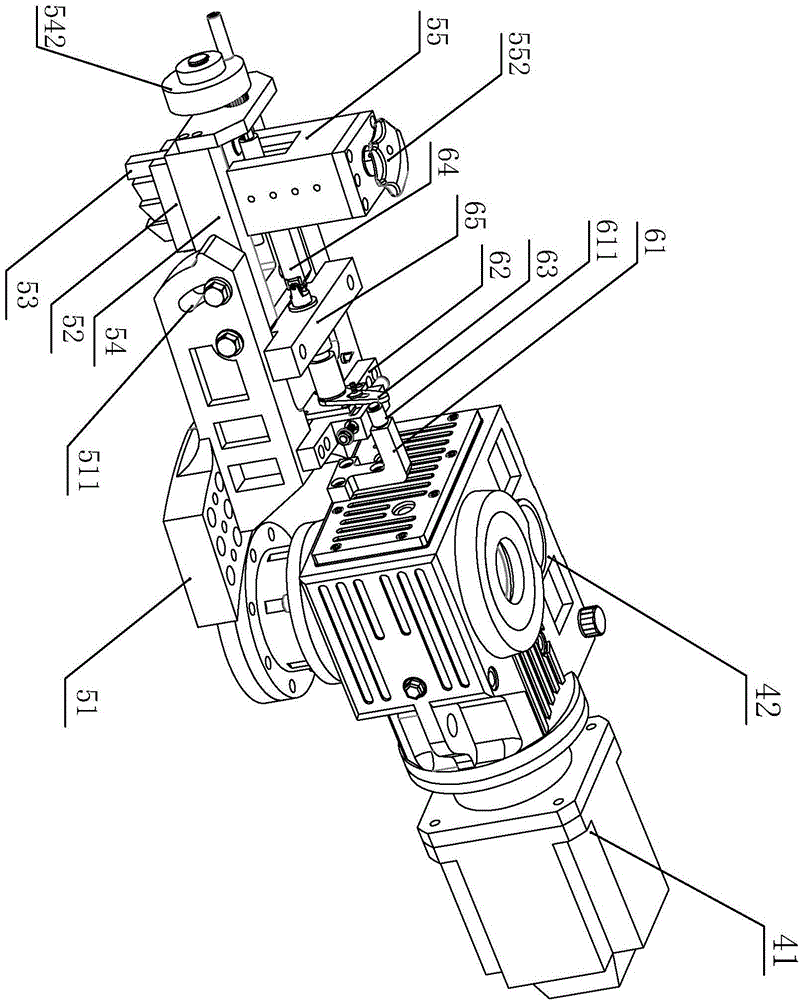

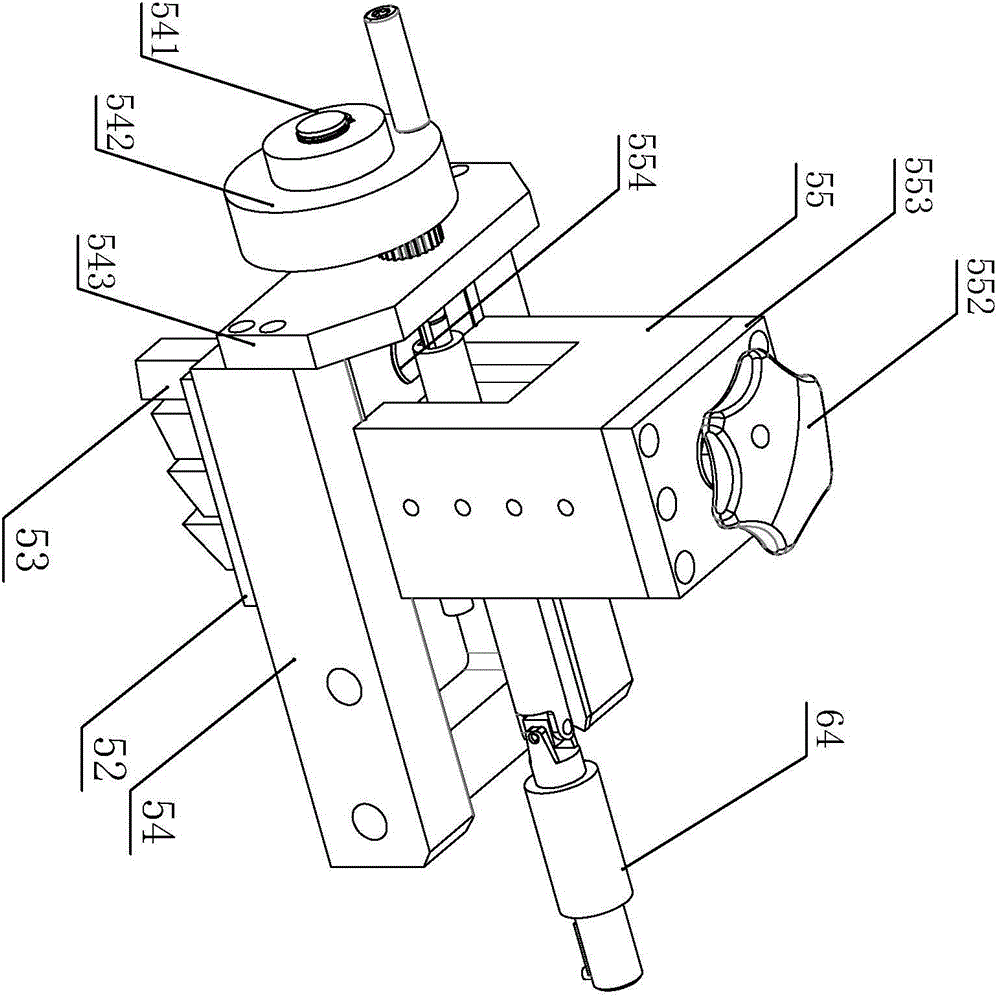

[0031] Such as Figure 1-Figure 10 as shown in Figure 1-Figure 6 As shown, this specific embodiment is a kind of internal expansion type pipe beveling machine. Including machine base 1, tensioning device 2, rotating device 3, power device 4, tool holder adjusting device 5 and tool holder progressive device 6, rotating device 3 includes rotating bearing 31 and mounting plate 32, rotating bearing 31 is a cross roller bearing , the cross roller bearing outer ring 312 is fixedly connected to the machine base 1 by bolts, the cross roller bearing inner ring 311 is fixedly connected to the mounting plate 32 by bolts, the mounting plate 32 is an annular internal gear, and the power unit 4 includes a servo motor 41 and The reduction box 42, the servo motor 41 and the reduction box 42 are in transmission cooperation, and a gear box 43 is arranged between the reduction box 42 and the mounting plate 32, and the mounting plate 32 and the gear box 43 are geared in cooperation.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com