Three-jaw chuck

A three-jaw chuck and chuck technology, applied in the direction of the chuck, can solve the problems of loose and slippery blanks, affecting the qualification rate of lathes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

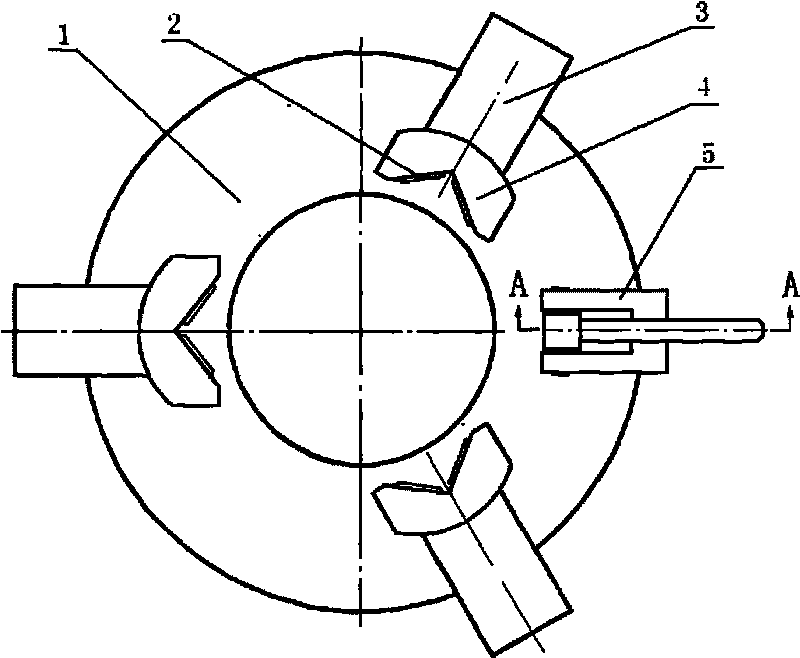

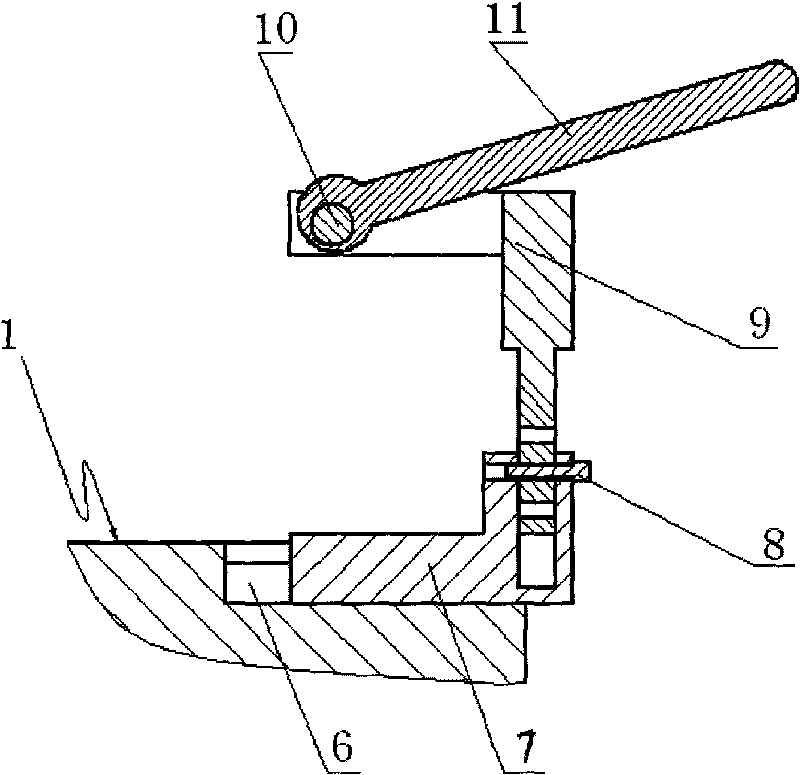

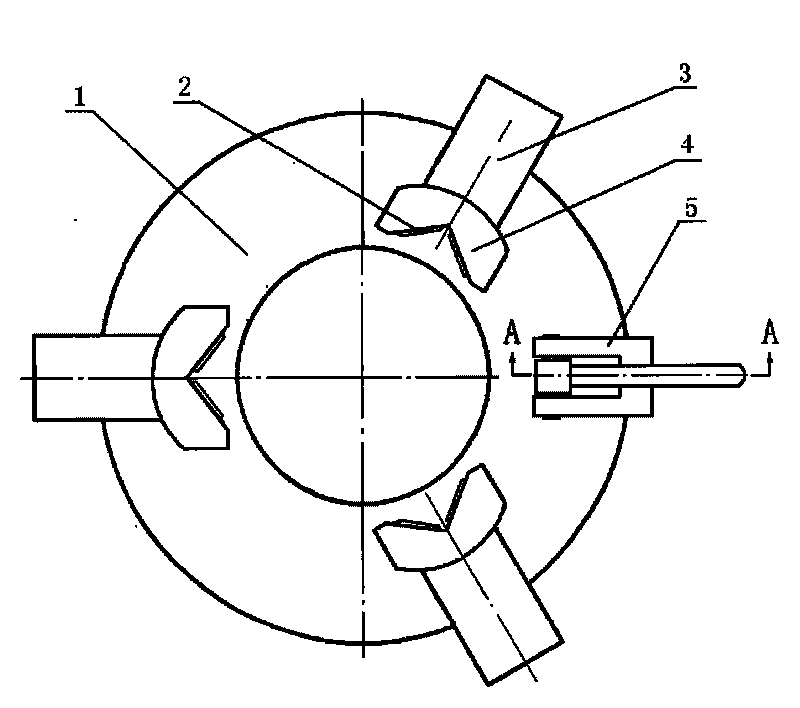

[0013] like figure 1 , figure 2 As shown, a three-jaw chuck includes a chuck body 1 and three jaws of the same structure. The chuck body 1 is provided with a workpiece pressing mechanism 5, and the workpiece pressing mechanism 5 includes a frame-shaped sliding The seat, the small shaft 10 and the eccentric hand wheel 11 rotating around the small shaft 10, the frame-shaped sliding seat has an upper opening plate 9 and an integrated lower sliding bar 7 parallel to the upper opening plate 9, the frame-shaped sliding seat has The outer side of the lower sliding bar 7 of the seat is provided with a longitudinal rectangular hole, and the upper opening plate 9 of the frame-shaped sliding seat has a downward extending support bar extending into the longitudinal rectangular hole of the lower sliding bar 7, and the support of the upper opening plate 9 The bar is provided with a plurality of spaced horizontal through holes, the lower sliding bar 7 and the supporting bar of the upper op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com