Patents

Literature

58results about How to "Reduce grinding heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

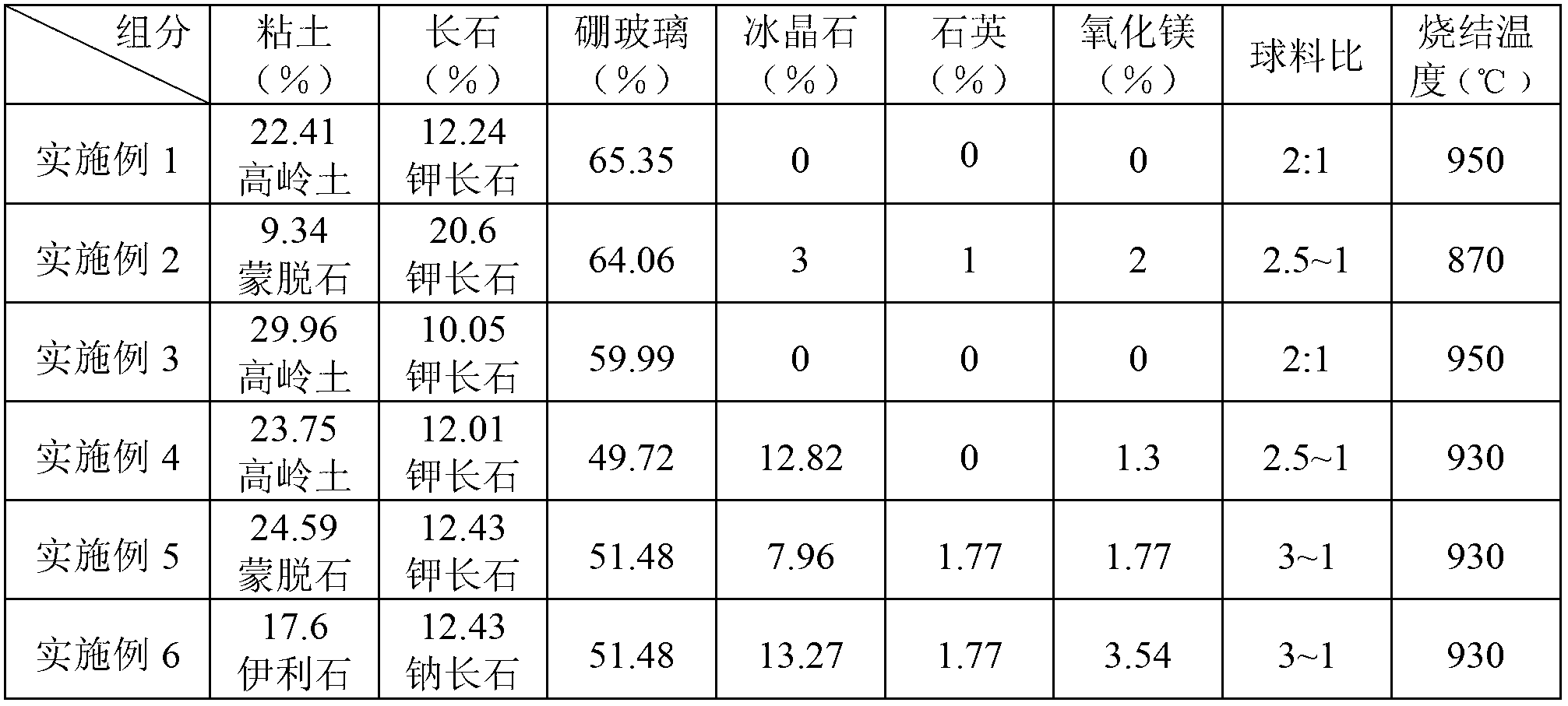

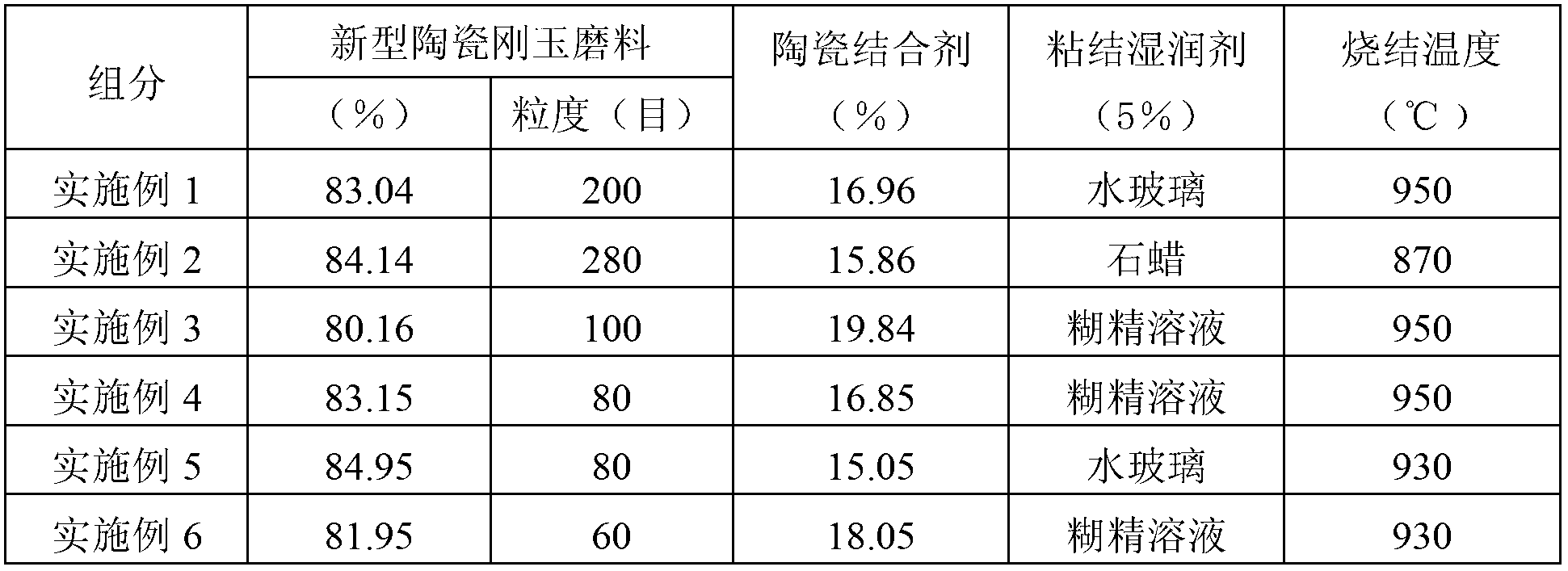

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Resin grinding wheel and manufacturing method thereof

ActiveCN102343560AReduce wearAvoid cloggingBonded abrasive wheelsGrinding devicesPyriteGrinding wheel

The invention provides a resin grinding wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin grinding wheel solves the problem that sulfur dioxide generated by pyrite mine of the traditional resin grinding wheel has corrosiveness. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in parts by weight: 140-200 parts of abrasive material, 50-65 parts of phenolic resin powder, 10-20 parts of phenolic resin liquid, 10-20 parts of quicklime powder, 12-25 parts of pyrite mine powder and 5-10 parts of cryolite powder. The invention also provides a manufacturing method of the resin grinding wheel. According to the manufacturing method, the content of sulfur dioxide generated in the processing process is reduced by using the quicklime powder for reacting with the sulfur dioxide.

Owner:NINGBO DAHUA GRINDING WHEEL

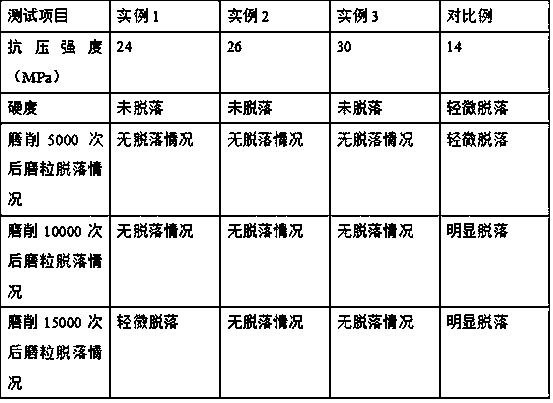

Preparation method of high-strength durable porous diamond grinding wheel

InactiveCN107791163ANot easy to fall offIncreased durabilityAbrasion apparatusGrinding devicesPorositySilicon dioxide

The invention discloses a preparation method of a high-strength durable porous diamond grinding wheel, and belongs to the technical field of grinding wheel preparation. Silicon dioxide, aluminum oxide, zirconium oxide and boric acid are used as main raw materials for ball milling, melting, quenching, secondary ball milling and drying to obtain ceramic bonding agent powder; the crystal interface energy is high, so that abrasives of the grinding wheel are not easy to fall during grinding, and the durability, namely the service life of the grinding wheel is improved; a bonding agent of film coating diamond abrasives is in a liquid state at a sintering temperature, and is filled in capillary holes between the abrasives to accelerate compactness of the grinding wheel; meanwhile, through a protection effect of titanium dioxide films on the surfaces of the abrasives, the exhausting of gas in the sintering process of the grinding wheel is influenced, and the service life of the grinding wheelis prolonged; air holes can accommodate grinding chips; the edge rate of the grinding wheel in the grinding process is higher, so that the grinding efficiency is improved; and through a proper porosity, the holding force of the diamond grinding wheel to the bonding agent is improved, so that the strength of diamond is improved, and the application prospect is broad.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

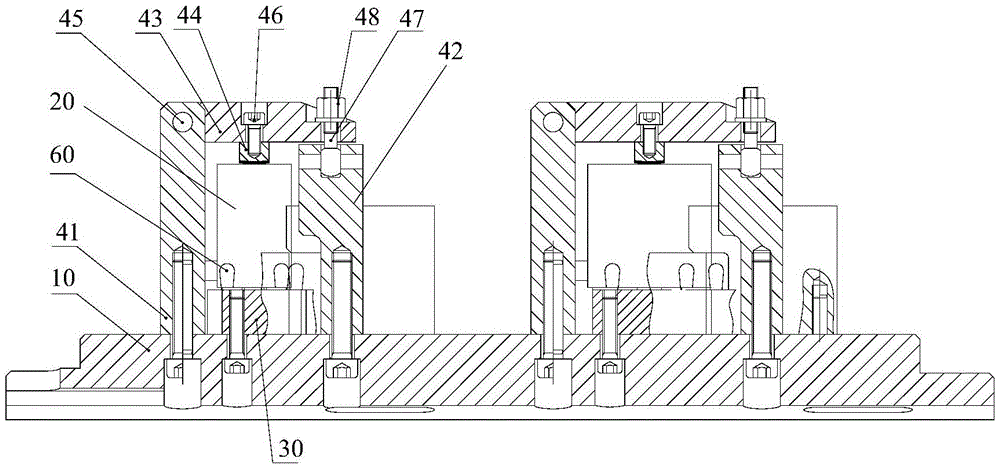

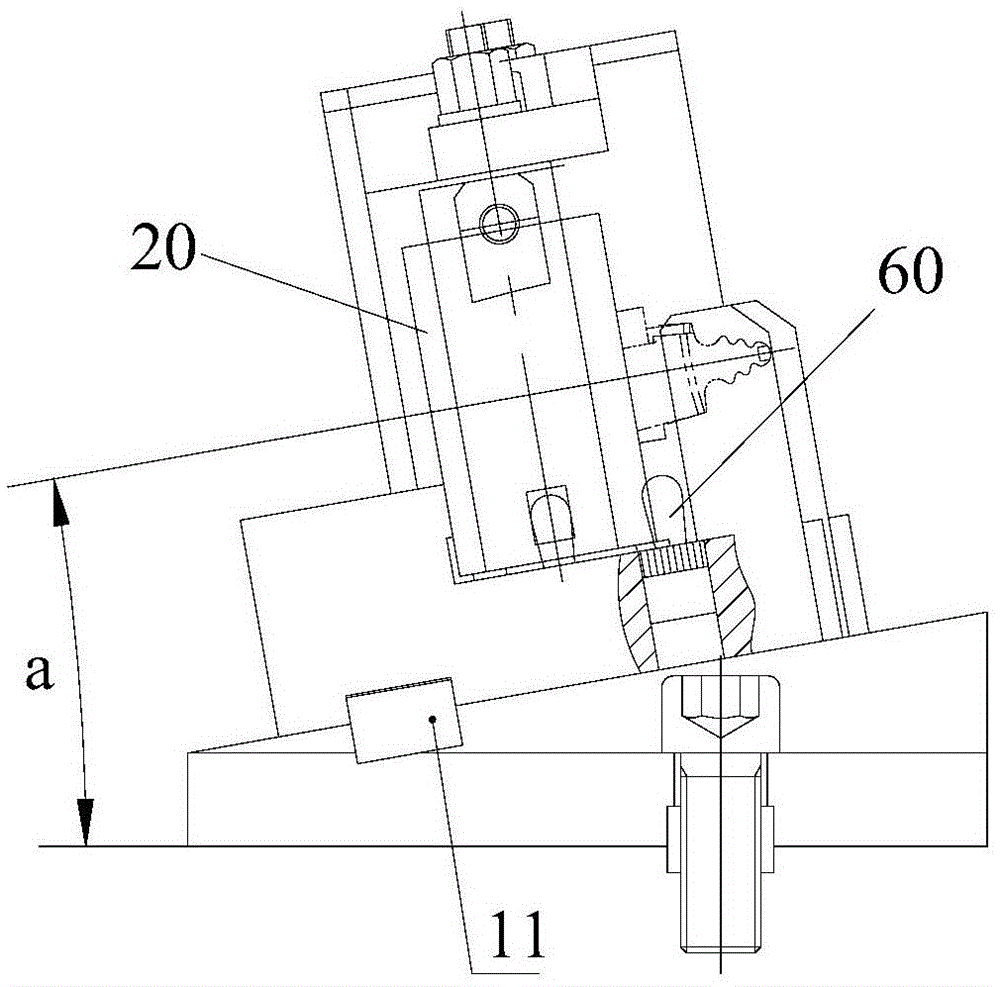

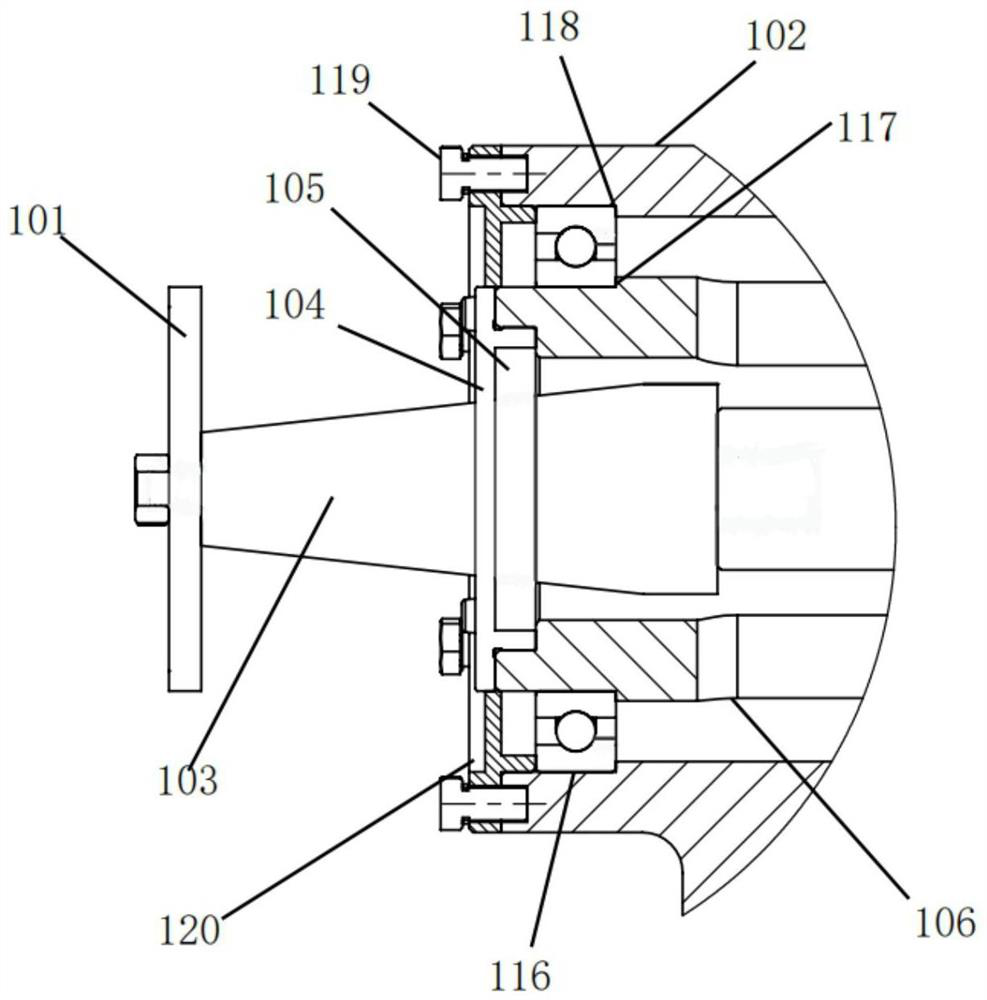

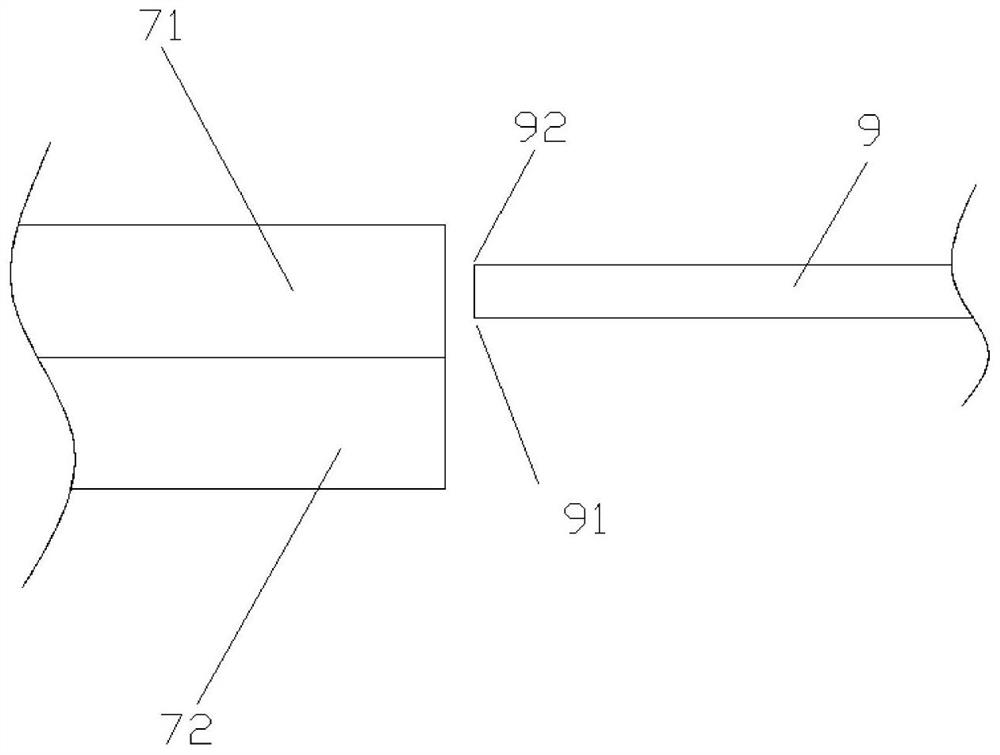

Blade tenon grinding fixture

ActiveCN105538096ASimplify structural design requirementsEasy to adjustGrinding machinesGrinding work supportsMachining processGrinding wheel

The invention discloses a blade tenon grinding fixture. The blade tenon grinding fixture comprises a baseplate achieving a support positioning effect; the upper surface of the baseplate serves as a mounting surface for mounting a blade to be machined; square boxes for auxiliary positioning are cast at a blade basin and a blade back of the blade to be machined; the mounting surface of the baseplate is a horizontally inclined angle surface; a positioning mechanism for clamping and positioning the square boxes is arranged on the mounting surface; and the baseplate is additionally provided with a drainage mechanism for guiding cooling liquid to a tenon of the positioned blade to be machined to reduce the grinding heat. As the mounting surface of the baseplate is designed as the horizontally inclined angle surface, the tenon symmetry center of the blade is conveniently adjusted in the machining process, and the prolonging of the service life of a formed grinding wheel is facilitated; and the drainage mechanism is arranged on the baseplate, so that the grinding heat is reduced, the quick positioning and clamping requirements are satisfied, the dimensional tolerance and the geometric tolerance of the grinded blade tenon reach the technical requirements, the reliability in the machining process is improved, and the service life of the formed grinding wheel for grinding is prolonged.

Owner:CHINA HANGFA SOUTH IND CO LTD

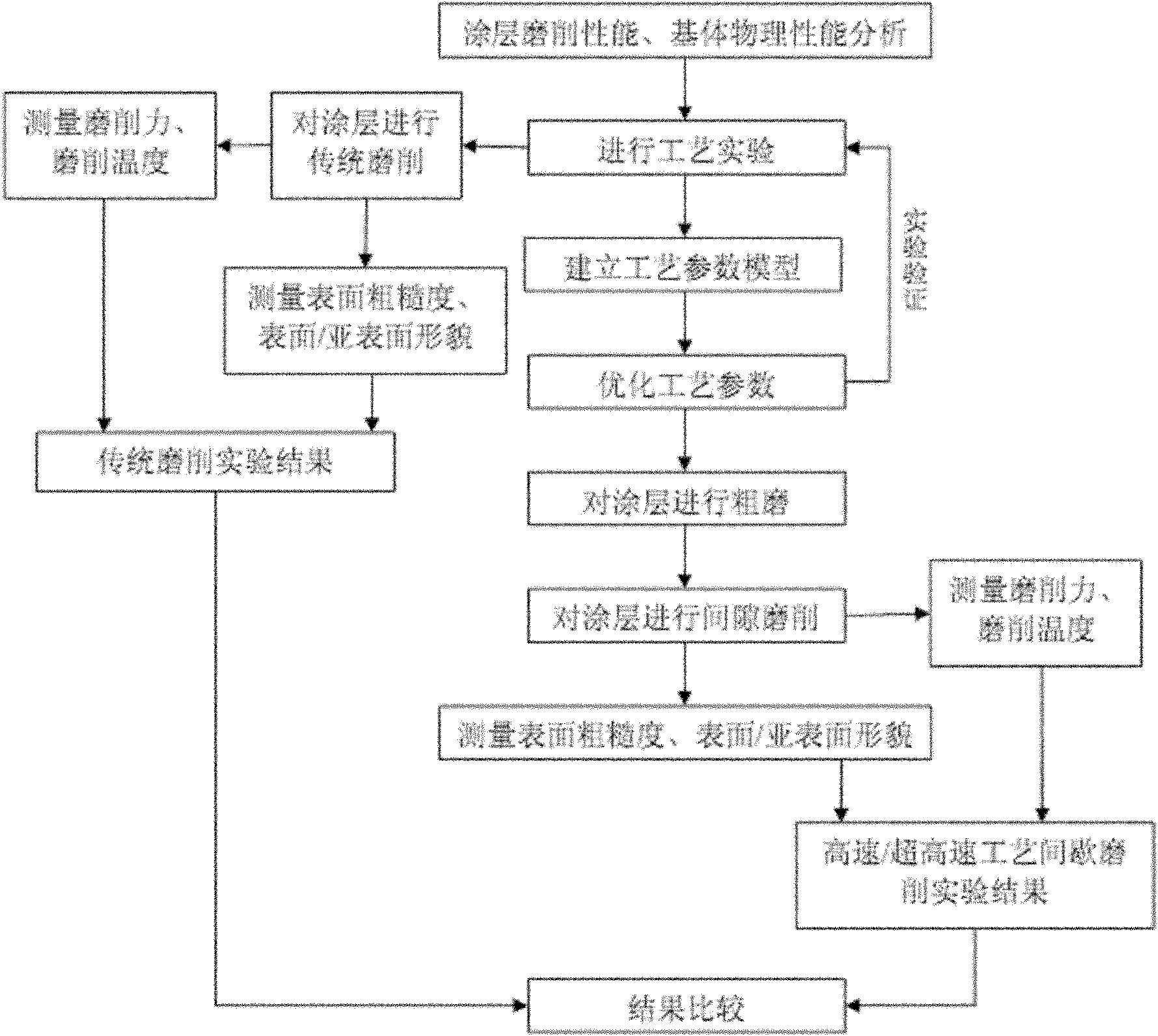

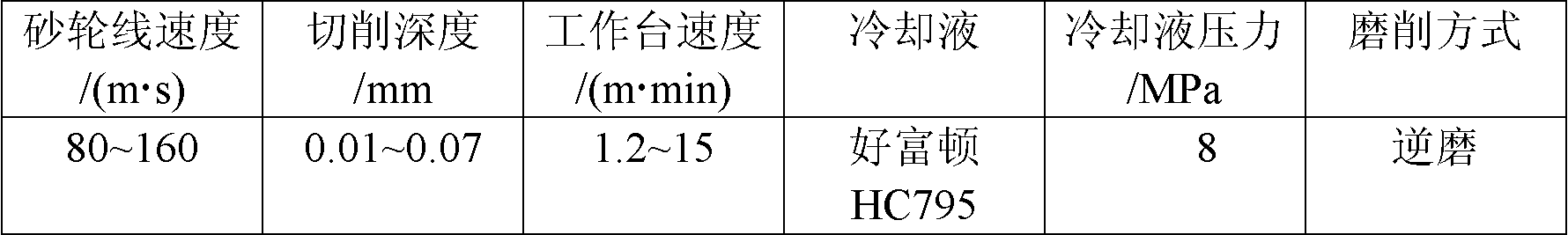

Batch-type grinding method of hard coating material

InactiveCN102085631AHigh removal rateReduce loss costGrinding machinesUltra high speedHigh-speed grinding

The invention relates to a batch-type grinding method of a hard coating material, comprising the following steps: carrying out alternate batch-type grinding by adopting a grinding wheel feeding way and a grinding wheel no-feeding way in the grinding process; when the grinding wheel feeding way is adopted, carrying out high-speed or ultra high-speed grinding; when the grinding wheel no-feeding wayis adopted, carrying out no-load reciprocatory grinding; and after every time of feed grinding of a grinding wheel, carrying out the no-load reciprocatory grinding for 2-20 times according to the actual condition; wherein the high-speed or ultra high-speed grinding comprises that the primary feed grinding depth is 10-15mu m, the feeding speed of an operating platform is 6000-30000mm / min, and the linear speed of the grinding wheel is 80-200m / s. In the invention, variation of the actual grinding depth caused by elastic deformation and heat deformation of the grinding wheel and workpieces can beeliminated to the utmost extent, the heat produced at high-speed grinding can be timely released, and the grinding wheel can maintain to be sharp, thus the material removing rate is improved, the grinding surface burning is effectively reduced, the grinding wheel loss and production cost are greatly reduced, and the good processing quality is obtained.

Owner:HUNAN UNIV

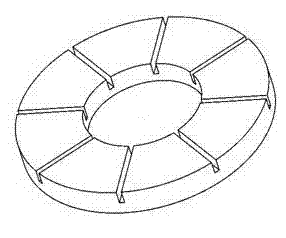

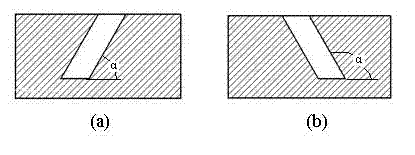

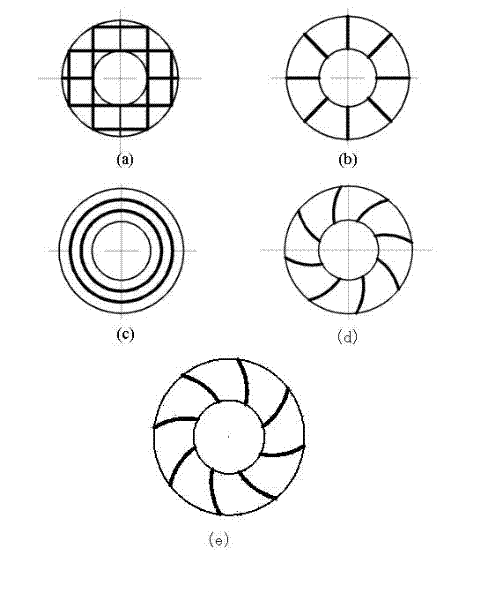

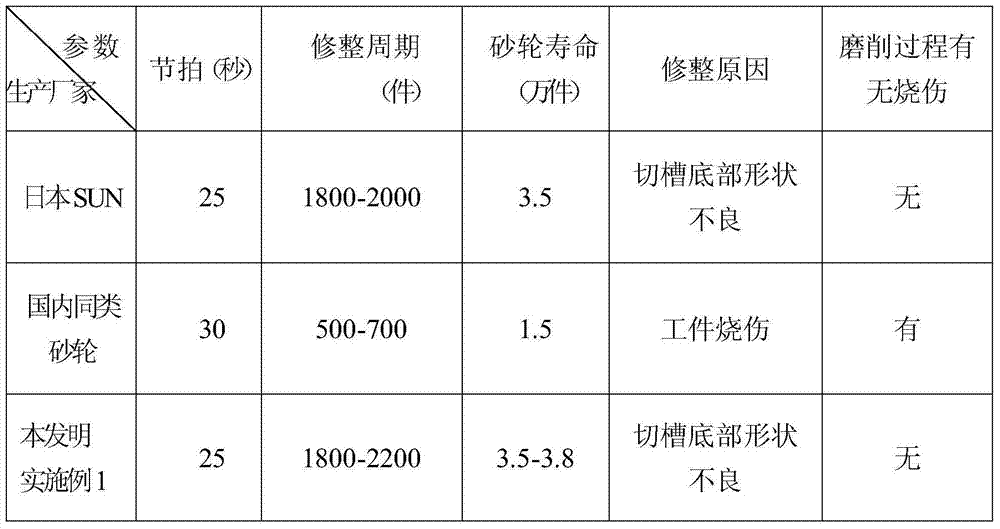

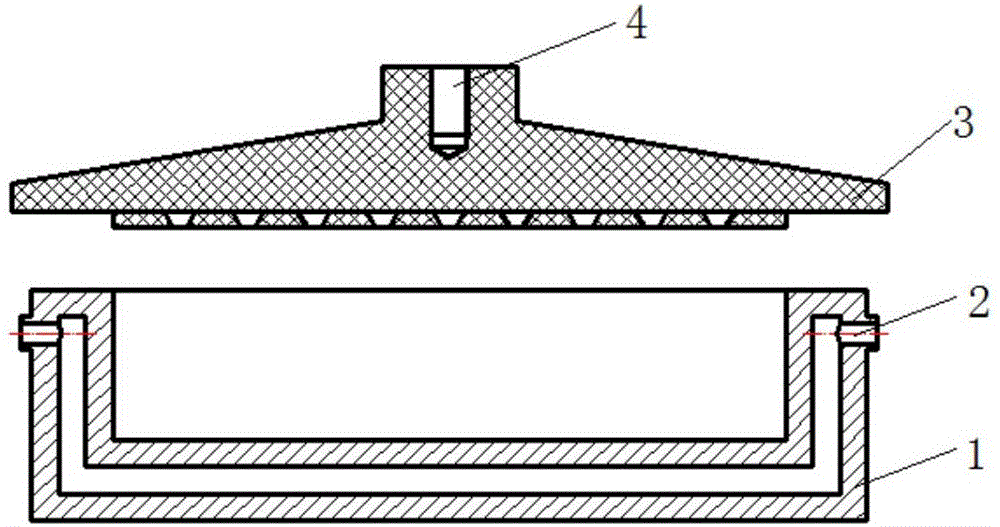

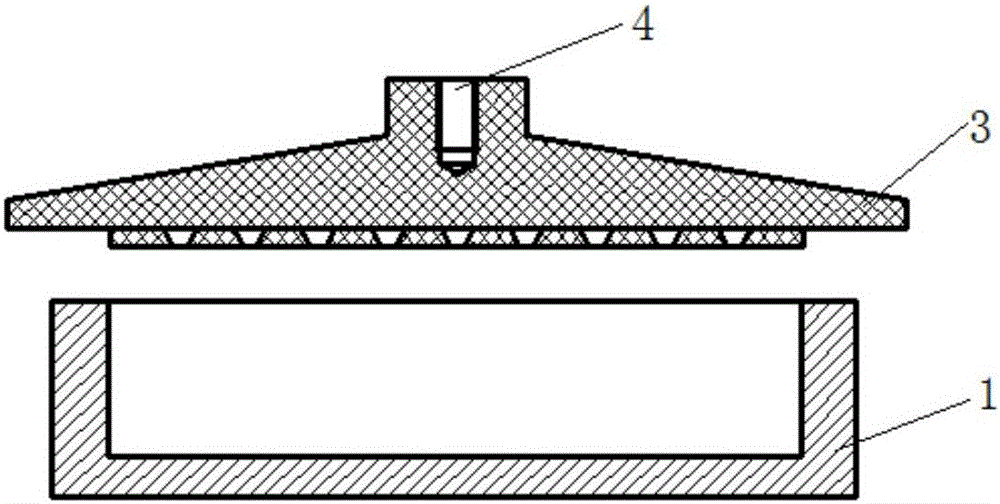

Slotting-type freezing and solidifying grinding material polishing pad and preparation method thereof

InactiveCN102335888AImprove protectionFacilitate the development of new usesFlexible-parts wheelsGrinding devicesPolishingEngineering

The invention discloses a slotting-type freezing and solidifying grinding material polishing pad, which is characterized in that the center of one surface of a polishing pad, which is opposite to a processed workpiece, is provided with a blind hole (1); the periphery of the blind hole (1) is provided with a groove (2); the diameter d of the blind hole (1) is equal to e-r, wherein e in the formula is the eccentricity of the polishing pad, r is the radius of the polished workpiece, the value of the eccentricity is always 20-105mm, the depth of the blind hole (1) is 10-20mm, the depth of the groove (2) is 50-70% of the depth of the blind hole (1), and the width of the groove (2) is 5-10mm. In the slotting-type freezing and solidifying grinding material polishing pad, different types of grooves of different shapes are manufactured on the traditional freezing and solidifying grinding material polishing pad. Various groove shapes are formed mainly by the action of a slotting die. The polishing pad can be used for polishing and machining various thin workpieces, and is especially suitable for machining heat sensitive materials, soft materials, crystal materials and the like, has the advantages of low machining cost, high machining efficiency, strong technical control capability and the like, is simple to manufacture, is environmentally-friendly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

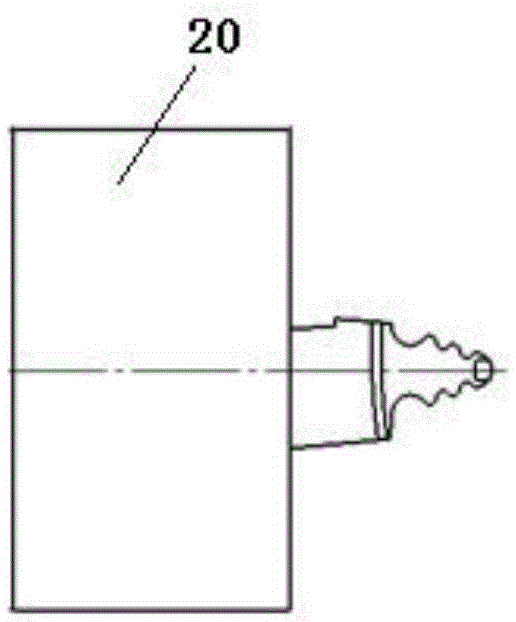

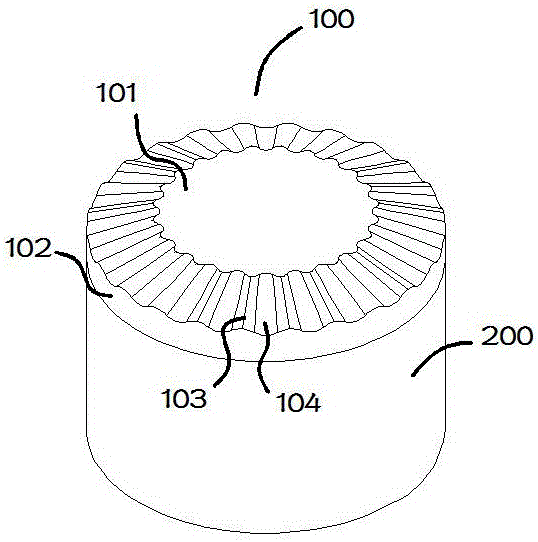

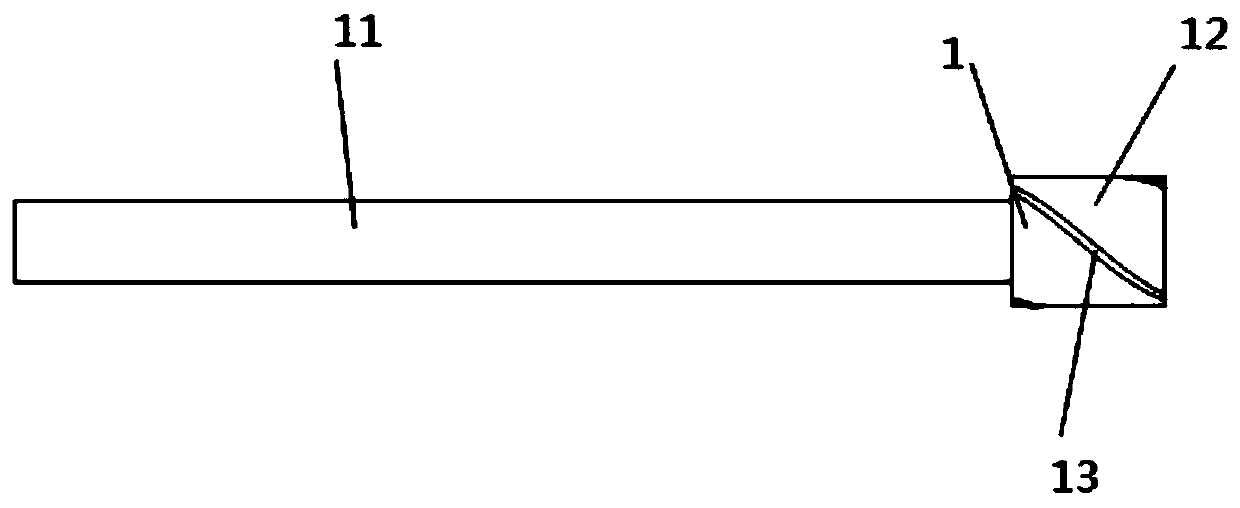

Drilling pre-formed polycrystalline diamond composite sheet with efficient chip discharge function

ActiveCN106761428AReduce grinding heatReduce chippingDrill bitsConstructionsEdge surfaceCemented carbide

The invention discloses a drilling pre-formed polycrystalline diamond composite sheet with an efficient chip discharge function. The drilling pre-formed polycrystalline diamond composite sheet comprises a polycrystalline diamond layer and a hard alloy matrix support body. The hard alloy matrix support body is adhered with the polycrystalline diamond layer; the polycrystalline diamond layer comprises an upper surface and an outer edge surface, cutting blade teeth with radial centers are formed in junction regions of the upper surface and the outer edge surface, and chip discharge grooves with radial centers are formed in the junction regions of the upper surface and the outer edge surface; the cutting blade teeth and the chip discharge grooves are connected with one another in certain angle directions, the cutting blade teeth radially extend to be annular distributed, and the chip discharge grooves are radially perforated to be annularly formed. The drilling pre-formed polycrystalline diamond composite sheet with the structure has the advantages that the drilling pre-formed polycrystalline diamond composite sheet is high in sharpness and has an efficient chip discharge merit, the drilling efficiency can be greatly improved, balling phenomena can be prevented, and the control stability of well drilling platforms can be guaranteed.

Owner:SF DIAMOND CO LTD

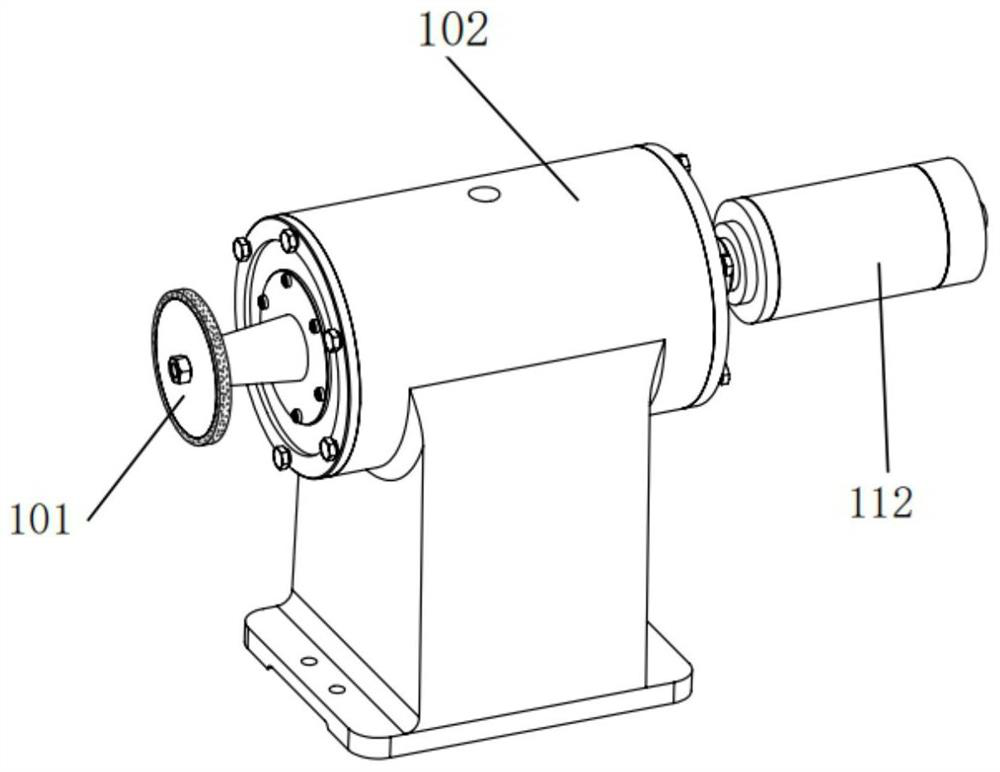

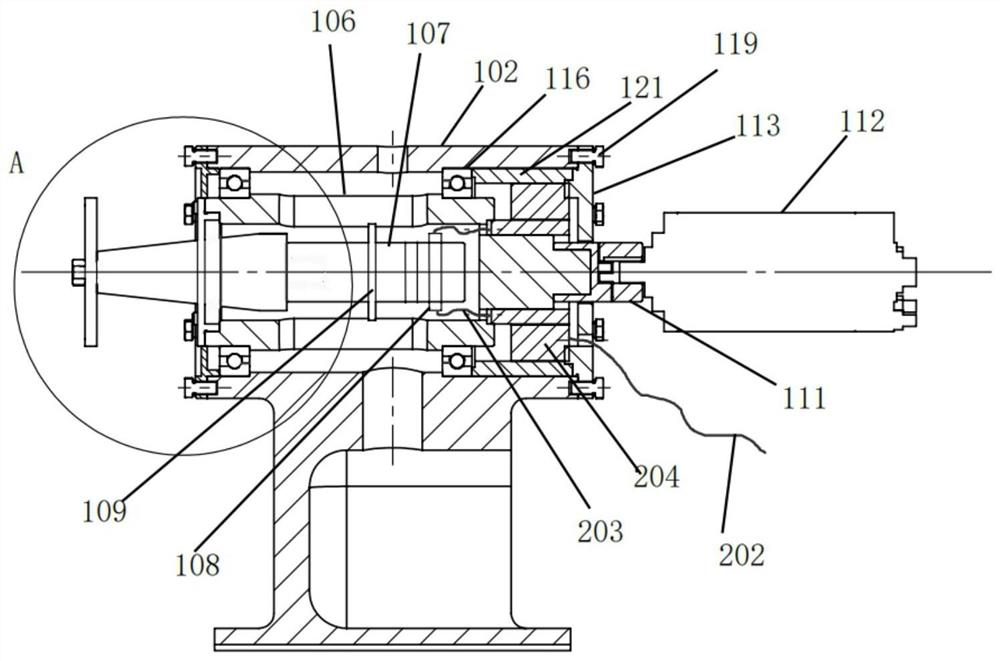

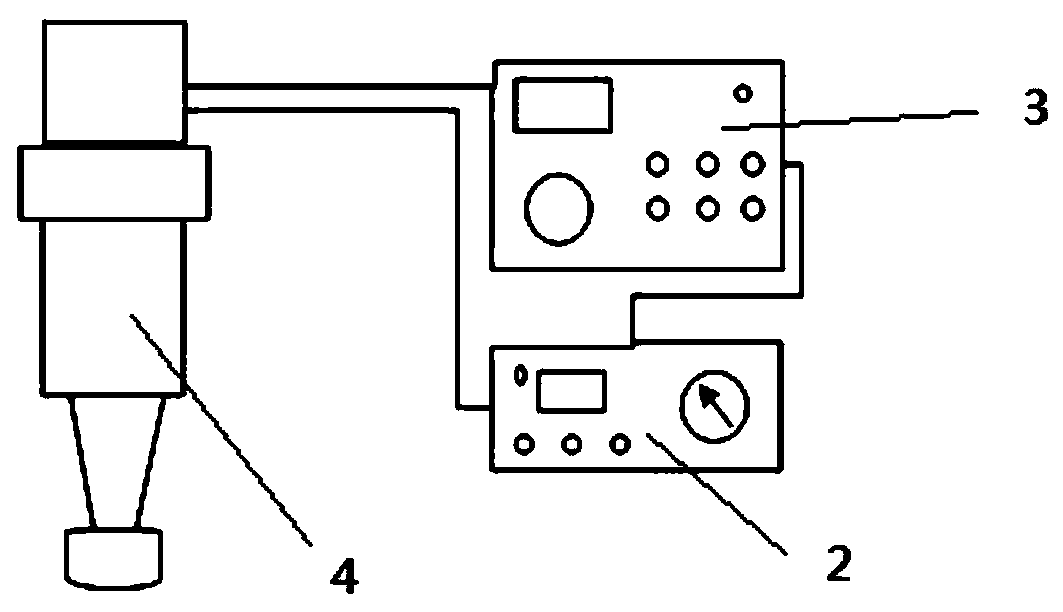

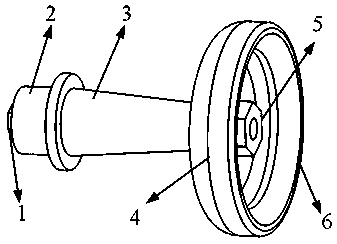

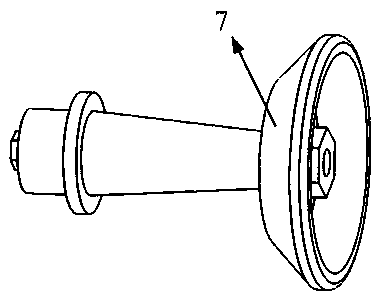

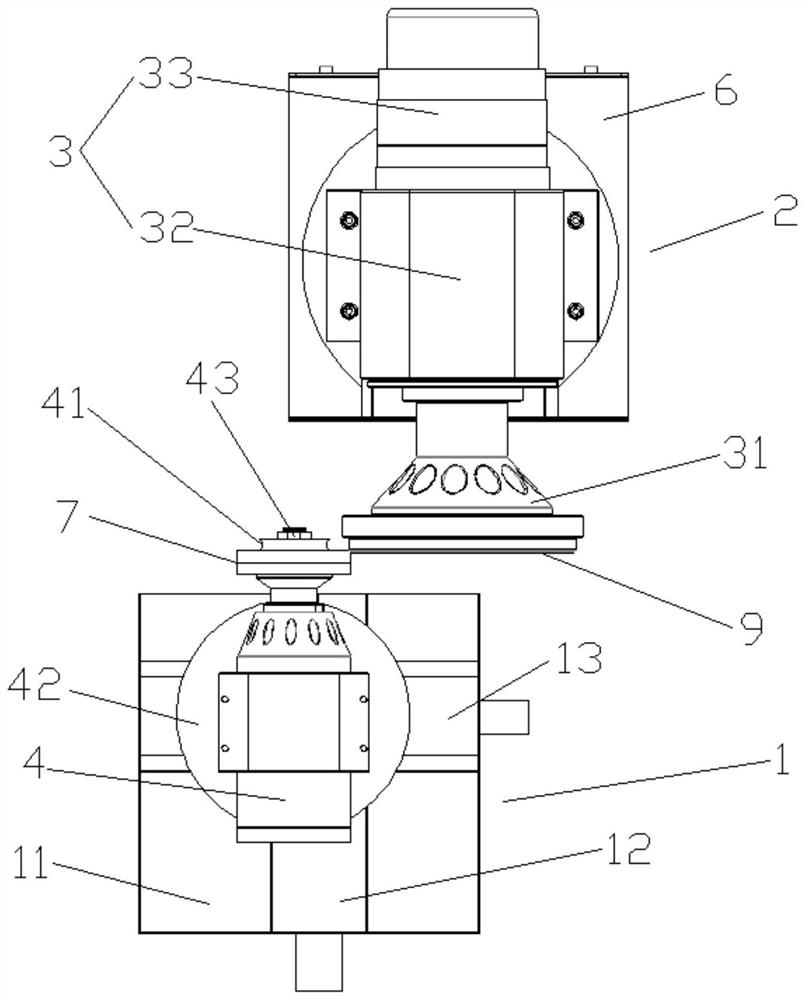

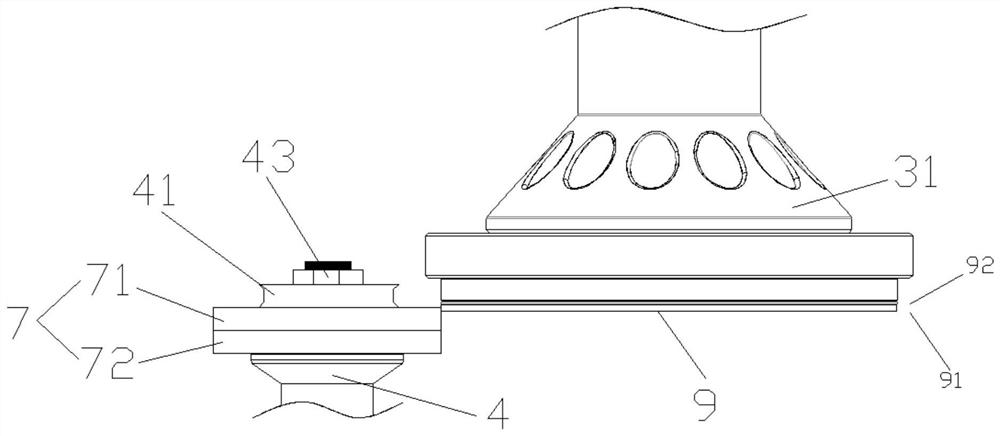

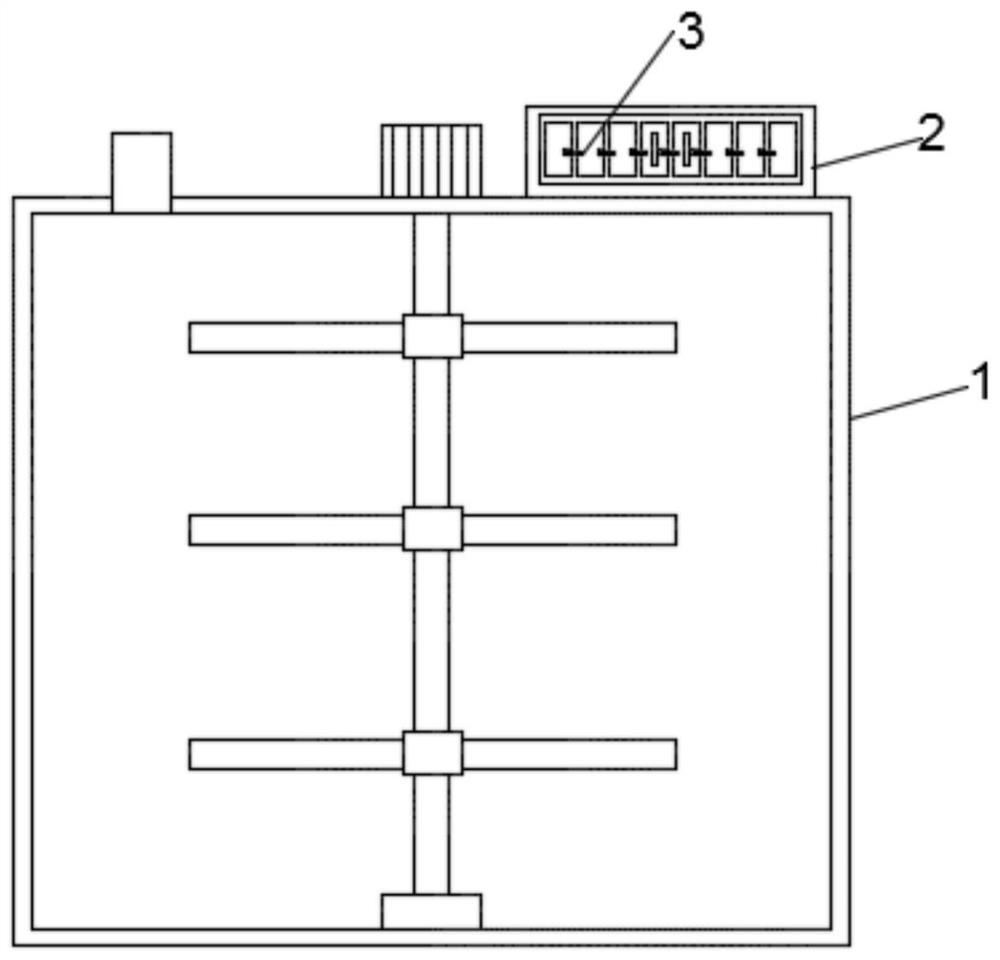

Rotary ultrasonic grinding machine tool and application

InactiveCN113118882AExtend your lifeImprove processing qualityGrinding drivesGrinding work supportsCouplingEngineering

The invention belongs to the technical field of hard and brittle material ultrasonic precision machining, and particularly relates to a rotary ultrasonic grinding machine tool. The rotary ultrasonic grinding machine tool comprises a rotary ultrasonic grinding main shaft, an ultrasonic wave power transmission device, a main shaft clamping and lifting device and a part clamping and feeding device. The rotary ultrasonic grinding main shaft comprises a grinding wheel, wherein the grinding wheel is installed at the output end of an amplitude-change pole, an amplitude-change pole flange is arranged in the middle of the amplitude-change pole and connected with the end face of a hollow sleeve, and a large-end mandrel of the amplitude-change pole stretches into the hollow sleeve and is connected with the output end face of an energy converter. A copper sheet is arranged on the energy converter, a positioning flange is arranged in the middle of the outer surface of the energy converter, the energy converter is connected with the inner surface of the hollow sleeve in a transition fit mode through the positioning flange, the hollow sleeve is installed in a support, and the tail end of the hollow sleeve is connected with an electric main shaft through a coupling. According to the rotary ultrasonic grinding machine tool, the grinding main shaft is directly driven by the electric main shaft, so that the grinding efficiency is improved, the grinding force and the grinding heat are reduced, and the part machining quality is improved.

Owner:ZHONGBEI UNIV +1

High-durability ceramic grinding tool

The invention discloses a high-durability ceramic grinding tool which is characterized by comprising the following components in parts by weight: 11-27 parts of zirconite, 31-50 parts of calcite, 3-14 parts of ethylene copolymer elastomer, 1-9 parts of closed-cell perlite, 15-45 parts of borate glass, 5-17 parts of solid paraffin, 11-25 parts of tourmaline concentrate micropowder, 3-4 parts of molybdenum disilicide, 34-61 parts of spodumene, 11-31 parts of mica, 3-5 parts of zinc oxide, 5-12 parts of ferric sodium pyrophosphate, 1-3 parts of calcium hydrogen phosphate and 5-9 parts of cryolite. The high-durability ceramic grinding tool has the advantages of sharp grinding grains, low trimming frequency, favorable sharpness, low grinding temperature, favorable toughness, low abrasion, high durability and long service life, and can be used for high depth, roughing feed, heavy load and high efficiency grinding.

Owner:QINGDAO XIANGHAI ELECTRONICS

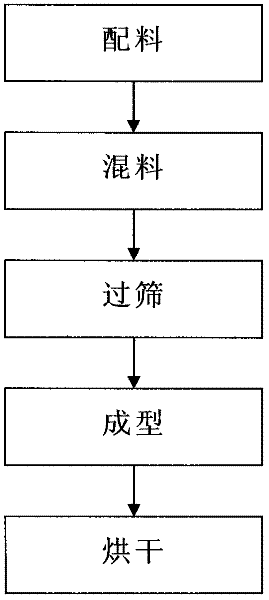

Preparation method for wear-resisting man-made oilstone

ActiveCN108247553APromote densificationImprove cooling effectAbrasion apparatusGrinding devicesSilicon dioxideFermentation

The invention relates to a manufacturing method of grinding materials and grinding tools, in particular to a preparation method for wear-resisting man-made oilstone. According to the preparation method, silicon dioxide, aluminum oxide, zirconium oxide and boric acid serve as main raw materials, ball milling powder is processed to obtain ceramic binder fragments, the ceramic binder fragments are subject to ball milling, drying and screening to obtain ceramic binder powder, rice hull ash is used as a raw material, palm wax and pericarp are added, fermentation is carried out under the ammonia atmosphere to obtain fermentation filter residues, the fermentation filter residues and diamond particles are mixed to obtain rigid powder, diamond-silicon carbide composite powder is obtained through roasting, and then the diamond-silicon carbide composite powder and additives such as magnesia powder and white corundum are mixed to obtain a to-be-sintered material; and finally, the to-be-sintered material is placed into a graphite jig, the wear-resisting man-made oilstone is obtained through processing, in the rice hull ash fermentation process, the micro rotting effect of microorganisms in thepericarp is used for fixing nitrogen in ammonia gas into the fermentation filter residues, the wear-resisting property of the man-made oilstone and the grinding effect on the high-hardness materials are improved, and the application prospect is wide.

Owner:义乌市安航科技有限公司

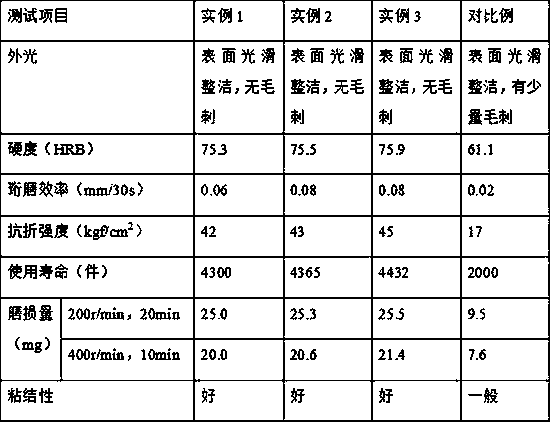

Efficient grooving resin wheel for preventing workpiece from being burnt and application thereof

ActiveCN103786105AAvoid burnsReduce grinding heatAbrasion apparatusPolycrystalline diamondWaste product

The invention discloses an efficient grooving resin wheel for preventing a workpiece from being burnt and application of the efficient grooving resin wheel. The efficient grooving resin wheel aims to solve the problems, such as workpiece burning, low grinding efficiency, a short maintaining period and incapability in reutilization of waste products, prone to occurrence in the grinding and grooving process of plunger products of a precise oil atomizer. The efficient grooving resin wheel is composed of a base body and a working abrasive layer. The efficient grooving resin wheel is characterized in that the working abrasive layer is made of a resin binder and mixed padding, wherein the resin binder is superfine phenolic resin; the mixed padding comprises, according to the volume ratio, 10-20 percent of superfine WA with the grain diameter ranging from 10 microns to 20 microns, 5-10 percent of nanoscale SiO2 with the grain diameter ranging from 0.03 micron to 0.05 micron, 5-15 percent of superfine Cu with the grain diameter ranging from 0.5 micron to 1.0 micron, 1-10 percent of nanoscale TiO2 with the grain diameter ranging from 0.03 micron to 0.05 micron, 1-3 percent of FeS, 1-10 percent of polycrystalline diamond and 15-30 percent of CBN. The efficient grooving resin wheel has the advantages that grinding efficiency is high, and the cutting edge is sharp; the shape of the efficient grooving resin wheel is well kept, the maintenance period is long, and the service life is long; the workpiece which is ground is high in accuracy, and the dimensional accuracy is not higher than 0.002 mm; the workpiece is not burned, and therefore the waste products caused by burning are eliminated.

Owner:沈阳中科超硬磨具磨削研究所

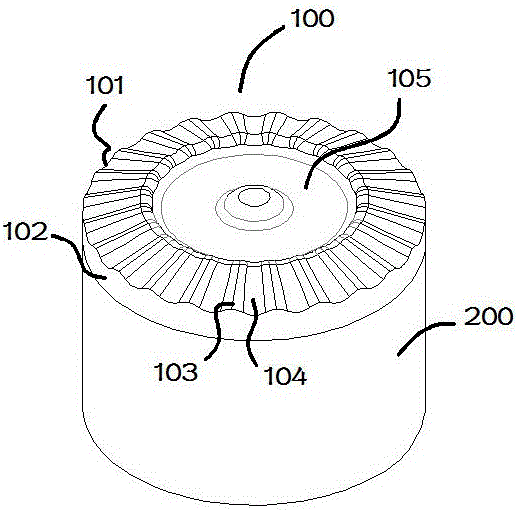

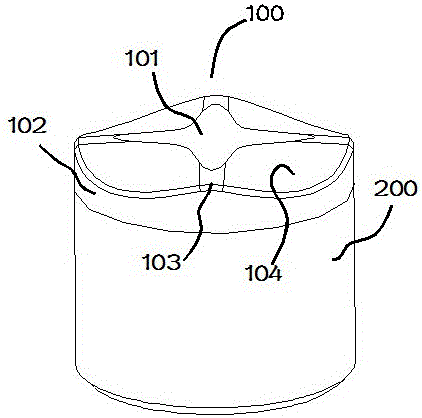

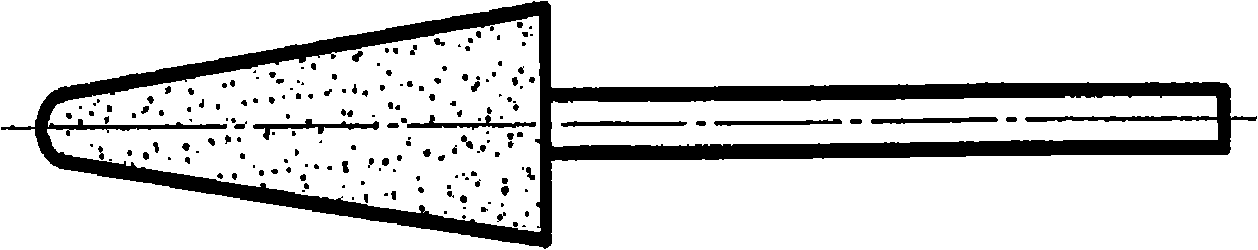

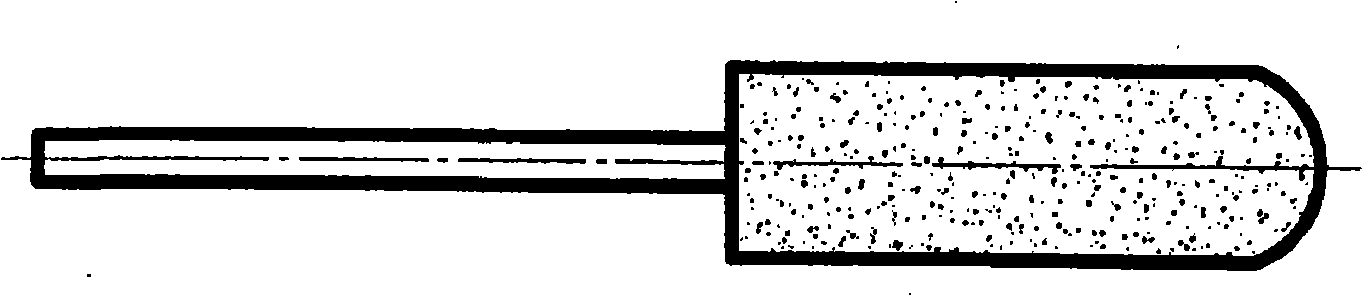

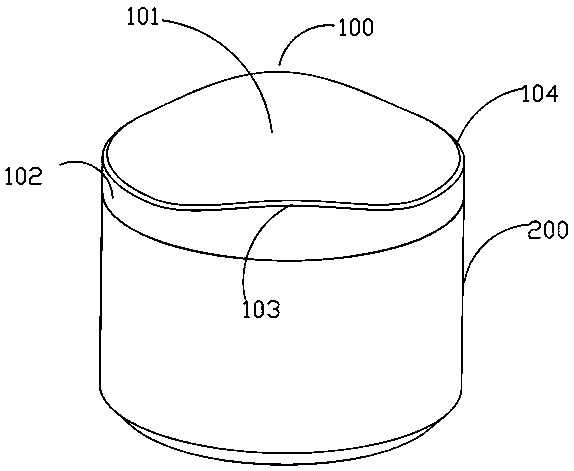

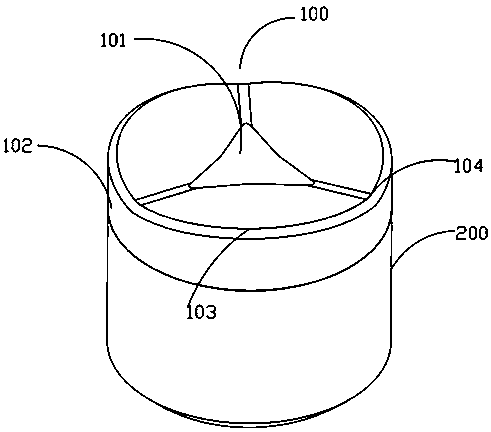

Soft projectile body polishing grinding head

InactiveCN101274420AGood flexibilityImprove flexibilityGrinding machine componentsTwist drillsElastomerEngineering

The invention relates to a soft elastomer polishing head which comprises a rotor shaft connected with a motor and a polishing head arranged on the other end of the rotor shaft, and is characterized in that: the polishing head consists of an abrasive core fixedly arranged on the rotor shaft and abrasive particles evenly embedded into the surface of the abrasive core; the material of the abrasive core is elastic rubber plastic; the abrasive particles are acicular and acicular blades thereof face outwards; the abrasive core adopts the material of EVA rubber plastic and the abrasive particles are evenly embedded into the surface of the abrasive core by adopting an electrostatic sand-planting method.

Owner:SHANGHAI MARITIME UNIVERSITY

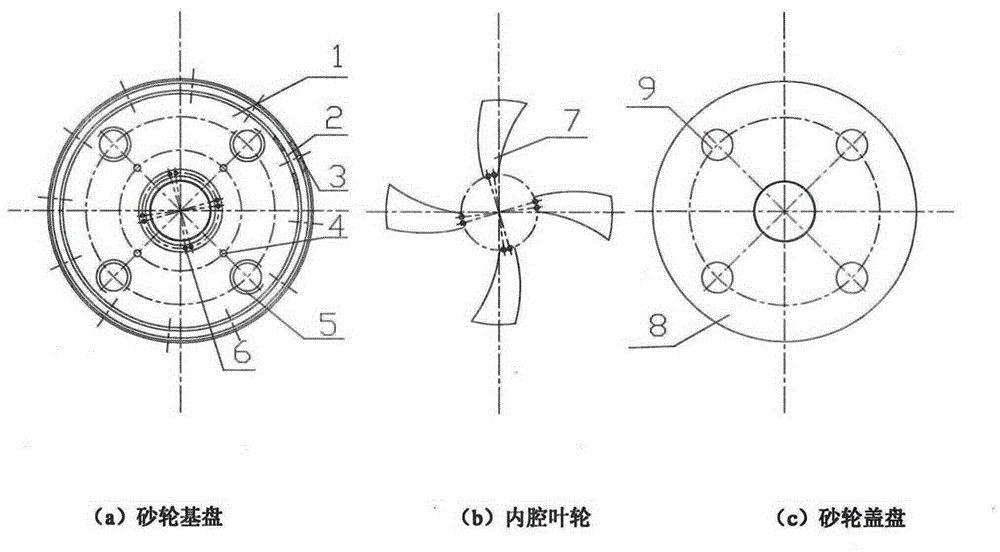

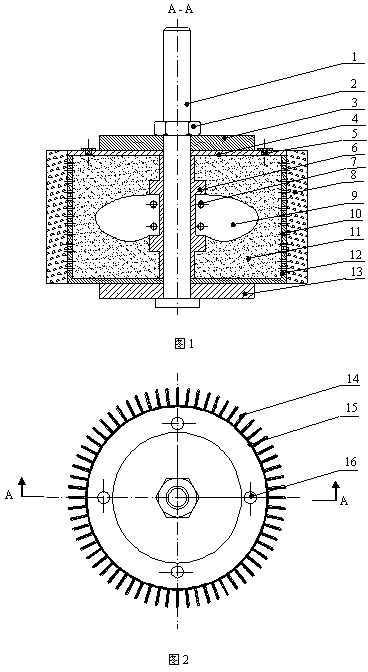

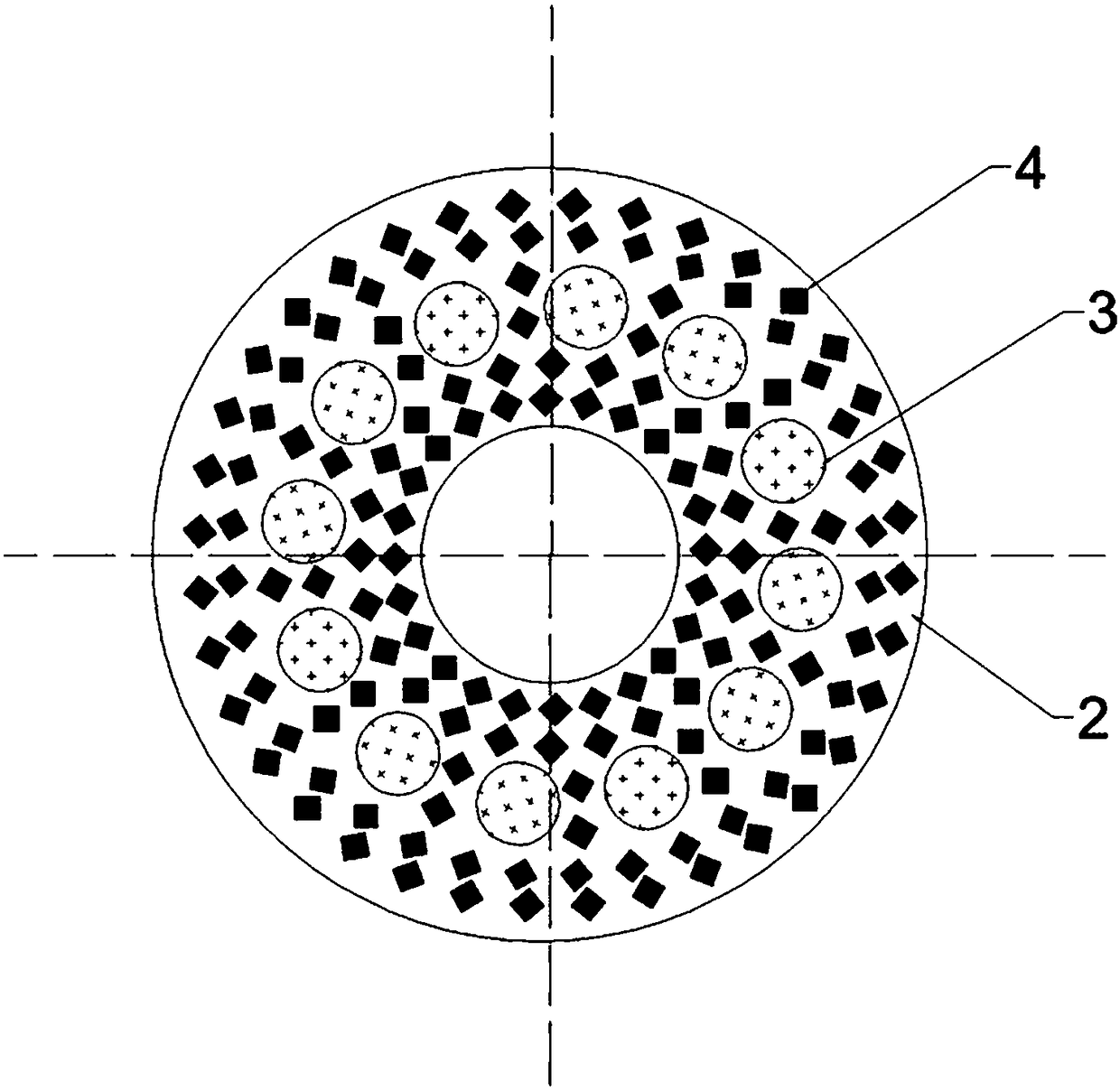

Impeller supercharging solid self-lubricating grinding wheel matrix structure

InactiveCN102794717ASimple self-lubricationReduce Adhesive WearBonded abrasive wheelsInlet valveCentrifugal force

The invention discloses an impeller supercharging solid self-lubricating grinding wheel matrix structure. An impeller centrifugal pump structure is introduced into manufacturing of a grinding wheel; and the matrix structure mainly comprises a grinding wheel base plate and an impeller cover plate. An impeller is arranged on an impeller pedestal designed in the inner cavity of the grinding wheel base plate, the outer edge of the grinding wheel base plate is provided with a ring slot, and a one-way air inlet valve is arranged on the inner wall of the ring slot; during grinding, a main shaft of the grinding wheel drives the impeller in the inner cavity to simultaneously rotate at a high speed, so that high-pressure airflow is generated in the inner cavity; the high-pressure airflow bursts through the one-way air inlet valve, so that a solid lubricating agent filled in the ring slot is continually and properly precipitated on the surface of the grinding wheel under driving coaction of the high-pressure airflow, a centrifugal force, grinding heat and the like through micro pores on the outer wall of the inner cavity of the ring slot. The structure is simple and facilitates to popularize; and through the structure, the solid lubricating agent in the grinding wheel can be conveyed to a grinding arc area reliably with low cost, so that dry grinding can be realized.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Composite binder grinding wheel for silicon carbide crystal thinning, preparation method and application

ActiveCN111331525ARealize thinning processingImprove surface qualityAbrasion apparatusGrinding devicesCarbide siliconAlloy

The invention provides a composite binder grinding wheel for silicon carbide crystal thinning, a preparation method and an application. The composite binder grinding wheel is prepared from the following raw materials of, by weight, 15%-45% of diamond abrasive, 15%-60% of pre-alloyed powder, 20%-45% of polytetrafluoroethylene, 3%-15% of cerium oxide and 0.5%-6% of a wetting agent. According to thecomposite binder grinding wheel for silicon carbide crystal thinning, the preparation method and the application, an alloy system used is Ga-Cu-Sn, the low-melting-point element of gallium is added into the alloy system, so that the forming temperature of the alloy powder is low, and the problem of heterogeneous forming of a resin metal binding agent is solved. Gallium metal is added to generate eutectic reaction to generate phases beta and delta with high gallium content and high brittleness, so that the conversion of a traditional alloy system from hard toughness to high brittleness is realized, and the self-sharpening property of a binding agent system is improved. The composite binding agent has the advantages of the metal binding agent and the advantages of a resin bonding agent, themetal binding agent forms a framework to improve strength and hardness, the resin powder increases elasticity of a grinding tool, impact resistance in the grinding process is reduced, and the surfacequality of a silicon carbide sheet is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

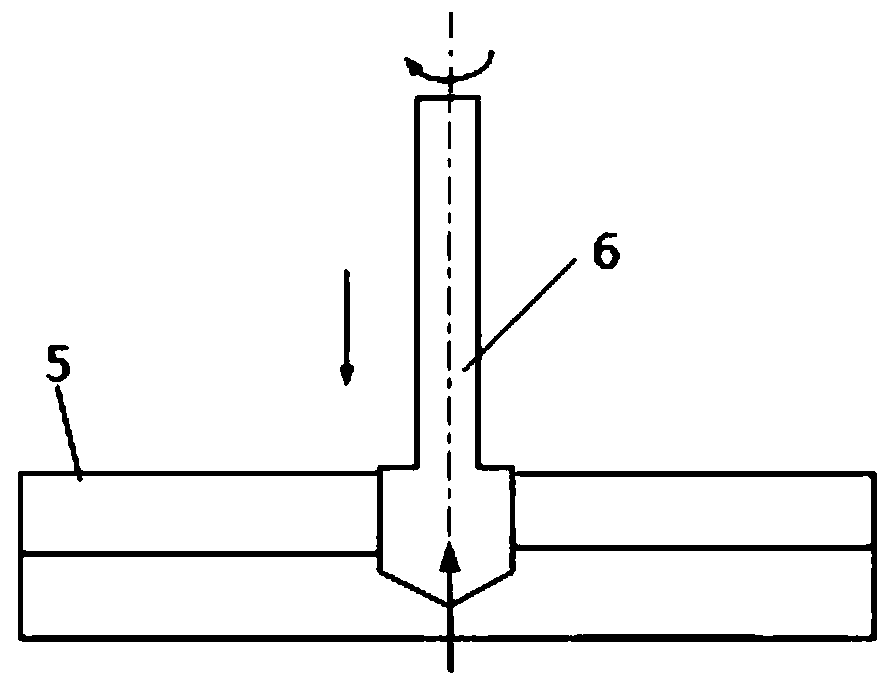

Hole making method for ultrasonic vibration assisted grinding of SiCp/Al composite

InactiveCN110091222AReduce frictionReduce contact timeGrinding machine componentsUltrasonic assistedUltrasonic cavitation

The invention discloses a hole making method for ultrasonic vibration assisted grinding of an SiCp / Al composite. The hole making method comprises the steps that through a grinding tool, hole making iscarried out on the SiCp / Al composite in a grinding manner, in combination with the ultrasonic assisted grinding, a tool bit in the grinding tool can continuously impact and scratch the machined surface under the joint effect of ultrasonic vibration, mechanical grinding and ultrasonic cavitation, the machined material is pulverized into fine particles to be removed, and ultrasonic assisted grinding hole making of the SiCp / Al composite can be achieved. Through the grinding method, the service life of the tool is long, machining precision is high, the grinding heat is low, and the workpiece machining precision is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Spraying, grinding and throwing abrasive belt flap wheel in gas phase and solid phase

InactiveCN103894941ASimple structureReduce Adhesive WearFlexible-parts wheelsSolid phasesEngineering

The invention relates to a spraying abrasive belt flap wheel in gas phase and solid phase for drying type polishing and throwing, wherein the spraying abrasive belt flap wheel is mainly oriented to machining of high-strength and high-tenacity materials difficult to machine. Fan blades and an inner cavity structure for differential rotation of a chassis of the abrasive belt flap wheel are introduced into manufacturing of the abrasive belt flap wheel. The abrasive belt flap wheel is mainly composed of an abrasive belt flap wheel mounting handle, the chassis, a cover disk, the differential fan blades, abrasive belt blades and other parts. In the grinding and throwing process, a main shaft of a machine tool drives the abrasive belt flap wheel mounting handle, a base, a cover plate and the like to rotate together at high speed, the differential blades of the inner cavity of the base are connected with a fan blade mounting sleeve, the rotating speed of the differential blades of the inner cavity of the base is not consistent with that of the abrasive belt flap wheel mounting handle so that driving force can be exerted on lubricating mediums filled in the inner cavity of the base, and the lubricating mediums are precipitated to the surface of the abrasive belt blades continuously and quantitatively under the joint action of the driving force and eccentric force. The abrasive belt flap wheel is simple in structure and easy to popularize, the lubricating mediums in the abrasive belt flap wheel can be reliably conveyed to the grinding and throwing arc area with low cost through the structure, and therefore the drying type polishing and throwing of the high-strength and high-tenacity materials difficult to machine can be achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

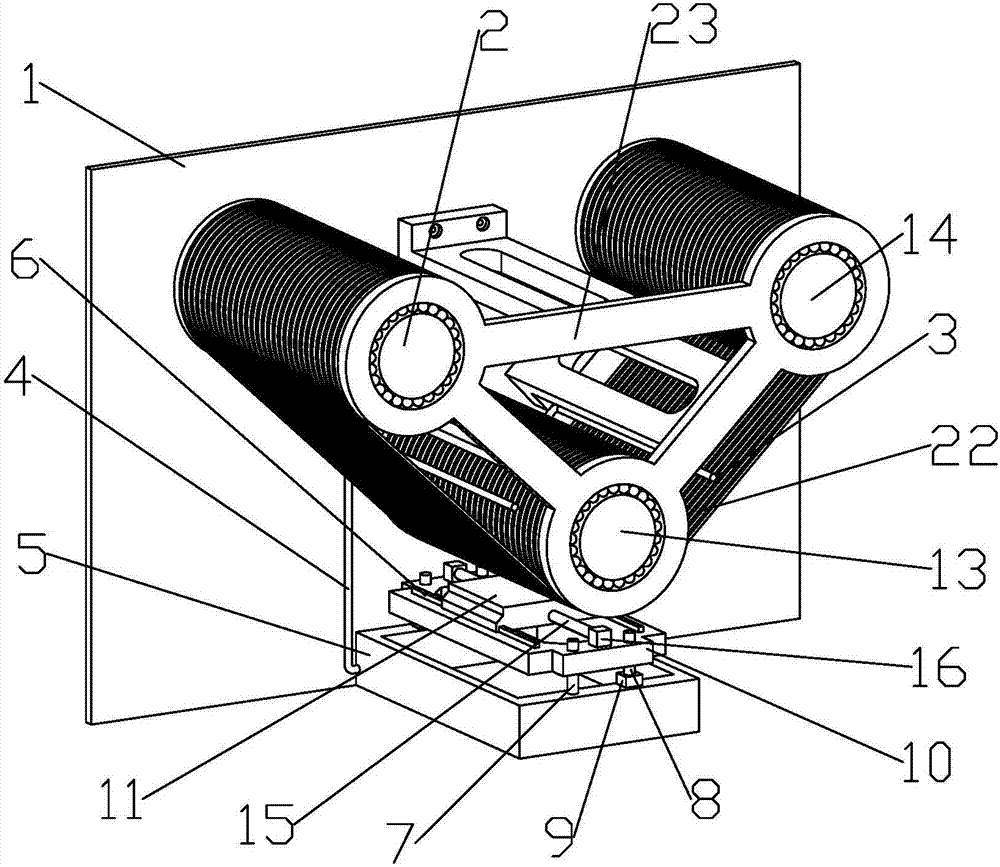

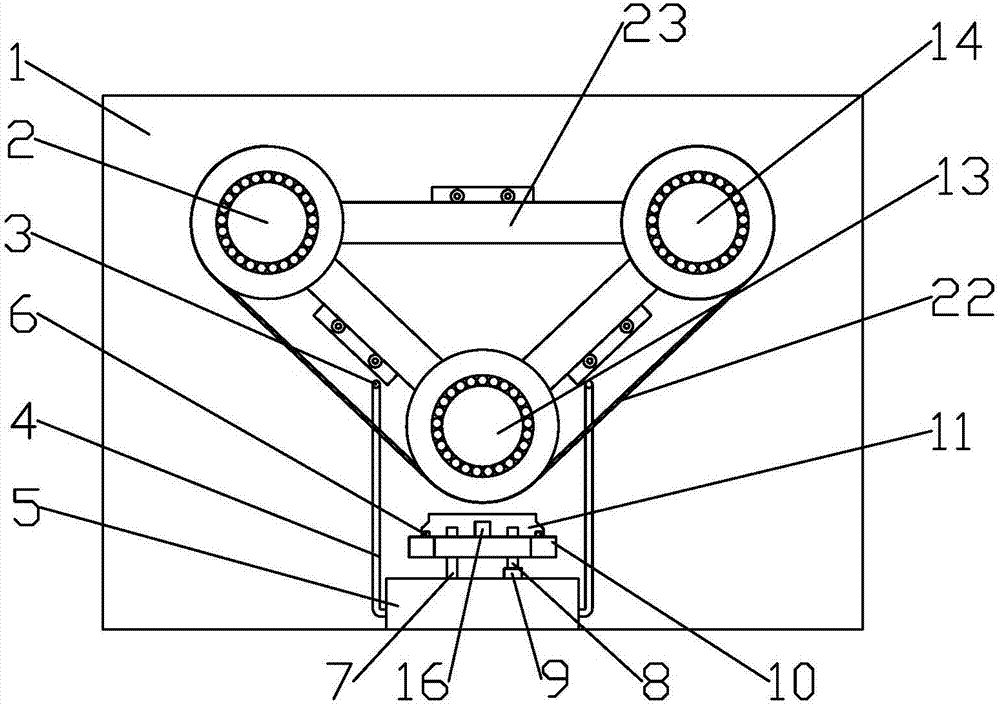

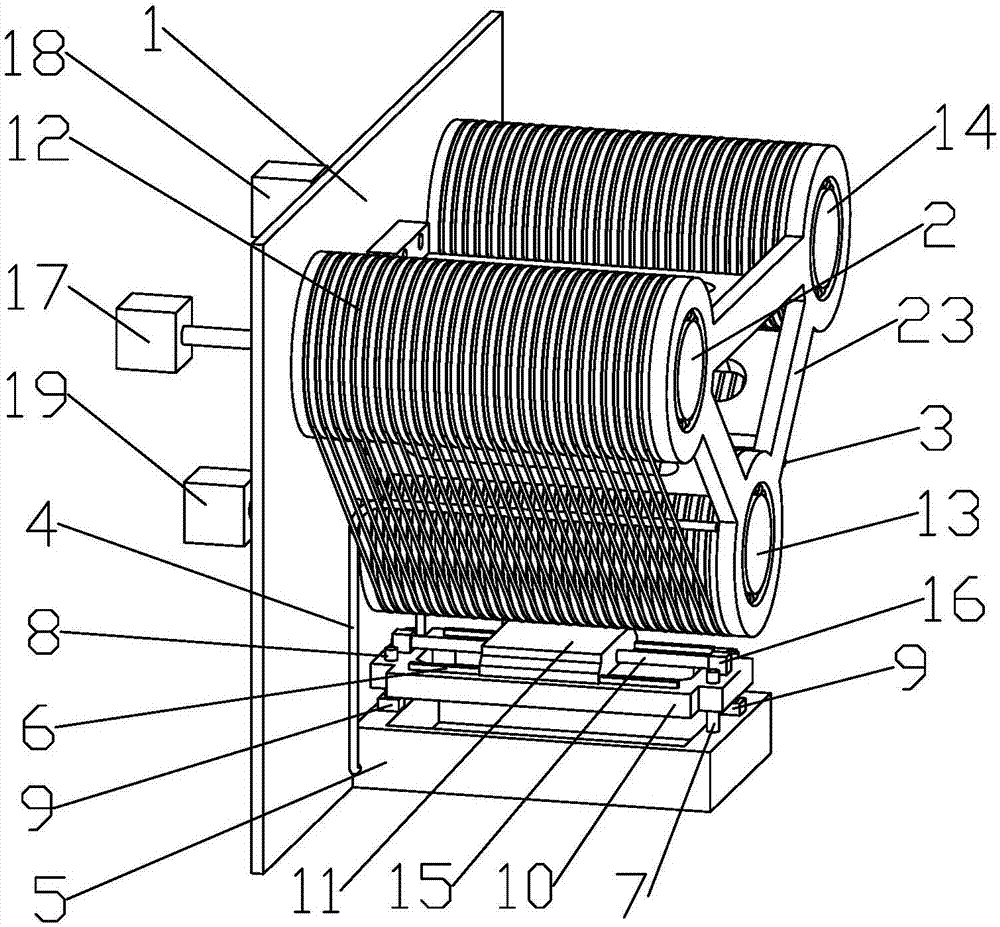

Contact-type wire belt grinding machining device

ActiveCN106965062AEasy to replaceHigh strengthGrinding machinesGrinding/polishing safety devicesMachined surfaceEngineering

Disclosed is a contact-type wire belt grinding machining device. The contact-type wire belt grinding machining device comprises a supporting unit disposed on the front side of a lathe body and used for supporting and moving a to-be-ground workpiece, an inverted triangle support located on the supporting unit and fixed to the front side surface of the lathe body, a grinding mechanism for grinding the to-be-ground workpiece and a cooling mechanism arranged on the front side surface of the lathe body and used for cooling the grinding mechanism. The supporting unit comprises a vertical movement mechanism arranged on a cooling liquid recycling trough of the cooling mechanism and used for driving the to-be-ground workpiece to vertically move, and a horizontal movement mechanism arranged on the vertical movement mechanism and used for driving the to-be-ground workpiece to horizontally move. The grinding mechanism comprises a diamond wire belt formed by spatially arranging a plurality of independent diamond wires and a take-up and pay-off mechanism arranged on the inverted triangle support and used for supporting the diamond wire belt and driving the diamond wire belt to grind the to-be-ground workpiece. By means of the contact-type wire belt grinding machining device, grinding heat generated during machining is greatly reduced, the residual stress caused by the grinding heat is reduced, and the surface quality of a machined surface is improved.

Owner:TIANJIN UNIV

Environmentally-friendly synthetic grinding fluid

InactiveCN103627501AHigh affinityImprove adsorption capacityLubricant compositionPolyethylene glycolSebacic acid

The invention provides an environmentally-friendly synthetic grinding fluid. The environmentally-friendly synthetic grinding fluid is prepared from 2.5wt% of oleic acid, 5wt% of triethanolamine, 2wt% of sebacic acid, 4wt% of triethanolamine, 2wt% of sodium benzoate, 4.5wt% of polyether, 5wt% of polyethylene glycol, 2wt% of sodium carbonate, 1wt% of ammonium molybdate, 4wt% of glycerin, 0.2wt% of benzotriazole, 0.2wt% of an antifoaming agent, 0.6wt% of isothiazolinone, 0.03wt% of fluorescent green and 66.97wt% of deionized water. The environmentally-friendly synthetic grinding fluid can maximumly reduce a grinding temperature and a grinding force, guarantee a workpiece grinding precision and surface quality, prolong a grinding wheel service life, improve grinding processing efficiency, satisfy antirust and anticorrosion requirements on a machine tool and a workpiece, reduce a use cost, satisfy environmental protection requirements and is suitable for a metallurgy roller in a steel industry.

Owner:TIANJIN INTELLECT SCI & TECH DEV

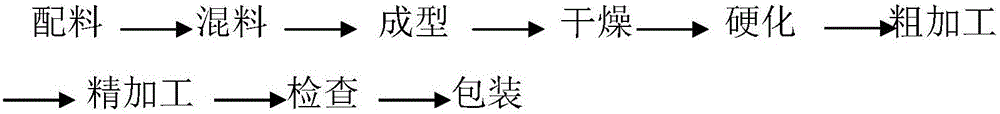

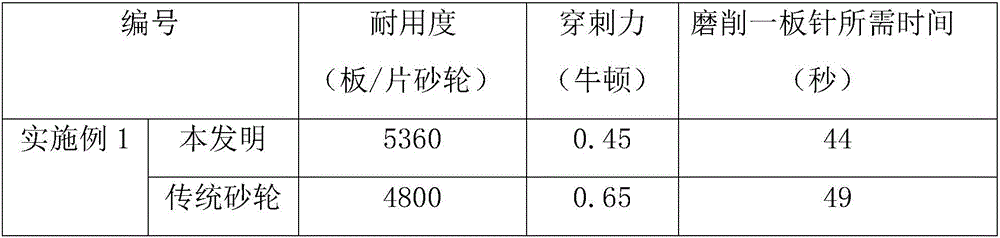

Medical grinding wheel for grinding insulin needles and manufacturing method thereof

InactiveCN105856080AImprove the finishReduce grinding scratchesAbrasion apparatusGrinding devicesOxideZinc

The invention particularly relates to a medical grinding wheel for grinding insulin needles and a manufacturing method thereof. The medical grinding wheel for grinding the insulin needles is characterized in that raw material components of the medical grinding wheel include, by weight, 60-65% of silicon carbide, 10-18% of micropowder-grade ceramic corundum, 8-12% of modified resin, 5-15% of glass beads, 1-4% of cryolite powder and 1-4% of zinc oxide, and the cryolite powder and the zinc oxide serve as filling agents. Micropowder-grade ceramic corundum abrasive materials can conduct self-sharpening at the nanoscale size during the grinding process, and micro grinding edges are exposed continuously, so that the cutting depth can be increased, and the grinding efficiency can be improved. Poor grinding faces caused by smoothed and blunted abrasive particles can be avoided through the micro grinding edges exposed continuously. During production of the grinding wheel, water pressure pads are adopted in the diameter direction and the thickness direction of the grinding wheel, and the balance performance and structure uniformity of the grinding wheel are improved by 50% more than the specified value of the national standard.

Owner:QINGDAO SISA ABRASIVES CO LTD

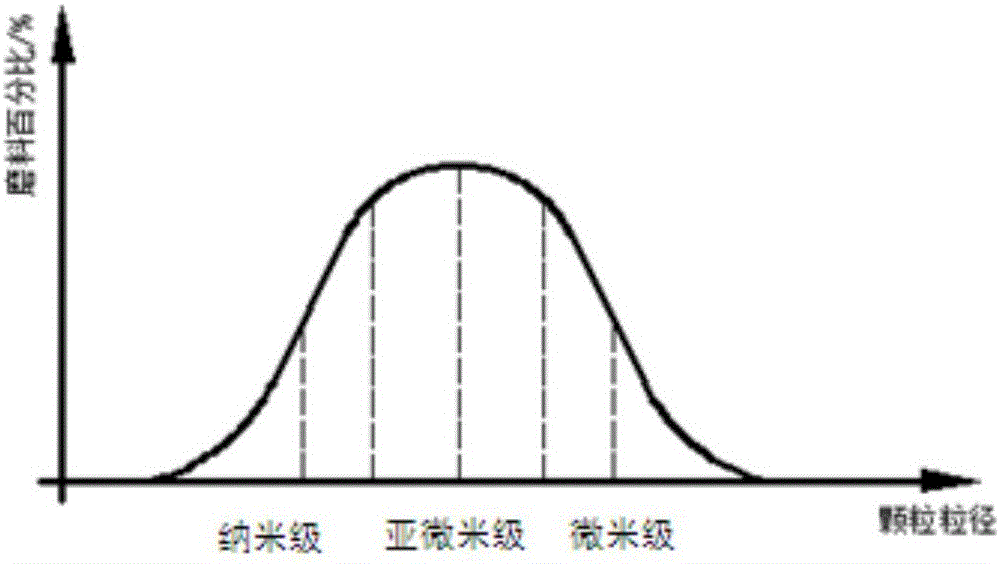

Nano corundum abrasive and preparation method thereof

ActiveCN105586005AOvercoming instability flawsChange the microstructureOther chemical processesSingle crystalSilicon dioxide

The invention discloses a nano corundum abrasive and a preparation method thereof. The abrasive comprises raw materials and a binder with the weight accounting for 0-6% of the total weight of the raw materials, wherein the raw materials comprise components in percentage by weight as follows: 0-5% of magnesium oxide, 0-5% of silicon dioxide, 0-3% of calcium oxide and the balance of nanocrystalline aluminum oxide powder. The prepared corundum abrasive adopting the nano structure has single crystal particles ranging from dozens of nanometers to hundreds of nanometers, sintered bodies have the enormous crystal boundary, only nanocrystals fall off under the action of external forces or in sharping or trimming, sharp cutting edges are produced continuously, the self-sharpening property is good, products are good in abrasion resistance and have less grinding heat, and the grinding efficiency is high.

Owner:洛阳三睿宝纳米科技有限公司

Production method of synthetic grinding fluid for metallurgy roller

InactiveCN103627502AImprove the lubrication effectImprove adsorption capacityLubricant compositionPolyethylene glycolSebacic acid

The invention provides a production method of a synthetic grinding fluid for a metallurgy roller. The production method comprises the following steps that 1, oleic acid and triethanolamine undergo a reaction in a reactor; the reaction system is stirred continuously at a rotation rate of 100r / min; the reaction system is heated to a temperature of 50-60 DEG C; and the reaction system is stirred sequentially for 30min for next use; 2, deionized water, sebacic acid and triethanolamine are orderly added into a reactor; a stirrer is started; and the mixture is stirred at a rotation rate of 100r / min for 1h; 3, sodium benzoate, polyether, polyethylene glycol, sodium carbonate, ammonium molybdate, glycerin, benzotriazole, an antifoaming agent, isothiazolinone, fluorescent green and triethanolamine oleate obtained by the step 1 are orderly added into the reactor used in the step 2; the reaction system is heated to a temperature of 50-60 DEG C; and the reaction system is sequentially stirred for 1h; and 4, the reaction product is cooled to a normal temperature to form the synthetic grinding fluid. The synthetic grinding fluid obtained by the production method has excellent lubrication, cooling, cleaning and rust resistance functions.

Owner:TIANJIN INTELLECT SCI & TECH DEV

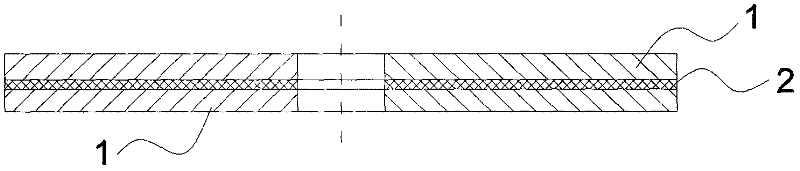

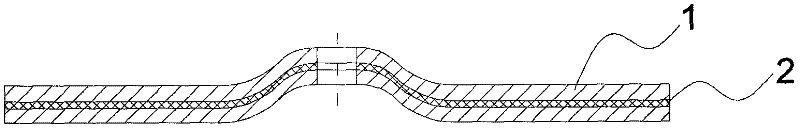

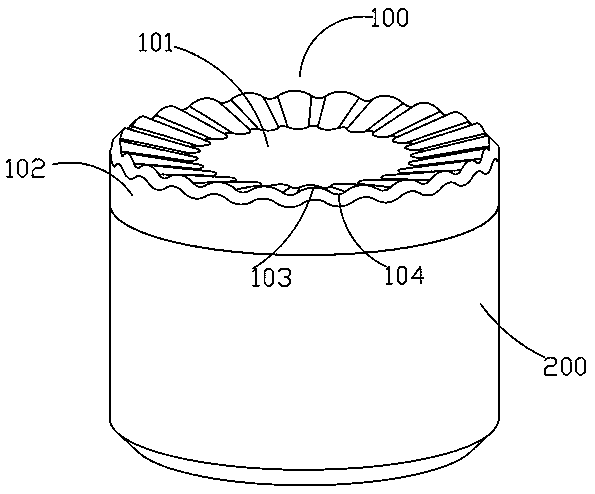

Layered frozen fixed abrasive polishing pad and preparation method thereof

ActiveCN106002663AEasy to makeEasy to shapeFlexible-parts wheelsGrinding devicesSurface layerLiquid nitrogen

The invention provides a layered frozen fixed abrasive polishing pad and a preparation method thereof. The layered frozen fixed abrasive polishing pad is characterized by being prepared through the following steps that firstly, a micron-grade abrasive and deionized water which are proportioned are uniformly stirred and subjected to mechanical dispersion, so that a dispersed and suspended liquid or colloidal to-be-frozen raw material of the abrasive is obtained and placed in a lower mold; secondly, an upper mold is matched with the lower mold, and then polishing liquid is subjected to still standing for 7-8 minutes till obvious concentration layering occurs; thirdly, liquid nitrogen is introduced into a liquid inlet till the polishing liquid is frozen and formed, or the molds are placed into a low-temperature testing box with the temperature being minus 60 DEG C-minus 80 DEG C to be frozen for 2-3 minutes; fourthly, the molds are overall inverted, and hot air is introduced into the liquid inlet for 1-2 minutes, or the hot air is blown to the outer surface layer of the lower mold for 1-2 minutes; and fifthly, the polishing pad preparation molds and the frozen fixed abrasive are separated, so that the polishing pad which is formed by being frozen after being subjected to natural sedimentation and classification and is composed of a micron-grade abrasive layer, a sub-micron grade abrasive layer, a nano-grade abrasive layer and a deionized water layer is prepared. According to the layered frozen fixed abrasive polishing pad and the preparation method thereof, the method is simple, and the polishing pad does not need to be replaced in the using process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

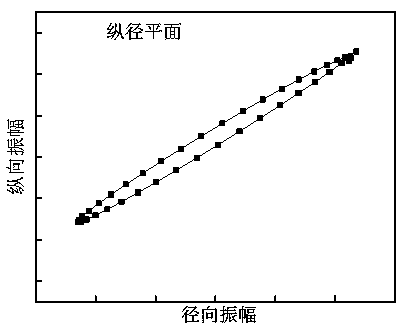

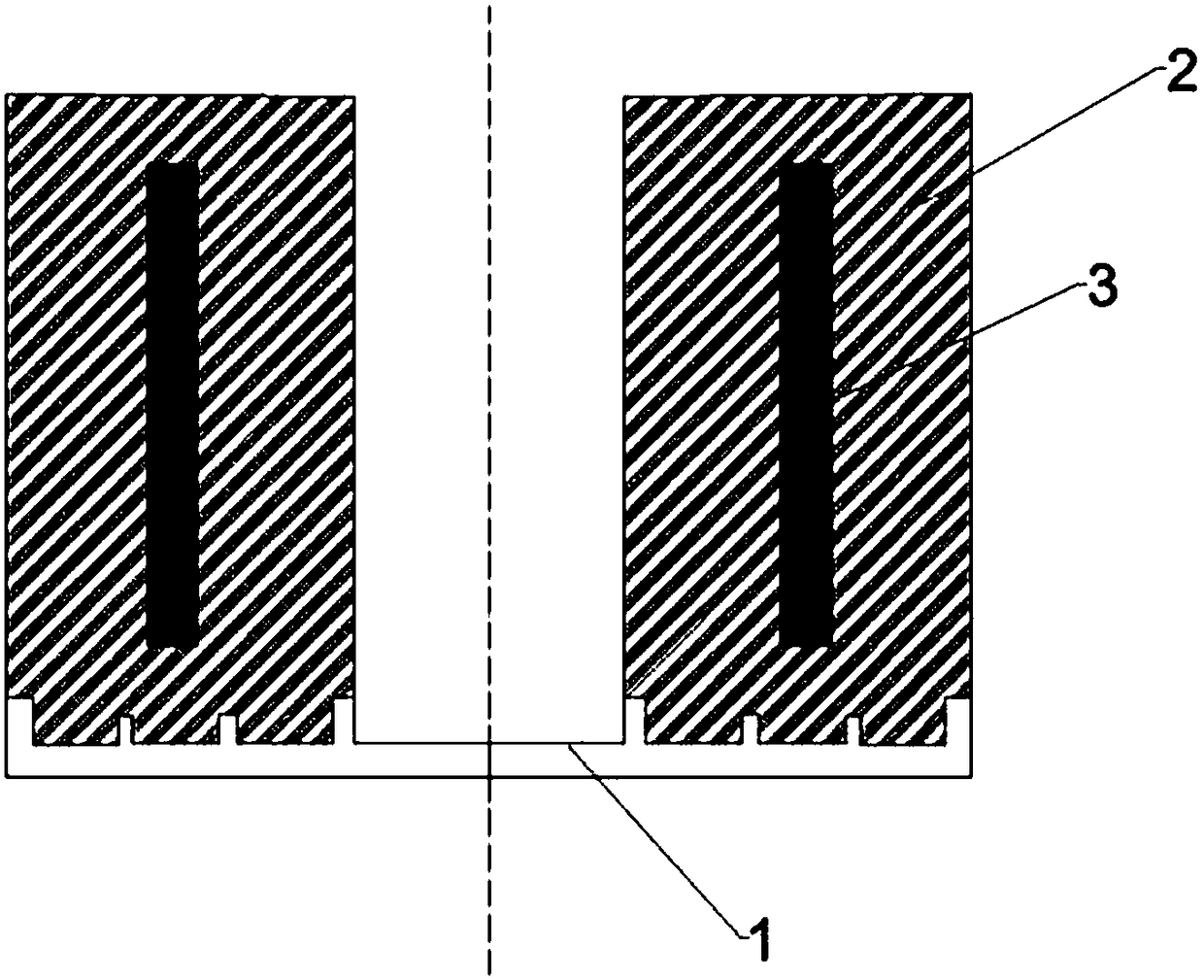

Ultrasonic single-excitation elliptical vibration grinding design method and device

PendingCN110202425AIncrease the degree of interferenceReduce grinding forceDesign optimisation/simulationSpecial data processing applicationsSonificationEngineering

The invention discloses an ultrasonic single-excitation elliptical vibration grinding design method and device. A transducer, an amplitude-change pole and a cup-shaped grinding tool of the device areconnected together through prestressed bolts and nuts, the transducer converts electrical signals provided by an ultrasonic generator into longitudinally-transmitted mechanical vibration, sound wavesof the longitudinal vibration are transmitted to the cup-shaped grinding tool through the transmission effect of the amplitude-change pole, and the cup-shaped grinding tool is divided into a disk segment and a circular pipe segment; and longitudinal vibration excitation of the amplitude-change pole enables the disk segment of the cup-shaped grinding tool to do transverse bending pitch circle typevibration, longitudinal vibration of the circular pipe segment is formed through coupling, and compounding of the three different vibration modes of longitudinal vibration-bending vibration-longitudinal vibration is achieved; through the bending vibration of the disk segment and the longitudinal vibration of the circular pipe segment, composite vibration of longitudinal and radial vibration is shown through coupling at the tail end of the circular pipe segment, in the longitudinal and radial plane, the longitudinal and radial vibration can be coupled to form an elliptical vibration trajectory,the design of a resonant system is simplified, and vibration of a grinding wheel disc is made more ideal.

Owner:HENAN POLYTECHNIC UNIV

Polycrystalline diamond composite sheet for drilling in plasticity stratum

The invention discloses a polycrystalline diamond composite sheet for drilling in a plasticity stratum. The polycrystalline diamond composite sheet includes a polycrystalline diamond layer and a hardalloy base supporting body bonded to the polycrystalline diamond layer, wherein the polycrystalline diamond layer includes an upper surface and an outer edge surface, and plough-cutting blade teeth and chip removing grooves are formed in the upper surface and the outer edge surface at the junction area of the supreme part; and the plough-cutting teeth are connected with the chip removing grooves at a certain angle and extend in a circular distribution mode in the radial direction. According to the polycrystalline diamond composite sheet for drilling in the plasticity stratum, the structure hasthe advantages of being high in sharpness and efficient in chip removing, the well drilling efficiency can be greatly improved, the mud balling phenomenon is prevented, and stability of well drillingplatform control is ensured.

Owner:SF DIAMOND CO LTD

Ceramic grinding tool for low-temperature high-strength ceramic binder

The invention discloses a ceramic grinding tool for a low-temperature high-strength ceramic binder. The ceramic grinding tool for the low-temperature high-strength ceramic binder is characterized by comprising the following substances in parts by weight: 15-30 parts of dextrin liquor, 6-9 parts of closed cell perlite, 21-40 parts of borax glass, 3-4 parts of molybdenum disilicide, 5-10 parts of calcite, 3-12 parts of magnesite, 1-3 parts of silicate ester, 10-20 parts of potassium feldspar, 1-3 parts of potassium oxide, 5-20 parts of leptynite, 20-34 parts of agate, 3-4 parts of carbide, 10-19 parts of yellow dextrin, 1-3 parts of calcium hydrophosphate, 20-40 parts of calcite and 5-9 parts of cryolite. The ceramic grinding tool of the low-temperature high-strength ceramic binder, which is disclosed by the invention, has the beneficial effects of being sharp in abrasive particle, less in trimming times, capable of carrying out grinding with great cutting depth, great feed, heavy load and high efficiency, good in self-sharpening performance, low in grinding temperature, good in toughness, small in abrasion, high in durability and long in service life.

Owner:QINGDAO GUOHANG XIANGYU TECH SERVICE

Wafer edge grinding method and device

ActiveCN112975641AReduce grinding heatReduce chippingEdge grinding machinesGrinding drivesWaferStructural engineering

The invention discloses a wafer edge grinding machining method and device, and belongs to the technical field of wafer machining. The device comprises an edge grinding mechanism and a fixing mechanism, the edge grinding mechanism comprises a first bottom plate and a grinding machine located on the first bottom plate, a first grinding wheel is arranged at the end, close to the fixing mechanism, of the grinding machine, the fixing mechanism comprises a second bottom plate and an adsorption device located on the second bottom plate, the adsorption device comprises a hollow motor and a vacuum adsorption pump, the end, close to the edge grinding mechanism, of the hollow motor is connected with a suction cup head used for adsorbing wafers, the suction cup head is connected with the vacuum adsorption pump through a pipeline, and the first grinding wheel comprises a first grinding ring and a second grinding ring. Grinding force and grinding heat in the wafer grinding process can be effectively reduced, the positions of the grinding machine and the wafer are convenient and stable to adjust, the angle can be finely adjusted when the wafers rotate, the edge grinding quality of the wafers is improved, steps of different shapes can be formed at the edges of the wafers, and the probability of edge breakage and fragmentation when the wafers are ground and thinned is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

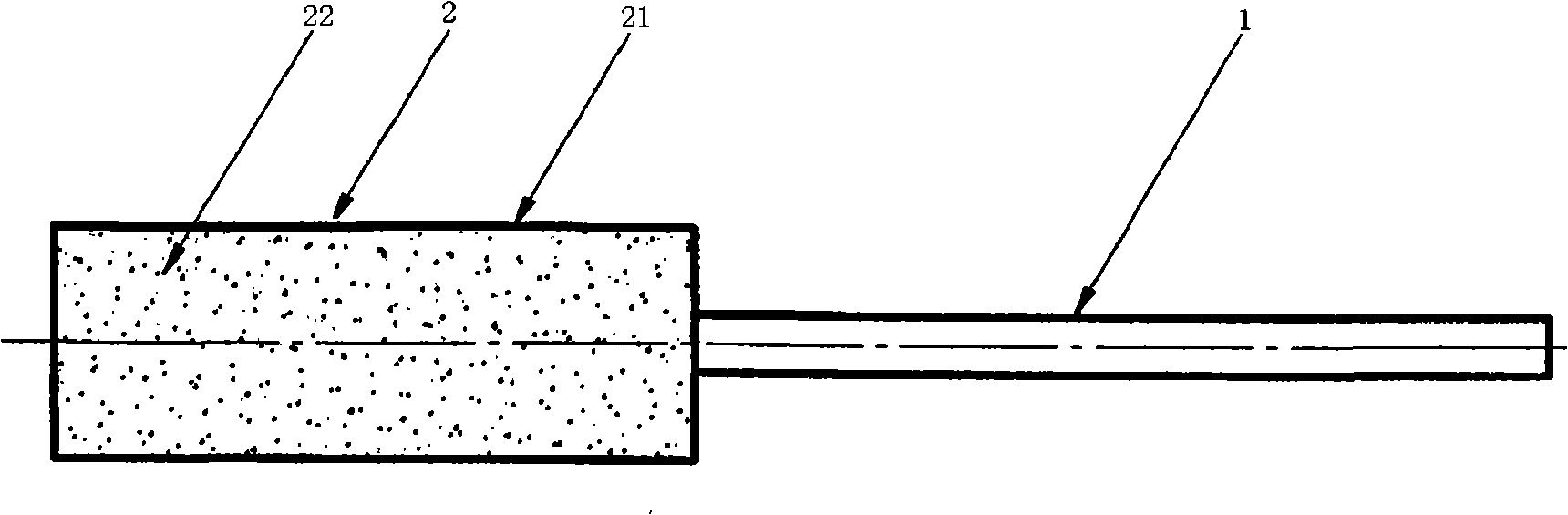

Metal resin composite material grinding wheel special for steel rail grinding and manufacturing method thereof

PendingCN108247552AHigh hardnessImprove thermal stabilityBonded abrasive wheelsGrinding devicesGrinding wheelMetal

The invention discloses a metal resin composite material grinding wheel special for steel rail grinding and a manufacturing method thereof, and belongs to the technical field of grinding wheels. The metal resin composite material grinding wheel comprises a base body and a grinding wheel working layer at the upper end of the base body. The grinding wheel working layer comprises brazed CBN agglomerates and resin bond zirconia corundum abrasives; and the brazed CBN agglomerates are cylindrical brazed CBN grinding blocks, and the round surfaces of the brazed CBN agglomerates are grinding surfaces.The brazed CBN agglomerates are evenly and vertically inserted into the resin bond zirconia corundum abrasives at intervals. The metal resin composite material grinding wheel special for steel rail grinding can maintain good sharpness under long time working conditions, generates less grinding heat, improves the removal efficiency of steel rail materials, and reduces the bluing phenomenon of therail burn; and the ground steel rail has better surface quality, lower roughness and finer rail surface.

Owner:江苏新砺河磨具科技有限公司

Special collision-resistance and modification microcrystalline ceramic abrasive material for machine tool industry, and manufacturing method thereof

ActiveCN110104974AHas a soft elastic effectLubriciousOther chemical processesSilicic acidUnsaturated monomer

The invention discloses a special collision-resistance and modification microcrystalline ceramic abrasive material for machine tool industry, and a manufacturing method thereof. The microcrystalline ceramic abrasive material comprises two parts, wherein the first part is a microcrystalline ceramic formed by sintering alumina powder, lanthanum nitrate hexahydrate and hydroxyapatite in a shuttle kiln, the second part is obtained by polymerizing three components A, B and C, the component A is a mixture of a vinyl olefin-based unsaturated monomer, a phosphorus bidentate ligand, lead powder, activecarbon powder and titanium dioxide powder, the component B is an acrylate-based olefin-based unsaturated monomer, the component C is a sodium silicate aqueous solution with a solute mass fraction of10%, and the second part is a microcapsule structure using the lead powder, the active carbon powder and the titanium dioxide powder as a core, using a silicic acid gel as a medium, and using the vinyl olefin-based unsaturated monomer and acrylate-based olefin-based unsaturated monomer polymer as a mold shell. According to the present invention, the special collision-resistance and modification microcrystalline ceramic abrasive material has characteristics of microcrystalline structure, fine and dense grinding blade, high strength, good toughness, self-loss resistance and durability.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

Methods for oxidation treatment of CBN abrasive particle and for preparation of ceramic binder CBN grinding tool by using CBN abrasive particle

The invention discloses methods for oxidation treatment of a CBN abrasive particle and for preparation of a ceramic binder CBN grinding tool by using the CBN abrasive particle. The methods are characterized in that a uniform and compact film is formed on the surface of the CBN abrasive particle with granularity of 70 to 150 mu m through oxidation treatment of the CBN abrasive particle at a temperature of 850 to 1050 DEG C, thereby improving bonding strength of glass powder on the CBN abrasive particle and enhancing bending strength and wear resistance of the ceramic binder CBN grinding tool. Compared with a CBN grinding tool prepared from an unoxidized CBN abrasive particle, the CBN grinding tool prepared from the CBN abrasive particle having undergone oxidation treatment has the following characteristics: a structure is uniform, bonding strength between a binder and the CBN abrasive particle is high, bending strength of the grinding tool is great, and high speed grinding requirements of the CBN grinding tool are met.

Owner:XI AN JIAOTONG UNIV

Roller grinding fluid and preparation method thereof

PendingCN113956912APrevent rustIncrease productivityTransportation and packagingRotary stirring mixersMetalworking fluidSoftened water

The invention belongs to the technical field of metal working fluids, and particularly relates to a roller grinding fluid and a preparation method thereof, and the roller grinding fluid comprises the following components in percentage by mass: 20-26% of ricinoleic soap, 6-10% of polyethylene glycol, 5-10% of an antirust agent, 2-6% of a cosolvent, 2-6% of a defoaming agent and the balance of softened water. The ricinoleic acid soap has large affinity to the metal surface and higher lubricating property than mineral oil, the ricinoleic acid soap and polyethylene glycol have a synergistic effect, the surface tension of the grinding fluid is reduced, and the grinding fluid has good wettability and can rapidly permeate into a contact area of a grinding wheel and a roller in the using process, and a firm lubricating film is formed in the contact area; and the lubricating film effectively reduces friction and abrasion between the grinding wheel and the roller, reduces grinding heat, improves roughness and precision of the roller, and is excellent in lubricating effect when the grinding wheel and the roller are matched for use.

Owner:SHENYANG PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com