Ultrasonic single-excitation elliptical vibration grinding design method and device

A technology of elliptical vibration and design method, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as inability to design system resonance frequency, achieve good economic benefits, increase interference degree, and achieve ideal vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

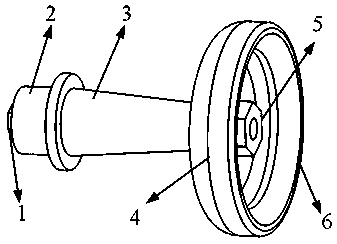

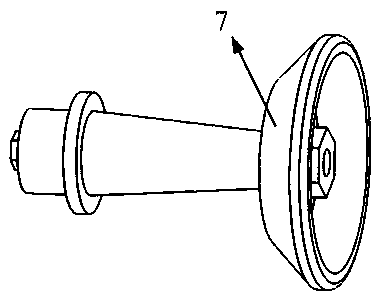

[0042] Example: see Figure 1-Figure 5, in the figure, 1-prestressed bolt, 2-transducer, 3-conical horn, 4-cup grinding tool grinding wheel, 5-nut, 6-abrasive grain layer, 7-bowl-shaped tool grinding wheel.

[0043] The ultrasonic single excitation elliptical vibration grinding device is composed of a prestressed bolt 1, a transducer 2, a horn 3, a cup-shaped grinding tool grinding wheel 4 and a nut 5. The transducer 2 is connected to the horn 3 through the bolt 1. During actual assembly, the pretightening force required by the bolt must be accurately calculated to achieve a good assembly effect. The cup-shaped grinding tool grinding wheel 4 is fixedly connected with the horn 3 through a nut 5 . According to actual processing requirements, abrasive grains are coated on the end of the grinding wheel 4 of the cup-shaped grinding tool to form a circumferential abrasive layer 6 .

[0044] The ultrasonic single excitation elliptical vibration grinding design method comprises the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com