Polymer paint coating and sintering device suitable for inner wall of micro container

A sintering device and polymer technology, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., can solve the problems that stress affects the film forming life, the crystalline coating layer falls off, and affects the thickness of the coating, etc., to achieve Strong uniformity, reduced thermal stress, and improved film-forming life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

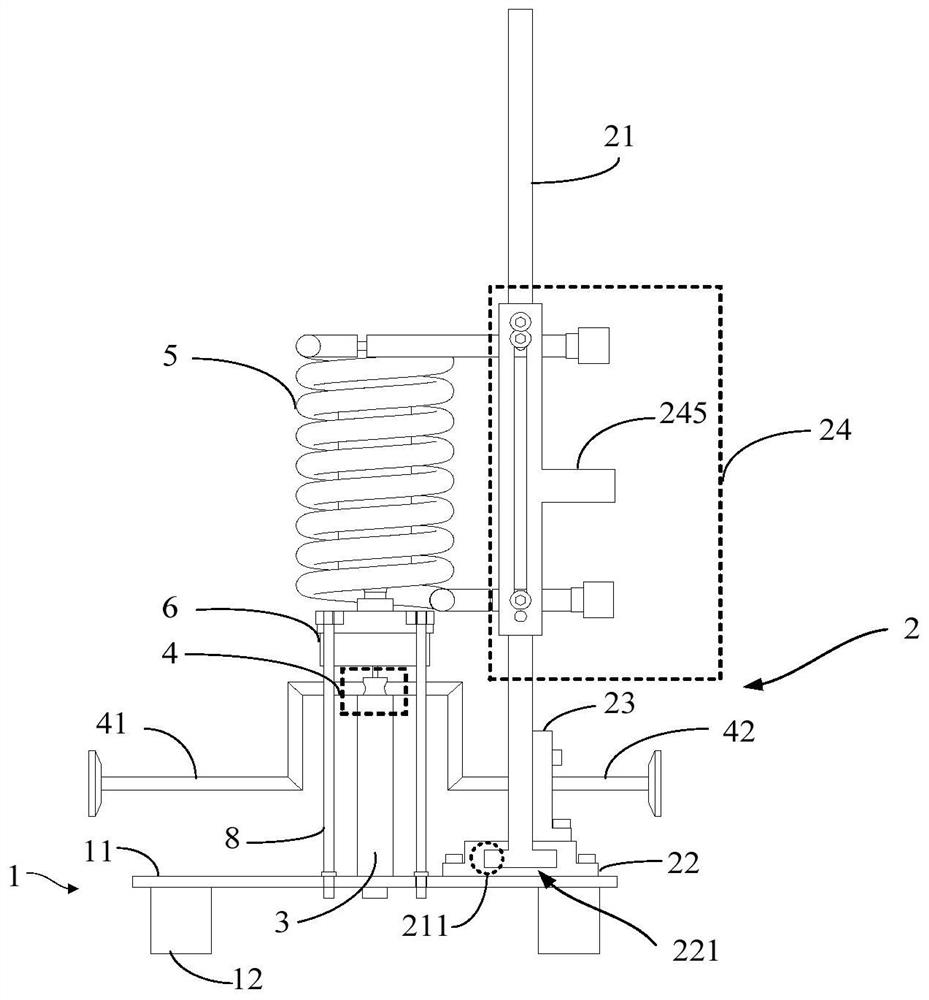

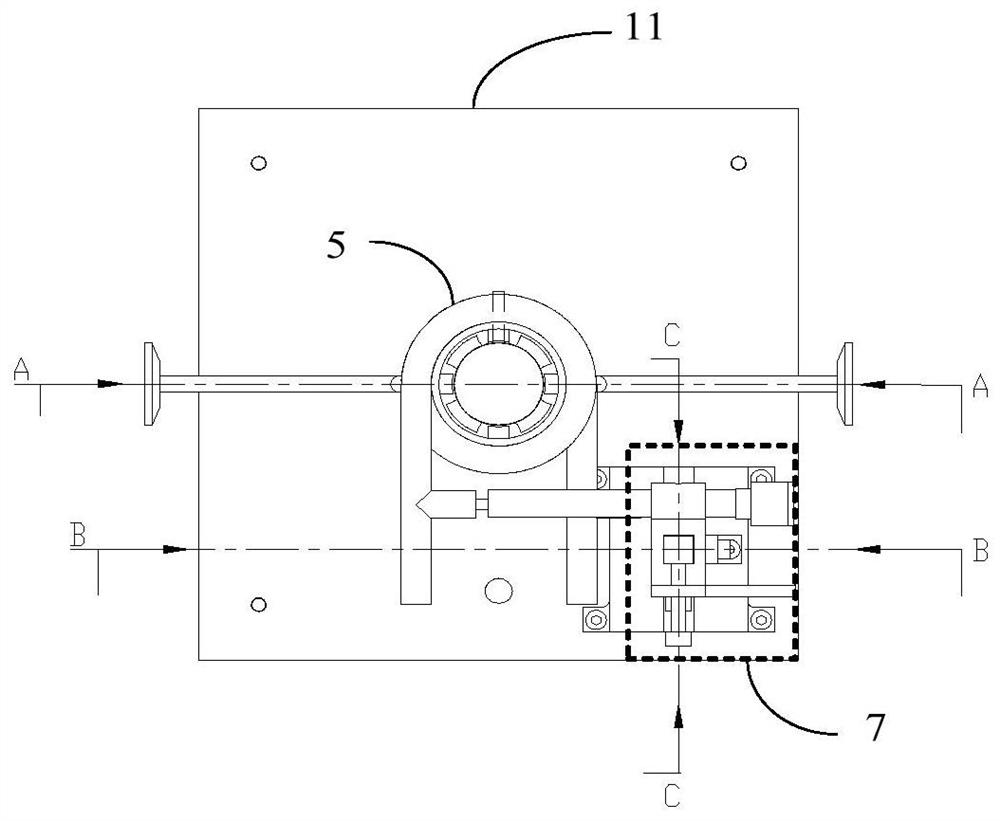

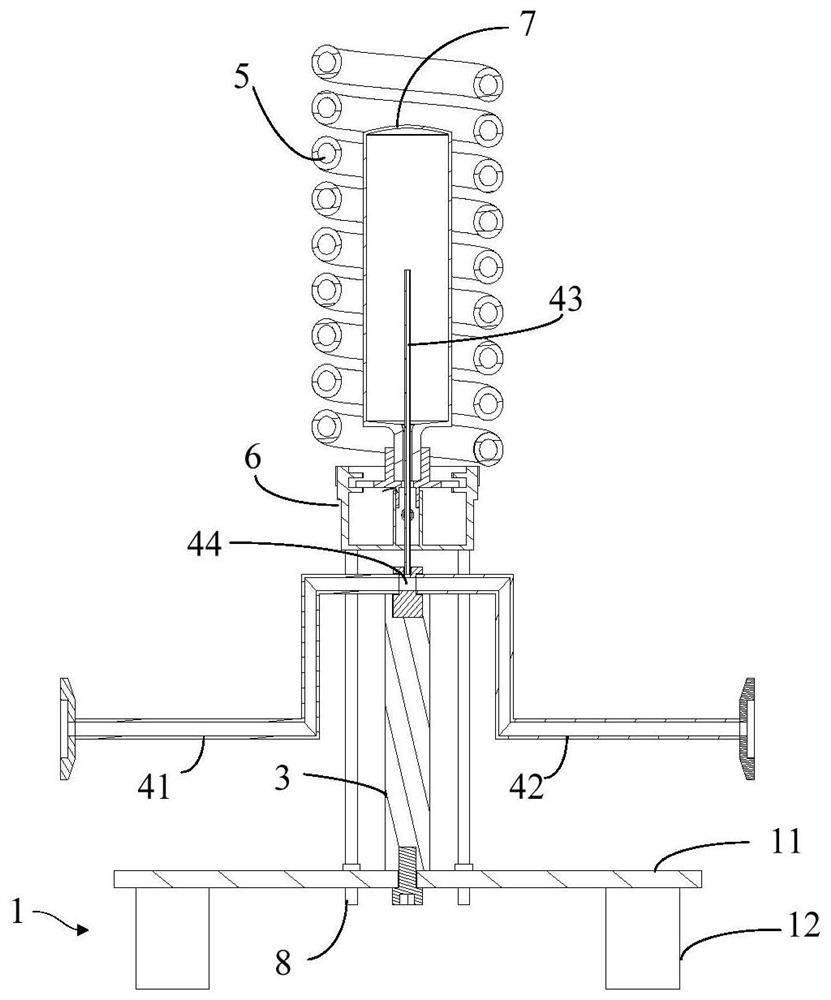

[0025] Such as Figure 1-Figure 3 As shown, the polymer paint coating and sintering device suitable for the inner wall of a tiny container of the present invention is suitable for a tiny non-metallic container, including a base 1, a translation lifting device 2 installed on the base 1 and fixed by a support column 3 The gas delivery device 4 on the base 1, wherein the translation lifting device 2 is connected with the spiral lamp tube 5, the gas delivery device 4 communicates with the container 7 to be processed through the support box 6, and the support box 6 is fixed on the on base 1. During use, the container 7 to be processed is placed inside the spiral lamp tube 5 to be heated by the movement of the translation lifting device 2 .

[0026] Each of the above-mentioned devices will be further described in detail below.

[0027] The base 1 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com