Method for preparing gradient nano-structure on surface of metal material

A technology of organizational structure and metal materials, applied in the direction of nanotechnology, can solve problems such as complex equipment, limited practicability, and complex equipment structure, and achieve the effects of reducing equipment loss and manufacturing costs, excessively gentle hardness gradient, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

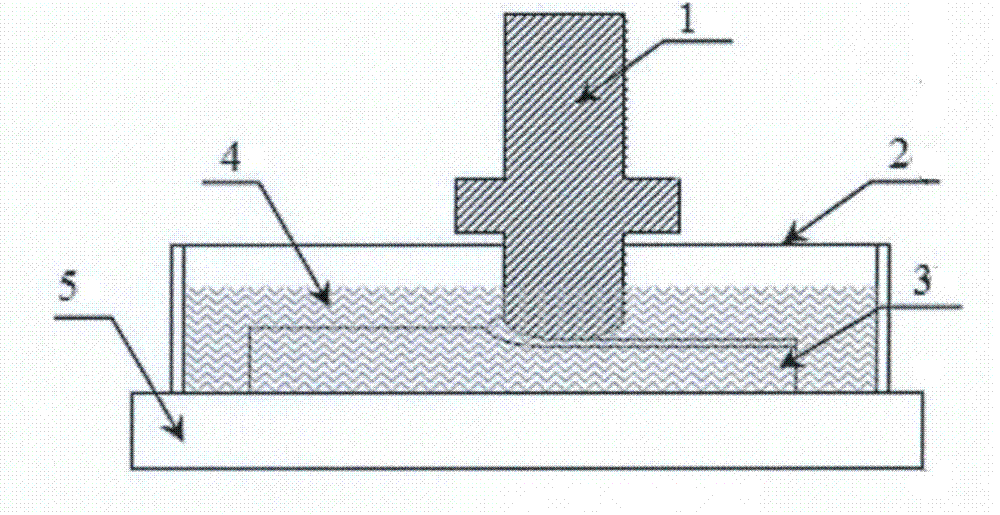

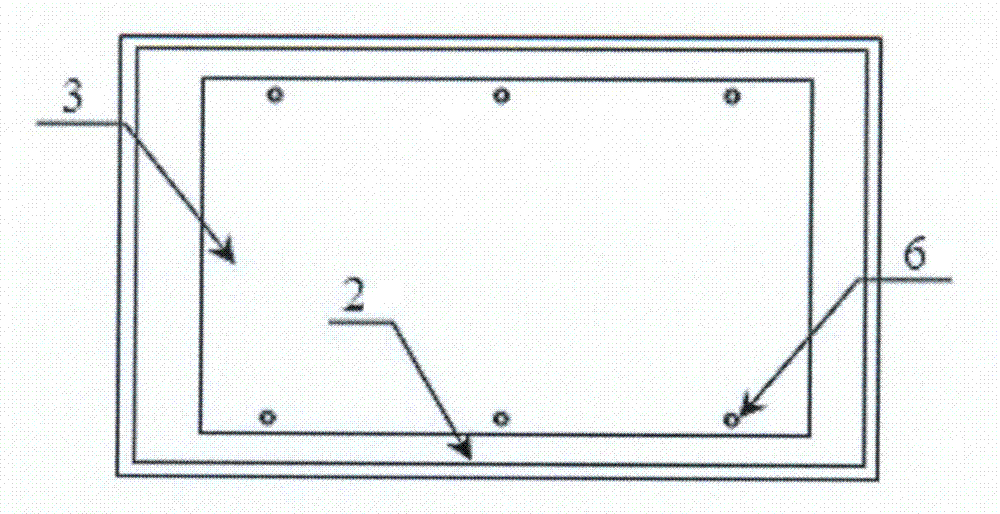

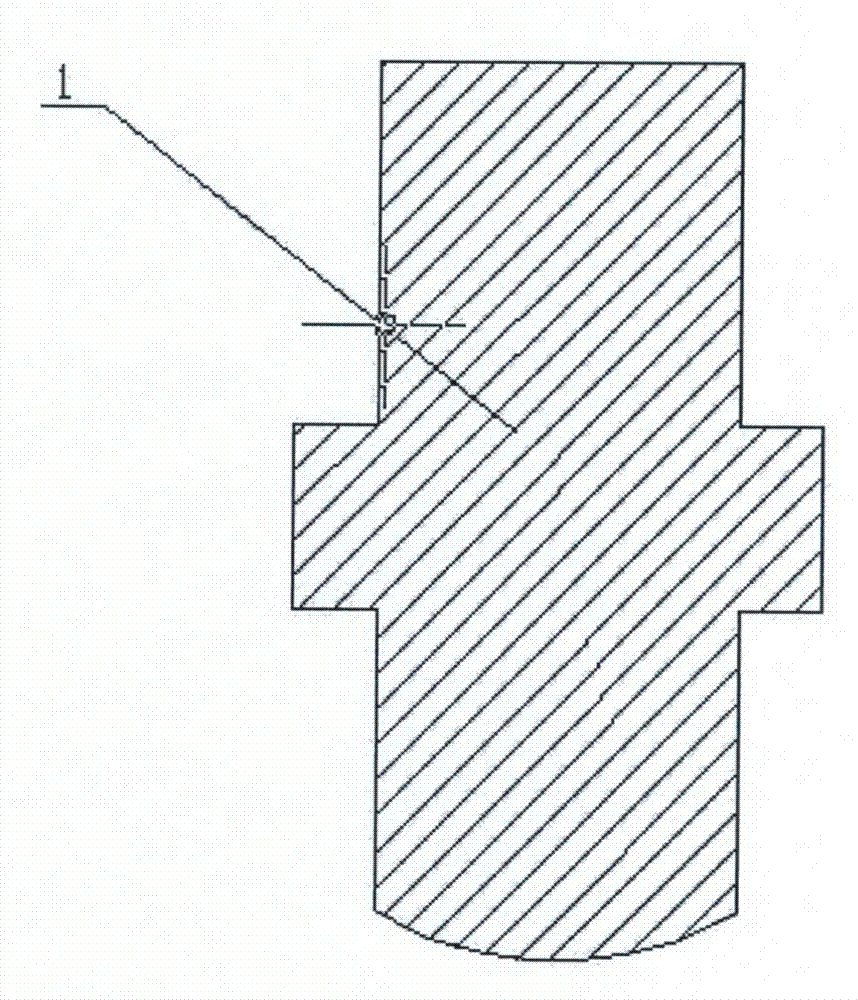

Method used

Image

Examples

Embodiment 1

[0036] Using the above method to process zirconium 702 material by low temperature shear deformation, the process parameters are:

[0037] Tool head speed: 200rpm;

[0038] Workpiece traveling speed: 100mm / min;

[0039] Morph Rate: 10-10 2 the s -1 ;

[0040] Shear deformation strain: 3-5;

[0041] Deformation temperature: -100°C;

[0042] Processing times: 1;

[0043] Zirconium 702 alloy with a purity of 96% (weight percent), hot extrusion delivery state, and an average grain size of 10 μm.

[0044] The depth of the surface deformation layer obtained after treatment is 300 μm, such as Figure 4 . According to XRD diffraction analysis, the surface grain size is calculated to be 21.25nm.

Embodiment 2

[0046] Using the above method to process zirconium 702 material by low temperature shear deformation, the process parameters are:

[0047] Tool head speed: 200rpm;

[0048] Workpiece traveling speed: 50mm / min;

[0049] Morph Rate: 10-10 2 the s -1 ;

[0050] Shear deformation strain: 3-5;

[0051] Deformation temperature: -100°C;

[0052] Processing times: 1;

[0053] Zirconium 702 alloy with a purity of 96% (weight percent), hot extrusion delivery state, and an average grain size of 10 μm.

[0054] The treated surface layer is nearly equiaxed nanocrystals, and the average grain size of the surface layer is about 12nm, such as Figure 5 As shown in (a)~(c), the bright field image, dark field image and selected area electron diffraction photo of the zirconium 702 material surface processed by the technology of the present invention.

Embodiment 3

[0056] Using the above method to process zirconium 702 material by low temperature shear deformation, the process parameters are:

[0057] Equipment: special high-speed surface shear deformation equipment;

[0058] Tool head speed: 200rpm;

[0059] Workpiece traveling speed: 100mm / min;

[0060] Morph Rate: 10-10 2 the s -1 ;

[0061] Shear deformation strain: 3-5;

[0062] Deformation temperature: -100°C;

[0063] Processing times: 1;

[0064] Zirconium 702 alloy with a purity of 96% (weight percent), hot extrusion delivery state, and an average grain size of 10 μm.

[0065] The treated surface layer is nearly equiaxed nanocrystals, and the average grain size of the surface layer is about 18nm, such as Image 6 As shown in (a)~(c), the bright field image, dark field image and selected area electron diffraction photo of the zirconium 702 material surface processed by the technology of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| deformation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com