Patents

Literature

412results about How to "Reduce loss cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

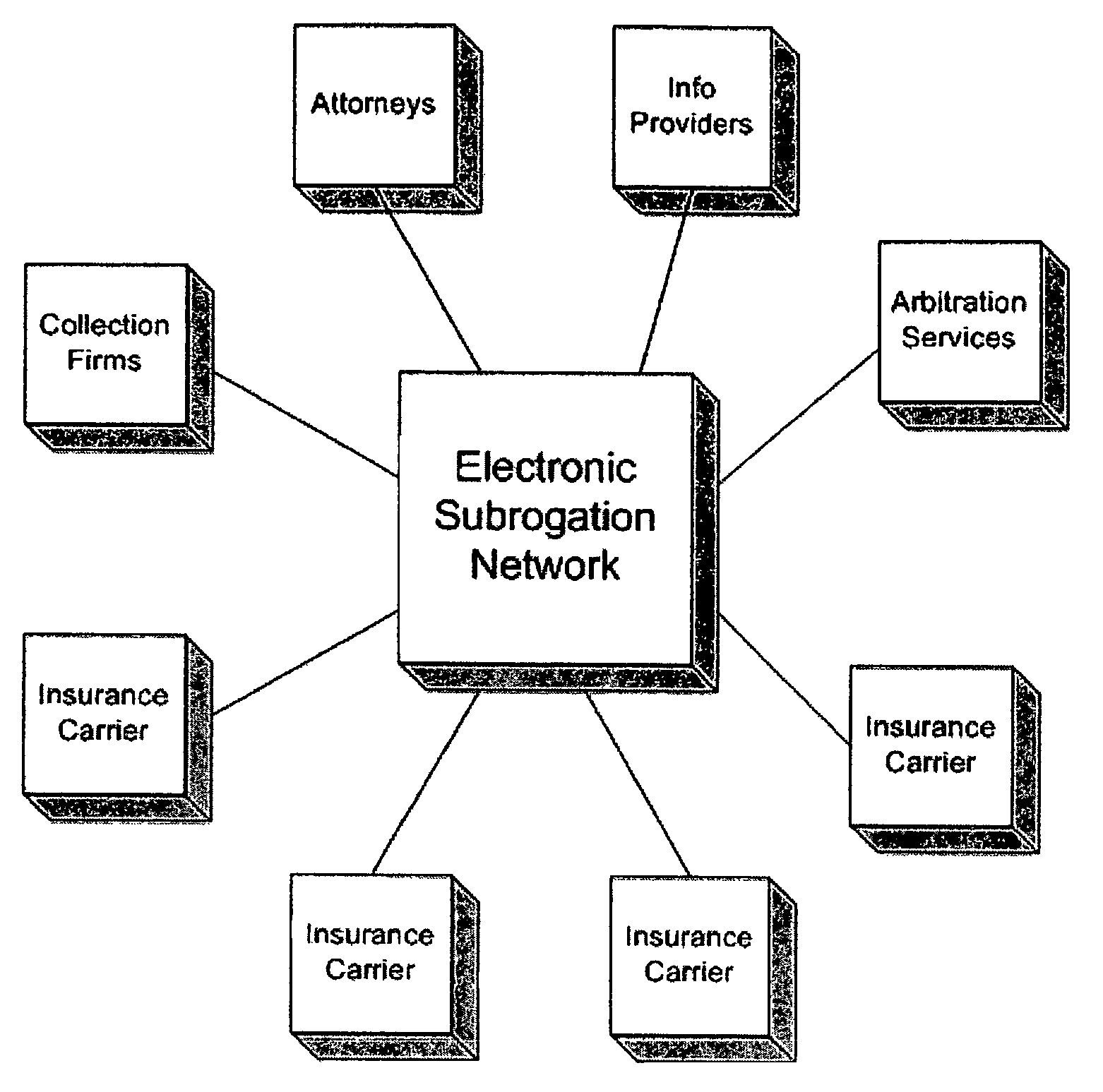

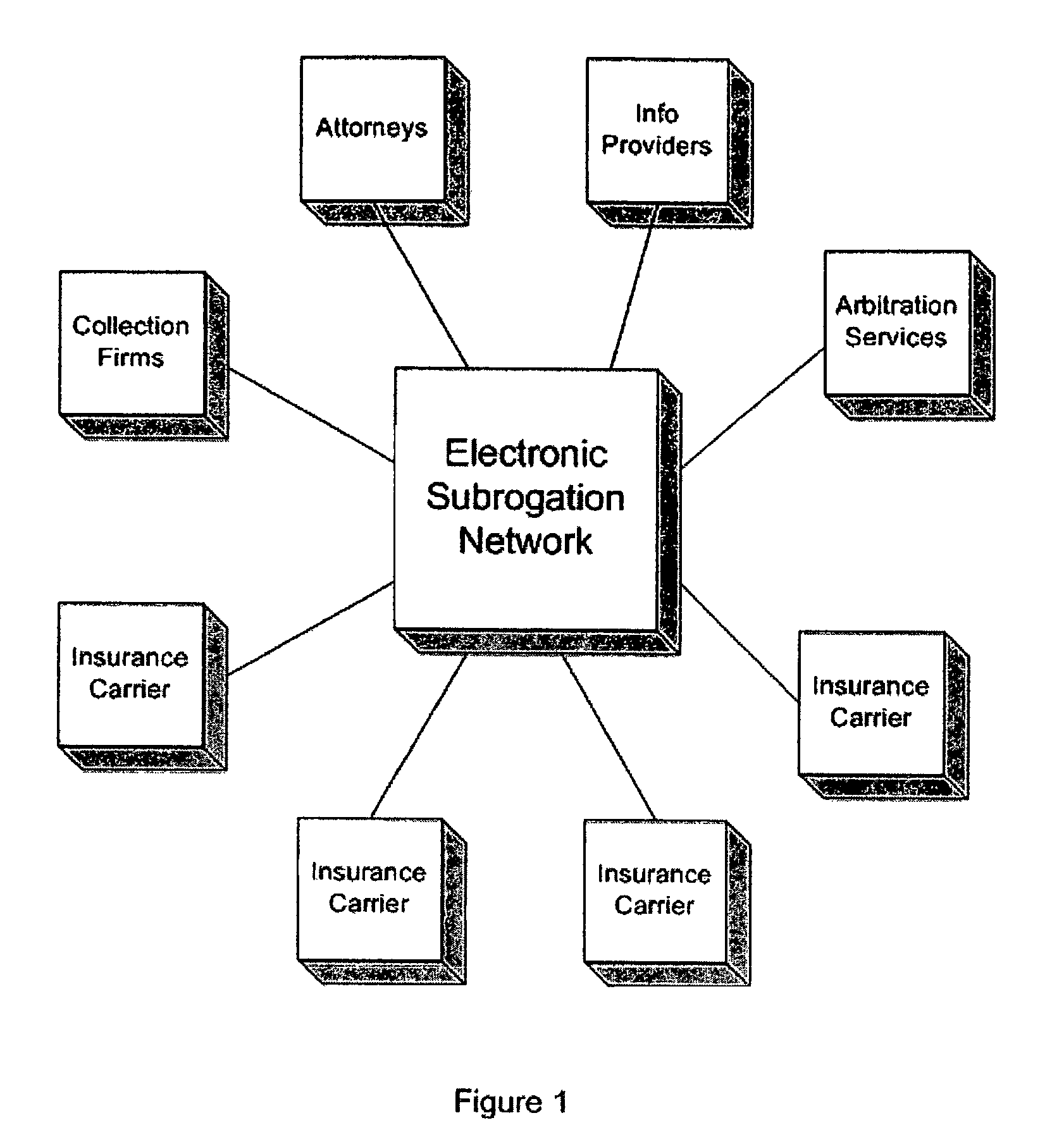

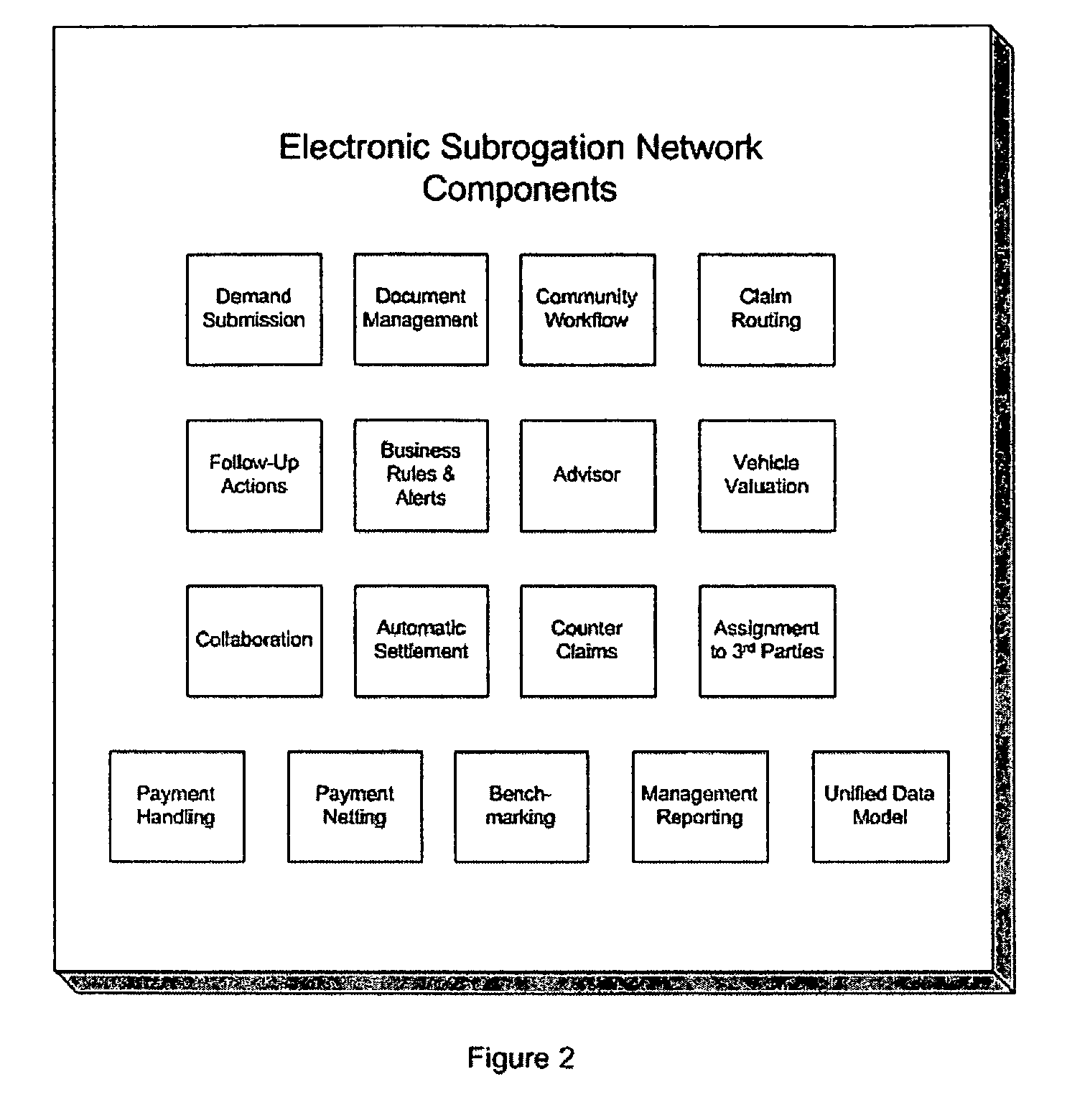

System and process for electronic subrogation, inter-organization workflow management, inter-organization transaction processing and optimized web-based user interaction

ActiveUS7962385B2Reduced processing power requirementsReduce message sizeFinanceOffice automationInter organizationalTransaction processing system

An intelligent electronic subrogation network (“ESN”) automates intra-organization workflow, inter-organization workflow and collaboration for insurance subrogation. This ESN is facilitated by a novel system architecture and process that includes an inter-organizational workflow management system, an inter-organizational transaction processing system, and a unique mechanism for optimizing and enriching web-based user interaction within any such system.

Owner:ARBITRATION FORUMS

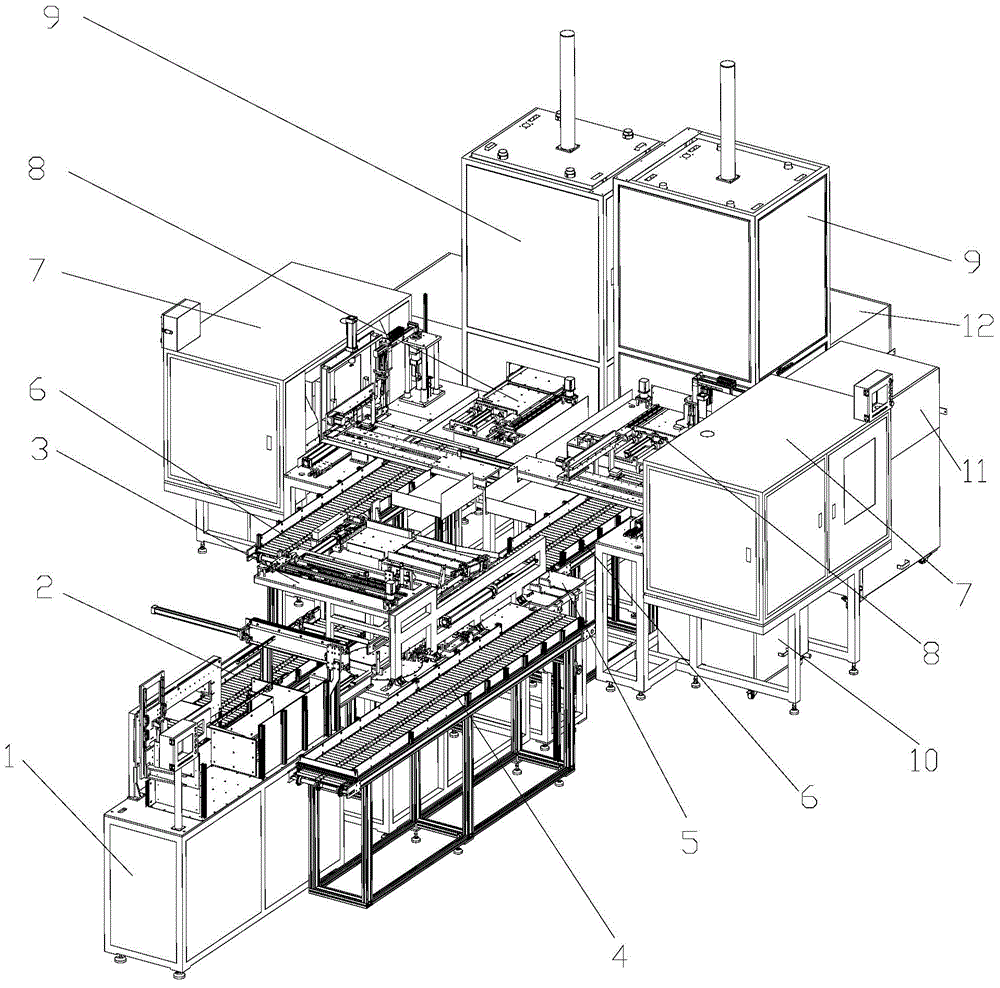

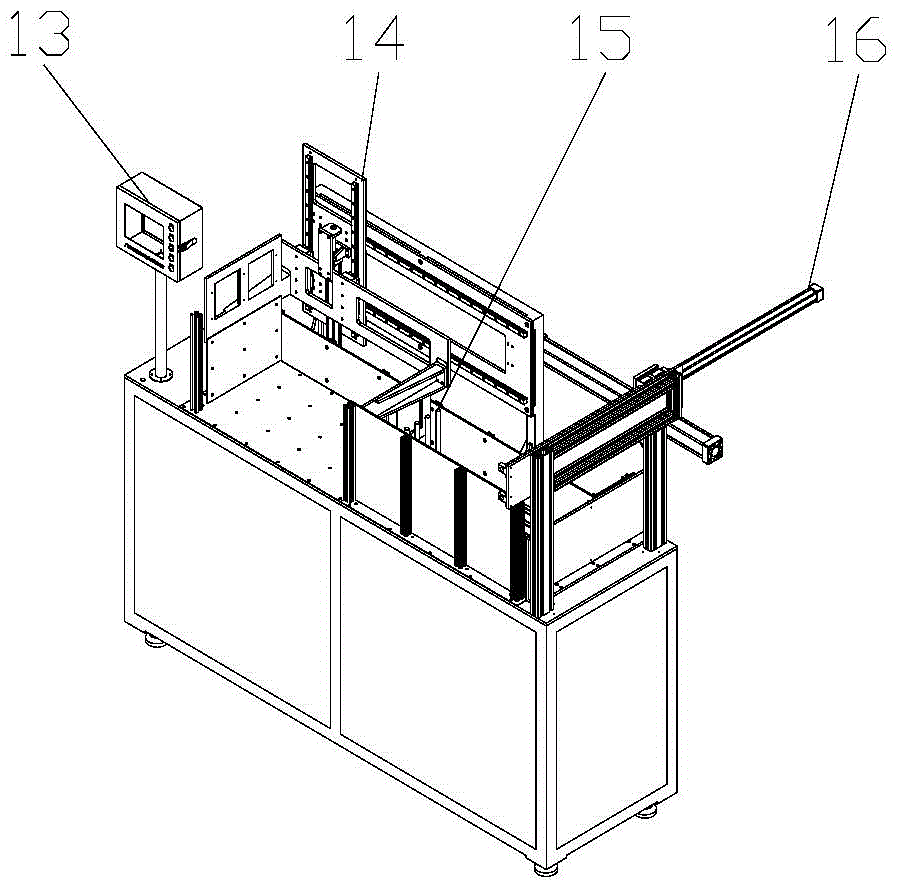

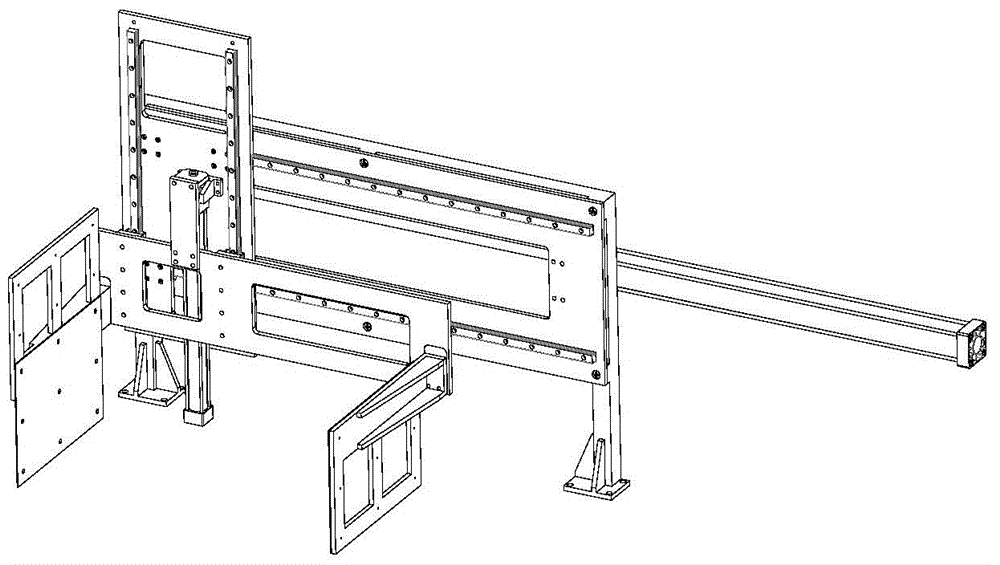

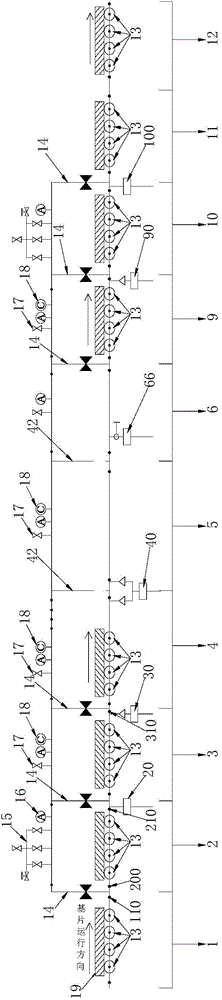

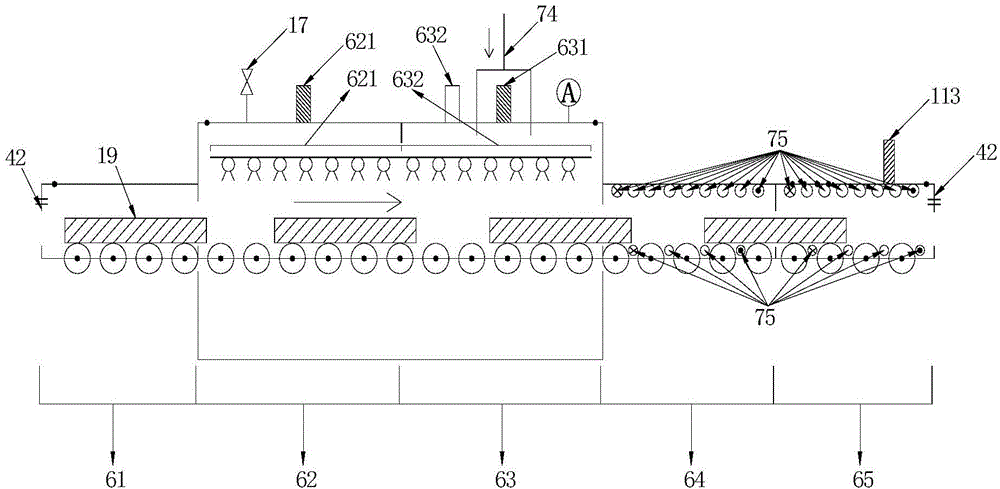

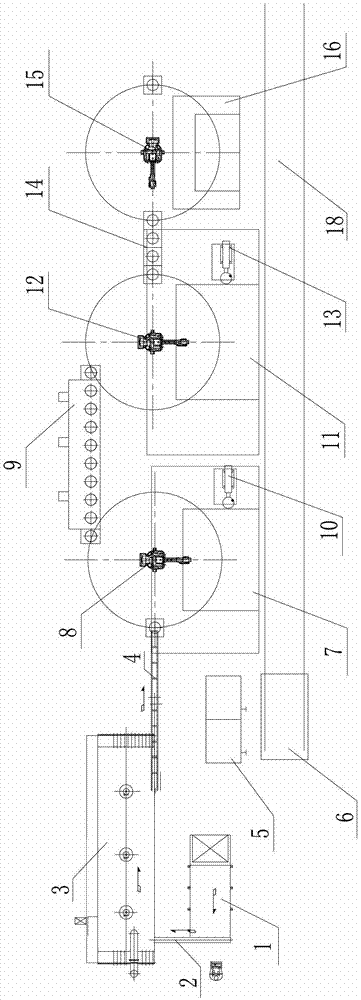

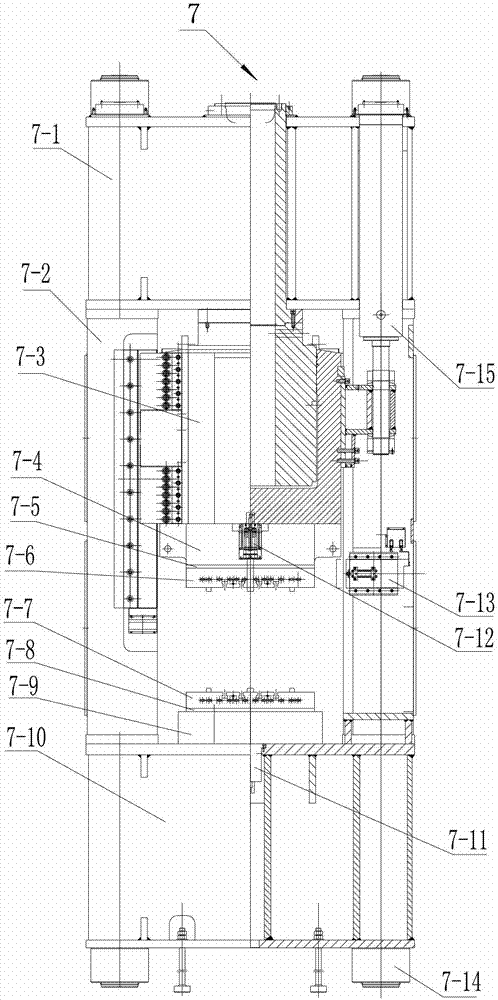

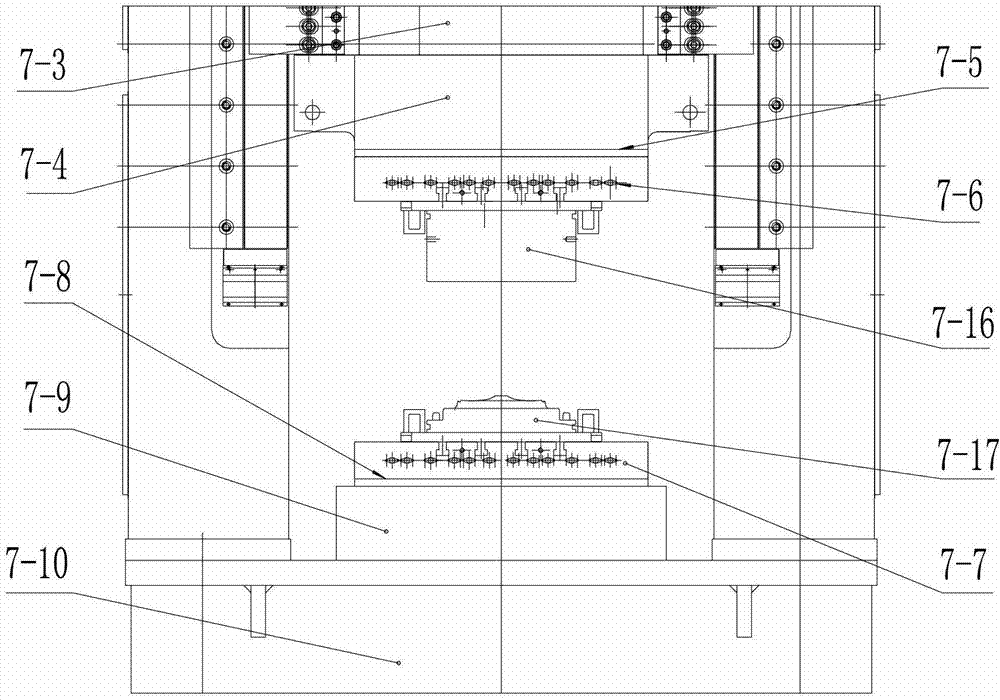

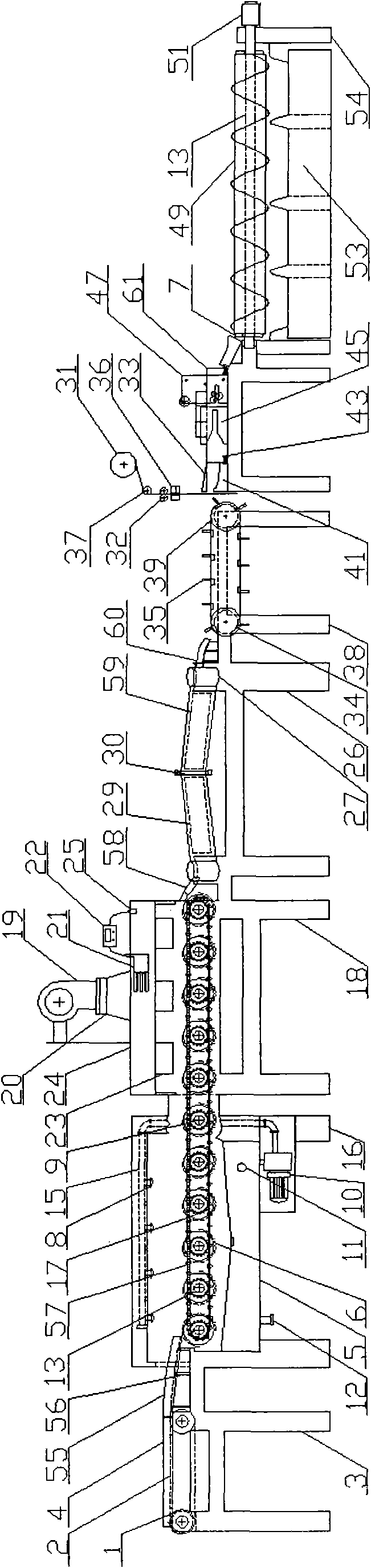

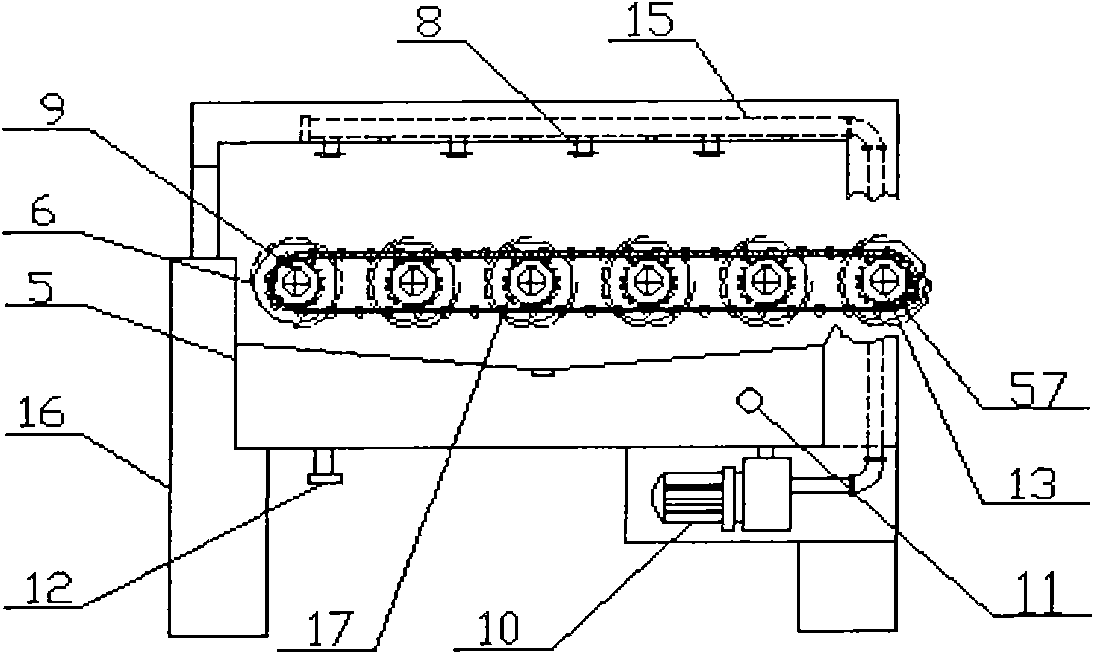

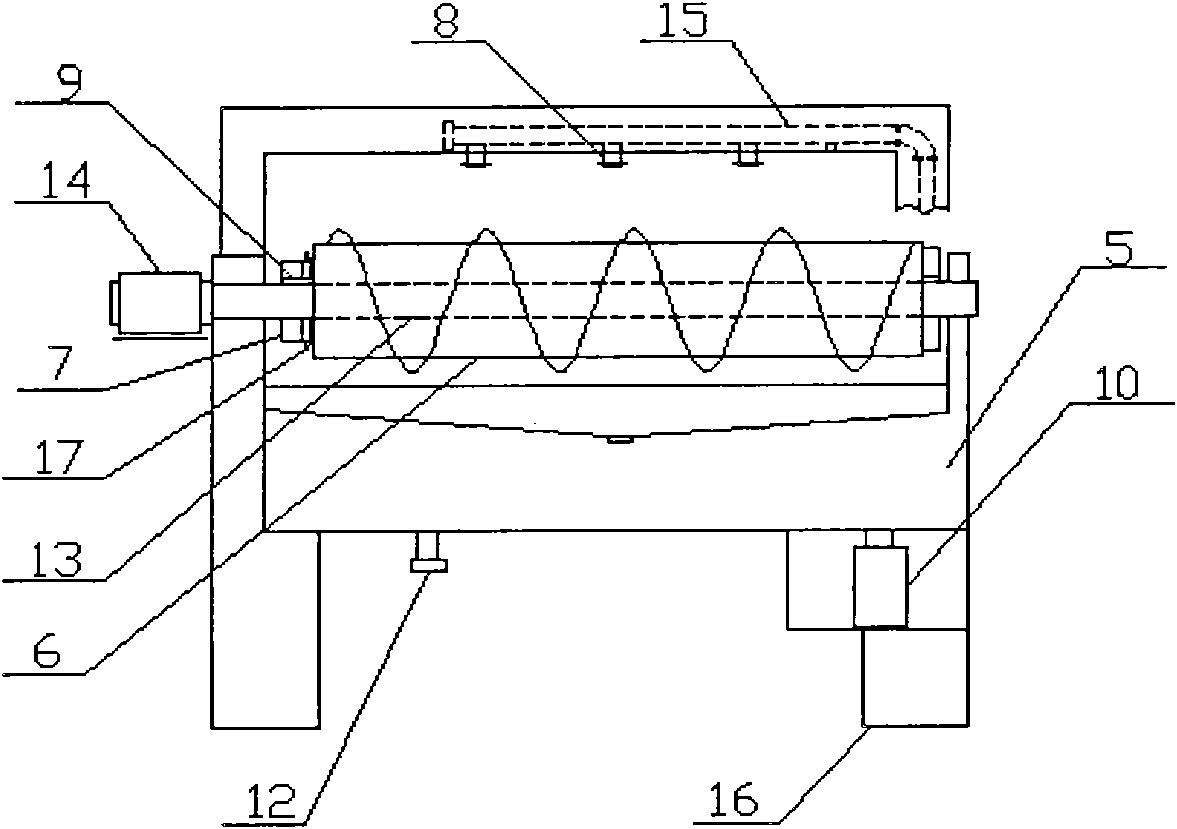

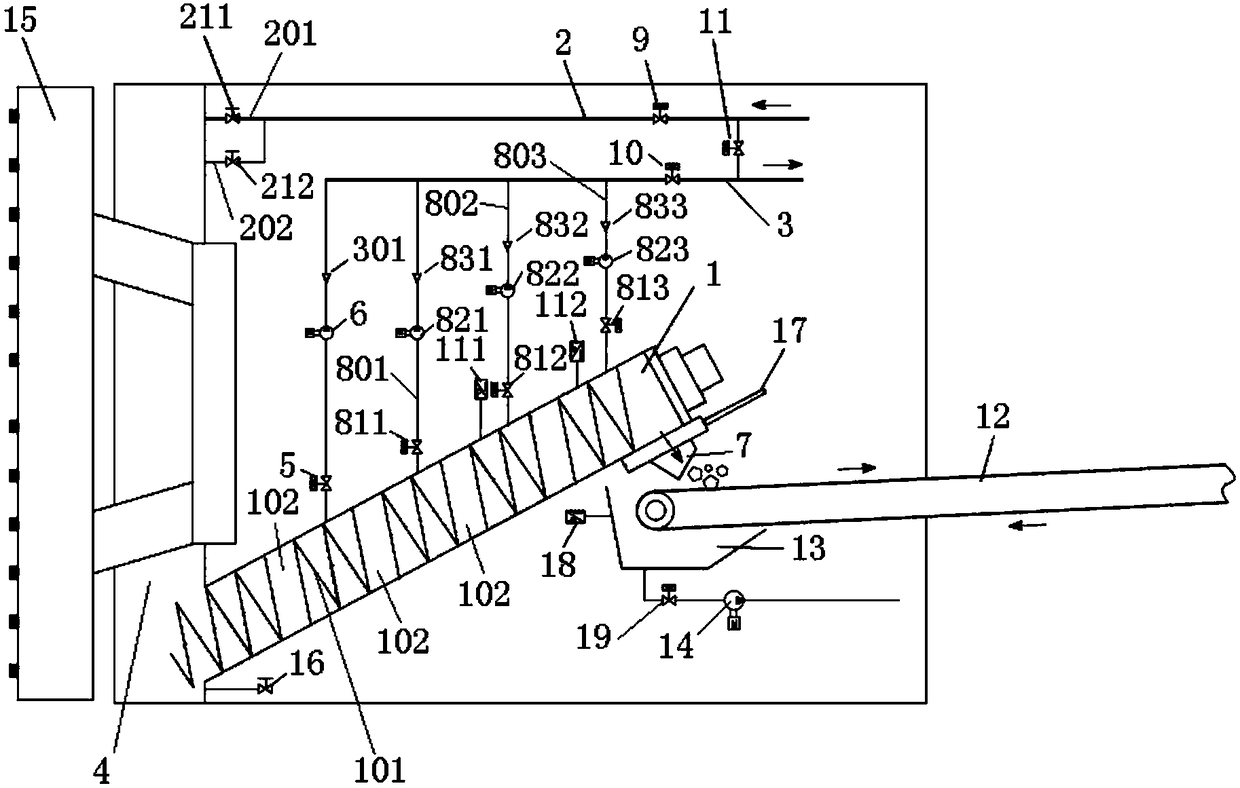

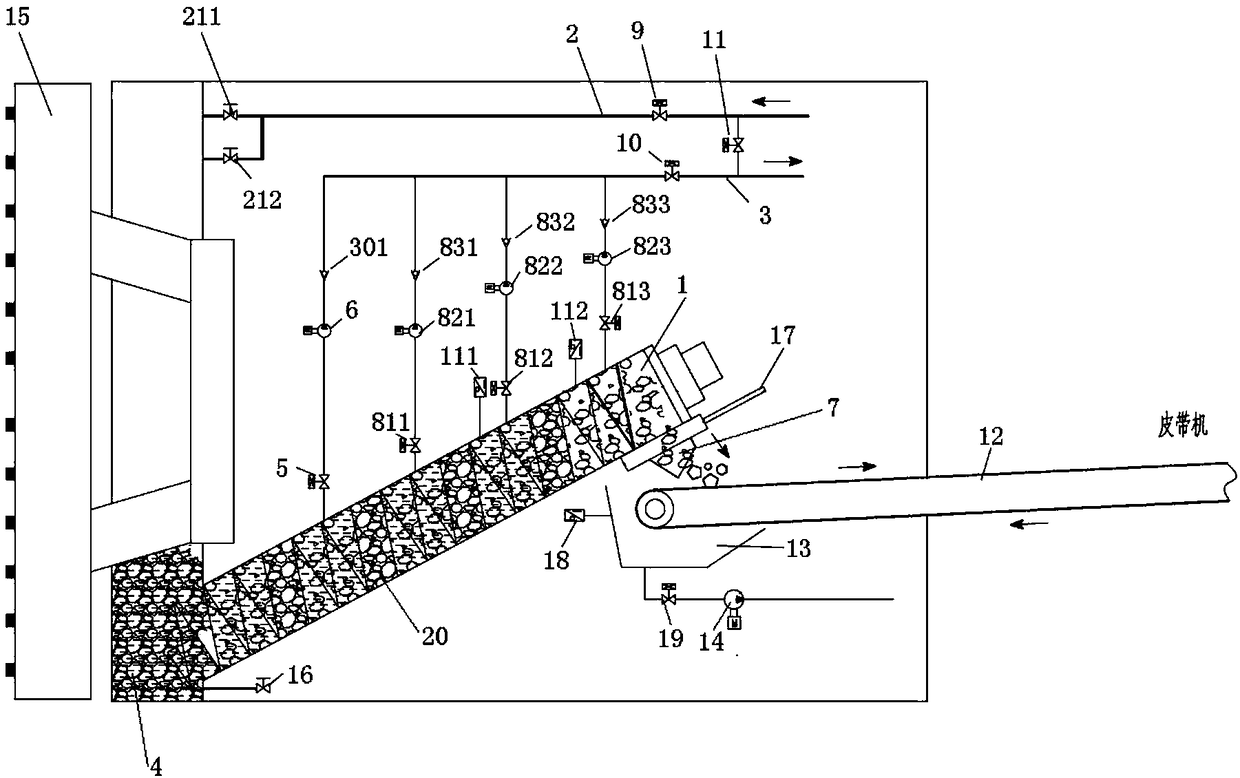

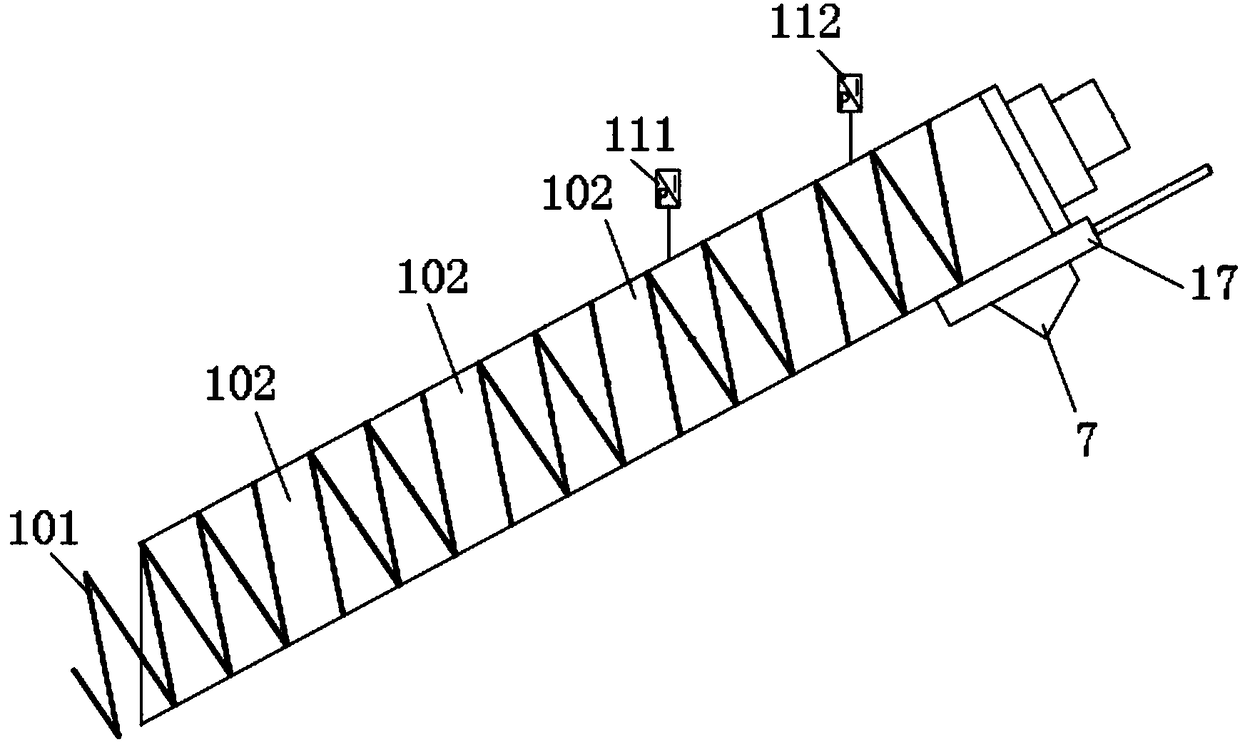

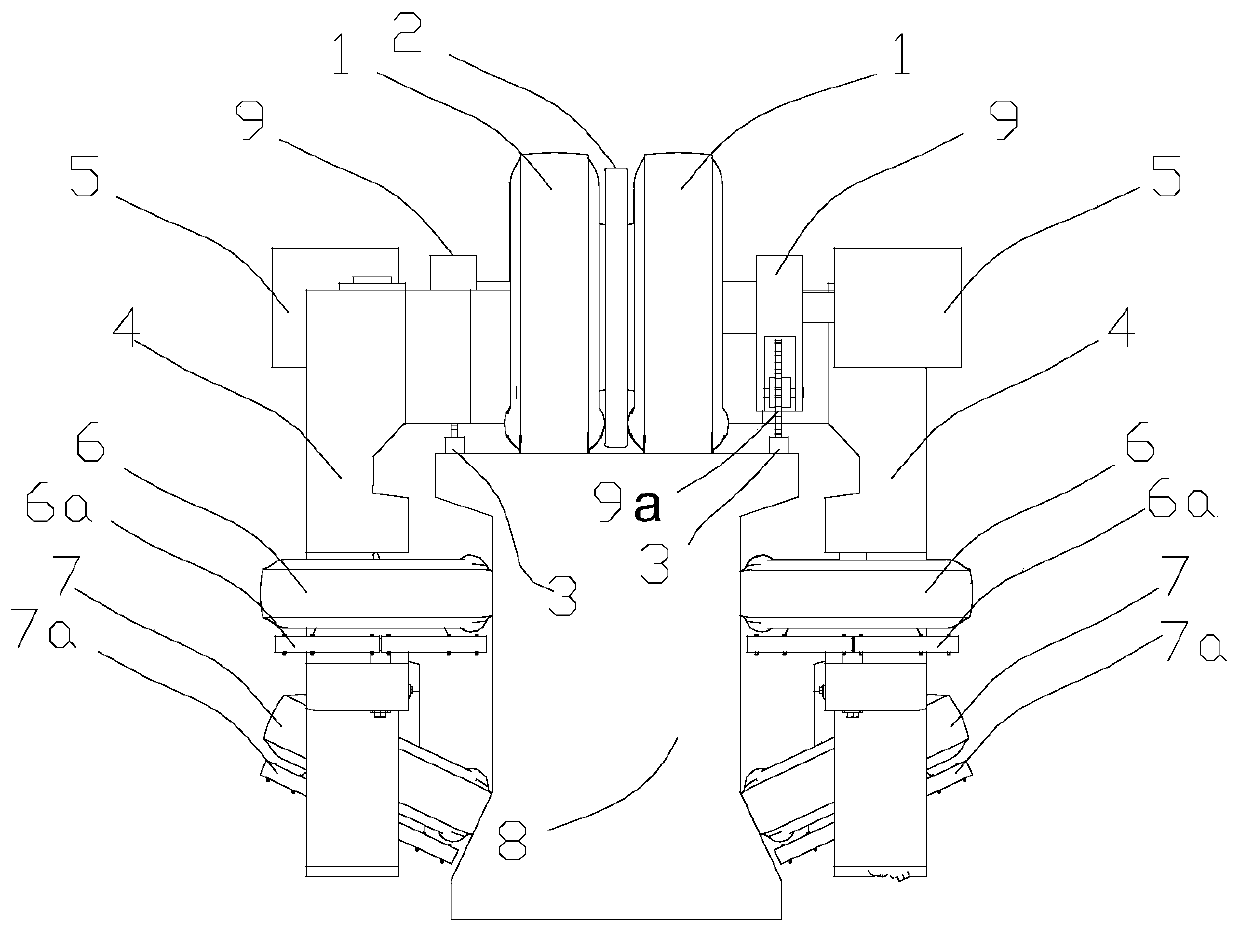

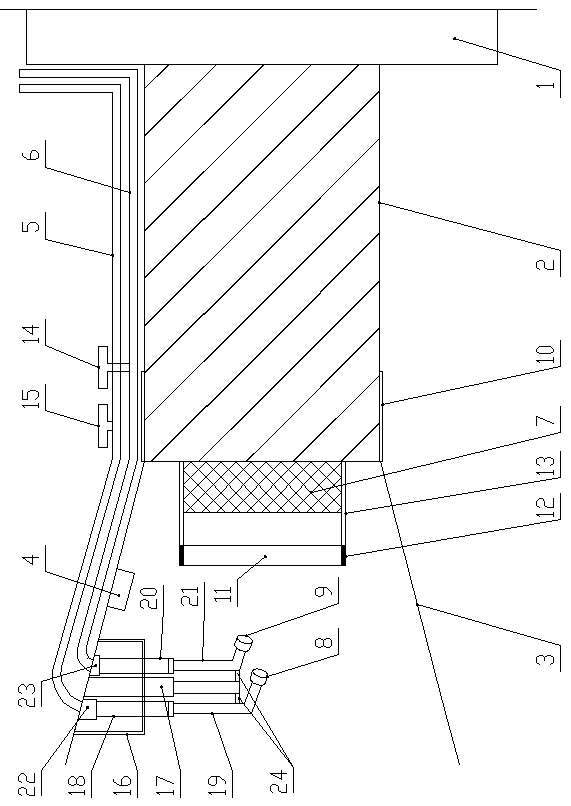

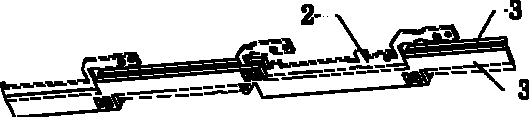

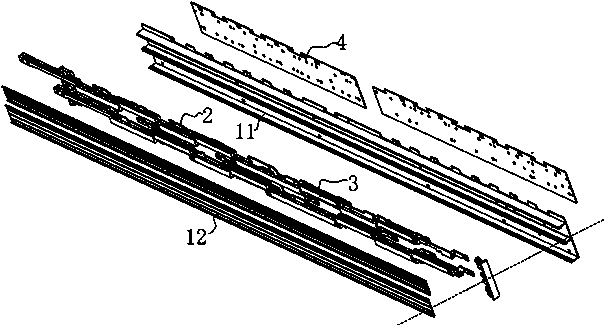

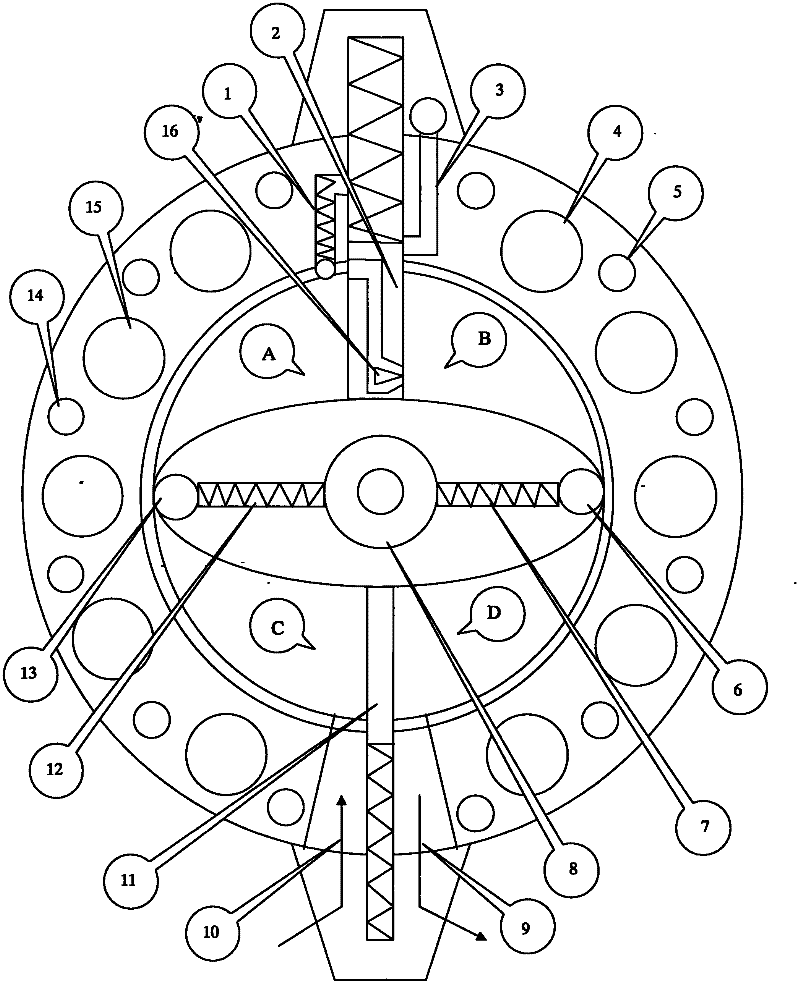

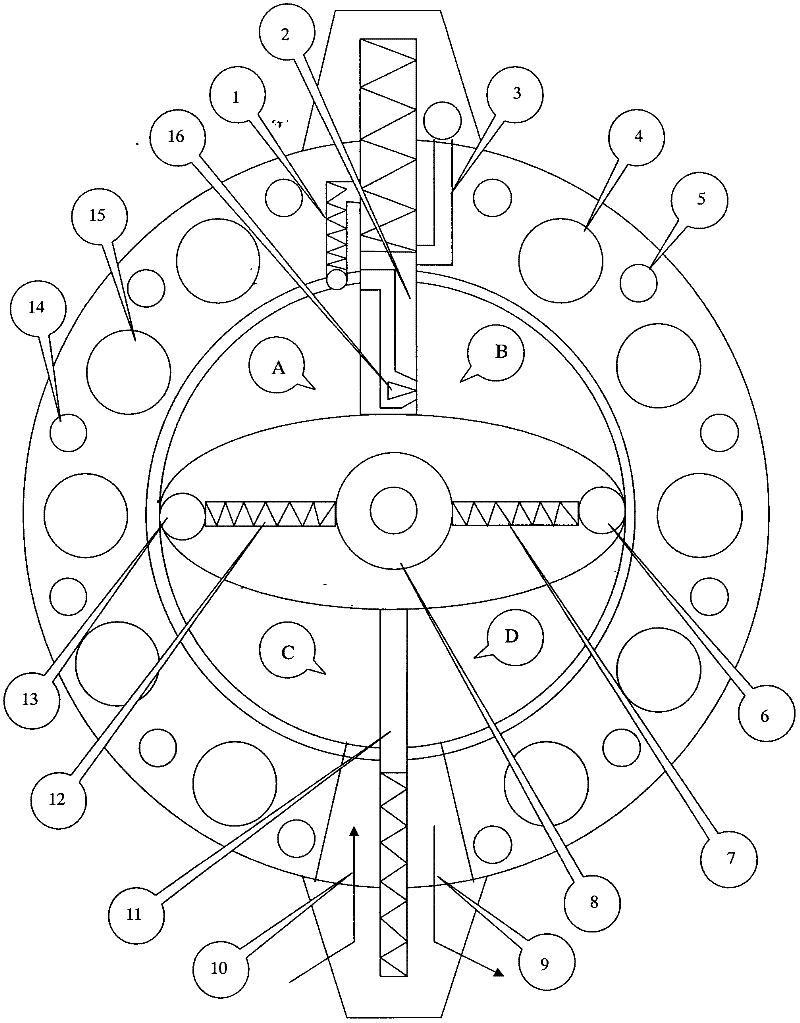

Novel waste power battery full-automatic dismantling device and method

ActiveCN104157927AReduce loss costReduce cooling costsSolid waste disposalWaste accumulators reclaimingPower batteryMaterial distribution

The invention relates to a novel waste power battery full-automatic dismantling device including: 1, a loading mechanism, 2, a loading conveyer, 3, a four-station material poking mechanism, 4, material distribution conveyers, 5, cutting devices, 6, separation feeding mechanisms, 7, separators, 8, outer shell storage boxes, and 9, electric core storage boxes. Along the power battery heading direction, the loading mechanism, the loading conveyer, the four-station material poking mechanism, the material distribution conveyers, the cutting devices, the separation feeding mechanisms and the separators are successively arranged; the outer shell storage boxes and the electric core storage boxes are respectively connected with the separators. The invention also relates to a novel waste power battery full-automatic dismantling method. The device has the advantages of simple structure and high dismantling efficiency, adopts a battery mechanical dismantling way integrating electrode head end one-time cutting and electric core clipping-out, and belongs to the power battery recycling processing field.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

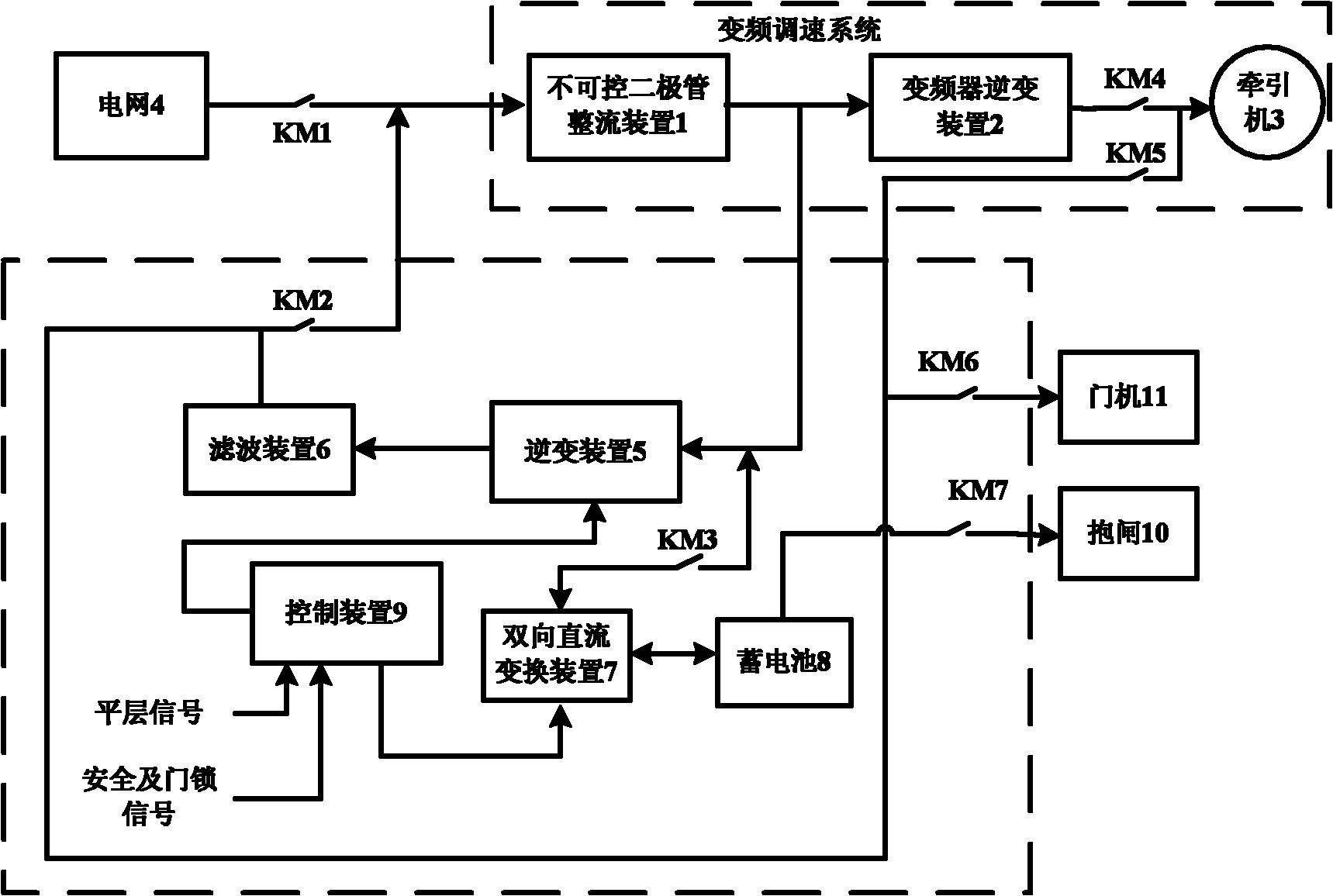

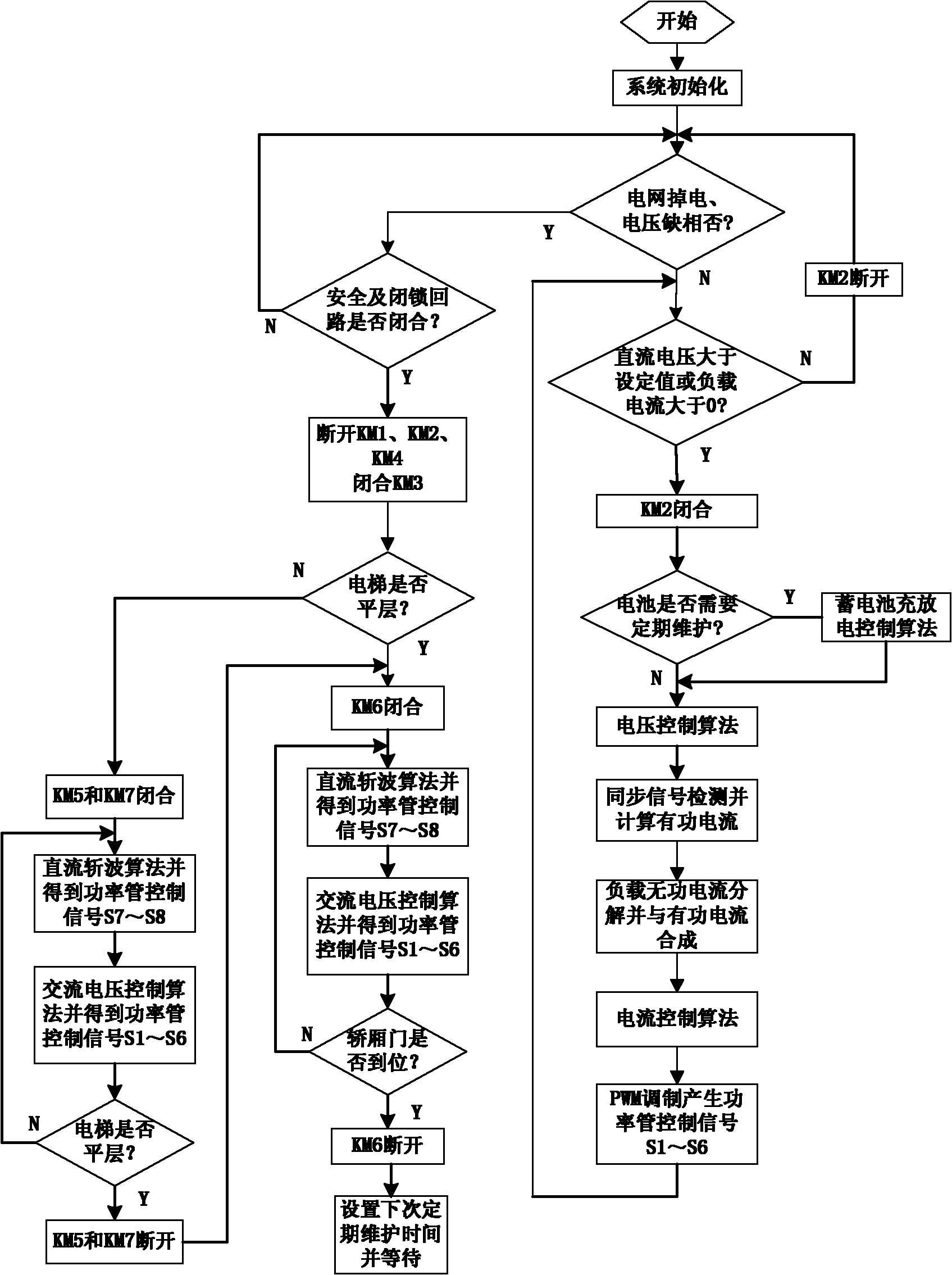

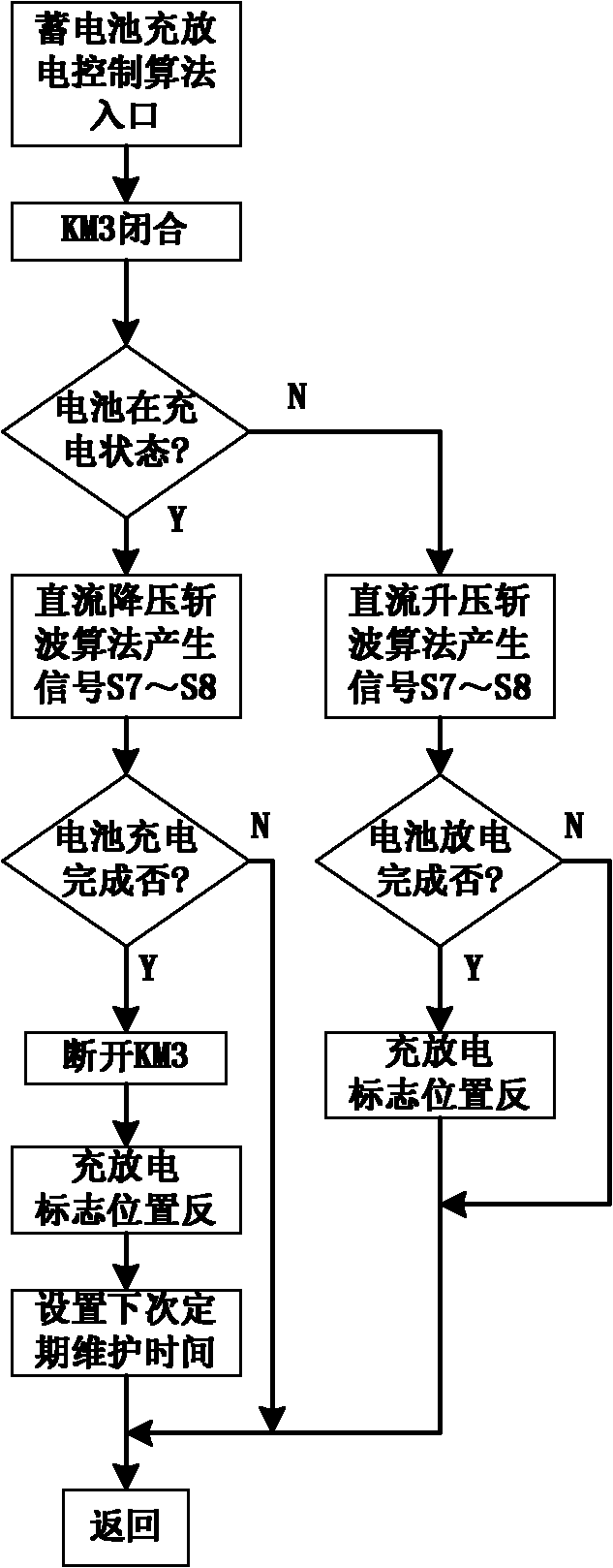

Lift energy feedback, reactive compensation and switched-off emergency running method and system

InactiveCN101917020AEffectively handle emergency power shortagesReduce lossBatteries circuit arrangementsPower network operation systems integrationFrequency changerControl power

The invention provides lift energy feedback, reactive compensation and switched-off emergency running method and system. The system comprises an energy feedback module, a reactive compensation module and a lift switched-off emergency running module. The energy feedback module comprising an inverted circuit, a control circuit and a filter circuit and the reactive compensation module can feed back energy generated when a lift brakes to a power grid and generate reactive current for compensating reactive power when the lift is in an electric running state; and a lift switched-off emergency running circuit can ensure that lift control power is taken over by the switching of a switch under abnormal power supply of the power grid, run the lift to the leveling position and open a car door and a hall door so that a passenger safely walks out of the lift. The system has the advantages of simple structure, reliable running, less loss, low cost, high power factor and no harmonic pollution on the power grid and integrates various functions of lift frequency converter plug-in type energy feedback, reactive compensation, emergency leveling, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

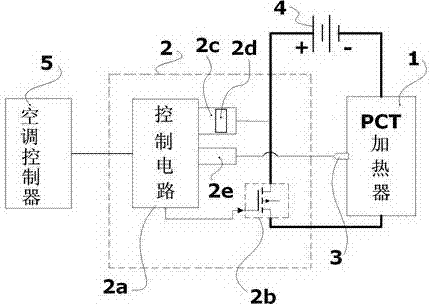

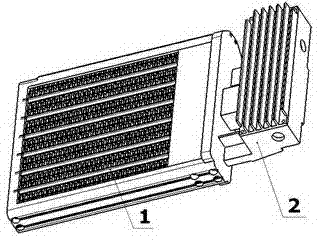

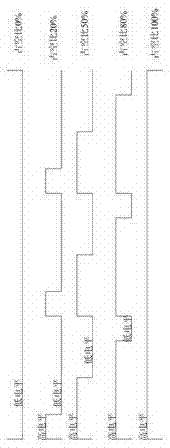

Automobile warm air control method and automobile warm air control device

InactiveCN102529641AEasy to install and distributeEasy to installAir-treating devicesVehicle heating/cooling devicesLinear controlWeak current

The invention discloses an automobile warm air control method and an automobile warm air control device. The method includes steps: using a control circuit to load weak-current voltage; using a PTC (positive temperature coefficient) heater to load strong-current voltage; using the control circuit to detect temperature of the PTC heater and comparing the temperature of the PTC heater with a target temperature value; and using the control circuit to detect the voltage and the current of a strong-current circuit of the PTC heater through a photocoupling strong-weak current isolation circuit. The automobile warm air control method and the automobile warm air control device are characterized in that a driving circuit receives duty cycle pulse width modulation signals outputted by the control circuit by the aid of an IGBT (insulated gate bipolar transistor) to lead a collector and an emitter to be on or off; and a strong-current power source is applied to the PTC heater through the IGBT. Strong-current voltage of different frequencies is outputted under pulse width modulation control and duty cycle change to realize linear control of the PTC heater. The automobile warm air control method and the automobile warm air control device have the advantages that overhigh surface temperature of the PTC heater can be effectively avoided so that reliability is high and risks and potential hazards are avoided; electrodeless power adjustment and smooth temperature control are realized, and overheating and overcooling are avoided; and cost is low.

Owner:NEW ENERGY AUTOMOBILE BRANCH FAW GROUP CORP

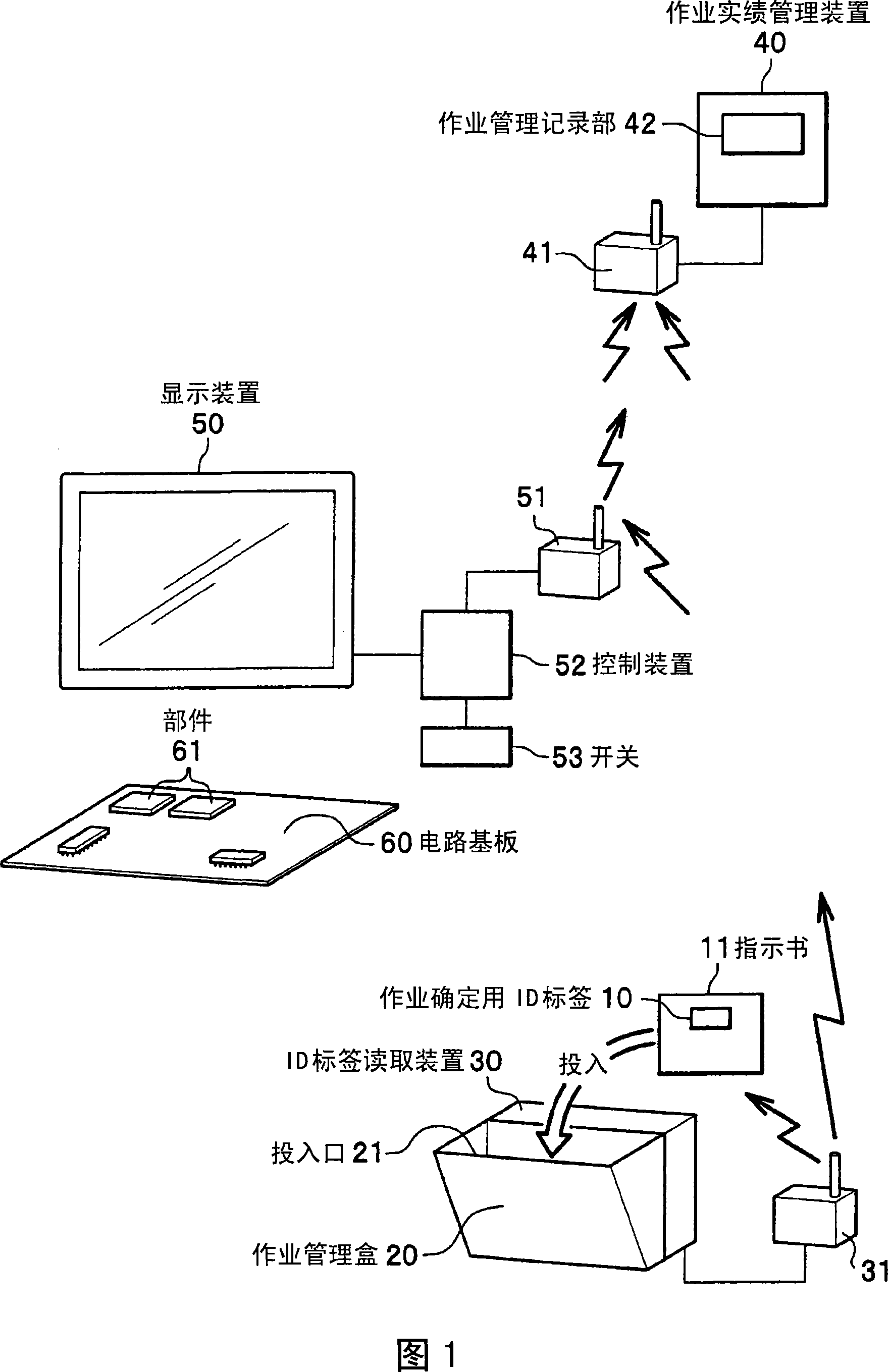

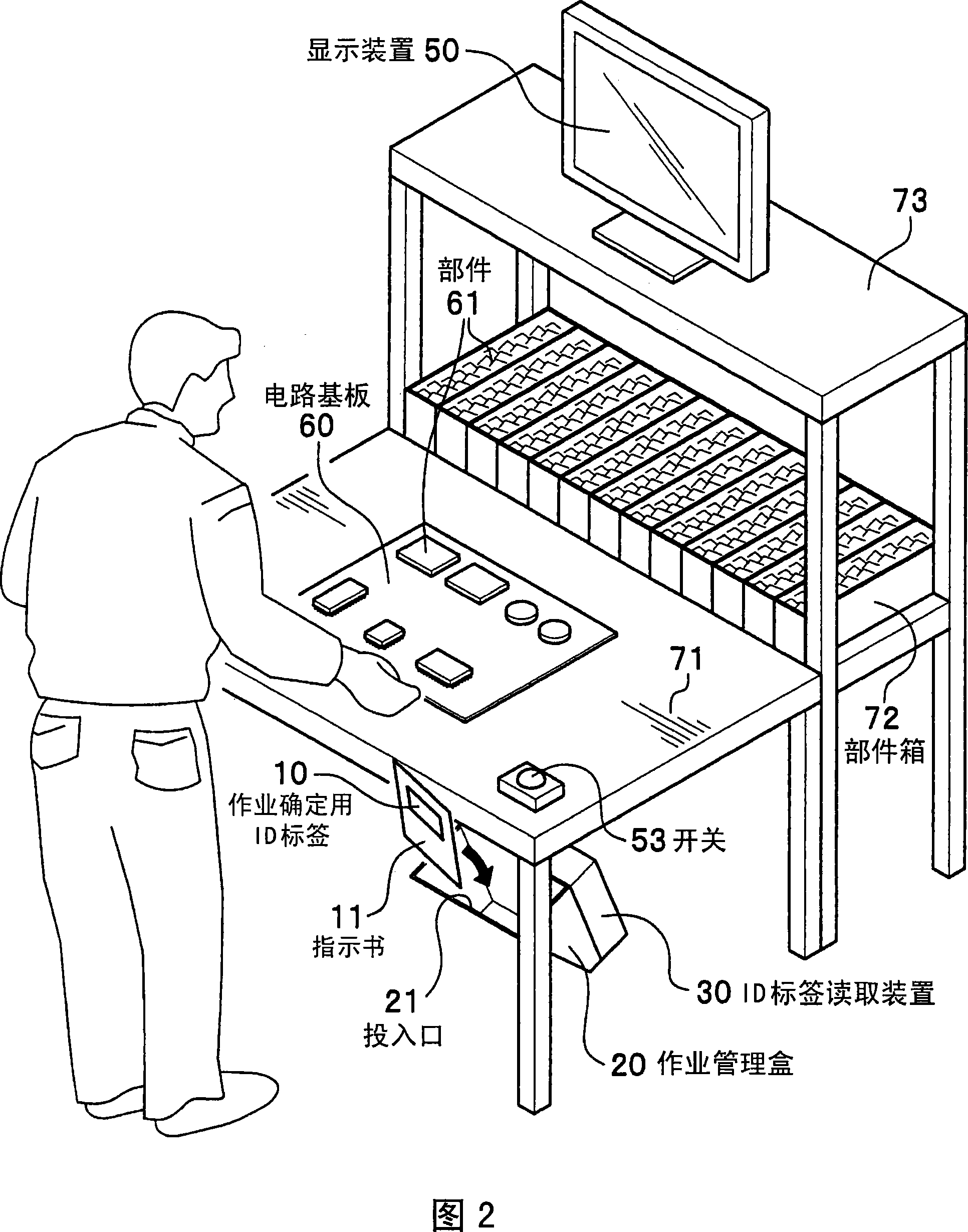

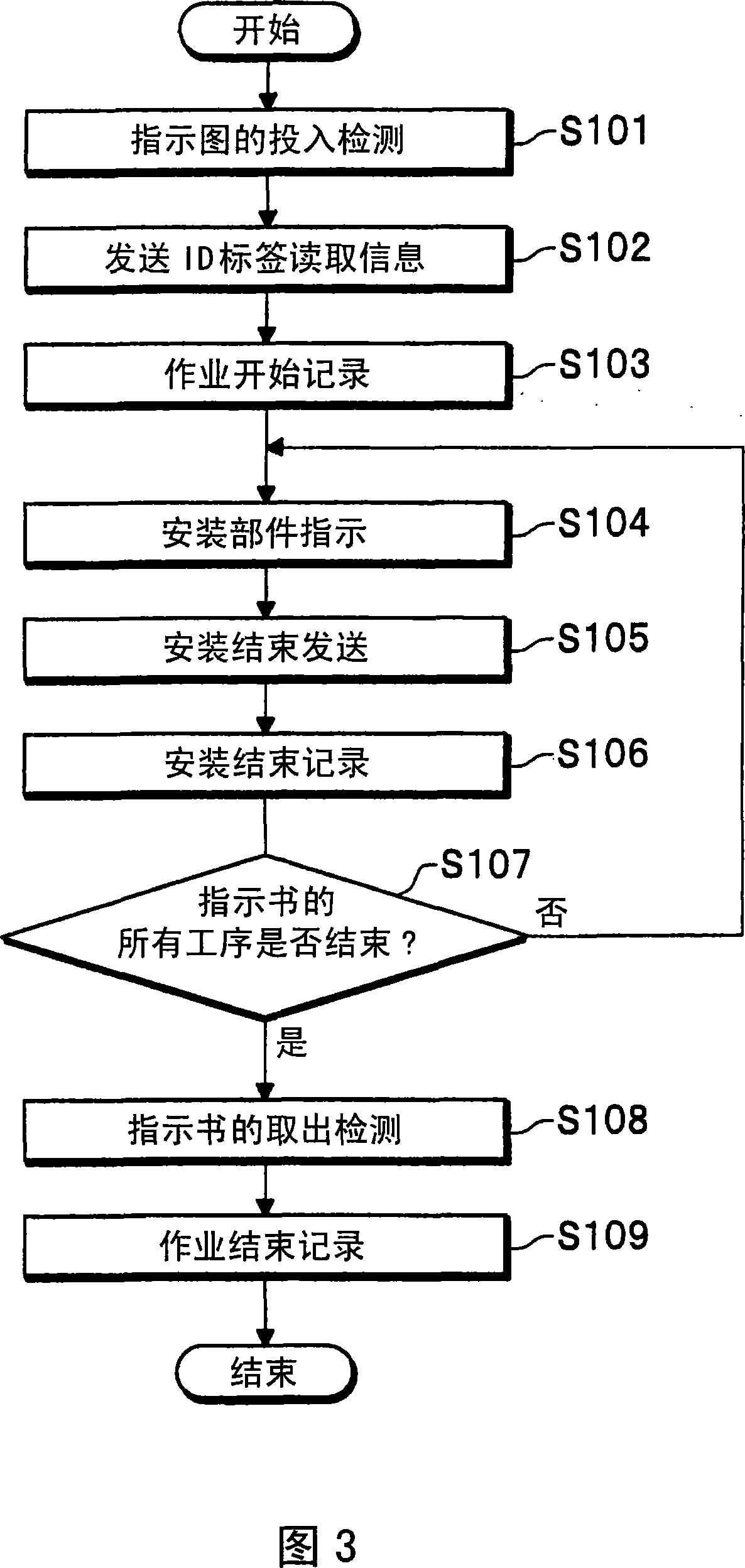

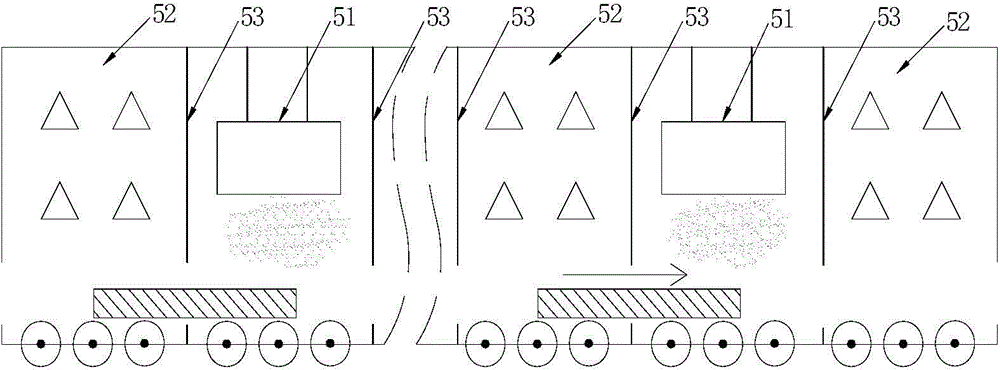

Work management apparatus, picking carriage, workability management system, workability management method and workability management program

ActiveCN101086666AReduce loss costsReliable collectionTotal factory controlProgramme total factory controlCollection systemManagement system

The invention aims at providing a work performance collection system for reliably collecting information of work performance without applying a burden to a worker in assembly of a work object article. This system includes a work specification ID tag into which information for specifying a work content of a work object article is written, a work management box having a throw-in port into which the work specification ID tag is thrown at the time of work, and an ID tag reader provided to a side surface of the work management box, for reading the work specification ID tag and transmitting the information read to a work performance management apparatus. A worker is required to only throw the work specification ID tag into the work management box at the start of work and to only take out the work specification ID tag at the end of work.

Owner:HITACHI LTD

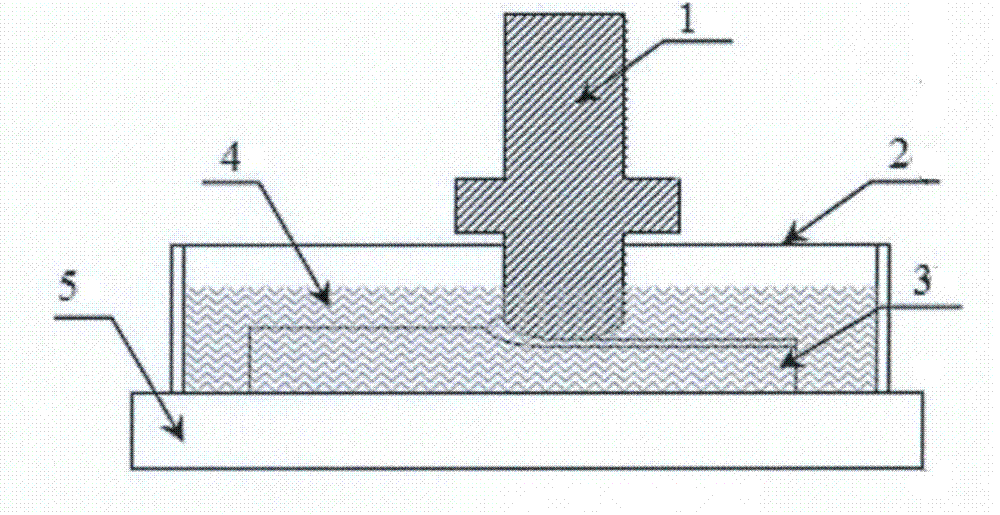

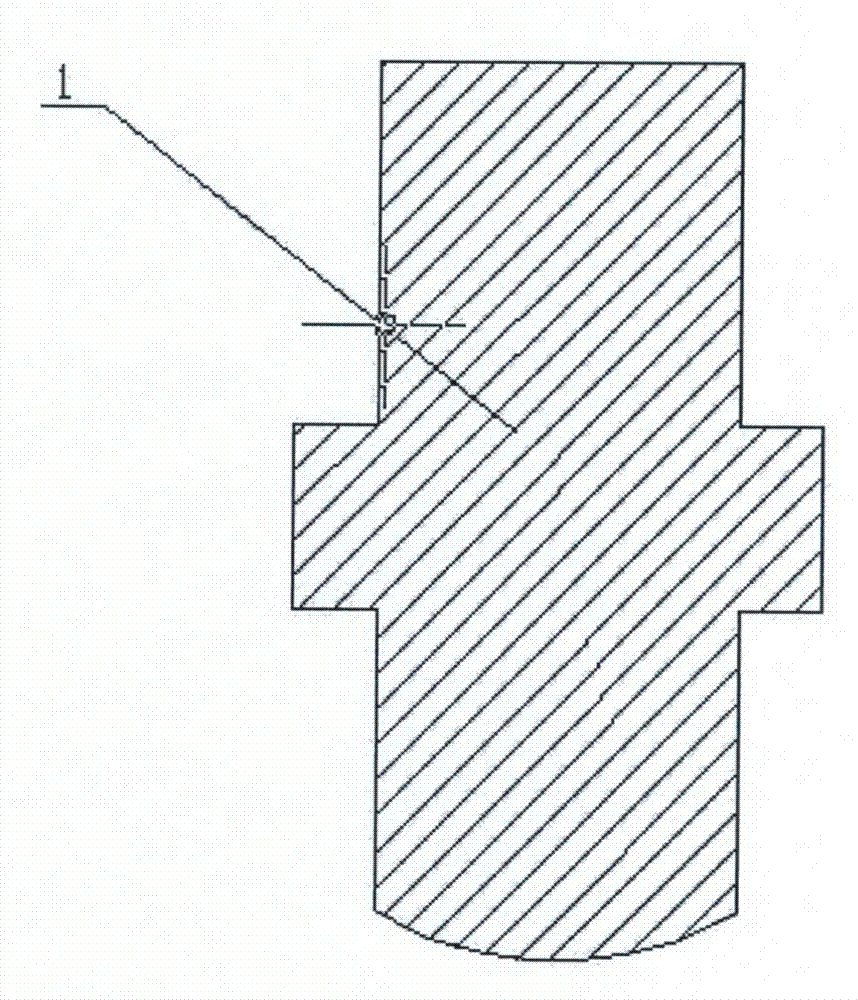

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

Continuous coating production system of sheet substrates

ActiveCN104060236AReduce stress lossComply with glass safety performance requirementsVacuum evaporation coatingSputtering coatingProduction lineComposite film

The invention discloses a continuous coating production system of sheet substrates. The continuous coating production system comprises a feeding area, a working area and a discharge area, all of which are orderly communicated with each other; the feeding area comprises a sheet feeding table; the working area comprises a plurality of pre-vacuumizing chambers, a first transition chamber, a coating deposition chamber, a quick atmosphere annealing chamber and a plurality of pre-vacuumizing chambers orderly in the coating process flow direction; the discharge area comprises a discharge table; each chamber of the working area is provided with the desired vacuum environment. The continuous coating production system further comprises a transporting device capable of realizing linear transmission; the transporting device penetrates through the whole feeding area, the working area and the discharge area. The continuous coating system has the advantages that the regional continuous film deposition and annealing of a one-layer or multi-layer composite film containing a hot color coating material in the same production line are realized, the production efficiency is obviously improved, and meanwhile, the material loss cost of the material in the off-line annealing process after coating is reduced. Due to unique structural design of the system, the problem of tempering stress loss can be obviously solved; the stress of the tempered glass based smart glass produced by the system is up to the stress standard of the national building energy-saving safety glass, namely greater than or equal to 90Mpa.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for producing fatty acid by hydrolyzing lipid through three liquid-phase lipase catalytic systems

ActiveCN103184245AReduce manufacturing costSolve the problem of energy consumptionFermentationInorganic saltsAlcohol

The invention discloses a method for producing fatty acid by hydrolyzing lipid through three liquid-phase lipase catalytic systems. The method comprises the following steps: firstly, preparing enzyme solution with the lipase concentration of 5-20000 U / mL, and adding soluble inorganic salts, alcohol / ketonic hydrophilic fraction and lipid to the enzyme solution so as to form three liquid-phase systems; secondly, laying the prepared three liquid-phase systems into an agitated vessel for reaction, standing or centrifuging the systems after the reaction so as to divide the systems into an upper layer, a middle layer and a lower layer, and collecting products in the upper layer so as to obtain fatty acid phase. The method adopts the three liquid-phase systems to extract fatty acid in crude enzyme solution, performs direct hydrolyzing to produce fatty acid, can not only greatly reduce the production cost of enzyme, but also solve the problems of high energy consumption for glycerol and enzyme separation, high cost, high pollution and the like.

Owner:SOUTH CHINA UNIV OF TECH

Large-scale aluminum alloy hub isothermal forging production line

ActiveCN102873253ASimplify the pressing processRealize visual operationShaping safety devicesForging/hammering/pressing machinesProduction lineHeating furnace

The invention relates to a large-scale aluminum alloy hub isothermal forging production line. The large-scale aluminum alloy hub isothermal forging production line is characterized by comprising a bar cutting machine, a bar heating furnace, a plurality of delivery manipulators, a pre-forging hydraulic press, a hub finish-forging hydraulic press, an aluminum alloy hub broaching and trimming hydraulic press and a pressing die. A cold material conveying roller table is arranged between the bar cutting machine and the bar heating furnace, a hot material conveying roller table is arranged between the other end of the bar heating furnace and the delivery manipulators, a die heating furnace, a die change trolley and a change trolley rail are arranged on one side of the pre-forging hydraulic press, a pre-forging lubrication spraying device is arranged on the other side of the pre-forging hydraulic press, a middle heating furnace or a delivery roller table is arranged between each two manipulators, and a finish-forging lubrication spraying device is arranged on one side of the hub finish-forging hydraulic press. The large-scale aluminum alloy hub isothermal forging production line has the advantages that by means of structural and technical combination of hot die forging, broaching and trimming, one-time pressing of aluminum alloy hubs can be realized, the pressing process of the aluminum alloy hubs is simplified, cost, time and labor for later-stage secondary processing and shaping can be greatly saved, and production efficiency is improved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Method for enriching polyunsaturated fatty acids by virtue of enzyme method

The invention discloses a method for enriching polyunsaturated fatty acids by virtue of an enzyme method. The method comprises the following steps: (1) preparing an enzyme solution that lipase concentration is 5-20000U / mL, and adding soluble salt, a hydrophilic solvent and fish oil to the enzyme solution so as to prepare a three-liquid-phase system; (2) adding the prepared three-liquid-phase system to a stirring kettle and reacting, standing by or centrifuging until layering after reaction, and collecting a supernatant product so as to obtain a lipid product phase; and (3) adding alkaline liquor to the lipid product phase and adding a hydrophobic organic solvent, standing by and reserving a supernatant phase, recovering the hydrophobic organic solvent, reserving and extracting an upper phase which is an omega-3 enriched glyceride product and regulating pH value of a lower phase to be lower than 2 by virtue of acid; and then extracting by virtue of the hydrophobic organic solvent so as to obtain hydrolyzed fatty acid. The method disclosed by the invention has the advantages of low energy consumption, high raw material utilization rate, mild reaction conditions and the like; and the technical problem of an existing enzymatic hydrolysis method which is difficult to achieve industrialization in the production of fatty acid.

Owner:SOUTH CHINA UNIV OF TECH

Full-automatic grapefruit package production line

InactiveCN101792031ALow costIngenious designWrapper folding/bending apparatusWrappingProduction lineAgricultural engineering

The invention discloses a full-automatic grapefruit package production line, which is assembled by a rack, a transmission mechanism, a feeding mechanism, a cleaning mechanism, a drying mechanism, a material arranging mechanism, a film wrapping mechanism and a grading mechanism, wherein the rack is mutually and successively connected with the rack of each mechanism in a welding mode, the transmission mechanism is composed of the roll shaft transmission parts of the cleaning mechanism and the drying mechanism and the belt transmission parts of the feeding mechanism, the material arranging mechanism and the film wrapping mechanism. The invention overcomes the defects of low production efficiency, large labor strength, single function and low automaticity of the existing grapefruit package technology, has the advantages of artful design, simple structure, convenient manufacture, low cost and wide application range and can be used for directly packaging the grapefruit of different kinds and sizes in different producing areas. The invention efficiently, reliably, conveniently and directly reduces product loss and wastage and expands market sales range so as to satisfy the requirements of economic growth and improved living standards as well as improve economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

Production process for electric toothbrush casing

ActiveCN105818322AHighlight the aestheticsEasy to assembleLiquid surface applicatorsVacuum evaporation coatingRisk sharingLaser engraving

The invention relates to a production process for an electric toothbrush, in particular to a production process for an electric toothbrush casing. The production process comprises the steps that firstly spraying is conducted, specifically, a shading light oil layer is sprayed on the front or the reverse of a transparent decorating part; secondly laser engraving is conducted, specifically, the laser engraving technique is adopted and the a needed shape is hollowed out on the shading light oil layer; thirdly electroplating is conducted, specifically, a metal layer or a metallic oxide layer is vacuum plated on the front of the transparent decorating part; fourthly injection molding is conducted, specifically, a transparent soft rubber layer is injected on the light source region of an electric toothbrush handle; and fifthly assembling is conducted, specifically, the transparent decorating part is assembled on the transparent soft rubber layer and the reverse of the transparent decorating part is attached to the transparent soft rubber layer. According to the production process, processing risk sharing is achieved; the loss cost caused by processing errors is lowered; and the implicit glowing effect is achieved, and the lighting effect is even and gentle.

Owner:GUANGDONG ROMAN TECH CO LTD

Technological method for symmetrical paired universal rolling of deformed steel

InactiveCN103143562APromote productionImprove yieldMetal rolling arrangementsInternal stressBar product

The invention discloses a technological method for the symmetrical paired universal rolling of deformed steel. The technological method comprises the following steps of: (1) roughly rolling a raw blank into an intermediate blank of a double-connected rolling piece in a rough rolling unit; (2) cutting off irregular deformed head and tail parts of the intermediate blank by using a sawing and shearing facility; (3) simultaneously carrying out fine rolling on the intermediate blank of the double-connected rolling piece in a fine rolling unit to obtain a double-connected final-section sectional bar; and (4) cooling the rolled double-connected final-section sectional bar to room temperature, and subdividing and straightening the double-connected final-section sectional bar to obtain single final-section sectional bar products through subdividing and straightening facilities. The technological method disclosed by the invention is wide in application range and suitable for rolling various deformed steels, solves the existing problem of post-cooling bending of the single rolled deformed steel, simultaneously optimizes a rolling production line, reduces energy consumption of production, equipment loss and production cost, and improves the production efficiency, and in addition, the rolled piece is good in surface quality, small in internal stress, and good in comprehensive machining quality and mechanical performance.

Owner:CISDI ENG CO LTD

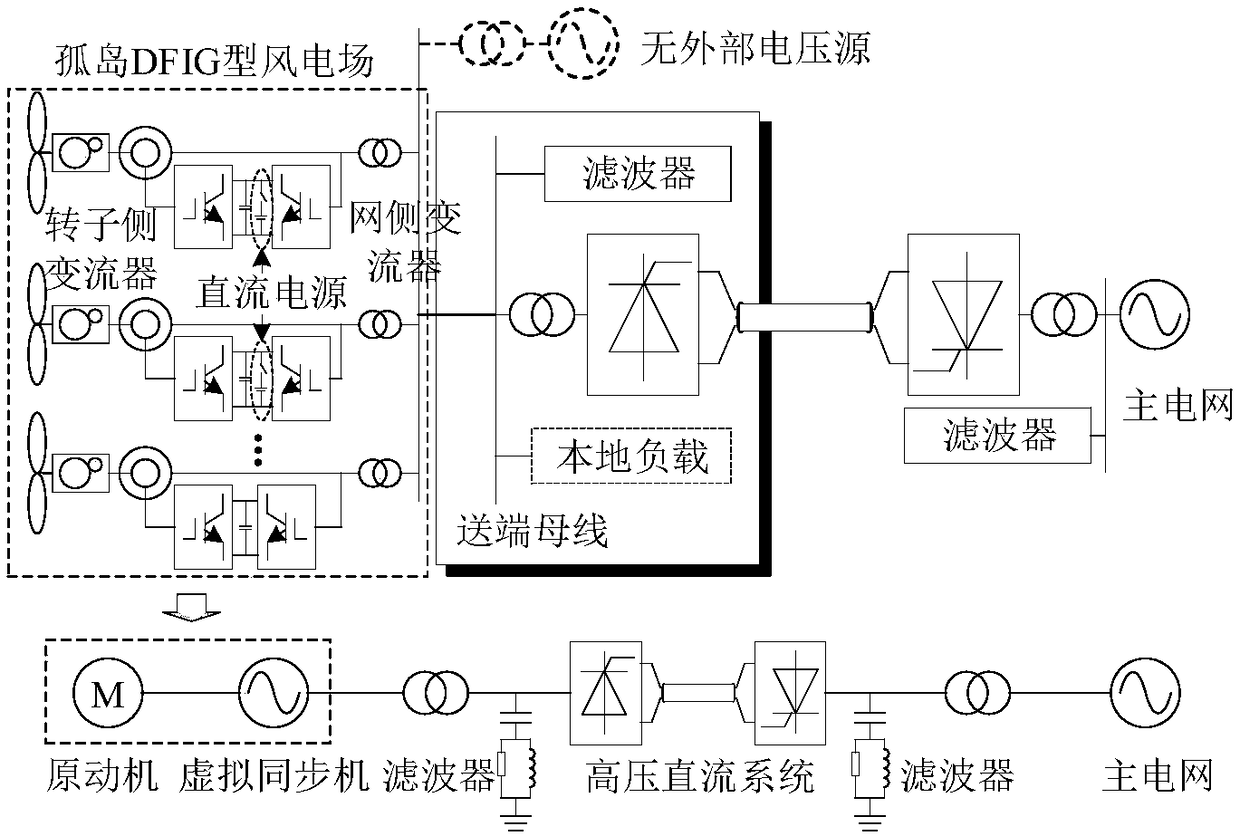

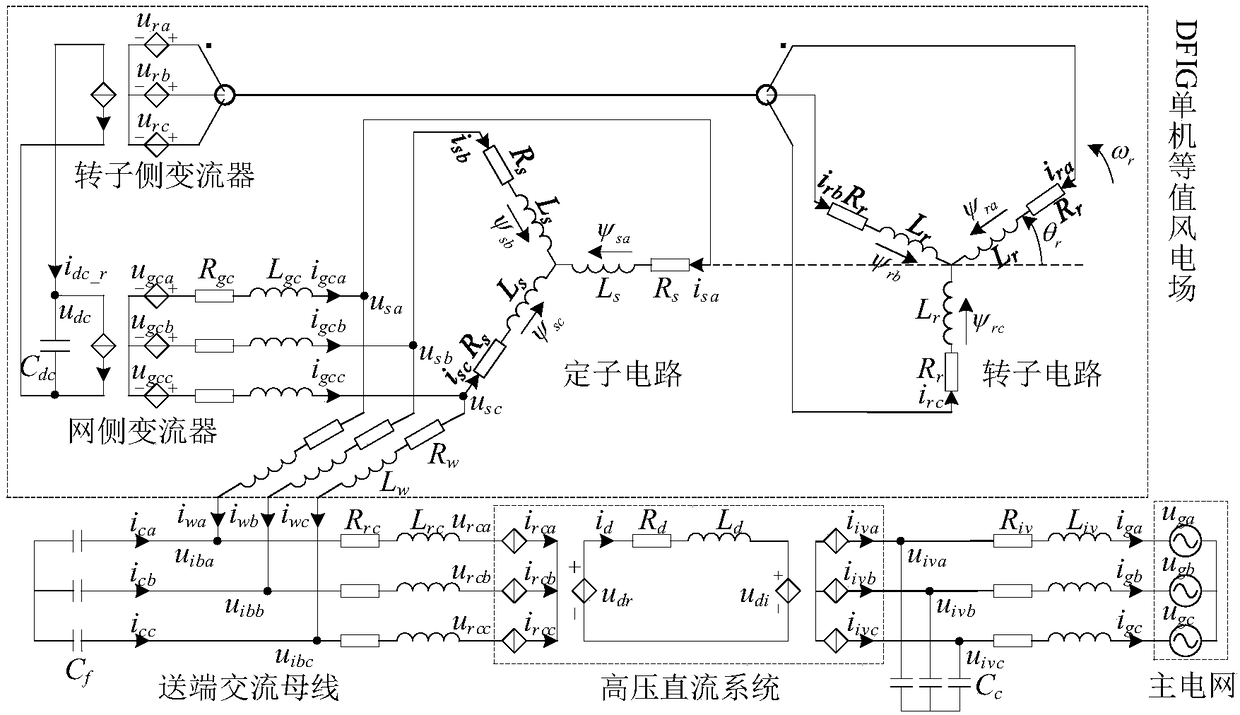

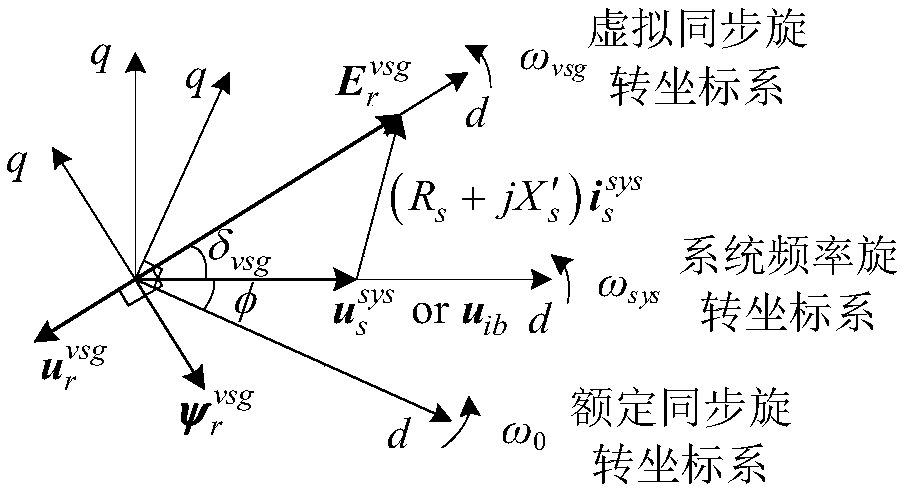

Virtual synchronous control method and device for island double-fed wind power plant high-voltage direct current grid connection

ActiveCN108110799AImprove active benefitsIncrease capacitySingle network parallel feeding arrangementsWind energy generationFrequency stabilizationNew energy

The invention relates to a virtual synchronous control method and device for island double-fed wind power plant high-voltage direct current grid connection. The method comprises the following steps: configuring a direct current power supply for a direct current bus of a DFIG wind turbine generator back-to-back converter, and adopting a vector control method of fixed alternating voltage to providestarting power supply for black starting of a high-voltage direct current system; using VSG into the control for grid connection and normal operation of a DFIG wind turbine generator, after the VSG realizes reactive voltage droop control through a rotor side converter, wherein a grid-side converter can be flexibly switched into unit power factor control, and simultaneously the direct current powersupply exits; adopting frequency regulation and correction control method, and realizing system sending end bus frequency stabilization and active balance by a rectifier; adopting batched successivestarting in the whole wind power plant, and thus realizing virtual synchronous control for island DFIG type wind power plant high-voltage direct current grid connection. The power loss and construction cost can be reduced, the stability is improved, and the method can be applied in the high-voltage direct current grid connection field of new energy resources.

Owner:STATE GRID CORP OF CHINA +1

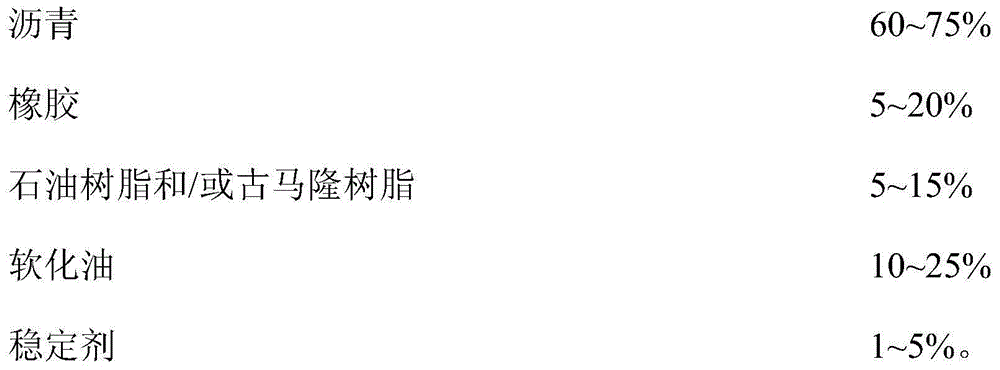

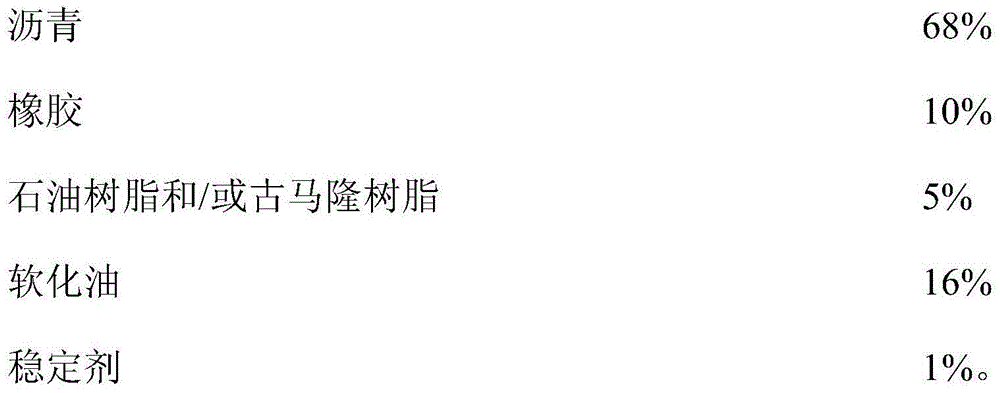

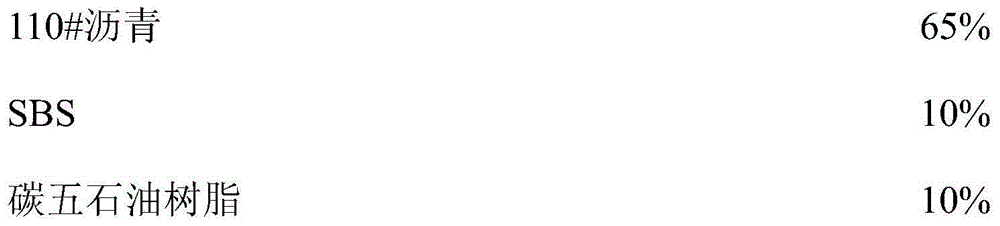

Asphalt rubber material for producing SBS elastomer modified asphalt waterproof roll material as well as preparation method and application thereof

The invention provides an asphalt rubber material for producing an SBS elastomer modified asphalt waterproof roll material. The asphalt rubber material is prepared from the following main raw materials in percentage by mass: 60-75% of asphalt, 5-20% of rubber, 5-15% of petroleum resin and / or coumarone resin, 10-25% of softening oil and 1-5% of a stabilizer. The asphalt rubber is high in ductility, softening point and needle penetration. When the asphalt rubber is used for preparing SBS elastomer modified asphalt waterproof roll material, the low-temperature flexibility, high-temperature resistance, cohesive strength and waterproof performance of the waterproof roll material can be improved; the waterproof roll material shows excellent waterproof performance; the energy loss, the material loss, the labor cost and the production cost can be reduced; and the quality is very easy to control.

Owner:中油佳汇(广东)防水股份有限公司

Stepwise decompression type shield machine

The invention discloses a stepwise decompression type shield machine. The stepwise decompression type shield machine comprises a shield main machine, a screw conveyor, a main mud inlet pipeline and amain mud discharging pipeline; the screw conveyor, the main mud inlet pipeline and the main mud discharging pipeline are arranged inside a shield of the shield main machine, the main mud inlet pipeline communicates with a soil bin at the front part of the shield main machine, and an inlet of the screw conveyor communicates with the soil bin; blades on a spiral shaft of the screw conveyor are provided with one or more segment interval areas in the axial direction, and the main mud discharging pipeline communicates with a cylinder of the screw conveyor and is provided with a first valve and a first mud pump; and the first mud pump is used for discharging mud in the screw conveyor through the main mud discharging pipeline, and a slag discharging outlet is formed in the tail of the screw conveyor. According to the stepwise decompression type shield machine, in a mud shield tunneling mode, the content of large-particle solids in a mud system can be effectively decreased, thus the installedpower of the pipeline conveying the mud is decreased, the equipment loss and the operating cost are reduced, slag in the screw conveyor is discharged through the slag discharging outlet, the slag precipitated in the screw conveyor can be continuously discharged, and the production efficiency is high.

Owner:CHINA RAILWAY CONSTR HEAVY IND

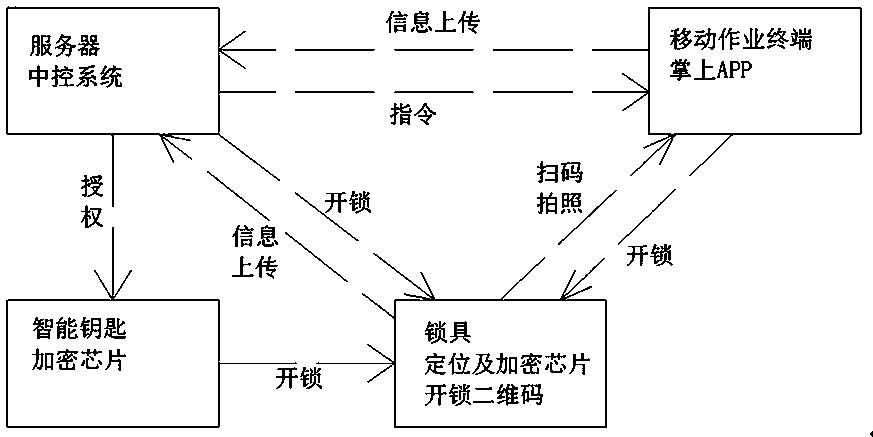

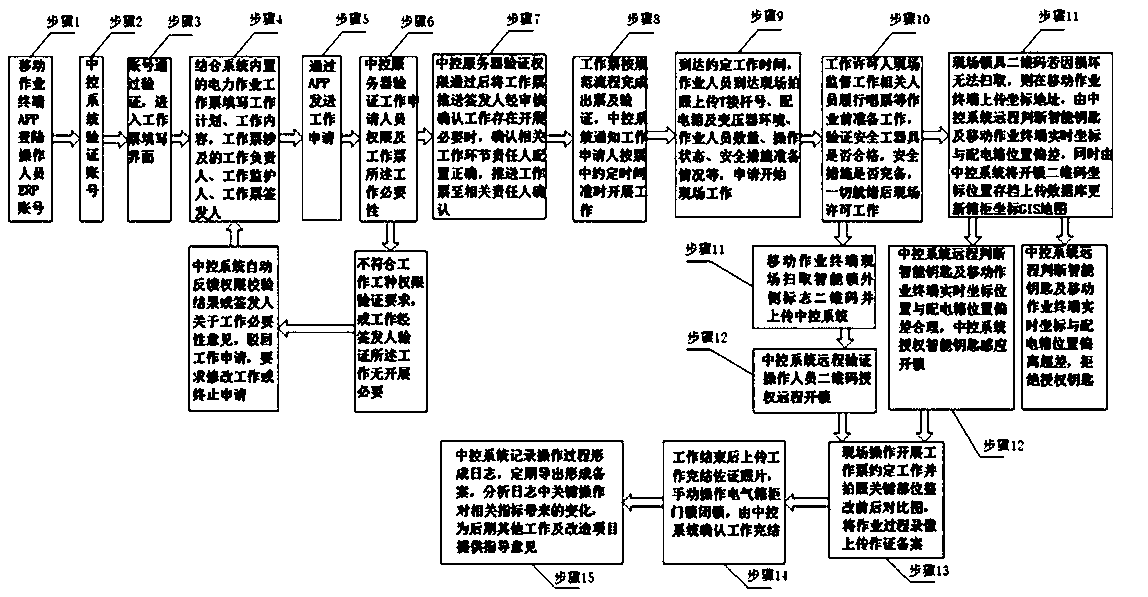

Work ticket managing system for electrical cabinet based on intelligent lock

PendingCN109326034ALock accuratelyEasy to operateData processing applicationsIndividual entry/exit registersJob numberControl system

The invention provides a work ticket managing system for an electrical cabinet based on an intelligent lock. The managing system comprises a server, a central control system, a palm APP, an ERP job number, a mobile work terminal, an electrical cabinet, a lock, and an unlocking two-dimensional code. The palm APP is installed on the mobile work terminal. The lock is fixed on the electrical cabinet and is provided with electronic and mechanical double encryption. The lock is internally provided with an integrated chip which has the functions of positioning, encryption, communication, storage, andrecording. The unlocking two-dimensional code is provided on the outer surface of the electrical cabinet. The palm APP and the intelligent lock are connected to the central control system through thenetwork. According to the work ticket managing system for an electrical cabinet based on an intelligent lock, the account map management and work ticket management of the electrical cabinet are standardized, the automated operation process related to the opening and closing of the electrical cabinet is effectively standardized, the loss cost of the physical lock of the cabinet and the labor costof manually replacing the lock are reduced, and the operation is convenient, so that the efficiency of on-site work is effectively improved, the intensive and lean management is realized, and the enterprise management efficiency is improved.

Owner:XINING POWER SUPPLY CO OF STATE GRID QINGHAI ELECTRIC POWER CO +2

Wastewater purification active coke adsorbent and preparation method thereof

InactiveCN101766990AGood adsorption and purification performanceAdvanced preparation technologyOther chemical processesWater/sewage treatment by sorptionTarChemistry

The invention provides a wastewater purification active coke adsorbent and a preparation method thereof, and the wastewater purification active coke adsorbent is obtained by carrying out the steps of deashing, kneading, molding, drying, carbonization, activation and the like on lignite and coking coal which are crushed into a certain fineness, as well as tar, asphalt, solid metal salts and water. The wastewater purification active coke adsorbent prepared by adopting the raw materials and the method not only realizes good purification effect, but also has the advantages of low cost, simple preparation and strong practicality.

Owner:赵英杰

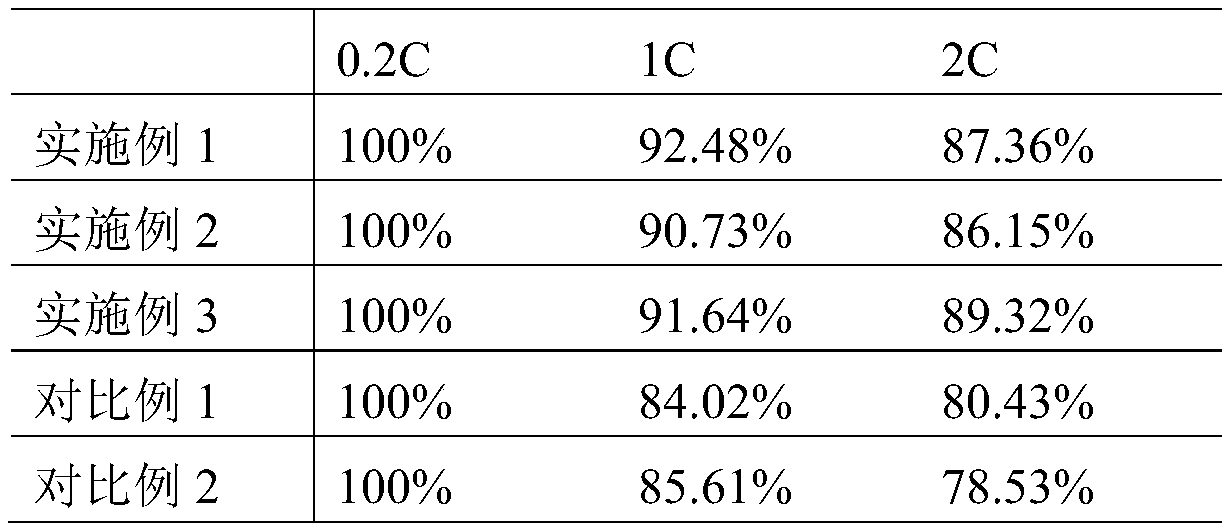

Preparation method of modified vinylidene fluoride polymer powder

ActiveCN110452336AEvenly distributedImprove hydrophilicityLi-accumulatorsCell component detailsPolymer scienceFluoride

The invention relates to a preparation method of modified vinylidene fluoride polymer powder. The method includes: polymerizing (meth)acrylic acid, hydroxyalkyl (meth)acrylate and (meth)acrylamide onthe surface of a vinylidene fluoride polymer, separating the product, and conducting washing, drying and crushing to obtain modified vinylidene fluoride polymer precursor powder; reacting the modifiedvinylidene fluoride polymer precursor powder with a phenolic substance in water, separating the product, and conducting washing, drying and crushing to obtain the modified vinylidene fluoride polymerpowder. The modified vinylidene fluoride polymer powder has improved hydrophilicity and solvent resistance, improves the adhesion between vinylidene fluoride polymer powder and a base film, improvesthe powder dropping phenomenon, reduces the cost loss, improves the cohesiveness between a polymer layer and a pole piece, also reduces the loss of lithium batteries during cycling, and improves the battery rate performance.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

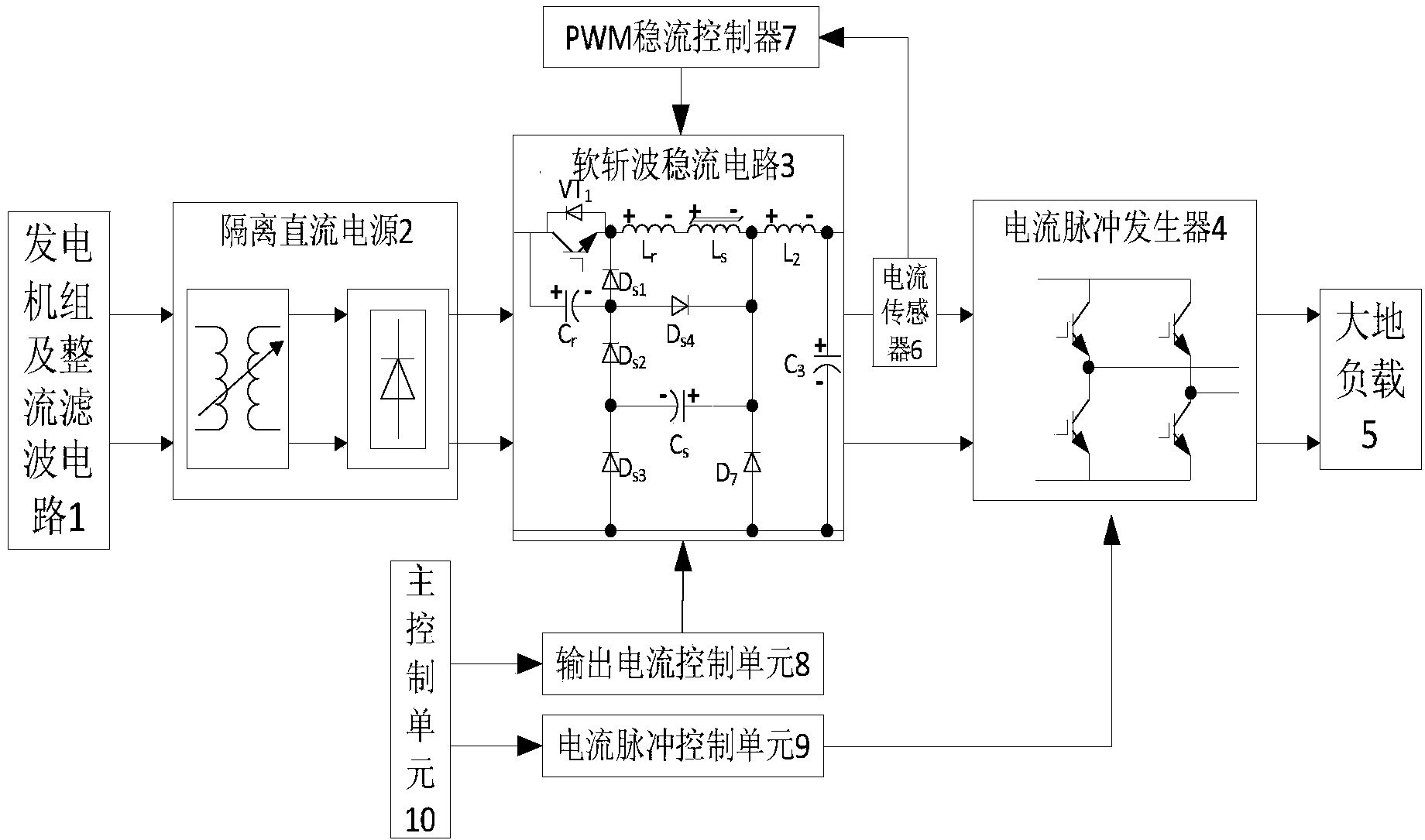

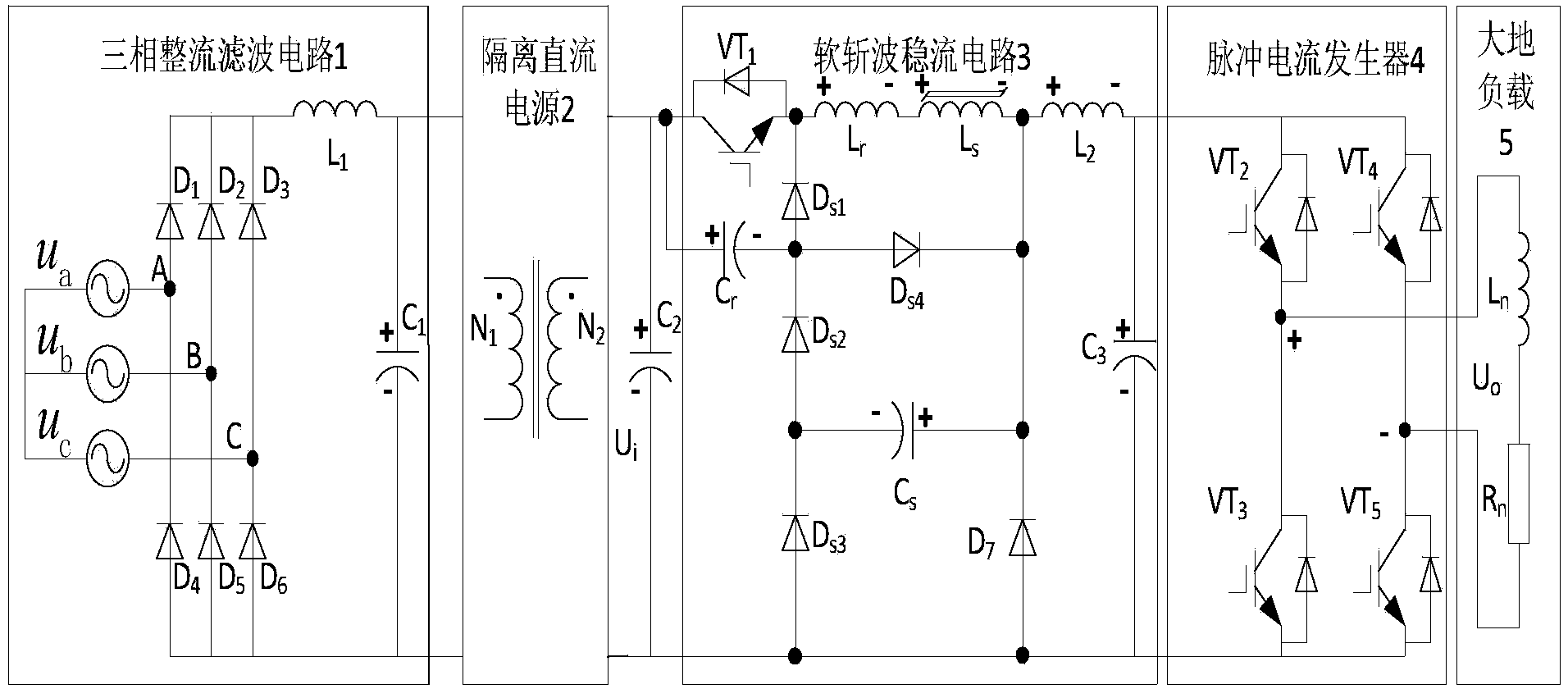

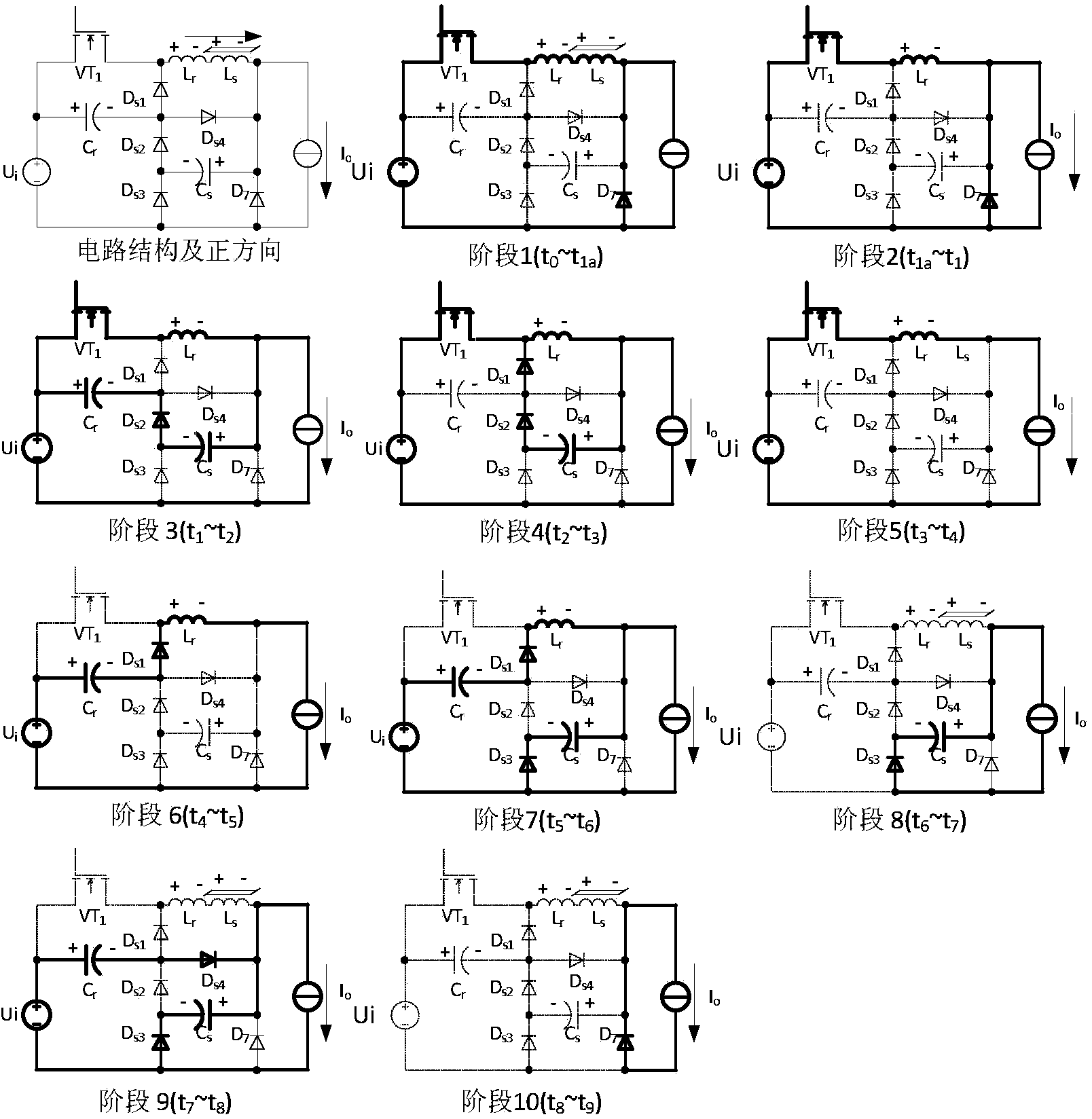

Electrical source emission device and control method with soft chopping wave characteristic

InactiveCN103944440AQuick responseHigh precision of steady flowDc-dc conversionElectric variable regulationCapacitanceElectromagnetic interference

The invention relates to an electrical source emission device and control method with a soft chopping wave characteristic. The device is formed by connecting a three-phase alternative current generator set with a ground load through an isolated direct current power supply, a soft chopping wave steady flow circuit and a current pulse generator. A passive lossless soft switch structure is adopted in the soft chopping wave steady flow circuit, the passive lossless soft switch structure is composed of a main switching tube VT1, a main diode D7, buffer capacitance Cr, energy-storage capacitance Cs, a buffer inductance Lr, a saturation inductance Ls, diodes ranging from Ds1 to Ds4 and filter circuits L2 and C3, and the structure can achieve the soft opening up and soft shutting off of the main switching tube VT1of soft chopping wave steady flow circuit, and the soft shutting off of the main diode D7. Compared with an existing hard chopping wave steady flow electric source transmission device, the power density of the instrument is improved, application region of the device is expanded, electromagnetic interference is reduced, and the steady flow accuracy of the device is improved. The device is within normal operation range, no extra voltage stress is introduced to the main switching tube VT1, the mean free error time is increased, and the service life of the device is prolonged.

Owner:JILIN UNIV

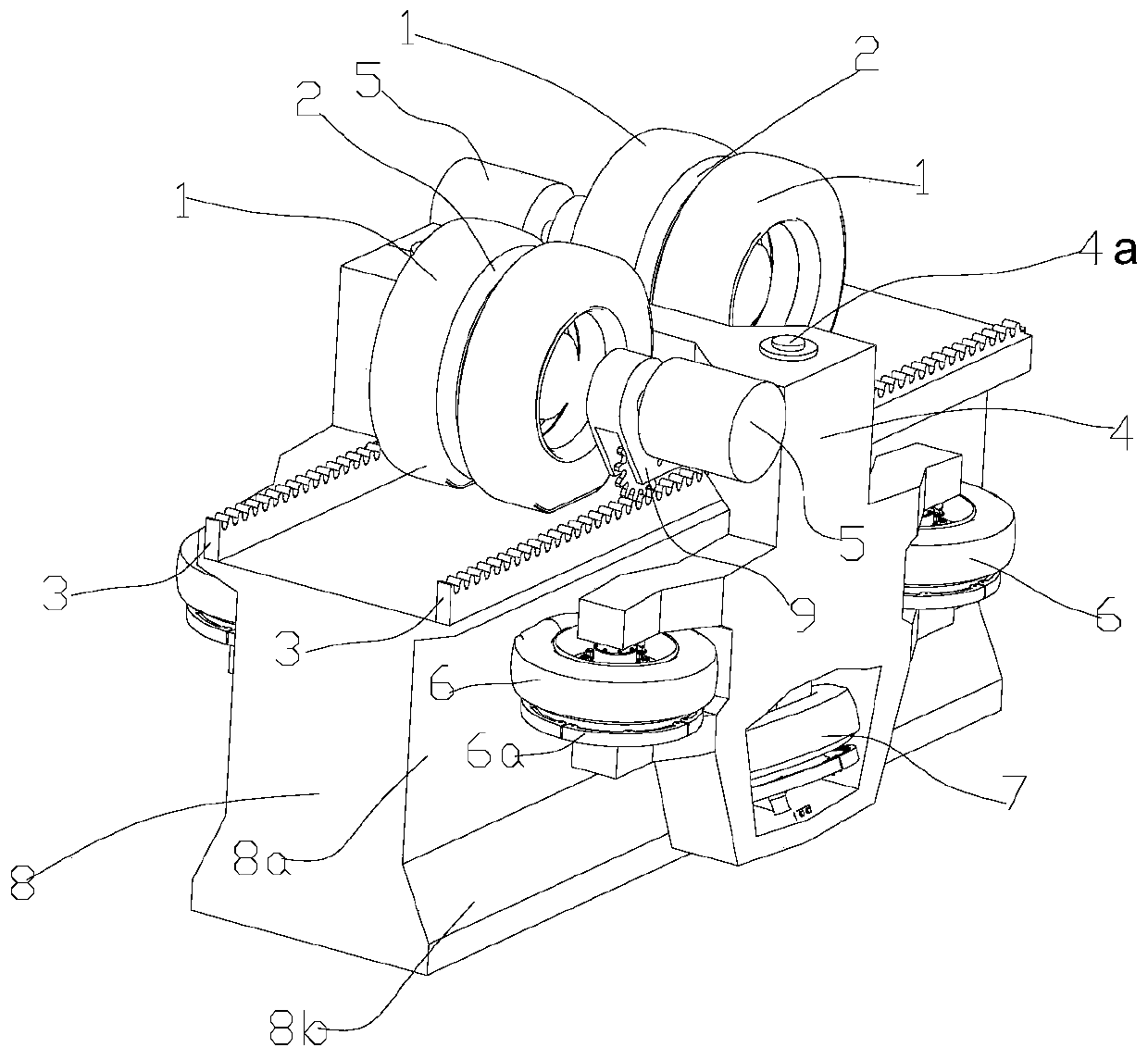

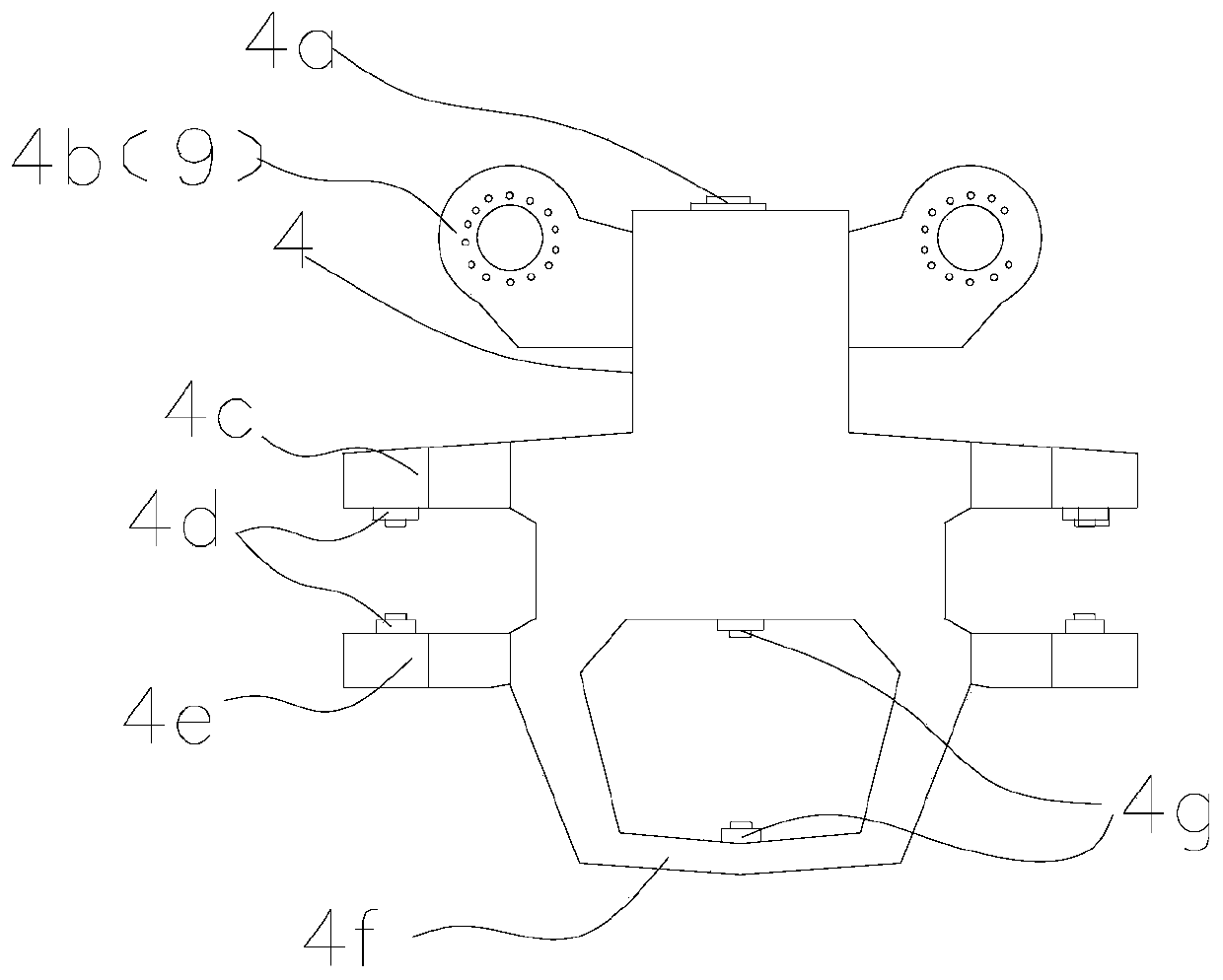

Straddle type monorail vehicle walking structure and rail beam thereof

ActiveCN109835353ASolve the problem of insufficient adhesionImprove climbing abilityMonorailsElectric motor propulsion transmissionEngineeringStraddle

The invention discloses a straddle type monorail vehicle walking structure and a rail beam thereof. The structure comprises a framework spanned on a rail beam body; the framework comprises a cross beam and side beams arranged on two sides of the cross beam; the upper surface of the cross beam is provided with a vehicle body connecting interface and primary and secondary suspension mounting interfaces, the side beams comprise an upper side beam (4c) and a lower side beam (4e), two ends of the upper side beam and the lower side beam are respectively provided with a first hub fixed seat (4d), andthe lower parts of the side beams are provided with a second hub fixed seat (4g); walking wheels (1) are installed at the front end and the rear end of the cross beam respectively, a guide wheel (6)is installed on the first hub fixed base of the side beam, and a stabilizing wheel (7) is installed on the second hub fixed base of the side beam. A gear box (4b) and a traction motor (5) are arrangedon the cross beam in an oblique opposite angle manner, and the walking wheels and the gear box are mounted on an output shaft of the traction motor; a gear transmission system (9) is arranged in thegear box, and a gear rotating wheel (9a) meshed with a tooth-shaped rail (3) is arranged below the gear transmission system.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

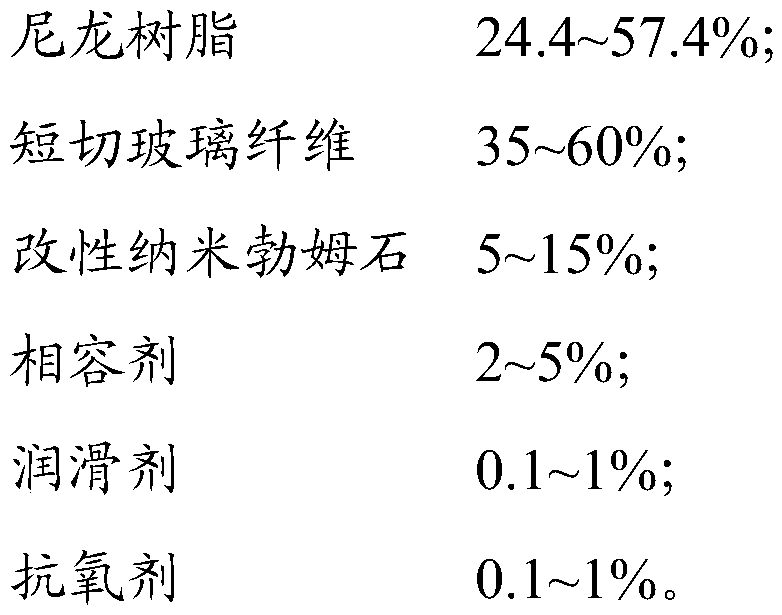

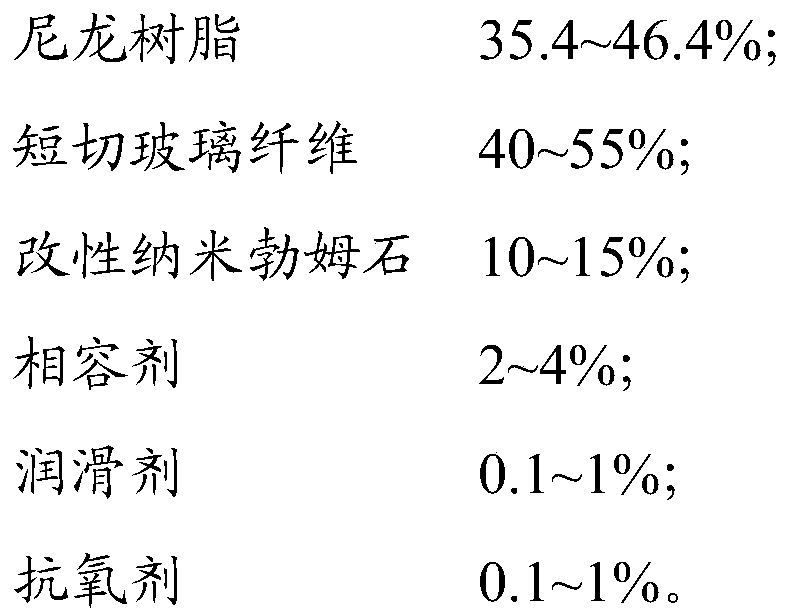

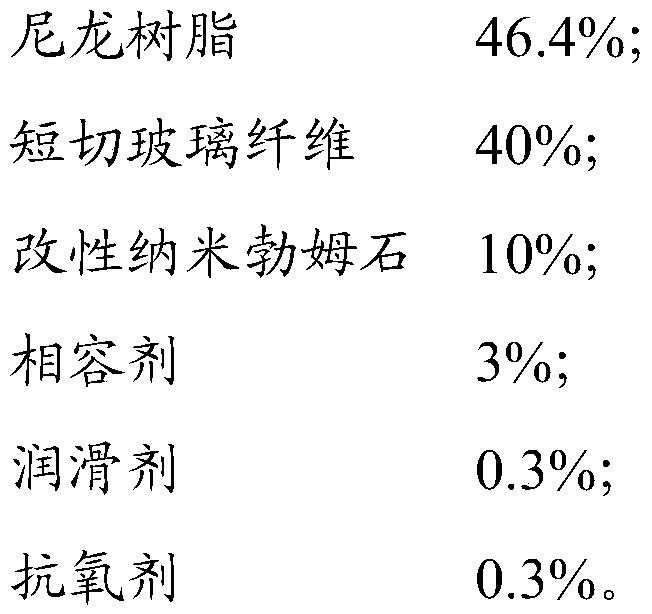

Nylon composite material

The invention relates to a nylon composite material which comprises the following components in percentage by weight: 24.4-57.4% of nylon resin, 35-60% of chopped glass fiber, 5-15% of modified nano boehmite, 2-5% of compatilizer, 0.1-1% of lubricant and 0.1-1% of antioxidant. The glass-fiber-reinforced nylon composite material has the characteristic of high strength. The modified nano boehmite and glass fibers are used for synergic reinforcement, thereby maintaining the advantages of the glass-fiber-reinforced nylon composite material, enhancing the strength and toughness of the material, overcoming the defects of poor dimensional stability and surface defects of the material due to high glass fiber content and having small influence on the material color. The nylon composite material has the advantages of excellent mechanical properties and favorable flowability, and is applicable to manufacturing of machines and automobile parts in need of high strength.

Owner:惠州市华聚塑化科技有限公司

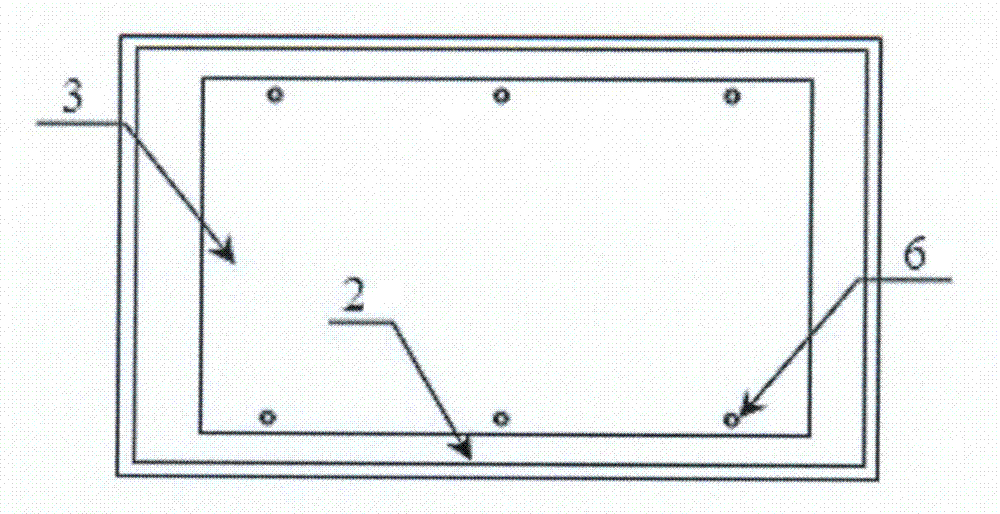

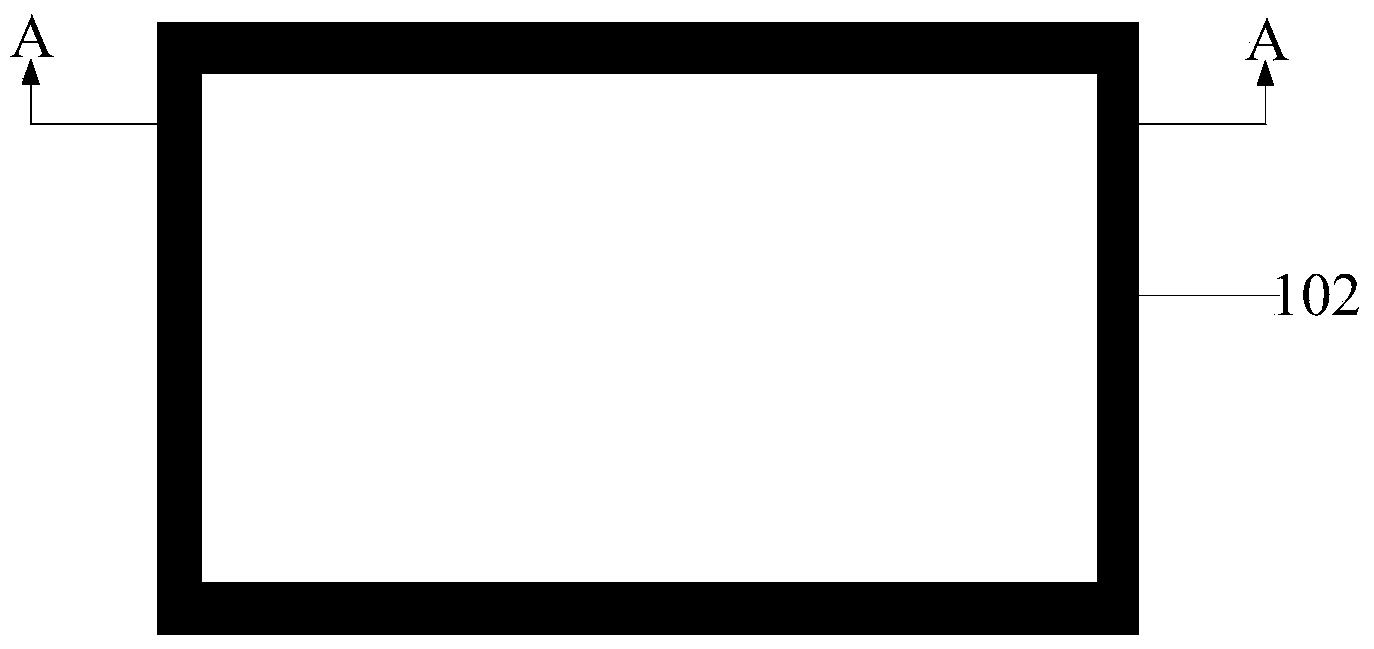

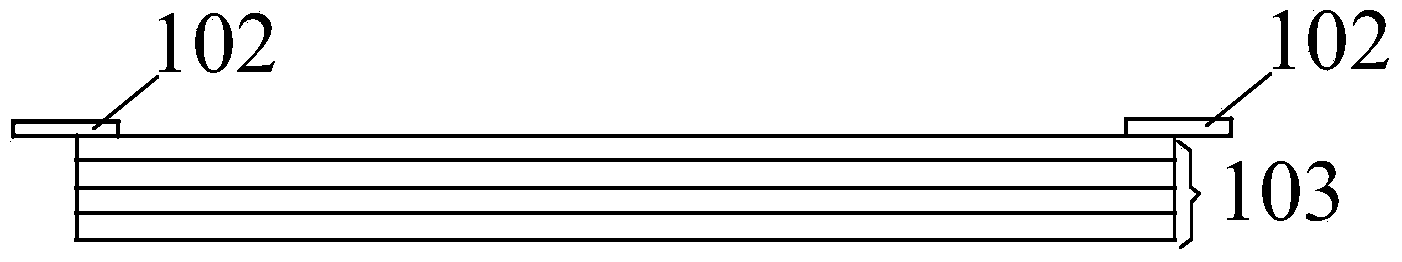

Optical film, manufacturing method thereof, backlight module and display device

InactiveCN104166271ALow costSave on attachment costsLaminationLamination apparatusDisplay deviceEngineering

The invention provides an optical film, a manufacturing method thereof, a backlight module and a display device. The optical film comprises a shading structure and an optical diaphragm group. The shading structure is arranged on the edge of the optical diaphragm group, and the shading structure is used for shading leaked light on the edge of the optical diaphragm group. According to the optical film, the manufacturing method of the optical film, the backlight module and the display device, the shading structure is arranged on the edge of the optical diaphragm group, the material cost, the attaching cost and the loss cost of related materials are saved, and therefore the production cost is greatly reduced.

Owner:HEFEI BOE DISPLAY LIGHT +1

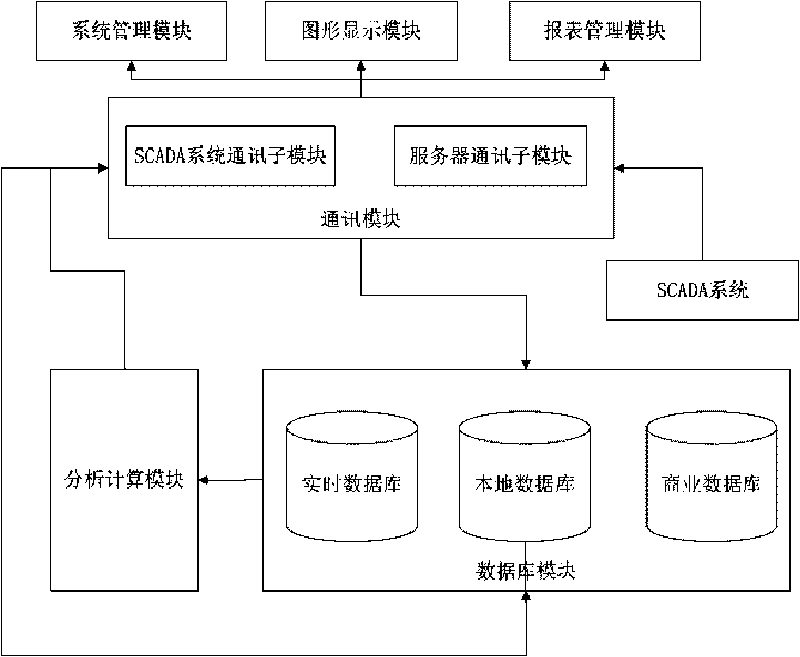

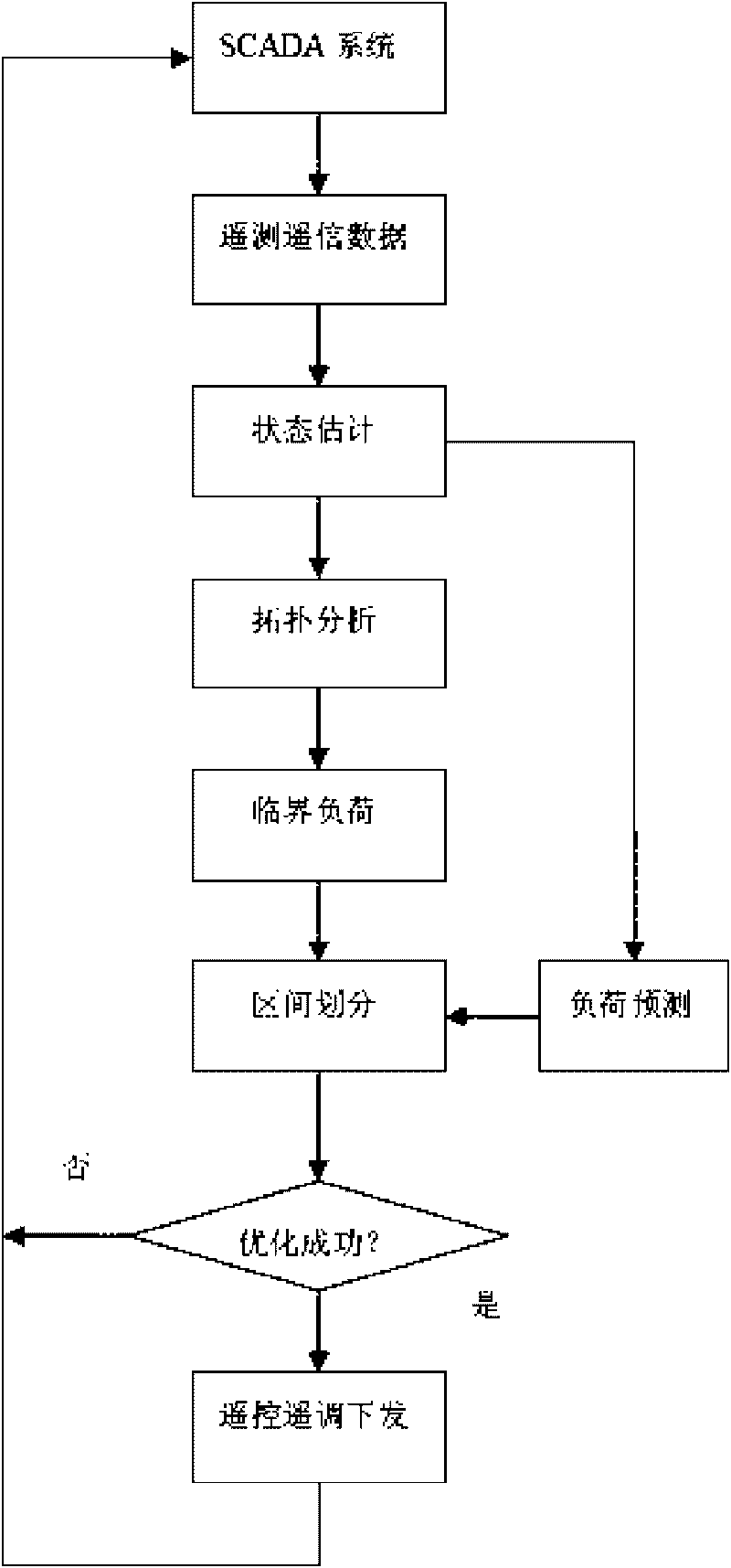

Auxiliary control system for economical operation of regional electric network transformer

InactiveCN101707379AReduce work intensityReduce lossSingle network parallel feeding arrangementsSystems intergating technologiesGraphicsControl system

The invention relates to an auxiliary control system for economical operation of a regional electric network transformer, which is applied to the technical field of electric power. The system comprises a database module, a communication module, an analysis and calculation module, a graphic display module, a report management module and a system management module, wherein the input end of the communication module is respectively connected with an automatic dispatch system and the analysis and calculation module to receive the measured data and form an economical operation control policy and an optimized operation curve to be output to the system management module, the graphic display module and the report management module; the database module is connected with the communication module to transmit the measured data; and the output end of the database module is connected with the analysis and calculation module to transmit the measured data, the economical operation control policy and the optimized operation curve. The invention can realize the purpose of controlling the overall process to be completed automatically, can greatly reduce the working strength of field operators, reduce the network loss and increase the power factor at the load side of the electric network, and has positive significance of energy saving and consumption reduction for the whole electric power system.

Owner:SHANGHAI JIAO TONG UNIV +2

Mining automatic high-pressure flushing type camera device and monitoring method thereof

ActiveCN111327801AAvoid direct destructionImprove cleanlinessTelevision system detailsFouling preventionCamera lensSprayer

The invention discloses a mining automatic high-pressure flushing type camera device. The device comprises a base, a camera, a conical cover, a dust induction recognizer, a controller, a high-pressureairflow hose, a high-pressure water flow hose and a telescopic spray pipe mechanism, a camera lens on the left of the camera is positioned in the conical cover; a dustproof transparent assembly is arranged on the left of the camera lens. The dust induction recognizer is arranged in the conical cover and used for monitoring dust attached to the surface of the left side of the dustproof transparentassembly, the telescopic spray pipe mechanism is arranged at the top of the left side of the conical cover and can stretch out and draw back vertically, and the lower end of the telescopic spray pipemechanism is provided with an airflow sprayer and a water flow sprayer for spraying towards the dustproof transparent assembly. According to the invention, automatic induction is realized through thedust induction recognizer; cleaning is achieved by combining high-pressure water flow, air flow and other pressure intensities, the cleanliness of the dustproof glass can be effectively guaranteed, the high-pressure air flow can effectively achieve the effects of drying and water stain removing, and therefore the workload of manual wiping can be effectively reduced, damage to the camera lens is reduced, and the service life of the camera lens is prolonged.

Owner:HENAN POLYTECHNIC UNIV

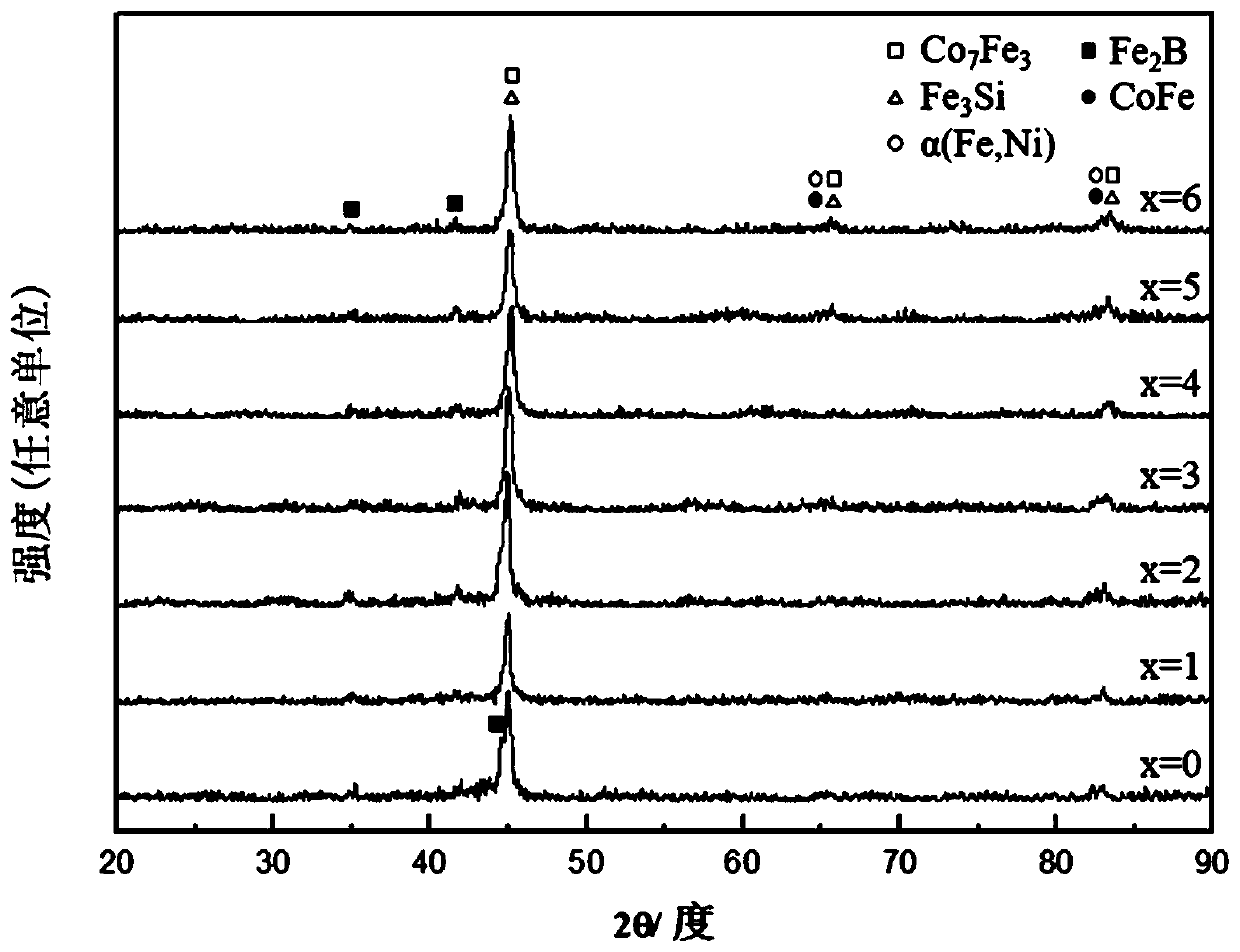

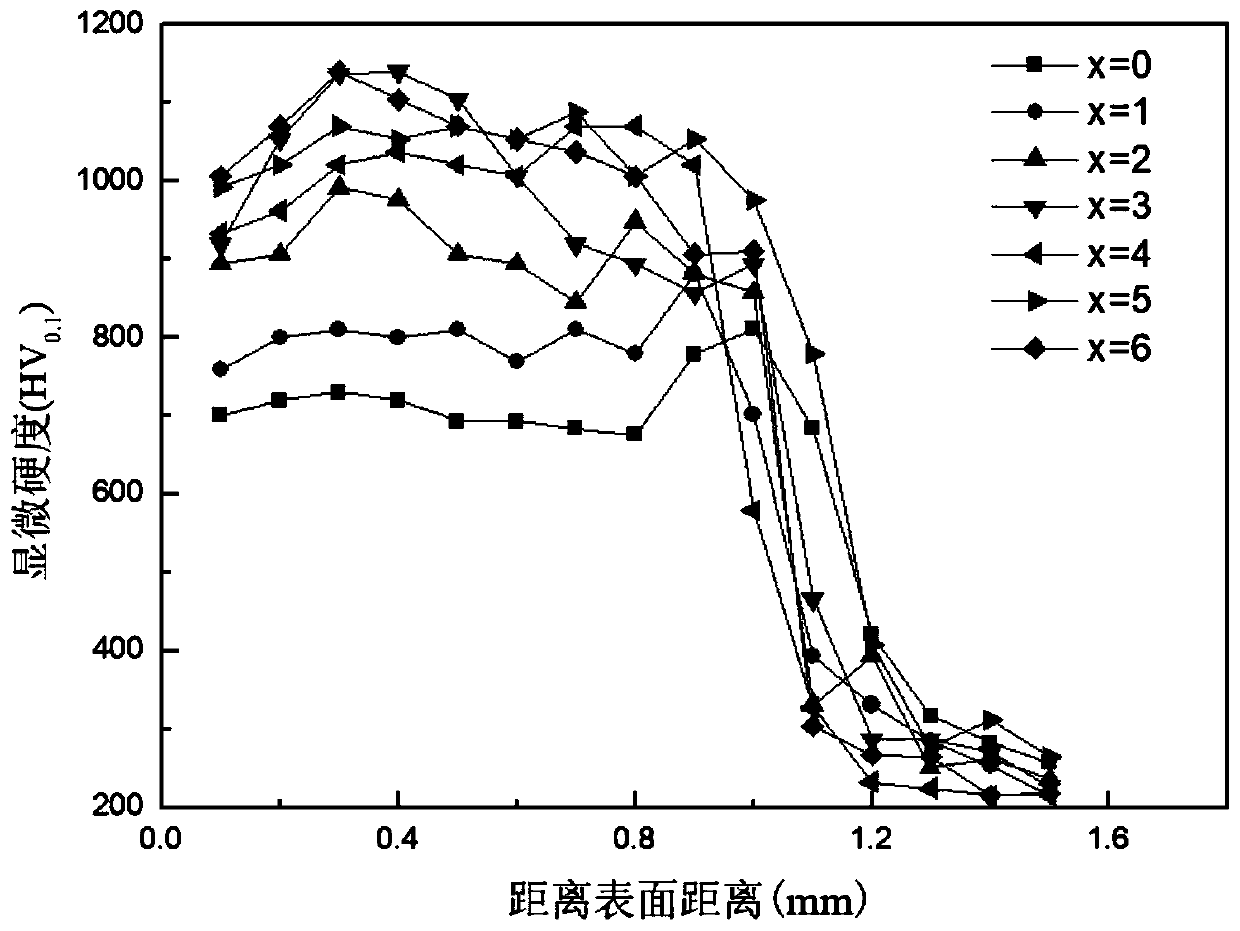

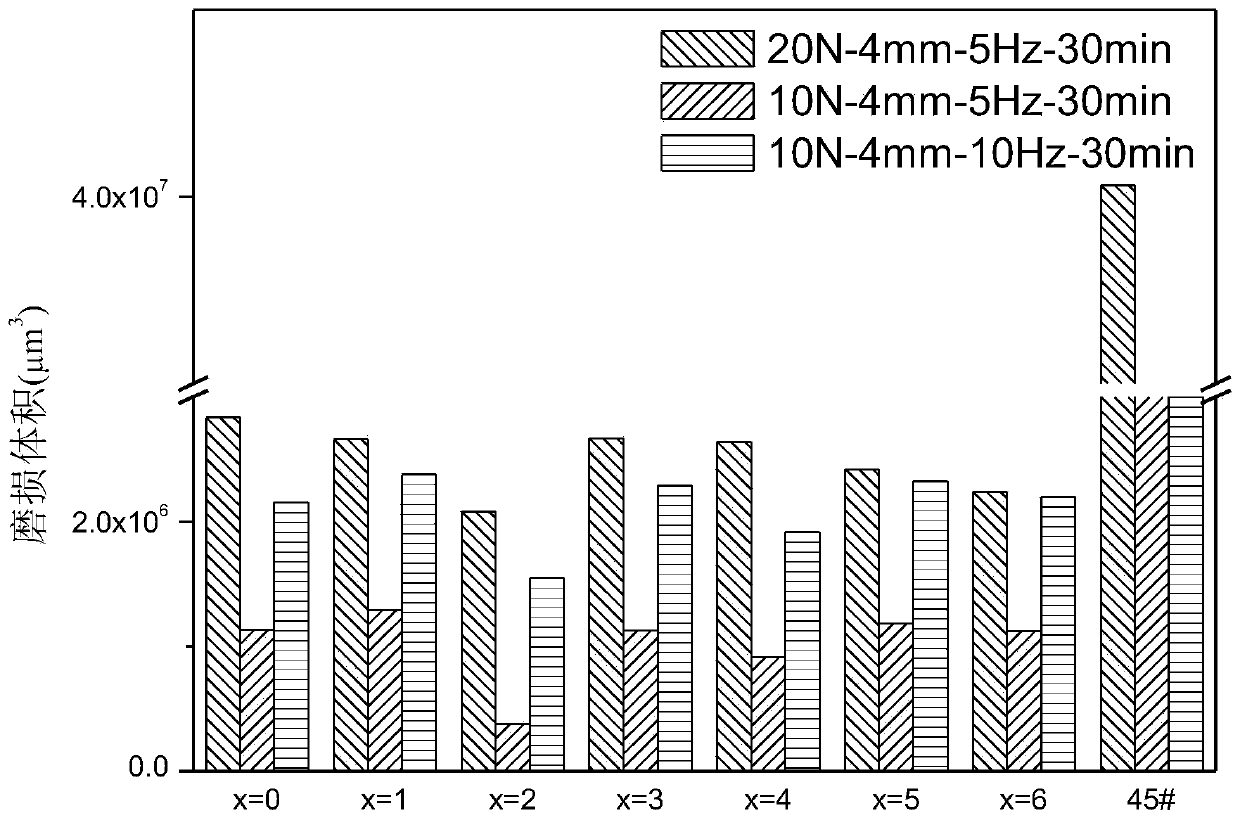

Iron-based amorphous nanocrystalline laser cladding composite coating, preparation method and test method

InactiveCN109898082APrevent oxidationSi content increasedMaterial nanotechnologyMaterial strength using tensile/compressive forcesBreaking strengthManufactured material

The invention provides an iron-based amorphous nanocrystalline laser cladding composite coating, a preparation method and a test method. The cladding composite coating meets a molecular formula: FeaCobNicBdSiyNbe, wherein a, b, c, d, y and e represent the corresponding alloy element atomic percent: a is larger than or equal to 32 and less than or equal to 44, b is larger than or equal to 10 and less than or equal to 15, c is larger than or equal to 10 and less than or equal to 15, d is larger than or equal to 18 and less than or equal to 20, y is larger than or equal to 4 and less than or equal to 23, e is larger than or equal to 4 and less than or equal to 5, and a+b+c+d+y+e is equal to 100. The preparation method comprises the preparation steps of weighing the raw materials, mixing the raw materials to obtain alloy powder, pretreating a base plate, flatly spreading the alloy powder to the surface of the base plate, and using a laser beam to perpendicularly laser-clad the alloy powder. The composite coating has a certain amorphous content, high microhardness, excellent abrasive resistance and outstanding breaking strength; and the preparation process is simple, and the raw materials do not contain rare earth or volatile elements, so that the iron-based amorphous nanocrystalline laser cladding composite coating has broad application prospects.

Owner:SOUTHEAST UNIV

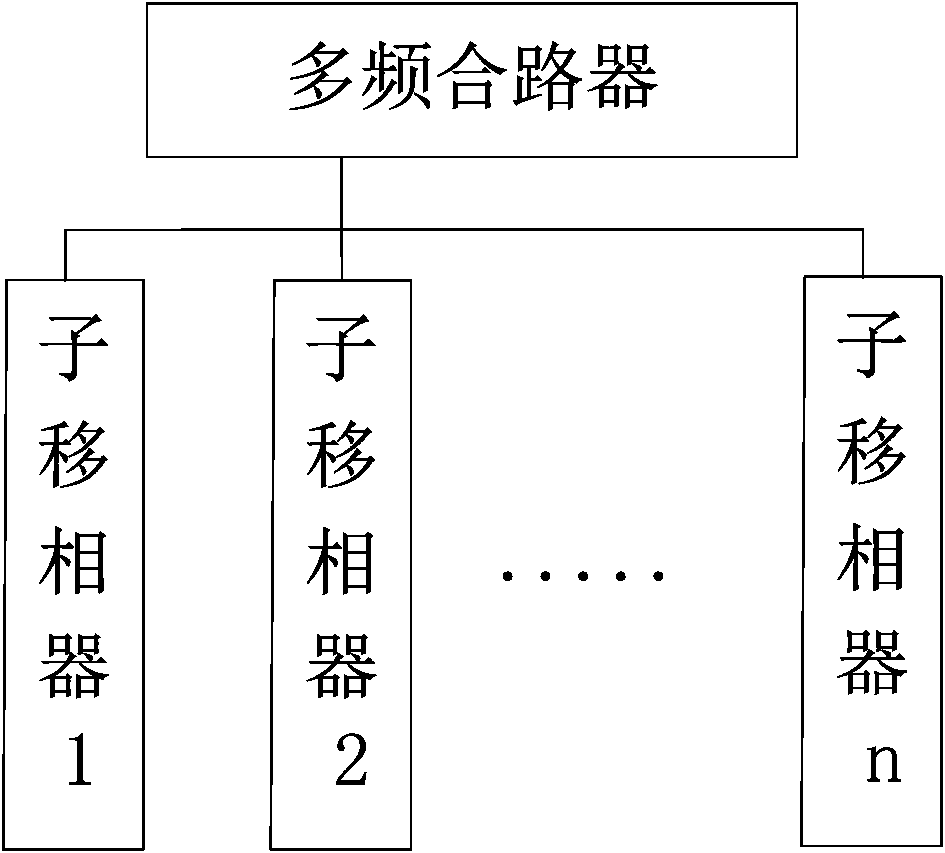

Integrated feeding network of 4G antenna

The invention discloses an integrated feeding network of a 4G antenna. Through a reasonable arrangement and using the planarity design of a transmission line and a phase shifter assembly, a combiner network and a phase shifter network are combined into a whole. Therefore, complexity of a common network is effectively reduced, extra loss and production cost which are caused by an existing network connection mode are effectively reduced, assembly difficulty is greatly reduced, and the performance of the antenna is greatly improved. The integrated feeding network is compact in overall structure and has a qualitative leap in reliability and uniformity of volume production.

Owner:重庆晖速智能通信有限公司

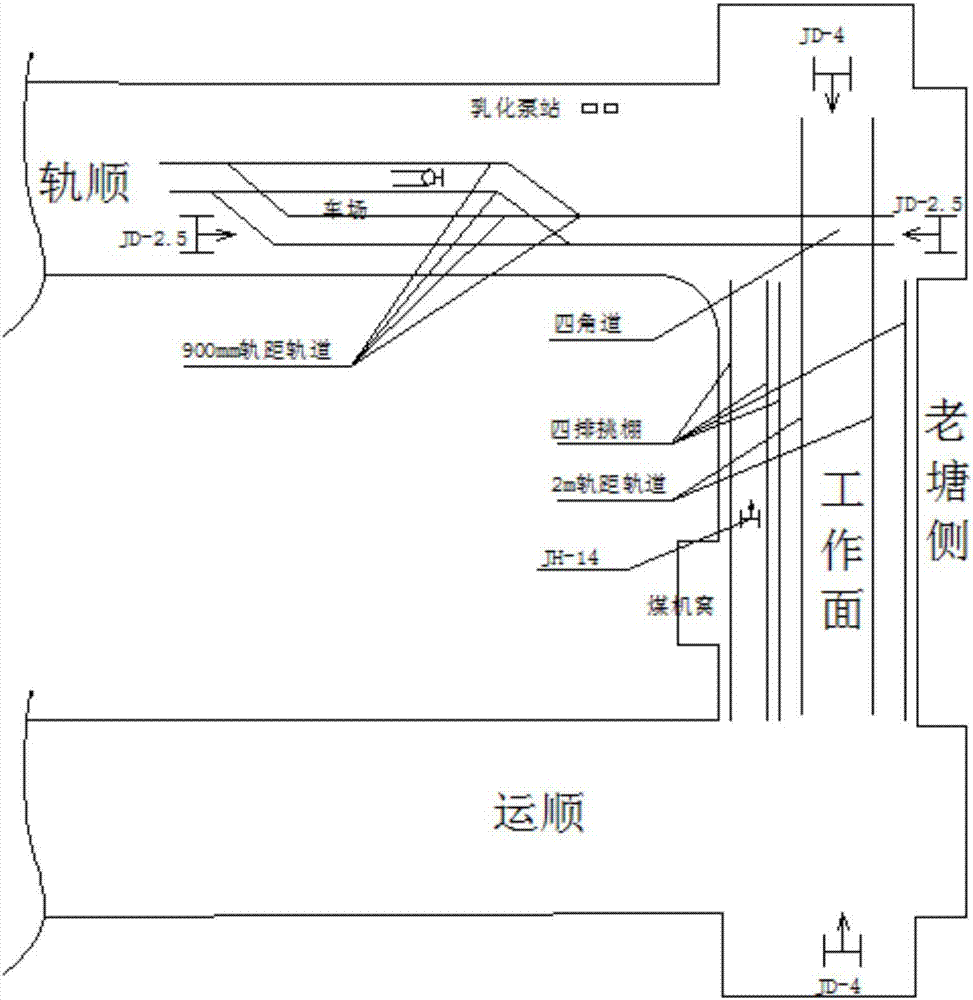

Quick installation method for fully-mechanized coal mining equipment of fully-mechanized coal mining face

ActiveCN107355248AReduce usageReduce construction labor costsMine roof supportsUnderground transportEngineeringWinch

The invention provides a quick installation method for fully-mechanized coal mining equipment of a fully-mechanized coal mining face. The quick installation method comprises the following steps that 1, preparation work is conducted; and 2, equipment installation is conducted, and the specific steps comprise that 21, scraper installation is conducted, specifically, a system winch is used for hitting and conveying a scraper chute car to the position of an upper-opening four-corner-channel, and then a cut-hole opposite-pull winch is used for hitting and conveying the scraper chute car to a corresponding position of installation; and then a hydraulic crane is utilized to hoist the chute car to be separated from an installation forklift, after the installation forklift is hit away, the crane continues to hoist and rotate, and the chute car is installed to be in place; and 22, installation of hydraulic supports is conducted, specifically, after hitting, conveying and installing of a working face scraper and a coal machine are completed, a cut-hole upper-opening winch is used for hitting and conveying a hydraulic forklift to pass a four-corner channel to be parked in front of the winch, the hydraulic forklift is parked to be stable and hidden to be compact, and it is ensured that a support car can be smoothly hit and conveyed to the four-corner channel; and then the hydraulic supports are installed sequentially. The fully-mechanized coal mining face equipment is installed and dismantled by using mechanized equipment, the labor intensity of employees is relieved, the working efficiency is further improved, and a future development direction of installation and demolition of fully-mechanized coal mining equipment is pointed out.

Owner:HUAINAN MINING IND GRP

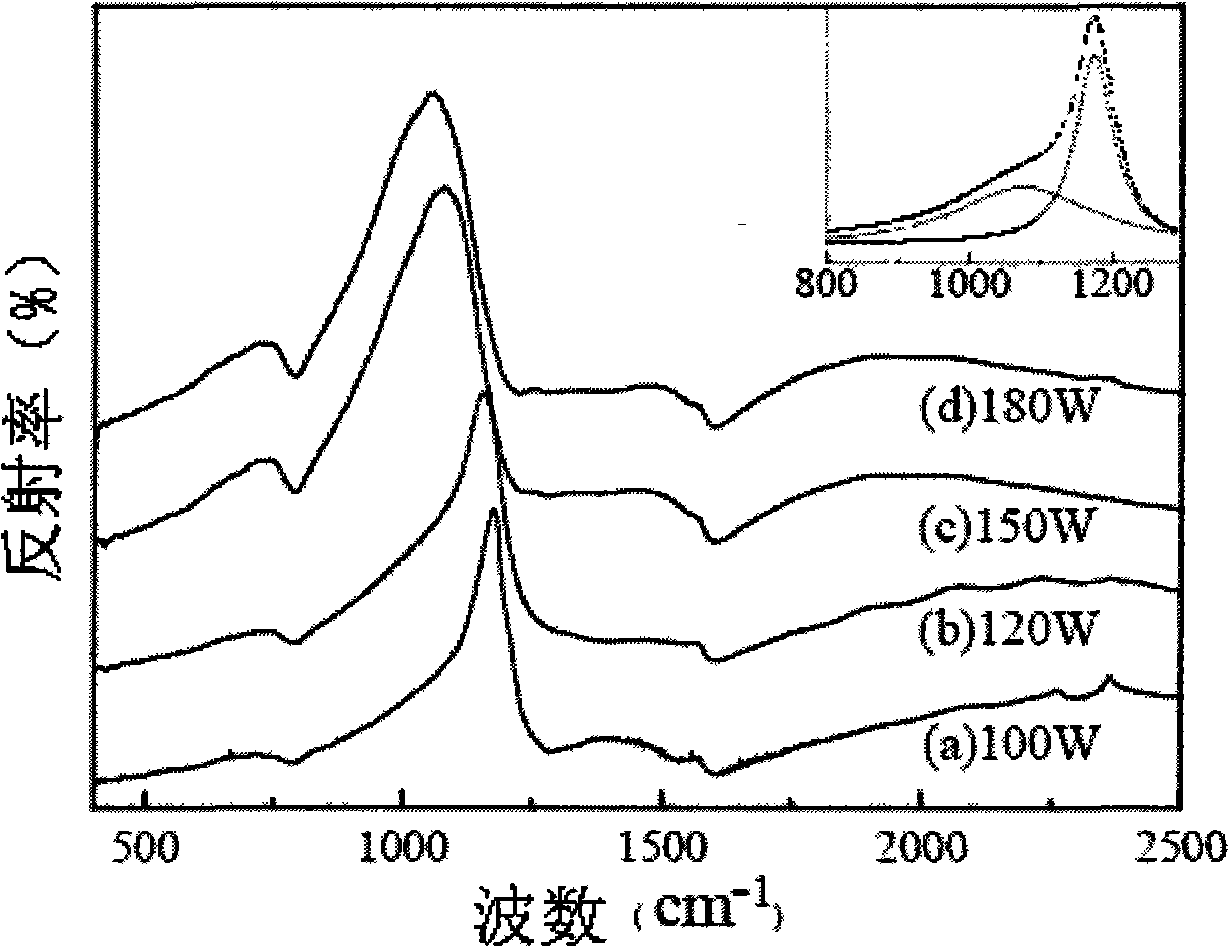

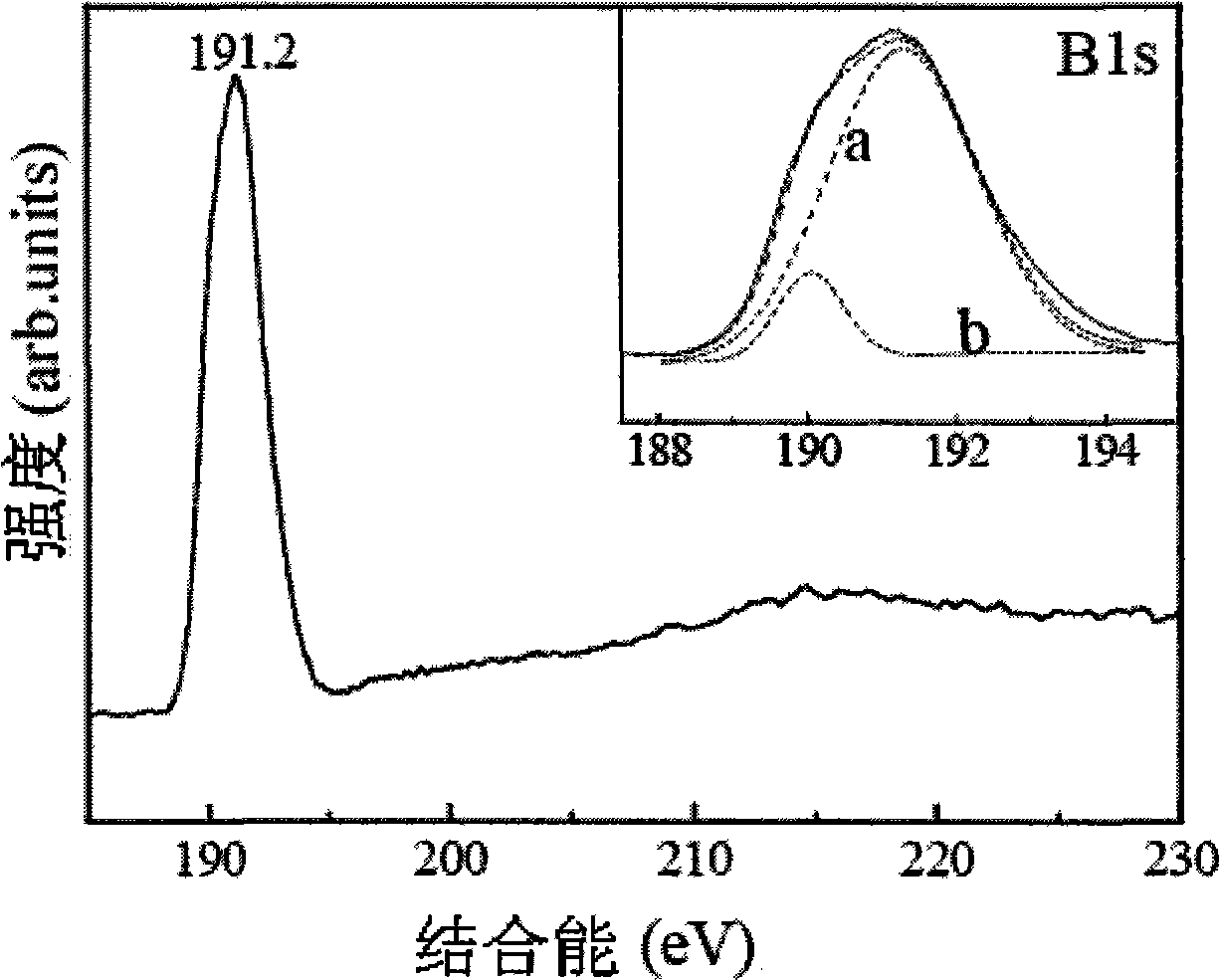

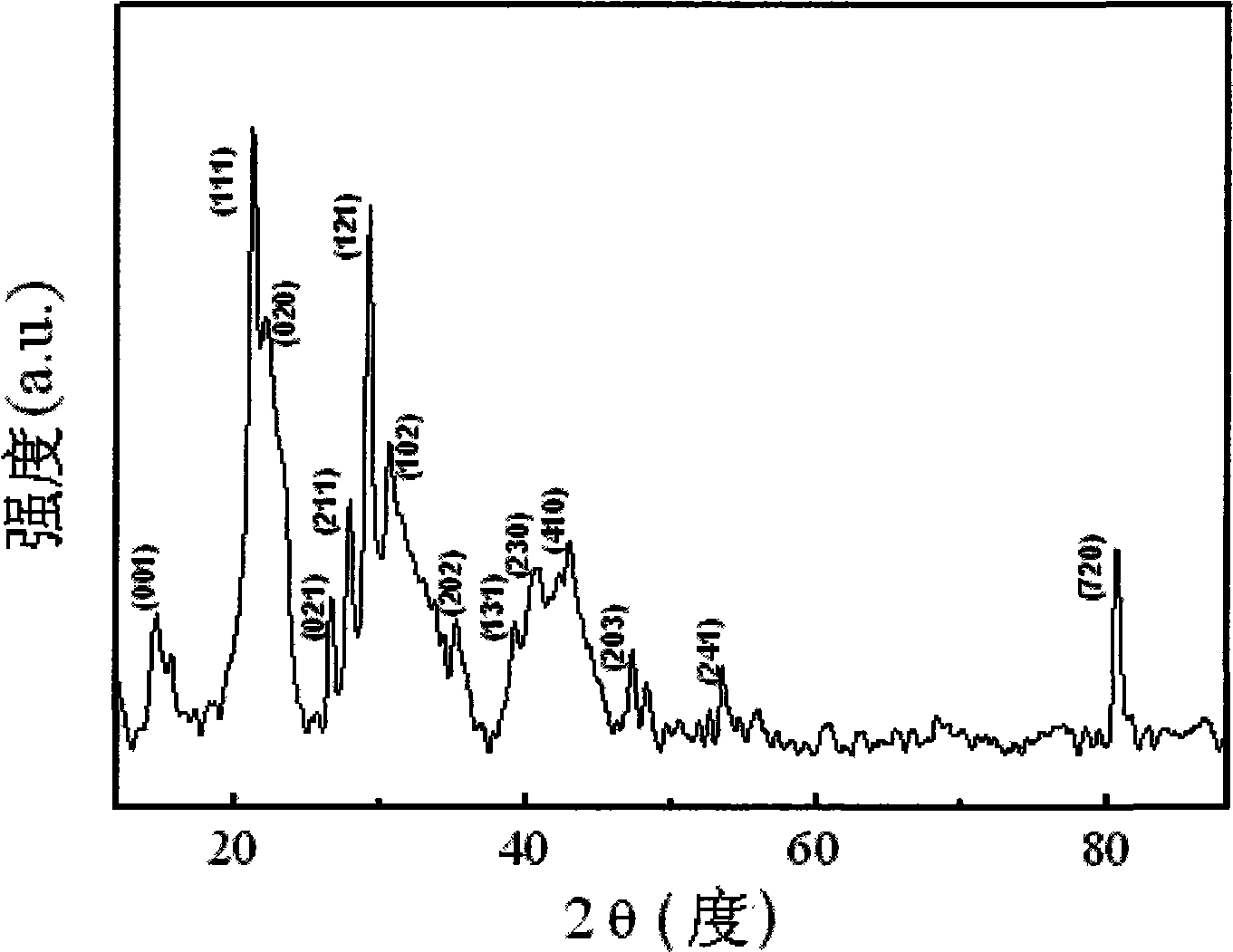

Method for growing boron nitride membrane on graphite substrate

InactiveCN101545095AReduce stressNo crackVacuum evaporation coatingSputtering coatingGraphite substrateBoron nitride

The invention relates to a method for growing a boron nitride membrane on a graphite substrate, and belongs to the technical field of functional membrane materials. The method comprises cleaning treatment of the graphite substrate and a technical process of magnetron sputtering deposition. The cleaning treatment of the graphite substrate comprises mechanical polishing, deionized water rinsing and ultrasonic cleaning of the graphite substrate soaked in acetone solution and ethanol solution respectively. The magnetron sputtering deposition process comprises the following steps: using hexangular boron nitride as a sputtering target material; and under the atmosphere of argon and nitrogen, adjusting radio-frequency power at 100 to 180 watts, depositing the sputtering target material for 0.5 to 70 hours, and growing a cBN or / and eBN membrane on the graphite substrate. The method has the following remarkable characteristics: the purity of the grown BN membrane is high; the membrane which is not prepared by biasing the substrate has low stress, and the surface of the membrane has no crack; the substrate is not heated so as to reduce the process requirement of equipment and lower energy loss and preparation cost; and the BN membrane does not peel off when the BN membrane is placed in the air for a long time.

Owner:JILIN UNIV

Engine with central axis elliptical rotor and compressed air bridged fuel oil clamped injection

InactiveCN102418595ASimple structureReduce volumeInternal combustion piston enginesRolling resistanceFuel oil

The invention discloses an engine with central axis elliptical rotor and compressed air bridged fuel oil clamped injection, and relates to a central axis elliptical rotor engine device. The engine is characterized in that: four travels, namely air inlet, compression, work doing and exhaust are simultaneously alternately finished in spaces with periodically changed volume, and two-time work doing travels are finished when a rotor rotates a circle. The engine has the advantages that: 1, a mode that high-temperature high-pressure compressed air performs fuel oil clamped injection replaces a novel combustion mode that premixed gas is subjected to compression ignition, so that the problem of high oil consumption is solved, and the fuel adaptability of the engine is improved; 2, a fixed displacement pump supplies fuel oil according to the actual condition, so that high-efficiency combustion work doing with a variable air-fuel ratio can be realized; 3, a central axis elliptical rotor replaces an eccentric axis triangular rotor, so that the processing cost of parts is reduced while stability is improved; and 4, contact surfaces of two ends of the elliptical rotor and the inner wall of a cylinder are lubricated and sealed by a roller, and sliding friction is changed into rolling friction, so that system loss and operating cost are effectively reduced.

Owner:曾涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com