Engine with central axis elliptical rotor and compressed air bridged fuel oil clamped injection

An elliptical rotor and compressed air technology, which is applied to combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problems of high fuel consumption and operating costs, heavy mass, and low compression ratio, and reduce system loss and operating costs. Structure Simple, Lightweight Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

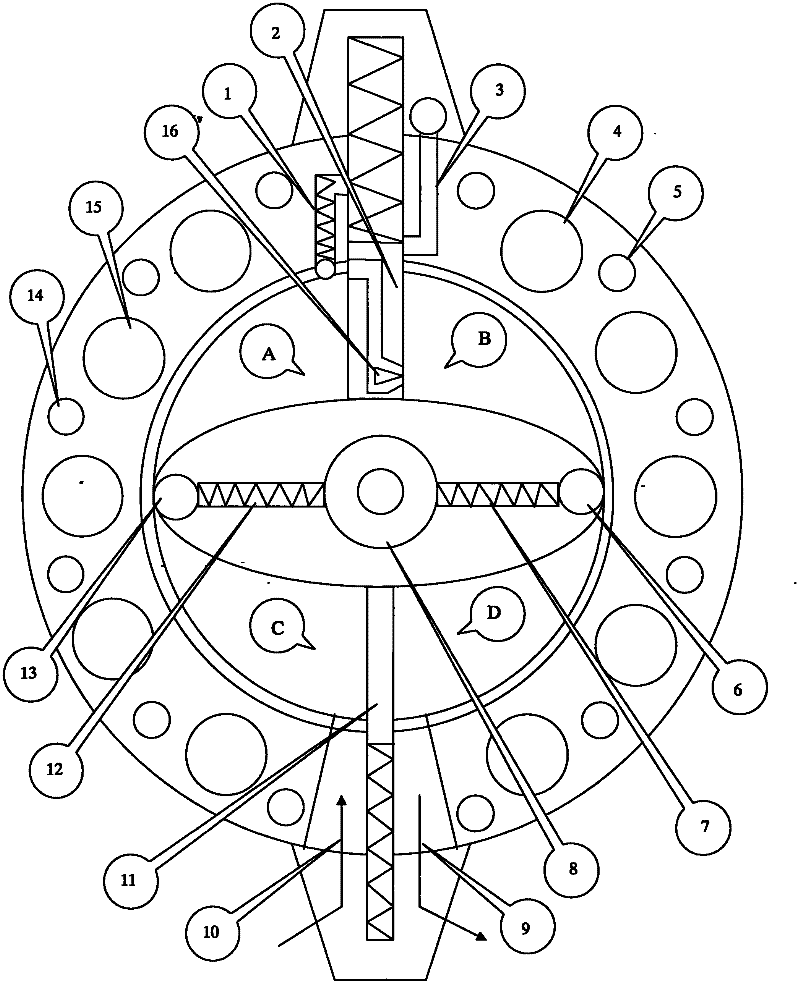

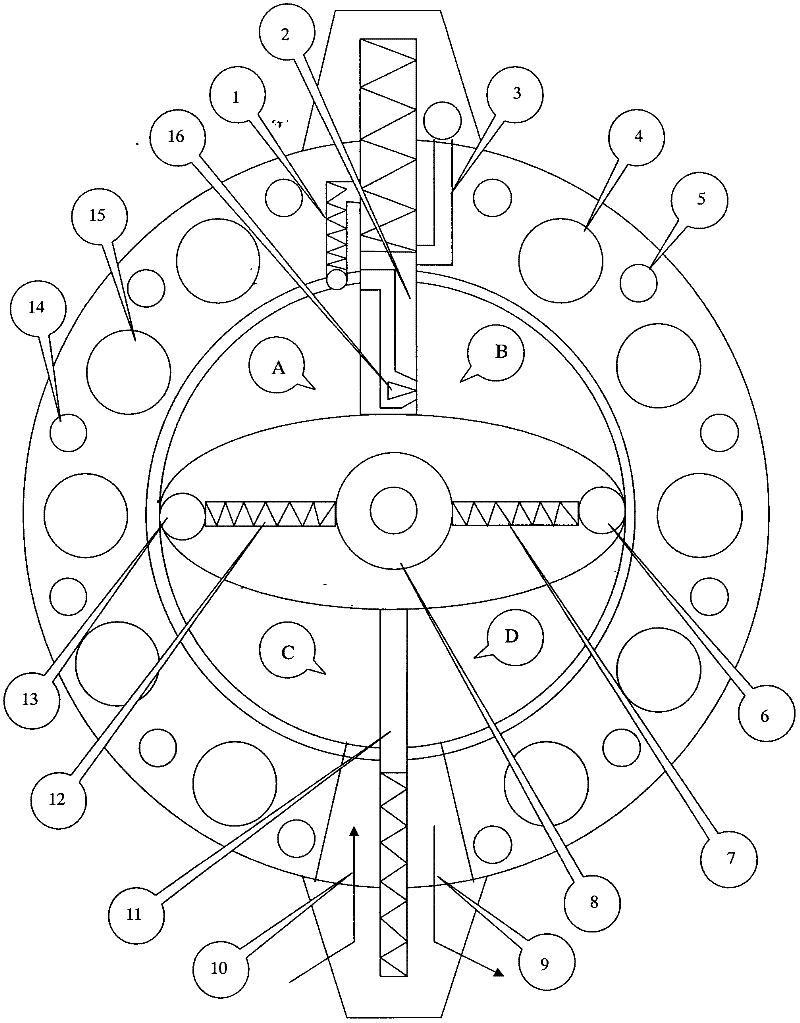

[0021] According to the drawings, A, B, C, and D are four periodically changing spaces separated by the elliptical rotor and two slides. A is the compression chamber, B is the work chamber, C is the exhaust chamber, D It is the intake chamber. When the elliptical rotor rotates clockwise, the air in the A compression chamber is compressed in the 1 compressed air pipe, and the fuel and compressed air in the B working chamber are burning to do work, pushing the rotor to move clockwise. , the exhaust gas after the last combustion work in the C exhaust cavity is discharged through 9 exhaust ports, and the D intake cavity is re-entering fresh air from 10 air intake ports, so in the present invention, air intake, compression, work and The four strokes of exhaust are carried out alternately in different spaces at the same time.

[0022] When the volume of the A compression chamber is the smallest, the compressed air is temporarily stored in the 1 compressed air pipe, and the 2 bridgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com