Optical film, manufacturing method thereof, backlight module and display device

A technology for optical film layers and manufacturing methods, which is applied in lamination devices, chemical instruments and methods, optics, etc., can solve problems such as increased production costs, and achieve the effects of saving material costs and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

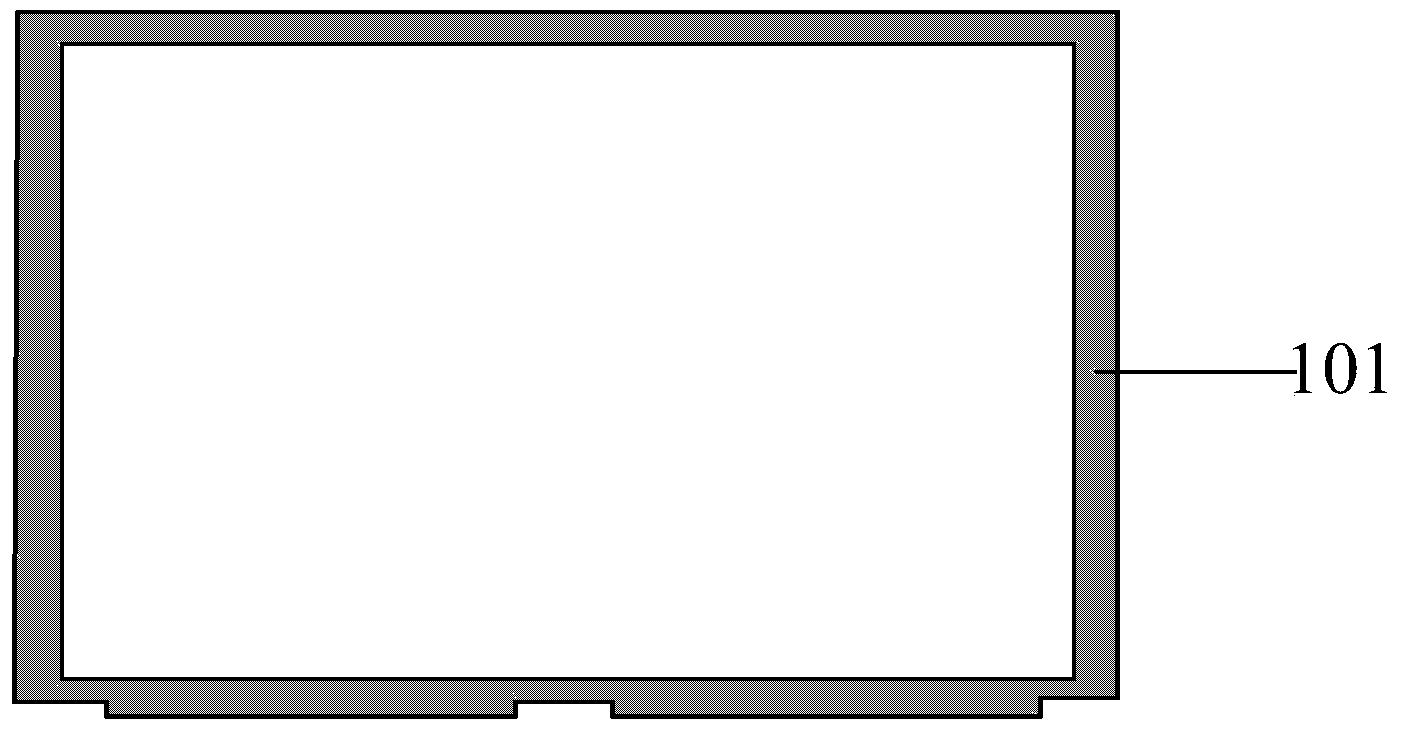

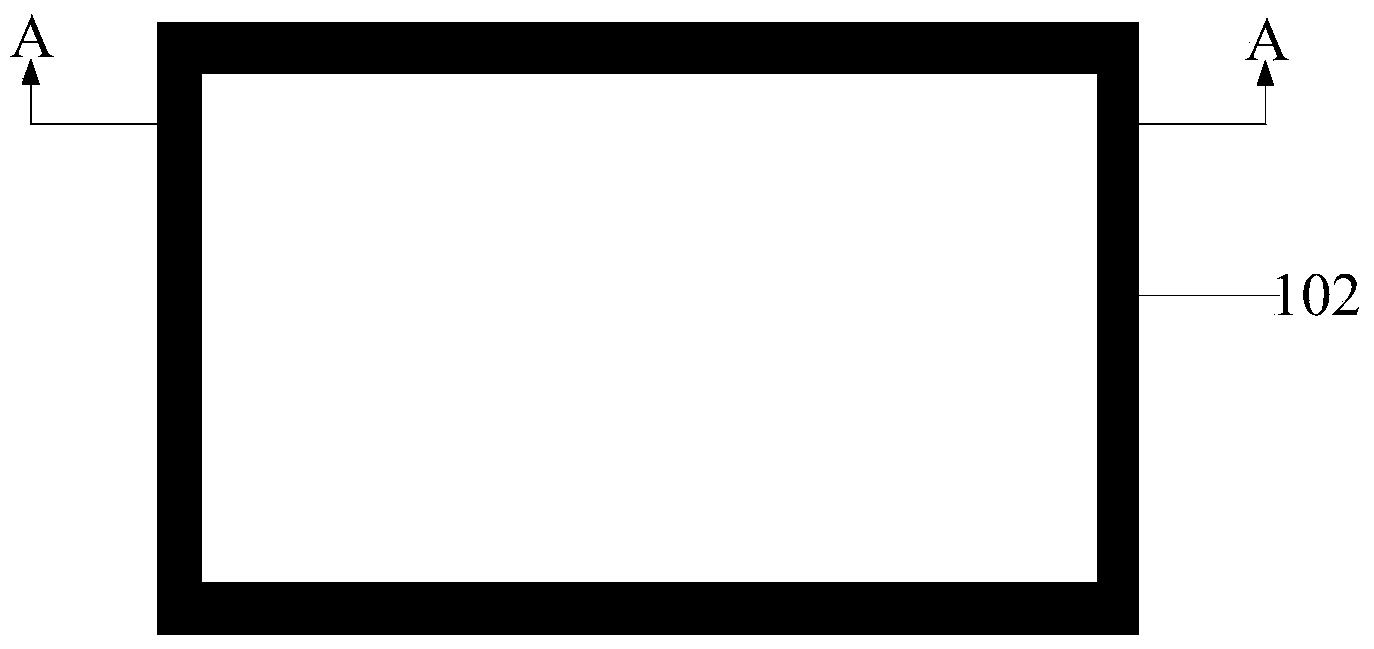

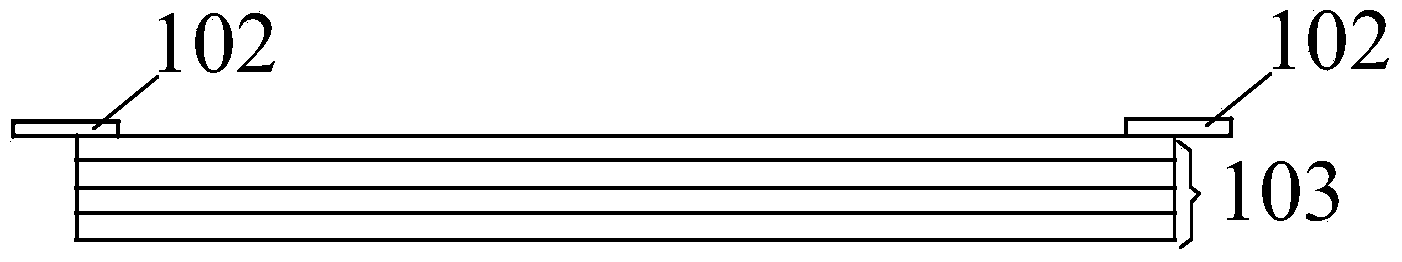

[0052] figure 2 It is a schematic structural diagram of an optical film layer provided in Embodiment 1 of the present invention, image 3 for figure 2 A-A cross-section of the optical layer shown. Such as figure 2 , image 3 As shown, the optical film layer includes a light-shielding structure 102 and an optical film group 103, the light-shielding structure 102 is arranged on the edge of the optical film group 103, and the light-shielding structure 103 is used to shield the optical film group light leaks at the edges. Preferably, the optical film set includes a prism sheet, a diffusion sheet, and a composite prism sheet. Optionally, the light shielding structure 102 is partially located on the edge of the optical film set 103 and partially located outside the optical film set 103 .

[0053] Figure 4 It is a schematic diagram of the application of the optical film layer in this embodiment. Such as Figure 4 As shown, the optical film set 103 is located on the light...

Embodiment 2

[0059] This embodiment provides a backlight module, including the optical film layer provided in Embodiment 1. For details, please refer to the description in Embodiment 1 above, which will not be repeated here.

[0060] In the backlight module provided by this embodiment, the light-shielding structure is arranged on the edge of the optical film group, which saves material cost, attachment cost and loss cost of related materials, thereby greatly reducing production cost.

Embodiment 3

[0062] This embodiment provides a display device, including a backplane, a plastic frame, a display panel, and the backlight module provided in Embodiment 2. see Figure 4 and Figure 5 , the display panel (not shown in the figure) is located on the light emitting side of the backlight module, the plastic frame 105 is located on the outside of the display panel and the backlight module, and the back plate 106 is wrapped in the The backlight module and the outside of the plastic frame 105 . For details about the optical film layer and the backlight module, reference may be made to the descriptions in Embodiment 1 and Embodiment 2 above, and will not be repeated here.

[0063] In the display device provided by this embodiment, the light-shielding structure is arranged on the edge of the optical film group, which saves material cost, attachment cost and loss cost of related materials, thereby greatly reducing production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com