Electrical source emission device and control method with soft chopping wave characteristic

A technology of transmitting device and electric source, which is applied in the direction of control/regulation system, output power conversion device, electrical components, etc., can solve the problem of narrowing the duty cycle variation range of step-down chopper and current stabilization circuit, low power density, high-pass State loss and economic cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail,

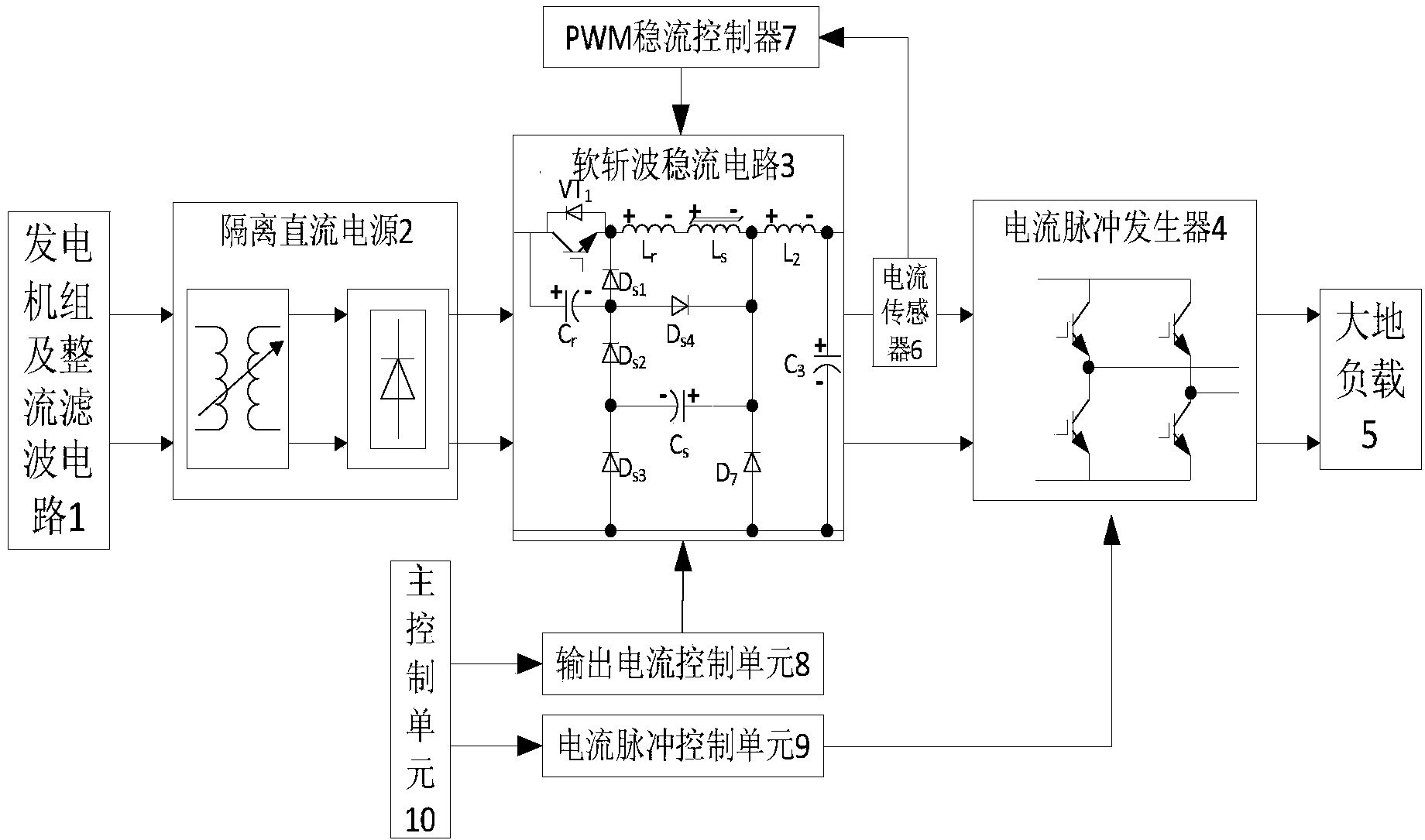

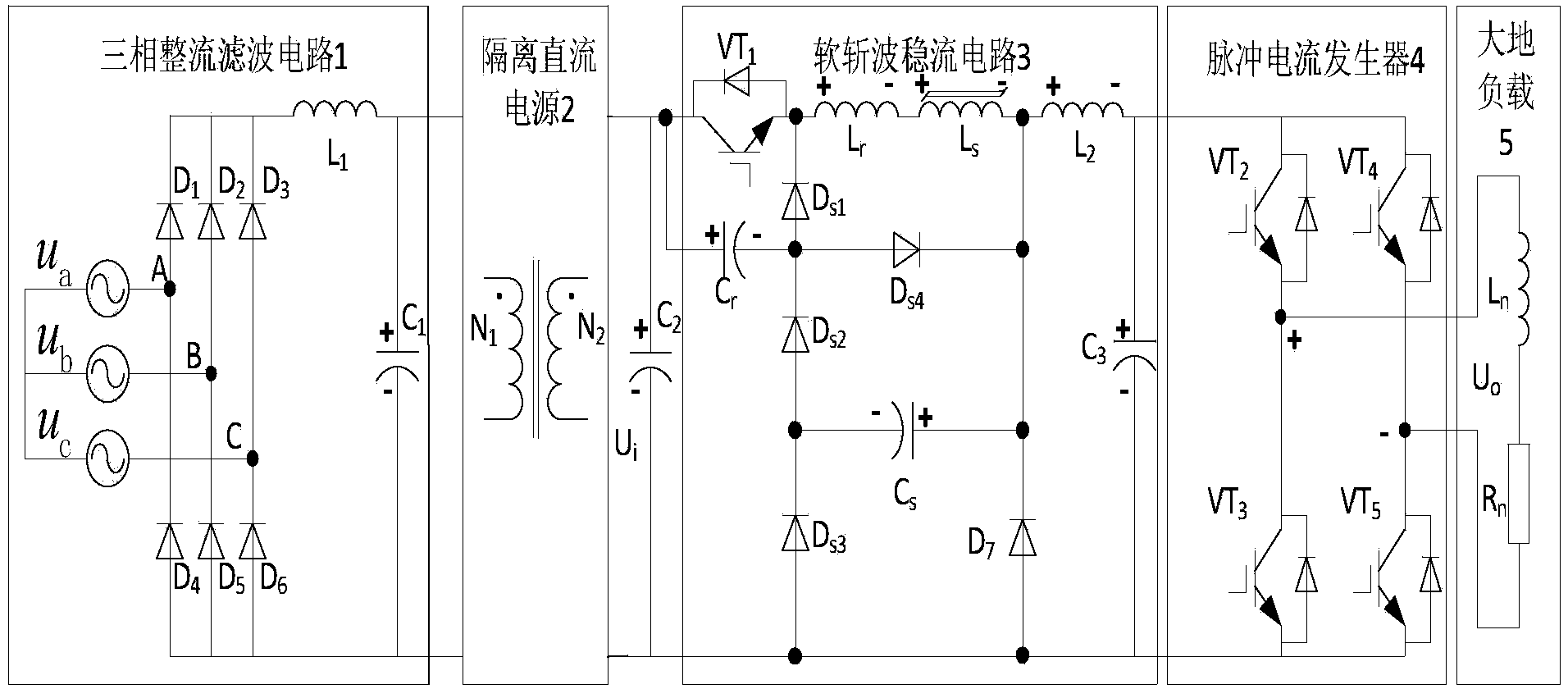

[0054] figure 1 It is a structural block diagram of an electric source emission device with soft chopping characteristics, which is connected by a generator set and a rectification filter circuit 1 through an isolated DC power supply 2 and a soft chopping current stabilization circuit 3, and the soft chopping current stabilization circuit 3 The positive pole is connected to the ground load 5 through the current sensor 6 and the current pulse generator 4, the negative pole output of the soft chopper current stabilization circuit 3 is connected to the ground load 5 through the current pulse generator 4, and the current sensor 6 is connected to the ground load 5 through the PWM steady current controller 7. The soft chopper current stabilization circuit 3 is connected, the main control unit 10 is connected with the soft chopper current stabilization circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com