Patents

Literature

178results about How to "Improve load adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

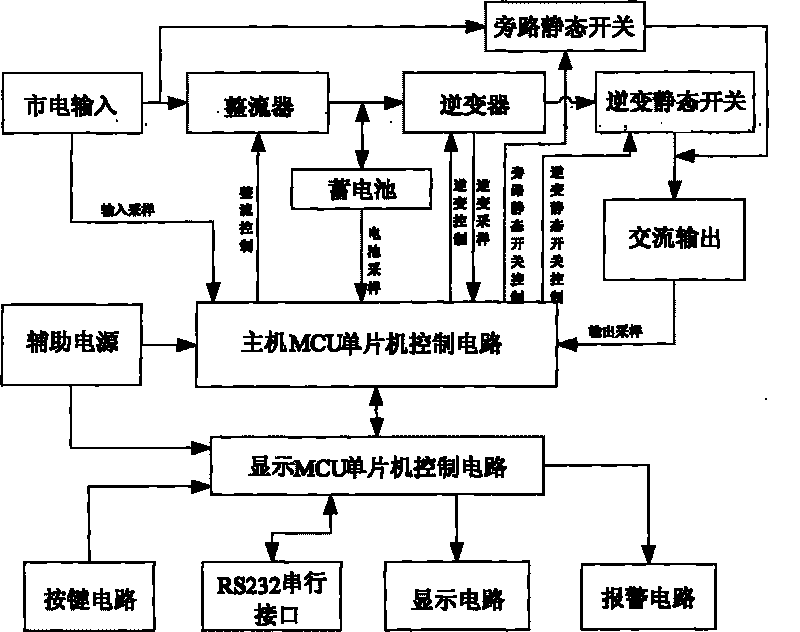

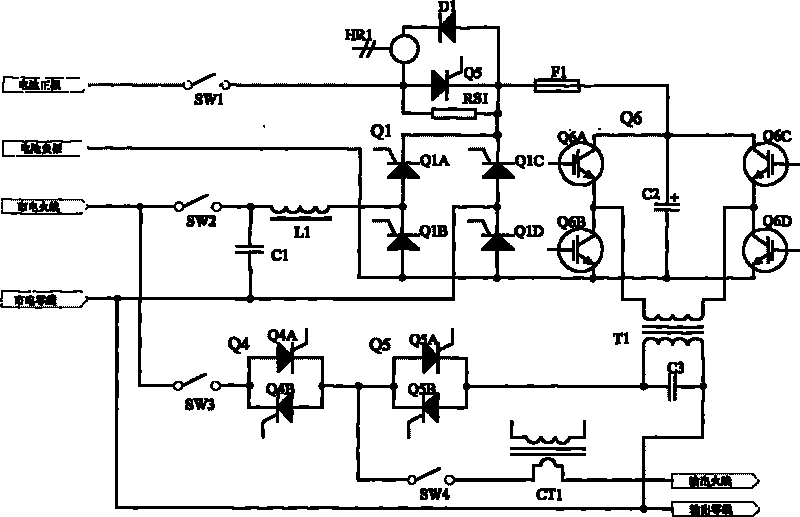

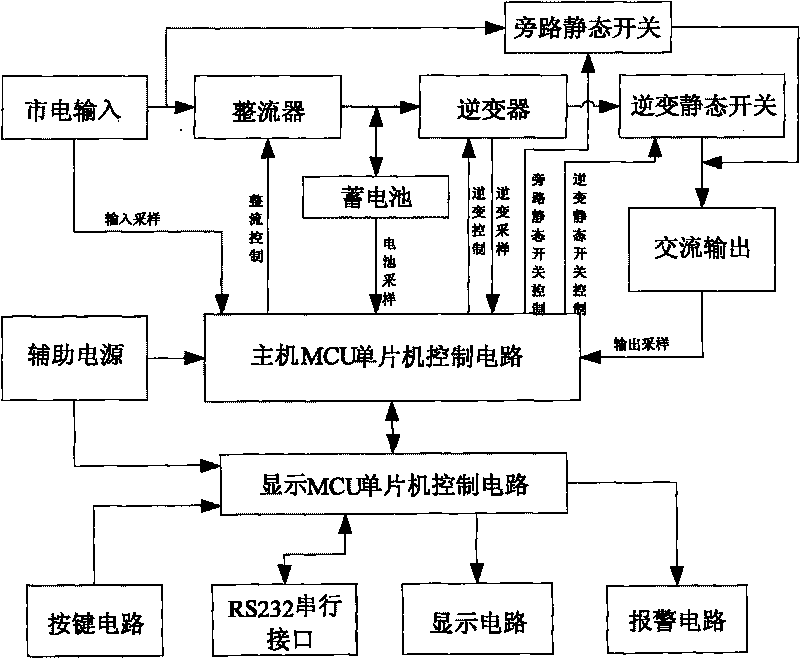

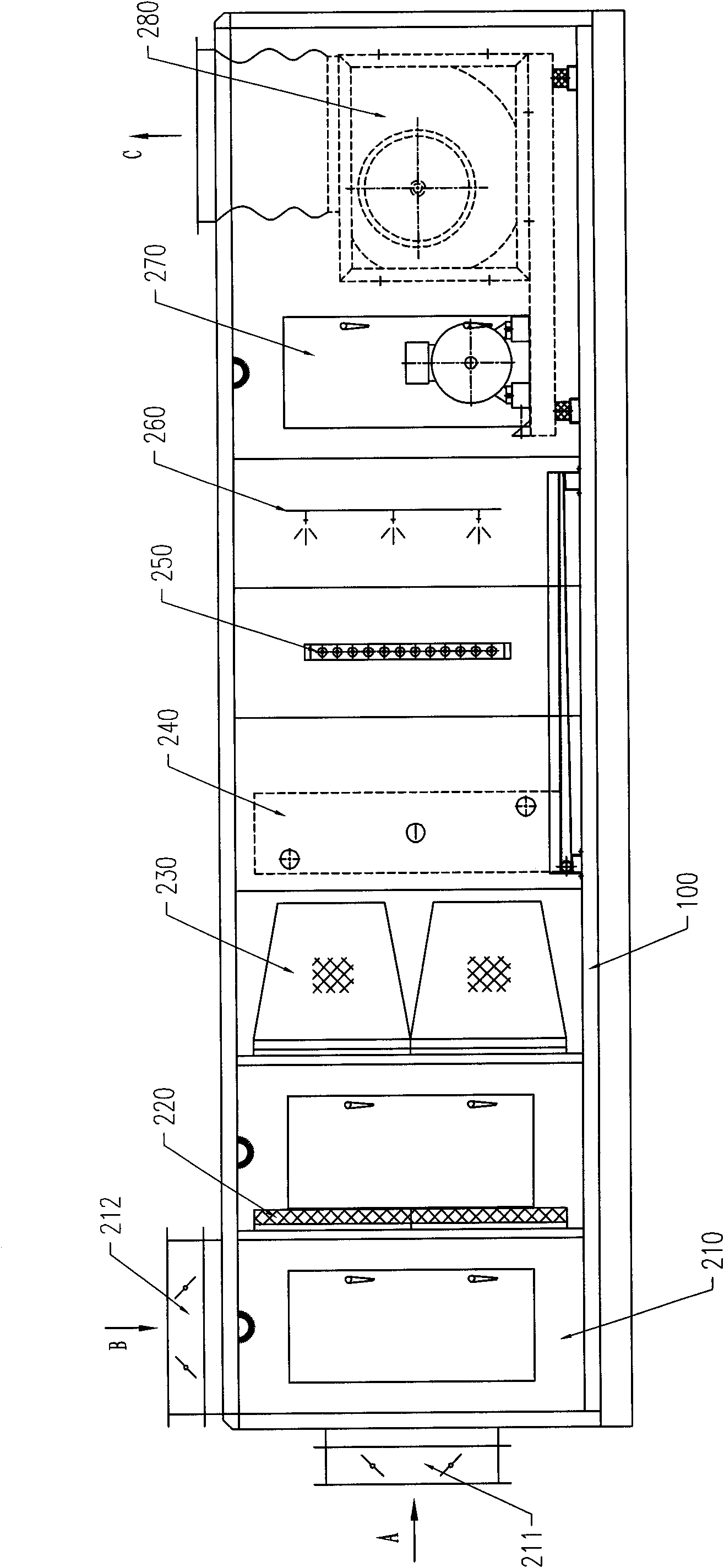

Multi-mode working UPS

InactiveCN101699702AStrong load adaptabilityWide range of usesBatteries circuit arrangementsAc-dc conversionWork statusData signal

The invention discloses a multi-mode working UPS, which comprises commercial power input, a storage battery, a rectifier, an inverter, a bypass static switch, an inverted static switch, an MCU singlechip control circuit, an external input circuit and an external output circuit. One path of the commercial power input is transmitted to alternating current output orderly through the rectifier, the inverter and the inverted static switch, while the other path is transmitted to the alternating current output through the bypass static switch; the storage battery is connected to a connection point of the output end of the rectifier and the input end of the inverter; and the MCU singlechip control circuit outputs a bypass static switch control signal to the bypass static switch, outputs an inverted static switch control signal to the inverted static switch, outputs an inverter control signal to the inverter, outputs a working condition data signal to the external output circuit, inputs a commercial power input sampling signal and inputs a signal input by the external input circuit. The multi-mode working UPS overcomes the defect that the conventional UPS only has a single double conversion online working mode and provides a power supply with a plurality of working modes.

Owner:佛山市柏克电力设备有限公司

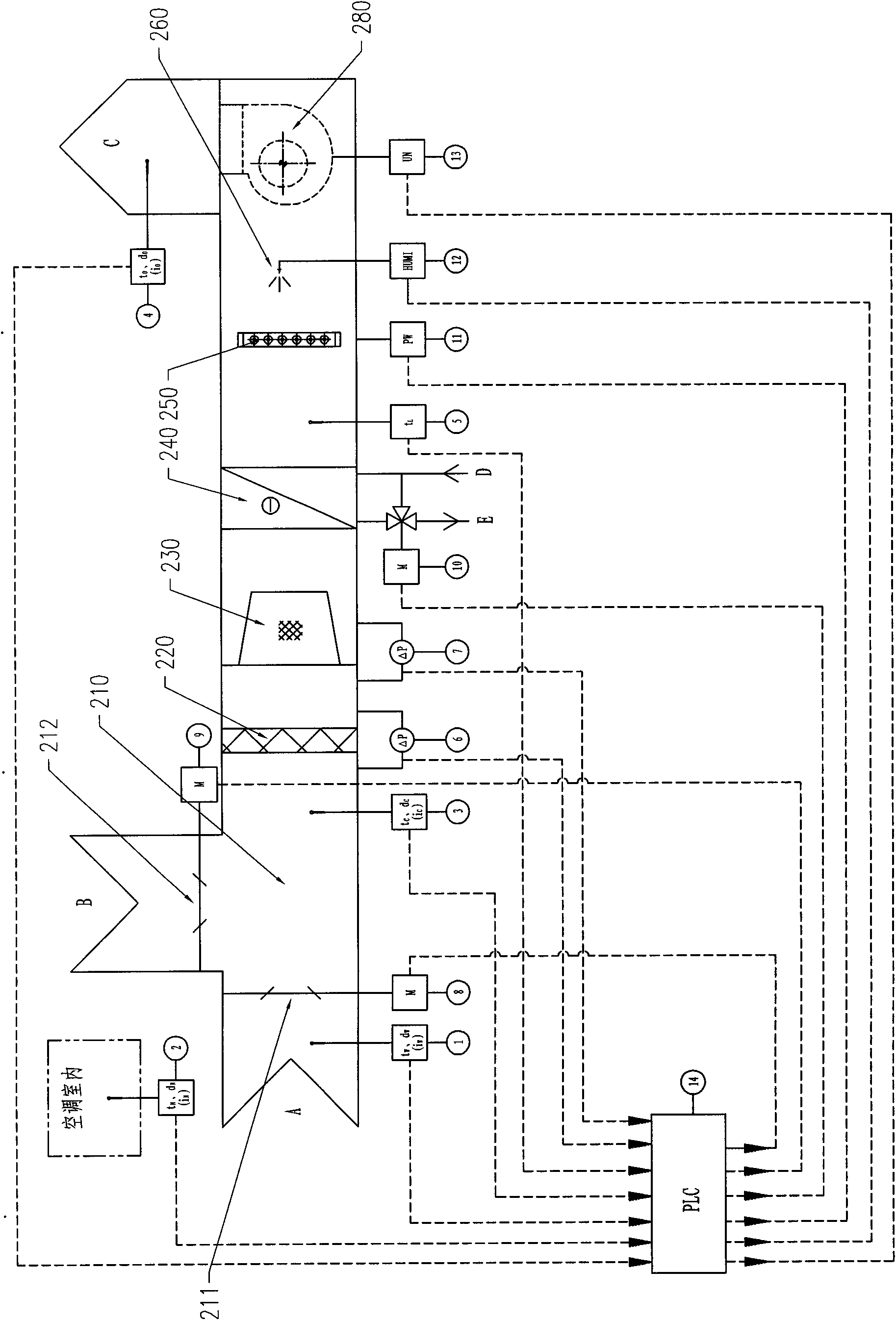

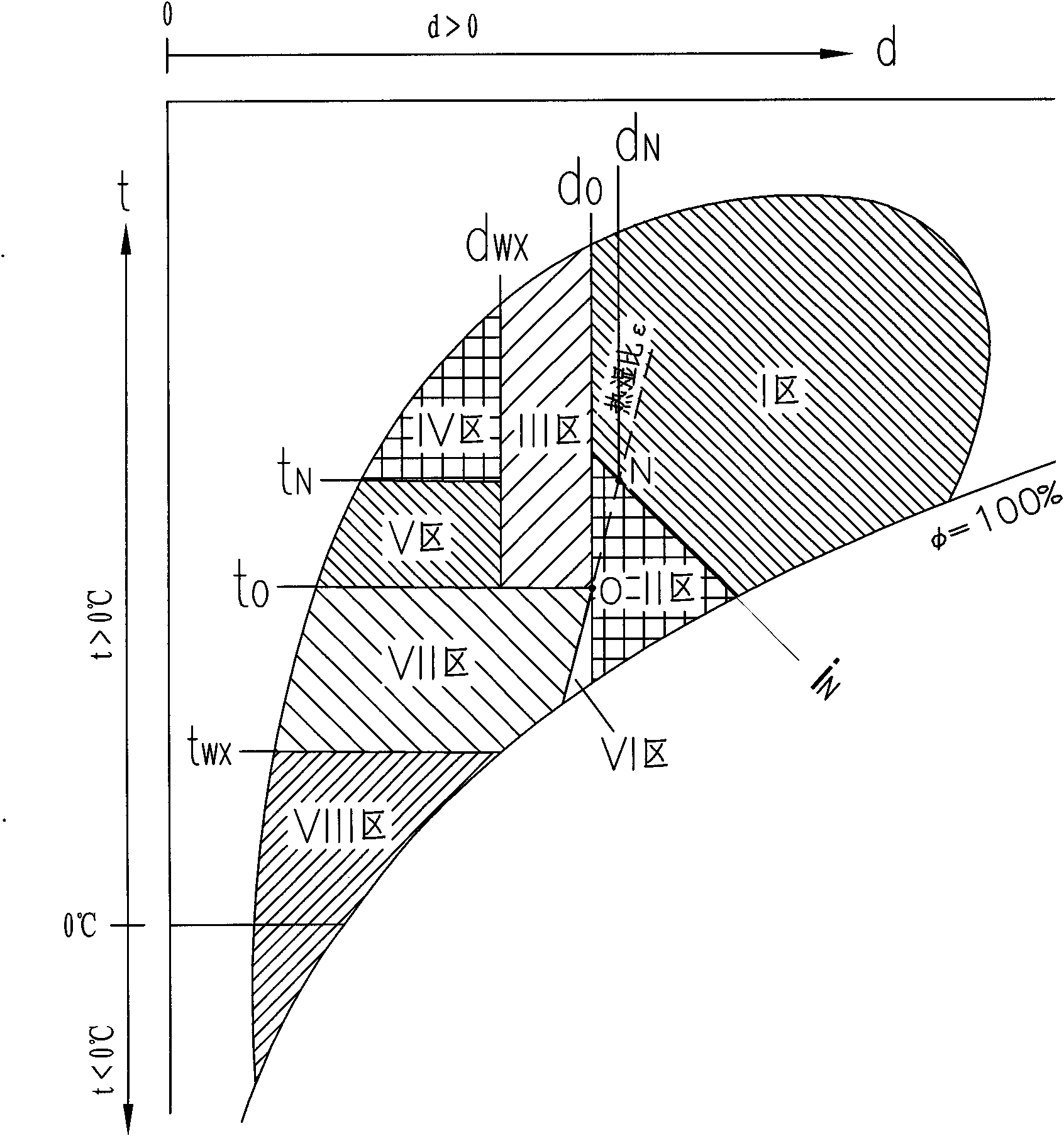

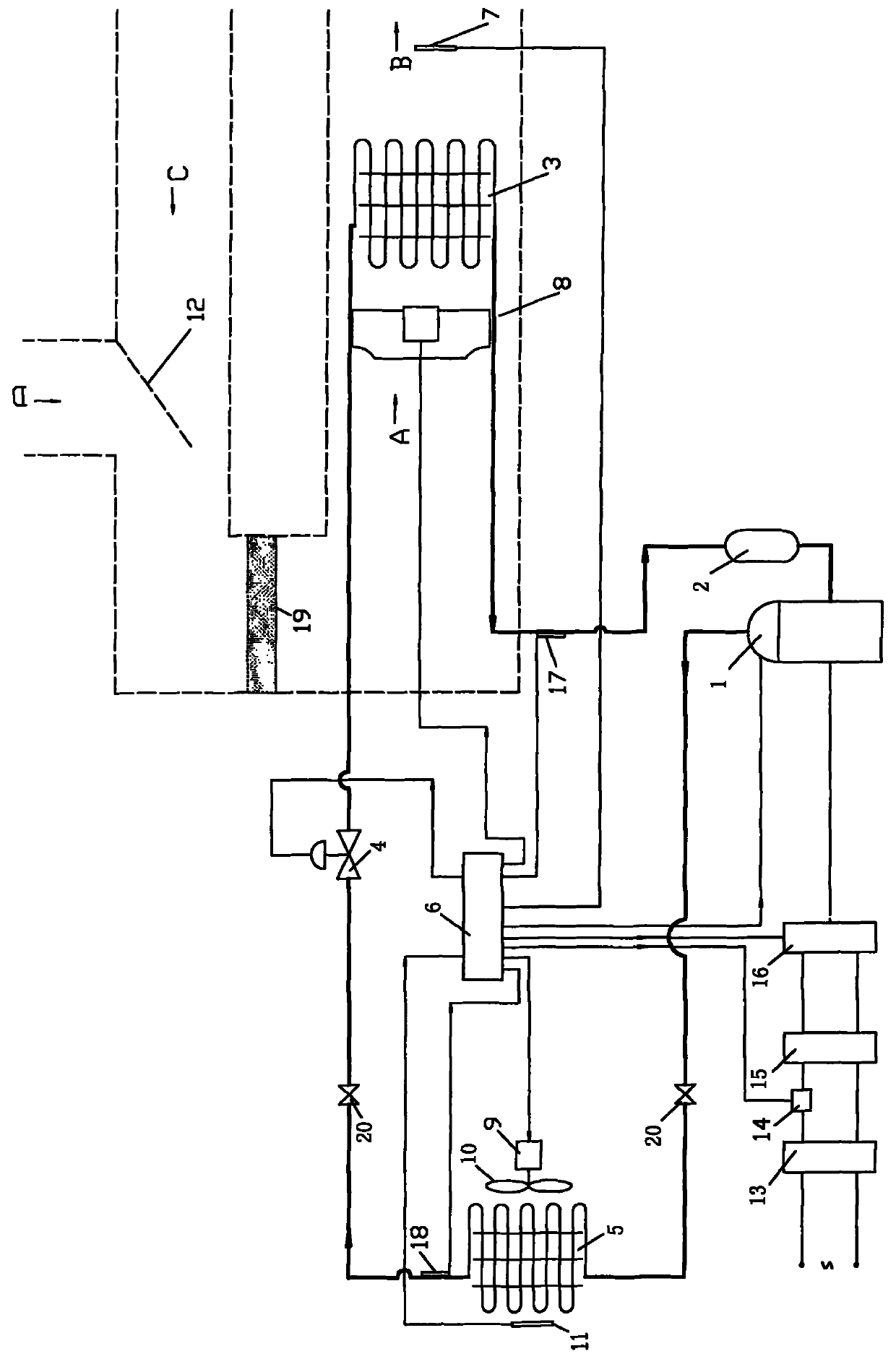

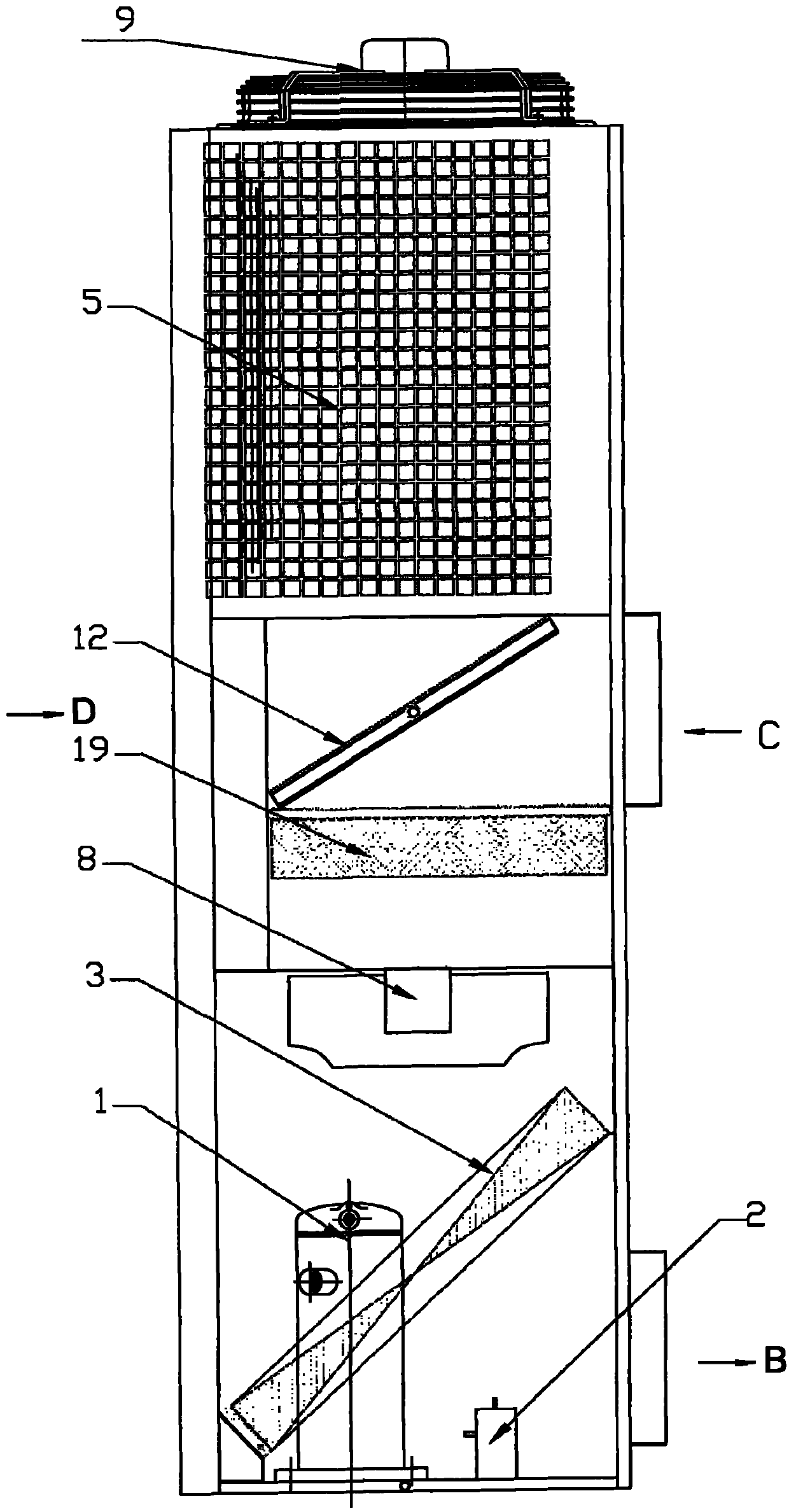

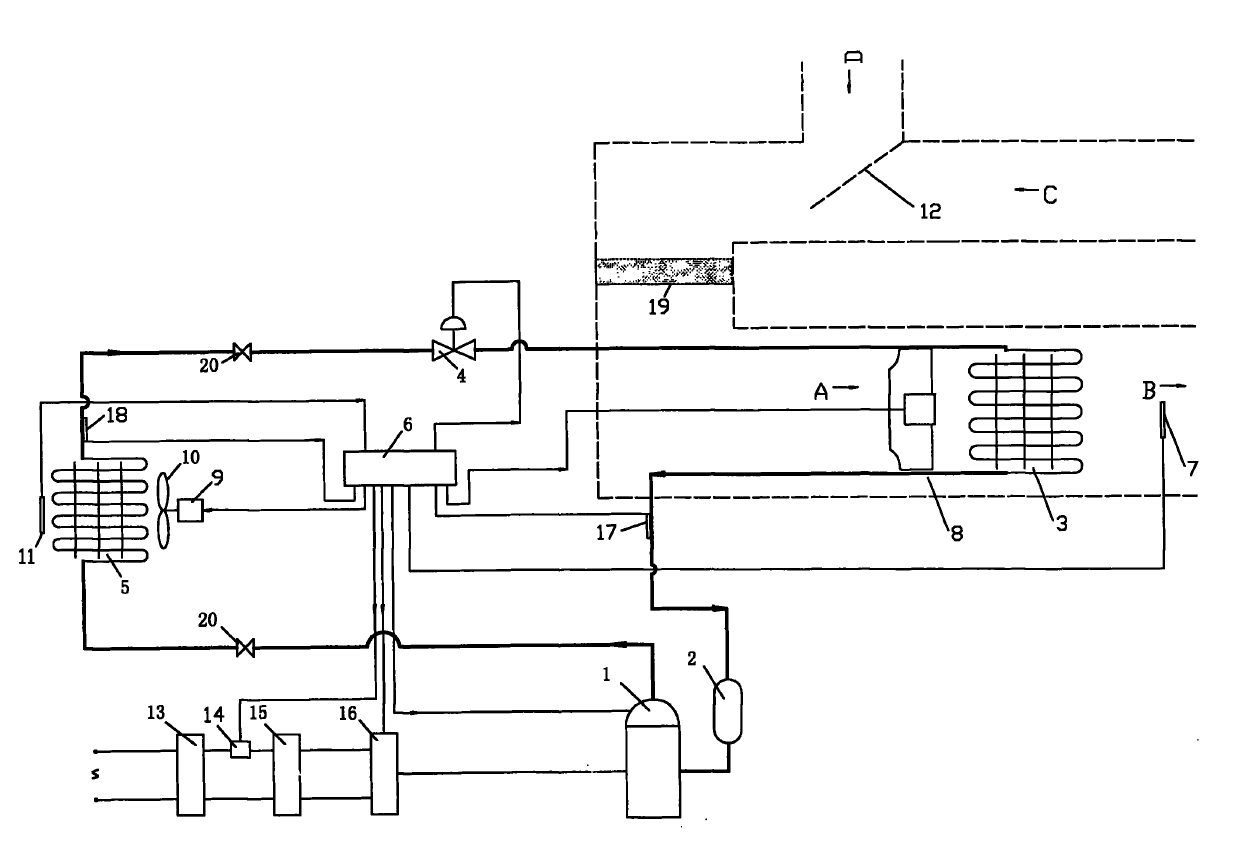

Multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with thermometal compound box body structure

ActiveCN101782263AReduce resistanceFully contactedSpace heating and ventilation safety systemsLighting and heating apparatusControl systemNuclear power

The invention relates to a multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with a thermometal compound box body structure special for nuclear power stations. The air conditioning unit comprises a control system and a box body structure, wherein a primary-efficiency filter, a medium-efficiency filter, a surface cooler, a heater, a humidifier and a blow-off device are sequentially arranged in the box body; the front side of the primary-efficiency filter is provided with a fresh air and return air mixing section, and inlets of fresh air and return air are respectively provided with a fresh air proportioning valve and a return air proportioning valve; the control system adopts a programmable logic controller (PLC) and adopts air conditioning multi-operating mode zone control to realize the energy-saving operation of the unit; the surface cooler adopts a large temperature difference cold water heat exchanging technology and can save the investment and operation expenses of a water system; and the box body adopts a double-layer compound structure and an anti-shock device to meet the special requirements on the nuclear power stations. The invention has the characteristics of high efficiency, energy saving, good tightness, strong anti-shock capacity, safety, reliability, long service life, and the like.

Owner:广东吉荣核电设备暖通技术有限公司

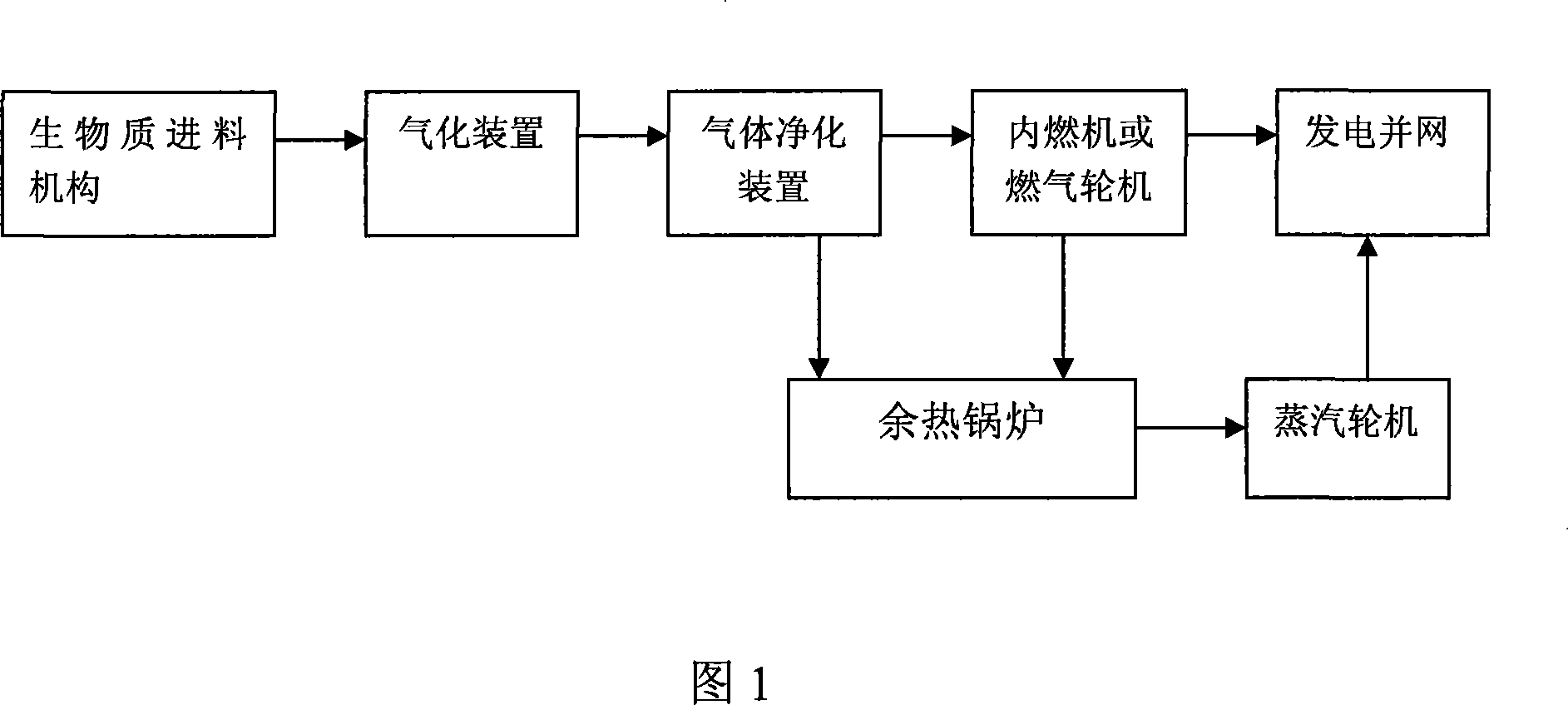

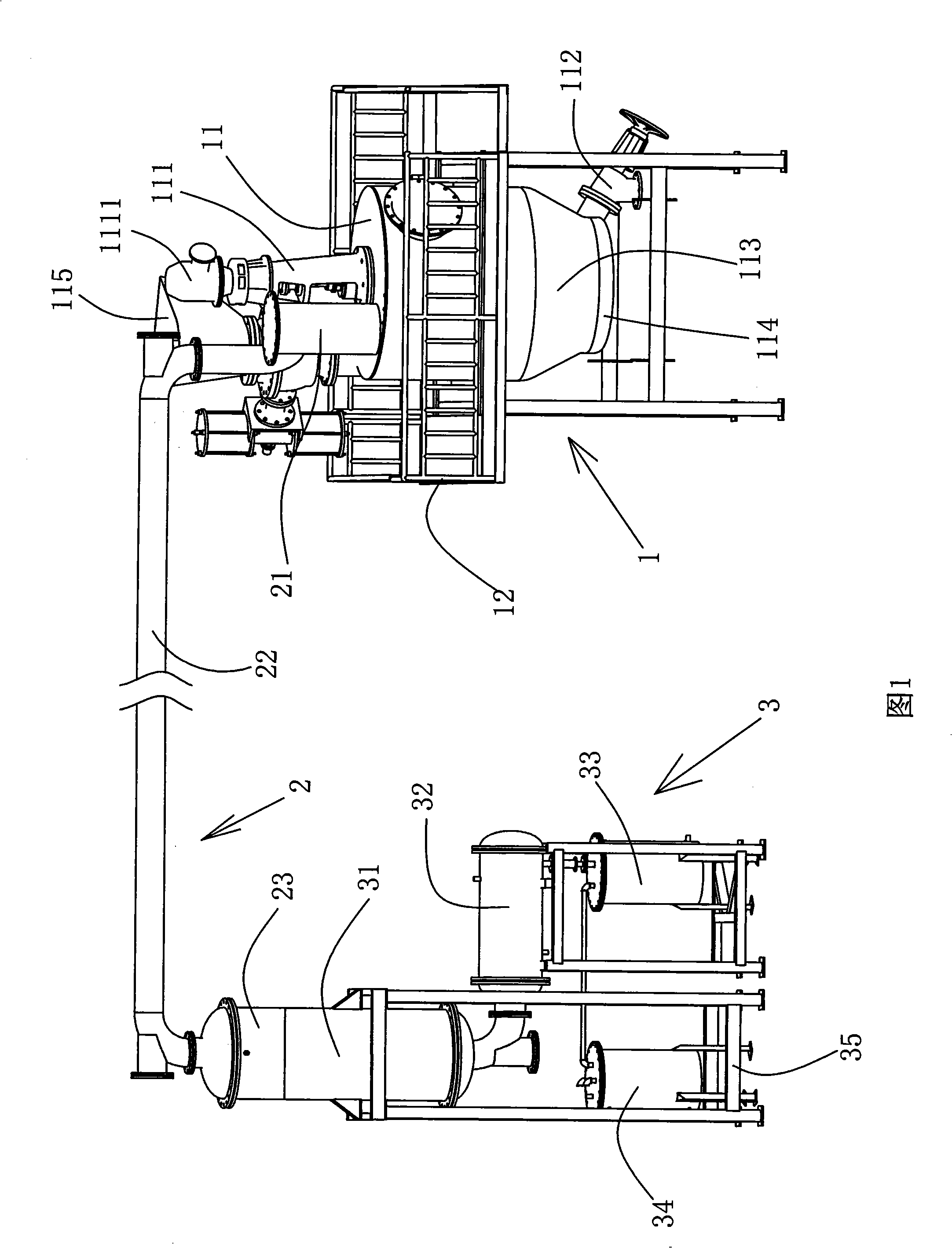

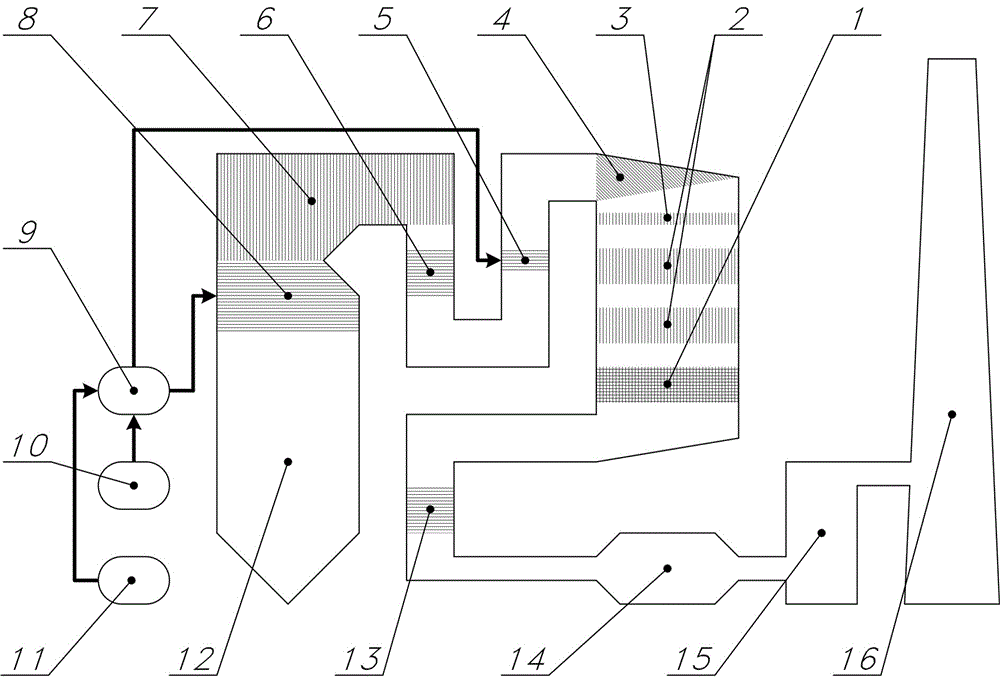

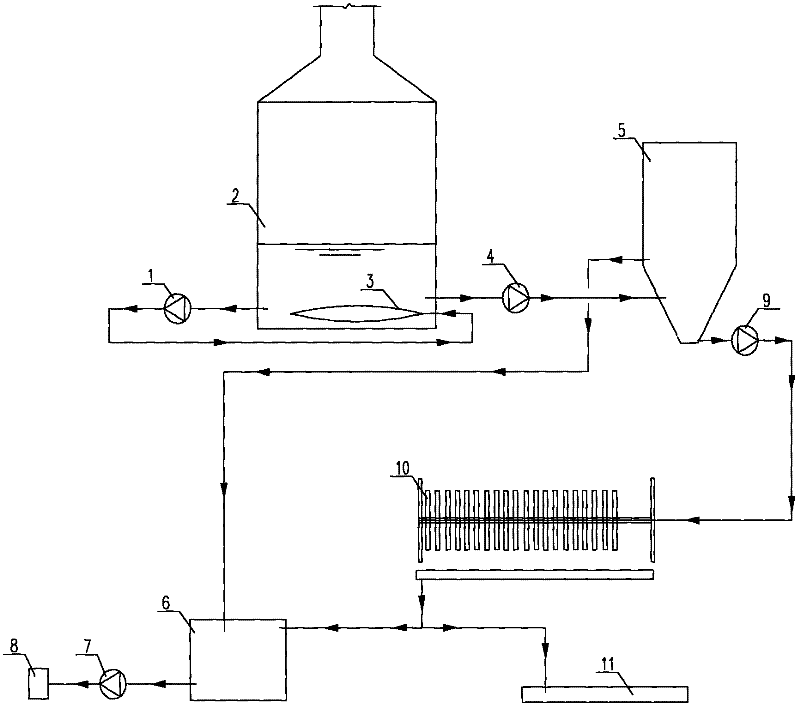

Power generation method using biomass

InactiveCN101158312AAdaptableStrong production intensityProductsInternal combustion piston enginesAgricultural residueInternal combustion engine

The invention relates to a method for generation by a biomass. The method utilizes the gasification technology, which converts the forestry and agricultural residues comprising wasted straws, sawdust, haulms, rice husks, bagasse, etc. into the flammable gas approaching the coal gas; after the dust and the tar of the flammable gas is removed by a purifier, the flammable gas is conveyed in a gas internal combustion engine or a gas turbine for generation. The invention has strong raw material adaptability, can dispose the biomass raw material of different types, and has the advantages of large production intensity, high gas heat value, little tar content, high gasification efficiency, strong load adaptability, easy start and stop, large adjustable range, stable operation, extremely high flexibility in scale. Furthermore, the generation scale depends on the quantity of the raw material and the requirement of the power, and can be designed and matched according to the requirement of the user.

Owner:WUHAN LIREN INVESTMENT

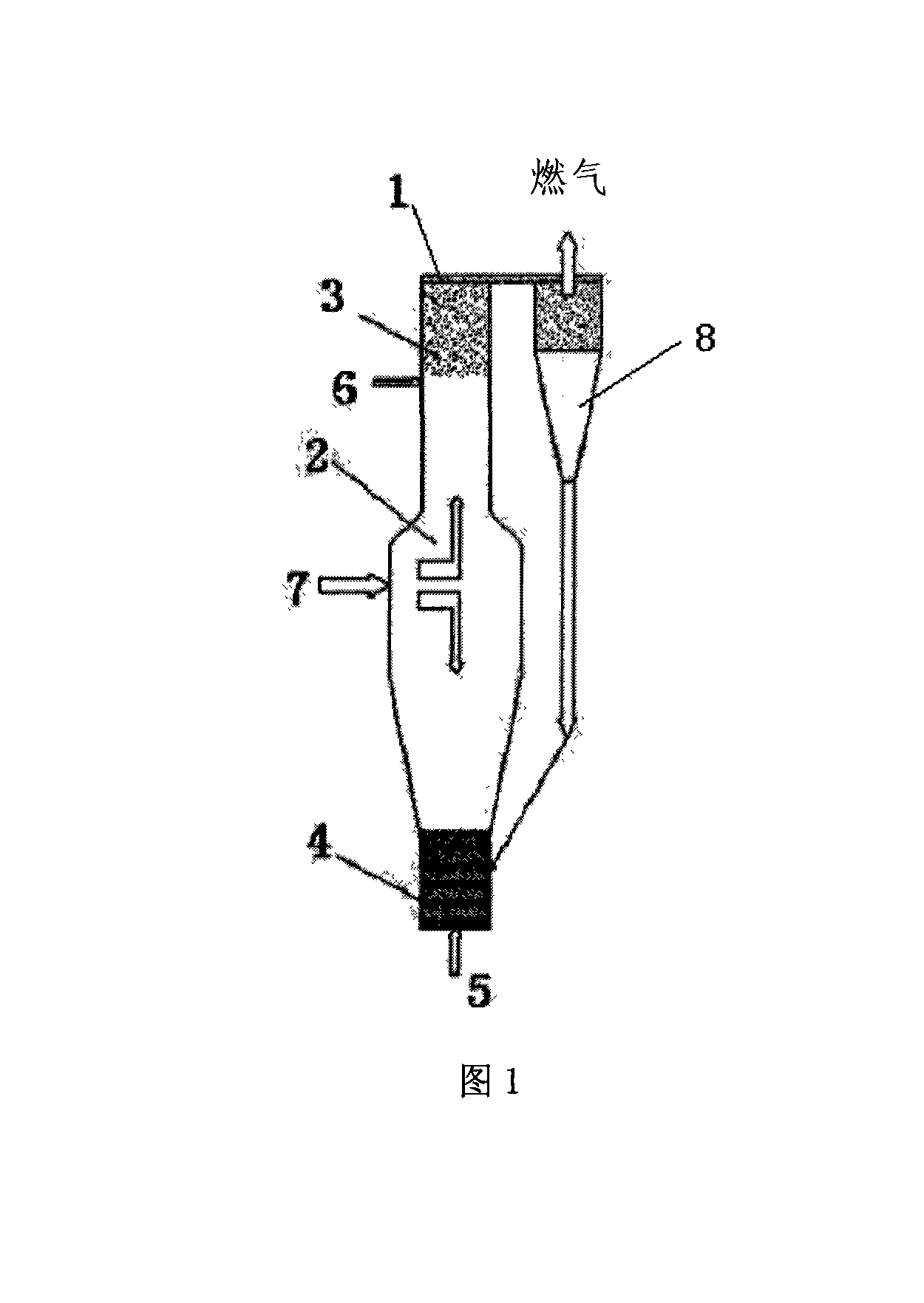

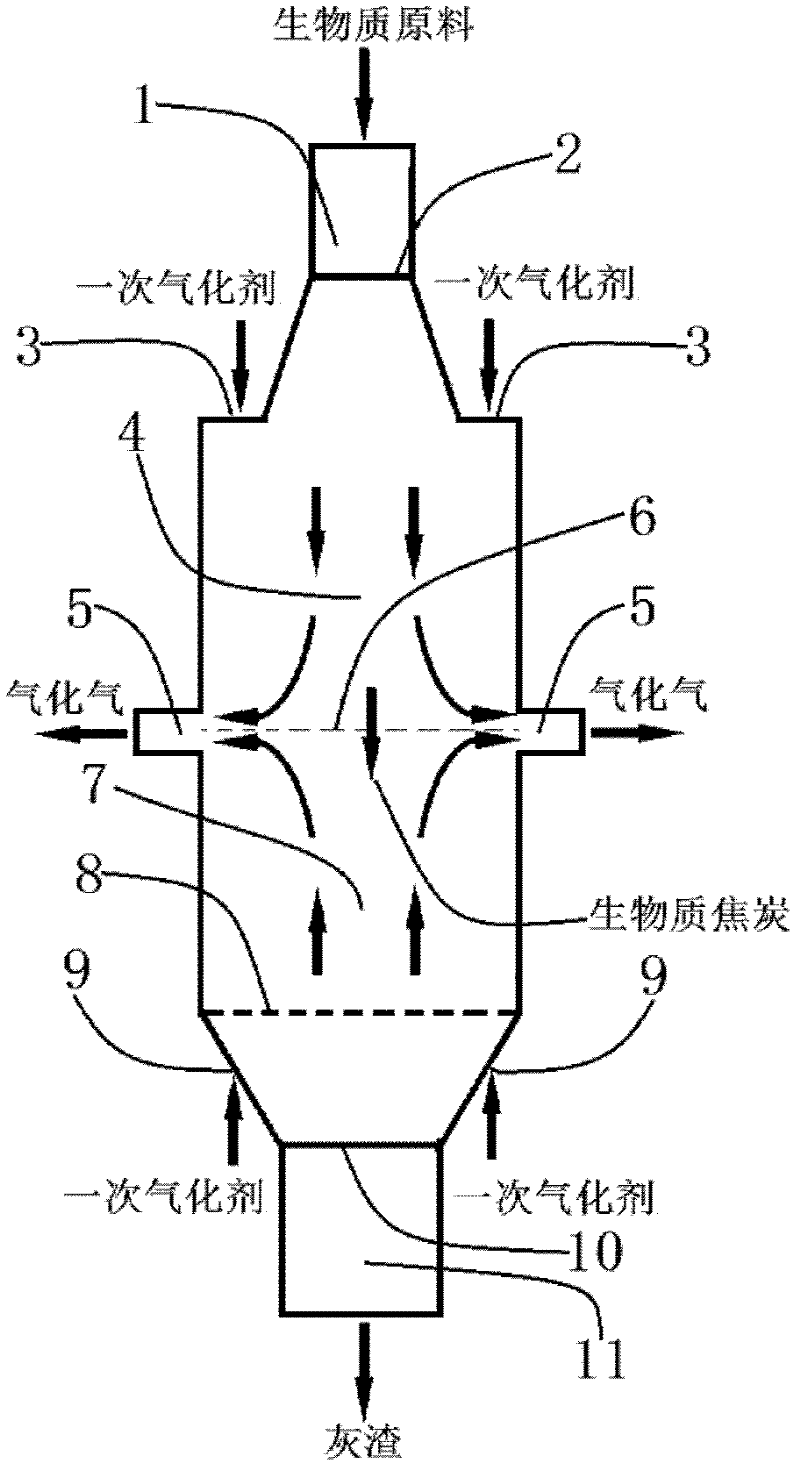

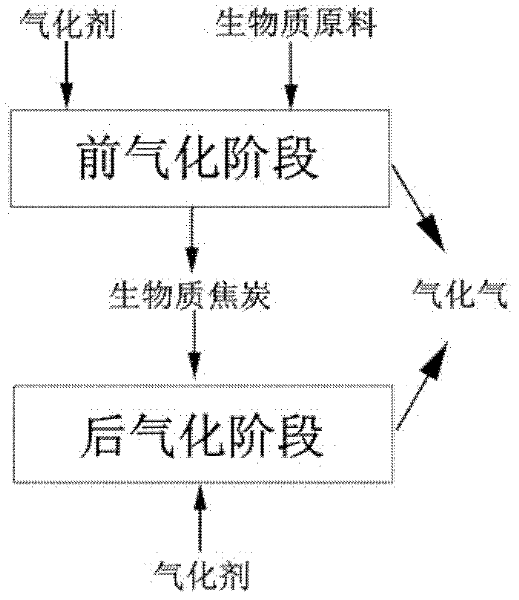

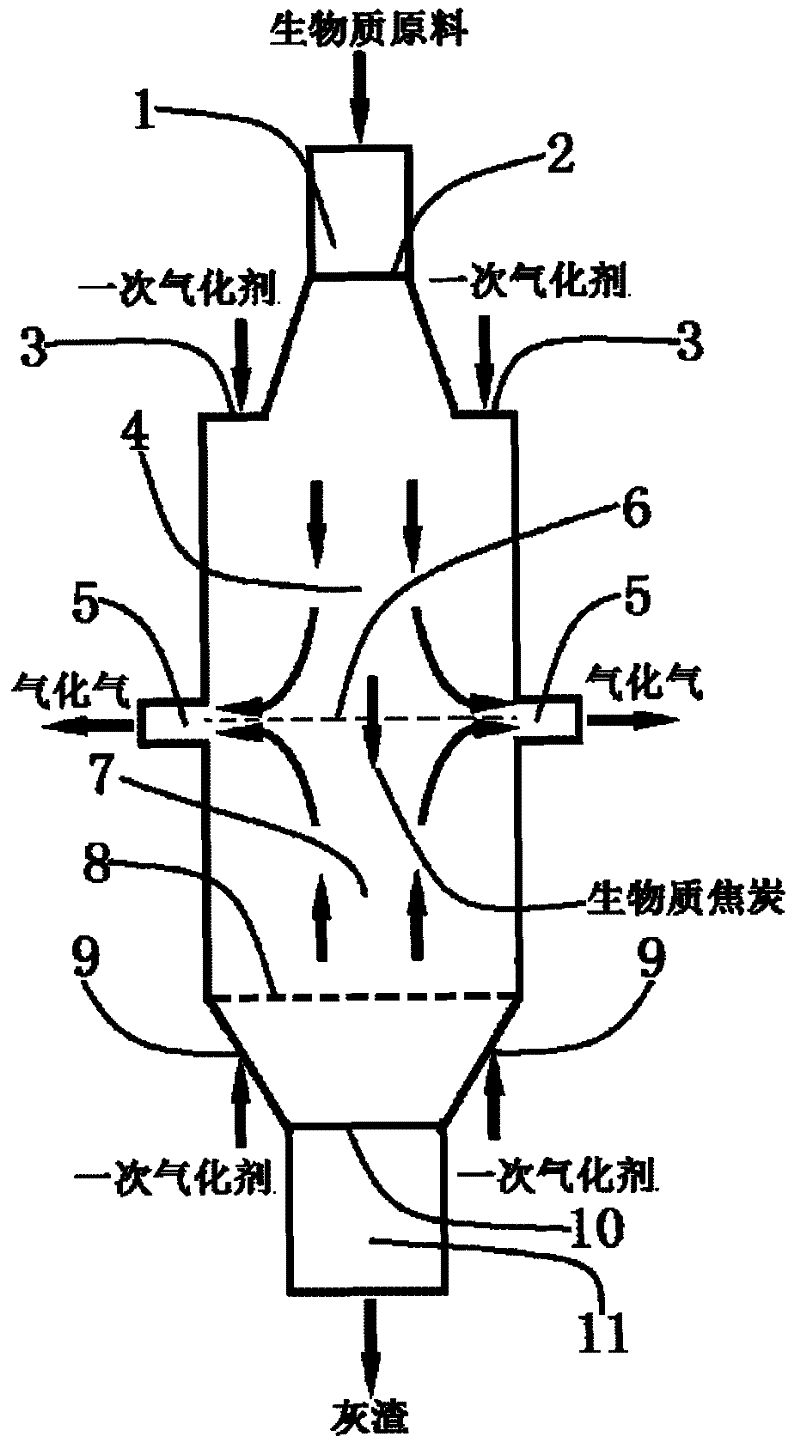

Method and device for biomass compound gasification

InactiveCN101225315AImprove gasification efficiencyReduce tar contentBiofuelsSpecial form destructive distillationTarBiomass

The invention discloses a biomass complex gasification method and a device of the gasification. The thermal decomposition, the gasification, part of the oxidation process are combined in one reactor by the integrating the fluidized bed and the airflow bed. Firstly, the biomass is decomposed at 500 to 600 degrees C and generates hard coke; secondly, the hard coke with large grain sizes are partly oxidized and gasified in the hard coke gasifying section, which provides heat and generates combustible gas for the thermal decomposition section; thirdly, the reaction gases with small hard coke grains discharged from the thermal decomposition section and the catalyst fast flows upwards through the macromolecular gasifying section, and the reaction gas are partly oxidized because of the function of the secondary gasifying agent, the heavy tar component is forced simultaneously through thermal cracking reaction and catalytic cracking reaction with the catalyst at the temperature over 1000 degrees C and transformed to lightweight combustible gas; at last, the unreacted hard coke is sent back to the furnace through the gas-solid separation device and the solid recycling device. The biomass complex gasification method has the advantages of high gasification efficiency, low tar content, high control ability of the gas component, stable operation and easy enlargement.

Owner:江苏中科龙城能源系统有限公司

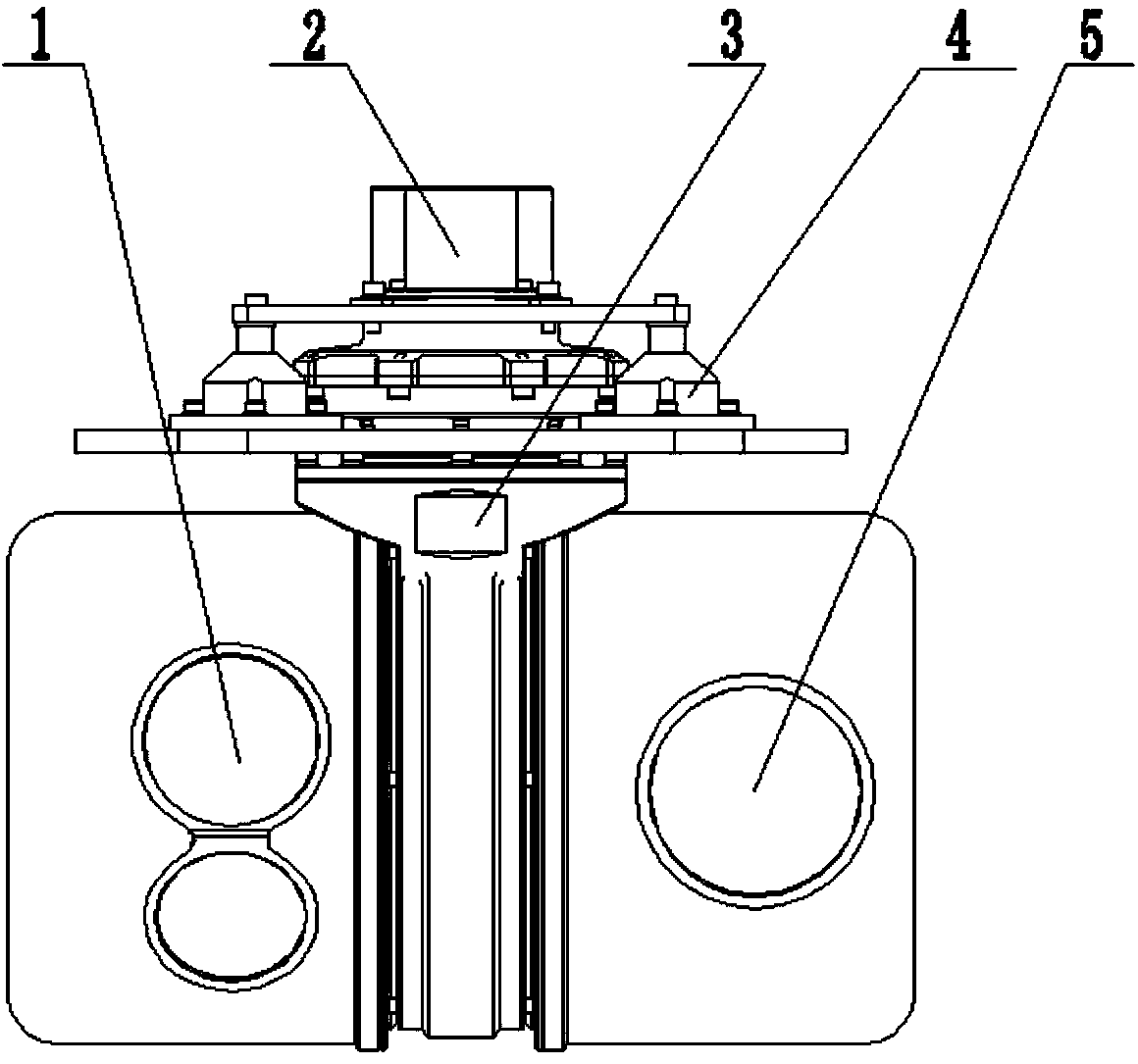

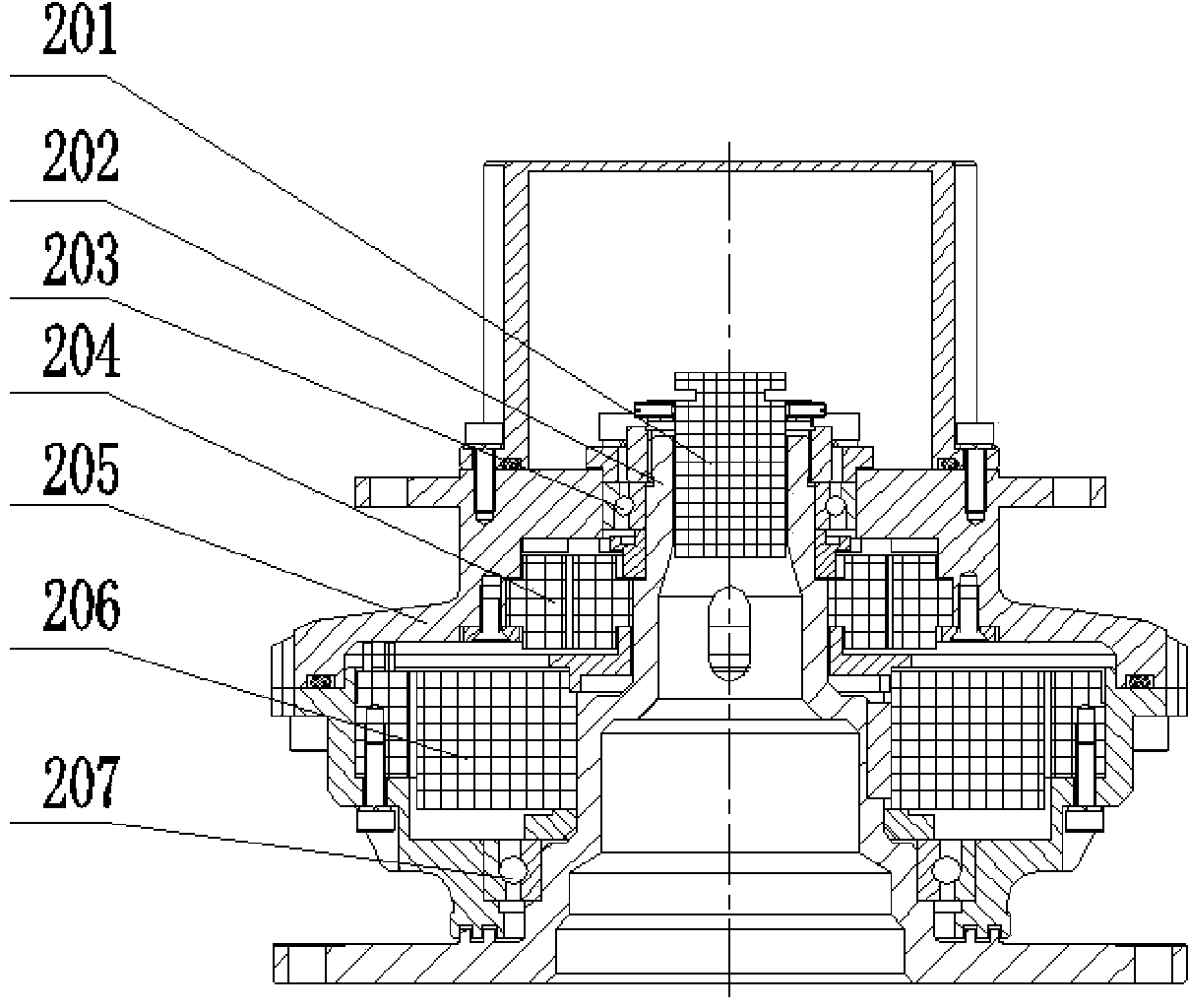

Unmanned plane electro-optical pod

The invention relates to an electro-optical pod mainly used in the field of electric power line routing inspection, in particular to an unmanned plane electro-optical pod. The unmanned plane electro-optical pod comprises a pod stabilizing platform, sensor assemblies, an azimuth assembly, a pitching assembly and a camera assembly, wherein the pod stabilizing platform is fixedly arranged on an unmanned plane through a shock absorption frame assembly, the sensor assemblies are fixedly arranged on the pod stabilizing platform, are mutually connected and are used for monitoring in-site environment, the azimuth assembly is used for realizing azimuth driving and azimuth measurement, the pitching assembly is used for realizing pitching driving and angle measurement, and the camera assembly is fixedly arranged on the pitching assembly. Therefore the unmanned plane electro-optical pod has the following advantages that 1, various detection measures are combined, and the searching, monitoring and detail identification capability of an unmanned plane line inspection system is improved; 2, the integration degree is high, the structure is compact, the environment adaptability and the load loading adaptability are high, and the upgrading regeneration and the function expansion can be convenient; 3, an external electric interface is simple, the inside of the pod can be opened, and inner sensors can be conveniently maintained or replaced; 4, the stepping photo taking functions are realized, and the fully covering automatic photo shooting on specific regions can be completed.

Owner:武汉华中天经通视科技有限公司

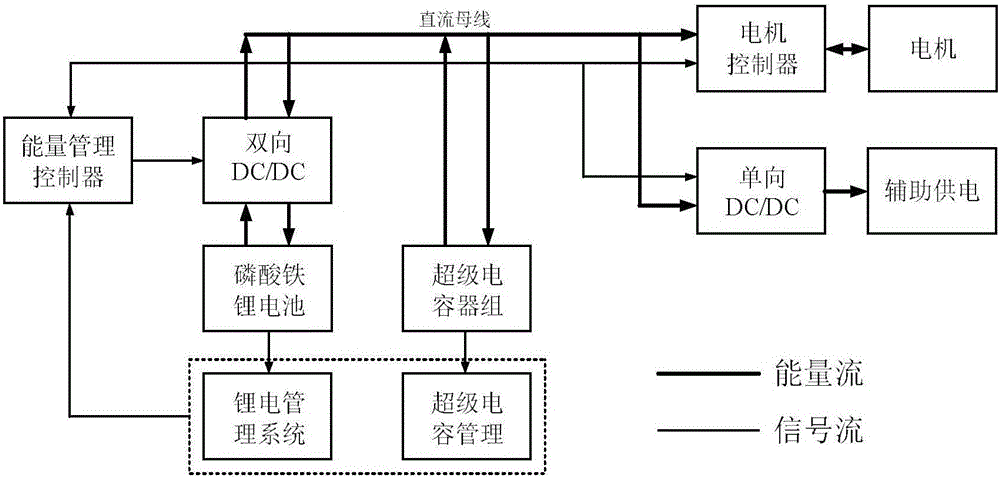

Double-source energy system of battery electric vehicle, power supply control method, fast charging method and slow charging method

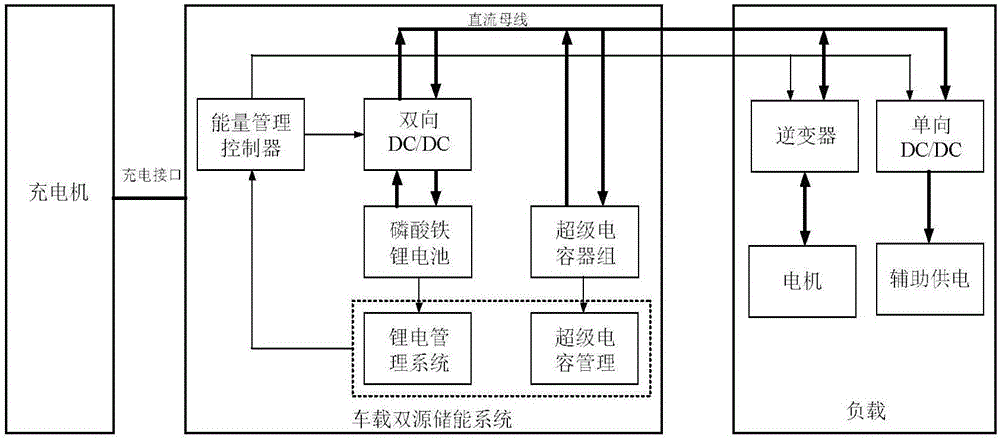

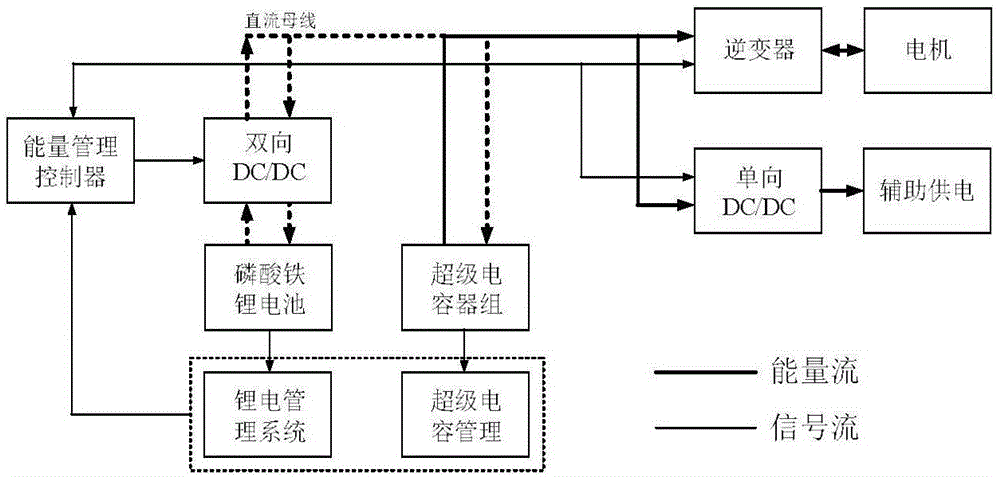

PendingCN106696721AEnhance load adaptabilityIncrease energy densityCharging stationsConverter typesCapacitanceEnergy management controller

The invention discloses a double-source energy system of a battery electric vehicle. The double-source energy system comprises an energy management controller, a lithium battery management system, a super-capacitor management system, a lithium battery, a super-capacitor bank, a bidirectional DC / DC module, a unidirectional DC / DC module, a motor controller, a motor and the like, wherein the energy management controller is connected with the lithium battery management system, the super-capacitor management system, the bidirectional DC / DC module, the unidirectional DC / DC module and the motor controller, the lithium battery is connected with the lithium battery management system and the bidirectional DC / DC module, the bidirectional DC / DC module is connected with the motor controller and the unidirectional DC / DC module through a direct-current bus, the super-capacitor bank is connected with the super-capacitor management system, the super-capacitor bank is connected with the motor controller and the unidirectional DC / DC module, and the unidirectional DC / DC module is connected with an auxiliary power supply device. The double-source energy system of the battery electric vehicle is enhanced in load adaptability by combining high energy density of the lithium battery with high power density of super-capacitors.

Owner:四川新筑通工汽车有限公司

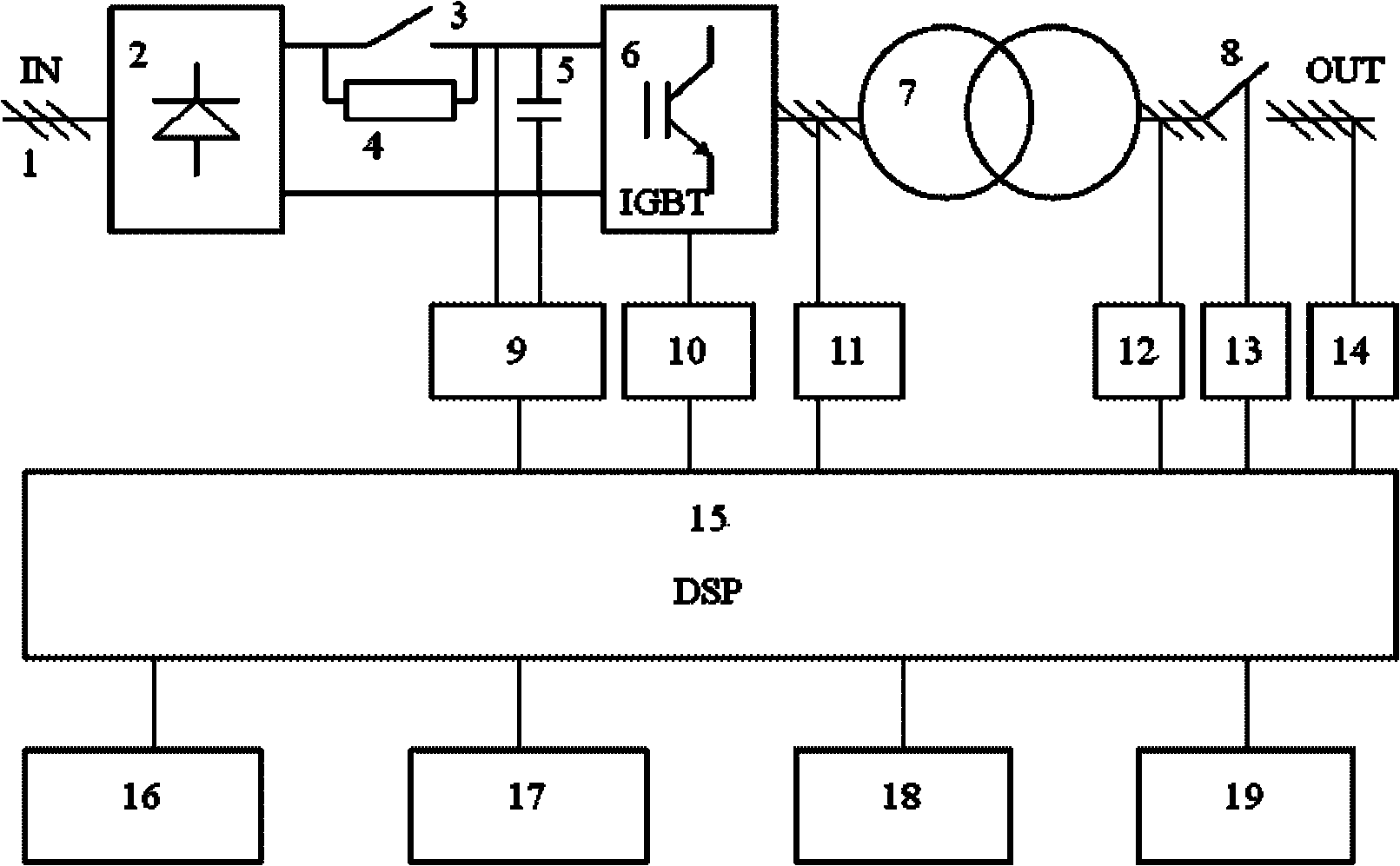

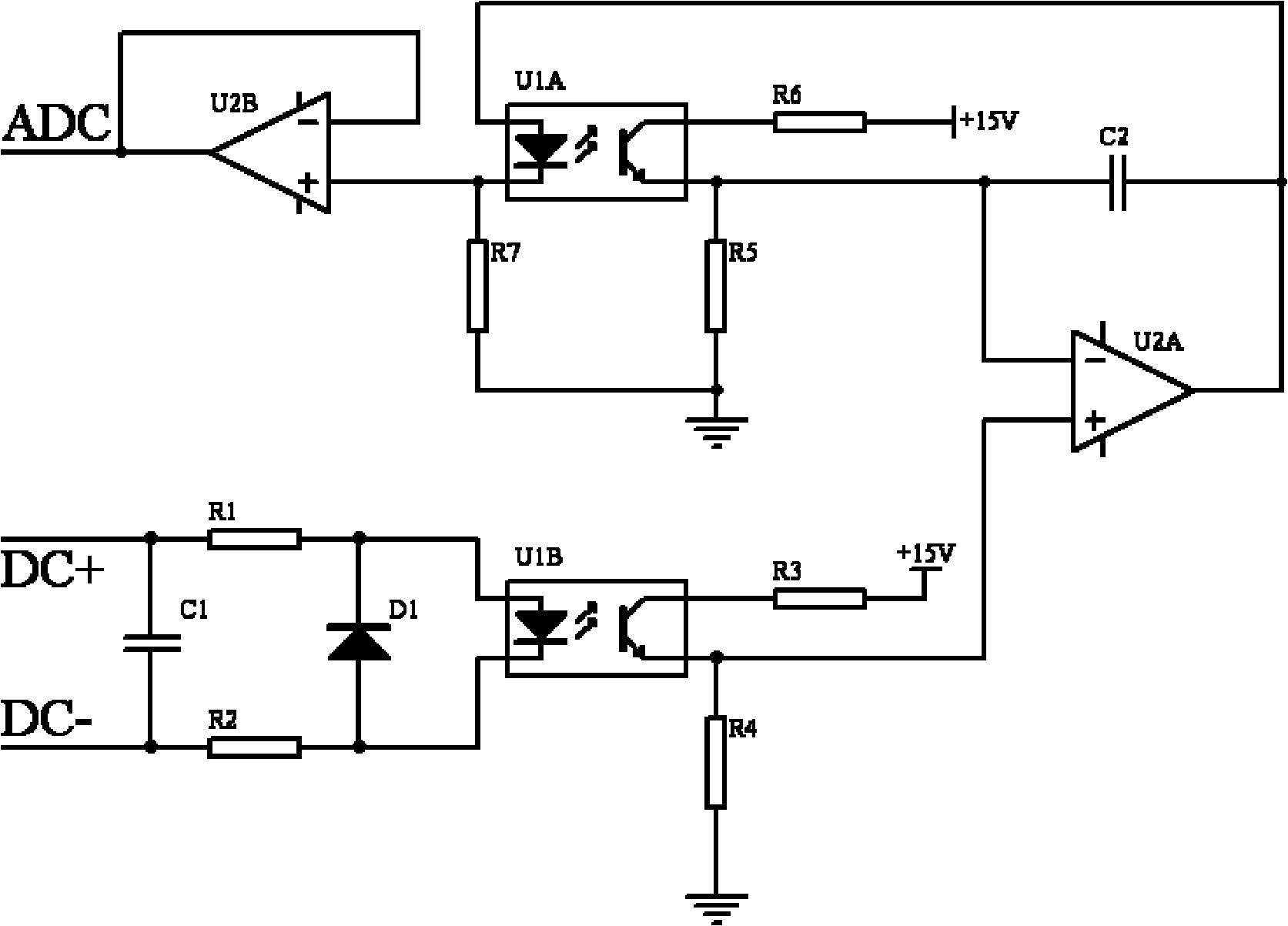

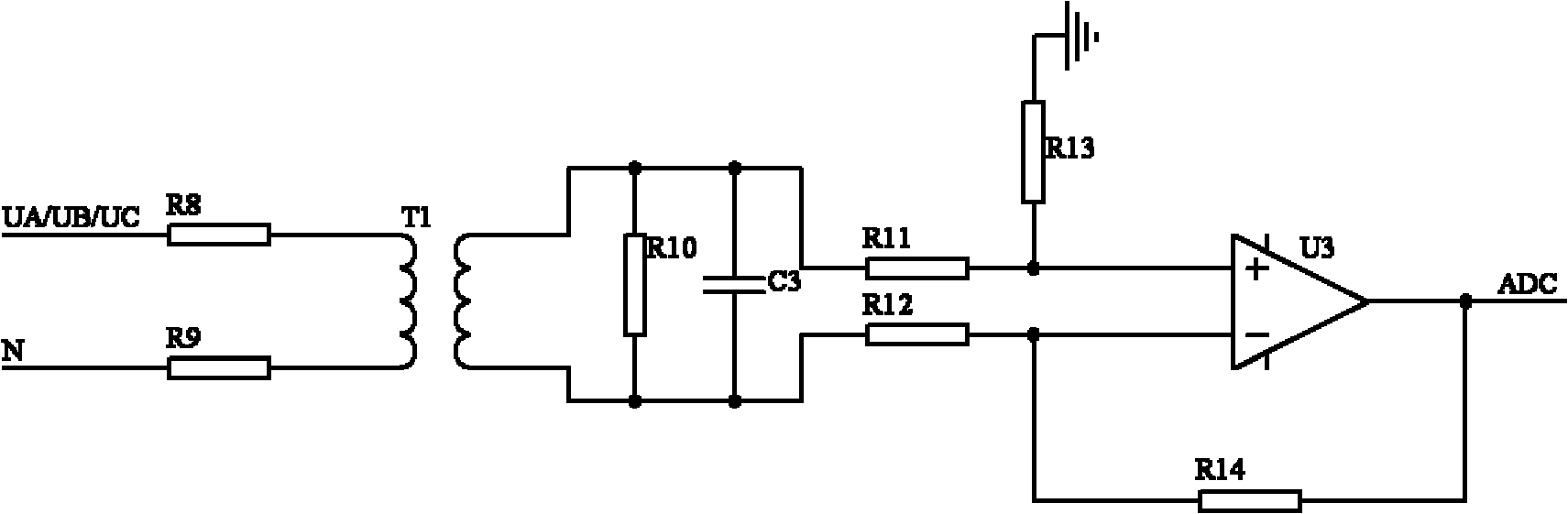

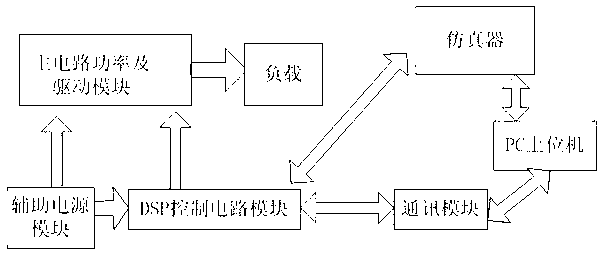

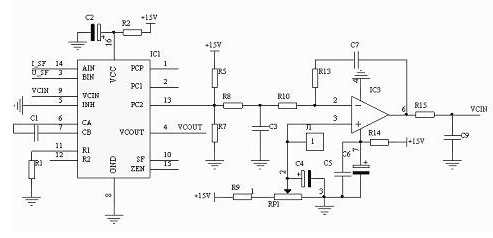

Triphase variable-frequency power supply with high power and operating method thereof

ActiveCN102158100AImprove load adaptabilityImprove adaptabilityEmergency protective circuit arrangementsAc-ac conversionOutput transformerDigital signal processing

The invention provides a triphase variable-frequency power supply with high power and an operating method thereof, belonging to the technical field of variable-frequency power supplies. The variable-frequency power supply comprises a triphase grid input circuit, a rectifying circuit, an inverter unit, an output transformer, a direct-current (DC) bus monitoring circuit, an inverter driving circuit, an inverter output monitoring circuit, a transformer output monitoring circuit, an output switch driving circuit, a variable-frequency power supply output monitoring circuit, a digital signal processor (DSP), a keyboard and display circuit, a communication circuit, a vibration detection circuit and a protection circuit, wherein the triphase grid input circuit is connected with the rectifying circuit; the rectifying circuit is connected with the inverter unit; the inverter unit is connected with the output transformer and the DSP by the inverter driving circuit; the output transformer is connected with an output end of the power supply; and an input end and an output end of the output transformer, the output end of the power supply and the output switch are connected with the DSP. The variable-frequency power supply operates under the control of software.

Owner:SHANDONG WOCEN POWER SUPPLY EQUIP

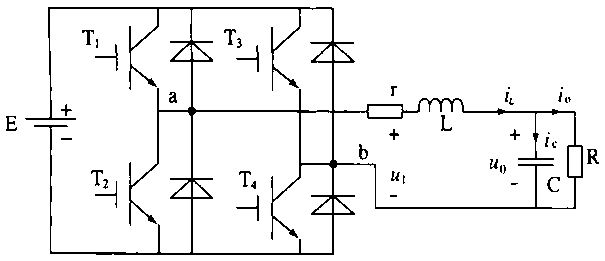

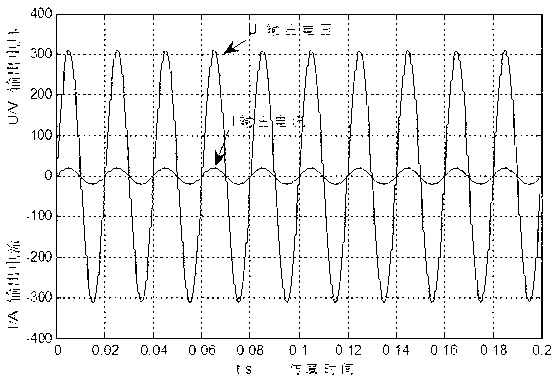

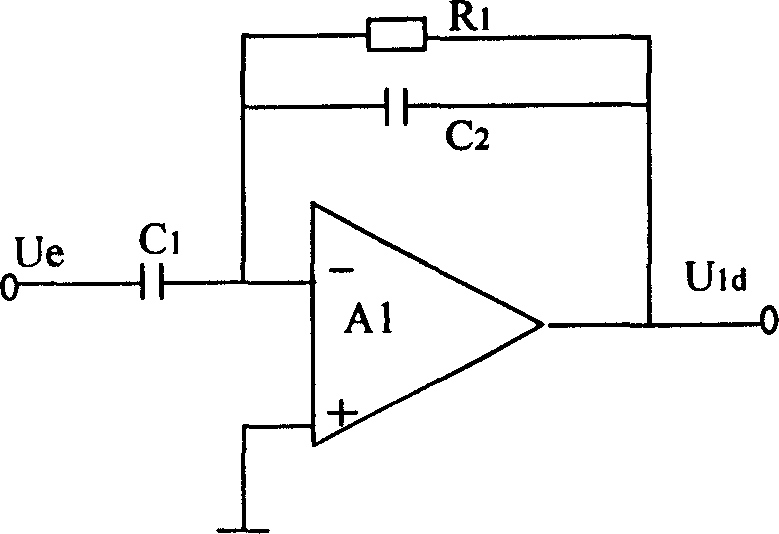

Inverter control method based on fractional order PI forecasting function

ActiveCN103269176AGood steady state characteristicsShort response timeWind energy generationDc-ac conversion without reversalPower inverterAnti jamming

The invention discloses an inverter control method based on a fractional order PI forecasting function and belongs to the technical field of inverter control. According to the control method, an optimized control value is obtained by optimization computing, the control value is used as an input signal of an inverting driving circuit, the purpose that inverter output currents are controlled so that output voltages of the inverter can be affected is achieved, steady-state characteristics are good, response time is short, loading adaptability is strong, anti-jamming capability is strong, and the inverter control method is suitable for a grid-connected inverter in a wind generating system.

Owner:南京市嘉隆电气科技股份有限公司

High pressure and low pressure bypass system

ActiveCN103925021AImprove load adaptabilityRapid lifting of loadsSteam engine plantsLoad SheddingEngineering

The invention discloses a high pressure and low pressure bypass system. The high pressure and low pressure bypass system comprises a high pressure bypass system connected with a high pressure cylinder, a low pressure bypass system connected with an intermediate pressure cylinder and a low pressure cylinder, a circulation pipeline and a condenser. The high pressure bypass system comprises an overheating pipeline, a backheating pipeline and a high pressure bypass pipeline. The low pressure bypass system comprises a reheating pipeline and a reheating condensation pipeline. The circulation pipeline comprises a circulating water pipeline and a high pressure temperature reducing pipeline. The high pressure and low pressure bypass system has the advantages that the structure is reasonable, the service life is long, unit load adaptability is improved, and a unit can be suitable for frequent start and stop and rapid load rise and fall; under the working condition that a turbine is started or load shedding is conducted, the temperature and the pressure of live steam are reduced through the bypass system, and then the live steam is fed into a reheater, dry burning of the reheater is avoided, and therefore the reheater is protected; in the sudden shedding of part of or all of loads of the unit, a bypass is quickly opened, a working medium is recycled to the condenser, running stability of a boiler is changed, and motion of a safety valve is reduced and even avoided.

Owner:SHANGHAI PINGAN HIGH PRESSURE REGULATING VALVE FACTORY

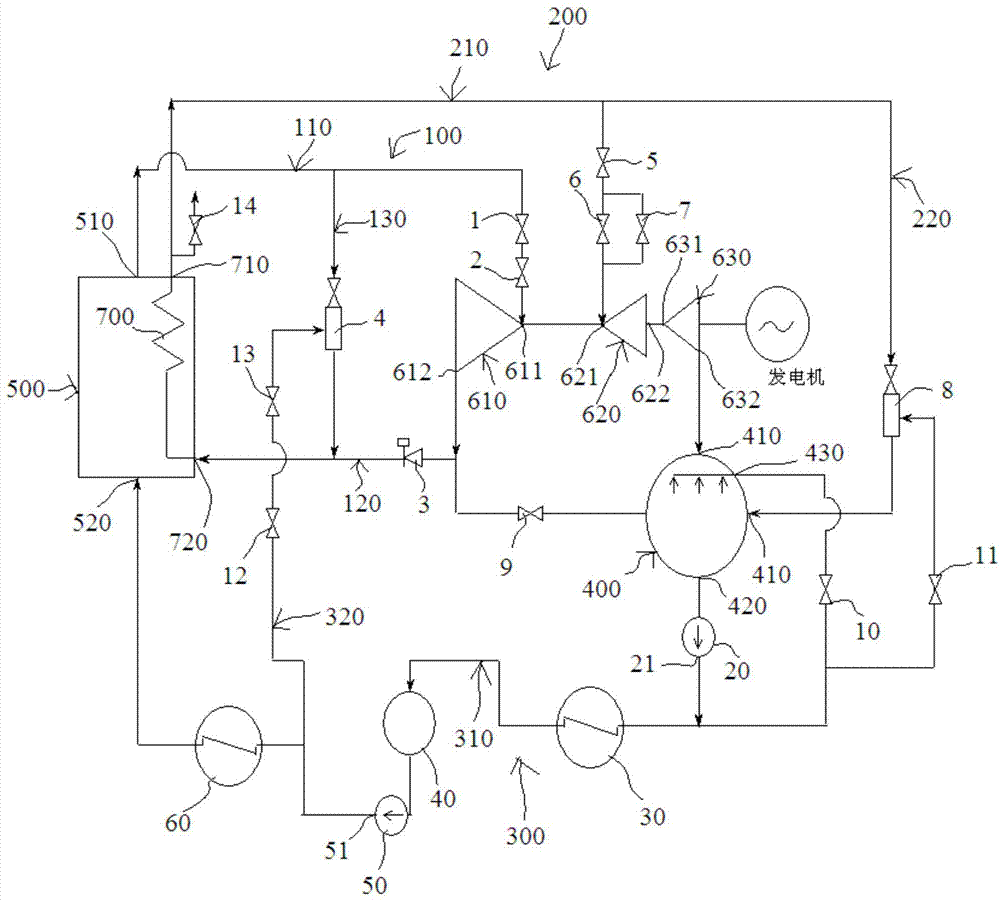

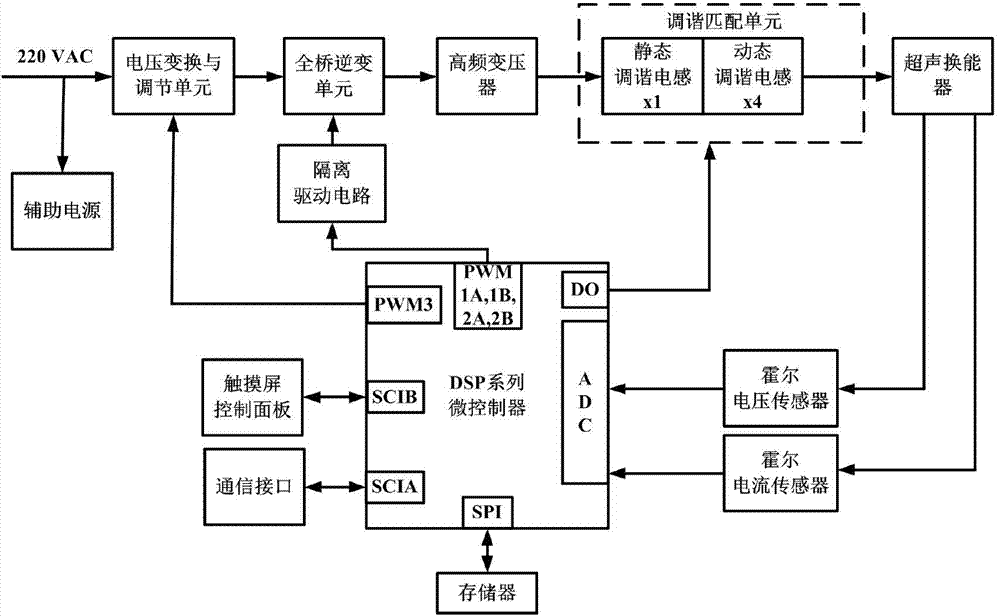

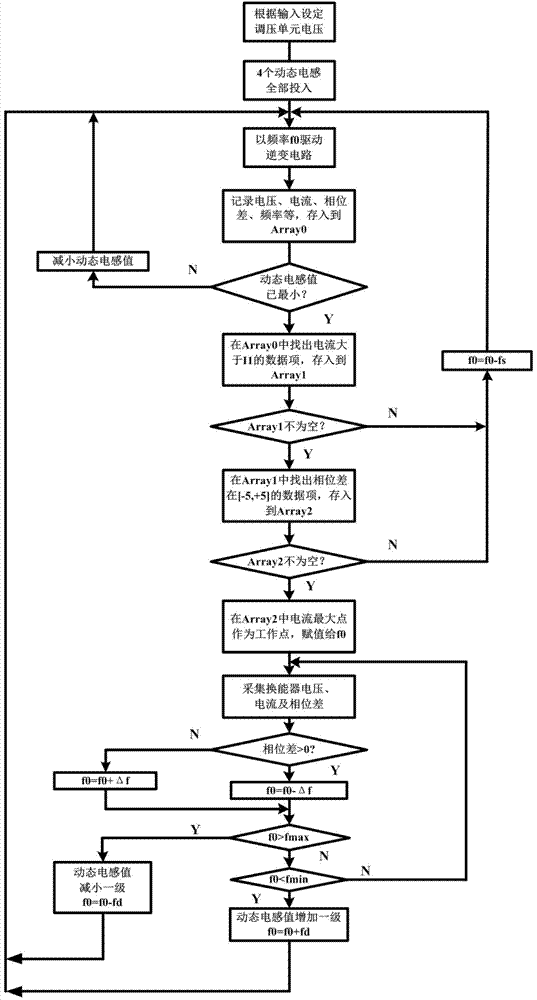

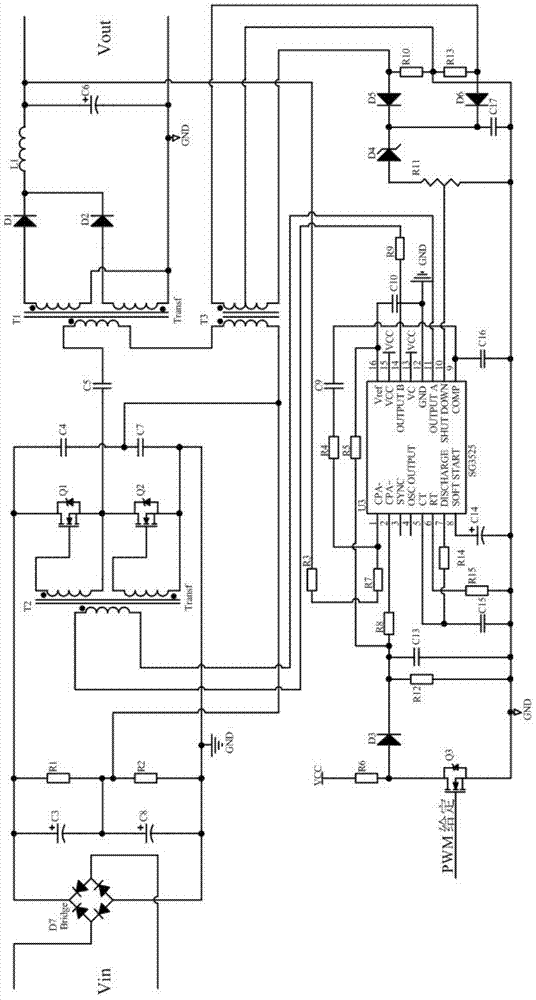

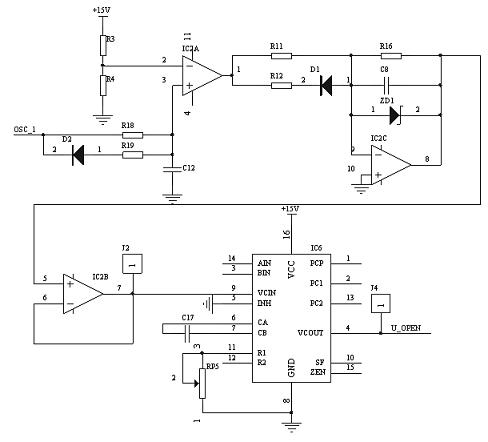

Ultrasonic power supply system for casting and automatic tracking method of resonance working points

ActiveCN104772450AWide frequency tracking rangeImprove load adaptabilityUltrasonic sensorTransformer

The invention discloses an ultrasonic power supply system used in an aluminum alloy casting process and an automatic tracking method of resonance working points. The ultrasonic power supply system comprises a voltage transformation and adjustment unit, a single-phase full-bridge inversion unit, a high-frequency transformer, a tuning matching unit, an ultrasonic transducer, a driving circuit, a voltage detecting unit, a current detecting unit, a touch screen control panel, a communication interface, a control unit and an auxiliary power supply. The voltage transformation and adjustment unit is used for adjusting an inverter voltage to realize the output power adjustment of the ultrasonic transducer; the tuning matching unit is used for tuning the ultrasonic transducer in real time; the control unit is used for receiving voltage and current signals, controlling the driving frequency of the voltage transformation and adjustment unit, the tuning matching unit and the inversion unit according to an automatic tracking algorithm of the resonance working points, and guaranteeing that the ultrasonic transducer always works on the resonance points. In the aluminum alloy casting process, the ultrasonic power supply system is fast in tracking speed of the resonant frequency, wide in tracking range and high in stability.

Owner:CENT SOUTH UNIV

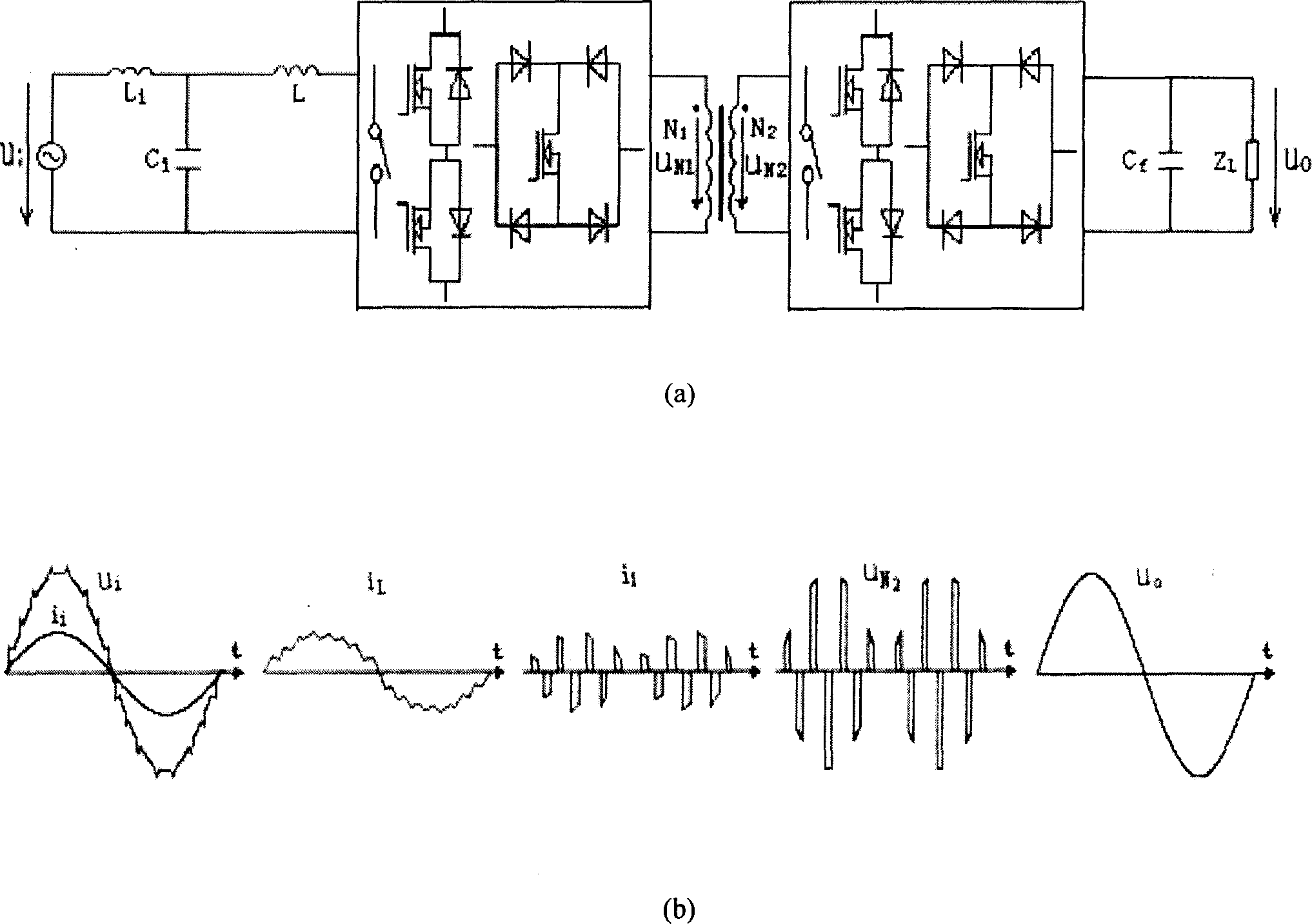

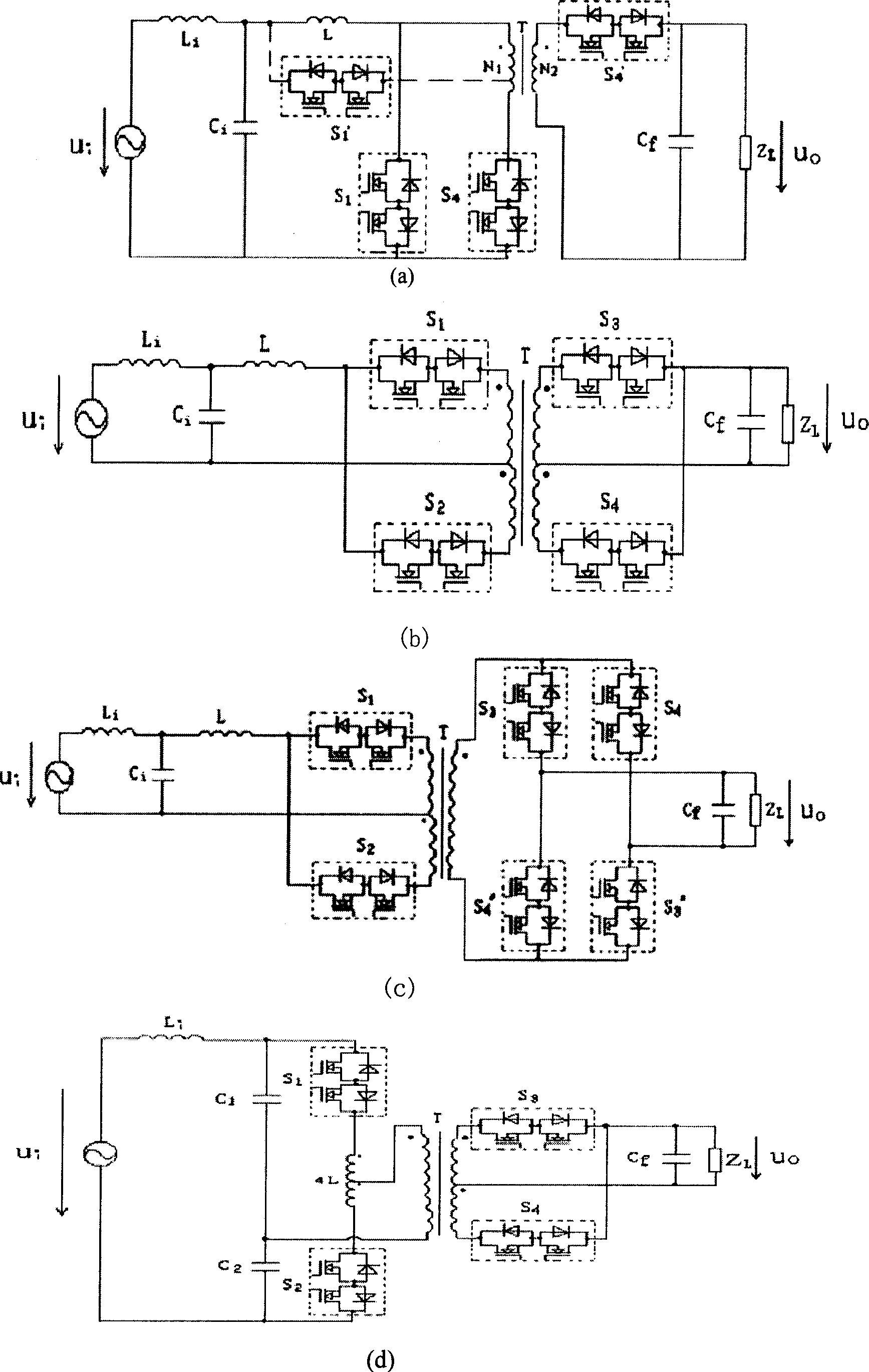

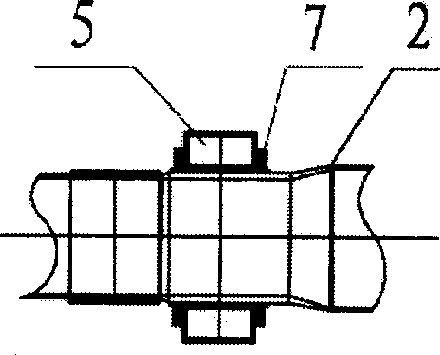

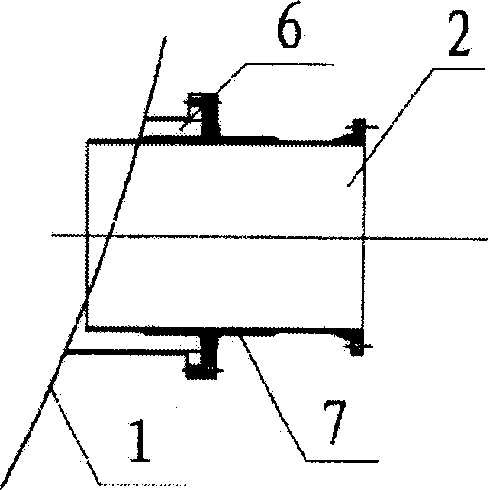

Step-up high frequency link A-A transducer

ActiveCN1794549AImprove conversion efficiencyHigh power side power factorConversion without intermediate conversion to dcPower factorTransformer

This invention relates to a boost high frequency AC / AC converter, which circuit is cascaded by an energy storage inductor, an input cycle converter, a HF transformer, an output cycle converter and an input and output filter circuit to turn a bad unstable AC current to a stable shared high grade sine AC current having the advantages of high frequency electric isolation, simple topological circuit, two stages of power transformation, two-way power-flow, high power factor at the supply side.

Owner:FUZHOU UNIV

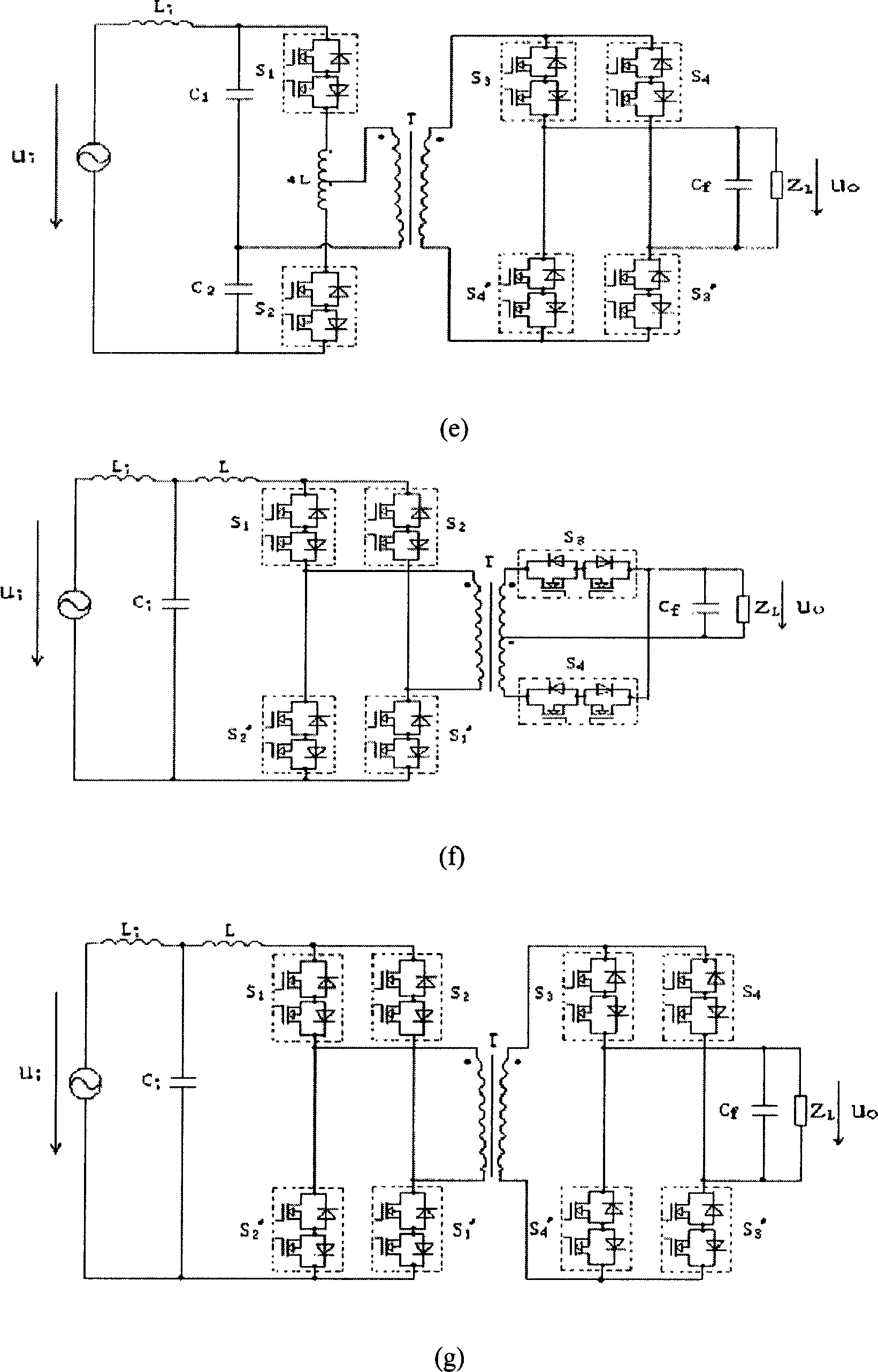

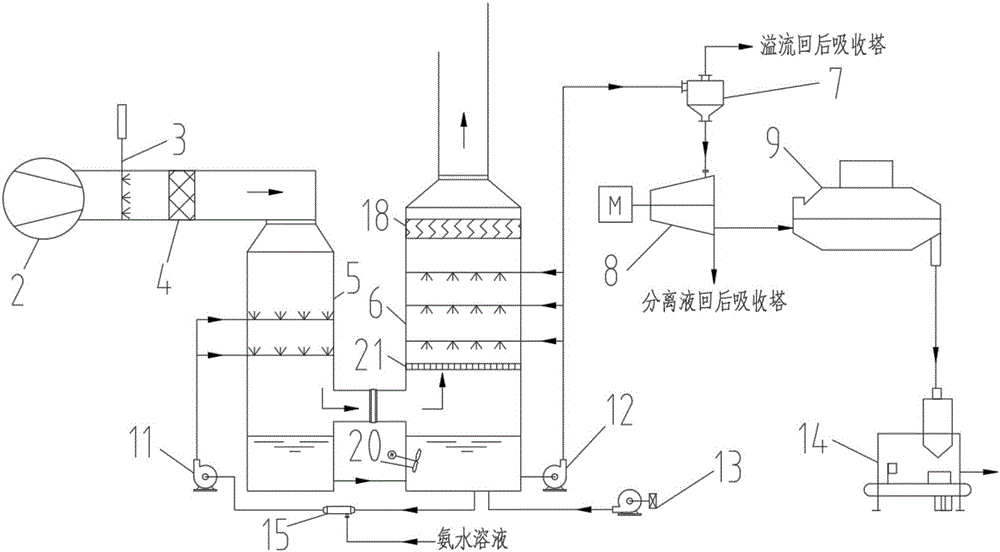

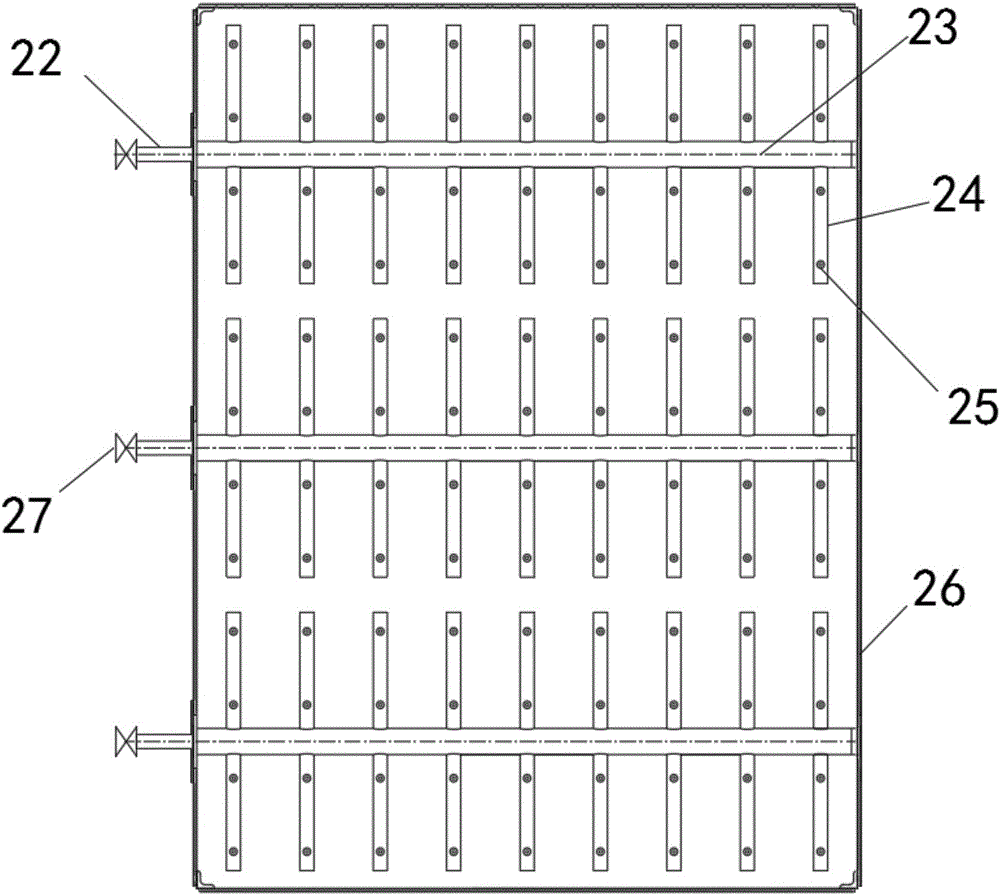

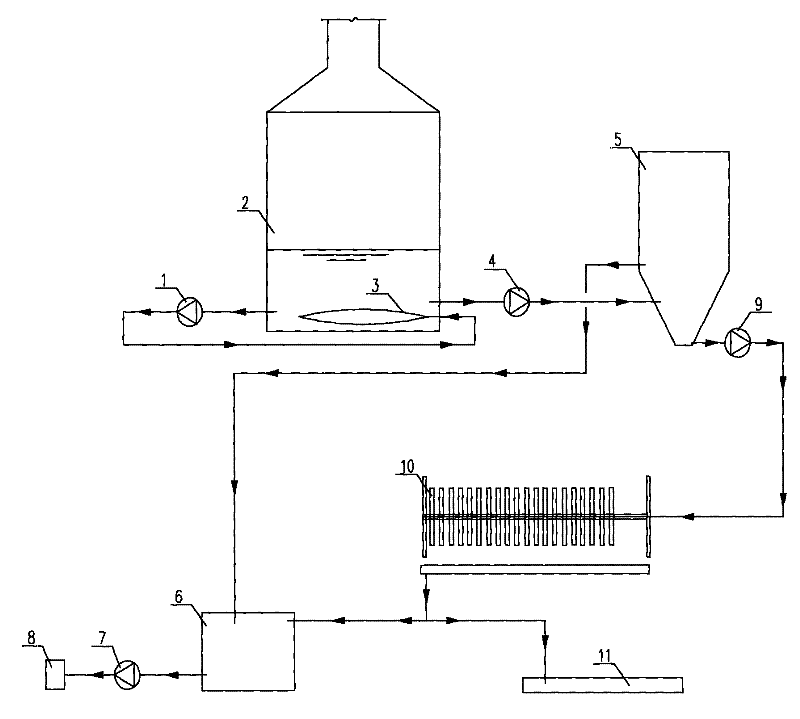

Desulfurization and denitration technology and system by ozone oxidation double-tower ammonia method

ActiveCN106166434AHigh process integrationReduce resistanceDispersed particle separationAir preheaterFlue gas

The invention relates to a desulfurization and denitration system by an ozone oxidation double-tower ammonia method. The desulfurization and denitration system sequentially comprises a hydrogen peroxide spraying device, a draught fan, an ozone spraying device, a flue gas mixing device, a front adsorption tower, a rear adsorption tower, a cyclone separator, a centrifugal separator and a drier, wherein the hydrogen peroxide spraying device is arranged at an outlet of a boiler coal economizer, the outlet of the boiler coal economizer is connected to the draught fan through an air preheater and a dust remover and is connected to the front adsorption tower; the ozone spraying device is mounted in front of an inlet flue of the front adsorption tower; and the flue gas mixing device is arranged between the ozone spraying device and the inlet flue of the front adsorption tower. The desulfurization and denitration system disclosed by the invention has the beneficial effects that the integration degree of a technology is high, the desulfurization and the denitration are integrated, the double-tower structure are stable in properties, the desulfurization efficiency and the denitration efficiency are high, the source of an adsorption tower machine is reliable, the added value of by-products is high, little secondary pollution exists, and the operation cost is low.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

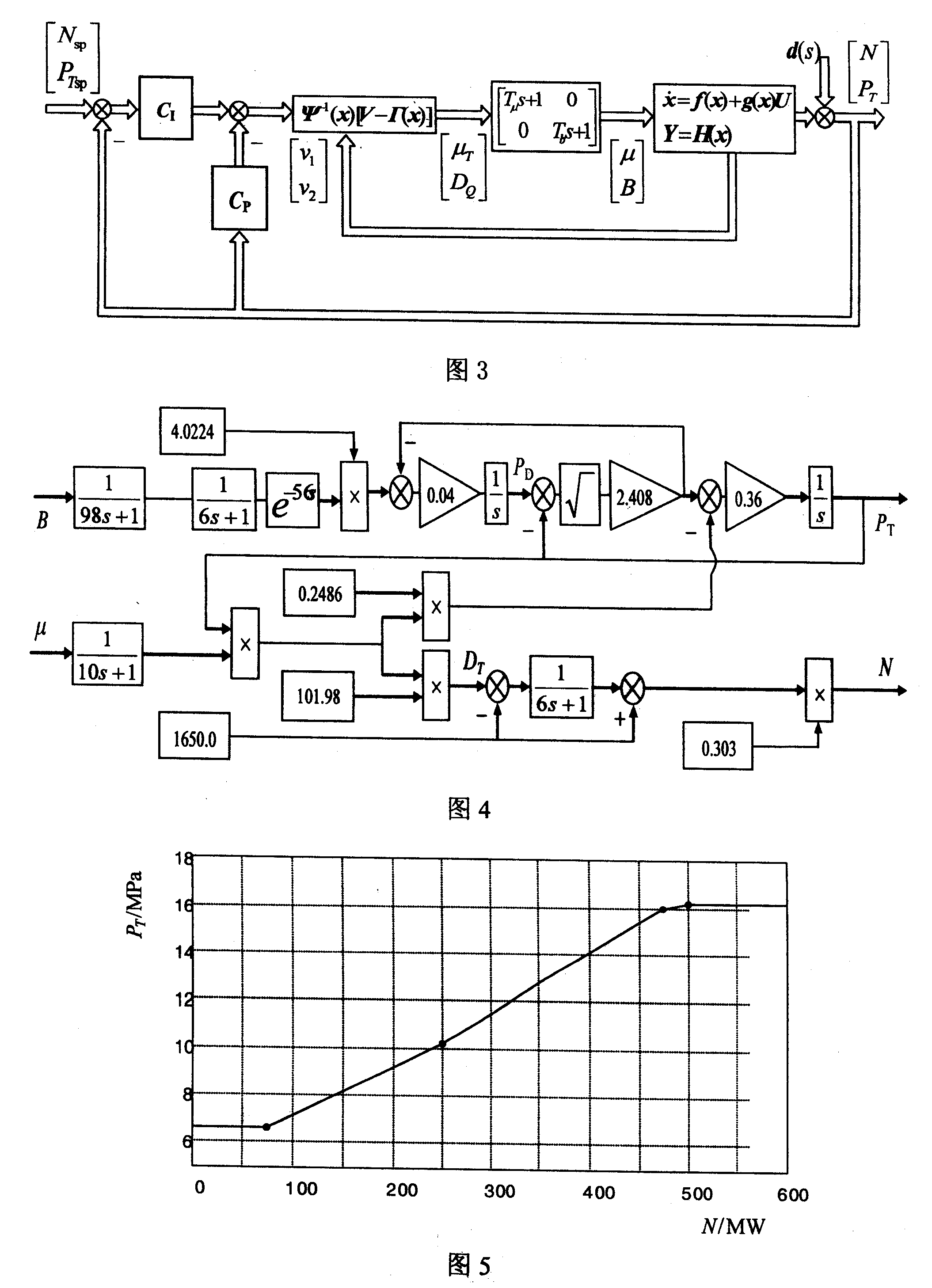

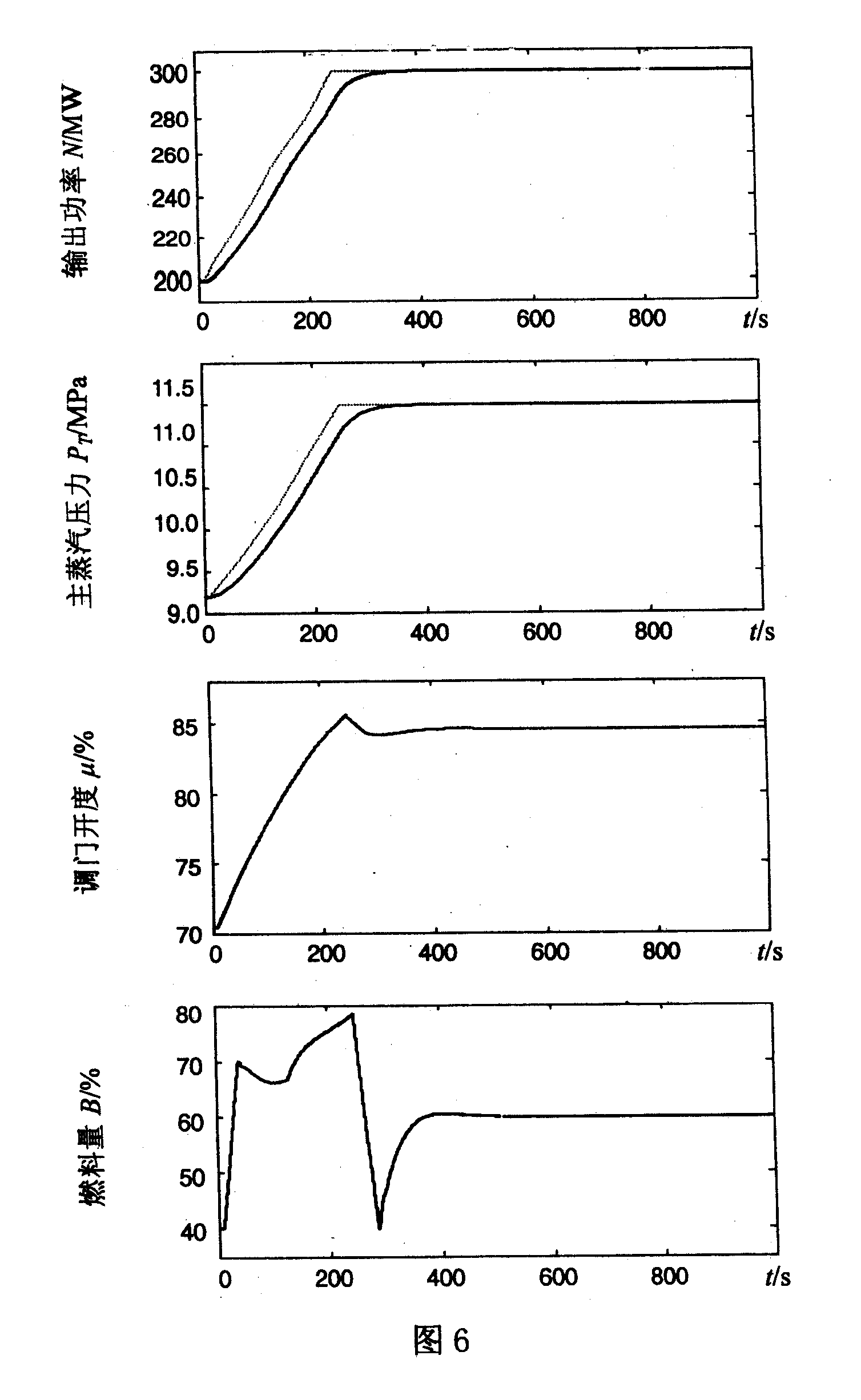

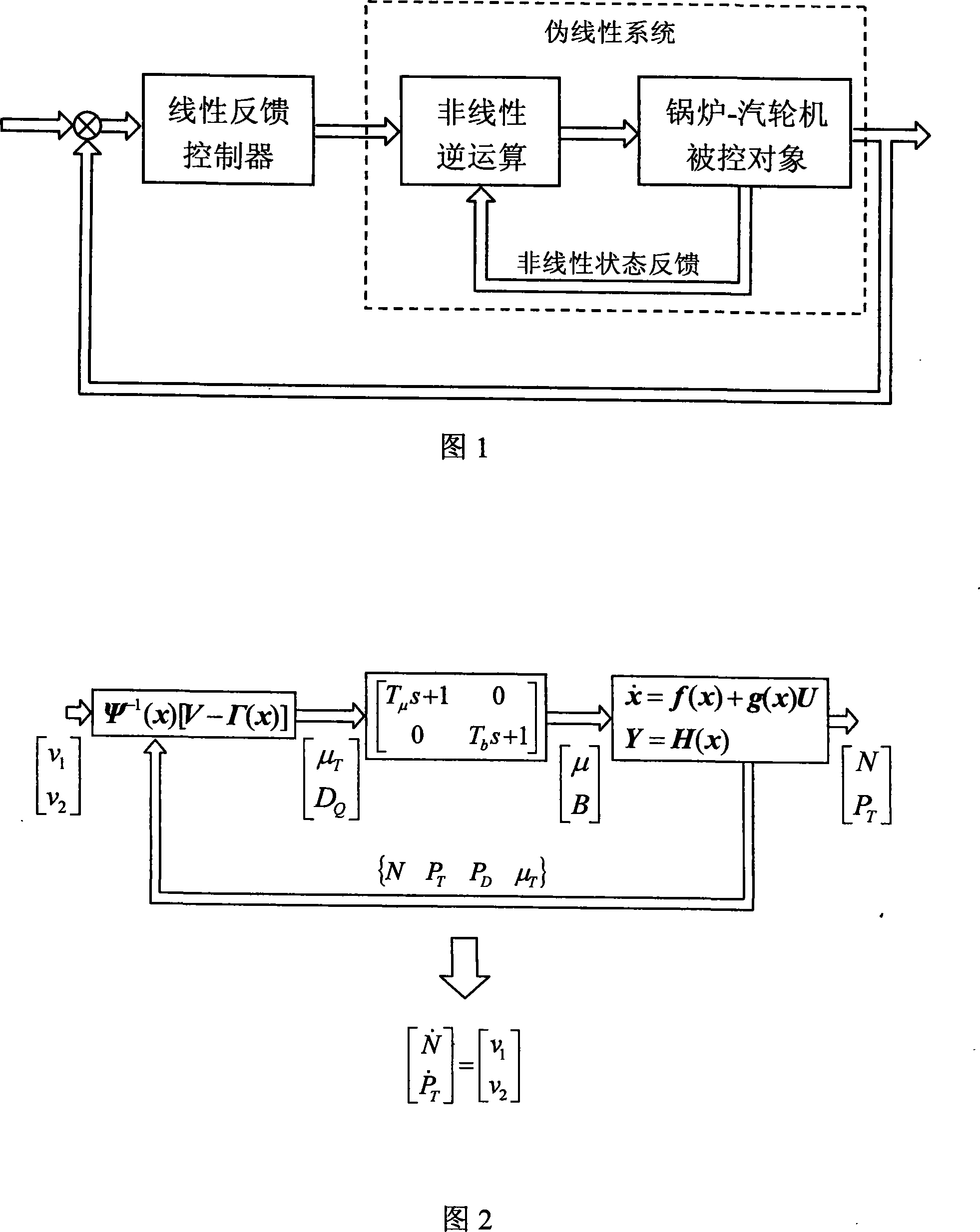

Non linear coordination control method for unit power generation unit

InactiveCN101242156ASimple designImprove load adaptabilityBoiler controlElectric generator controlControl systemUnit system

The invention belongs to the technique field of device control, in particular to a nonlinear coordination control method of unit system electric generating set. The invention provides a nonlinear coordination control structure for the nonlinear character of controlled object in the unit system set. The structure is composed of inner and outer two circuits: selecting the important process parameter representing nonlinear character, forming the inner circuit through state feedback and relevant reverse operation, composing a virtual linear system; designing a linear feedback control outer circuit for the virtual linear system for guaranteeing the stability and dynamic property of the whole coordination control system. With the method provide in the invention, the engineer can design the nonlinear coordination control system with good load adaptability conveniently for unit system set of various types.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

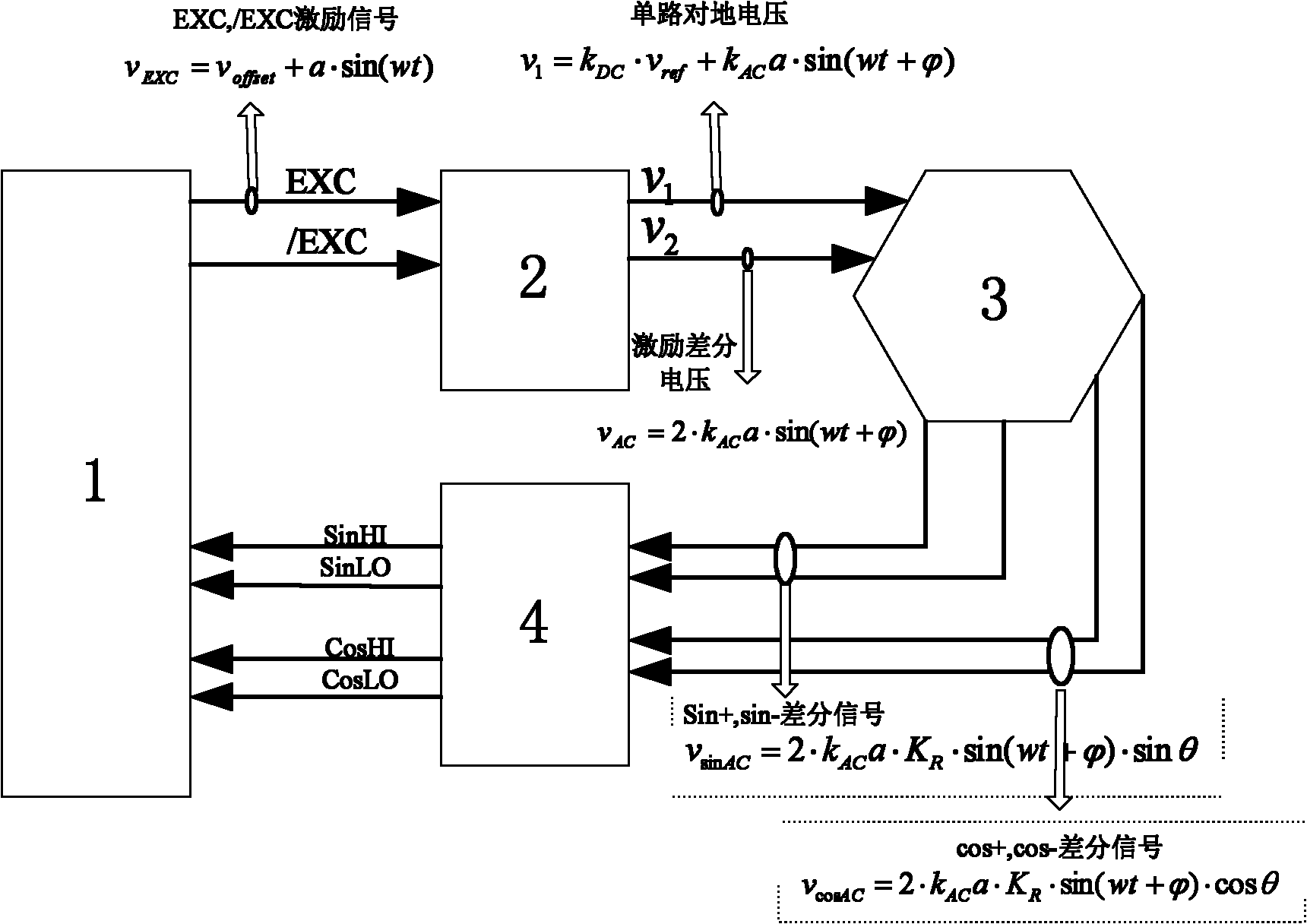

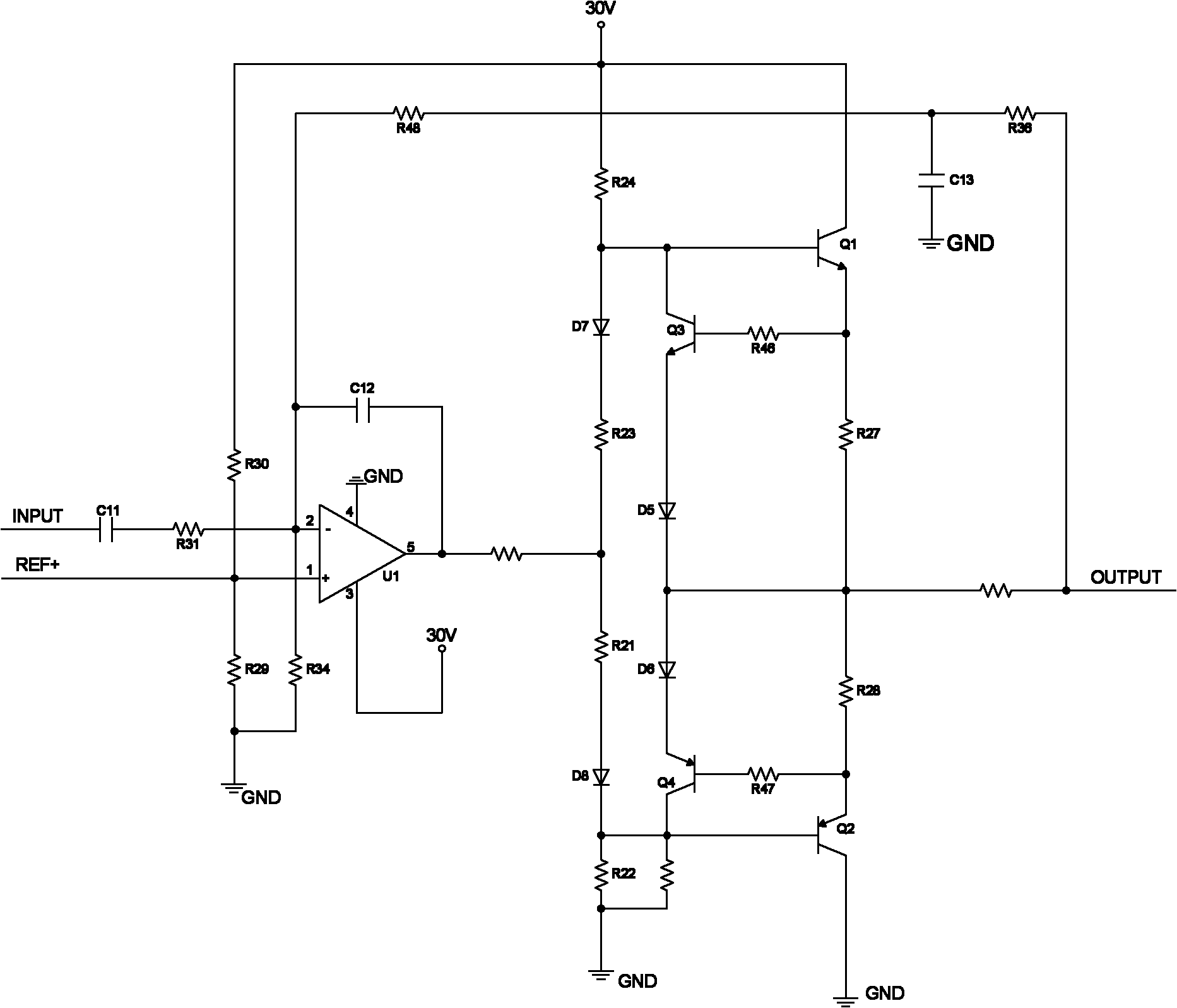

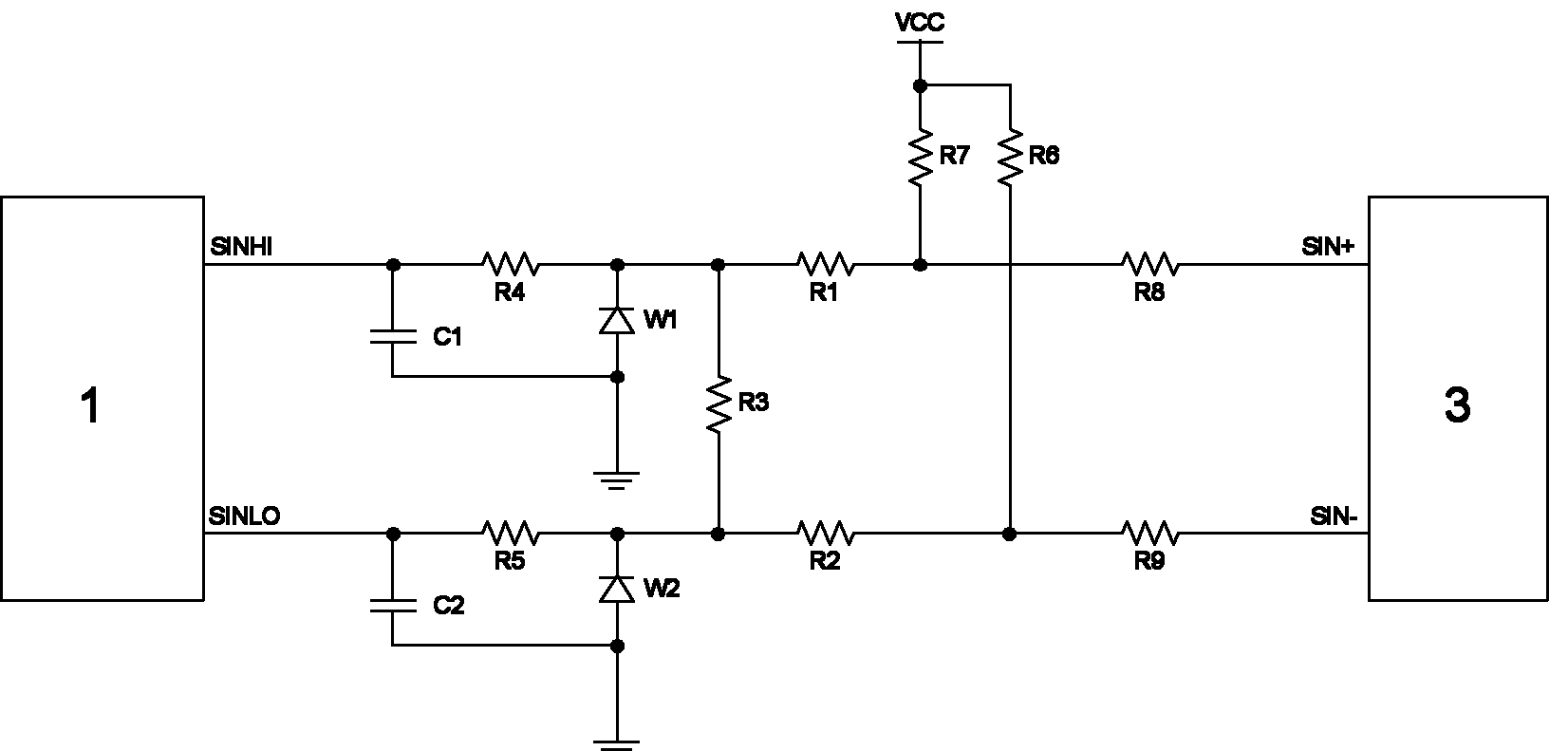

Motor Position Detection Circuit Using Isolated Resolver

ActiveCN102291067AImprove stabilityStrong load adaptabilityElectronic commutatorsPush pullEngineering

The invention discloses a motor position detecting circuit utilizing an isolating type rotating transformer, and the motor position detection comprises a decoding chip, a Buffer circuit and a differential signal regulating circuit, wherein the output end of the decoding chip is connected with the input end of the Buffer circuit; the output end of the Buffer circuit is connected with the input end of the rotating transformer; the rotating transformer outputs a sine-cosine differential signal to the differential signal regulating circuit; the sine-cosine differential signal processed by the differential signal regulating circuit is input to the decoding chip; and the Buffer circuit comprises a front end filtering circuit, an operating and amplifying control circuit, a push-pull circuit and a drive protecting circuit. The power amplification of an excitation signal is realized by adopting the Buffer circuit which is powered by a power supply and has protection, thus the isolating type rotating transformer-adopted motor position detecting circuit can adapt to the drive capability of different loads, can realize a large-range change of differential voltage peaks and has the advantages of enhanced circuit stability, strong load adaptability and good interference resistance; and the differential signal regulating circuit with direct current bias can realize level matching between different rotating transformers and different decoding chips, so that the isolating type rotating transformer-adopted motor position detecting circuit has the advantages of simple circuit structure, low cost and wide application range.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

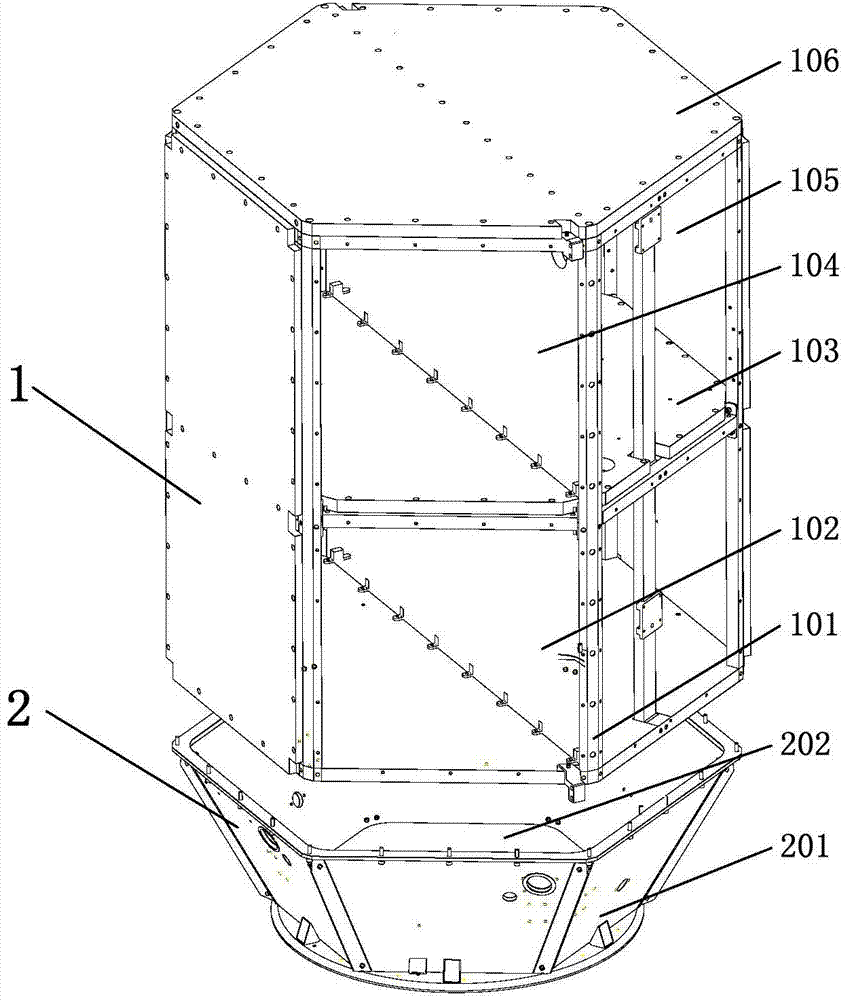

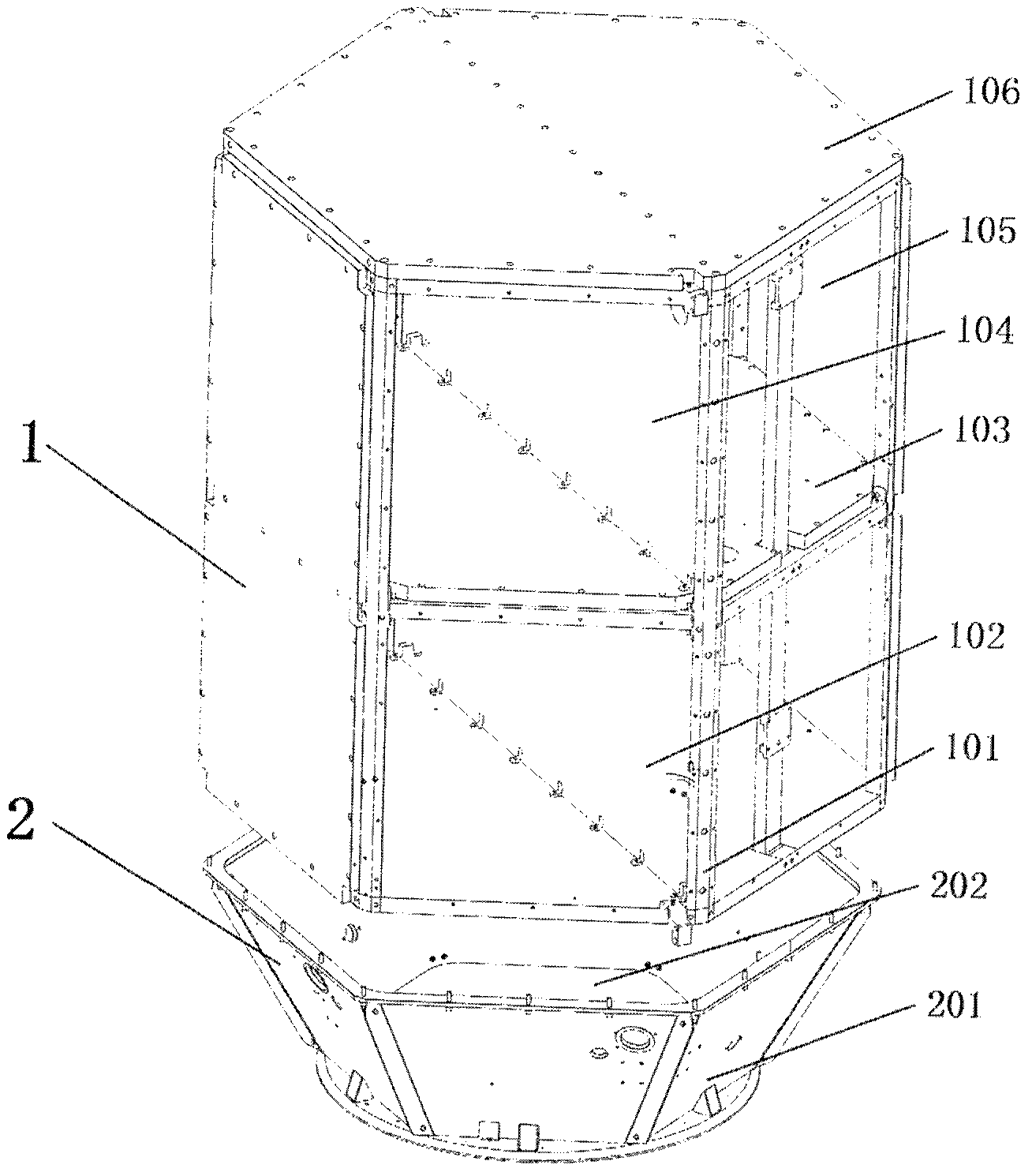

Rapid response satellite structure

The invention discloses a rapid response satellite structure. The rapid response satellite structure comprises a body structure and a propelling module. The body structure is composed of a carbon fiber frame (comprising a bottom plate), a lower partition plate, a middle plate, an upper partition plate, a side plate and a top plate; the propelling module is composed of a force bearing cylinder and a propelling modular bottom plate. By the adoption of the rapid response satellite structure, the problems that a research and assembly period is long, and the adaptation to a load is poor are solved. The rapid response satellite structure has the advantages of being simple in structure, light in weight, rapid to assemble, high in expansibility, high in adaptability and the like.

Owner:SHANGHAI SATELLITE ENG INST

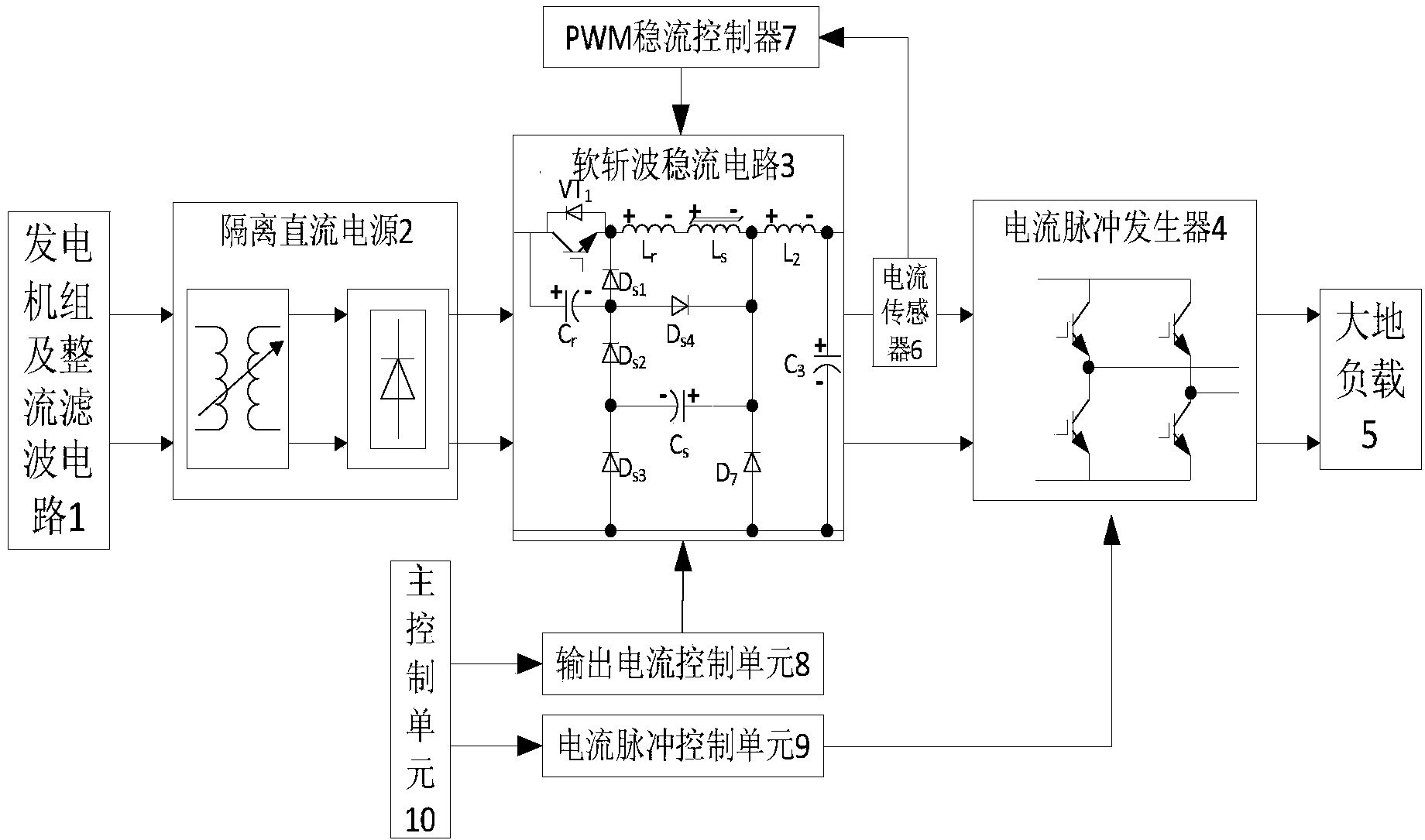

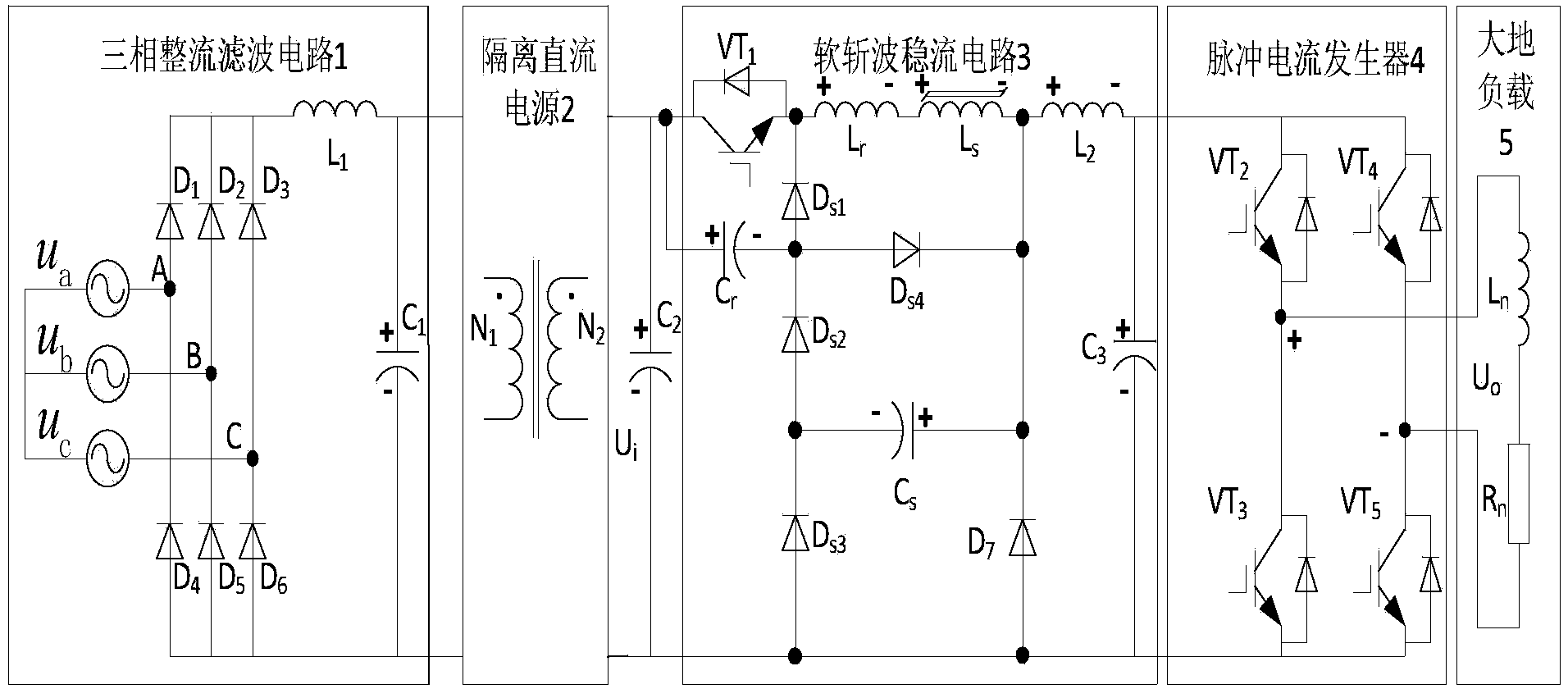

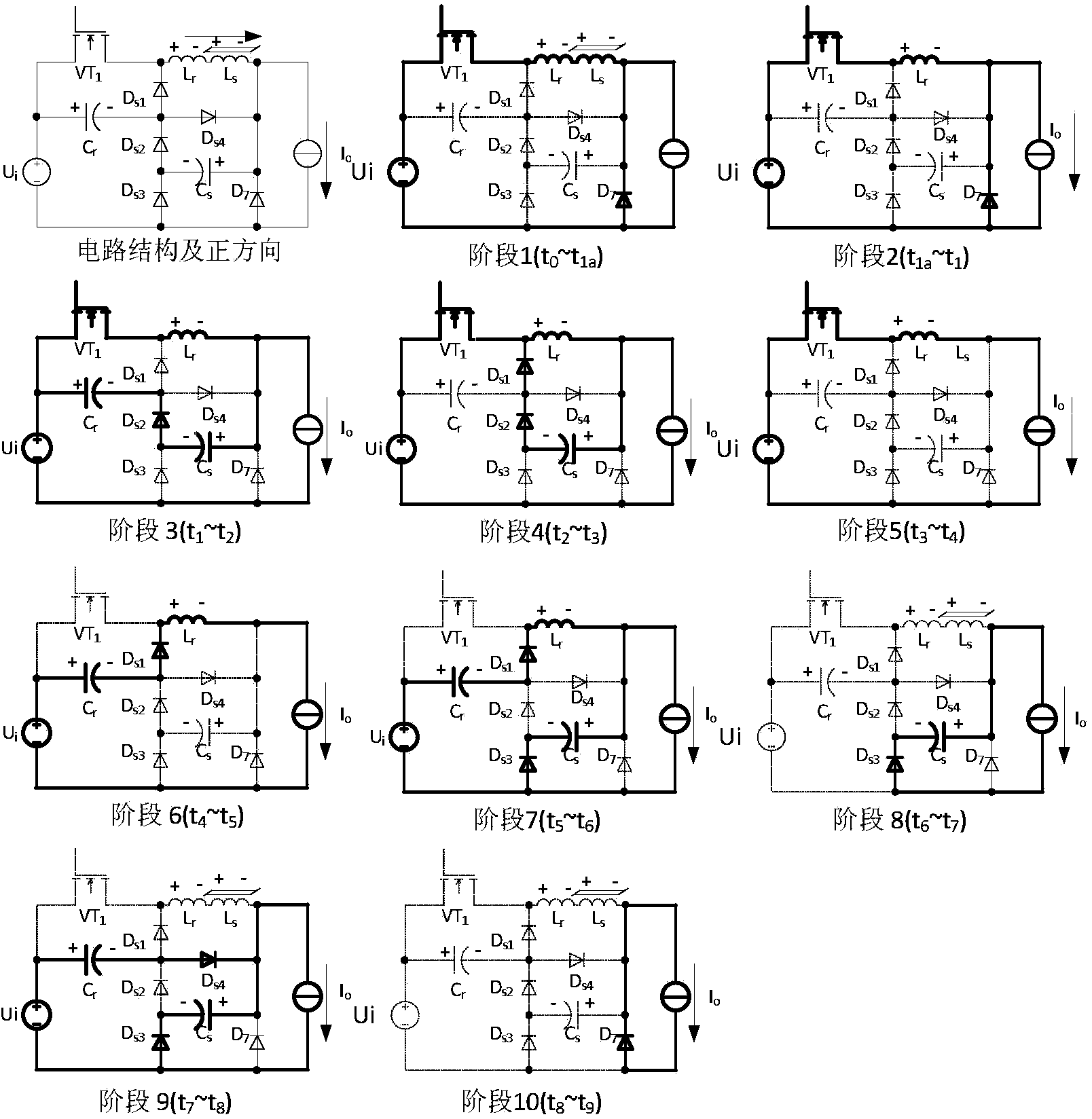

Electrical source emission device and control method with soft chopping wave characteristic

InactiveCN103944440AQuick responseHigh precision of steady flowDc-dc conversionElectric variable regulationCapacitanceElectromagnetic interference

The invention relates to an electrical source emission device and control method with a soft chopping wave characteristic. The device is formed by connecting a three-phase alternative current generator set with a ground load through an isolated direct current power supply, a soft chopping wave steady flow circuit and a current pulse generator. A passive lossless soft switch structure is adopted in the soft chopping wave steady flow circuit, the passive lossless soft switch structure is composed of a main switching tube VT1, a main diode D7, buffer capacitance Cr, energy-storage capacitance Cs, a buffer inductance Lr, a saturation inductance Ls, diodes ranging from Ds1 to Ds4 and filter circuits L2 and C3, and the structure can achieve the soft opening up and soft shutting off of the main switching tube VT1of soft chopping wave steady flow circuit, and the soft shutting off of the main diode D7. Compared with an existing hard chopping wave steady flow electric source transmission device, the power density of the instrument is improved, application region of the device is expanded, electromagnetic interference is reduced, and the steady flow accuracy of the device is improved. The device is within normal operation range, no extra voltage stress is introduced to the main switching tube VT1, the mean free error time is increased, and the service life of the device is prolonged.

Owner:JILIN UNIV

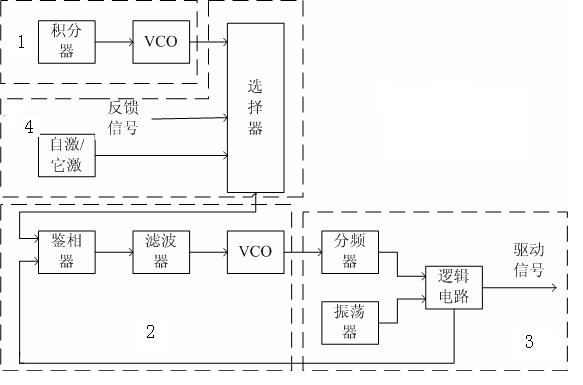

Frequency self-adaptive circuit of parallel resonant induction heating power supply

ActiveCN102573157AReliable startIncrease active powerInduction current sourcesInduction heating controlPower inverterResonance

The invention belongs to the electric technical field and discloses a frequency self-adaptive circuit of a parallel resonant induction heating power supply. The frequency self-adaptive circuit comprises a swept-frequency start circuit (1), a frequency tracking circuit (2), an overlap area processing circuit (3) and a signal gating circuit (4), wherein the swept-frequency start circuit (1) is used for outputting swept-frequency driving signals which change continuously in frequency, driving an inverter through the signal gating circuit and detecting feedback signals output by the inverter, and when the amplitude of the feedback signals achieves a threshold value, a system is converted from swept-frequency start to frequency tracking, and the frequency tracking circuit is used for tracking the changes of a load in resonance frequency in a real-time manner; and the overlap area processing circuit is used for adjusting an overlap area of two lines of driving signals. The frequency self-adaptive circuit disclosed by the invention can realize reliable start and tracking within a wider load frequency range without artificial adjustment and has the characteristics of simple structure, good adaptability of the load and reliable start.

Owner:LUOYANG SHENGHUA INDUCTION HEATING

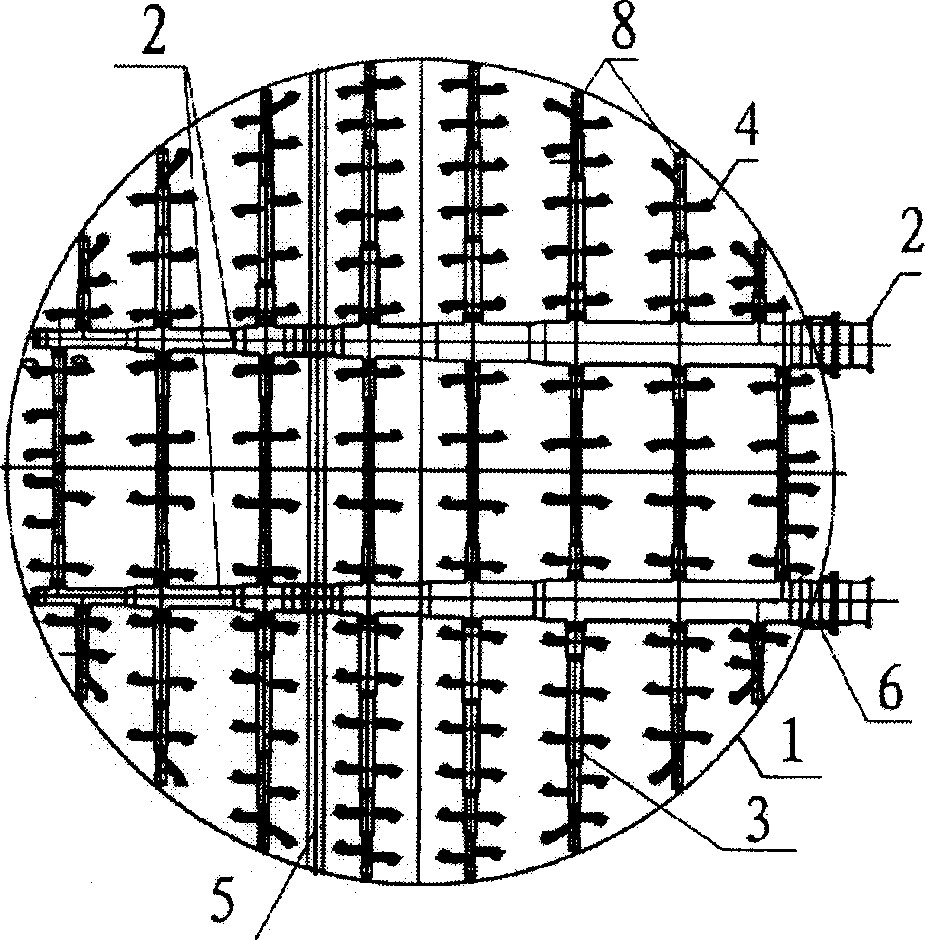

Circulating slurry sprinkling device for desulfurization of flue gas

ActiveCN1843580AReduce power consumptionReduce energy consumptionDispersed particle separationFlue gasSpray nozzle

The invention relates to a smoke desulfuration cycle slurry spray device, which are layered in the adsorption tower. Each spray device is formed by at least two parallel spray main tube and the spray sub tubes branched from the spray main tube. The dual-direction ejectors that branched from the spray sub tubes are interlaced into mesh spray layer; two parallel spray main tubes are through the hole of support beam inside the adsorption tower, and horizontally fixed via single-beam support. The invention can solve the problems that not enough mixed between the smoke and cycle slurry; lower desulfuration effect; and easy abrasion and leakage at the interface between the spray tubes and the adsorption tower. The invention can be used in wet smoke desulfuration adsorption tower to utilize the limestone or lime slurry to adsorb the sulfur dioxide and sulfur trioxide.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

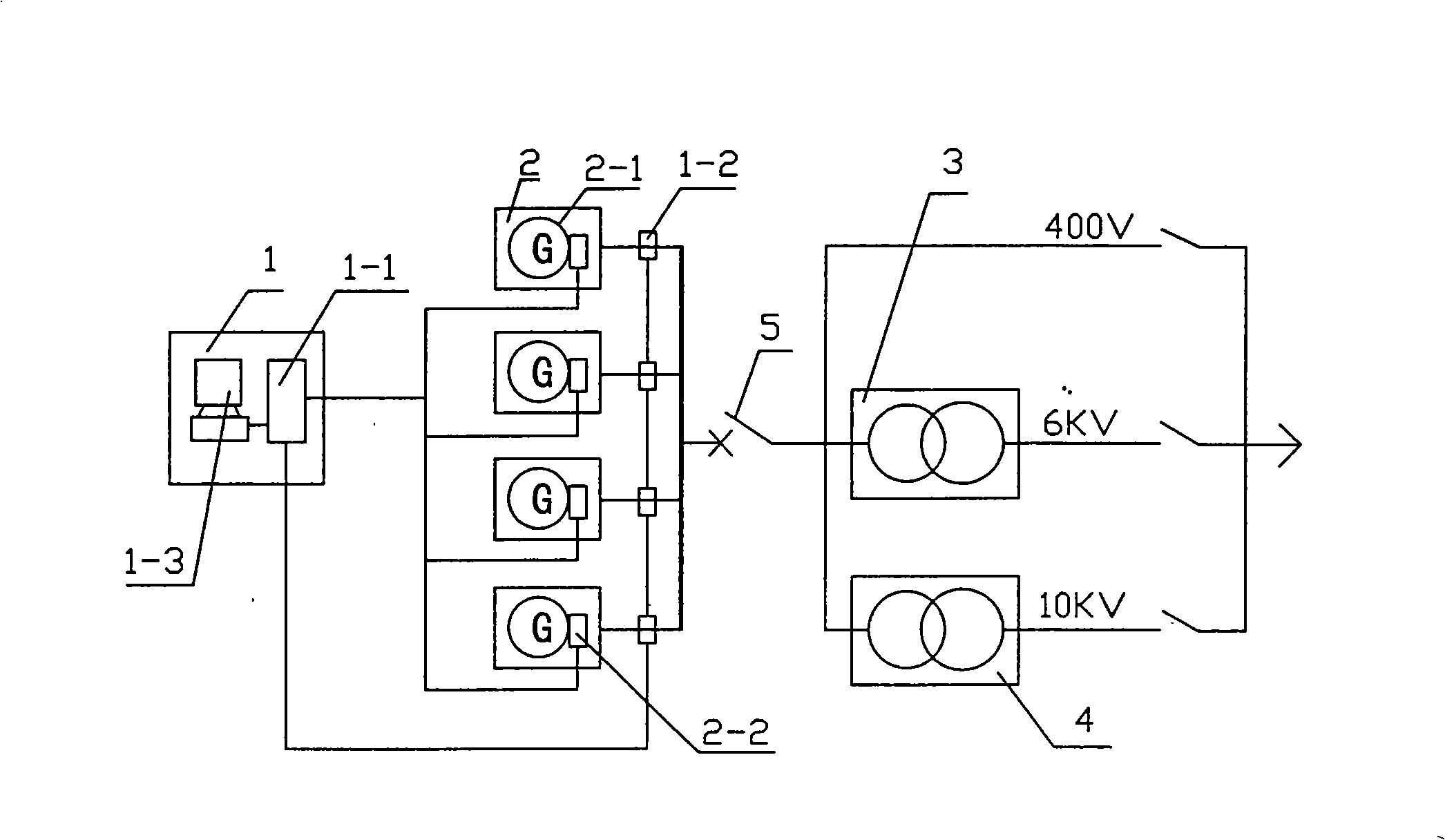

Mobile area burst stop current failure emergency electric power safeguard system

InactiveCN101257222AImprove load adaptabilityRealize high power supplySingle network parallel feeding arrangementsEmergency power supply arrangementsElectricityLow voltage

The invention relates to a movable type region burst power failure / off emergency power guarantee system which is composed of 1-6 generator cars, 1-2 boost transformer electrical cars and a command allocation monitor car associated with a power supply monitor device, therein, electric power output terminal of the generator car is parallel connected each other, and connects with the boost transformer electrical car or low-voltage power network input terminal through cable, the power supply monitor device connects with output terminal of the generator car through a signal sensor respectively. The system unifies functions of single car generating electricity or a plurality of cars generating electricity, multi-phase voltage electric transmission / transformation and monitor command, and can solve problem of burst rescue and relief work emergency power guarantee with various load and voltage in city and mining area.

Owner:南阳宜和城市保障专用车辆研究所

Reduction method for processing waste plastic and system thereof

ActiveCN101302432AGood load adaptabilityQuality improvementElectrical coke oven heatingProductsCatalytic pyrolysisLiquid fuel

The invention relates to a reduction method and a reduction system for processing waste plastics. The method and the system take an IGBT heating module as the core, and can save over 40 percent of energy compared with the prior vacuum tube high-frequency equipment and the prior thyristor induction heating equipment. The method and the system adopt the novel catalytic pyrolysis method, namely the prior mode of directly placing catalyst zeolite into the waste plastics is changed and the waste plastics are gasified into oil gas and then degraded by Y-shaped molecular sieves. Therefore, the pyrolysis effect of the method and the system is more obvious; the quality of liquid fuel gasoline and diesel fuel produced is better; and the gasoline and the diesel fuel produced reach or exceed the national standards of No.70 gasoline SHO 42-92 and No. 0 diesel fuel GB 252-94. Moreover, No. 90 to No. 93 unleaded gasoline can be modulated by utilization of the gasoline.

Owner:吴振奇

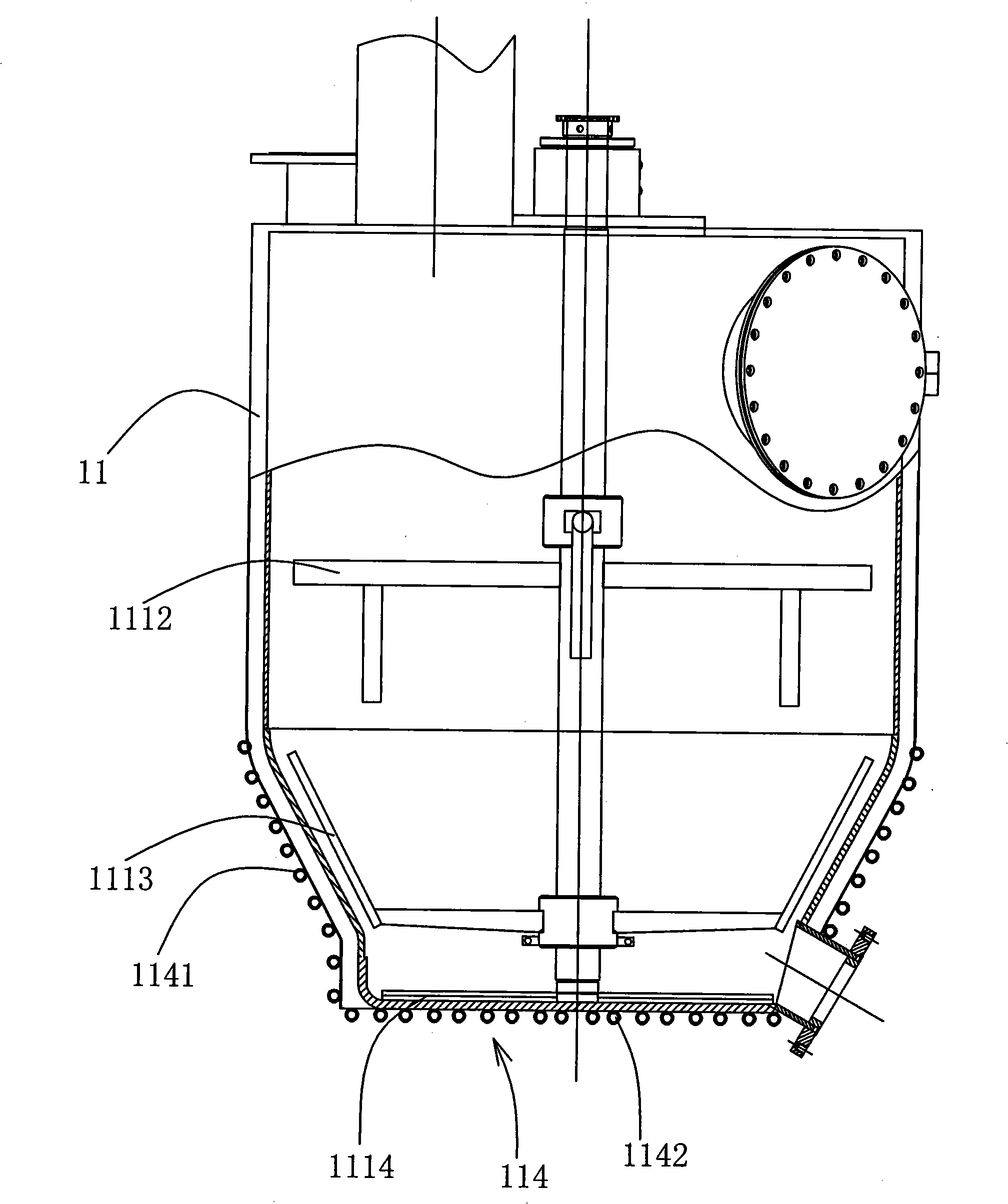

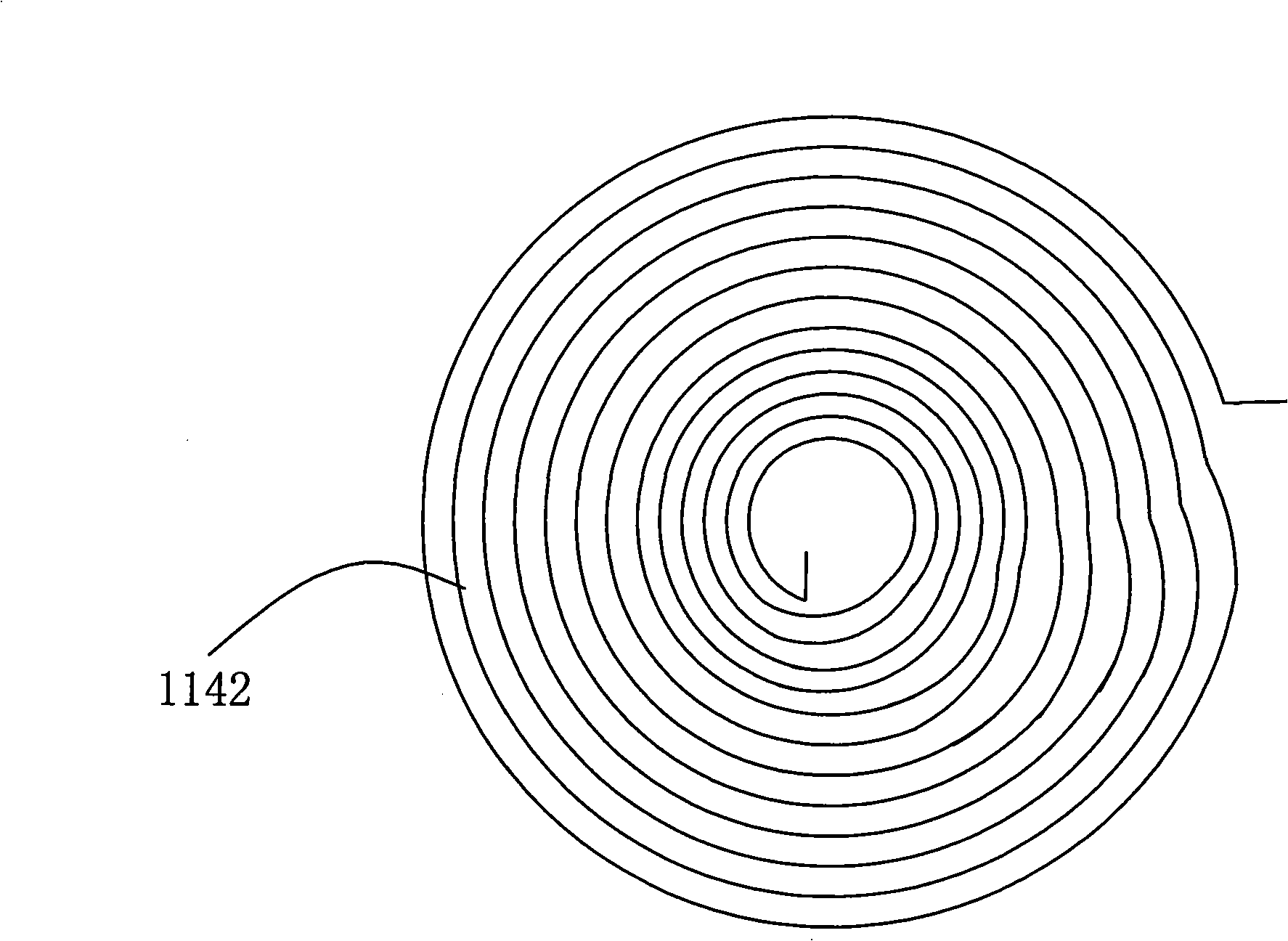

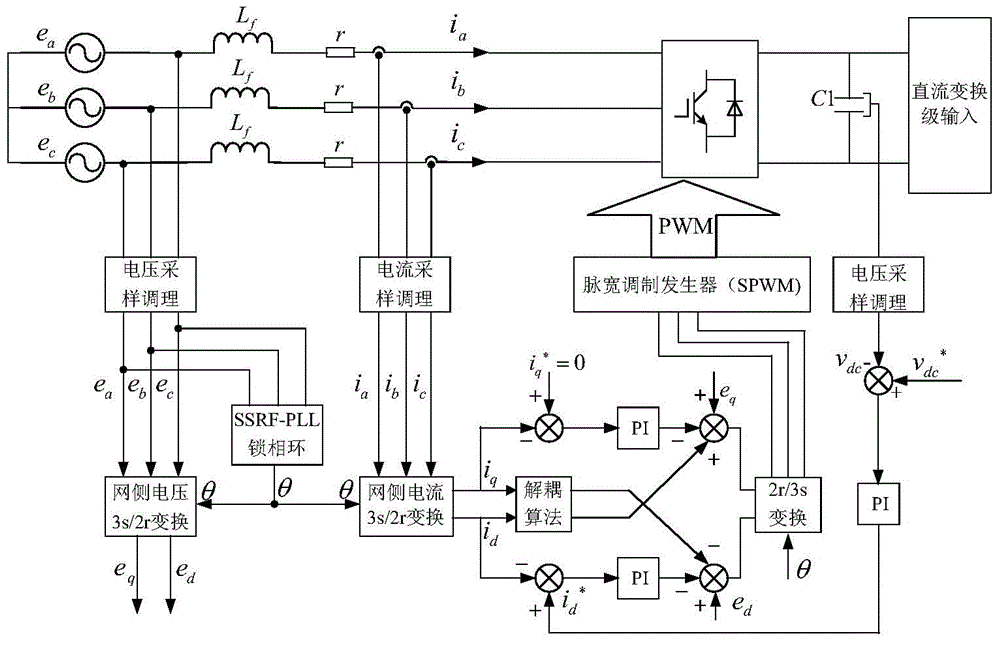

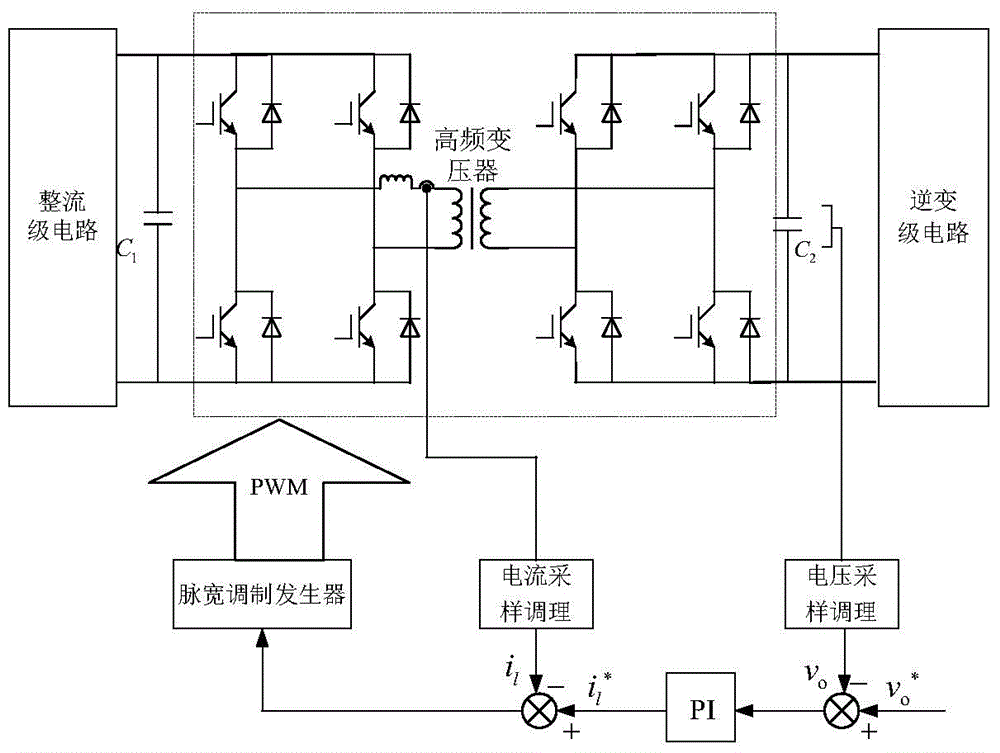

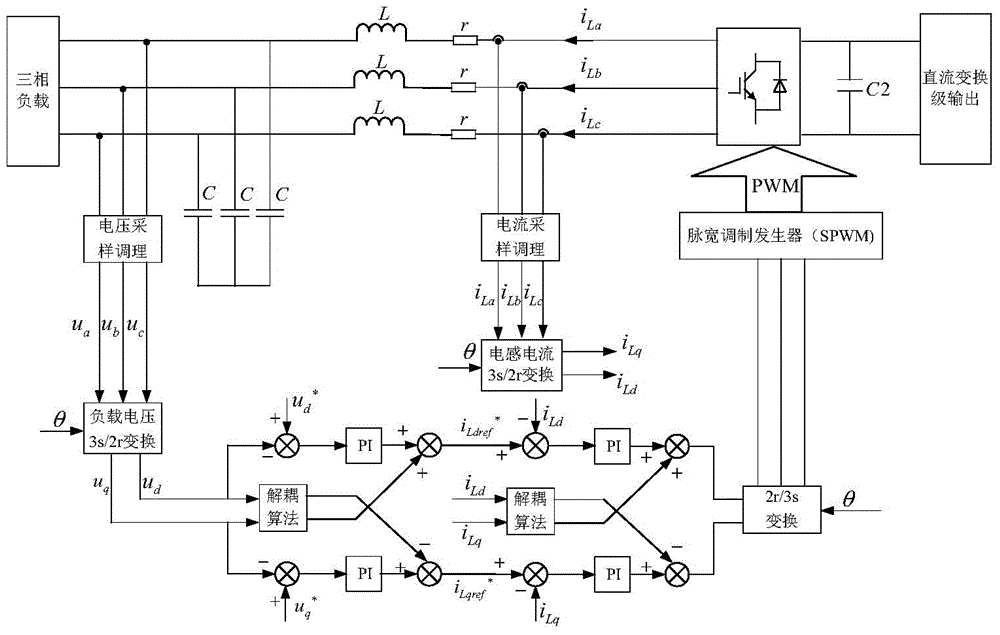

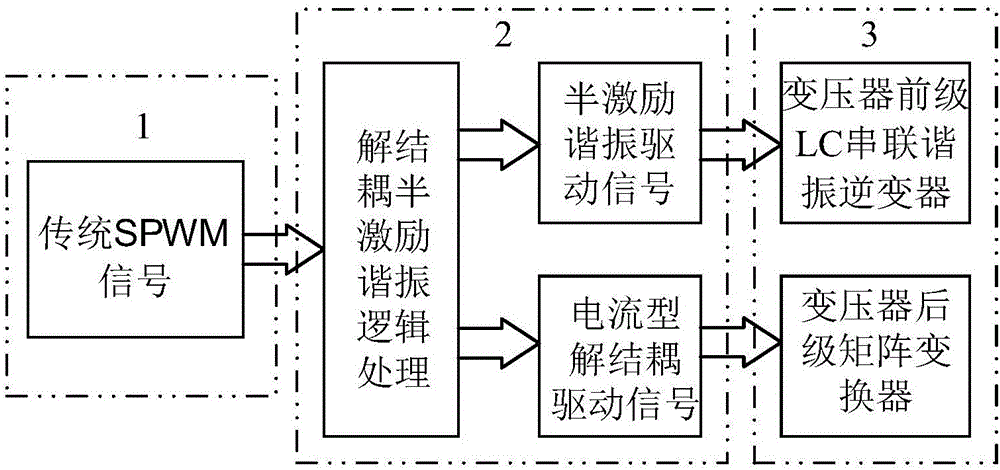

Control method for double PWM solid-state transformer

InactiveCN104993713AReduce lossGood temperature characteristicsAc-dc conversionDc-dc conversionPower factorClosed loop

The invention discloses a control method for a double PWM solid-state transformer. The control method is implemented based on a double PWM solid-state transformer structure. For rectifier control, a double closed-loop control mode (direct-current voltage at outer loop and grid-side current at inner loop) is adopted under a dq synchronous rotating coordinate system to realize sinusoidal control on the grid-side current and make the unit power factor be 1; for direct-current transformation control, a double closed-loop control mode (output voltage at outer loop and inductive current at inner loop) is adopted to realize voltage level transformation, power transmission and electrical isolation; and for inverter control, a double closed-loop control mode (output voltage at outer loop and inductive current at inner loop) is adopted under the dq synchronous rotating coordinate system. Reliable high-quality power can be provided for users, and the bad influence of nonlinear load on the power grid can be improved effectively. The control method has higher load adaptability and dynamic response.

Owner:TAIYUAN UNIV OF TECH

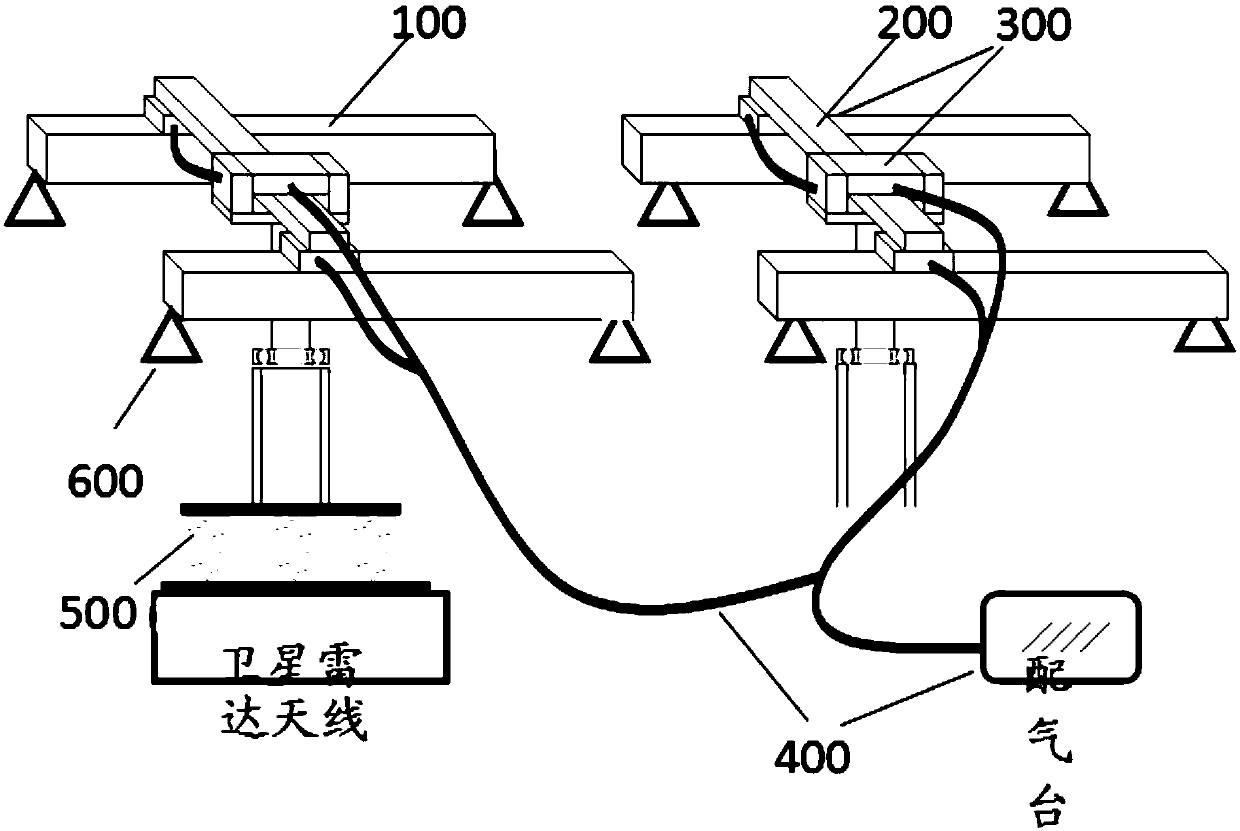

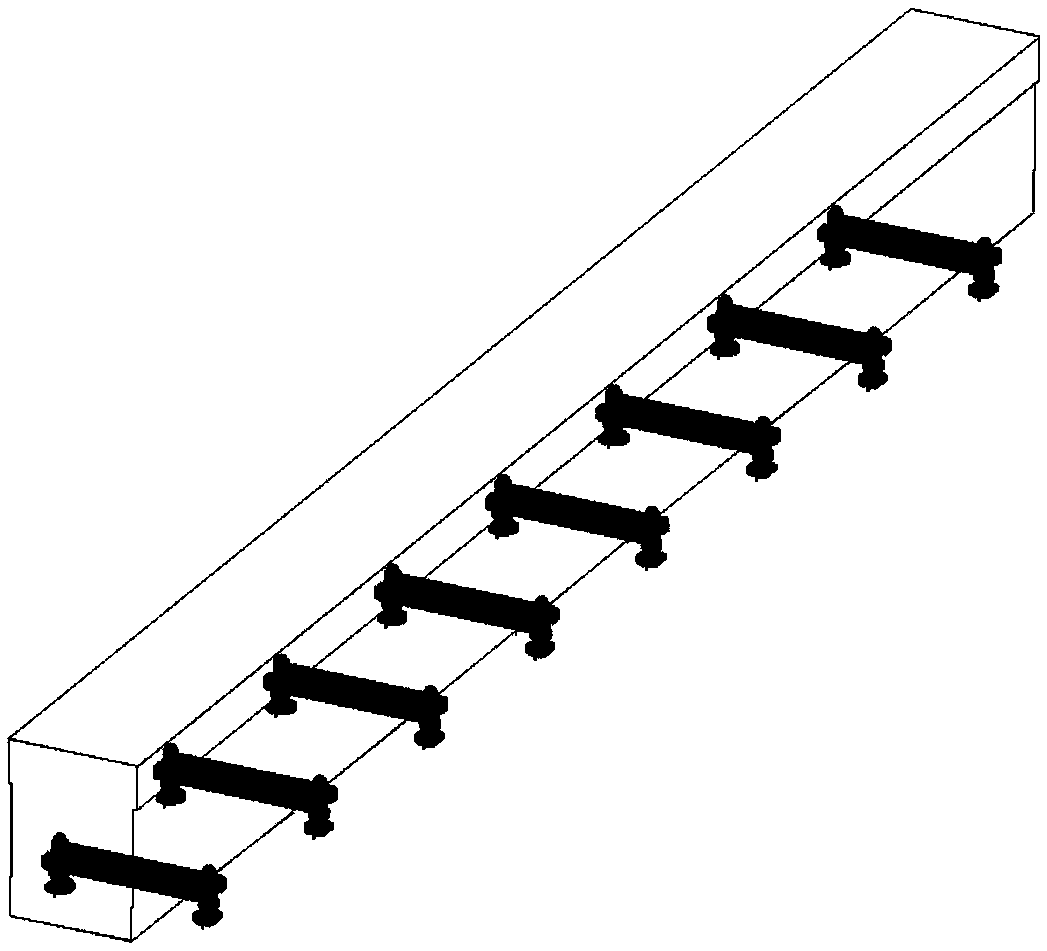

High-bearing and low-friction suspension type antenna unloading device

ActiveCN109515770AReduce processing difficultyReduce pipeline complexityCosmonautic condition simulationsLow frictionGravitation

The invention provides a high-bearing and low-friction suspension type antenna unloading device. The high-bearing and low-friction suspension type antenna unloading device comprises long air flotationguide rails, short air flotation guide rails, an air supply and distribution system, a double-suspension-bar suspension assembly and a bearing truss. The long air flotation guide rails are arranged on the bearing truss and driven by the air supply and distribution system to move relative to the bearing truss. The two ends of each short air flotation guide rail are arranged on the two corresponding long air flotation guide rails correspondingly, and the short air flotation guide rails are driven by the air supply and distribution system to move relative to the long air flotation guide rails. The double-suspension-bar suspension assembly is connected with the two ends of each short air flotation guide rail in a sliding mode, driven by the air supply and distribution system to move relativeto the short air flotation guide rails and used for achieving suspension of load antennas. By the adoption of the high-bearing and low-friction suspension type antenna unloading device, the long air flotation guide rails and the short air flotation guide rails are driven by the air supply and distribution system, so that linear movement of the double-suspension-bar suspension assembly in the orthogonal direction of the long guide rails is achieved. The double-suspension-bar suspension assembly is connected with satellite radar antennas, so that gravity unloading of the satellite radar antennasis achieved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Total energy-saving environmental base station air-conditioning

ActiveCN101769576AHigh control precisionSignificant positive effectSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlProcess engineering

The present invention relates to a total energy-saving environmental base station air-conditioning comprises a controlling device and a refrigeration circulating loop formed by connecting with a compressor, a low-pressure reservoir, an indoor steamer, an expansion valve and a condenser in turn. The present invention is characterized in that a new wind cooling device is arranged; the new wind cooling device is composed of a proportion new wind valve and an indoor circulating high-efficiency blower without a volute; and the indoor circulating high-efficiency blown without a volute not only is a steamer blower, but also is a new wind leading-in blower. When outdoor new wind temperature is lower than the set value of indoor temperature, the controlling device is used for controlling and stopping the compressor to run or reducing running efficiency. New wind is leaded in through the indoor circulating high-efficiency blower without a volute. The new wind valve is opened, and new wind opening degree is adjusted to reach the purposes of indoor temperature control and energy saving. At the same time, the compressor uses environmental R407C refrigeration agent and transducer technology. Compared with usual air-conditioning systems, the present invention has the advantages of obvious energy saving, high control precision, energy saving, environmental protection and the like.

Owner:广东吉荣空调有限公司

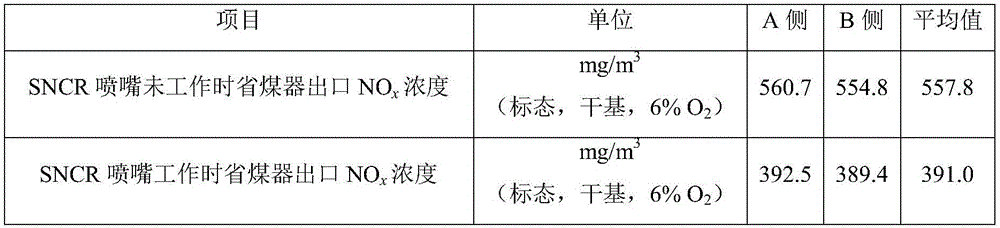

SNCR-SCR combined denitration system based on demercuration and deamination modified catalyst and denitration method achieved by adopting system

InactiveCN106582225AImprove load adaptabilityRequirements for realizing full-load denitrificationDispersed particle separationAtmospheric pollutantsFlue gas

The invention belongs to the technical field of control over atmospheric pollutants discharged by coal-fired boilers, and particularly relates to an SNCR-SCR combined denitration system based on a demercuration and deamination modified catalyst and a denitration method achieved by adopting the system. The SCR system comprises an SCR nozzle, a flow guiding blade, a flow straightening grid and SCR denitration catalyst layers which are located between a coal economizer and an air preheater, and a denitration modified catalyst layer is arranged under the SCR denitration catalyst layers and comprises a catalyst carrier, active denitration ingredients and active demercuration and deamination ingredients. According to the combined denitration system, mercury and ammonia in flue gas can be removed simultaneously, and the removal rate of zero-valent mercury in the flue gas and the removal rate of ammonia in the flue gas can reach 99% or above and 95% or above respectively.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

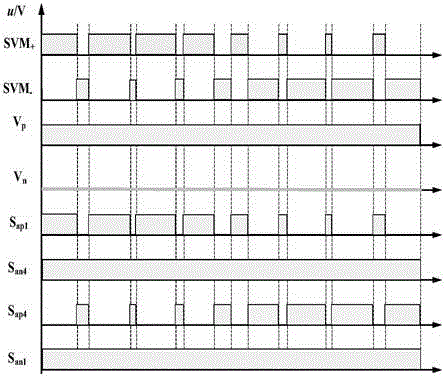

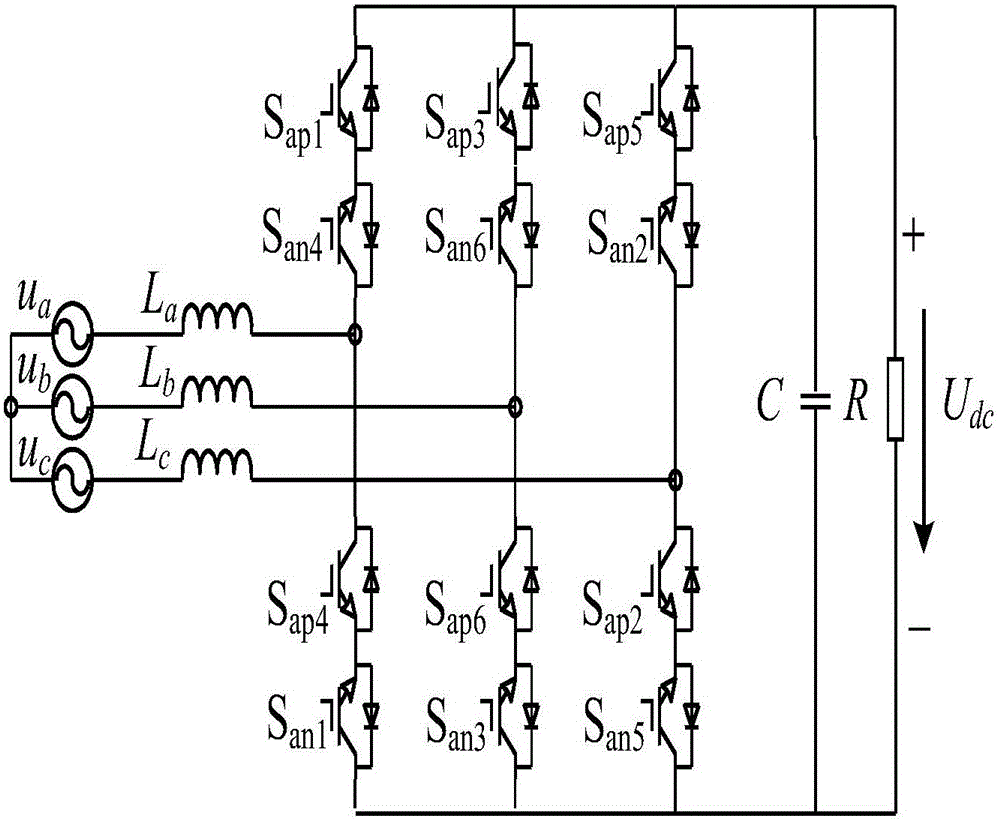

Voltage switching instruction based decoupling-coupling SVM demodulation method of matrix converter

InactiveCN106208766AReduce complexityModulation method is simpleAc-dc conversionMatrix convertersCoupling

The invention relates to a voltage switching instruction based decoupling-coupling SVM demodulation method of a matrix converter. A bidirectional controllable switch circuit is decomposed to a one-way controllable switch circuit by means of a decoupling-coupling idea, and thus, the matrix converter can be decomposed to a positive group of general voltage type converters and a negative group of general voltage type converters; and with the adoption of a voltage type six-section space vector method, appropriate coupling logic synthesis is performed on the obtained SVM signal and a voltage positive-negative switching instruction signal to obtain flexible and independent control on the bidirectional switch of the matrix converter, thus, a three-phase voltage type non-isolation matrix rectifier achieves functions of AC input and DC output by a simple control logic, and the matrix converter can have functions of positive DC output and negative DC output. The method has the advantages that the control method is simple, the positive DC output voltage polarity and the negative DC output voltage polarity of the matrix rectifier can be achieved, the adaptability to a load is high, the DC voltage utilization rate is improved, the bidirectional flow of switching frequency energy is reduced, and a compact structure and high efficiency are achieved.

Owner:YANSHAN UNIV

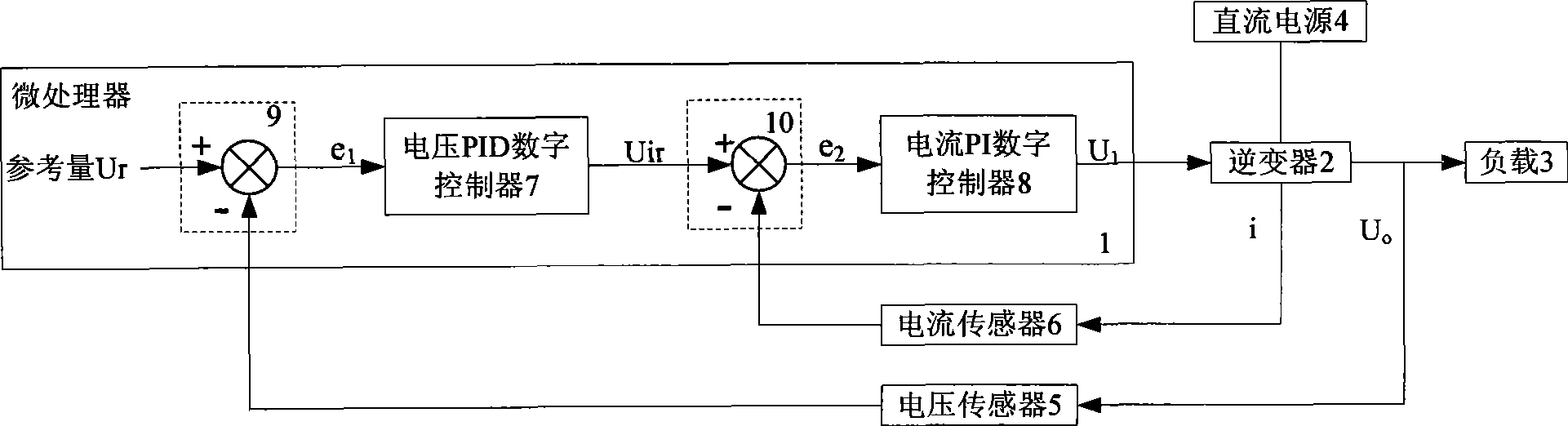

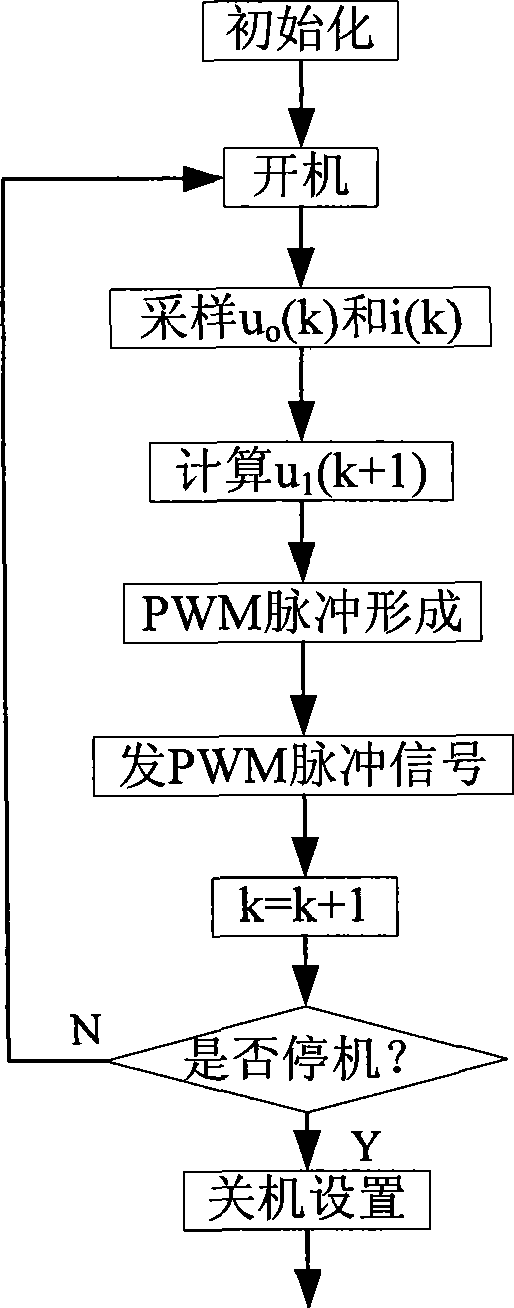

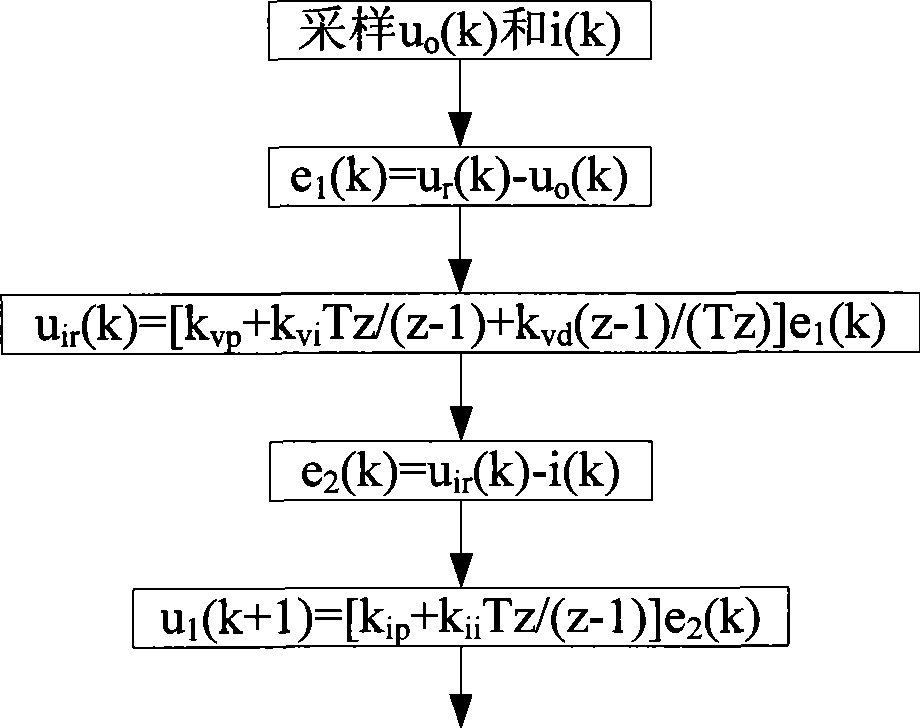

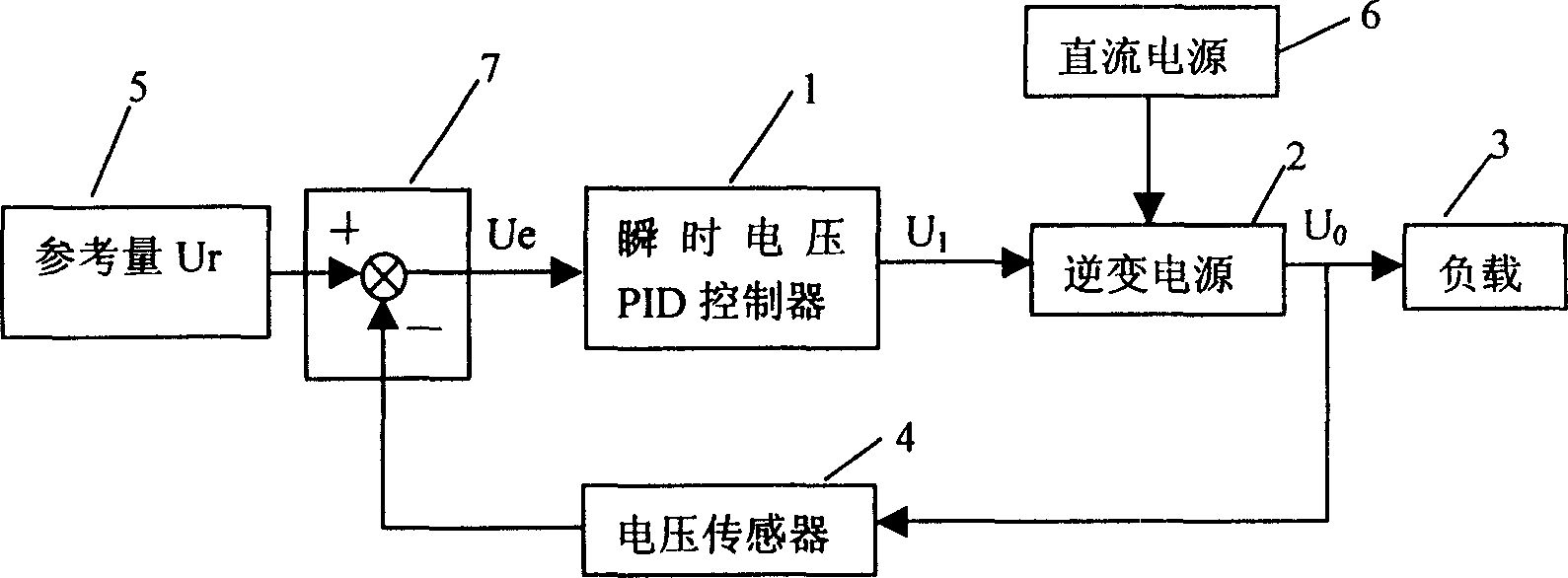

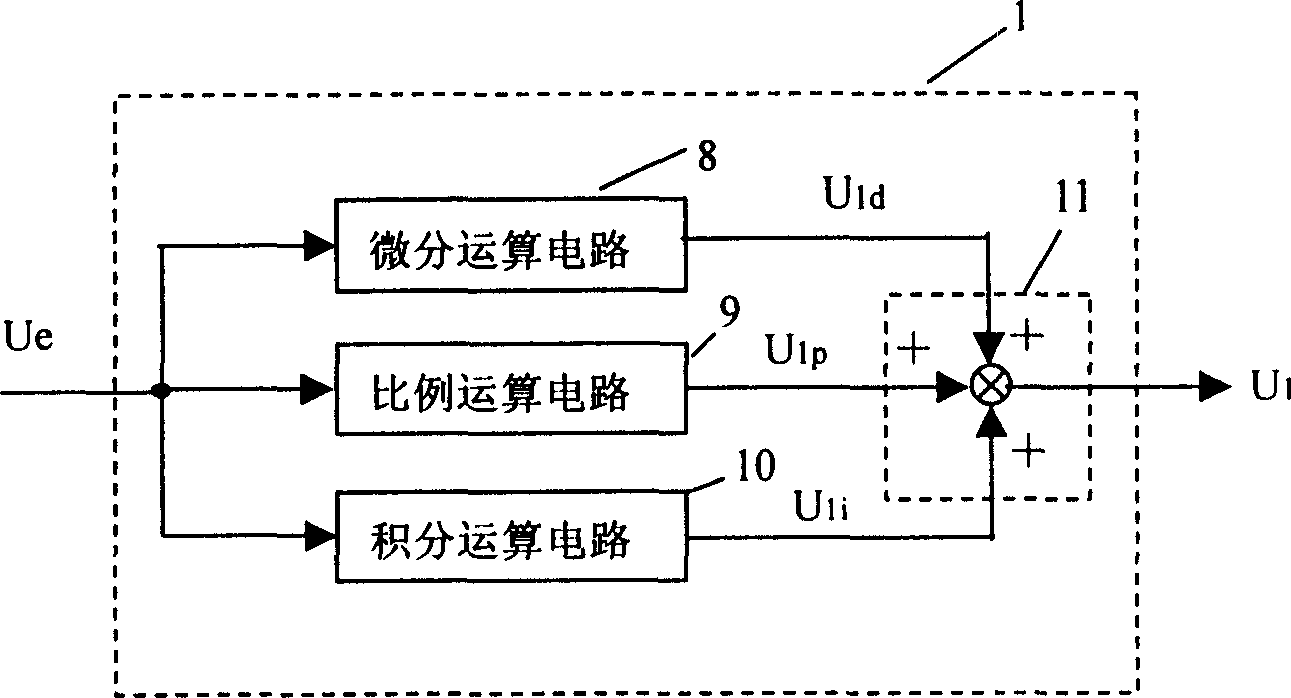

Inverter for instant voltage PID current PI digital control

ActiveCN101505110ARobustStable response performanceDc-ac conversion without reversalDistortionActive power filter

The invention discloses an instantaneous voltage PID current PI digital control inverted power supply. The output end of the current PI digital controller is connected with the control end of the inverter; the output end of the inverter is connected with the input end of a voltage transducer and a load; the output end of a voltage transducer is connected with the negative input end of a first substracter; the positive input end of the substracter receives reference quantity; the output end of the first substracter is connected with the input end of a voltage PID digital controller; the direct current end of the inverter is connected with a direct current power supply; the current led out from the inverter is connected with the input end of a current transducer; the output end of the current transducer is connected with the negative input end of a second substracter; the positive input end of the second substracter is connected with the output end of the voltage PID digital controller; and the output end of the second substracter is connected with the input end of the current PI digital controller. The inverted power supply is high in precision, quick and smooth in response, and small in total harmonic wave distortion of output voltage under nonlinear load condition. The inverted power supply can be widely applied to alternating stabilized power supplies, uninterruptible power supplies, active power filters and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and device for mixed flow type gasification of biomass

InactiveCN102226105AReduce tar contentStrong ability to control gas componentsProductsReagentsMixed flowTar

The invention discloses a method and device for mixed flow type gasification of biomass. The gasification process comprises a front gasification stage and a post gasification stage. In the front gasification stage, the biomass material is subjected to pyrolysis gasification by using a bottom feed type gasification process, in the post gasification stage, the biomass material is subjected to pyrolysis gasification by using a top feed type gasification process, so that the biomass coke that does not completely react in the front gasification stage and part of fuel gas together enter a top feed type gasification device for gasification reaction. By using the method and the device disclosed by the invention, the bottom feed type gasification process and the top feed type gasification process are optimally combined to fully play the advantages of the two gasification processes. Meanwhile, the method and the device have the characteristics of low tar content, strong gas component regulation and control capacity, strong load adapting capacity, stability in operation and so on, have strong scale-up capacity, and can be widely used in gas supply, heat supply, power generation, liquid fuel synthesis and other fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Inverter of instantaneous voltage PID analogue controlled

ActiveCN1758520AShort transition timeSmall overshootAdaptive controlDc-ac conversion without reversalHarmonicControl theory

This invention discloses an inverse power supply for analog-controlling instantaneous voltages, in which, PID controller output end is connected with the input of the inverse supply, the output of which is connected with the input of the voltage sensor and the load, its output and a reference volume are connected with the negative and positive input of a subtracter, the output of which is connected with the input of the PID controller and the inverse supply is connected with the DC supply, which has the advantages of quick dynamic response, low rate of general harmonic aberration and accurate stability under non-linear load.

Owner:HUAZHONG UNIV OF SCI & TECH

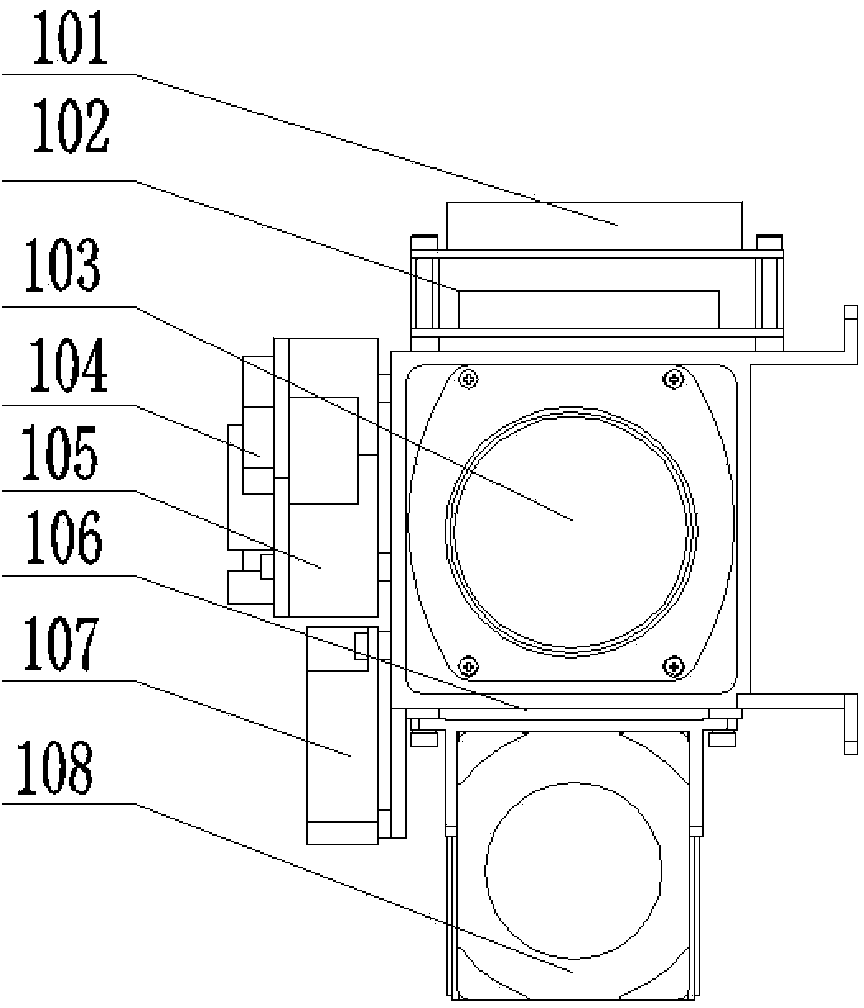

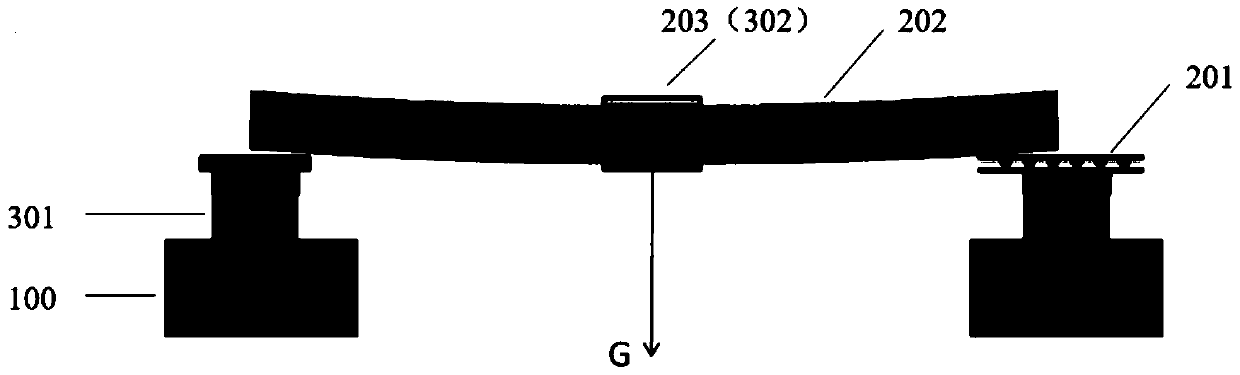

A rapid assembly satellite structure

The invention discloses a rapid assembly satellite structure, comprising: a body structure [1] and a propulsion cabin [2]; the body structure [1] is composed of a carbon fiber frame (including a bottom plate) [101], a lower partition [102], a middle plate [103], upper bulkhead [104], side plate [105] and top plate [106] are formed; Propelling compartment [2] is made up of load-bearing tube [20]] and propelling compartment bottom plate [202]. The invention solves the problems of long development and assembly period, weak adaptability to loads, etc., and achieves beneficial effects such as simple structure, light weight, rapid assembly, strong expandability, and strong adaptability.

Owner:SHANGHAI SATELLITE ENG INST

System for desulfuration and ash removal of flue gas from steel plant sintering by ammonia method

InactiveCN102350202AGuarantee normal productionEasy to transportDispersed particle separationFiltration circuitsSludgeFiltration

The invention relates to a system for desulfuration and ash removal of flue gas from steel plant sintering by an ammonia method, and belongs to the field of mechanical equipment. The system for desulfuration and ash removal of flue gas from steel plant sintering by an ammonia method comprises a hydraulic backflushing stirring pump, an annular stirring device, an ash solution elevator pump, a deposition tank, a sludge pump, a pressure filter, a middle lifting tank and a middle elevator pump. An ash removal unit of the system for desulfuration and ash removal of flue gas from steel plant sintering by an ammonia method changes the conditions that the existing system for desulfuration and ash removal by an ammonia method adopts a bag-type filter or a self-cleaning filter and thus slag removal is difficult; blocking appears easily; maintenance is carried out frequently; operation management is complex; and a filter inner frame is easy to be damaged because of over-high backwashing pressure. The ash removal unit of the system for desulfuration and ash removal of flue gas from steel plant sintering by an ammonia method adopts deposition and press filtration two-step ash treatment so that clear liquid two-step shunting is realized and an ash removal rate reaches above 90%, has a low operation cost, realizes ash cake forming and convenient transport, and guarantees normal production of a desulfuration unit of the system for desulfuration and ash removal of flue gas from steel plant sintering by an ammonia method. Therefore, the system provided by the invention is suitable for desulfuration and ash removal of flue gas from steel plant sintering.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com