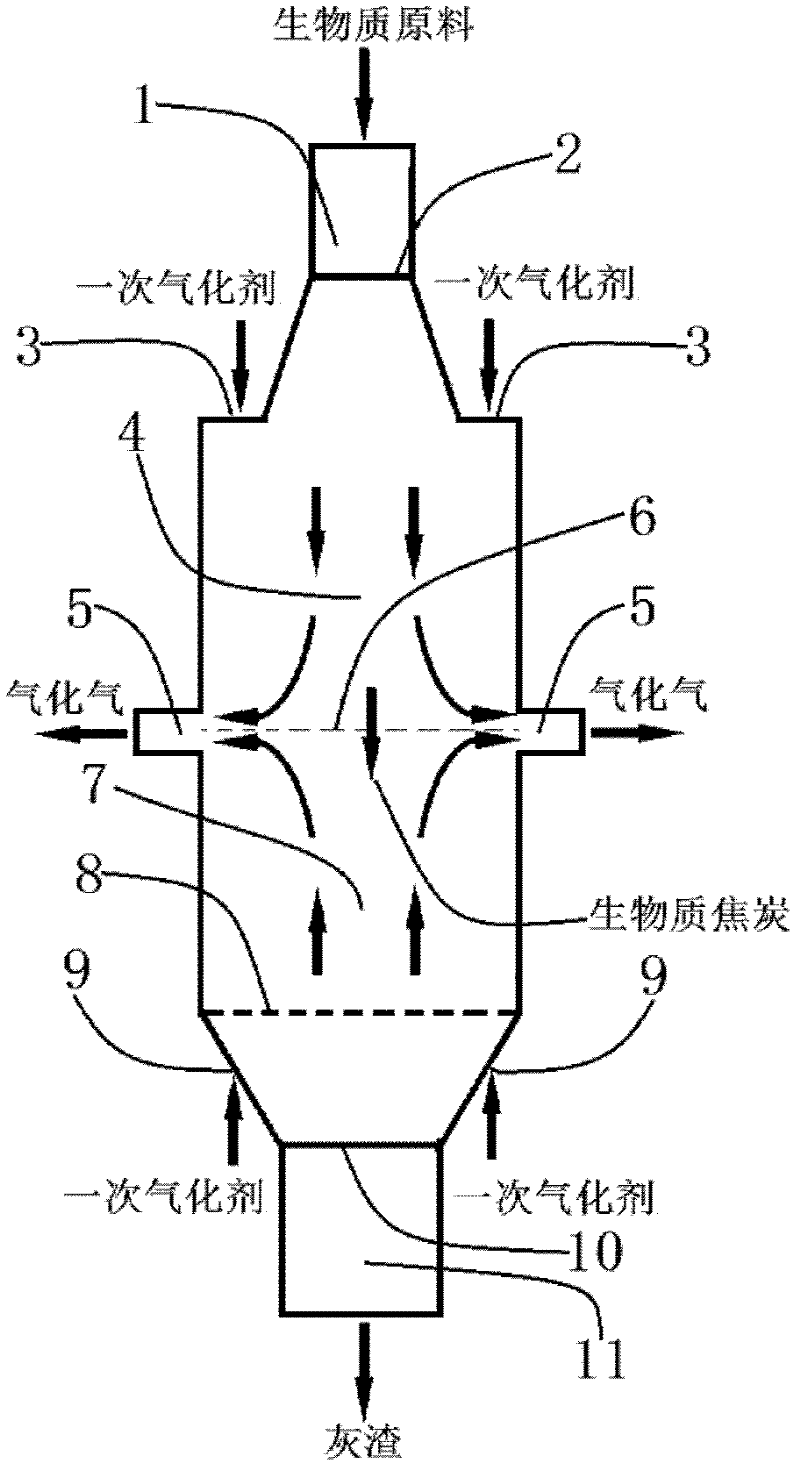

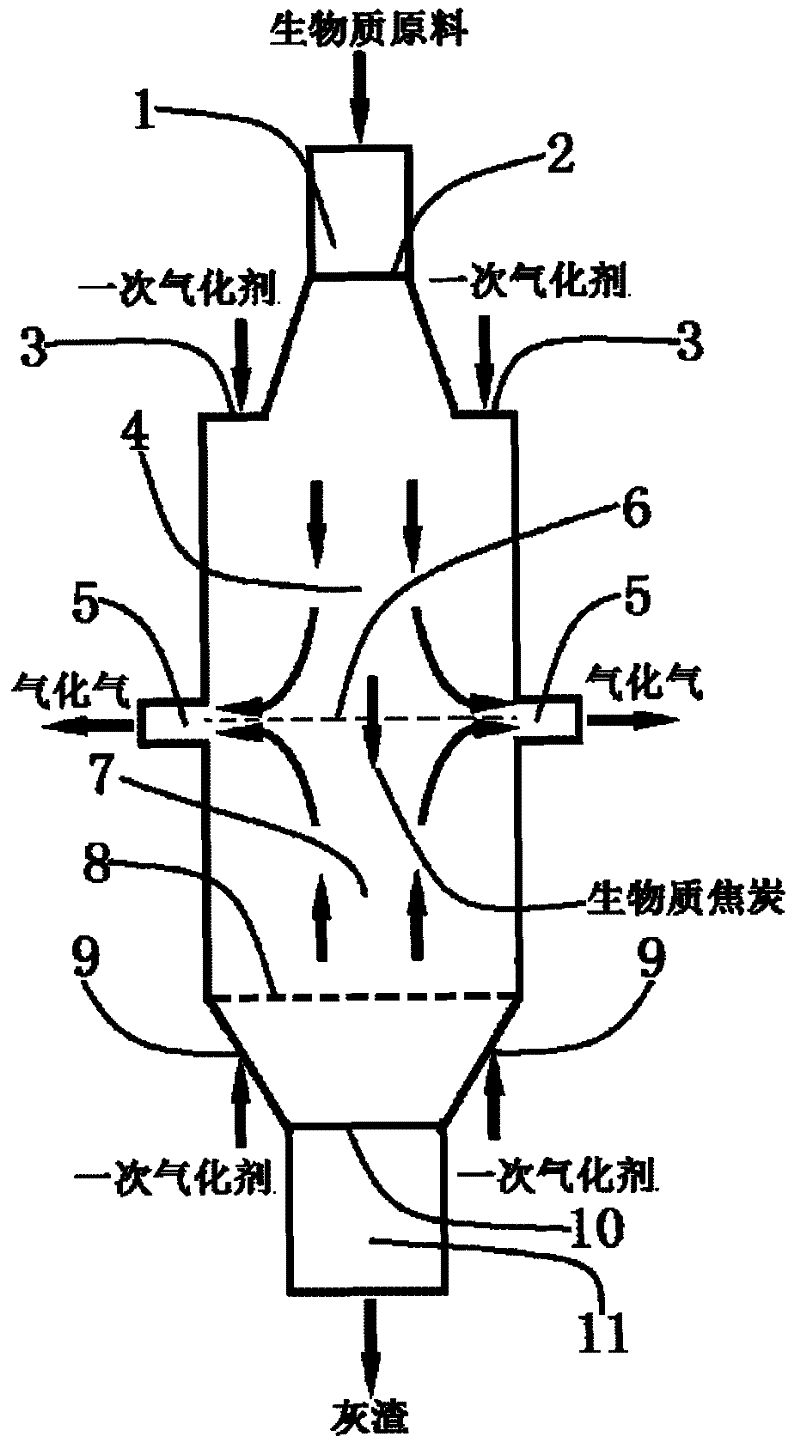

Method and device for mixed flow type gasification of biomass

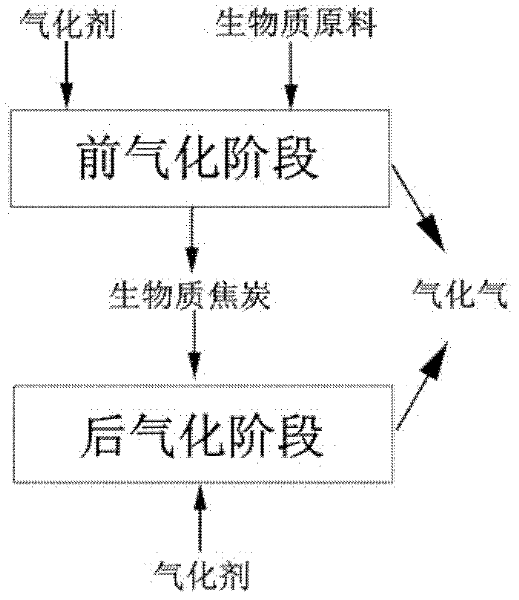

A gasification device and a mixed-flow technology, which are applied in the field of biomass mixed-flow gasification methods and devices, can solve the problems of high tar content, poor economy and low strength of downdraft gasification, etc. The effect of strong regulation ability, strong load adaptability and strong scale amplification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Wood chips with an average particle size of about 50mm are used as raw materials, and are fed into the downdraft gasification section 4 through the feeding device 1, and the feeding speed is about 300-350kg / h. Air is blown in at a flow rate of 240Nm 3 / h and 100Nm 3 / h or so. The wood chips are pyrolyzed and gasified in the downdraft gasification section 4, and the temperature in the middle of the gasification section is 730-800°C; the wood chips are converted into biomass coke after passing through the downdraft gasification section, and the unreacted biomass coke enters the The updraft gasification section continues to gasify, and the temperature in the middle of the gasification section is 750-830°C; the gas outlet temperature of the gasification process is 330-400°C, and the approximate range of each component of the gas is: 11.7-12.8vol%H 2 , 19.6~24.0vol%CO, 8.3~10.6vol%CO 2 , 1.2~1.5vol%CH 4 , 0.4~0.7vol%C 2 h m , 45.7~51.1vol%N 2 , the calorific value of ...

Embodiment 2

[0041] In the same gasification device as in Example 1, wood chips are used as raw materials, the feeding rate is about 550-600 kg / h, and the air flow rates in the up and down suction gasification sections are respectively 400 Nm 3 / h and 180Nm 3 / h, the obtained temperature distribution and gas composition are basically the same as in Example 1.

Embodiment 3

[0043] Enlarge the gasification device in Example 1, increase the feeding rate of wood chips to 1500-1600kg / h, increase the gasification agent in the same proportion as in Example 1, and other steps are similar to Example 1. The temperature distribution and gas composition obtained by gasification It is basically the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com