Process for preparing sorbic acid

A preparation process, sorbic acid technology, applied in the production process field of sorbic acid, can solve the problems of affecting heat transfer efficiency, long reaction time, high heating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

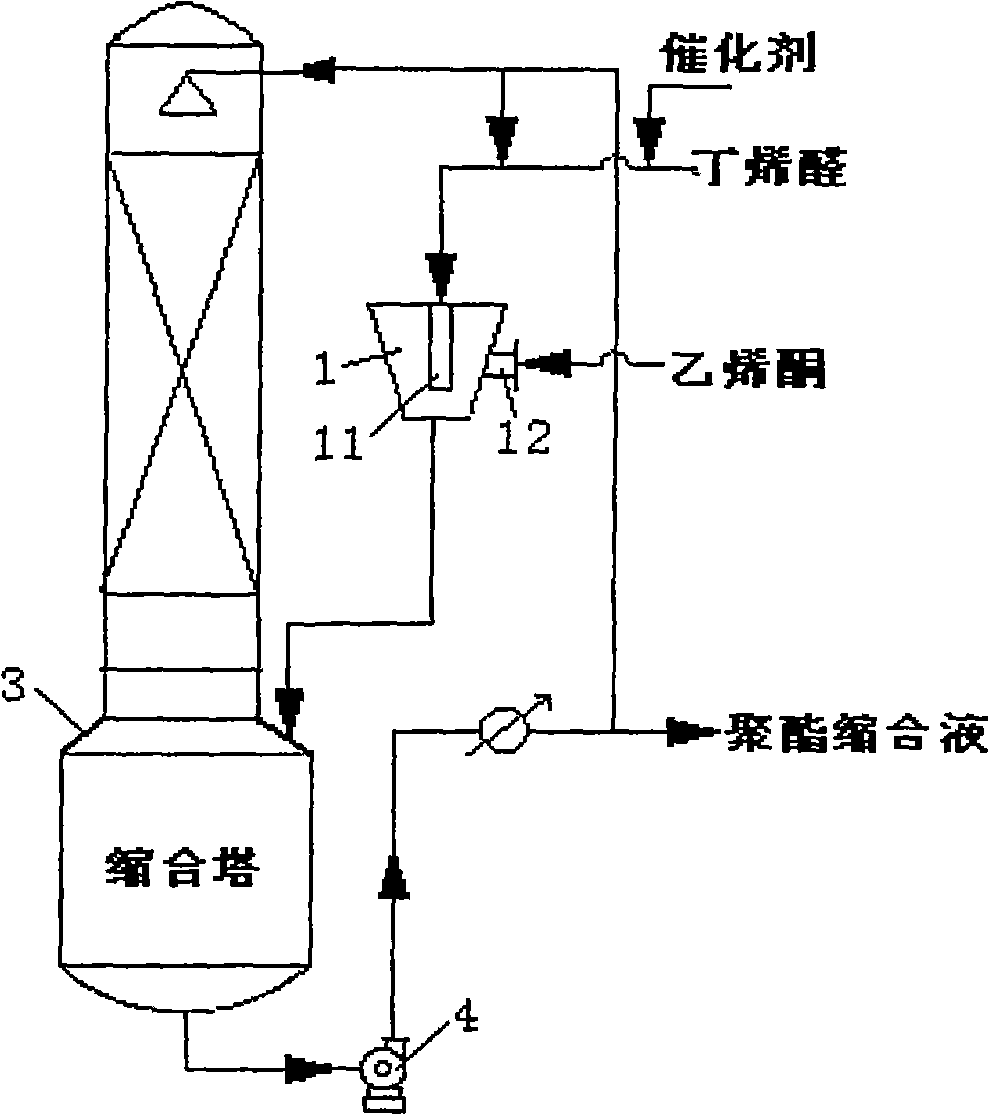

[0037] The composition of the combined polymerization reactor is as follows figure 1 shown.

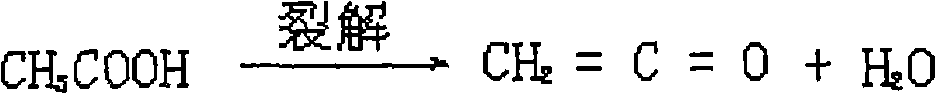

[0038] Raw material acetic acid and reclaimed acetic acid are formulated into 91.5% (volume) acetic acid solution, added in the acetic acid vaporizer with a flow rate of 700L / h, heated with steam to evaporate the acetic acid, and the formed acetic acid vapor enters the acetic acid cracking furnace, Simultaneously control weight ratio is that 0.28% triethyl phosphate (in terms of acetic acid) enters the cracking furnace together with the acetic acid vapor at the inlet of the cracking furnace pipeline by the acetic acid vapor. The temperature of the cracking furnace is controlled by DCS automatically adjusting the amount of coke oven gas burned. During the cracking process, the furnace temperature of the first stage is 783±1°C, the temperature of the second stage is 805±1°C, and the temperature of the third stage is 826±1°C, and is controlled by a vacuum pump. The vacuum degree in the ...

Embodiment 2

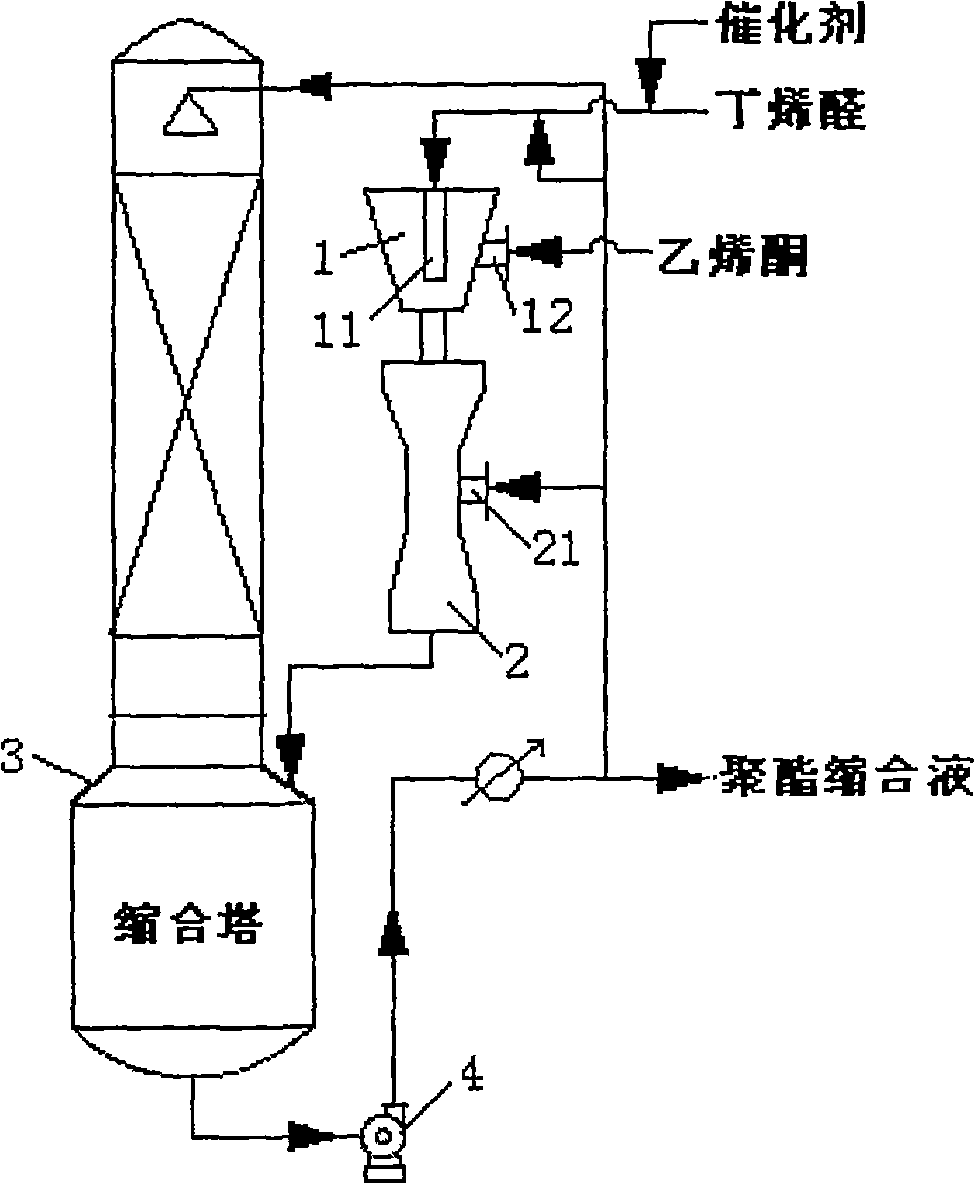

[0045] The composition of the combined polymerization reactor is as follows figure 2 shown, with figure 1 Compared with the addition of a pressurized absorption reactor 2 between the jet absorption reactor 1 and the packed tower 3, a feed liquid inlet 21 is also provided on the side of the pressurized absorption reactor.

[0046] Raw material acetic acid and reclaimed acetic acid are formulated into 91.0% (volume) acetic acid solution, are added in the acetic acid vaporizer with the flow rate of 680L / h, are heated and evaporated with steam, and the acetic acid vapor that forms enters in the acetic acid cracking furnace, while controlling the weight ratio to be 0.28% triethyl phosphate (in terms of acetic acid) enters the cracking furnace together with the acetic acid vapor at the inlet of the cracking furnace pipeline by the acetic acid vapor. During the cracking process, DCS automatically adjusts the amount of coke oven gas burned to control the temperature of the cracking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com