SNCR-SCR combined denitration system based on demercuration and deamination modified catalyst and denitration method achieved by adopting system

A technology of SCR system and denitrification catalyst, which is applied in the field of air pollutant control, can solve the problems of simultaneous removal of mercury pollutants and blockage of air preheater, achieve high zero-valent mercury oxidation efficiency, and ensure normal and stable operation , The effect of reducing the ammonia escape concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the denitrification modified catalyst layer 1 comprises the following steps: soaking the catalyst unit of the SCR denitrification catalyst layer 2 in the soaking solution for 6-12 hours, and the amount of the soaking solution is 1 m 3 The catalyst unit uses 700-800mL of impregnation solution, the impregnation solution contains at least one of copper nitrate, molybdenum nitrate and ruthenium nitrosyl nitrate, the concentration of copper nitrate is 15-35g / L, and the concentration of molybdenum nitrate is 10-20g / L and the concentration of ruthenium nitrosyl nitrate is 10-25g / L, take it out and filter it dry, put it in a calciner and dry it at a temperature of 100-120°C for 10-15h, then roast it at a temperature of 400-500°C for 4-6h, and finally A denitrification modification catalyst layer 1 containing at least one of 1.5-2.5% Cu, 0.8-1.2% Mo and 0.8-1.2% Ru metal elements is obtained, and the existing forms are CuO, MoO3 and RuO 2 .

[0047] T...

Embodiment 1

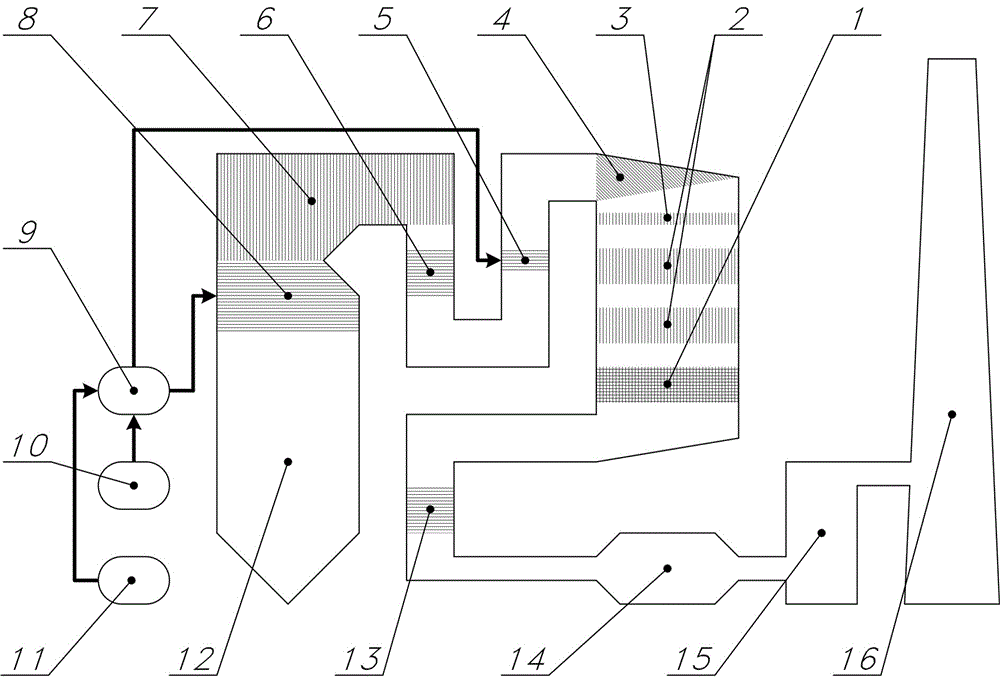

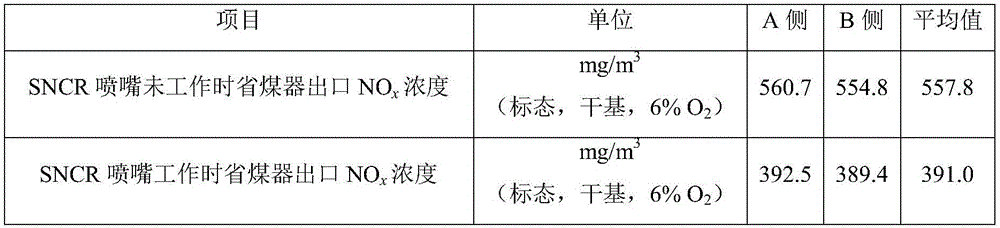

[0067] The denitrification system of a 600MW unit in a coal-fired power plant was upgraded to transform the original SCR denitrification system into an SNCR-SCR combined denitrification system, and in the original two-layer SCR denitrification catalyst layer, the catalyst unit of the bottom catalyst layer After being treated with nitrate impregnation solution and modified after roasting, the denitration modified catalyst layer is obtained, so that the denitration system becomes a form of one layer of SCR denitration and denitration catalyst layer + one layer of denitration modified catalyst layer.

[0068] The preparation method of the denitrification modification catalyst layer comprises the following steps: soaking the catalyst unit of the SCR denitration catalyst layer for 10 hours in an immersion solution, the amount of the immersion solution being 1 m 3 The catalyst unit uses 700mL impregnating solution, the concentration of molybdenum nitrate in the impregnating solution ...

Embodiment 2

[0075] The denitrification system of a 200MW unit in a coal-fired power plant was upgraded, the original SNCR denitrification system was upgraded to an SNCR-SCR combined denitrification system, and a layer of SCR denitrification and denitrification catalyst layer and a layer of denitrification modified catalyst layer were added to make the denitrification system It becomes a form of one layer of SCR denitration and denitration catalyst layer + one layer of denitration modification catalyst layer.

[0076] The preparation method of the denitrification modification catalyst layer comprises the following steps: soaking the catalyst unit of the SCR denitration catalyst layer for 10 hours in an immersion solution, the amount of the immersion solution being 1 m 3 The catalyst unit uses 700mL impregnating liquid, the concentration of copper nitrate in the impregnating liquid is 25g / L, the concentration of molybdenum nitrate is 15g / L, take it out and dry it, put it in a calciner and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com