System for desulfuration and ash removal of flue gas from steel plant sintering by ammonia method

A technology for sintering flue gas and ammonia desulfurization, applied in separation methods, chemical instruments and methods, filtration circuits, etc., can solve the problems of complex operation management, ash deposition, equipment wear and corrosion, etc., to achieve simple operation management and ensure normal operation. The effect of low production and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

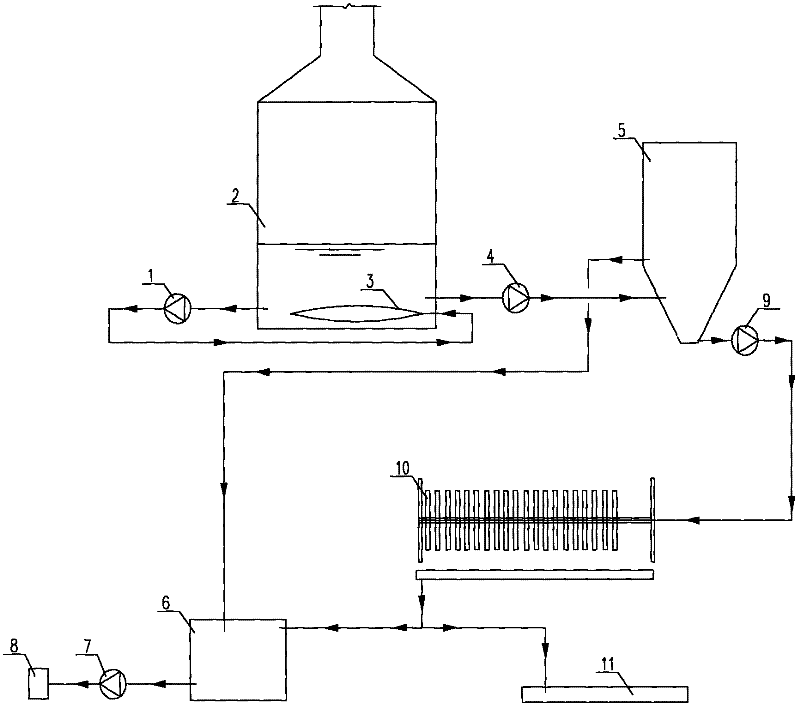

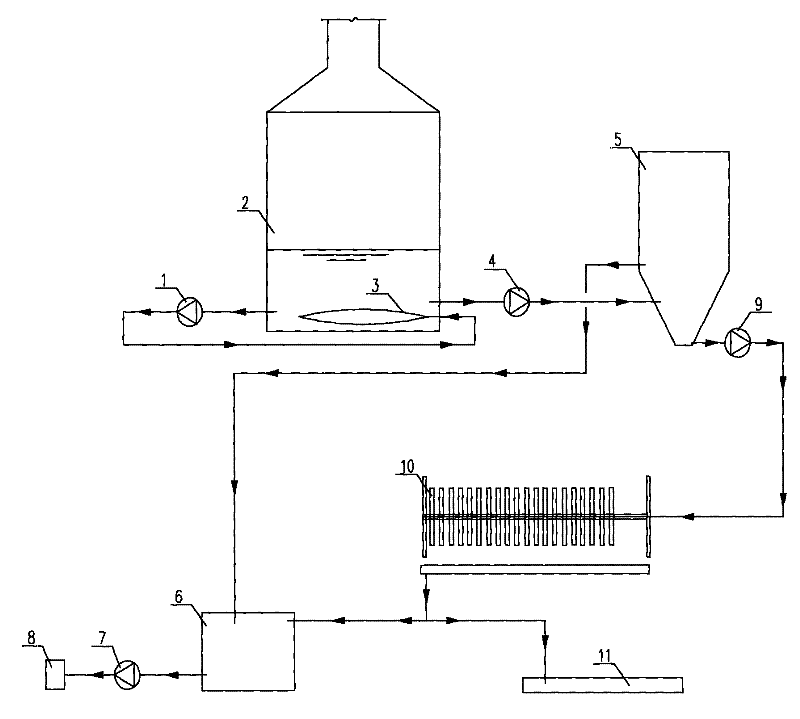

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see Attachment

[0018] Ammonia desulfurization and ash removal system for sintering flue gas in iron and steel plants. The ash removal system consists of hydraulic recoil stirring pump 1, annular stirring device 3, ash solution lifting pump 4, sedimentation tank 5, sludge pump 9, pressure Filter machine 10, intermediate lifting tank 6, intermediate lifting pump 7 are formed. The first outlet on the concentrated cooling tower 2 is connected to the inlet of the hydraulic recoil stirring pump 1 through a pipeline, and the outlet of the hydraulic recoil stirring pump 1 is connected to the annular stirring device 3 arranged at the bottom of the concentrated cooling tower 2 through a pipeline, The ring-shaped stirring device is composed of ring-shaped pipes and evenly distributed nozzles, forming a tangential circulation stirring in the concentration cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com