New correcting method and device of metal conveyor belt

A technology of deviation correction device and conveyor belt, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of weak deviation correction, belt wrinkling, cracking, etc., and achieve the effect of overcoming side deformation and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

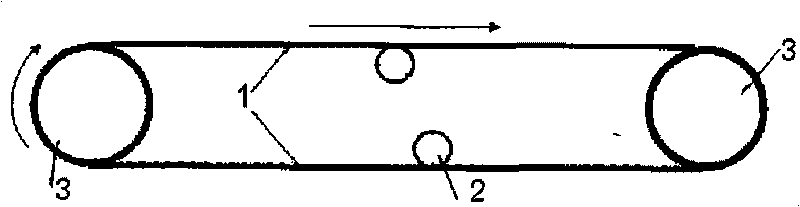

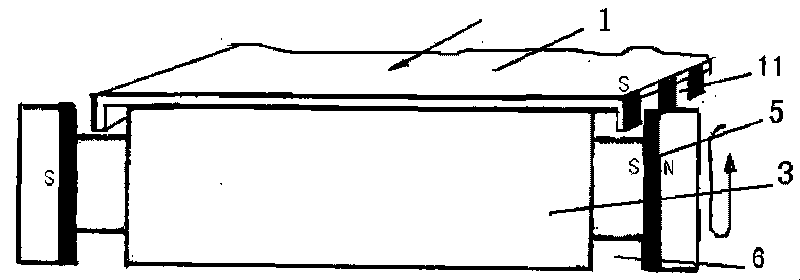

[0017] The invention is a new deviation correcting method for metal conveyor belts. figure 1 It is a schematic diagram of the operation of the metal conveyor belt. The metal conveyor belt 1 moves under the drive of the two transmission rollers 3. During the movement, the phenomenon of deviation will inevitably occur, thereby affecting the normal production. If the conveyor belt is relatively long, then 1-10 supporting rollers 2 need to be placed between the two driving rollers, and grooves 6 or flanges 7 similar to the driving rollers are also arranged on the supporting rollers 2 and a magnetic correction device of corresponding magnetism. The deviation correction method of the metal conveyor belt adopts magnetic force correction, which can reduce or prevent deviation. Magnetic correction is divided into two types: permanent magnet and electromagnetic. Be explained below in conjunction with accompanying drawing:

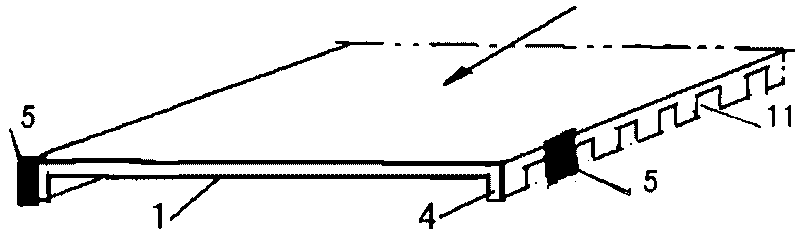

[0018] figure 2 A schematic diagram of the structure of a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com