Compact type belt conveyor

A belt conveyor, a compact technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as belt deviation, achieve the effects of preventing slipping, convenient and quick adjustment, and avoiding deviation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

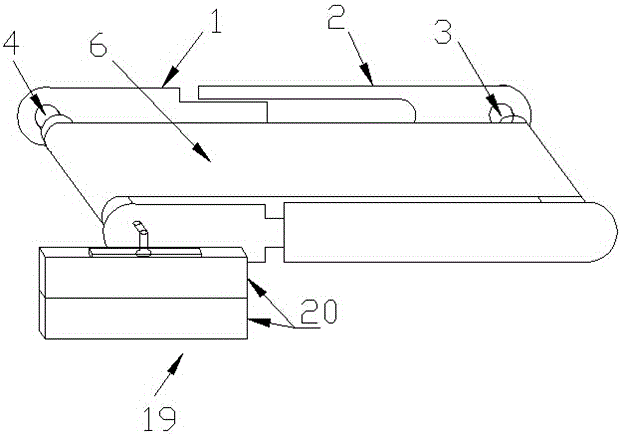

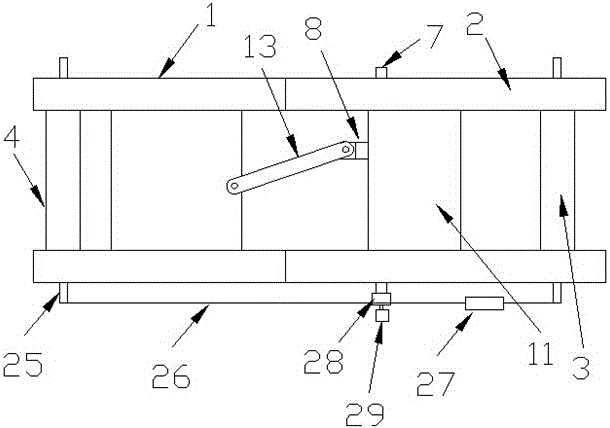

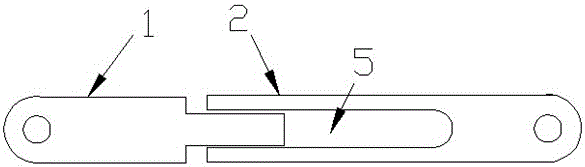

[0029] Such as Figure 1 to Figure 11 As shown, the compact belt conveyor includes a first "H"-shaped frame 1, a second "H"-shaped frame 2, a driving drum 3 and a reversing drum 4, and the second "H"-shaped frame 2 The inner surface is provided with a slide rail 5, the first "H" shaped frame 1 can slide in the slide rail 5, the driving roller 3 is arranged at one end of the second "H" shaped frame 2, and the redirection The roller 4 is arranged at one end of the first "H"-shaped frame 1, and the conveyor belt 6 is matched with the first "H"-shaped frame 1 and the second "H"-shaped frame 1 and the second "H"-shaped The frame 2 constitutes a belt conveyor; it also includes a lead screw 7 nut mechanism, and the lead screw 7 nut mechanism includes a lead screw 7 and a nut block 8 that is rotatably sleeved on the lead screw 7, and the second "H" shape The frame 2 is provided with a through hole 9 matching the diameter of the lead screw 7, and the second "H" shaped frame 2 is also ...

Embodiment 2

[0031] The only difference from Embodiment 1 is that, as Figure 12 As shown: there are two nut blocks 8 and two rods 13, and the two rods 13 are respectively hinged at the positions near the two ends in the width direction of the first "H" shaped frame 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com