Integrated storage cabinet with flexible material distribution effect

An all-in-one, storage cabinet technology, applied in loading/unloading, tobacco, food science, etc., can solve the problems of high manufacturing requirements and costs, complex storage cabinet structure, bulky and bulky structure, etc. The effect of uniformity and solving deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

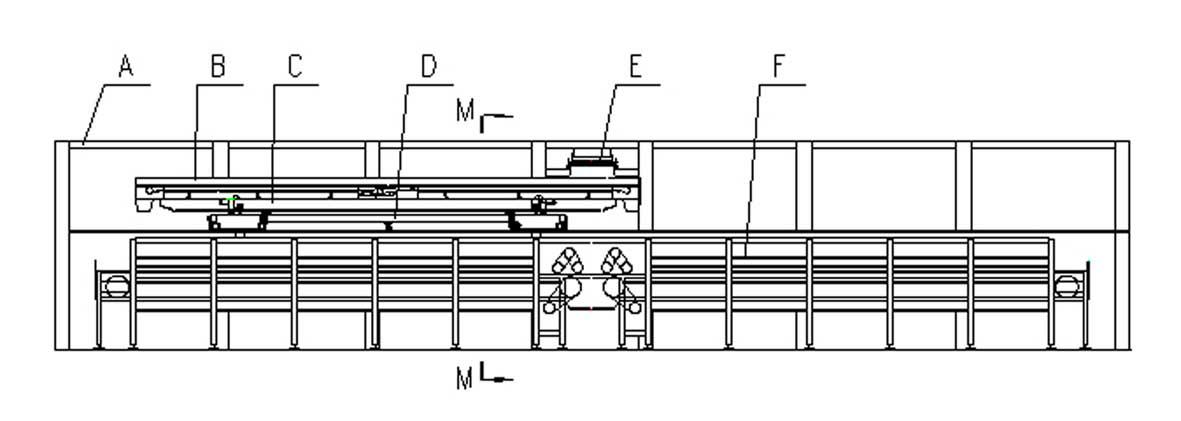

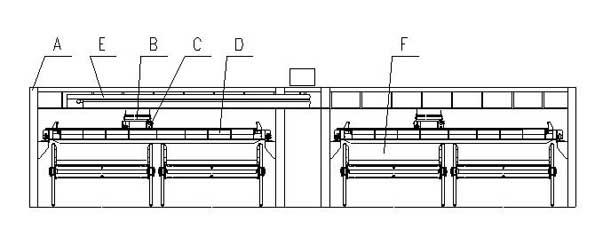

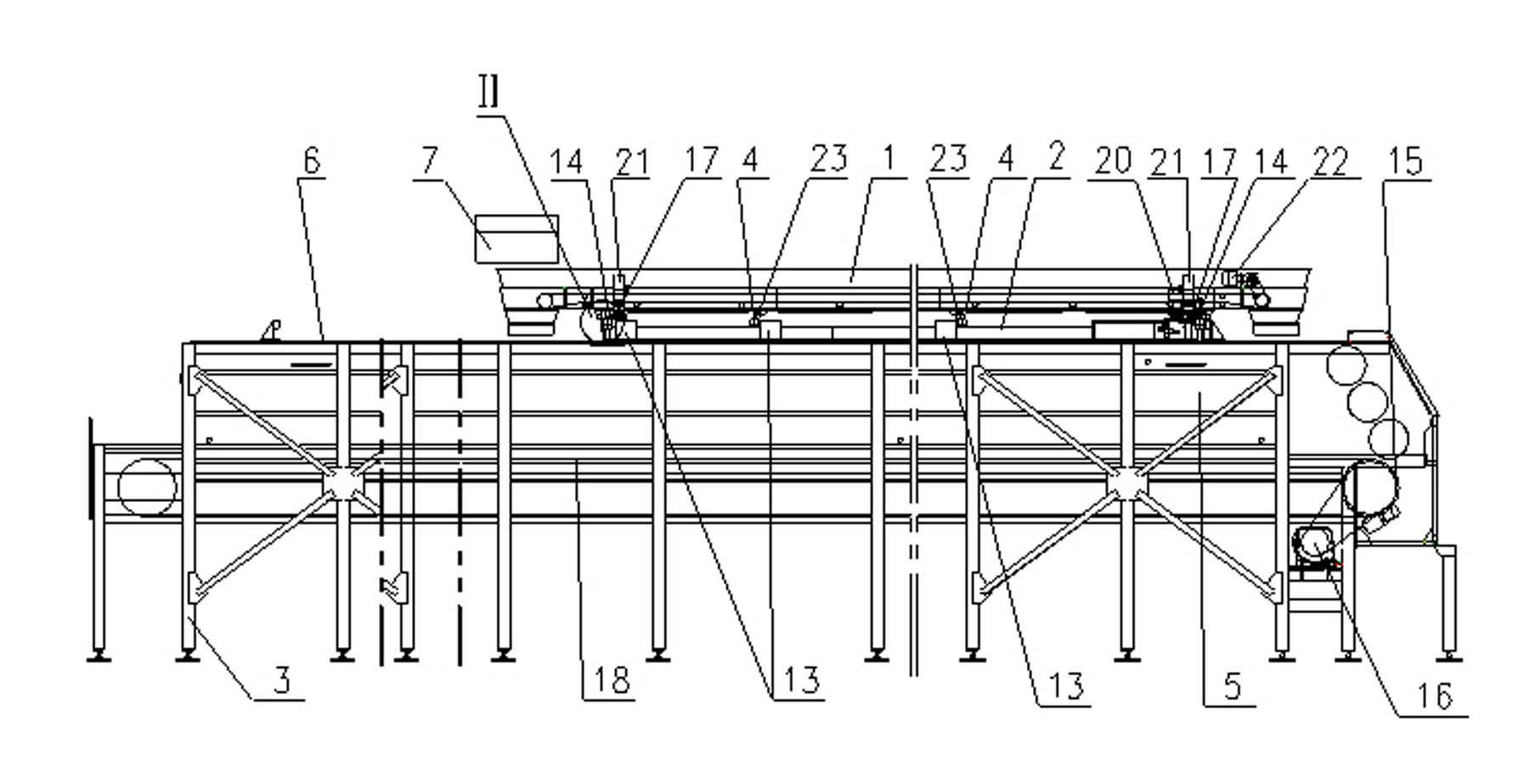

[0020] like image 3 , Figure 4 , Figure 5 As shown, the present invention includes a storage cabinet 5, a longitudinal reciprocating carriage 2 positioned above the storage cabinet and capable of reciprocating longitudinally along the storage cabinet, a transverse reciprocating carriage 1 arranged above the longitudinal reciprocating carriage 2 and capable of reciprocating laterally along the storage cabinet, and mounted on a horizontal The conveyor belt driven by the conveyor belt drive motor 22 on the reciprocating vehicle is on the inside of the storage cabinet frame 3 such as Image 6 As shown, L-shaped chain rails 18 are arranged longitudinally and symmetrically along the storage cabinet, and a conveyor chain belt 19 is installed on the chain rail. Drive the conveyor chain 11 set on the sprocket 15 to drive the conveyor chain belt 19 to run on the chain rail 18; the width of the storage cabinet 5 is 1400-5500mm, and the storage capacity of the storage cabinet is 2-60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com