Patents

Literature

34 results about "Rot-proof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rot-proof or rot resistant is a condition of preservation or protection, by a process or treatment of materials used in industrial manufacturing or production to prevent biodegradation and chemical decomposition. Decomposition is a factor in which organic matter breaks down over time. It is commonly caused by fungus, mold or mildew.

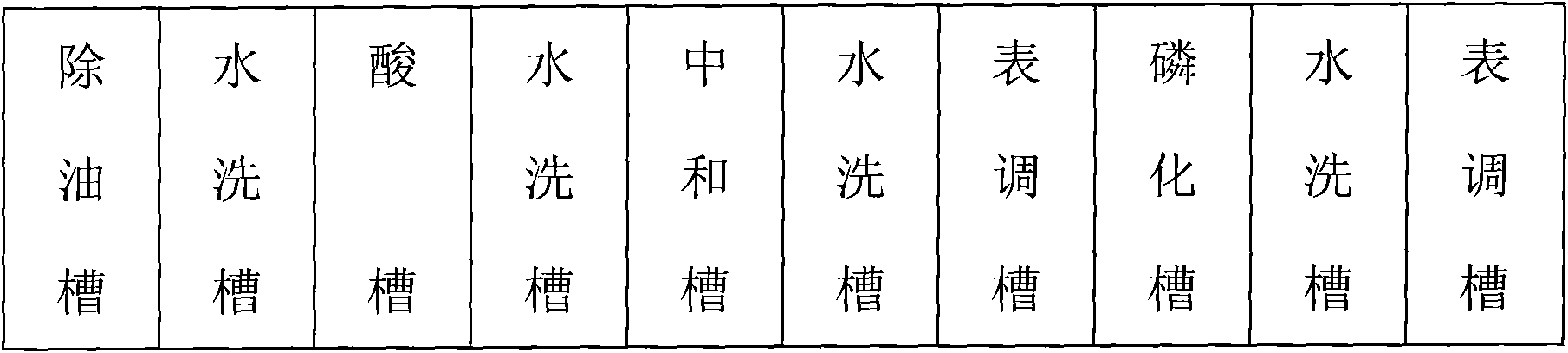

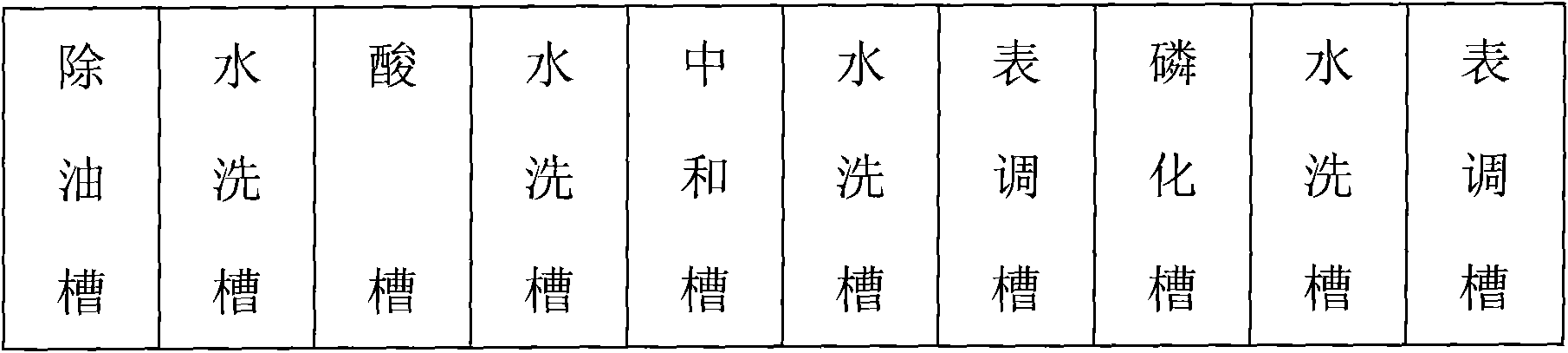

Pre-treating technique for composite metal plastic pipe

ActiveCN101671825ASolve the problem of anti-rust and anti-corrosionImprove adhesionPretreated surfacesMetallic material coating processesSteel tubeMetal

The invention discloses a pre-treating technique for a composite metal plastic pipe which pre-treats a steel tube with a parkerizing process. The treating process orderly consists of removing grease,washing with water, washing with acid, washing with water, neutralizing, washing with water, regulating surface, parkerizing, washing with water, regulating surface and drying. By pre-treating a composite metal plastic pipe with the parkerizing process, the invention not only solves the rust-proof and rot-proof problems in the middle processes of the composite metal plastic pipe, but also promotesthe adhesive attraction of the macromolecular powder doped plastic-coated steel tube. By adopting dipping mode, with simple and convenient operation, the invention can treat the worepieces with various geometrical shapes. The invention can obtain an excellent effect which the spraying and printing techniques cannot obtain. According to the characteristic of the composite metal plastic pipe, the invention optimizes the parameters in parkerizing process and detects and maintains during the pre-treating process, to ensure that the whole treating process can be finished under any condition and toensure the quality during the pre-treating process.

Owner:GUANGDONG LIANSU TECH INDAL

Single-component room-temperature industrial water crosslinked coating

ActiveCN1528835AGood physical propertiesGood weather resistanceEmulsion paintsEpoxy resin coatingsCross-linkRoom temperature

The invention provides a kind of water industrial paint which is single group multi-room cross linking. The paint uses water filming polymer as the base material, the active paint filler and the film surface modifying agent is used as the modification material, and adds in other color fillers, dispersant, antifoam agent, thickener, rot-proof and sterilization agent, filming assistant and water. The paint can form the paint film through cross linking in room temperature, it needn't heating and solidification, it has excellent film rigidity and dirt resisting performance; there can acquire three layers of film only by on time painting; the rot-proof performance is great; the construction of the product is convenient, the applied range is spread, it can upgrades the efficiency of working, saves the cost, reduces the consumption, the product has a good prospect.

Owner:广东鸿昌化工有限公司

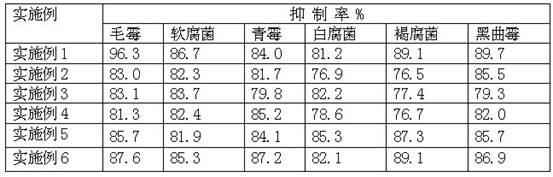

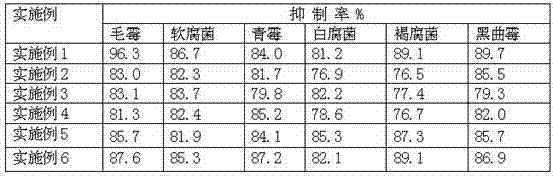

Preservative composition containing Chinese medicinal herbs and application thereof

InactiveCN102028002AInhibitory activityReduce water evaporationBiocideFood preservationMedicinal herbsDistillation

The invention relates to a preservative composition containing Chinese medicinal herbs and application thereof, belonging to the technical field of preservatives. The preservative composition is prepared by adopting the steps of: 1, weighting 0.1-0.78 percent of goldthread, 0-1 percent of the tuber of stemona, 0.1-0.84 percent of golden cypress, 0-0.58 percent of liquorice root, 0.1-1.5 percent of liquorice, 0-0.8 percent of poria cocos and 94.6-99.6 percent of water according to the weight proportion, uniformly stirring, soaking for 6-8h, heating to 110-130 DEG C, preserving the temperature for 30-50min, decocting, press-filtering, and collecting filtrate for later use; and 2, adding alcohol, which is 1.5-2.5 times the volume of the filtrate, in the filtrate, standing at a temperature of4 DEG C for 24-26h, filtering out sediment, decompressing and recycling the alcohol at a temperature of 75 DEG C, carrying out rotary distillation and condensation at a temperature of 85 DEG C until the volume is 8-15 percent of the original volume. The prepared preservative is natural and non-toxic, has no residual, good rot proofing effect on the foods, refreshing efficacy, low production cost and wide application range, and is safe in use.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Wood or bamboo rot-proof processing method

InactiveCN101856827AGrowth inhibitionPrevent mildewWood treatment detailsWood impregnation detailsChemical treatmentControllability

The invention discloses a wood or bamboo rot-proof processing method, comprising the following steps: soaking the wood, stewing the bamboo, and then steaming the bamboo. The invention has simple operation process, good controllability, low cost, easy industrialization and wide application prospect, and requires no complex chemical treatment and expensive equipment.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Wood micro charring method

The invention relates to a wood tiny charring method that the feature is sending the wood into charring kiln, taking ventilating stacking, closing the kiln gate, heating the temperature to about 80 degree centigrade, fast heating to 130 degree centigrade after the wood dry, keeping for a while until the tiny charring qualified, shutting down the heating source, cooling to below 50 degree centigrade, storing the wood. The product has large range for application. It has the advantages of moth proof, antisepsis, mould proof, little internal stress, good adaptability to kinds of weather, etc.

Owner:ZHEJIANG FORESTRY UNIVERSITY

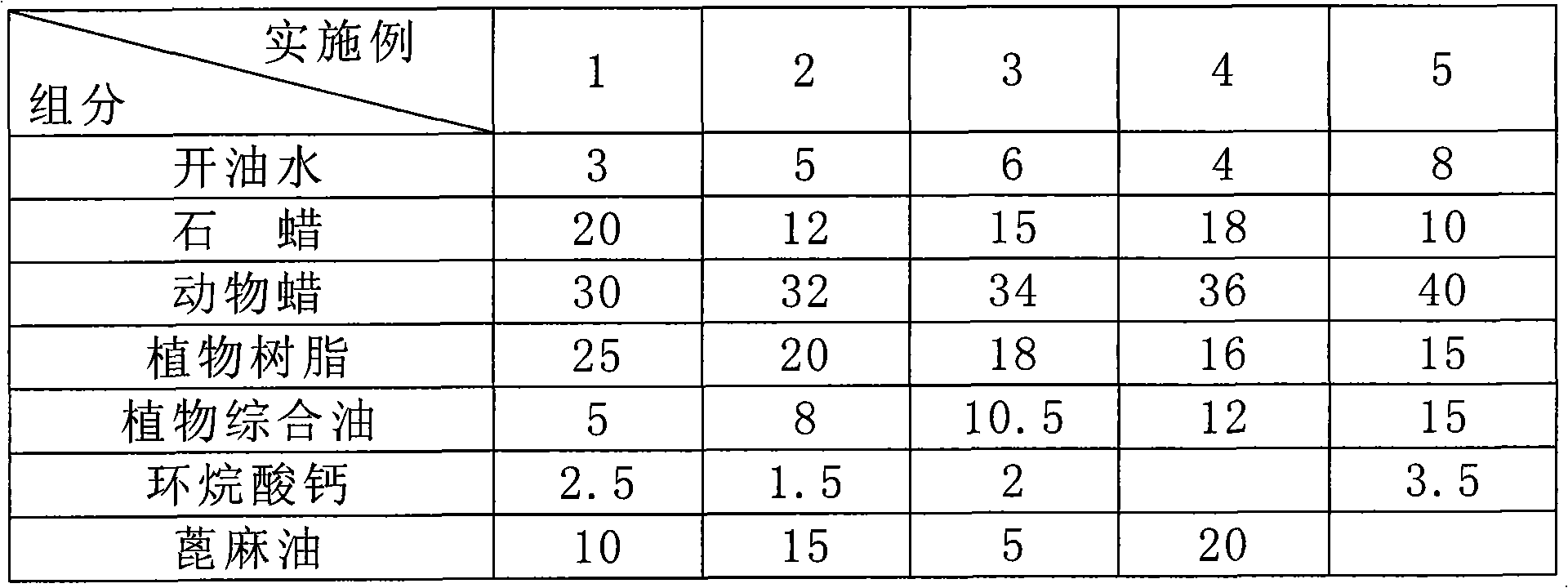

Environmental protection type wood wax oil and preparation method thereof

InactiveCN101659832AWide variety of sourcesLow priceWax coatingsNatural resin coatingsParaffin waxPropolis

The invention provides an environmental protection type wood wax oil and a preparation method thereof, belonging to the technical field of chemical products. The wood wax oil and the preparation method solve the problems that the existing wood wax oil has higher production cost, unreasonable compatibility between raw materials, and poorer uniformity after being mixed. The wood wax oil is preparedby the following components according to part by weight: 3-8 parts of boiled oil water, 10-20 parts of paraffin wax, 30-40 parts of animal wax, 15-25 parts of propolis and 5-15 parts of plant composite oil. The preparation method has simple process flow, few steps, wide raw material sources and low cost; and the prepared product has better uniformity, low toxicity, no pollution and the effects ofmould proof, moisture proof, damp proof, moth proof, surface conservation, beautification and the like.

Owner:王增平

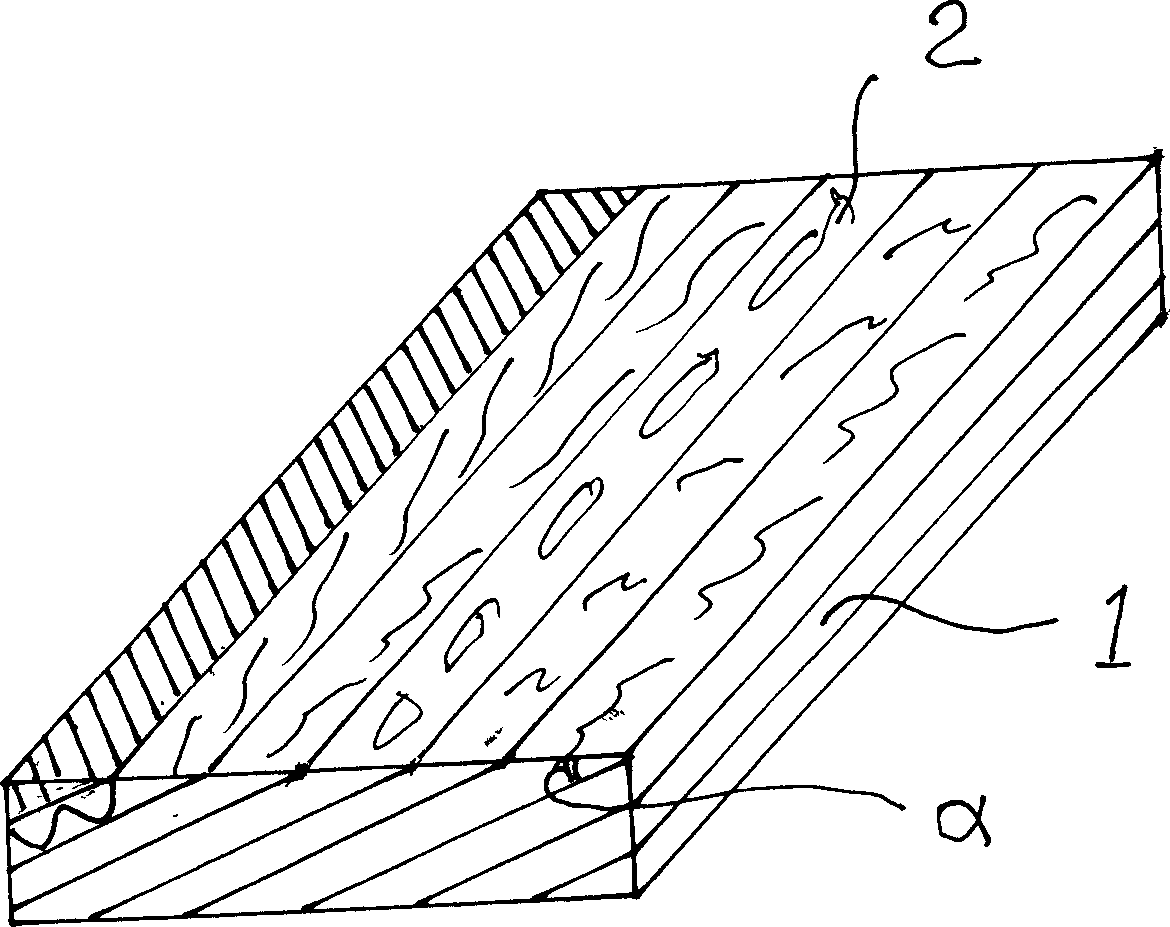

Method for producing mass material of compactness toughening veneer

InactiveCN1603075AHave densityHigh densityWood treatment detailsWood veneer joiningVacuum pumpingWood machining

The invention belongs to laminated veneer lumber technique field, discloses a method which is used to produce compactness intensification laminated veneer lumber. Its main technique features is that including manufacturing the wood to veneer sheet, drying to remove moisture, putting in the container after vacuum pumping, injecting soak, double heating vacuum, pressing overlapped assembly to forming, clipping putting into storage. The laminated veneer lumber prepared by the technique has the features that the thickness can be compressed more than ten percent; the density, hardness, strength can be increased one time; the effects of the water proof, corrosion protection, moth proof are good; and neatness of the surface manufacturing is high. The veneer lumber is manufactured along the certain angle, and can be gained the surface with woodiness figuring shape.

Owner:白世魁

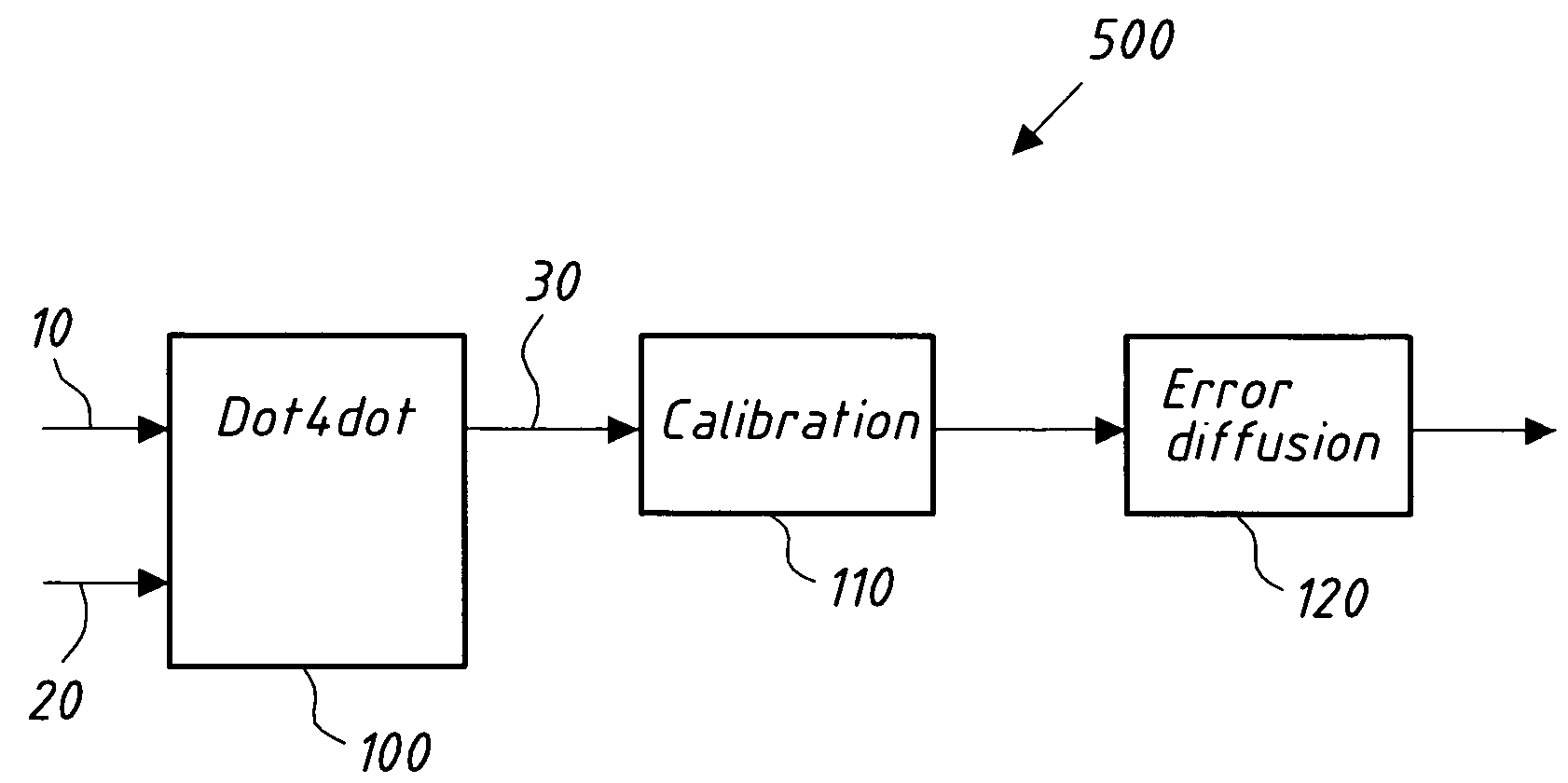

Method for making a dot for dot proof

Owner:AGFA NV

Digital workflow processes for generating product proofs

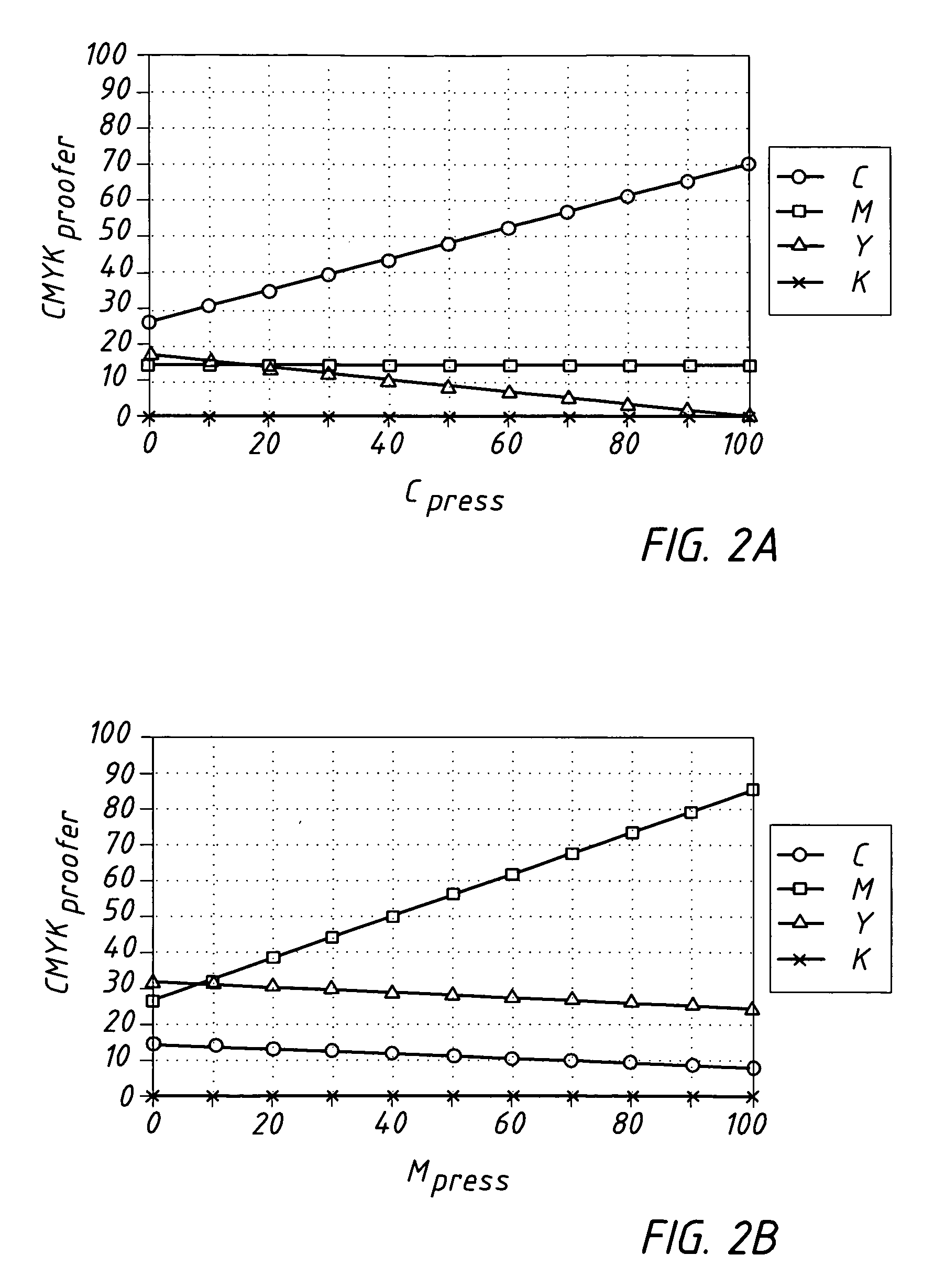

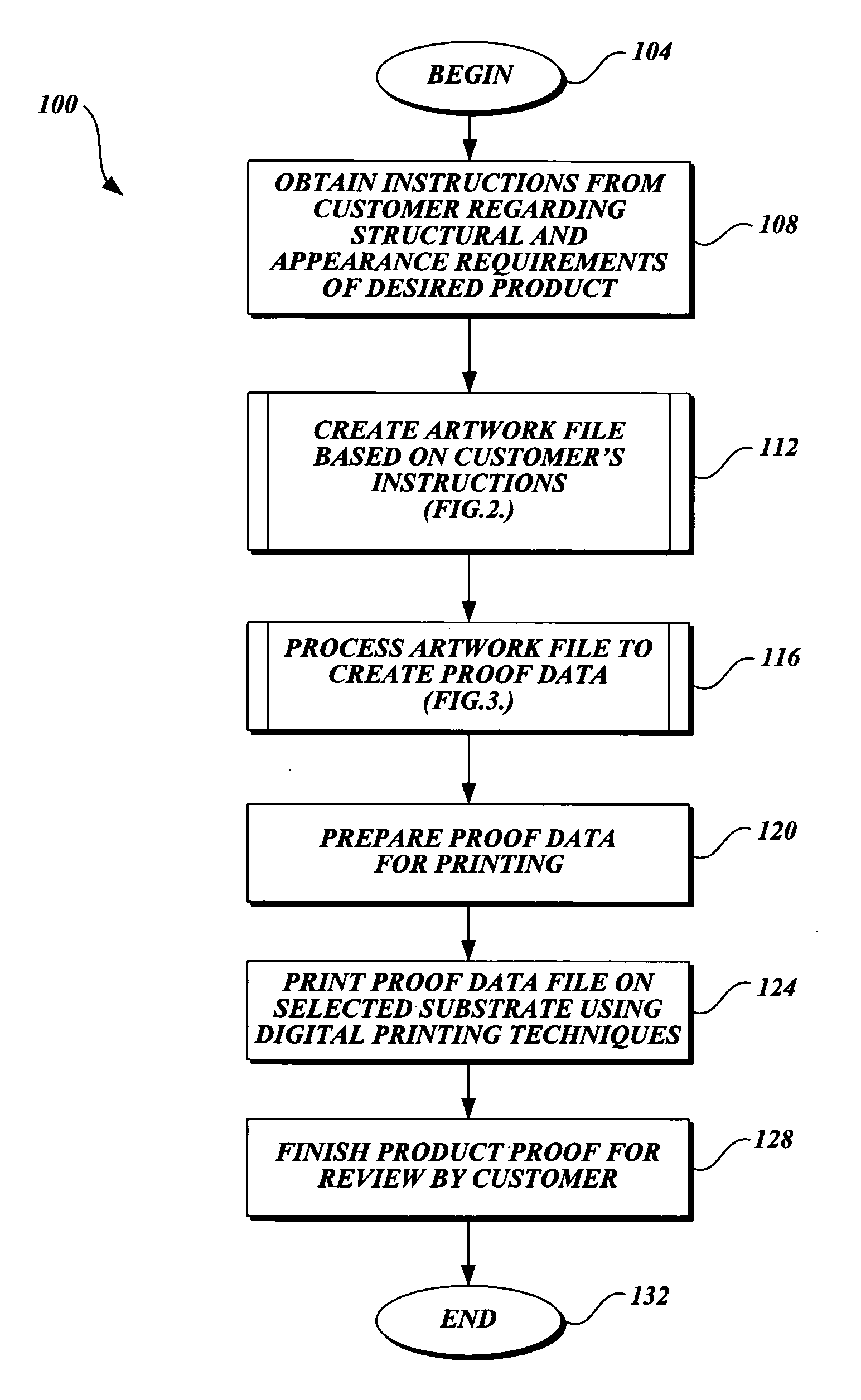

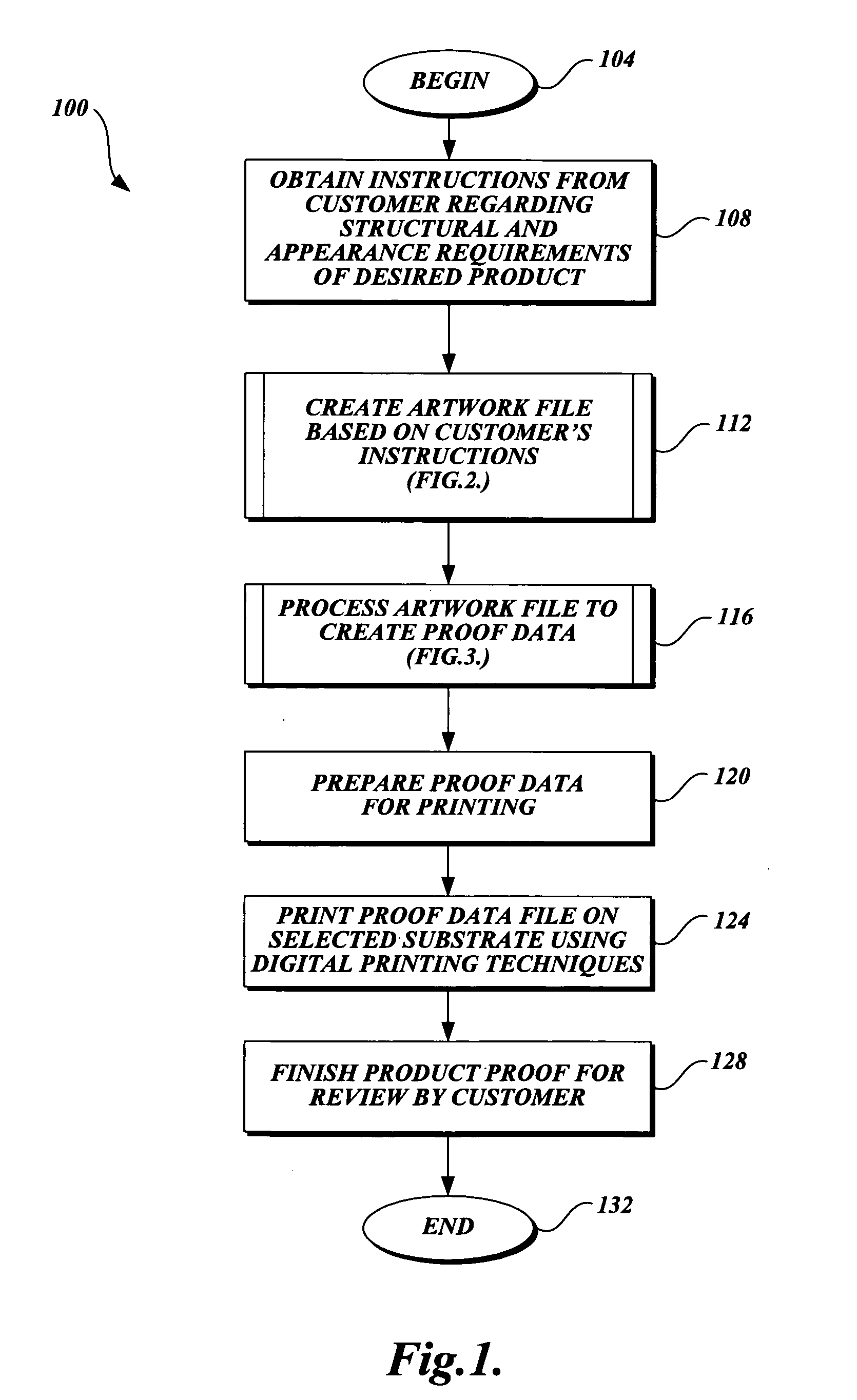

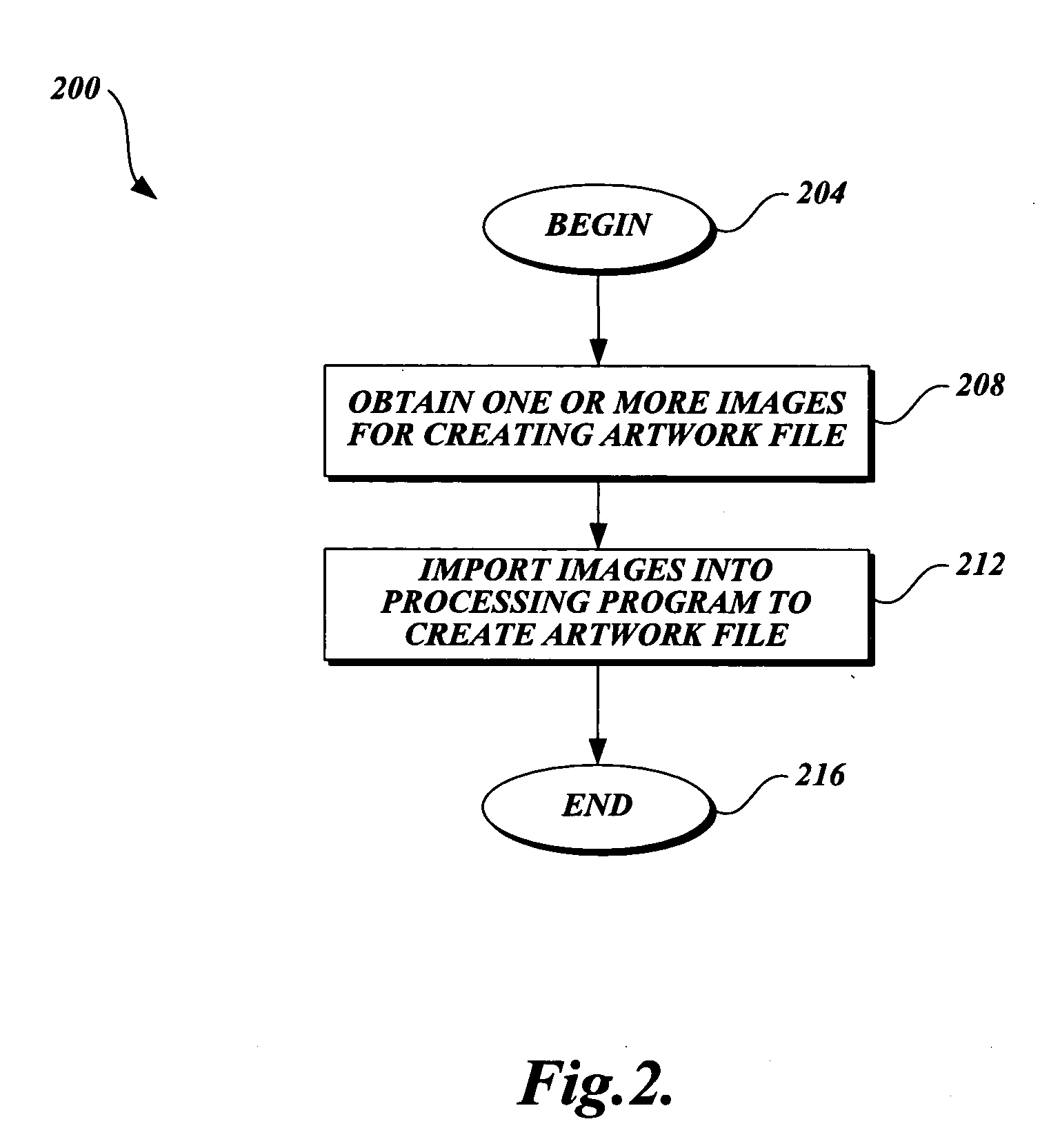

InactiveUS20070000402A1Low costLess production timePrinting press partsPictoral communicationDigital printingPrinting press

Embodiments of the present invention provide digital workflow methods for generating product proofs that achieve the benefits of digital printing, including lower costs, and less production time, while also providing an appearance that accurately resembles the final product printed on, for example, conventional contact printing presses.

Owner:INT PAPER CO

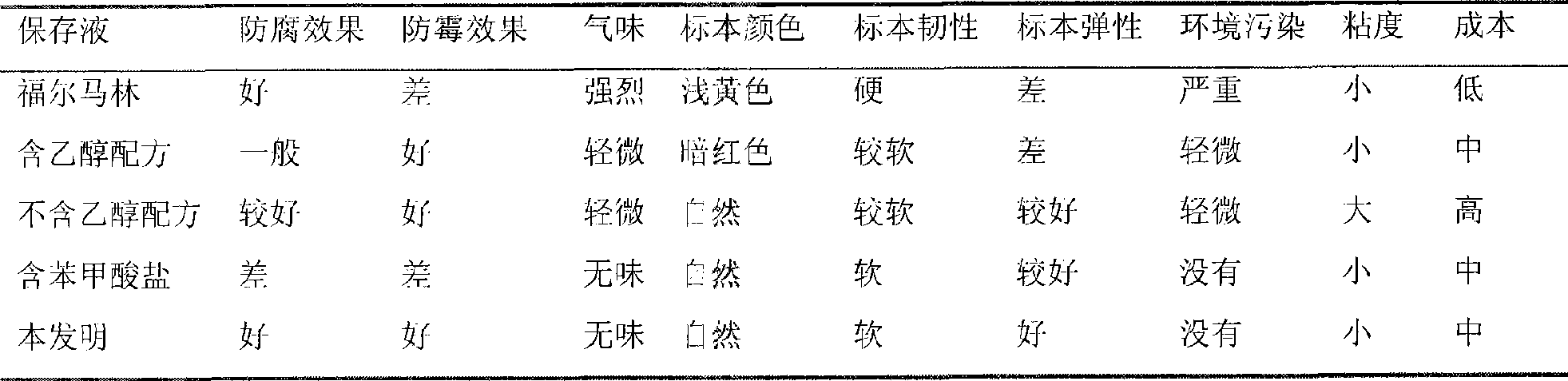

Composition for preserving cadaver sample and preparation method thereof

The invention discloses a composition for preserving corpse samples, and relates to corrosion prevention, rot resistance and preservation of corpses in medical teaching and scientific work. The composition comprises rot-proof and mold-proof active component, infiltration modifier and wetting agent, wherein the rot-proof and mold-proof active component is diacetate; the infiltration modifier is one or a mixture of two or more than two of nitrate, sulfate or hydrochloride according to any proportion; and the wetting agent is polylol. The invention also provides a method for preparing the composition for preserving the corpse samples. The method is special for preserving the corpse samples after setting treatment; the composition contains sodium diacetate, is used for preserving animal or human corpses, and can effectively solve the problems of corrosion prevention, rot resistance and preservation of the corpses; and the preservation liquid has the characteristics of long rot resistance time, good effect, no formaldehyde, safety and non-toxicity, easily obtained raw materials, and low price.

Owner:WENZHOU MEDICAL UNIV

Softening steam for treating wicker

InactiveCN104441157ASimple processing methodImprove effective utilizationBiocidePest repellentsAdditive ingredientHouttuynia

The invention provides softening steam for treating wicker and relates to the technical field of production of wicker-woven products. The softening steam is prepared through cooking the following raw material ingredients in parts by weight with water: 2-4 parts of alcohol, 3-7 parts of toilet water, 4-8 parts of boric acid, 1-3 parts of datura flower, 2-4 parts of lavandula angustifolia, 2-4 parts of cassia twig, 1-3 parts of dahurian rhododendron leaf, 3-5 parts of cordate houttuynia, 2-4 parts of jasmine flower, 4-8 parts of gardenia flower and 5-8 parts of Chinese honeylocust fruit. According to a treatment method, living wicker is treated firstly, the method is simple, insect proofing, moth proofing and mildew and rot proofing effects on the wicker are achieved, and the service lives of the wicker-woven products can be prolonged; the prepared softening steam plays a role in softening the wicker, and volatile substances contained in the steam can also be used for sterilizing and flavoring the wicker.

Owner:ANHUI HONGFU CRAFTS

Antibiosis deodorization ultraviolet-resisting and fungus-proof dressing technique for textile

InactiveCN101126199AFeel goodImprove gross effectBiochemical fibre treatmentSingeingAntibiosisUltraviolet radiation

The invention relates to the field of the after-finishing of textile products technics, in particular to an antibacterial, odor-proof, anti-ultraviolet radiation and rot proofing textile fabric of the textile fabric, including the following four steps: A: raw fabric singeing; b: routine desizing; c: cold pad-batch enzyme desizing; d: sizing treatment. The sizing classification includes the anti-ultraviolet radiation treatment and the antibacterial and rot proofing treatment. The invention adds a cold pad-batch enzyme desizing after having a routine desizing, making the treated textile fabric not only improves the handle of the textile fabric, increases the semifinished effect and restores the swelling feel of the cotton, but also has a reinforcing function to the subsequent afterfinished effect, increasing the effects of anti-ultraviolet radiation treatment and the antibacterial and rot proofing treatment. The anti-ultraviolet radiation treatment and the antibacterial and rot proofing treatment are executed separately, solving the problem that the anti-ultraviolet radiation additive and the antibacterial and rot proofing additive are incapable of being treated in the same apposition, making the textile products have a reliable and washable antibacterial and rot proofing effect and a high-efficiency ultraviolet radiation shielding effect.

Owner:谢伯清

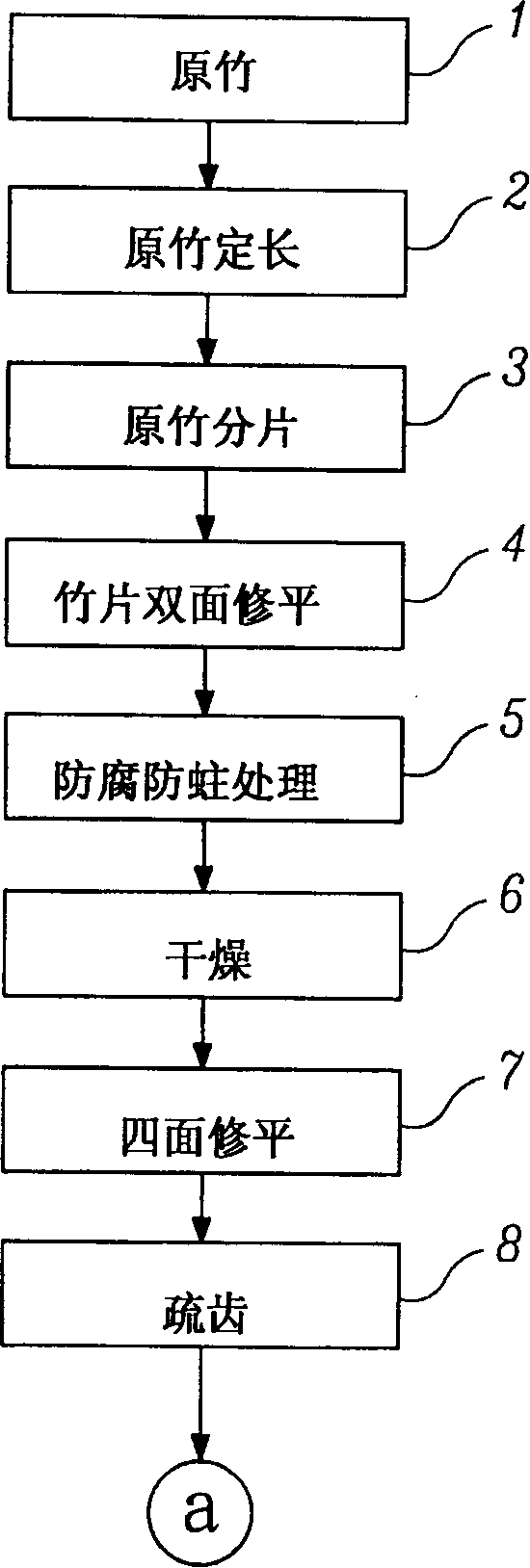

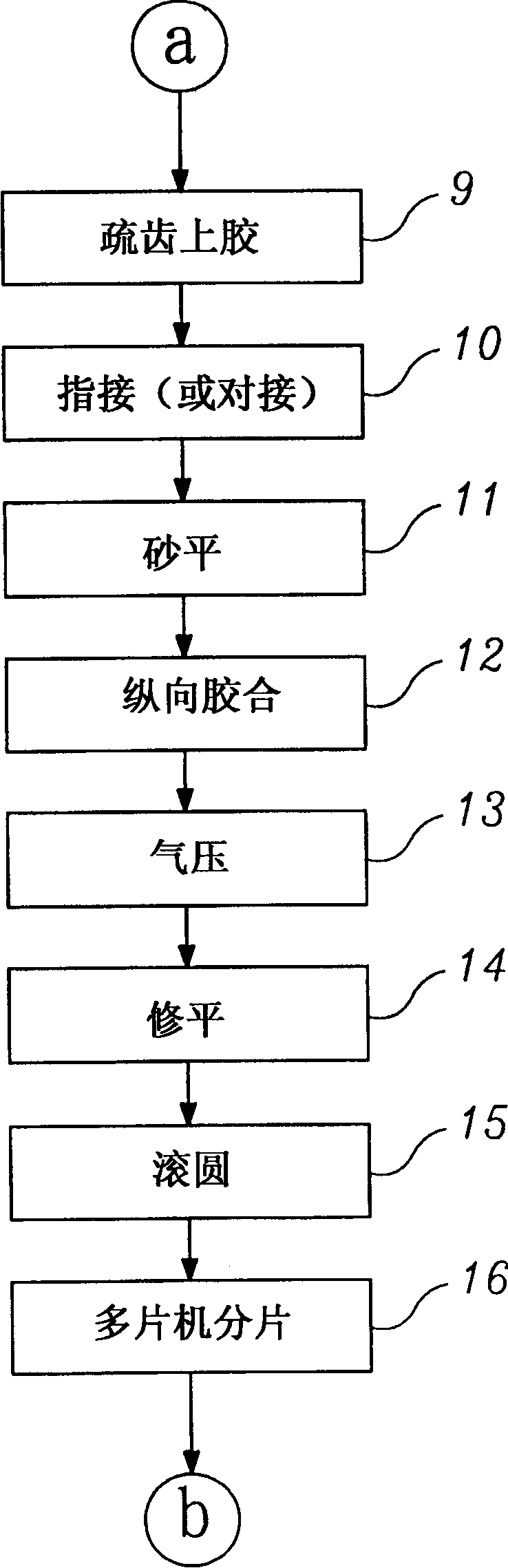

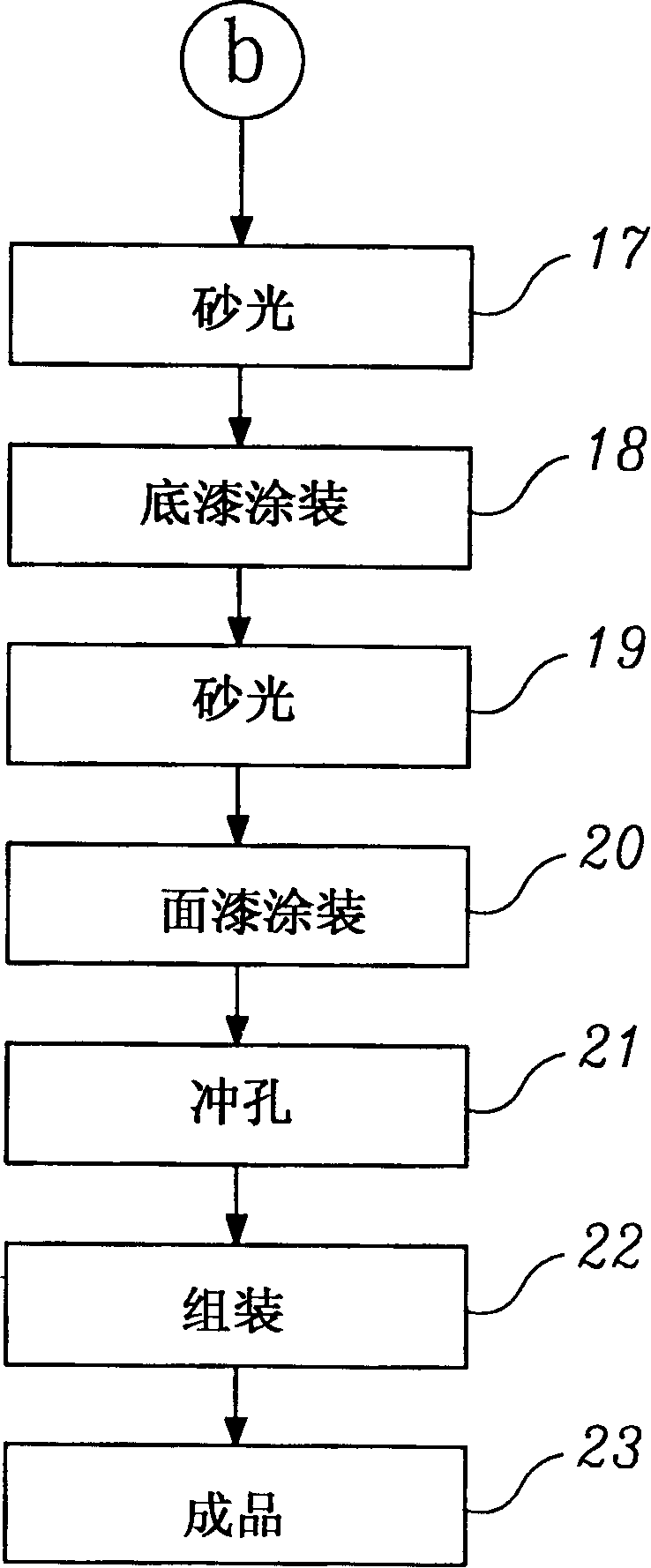

Bamboo louvre blade and its production method

InactiveCN1395021AOvercome the problem of length extensibility requirementsImprove stabilityCane mechanical workingLight protection screensEngineeringRot-proof

The present invention relates to a bamboo window curtain blade and its production method. Said method includes the following steps: selecting bamboo material, defining length of raw bamboo, spliting raw bamboo to obtain bamboo sheet, rot-proofing and moth-proofing treatment, drying, flattening four sides of bamboo sheet, joining, moulding and broaching, glueing, joint, sand-flattening, veneering, matching, sand-polishing, coating prime paint, sand-polishing and coating face paint so as to obtain the invented product.

Owner:程丰原

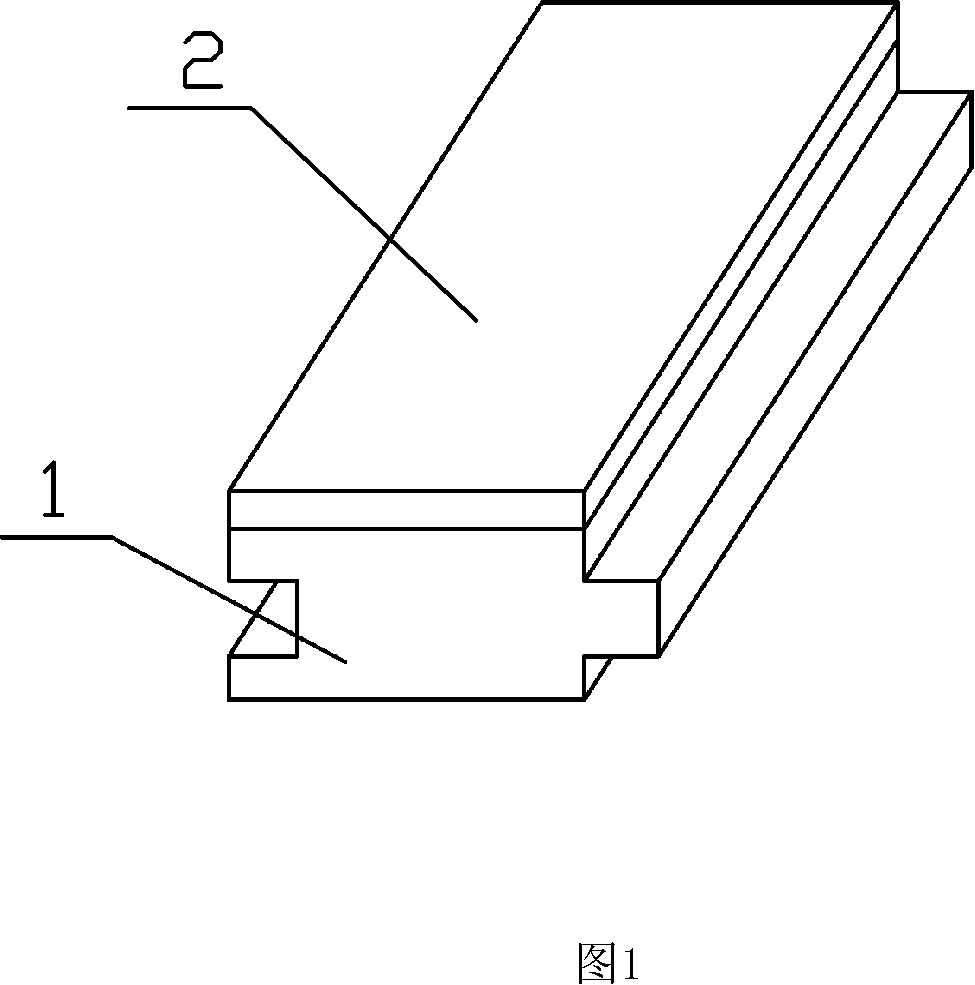

Production technology for wood-plastic water-proof outdoor floor and products produced thereby

ActiveCN101152760AHigh densityImprove waterproof performanceSynthetic resin layered productsFlooringMildewVolumetric Mass Density

The present invention discloses a wood-plastic waterproof outdoor floor production process and product. The steps are: wood is smashed into wood powder, 25 pieces to 40 pieces of wood powder and 60 pieces to 75 pieces of plastic powder are mixed and are blending modified in a blending machine to make a mixing powder. The mixing powder is added into an extrusion machine and is extruded. The extrusion temperature is from 20 DEG C to 150 DEG C, and the extrusion speed is from 130 to 170 revolutions per minute. The mixing powder is extruded by a module head and becomes a proximate matter. The proximate matter is cooled and formed. The cooled and formed proximate matter is added into a fixed-length cutting machine and is cut into finished goods. Products of the invention are formed through extrusion and are characterized in that the density is high. So the product is strong in waterproofing performance, bending resistant and stretching resistant, good in impact resisting, inflaming retarding, mothproof, mildew proof and rot proof. The product is suitable for outdoor use. The secondary processing performance of the product is good. The product has the wood processing performances of being lopped, nailed, drilled and planed and so on. The product is painting avoided and the foot sense is good. Little wood grade or quality requirement is needed in the production. The product can be completely recycled and the environmental protection effect is satisfying.

Owner:浙江永吉木业有限公司

Low-chromium type zinc-chromium coating

InactiveCN1528836AImprove corrosion resistanceImprove protectionAnti-corrosive paintsCelluloseAdhesive

The invention refers to a kind of low chrome type zinc-chrome paint, the paint is made up of three substances of A, B, C, A: B=35-45:65:55, C accounts for 0.2%-0.4% of A plus B, Cr6+ is less than 2% in paint. A is the compound of slice zinc, slice aluminium, dicarboxylic diethyl ether and alkyl radical phenol polyethylene ethyl ether. The ingredient B is made up of mixed water liquid of chrome salt and hydrogen phosphate salt, C is carboxy cellulose. The invention uses chrome salt and hydrogen phosphate salt as the double inorganic adhesives and passivant, it uses hydrogen phosphate salt to replace part of chrome salt, thus it reduces the chrome quantity of the paint. The paint has a high rot-proof performance, the chrome in paint can be decreased to microcontent, it has advantage to the environment protection.

Owner:昆明达克罗科技有限责任公司

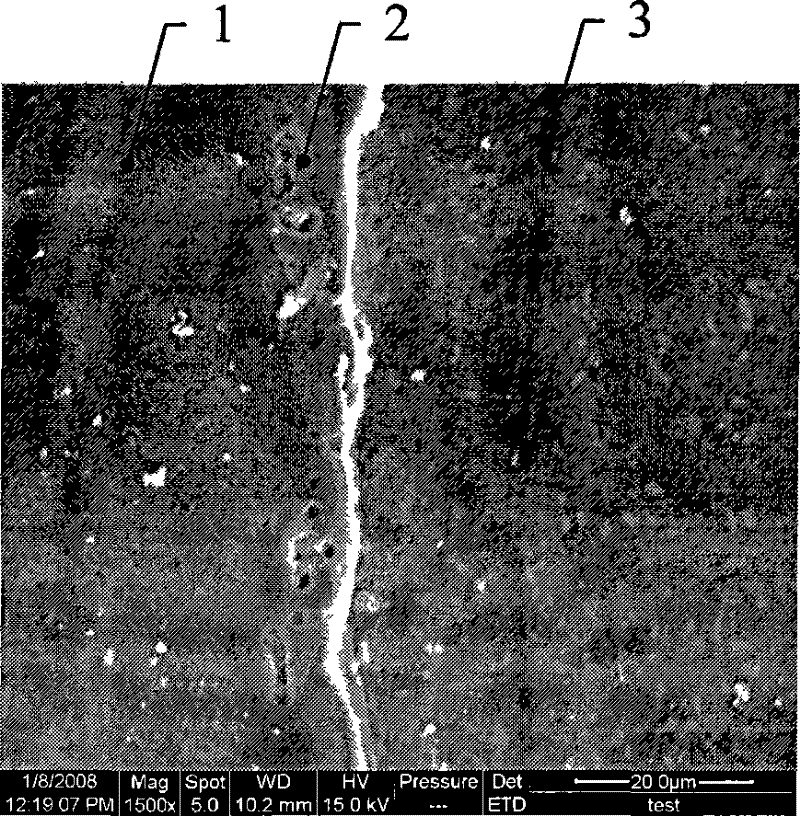

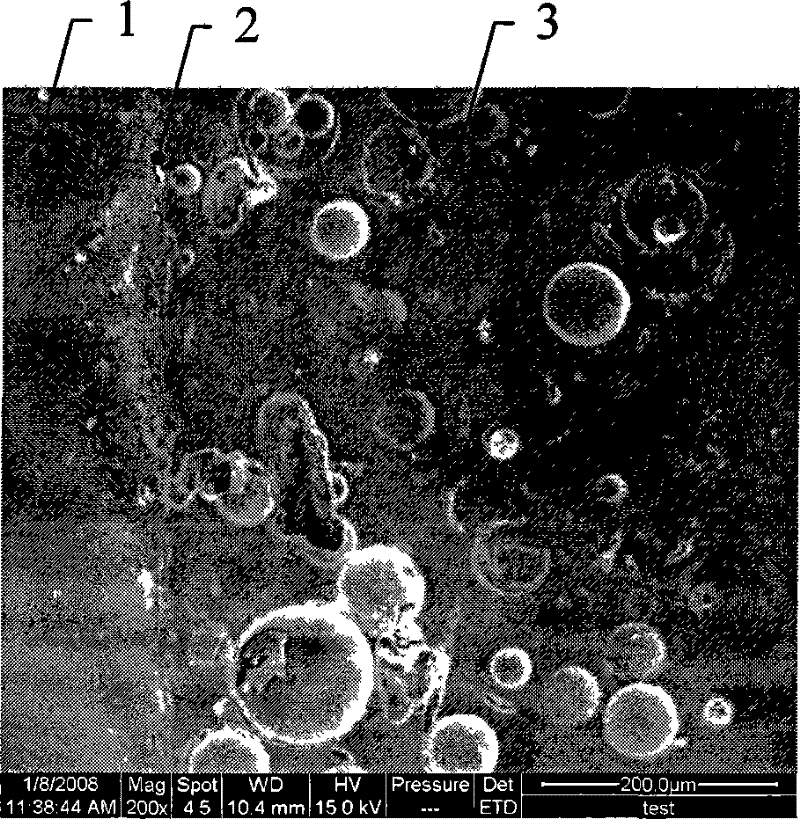

Method of preparing corrosive thermal insulation anti-ablation composite coating on light alloy surface

InactiveCN101306418BGood heat insulationImprove insulation performanceAnodisationPretreated surfacesThermal insulationSpray coating

The invention discloses a method for preparing a rot proof, heat proof, burn resistance and anti-corrosion composite coating on a light alloy surface, and relates to a method for preparing a composite coating on a light alloy surface. The method solves the deficiencies existing in the prior method for preparing the composite coating on the light alloy surface that the thermal protective performances, such as the heat proof and the burn resistance and the anti-corrosion performances, of the prepared coating are poor, or the binding force is poor, the coating is easy to scale off and out of work, and the quality and the thickness of the coating are difficult to be controlled. The method for preparing the rot proof, heat proof, burn resistance and anti-corrosion composite coating on the light alloy surface is performed according to the following steps: firstly, de-oiling and connecting; secondly, electrifying; thirdly; drying; fourthly, preparation of spray coating liquid; fifthly, coating and drying; sixthly, the repetitive operation of the step five, and thereby the rot proof, heat proof, burn resistance and anti-corrosion composite coating is prepared on the light alloy surface. The light alloy surface prepared on the light alloy surface has the properties of rot proof, heat proof, burn resistance and anti-corrosion, and the binding force of the coating and the basal body is high.

Owner:HARBIN INST OF TECH

Spot proof and removing agent for middle and low pressure boiler

InactiveCN101016422ACorrosion resistanceEnhanced descalingMechanical apparatusFurnace componentsPollutionNuclear chemistry

The invention discloses an anti-descaling powder agent for medium low pressure boiler, which comprises the following steps: compositing with sodium carbonate and humic acid sodium; allocating 45-85 wt sodium carbonate and 15-25 wt humic acid; getting the product. This invention possesses merits as follow: collecting scale prevention and conservation as one body; forming a smooth protective film in the boiler; inhibiting corrosion of oxyhydrogen molecule; setting antiscaling ratio at 90% without toxic and pollution.

Owner:任桂民

Wood or bamboo rot-proof processing method

InactiveCN101856827BGrowth inhibitionPrevent mildewWood treatment detailsWood impregnation detailsChemical treatmentControllability

The invention discloses a wood or bamboo rot-proof processing method, comprising the following steps: soaking the wood, stewing the bamboo, and then steaming the bamboo. The invention has simple operation process, good controllability, low cost, easy industrialization and wide application prospect, and requires no complex chemical treatment and expensive equipment.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

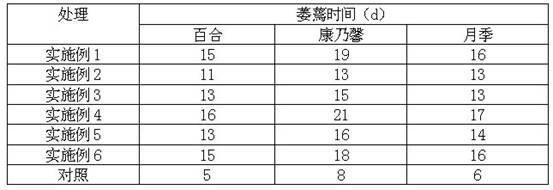

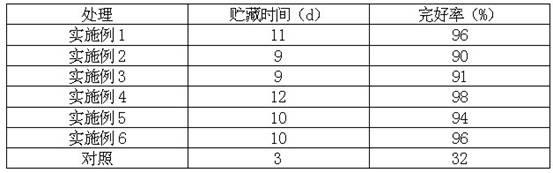

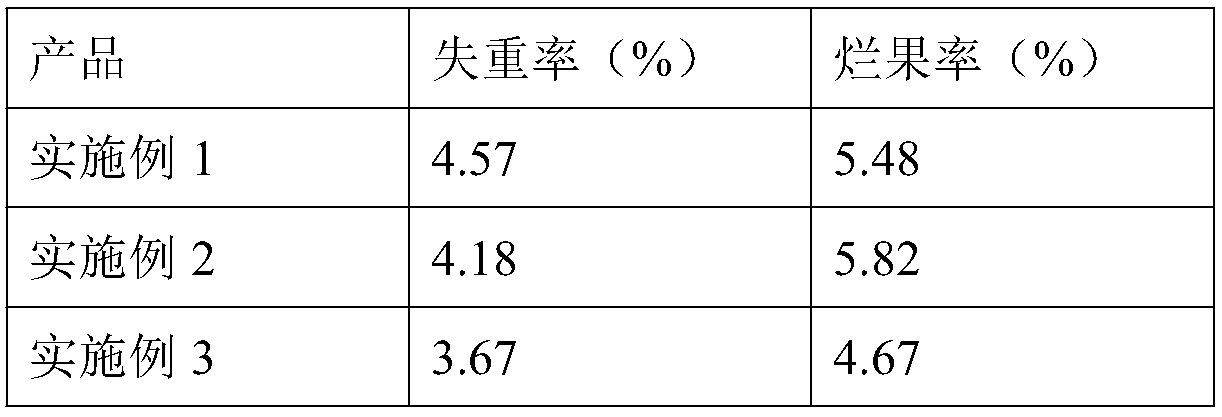

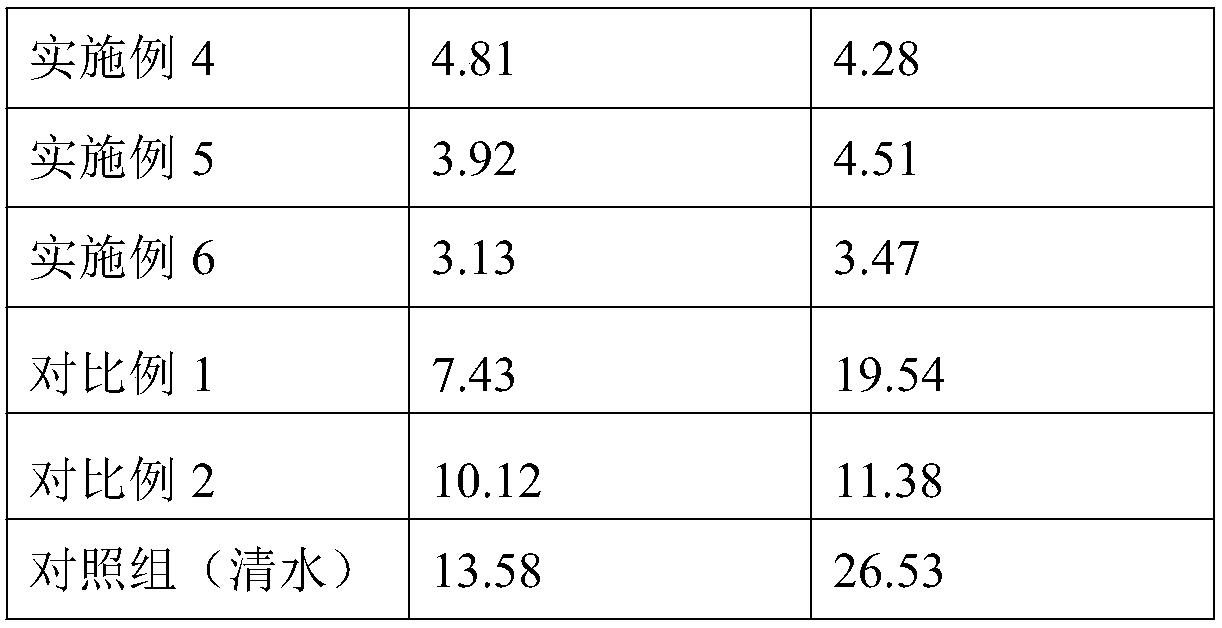

Method for prolonging preservation period of dragon fruits

InactiveCN109169875AExtended shelf lifeRespiratory suppressionFruits/vegetable preservation by coatingPreservativeMoisture

The invention discloses a method for prolonging the preservation period of dragon fruits. The method comprises the following steps: S1, picking fresh mature dragon fruits; S2, spraying the dragon fruits with a preservative; and S3, airing moisture on the surfaces of the dragon fruits and performing packaging and storing. The preservative in the method for prolonging the preservation period of thedragon fruits is prepared from multiple kinds of raw materials and surfactants with rot-proof and sterilization functions, so the preservative forms a layer of film on the surfaces of fruits, the nutritional components of the preserved dragon fruits can be preserved for a long time without loss, and the preservative has the advantages of rot-proof property, preservation, sterilization, water lossprevention, obvious preservation effects and the like and provides a better storage way for fruits.

Owner:广西海泉农业有限公司

Preservative for dragon fruits and preparation method thereof

InactiveCN109169876AExtended shelf lifeReduce lossFruits/vegetable preservation by coatingSalicylic acidCis-Butenedioic Acid

The invention discloses a preservative for dragon fruits and a preparation method thereof. The preservative for dragon fruits is prepared from the following raw materials in parts by weight: 10-20 parts of tea saponin, 1-3 parts of salicylic acid, 0.5-2 parts of tea polyphenol, 0.5-3 parts of tea tree essential oil, 1-2 parts of lemon grass essential oil, 5-10 parts of ascorbic acid, 3-5 parts ofchitosan, 3-6 parts of maleic hydrazide and 1-3 parts of konjac glucomannan. The preservative for dragon fruits is prepared from multiple kinds of raw materials and surfactants with rot-proof and sterilization functions, so the preservative forms a layer of film on the surfaces of fruits, the nutritional components of the preserved dragon fruits can be preserved for a long time without loss, and the preservative has the advantages of rot-proof property, preservation, sterilization, water loss prevention, obvious preservation effects and the like and provides a better storage way for fruits.

Owner:广西海泉农业有限公司

Pre-treating technique for composite metal plastic pipe

ActiveCN101671825BSolve the problem of anti-rust and anti-corrosionImprove adhesionPretreated surfacesMetallic material coating processesPre treatmentMaterials science

The invention discloses a pre-treating technique for a composite metal plastic pipe which pre-treats a steel tube with a parkerizing process. The treating process orderly consists of removing grease, washing with water, washing with acid, washing with water, neutralizing, washing with water, regulating surface, parkerizing, washing with water, regulating surface and drying. By pre-treating a composite metal plastic pipe with the parkerizing process, the invention not only solves the rust-proof and rot-proof problems in the middle processes of the composite metal plastic pipe, but also promotes the adhesive attraction of the macromolecular powder doped plastic-coated steel tube. By adopting dipping mode, with simple and convenient operation, the invention can treat the worepieces with various geometrical shapes. The invention can obtain an excellent effect which the spraying and printing techniques cannot obtain. According to the characteristic of the composite metal plastic pipe, the invention optimizes the parameters in parkerizing process and detects and maintains during the pre-treating process, to ensure that the whole treating process can be finished under any condition and to ensure the quality during the pre-treating process.

Owner:GUANGDONG LIANSU TECH INDAL

Manufacture method of mildew-proof and rot-proof wood crafts

InactiveCN109500953AReduce moisture absorption performanceLow water absorptionRadiation/waves wood treatmentWood treatment detailsFood chainMoisture

The invention relates to the technical field of wood craft processing, and discloses a manufacture method of mildew-proof and rot-proof wood crafts. Metasequoia glyptostroboides wood is sun cured to remove the content of free water and immersed in a solution made of lotus leaves and saponin, effective components permeate into cells, an alkaline membrane can be formed in the wood to play a role ofisolating water molecules, external water molecules cannot enter the wood, a heat treatment and drying technology is further adopted, the chemical components of the treated Metasequoia glyptostroboides wood are changed, the free hydroxyl functional groups are greatly reduced, the moisture-absorbing quality and the water-absorbing quality of the wood are remarkably reduced, hemicellulose is degraded into free acid, the food chain of rot fungi is cut off, the rot resistance is improved, the compressive strength and the hardness are improved, the dispersing speed of the molecules is accelerated by using anti-mildew and rot-proof liquid at a high temperature, and a long-lasting mildew-proof effect is achieved.

Owner:嘉兴保利文化创意有限公司

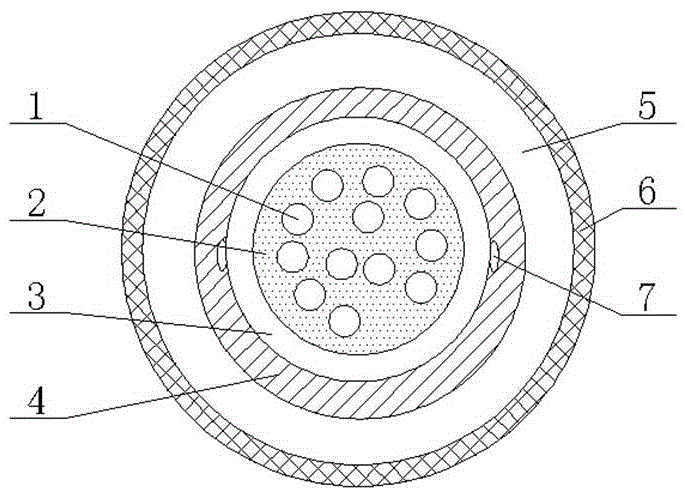

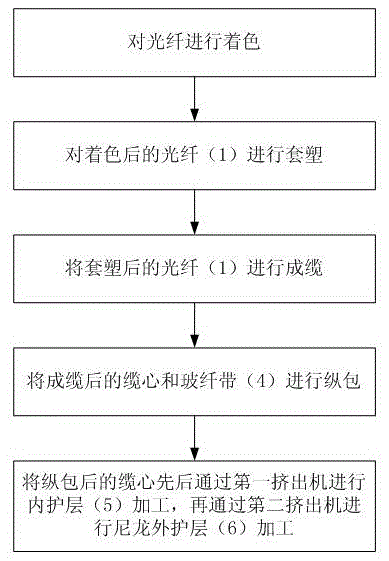

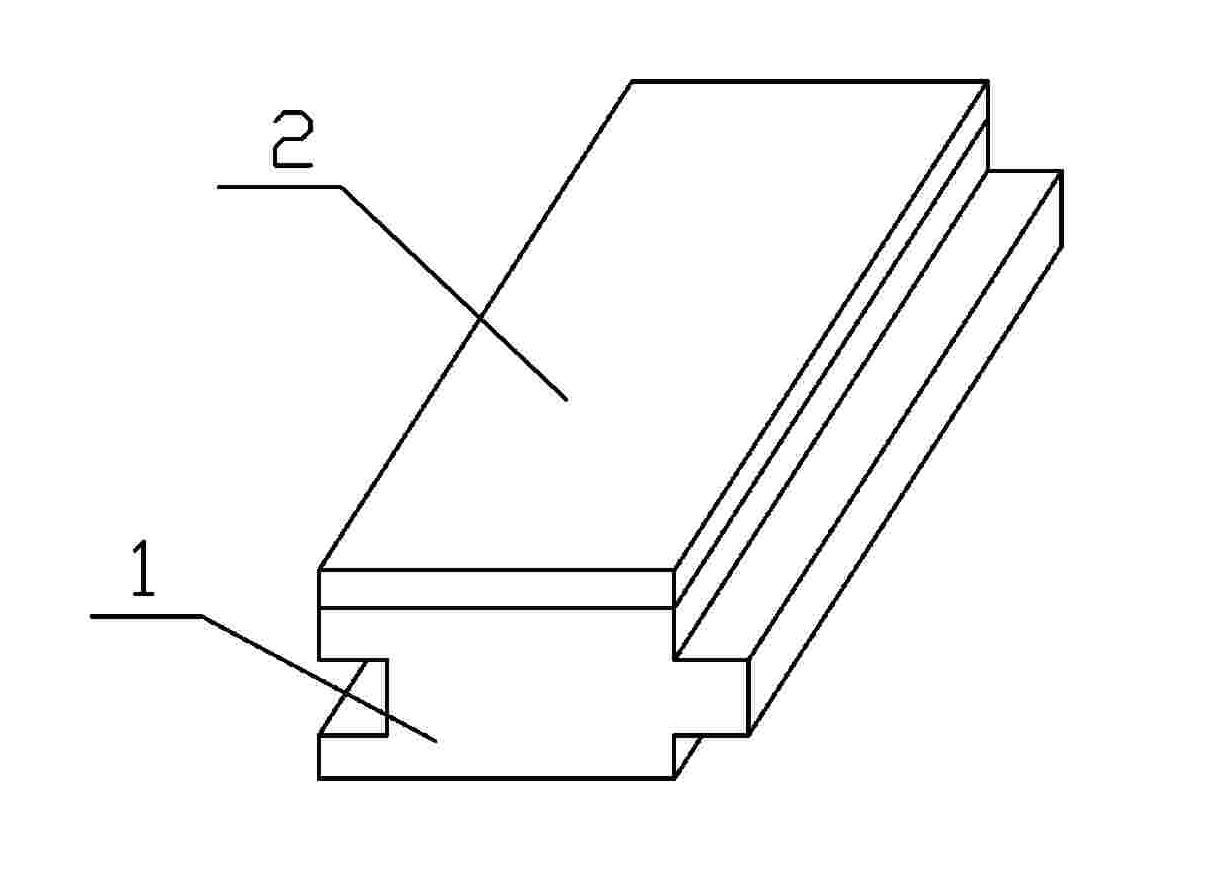

All-dielectric beam tube glass fiber band nylon anti-lighting, rat proof and anti-termite optical cable and manufacture method

The present invention discloses an all-dielectric beam tube glass fiber band nylon anti-lighting, rat proof and anti-termite optical cable. The all-dielectric beam tube glass fiber band nylon anti-lighting, rat proof and anti-termite optical cable comprises at least one optical fiber (1), a loose tube (3), a glass fiber band (4), an inner sheath (5) and a nylon outer sheath (6); the optical fiber (1) is arranged in the loose tube (3), and casing fillers (2) are filled between the optical fiber (1) and the loose tube (3); a nonmetal reinforce (4), the inner sheath (5) and the nylon outer sheath (6) coat the loose tube in order, and a water-blocking yarn (7) is arranged between the loose tube (3) and the glass fiber band (4). An all-dielectric structure is employed, good shielding is provided for the thunder and the heavy current, and the safety and the practicality are very high.

Owner:成都亨通光通信有限公司

Rot-proof ointment for fruit tree incision

Disclosed is a rot-proof ointment for a fruit tree incision, which comprises the following components: by weight, 150 grams of lard, 100 grams of beeswax, 100 grams of rosin, two vials of 800 thousand-unit penicillin, 100 grams of alcohol, and one bottle (20 ml) of pinene. The rot-proof ointment for the fruit tree incision employs no arsenic-containing preparation so that the rot-proof ointment is non-toxic and does not produce damage on the body if being consumed by people. In addition, the raw materials used in the rot-proof ointment are low in price. Experiments show that the rot-proof ointment has good effect on treating rot diseases, thereby having broad market application prospect.

Owner:李三济

Antisepsis and antistaling agent for mango as well as preparation method and use thereof

InactiveCN101480202BReduce usageInhibition of transpirationFruit and vegetables preservationSucroseDisinfectant

The invention relates to a mango preserving technology. In order to achieve integrative pre-plucking and post-plucking preserving effect, the invention comprises four composite preserving pretreatment measures of disinfectant and calcium fertilizer spraying before mango plucking and heat treatment, rot-proof film-coating preservative treatment and ethylene inhibitor treatment after the plucking. The rot-proof film-coating preservative comprises 0.25 percent to 2 percent of glucomannan or / and 0.25 to 2 percent of CTS with 95 percent degree of deacetylation, 0.1 to 1 percent of sucrose fatty acid ester or / and 0.1 to 1 percent of glycerel monostearte, 0.1 to 0.5 percent sorbitol or glycerol, 0.5 to 1.5 percent of calcium chloride or calcium citrate, 0.05 to 0.1 percent of potassium sorbate, 0.01 to 0.1 percent of one or more of the following ingredients: iprodione, Sportak and mancozeb, 0.005 to 0.01 percent of gibberellin and 0.025 to 0.05 percent of vitamin K. The invention can decrease the respiratory intensity, postpone the respiratory climacterics, delay the postripeness time and prolong the freshness period of mangos. Compared with the prior art, the freshness period of the mangos can be prolonged by 10 to 20 days.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Production technology for wood-plastic water-proof outdoor floor and products produced thereby

ActiveCN101152760BHigh densityImprove waterproof performanceSynthetic resin layered productsFlooringMildewVolumetric Mass Density

The present invention discloses a wood-plastic waterproof outdoor floor producing process and product. The steps are: wood is smashed into wood powder, 25 portions to 40 portions of wood powder and 60 portions to 75 portions of plastic powder are mixed and are blending modified in a blending machine to make a mixing powder. The mixing powder is added into an extrusion machine and is extruded. Theextrusion temperature is from 20 DEG C to 150 DEG C, and the extrusion speed is from 130 to 170 revolutions per minute. The mixing powder is extruded by a module head and becomes a profile. The profile is cooled and formed. The cooled and formed profile is added into a fixed-length cutting machine and is cut into finished goods. Products of the invention are formed through extrusion and are characterized in that the density is high. So the product is strong in waterproofing performance, bending resistant and stretching resistant, good in impact resisting, inflaming retarding, mothproof, mildew proof and rot proof. The product is suitable for outdoor use. The secondary processing performance of the product is good. The product has the wood processing performances of being lopped, nailed, drilled and planed and so on. The product is painting avoided and the foot sense is good. Little wood grade or quality requirement is needed in the production. The product can be completely recycled and the environmental protection effect is satisfying.

Owner:浙江永吉木业有限公司

Wood micro-charring method

The invention relates to a wood tiny charring method that the feature is sending the wood into charring kiln, taking ventilating stacking, closing the kiln gate, heating the temperature to about 80 degree centigrade, fast heating to 130 degree centigrade after the wood dry, keeping for a while until the tiny charring qualified, shutting down the heating source, cooling to below 50 degree centigrade, storing the wood. The product has large range for application. It has the advantages of moth proof, antisepsis, mould proof, little internal stress, good adaptability to kinds of weather, etc.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Preservative composition containing Chinese medicinal herbs and application thereof

InactiveCN102028002BInhibitory activityReduce water evaporationBiocideFood preservationMedicinal herbsDistillation

The invention relates to a preservative composition containing Chinese medicinal herbs and application thereof, belonging to the technical field of preservatives. The preservative composition is prepared by adopting the steps of: 1, weighting 0.1-0.78 percent of goldthread, 0-1 percent of the tuber of stemona, 0.1-0.84 percent of golden cypress, 0-0.58 percent of liquorice root, 0.1-1.5 percent of liquorice, 0-0.8 percent of poria cocos and 94.6-99.6 percent of water according to the weight proportion, uniformly stirring, soaking for 6-8h, heating to 110-130 DEG C, preserving the temperature for 30-50min, decocting, press-filtering, and collecting filtrate for later use; and 2, adding alcohol, which is 1.5-2.5 times the volume of the filtrate, in the filtrate, standing at a temperature of 4 DEG C for 24-26h, filtering out sediment, decompressing and recycling the alcohol at a temperature of 75 DEG C, carrying out rotary distillation and condensation at a temperature of 85 DEG C until the volume is 8-15 percent of the original volume. The prepared preservative is natural and non-toxic, has no residual, good rot proofing effect on the foods, refreshing efficacy, low production cost and wide application range, and is safe in use.

Owner:ZHEJIANG FORESTRY UNIVERSITY

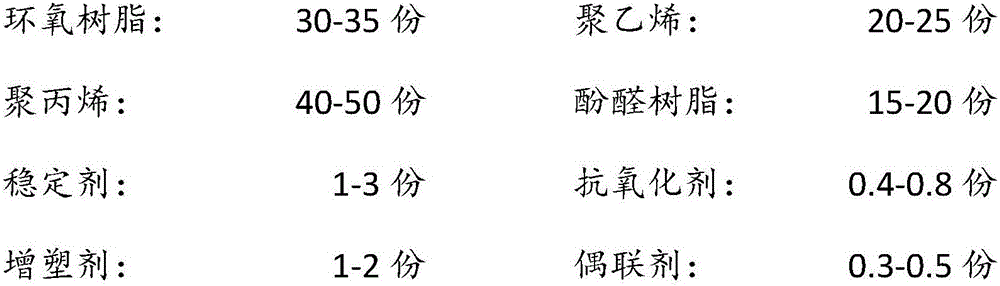

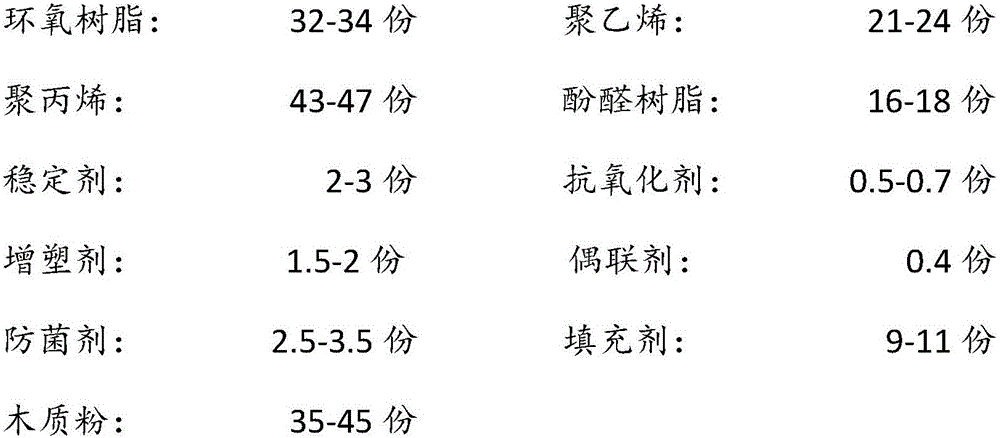

Composite material for manufacturing mildew-proofing rot-proofing door plate and preparation method thereof

The invention discloses a composite material for manufacturing a mildew-proofing rot-proofing door plate and a preparation method thereof. The composite material is prepared from the following components in parts by mass: 30-35 parts of epoxy resin, 20-25 parts of polyethylene, 40-50 parts of polypropylene, 15-20 parts of phenolic resin, 1-3 parts of a stabilizing agent, 0.4-0.8 part of antioxidant, 1-2 parts of plasticizer, 0.3-0.5 part of a coupling agent, 2-4 parts of a fungi-proofing agent, 8-12 parts of filler and 30-50 parts of wood powder. According to the composite material for manufacturing a mildew-proofing rot-proofing door plate and the preparation method thereof, the material can be used for effectively improving the problem that a domestic door plate mildews and is easily corroded, the door plate has high mildew-proofing and rot-proofing performance, the service life of the door plate is prolonged, and the quality of the door plate is ensured.

Owner:FOSHAN JUYE TECH CO LTD

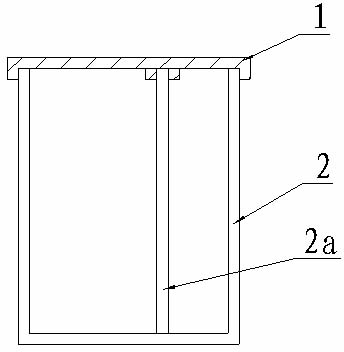

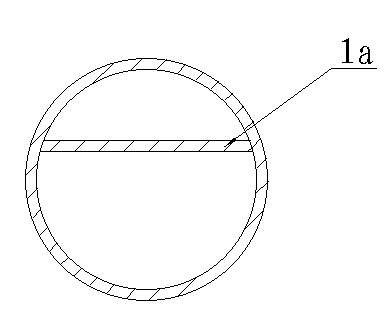

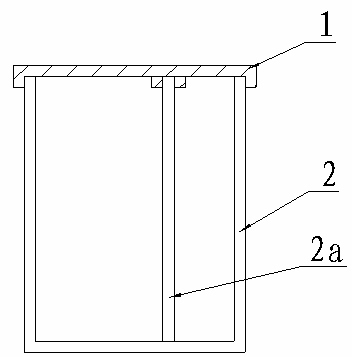

Classified rot-proof trash can

InactiveCN102367091AReduce usageReduce pollutionWaste collection and transferRefuse receptaclesLitterEngineering

The invention relates to a classified rot-proof trash can, belonging to the field of household articles. The classified rot-proof trash can comprises a can body and a snap ring, wherein the internal diameter of the snap ring is adaptive to the external diameter of the can body; the can body is provided with a baffle; and the snap ring is provided with a clamping bar corresponding to the baffle. The trash can is divided into two independent zones so as to separate perishable trashes from other trashes, use frequency of garbage bags can be reduced, waste and environment pollution are reduced.

Owner:栾清杨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com