Patents

Literature

42results about How to "Have density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsDry mixingHeavy duty

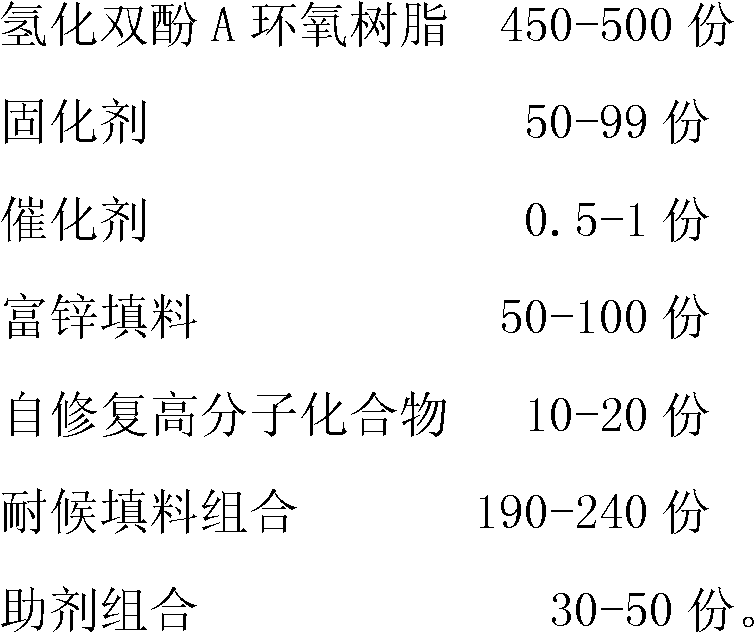

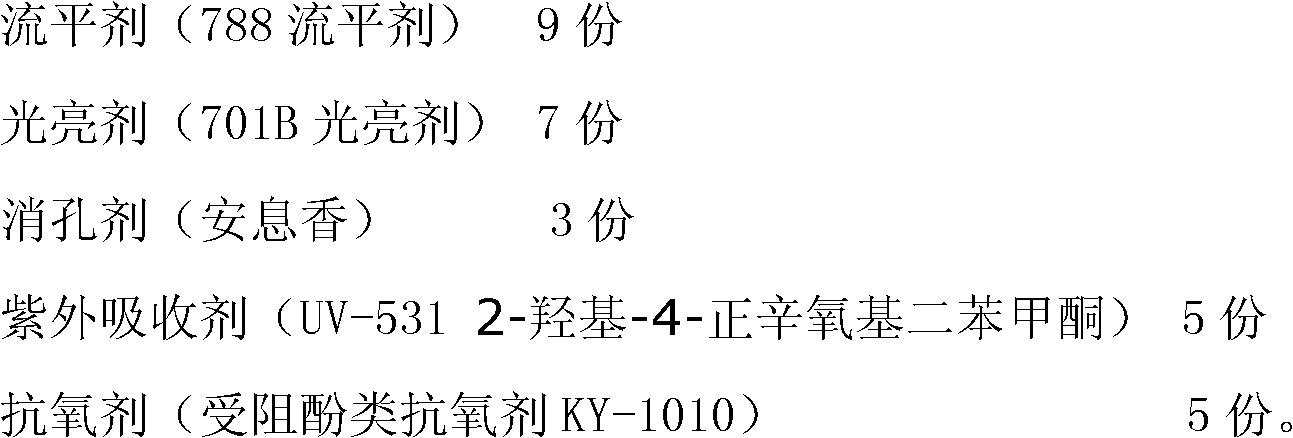

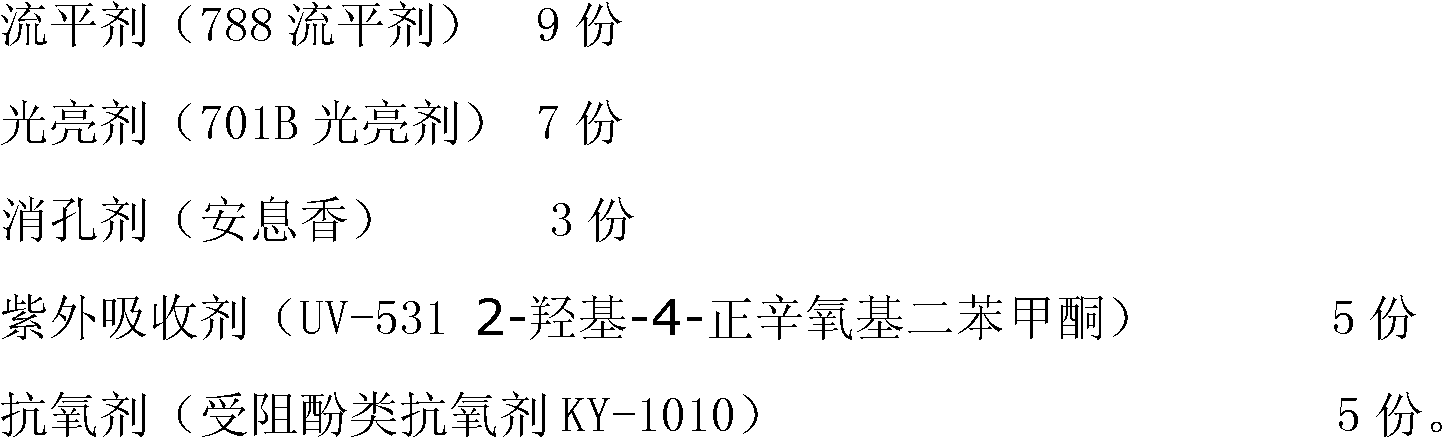

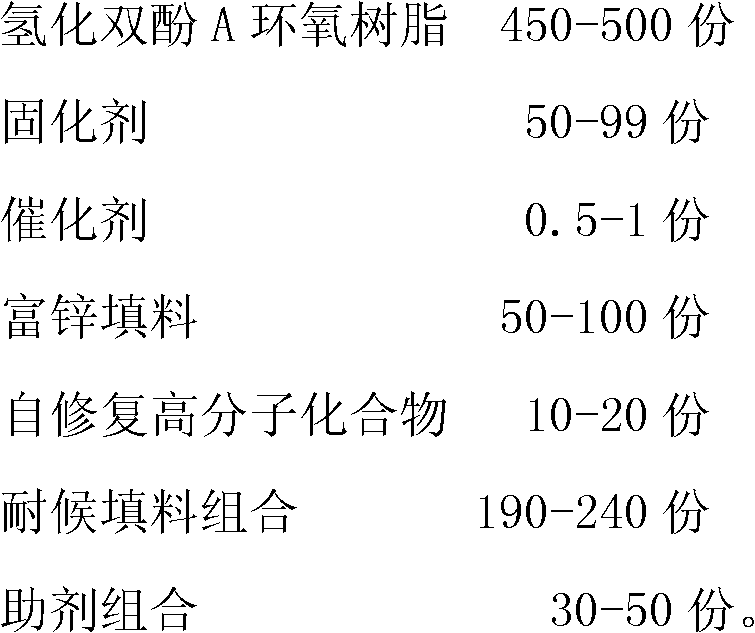

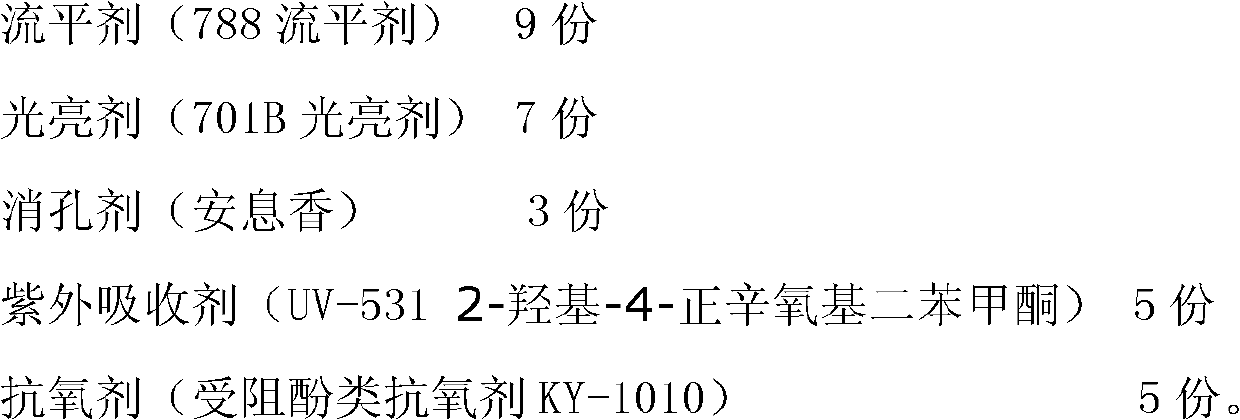

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

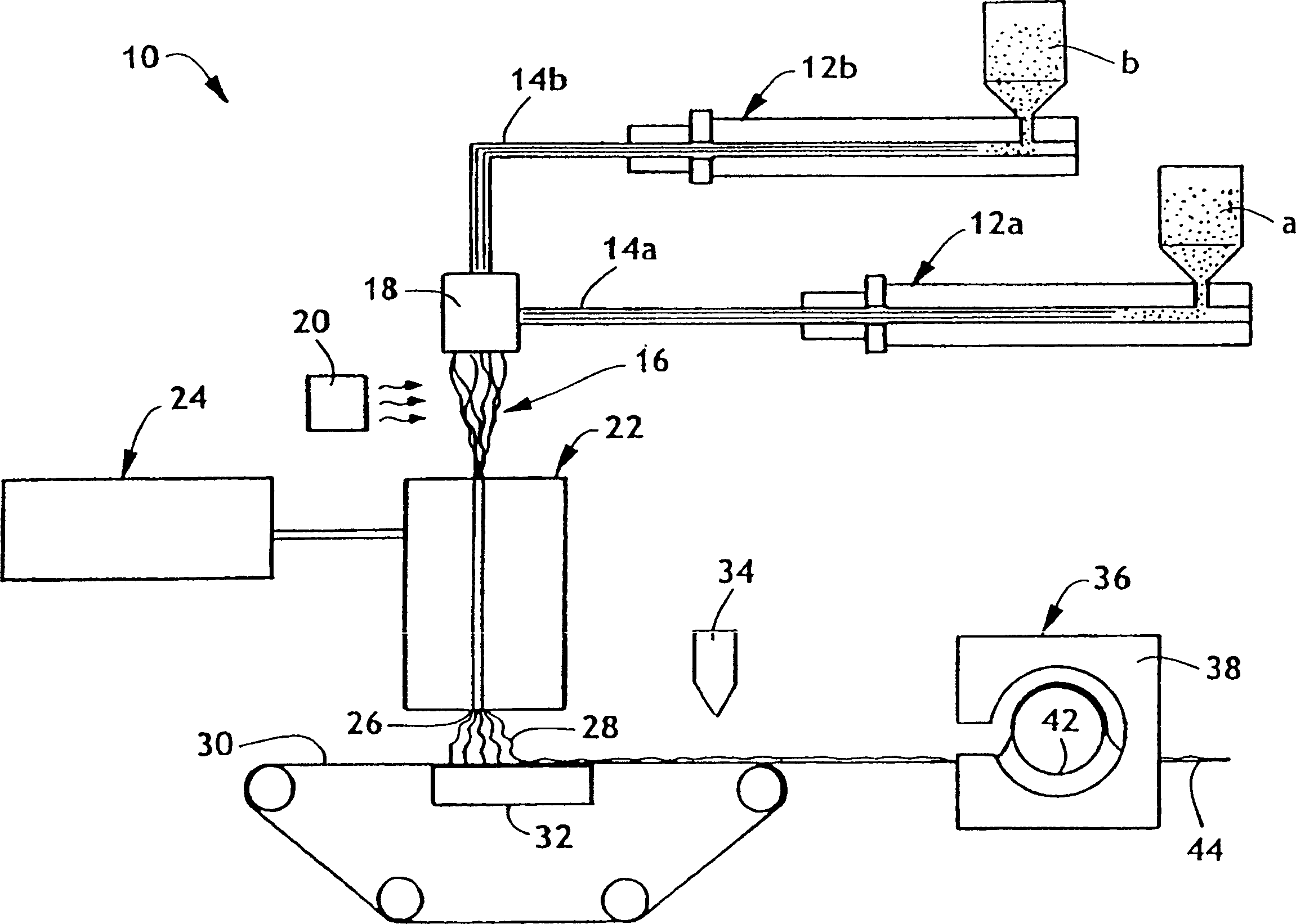

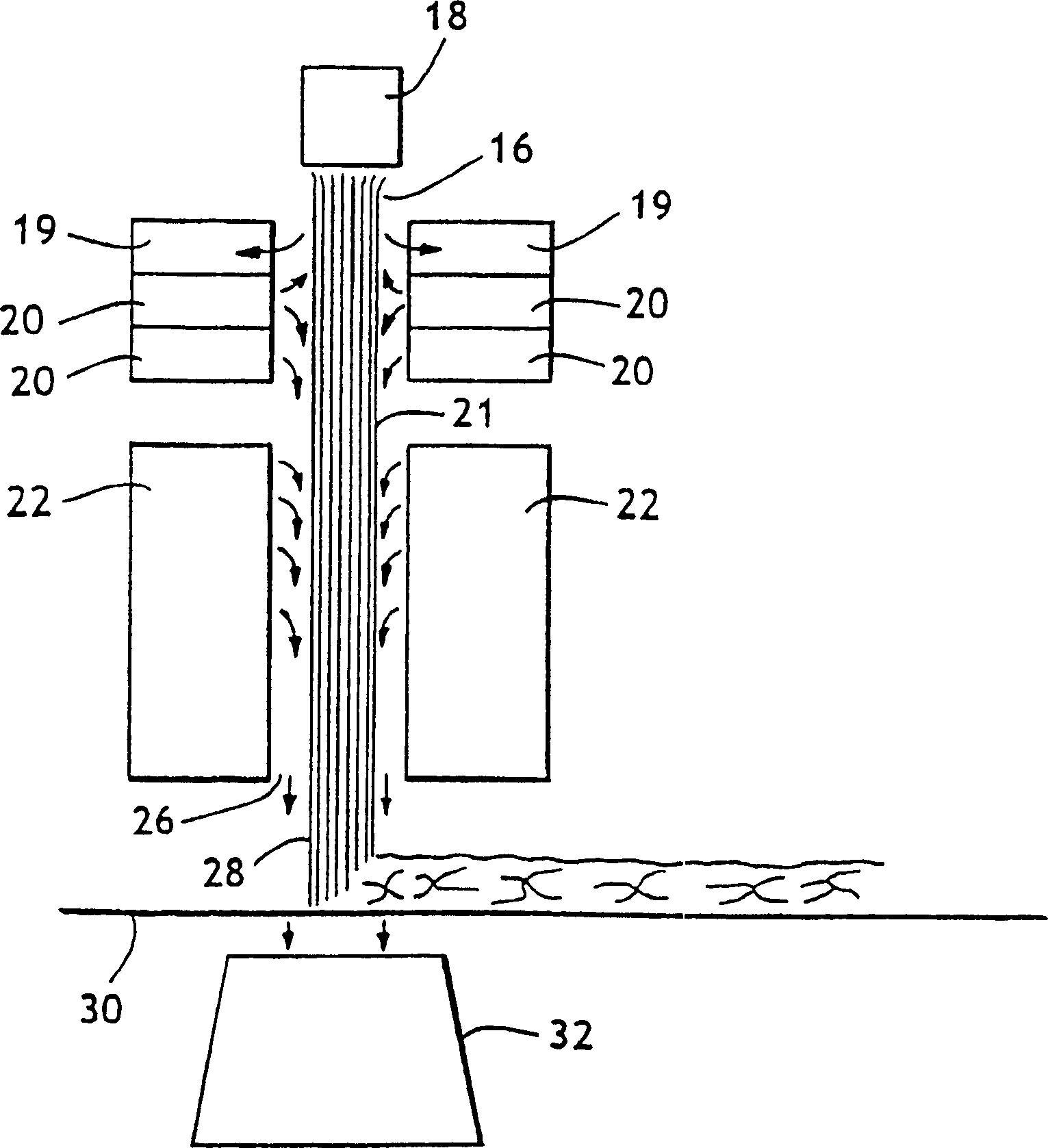

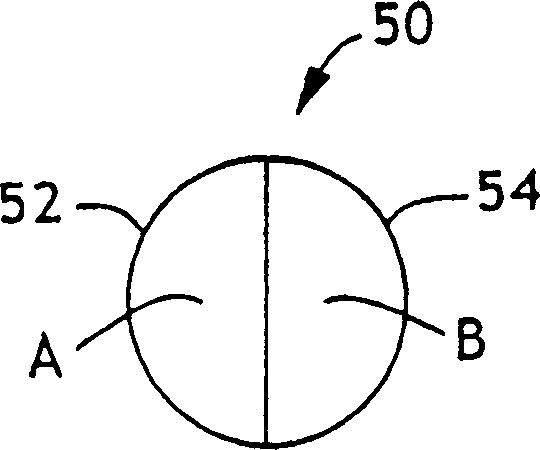

Crimped multicomponent fibers and methods of making same

InactiveCN1331766AWith reboundWith strengthMelt spinning methodsConjugated synthetic polymer artificial filamentsNonwoven fabricPropylene Polymers

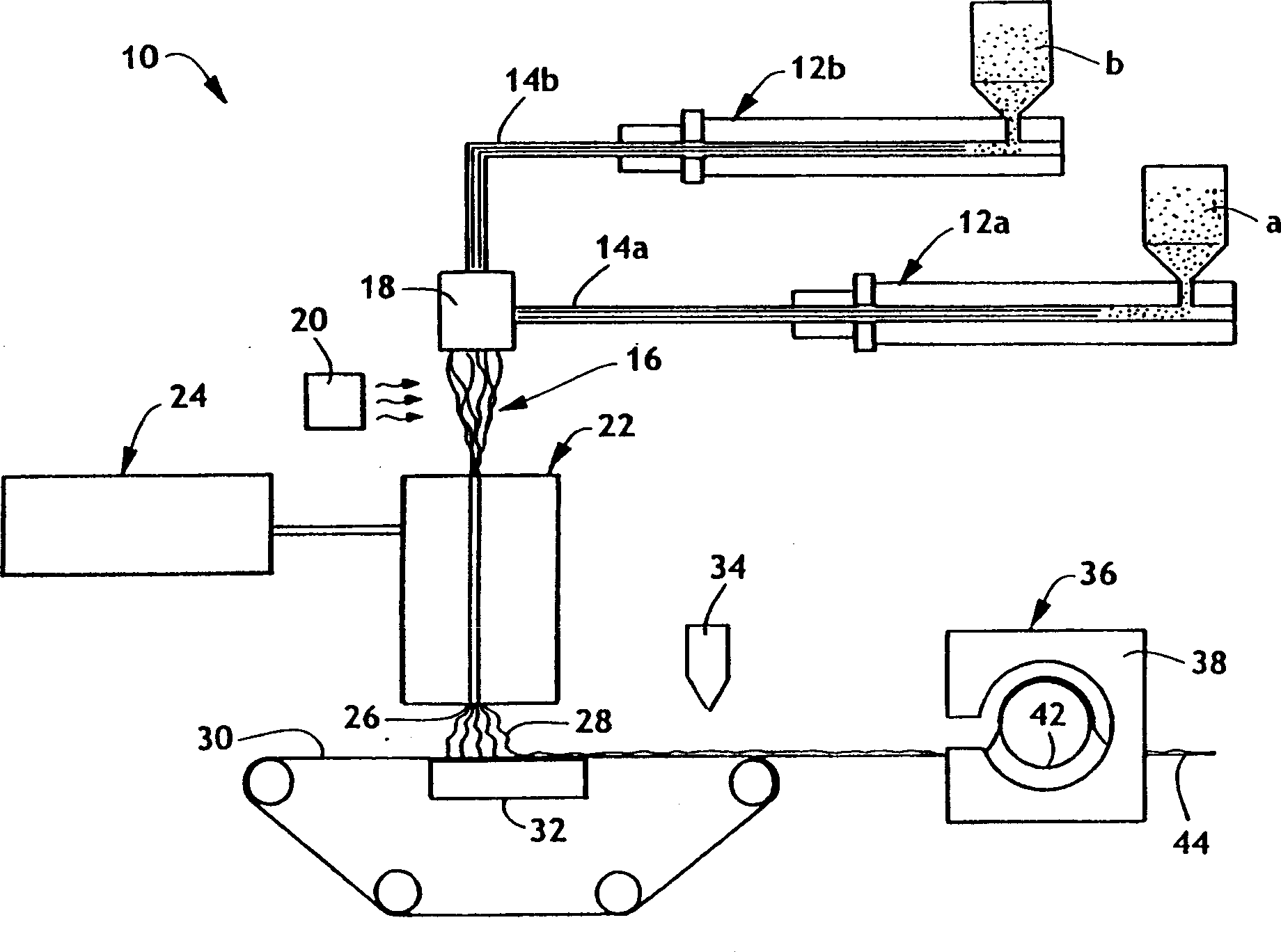

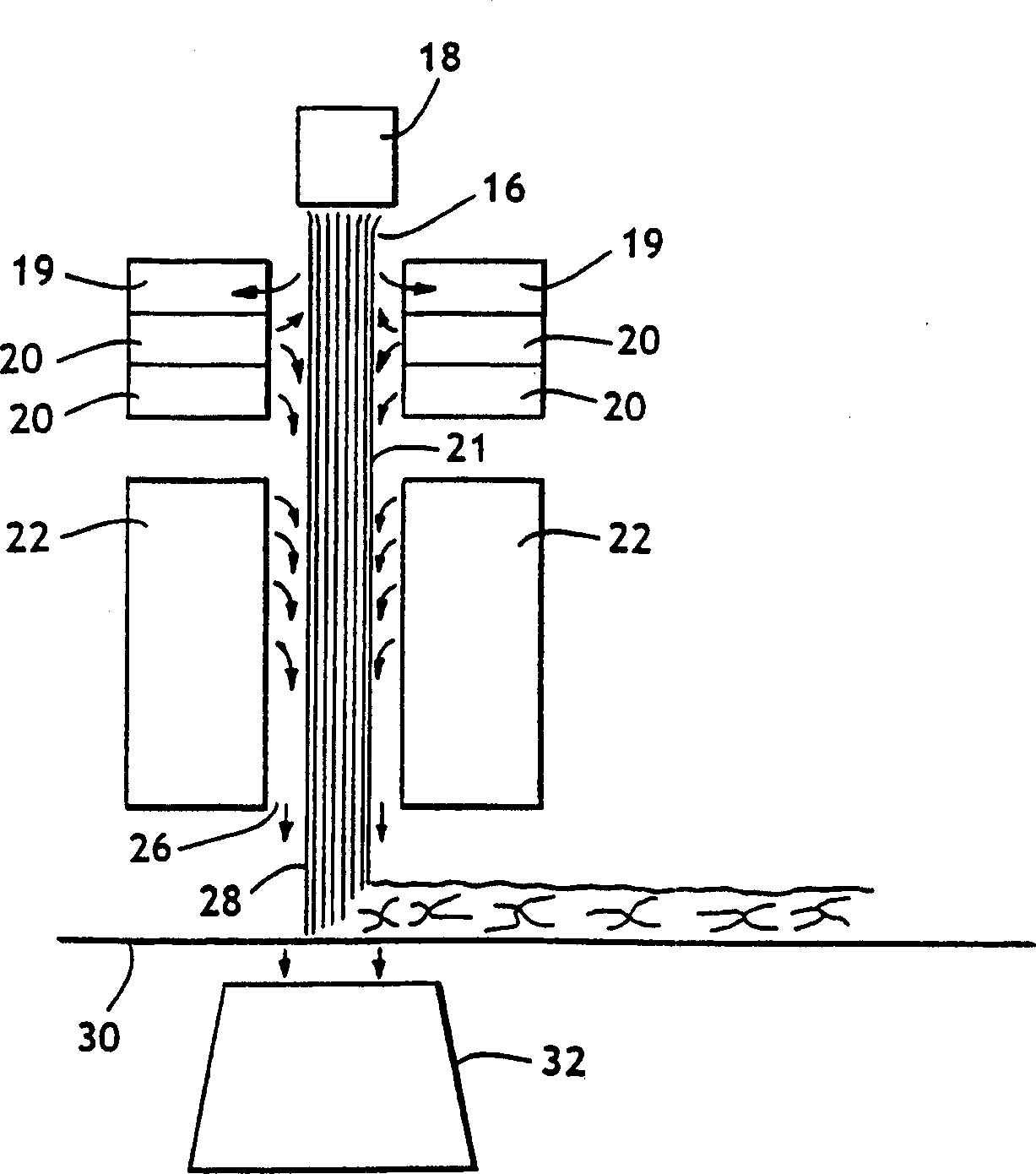

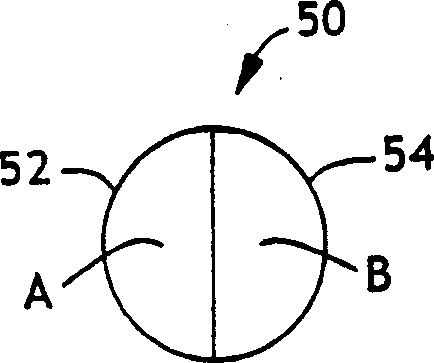

The present invention provides continuously crimped propylene polymer nonwoven fabrics as well as processes for forming crimped multicomponent propylene polymer fibers by melt-attenuating extruded multicomponent fibers with heated or unheated air wherein the fibers spontaneously crimp without the need for additional heating and / or stretching steps.

Owner:FIBERTEX PERSONAL CARE

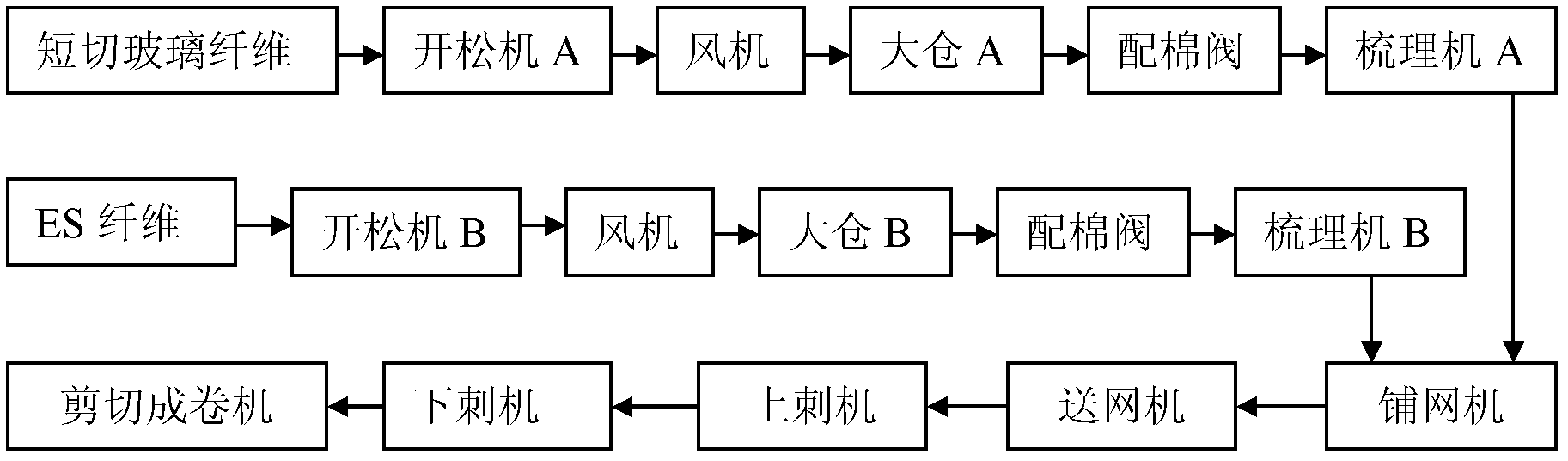

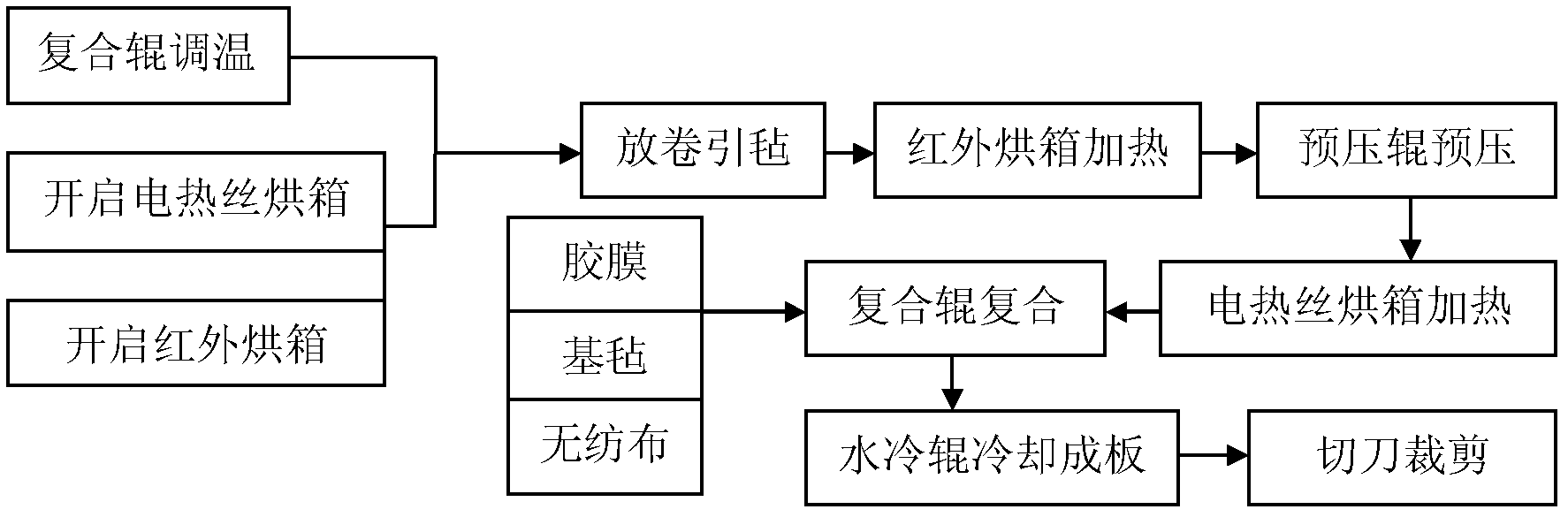

Light composite board, production method and application thereof

ActiveCN103101255AWith strengthHave densitySynthetic resin layered productsLaminationGlass fiberFiber

The invention belongs to the technical field of high polymer materials and discloses a light composite board which can serve as automotive interior parts, a production method and application thereof. The light composite board is prepared from the following components in percentage by mass: 30-70 percent of polyolefine fiber and 30-70 percent of glass fiber. The invention also discloses a method for manufacturing a ceiling of the automotive interior part from the light composite board. The method comprises the following steps of: cutting the light composite board according to the required size, and removing slitter edges to obtain a ceiling framework; heating to the temperature of 170-220 DEG C, and laminating a facing layer to obtain a thickened decorative ceiling framework; performing mold pressing by a corresponding mold at normal temperature, wherein the pressure is 0.05-0.5MPa, and the mold pressing time is 20-40 seconds; and removing the excessive facing layer, trimming the side hole burrs, and checking and warehousing to obtain the ceiling of the automotive interior part. The invention also discloses a method for manufacturing a protective bottom plate of the automotive interior part from the light composite board. The light composite board is excellent in comprehensive performance.

Owner:滁州格美特科技有限公司

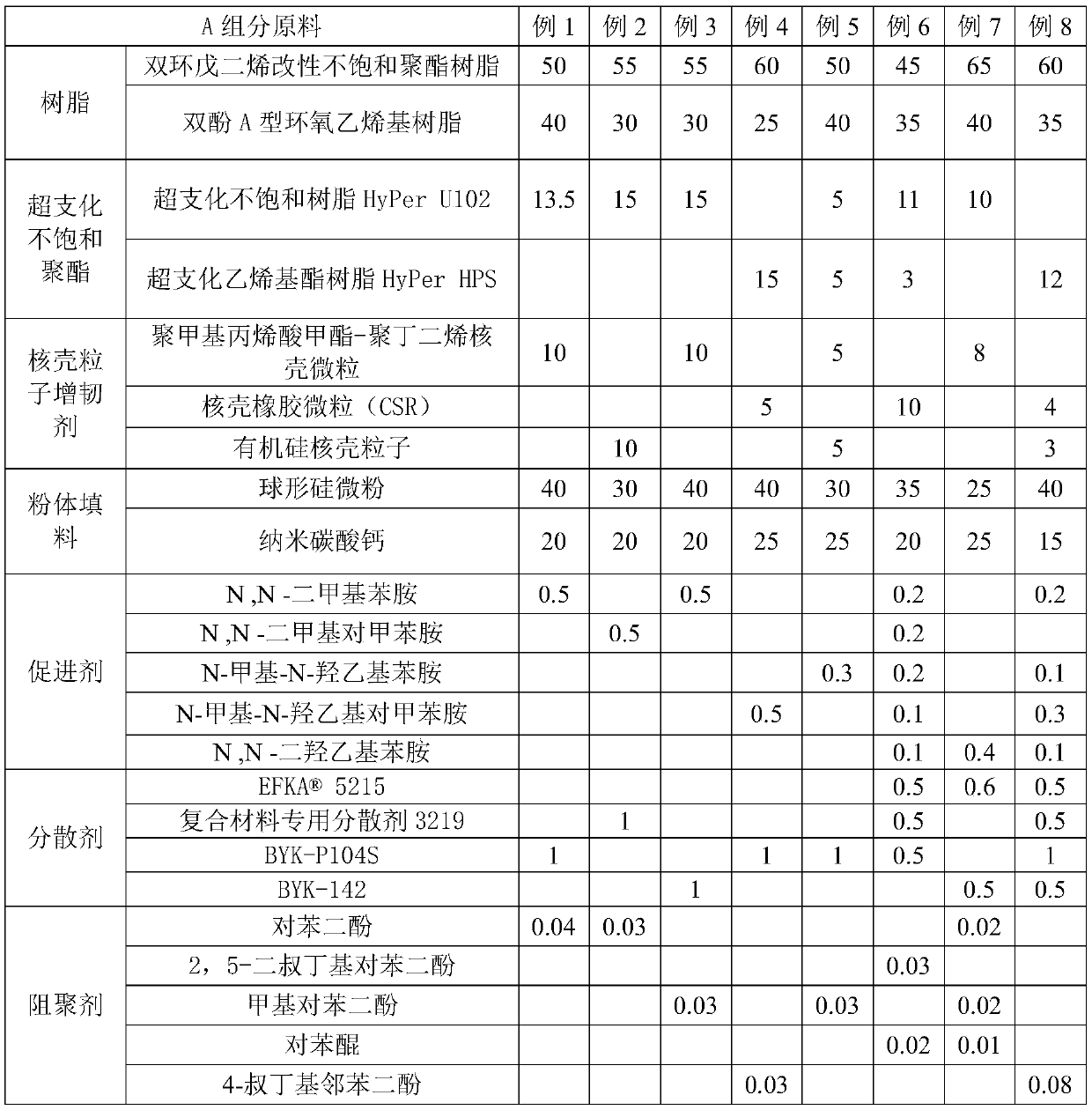

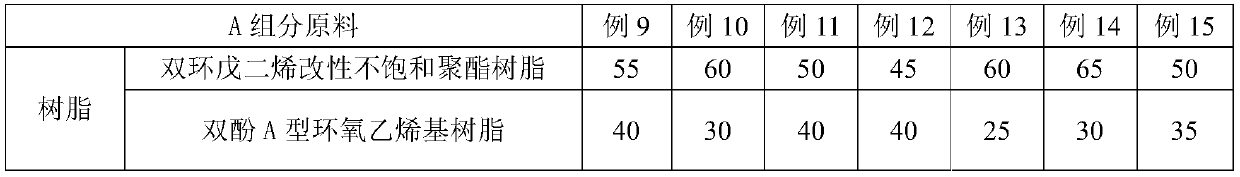

Toughened environmental-friendly back mesh glue as well as preparation method and application thereof

ActiveCN107090264AFast aggregationFast curing at room temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterToughening

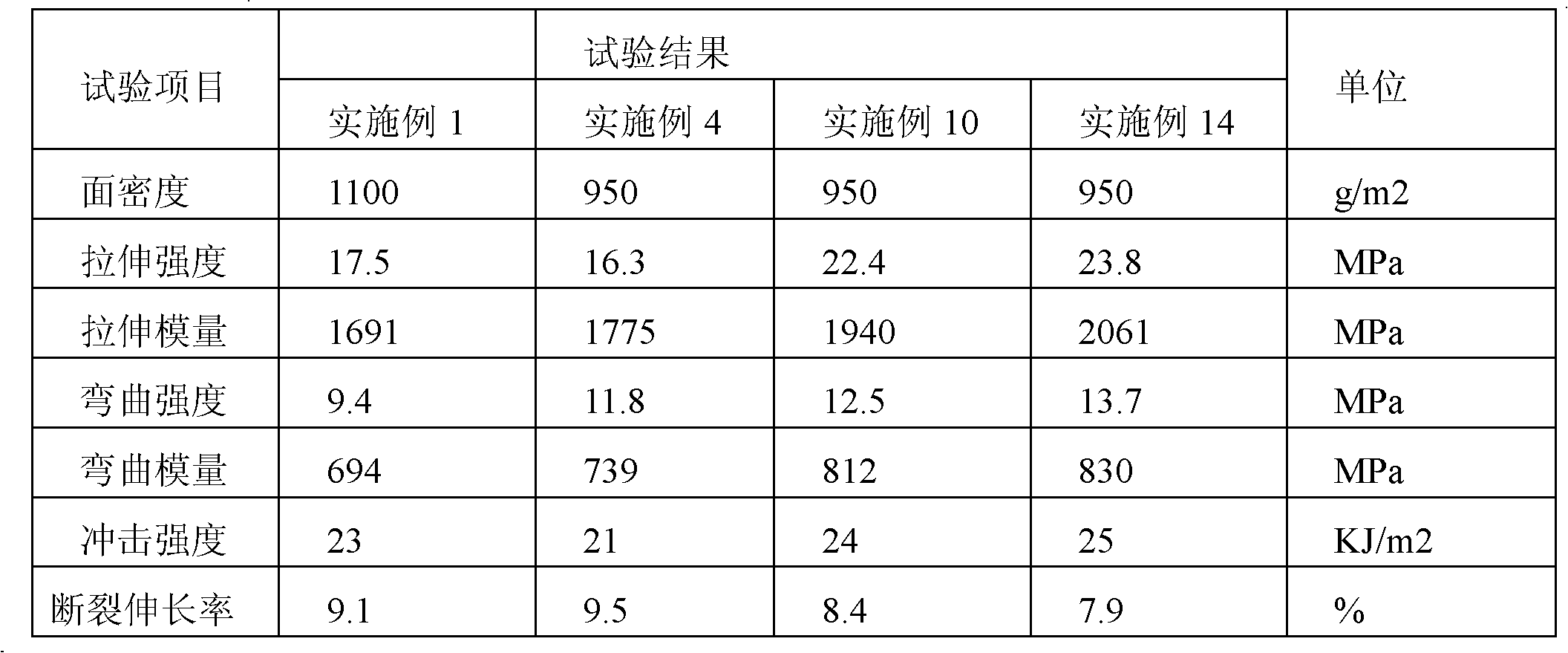

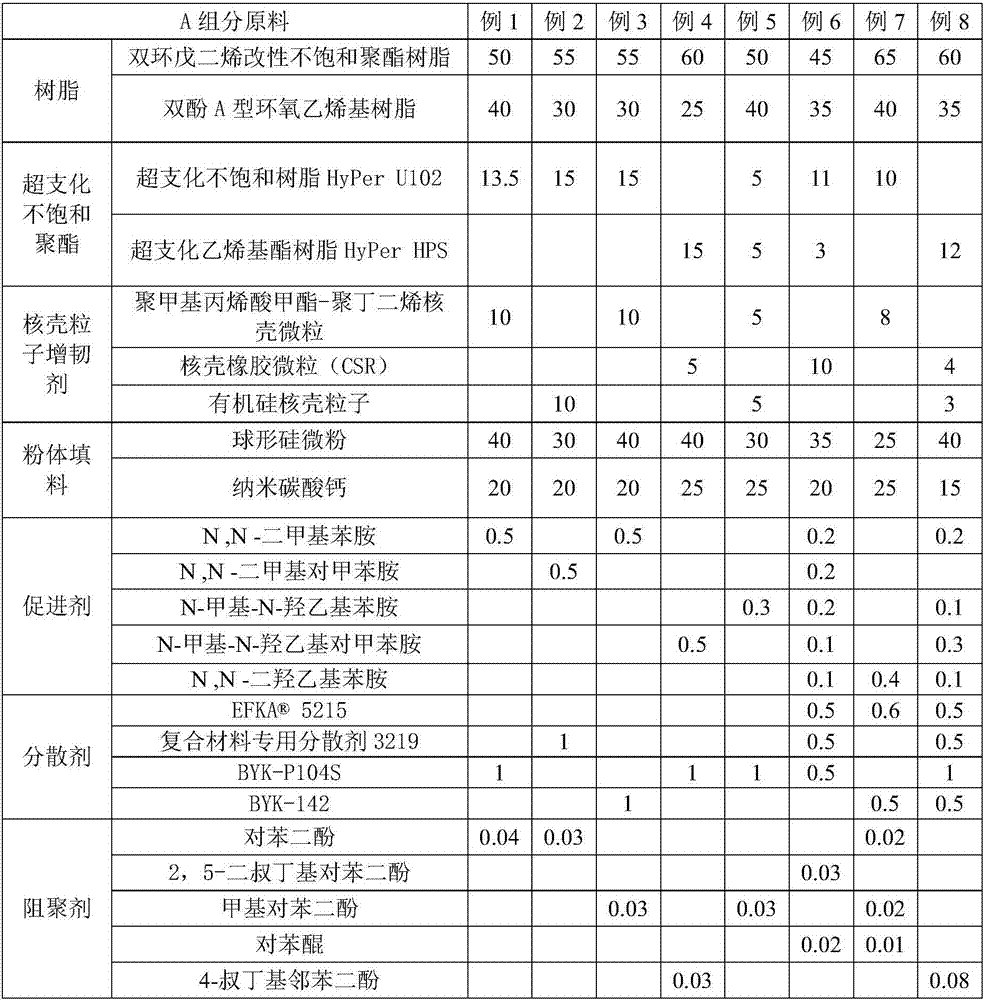

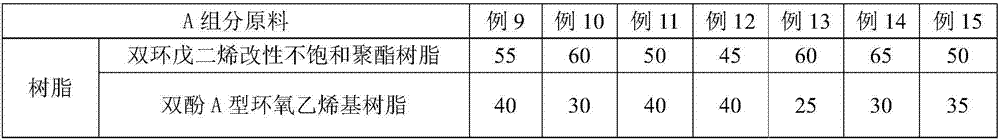

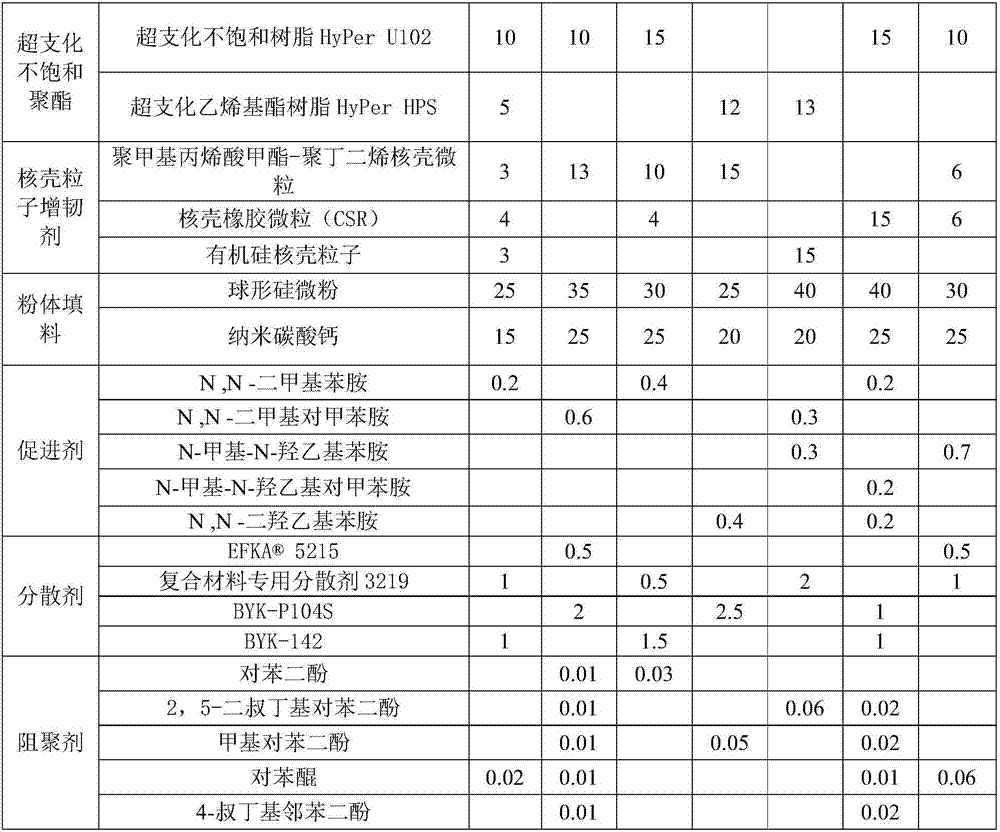

The invention discloses toughened environmental-friendly back mesh glue as well as a preparation method and application thereof. A component A is prepared from the following components in parts by weight: 45-65 parts of dicyclopentadiene modified unsaturated polyester resin, 25-40 parts of bisphenol-A epoxy vinyl ester resin, 10-15 parts of hyperbranched unsaturated polyester, 1-2.5 parts of a dispersant, 5-10 parts of a core-shell particle toughening agent, 25-40 parts of spherical fine silicon powder, 15-25 parts of nano calcium carbonate, 0.2-0.8 part of an accelerator and 0.02-0.08 part of a polymerization inhibitor. A component B is prepared from the following components in parts by weight: 10-70 parts of a solidifying agent, 30-40 parts of a blending agent, 30-50 parts of an inorganic filler and 3-10 parts of a stabilizer. After the component A and the component B are mixed, the solidifying agent accounts for 0.5-3.5 percent of the total weight of the mixture. The back mesh glue is small in viscosity, good in permeability, moderate in rheology and low in content of total volatile organic compounds (VOCs); and the mechanical strength, particularly the impact resistance, of a back mesh stone is remarkably superior to that of the existing product.

Owner:江苏大力士云石护理材料有限公司

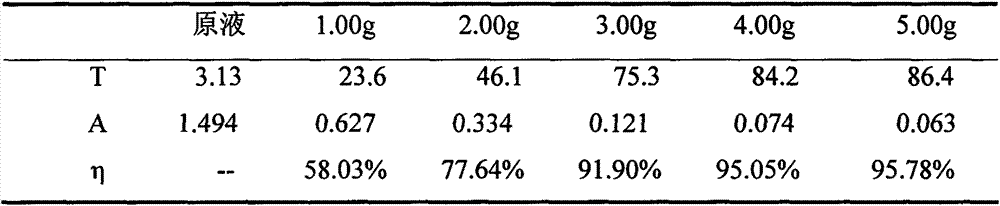

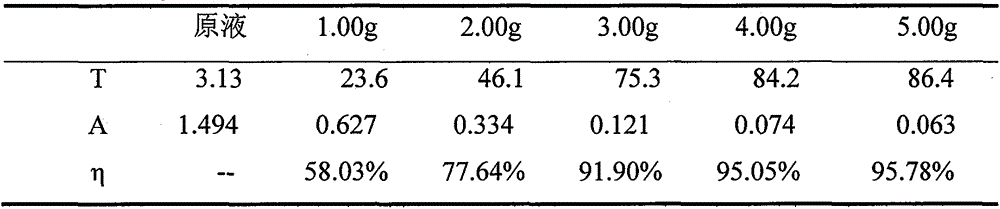

Preparation method and application method of granular activated carbon for xylose decoloring

ActiveCN103754868AHave densityHas thermal conductivityOther chemical processesCarbon compoundsEmulsionPhosphoric acid

The invention discloses a preparation method and an application method of granular activated carbon for xylose decoloring, which belongs to the field of preparation methods and application methods of activated carbon. The preparation method comprises the following steps: (A) preparing raw materials, namely, weighing phosphoric acid method powder activated carbon made from saw dust, an acrylic emulsion and water according to a ratio of acrylic emulsion to phosphoric acid method powder activated carbon to water being (0.37-0.39):1:1; (B) mixing the raw materials, namely, mixing the weighed raw materials and sufficiently stirring till the granules are uniformly mixed; (C) forming granules, namely, extruding the uniformly mixed raw materials to form granules by using a pelletizing machine at the constant temperature of 90 DEG C, so as to make granules with the particle size of 2-5mm, cooling the granules to be 40-50 DEG C, and drying; (E) separating and cooling. The granular activated carbon prepared by using the method is good in adsorption property, high in strength, acid-alkali resisting, recyclable and reusable, the liquid adsorption amount of unit volume is equivalent to that of other granular activated carbons, and the production environment is improved.

Owner:HUNAN KAIFENG ACTIVE CARBON ENVIRONMENTAL PROTECTION SCI & TECH

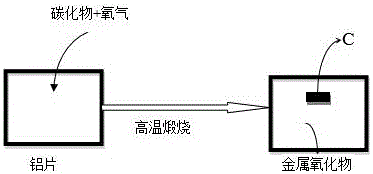

Preparation method for aluminum-graphene metallic composite

The invention discloses a preparation method for an aluminum-graphene metallic composite. According to the method, (1) fluorides are added into alkali chlorides, even mixing is conducted, and then metallic or nonmetallic carbide powder is added; (2) an aluminum sheet is placed in an alumina crucible, a mixture in the step (1) is placed on the aluminum sheet, the alumina crucible is covered up and placed in a vertical heating furnace, the temperature is increased to 700-800 DEG C under the ordinary pressure, and roasting is conducted for 0.5-5 h; and (3) a liquid mixture formed in the step (2) is poured into the crucible and cooled for 1-2 h at the room temperature, after the liquid mixture is solidified, a sufficient quantity of sodium chloride solutions are added, a solid mixture is left after filtering, the aluminum sheet in the solid mixture is slowly grabbed out and placed on cover glass through a tweezer, the aluminum sheet is placed in deionized water, after water is changed for three times, drying is conducted, and the aluminum-graphene metallic composite is obtained. The technique is simple, capable of saving energy and low in cost; and the hardness, strength and ductility of the prepared aluminum-graphene composite are at least two to three times higher than those of pure aluminum materials.

Owner:NANCHANG UNIV

Valve seat ring and manufacturing method thereof

The invention discloses a valve seat ring and a manufacturing method thereof. The valve seat ring is made from a powder metal material which is specifically composed of graphite, superfine silica powder, natural manganese sand, electrolytic nickel powder, chromium-molybdenum alloy powder, superfine high-purity cobalt powder, zinc stearate and high-quality water atomized pure iron powder. According to the valve seat ring and the manufacturing method thereof, a special metal material ratio is adopted, the valve seat ring is manufactured through the powder metallurgy method, and the obtained valve seat ring has the advantages of being high in density and hardness, excellent in heat resistance and thermal shock resistance, good in machining property and air tightness, low in abrasion, capable of being matched with a valve well and the like and is more suitable for engines consuming unleaded gasoline and alternative fuel.

Owner:安徽顺驰电缆股份有限公司

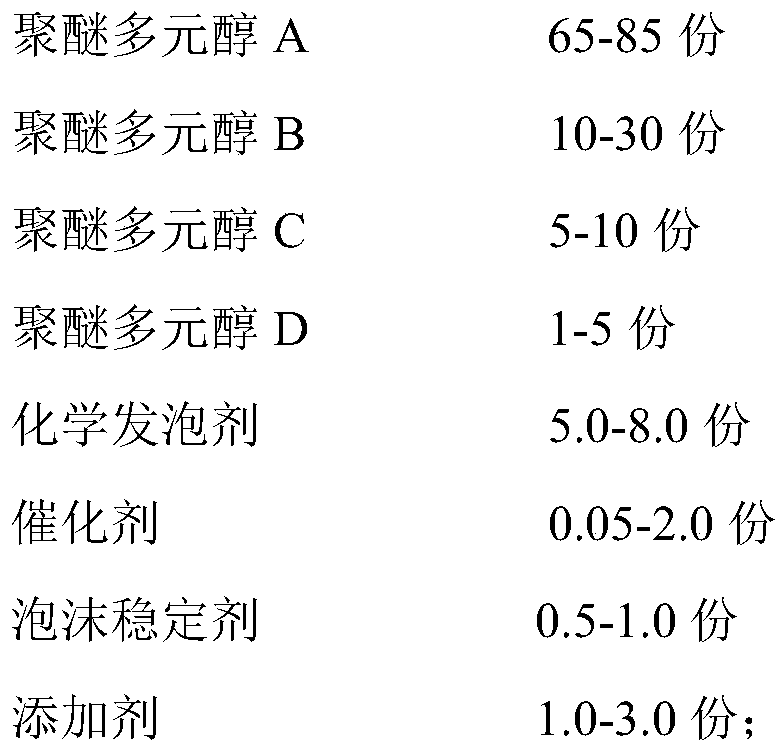

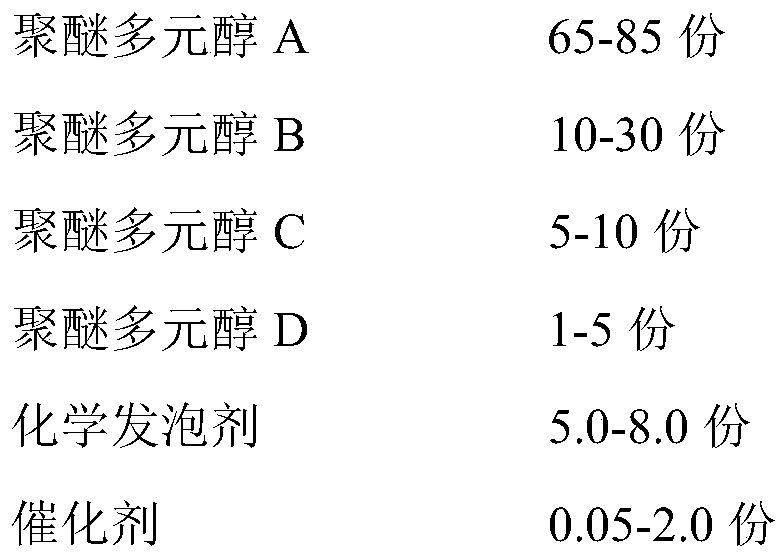

Polyurethane flower arrangement mud material and preparation method thereof

InactiveCN110922552ANo pollutionEasy density adjustment processFloral handlingPolymer sciencePtru catalyst

The invention belongs to the technical field of polyurethane application and particularly relates to a polyurethane flower arrangement mud material and a preparation method thereof. The polyurethane flower arrangement mud material comprises a component A and a component B. The mass ratio of the component A to the component B is 1: 0.9-1.1, the component A is composed of polyether polyol A, polyether polyol B, polyether polyol C, polyether polyol D, a chemical foaming agent, a catalyst, a foam stabilizer and an additive, and the component B is polymerized diphenylmethane diisocyanate. The polyurethane flower arrangement mud material disclosed by the invention has the advantages of adjustable density and color, high aperture ratio, good water absorption and environment-friendly foaming system, and the prepared flower arrangement mud material can be recycled, so that the damage to the environment is avoided. The preparation method disclosed by the invention is simple and easy to implement, energy-saving and consumption-reducing.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

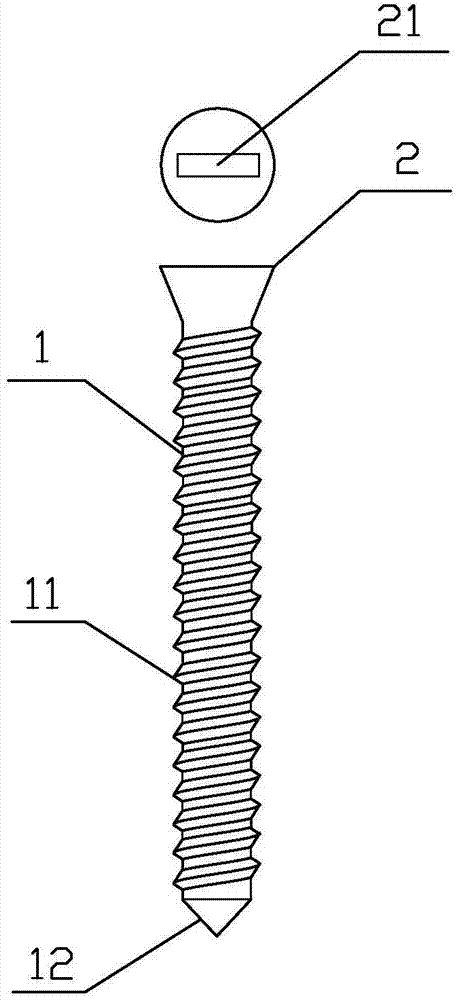

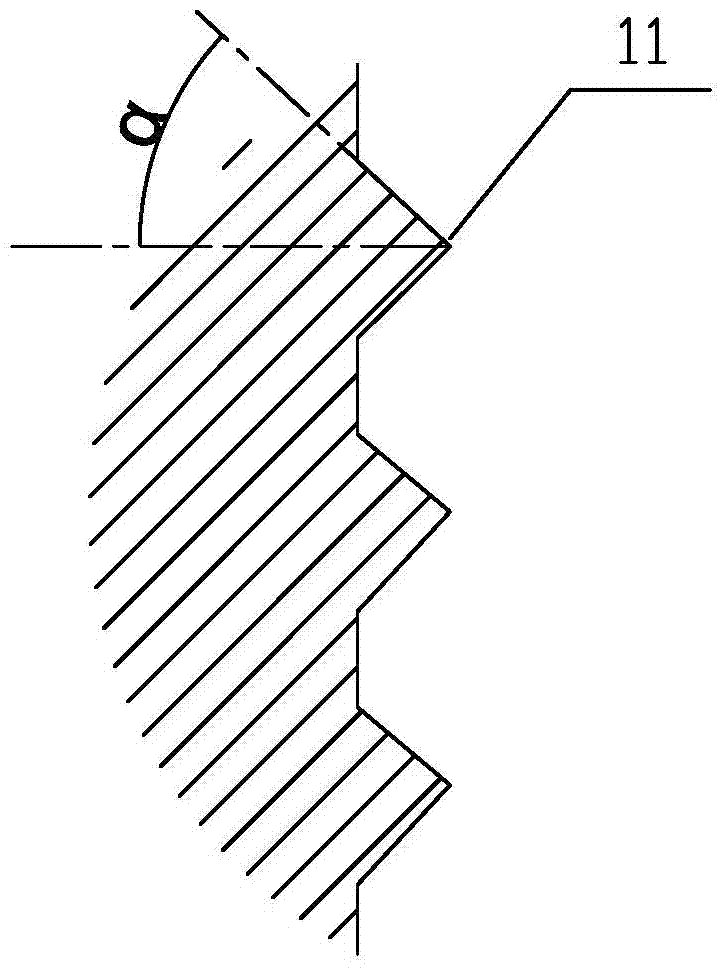

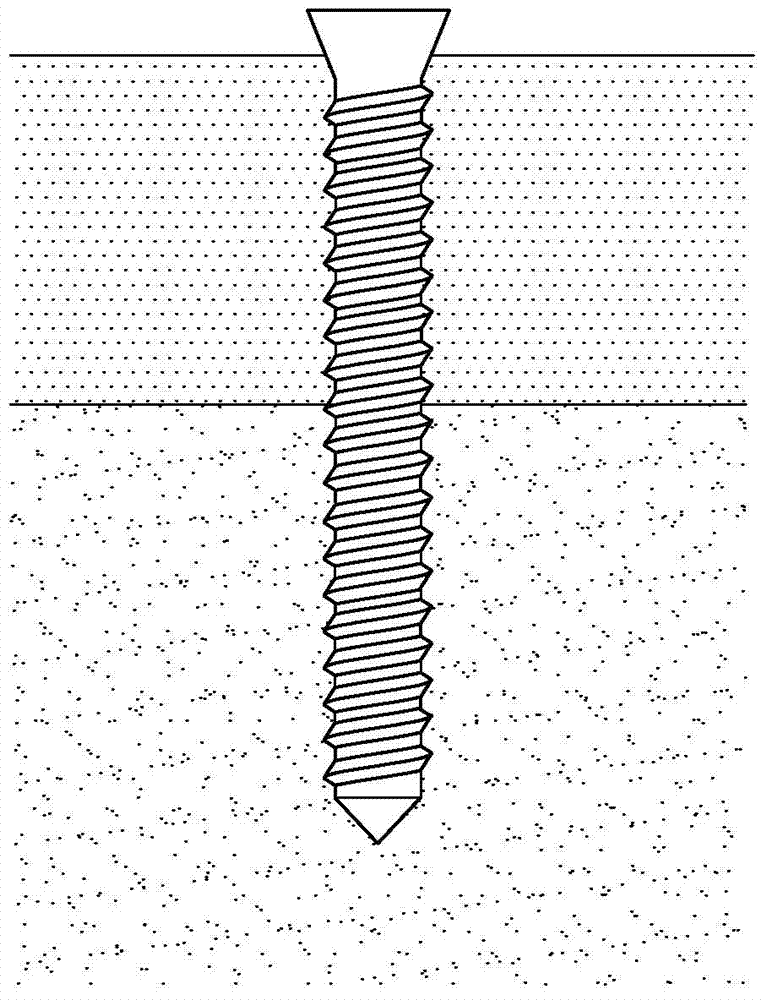

Full-thread degradable pure-magnesium bolt

InactiveCN104257424ADisadvantages of Avoiding Tail DeformationReduce distortionInternal osteosythesisFastenersBiomechanicsBone tissue

The invention discloses a full-thread degradable pure-magnesium bolt, and relates to the field of medical implants. The full-thread degradable pure-magnesium bolt comprises a body and a nut, wherein threads are formed in the body; a profile counter bore is formed in the nut. The full-thread degradable pure-magnesium bolt is characterized in that the ratio of the length of the threads to the length of the body is 1:1; the nut is a tension nut; and the inclination angle between the side, connected with the body, of the tension nut and the center line of the body is 22 degrees to 30 degrees. The full-thread degradable pure-magnesium bolt can be degraded automatically, is low in cost, has higher histocompatibility and higher biomechanical property, can induce the generation of bone tissues, and can meet the requirements of patients.

Owner:赵德伟 +4

Micro processing process for silicon nitride ceramic parts

A microprocessing technology for silicon nitride ceramic workpiece with high hardness and resistance to high temp and oxidization includes such steps as shaping by hot die pressing or plasma discharge sintering of Si powder, fine processing by precise machining, or fine electrospark machining, or fine electrospark machining, or photoetching, or reactive ion etching, and heating in N2 for nitrifying reaction. It has high compactness.

Owner:TSINGHUA UNIV

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266BGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsEpoxyHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

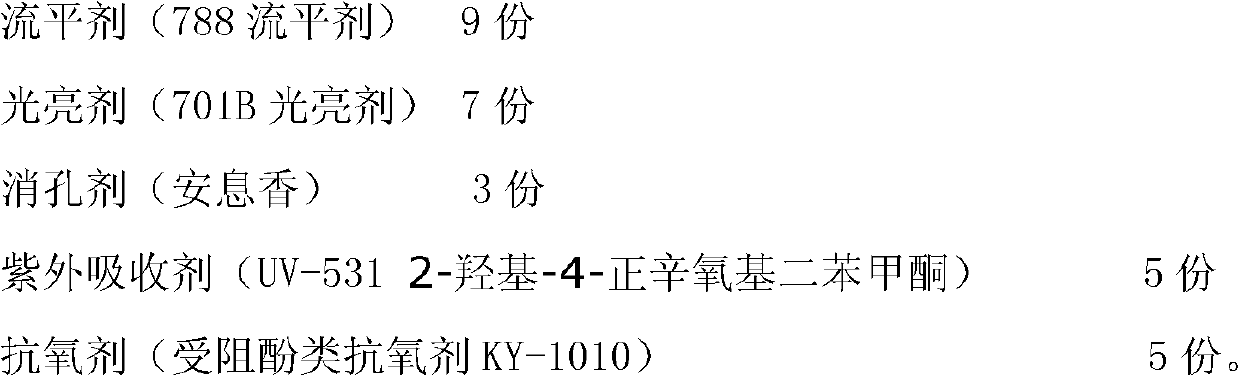

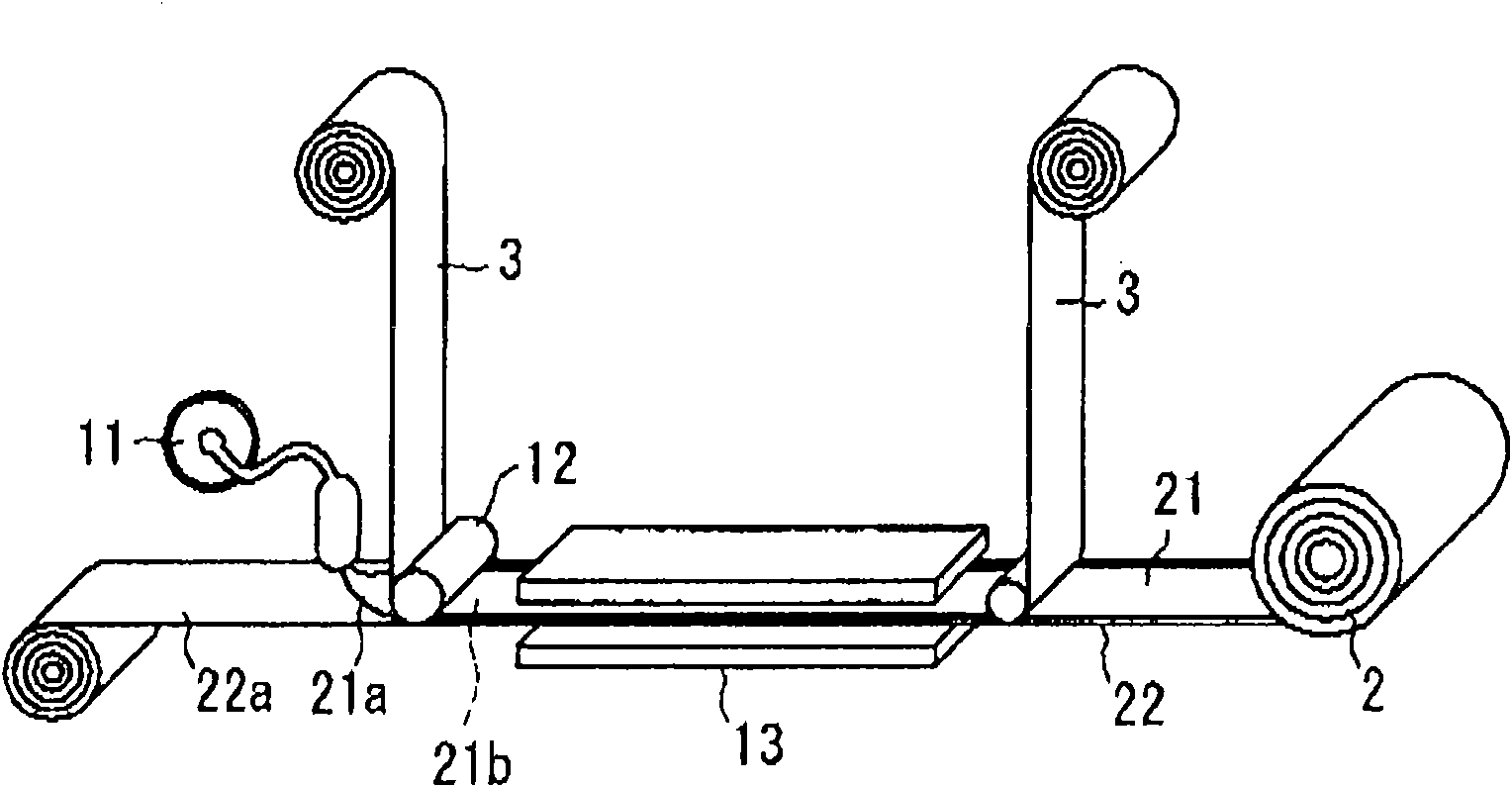

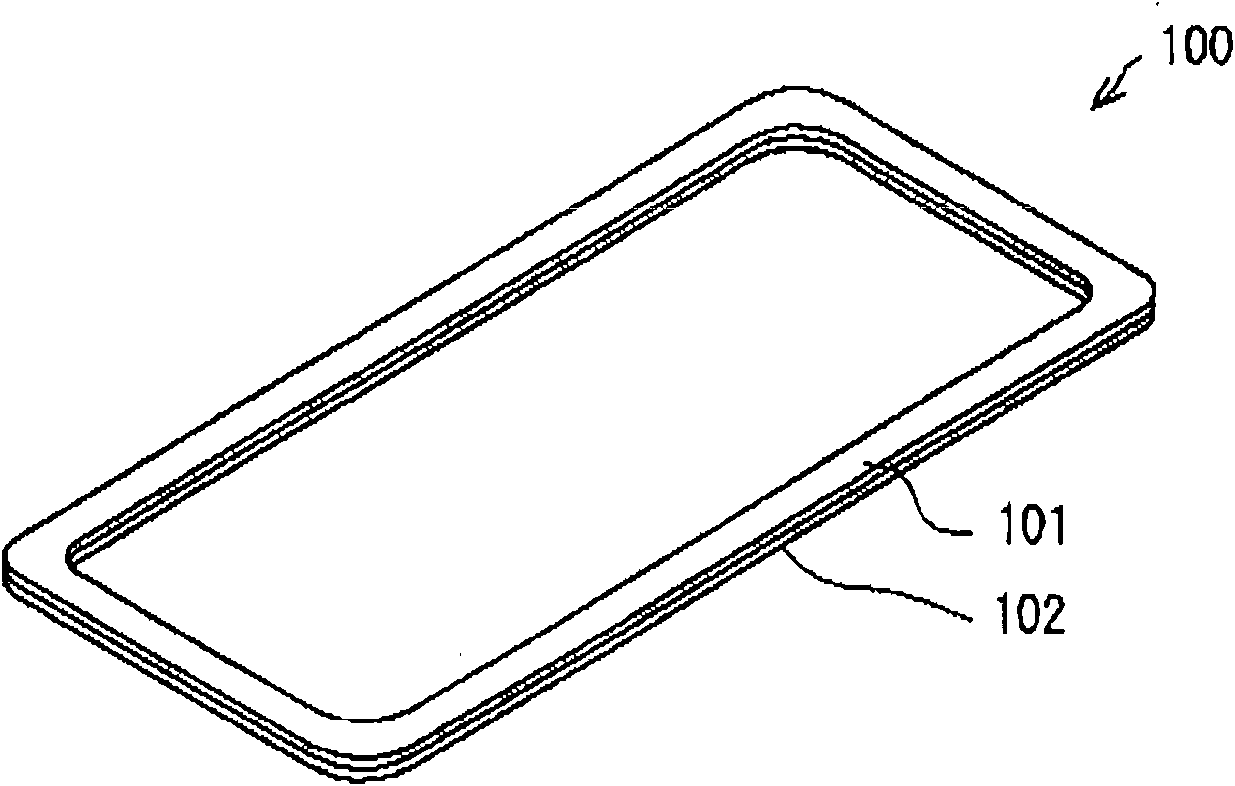

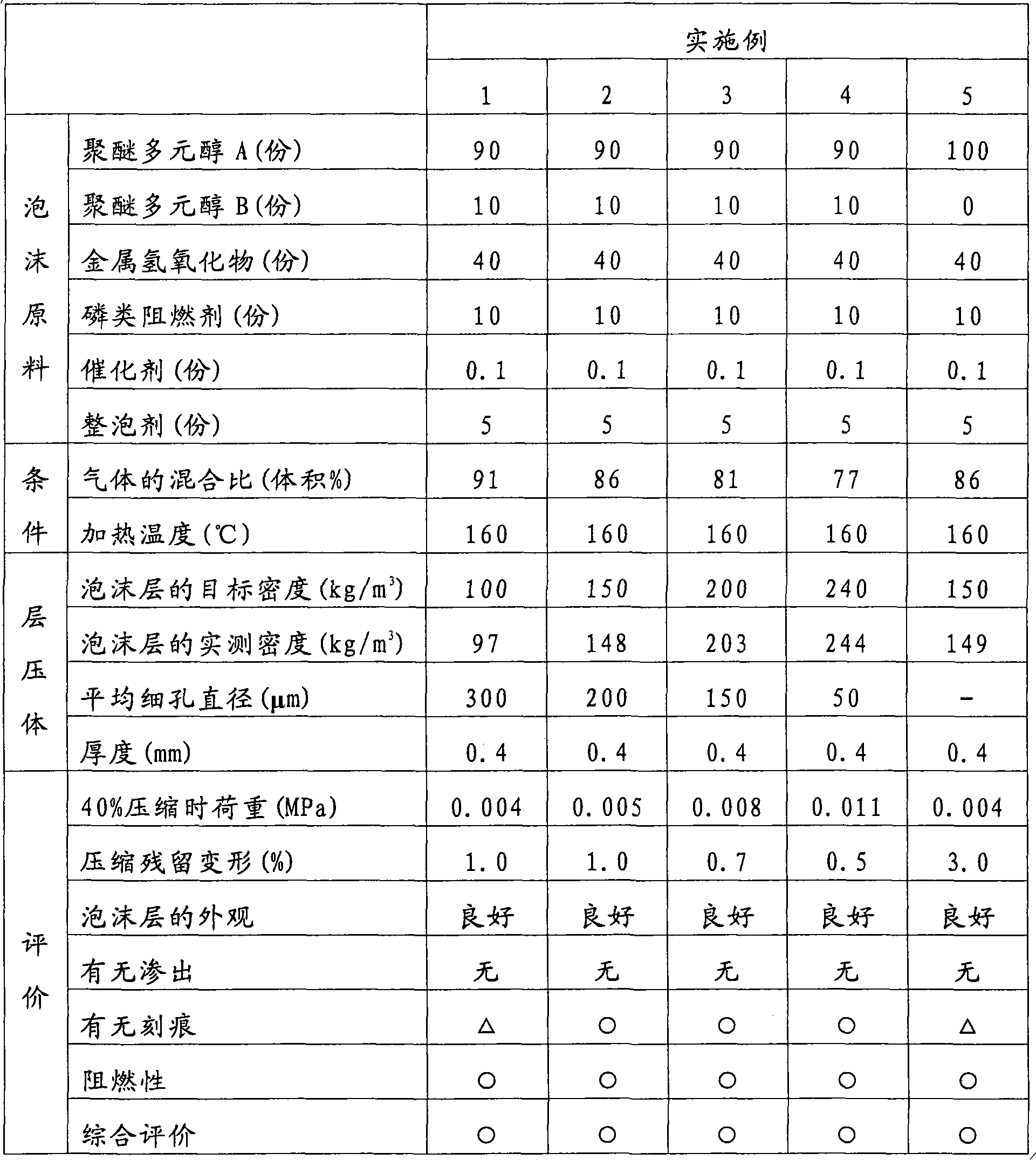

Polyurethane foam laminate, manufacturing method thereof, and gasket

ActiveCN101850639AHas no seepageGood lookingDomestic sealsSynthetic resin layered productsPolymer sciencePolyol

The invention relates to a polyurethane foam laminated body, a manufacturing method thereof and a washer. The manufacturing method includes: mixing foam materials including polyisocyanate, polyhydric alcohol and flame retardant and gas to generate a gas-liquid mixture; then, supplying the gas-liquid mixture to a resin film; heating the gas-liquid mixture, making the foam materials react and solidify, and obtaining the resin film layer having the resin film and the laminated body having the foam layer including the generated polyurethane foam; the flame retardant contained in the foam materials includes metal hydroxide powders composed of aluminium hydroxide and etc, and liquid flame retardants such as phosphor flame retardant; when the polyhydric alcohol is 100 shares by mass, the metal hydroxide powders are 20-60 shares by mass; the liquid flame retardants are 5-20 shares by mass; furthermore, the density of the foam layer is 100-280kg / m3. The laminated body is able to be made into the washer.

Owner:INOAC CORP +1

Method for preparing OPO structure lipid through enzyme catalysis under supercritical CO2 condition

ActiveCN109251943AAvoid deactivationHave densityHydrolasesOn/in organic carrierLipid formationGlycerol Tripalmitate

The invention belongs to the field of enzyme catalysis, and in particular relates to a method for preparing OPO structure lipid through enzyme catalysis under the supercritical CO2 condition. The method for preparing the OPO structure lipid through immobilized enzyme catalysis specifically comprises the following steps: taking halogenated carboxylic acid, imidazole compounds, carbonyldiimidazole and a lipase solution as raw materials, and carrying out reaction to obtain an acylated lipase solution; adding zinc nitrate into deionized water; dissolving 2-methylimidazole, the acylated lipase solution and polyvinylpyrrolidone in the deionized water; mixing the solutions, thus obtaining immobilized lipase; and taking glycerol tripalmitate and oleic acid as reaction substrates, adding the immobilized lipase, placing in a reaction still, introducing medium CO2, carrying out reaction, and carrying out separating, thus obtaining the OPO structure lipid. For the method, the reaction conditions are mild, the operation is simple, the utilization rate of the raw materials is high, the conversion rate is high, the purity is high, meanwhile, an enzyme catalyst can be repeatedly utilized, the selectivity is high, the pollution to the environment is small, the production cost is reduced, and the method is expected to realize industrial production.

Owner:JIANGSU UNIV

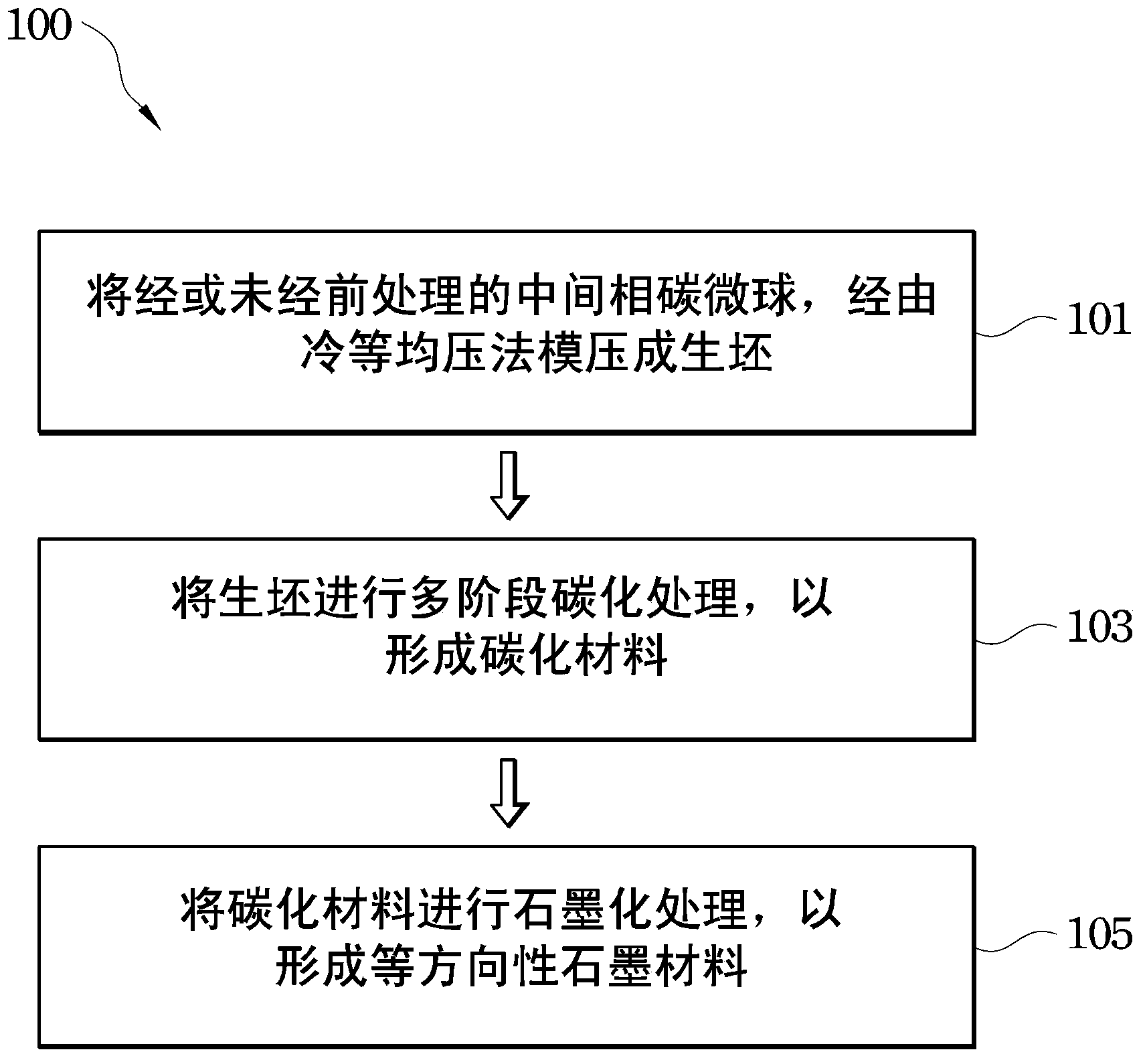

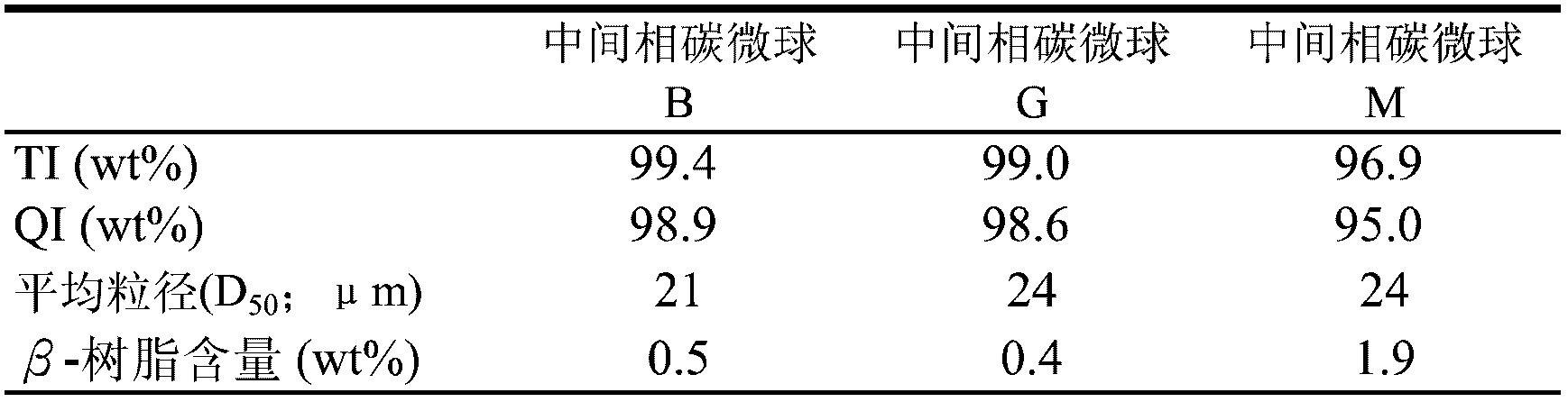

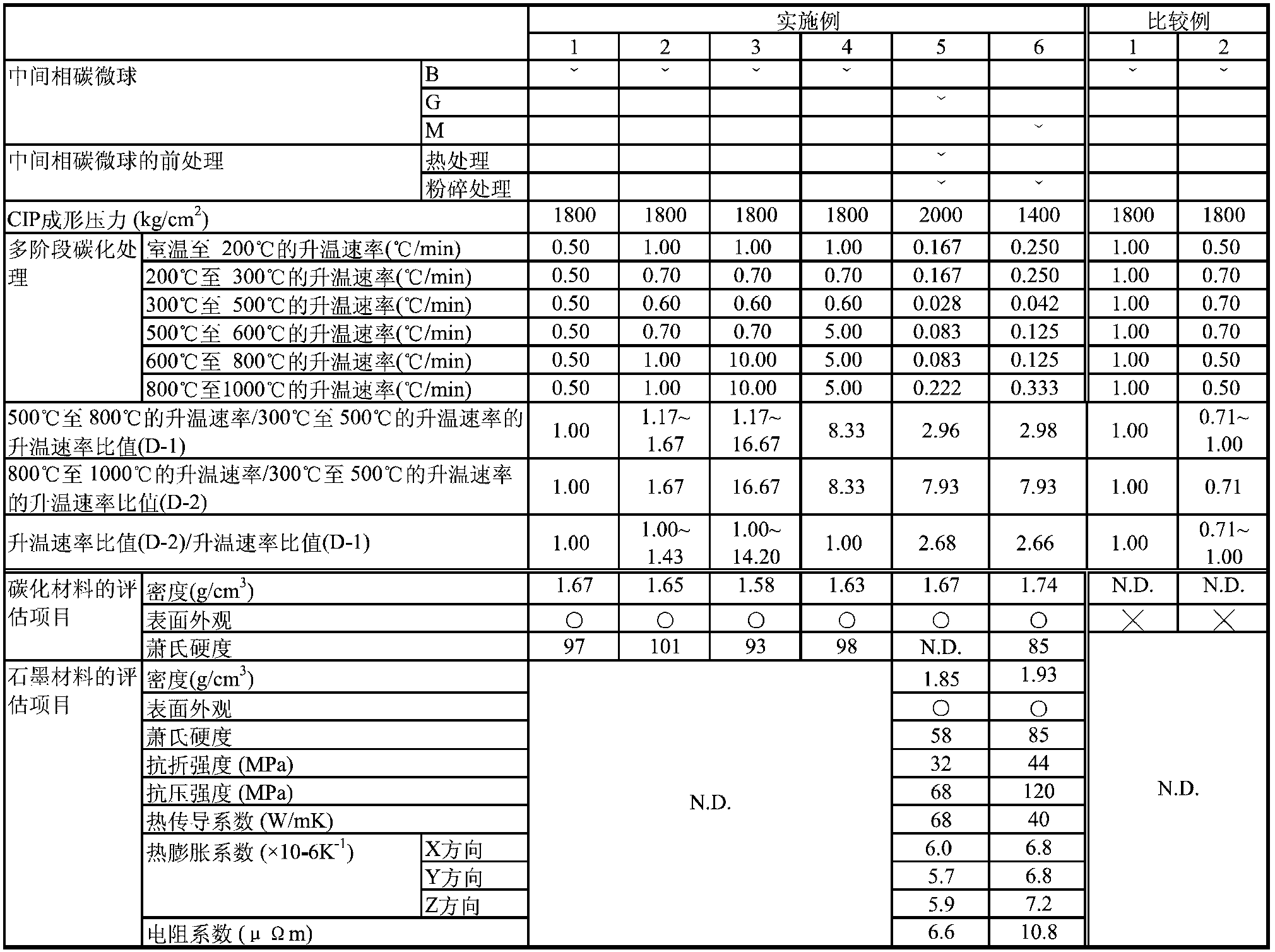

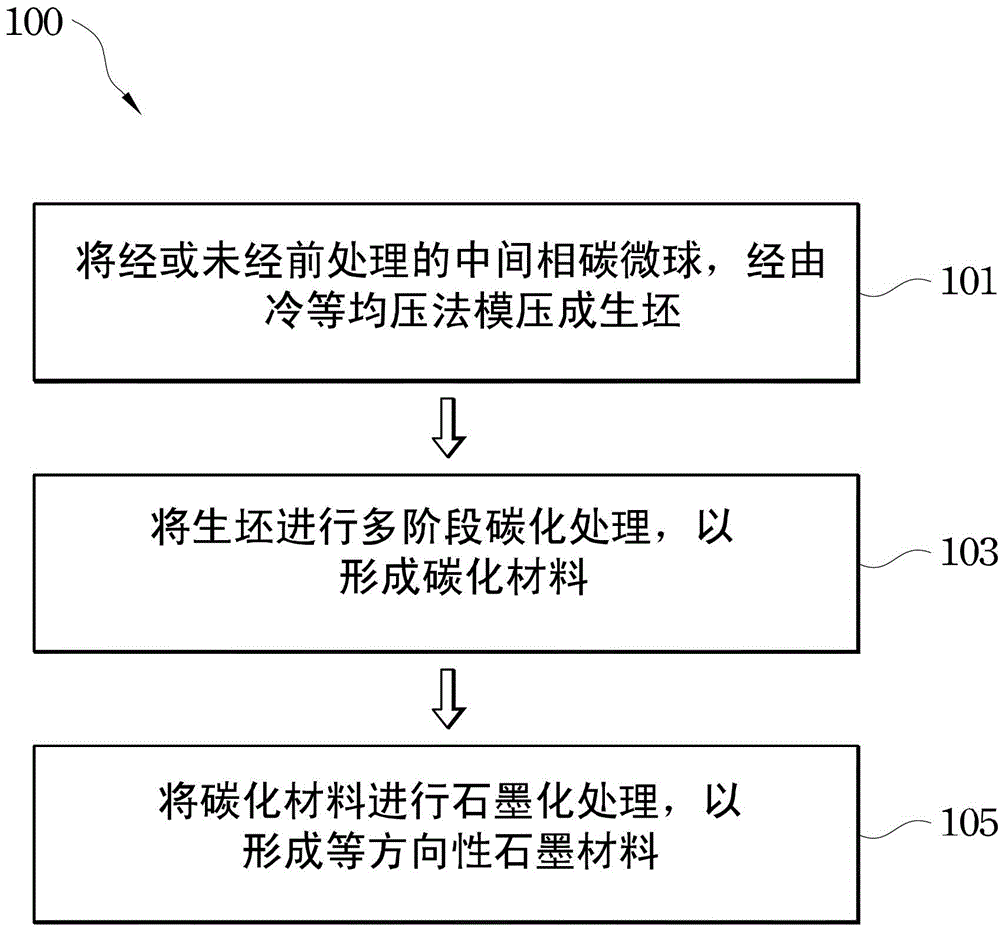

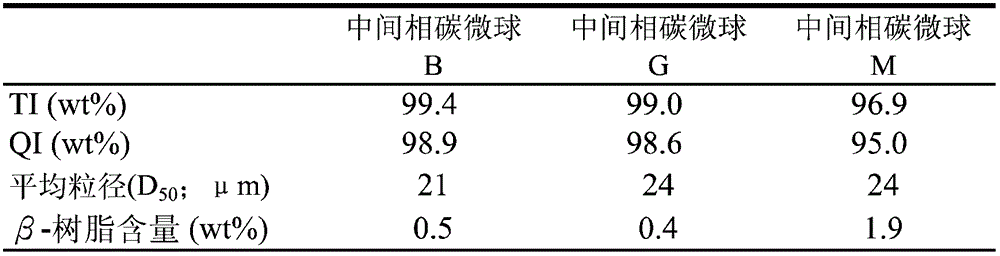

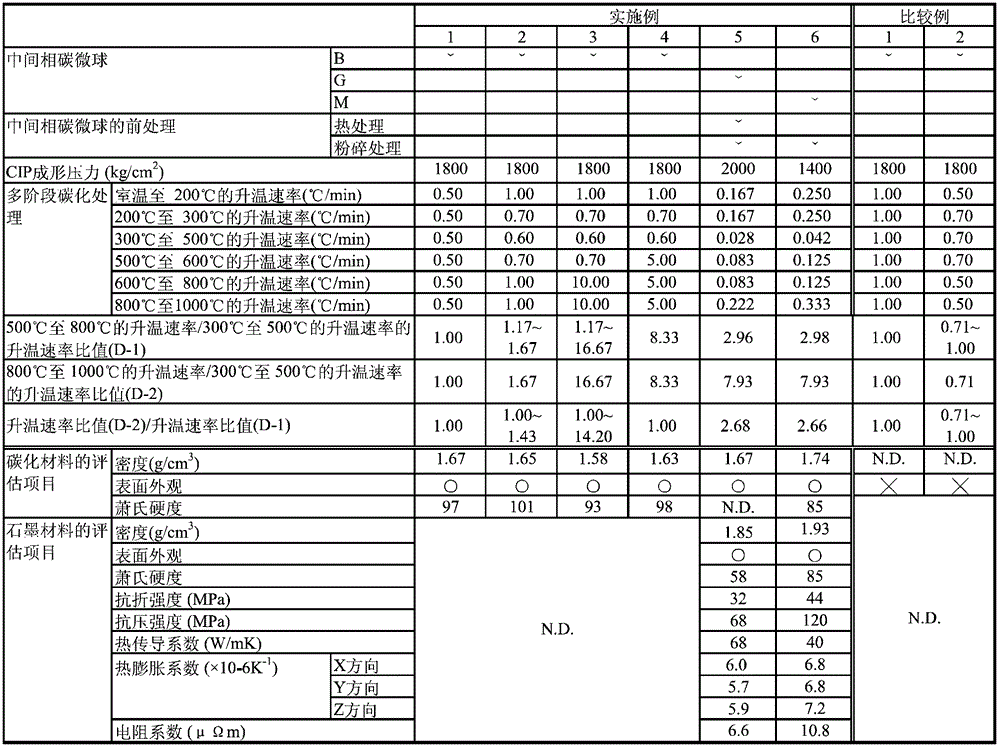

Isotropic graphite material and manufacturing method

The invention discloses an isotropic graphite material and a manufacturing method. Intermediate-phase carbon microspheres subjected or not subjected to pre-treatment, is moulded into green pressing through cold isostatic pressing and subjected to multi-step carbonation to effectively shorten processing time and obtain isotropic graphite material with excellent isotropic properties, intact and flawless surface and excellent mechanical, thermal and electric properties.

Owner:CHINA STEEL

Chemical pump used rubber sealing material

The invention discloses a chemical pump used rubber sealing material. The chemical pump used rubber sealing material is characterized by being prepared from the following ingredients: butadiene styrene rubber, fluororubber, polyethylene glycol, stearic acid, an anti-aging agent, sulfur, polypropylene and a modified filler. Compared with the prior art, the chemical pump used rubber sealing material prepared by the invention has the advantages of good flexibility, low density, compression resilience, wide temperature using range and the like, also has the advantages of higher tensile strength, tearing strength and abrasive resistance, large elasticity modulus, high temperature resistance, chemical corrosion resistance, good heat-conducting property, low thermal expansion coefficient and the like and has self-lubricating property; all the ingredients are uniformly dispersed in the sealing material, therefore, the stability is high, so as to further improve the property of the sealing material; the heat dispersion of the sealing material can be greatly improved through the synergistic effect of all the ingredients and the modified filler, so as not to generate the phenomenon of temperature accumulation.

Owner:安徽富乐泰水泵系统有限公司

Crimped multicomponent fibers and methods of making same

InactiveCN1100904CWith reboundWith strengthMelt spinning methodsConjugated synthetic polymer artificial filamentsPolymer sciencePropylene Polymers

The present invention provides continuously crimped propylene polymer nonwoven fabrics as well as processes for forming crimped multicomponent propylene polymer fibers by melt-attenuating extruded multicomponent fibers with heated or unheated air wherein the fibers spontaneously crimp without the need for additional heating and / or stretching steps.

Owner:FIBERTEX PERSONAL CARE

Production technology of miniature component made of silicon carbide ceramic

The invention discloses a production technology of a miniature component made of silicon carbide ceramic. The production technology comprises the following steps: a, producing powder: using Si powderas a raw material, preparing a grinding medium, and performing wet ball milling to pulverize the Si powder so as to refine the Si powder till the diameter of 2-8 microns, wherein during ball milling,silicon carbide balls and a silicon carbide-lined tank are used; b, mixing silicon powder and coke, using silicon dioxide and petroleum coke, adding table salt and wood dust, placing in an electric furnace, continuously heating, and then taking out a material; c, designing silicon carbide powder in the step b into a presintered body, then machining into a thin sheet, and micromachining the thin sheet by using a precision grinding machine or a micro electrical discharge machining machine; d, placing a machined workpiece in a graphite or silicon carbide crucible; e, machining the carbonized workpiece, and finally grinding and polishing. Modern advanced machining technologies such as laser and ultrasonic are combined into product machining, so that the production efficiency and the quality ofa product are improved.

Owner:FOSHAN HUIZHONG SENTAI TECH CO LTD

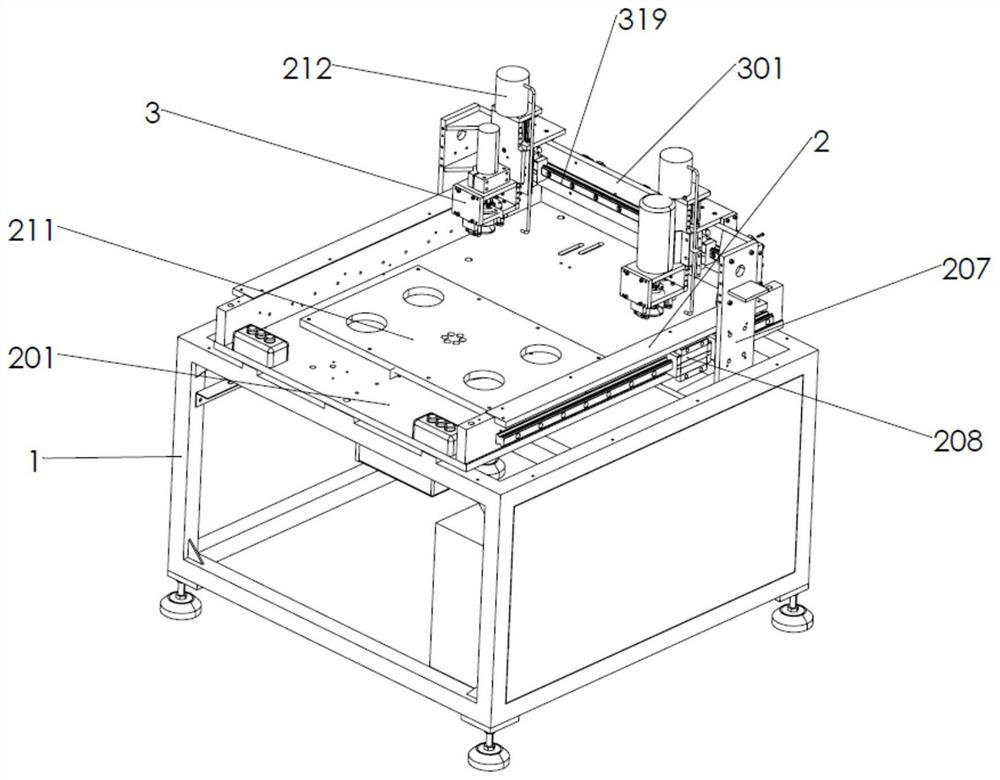

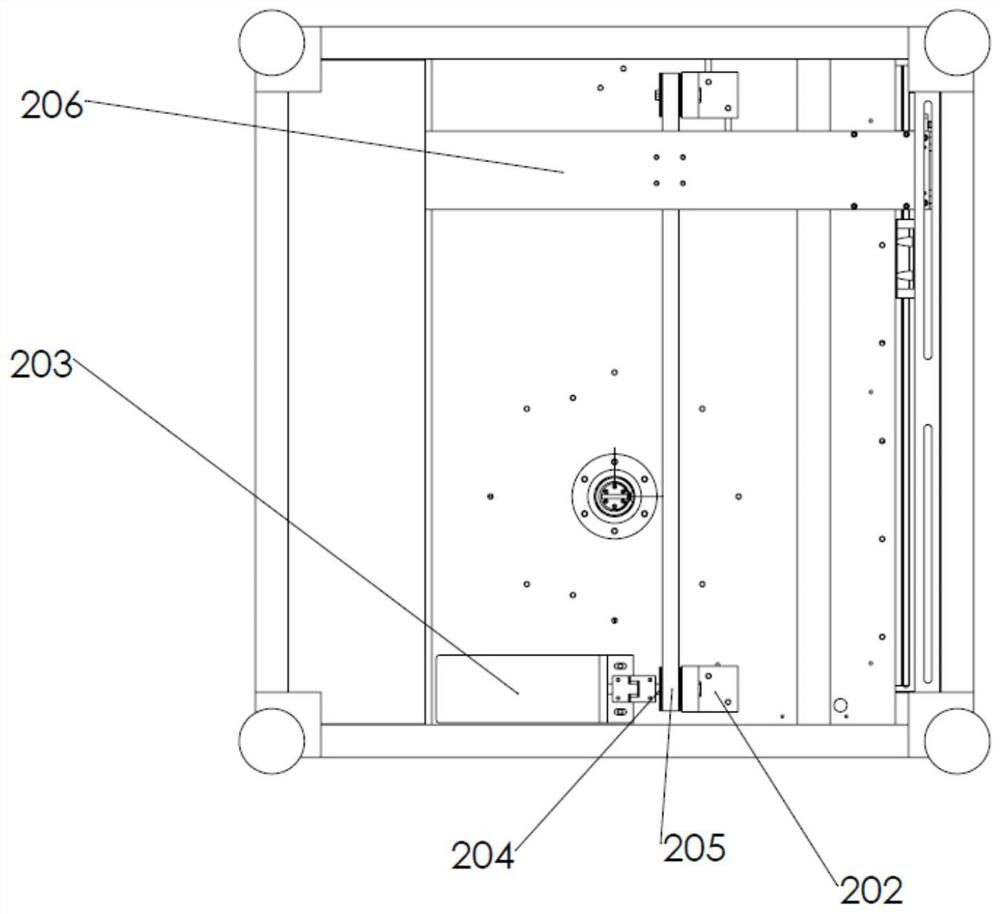

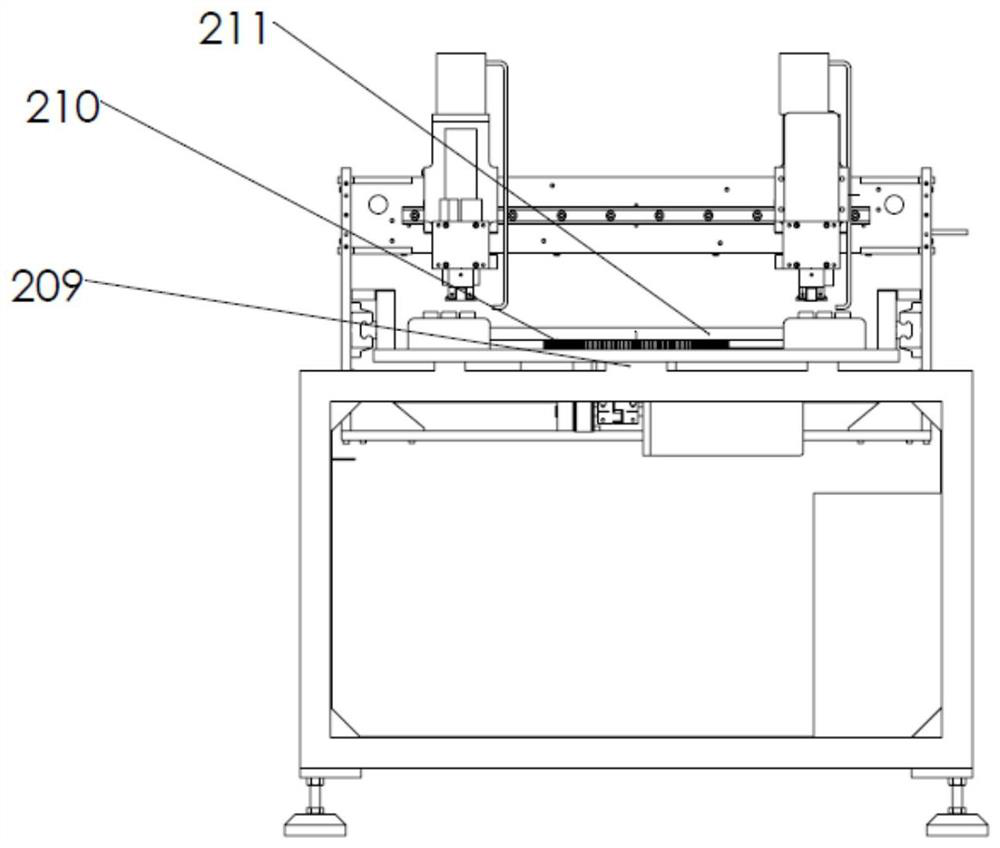

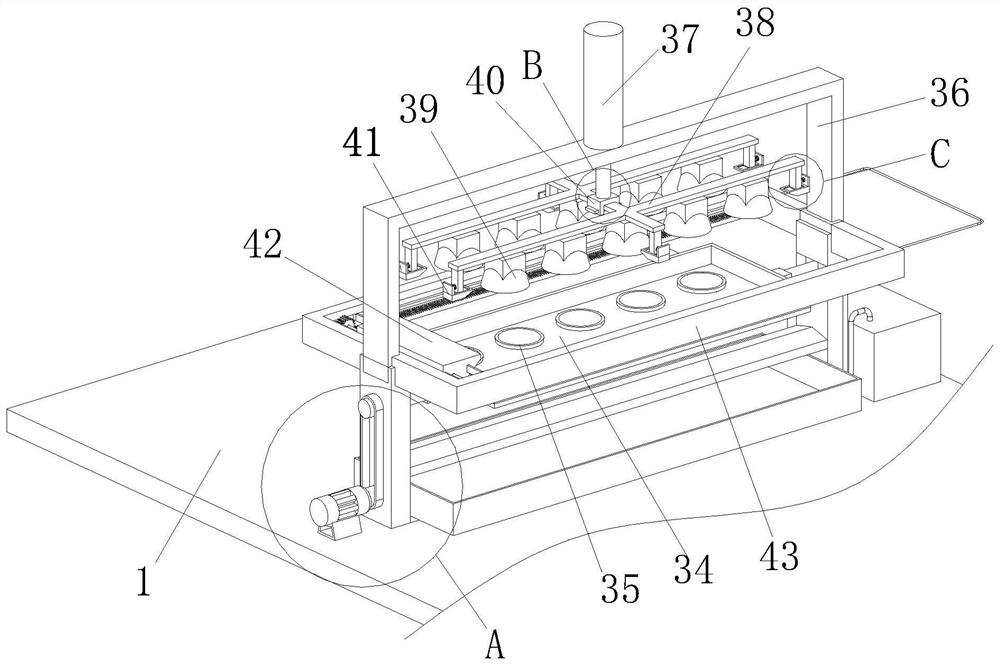

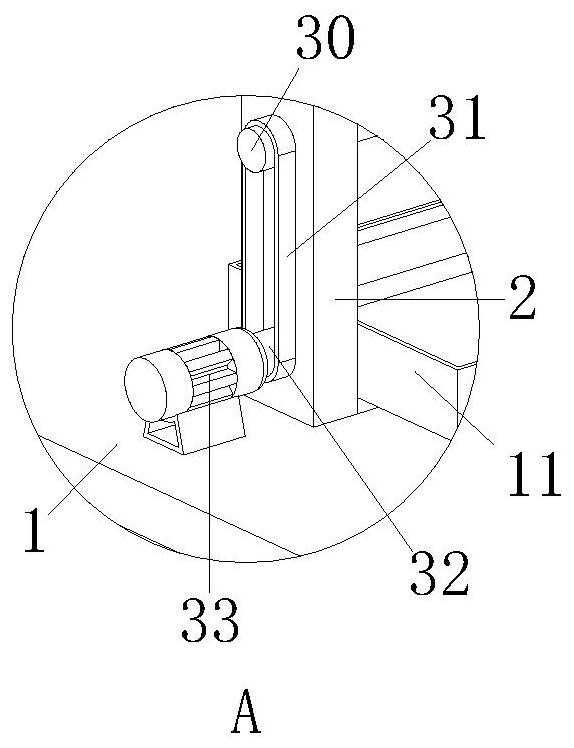

Grinding and polishing system based on stone machining

InactiveCN113523934AReduce roughnessImprove polishing effectPolishing machinesLapping machinesFriction effectElectric machinery

The invention relates to a grinding and polishing system for stone machining. The system comprises a machine frame, a moving mechanism arranged on the machine frame and a grinding and polishing mechanism arranged on the moving mechanism. The moving mechanism comprises a supporting bottom plate, wherein the supporting bottom plate is arranged on the machine frame, a motor fixing block is arranged at the bottom of the supporting bottom plate. A first driving motor is arranged on the motor fixing block, the output end of the first driving motor drives a synchronous wheel and a synchronous belt, and the synchronous belt is connected with a driving block. The two ends of the driving block are connected with first supporting frames, first guide rail sliding blocks are arranged on the inner sides of the first supporting frames, and the first guide rail sliding blocks are arranged on the two sides of the supporting bottom plate. According to the grinding and polishing system for stone machining, a piece of cylindrical felt is arranged, when machining is conducted, the felt rubs the machined plane, a polishing solution is effectively removed, the activity of the solution can also be improved through the heat generated by friction, and a dissolution reaction is promoted. In the adsorption process, polishing is carried out, and the felt continuously eliminates and forms an adsorption layer under the friction effect.

Owner:欧满权

Preparation method and application method of granular activated carbon for xylose decolorization

ActiveCN103754868BHave densityHas thermal conductivityCarbon compoundsOther chemical processesEmulsionPhosphoric acid

The invention discloses a preparation method and an application method of granular activated carbon for xylose decoloring, which belongs to the field of preparation methods and application methods of activated carbon. The preparation method comprises the following steps: (A) preparing raw materials, namely, weighing phosphoric acid method powder activated carbon made from saw dust, an acrylic emulsion and water according to a ratio of acrylic emulsion to phosphoric acid method powder activated carbon to water being (0.37-0.39):1:1; (B) mixing the raw materials, namely, mixing the weighed raw materials and sufficiently stirring till the granules are uniformly mixed; (C) forming granules, namely, extruding the uniformly mixed raw materials to form granules by using a pelletizing machine at the constant temperature of 90 DEG C, so as to make granules with the particle size of 2-5mm, cooling the granules to be 40-50 DEG C, and drying; (E) separating and cooling. The granular activated carbon prepared by using the method is good in adsorption property, high in strength, acid-alkali resisting, recyclable and reusable, the liquid adsorption amount of unit volume is equivalent to that of other granular activated carbons, and the production environment is improved.

Owner:HUNAN KAIFENG ACTIVE CARBON ENVIRONMENTAL PROTECTION SCI & TECH

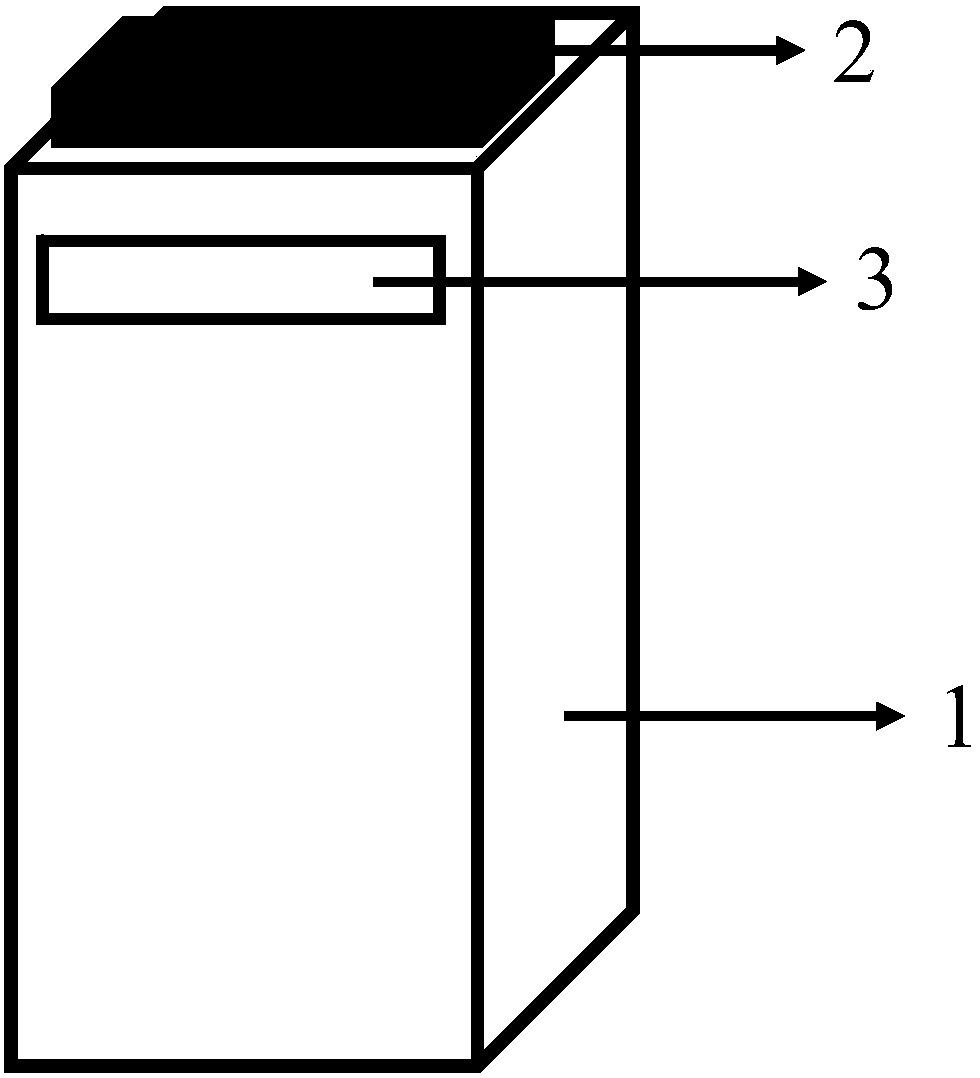

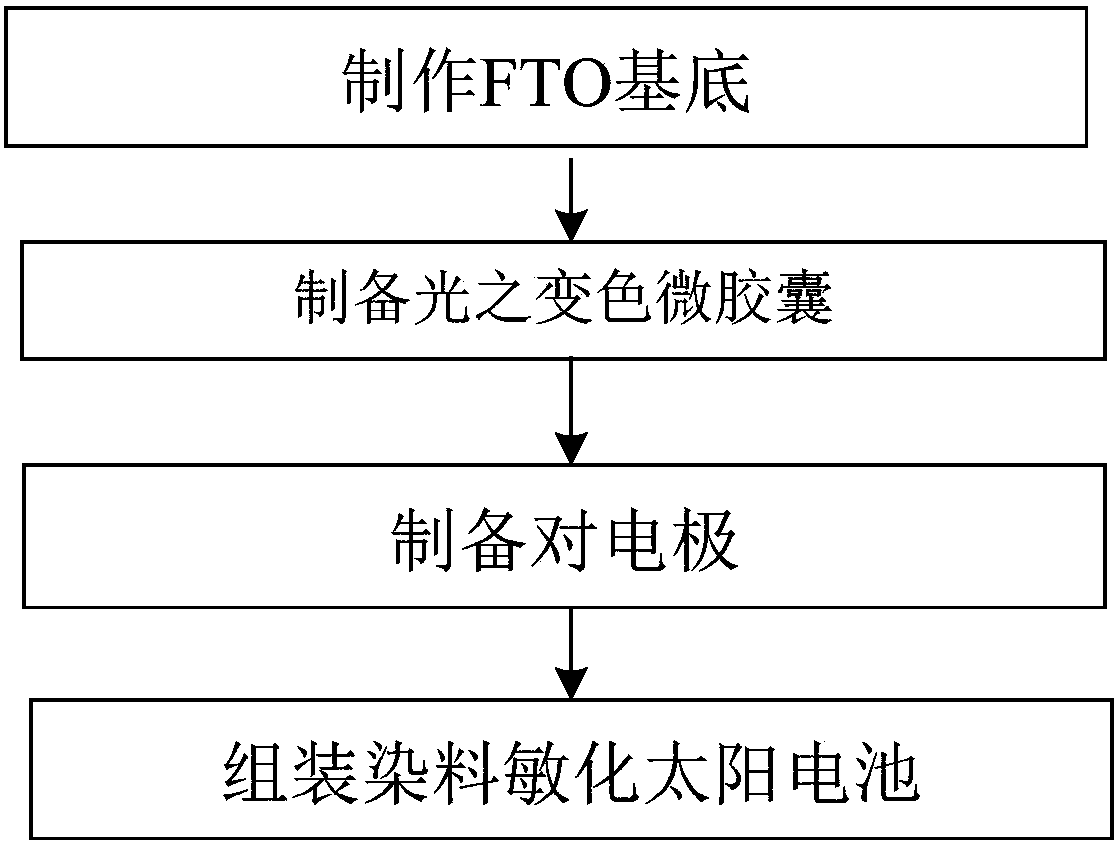

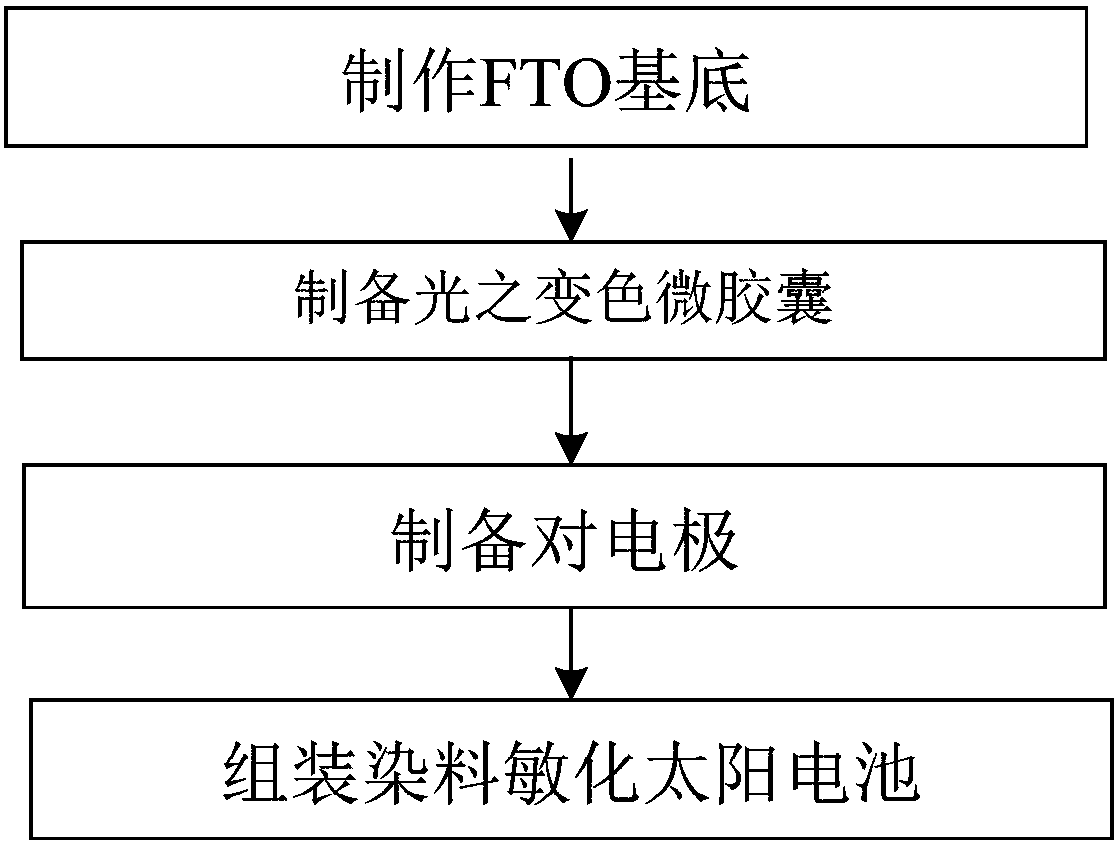

An electric cabinet with temperature adjustment function

ActiveCN105914042BImprove stabilityHinder recombinationLight-sensitive devicesPhotovoltaic energy generationTemperature controlFoaming agent

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Preparation method of low-cost feed for freshwater shrimps

InactiveCN107836597AMeet the needs of growthPromote growthFood processingClimate change adaptationAnimal scienceSemen

The present invention discloses a preparation method of a low-cost feed for freshwater shrimps. The preparation method comprises the following steps: trace elements, vitamins, shrimp head powder, tryptophan, phenylalanine, medical stone powder, soybean oil and water are mixed evenly to obtain a premix; fish meal, laminaria japonica powder, earthworm powder, animal internal organs, sesame seed meal, semen euryales powder, lotus root starch, dried water hyacinth powder, high-gluten flour and the premix are mixed, the mixture is crushed, a moisture content is adjusted, the mixture is stirred evenly, steam is ventilated to conduct a curing, a compound binder is added, the materials are granulated and the granulated materials are cooled to obtain the low-cost feed for the freshwater shrimps. The provided preparation method of the low-cost feed for the freshwater shrimps is simple and convenient in method, and can effectively control costs of the feed, and the obtained feed for the freshwater shrimps is scientific and reasonable in formula, can meet needs of growth of the freshwater shrimps in each stage, effectively improves meat quality and nutrition value of the freshwater shrimps, and promotes the growth of the freshwater shrimps.

Owner:定远县和润水产养殖专业合作社

Machining process for modified fabric

InactiveCN108729084AWith strengthHave densityLiquid/gas/vapor removalHeating/cooling textile fabricsFiberEngineering

The invention discloses a machining process for a modified fabric. The machining process comprises the following steps: moistening a fabric, and feeding the fabric through at least one pair of rollerswhich are heated to 100-260 DEG C, wherein the rollers are adopted to exert pressure of about 20-5800psi to the fabric passing through the rollers, the fabric is a woven, non-woven or knitted fabricor a fiber non-woven net fabric, the water content of the wet fabric accounts for 8-65% of the weight of a dry fabric, the pressure of the rollers is 8-1900psi, and the rollers are heated to 110-230 DEG C. By changing one or more parameters, physical properties of the fabric decided by different viscosities can be changed, such as the stiffness or the hand feeling; by changing passing speeds of the fabric between the rollers or the types of the roller, the physical properties of the fabric can be also changed.

Owner:RUGAO WANLONG GARMENT FACTORY

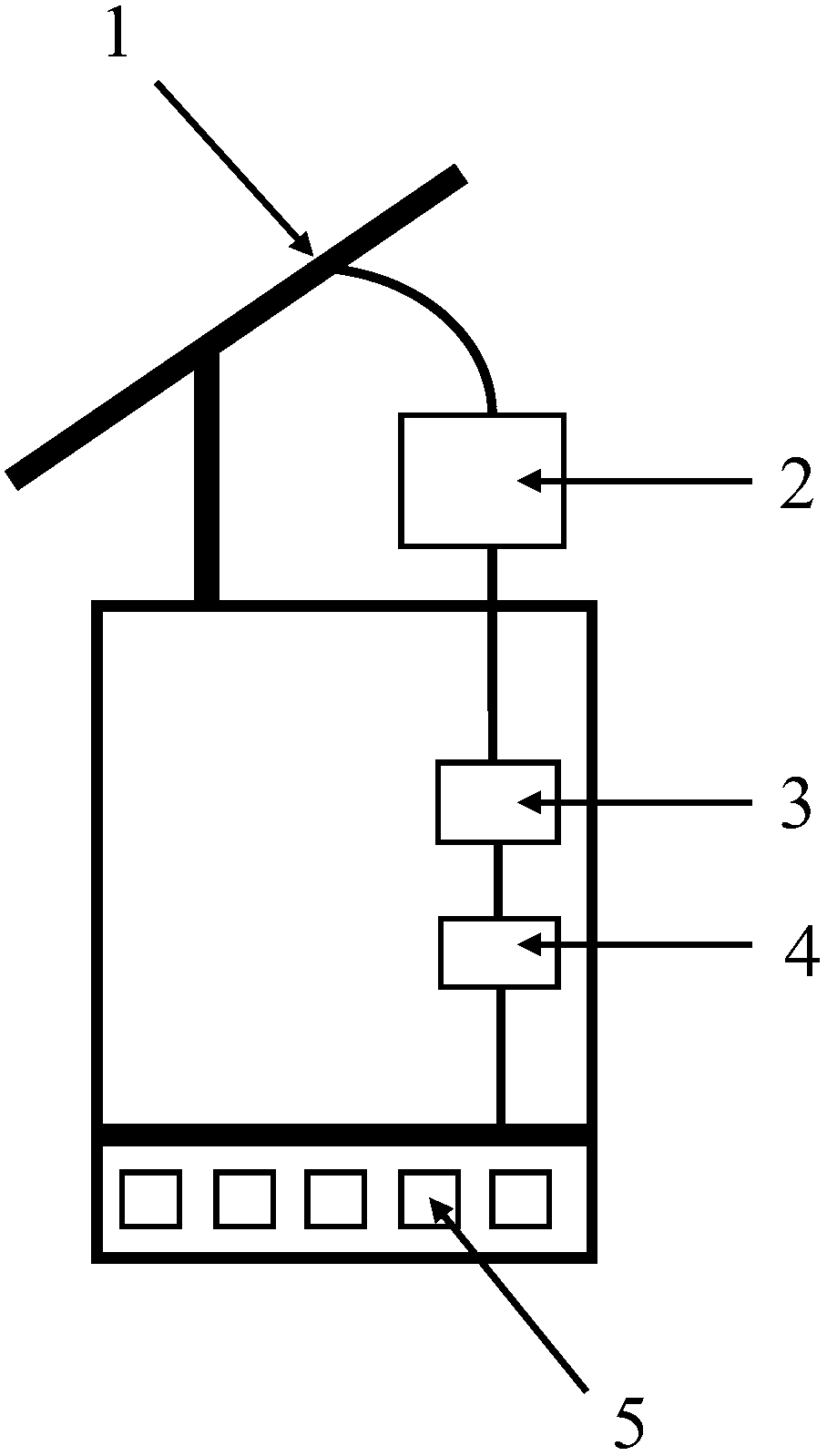

A kind of parking lot power generation equipment based on solar energy device

ActiveCN106128770BImprove stabilityHinder recombinationLight-sensitive devicesPV power plantsElectricityParking space

The invention relates to solar apparatus-based parking lot power generation equipment. The solar apparatus-based parking lot power generation equipment comprises a solar power generation apparatus, an electricity storage apparatus and a charging apparatus, wherein the solar power generation apparatus and the charging apparatus are electrically connected with the electricity storage apparatus respectively; the charging apparatus is arranged in a parking lot; the charging apparatus comprises a charger and charging interfaces; the charger is connected with the electricity storage apparatus; the charging interfaces are electrically connected with the charger; and the charging interfaces are arranged in corresponding charging area parking spaces in the parking lot.

Owner:泰州神威新材料科技有限公司

A kind of toughened environment-friendly back mesh adhesive, its preparation method and application

ActiveCN107090264BFast aggregationFast curing at room temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveFirming agent

The invention discloses toughened environmental-friendly back mesh glue as well as a preparation method and application thereof. A component A is prepared from the following components in parts by weight: 45-65 parts of dicyclopentadiene modified unsaturated polyester resin, 25-40 parts of bisphenol-A epoxy vinyl ester resin, 10-15 parts of hyperbranched unsaturated polyester, 1-2.5 parts of a dispersant, 5-10 parts of a core-shell particle toughening agent, 25-40 parts of spherical fine silicon powder, 15-25 parts of nano calcium carbonate, 0.2-0.8 part of an accelerator and 0.02-0.08 part of a polymerization inhibitor. A component B is prepared from the following components in parts by weight: 10-70 parts of a solidifying agent, 30-40 parts of a blending agent, 30-50 parts of an inorganic filler and 3-10 parts of a stabilizer. After the component A and the component B are mixed, the solidifying agent accounts for 0.5-3.5 percent of the total weight of the mixture. The back mesh glue is small in viscosity, good in permeability, moderate in rheology and low in content of total volatile organic compounds (VOCs); and the mechanical strength, particularly the impact resistance, of a back mesh stone is remarkably superior to that of the existing product.

Owner:江苏大力士云石护理材料有限公司

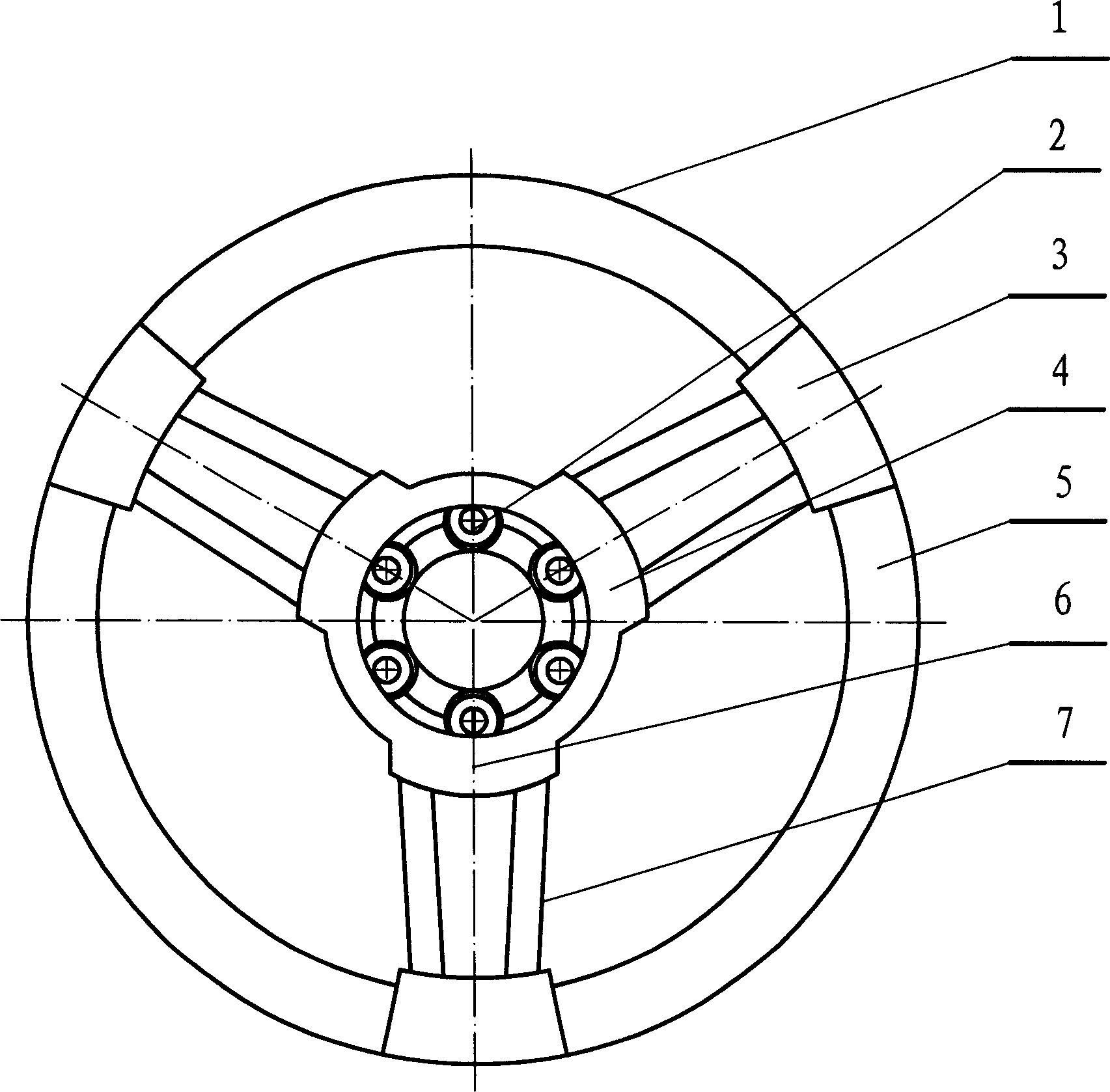

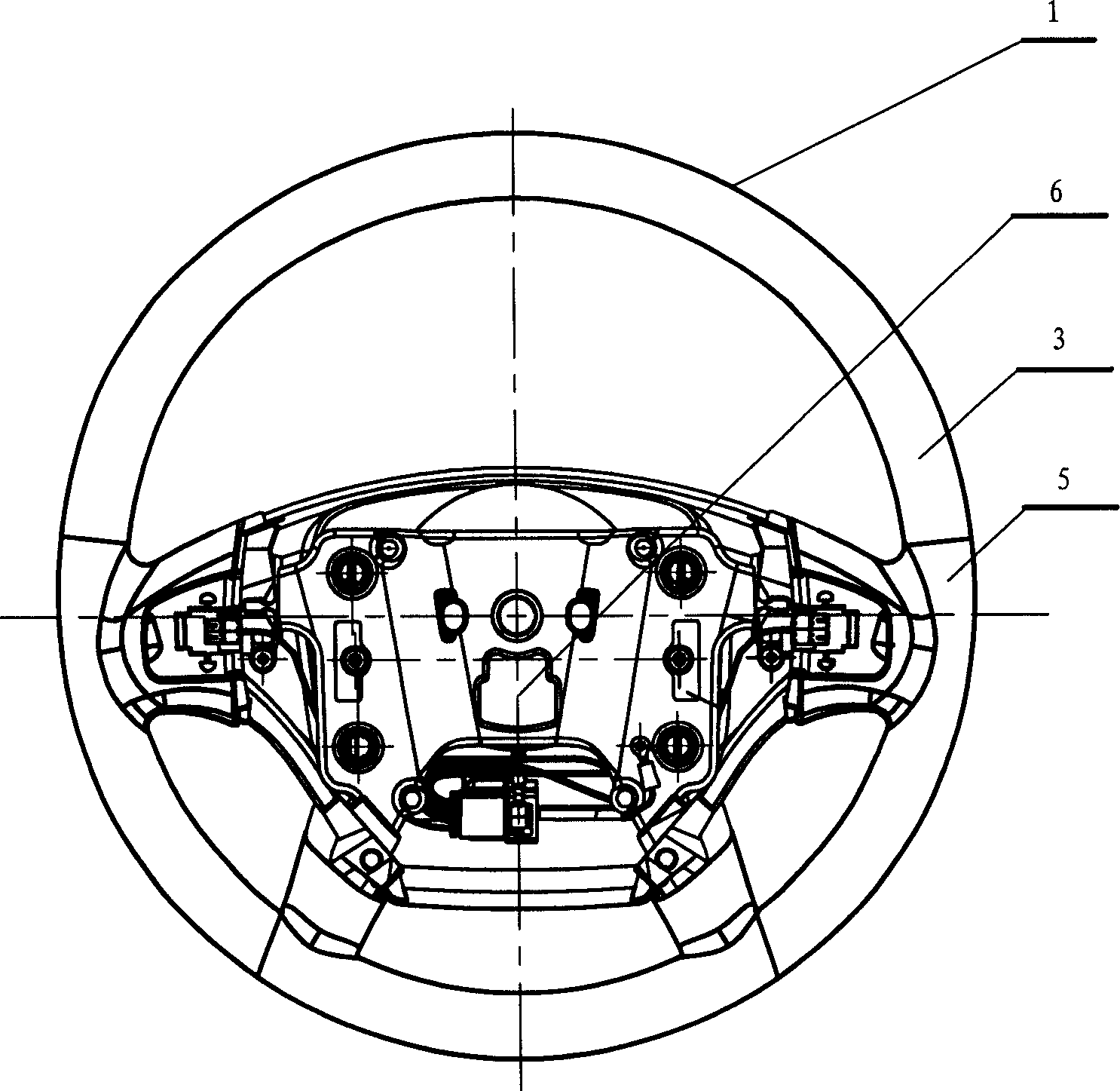

Second time of foaming steering wheel

A secondly foamed steering wheel for yacht or motor-driven vehicle is composed of the foamed wheel rim consisting of the primarily foamed body and the secondly foamed body, and the skeleton connected with said wheel rim.

Owner:林楚华

Micro processing process for silicon nitride ceramic parts

The invention relates to a micro-machining method of a silicon nitride ceramic component, which relates to a processing technology of a micro-component of a silicon nitride ceramic with high temperature resistance, oxidation resistance and high hardness. The method mainly includes three parts: (1) using hot pressing or plasma discharge sintering technology to pre-sinter the Si powder and control the density at 70-85%; (2) using precision machining or micro electric discharge machining Or photolithography and reactive ion etching and other silicon micromachining techniques are used to micro-process the Si powder pre-sintered body; (3) heat the micro-processed Si powder pre-sintered body parts in nitrogen to cause nitriding reaction to occur, Thus reaction sintering to obtain Si 3 N 1 Ceramic micro components. The invention combines the characteristics of micromachining and reaction sintering of silicon nitride ceramics, thereby realizing the micromachining and micromolding of silicon nitride ceramic microcomponents, and can increase the density by about 22%. It is very suitable for the preparation of microcomponents.

Owner:TSINGHUA UNIV

Method for preparing sugar ester through immobilized enzyme catalysis under supercritical CO2 process

ActiveCN109251944ASuitable for industrial productionEfficient use ofHydrolasesOn/in organic carrierNitrogen gasFatty acid

The invention belongs to the technical field of biological catalysis, and in particular relates to a method for preparing sugar ester through immobilized enzyme catalysis under the supercritical CO2 process. The method for preparing sugar ester through immobilized enzyme catalysis specifically comprises the following steps: taking bromopropionic acid, acetonitrile and imidazole compounds, and carrying out reaction to obtain a modifier; adding the modifier and carbonyldiimidazole into anhydrous dimethylsulfoxide, and carrying out stirring for reaction, thus obtaining an active body; adding theactive body into a lipase solution, and carrying out reaction to obtain an acylated lipase solution; adding monomer acrylamide into the acylated lipase solution, carrying out stirring for dissolving,introducing nitrogen gas, adding ammonium persulfate and tetramethylethylenediamine, and carrying out polymerization reaction, thus obtaining the immobilized lipase; and mixing sugar with fatty acid,thus obtaining a reactant, adding the immobilized lipase, placing in a reaction still, adding CO2 medium, and carrying out stirring reaction, thus obtaining the sugar ester. For the method provided bythe invention, the reaction conditions are mild, the operation is simple, the conversion rate is high, meanwhile, the enzyme catalyzer can be repeatedly used, the pollution to the environment is small, and the method is expected to realize the industrial production.

Owner:JIANGSU UNIV

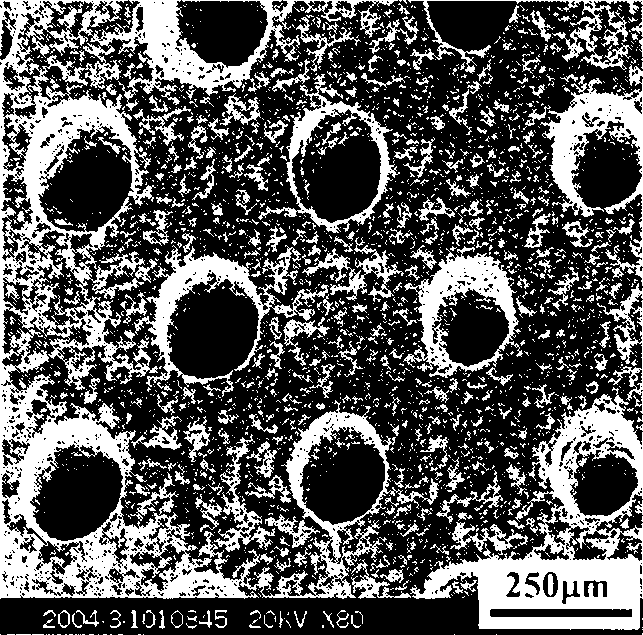

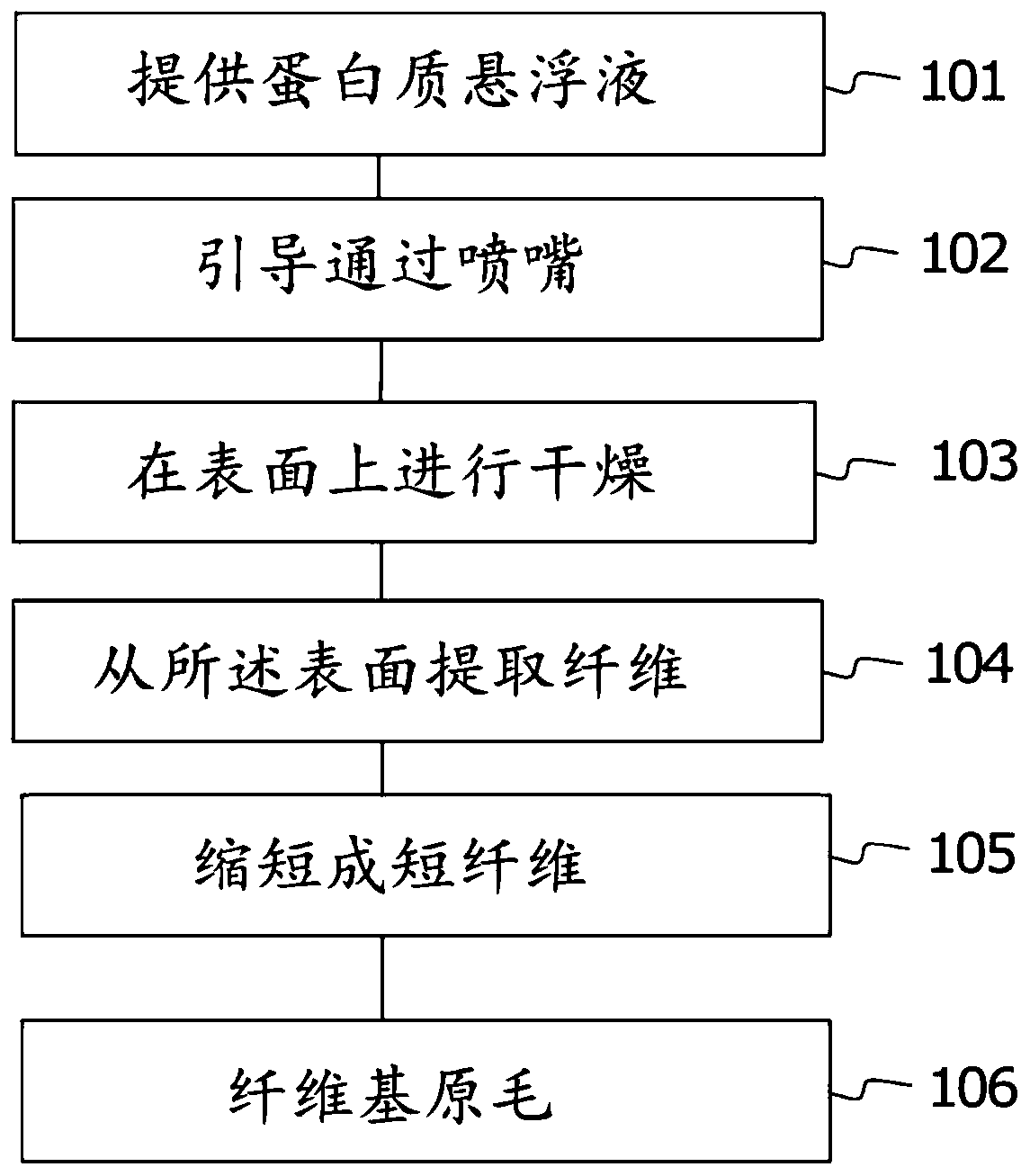

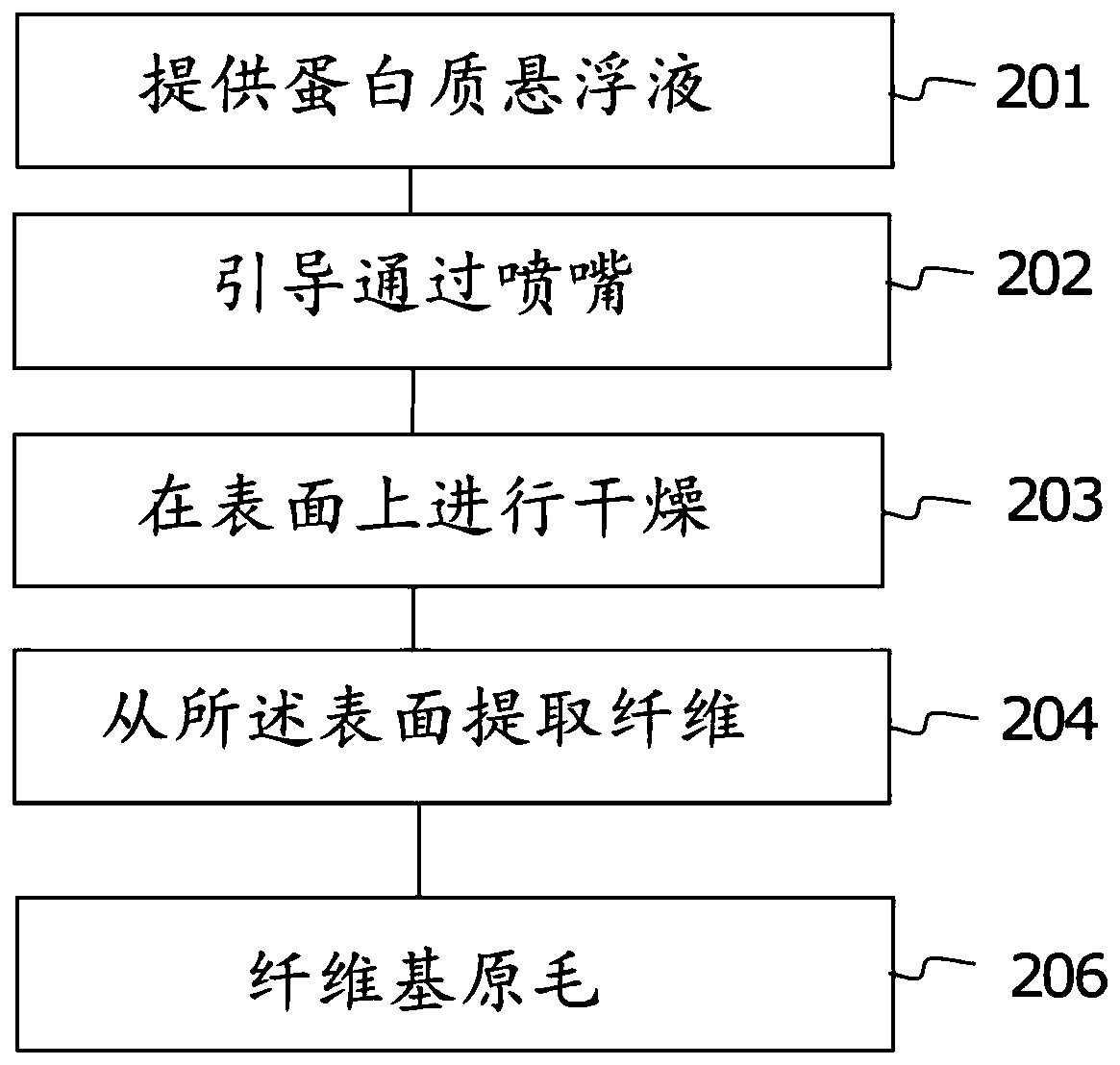

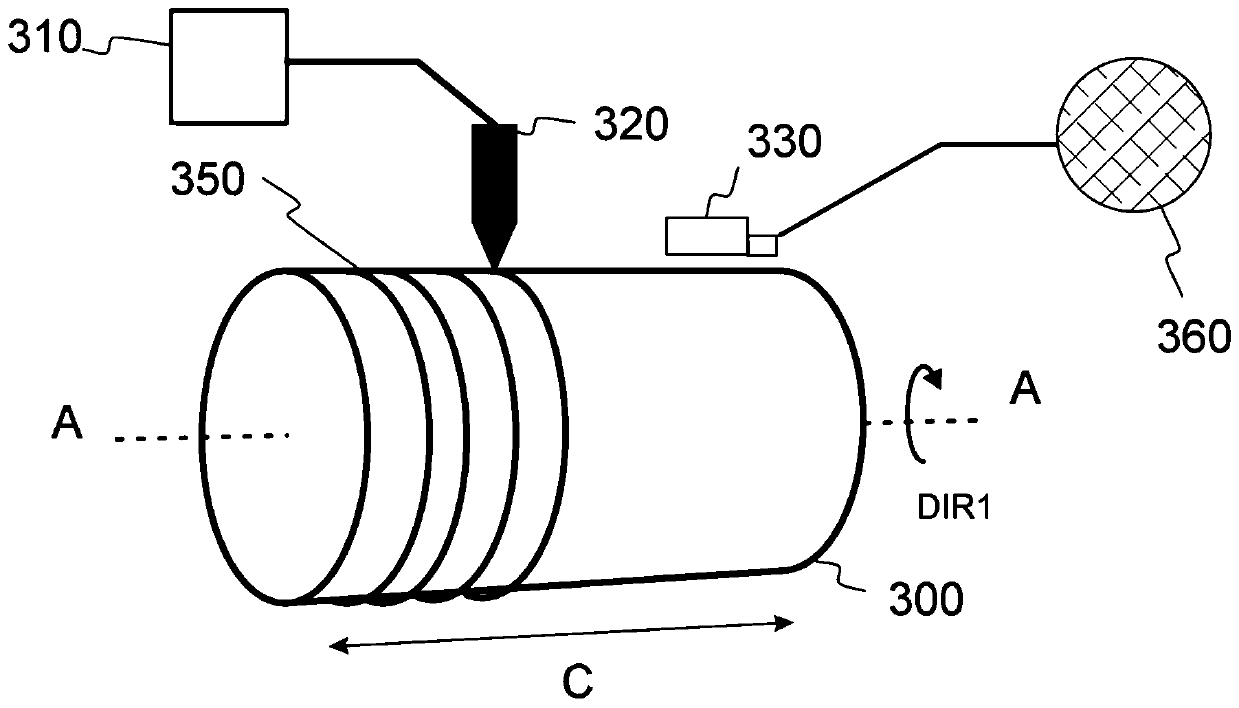

Method and apparatus for manufacturing a staple fiber based on natural protein fiber, a raw wool based on the staple fiber, a fibrous yarn made of the staple fiber, a non-woven material made of the staple fiber and an item comprising the staple fiber

ActiveCN110418861ADifferent performanceReduce fiber strengthSurgical adhesivesMonocomponent cellulose artificial filamentYarnFibril

A method for manufacturing a staple fiber based on natural protein fiber, the method comprising the steps of: - providing a protein suspension, - the protein suspension comprising fibrils of said natural protein fiber, - directing the protein suspension through a nozzle (520) onto a surface (500), - drying the protein suspension on the surface for forming a protein based fiber, - extracting the fiber from the surface and providing the staple fiber.

Owner:ECCO SKO +1

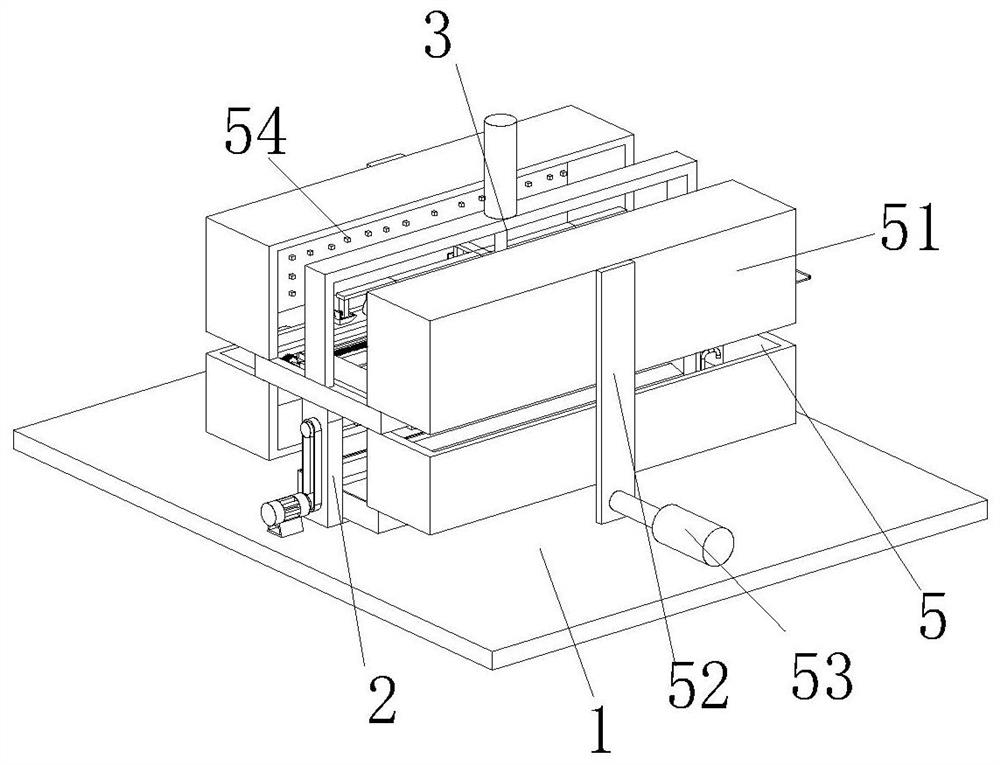

Preparation and processing equipment and method for aluminum oxide grinding medium

The invention provides preparation and processing equipment and method for an aluminum oxide grinding medium, and relates to the technical field of preparation and processing of grinding media. The preparation and processing equipment comprises a bottom plate, a supporting frame, a mold pressing device and a drying device, wherein the supporting frame is fixedly arranged on the bottom plate, the mold pressing device is arranged on the supporting frame, and the drying device is arranged below the mold pressing device. In addition, the preparation and processing equipment and method can solve the following problems that a, in the existing preparation and processing process of the aluminum oxide grinding medium, the volume density of the aluminum oxide grinding medium is unqualified, the quality of the aluminum oxide grinding medium is poor, the aluminum oxide grinding medium is prone to being broken in the using process, and therefore the equipment is damaged when a mill is used; and b, in the existing preparation and processing process of the aluminum oxide grinding medium, the product is not subjected to subsequent drying treatment in time after mold pressing, so that the aluminum oxide grinding medium is not of a regular spherical structure during forming, and the shape of the product is changed.

Owner:淄博和润马科托矿业技术有限公司

Isotropic graphite material and manufacturing method thereof

The invention discloses an isotropic graphite material and a manufacturing method. Intermediate-phase carbon microspheres subjected or not subjected to pre-treatment, is moulded into green pressing through cold isostatic pressing and subjected to multi-step carbonation to effectively shorten processing time and obtain isotropic graphite material with excellent isotropic properties, intact and flawless surface and excellent mechanical, thermal and electric properties.

Owner:CHINA STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com