Patents

Literature

82results about How to "Coating thickness controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

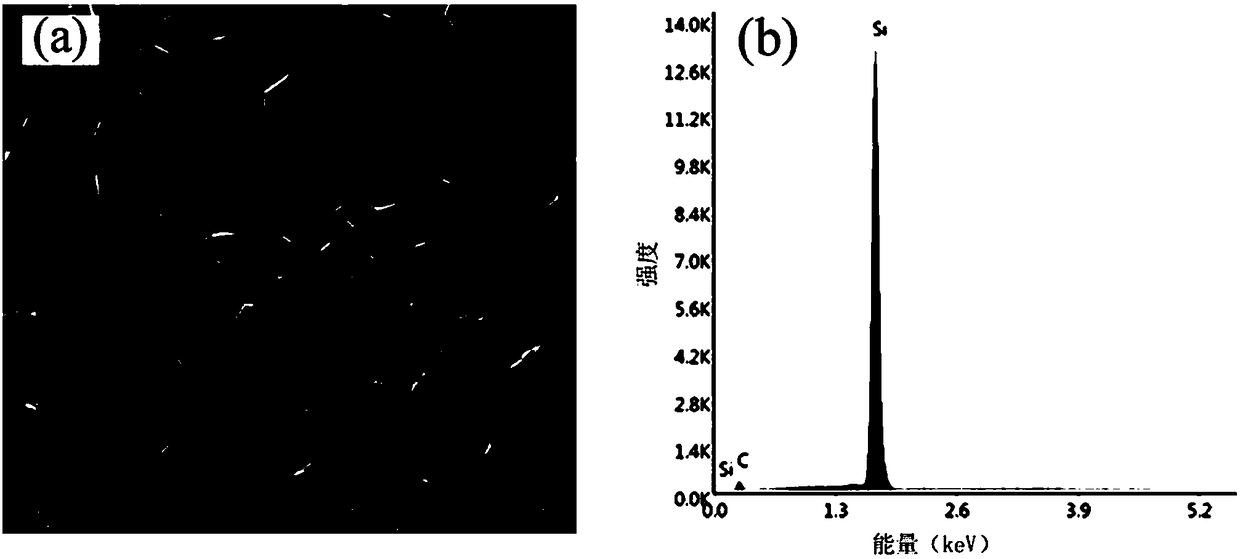

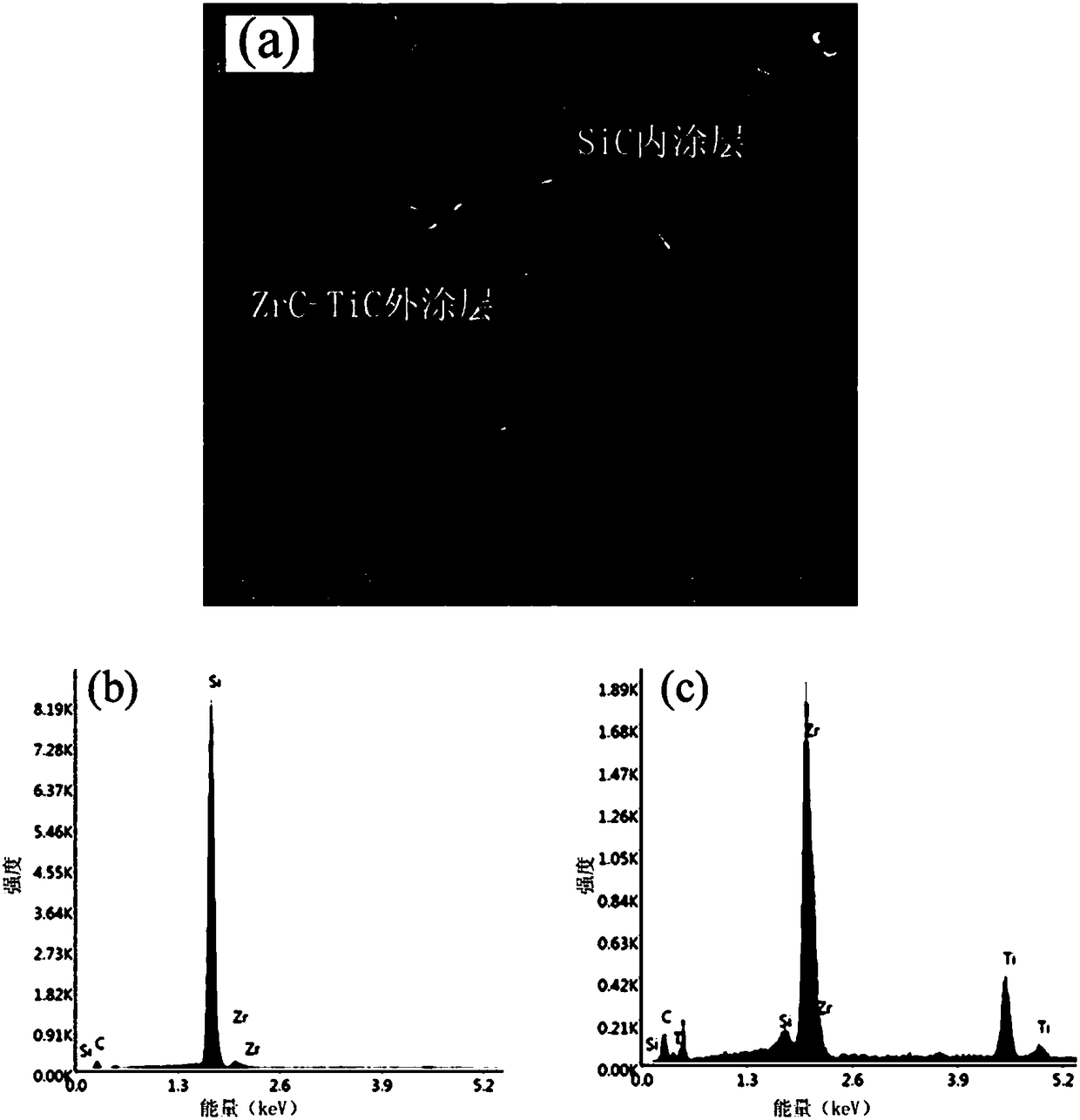

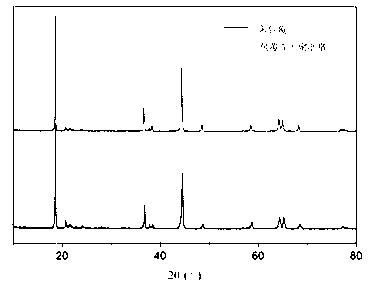

C/C composite material superhigh temperature ceramic coating, and preparation method thereof

InactiveCN108530110AExtended service lifeReduce Mismatch ProblemsUltra-high-temperature ceramicsCeramic coating

The invention discloses a C / C composite material superhigh temperature ceramic coating, and a preparation method thereof. The C / C composite material superhigh temperature ceramic coating is composed of an anti-oxidation SiC transition internal layer and a superhigh temperature ablation-resistant ceramic external layer; the superhigh temperature ablation-resistant ceramic external layer is composedof more than one ingredients selected from SiC, ZrC, HfC, TaC, TiC, ZrB2, HfB2, TaB2, and TiB2. The preparation method is suitable for industrialized production, is simple in equipment, is convenientin operation, is capable of controlling coating thickness, satisfying preparation requirements of large size C / C composite material superhigh temperature ceramic coating with complex shapes, and is asuperhigh temperature ceramic coating preparation method with excellent development potential.

Owner:CENT SOUTH UNIV

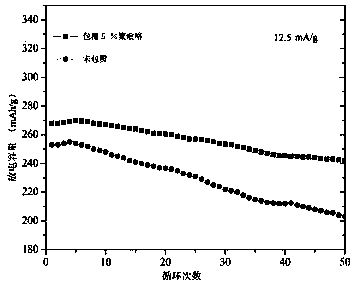

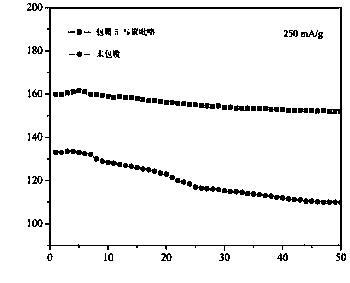

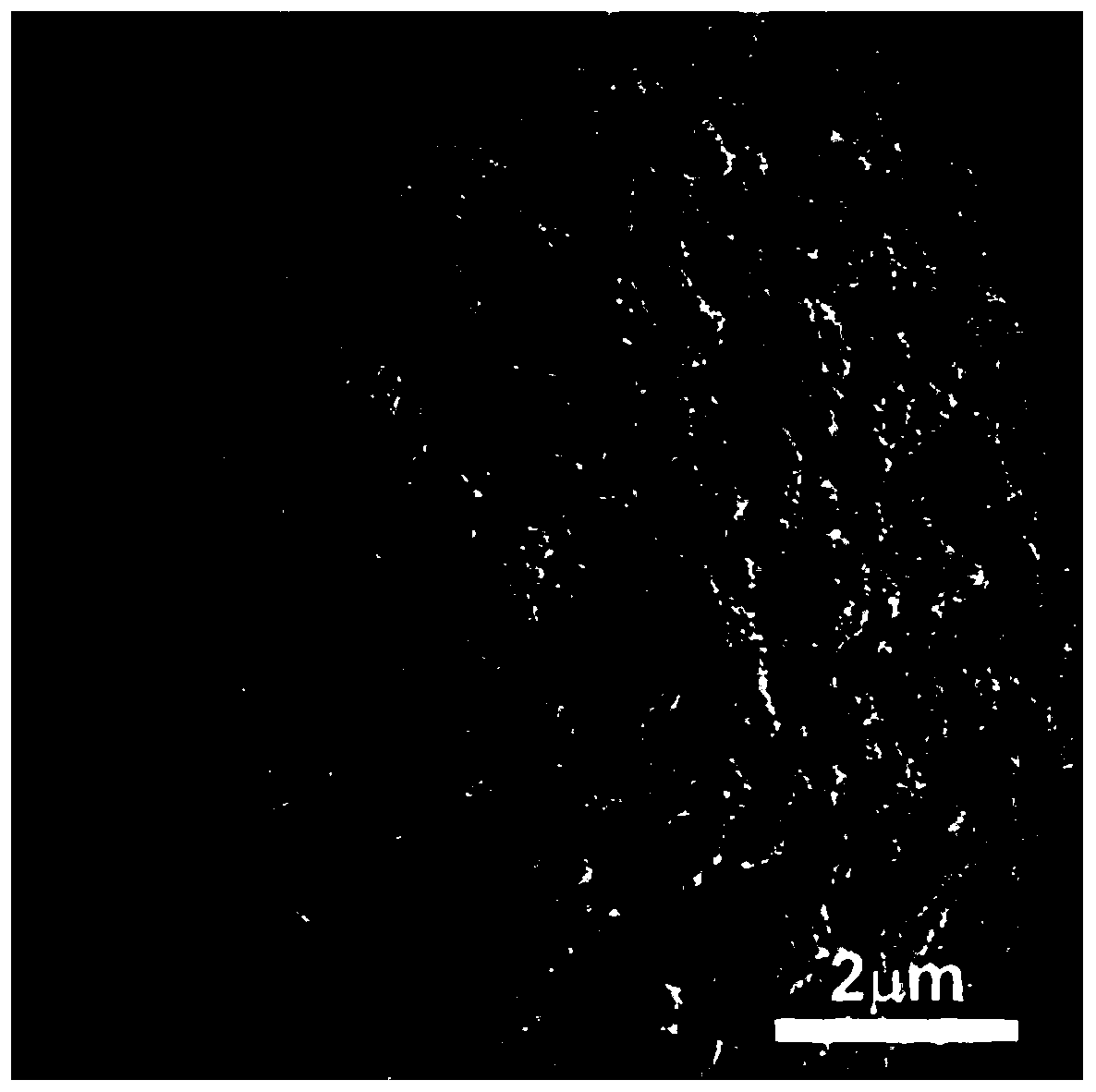

Modification method of lithium-enriched manganese-based solid solution lithium battery cathode material

InactiveCN103985853AEasy to prepareCoating thickness controllableCell electrodesSecondary cellsElectrically conductiveLithium electrode

The invention relates to a modification method of a lithium-enriched manganese-based solid solution lithium battery cathode material. The modification method comprises following steps: (1) prepared Li2MnO3-LiMO2 (M is used for representing at least one selected from Ni, Co, and Mn), and a conductive polymer monomer are uniformly dispersed in an acid solution via ultrasonic dispersion so as to obtain a mixed solution; (2) an oxidizing agent acid solution with a certain concentration is prepared, and is added into the mixed solution, and an obtained mixture is stirred and reacted; and (3) an obtained product is subjected to pumping filtration, centrifugation, washing, and drying so as to obtain the lithium-enriched manganese-based solid solution lithium battery cathode material coated with the conductive polymer. The modification method is simple; the thickness of the coating is controllable; large scale production can be realized; first time irreversible capacity loss of lithium-enriched cathode material is reduced; rate capability of the lithium-enriched manganese-based solid solution lithium battery cathode material is improved; demands on high power lithium ion batteries are satisfied; and the flexible conductive polymer is capable of increasing compacted density of the lithium-enriched manganese-based solid solution lithium battery cathode material, and reducing destroy on the lithium-enriched manganese-based solid solution lithium battery cathode material caused by compacting processes.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

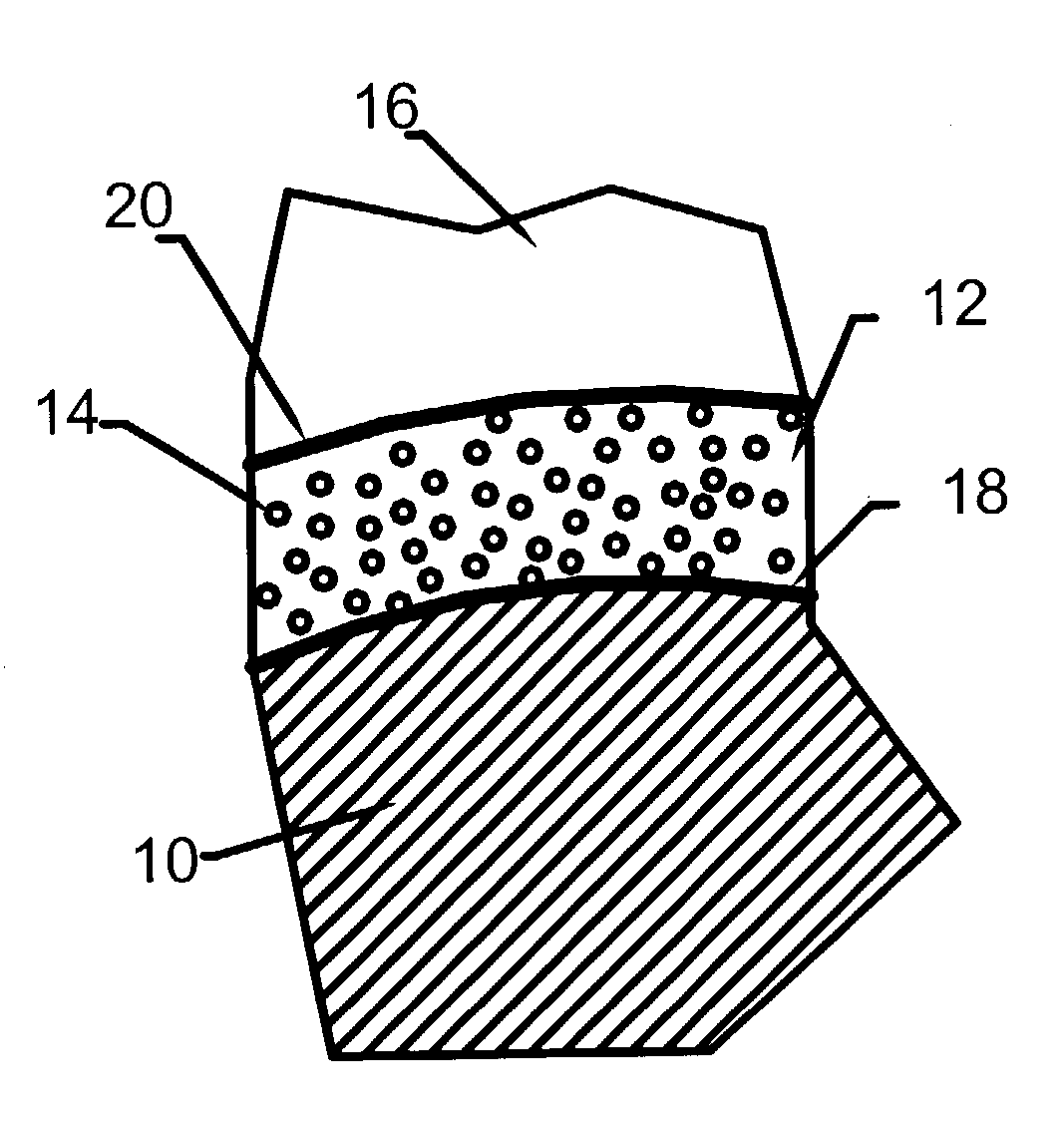

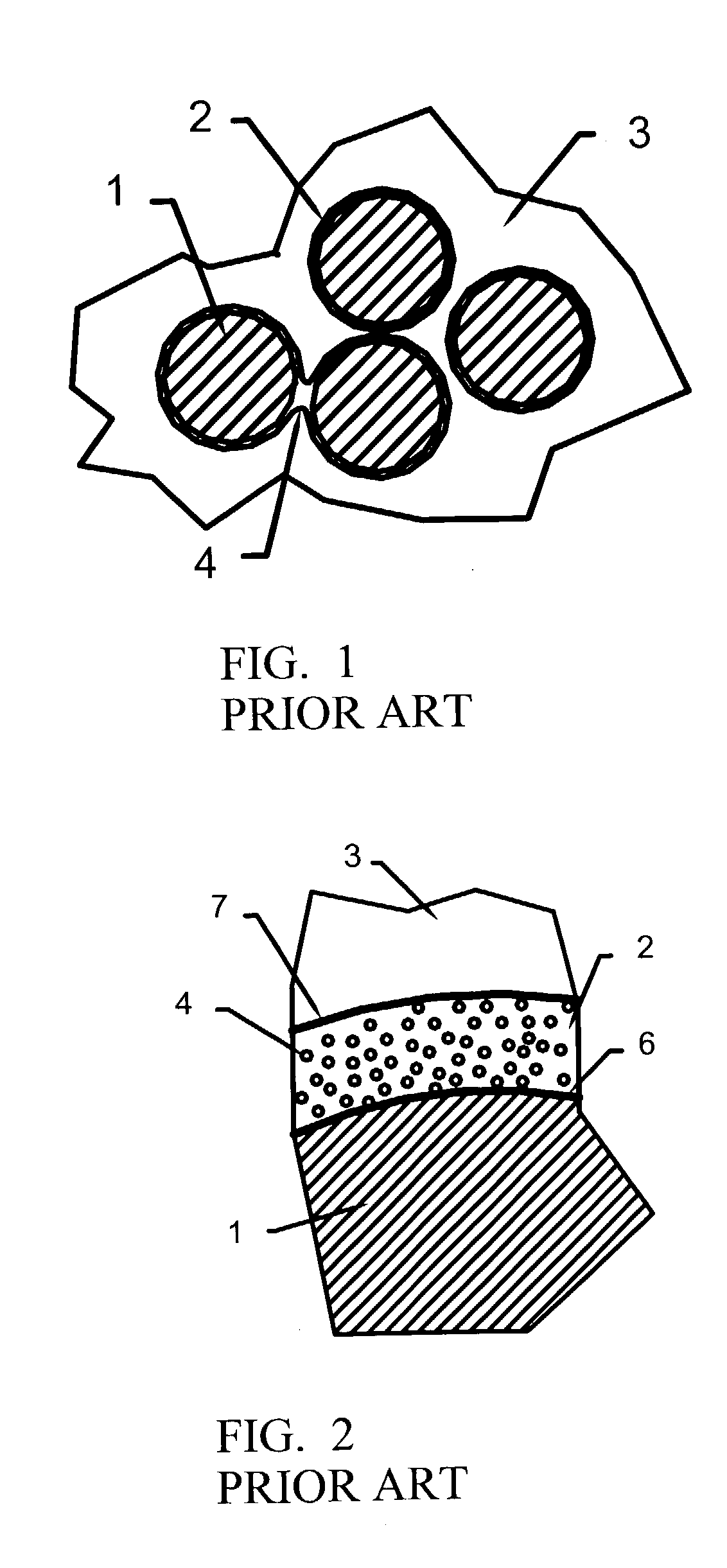

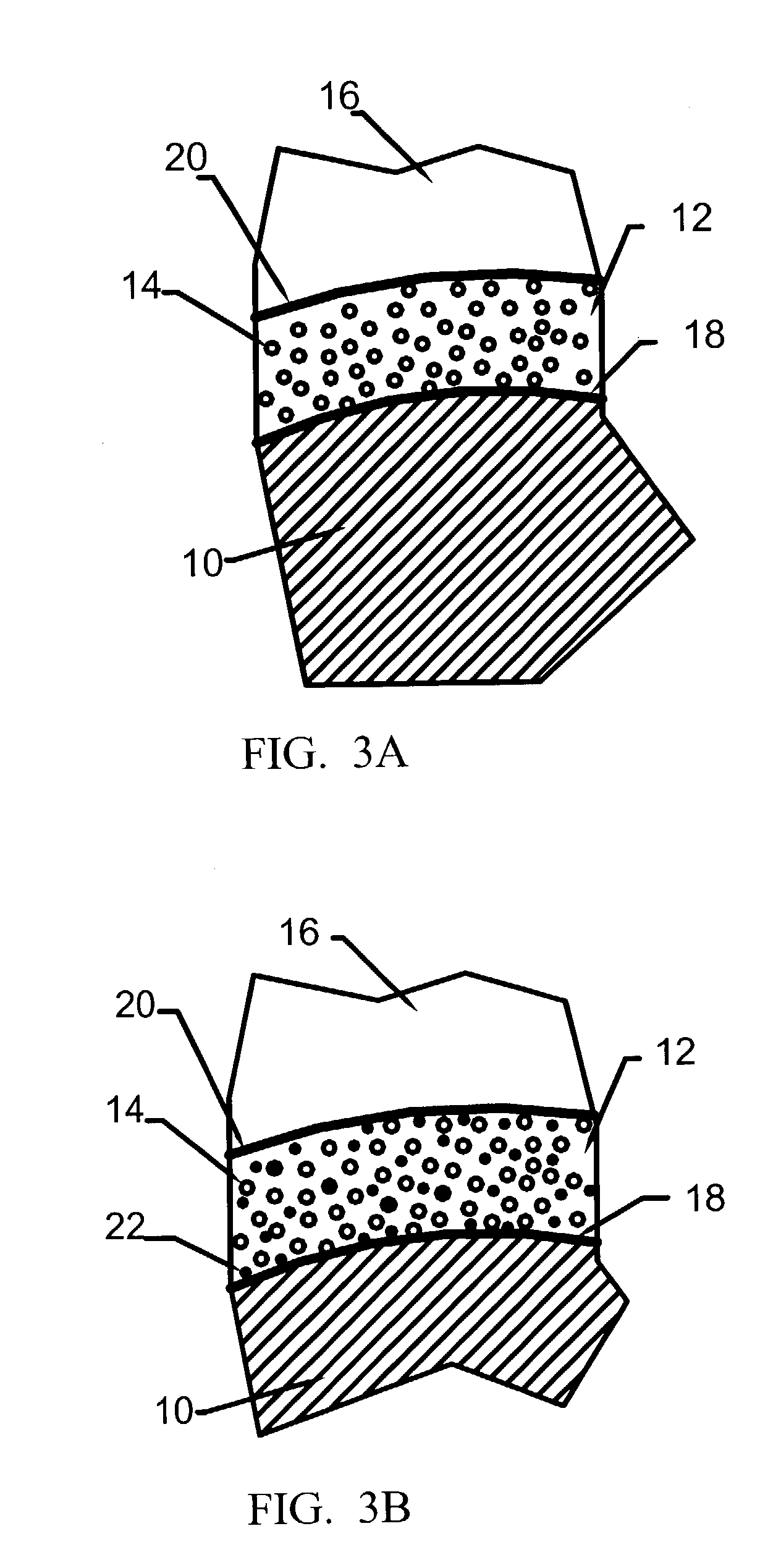

Ceramic forming polymer derived ceramic composite and methods

InactiveUS20040138046A1Resists oxidationLess-expensive to applyLiquid surface applicatorsCoatingsCeramic compositeHydrogen

A ceramic composite having a ceramic coating formed from a ceramic forming polymer of adjustable composition. The ceramic forming polymer is capable of producing a weak interface-type fiber coating for the ceramic composite, resists oxidation and is less expensive to apply. The invention also includes methods of using a ceramic forming polymer to provide fiber coatings tailored to the type of matrix, fiber, or other reinforcement used. The material forms micro-porous and nano-porous coatings on the fibers. The porosity in the coatings provides a low strength interface between the fiber and matrix that imparts the toughness needed in the composite. The material can be provided with controlled ratios of carbon, silicon, oxygen and hyrdrogen to optimize bonding to the fibers, bonding of the matrix to the fiber coating, and environmental protection of the fibers.

Owner:STARFIRE SYST

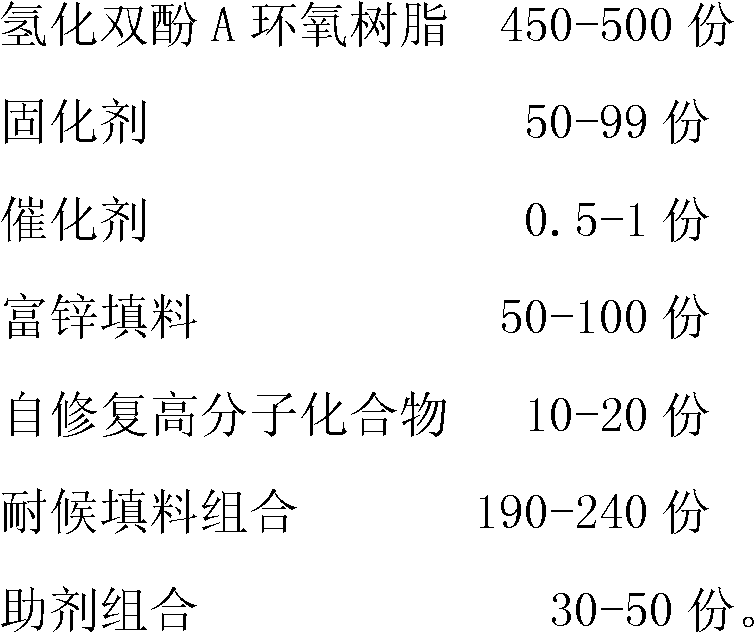

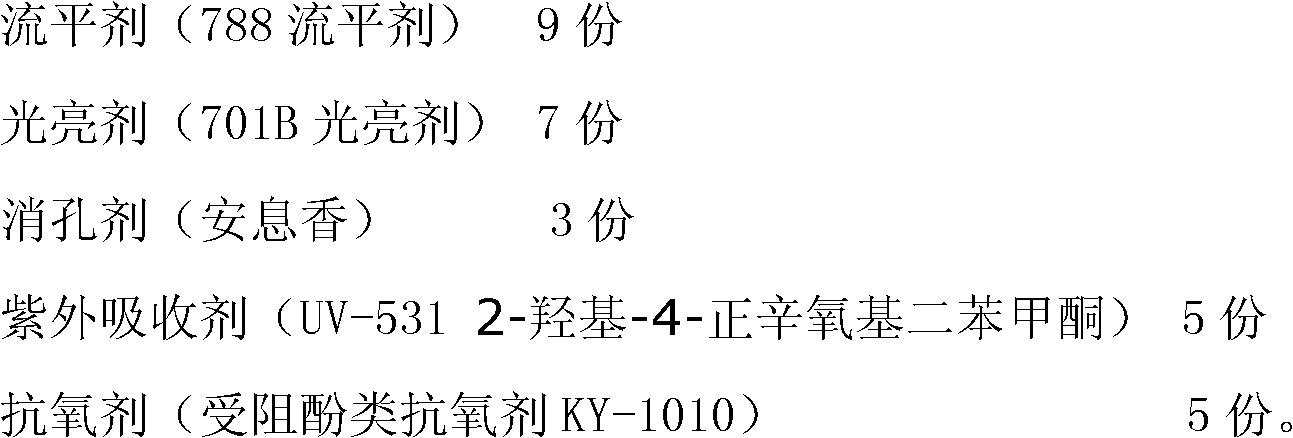

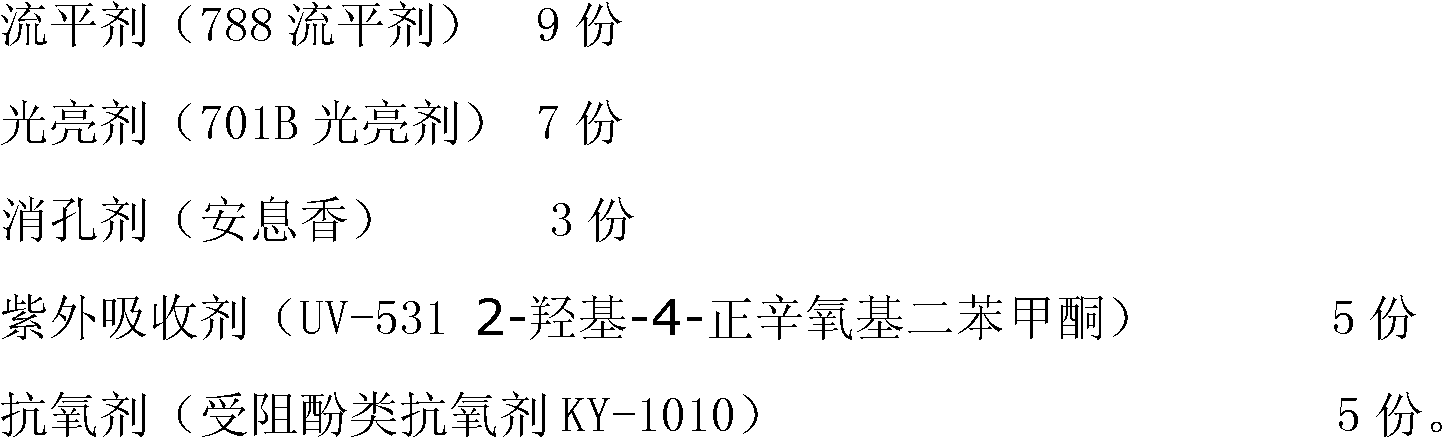

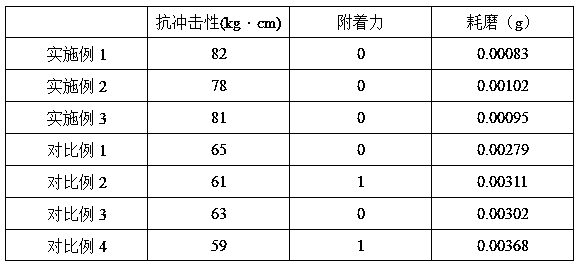

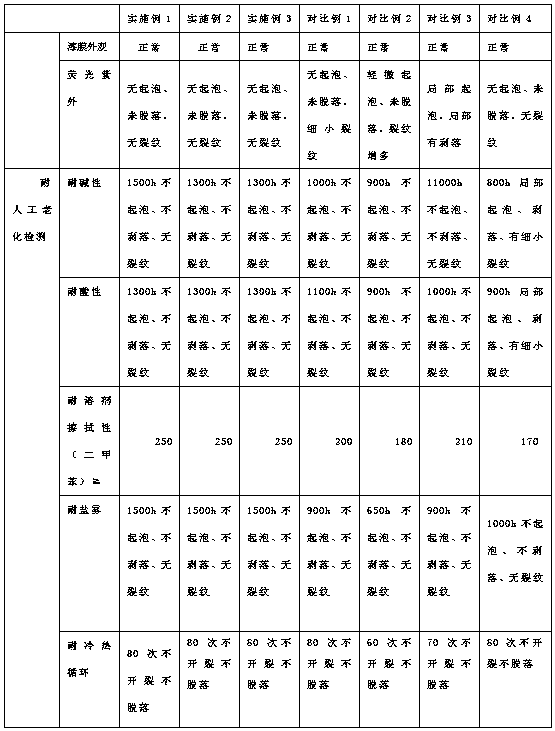

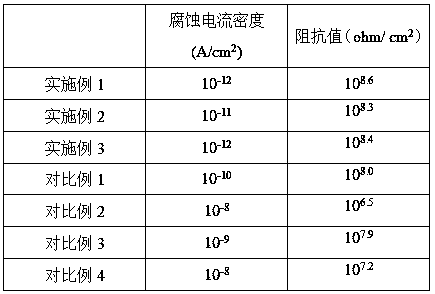

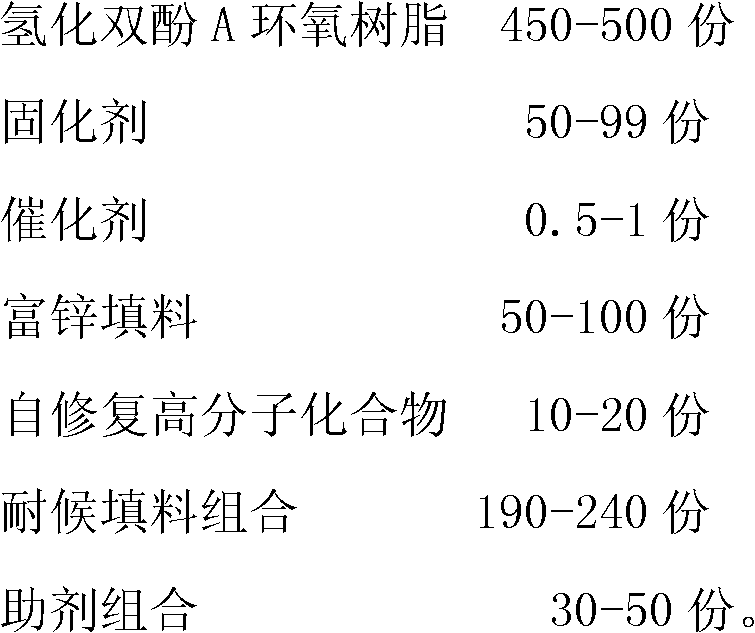

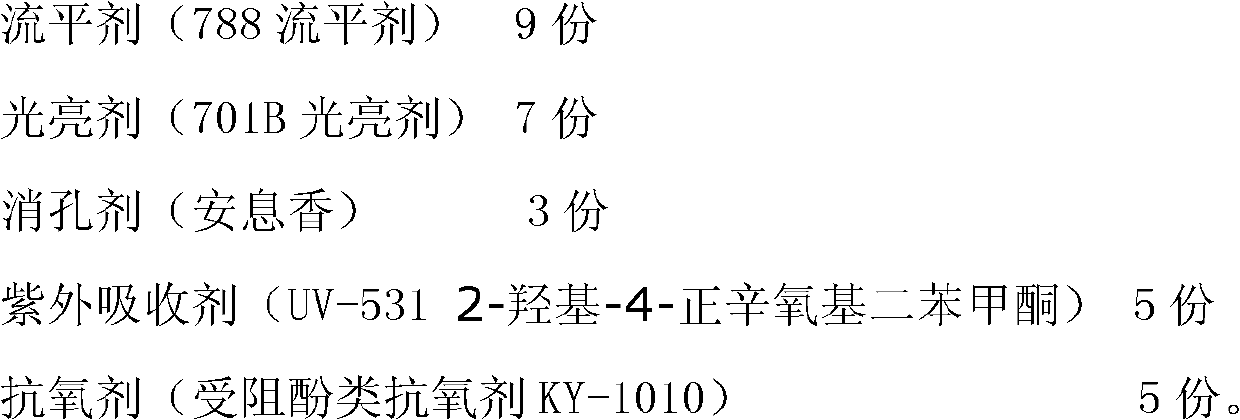

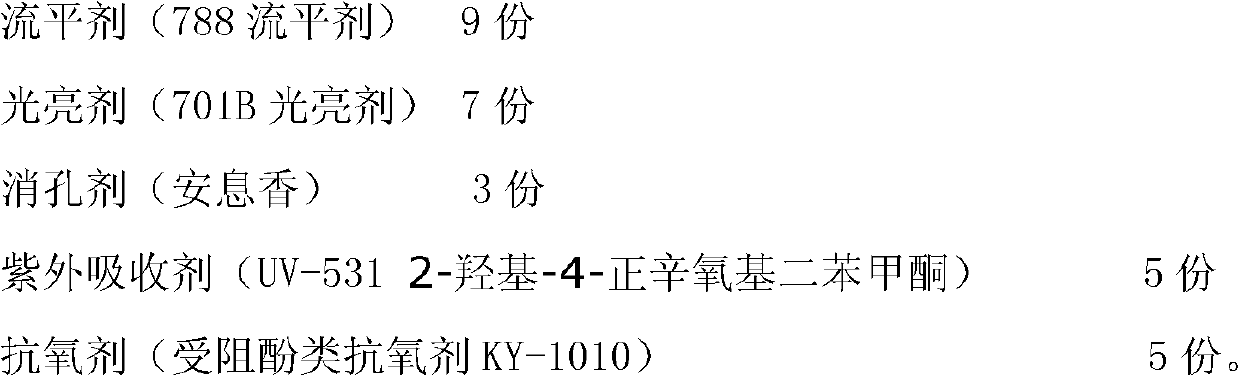

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsDry mixingHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

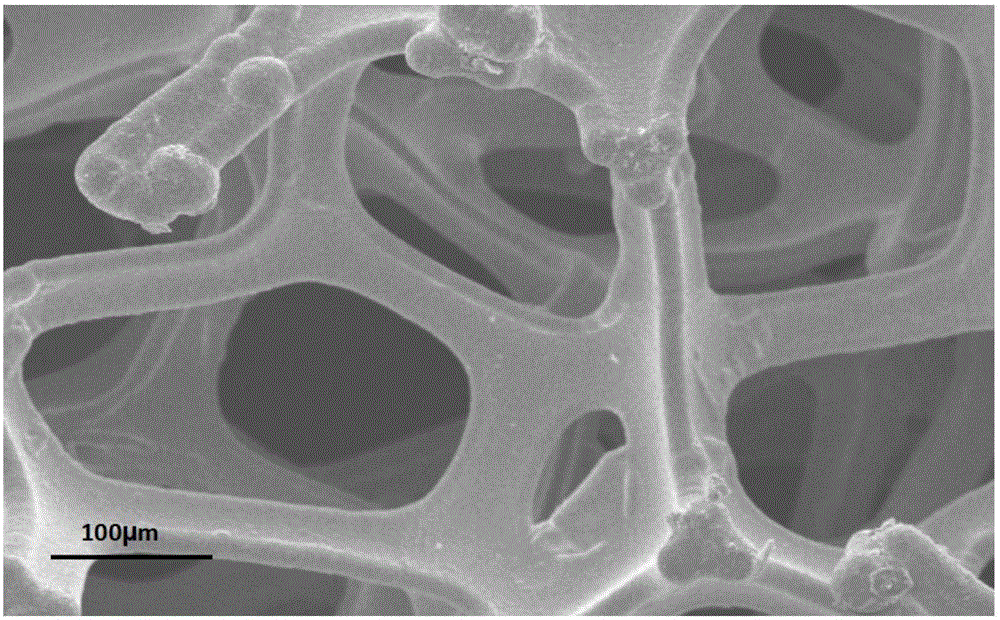

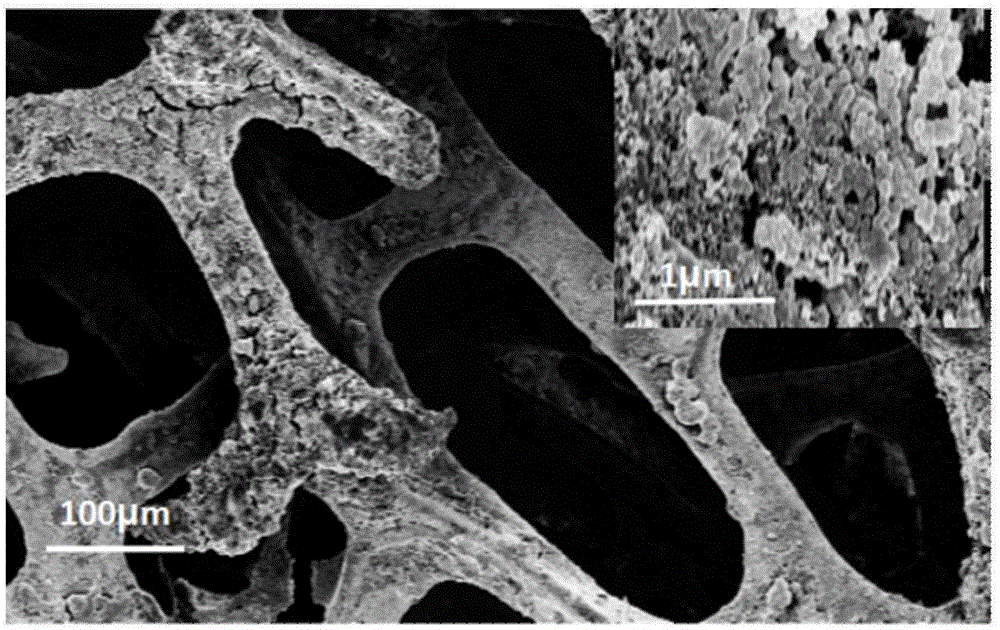

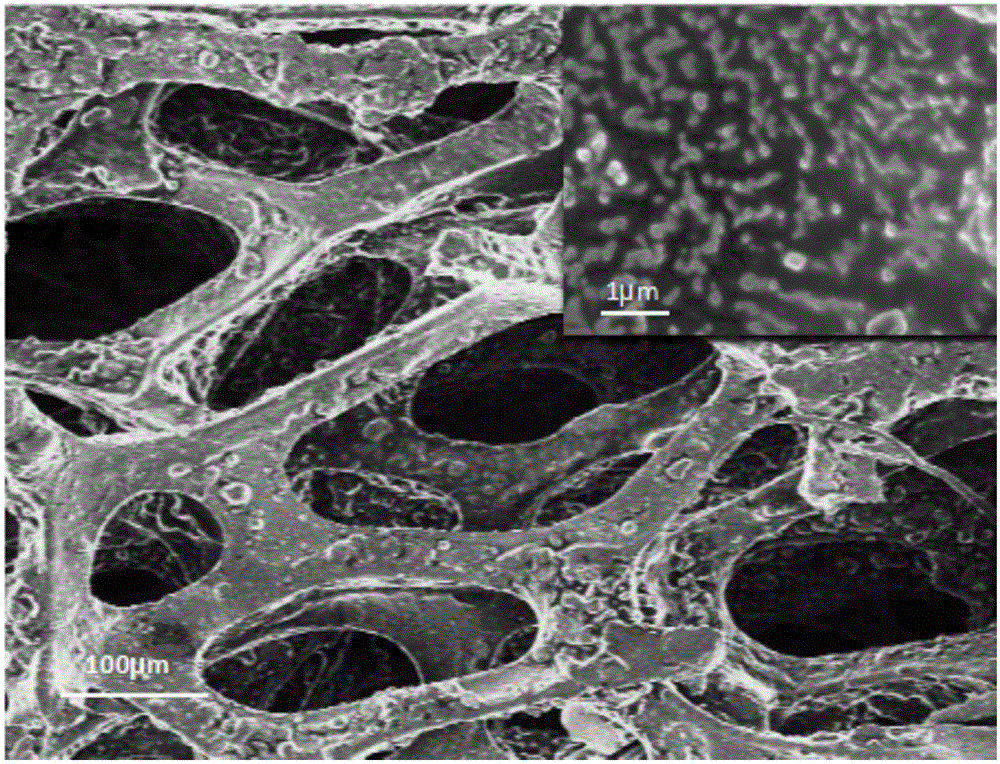

Novel oil-water separation material and application method thereof

ActiveCN105879429AWill not polluteImprove hydrophobicityFatty/oily/floating substances removal devicesNon-miscible liquid separationMetallic NickelChemistry

The invention relates to a novel oil-water separation material and an application method thereof, solving the problems that the durability of an existing material is not enough and the like. The novel oil-water separation material is particularly composed of a substrate and a coating attached to the surface of the substrate; the substrate is made of one of foamed nickel, foamed copper and foamed titanium; emulsion for forming the surface coating of the substrate is composed of modified resin, an organic solvent, low-surface-energy substances and nano-particles; and the novel oil-water separation material is prepared into a container with a connector and the connector of the container is connected with an inlet of a pump to establish an oil (organic matter)-water separation system. The oil (organic matter)-water separation system still keeps very good hydrophobicity when continuously operating separation for 7 days; and the separation efficiency is very high and the separation working amount can reach more than ten thousands times of self weight.

Owner:NORTHEAST GASOLINEEUM UNIV

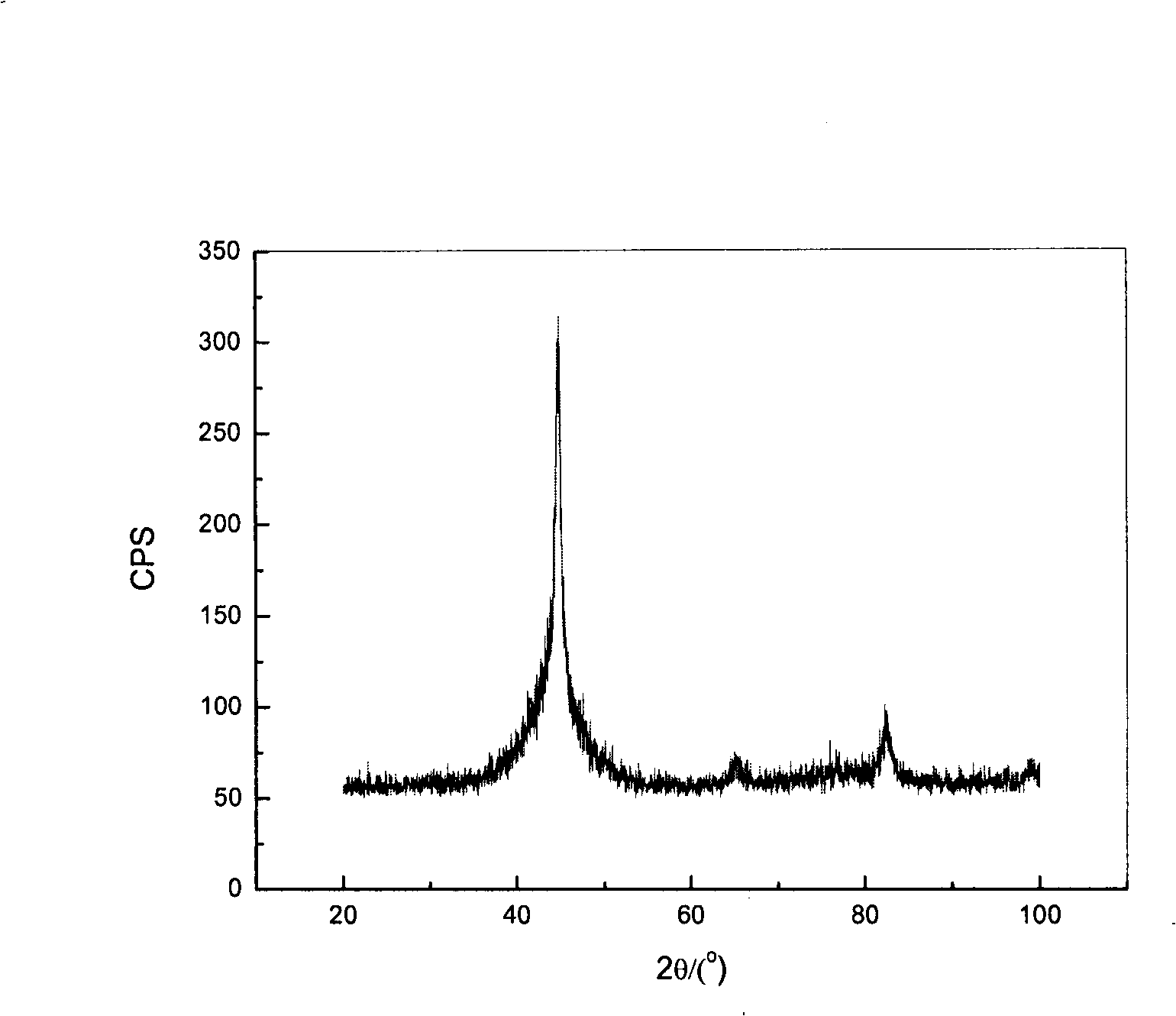

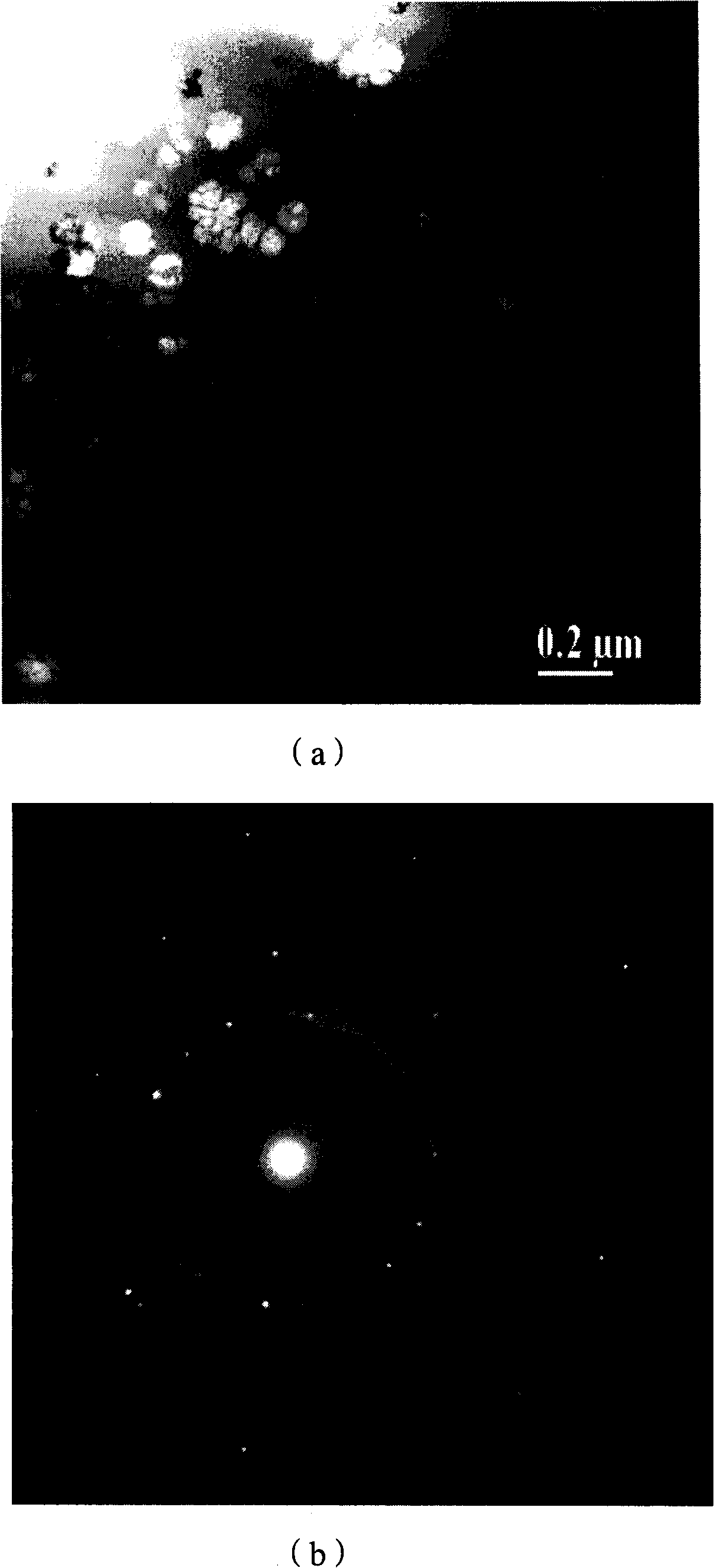

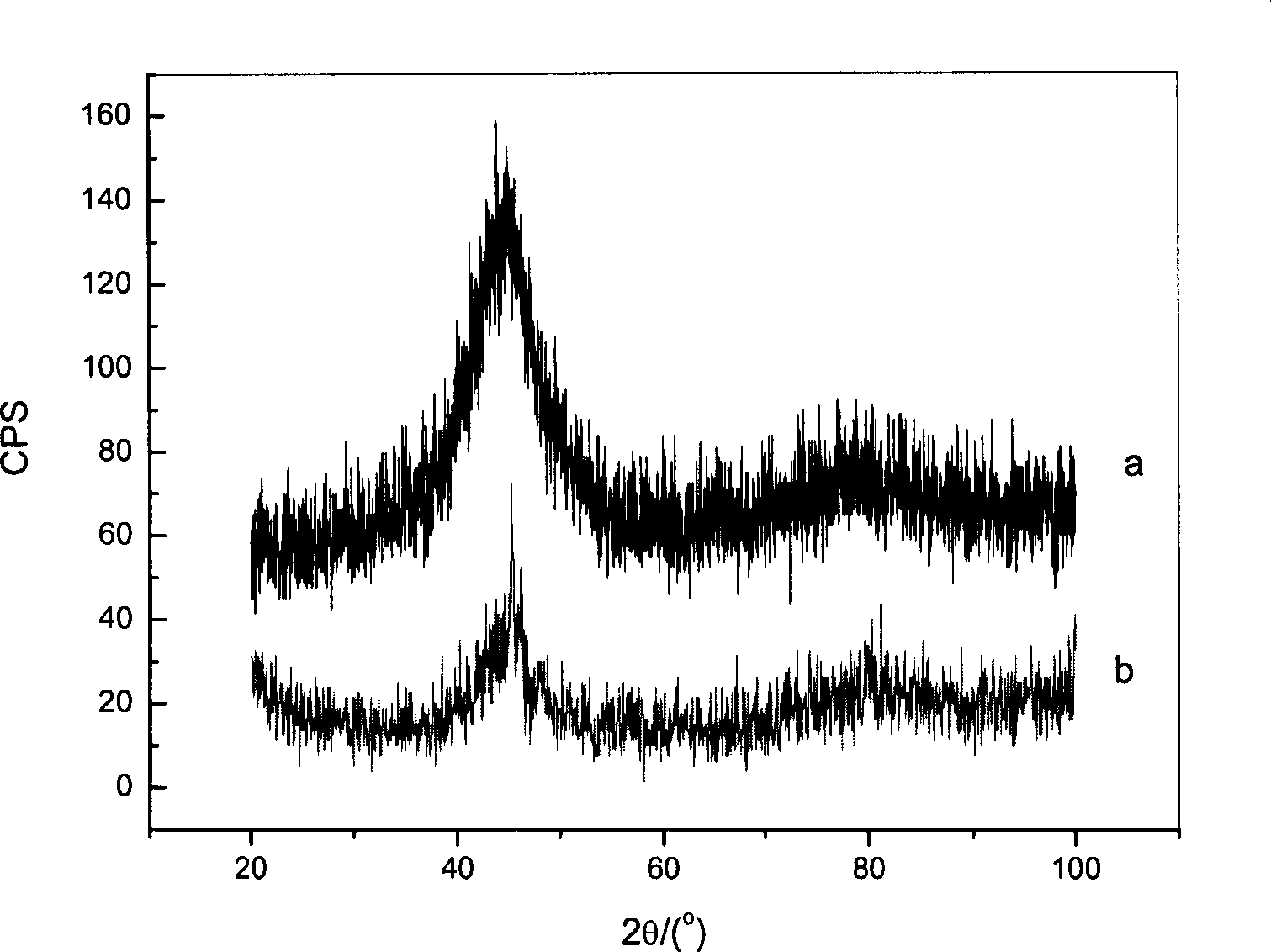

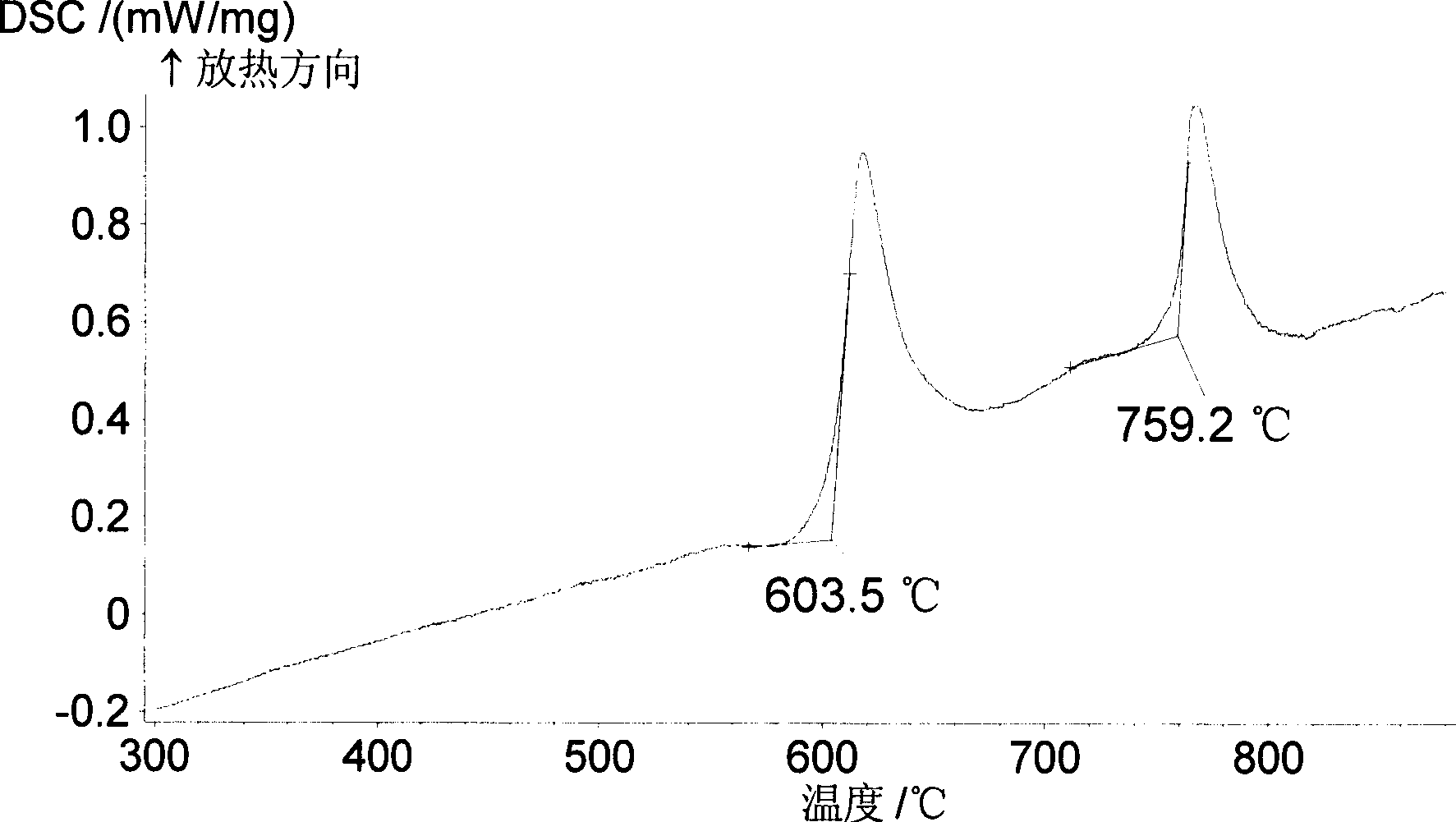

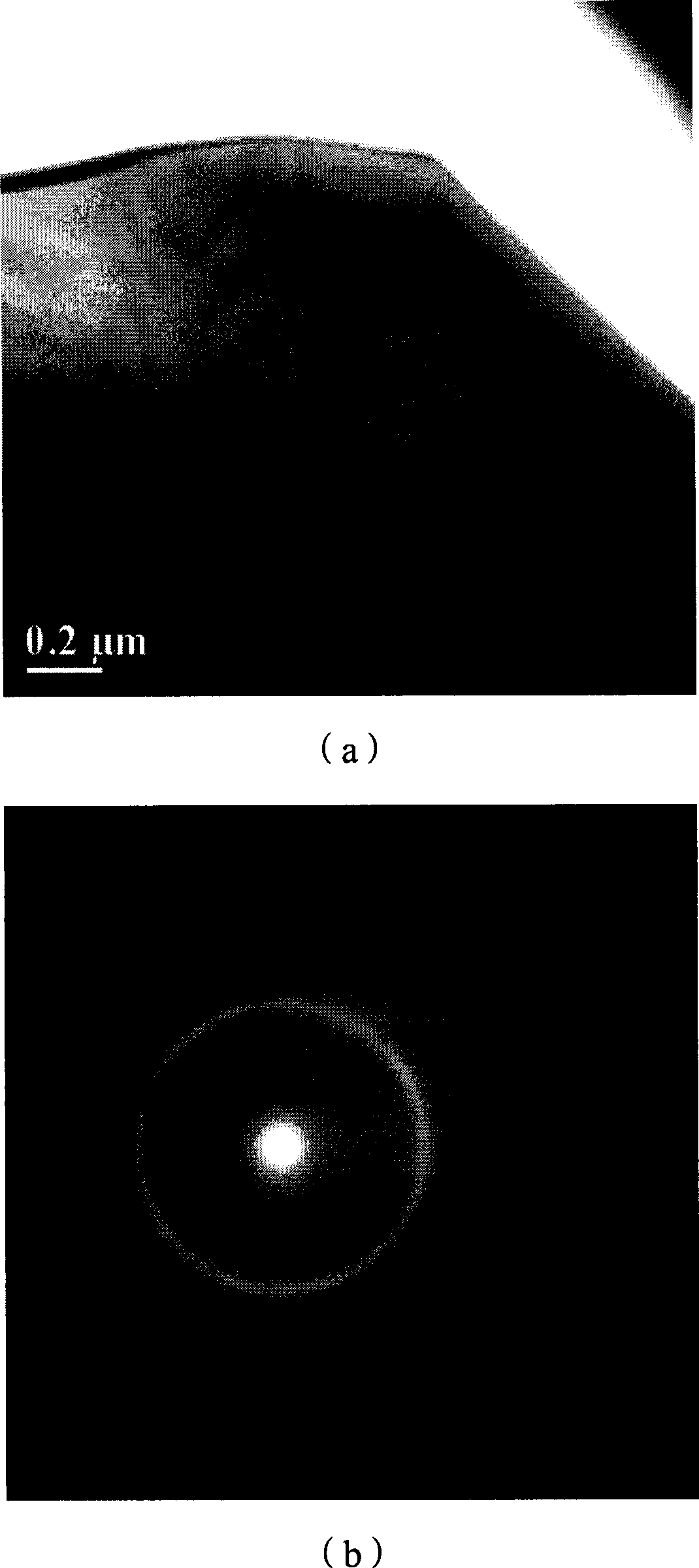

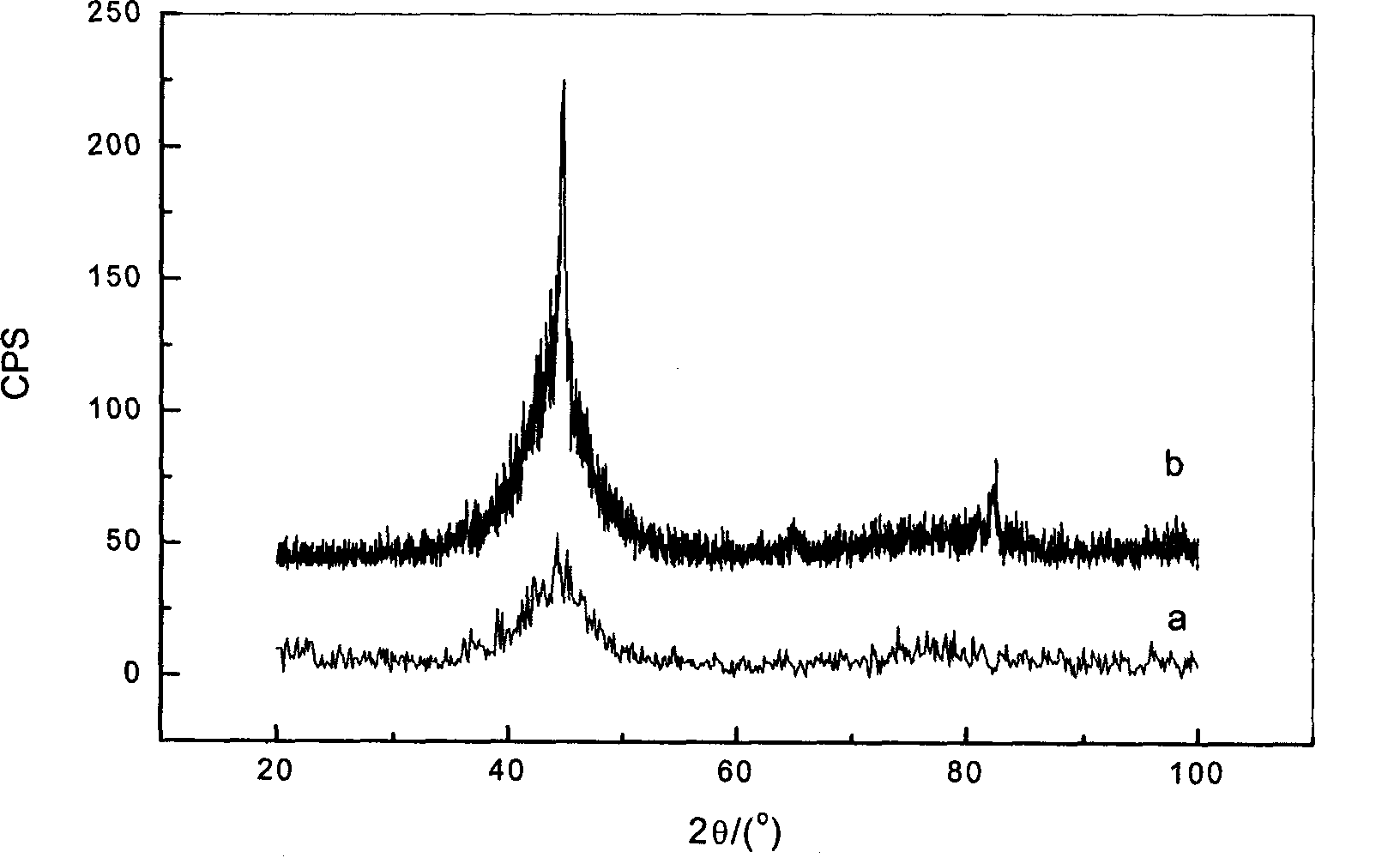

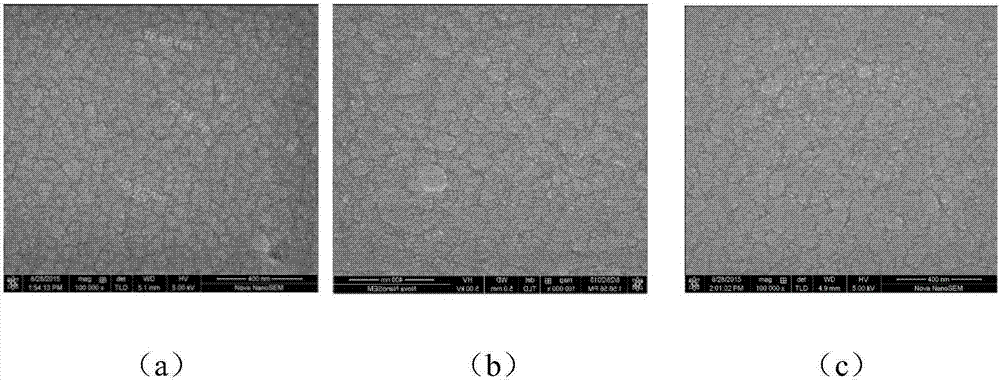

Nanocrystalline alloy coating and preparation thereof

The invention relates to a nano-crystalline alloy coating layer and a preparation method thereof. Particularly, the invention relates to a nano-crystalline alloy coating layer, the components of which, expressed by atomic ratio, satisfy the relational expression: (Fe1-aM1a)100-x-y-z-Alpha-Beta-GammaCuxSiyBzM2AlphaM3BetaXGamma, wherein, M1 is one or both of Co and Ni, M2 is at least one of Nb, W, Ta, Zr, Hf, Ti and Mo, M3 is at least one of V, Cr, Mn, Al, Sc, Y, Au, Zn, Sn and Re, X is at least one of C, Ge, P, Ga, Sb, In, Be and As, a is more than or equal to 0 and less than or equal to 0.5, x is more than or equal to 0.1 and less than or equal to 3, y is more than or equal to 0 and less than or equal to 30, z is more than or equal to 0 and less than or equal to 25, and furthermore, y plus z is more than or equal to 5 and less than or equal to 30, Alpha is more than or equal to 0.1 and less than or equal to 30, Beta is more than or equal to 0 and less than or equal to 10 and Gamma is more than or equal to 0 and less than or equal to 10, the volume percent of nano-crystals contained in the nano-crystalline alloy coating layer is above 50 percent and the crystal size of the nano-crystals is below 100nm. The invention also relates to the application and a preparation method of the nano-crystalline alloy coating layer.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

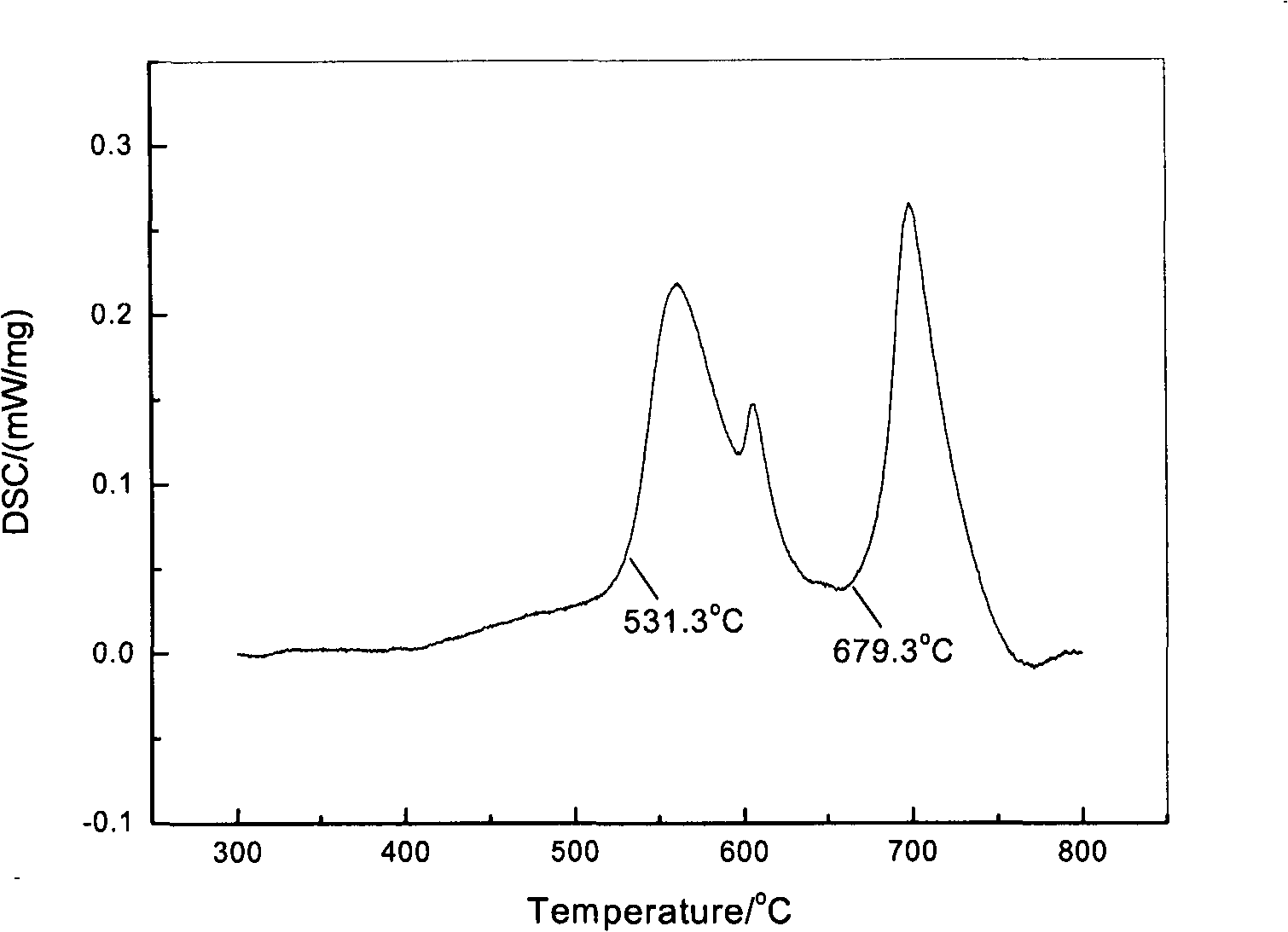

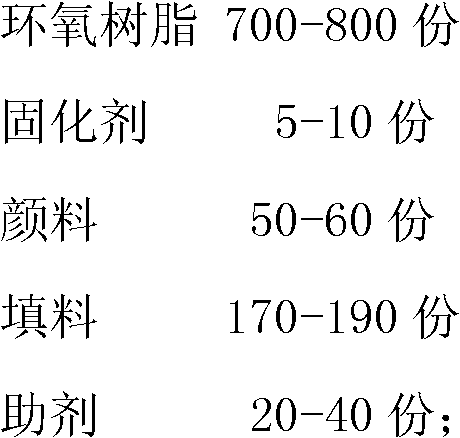

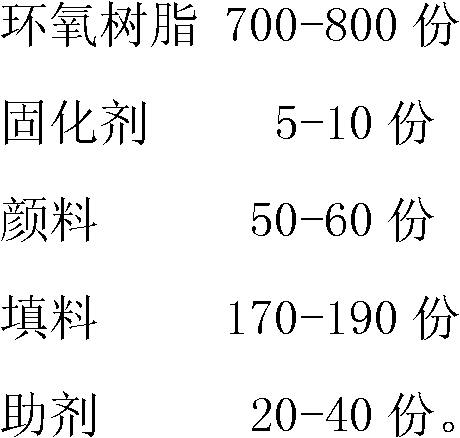

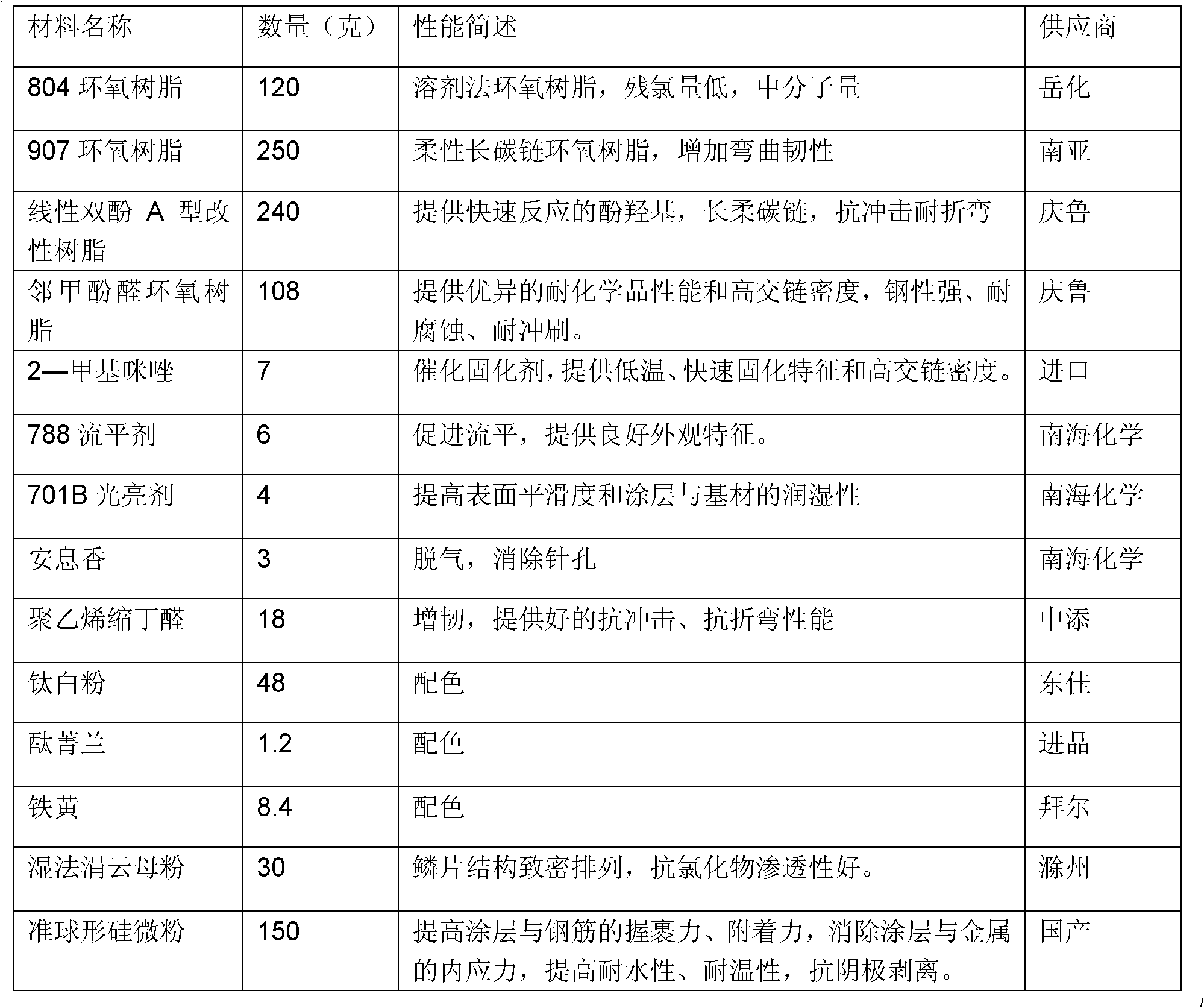

Special heavy-duty anti-corrosion powder coating for steel bar coating

InactiveCN102277063AImprove insulation performanceImprove permeabilityAnti-corrosive paintsPowdery paintsEpoxyRebar

The invention relates to a special heavy-duty anti-corrosion powder coating for steel bar coating. Its raw material components and parts by weight are: 700-800 parts of epoxy resin; 5-10 parts of curing agent; 50-60 parts of pigment; 170 parts of filler -190 parts; 20-40 parts of additives; add the above materials to a high-speed mixer, add them to an extruder after dry mixing, and melt, knead, cool, and tablet at an extrusion temperature of 90-100 ° C. After being pulverized, classified, sieved, and packaged by a pulverizer, it becomes a finished product of powder coating. The special heavy-duty anti-corrosion powder coating for steel bars prepared by the present invention is mainly used in railways, highways, bridges, basements of high-rise buildings, underground garages, seaports, wharves, dams, sewage treatment pools, chemical industries and other industries that require heavy anti-corrosion. The stability of steel bars can prolong the final service life of buildings for more than 30 years. Experiments have proved that the corrosion resistance of steel bars coated with epoxy coating is 800 times higher than that of bare steel bars.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

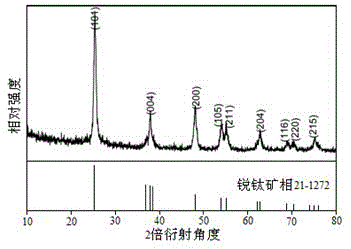

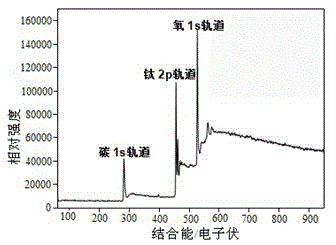

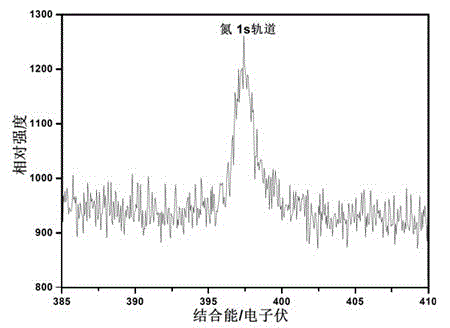

Aluminum product coated with nitrogen-doped graphene/nitrogen-doped TiO2 photo-catalytic material

InactiveCN103949278AImprove adsorption capacityPromote decompositionDispersed particle separationCatalyst activation/preparationDoped grapheneMeth-

The invention provides an aluminum product coated with a nitrogen-doped graphene / nitrogen-doped TiO2 photo-catalytic material. The aluminum product is prepared according to the following steps: preparing graphene oxide by using a method disclosed from the page 4806 to the page 4814 of volume 2010-4 of the journal of Nanometer of the American Chemical Society; adding deionized water, and performing ultrasonic dispersion to obtain graphene oxide dispersion liquid; respectively adding a hexamethylene tetramine solution and a titanium trichloride solution, uniformly mixing, performing hydrothermal reaction, centrifugally washing a precipitate, and drying to obtain the nitrogen-doped graphene / nitrogen-doped TiO2 composite photo-catalytic material; washing and drying an aluminum profile needing to be coated; adding the composite photo-catalytic material into acetonitrile or methyl methacrylate, and performing ultrasonic dispersion; and uniformly spraying the dispersion liquid onto the surface of the aluminum profile, and drying to obtain the aluminum product coated with the nitrogen-doped graphene / nitrogen-doped TiO2 composite photo-catalytic material. According to the aluminum product, photo-catalysis can be generated under the irradiation of indoor light, indoor air is purified, and indoor pollutants are reduced.

Owner:SHANGHAI RONGFU NEW MATERIAL

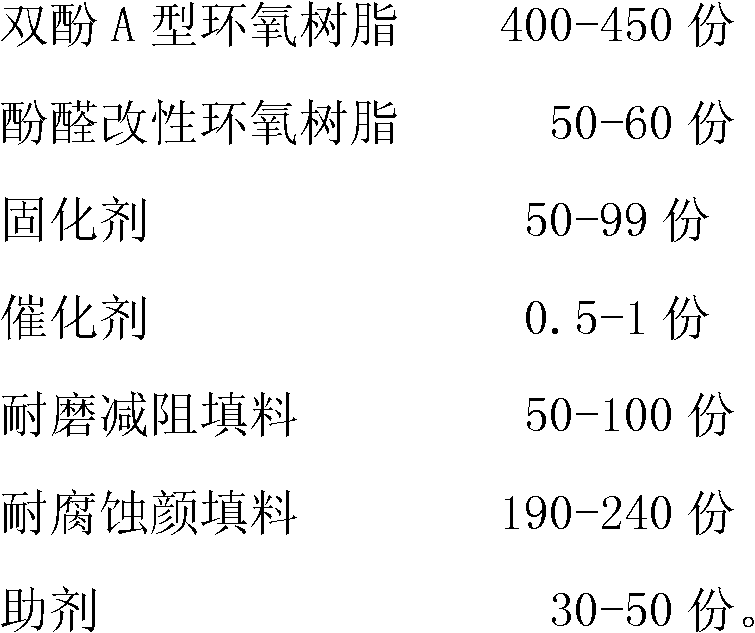

Fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes

InactiveCN102643595AImprove performanceImprove corrosion resistancePowdery paintsEpoxy resin coatingsWear resistantDry mixing

The invention relates to a fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes, which includes formula raw materials, by weight, 400-500 parts of bisphenol A-type epoxy resin, 50-60 parts of phenolic aldehyde modified epoxy resin, 50-99 parts of curing agent, 0.5-1 part of catalyst, 50-100 parts of wear-resistant damping filler, 190-240 parts of corrosion-resistant pigment and filler and 30-50 parts of auxiliaries. The preparation method of the fired epoxy powder coating includes, adding the above raw materials into a high-speed mixer, adding to an extruder after dry mixing, fusing, mixing, cooling and preforming at extrusion temperature ranging from 80 DEG C to 90 DEG C, crushing by a crusher, classifying, screening and packaging to be the powder coating. After being used by users and detected by relative authorized departments, the fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes excellent in corrosion resistance is excellent in coating efficiency and corrosion resistance, indexes thereof can meet those of the-like imported products, some of the indexes even exceed those of foreign products, and price is superior to that of the imported products. In addition, the fired epoxy powder coating special for hot rolling coating of large-caliber steel pipes is deeply appreciated by the users.

Owner:天津翔盛伟业粉末涂料有限公司

Amorphous soft magnetic alloy coatings and preparation method thereof

ActiveCN101441915ASimple processLess stress sensitiveMolten spray coatingMagnetic/electric field screeningMetallurgyMaterials science

The present invention relates to an amorphous soft magnetic alloy coating and the preparation method thereof, particularly relates to Fe-Co base amorphous soft magnetic alloy coating, characterized in that: (1) the sum of atom percentage content of Fe and Co is no less than 70&; (2) basically the coating is in amorphous structure. The invention also relates to the usage of the coating and the preparation method thereof.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

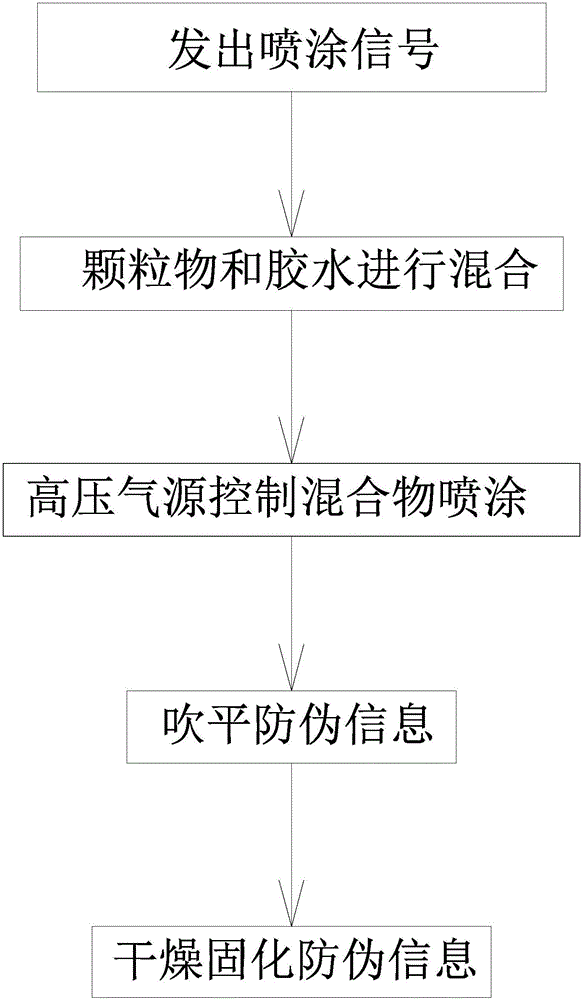

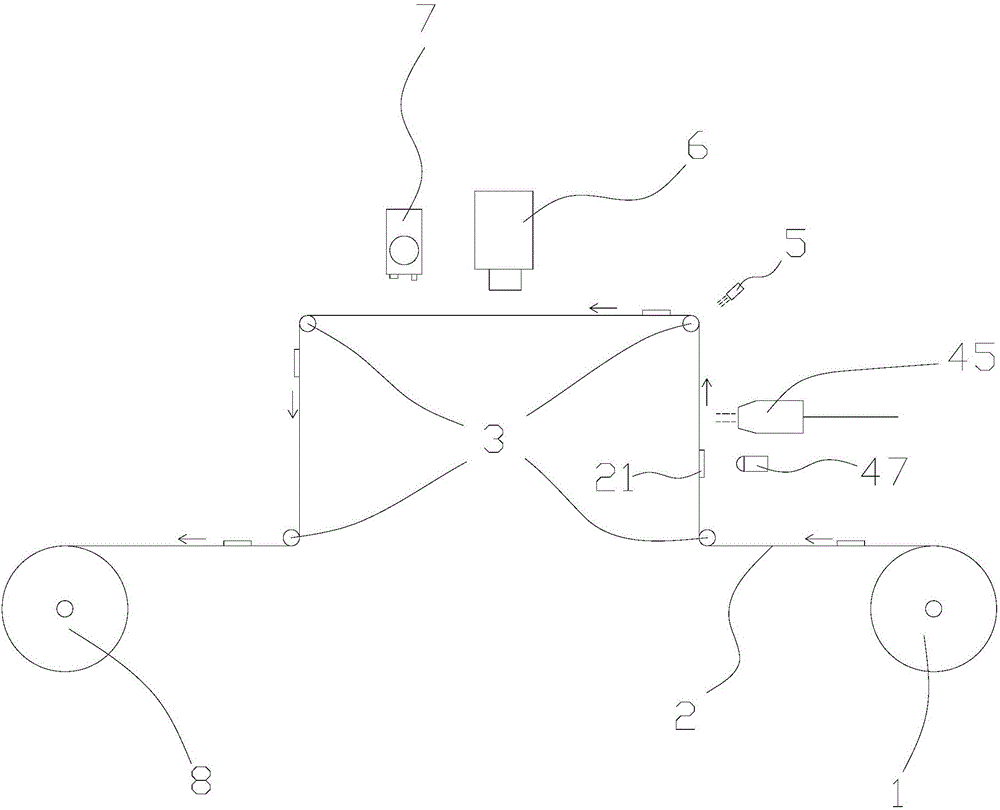

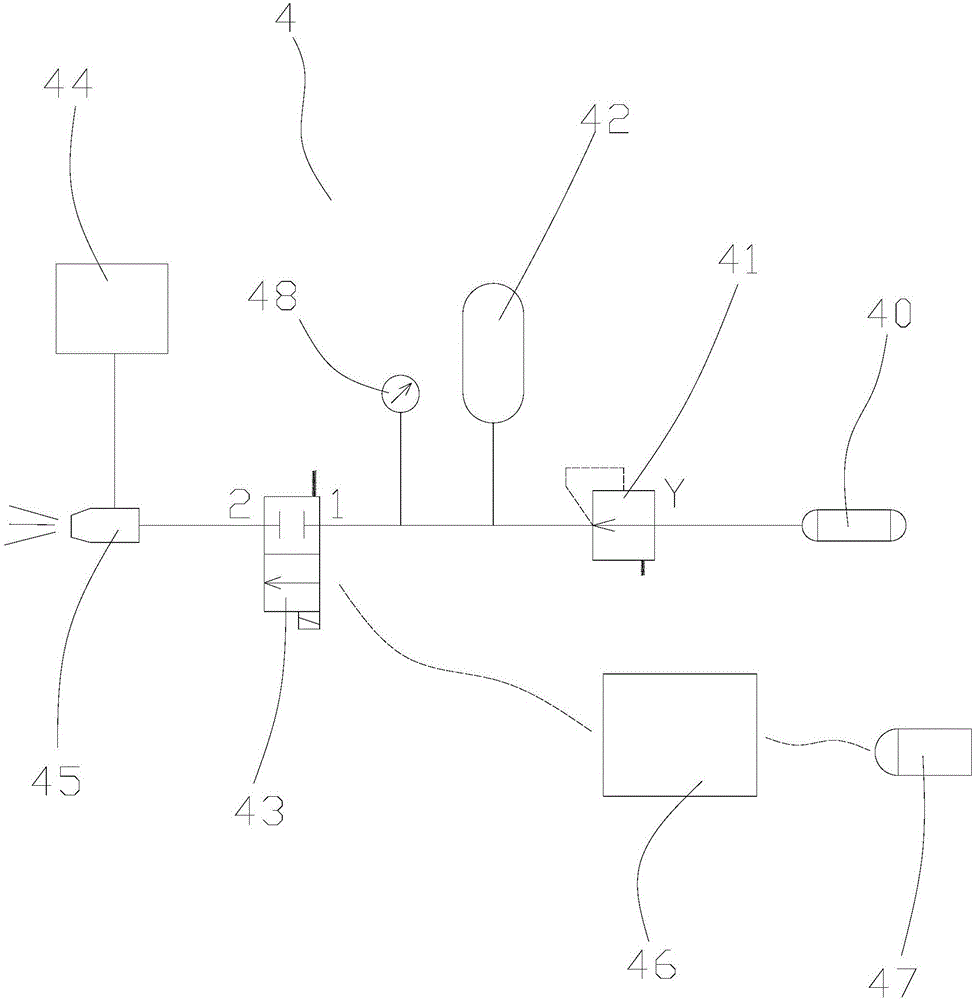

Anti-counterfeit label manufacturing method

InactiveCN106782045AImprove work efficiencyReduce manufacturing costStampsIdentification meansParticulatesHigh pressure

The invention discloses an anti-counterfeit label manufacturing method. The method comprises the steps of a, sending a spraying signal, and later spraying the mixture of particulate matter and a glue; b1, mixing the particulate matter and the glue to form the mixture of the particulate matter and the glue; b2, using a high pressure air source to spray the mixture to form random anti-counterfeit information; c, after spraying the mixture to form anti-counterfeit information, blowing the anti-counterfeit information to be flat; d, drying and solidifying the anti-counterfeit information to form an anti-counterfeit label. The anti-counterfeit label manufacturing method is applied to the technical field of anti-counterfeiting, and the design of random particulate matter spraying mode drastically improves the work efficiency and reduces the production cost. The anti-counterfeit label manufacturing method is high in technology applicability, and the production quality is easy to control; the anti-counterfeit label manufacturing method is small in equipment investment, and facilitates installation and transformation on existing printing and packaging equipment.

Owner:XIAMEN SCINBOCO IOT TECH

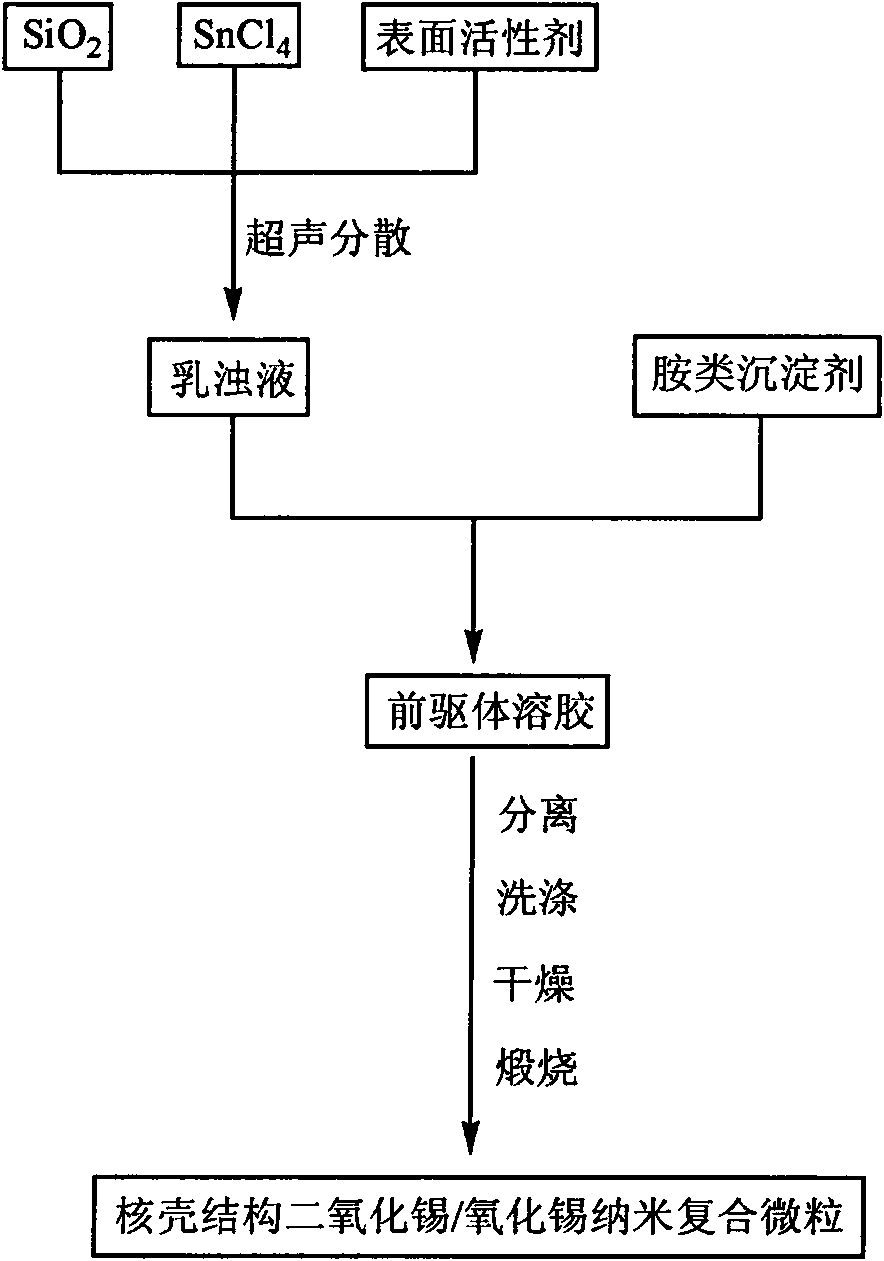

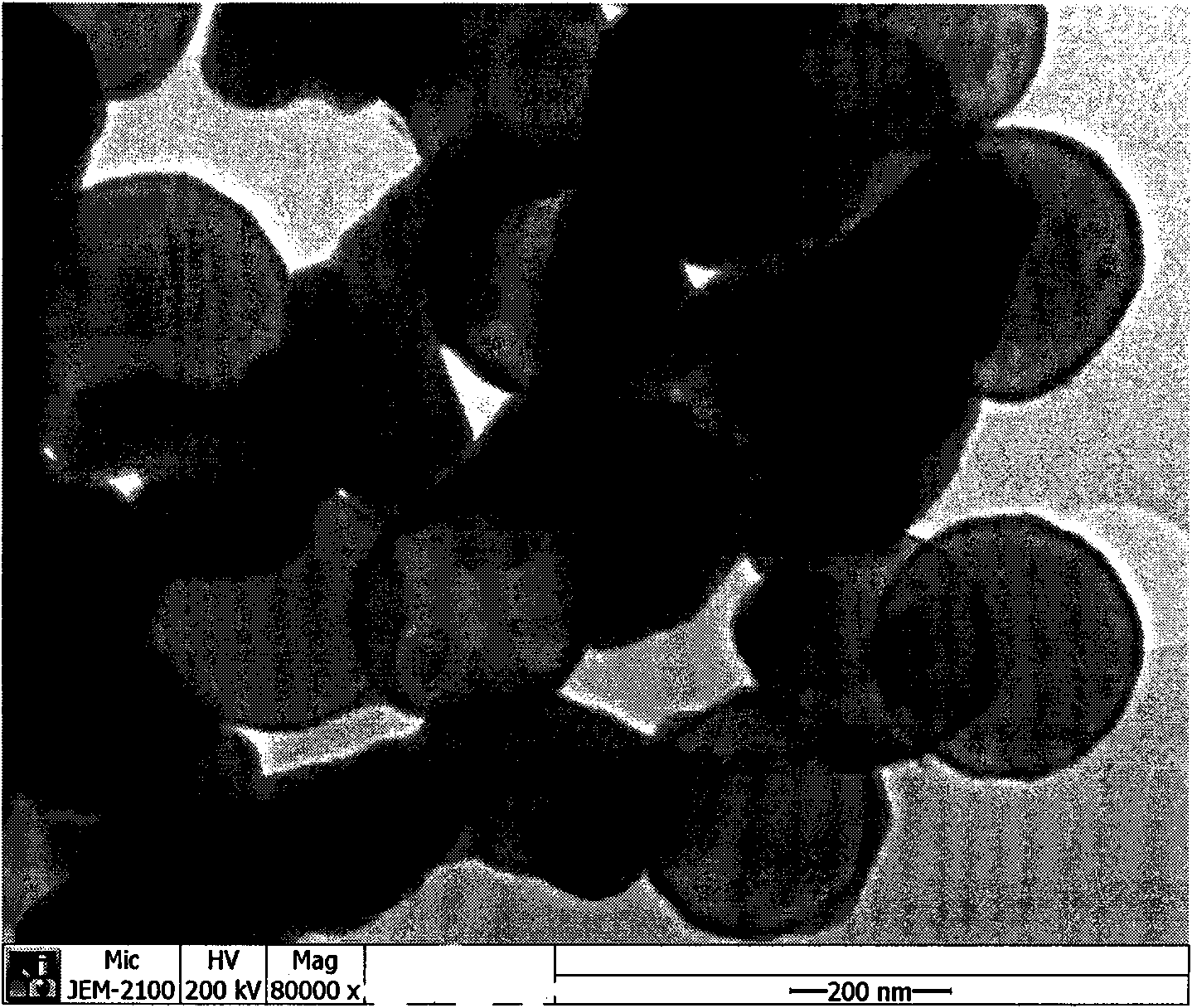

Silicon dioxide/tin oxide composite nanoparticle with nuclear shell structure and preparation method thereof

ActiveCN101613078AWide extinction wavelength control rangeEasy to useIndividual molecule manipulationSilicon oxideComposite nanoparticles

The invention discloses silica / tin oxide composite nanoparticles with nuclear shell structure which contain nano-silica inner cores and a tin oxide shells which are coated on the surface of the nano-silica inner cores. The invention also discloses a preparation method of the silica / tin oxide composite nanoparticles with nuclear shell structure, comprising the following steps: adopting nano-silica, soluble tin salt and amine precipitant as raw materials, dispersing the materials, preparing a precursor and finally obtaining the composite nanoparticles through drying and roasting. The silica / tin oxide composite nanoparticles have wider adjustment range for extinction wave length and effectively improve the usability of the SnO2 nanometer material. The preparation method of the invention has cheap cost, simple process, uniform product size, controllable thickness and high proportion for forming and coating films on the surface of silica with tin oxide.

Owner:GUANGZHOU BAIYUN CHEM IND

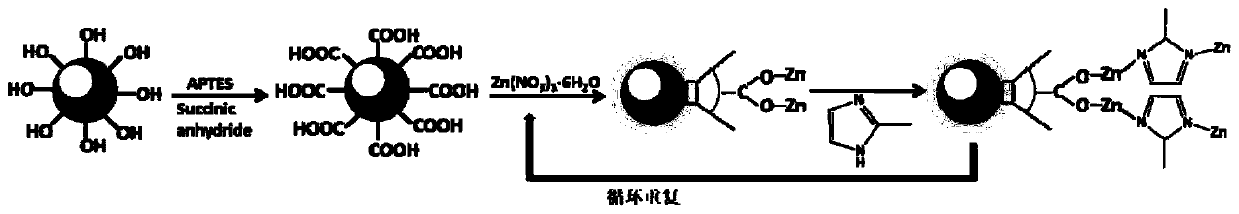

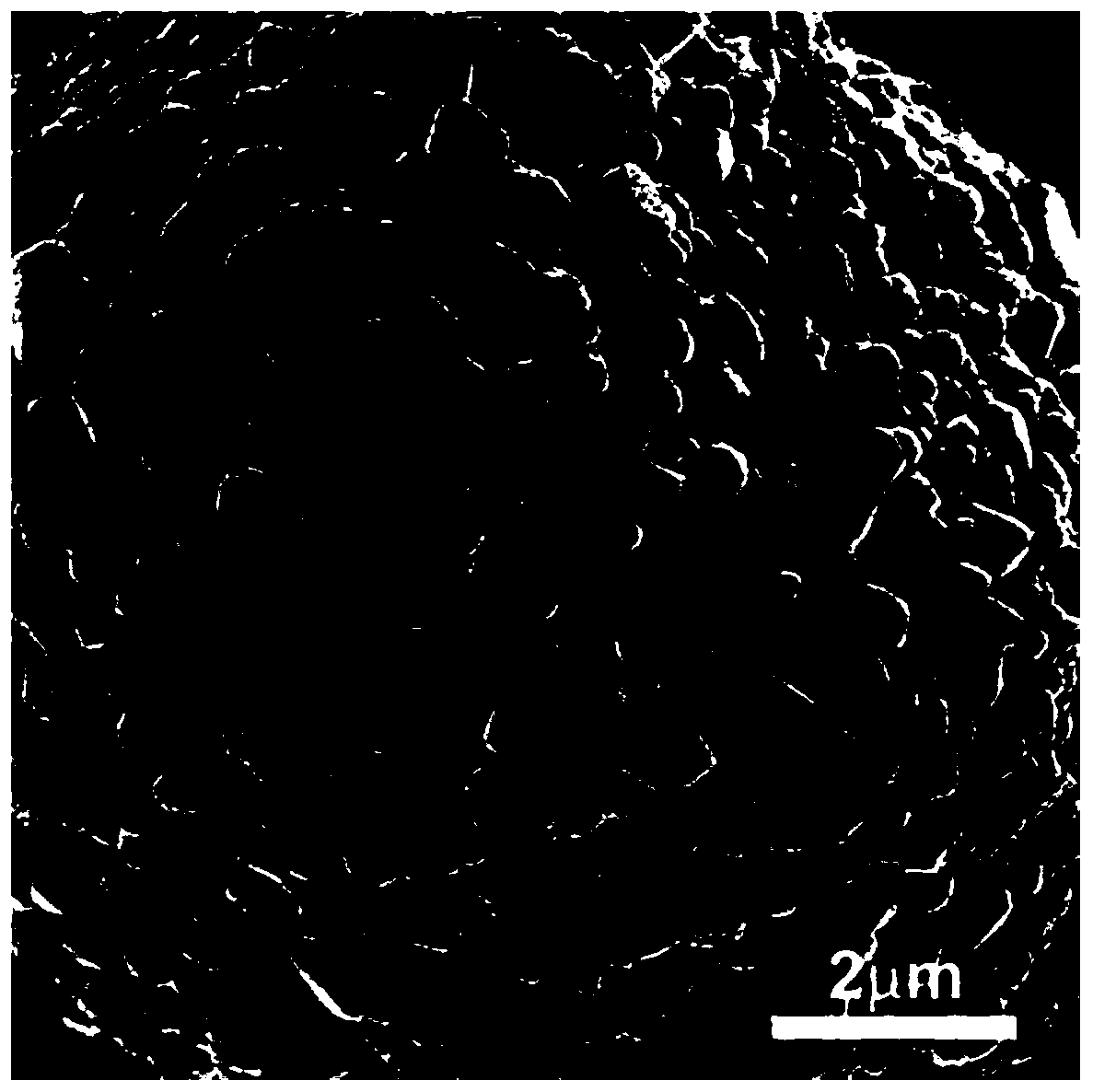

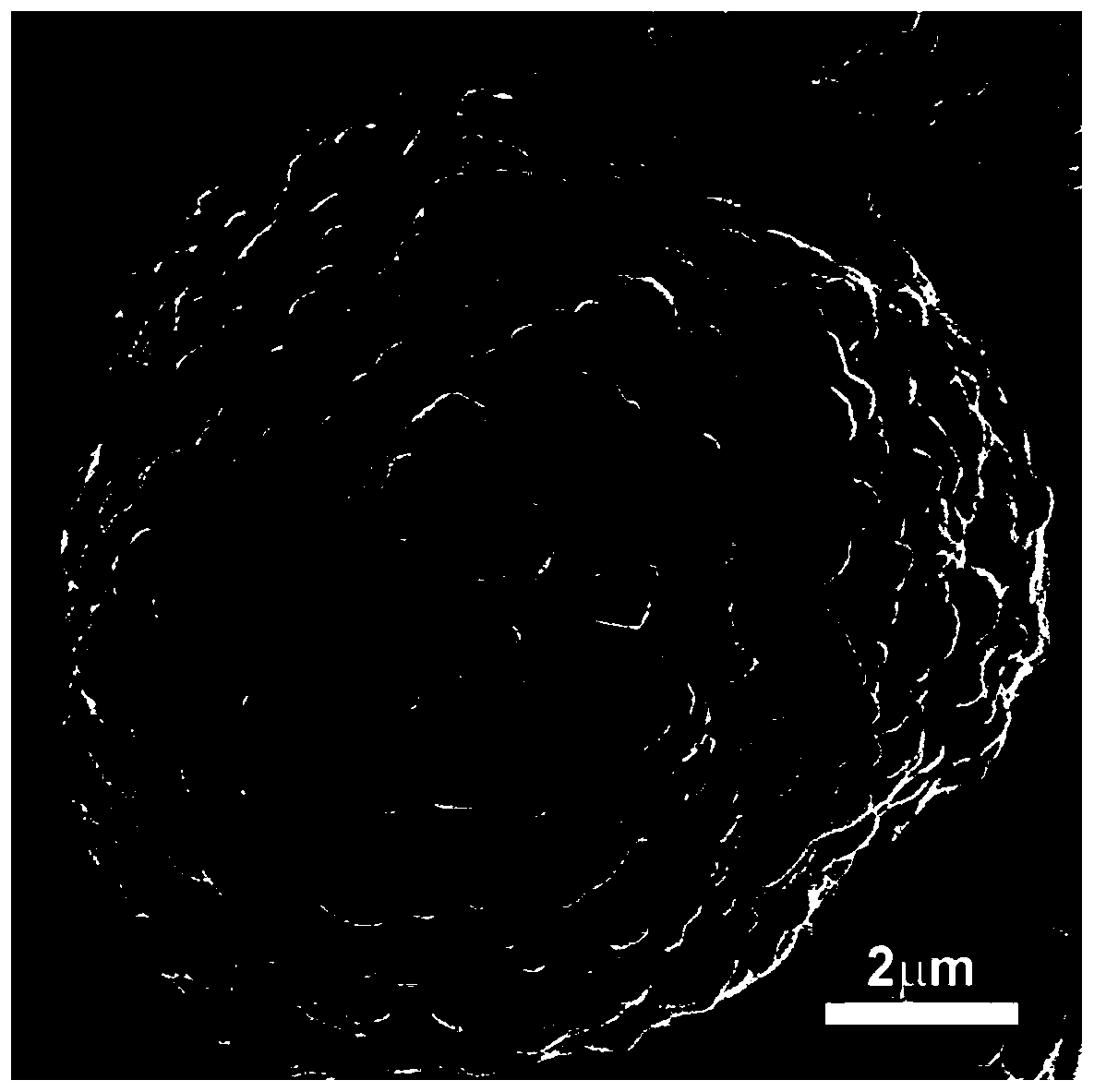

ZIF-8@SiO2 core-shell spheres as well as preparation method and application thereof

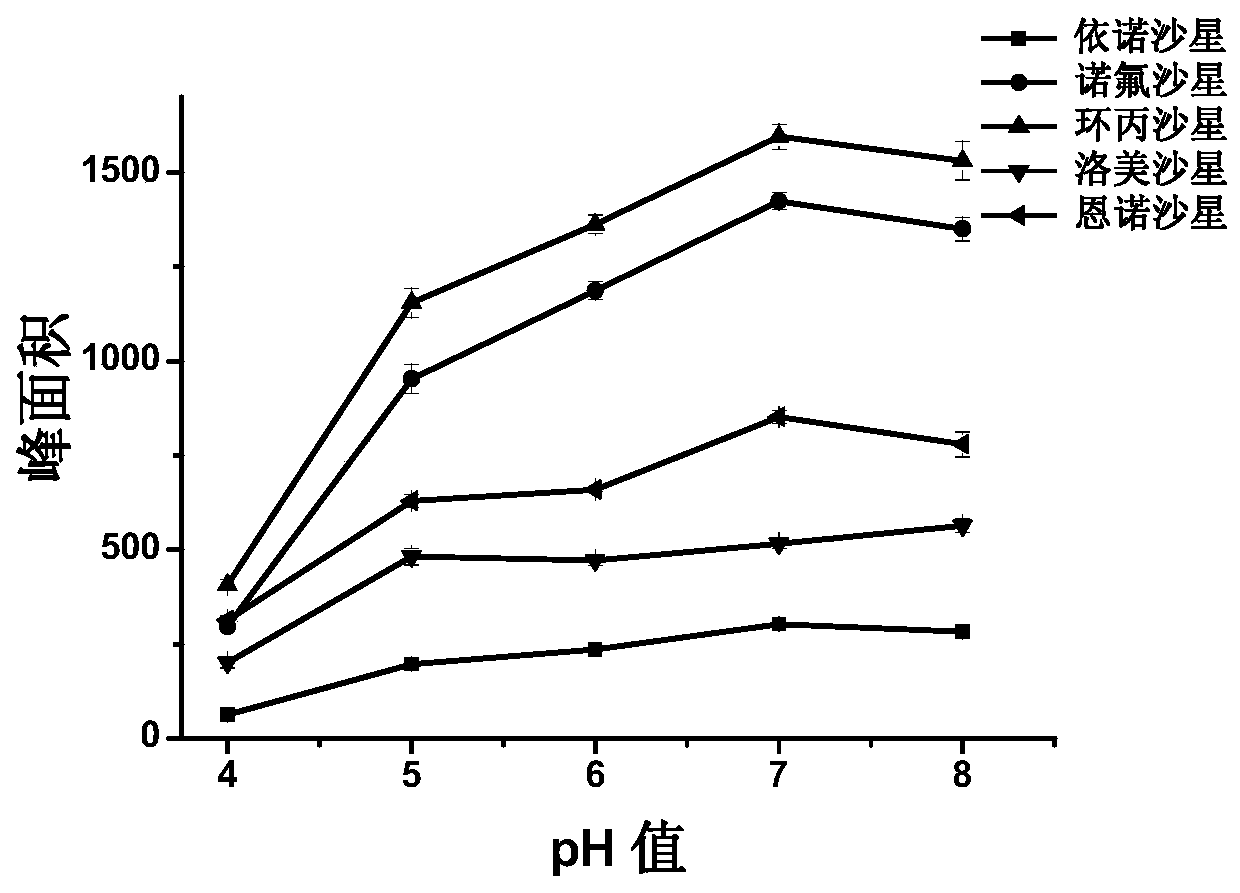

PendingCN110346487ACoating thickness controllableRegular shapeComponent separationMicrosphereMetal-organic framework

The invention discloses ZIF-8@SiO2 core-shell spheres. The ZIF-8@SiO2 core-shell spheres are composite microspheres having a core-shell structure in which SiO2 microspheres are taken as cores while ZIF-8 is taken as shells. The invention further provides a corresponding preparation method. The preparation method comprises the following steps: modifying SiO2 microspheres serving as cores with carboxyl to obtain SiO2-COOH; and then growing a zeolitic metal organic framework ZIF-8 shell layer on the surface layer by layer with a layer-by-layer alternative growth method. As proved by experiments,the composite microspheres have the characteristics of controllable coating thickness, regular appearance and high stability. The composite microspheres can be taken as a solid extraction material forpreparing an online solid extraction column, can be combined with high performance liquid chromatography for online enrichment detection of quinolone medicaments, has high repeatability and batch reproducibility, has high enriching performance for the quinolone medicaments, has the advantages of easiness, rapidness and efficiency in operation and small solvent dosage, and has a wide practical application prospect.

Owner:GUANGXI UNIV FOR NATITIES

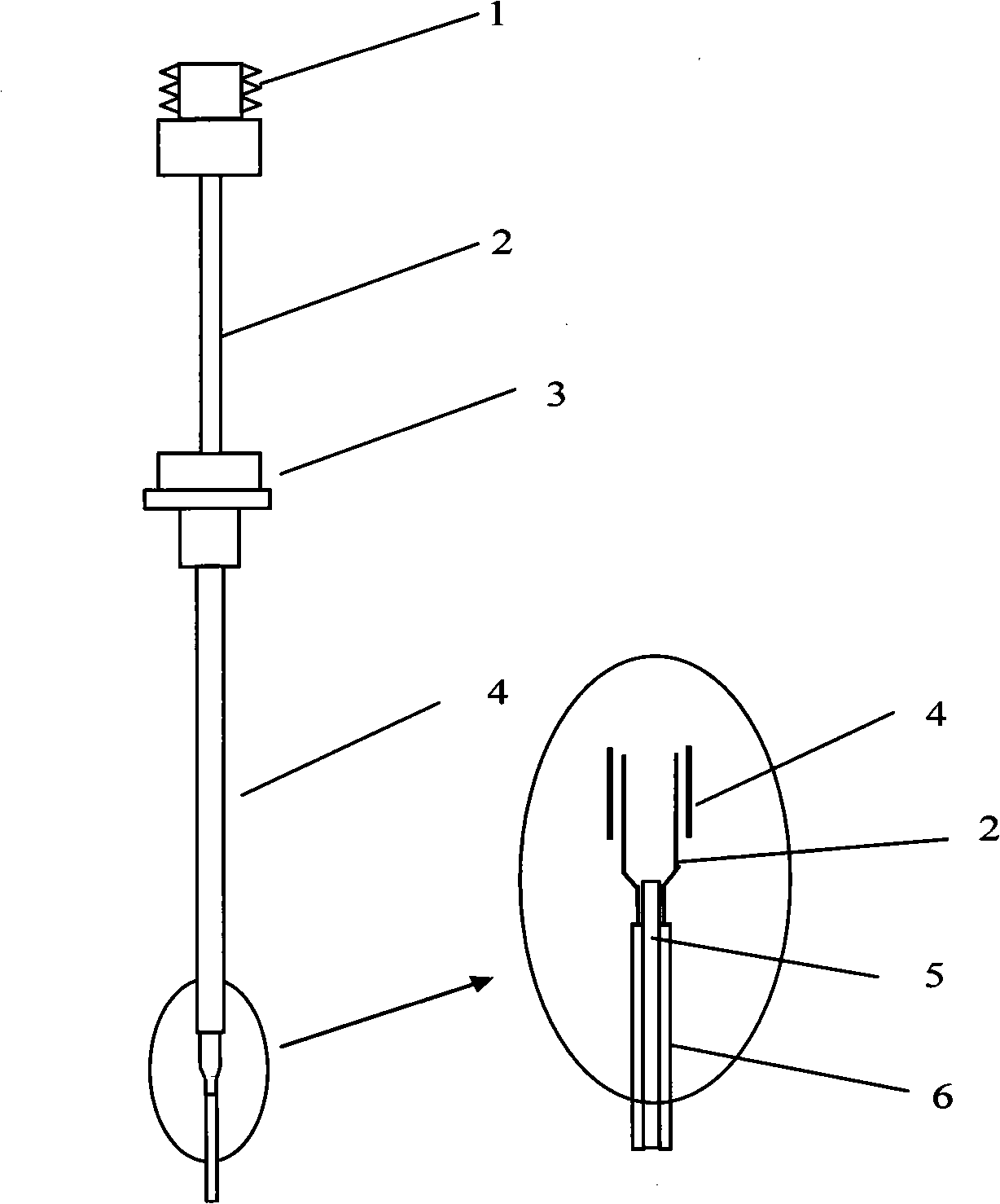

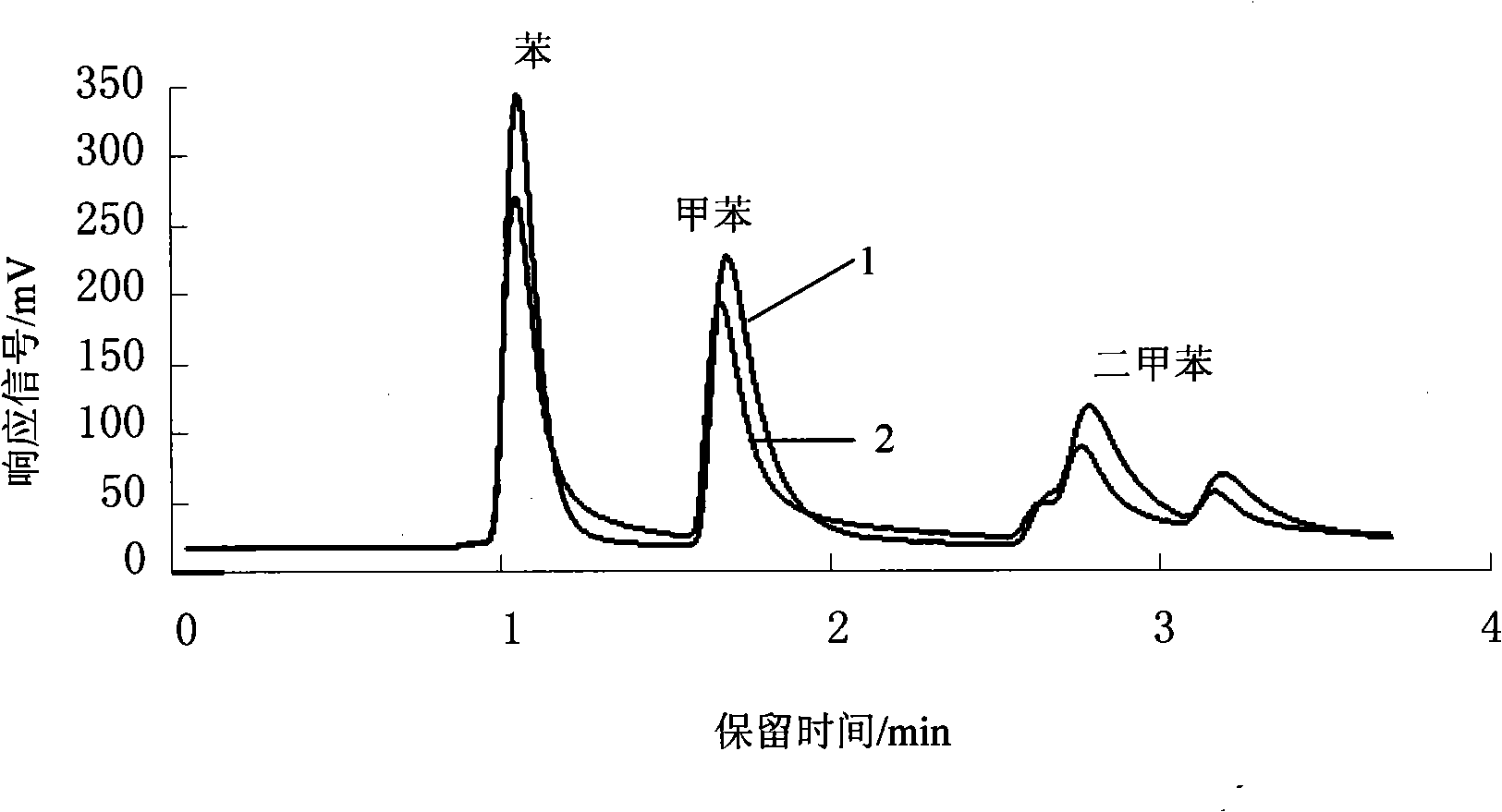

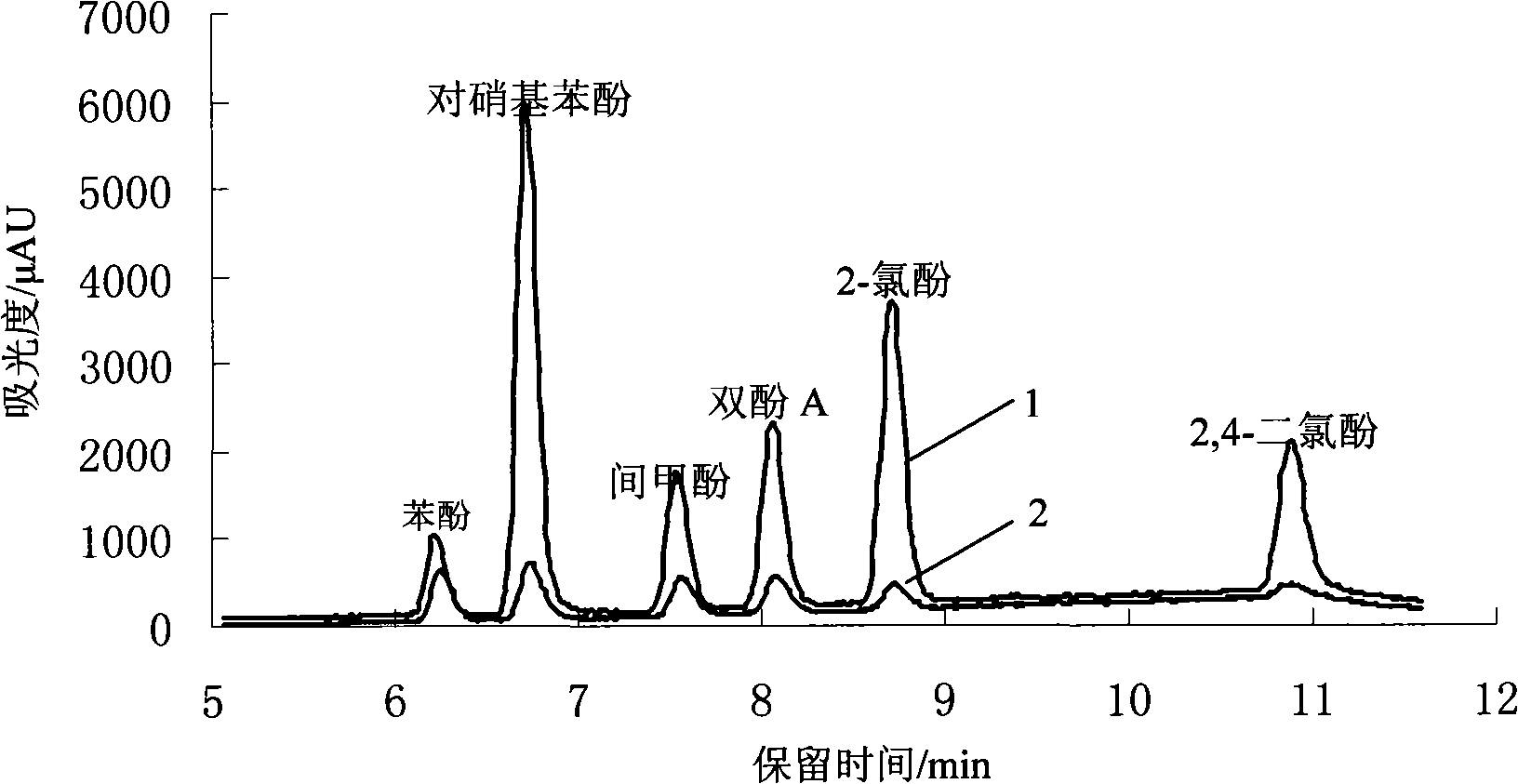

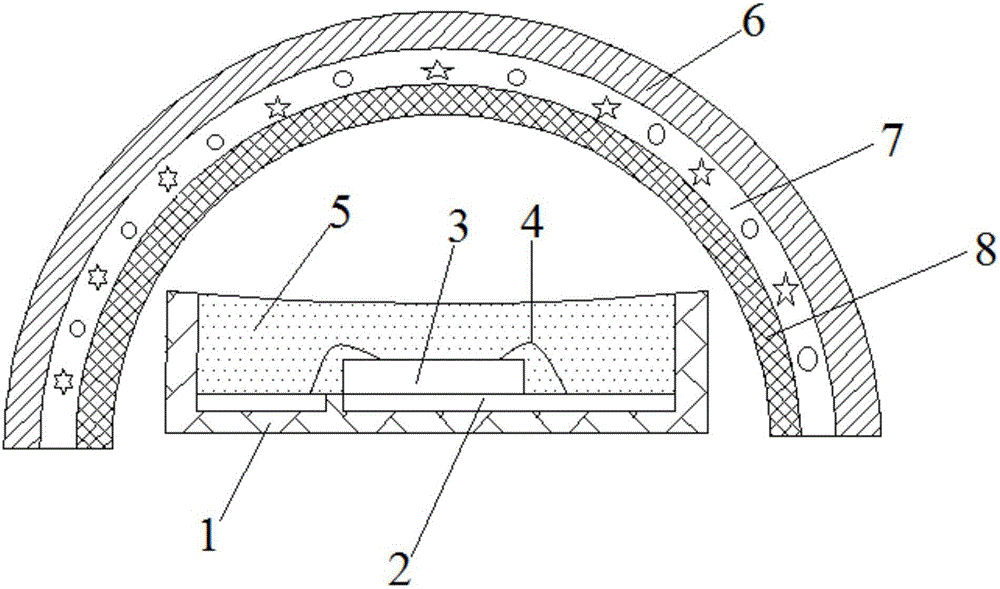

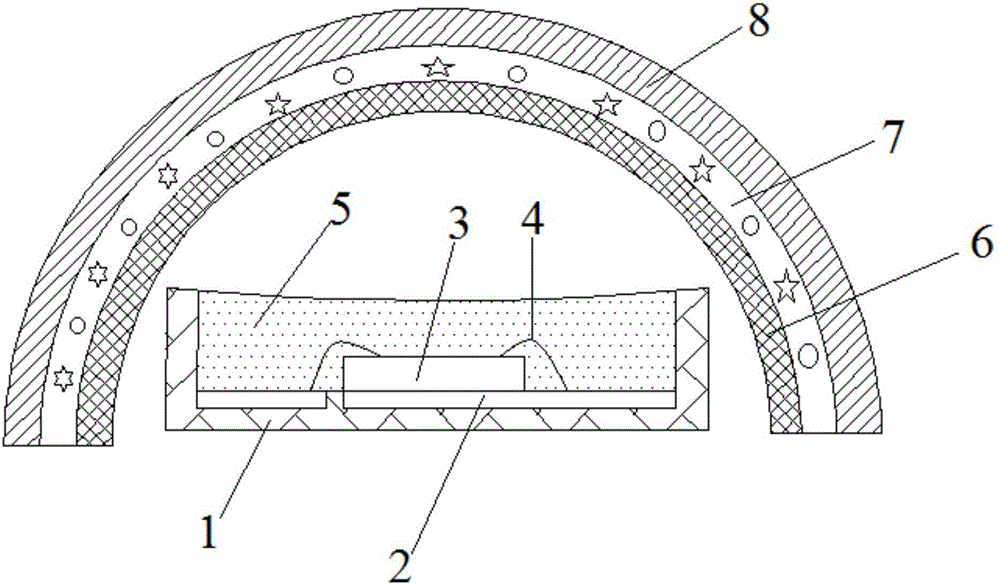

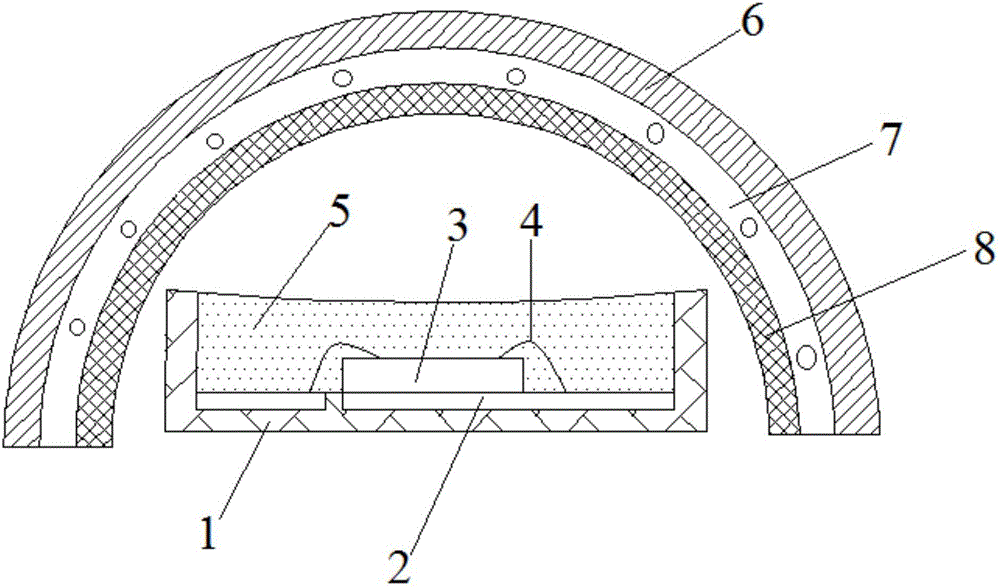

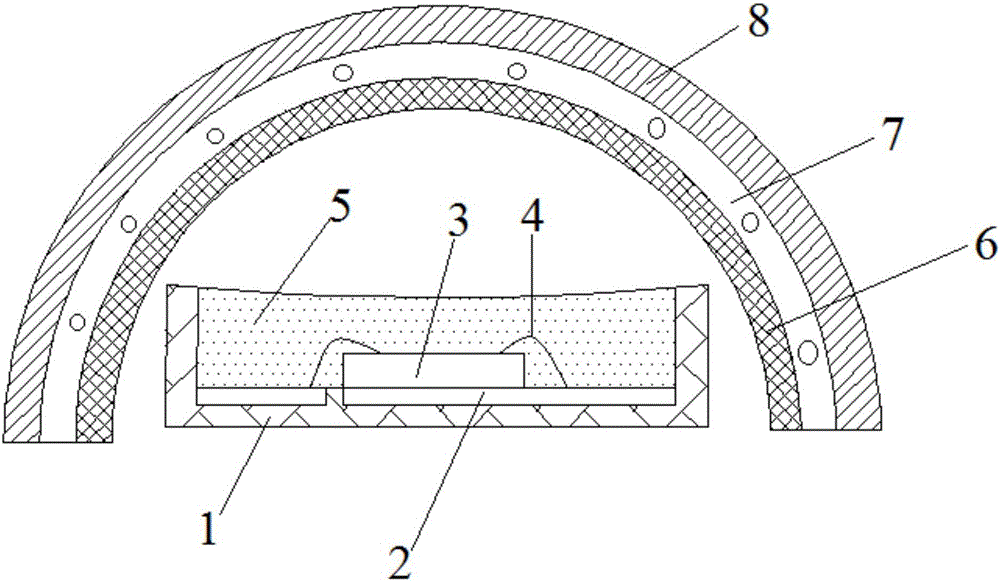

Solid phase micro-extraction extraction head using odd-tube carbon nano-tube as coating and its preparation method

InactiveCN101306351ALarge specific surface areaImprove conductivityOther chemical processesSolid solvent extractionFiberCarbon nanotube

A solid phase micro-extraction fiber which takes a single-walled carbon nanotube as the coating and the preparation method thereof relate to a solid phase micro-extraction fiber. The invention provides a solid phase micro-extraction fiber which takes the single-walled carbon nanotube as the coating as well as the preparation method thereof. A fixing clip, an inner tube, a gland bush, an outer tube, a metal wire and a single-walled carbon nanotube are provided, the top part of the inner tube is connected with the fixing clip, the lower part of the inner tube is arranged in the outer tube, the gland bush is arranged at the joint part of the inner tube and the top part of the outer tube, the top part of the metal wire is connected with the bottom part of the inner tube, and the surface of the metal wire is covered with the coating of the single-walled carbon nanotube. The suspension liquid of the single-walled carbon nanotube is prepared after the single-walled carbon nanotube is processed, then the single-walled carbon nanotube is subjected to electrophoretic deposition on the metal wire, and finally, the extraction fiber is inserted into the micro-extraction fiber inner tube. The coating is of the single-walled carbon nanotube with good electronic conductivity, and does not contain any other substances influencing the electronic conductivity thereof, and the carrier of the coating is the metal wire, thereby the electronic conductivity is good. The invention can be applied to the electrical absorption enhanced solid phase micro-extraction, and has the advantages of high extraction efficiency, high temperature, strong acid and strong alkali resistance, and strong adsorption capacity.

Owner:XIAMEN UNIV

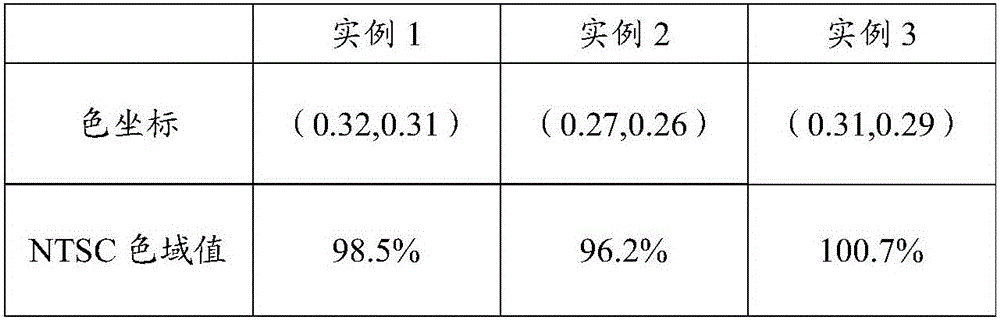

Manufacturing method of direct-light-type LED backlight

InactiveCN106784260AThe production process is simpleImprove light conversion efficiencySolid-state devicesSemiconductor devicesFluorescenceLight conversion efficiency

The present invention discloses a manufacturing method of a direct-light-type LED backlight. The method comprises: mixing mixed phosphors including quantum dot fluorescent powder with photocuring glue to obtain quantum dot fluorescent glue, coating the quantum dot fluorescent glue at the surface of a LED lens in the LED backlight, and coating a photocuring glue protective layer at the surface of the fluorescent glue after the fluorescent glue is solidified. The manufacturing method of direct-light-type LED backlight is simple in manufacturing technology, and the half-wave width of the quantum dot fluorescent glue made of quantum dot materials is small so as to greatly improve the color gamut value of the LED backlight, the color gamut value of the direct-light-type LED backlight can reach above 97% of NTSC, and the light conversion efficiency of a light source obtained through the technology is high, and the production cost is low. The photocuring glue protective layer can effectively reduce the erosion of moisture and oxygen for the quantum dot materials, can prevent the quantum dot materials from directly contacting a luminous chip, and is not liable to high-temperature influence of the luminous chip so as to improve the reliability of the LED light source.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

Amorphous soft magnetic alloy coatings and preparation method thereof

ActiveCN101441914ALow costImprove shielding effectMolten spray coatingMagnetic materialsMetallurgyCoating

The present invention relates to an amorphous soft magnetic alloy coating and the preparation method thereof. Particularly the invention relates to a amorphous soft magnetic alloy coating characterized in that content of the coating material is as following: Cr from 0.5 wt% to 8 wt%, Mo from 1 wt% to 12 wt%, Sn from 1 wt% to 8 wt%, P from 3 wt% to 10 wt%, C from 0.1 wt% to 1.5 wt%, B from 0.1 wt% to 3 wt%, Si from 0.1 wt% to 6 wt%, and balance of Fe; over 50 volume% of the coating is amorphous structure. The present invention also relates to the usage of the coating and the preparation method thereof.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

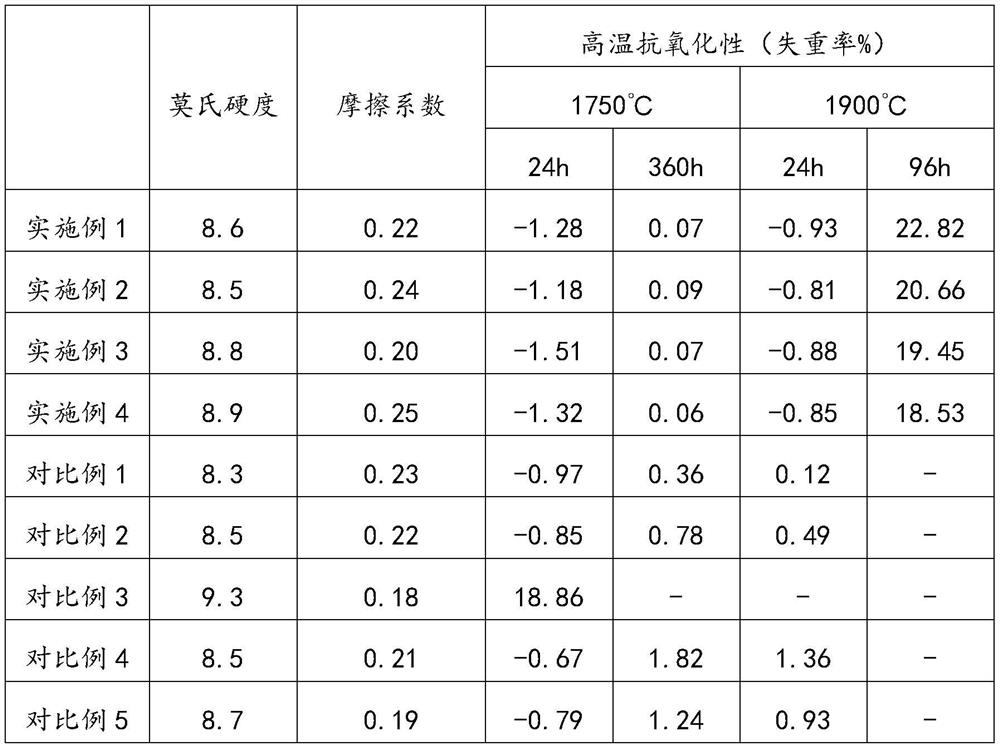

High-performance carbon-carbon crucible surface coating and preparation method thereof

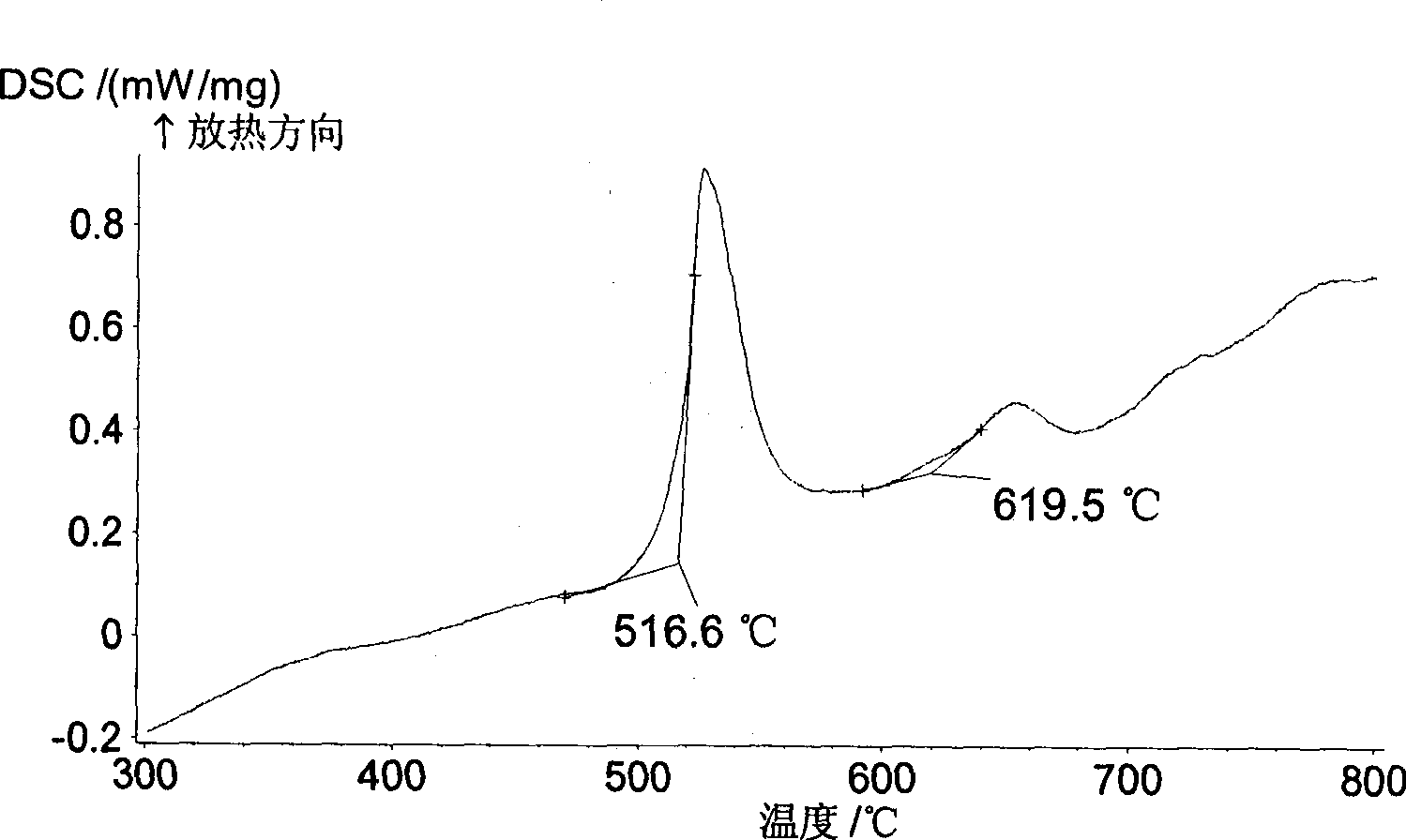

ActiveCN113773119AImprove high temperature oxidation resistanceImprove wear resistanceThermal dilatationOxidation resistant

The invention discloses a high-performance carbon-carbon crucible surface coating and a preparation method thereof, and relates to the technical field of carbon-based composite materials. The invention discloses a high-performance carbon-carbon crucible surface coating. The coating is mainly characterized in that a SiC transition layer and a LaB6 / Y3Al5O12 outer coating are sequentially deposited on a substrate of a carbon-carbon crucible, the SiC transition layer is deposited by adopting a multi-time embedding method, and the LaB6 / Y3Al5O12 outer coating is formed by coating by adopting a slurry method; and the SiC transition layer is formed by dipping treatment of an organic silicon impregnant and then brushing of outer coating slurry. The invention further discloses a preparation method of the carbon-carbon crucible surface coating. The carbon-carbon crucible surface coating provided by the invention has excellent high-temperature strength, high-temperature toughness and high wear resistance, is good in thermal shock resistance and chemical stability, and has relatively high thermal expansion compatibility with a carbon-carbon matrix, so that the service life of the carbon-carbon crucible is remarkably prolonged, the damage resistance degree of the carbon-carbon crucible is remarkably improved, and the carbon-carbon crucible can be used for resisting oxidation for a long time at 1,750 DEG C.

Owner:醴陵市东方电瓷电器有限公司

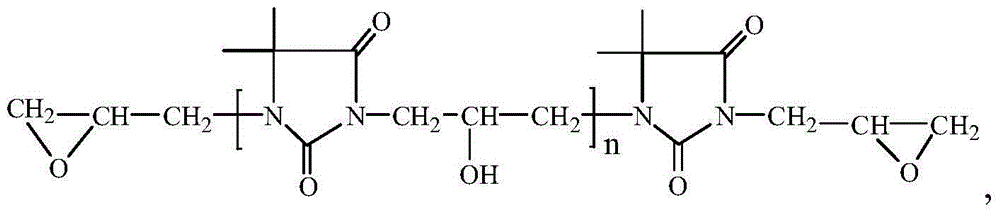

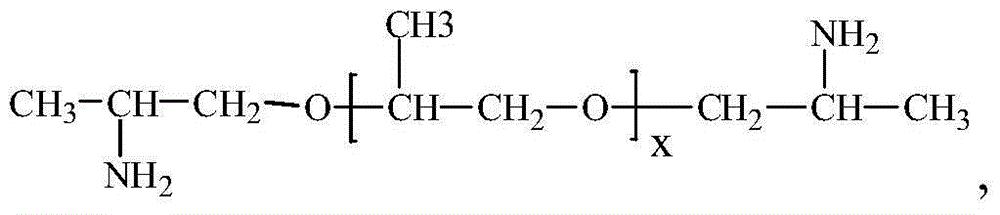

Surface-organically-modified boron nitride powder, preparation method and applications thereof

The present invention discloses surface-organically-modified boron nitride powder, wherein a hydantoin epoxy resin cross-linked polymerization product layer is coated on the particle surface, the hydantoin epoxy resin cross-linked polymerization product content in the surface-organically-modified boron nitride powder is 5-10 wt.%, and the raw materials for preparing the surface-organically-modified boron nitride powder comprise 20-30 wt.% of boron nitride, 1-3 wt.% of a hydantoin epoxy resin, 0.1-2 wt.% of an organic amine curing agent, and the balance of water. According to the present invention, the surface-organically-modified boron nitride powder has characteristics of good compatibility with polymer substrates and easy dispersion in the substrate, and can maintain good construction or processing fluidity under the high filling rate of 47.5 wt.%, and the thermal conductivity of the prepared epoxy composite material is up to 2.42 W / m.K.

Owner:FOSHAN SANSHUI JINGE NEW MATERIALS CO LTD

Protection coating for TiAl alloy, and production method thereof

ActiveCN108265259ASimple processEasy to operateMolten spray coatingOxidation resistantCeramic coating

The invention relates to a protection coating for TiAl alloy, and a production method thereof. The protection coating for the TiAl alloy is characterized in that a transition coating is produced on the surface of a TiAl base alloy through a plasma spraying technology, and a ceramic coating is produced on the surface of the transition coating; the coatings can effectively improve the oxidation resistance of the alloy and maintain the mechanical properties of the TiAl alloy in order to meet the requirements of the alloy used as a structural material in a high temperature environment, and the addition of a proper amount of TiO2 can improve the large porosity, poor compactness and other defects of the coating; and the transition coating can enhance the bonding strength between the alloy and the coating, and also can solve the oxygen atom penetration problem caused by the untightness of the ceramic coating, and further enhances the oxidation resistance of the alloy. The method adopted by the invention has the advantages of simplicity, convenience in operation, and high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

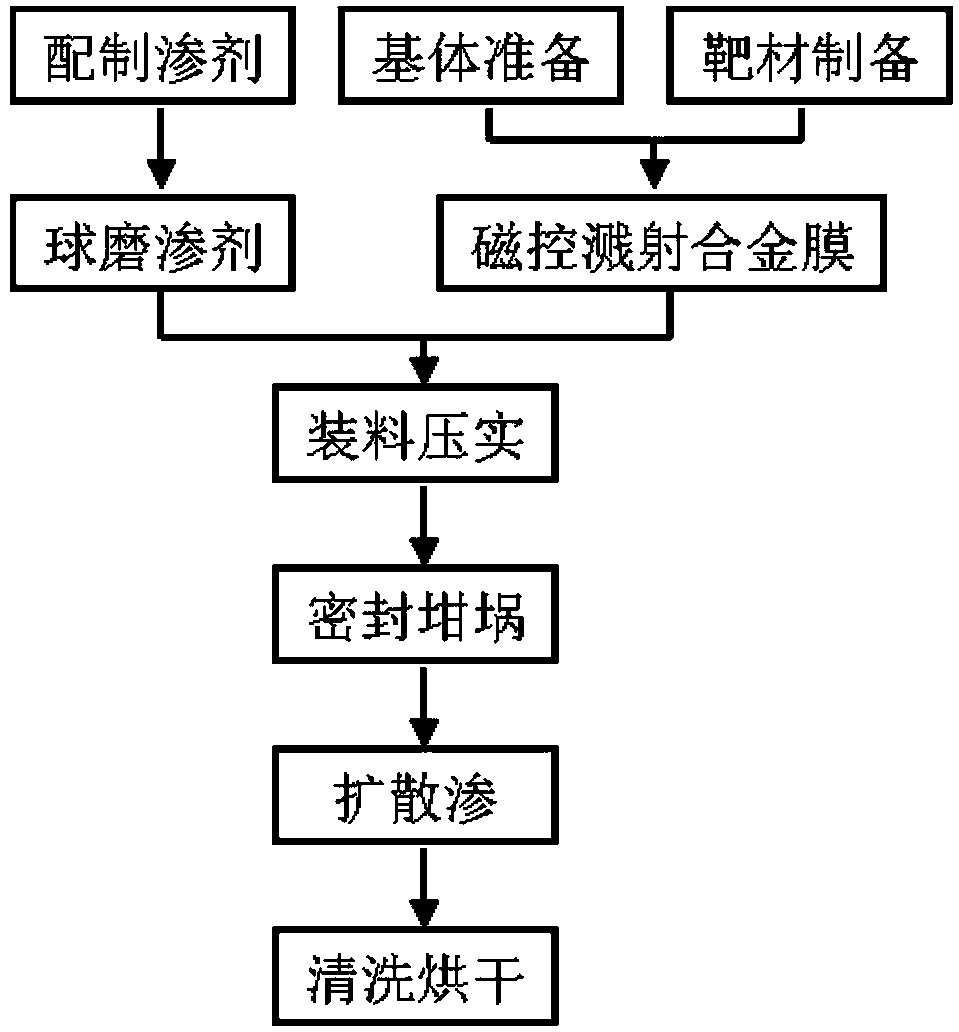

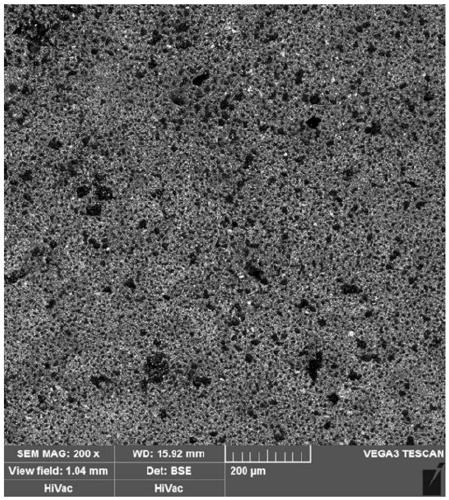

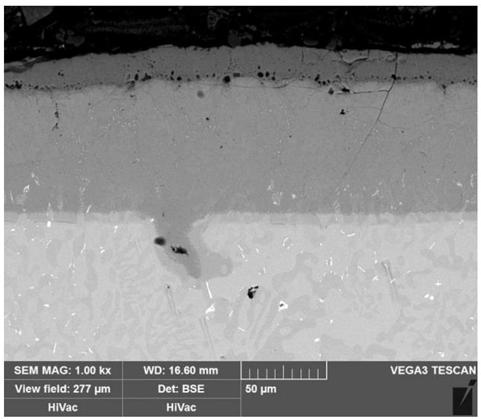

Two-step preparation method for Zr, Ti, Al multivariate modified silicide seepage layer

ActiveCN109576661ADense tissueOptimizing Coating ThicknessVacuum evaporation coatingSputtering coatingSputteringSuperalloy

The invention relates to a two-step preparation method for a Zr, Ti, Al multivariate modified silicide seepage layer. Firstly, the type and content of the modified element are optimized through the component control of an alloy target; and secondly, by controlling the deposition thickness and diffusion seepage process parameters of magnetron sputtering Ti-Al-Nb-Zr alloy film, and the multivariatemodified silicide seepage layer with controllable content of Zr, Ti, Al modified elements, controllable alloy film thickness, controllable coating thickness and dense microstructure is prepared on thesurface of Nb-base ultra-high-temperature alloy. The two-step preparation method has the advantages that the process is simple, the operation is convenient, the cost is low, the seepage layer optimization is conveniently achieved, and the two-step preparation method is suitable for application and popularization.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

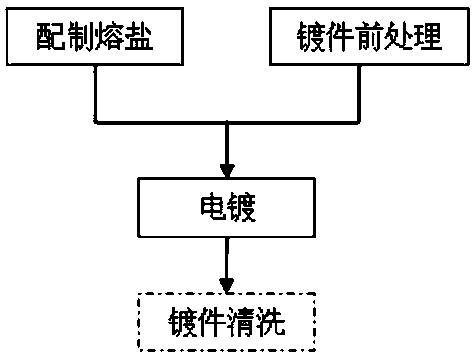

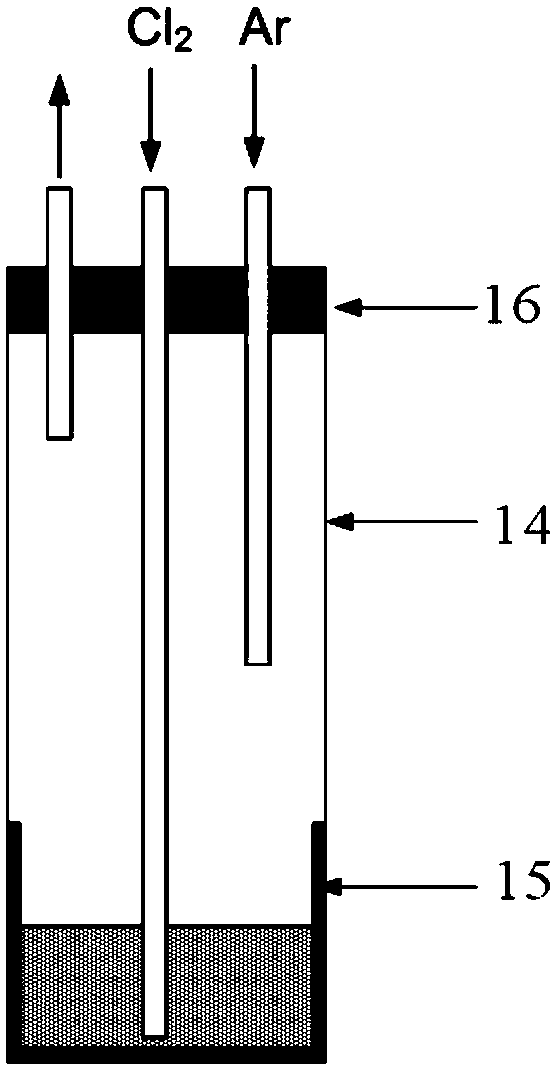

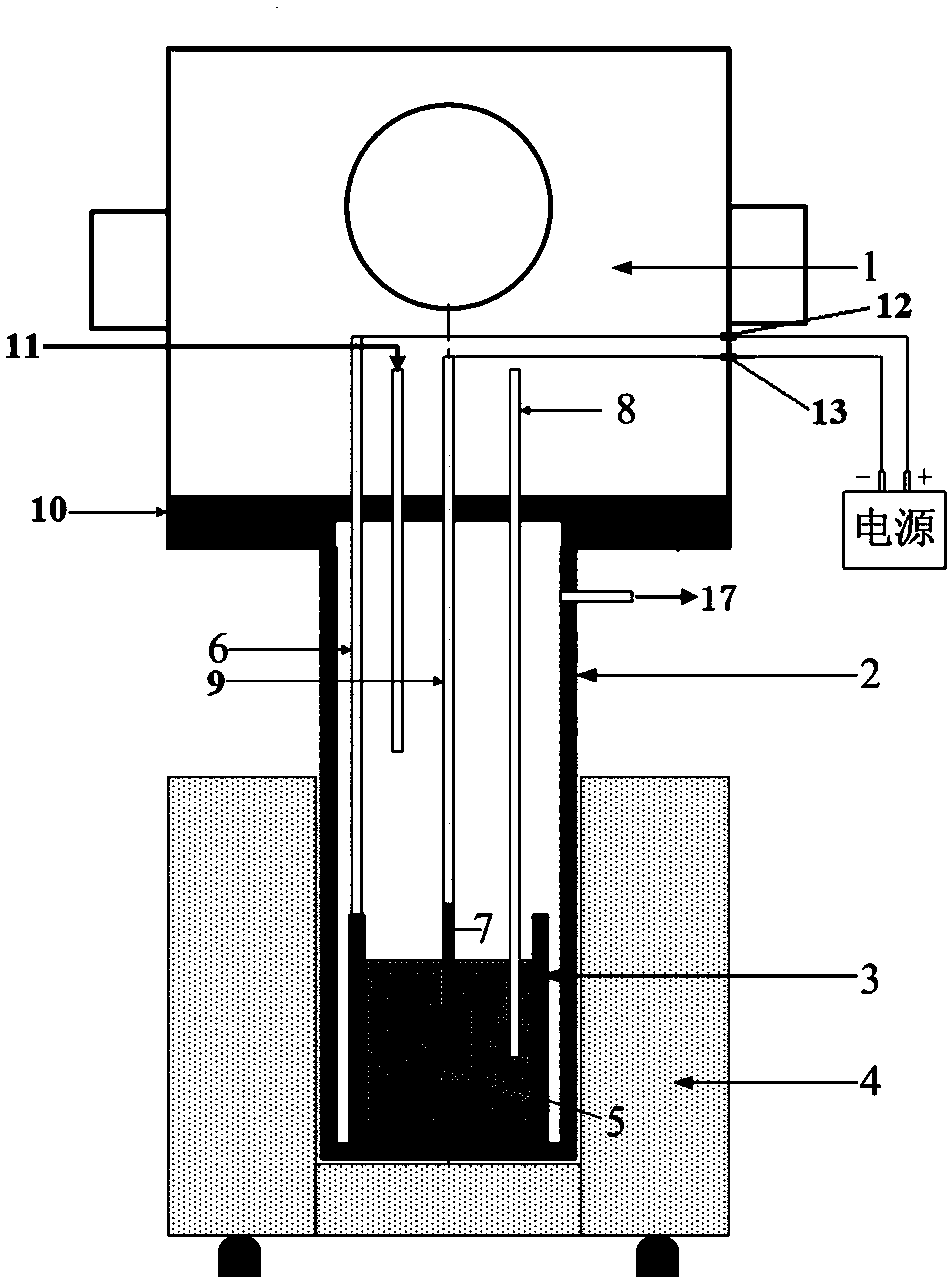

Preparation method for black rhenium coating

ActiveCN107699928AConcentration is easy to controlStable dissolutionSealing devicesRheniumMolten state

The invention discloses a preparation method for a black rhenium coating. The preparation method comprises the following steps that S1, molten salt chlorination is performed, wherein under inert gas protection, after CsCl is heated to a molten state, K2ReCl6 is added, the molten salt containing K2ReCl6 is obtained, chlorine is introduced into the molten salt containing K2ReCl6, chlorinating is performed, and after cooling, the chlorinated molten salt is obtained; and S2, electroplating is performed, wherein the chlorinated molten salt obtained in the step S1 is heated to the molten state underinert gas protection, a plating piece base body is immersed into the chlorinated molten salt in the molten state, the chlorinated molten salt in the molten state is a plating solution, the plating piece base body is used as a negative electrode, an inert electrode is used as a positive electrode, electroplating is performed after electrification, and the black rhenium coating is obtained on the plating piece base body. The preparation method is low in cost and high in deposition rate, and the prepared black rhenium coating is good in uniformity.

Owner:NAT UNIV OF DEFENSE TECH

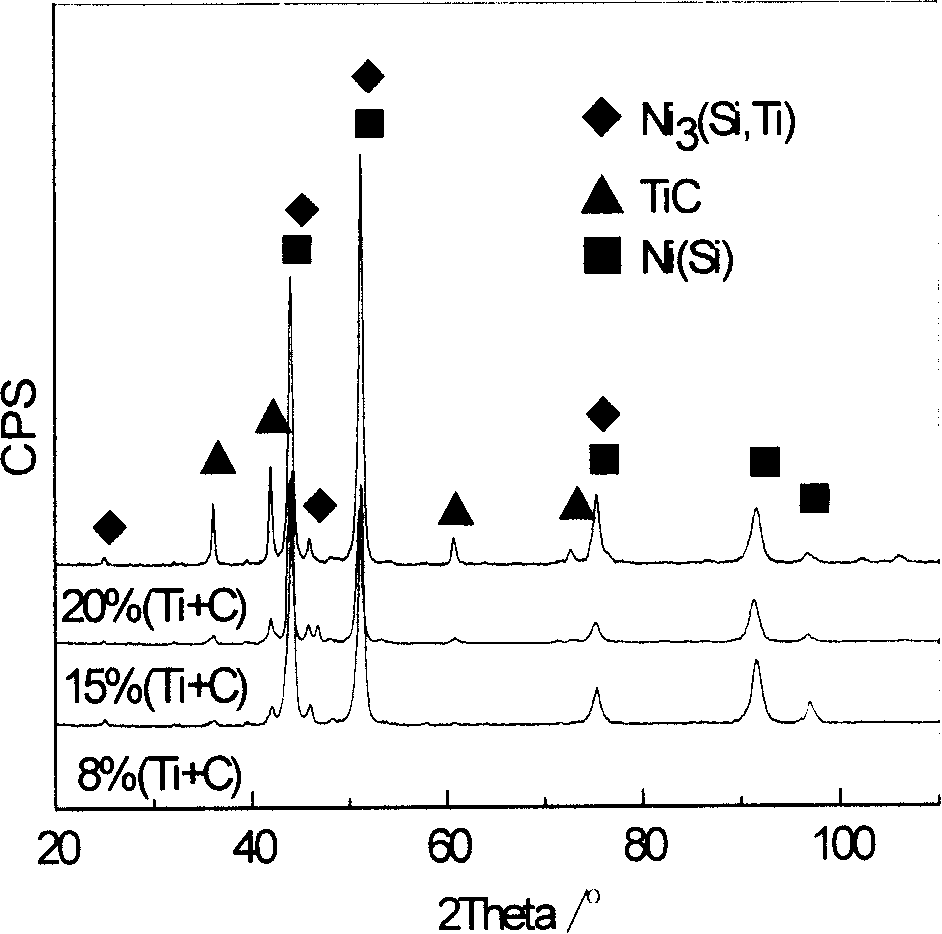

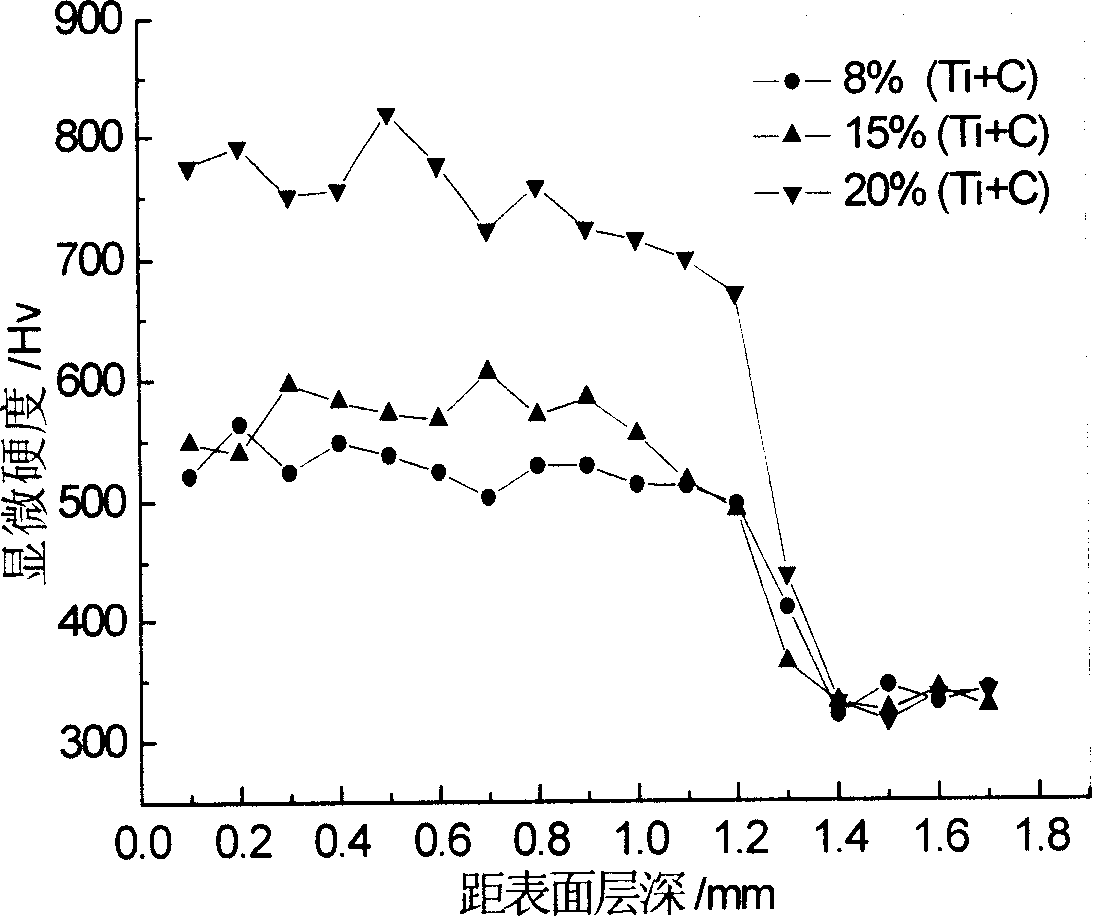

Ni3(Si,Ti)-TiC composite coating material and preparation method thereof

InactiveCN101161865AUniform coating structureHigh hardnessMetallic material coating processesLaser beam welding apparatusThermal sprayingChemical composition

The present invention relates to a nickel trisilicon titanium intermetallic compound-titanium carbide composite coating material and a method for preparing the same; a composite coating mainly consisting of Ni3(Si, Ti) intermetallic compound and TiC ceramic is made on a high-temperature ultratek substrate by laser cladding in situ; the coating material mainly comprises four elements: Ni, Si, Ti and C; the chemical components of the four elements have the following weight percentages: 8 percent to 20 percent Ti powder plus C powder; 78 percent Ni, 13 percent Si and 9 percent Ti; the preparation method adopts the laser to clad and has the following parameters: the output power is between 1000 W and 1500 W; the scanning speed is 4-6 mm / s. the spot diameter is 4 mm; the protective gas is Ar gas in cladding; the cladding substrate material is high-temperature ultratek; the invention has the following procedures: according to the mixture ratio, the coating material is mixed uniformly and pre-coated or hot-sprayed on the surface of the high-temperature ultratek substrate; the thickness is between 1 mm and 1.2 mm; the laser is adopted to have multilayer and multi-path cladding; each channel has related joint of 1.8 mm, thereby achieving the cladding layer with different thickness.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

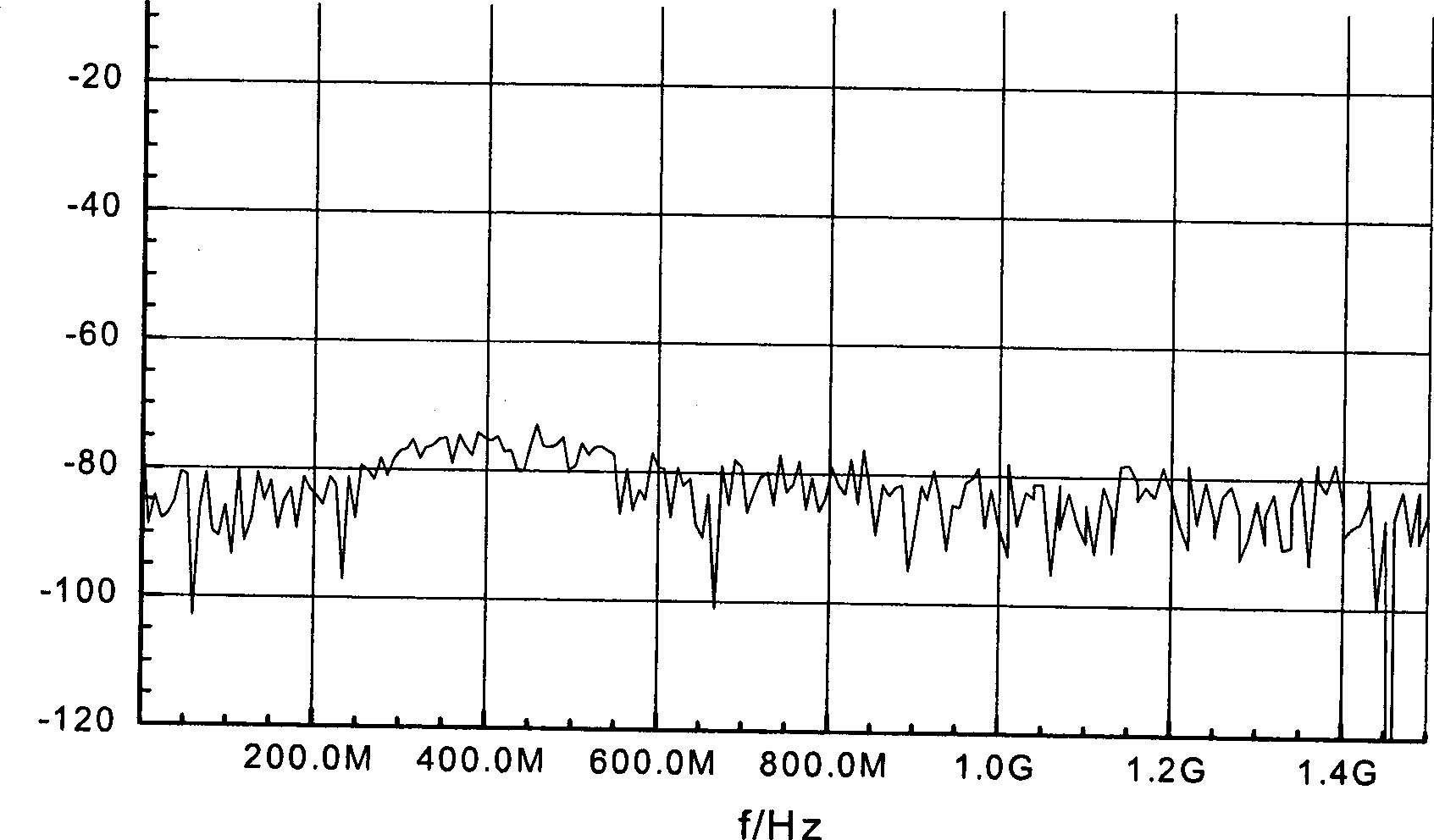

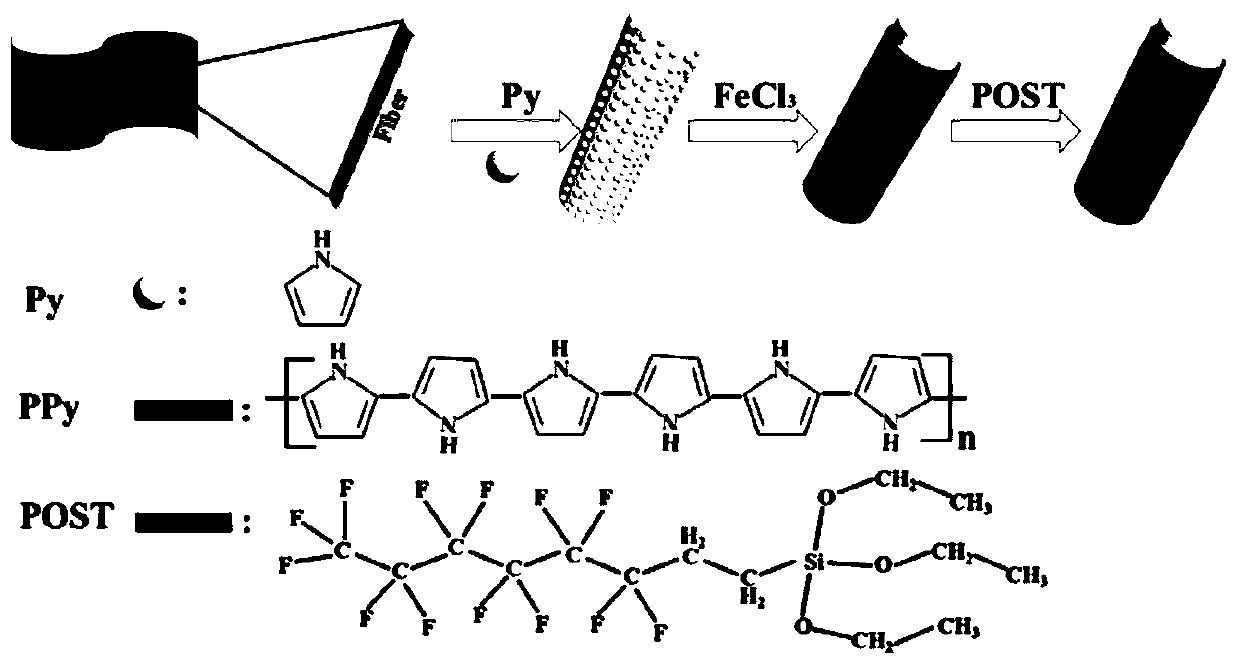

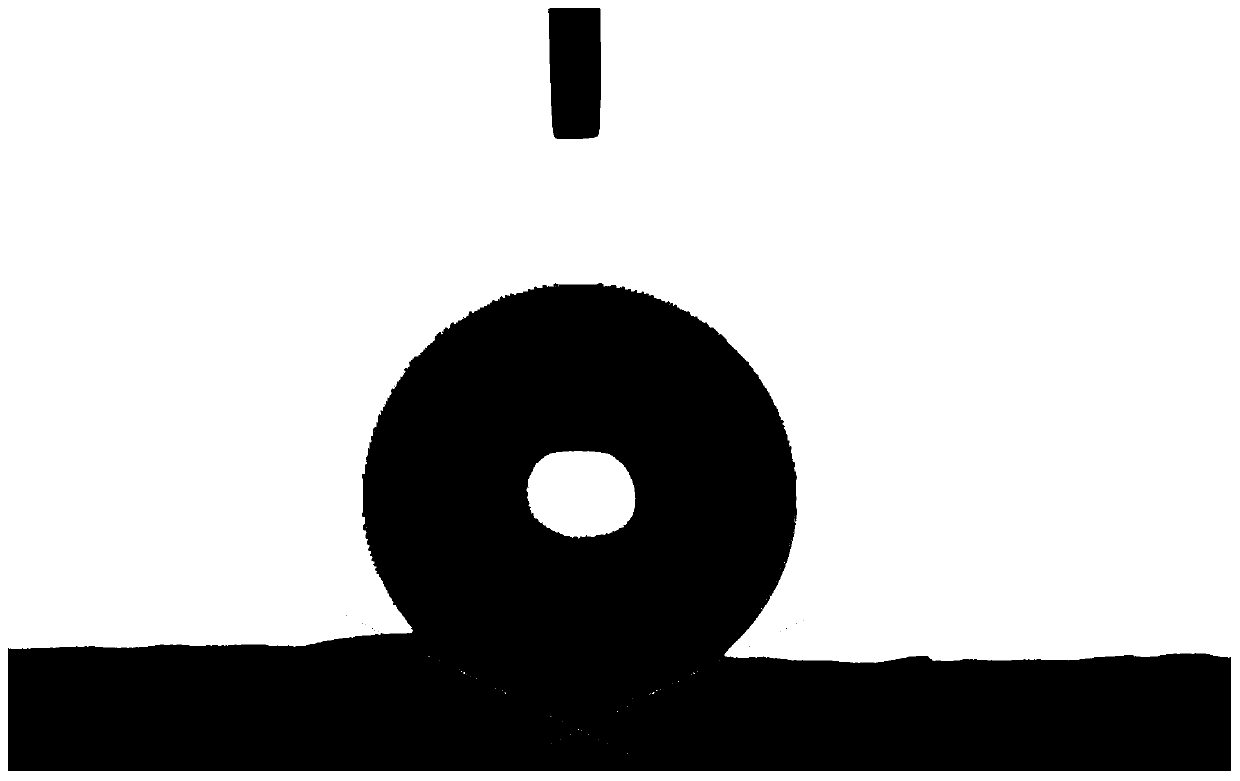

Method for preparing durable fabric with electromagnetic shielding performance through superhydrophobic finishing

PendingCN110284330AExcellent electromagnetic shielding durabilityIncreased durabilityLiquid repellent fibresVegetal fibresPolypyrroleIn situ polymerization

The invention discloses a method for preparing a durable fabric with the electromagnetic shielding performance through superhydrophobic finishing. The method comprises the steps that the fabric obtained after cleaning and impurity removing is soaked in a pyrrole monomer (Py) solution, and then taken out and put in a dopant-containing ferric trichloride solution for in situ polymerization, so that a polypyrrole conductive (PPy) coating is formed on the surface of the fabric, then chemical vapor deposition is conducted on 1H,1H,2H,2H-perfluorooctyl triethoxylsilane (POST) on the surface of the fabric, and the durable fabric with the electromagnetic shielding performance is obtained. According to the prepared durable fabric with the excellent electromagnetic shielding performance, the prepared coated fabric is high in electromagnetic shielding effectiveness and controllable in coating thickness, the required experimental operation conditions are simple in requirement and low in energy consumption, expensive equipment is not needed, and the production cost is low.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

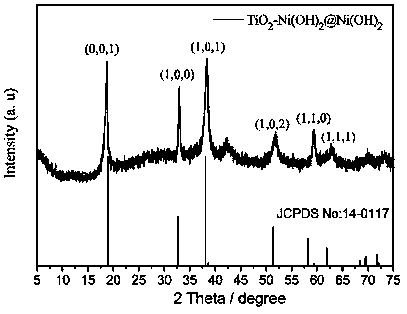

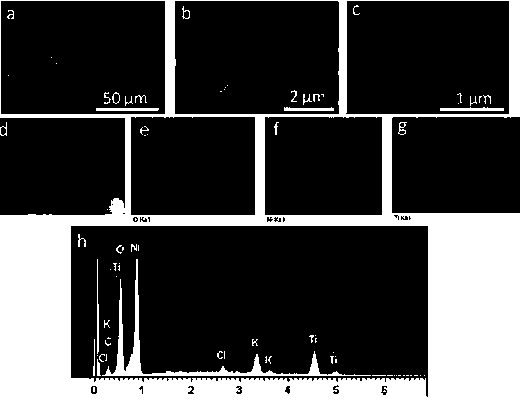

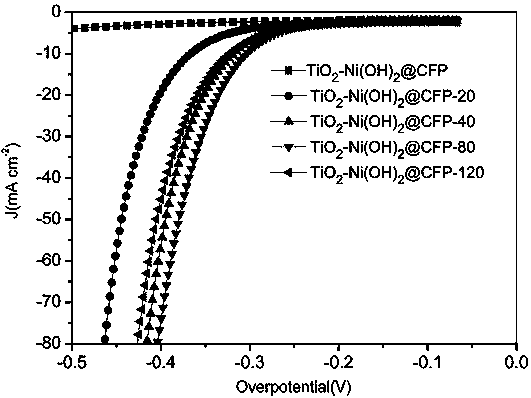

Preparation method of composite electro-catalytic material for alkaline electro-catalytic hydrogen evolution

ActiveCN110565113AIncrease surface areaImprove electrocatalytic activityMetal/metal-oxides/metal-hydroxide catalystsElectrodesFiberAir atmosphere

The invention discloses a preparation method of a composite electro-catalytic material for alkaline electro-catalytic hydrogen evolution. The method comprises the following steps: growing a layer of Ni(OH)2 nano sheet structure on carbon fiber paper; coating the surface of the Ni(OH)2 nano sheet structure with a titanium oxide layer by vacuum plating; performing annealing crystallization in a muffle furnace at a temperature of 360 DEG C in an air atmosphere to obtain a TiO2-Ni(OH)2@CFP composite structure material; and performing annealing crystallization on the TiO2-Ni(OH)2@CFP in an air atmosphere by controlling different coating times to obtain the composite electro-catalytic material after coating for different times. The method uses CFP as a base material of a catalyst, a surface areaof a composite electrode is increased, mass transfer is facilitated and the electrochemical activity of the electrode is improved. At the same time, Ni(OH)2 is grown on the base material by hydrothermal, the cost is reduced, combination of Ni(OH)2 and the base material is relatively firm, and distribution is uniform to improve stability of the catalyst. The introduction of TiO2 plays a great rolein improving catalytic performance of the catalyst and reducing hydrogen evolution overpotential, and significant improvement of the electro-catalytic hydrogen evolution activity is realized.

Owner:JINGGANGSHAN UNIVERSITY

Graphene oxide-containing anticorrosive paint special for steel structure and preparation method thereof

InactiveCN110951360AImprove adhesionFunction increaseAnti-corrosive paintsEpoxy resin coatingsEpoxyMeth-

The invention belongs to the technical field of corrosion prevention and particularly relates to a graphene oxide-containing anticorrosive coating special for a steel structure and a preparation method thereof. A paint primer is prepared from 30 to 35 parts of epoxy resin, 12 to 15 parts of tetrabutyl titanate, 8 to 10 parts of chromium acetylacetonate, 8 to 10 parts of polyvinyl formal and 90 to100 parts of zinc powder. A finish paint is prepared from 65 to 70 parts of tetrafluoroethylene, 20 to 25 parts of graphene oxide, 12 to 15 parts of styrene, 3 to 5 parts of acrylic acid, 12 to 15 parts of methyl isobutyl ketone, 0.8 to 1.0 part of azodiisobutyronitrile and 0.5 to 0.6 part of dibutyltin dilaurate. The primer prepared by the preparation method is good in adhesive force with a steelassembly of a power transmission tower, good in adhesiveness, and excellent in electrochemical or chemical corrosion resistance, the weather resistance and corrosion resistance of a coating layer areimproved, the curing time is short, the durability is good, the spraying is simple, the coating thickness is controllable, the weather resistance is good, the ultraviolet damage is resisted, and theadaptability is wide.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

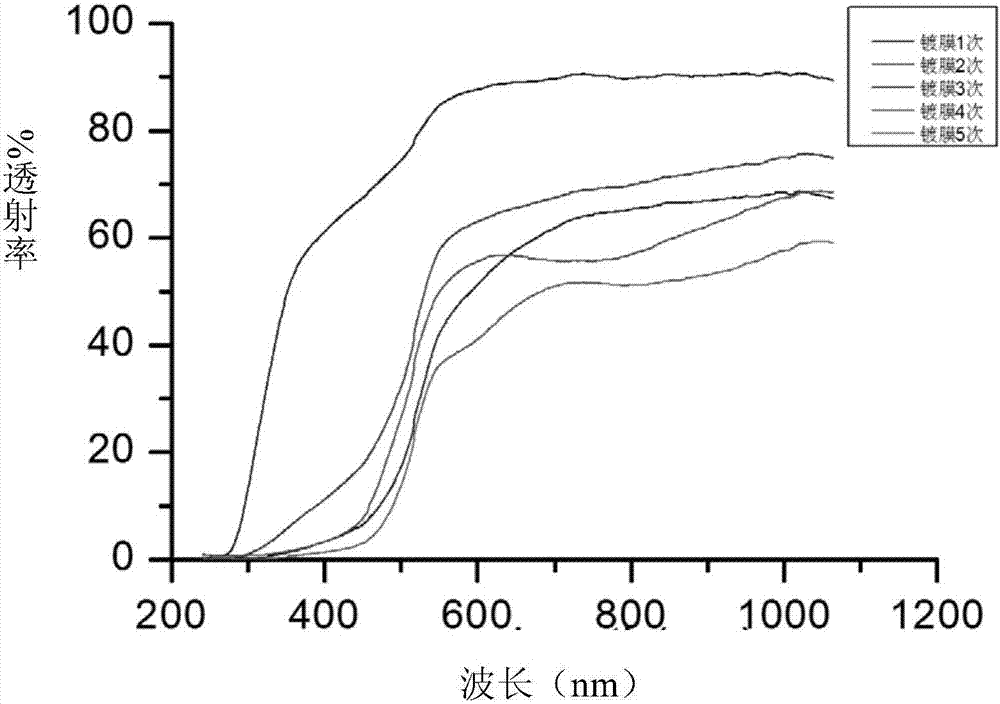

Optical fiber temperature sensor and preparation method of cadmium sulfide films of optical fiber temperature sensor

ActiveCN107365983ATightly boundCoating thickness controllableThermometers using physical/chemical changesLiquid/solution decomposition chemical coatingWater bathsCadmium sulfate

The invention provides a preparation method of cadmium sulfide films of an optical fiber temperature sensor. The preparation method comprises the following steps that after optical fibers are fixed to an insertion core, the exposed ends of the optical fibers are polished; film coating is conducted, wherein thiourea, cadmium sulfate and ammonium hydroxide are mixed according to the mass-volume ratio and dissolved in deionized water to form a reaction solution, wherein the mass-volume ratio of thiourea to cadmium sulfate to ammonium hydroxide is 5.694g:0.184g:45mL; then the exposed ends are inserted into the reaction solution, the reaction is conducted for 9 minutes by the use of the chemical water-bath method at the temperature of being 65 DEG C, and therefore film coating of one cadmium sulfide film is accomplished for the first time; the step of film coating is repeated for n times, and the exposed ends with the deposited (n+1) cadmium sulfide films are obtained, wherein the n is a natural number which is larger than 0; and annealing treatment is conducted on the optical fibers which are obtained through the repeated film coating step. According to the preparation method, the chemical water-bath method is adopted to achieve coating of the cadmium sulfide films, and therefore the cadmium sulfide films can be closely combined with the ends of the optical fibers, and the coating film thickness is controllable.

Owner:SHENZHEN INST OF ADVANCED TECH

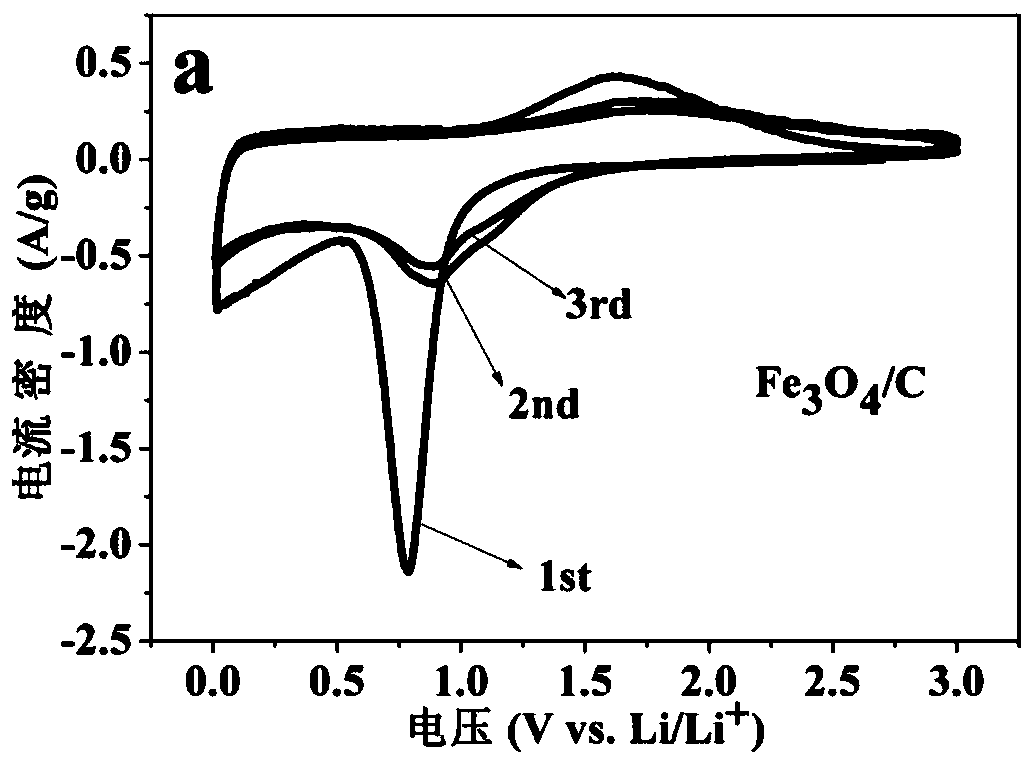

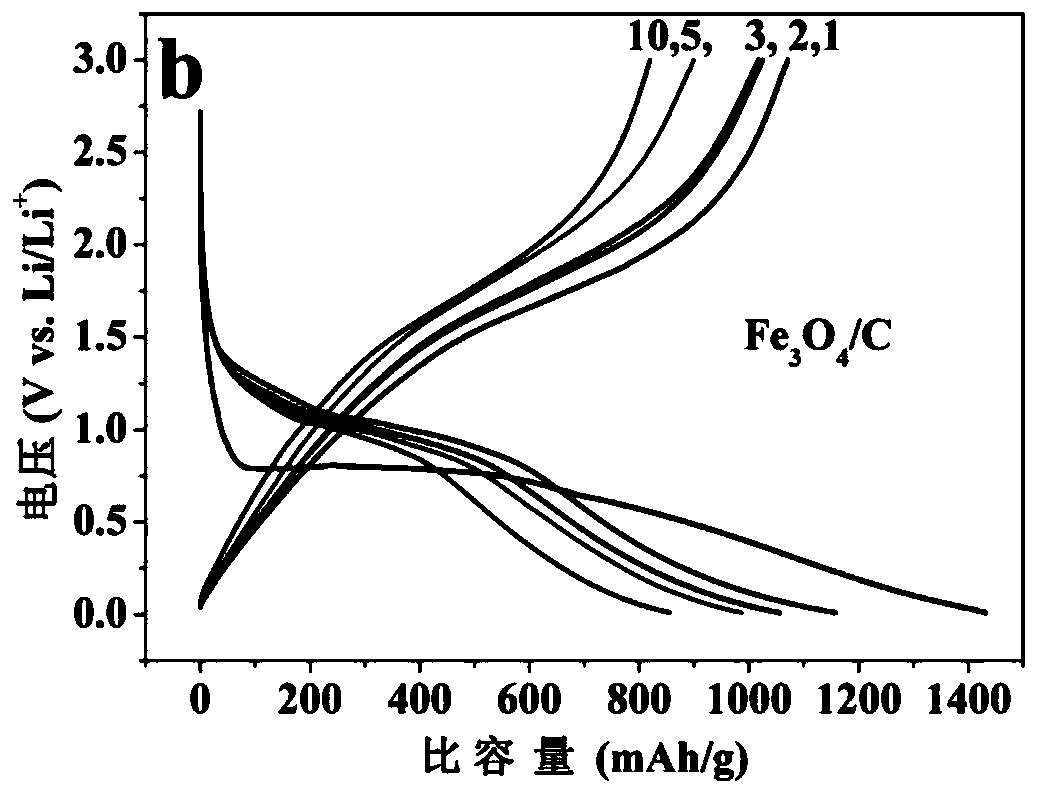

In-situ carbon-coated Fe3O4 composite material, preparation method thereof and application thereof in lithium ion battery

ActiveCN111244440AStable structureCoating thickness controllableSecondary cellsNegative electrodesPosterior compositesLithium-ion battery

The invention relates to an in-situ carbon-coated Fe3O4 composite material as well as a preparation method thereof and an application thereof in a lithium ion battery, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps of adding a trivalent Fe salt aqueous solution into a BFA aqueous solution to form a gel precipitate; drying the gel precipitate to obtain BFA-Fe; carrying out carbonization treatment on the obtained BFA-Fe, so that the in-situ carbon-coated Fe3O4 composite material is prepared, the surfaces of Fe3O4 particles are comprehensively coated with the in-situ carbon, the surface coating uniformity is good, the coating thickness of the surface carbon material is controllable, and the structure of the coated composite material is more stable.

Owner:合盛科技(宁波)有限公司

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266BGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsEpoxyHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

Metal-organic framework material coated ternary positive electrode material and preparation method thereof

The invention discloses a metal-organic framework material coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly dispersing a ternary positive electrode material in a mixed solution of absolute ethyl alcohol and N, N-dimethyl formamide; (2) sequentially adding zirconium salt and an organic ligand into the dispersion liquid under a stirring condition, and performing complete stirring; (3) transferring the uniform dispersion obtained at the step (2) into a reaction kettle, and carrying out solvothermal reaction; (4) taking out the reaction kettle, collecting a bottom product, performing centrifugal washing, and drying the centrifuged product to obtain the metal-organic framework material coated ternarypositive electrode material. According to the method provided by the invention, a layer of metal can be uniformly coated on the surface of the ternary positive electrode material, and the thickness of the coating can be controlled. Through the ternary positive electrode material modified on the surface of the organic framework material, the method can effectively reduce corrosion and decomposition of the ternary positive electrode material in an electrolyte and improve the cycle stability of a battery.

Owner:ZHEJIANG UNIV

Fabrication method of quantum dot lens-type direct LED backlight source

InactiveCN106784238AImprove color gamutSolve the problem of easy reunion failureSolid-state devicesNon-linear opticsGamutAdhesive

The invention discloses a fabrication method of a quantum dot lens-type direct LED backlight source. The method comprises the following steps of firstly preparing a fluorescent adhesive A and dropping the fluorescent adhesive A into an LED bracket; preparing a quantum dot fluorescent adhesive B and coating the surface of an LED lens with the quantum dot fluorescent adhesive B and then coating the surface of the quantum dot fluorescent adhesive B with an ultraviolet-curing adhesive protection layer. A quantum dot fluorescent material is adopted by the quantum dot fluorescent adhesive B and the half-wave width is small, so that the color gamut value of the LED backlight source can be greatly improved and the color gamut value can reach over 96% of NTSC. Quantum dot fluorescent powder is prepared in the fluorescent adhesives, so that the problem of agglomeration and failure of the quantum dot fluorescent powder is solved. The fabrication method is simple in process and low in cost, and industrial production is easy to implement. Meanwhile, the quantum dot fluorescent adhesive B coats the LED lens, and is coated with packaging glue for protection, so that erosion of moisture and oxygen to the quantum dot fluorescent material is reduced, meanwhile, the quantum dot fluorescent material is prevented from being in direct contact with a light-emitting chip and being affected by a high temperature of the light-emitting chip, and the reliability of a lamp bead is improved.

Owner:WUHU JUFEI PHOTOELECTRIC TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com