Fabrication method of quantum dot lens-type direct LED backlight source

A technology of LED backlight source and manufacturing method, applied in optics, nonlinear optics, instruments, etc., can solve the problems of complex manufacturing process of quantum dot backlight source, easy agglomeration failure of materials, low light conversion efficiency, etc., so as to reduce the difficulty and product quality. The effect of defective rate, improved color gamut value, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

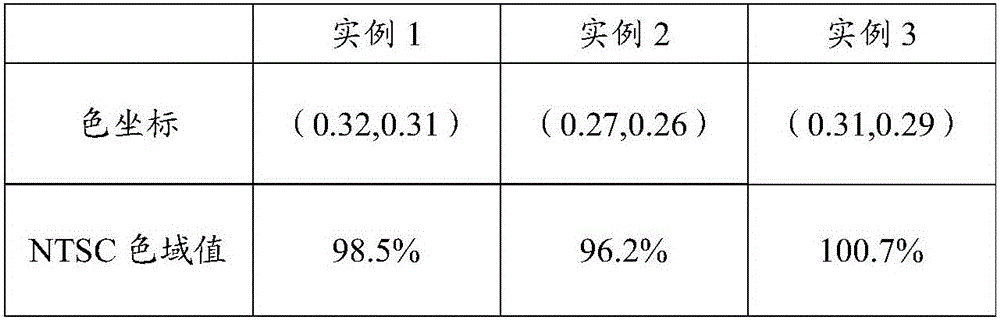

Embodiment 1

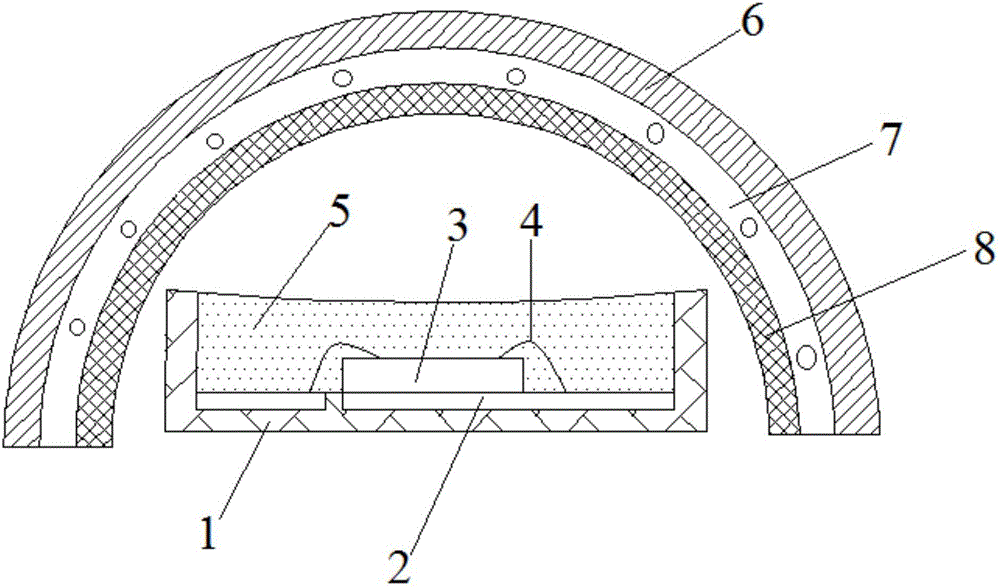

[0030] This embodiment provides a method for manufacturing a quantum dot lens type direct LED backlight, which includes the following steps:

[0031] a. Weigh 0.08g of luminescent material A, which is CsPbCl with an emission wavelength of 530nm 3 , CsPbI 3 Green light quantum dot phosphor, wherein, the CsPbI 3 Fluorescent powder is 0.04g, weigh 24g of epoxy packaging glue, mix it with luminescent material A, and vacuum defoam and stir to obtain fluorescent glue A. The quantum dot phosphor is in powder form, or it can be dispersed in a solvent shape;

[0032] b. Drop the fluorescent glue A into the LED bracket fixed with the light-emitting chip, control the volume of the fluorescent glue A to account for 90% of the cup shell volume of the bracket, the light-emitting chip is a blue light chip with a wavelength of 455nm, and drop The LED bracket with fluorescent glue A is placed in an oven, baked at 80°C for 8 hours to obtain LED lamp beads; then select a suitable FPC accordin...

Embodiment 2

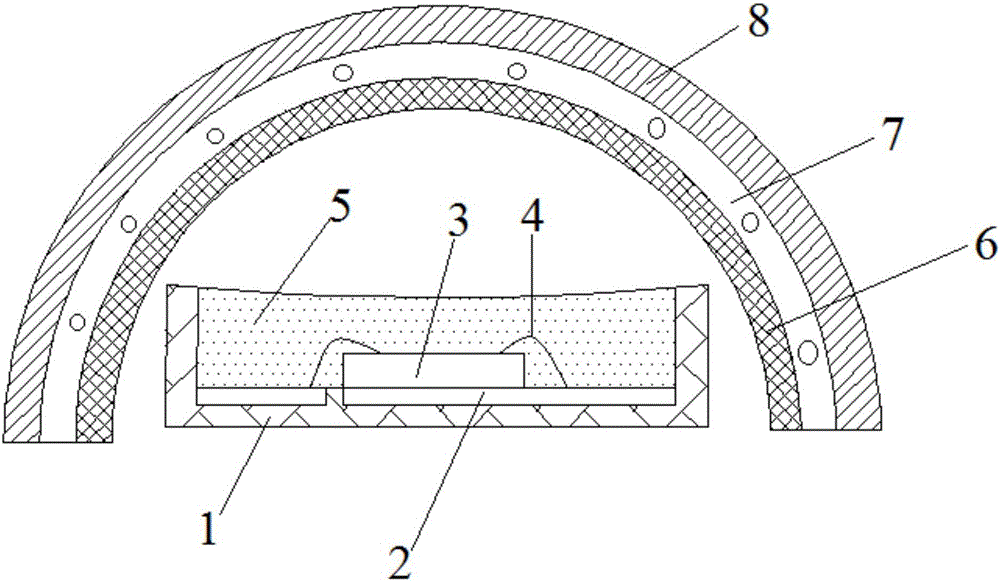

[0038] This embodiment provides a method for manufacturing a quantum dot lens type direct LED backlight, which includes the following steps:

[0039] a. Weigh 1.86g of luminescent material A, said luminescent material A includes 0.52g of silicate green phosphor powder with emission wavelength of 540nm, 1.34g of fluoride red phosphor powder with emission wavelength of 625nm, and weigh 1.86g of organic Silicone encapsulating glue, mixing it with luminescent material A, vacuum defoaming and stirring, to obtain fluorescent glue A;

[0040] b. Drop the fluorescent glue A into the LED bracket fixed with the light-emitting chip, and control the volume of the fluorescent glue A to account for 100% of the volume of the cup shell of the bracket. The light-emitting chip is an ultraviolet light chip with a wavelength of 290nm, and The LED bracket dripped with fluorescent glue A is placed in an oven, baked at 160°C for 0.5h to obtain LED lamp beads; then select a suitable FPC according to ...

Embodiment 3

[0046] This embodiment provides a method for manufacturing a quantum dot lens type direct LED backlight, which includes the following steps:

[0047] a. Weigh 0.12g of luminescent material A, said luminescent material A includes 0.02g of ZnTe green light quantum dot phosphor powder with emission wavelength of 526nm, 0.1g of nitride red light phosphor with emission wavelength of 526nm, and weigh 3.05g of epoxy Encapsulation glue, and mix it with luminescent material A, vacuum defoaming and stirring, to obtain fluorescent glue A, the quantum dot fluorescent powder is in powder form, or can also be in a solvent dispersed form;

[0048] b. Drop the fluorescent glue A into the LED bracket fixed with the light-emitting chip, control the volume of the fluorescent glue A to account for 95% of the cup shell volume of the bracket, the light-emitting chip is a blue light chip with a wavelength of 440nm, and drop The LED bracket with fluorescent glue A is placed in an oven, baked at 120°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com