Liquid crystal display panel, display device, and manufacturing method of liquid crystal display panel

A technology for a liquid crystal display panel and a manufacturing method, which is applied to instruments, nonlinear optics, optics, etc., can solve the problems of insufficiently vivid and true colors, decreased aperture ratio, large equipment deviation, etc., to improve display quality, improve brightness, increase The effect of opening ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

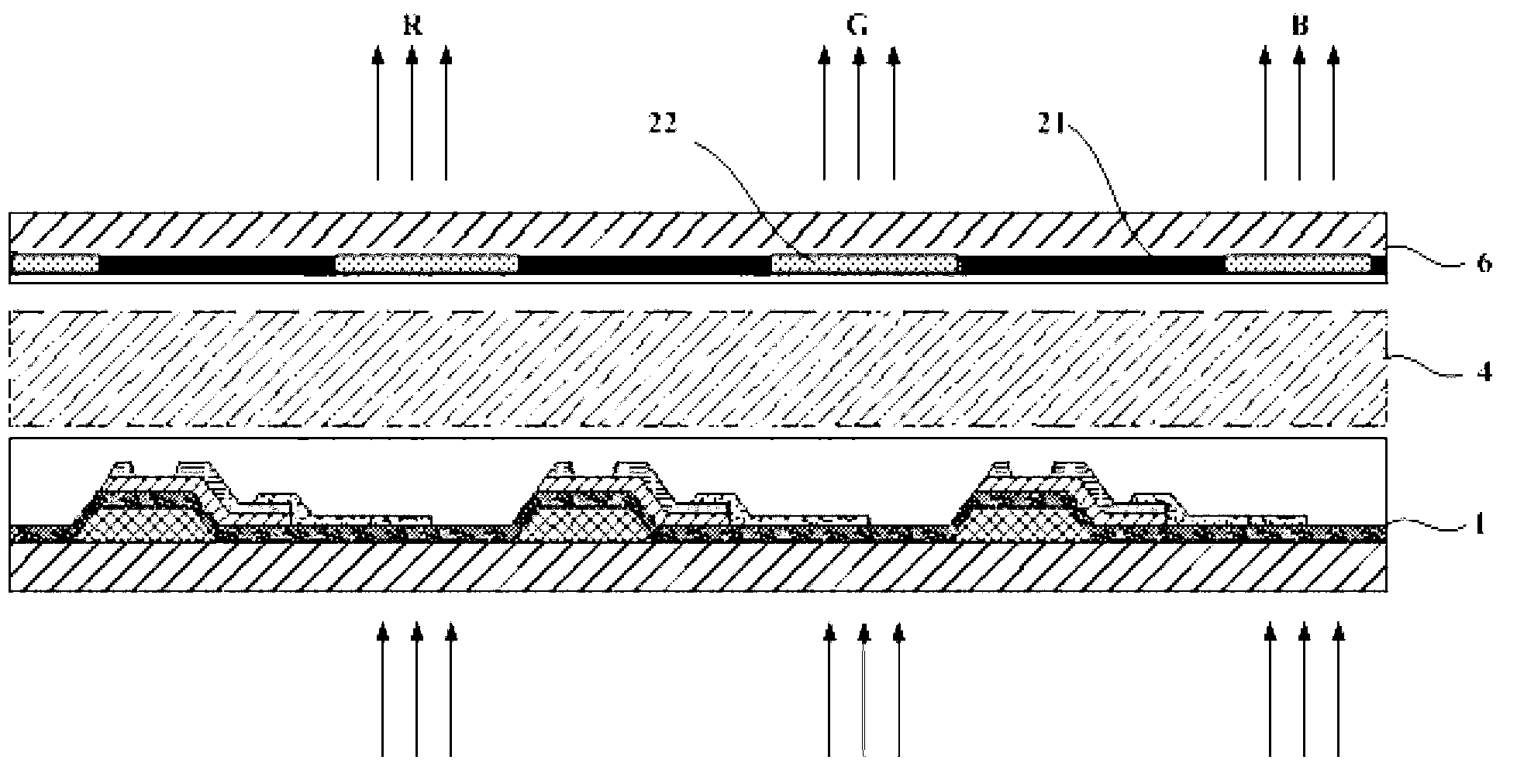

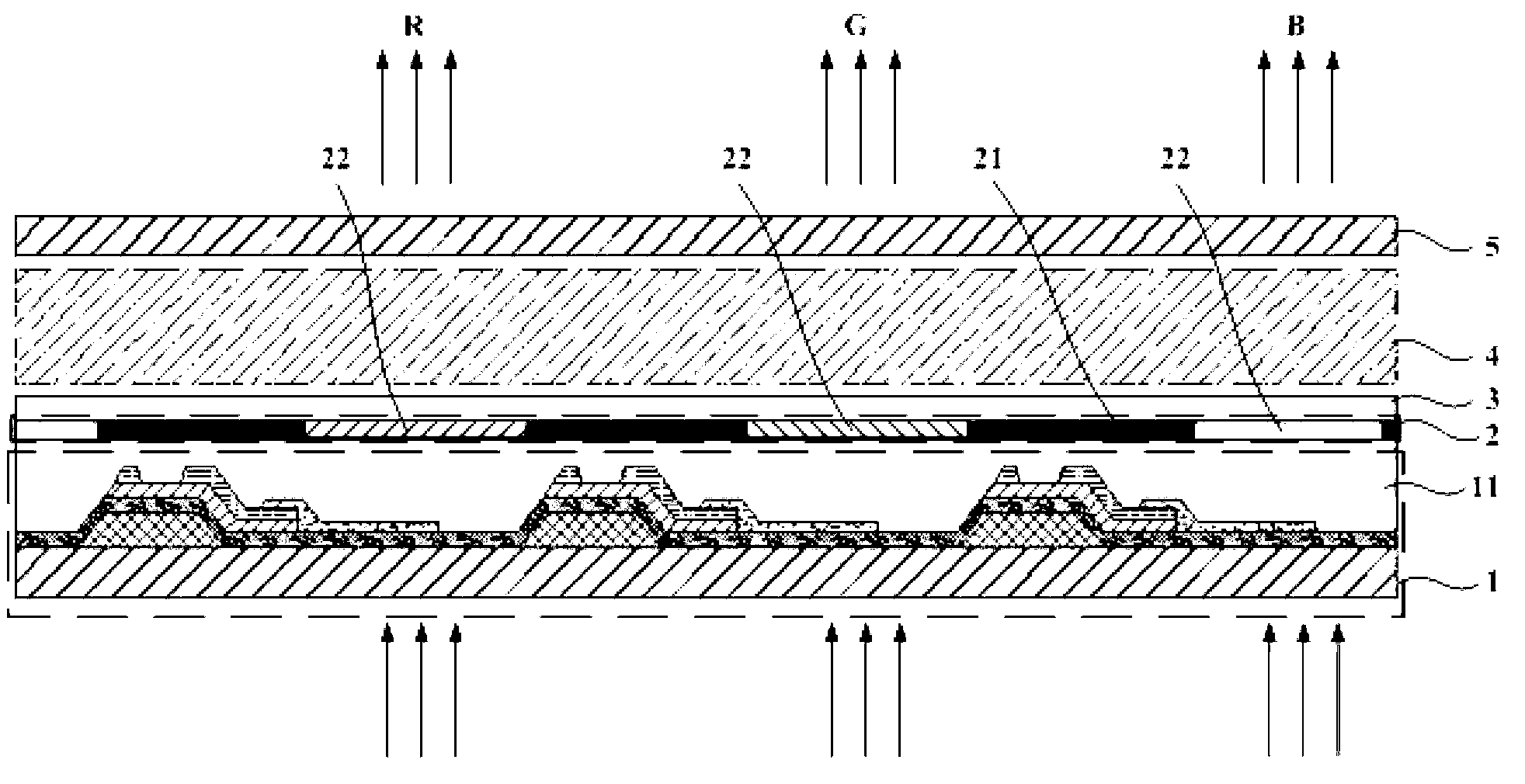

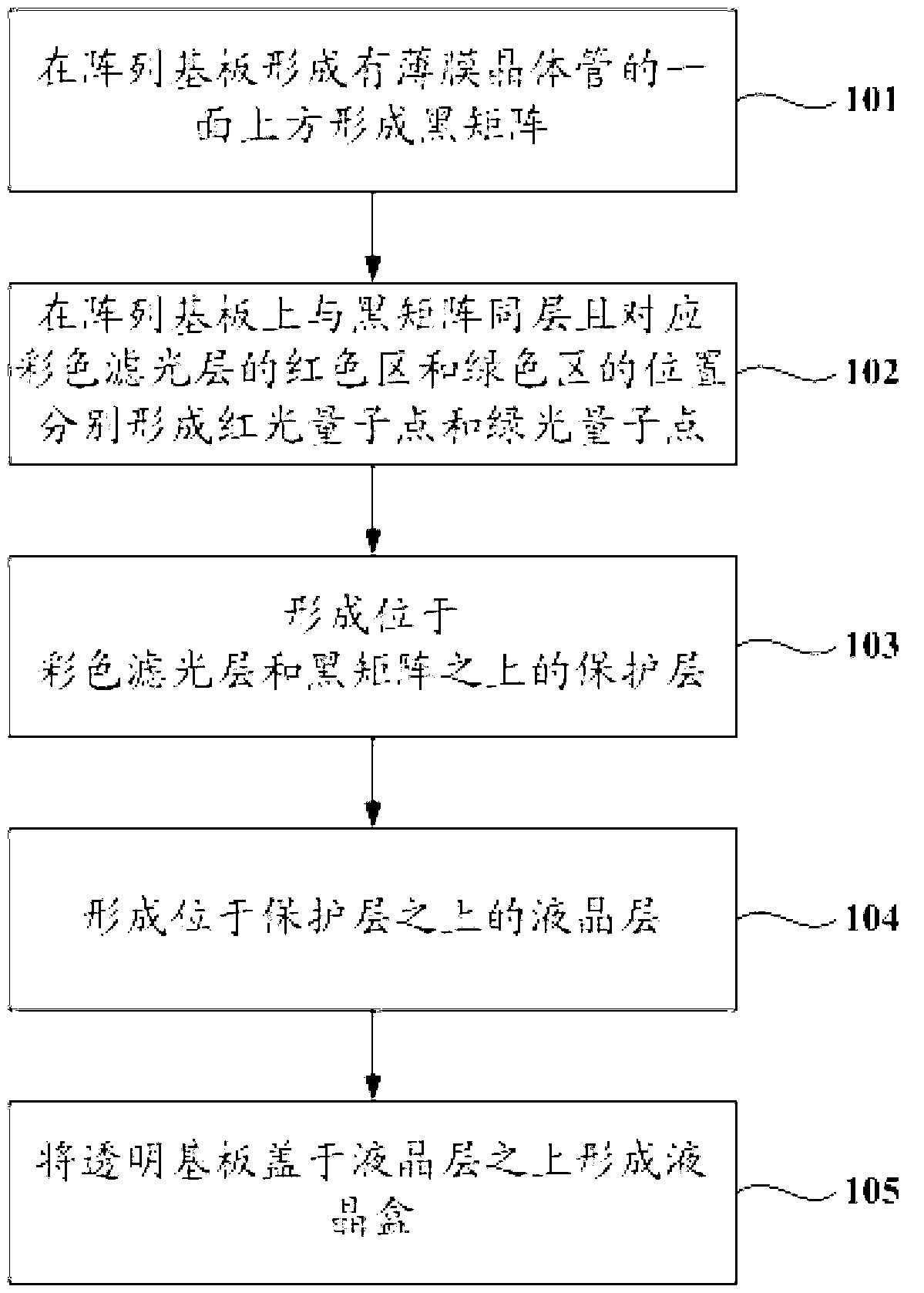

[0044] In order to improve the color gamut of the picture, the invention provides a liquid crystal display panel, a display device and a manufacturing method of the liquid crystal display panel. The liquid crystal display panel includes an array substrate, and further includes: a color filter located on the array substrate, the color filter includes a black matrix and a color filter layer with different color regions, wherein the Different color regions of the color filter layer have quantum dots of different sizes, and the quantum dots of different sizes generate corresponding colors through excitation; a protective layer located on the color filter; located on the protective layer a liquid crystal layer; a transparent protective plate located on the liquid crystal layer.

[0045] In this technical solution, due to the use of quantum dots that can generate different monochromatic lights through excitation, the emission spectrum of quantum dots is narrow and the luminous effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com