Patents

Literature

112results about How to "Avoid high temperature effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

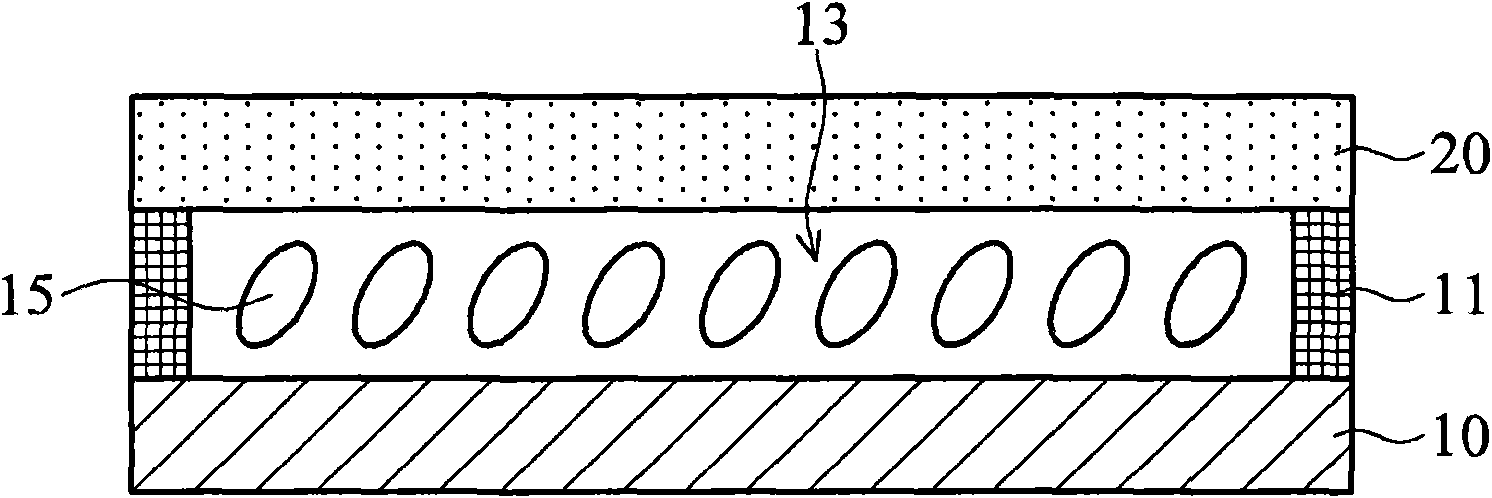

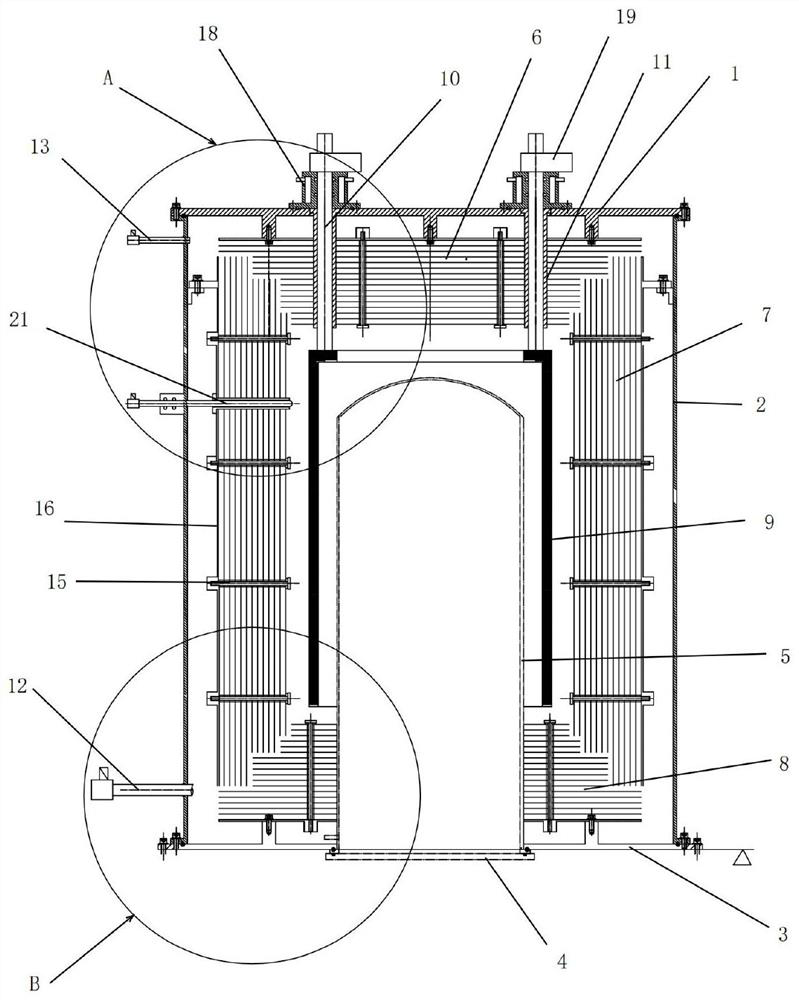

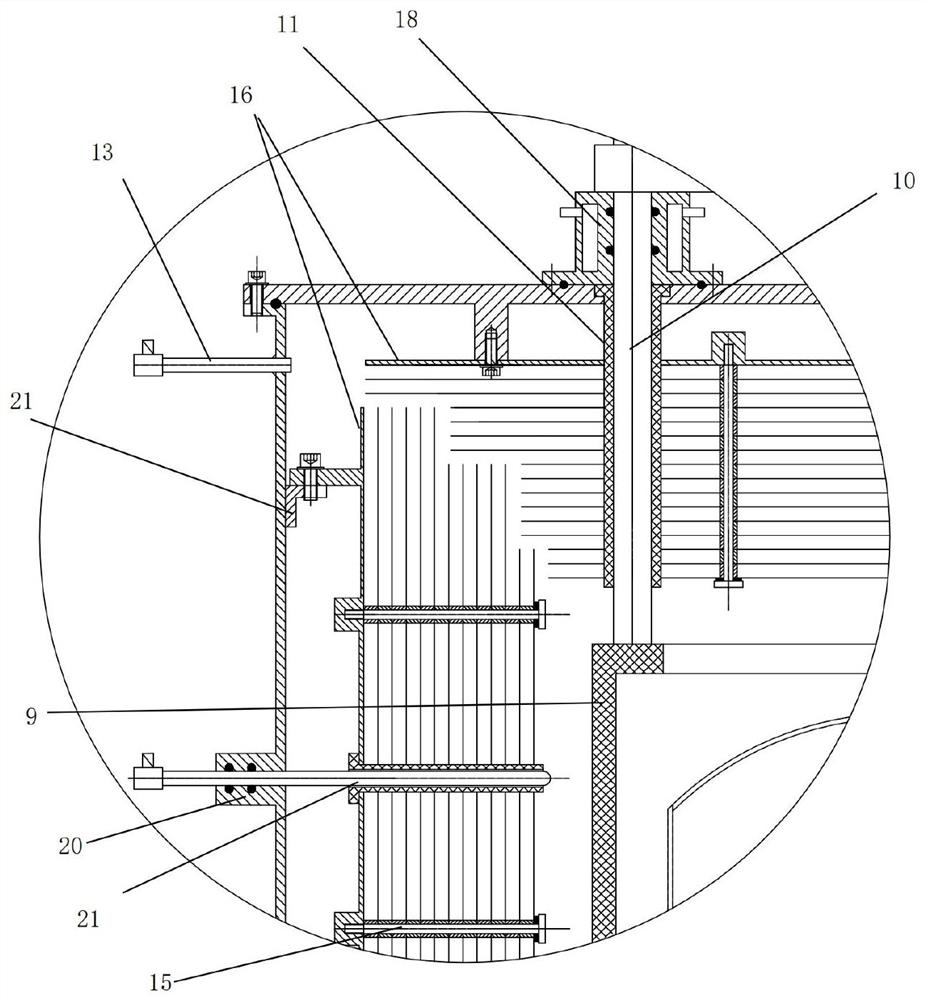

Ash fusion tester

ActiveCN101776625AImprove machine efficiencyImprove efficiencyInvestigating phase/state changeGraphiteEngineering

The invention discloses an ash fusion tester comprising a high-temperature furnace, an ash cone supporting plate, a graphite cup, an image taking mechanism and a control mechanism, wherein the high-temperature furnace is internally provided with an alundum tube; the ash cone supporting plate and the graphite cup are both arranged in the alundum tube; the ash cone supporting plate comprises more than two supporting plate bodies which are sequentially arranged form top to bottom; and the supporting plate bodies are provided with more than one ash cone hole for holding an ash cone. The invention provides the ash fusion tester with simple and compact structure, low cost, high degree of automation and high overall efficiency.

Owner:HUNAN SUNDY SCI & TECH DEV

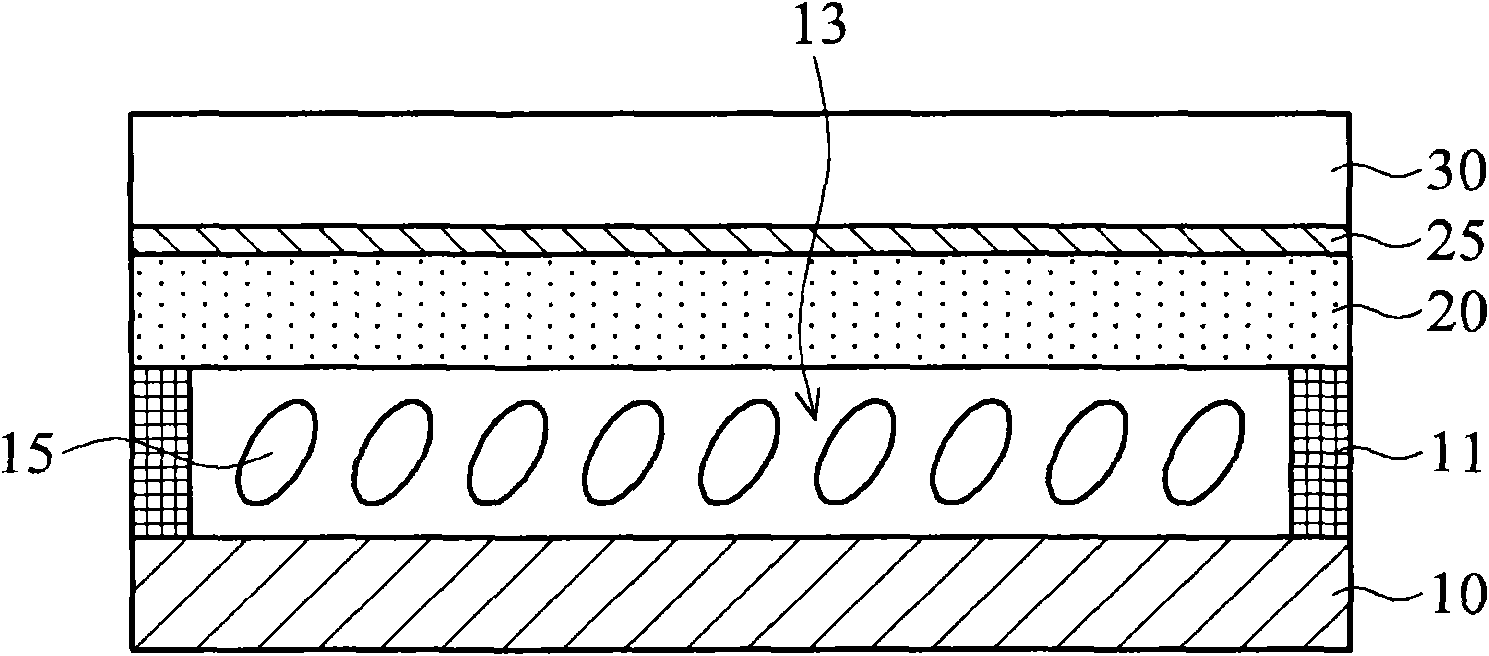

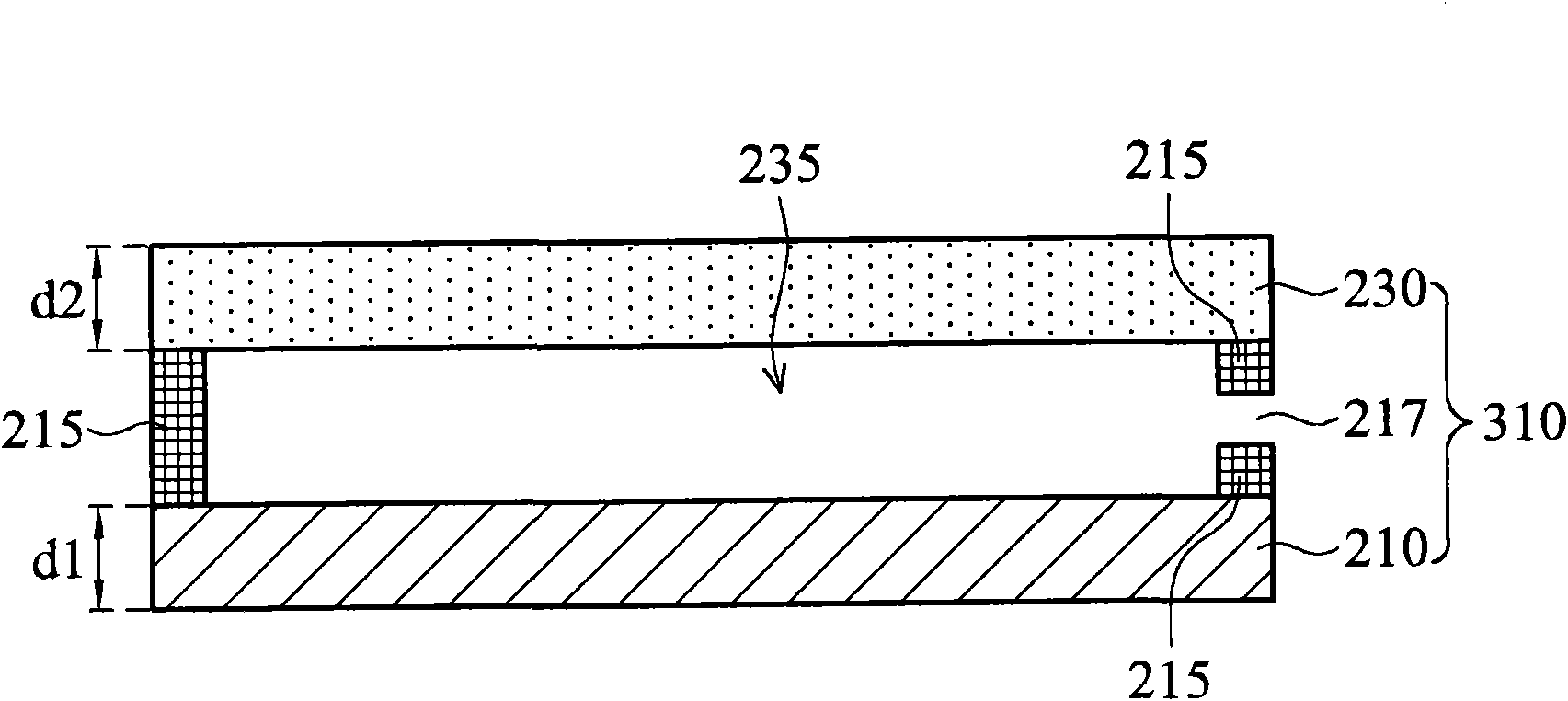

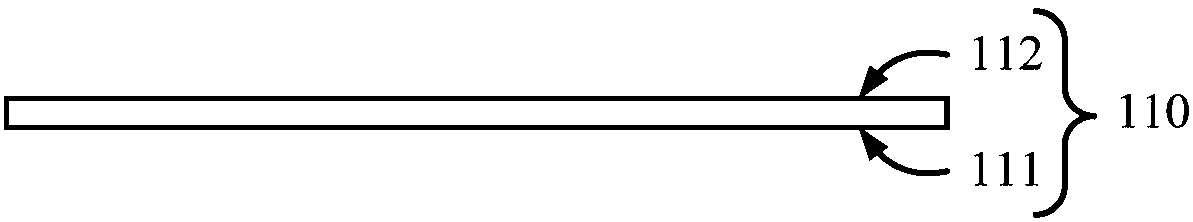

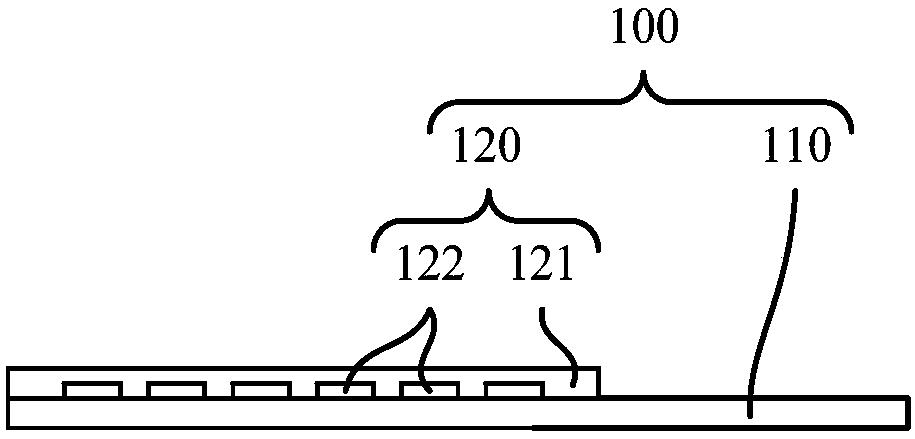

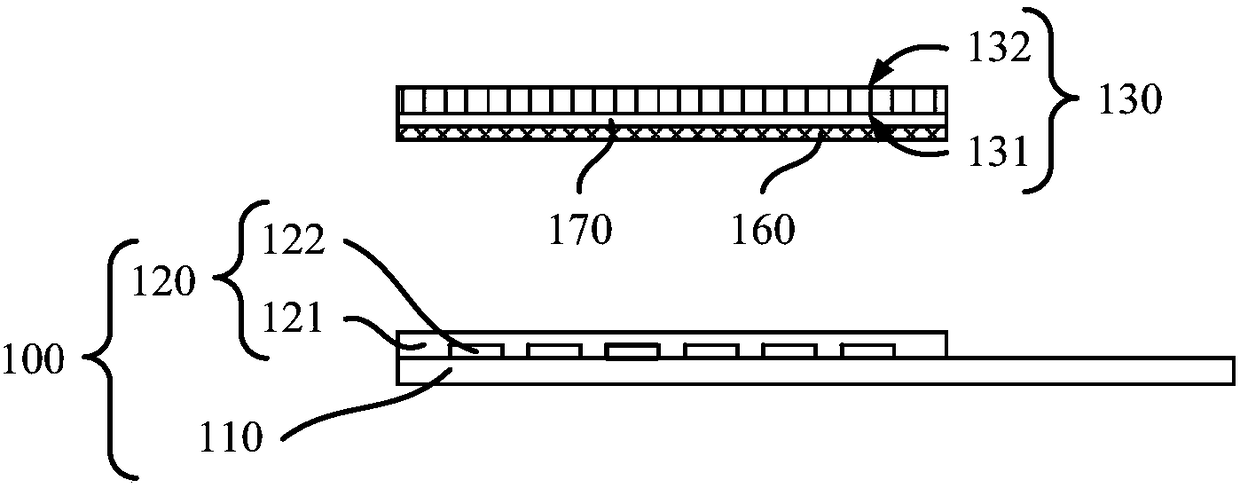

Method for manufacturing touch display panel

InactiveCN102693030AAvoid high temperature effectsReduce thicknessStatic indicating devicesInput/output processes for data processingEngineering

The invention provides a method for manufacturing a touch display panel, and aims to reduce the thickness and the weight of the touch display panel, simplify the manufacturing procedure and reduce the cost of the manufacturing procedure. The method comprises the following steps of: supplying a display panel which comprises a first substrate and a second substrate opposite to the first substrate; thinning the display panel to form a thinned display panel; and forming a touch sensor on the outer side surface of the thinned display panel.

Owner:INNOLUX CORP +1

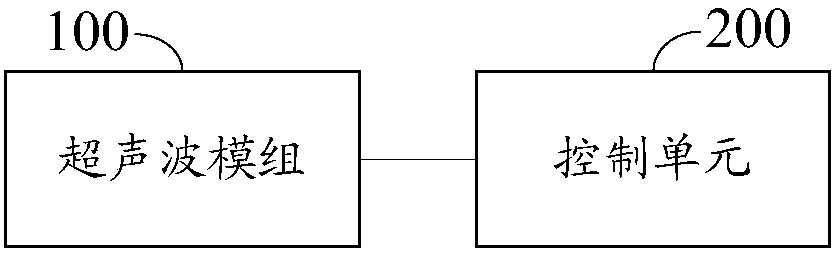

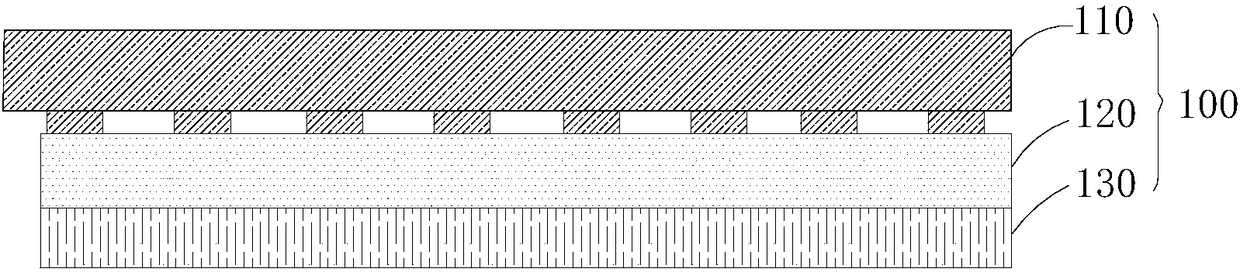

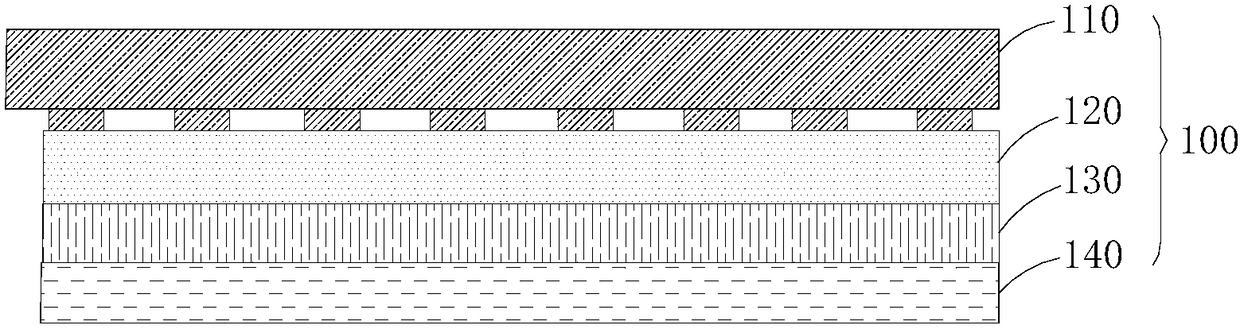

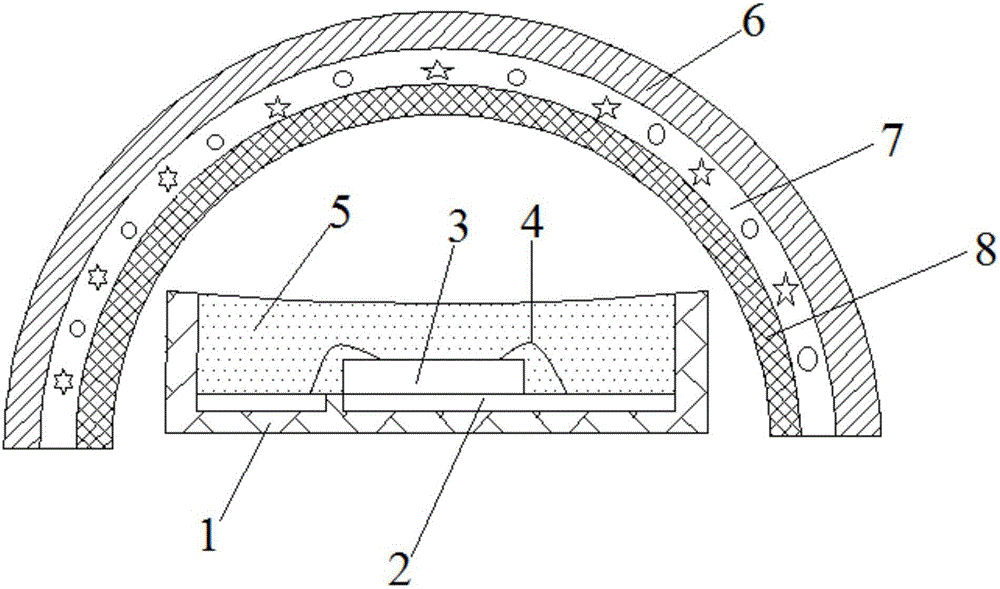

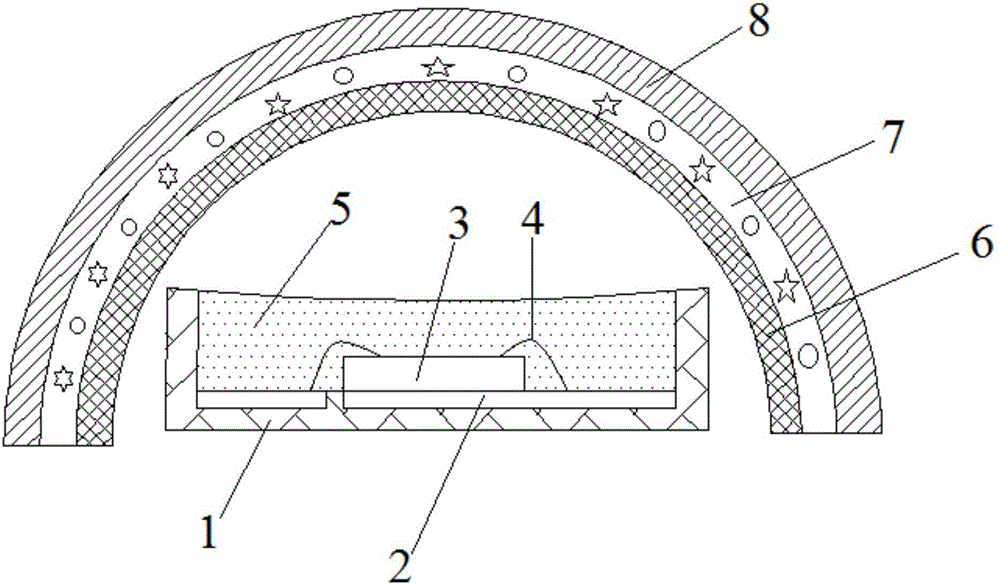

Electronic device

InactiveCN109491552AAvoid high temperature effectsImprove reliabilityPrint image acquisitionInput/output processes for data processingElectric signalUltrasound

The invention relates to an electronic device comprising a display screen. An ultrasonic module is arranged in that display screen, and the electronic device further comprises a control unit. Each structure located above the ultrasonic module in the display screen can conduct ultrasonic wave. The top surface of the ultrasonic module faces the surface of the display screen for displaying an image,and the ultrasonic module is used for emitting ultrasonic waves and receiving ultrasonic waves reflected from a target under the control of the control unit, and converting the reflected ultrasonic waves into electrical signals. The control unit is used for judging that when the strength of the electric signal is greater than a set threshold value, a target is considered to be close to the electronic device. The electronic device uses ultrasonic wave to detect whether a target is close to the electronic device. Because the ultrasonic wave has the ability to penetrate the material, the short-range sensing function can be realized without opening holes in the electronic device, thereby improving the waterproofing performance of the electronic device.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

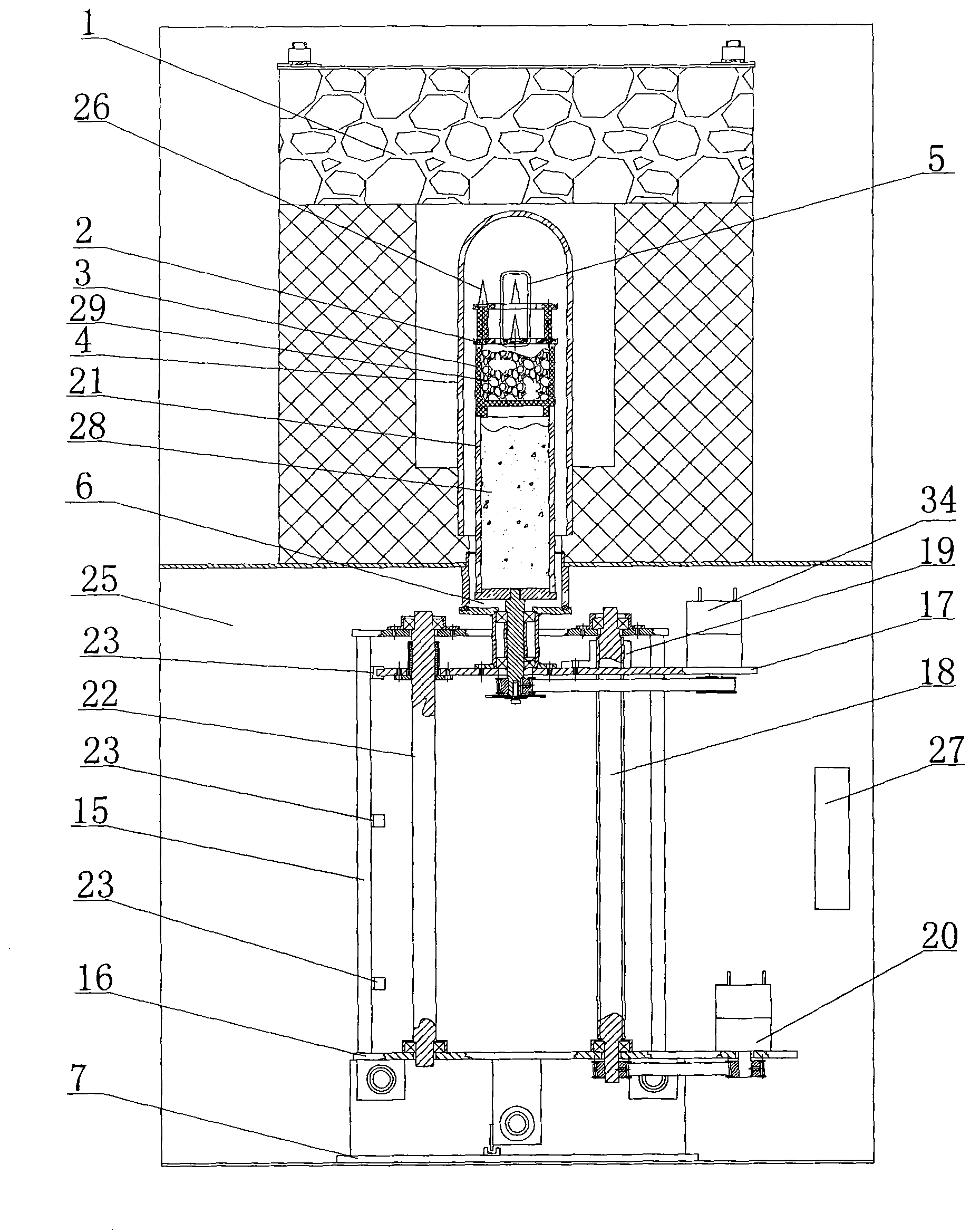

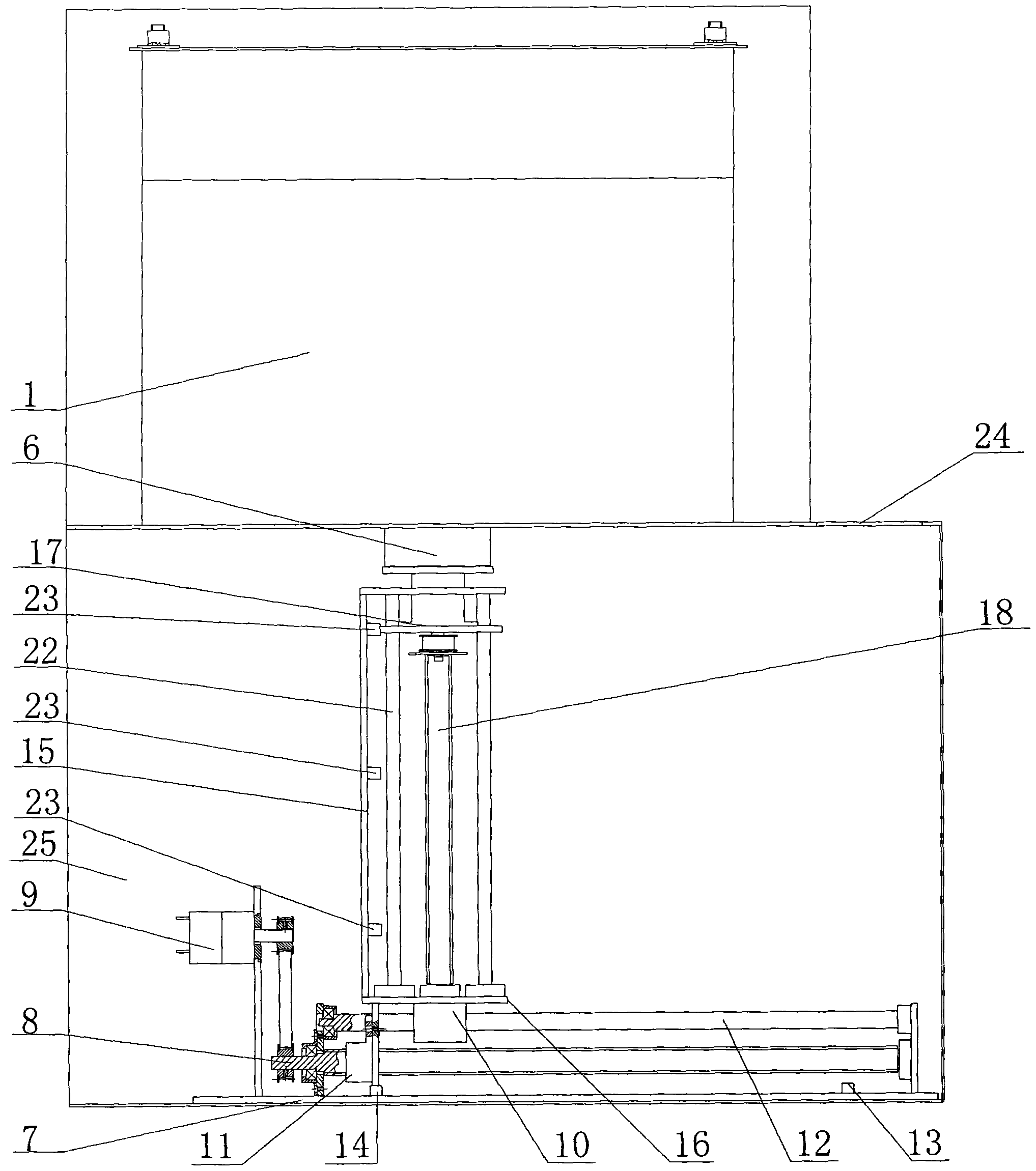

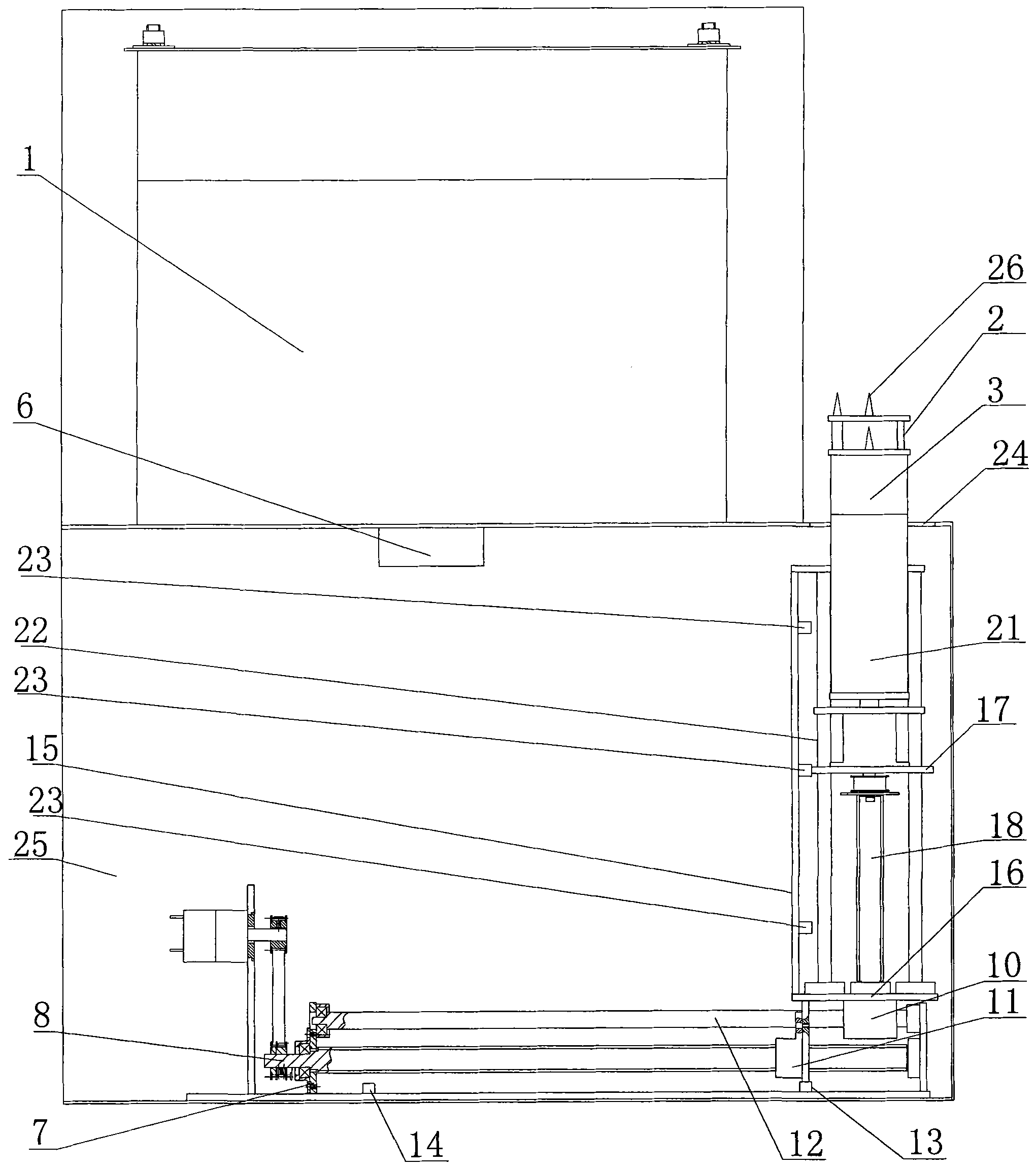

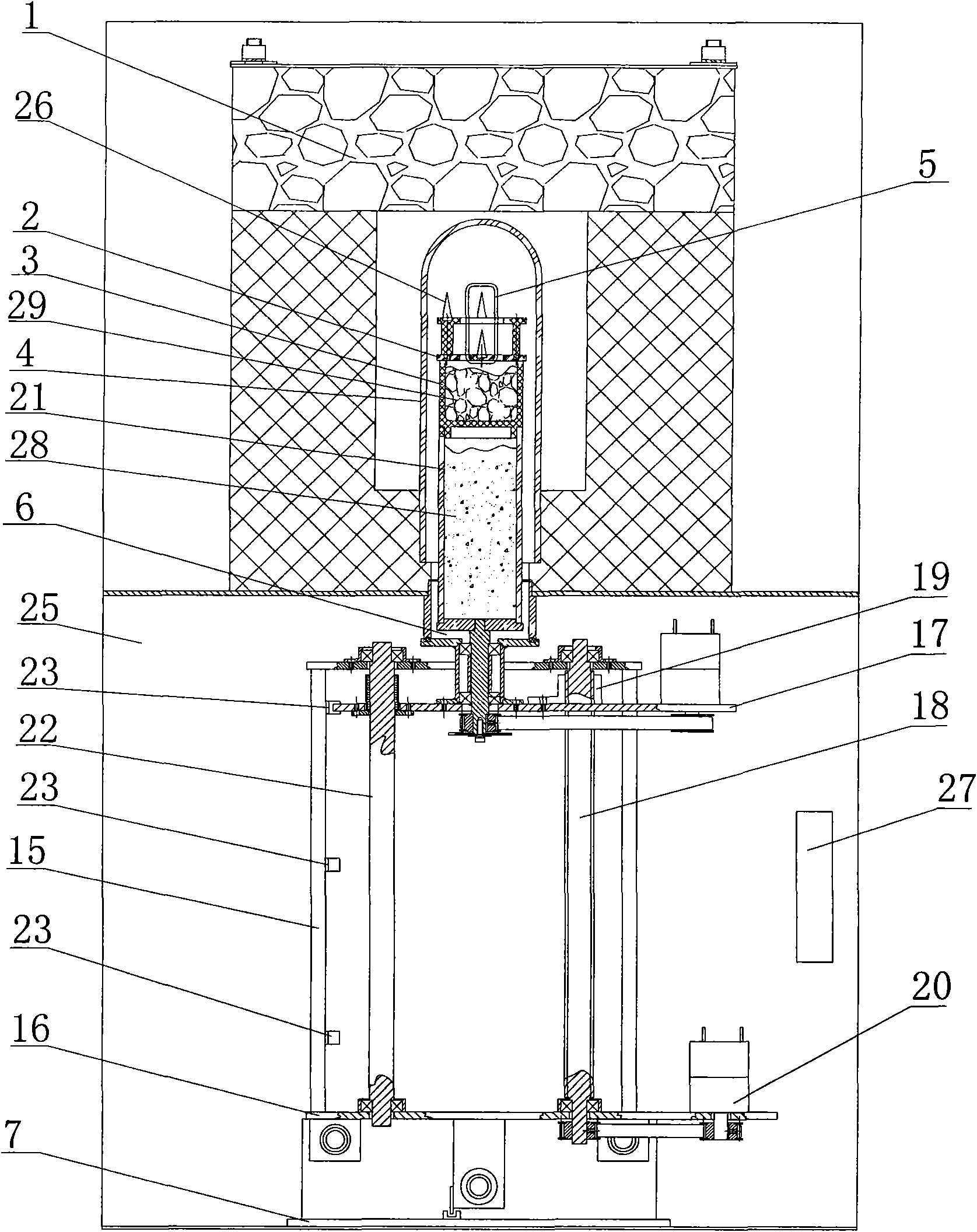

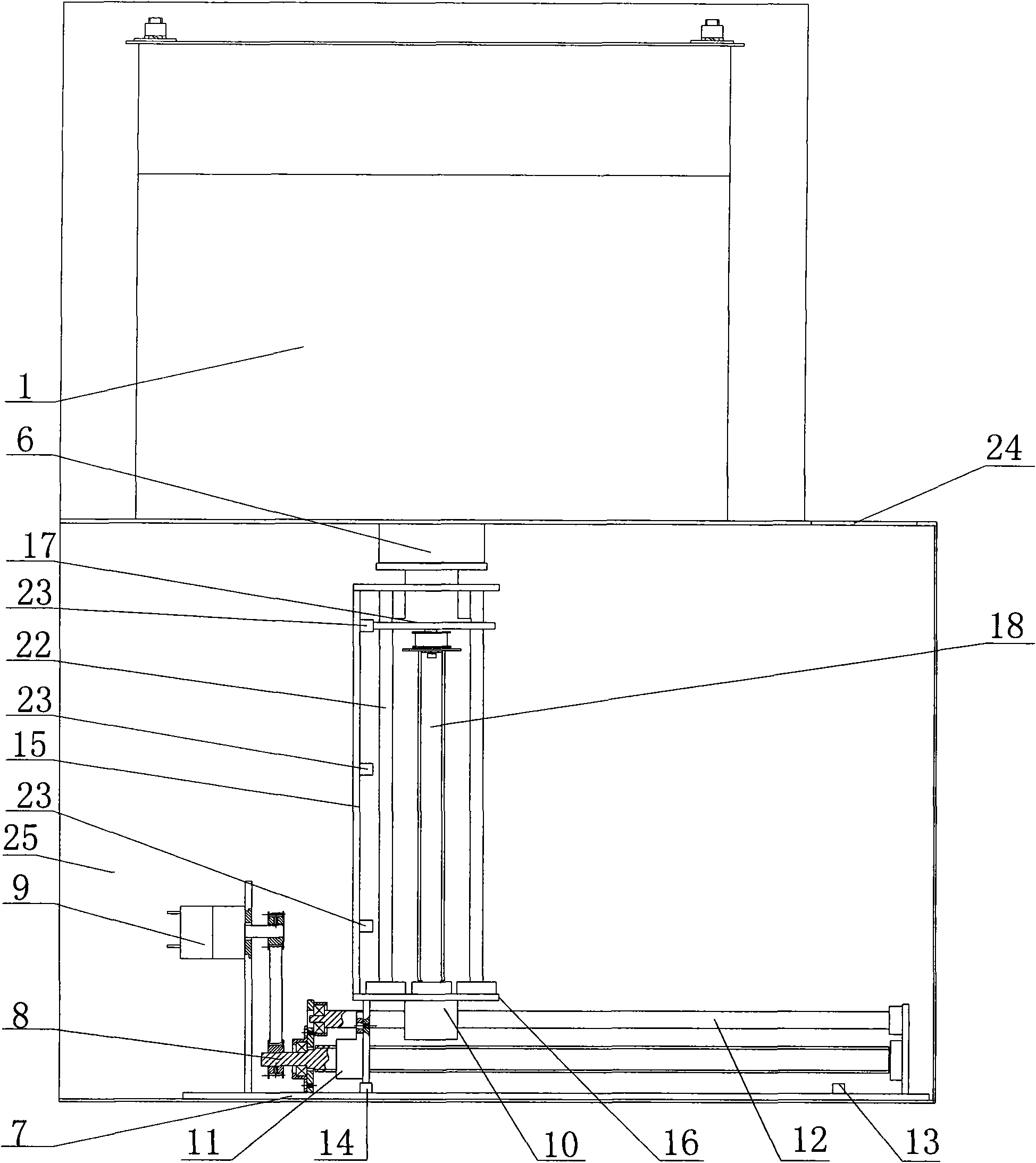

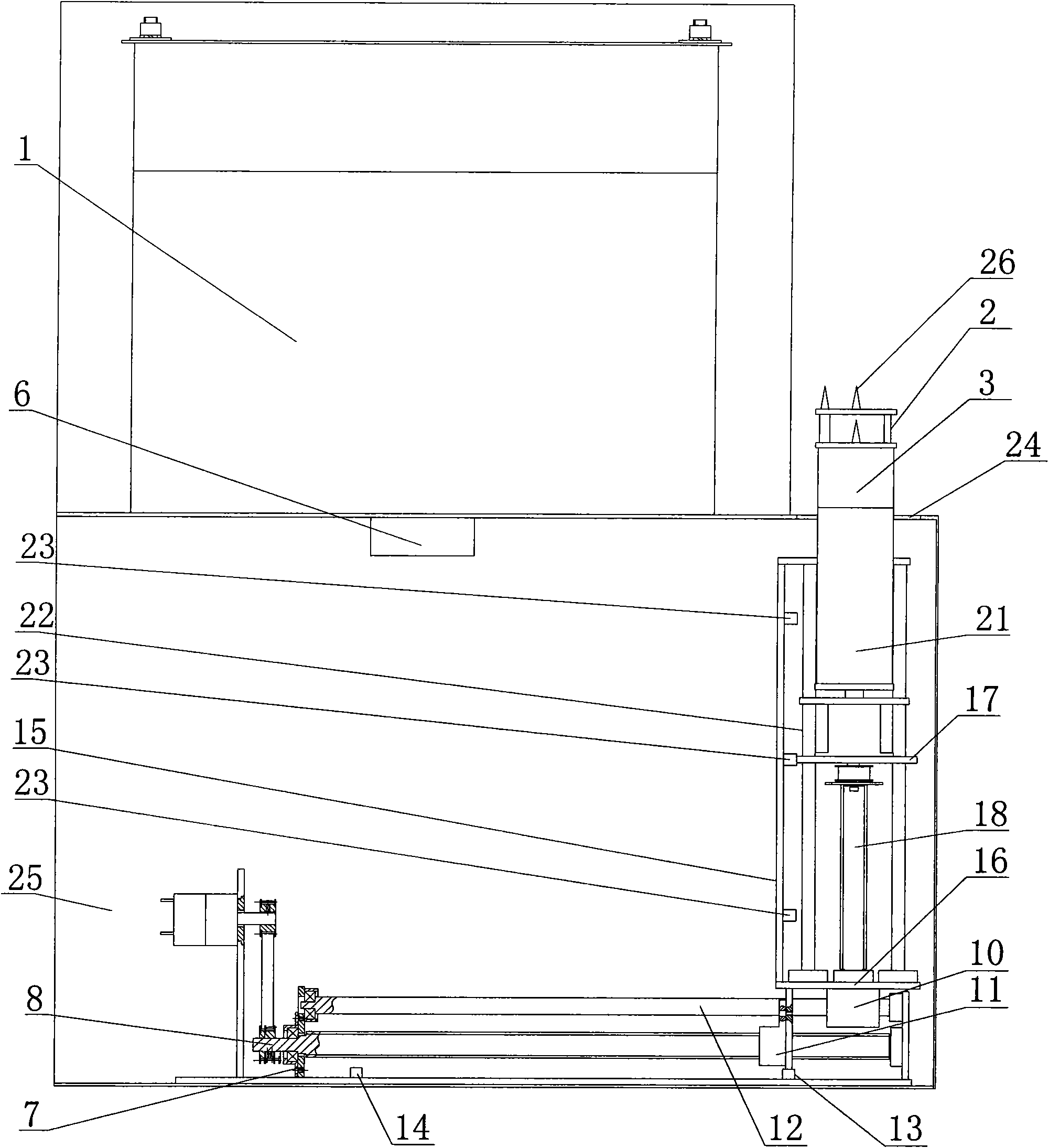

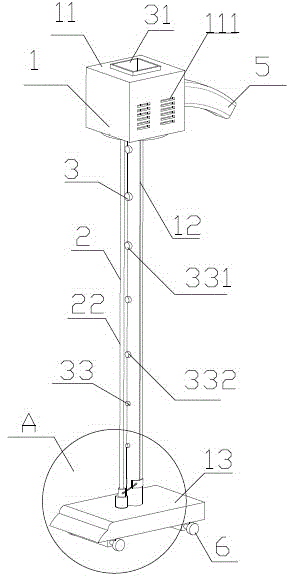

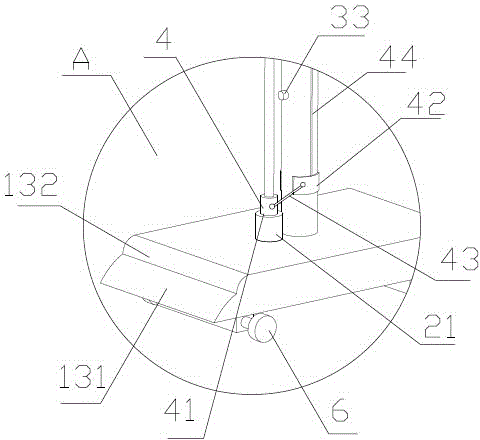

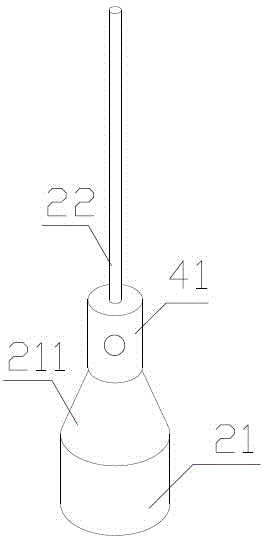

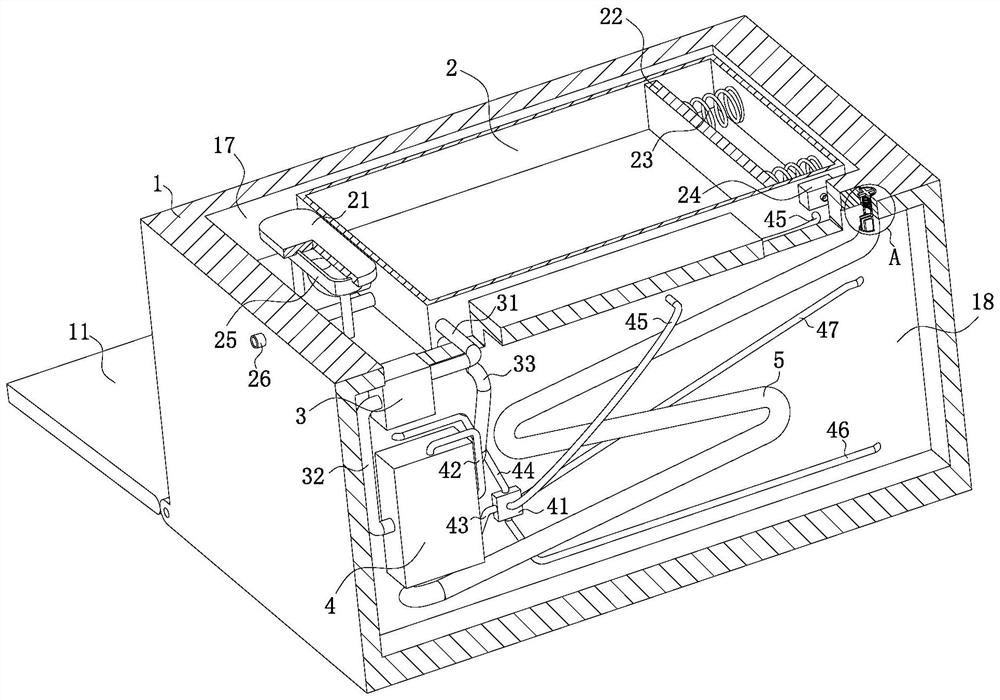

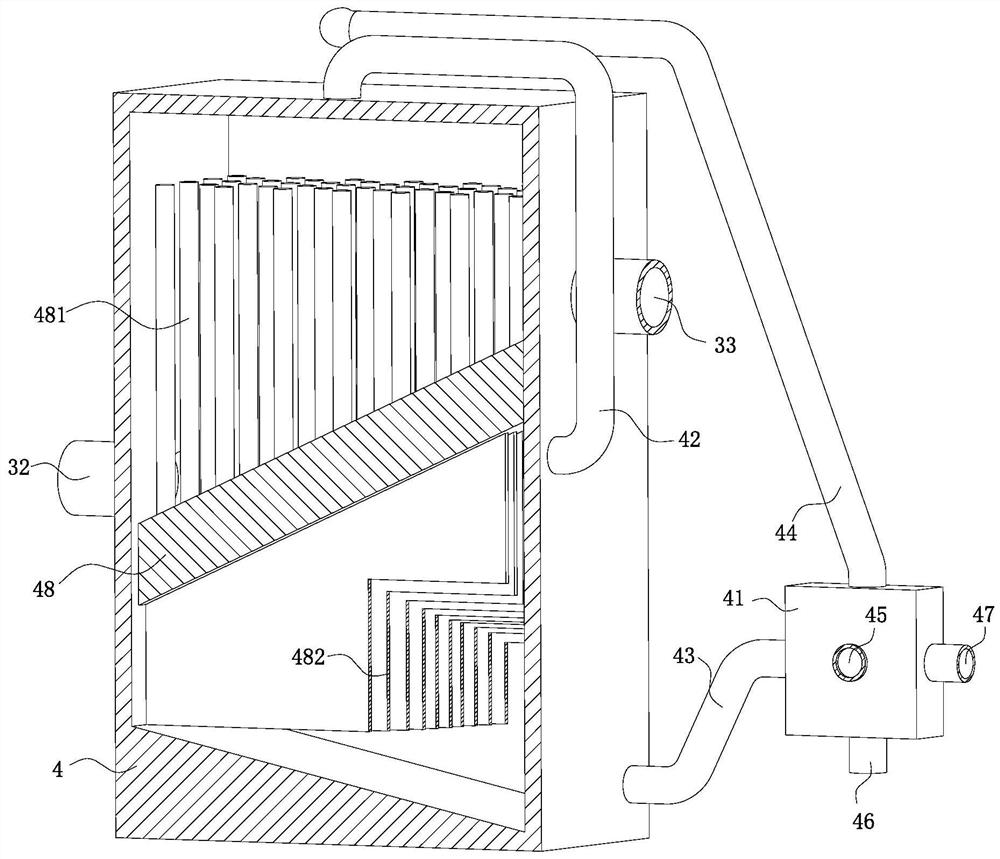

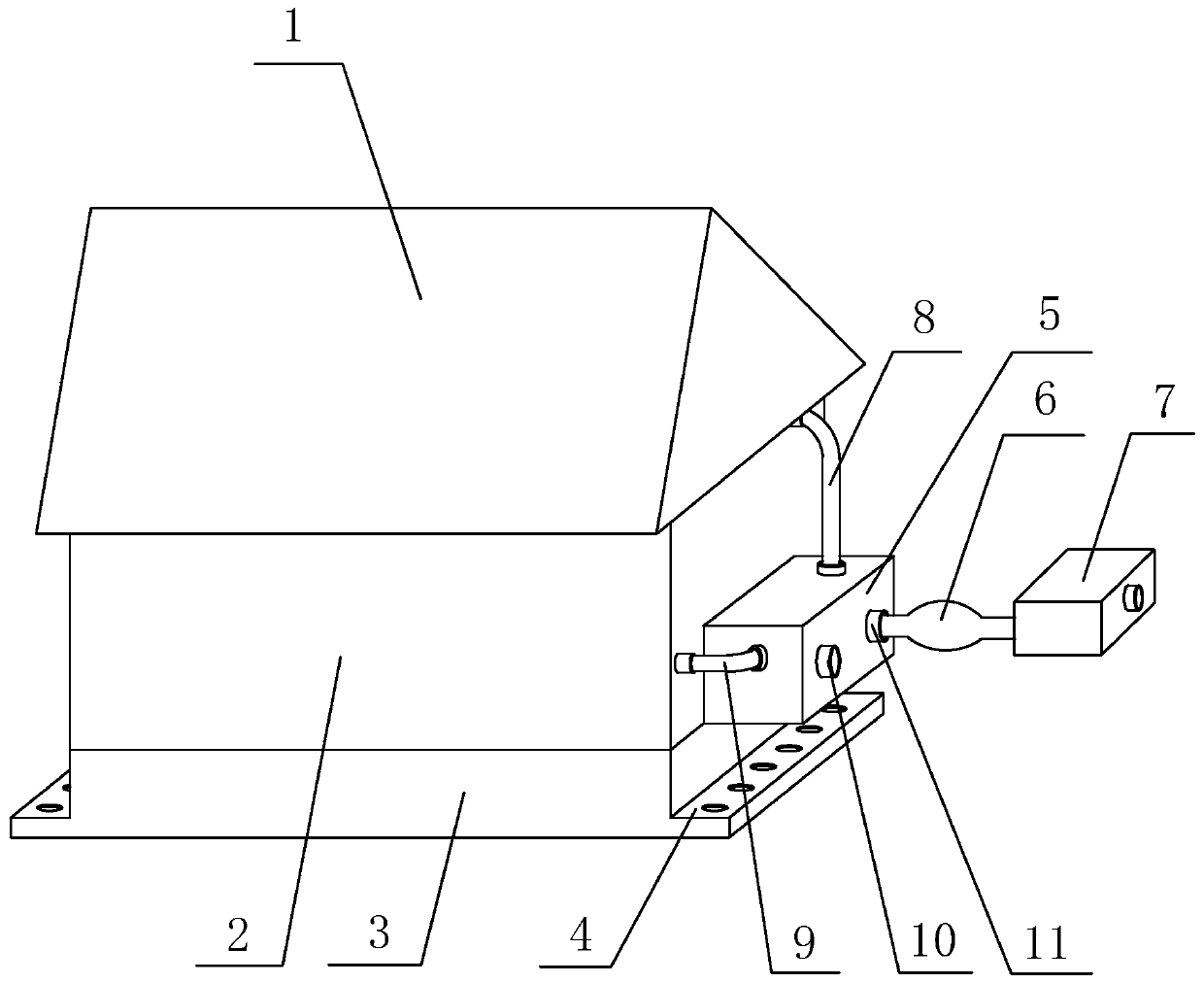

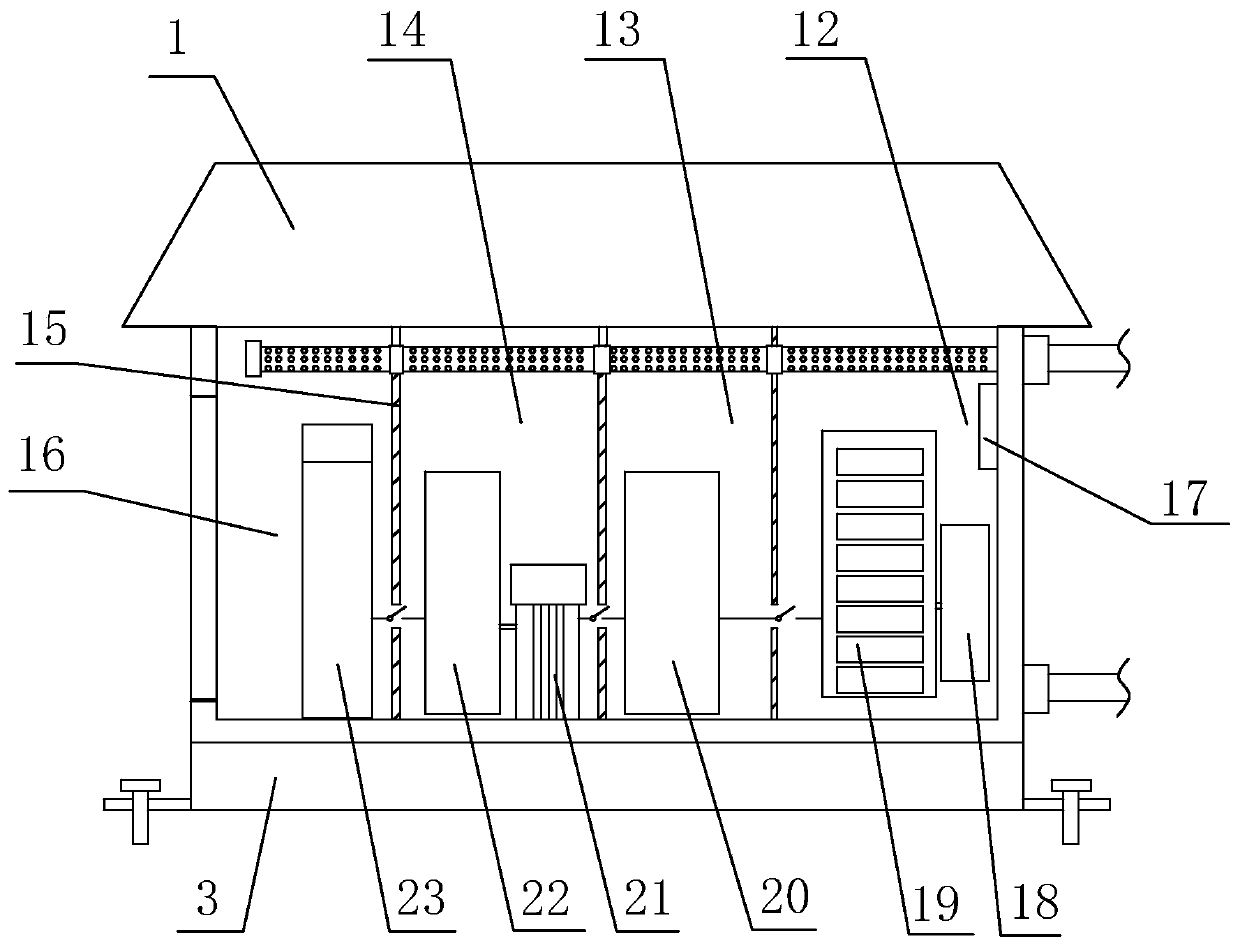

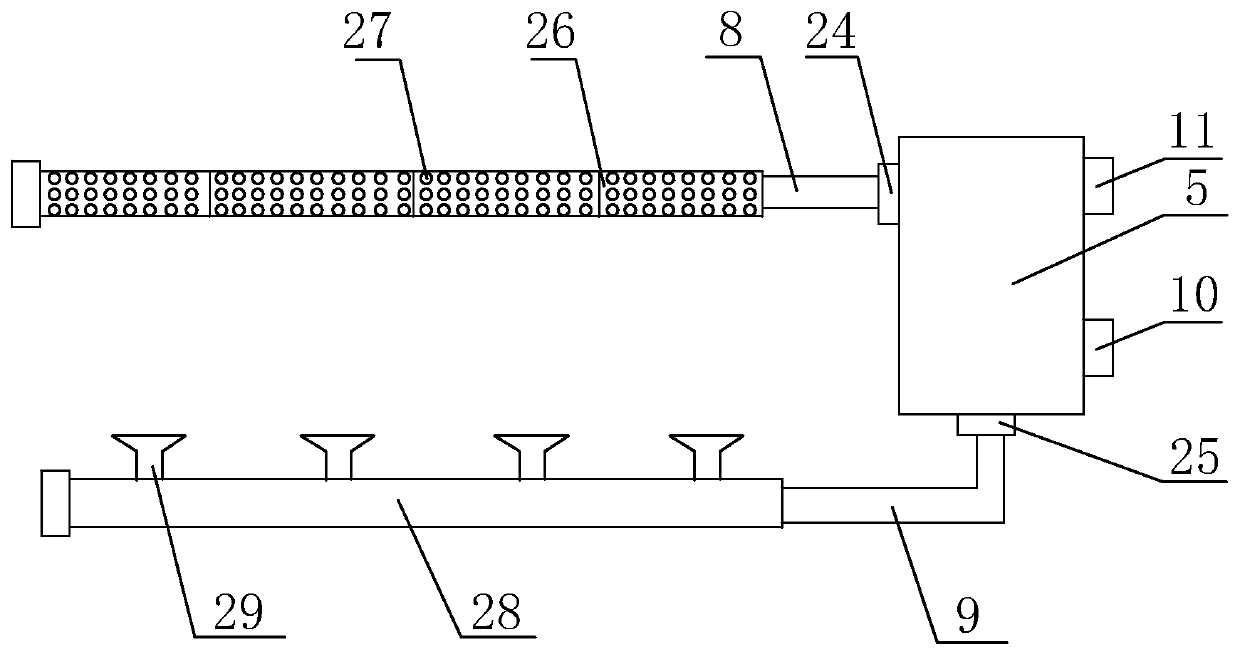

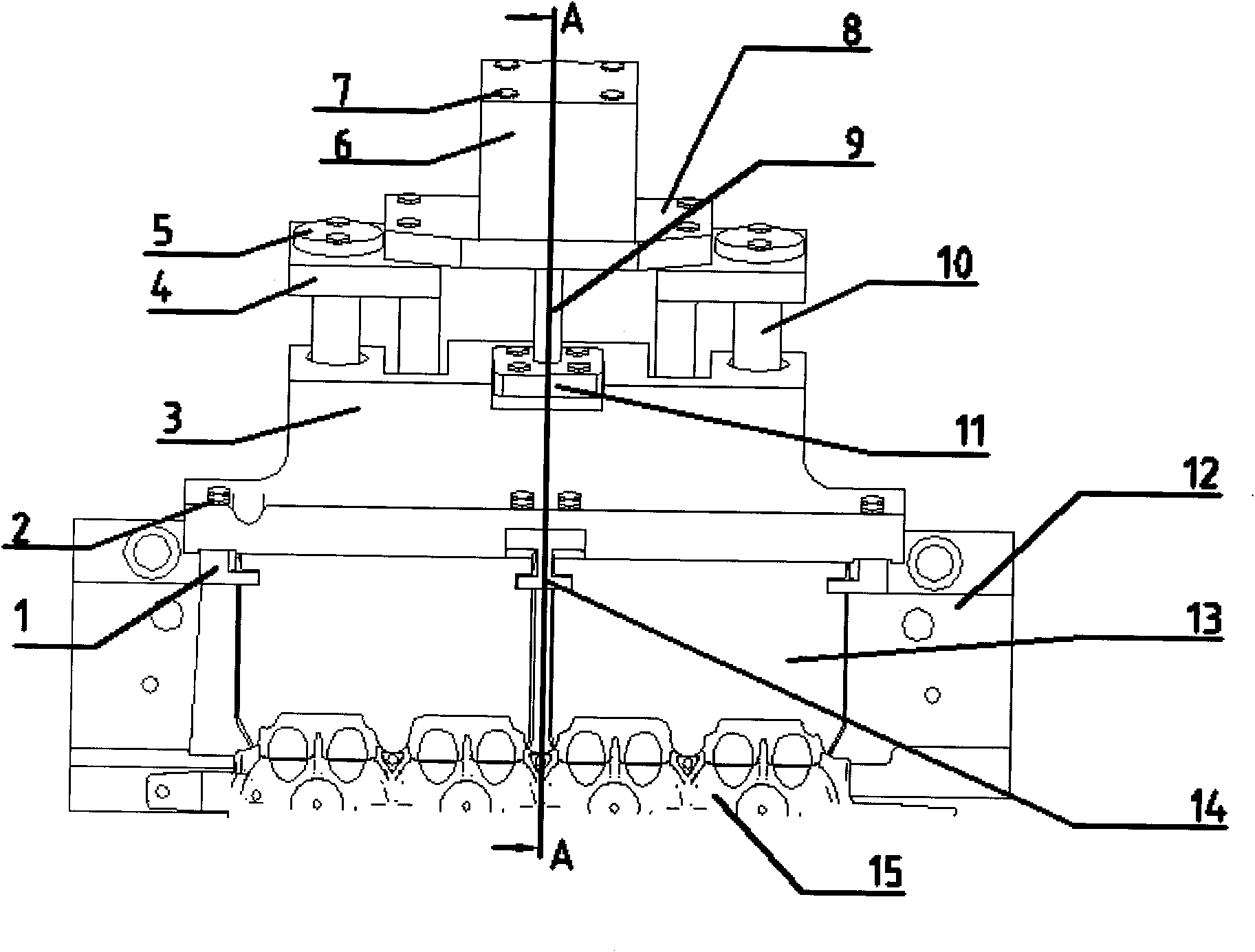

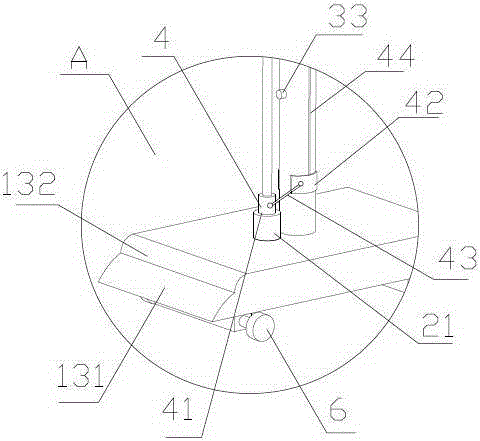

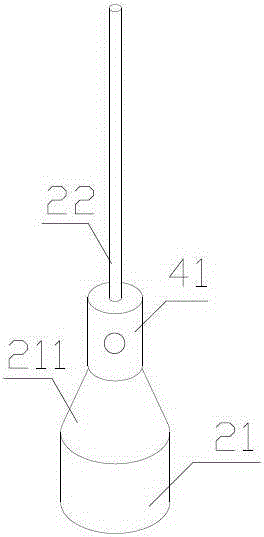

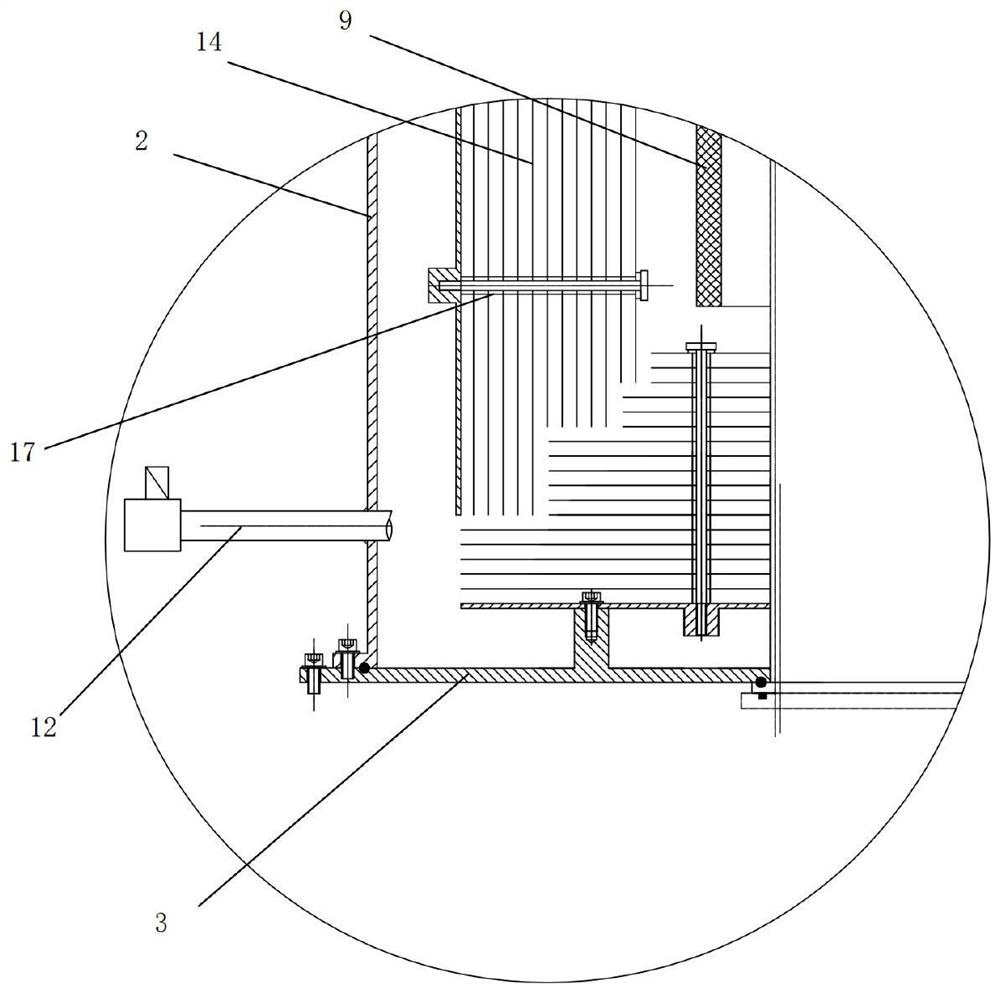

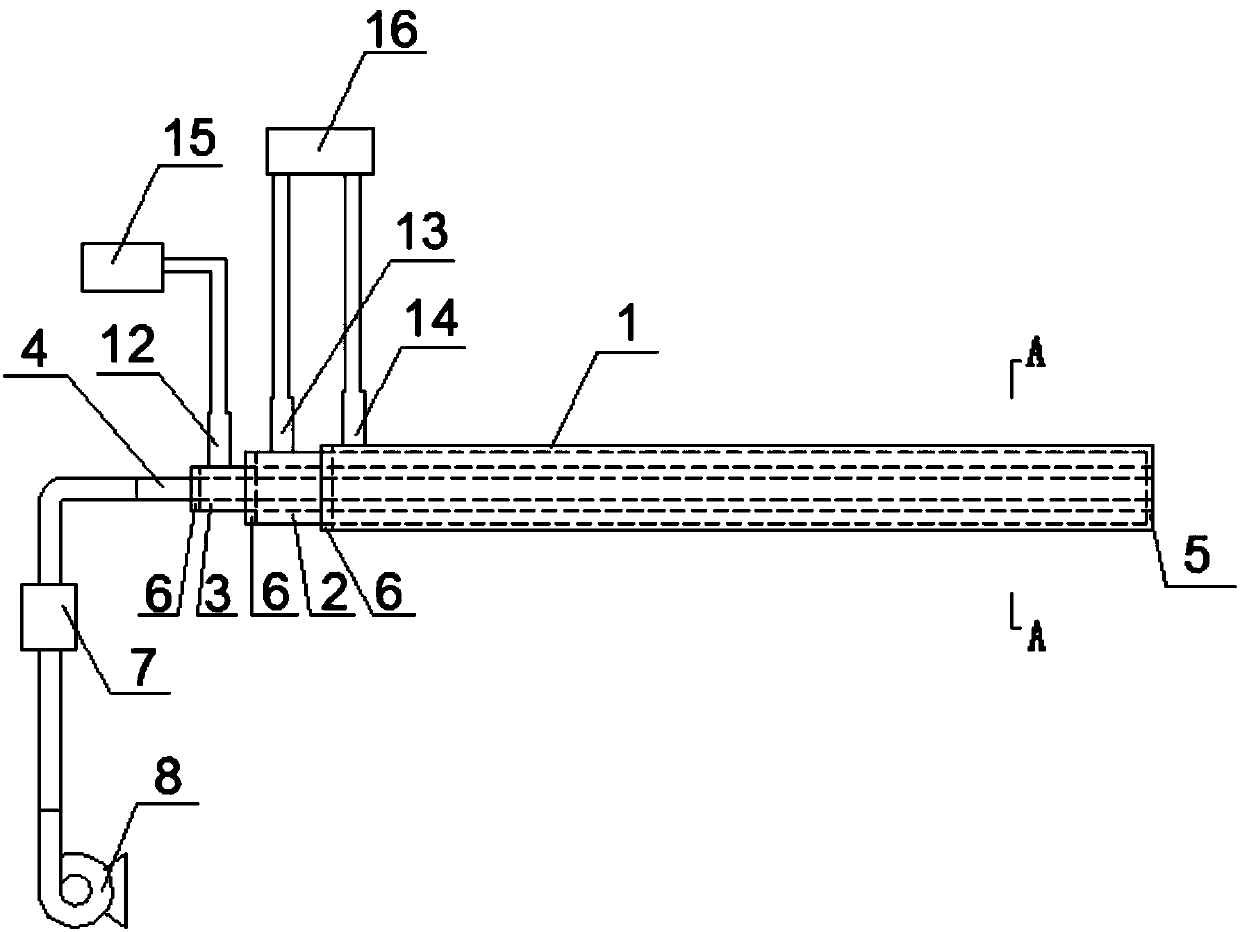

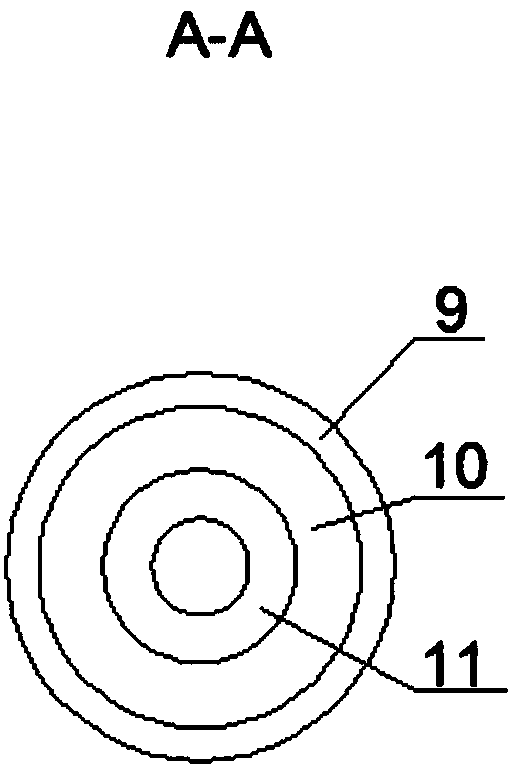

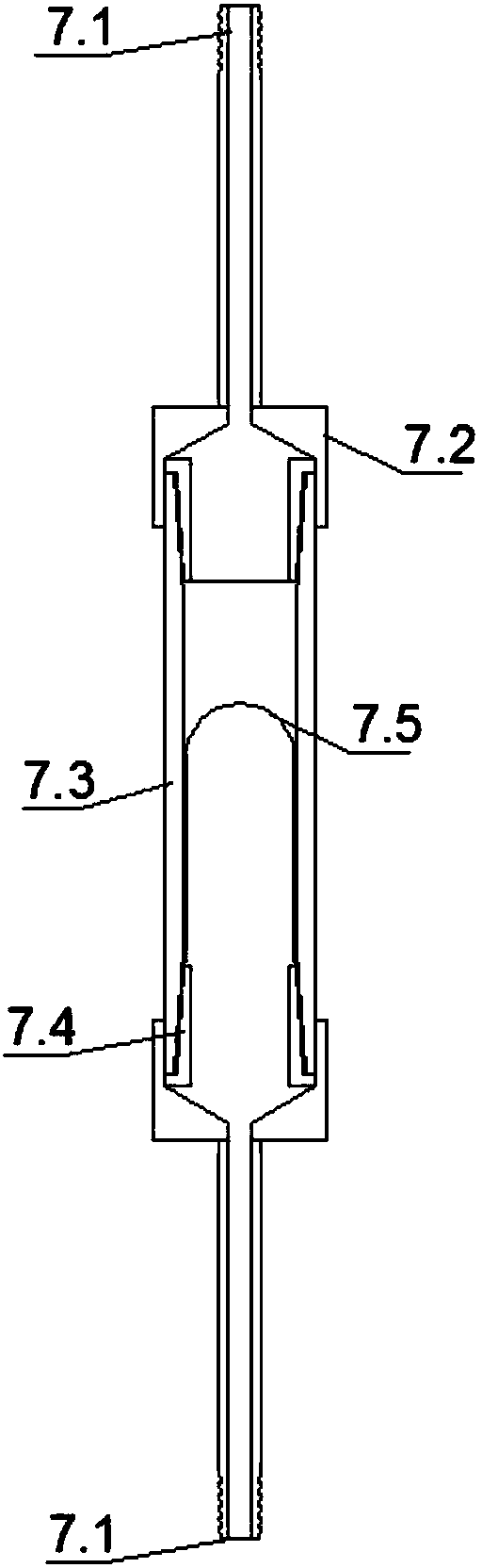

Ash fusibility testing instrument capable of automatically conveying and taking samples

ActiveCN101832958ACompact structureLow costWithdrawing sample devicesInvestigating phase/state changeGraphiteEngineering

The invention discloses an ash fusibility testing instrument capable of automatically conveying and taking samples, which comprises a high temperature furnace, an ash cone supporting plate, a graphite cup, an image taking mechanism and a control mechanism, wherein an alundum tube is arranged in the high temperature furnace; the ash cone supporting plate and the graphite cup are placed in the alundum tube; a box body is arranged below the high temperature furnace; an automatic sample conveying mechanism is arranged in the box body; the automatic sample conveying mechanism comprises a sample conveying rod, a lifting drive component and a translation drive component; the sample conveying rod is fixed on the lifting drive component; the lifting drive component is fixed on the translation drive component; a sample conveying opening which is arranged on the high temperature furnace and is used for the sample conveying rod to pass through is positioned right below the alundum tube; and a sample connection which is used for the sample conveying rod to pass through is arranged at the top of the box body. The ash fusibility testing instrument capable of automatically conveying and taking the samples, which is provided by the invention, has the advantages of simple and compact structure, low cost, high degree of automation and high overall efficiency.

Owner:HUNAN SUNDY SCI & TECH DEV

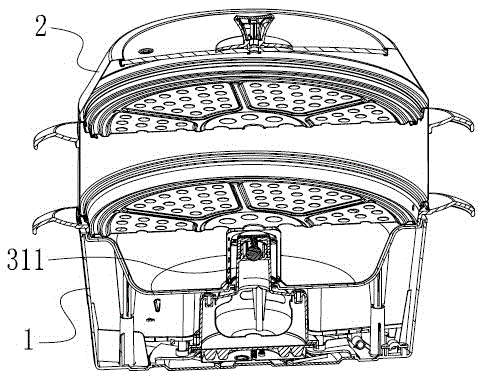

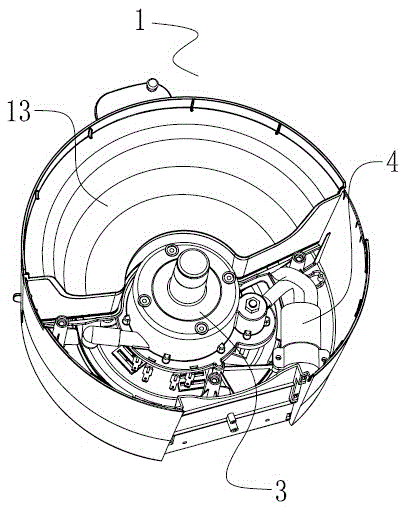

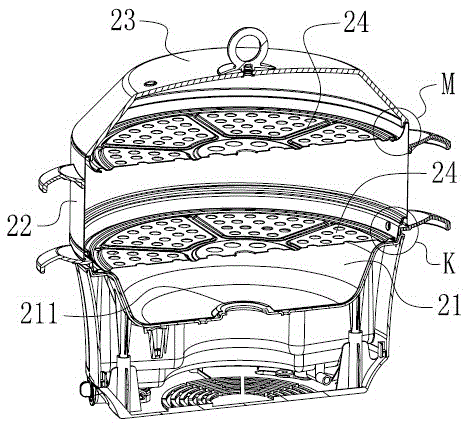

Micropressure steam hotpot

ActiveCN105615628AShorten the flow distanceReduce heat lossSteam cooking vesselsKitchen utensilsHeating efficiency

The invention relates to the technical field of kitchenware used for cooking food in steam and discloses a micropressure steam hotpot which comprises a base and a steamer placed on the base.A steam generator is arranged in the base, the steamer comprises a bottom pot and a pot cover, the steam generator comprises a shell, a steam outlet is arranged at the top of the shell, a pressure control valve blocks the steam outlet, a pressure control valve cover covers the steam outlet and covers the pressure control valve between the steam outlet and the top of the pressure control valve cover, the pressure control valve can move up and down, the pressure control valve cover is provided with steam flow holes, a through hole is formed in the bottom of the bottom pot, and after the steamer is placed on the base, the pressure control valve cover penetrates the through hole to extend into the bottom pot.The steam hotpot has effect of ejecting steam, thereby being conducive to the steamer to be quickly filled with the steam, and heating efficiency is improved.

Owner:BEIJING LIVEN SCI TECH

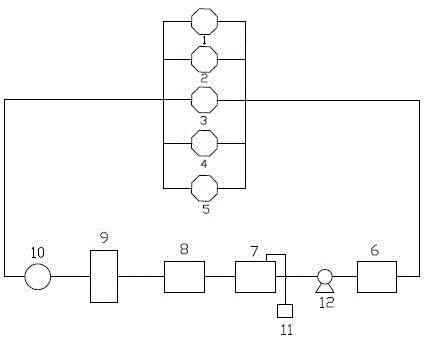

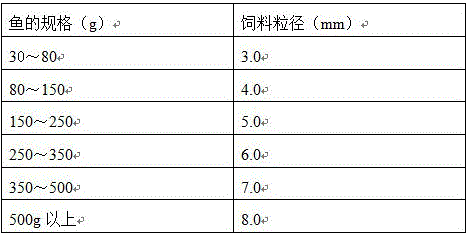

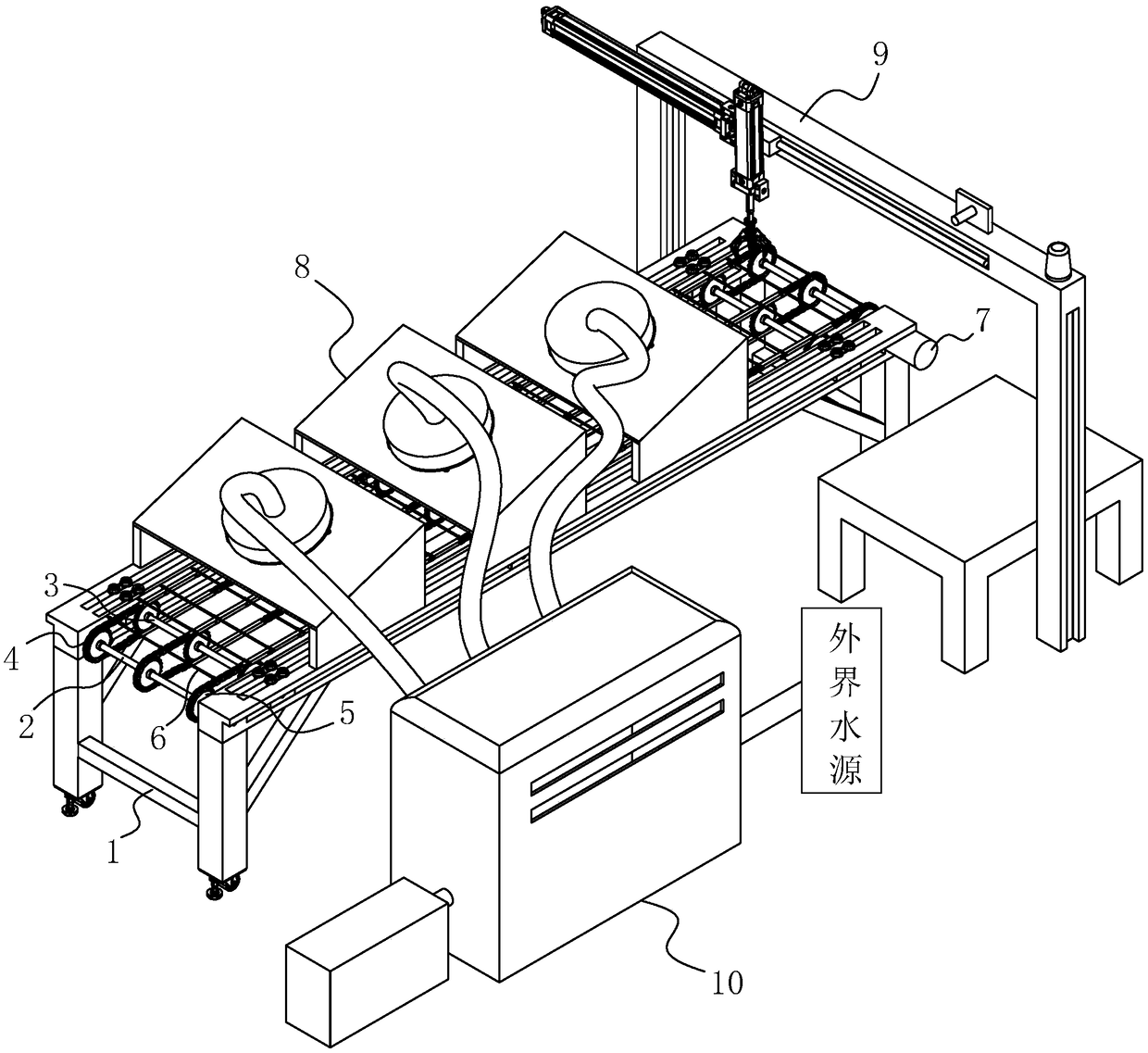

Closed type circulating water breeding method of hexagrammos otakii

ActiveCN105638525AGuaranteed continuous optimalityComplete processing facilitiesClimate change adaptationPisciculture and aquariaDiseaseWater source

The invention discloses a closed type circulating water breeding method of hexagrammos otakii. The method includes the steps of selecting a breeding water source, establishing a breeding environment, controlling the breeding density and the breeding water temperature, adjusting the breeding water quality, adjusting and controlling breeding water oxygen dissolution, selecting and putting in breeding bait, managing breeding sub-ponds, and preventing and controlling breeding diseases. An oxygen and water mixer is added to the tail end of a water processing device, an oxygen dissolution probe and an emergency gas chamber are added in a breeding pond, and an ultraviolet lamp box is communicated between a biological pond and the oxygen and water mixer. The breeding environment is controllable, closed type circulating water processing facilities are complete, the continuous optimism of the breeding environment is ensured, the water temperature is controllable, the fluctuation of the breeding water temperature is avoided, matched feed is put in, bait waste is avoided, the bait coefficient is decreased, the breeding economic benefits are improved, fish separating operation is conducted at the right moment according to the breeding conditions, polarization is avoided, the yield is increased, the breeding cycle is shortened, the time to market can be controlled, and economic benefits are improved.

Owner:国信东方(烟台)循环水养殖科技有限公司

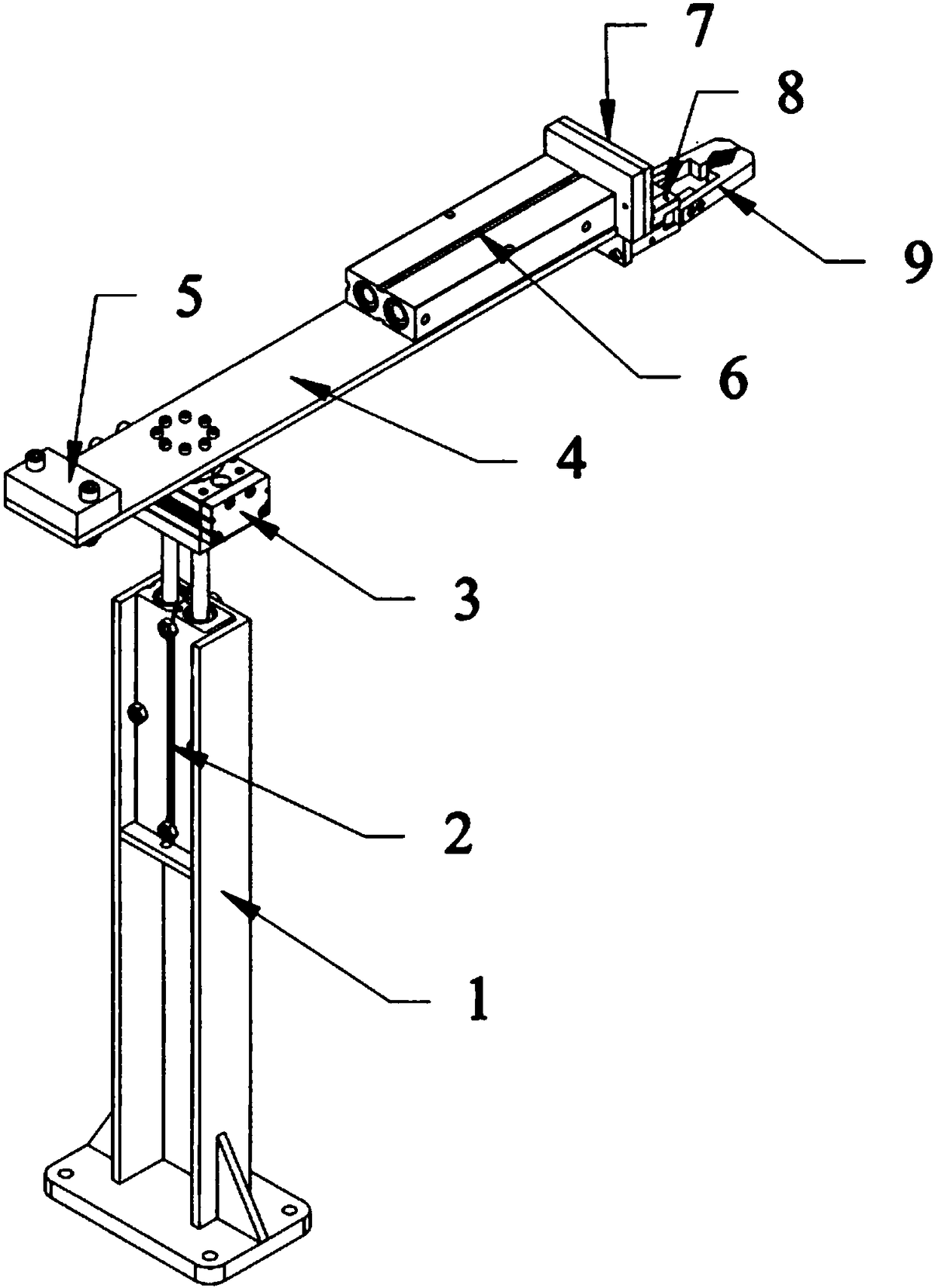

Feeding and discharging robot

InactiveCN108098439AIncrease productivityReduce manual labor intensityGripping headsMetal working apparatusEngineeringRobot

The invention provides a feeding and discharging robot. The feeding and discharging robot comprises a base, a lifting air cylinder, a rotary air cylinder, an air cylinder installation plate, a balanceweight, a horizontal air cylinder, a finger installation plate and pneumatic fingers. The pneumatic fingers are installed on the pneumatic finger installation plate, the finger installation plate isarranged on the horizontal air cylinder, the horizontal air cylinder is installed on the air cylinder installation plate, the balance weight is arranged on the air cylinder installation plate, the aircylinder installation plate is arranged on the rotary air cylinder, the rotary air cylinder is arranged on the lifting air cylinder, and the lifting air cylinder is arranged on the base. The liftingair cylinder, the rotary air cylinder and the horizontal air cylinder independently or synergistically move to control pincers on the pneumatic fingers to complete grabbing and releasing of parts, thewhole process is completely automatic, the production efficiency of feeding and discharging can be improved, and the labor intensity of a worker is reduced.

Owner:CHANGSHA ZHIWEI ELECTRONICS TECH CO LTD

Display module and forming method thereof

InactiveCN109508578AReduce yield lossImprove toughnessPrint image acquisitionEngineeringElectrical and Electronics engineering

Owner:SHANGHAI OXI TECH

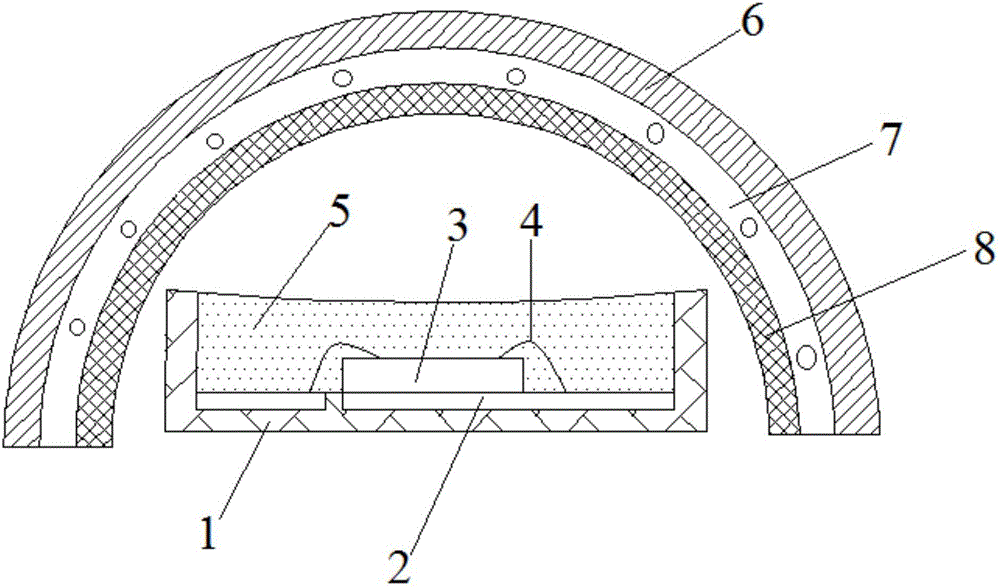

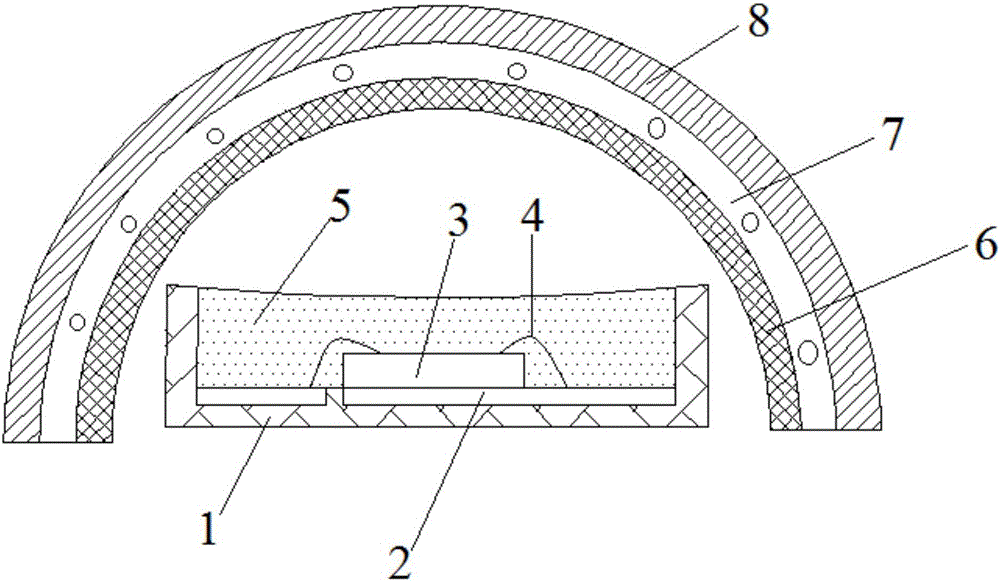

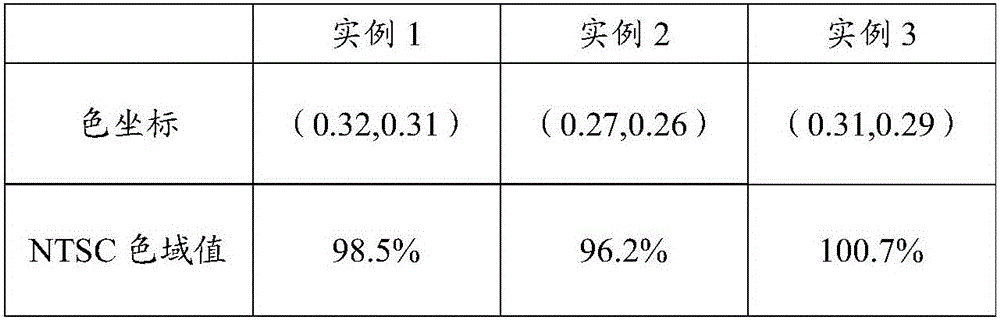

Manufacturing method of direct-light-type LED backlight

InactiveCN106784260AThe production process is simpleImprove light conversion efficiencySolid-state devicesSemiconductor devicesFluorescenceLight conversion efficiency

The present invention discloses a manufacturing method of a direct-light-type LED backlight. The method comprises: mixing mixed phosphors including quantum dot fluorescent powder with photocuring glue to obtain quantum dot fluorescent glue, coating the quantum dot fluorescent glue at the surface of a LED lens in the LED backlight, and coating a photocuring glue protective layer at the surface of the fluorescent glue after the fluorescent glue is solidified. The manufacturing method of direct-light-type LED backlight is simple in manufacturing technology, and the half-wave width of the quantum dot fluorescent glue made of quantum dot materials is small so as to greatly improve the color gamut value of the LED backlight, the color gamut value of the direct-light-type LED backlight can reach above 97% of NTSC, and the light conversion efficiency of a light source obtained through the technology is high, and the production cost is low. The photocuring glue protective layer can effectively reduce the erosion of moisture and oxygen for the quantum dot materials, can prevent the quantum dot materials from directly contacting a luminous chip, and is not liable to high-temperature influence of the luminous chip so as to improve the reliability of the LED light source.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

Gas turbine and annular combustion chamber thereof

InactiveCN107702148AIncrease temperatureAvoid high temperature effectsContinuous combustion chamberCombustion chamberGuide tube

The invention relates to the field of gas turbines, and discloses an annular combustion chamber of a gas turbine and a gas turbine. The annular combustion chamber includes an inner casing and an outer casing fitted on the inner casing, and an annular combustion chamber is arranged between the inner casing and the outer casing. The flame cylinder, the gap between the flame cylinder and the inner casing and the outer casing is used for air circulation; it also includes a plurality of premixing devices distributed along the circumference, and each premixing device includes an air guide cylinder , the air guide tube is connected with the outer casing; the air guide tube is provided with a premixing pipe along the axial direction, and the premixing pipe is respectively connected with the air guide tube and the flame tube; the end of the air guide tube away from the outer casing is fixed There are nozzles, and the head of the nozzle extends into the premixing pipeline, and the premixing pipeline is used to deliver the mixture of gas and air to the flame tube.

Owner:新奥能源动力科技(上海)有限公司

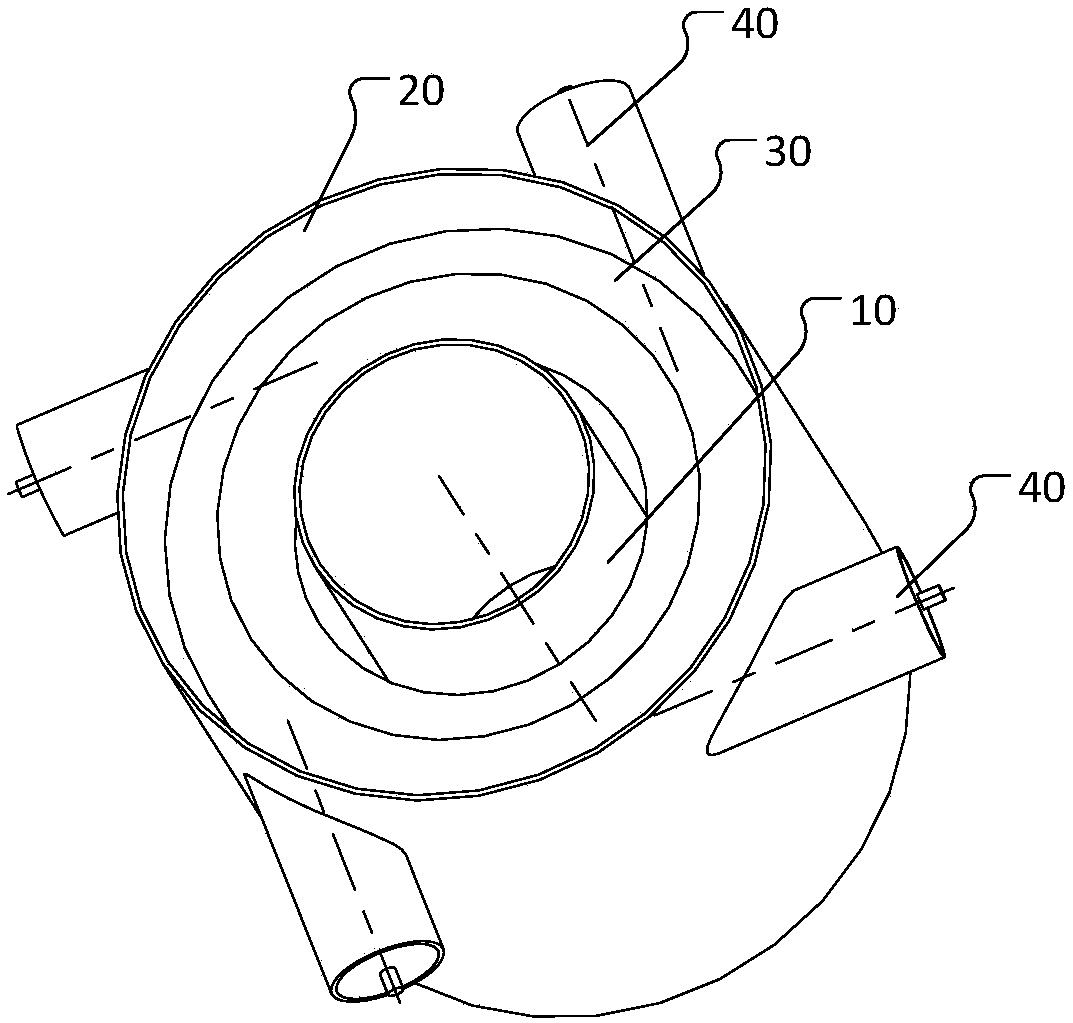

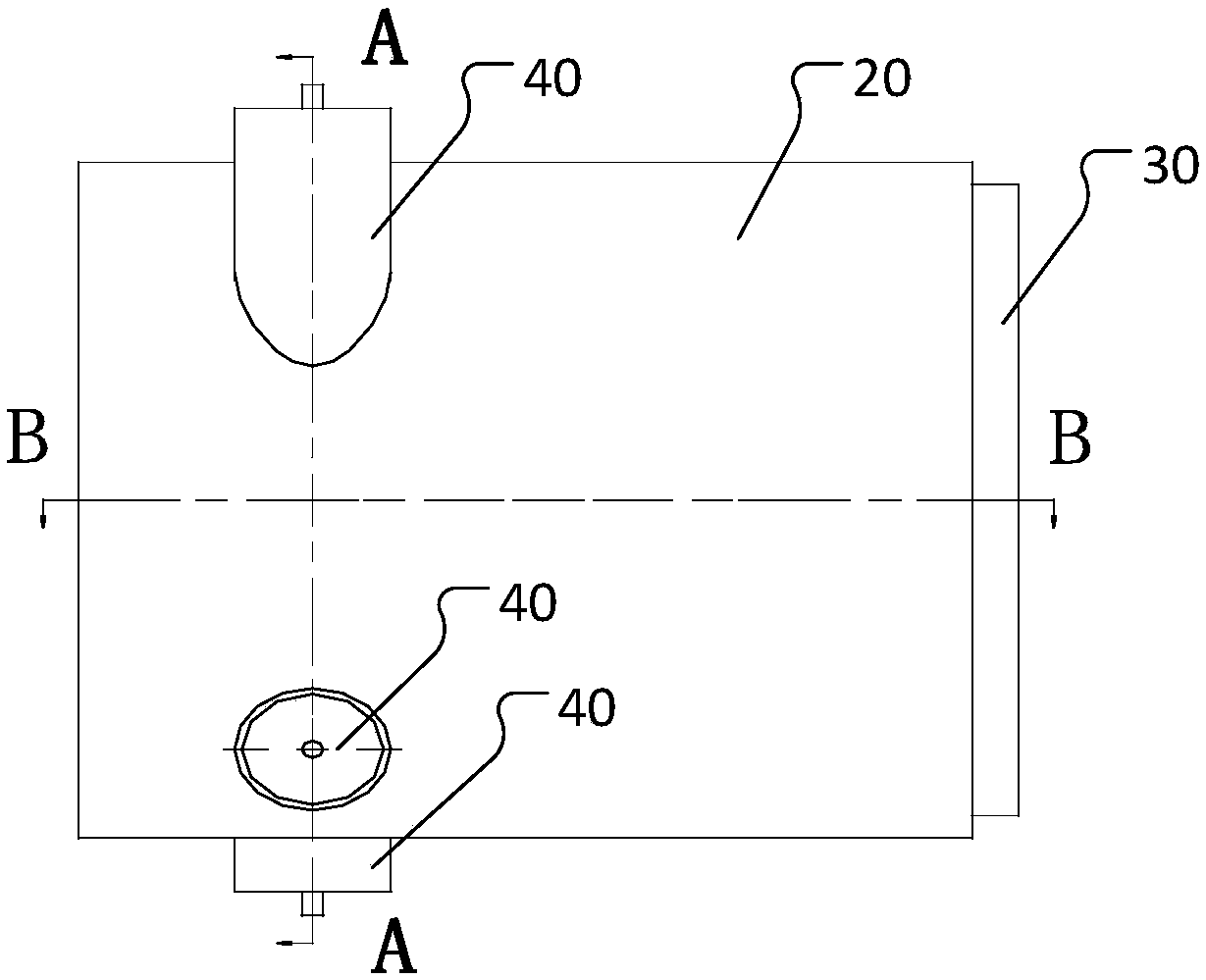

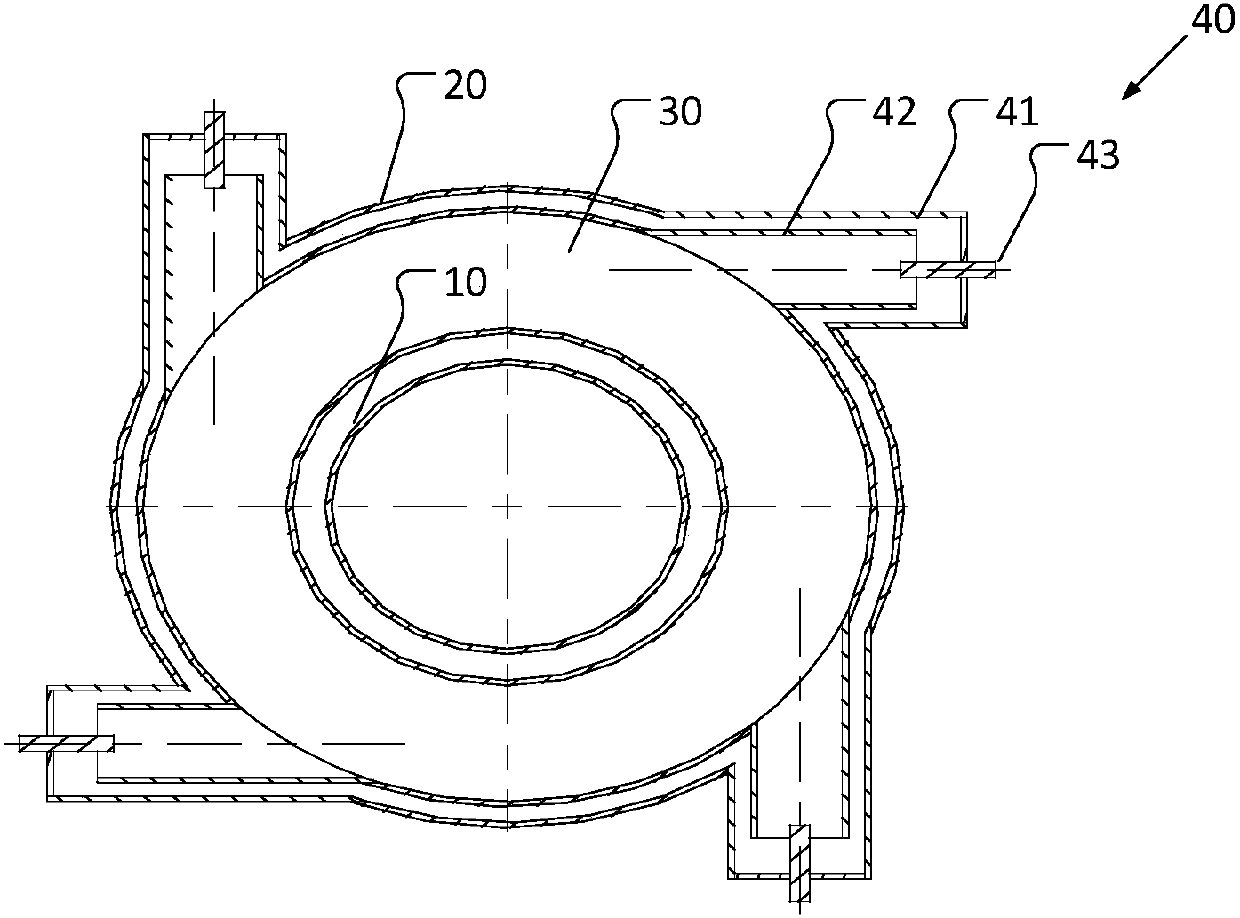

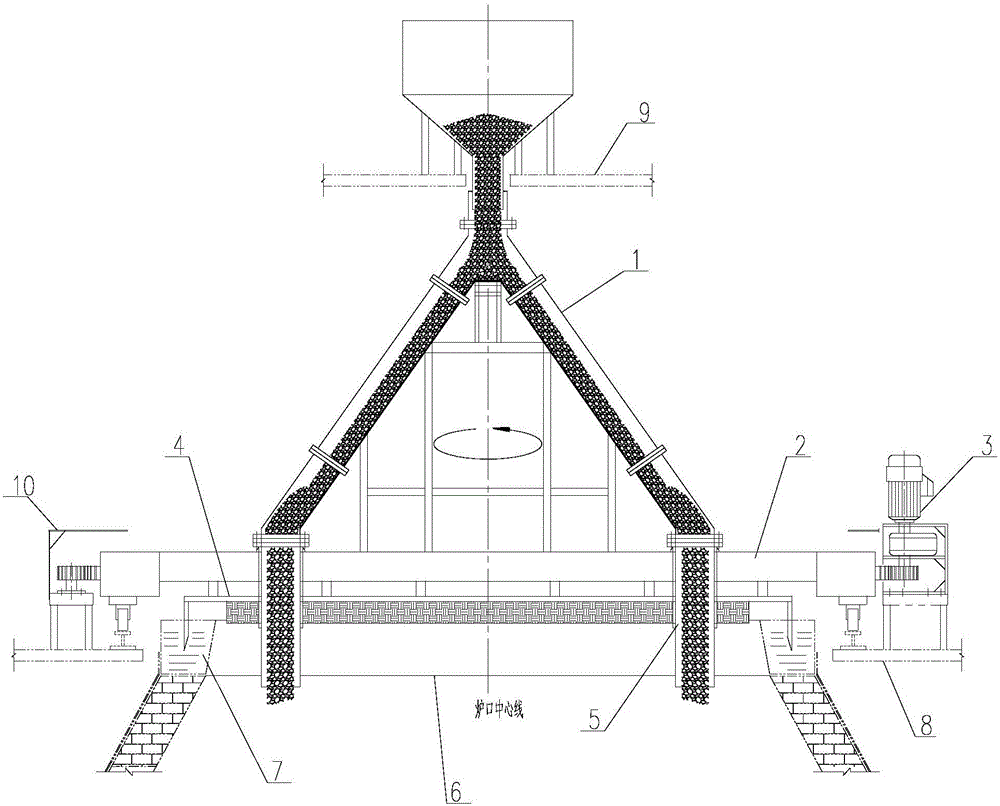

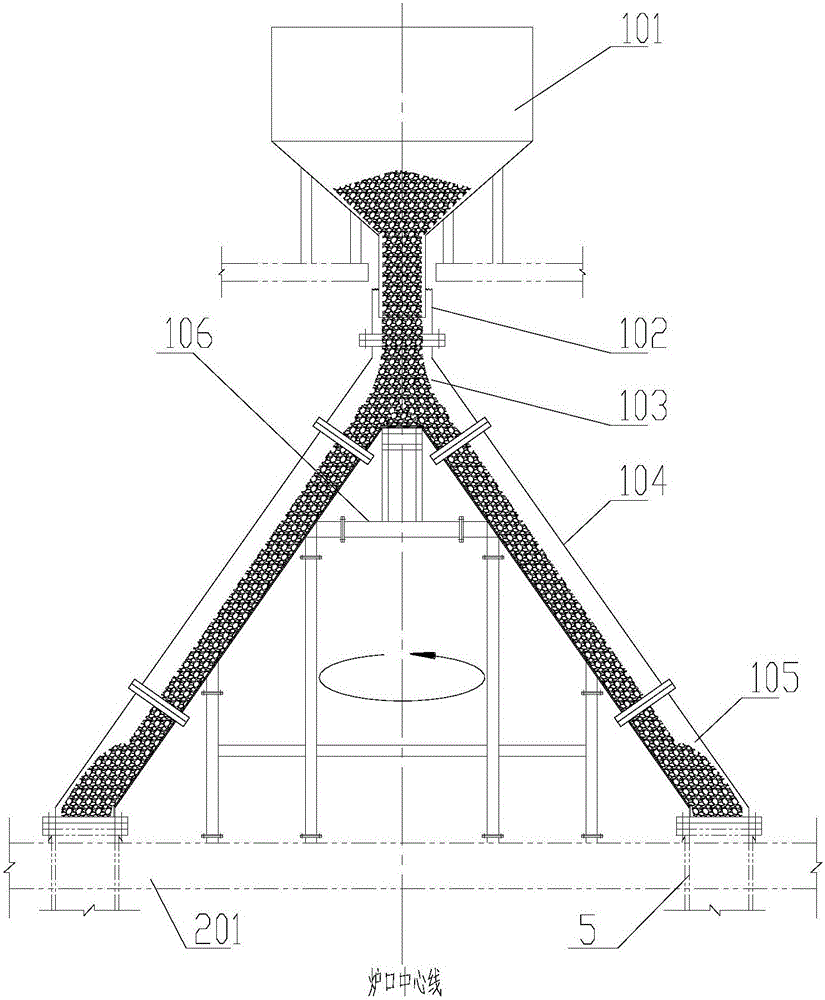

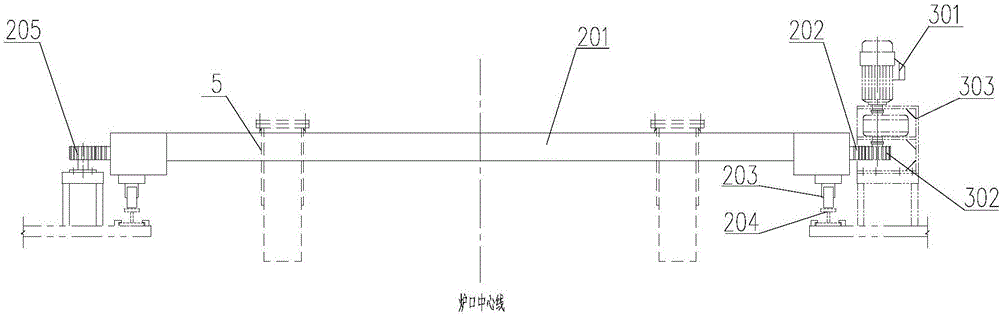

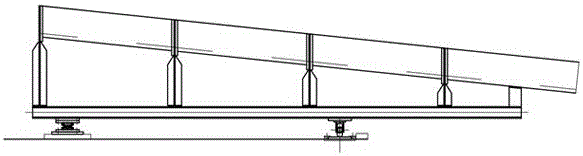

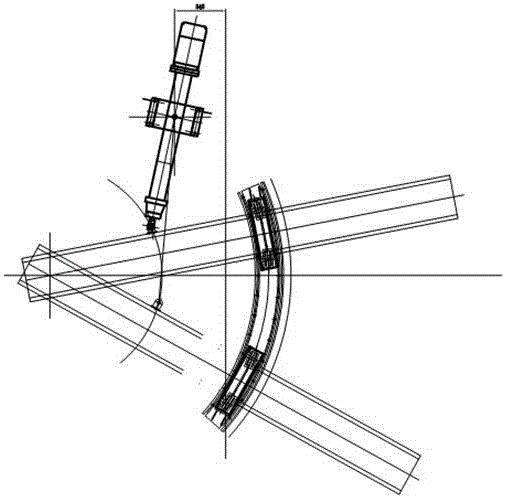

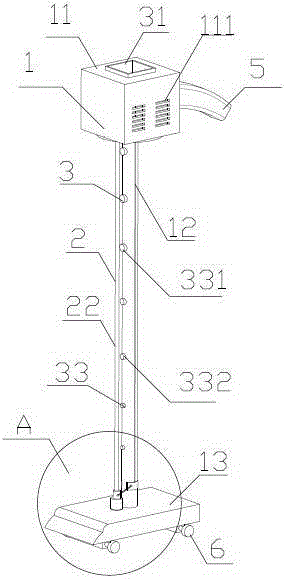

External transmission liquid seal type rotary material distribution device

ActiveCN106382822AAvoid high temperature effectsImprove production continuityCharge manipulationGear wheelMaterial distribution

The invention relates to an external transmission liquid seal type rotary material distribution device which comprises a material distribution unit, a rotating device, a driving mechanism and a rotation liquid seal cover. The rotating device is composed of a rotation disc and a gear disc; the material distribution unit is composed of a material receiving hopper, a seal type movable connection pipe, a forking body, a material guide body and a material discharging body; the gear disc and a driving gear are in meshed transmission so as to drive the rotating device and the whole material distribution unit except for the material receiving hopper to rotate around the center of a furnace opening; an annular liquid seal plate at the edge of the outer side of the rotation liquid seal cover extends into liquid in an annular liquid seal groove to achieve sealing of the furnace opening; and a discharging point adjusting structure is arranged on the rotation disc. The material distribution unit, the rotating device and the driving mechanism of the external transmission liquid seal type rotary material distribution device are all arranged outside a furnace, space in the furnace is not occupied, the external transmission liquid seal type rotary material distribution device is simple and reasonable in structure, stable and reliable in work and convenient to overhaul, and high-temperature influences on the furnace opening can be effectively avoided; and the rotation liquid seal cover is adopted for achieving sealing of the furnace opening during rotary material distribution, and rapid adjustment of a discharging point can be achieved through combination of different types of adjusting connecting plates and discharging bodies.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

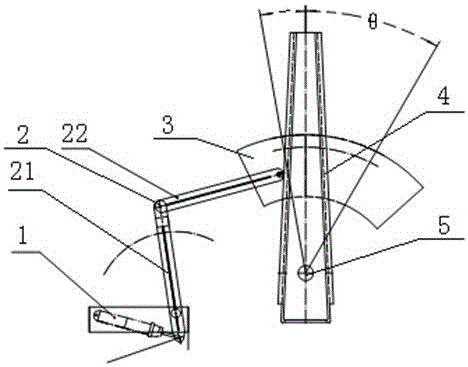

Movable slagging chute for smelting furnace

InactiveCN106440825AAvoid high temperature effectsIncrease the driving torqueCharge manipulationSlagPropeller

The invention relates to a movable slagging chute for a smelting furnace. The movable slagging chute comprises a propeller, a push rod, a movable chute, a rotating base, an idler wheel and a rotating shaft frame, wherein the movable chute has an integrated structure; a rotating base is arranged under one end of the movable chute; the idler wheel is arranged under the other end of the movable chute away from the rotating base; the idler wheel is arranged on a chute wheel rail and is capable of driving the movable chute to move on the chute wheel rail under the driving of the push rod; the rotating shaft frame is arranged on the movable chute. The movable slagging chute for the smelting furnace can realize the connection between the propeller and the movable chute by adopting the push rod structure; the influence of high-temperature slag on the propeller is reduced; the problems of high fault rate and low reliability of the movable slagging chute for slagging at a slag port of the smelting furnace are solved; the safe and reliable slagging operation is ensured; the integrated movable chute is adopted, so that the loading capacity of the chute is increased, the service life is prolonged and the motion of the movable chute is benefited.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

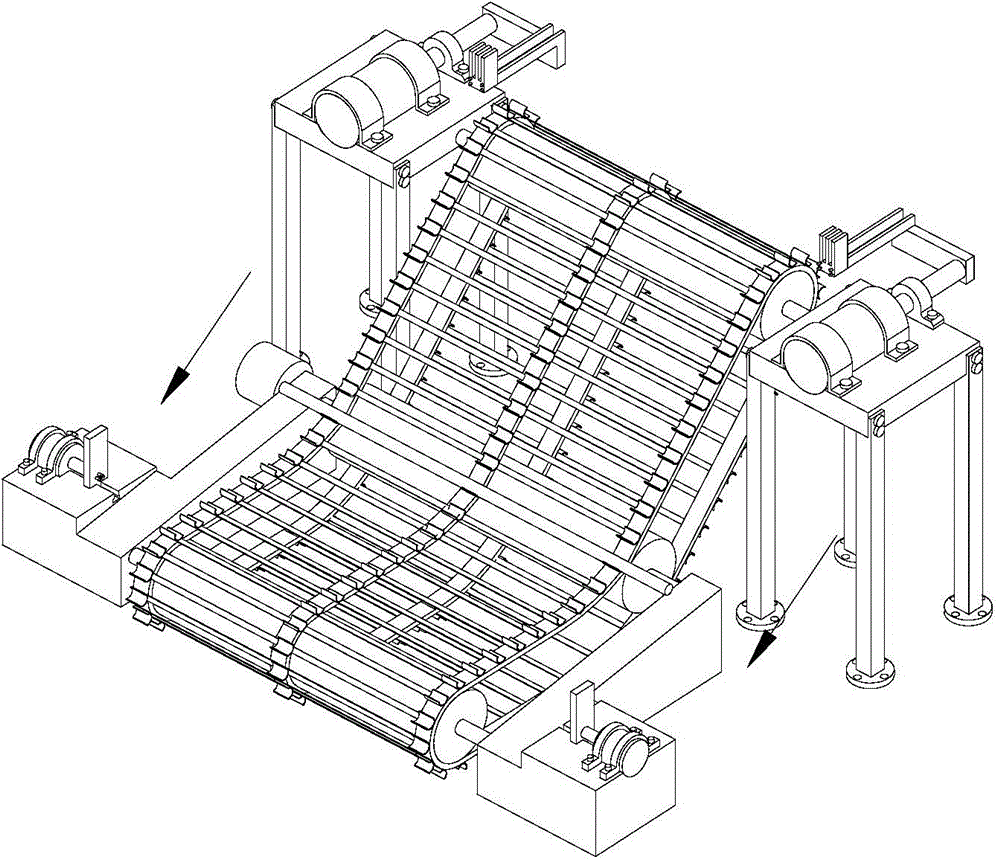

Die casting conveying device

The invention discloses a die casting conveying device, and relates to a conveying device. The die casting conveying device comprises a frame mounted on the ground, two first rotating shafts rotationally connected to the two ends of the frame, multiple second rotating shafts slidingly connected between the two sides of the frame, multiple chain wheels uniformly distributed on the first rotating shafts and the second rotating shafts, multiple chains engaged with the chain wheels positioned on the same vertical surface, multiple metal strips arranged on all the chains at equal intervals, a motorarranged on one side of the frame and connected with one first rotating shaft through a motor shaft, an air cooling mechanism arranged rightly above the frame and used for accelerating the flowing speed of air on the surfaces of die castings, and a stacking mechanism arranged at the tail end of the frame and used for taking down the die castings from the frame to stack. The die casting conveyingdevice achieves the effect of preventing damage of the conveying device by the die castings with higher temperature.

Owner:厦门浙辉工贸有限公司

Safe cutting device suitable for furniture packing

ActiveCN104369229AAvoid affecting efficiencyImprove stressMetal working apparatusEngineeringMachining

The invention relates to the field of furniture machining devices, in particular to a safe cutting device suitable for furniture packing. According to the technical scheme, the safe cutting device comprises a rack and an electric heat device arranged on the rack and further comprises an oil spraying device for oiling the electric heat device and a cleaning device for cleaning the electric heat device. The safe cutting device is simple in structure, cuts the furniture packing heated electric heat wires and meanwhile has the automatic oiling function and the automatic electric heat wire cleaning function, efficiency is improved, and operation safety is improved.

Owner:ZHEJIANG BOTAI FURNITURE

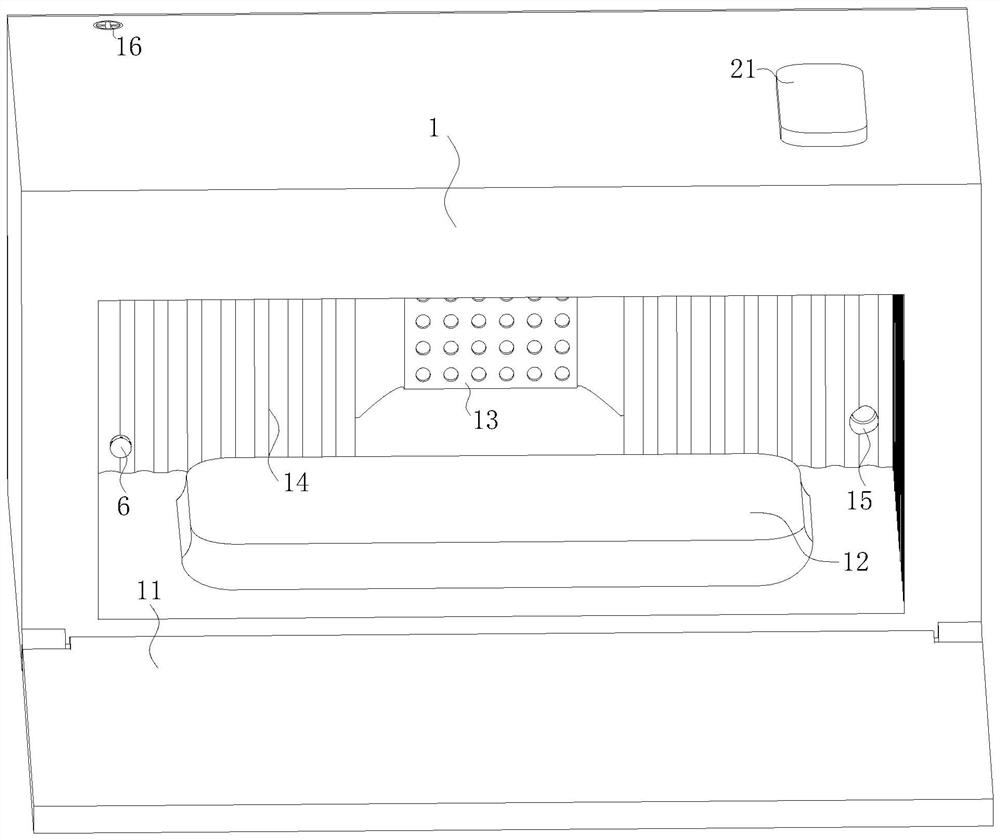

Integrated food steaming oven

ActiveCN111616587AImprove qualityGreat tasteSteam cooking vesselsRoasters/grillsThermodynamicsEngineering

The invention belongs to the technical field of kitchen equipment, and particularly relates to an integrated food steaming oven. The integrated food steaming oven comprises a box body and a box cover,and a working space for storing food is formed in the box body; the box cover is connected to the box body through a hinge; a protective cover and a heating device are mounted in the working space inthe box body; a circulating fan is mounted in the protective cover; an air outlet hole is formed in the working space; a steam nozzle is mounted in the working space; a first cavity is formed in theupper portion of the box body; a water tank is fixedly mounted in the first cavity; a second cavity is formed in the rear side of the box body; a steam generator is mounted in the second cavity; a circulating water pump is mounted in the second cavity; the circulating water pump, the steam generator and the water tank are connected through water pipes; the steam generator is connected with the steam nozzle through an air pipe; and a steam discharge pipe is fixedly mounted in the second cavity. The integrated food steaming oven is simple in structure, the water tank and the steam generator canbe cleaned, and residual water is avoided.

Owner:GUANG DONG SHUNDE CHENGHE ELECTRIC APPLIANCE CO LTD

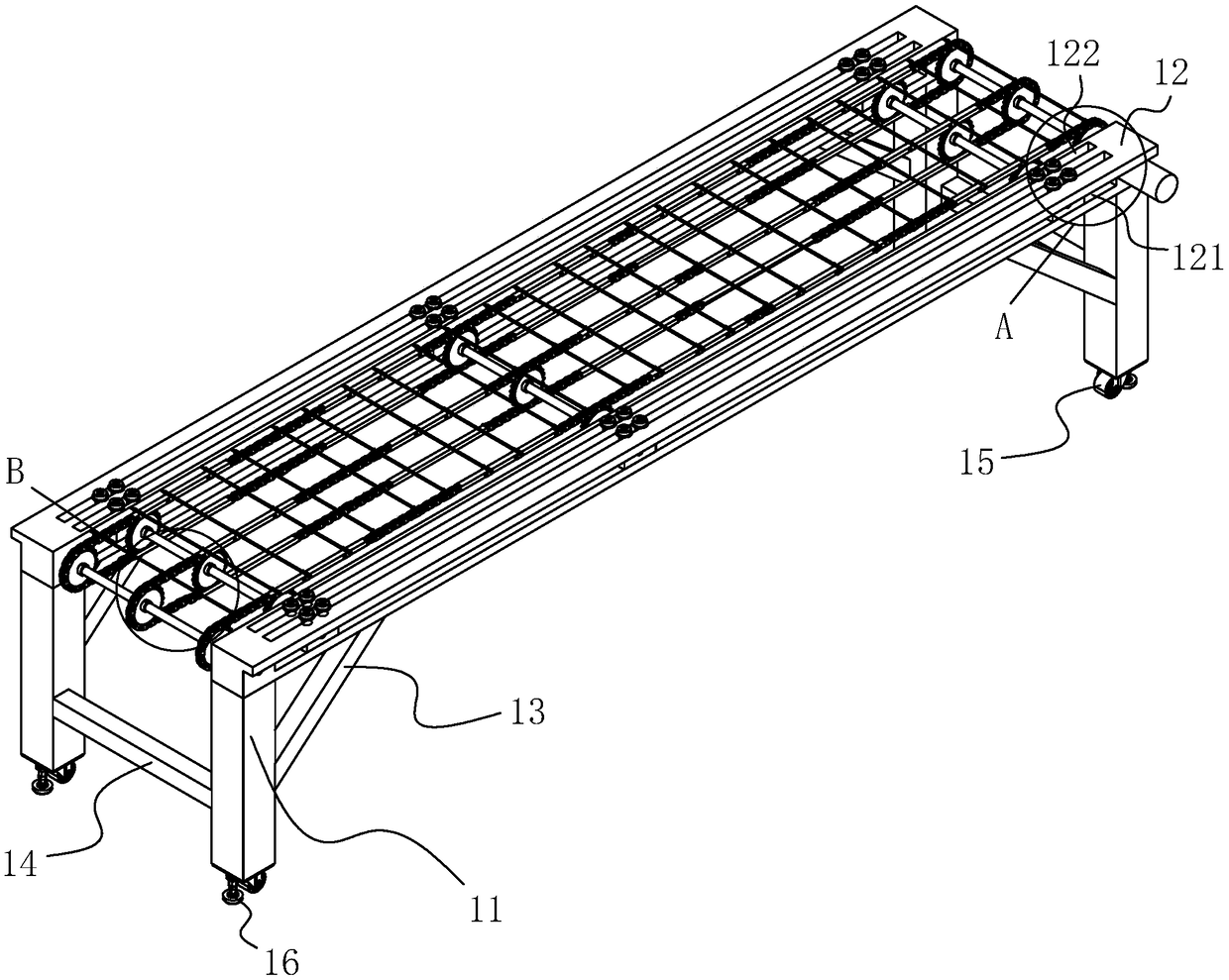

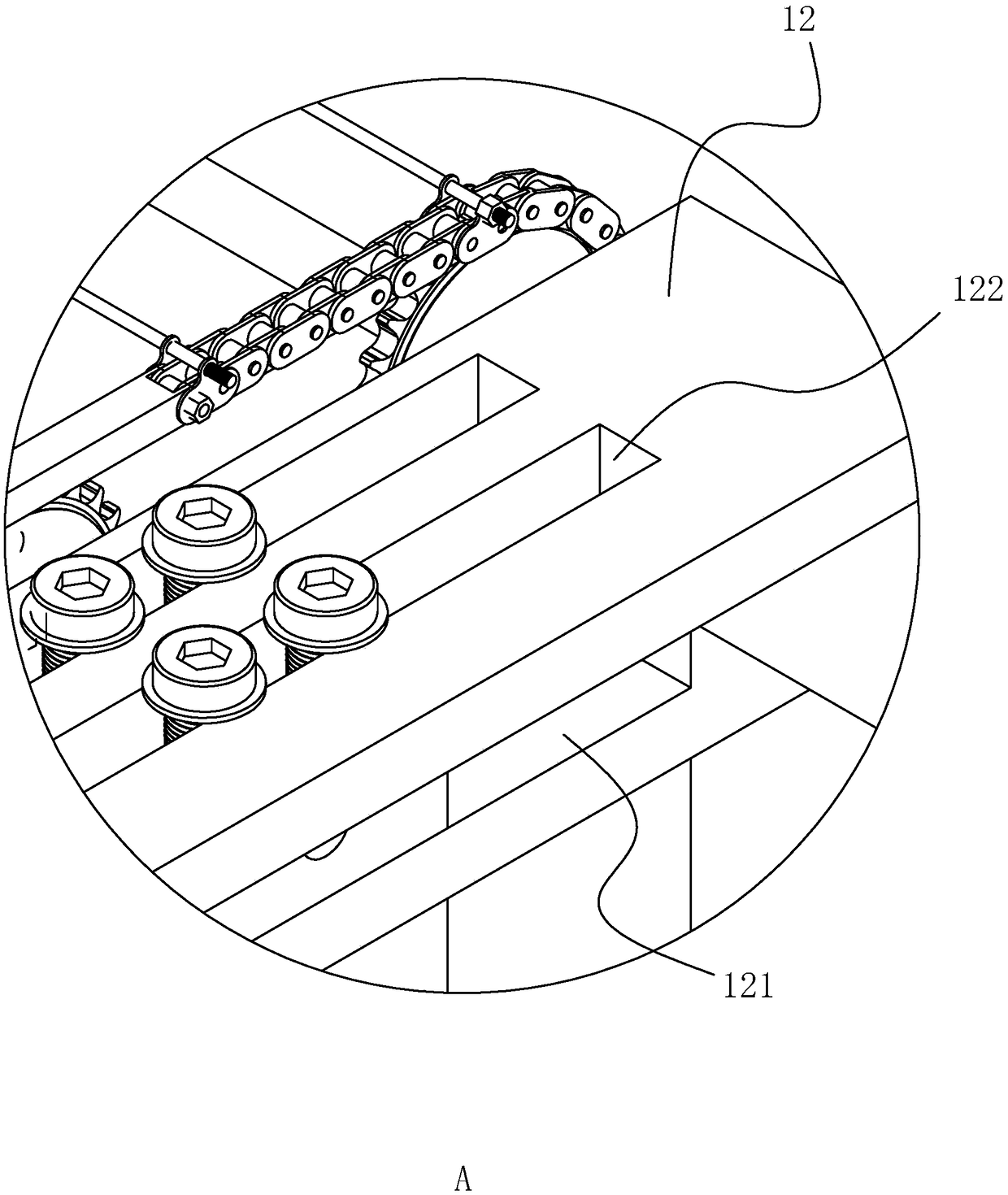

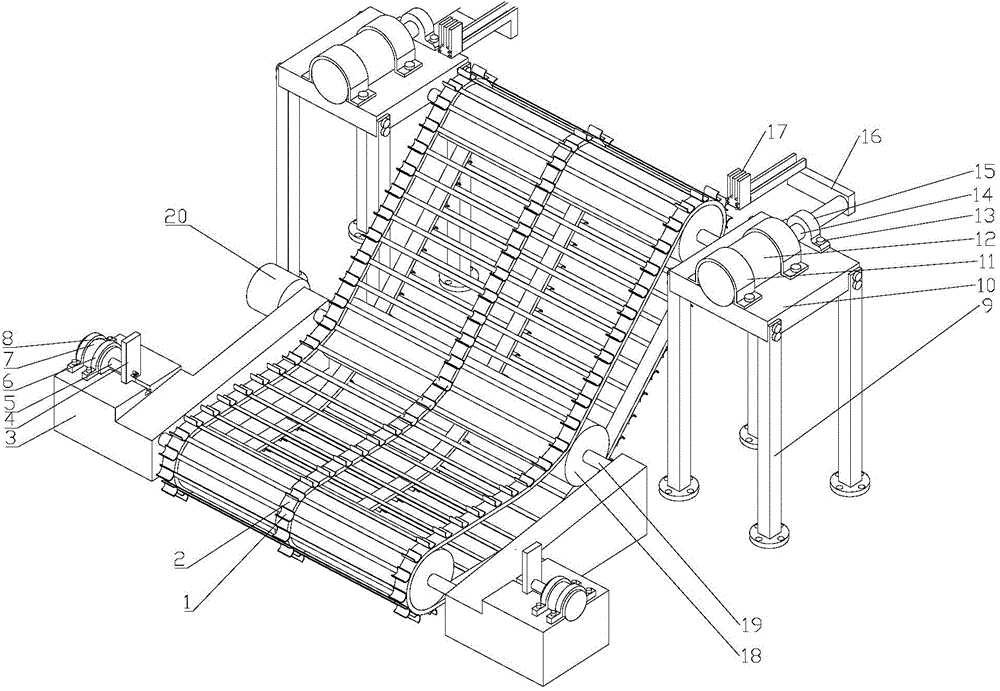

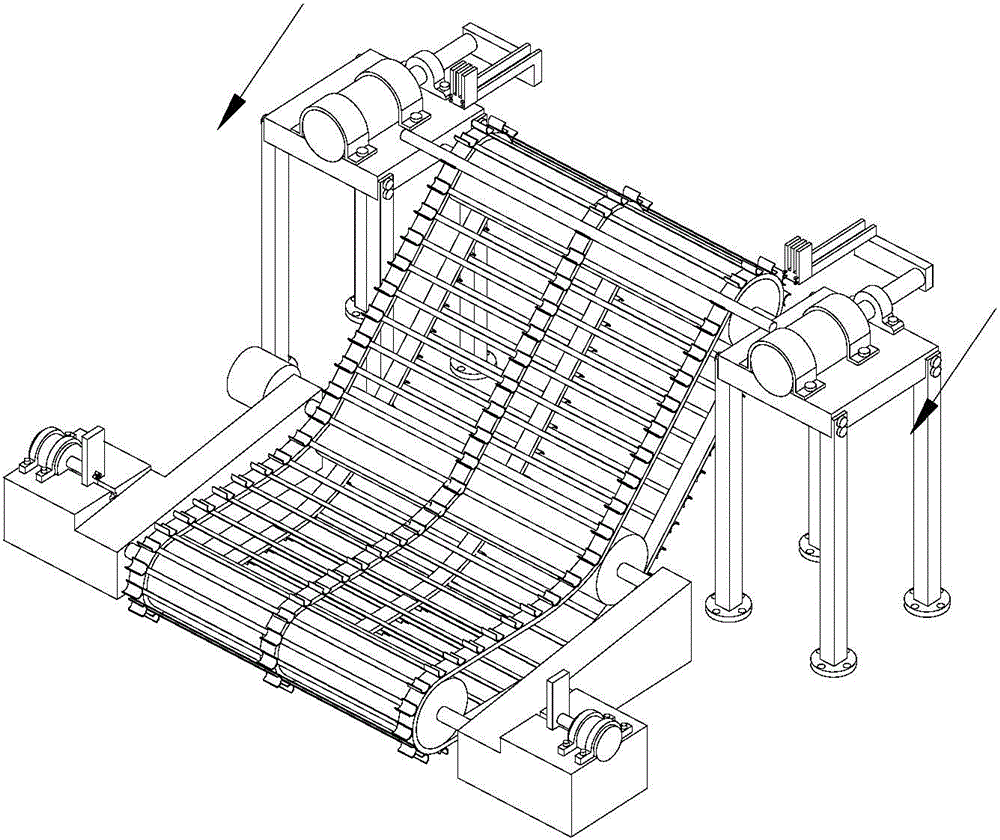

High temperature rod member unloading conveyer

InactiveCN104959868ARealize automatic transfer functionEasy to operateMetal working apparatusEngineeringSprocket

The invention discloses a high temperature rod member unloading conveyer. The high temperature rod member unloading conveyer is characterized by comprising high temperature rod member unloading mechanisms, a conveying mechanism and a positioning mechanism. Each unloading mechanism comprises a pedestal, a fixing support, an unloading hydraulic cylinder, a positioning support, a high temperature connecting rod member and an unloading claw. The conveying mechanism comprises a driving sprocket, a driving chain, a discharge hook, two pedestals and a motor. Each positioning mechanism comprises a hydraulic cylinder fixing support, a positioning hydraulic cylinder and a positioning slide block. The high temperature rod member unloading conveyer can cooperate with a robot to automatically unload, the work efficiency can be raised, and the labor force can be saved.

Owner:HEFEI UNIV OF TECH

Fabrication method of quantum dot lens-type direct LED backlight source

InactiveCN106784238AImprove color gamutSolve the problem of easy reunion failureSolid-state devicesNon-linear opticsGamutAdhesive

The invention discloses a fabrication method of a quantum dot lens-type direct LED backlight source. The method comprises the following steps of firstly preparing a fluorescent adhesive A and dropping the fluorescent adhesive A into an LED bracket; preparing a quantum dot fluorescent adhesive B and coating the surface of an LED lens with the quantum dot fluorescent adhesive B and then coating the surface of the quantum dot fluorescent adhesive B with an ultraviolet-curing adhesive protection layer. A quantum dot fluorescent material is adopted by the quantum dot fluorescent adhesive B and the half-wave width is small, so that the color gamut value of the LED backlight source can be greatly improved and the color gamut value can reach over 96% of NTSC. Quantum dot fluorescent powder is prepared in the fluorescent adhesives, so that the problem of agglomeration and failure of the quantum dot fluorescent powder is solved. The fabrication method is simple in process and low in cost, and industrial production is easy to implement. Meanwhile, the quantum dot fluorescent adhesive B coats the LED lens, and is coated with packaging glue for protection, so that erosion of moisture and oxygen to the quantum dot fluorescent material is reduced, meanwhile, the quantum dot fluorescent material is prevented from being in direct contact with a light-emitting chip and being affected by a high temperature of the light-emitting chip, and the reliability of a lamp bead is improved.

Owner:WUHU JUFEI PHOTOELECTRIC TECH CO LTD

Insulated dust-proof coating

InactiveCN105255342AWith super weather resistanceIncrease elasticityPolyurea/polyurethane coatingsPolyether coatingsPolyesterEmulsion

The invention discloses an insulated dust-proof coating. The insulated dust-proof coating comprises the following components in parts by weight: 20-32 parts of a waterborne polyurethane emulsion, 12-14 parts of dimethyldichlorosilance, 34-42 parts of poly-terephthalyl alcohol, 12-18 parts of oxalic acid polyester, 8-14 parts of glass steel particles, 5-9 parts of titanium dioxide, 8-12 parts of hydroxyethyl cellulose, 3-5 parts of a dispersing agent and 100-110 parts of ionized water. The insulated dust-proof coating has the characteristics of super weather resistance, high elasticity, super wear resistance, wind-sand resistance, high-low temperature performance resistance and the like. The insulated dust-proof coating has insulativity and is capable of preventing high temperature influences caused by electric conduction.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

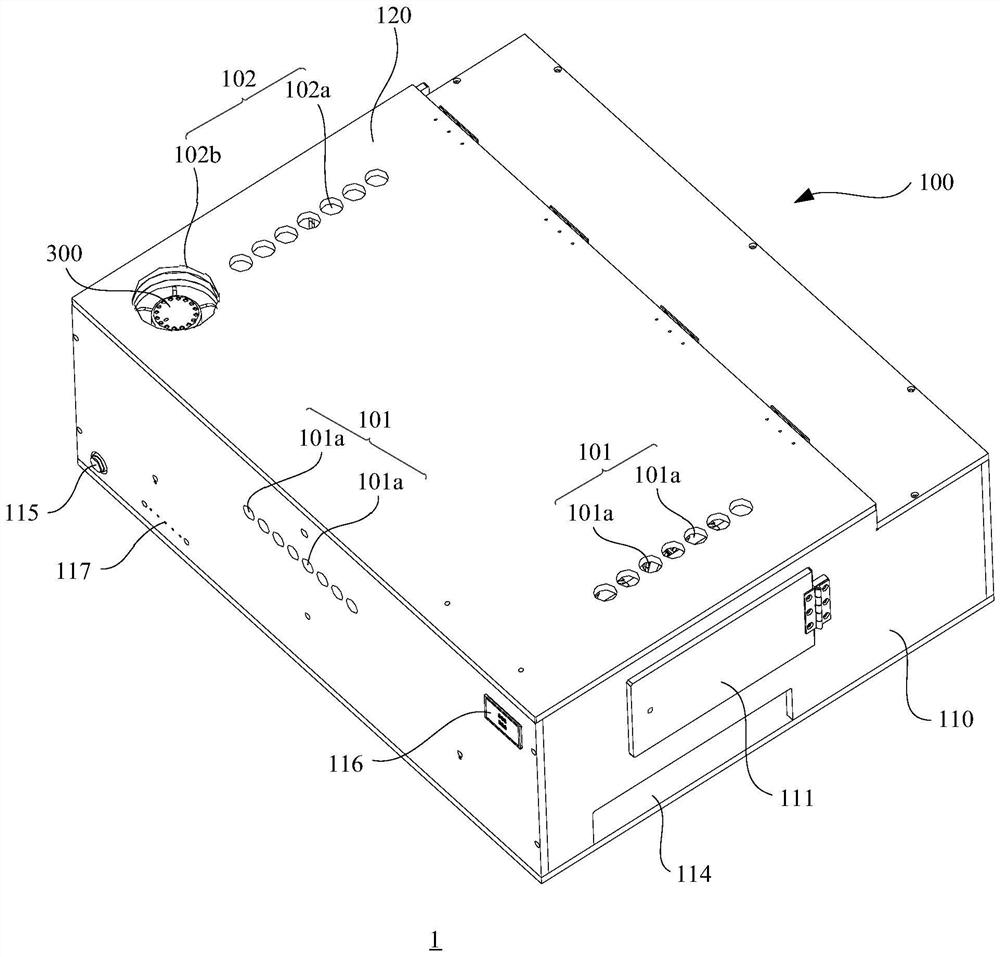

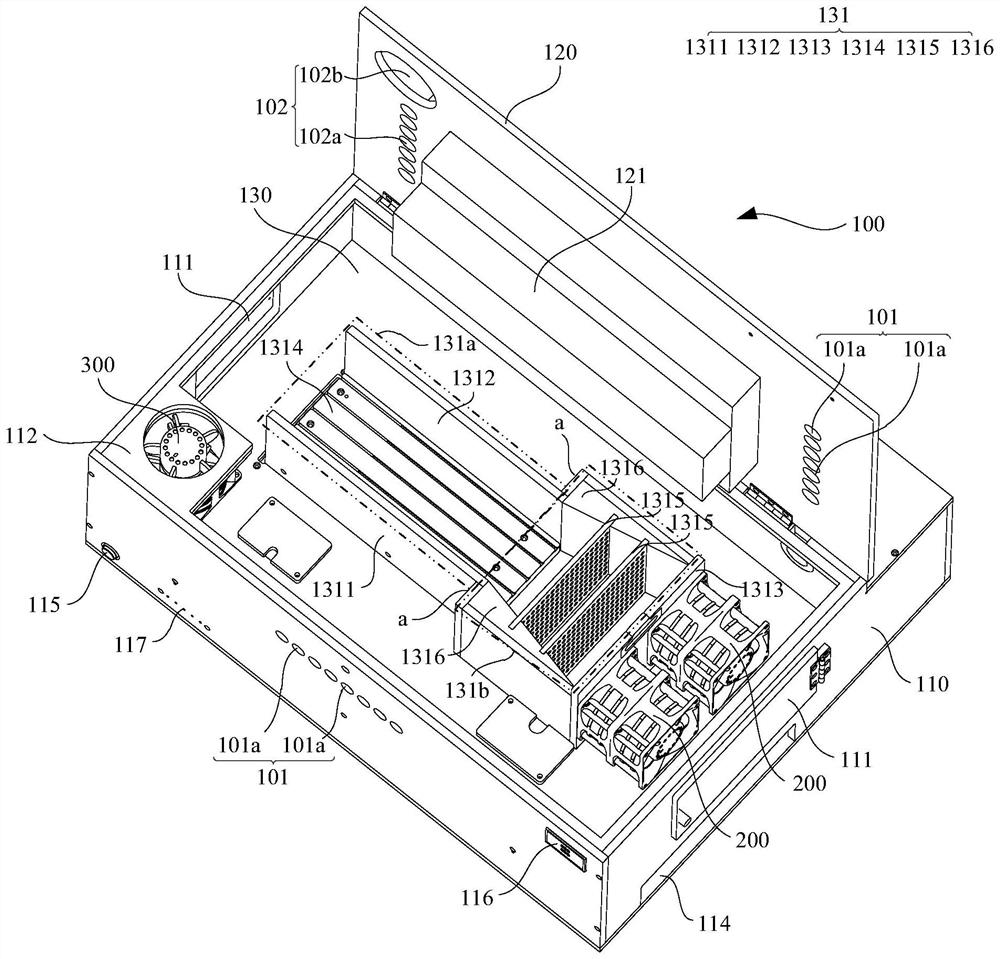

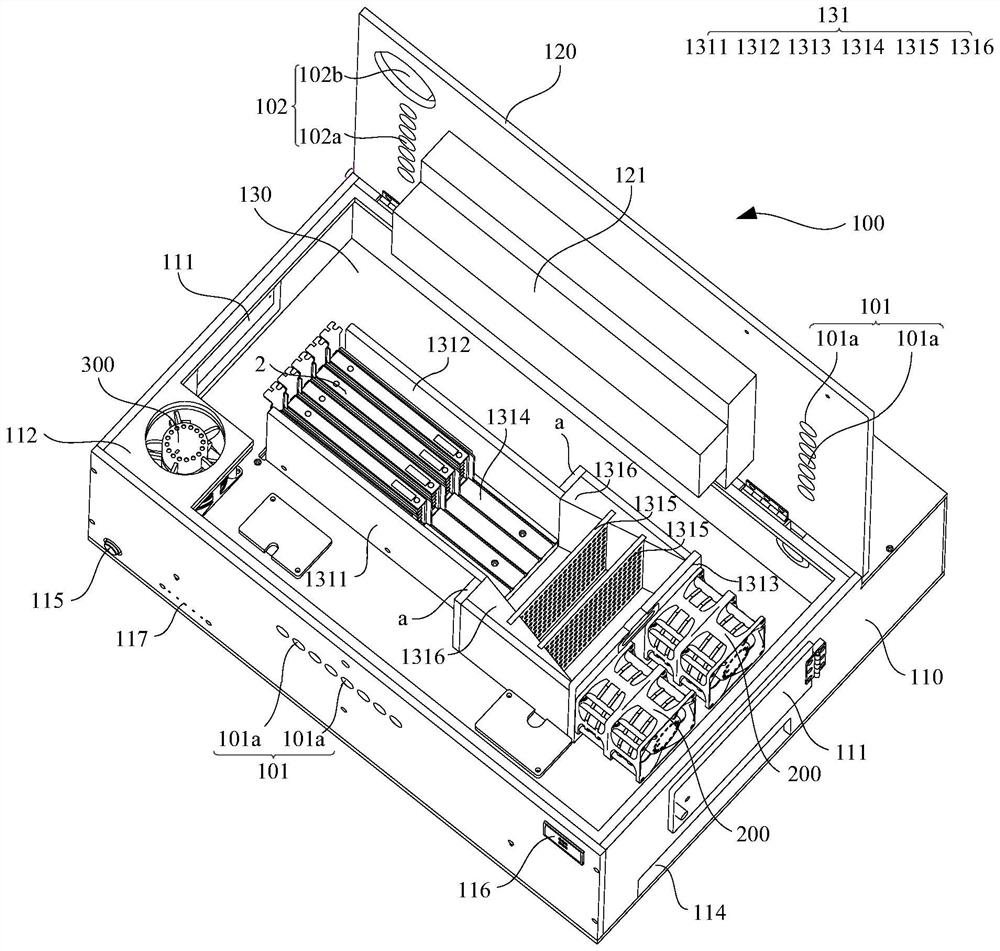

Outdoor box-type energy storage battery power station and method

InactiveCN111416372AGuaranteed stabilityDestabilized environmentElectrical storage systemTransformer housesPhysicsPower storage

The invention discloses an outdoor box-type energy storage battery power station and a method. The energy storage battery power station comprises a box body; a fresh air exchanger is arranged on one side of the box body, is communicated with a gas compressor through a heat preservation buffer pipe and is communicated with an air supply hose; the fresh air exchanger is further communicated with anair exhaust hose; the interior of the box body is divided into an energy storage chamber, a converter chamber, a power distribution chamber and a control chamber by partition walls; and each working chamber is internally provided with an electric heater. The method comprises the following steps: in the power storage and discharge process of an energy storage battery power station, a gas compressorsends compressed low-temperature gas into a box body through an air supply hose at a high temperature in summer, so that cooling is realized; and in winter, a fresh air exchanger is opened or closedaccording to specific conditions, electric heaters are started, and the temperature in the box body is increased. With the outdoor box-type energy storage battery power station and the method of the invention adopted, a good gas environment in the box body is maintained, the temperature environment in the box body is maintained at a proper temperature suitable for the working of electrical apparatus elements, and working stability is ensured.

Owner:南通阿斯通电器制造有限公司

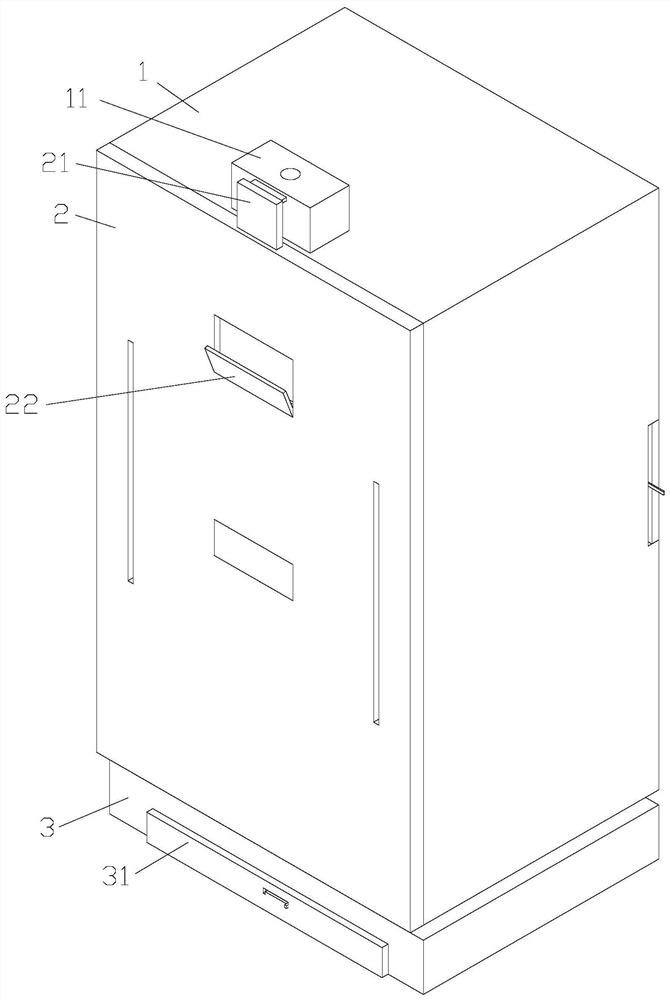

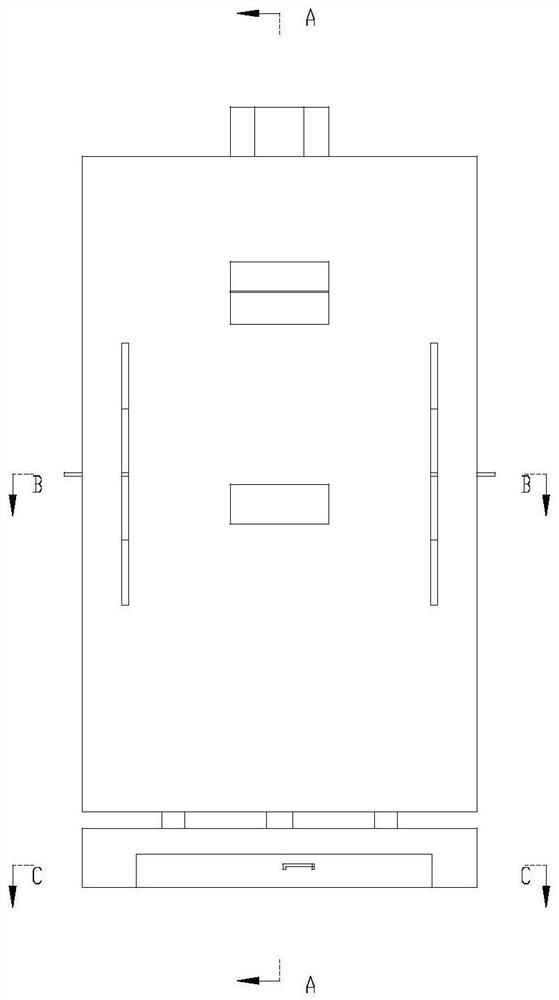

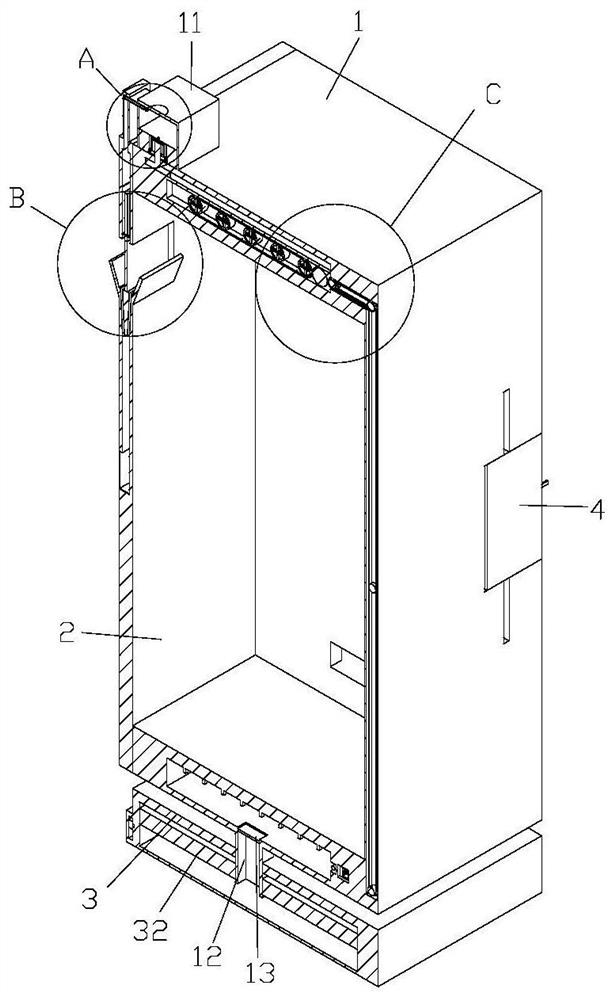

Automatic temperature control aging device

PendingCN114137352ARealize automatic temperature controlStable temperatureTemperature control using electric meansEnvironmental/reliability testsTemperature controlEngineering

The invention provides an automatic temperature control aging device. The automatic temperature control aging device comprises a temperature control box, and a temperature sensor, an air inlet fan, an air exhaust fan and a control panel which are arranged in the temperature control box, an air inlet part and an air outlet part are arranged on the box wall of the temperature control box, an aging cavity and an electric control cavity are formed in the temperature control box, and the air inlet part and the air outlet part are both communicated with the aging cavity; an air duct is arranged in the aging cavity, and the air duct comprises a mounting area for mounting an electronic product; the temperature sensor is arranged in the air duct, the two ends of the air duct are the air inlet end and the air outlet end respectively, the air inlet fan is arranged at the air inlet end, and the exhaust fan is arranged close to the air outlet end. The control panel is arranged in the electric control cavity, and the temperature sensor and the exhaust fan are electrically connected with the control panel; a main air area is formed in the air duct, and a mixed air area is formed between the air duct and the inner wall of the temperature control box. The automatic temperature control aging device is small in size, good in flexibility, modularized, capable of automatically controlling temperature and low in energy consumption.

Owner:寒武纪(昆山)信息科技有限公司

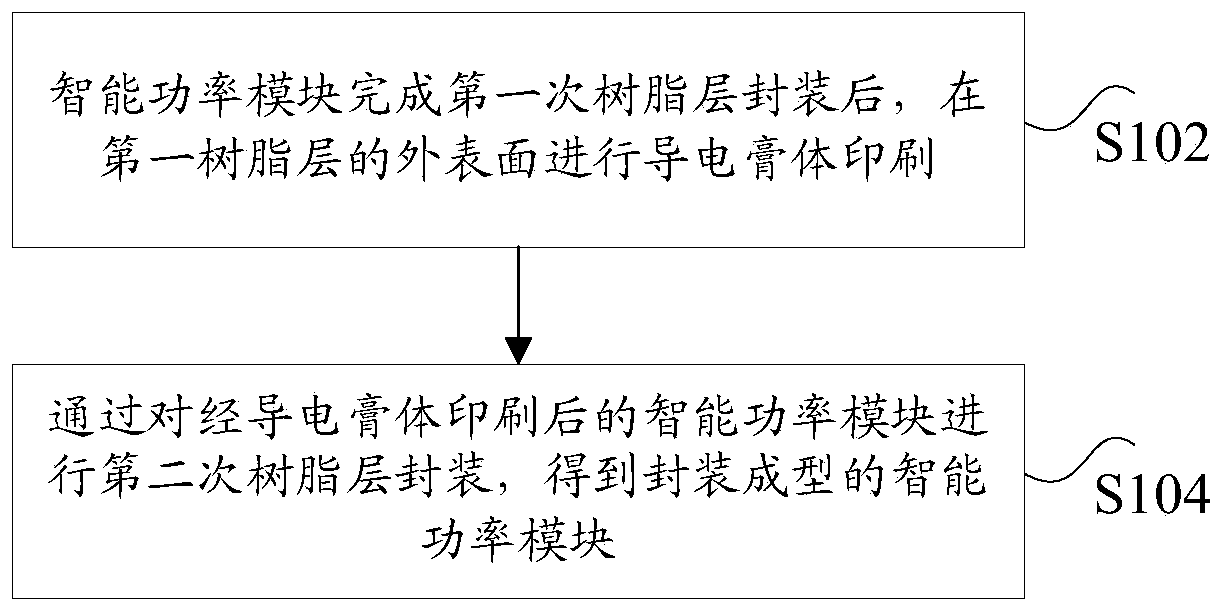

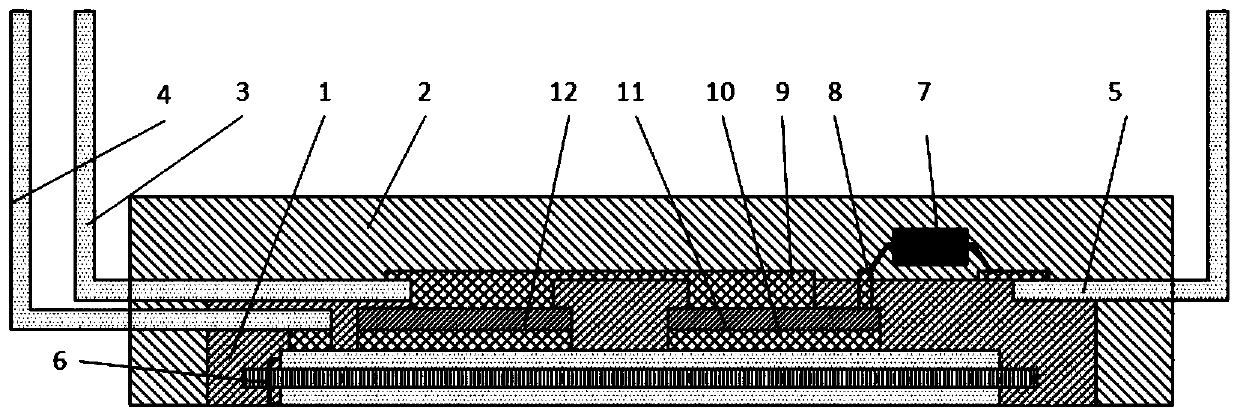

Packaging method of intelligent power module and intelligent power module

PendingCN110120354AImprove reliabilityIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteStray inductance

The invention discloses a packaging method of an intelligent power module and the intelligent power module. The method comprises the steps: carrying out the conductive paste printing on the outer surface of a first resin layer after the intelligent power module completes first resin layer packaging, wherein a power chip in the intelligent power module is arranged in the first resin layer; and carrying out second resin layer packaging on the intelligent power module printed by the conductive paste to obtain a packaged and formed intelligent power module, wherein a driving chip of the intelligent power module is placed in the second resin layer. The technical problems that a traditional intelligent power module is electrically connected in a lead bonding mode, so that stray inductance is high, and the current bearing capacity is insufficient are solved.

Owner:EDGELESS SEMICON CO LTD OF ZHUHAI

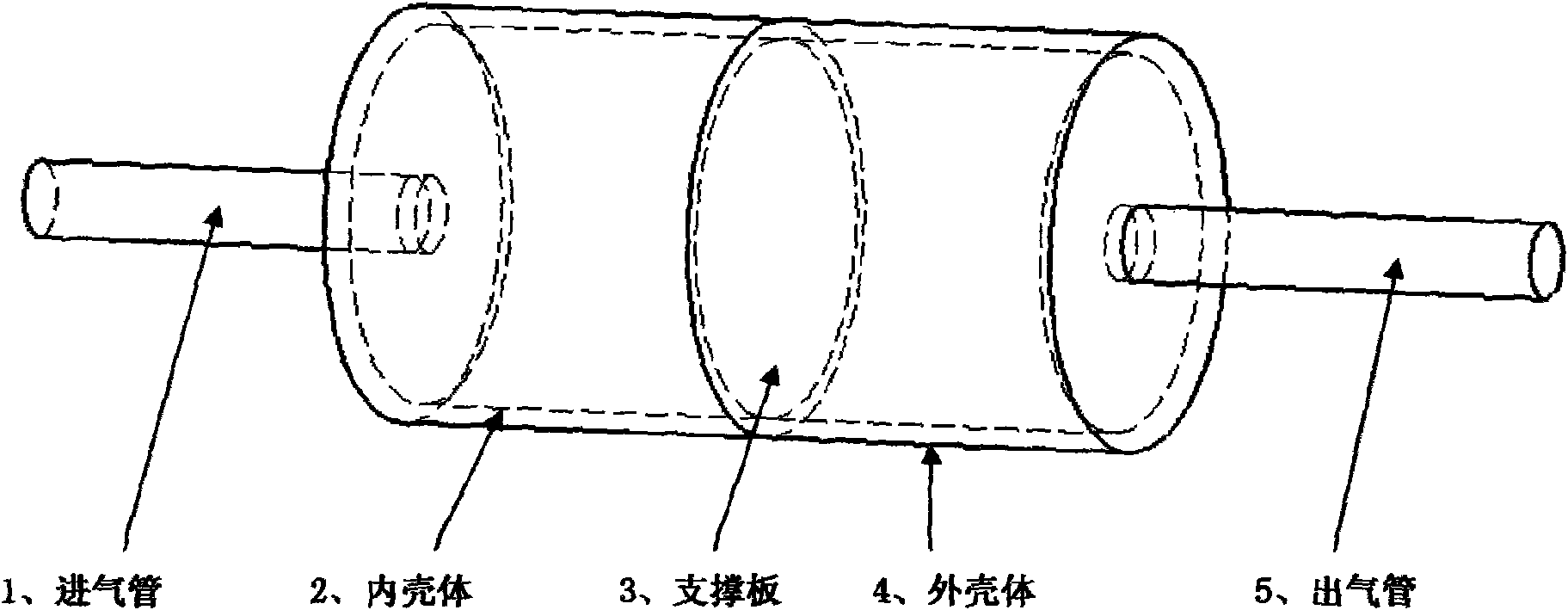

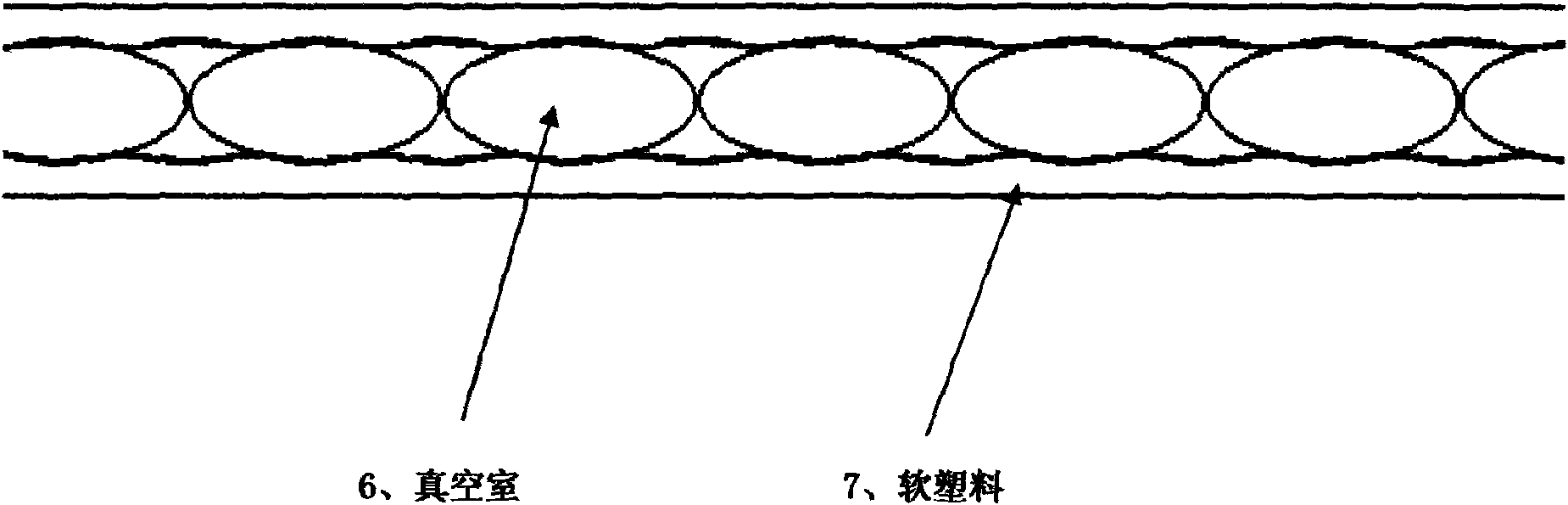

Sound insulation structure, sound insulation material and silencing device for automobile

InactiveCN101654120AImprove sound insulationStrong heat insulationSuperstructure subunitsEngineeringVacuum chamber

Owner:CHERY AUTOMOBILE CO LTD

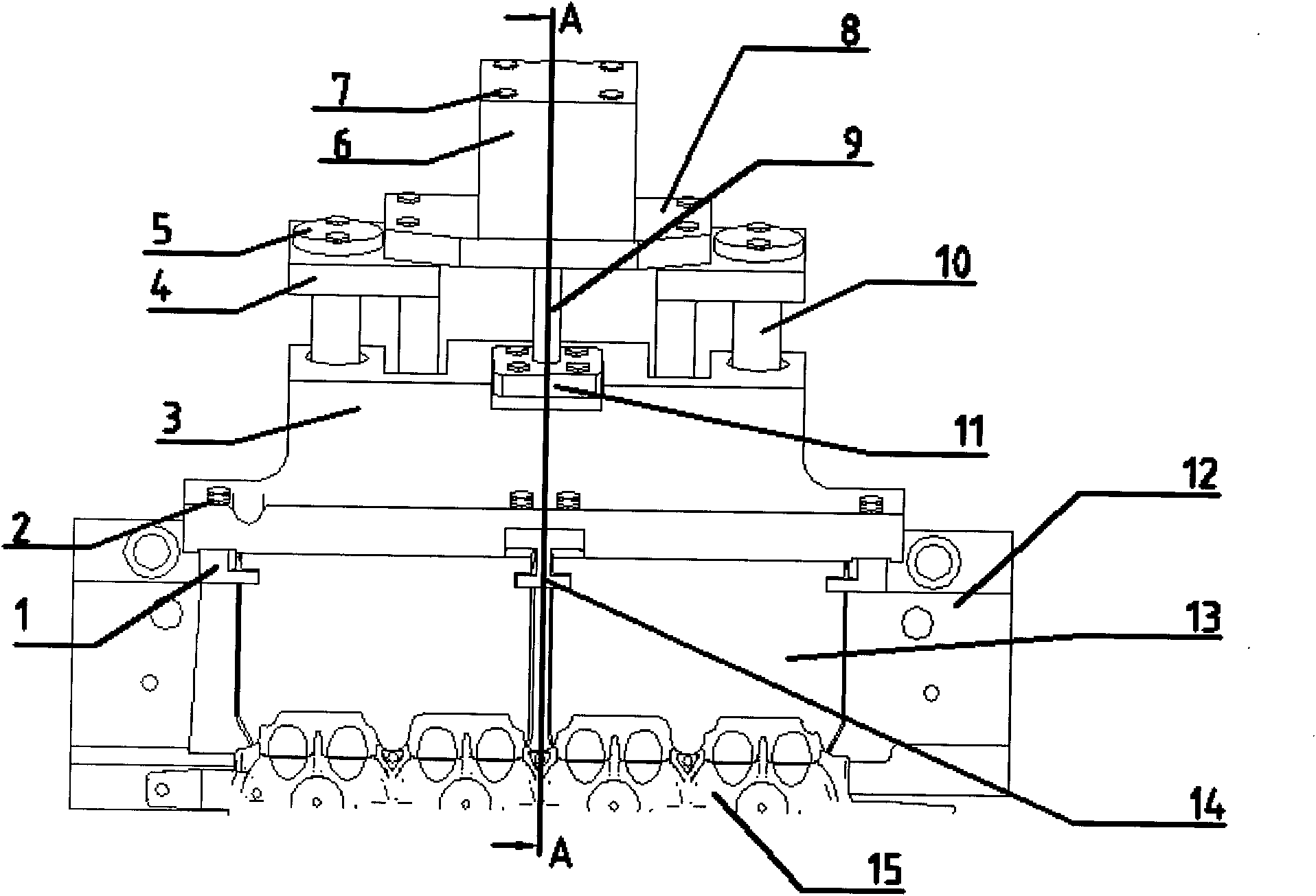

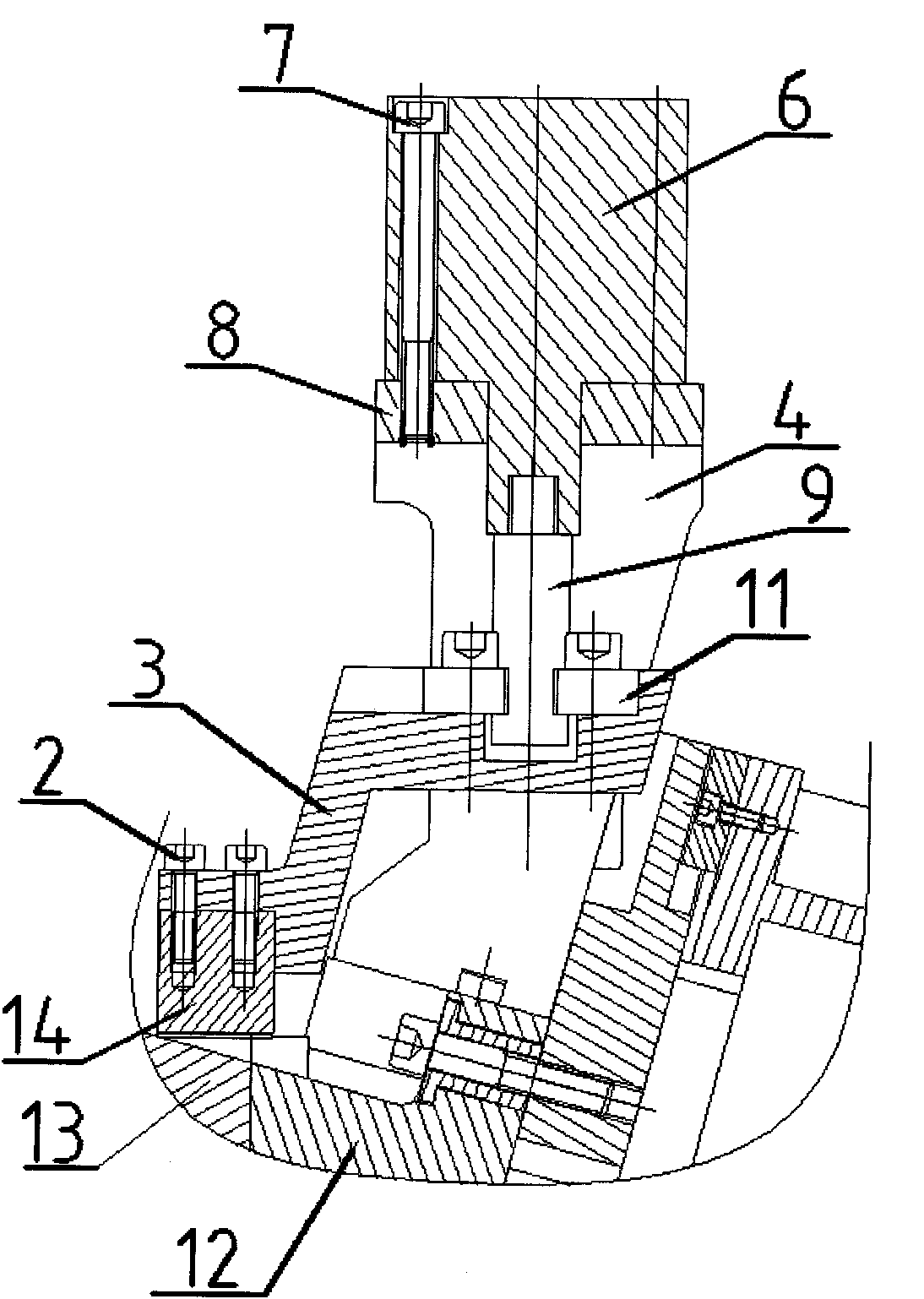

Core-pulling mechanism of hot core box die

ActiveCN101780526AAvoid high temperature effectsNot easy to ageMoulding machinesEngineeringMechanical engineering

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

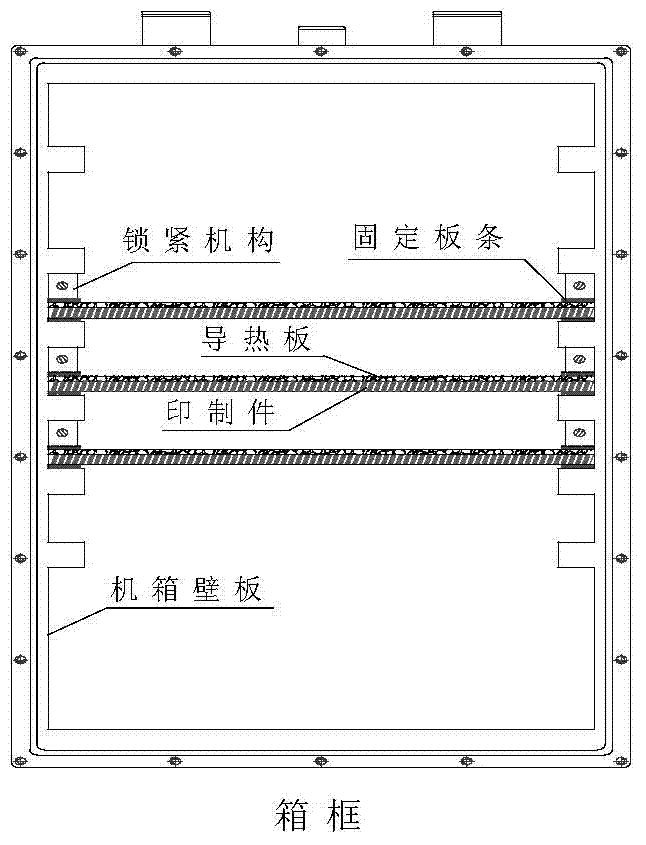

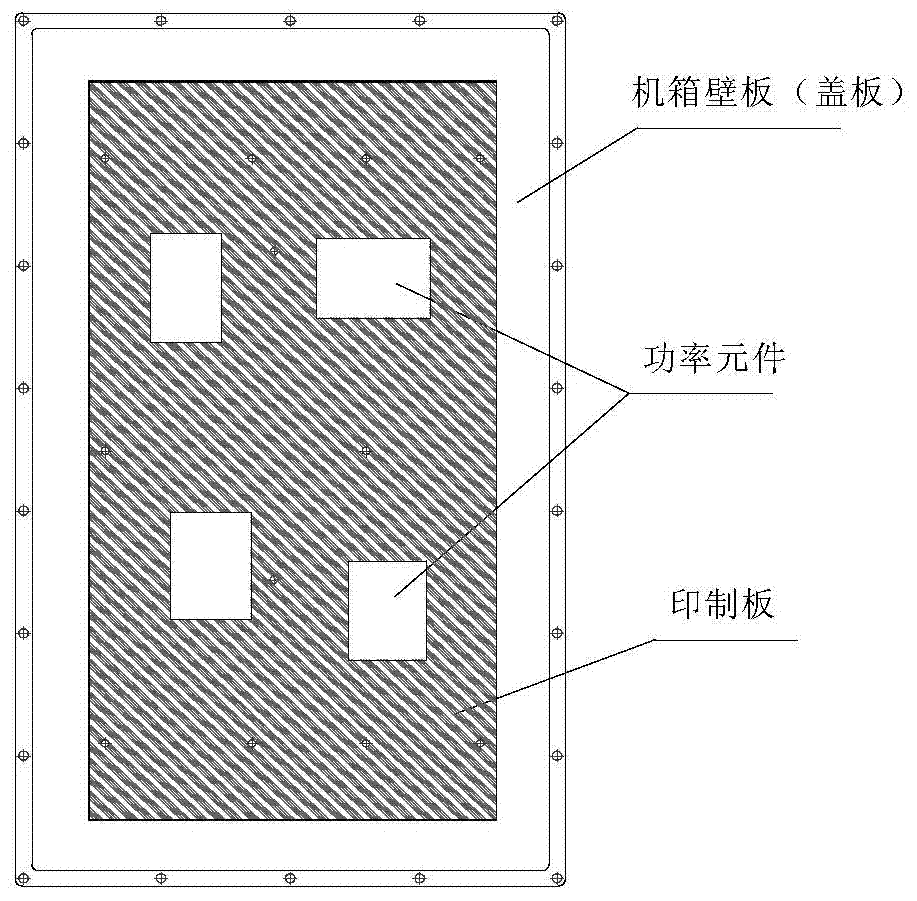

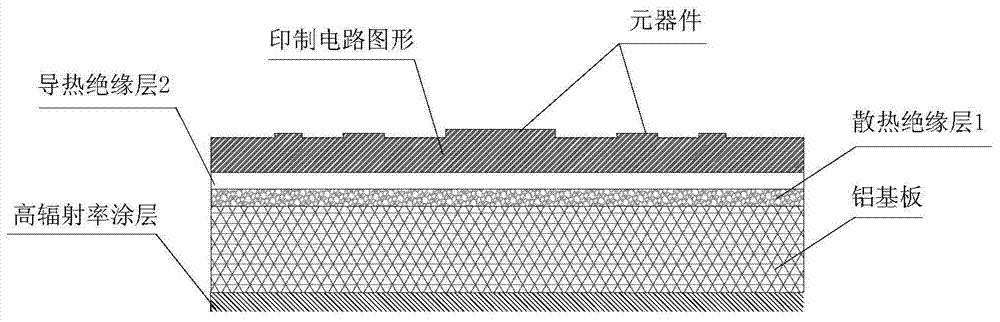

Preparation method of embedded printed structural parts

ActiveCN103702545AAvoid high temperature effectsDistribute quicklyCooling/ventilation/heating modificationsEngineeringCopper foil

The invention discloses a preparation method of embedded printed structural parts. The method comprises the following steps: taking one surface of a case cover plate as a reference surface, confirming frames of a fixing position and a circuit pattern on the reference surface according to a circuit pattern negative plate, leveling the reference surface, then performing insulating treatment on the surface of the case cover plate, forming a heat dissipation insulating layer on the surface of the case cover plate, coating a heat conduction insulating layer on the heat dissipation insulating layer of the reference surface, loading copper foils on the heat conduction insulating layer, manufacturing a circuit pattern on surfaces of the copper foils, then coating a protection layer on the circuit pattern on the surfaces, performing shape processing on the case cover plate, performing surface protection treatment on an exposed surface of the case cover plate, and coating thermal control material on the exposed surface. Heat emitted by the high-power elements connected with a printed circuit is directly conducted to the case cover plate, and then is radiated to external environment through the case cover plate, heat is rapidly emitted to external space, other devices in a case are prevented from being affected by high temperature, and the method provides guarantee for the stable and reliable operation of a complete machine.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

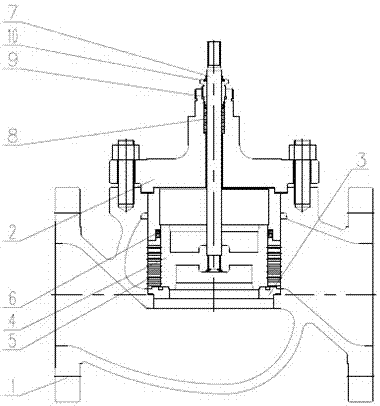

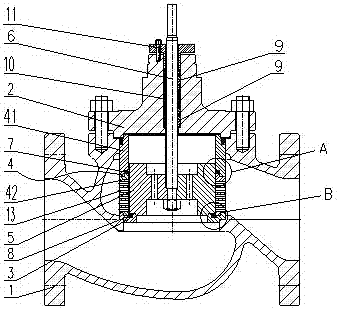

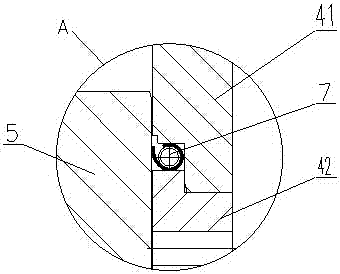

High-temperature and high-pressure special adjusting valve

PendingCN107461503AEasy on-site maintenanceEasy to replaceSpindle sealingsValve members for absorbing fluid energyGraphiteEngineering

The invention discloses a high-temperature and high-pressure special adjusting valve. The high-temperature and high-pressure special adjusting valve comprises a valve body, a valve cover, a valve seat, a valve cage, a valve plug and a valve rod. The valve cover is arranged above the valve body. An inner space is formed between the valve cover and the valve body, and the valve seat is arranged at the lower portion of the inner space. The valve cage is arranged between the valve seat and the valve cover and comprises an upper valve cage body and a lower valve cage body which are arranged from top to bottom. An upper sealing piece is arranged between the upper valve cage body and the lower valve cage body. The valve plug is arranged in the valve cage. The valve plug is arranged above the valve seat, and a lower sealing piece is arranged between the valve plug and the valve seat. The valve rod is arranged in the valve plug. The valve plug and the valve rod are connected through a front positioning anti-loosening thread. The upper portion of the valve rod penetrates the center of the valve cover, graphite filler is arranged between the valve rod and the valve deck, and a filler gland is further arranged at the upper portion of the valve cover. According to the high-temperature and high-pressure special adjusting valve, the high-temperature sealing performance, high-pressure bearing, reliability and universality of the valve can be effectively improved, and the high-temperature and high-pressure special adjusting valve can be widely applied to various automatic high-temperature and high-pressure adjusting occasions.

Owner:上海范雨实业有限公司

A safety cutting device suitable for furniture filling

ActiveCN104369229BAvoid affecting efficiencyImprove stressMetal working apparatusEngineeringOperation safety

The invention relates to the field of furniture machining devices, in particular to a safe cutting device suitable for furniture packing. According to the technical scheme, the safe cutting device comprises a rack and an electric heat device arranged on the rack and further comprises an oil spraying device for oiling the electric heat device and a cleaning device for cleaning the electric heat device. The safe cutting device is simple in structure, cuts the furniture packing heated electric heat wires and meanwhile has the automatic oiling function and the automatic electric heat wire cleaning function, efficiency is improved, and operation safety is improved.

Owner:ZHEJIANG BOTAI FURNITURE

Vacuum sealing reflecting screen hearth structure of vertical high-temperature furnace

PendingCN112857045AAvoid spillingReduce consumptionFurnace coolingElectric heating for furnacesHearthHot Temperature

The invention relates to a vacuum sealing reflecting screen hearth structure of a vertical high-temperature furnace. The vacuum sealing reflecting screen hearth structure is characterized in that a furnace cover, a furnace shell and a furnace bottom flange are fastened through bolts and sealed through sealing rings; a vacuum sealing hearth defined by a sealing flange and a process pipe is hermetically mounted in the furnace bottom flange; a process cavity defined by the process pipe is formed in the vacuum sealing hearth, and is used for carrying out the technological process of a process piece; a furnace cover heat insulation screen, a furnace shell heat insulation screen and a furnace bottom heat insulation screen are arranged in the vacuum sealing hearth; labyrinth-shaped sealing joints are formed among the furnace cover heat insulation screen, the furnace shell heat insulation screen and the furnace bottom heat insulation screen; a heating cavity is formed among the furnace cover heat insulation screen, the furnace shell heat insulation screen, the furnace bottom heat insulation screen and the process pipe; and a heater is arranged in the heating cavity. The furnace cover heat insulation screen, the furnace shell heat insulation screen and the furnace bottom heat insulation screen which are formed by stacking multiple layers of heat insulation screens at intervals are arranged in the vacuum sealing hearth, and the labyrinth-shaped sealing joints in the three sets of heat insulation screens permit heat diffused outwards in the vertical high-temperature oxidation furnace to be reflected, so that the temperature reached by heating can be stably kept, the energy consumption is reduced, and the high-temperature influence on assemblies outside the furnace is also reduced.

Owner:赛瑞达智能电子装备(无锡)有限公司

Feed for avoiding beef-cattle summer heatstroke

InactiveCN107242367AAvoid heatstrokeAvoid being affected by high temperatureFood processingAnimal feeding stuffOphiopogon japonicusLicorice roots

The invention discloses a feed for avoiding beef-cattle summer heatstroke. The feed is prepared from, by mass, 30-50 parts of straw, 10-20 parts of wheat bran, 10-15 parts of soybean cakes, 10-15 parts of peanut cakes, 10-20 parts of silkworm chrysalis, 20-30 parts of sweet potato powder, 1-2 parts of radix ophiopogonis, 2-4 parts of licorice roots and 2-3 parts of lonicera japonica. The feed can effectively avoid beef-cattle heatstroke, can promote beef-cattle feeding, can promote appetite and can strengthen the spleen, and beef-cattle healthy growth in summer can be achieved.

Owner:四川成派生物科技有限公司

Explosion-proof safe inflatable ring main unit

ActiveCN113708285AReduce the temperaturePlay a cooling roleSwitchgear arrangementsGeneral water supply conservationWater storageWater flow

The invention discloses an explosion-proof safe inflatable ring main unit which comprises a cabinet body and a cabinet door, wherein a gas conveying cavity is formed in the side wall of the cabinet body, a gas inlet and a gas outlet which are communicated with the gas conveying cavity are formed in the inner wall of the cabinet body, and a gas supply assembly is arranged in the gas conveying cavity; and a water storage cavity is formed in the bottom part of the cabinet body, a first water conveying cavity communicated with the water storage cavity is formed in one side of the gas conveying cavity, and a first push plate matched with the air supply assembly is arranged in the water storage cavity. Water flow is used for cooling gas in the cabinet body, so that the temperature in the cabinet body is reduced, elements in the cabinet body are prevented from being affected by high temperature, and the service life of the elements is guaranteed.

Owner:HANGZHOU HOUYU TECH CO LTD

Rapid flame-retardant solid combustion particle sampling device and sampling steps thereof

ActiveCN108332993AAvoid the influence of high temperature in the furnaceAvoid high temperature effectsWithdrawing sample devicesDistortionProduct gas

The invention relates to a fast flame-retardant solid combustion particle sampling device and sampling steps thereof. The device comprises a sleeve, a filter cylinder and an air pump, wherein the sleeve is communicated with the filter cylinder and the air pump in sequence, the sleeve consists of multiple layers of pipes, one end of the sleeve is a sampling end provided with a blocking plate, everytwo adjacent pipes are connected by an annular plate at the other end of the sleeve, an interlayer is formed between the adjacent pipes by the blocking plate and the annular plates, each interlayer comprises a first chamber, a second chamber and a third chamber from outside to inside, the first chamber is communicated with the second chamber, and through holes communicated with the third chamberare formed in the inner wall, close to the sampling end, of the innermost pipe; a flame retardant gas inlet, a cooling water inlet and a cooling water outlet are formed in the sleeve. One part of theinterlayer chambers formed between the interlayer sleeve tubes are used for discharging inert gas from the sampling end, and the other part of the interlayer chambers are used for cooling inert gas, so that sample distortion due to oxidation and burning of a sample by air during sampling by the sampling device can be avoided.

Owner:HARBIN BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com