Method for manufacturing touch display panel

A technology for a display panel and a manufacturing method, which is applied to static indicators, data processing input/output processes, instruments, etc., can solve the problems of increasing the thickness and weight of touch panels, and avoid the influence of high temperature and reduce the thickness and weight. , to avoid the effect of color cast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

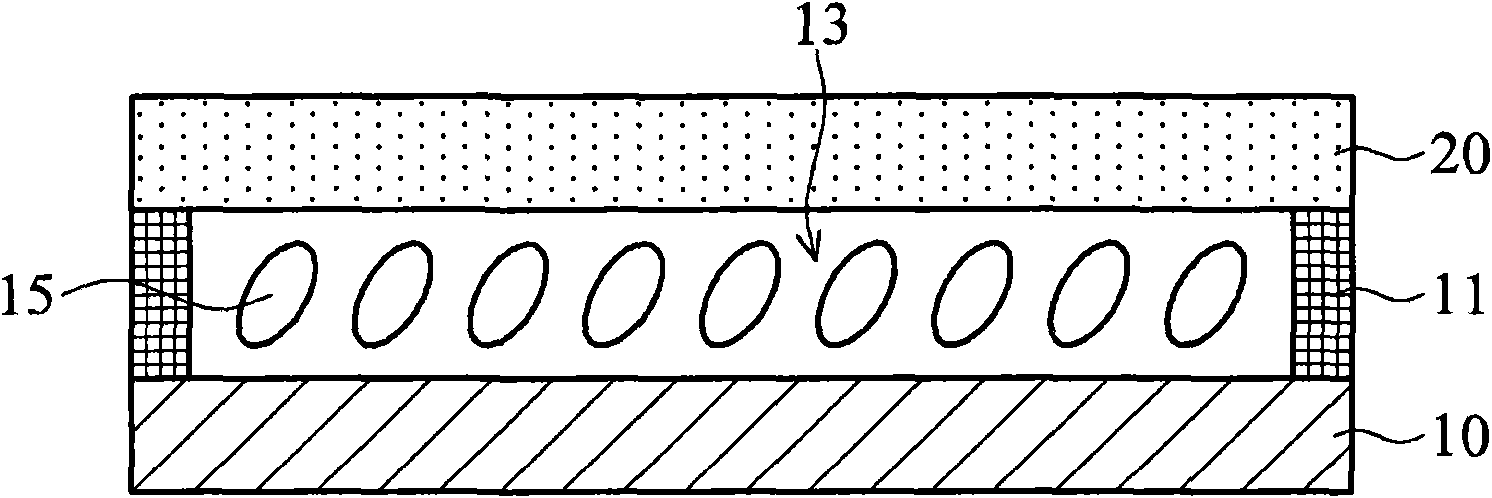

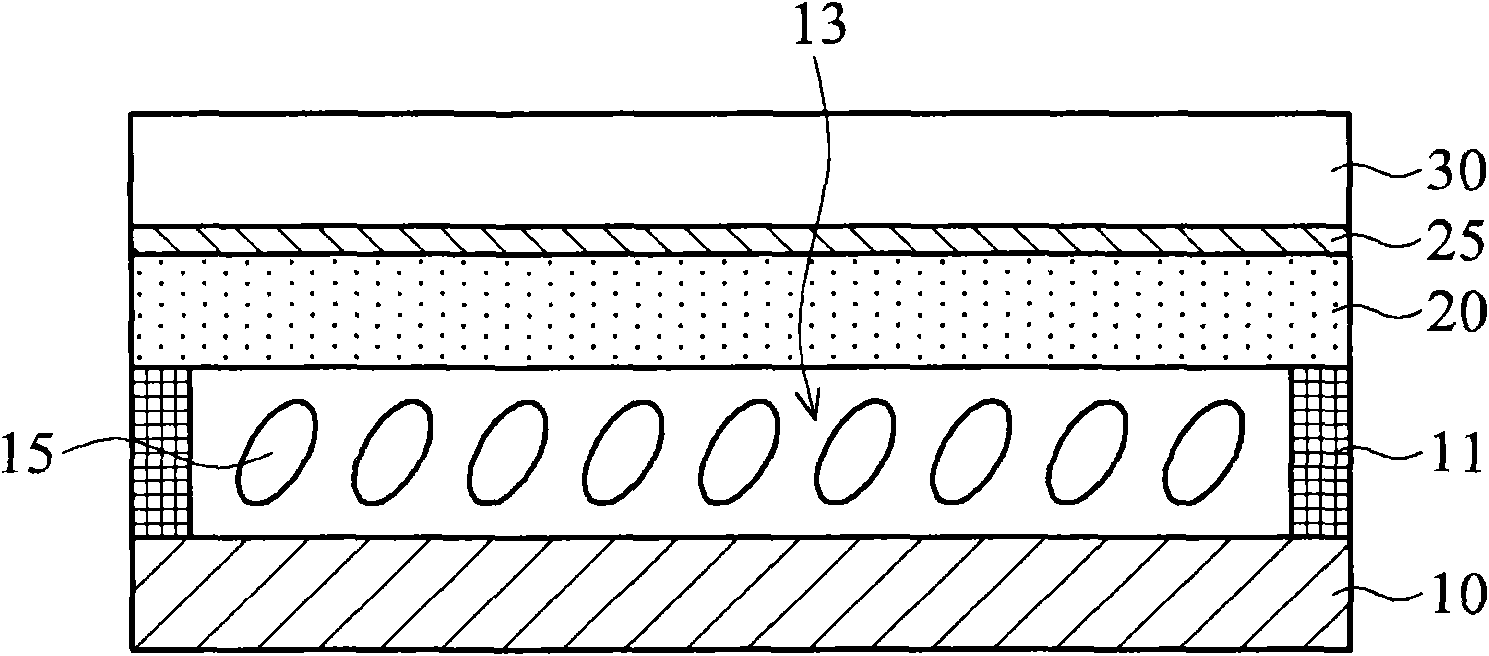

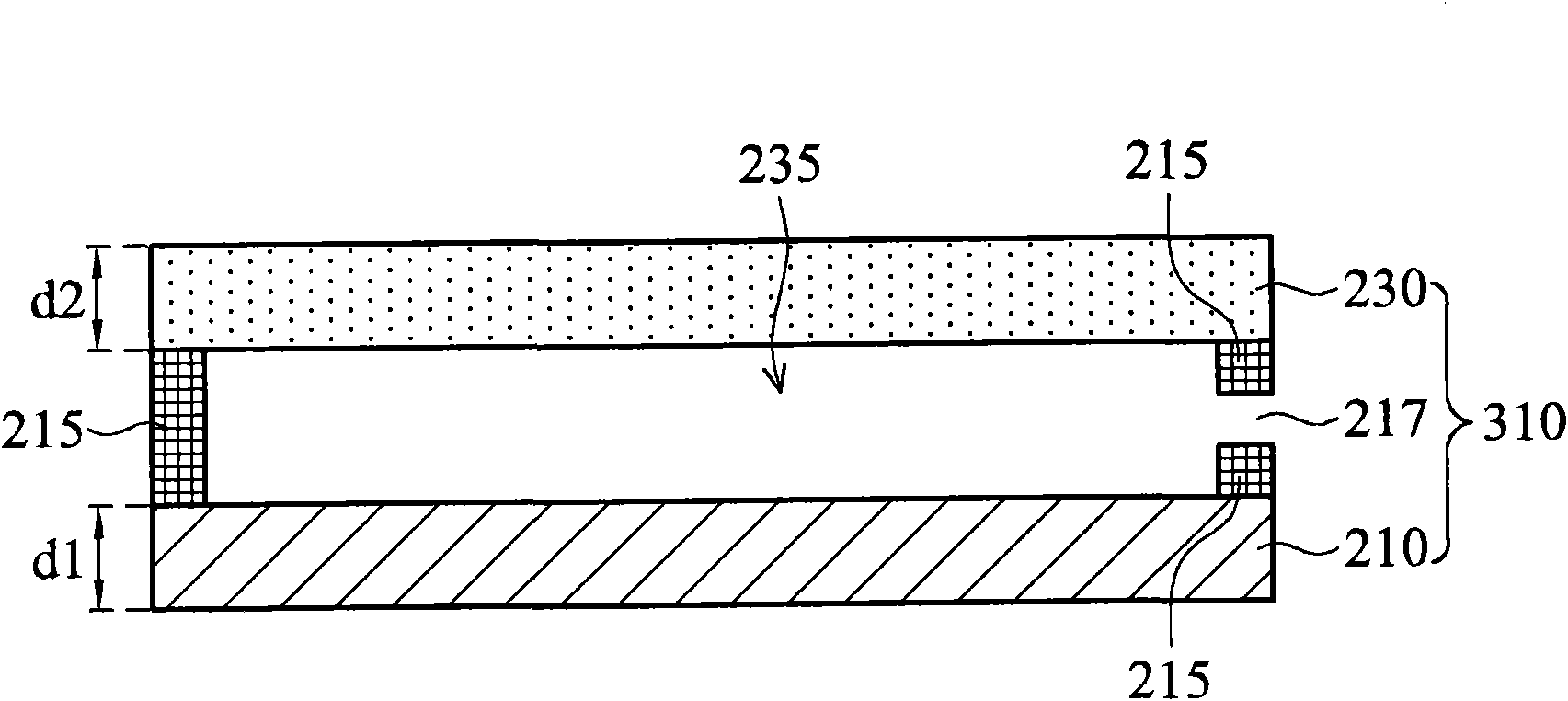

[0033] The present invention provides a method for manufacturing a touch panel, comprising the following steps: providing a display panel, wherein the display panel includes a first substrate and a second substrate oppositely arranged; thinning the a display panel; and forming a touch sensor on an outer surface of the thinned display panel. In the embodiment of the present invention, the color filter element is formed on the surface of the first substrate close to the second substrate, so the first substrate is called the color filter substrate in the embodiment of the present invention; similarly, the second substrate It is called a thin film transistor substrate. The specific implementation method is to Figures 2A-3C Take what is revealed as an example.

[0034] Figures 2A-2D A cross-sectional view showing various manufacturing stages of the touch display panel. The production method includes the following steps. First, see Figure 2A , providing a display panel 310 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com