Die casting conveying device

A conveying device and die-casting technology, which is applied in the field of conveying devices, can solve the problems of affecting the weight of die-casting products, melting of conveying parts, slow heat dissipation, etc., and achieve the effects of avoiding the influence of high temperature, good heat dissipation performance, and preventing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

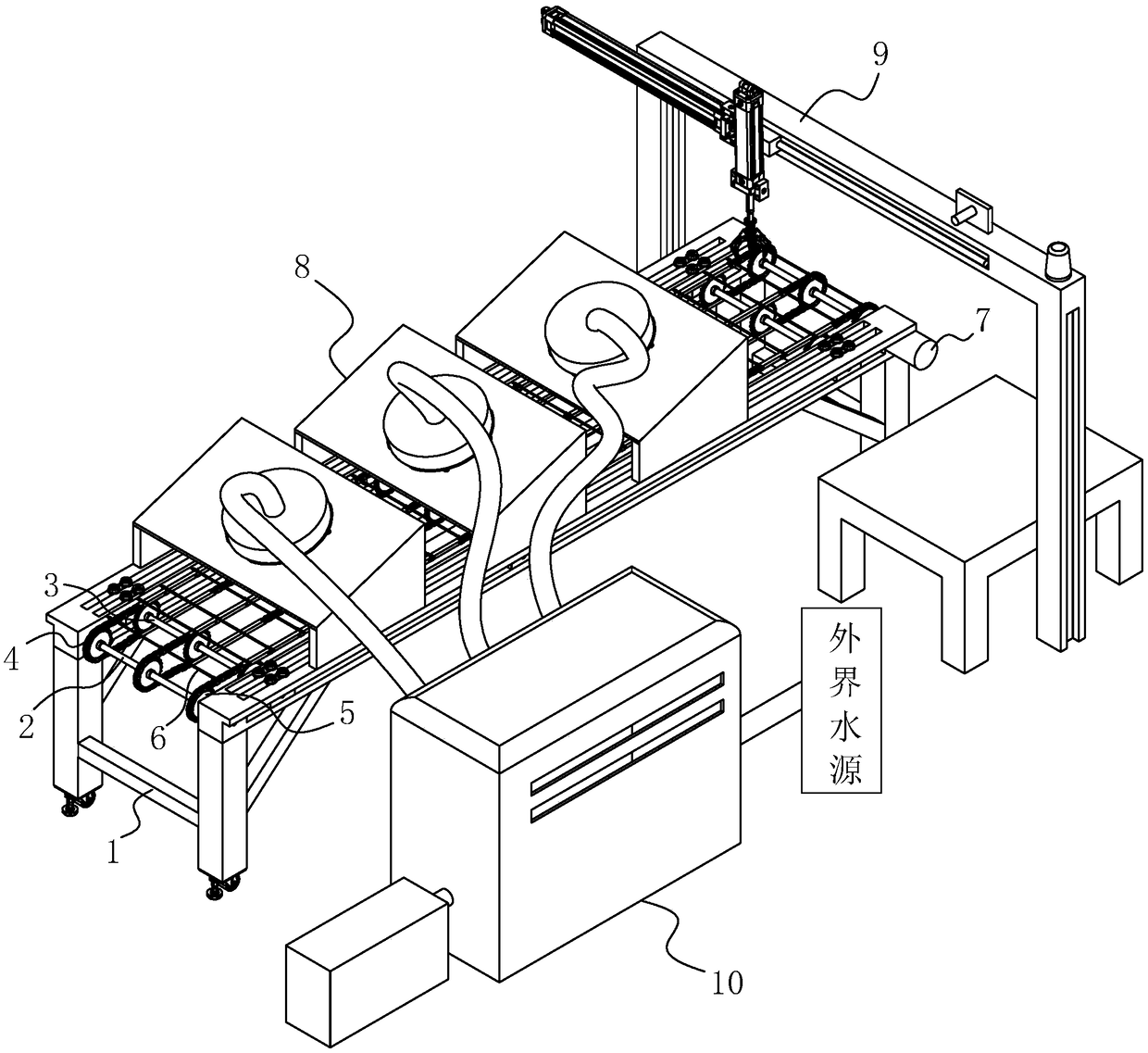

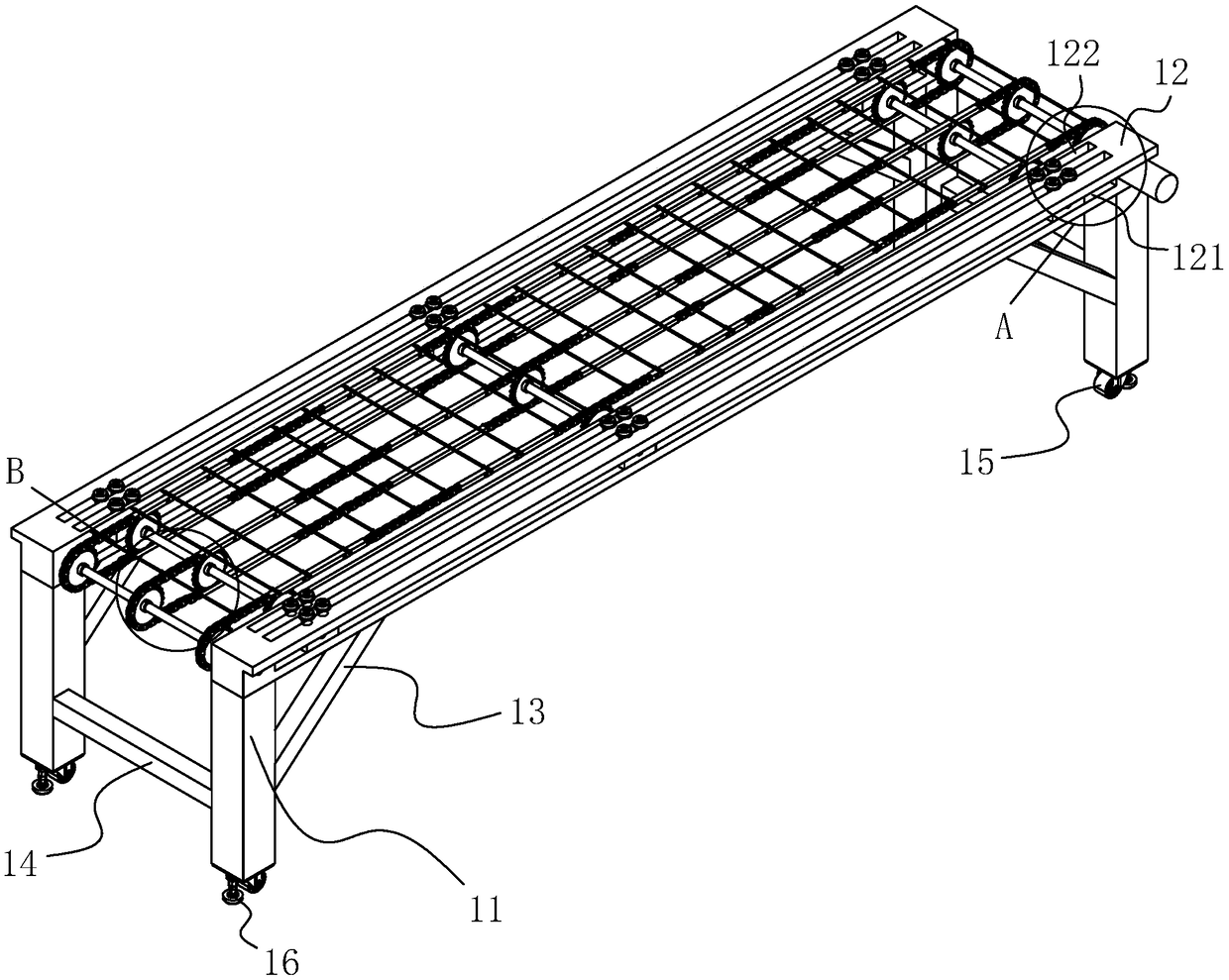

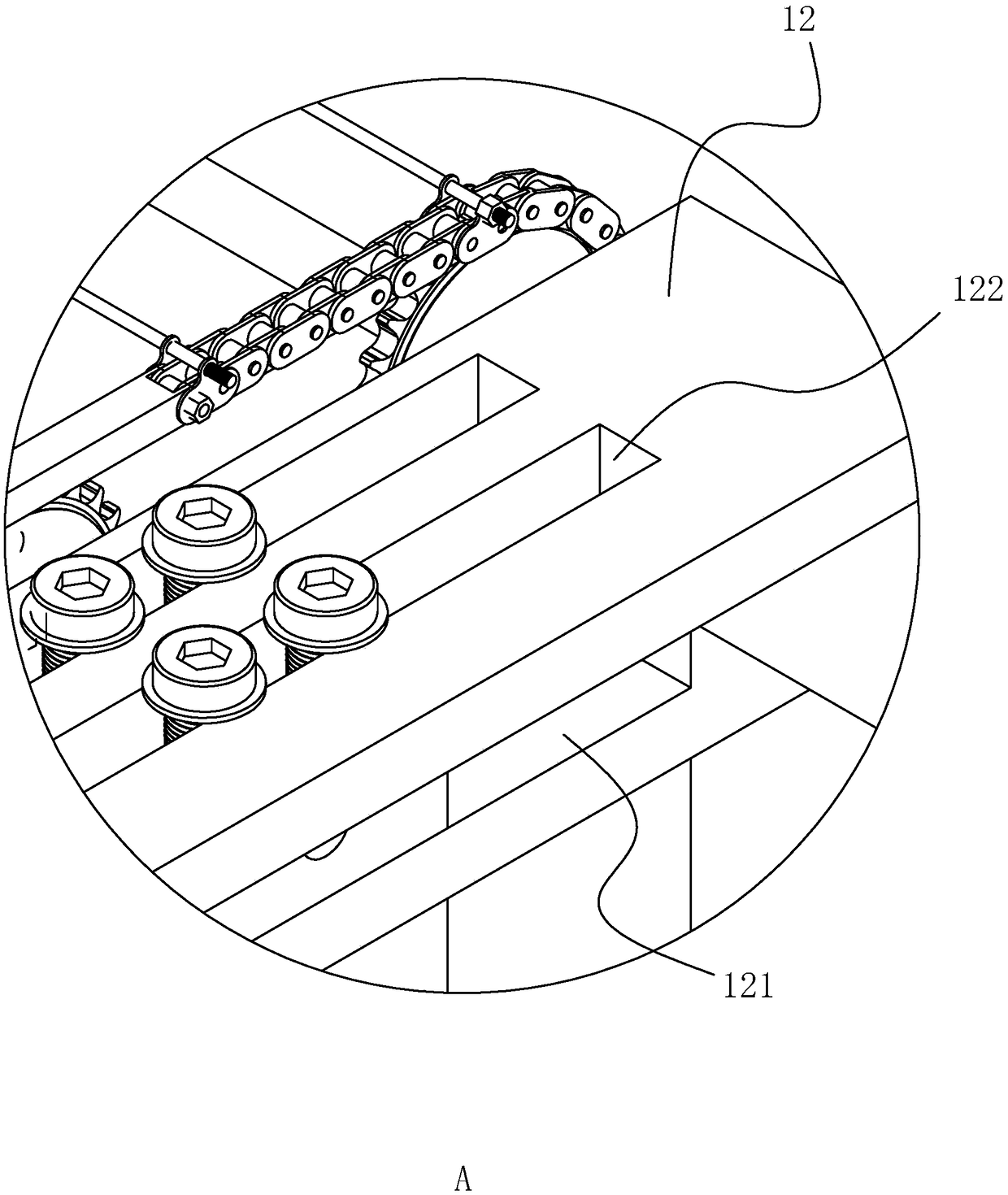

[0049] A die casting conveying device, such as figure 1 As shown, it includes a frame 1 arranged on the ground to play a main supporting role, two first rotating shafts 2 that are respectively arranged at both ends of the frame 1 and are connected to both sides of the frame 1 in rotation, and a plurality of shafts are arranged on the two sides of the frame 1. Between the two first rotating shafts 2 and parallel to the first rotating shafts 2, a plurality of second rotating shafts 3 are evenly distributed on the first rotating shafts 2 and the second rotating shafts 3 and arranged on each of the first rotating shafts 2 and the second rotating shafts. The positions on the two rotating shafts 3 and the sprockets 5 corresponding to the number, a plurality of chains 4 arranged along the length direction of the frame 1 and respectively meshed with the sprockets 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com