Integrated food steaming oven

A technology for steaming and roasting food, which is applied to steam cooking utensils, roasters/barbecue grids, heating devices, etc. It can solve the problems of water deterioration and other problems, achieve good food quality, better taste, and avoid temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

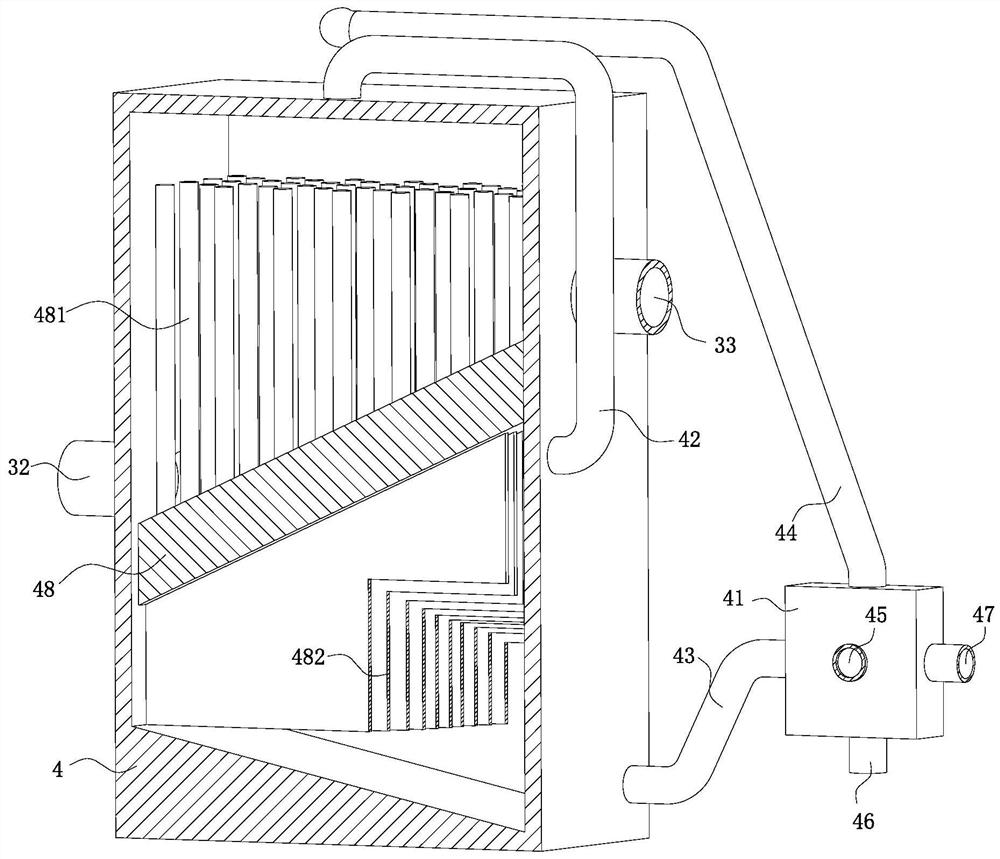

[0031] As an embodiment of the present invention, the steam generator 4 is rectangular, and is installed vertically in the second cavity 18; the steam generator 4 is provided with an accommodation chamber; a heating plate 48 is installed in the accommodation chamber The heating plate 48 is installed obliquely, and the position on the left side is lower; the heating plate 48 is fixedly equipped with heat conducting rods 481; the heat conducting rods 481 are evenly distributed; the upper ends of the heat conducting rods 481 are located at the same height , and does not contact the inner wall of the chamber of the steam generator 4; the lower surface of the heating plate 48 is fixed with a heat conducting plate 482; the heat conducting plate 482 is evenly distributed; the lower end of the heat conducting plate 482 is located at the same height, and does not touch The inner wall of the housing cavity; the heat conducting plate 482 is parallel to the side where the steam generator 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com