High temperature rod member unloading conveyer

A conveying device, high temperature technology, applied in metal processing and other directions, can solve the problems of lack of, inability to meet the working range of robots, transformation, etc., to achieve the effect of convenient maintenance, improved automation production level, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

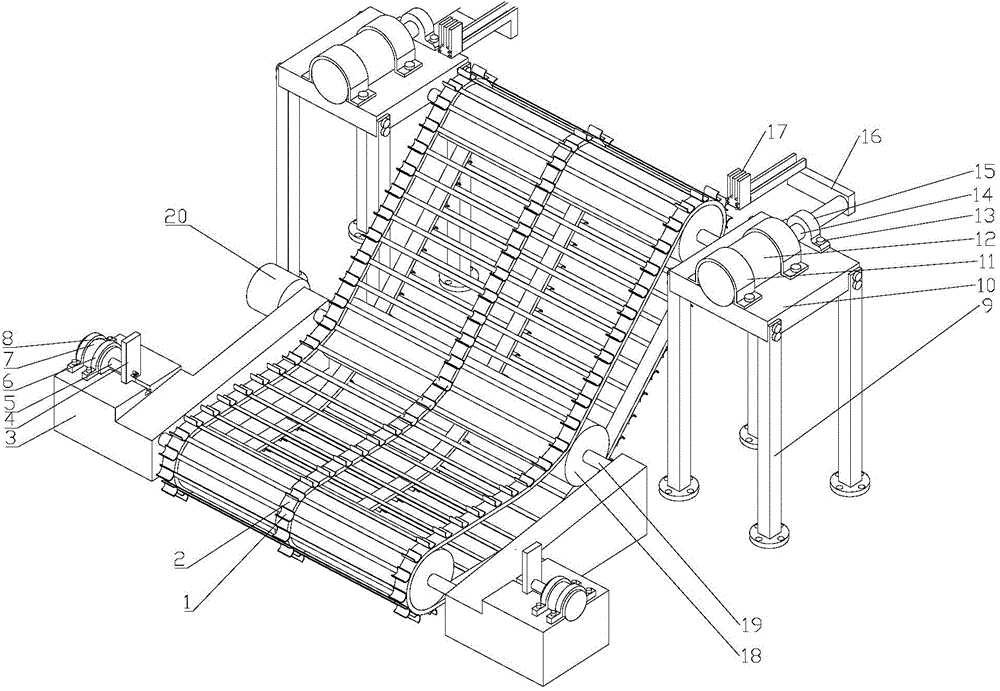

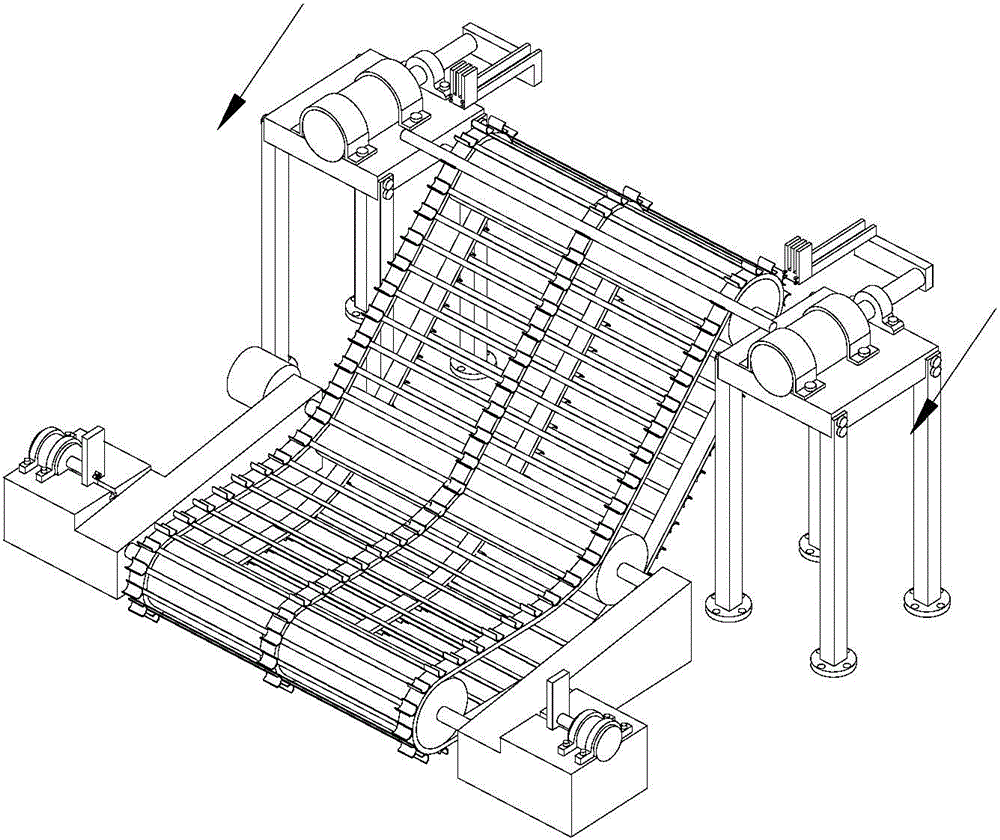

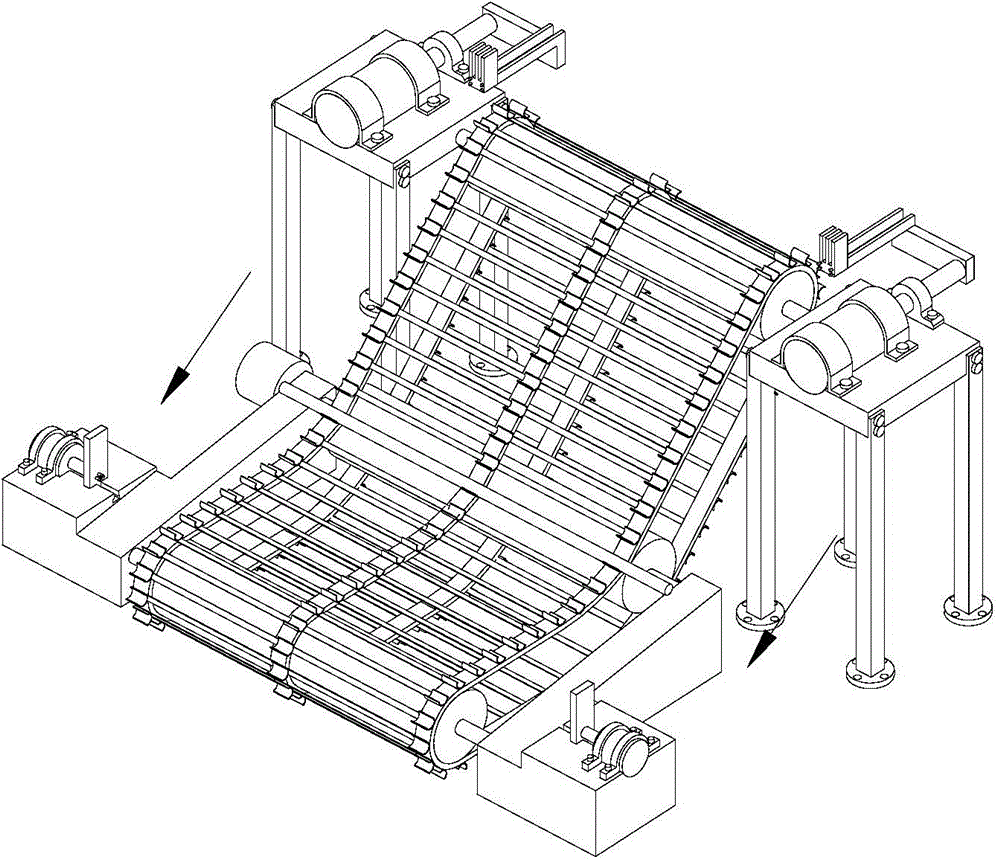

[0023] In this example, if figure 1 As shown, a high-temperature rod unloading transmission device includes: a high-temperature rod unloading mechanism responsible for taking out the heated high-temperature rod from the conveying line, responsible for conveying the rod taken out from the conveying line to a designated position The transmission mechanism for the industrial robot to transport to the next manipulator and the positioning mechanism responsible for axially positioning the high-temperature rod moving to the designated position, so that the industrial robot can accurately grab the rod and process it in the next process;

[0024] The high-temperature bar blanking mechanism includes two blanking mechanisms, and the two blanking mechanisms are respectively arranged on both sides of the transmission mechanism. Each blanking mechanism includes a base platform, a fixed frame 11, a hydraulic cylinder for blanking 12, and a positioning frame 15 , High temperature connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com