Patents

Literature

60 results about "Position-sensing hydraulic cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The position-sensing feature in the position-sensing cylinder provides instantaneous analog or digital electronic position feedback information from the cylinder that indicates the amount of rod extension throughout the range of stroke.

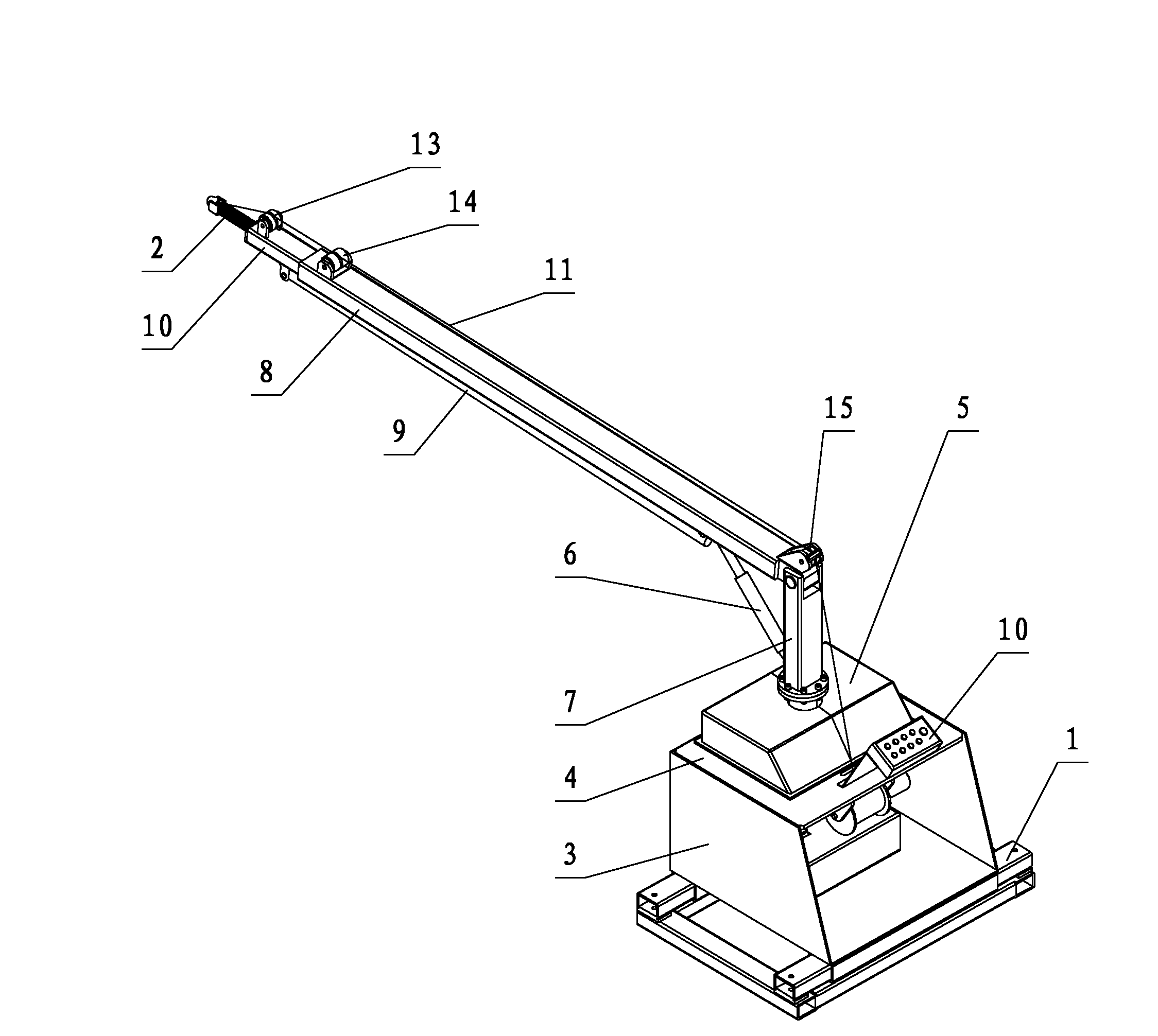

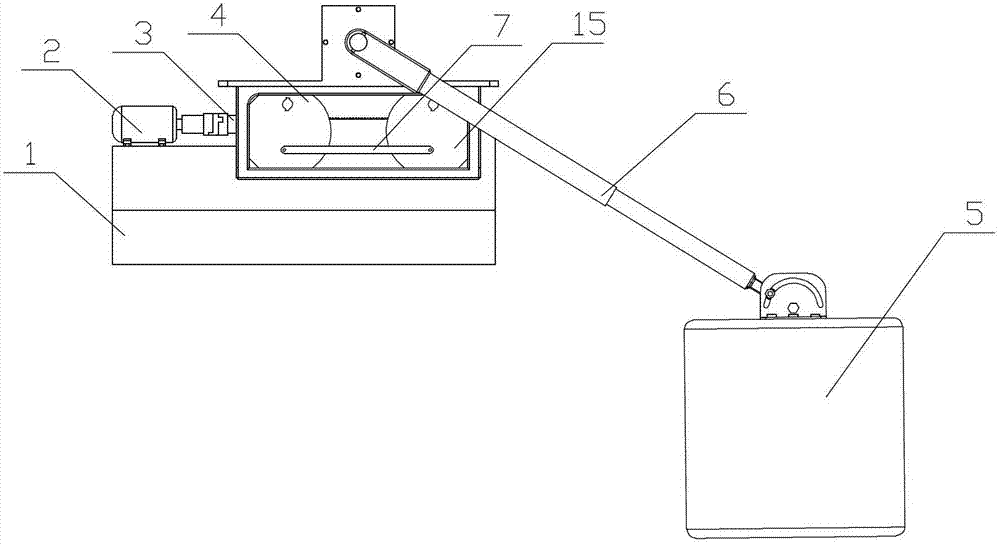

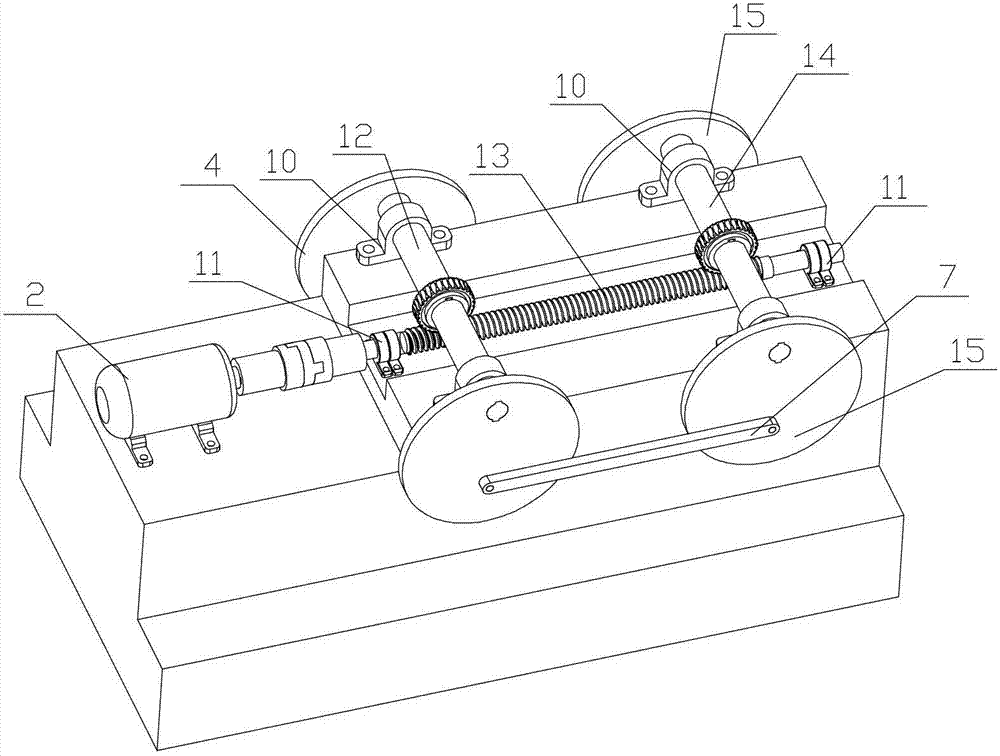

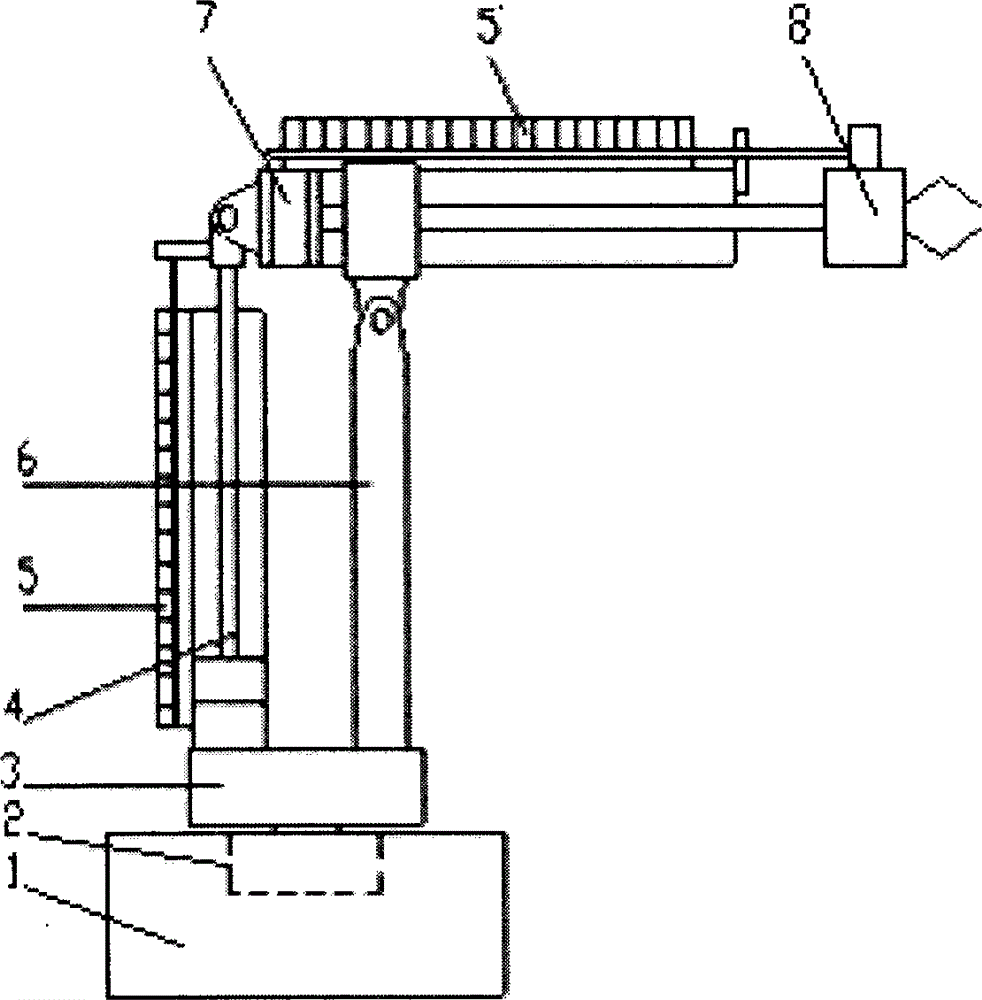

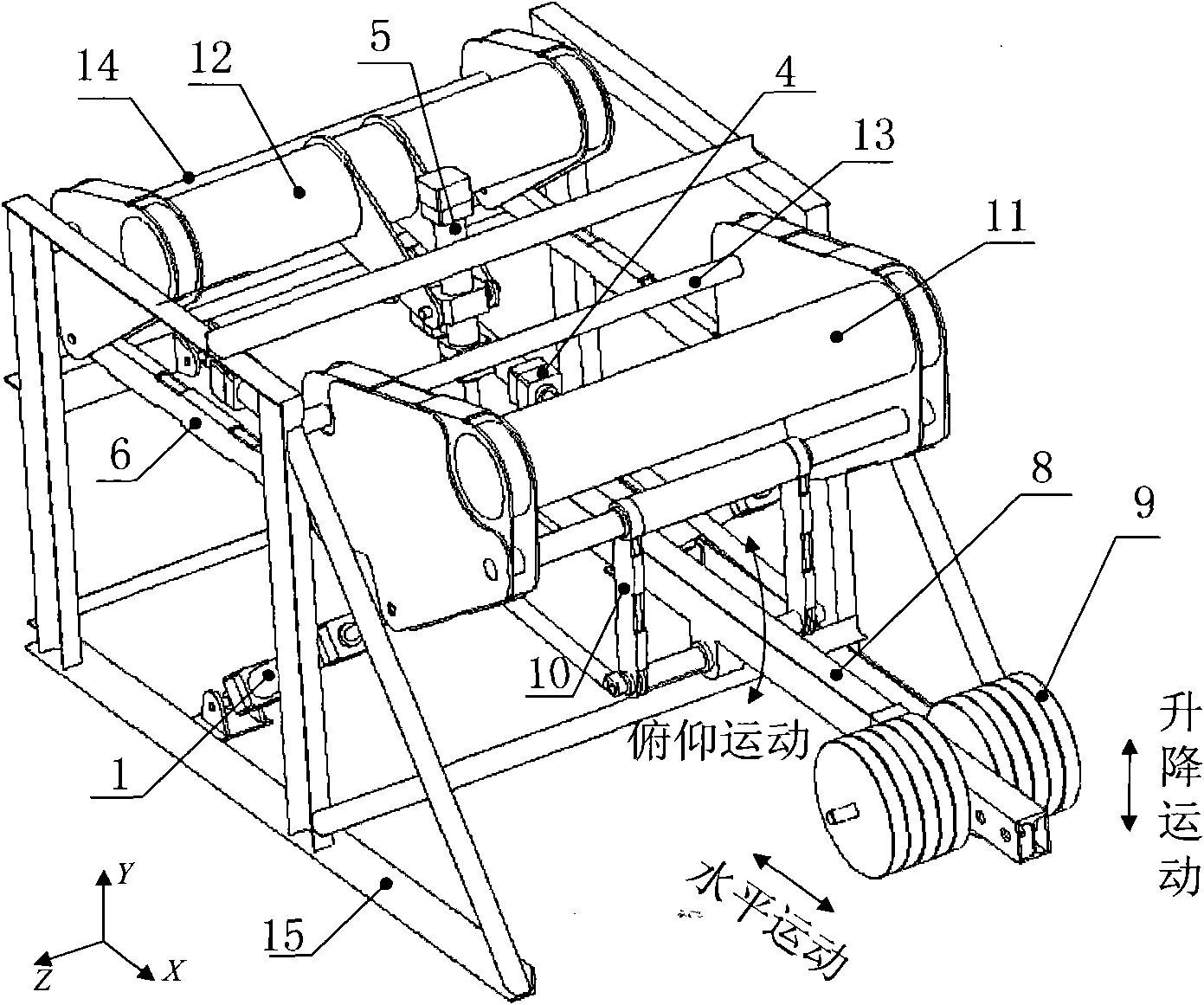

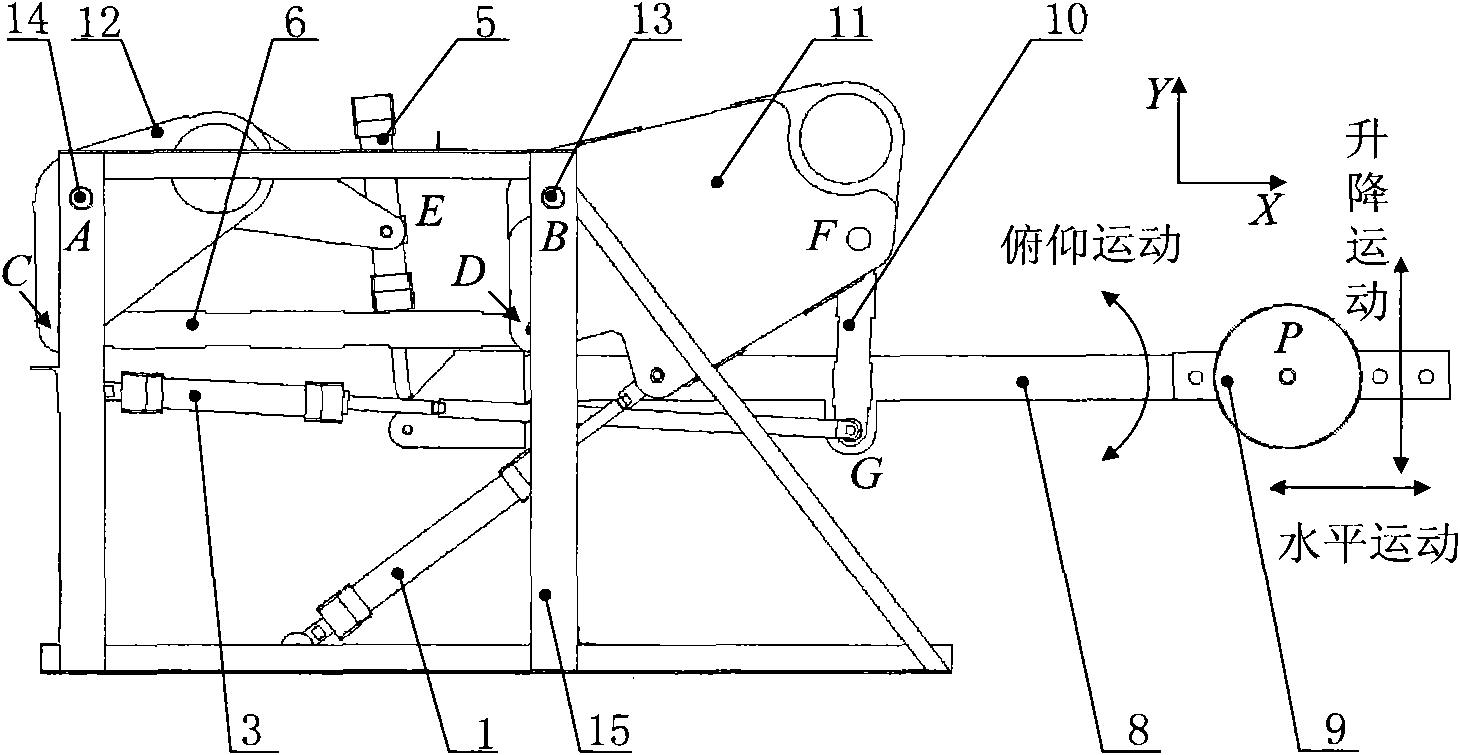

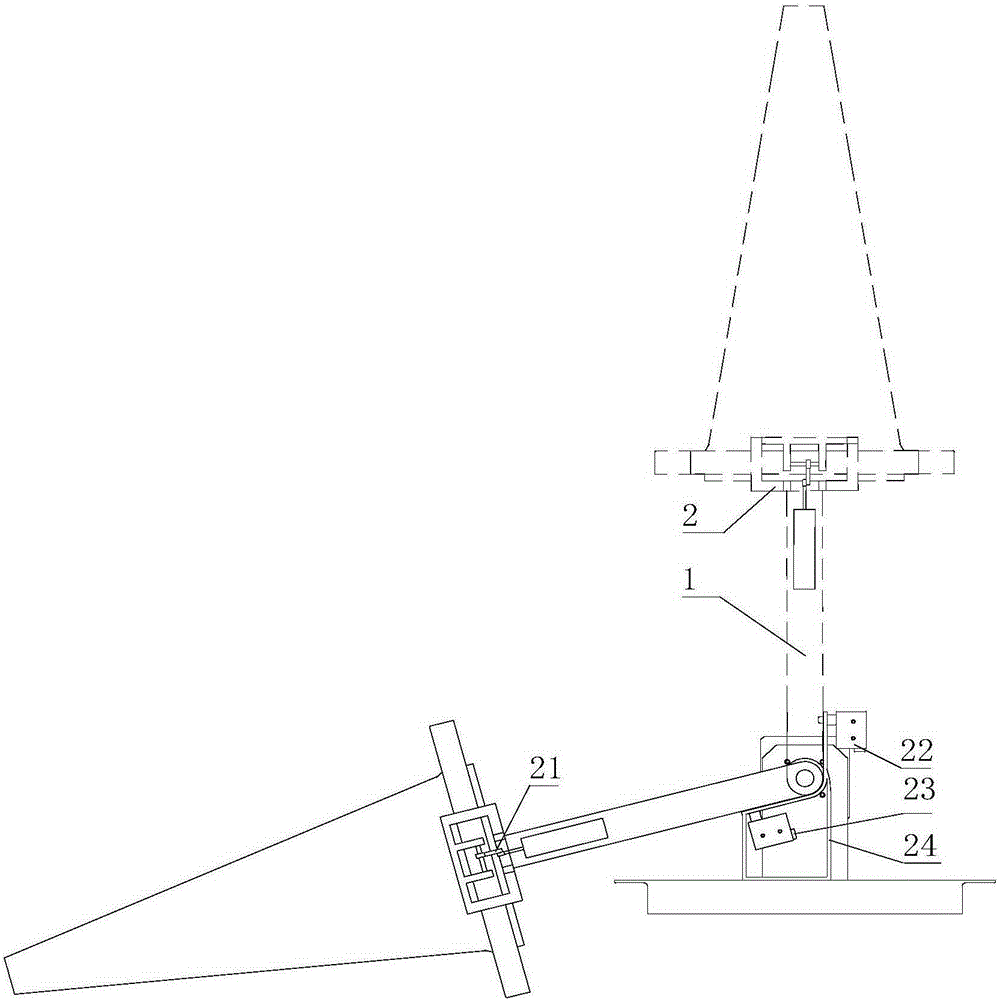

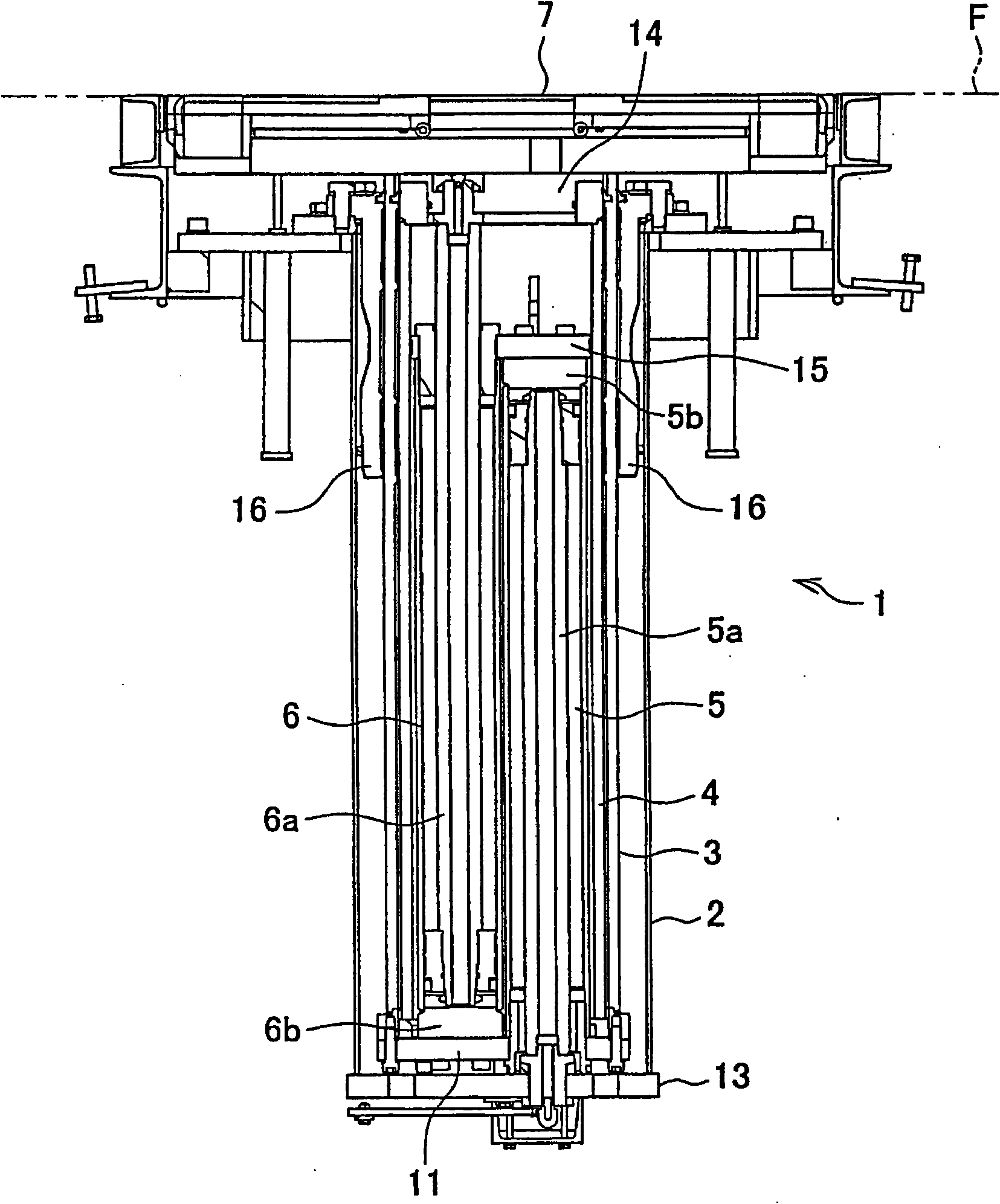

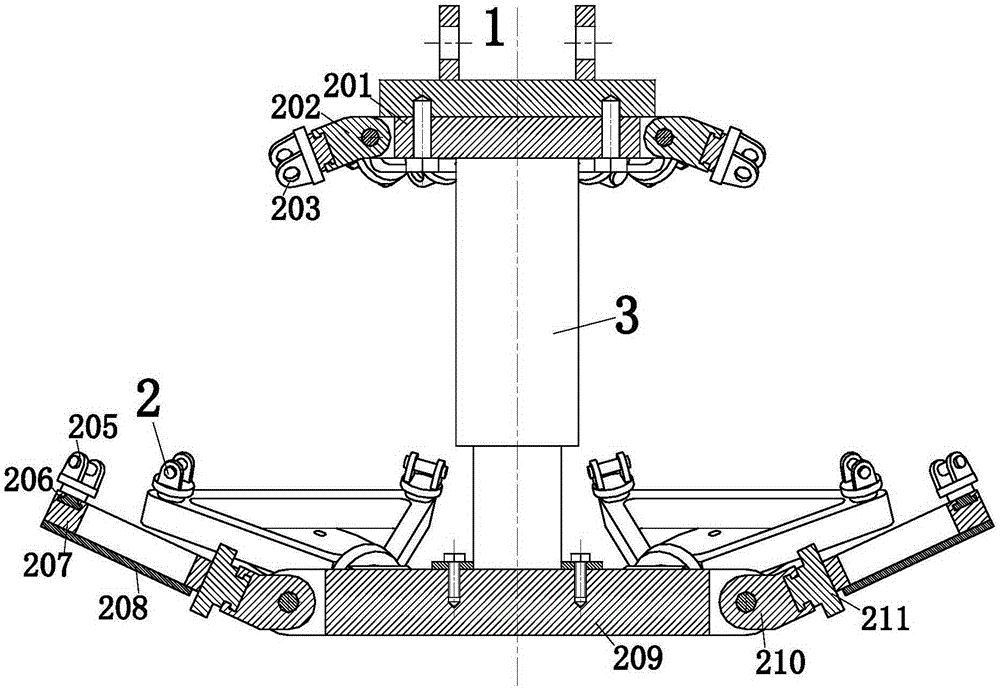

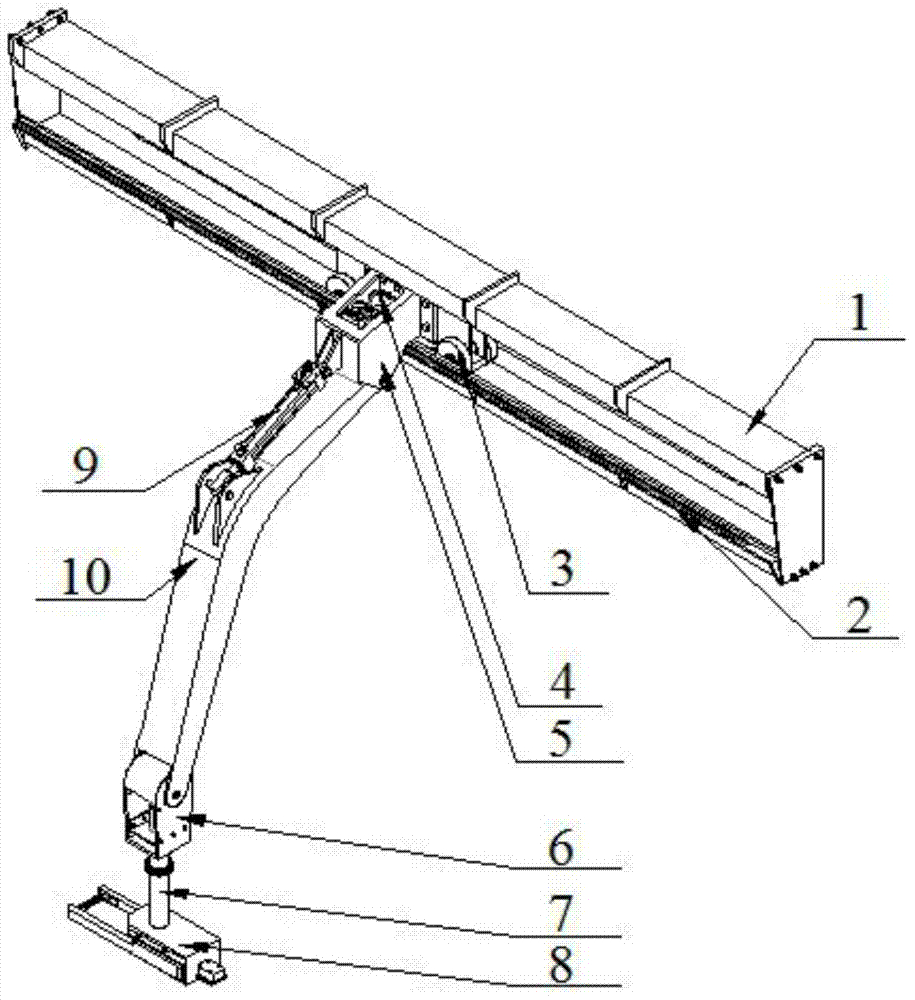

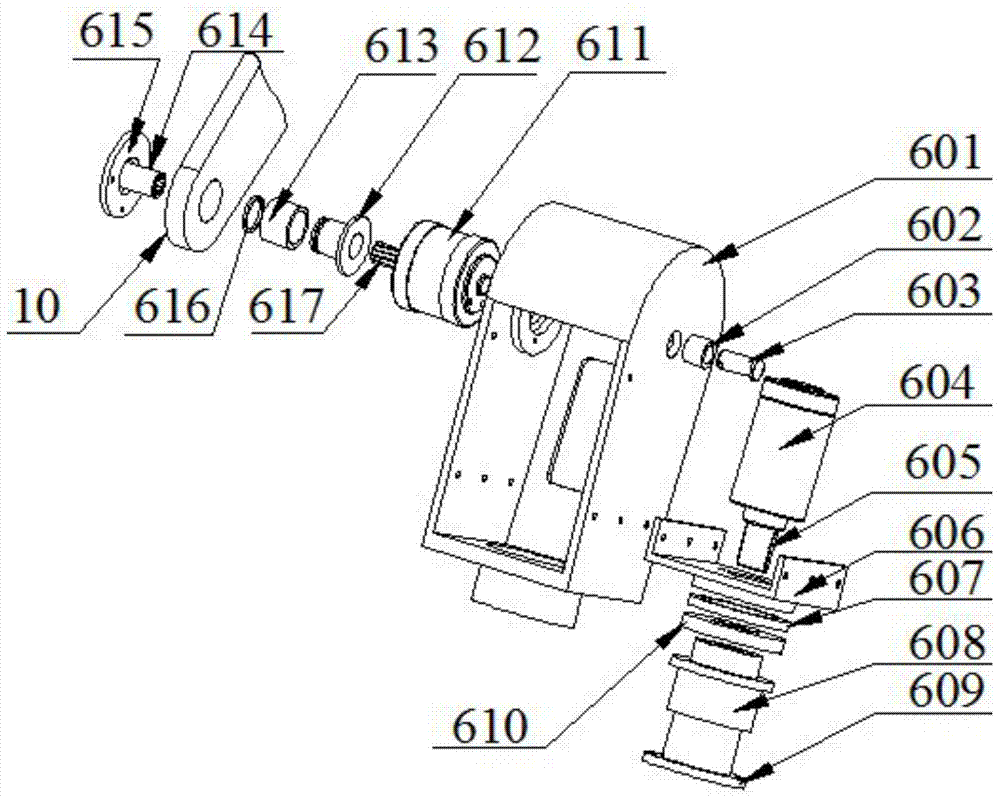

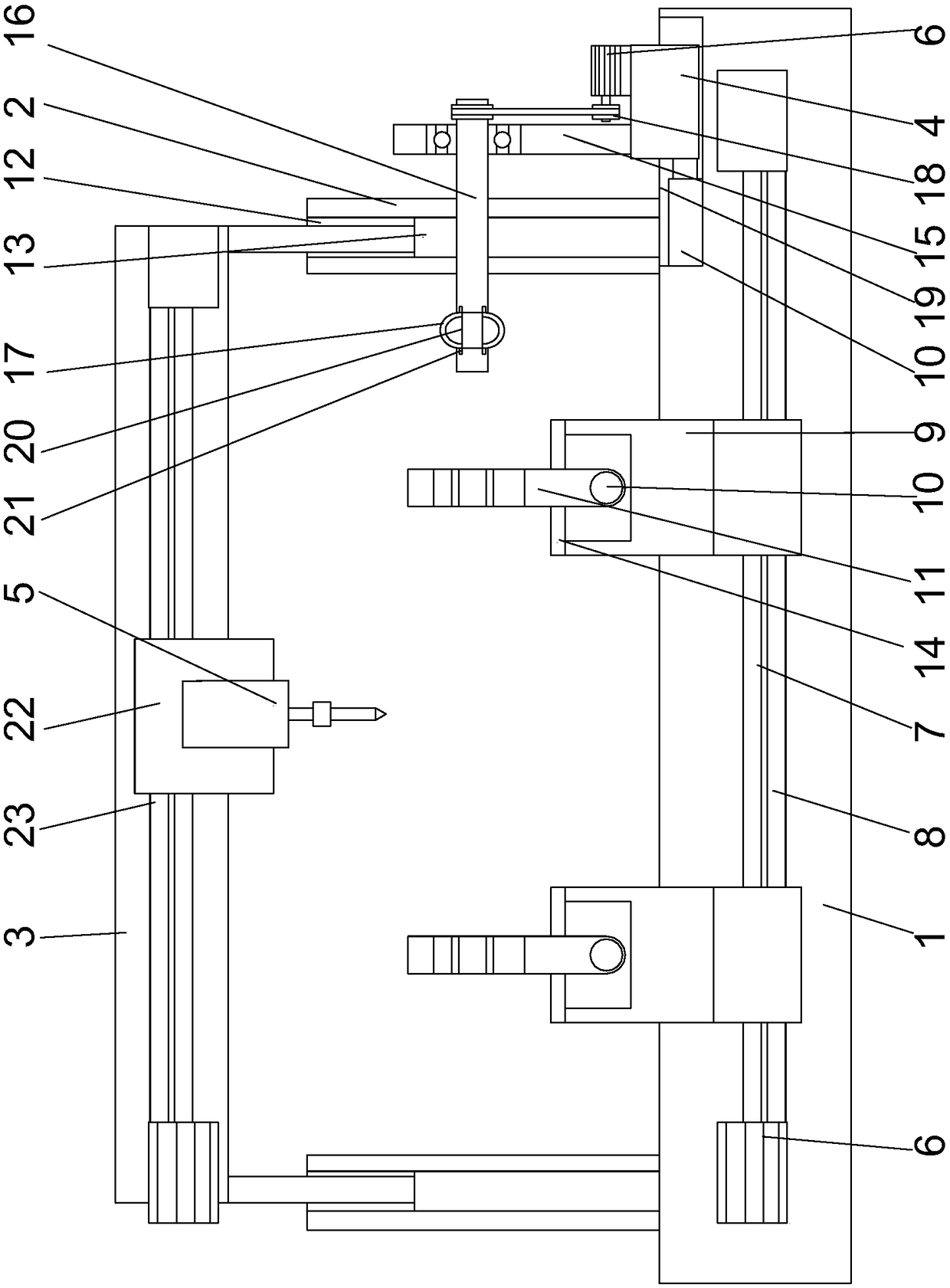

Draft gear for recovering underwater robot

InactiveCN103183111AOvercoming the impact of recyclingReduce difficultyVessel salvagingUnderwater equipmentThree degrees of freedomDegrees of freedom

The invention belongs to the field of recovery of underwater robots, and particularly relates to a draft gear for recovering the underwater robot. The draft gear comprises a hydraulic winch, a box body, a rotary straight girder, a rotating mechanism, a pitching hydraulic cylinder, a stretching hydraulic cylinder and a draft arm with three degrees of freedom, namely a rotating degree of freedom, a pitching degree of freedom and a stretching degree of freedom, wherein the box body is disposed on a mother ship, the hydraulic winch is arranged in the box body, and a traction rope connected with the underwater robot is connected with the hydraulic winch through the draft arm; one end of the rotary straight girder is connected with the rotating mechanism disposed on the box body, the other end of the rotary straight girder is hinged with the draft arm, the stretching hydraulic cylinder is arranged on the draft arm and drives the draft arm to stretch, the pitching hydraulic cylinder is arranged on the rotary straight girder, and an output end of the pitching hydraulic cylinder is hinged with the draft arm; and a hydraulic station is arranged in the box body and is used for supplying power to the hydraulic winch, the rotating mechanism, the pitching hydraulic cylinder and the stretching hydraulic cylinder. The draft gear disclosed by the invention has the advantages of simple and reliable structure, complete functions, easiness to operate and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

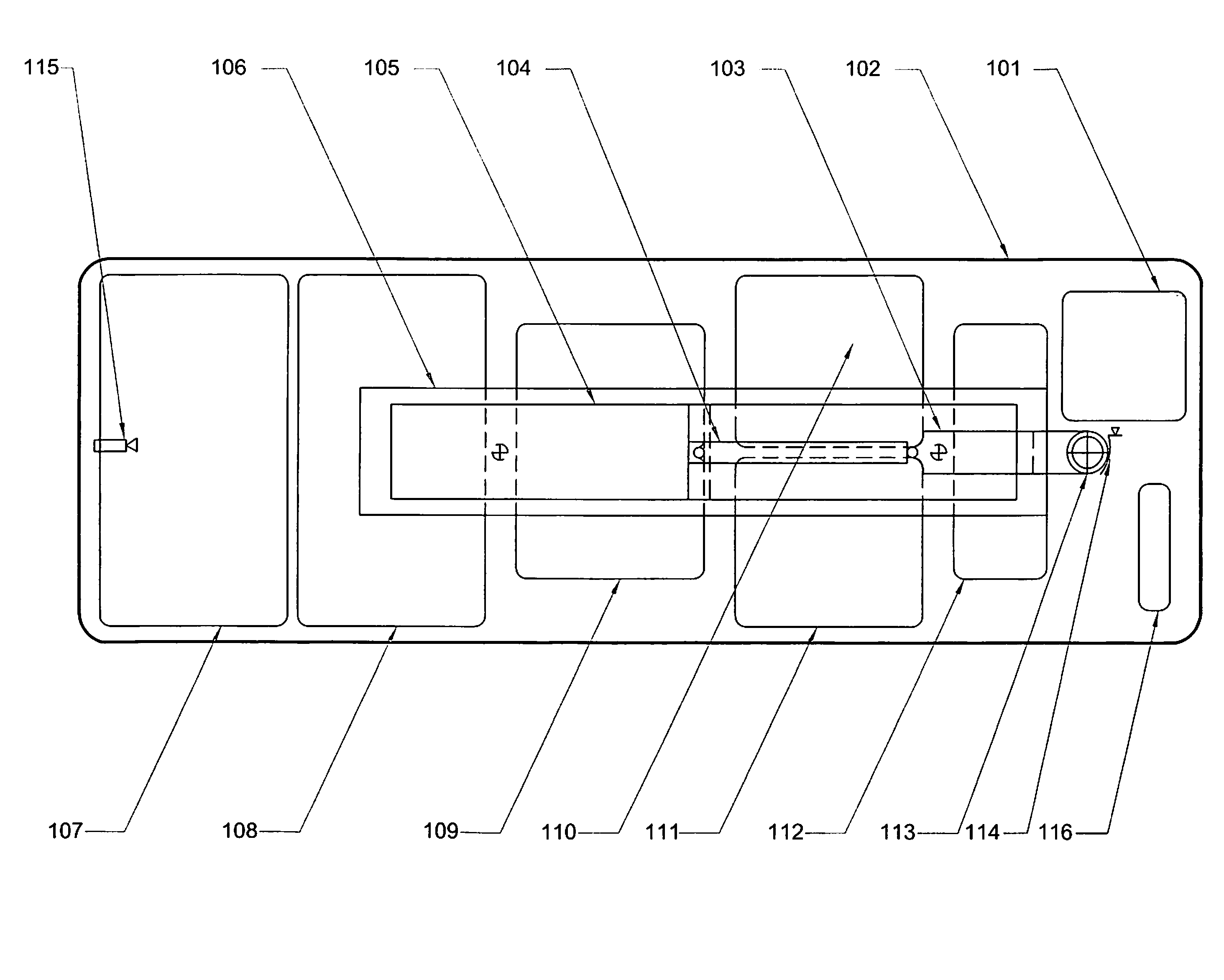

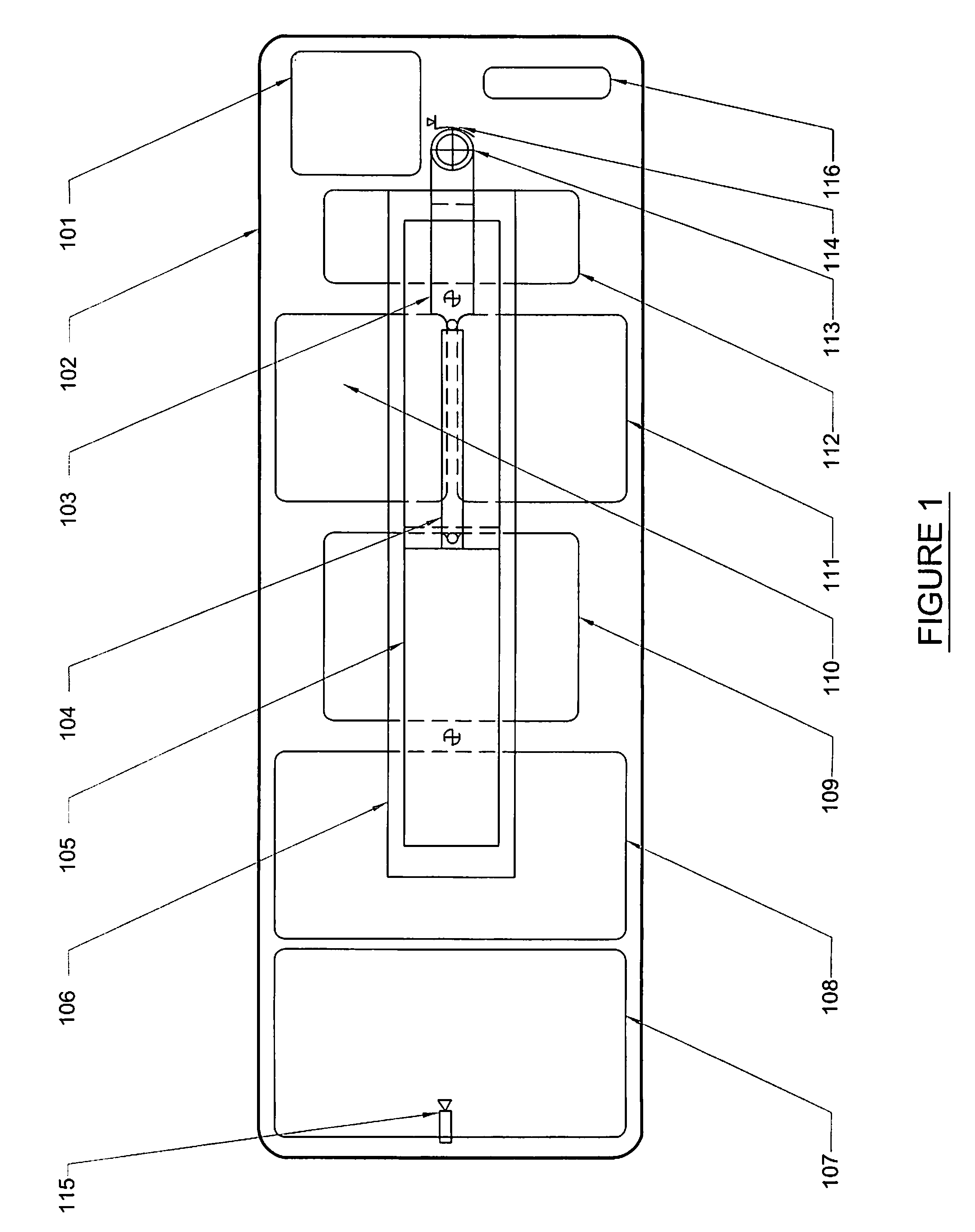

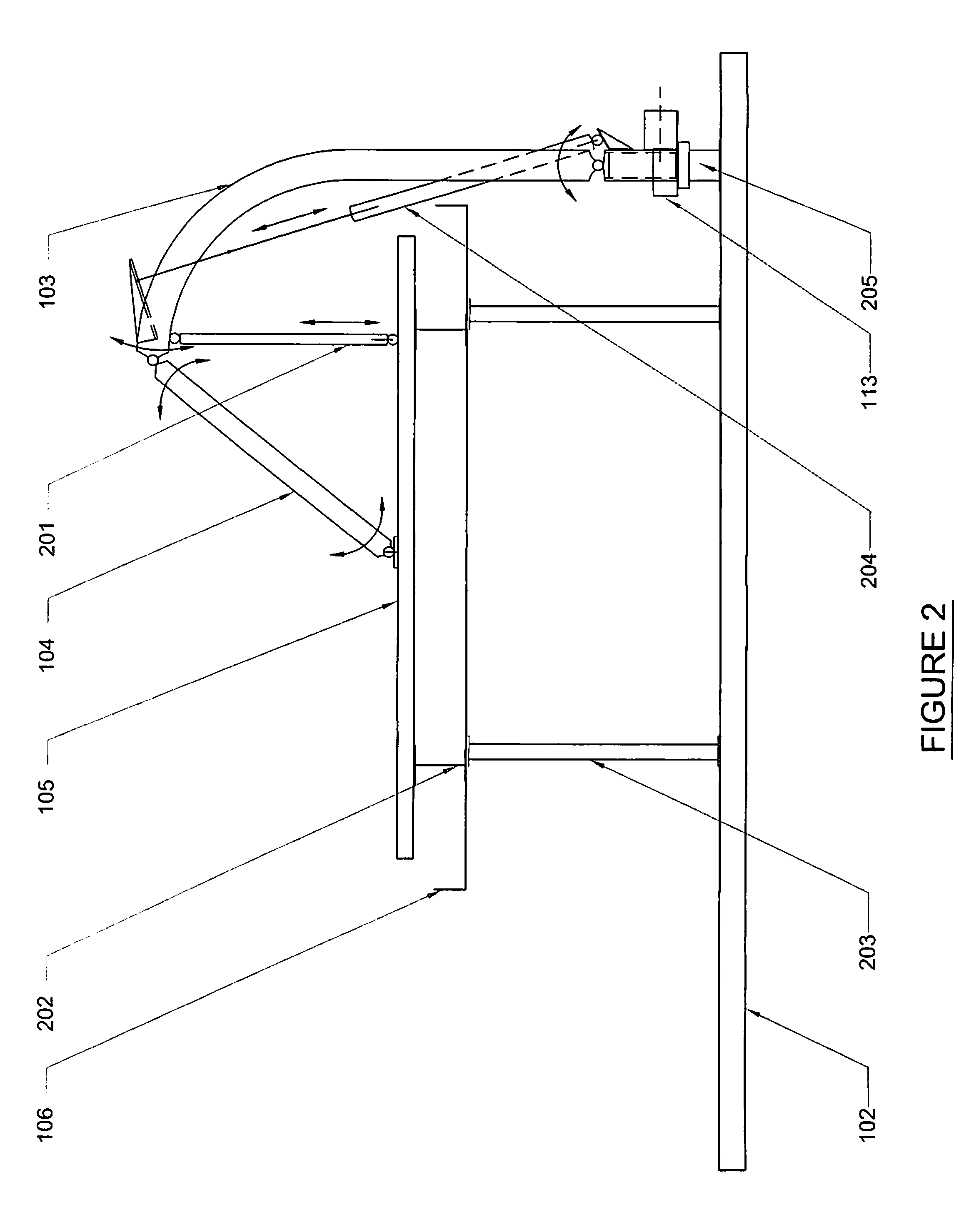

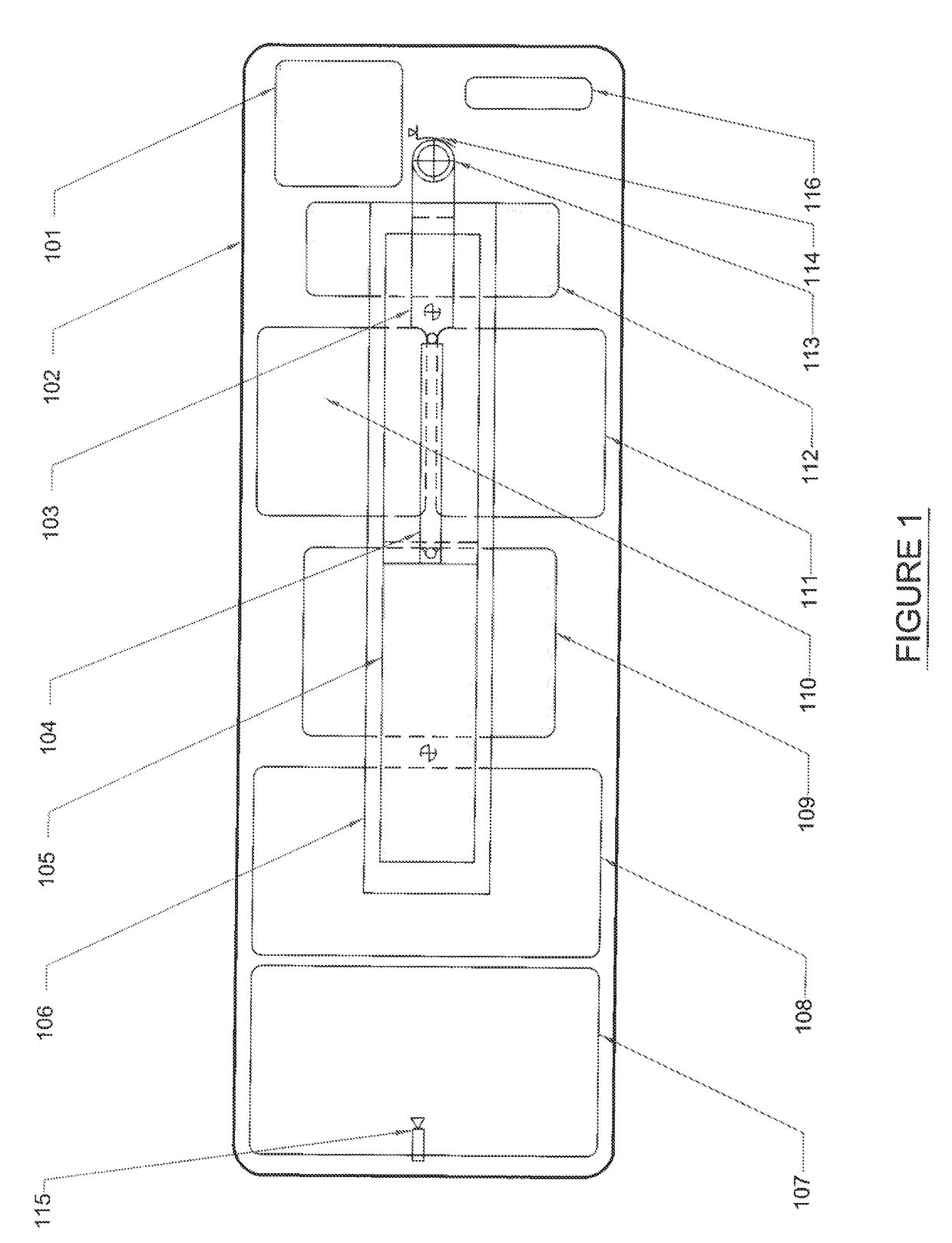

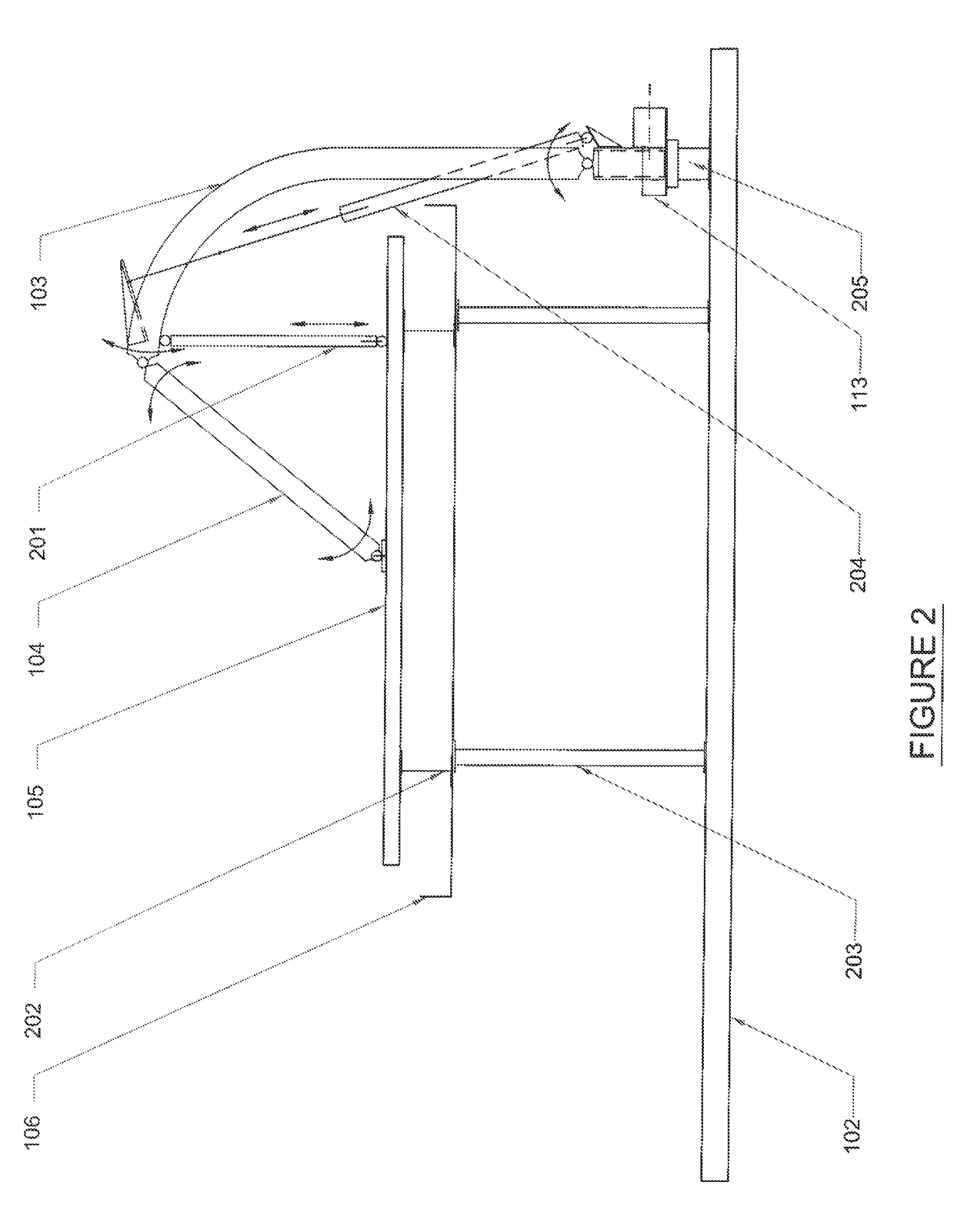

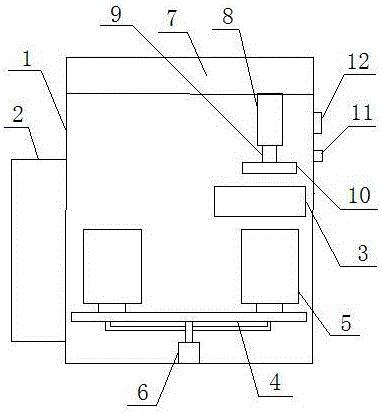

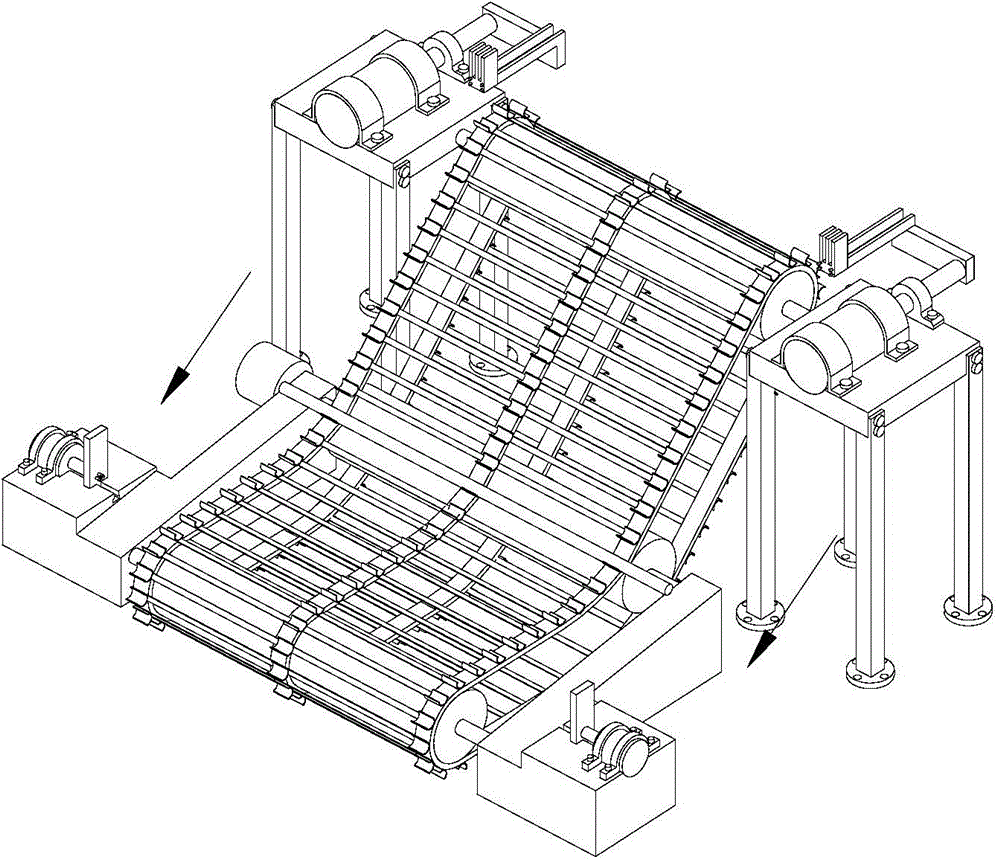

Automatic Photovoltaic Solar Panel Washer

InactiveUS20140150818A1Fast and safe and effective cleaningLarge capacitySolar heating energyPhotovoltaicsRest positionEngineering

An Automatic (Auto) Photovoltaic (PV) Solar Panel Washer comprising a main carrier joined by a connecting member to the main mast. A main hydraulic cylinder system comprising one or more hydraulic cylinders and connector arrangement on the main mast raises the main mast up or pushes it down, activating the connecting member, thereby raising or lowering the main carrier. The positioning hydraulic cylinder determines the angle of the main carrier by pushing one end down or bringing it up. A rotating device assembly rotates the main mast and main carrier clockwise or counterclockwise from rest position over its stationary post. The main carrier comprises a rigid frame with attachments including a cleaning assembly consisting of air cylinders with cleaning wiper systems, tracks for the air cylinder shafts, wash material pipes with spray devices attached, rinse material pipes with spray devices attached, and compressed air drying pipes with air spray devices.

Owner:CHOW REUBEN

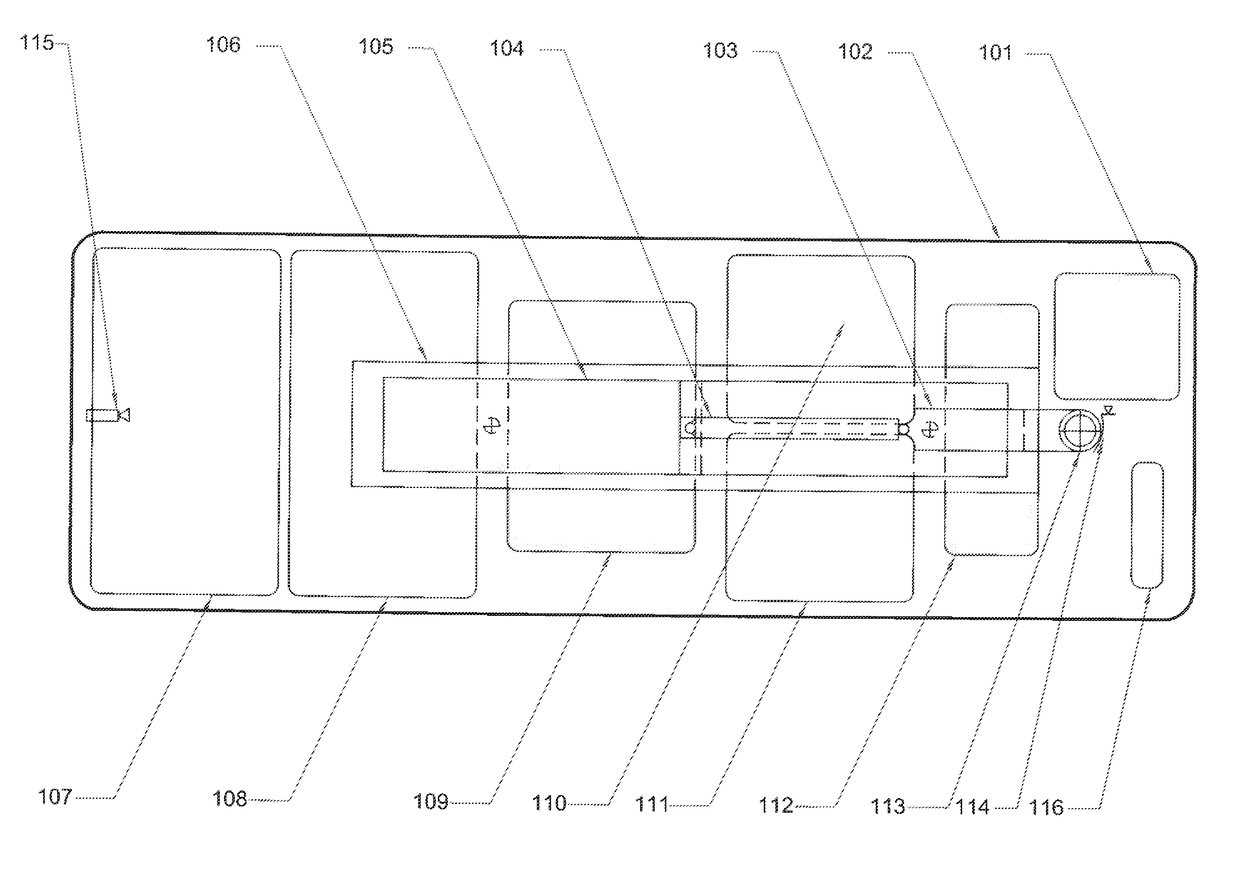

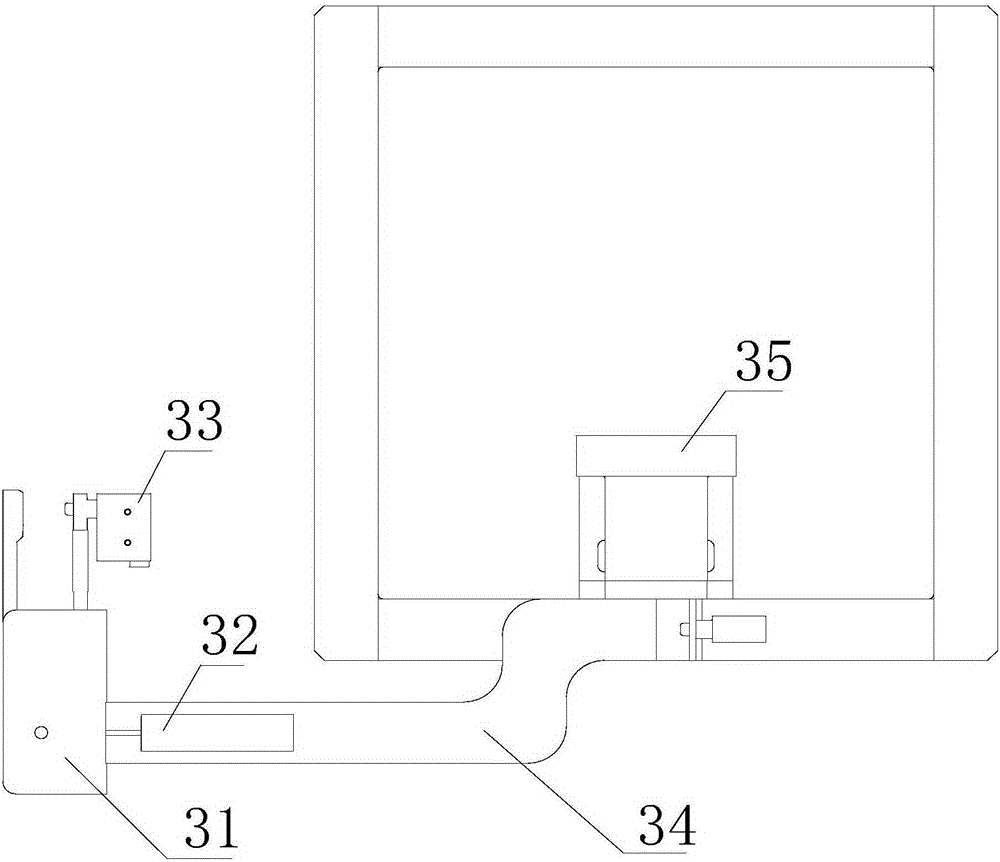

Multi-angle drilling device for pipe

ActiveCN105750937ARealize multi-angle drillingEasy to controlFeeding apparatusLarge fixed membersEngineeringPosition-sensing hydraulic cylinder

The invention discloses a multi-angle drilling device for a pipe.The multi-angle drilling device comprises a base and a transverse beam arranged on the base.A drilling device body is arranged on the transverse beam, a pipe rotating device is arranged on the base, a motor is arranged on the base, a lead screw is arranged on a rotating shaft of the motor, a fixing shaft matched with the lead screw is arranged below the lead screw, a supporting platform is arranged on the lead screw and arranged on the lead screw and the fixing shaft in a sleeving mode, two opposite hydraulic cylinders are arranged on the supporting platform, positioning buckles are arranged on stretchable rods of the two hydraulic cylinders, and the lower ends of the positioning buckles are fixedly connected to the hydraulic cylinders.According to the multi-angle drilling device, a transverse rod is driven by the motor to rotate, the pipe is rotated, and multi-angle and multidirectional drilling operation can be conveniently carried out on the pipe in the radial direction; as the pipe is moved through the lead screw, the drilling accuracy can be improved in the axial direction of the pipe.

Owner:江苏净傲机电科技有限公司

Automatic Photovoltaic Solar Panel Washer

ActiveUS20170272030A1Fast and safe and effective cleaningLarge capacitySolar heating energyFouling preventionRest positionEngineering

An Automatic (Auto) Photovoltaic (PV) Solar Panel Washer comprising a main carrier joined by a connecting member to the main mast. A main hydraulic cylinder system comprising one or more hydraulic cylinders and connector arrangement on the main mast raises the main mast up or pushes it down, activating the connecting member, thereby raising or lowering the main carrier. The positioning hydraulic cylinder determines the angle of the main carrier by pushing one end down or bringing it up. A rotating device assembly rotates the main mast and main carrier clockwise or counterclockwise from rest position over its stationary post. The main carrier comprises a rigid frame with attachments including a cleaning assembly consisting of air cylinders with cleaning wiper systems, tracks for the air cylinder shafts, wash material pipes with spray devices attached, rinse material pipes with spray devices attached, and compressed air drying pipes with air spray devices.

Owner:CHOW REUBEN

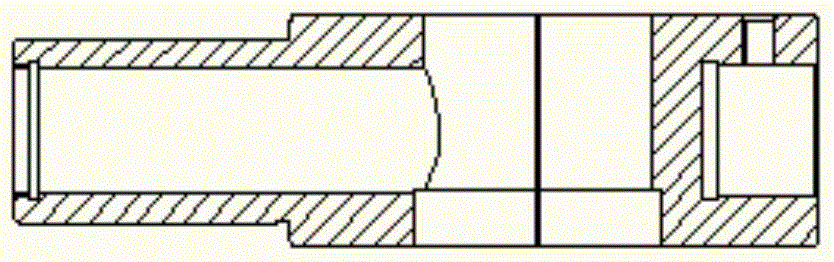

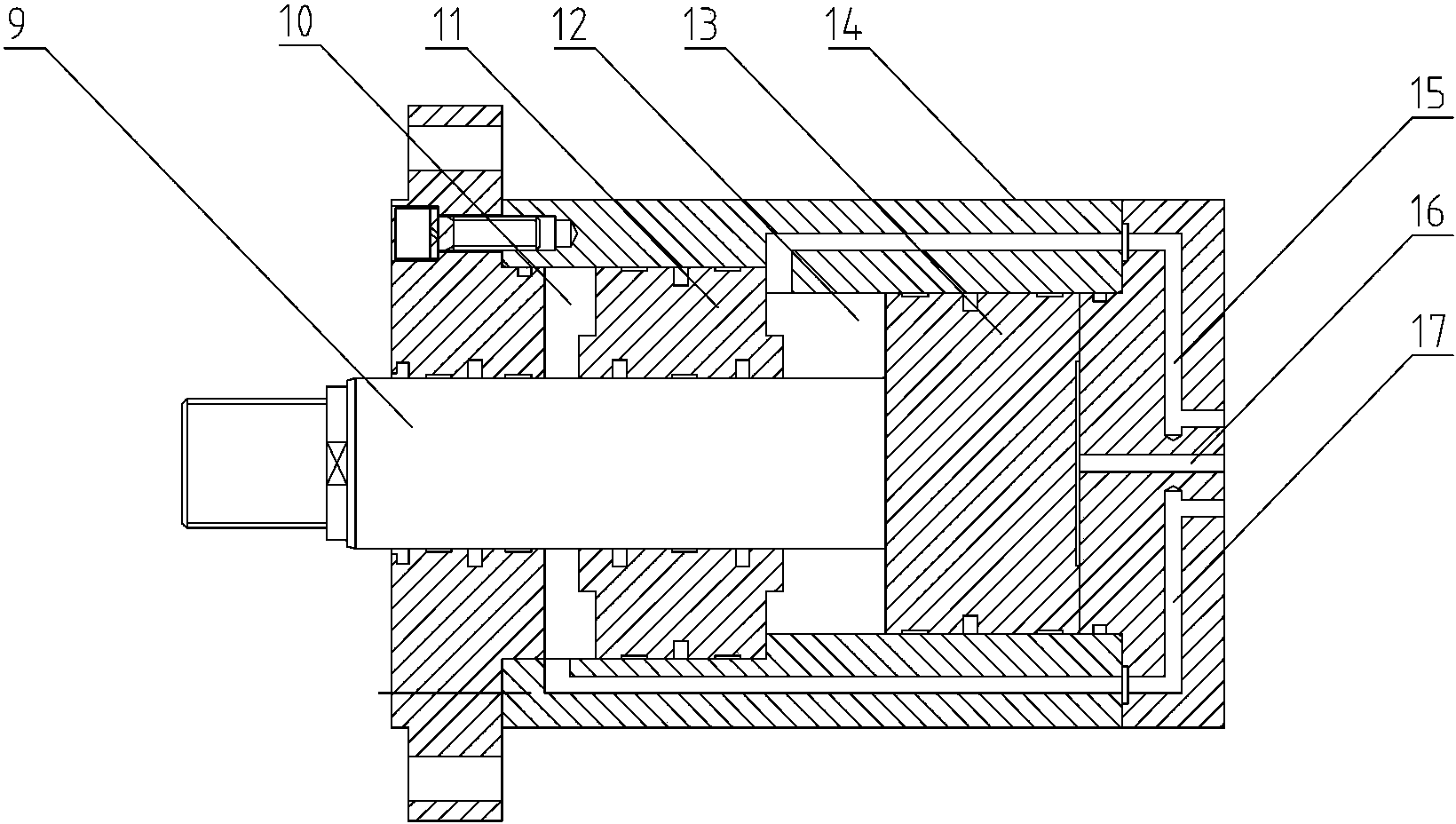

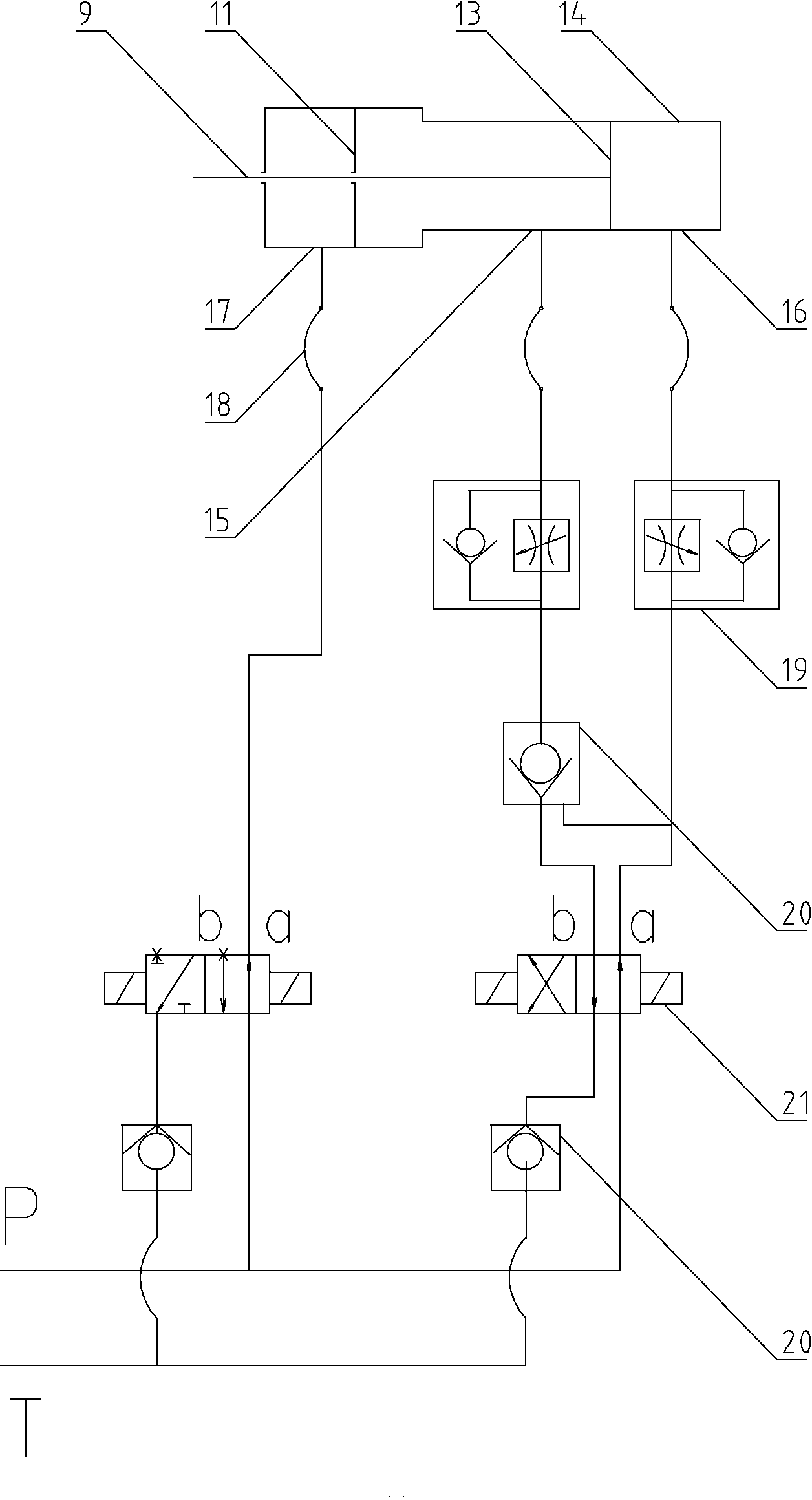

Position sensing hydraulic cylinder

A hydraulic cylinder has an internal shaft that rotates in response to extension or contraction of an output rod. A magnet is affixed to the shaft, the position of which is detected by a sensor internal to the hydraulic cylinder for determining the position of the output rod.

Owner:TEXAS HYDRAULICS

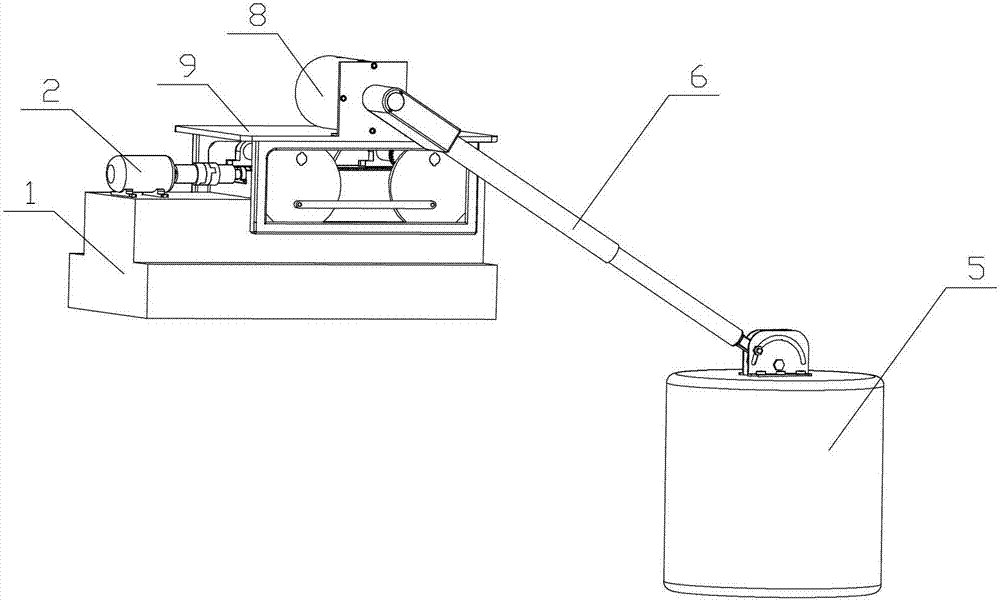

Wave energy generation simulation test device

InactiveCN102735963ASolve problems limited by spaceReduce testing costsElectrical testingElectric machineEngineering

The invention relates to a wave energy generation simulation test device which is characterized by comprising a base (1), a motor (2), a transmission rod (13), at least one eccentric wheel, a bedplate (9), a swinging hydraulic cylinder (8) and a buoy (5), wherein an eccentric wheel shaft is connected to the eccentric wheel and is arranged on the base (1) through a bearing block; a guide rail is matched with outer circumference of the eccentric wheel; a rolling groove is formed on the guide rail; the top of the guide rail is connected with the bedplate (9); the swinging hydraulic cylinder (8) is arranged on the bedplate (9); the free end of a swing rod (6) on the swinging hydraulic cylinder (8) is connected with the buoy (5); the motor (2) is arranged on the base (1); and a rotating shaft of the motor (2) is rotationally connected with the eccentric wheel shaft through the transmission rod (13). The wave energy generation simulation test device is low in cost, can really simulate wave energy generation in a lab environment and is used for performance analysis of a wave energy generation system.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Steel strip pipe cutting machine with grinding and deslagging functions

InactiveCN110142609AReasonable structureOther manufacturing equipments/toolsMaintainance and safety accessoriesEngineeringPosition-sensing hydraulic cylinder

The invention discloses a steel strip pipe cutting machine with the grinding and deslagging functions. The steel strip pipe cutting machine comprises a base, wherein supporting legs, a lifting hydraulic cylinder, universal wheels, a waste residue box, a conveying pump, a fan, a conveying screw, a motor A, a clamping device, a cutting box, a positioning hydraulic cylinder, a rotating motor and a clamping device are arranged on the base, wherein a guide plate, atomizing nozzles, guide supports, guide rollers, a lifting device, a cutting motor, a saw blade, a grinding support, a grinding motor and a grinding wheel are arranged in the cutting box. By arranging the grinding motor and the rotating motor, the material after cutting can be ground, meanwhile, the positioning hydraulic cylinder is arranged, so that the steel with the required length can be accurately cut. The steel strip pipe cutting machine is reasonable in structure and can be used for two purposes.

Owner:TIANJIN JINGTONG PIPE IND

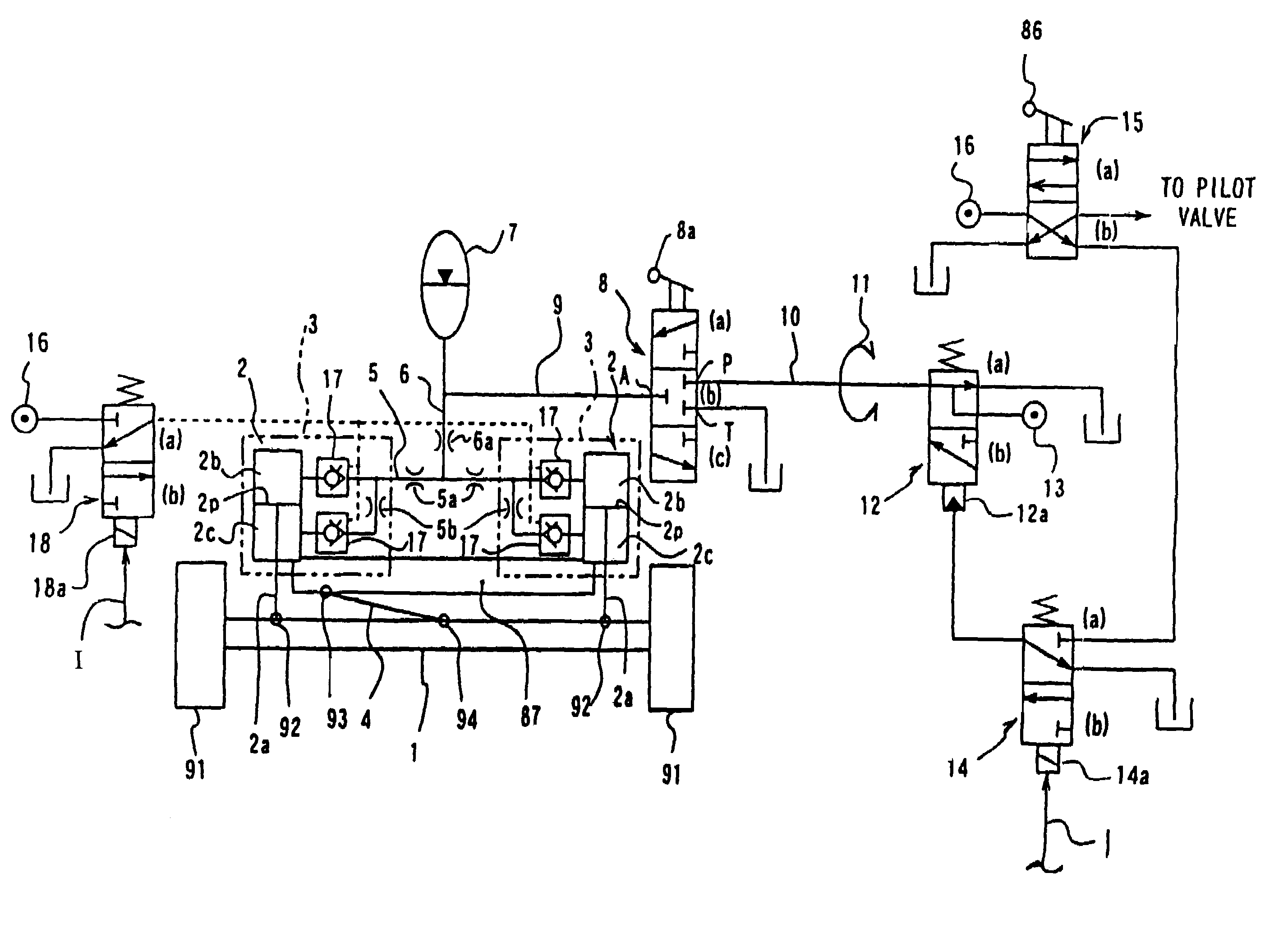

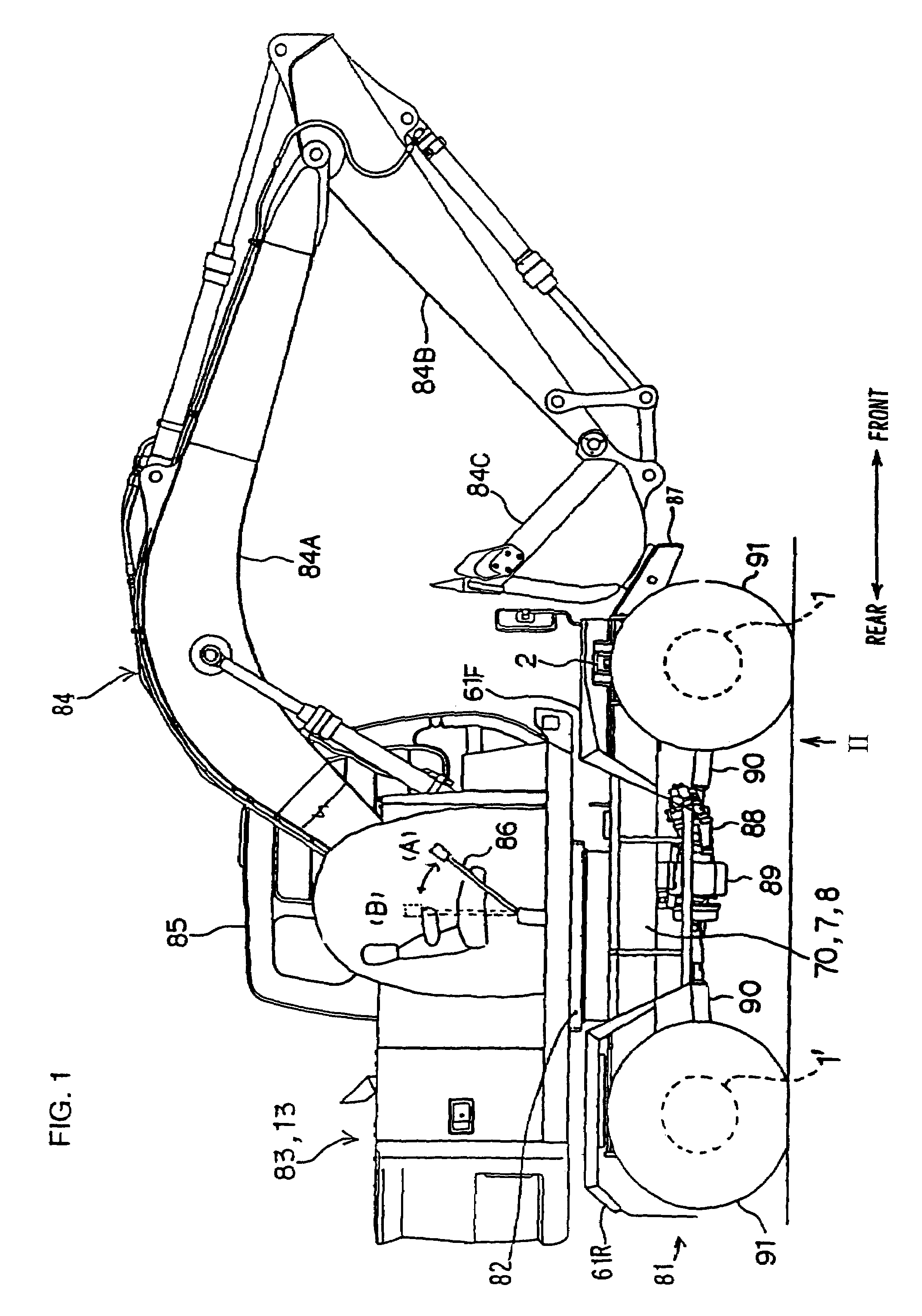

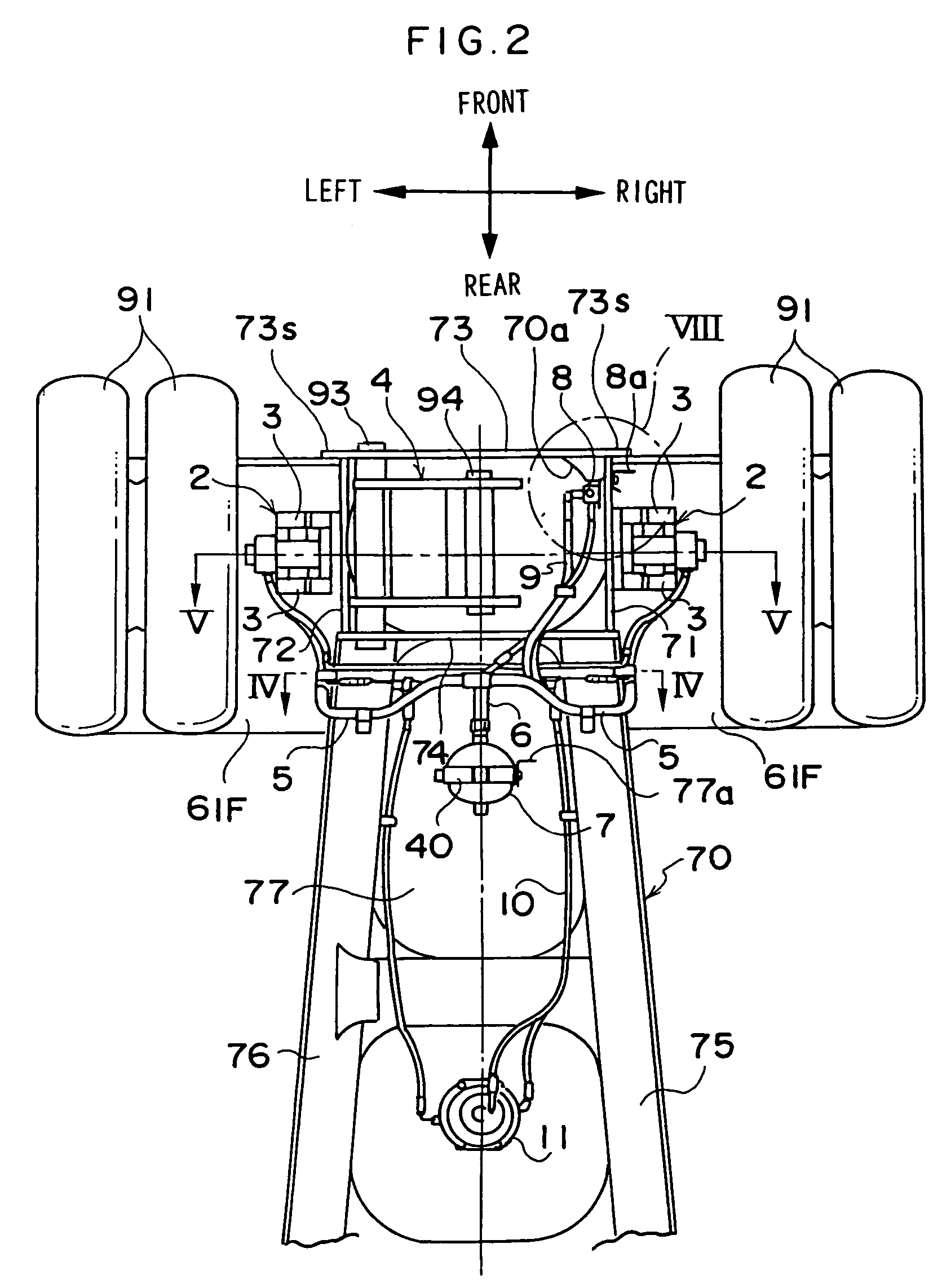

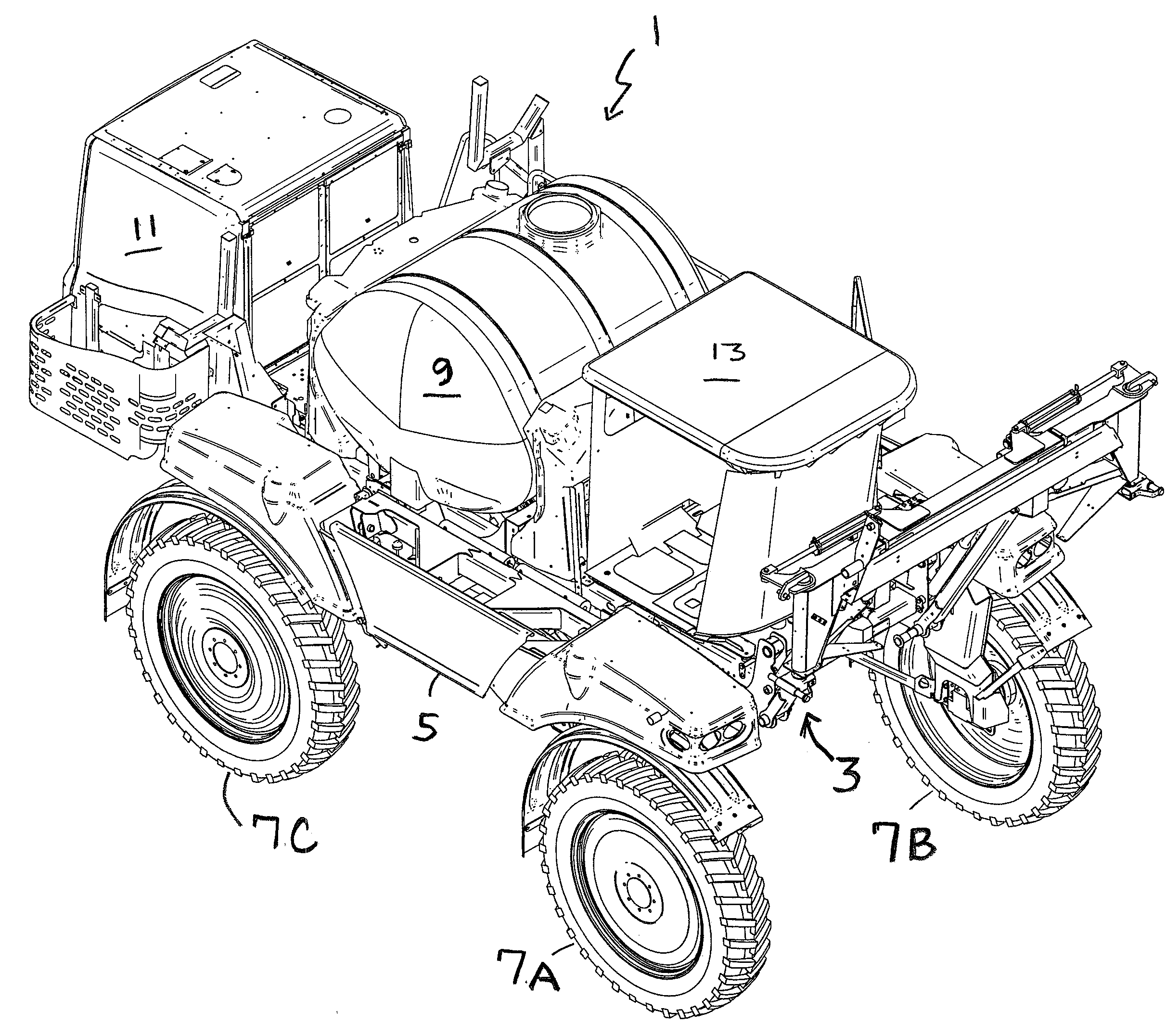

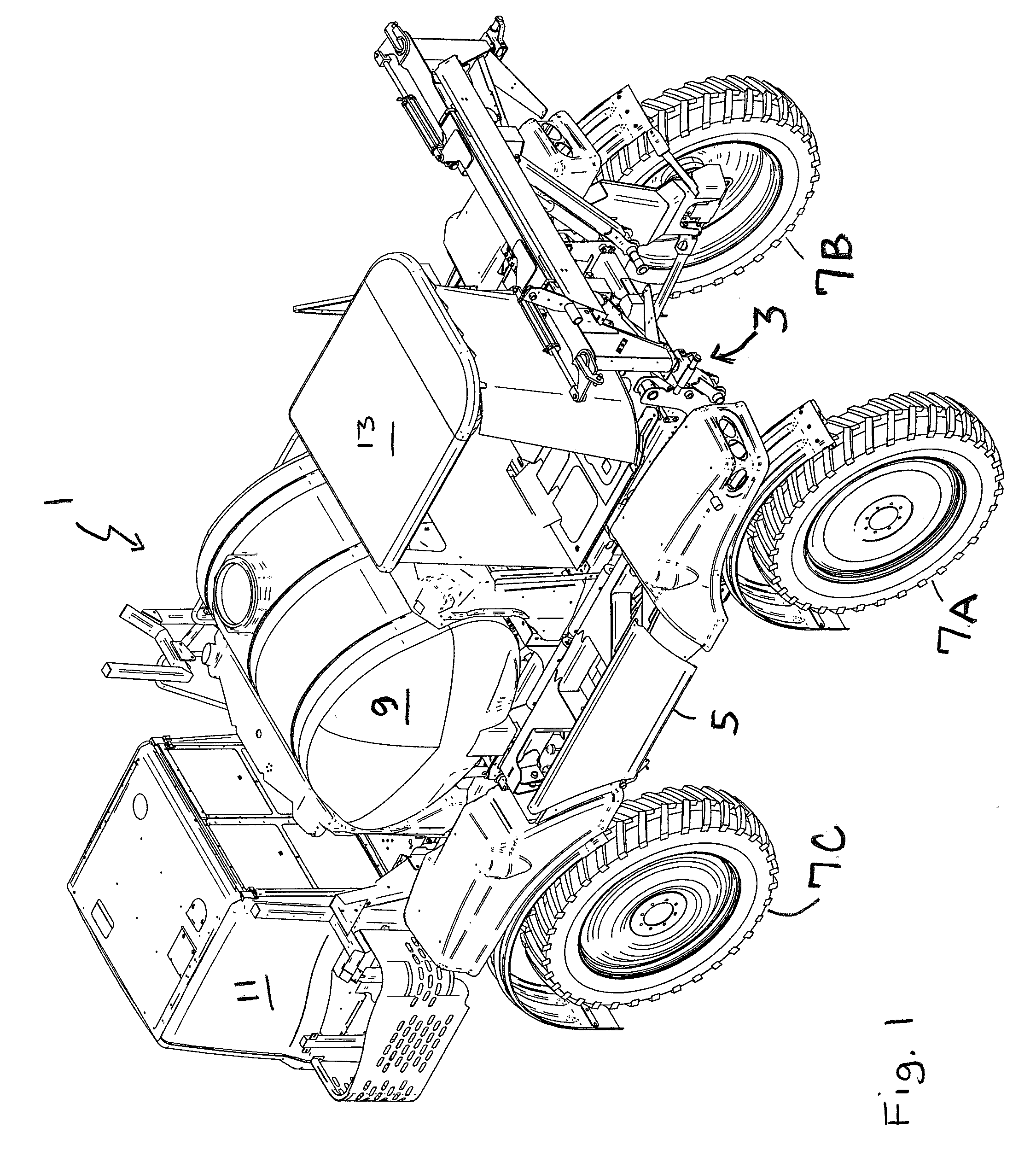

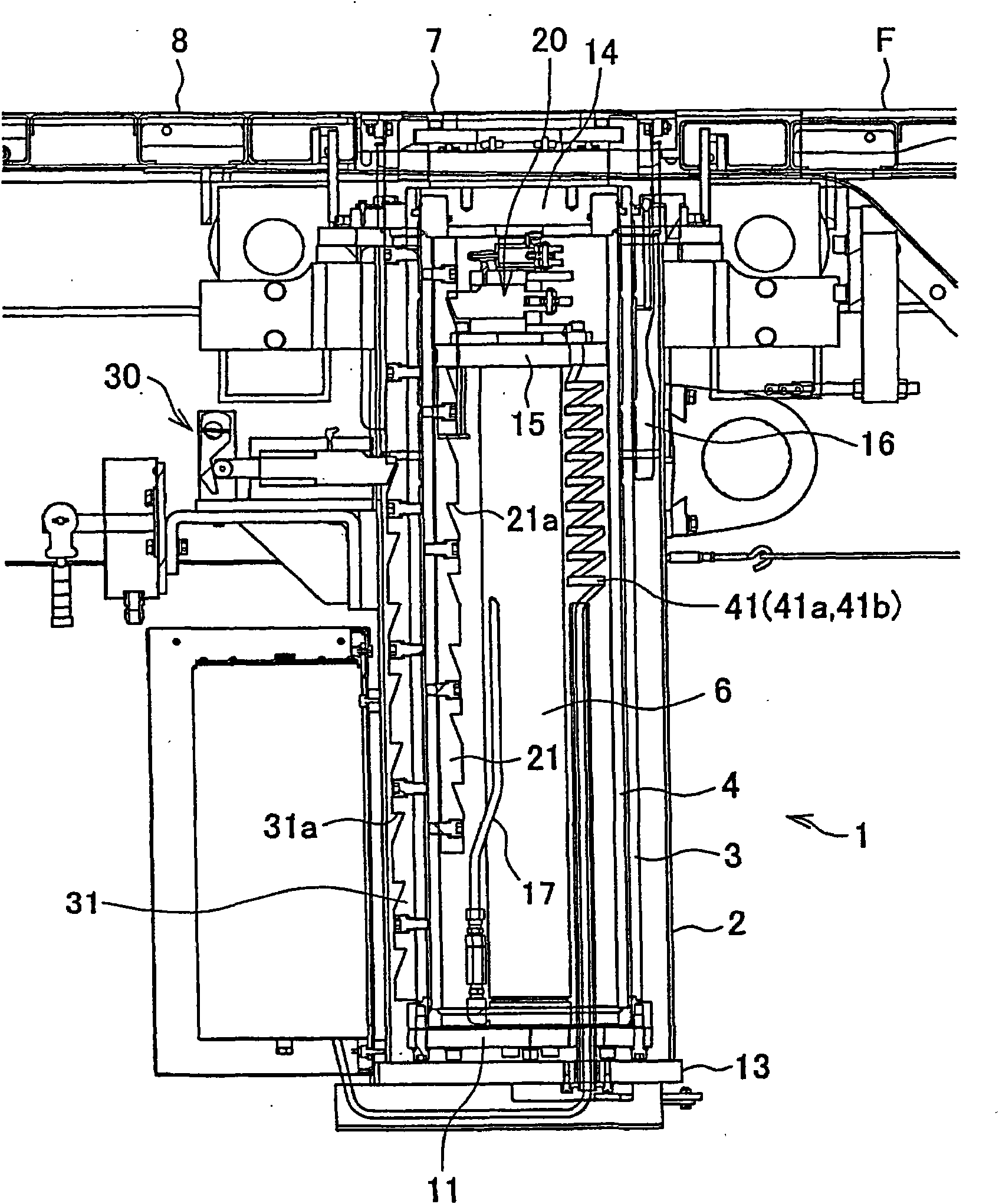

Wheeled type working vehicle

InactiveUS7104548B2Quantity minimizationReduce leakageVehicle cleaning apparatusSoil-shifting machines/dredgersEngineeringPosition-sensing hydraulic cylinder

The wheeled work vehicle according to the present invention has a link that links at least either one of the axles and provided at the front and the rear of the vehicle to a body, suspension hydraulic cylinders provided at the left side and the right side of the chassis to link the axle to the body in conjunction with the link and an accumulator that is made to communicate with oil chambers and of the hydraulic cylinders via restrictors.

Owner:HITACHI CONSTR MASCH CO LTD

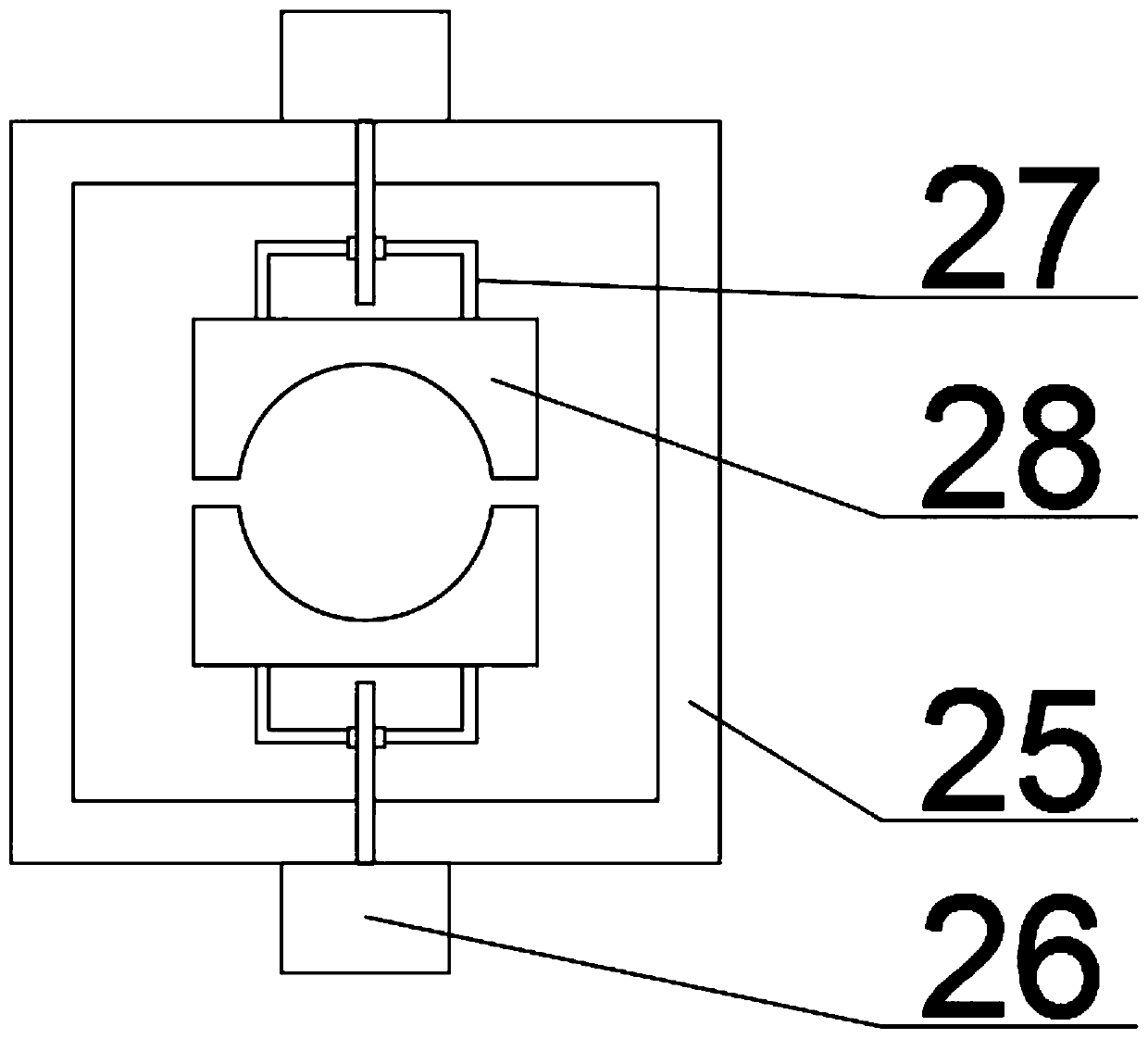

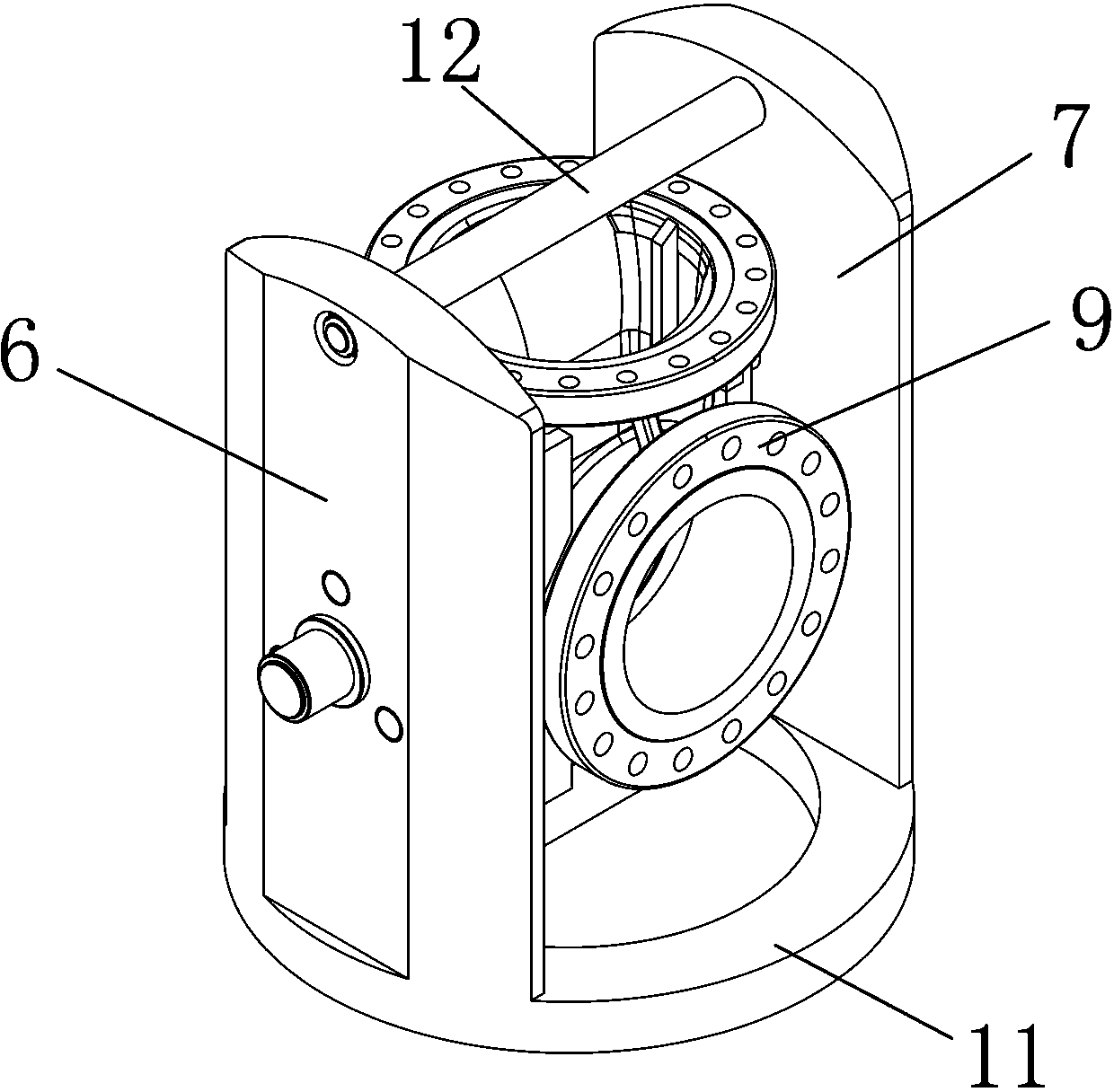

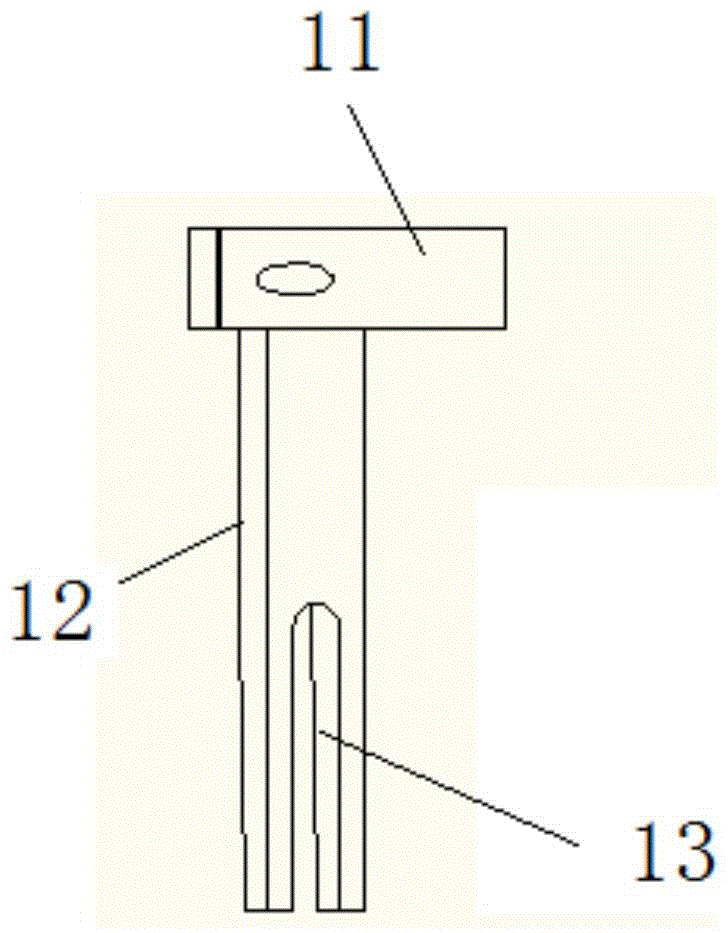

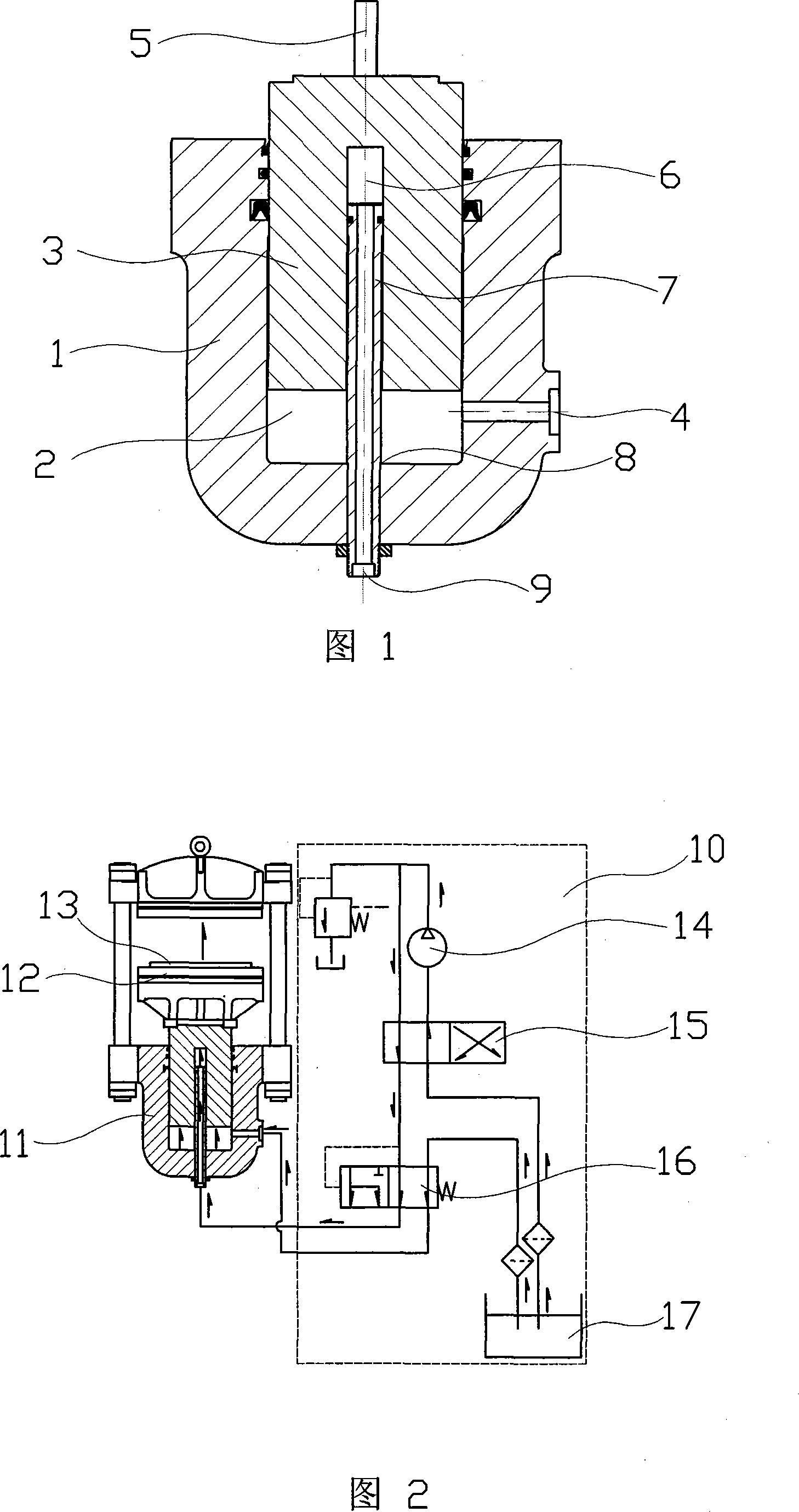

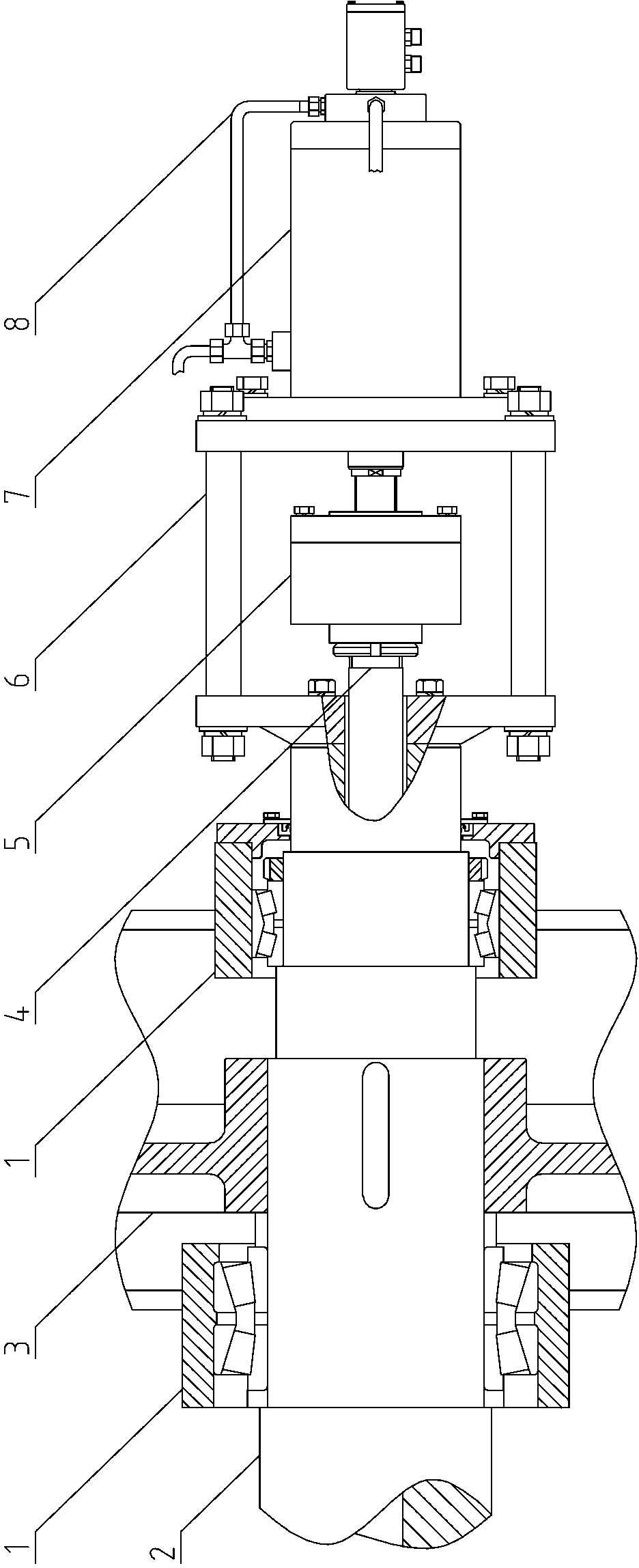

Optional-position lockable hydraulic cylinder

The invention aims to provide an optional-position lockable hydraulic cylinder which comprises a cylinder body, a locking box body, a piston rod, a locking lever, a turning block and a lock claw. A front cover is fixed at the front end of the cylinder body, a rear cover is fixed at the rear end of the cylinder body, the locking box body is fixed on the rear cover, one end of the locking box body is fixed with a box cover, a piston is arranged in the cylinder body, a first oil mouth and a second oil mouth are respectively formed in the front end and the rear end of the cylinder body, one end of the piston rod is disposed in the piston, the left portion of the locking lever is located in the locking box body, the right end portion of the locking lever penetrates the rear cover to be disposed in the piston, the turning block provided with a cavity is disposed on the upper left portion of the locking lever, and a multihead trapezoidal thread of the turning block is arranged at the position of the cavity of the turning block and is engaged with a multihead trapezoidal thread of the locking lever. The optional-positional lockable hydraulic cylinder is simple and reliable in structure and especially suitable for being applied to occasions when the piston rod needs to stay in a certain position and bears larger pushing and pulling force.

Owner:HARBIN ENG UNIV

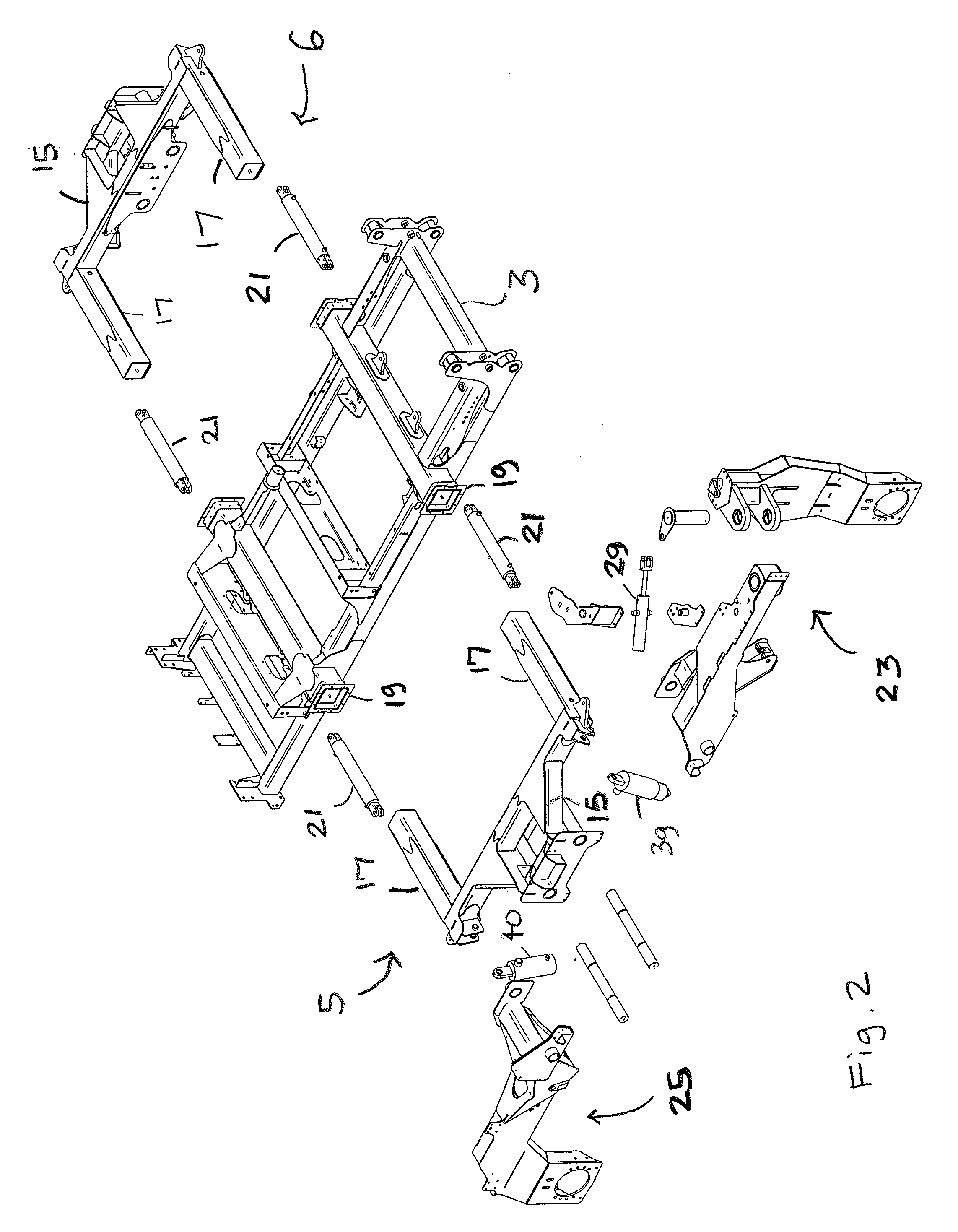

Suspension System for an Agricultural Vehicle

An agricultural vehicle comprises separate wheel suspension assemblies corresponding to each wheel of the vehicle. Each wheel suspension assembly includes a strut assembly wherein the strut assembly is connected to the chassis at a pivot and to a respective wheel, and a dual action hydraulic cylinder that is connected to both the strut assembly at a point distal from the pivot and the chassis of the vehicle. Motion of the strut assembly around the pivot is affected by action of the hydraulic cylinder. In some embodiments, the dual action hydraulic cylinders are in fluid communication with the diagonally opposite hydraulic cylinder such that when one cylinder moves into an extended or retracted position the other diagonally opposite cylinder is urged into the same position. In some embodiments, the wheel suspension assemblies are attached to slidable drawer assemblies on each side of the vehicle. These drawer assemblies can be moved relative to the centerline of the vehicle to change the spacing between the wheels on each side of the vehicle.

Owner:CNH IND AMERICA LLC

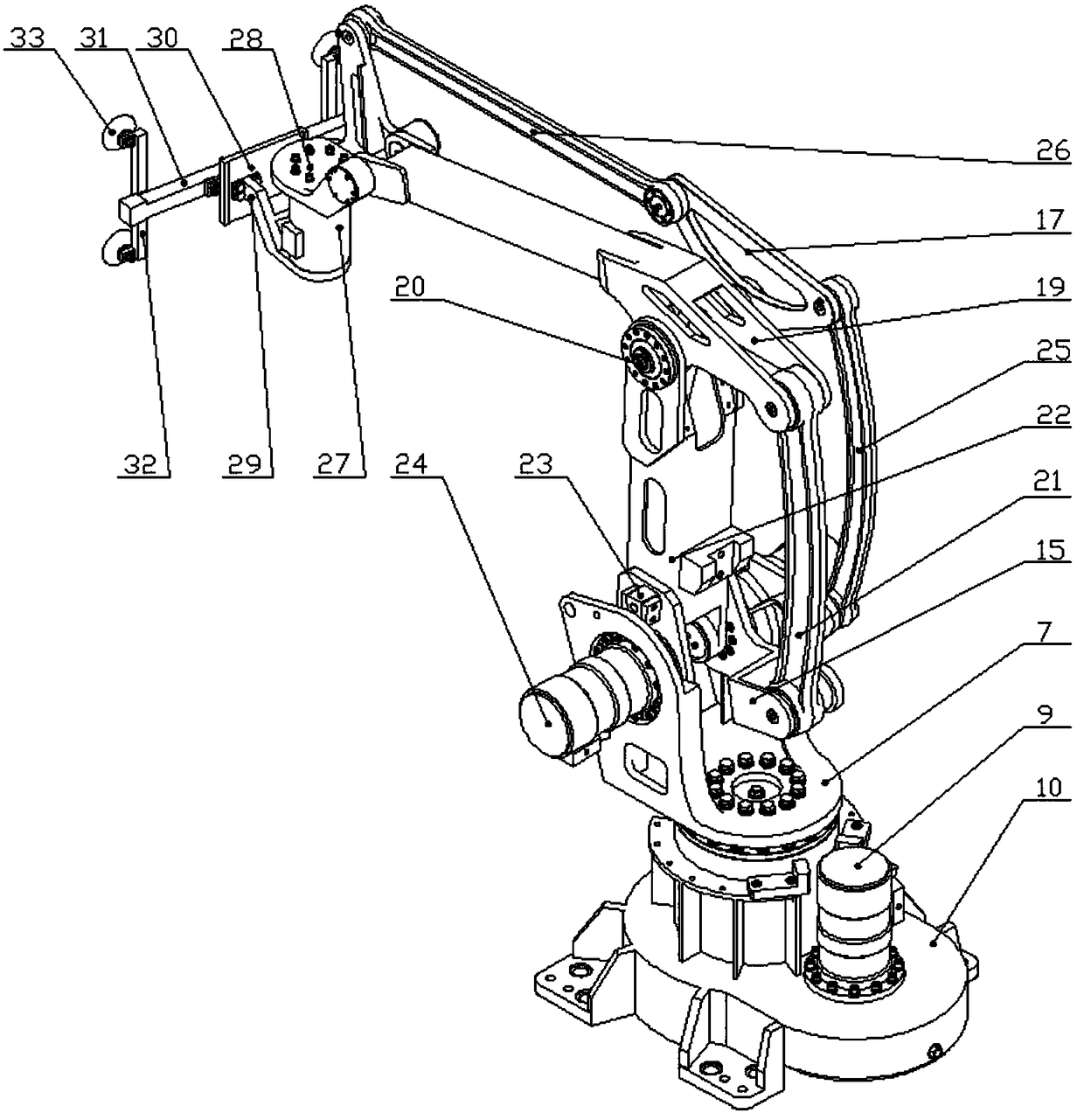

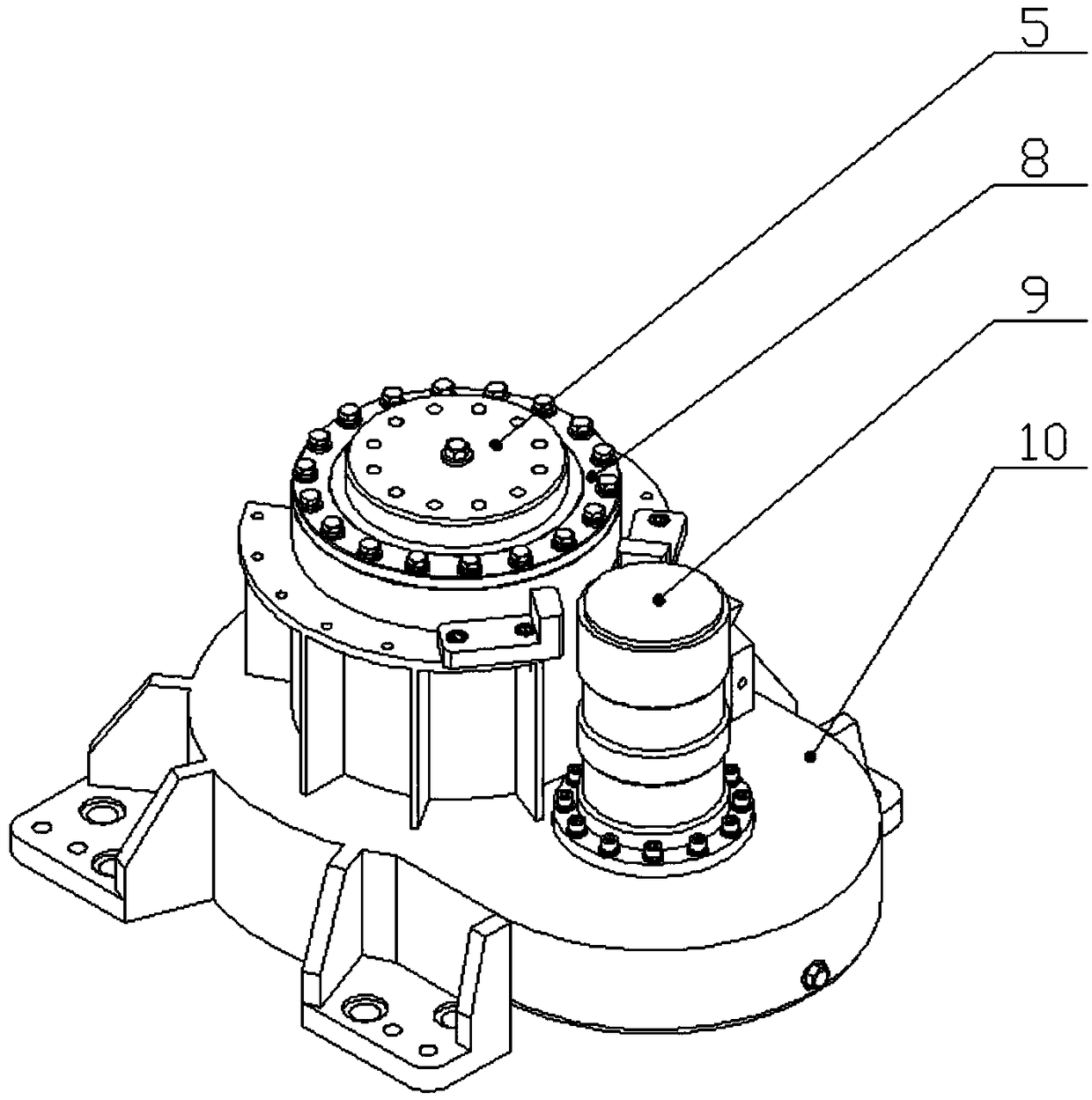

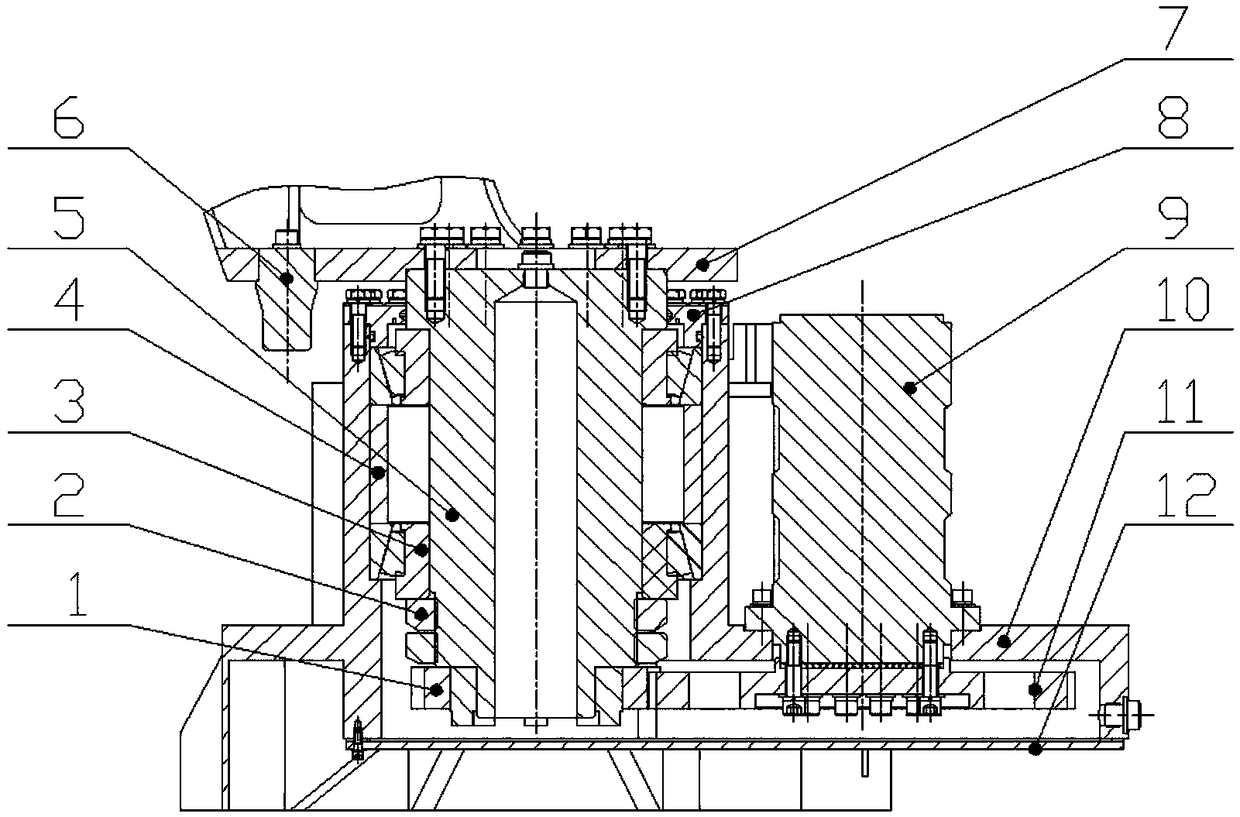

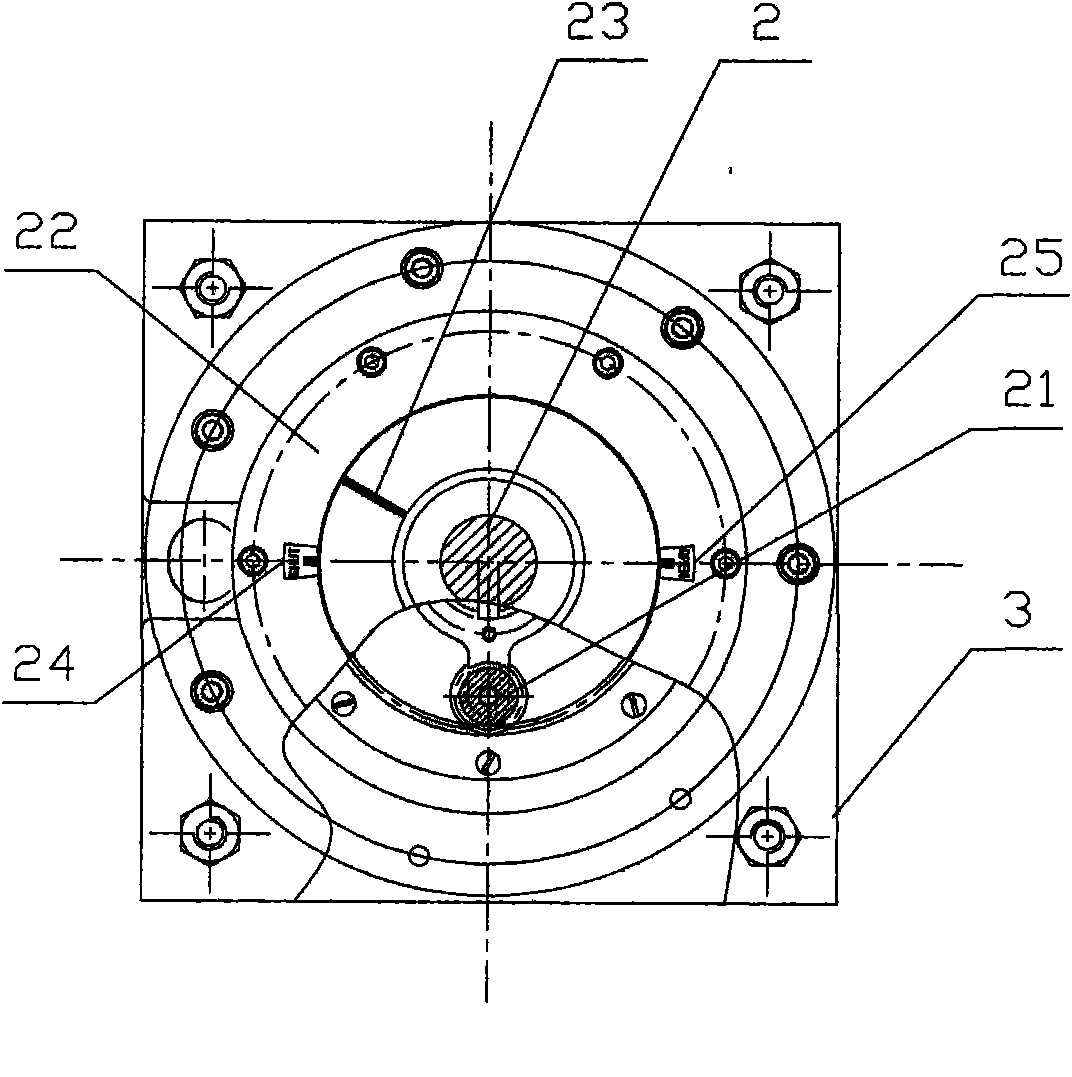

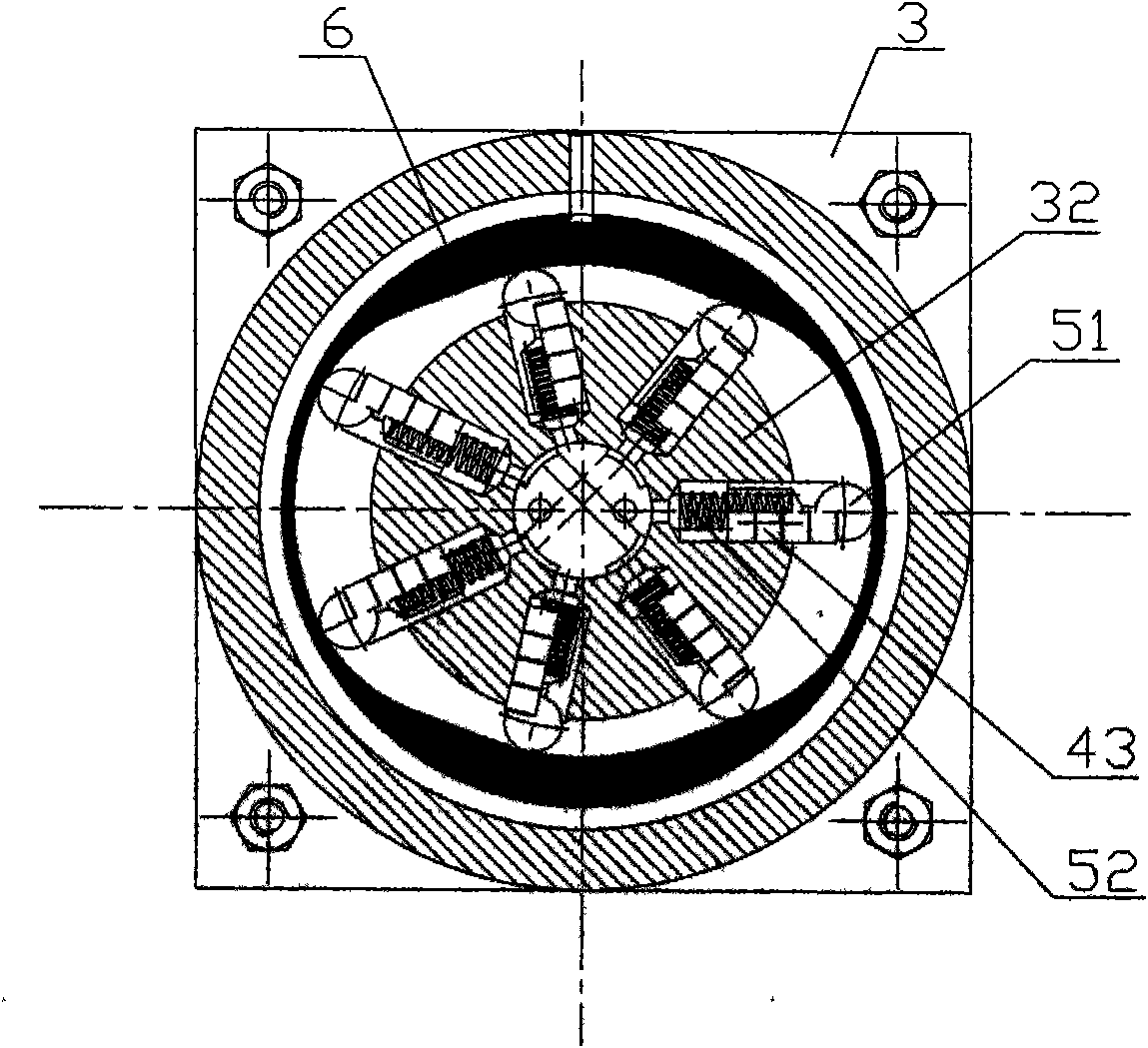

Prefabricated wallboard mounting manipulator

InactiveCN108547461APlay an auxiliary role in regulatingAchieve crawlingBuilding material handlingDrive shaftEngineering

The invention relates to a prefabricated wallboard mounting manipulator which comprises a waist rotation module, a large arm module, a wrist module and a vacuum suction cup device. The waist rotationmodule comprises a first swing hydraulic cylinder, a base shell, a shell upper cover, a shell lower cover, a large gear, a pinion, a transmission shaft, a positioning shaft sleeve, bearings and a positioning thread sleeve. The large arm module comprises a waist main body, a lower arm, a second swing hydraulic cylinder, a small shaft, a parallel arm and a limiting block. The wrist module comprisesan intermediate connecting piece, a long shaft, an upper arm, a short arm, a parallel rod, a lower connecting rod, an upper connecting rod, a third swing hydraulic cylinder and a movable platform. Thevacuum suction cup device comprises a mounting platform, a support connecting piece, a fixing connecting piece, a sliding rod, vacuum suction cups, a piston rod and a hydraulic cylinder. The prefabricated wallboard mounting manipulator is simple in structure, convenient to control, high in automation degree, capable of reducing operators greatly and high in working efficiency, and has the characteristics of high positioning precision, good stability, high expandability, high reliability, good safety and the like.

Owner:TONGJI UNIV

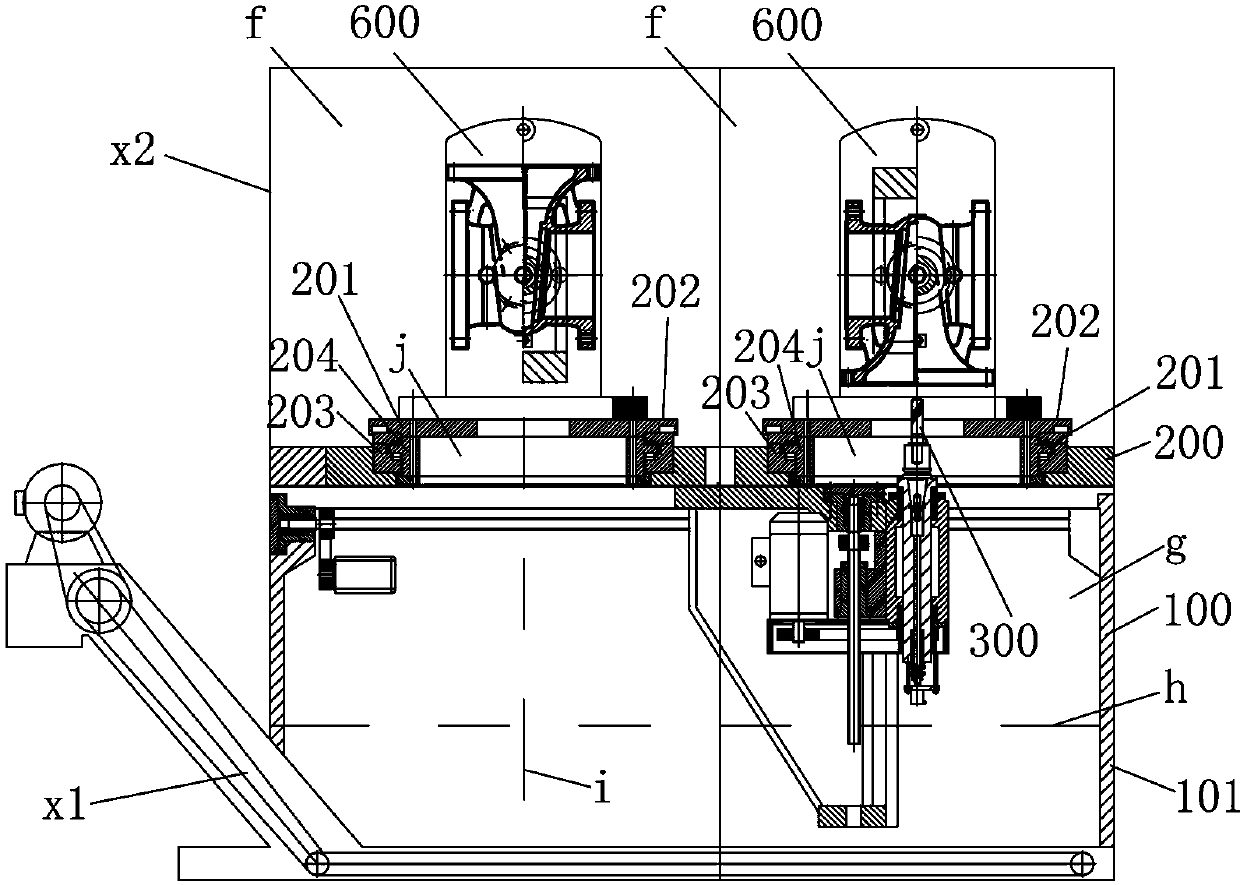

Inverted drilling machine

InactiveCN103801725APrecise processingFirm static statePositioning apparatusBoring/drilling componentsPosition-sensing hydraulic cylinderKnife blades

The invention relates to an inverted drilling machine which has the characteristics of easiness for assembling and disassembling and accuracy and reliability for indexing and comprises a bed and a working table. The working table is provided with a station part and a drilling tool part; the station part is provided with a station for loading a workpiece, a fixture part for carrying out indexing machining on the workpiece and a workpiece space positioned above the station; the fixture part comprises a fixture body space for accommodating the workpiece and left and right side fixture bodies respectively positioned at two opposite sides of the fixture body space; the left and right side fixture bodies are fixedly arranged on the working table; the left side fixture body is provided with a positioning hydraulic cylinder and a positioning plate; the right side fixture body is provided with a connecting block, a positioning block, a swing hydraulic cylinder, a locking hydraulic lock, a moving gear ring and a static gear ring; the drilling tool part comprises a drill stem; the drill stem is provided with a drill stem end face and a cutting blade; the cutting blade is provided with an edge part which is in contact with the workpiece; the edge part rotates to form a cutting mapped circle which is axially mapped; an abutting element is arranged on the drill stem end face in the range of the cutting mapped circle; the lowermost point of the edge part is higher than the highermost point of the abutting element; the highmost point of the abutting element is higher than the highermost point of the drill stem end face.

Owner:滕天阳

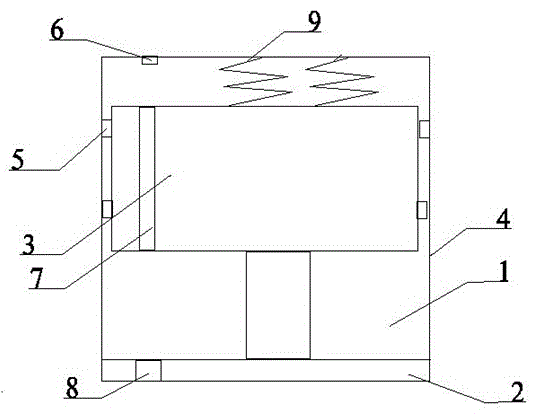

Compressing processor for waste zip-top cans

InactiveCN106003798AReasonable designSimple structurePressesEngineeringPosition-sensing hydraulic cylinder

The invention discloses a compressing processor for waste zip-top cans. The compressing processor comprises an outer box body; one side of the outer box body is provided with a discharging door, the upper end of the outer box body is provided with a feeding inlet, and the bottom of the outer box body is provided with a rotatable rotating disc; the radial edge of the rotating disc is symmetrically provided with two inner box bodies with the upper ends being opened and the bottom ends being closed, and the bottom of the outer box body is provided with a motor for driving the rotating disc to rotate; a hydraulic station is installed on the upper side of the interior of the outer box body, and a piston type hydraulic cylinder is installed at the bottom of the hydraulic station; and a compressing hammer is installed at the head of a piston rod of the hydraulic cylinder, and an oil inlet and an oil outlet of the hydraulic cylinder are connected with an oil inlet and an oil outlet of the hydraulic station through hydraulic oil pipes correspondingly. According to the compressing processor for the waste zip-top cans, the design is reasonable; the waste zip-top cans are fed into one of the inner box bodies through the feeding inlet; after the inner box body is full, a control button is pressed; and after the waste zip-top cans are compressed by the compressing hammer at the head of the piston rod of the hydraulic cylinder, a rotating button is pressed, the other empty inner box body is rotated to the position below the hydraulic cylinder, and meanwhile the compressed waste zip-top cans are discharged from the discharging door. The recycling efficiency of the whole process is high.

Owner:吴义坡

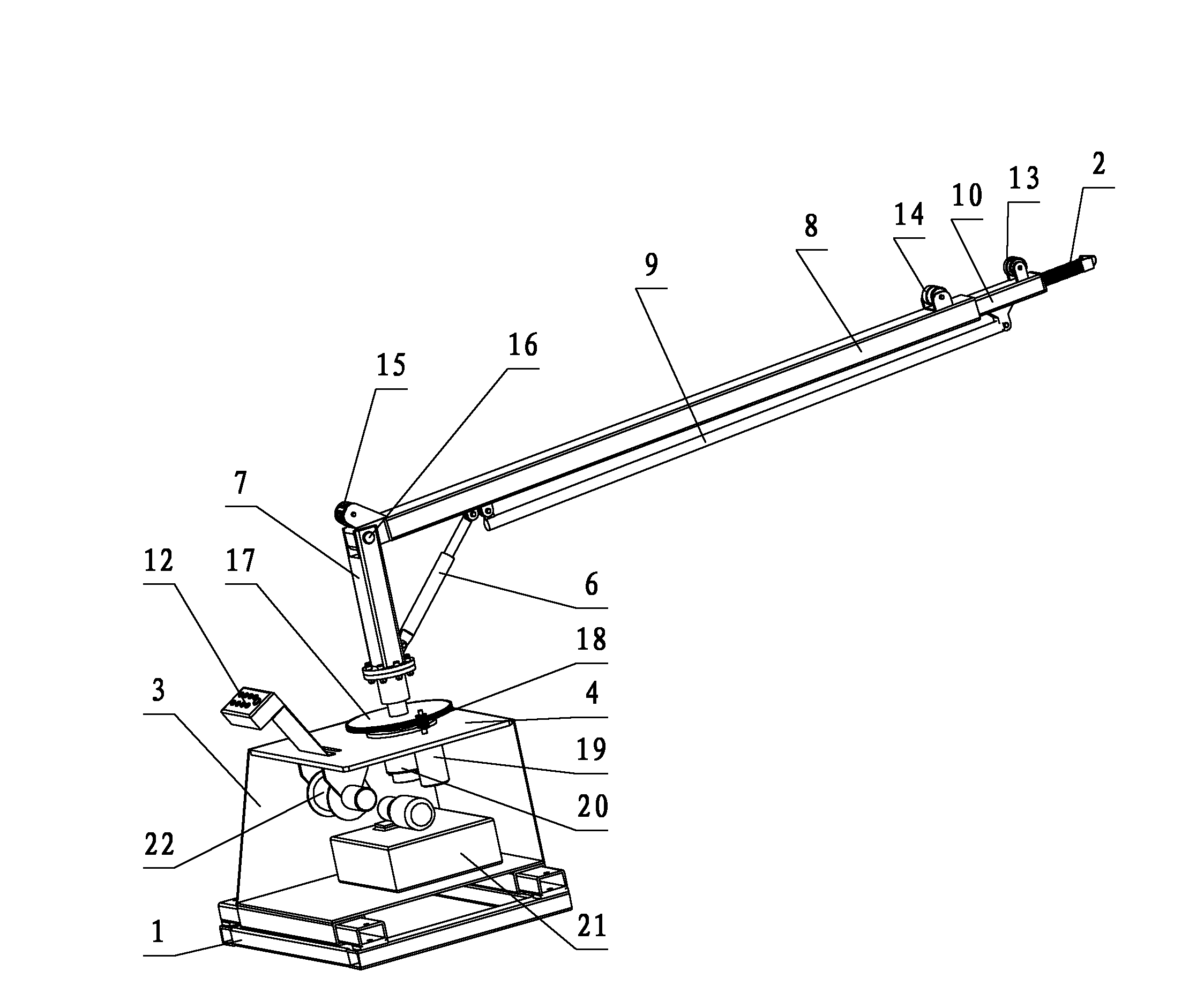

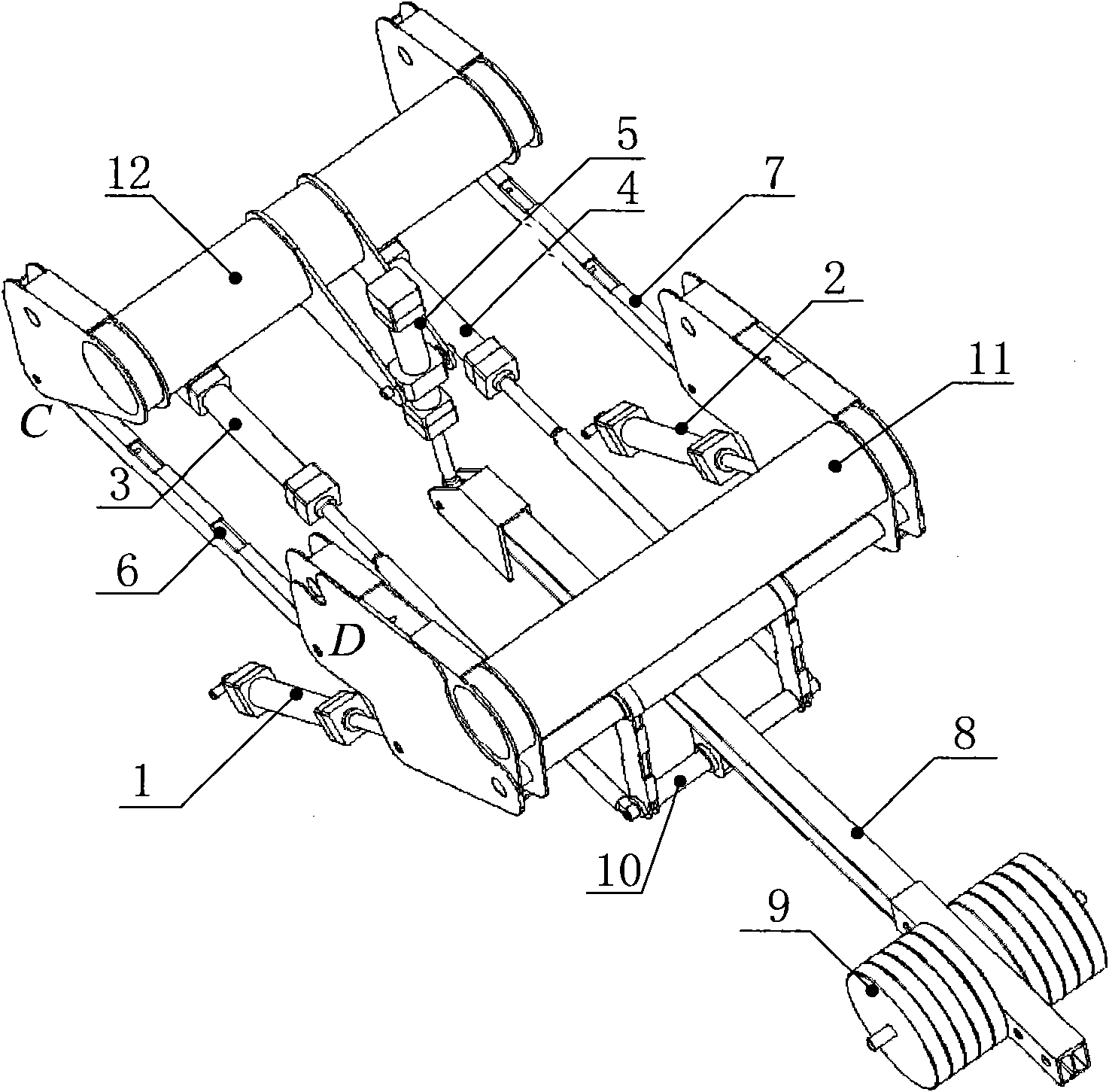

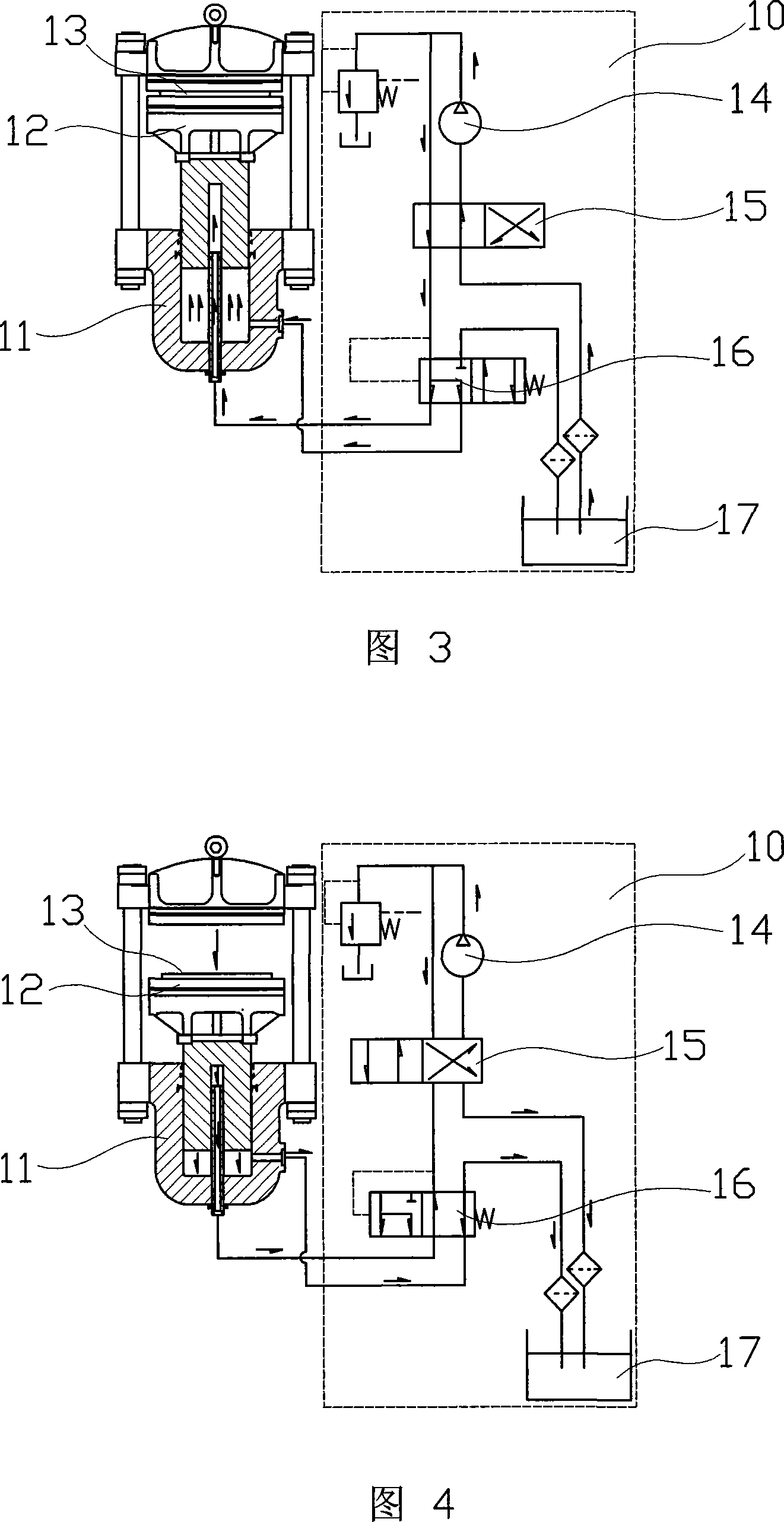

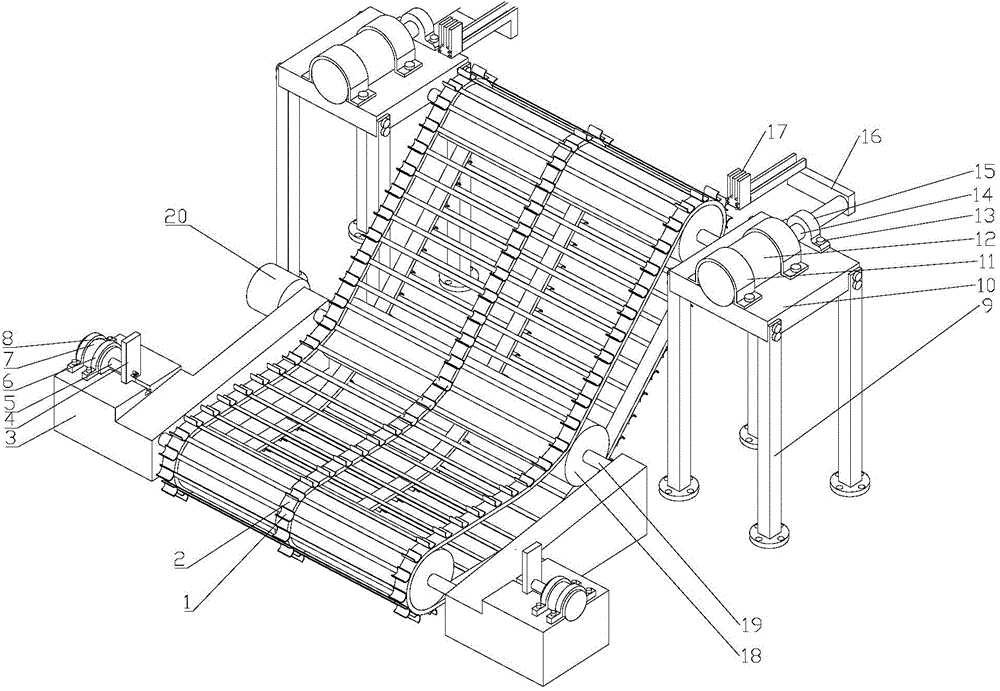

Three-degree-of-freedom polar-coordinate hydraulic drive manipulator

InactiveCN104647375AThe need to achieve arbitrary positioningSimple structureProgramme-controlled manipulatorGratingThree degrees of freedom

The invention relates to a three-degree-of-freedom polar-coordinate hydraulic drive manipulator. The three-degree-of-freedom polar-coordinate hydraulic drive manipulator consists of a base, a rotating hydraulic cylinder, a rotating table, a pitching hydraulic cylinder, a photoelectric detection device, a stand column, a telescopic hydraulic cylinder and a paw, wherein the stand column and the pitching hydraulic cylinder are installed on the rotating table, the telescopic hydraulic cylinder is hinged to the stand column and the pitching hydraulic cylinder, the paw is installed on a hydraulic cylinder rod of the telescopic hydraulic cylinder, the rotating table is connected with the rotating hydraulic cylinder in the base, the photoelectric detection device consists of an infrared photoelectric sensor and a transmission-type grating, the infrared photoelectric sensor is installed on a hydraulic cylinder body, the transmission-type grating is installed on the hydraulic cylinder rod, the grating is driven by the motion of the hydraulic cylinder rod to generate photoelectric signal pulse, whether an arm moves in place or not is judged by the controller according to a photoelectric signal fed back to an input end, then the motion and stopping of the hydraulic cylinder are controlled by the controller, the free positioning requirement of the manipulator can be realized, and the three-degree-of-freedom polar-coordinate hydraulic drive manipulator has characteristics of low cost and high universality.

Owner:GUANGXI UNIV

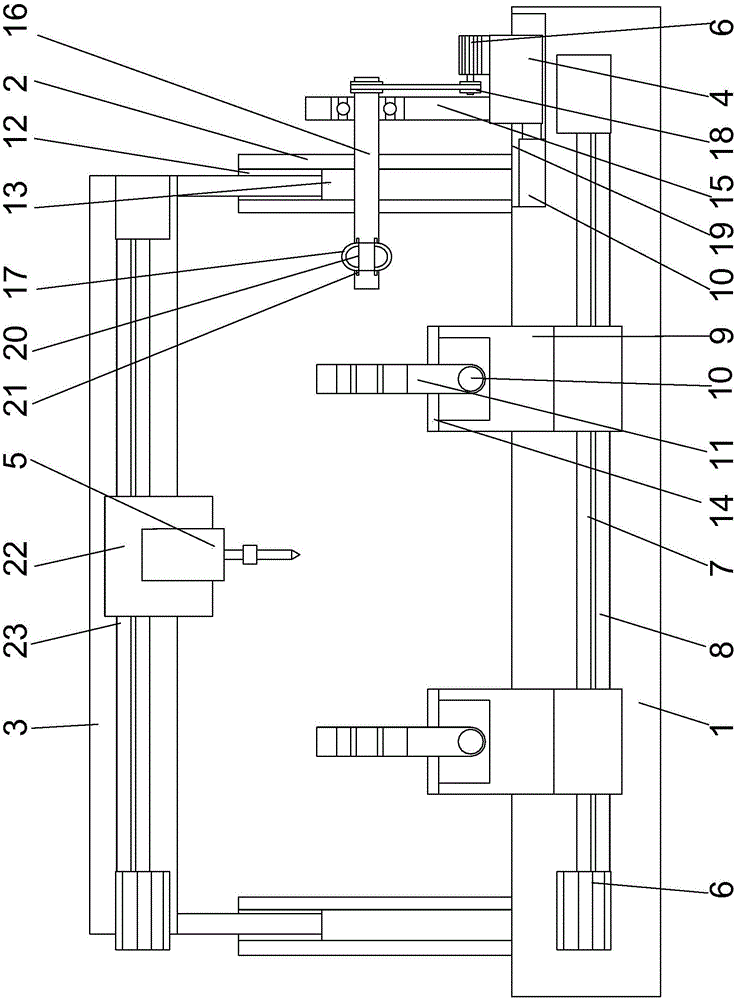

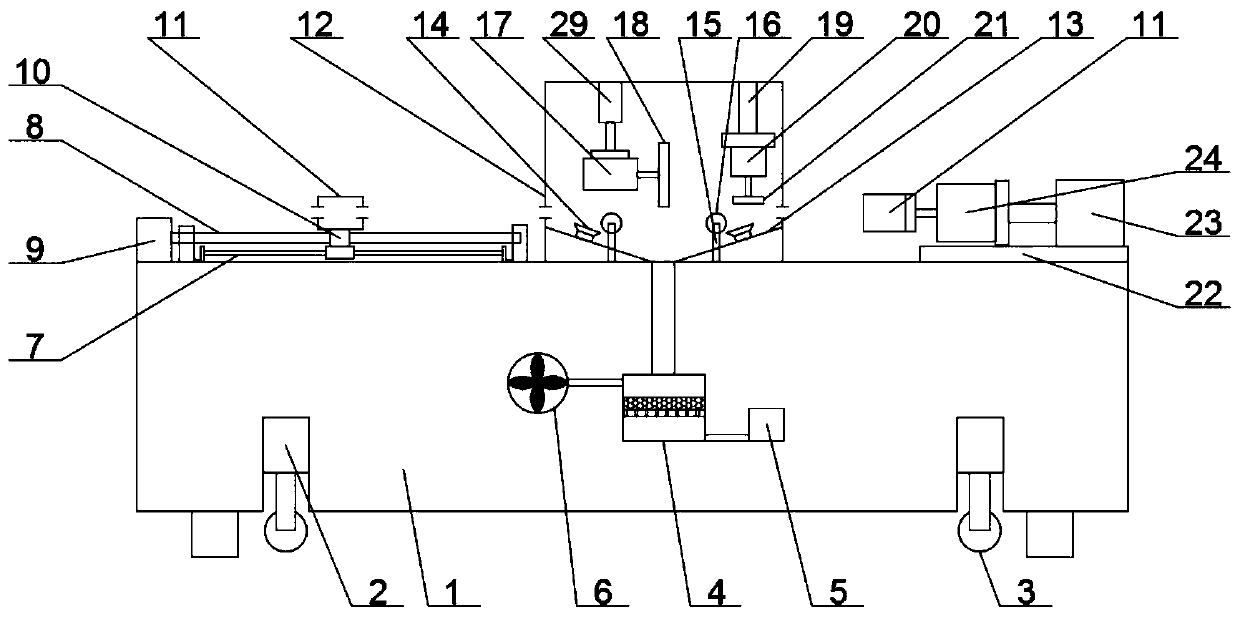

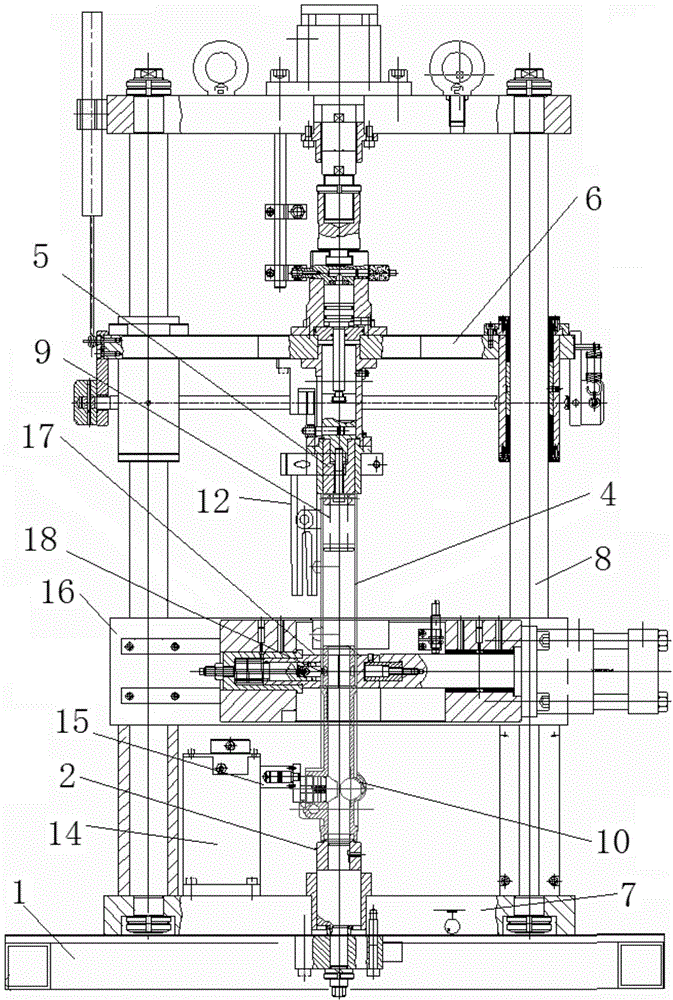

Experiment table for kinetic control of hydraulic servo driving system

InactiveCN101852229AReduce experiment costReduce riskFluid-pressure actuator testingControl engineeringPosition-sensing hydraulic cylinder

The invention relates to an experiment table for kinetic control of a hydraulic servo driving system. The experiment table comprises a supporting frame, a front big shaft, a rear big shaft, a first suspender, at least one vertical hydraulic cylinder, at least one horizontal hydraulic cylinder, a pitching hydraulic cylinder, a control unit and a detection unit, wherein the front big shaft and the rear big shaft are fixed on the supporting frame respectively; the suspender is connected with the front big shaft and can rotate around the front big shaft; the at least one vertical hydraulic cylinder is used for realizing movement of a girder and a load in the vertical direction; the at least one horizontal hydraulic cylinder is used for realizing movement of the girder and the load in the horizontal direction; the pitching hydraulic cylinder is used for realizing pitching movement of the girder and the load; the control unit is used for controlling the vertical hydraulic cylinder, the horizontal hydraulic cylinder and the pitching hydraulic cylinder to move; and the detection unit is used for detecting pressure values and displacement values of the vertical hydraulic cylinder, the horizontal hydraulic cylinder and the pitching hydraulic cylinder. By using the experiment table for carrying out an experiment on the stability and the reliability of a controller, the experiment can be transferred from an actual mechanical system into a laboratory so as to greatly reduce the experiment cost and the experiment risk.

Owner:TSINGHUA UNIV

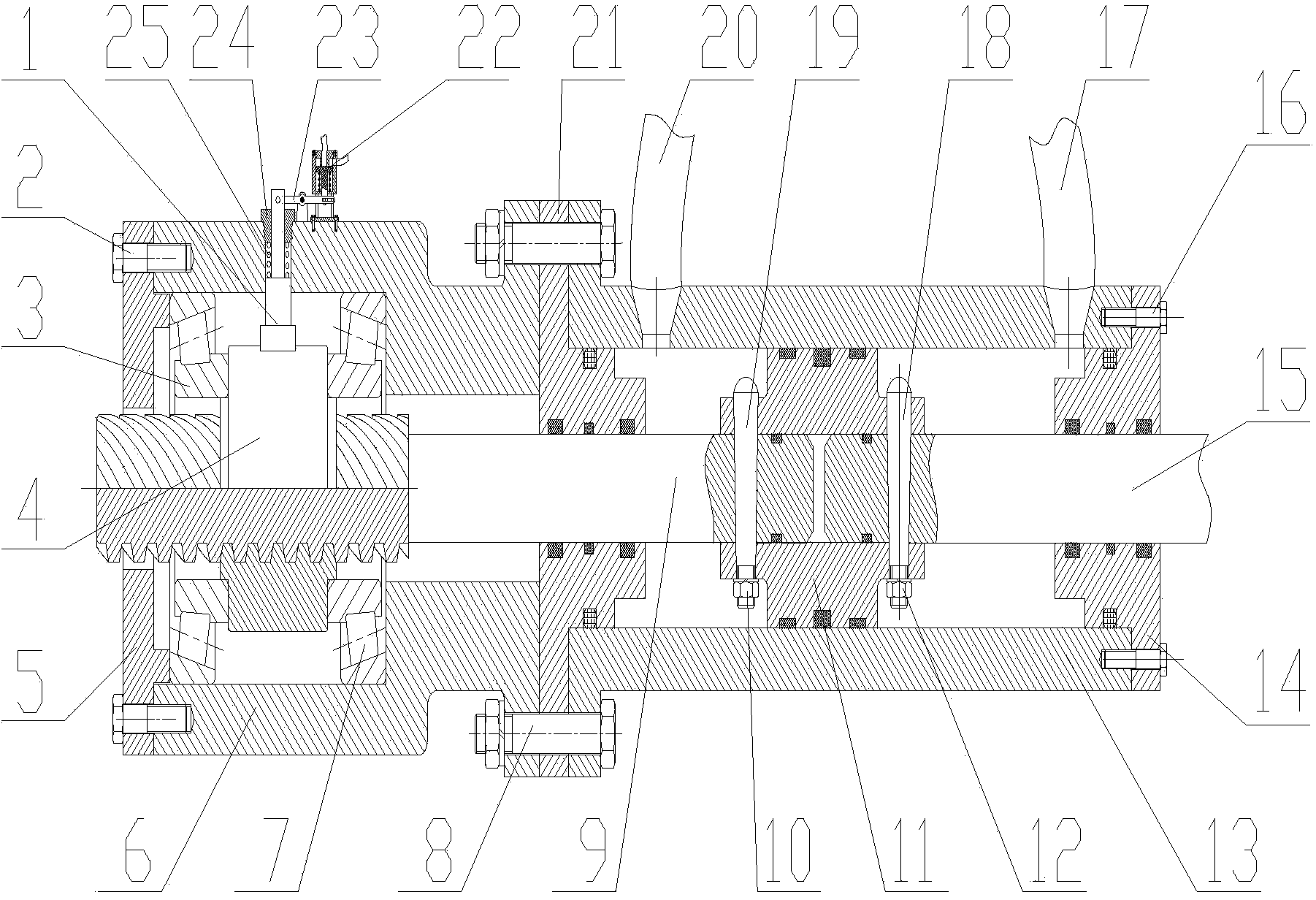

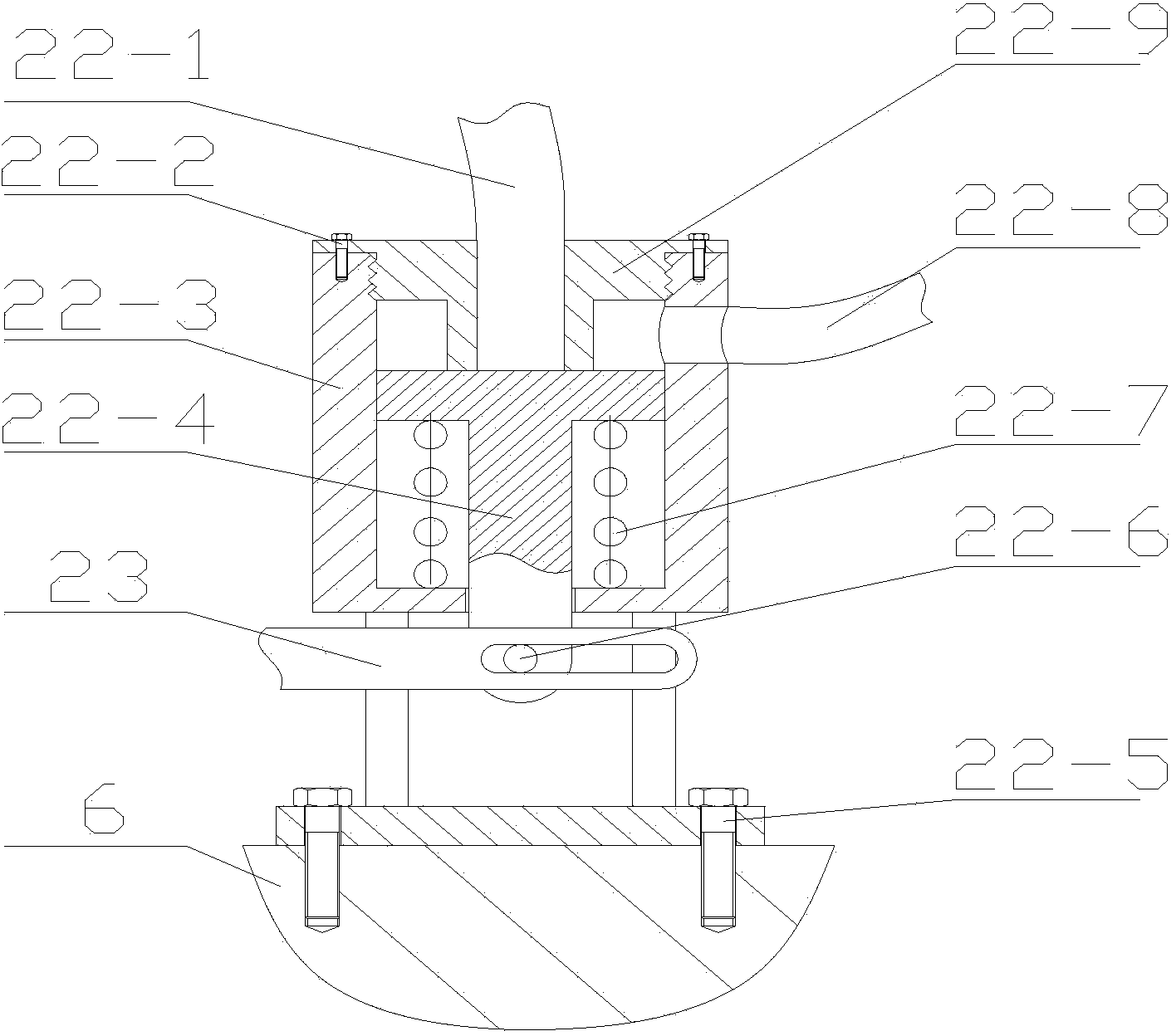

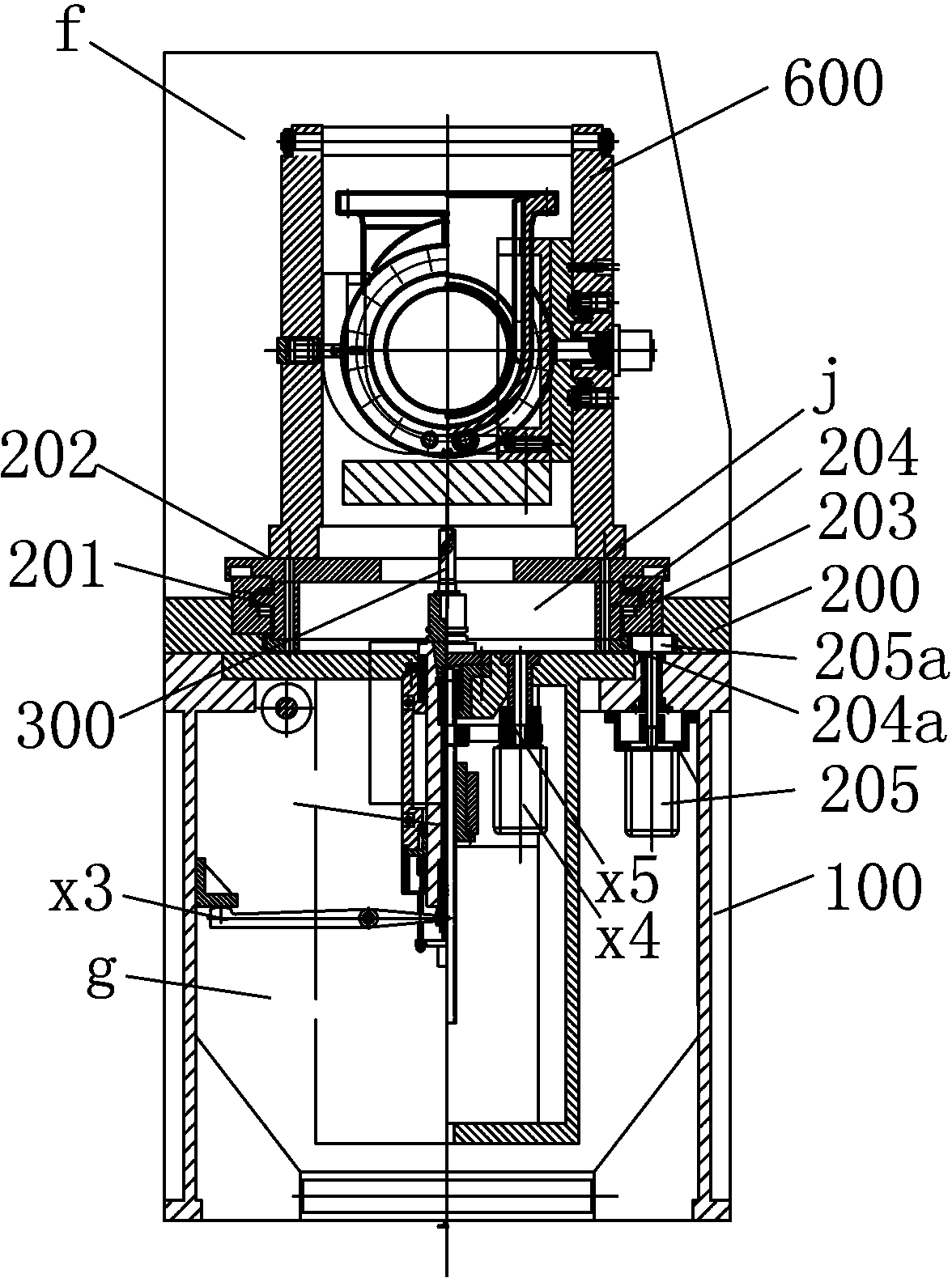

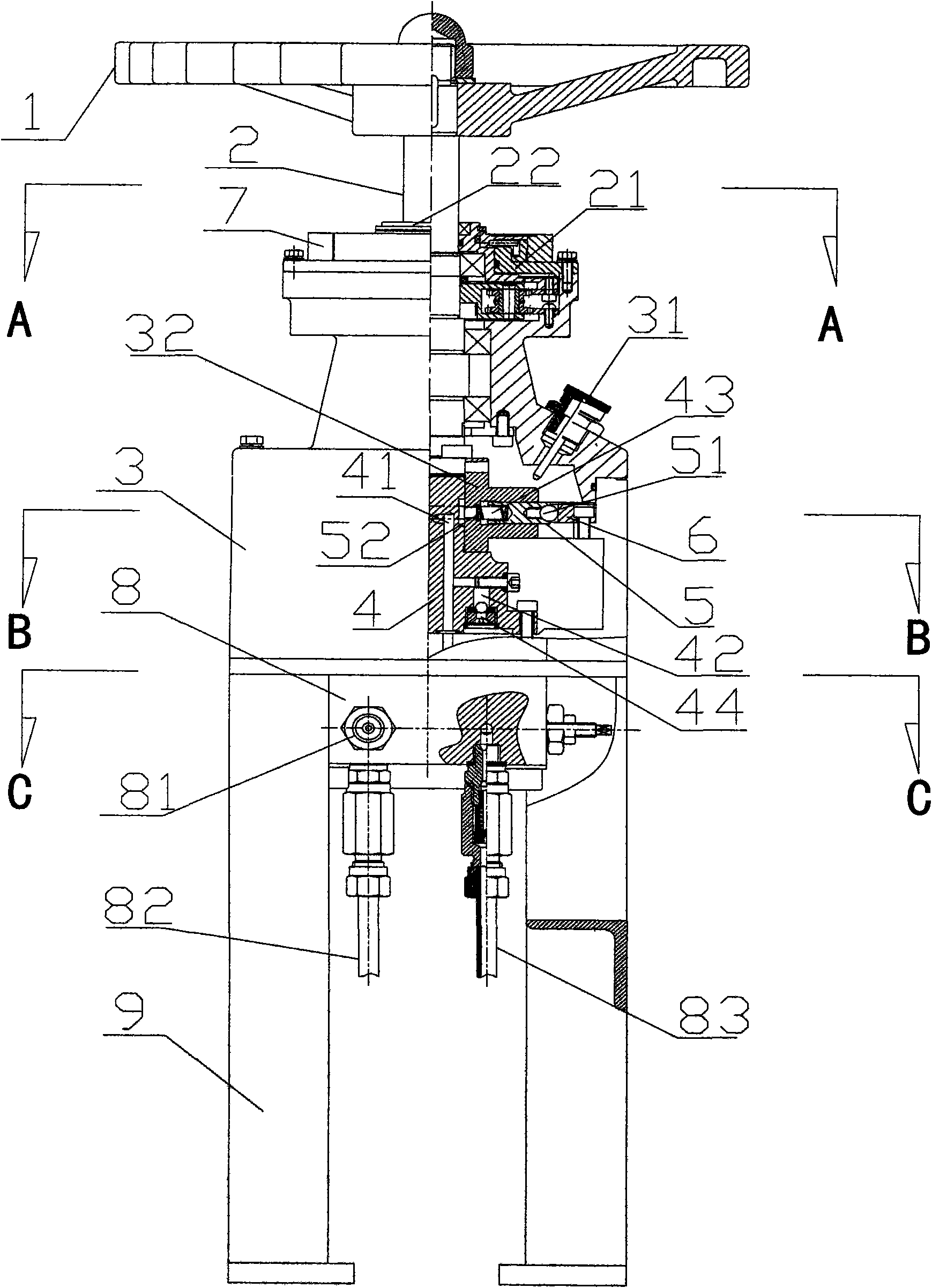

Press riveting device of steering engine hydraulic cylinder assembly

InactiveCN104399830AAccurate riveting angleAccurate locationMetal-working feeding devicesPositioning devicesControl engineeringPosition-sensing hydraulic cylinder

The invention discloses a press riveting device of steering engine hydraulic cylinder assembly. The press riveting device of steering engine hydraulic cylinder assembly comprises a base, a shell positioning seat which is installed on the base, and a support frame. The support frame is provided with a pressing block which presses a hydraulic cylinder positioning rod into a steering engine hydraulic cylinder upper port, a steering engine shell positioning mechanism, a clamp riveting mechanism of the steering engine shell and the steering engine hydraulic cylinder, and a steering engine hydraulic cylinder nozzle limiting mechanism. By employing such a structure, the press riveting device of steering engine hydraulic cylinder assembly has the advantages as follows: 1, the steering engine shell is positioned via the shell positioning seat and the shell positioning rod; the hydraulic cylinder is positioned via the hydraulic cylinder positioning rod; the steering engine hydraulic cylinder and the steering engine shell are press riveted by the pressure of the pressing block; therefore the press riveting angle, the press riveting position, and the press riveting coaxiality are precise. 2, the inner wall shape at the upper end of the steering engine hydraulic cylinder is matched with the outer wall shape at the end portion of the hydraulic cylinder positioning rod; and the inner wall shape at the lower end of the steering engine shell is matched with the outer wall shape of the support protrusion of the shell positioning seat; therefore, if the model of the steering engine hydraulic cylinder or the model of the steering engine shell is not correct, the assembling cannot be done, thus avoiding mismatch of the hydraulic cylinder and the shell.

Owner:WUHU STERLING STEERING SYST

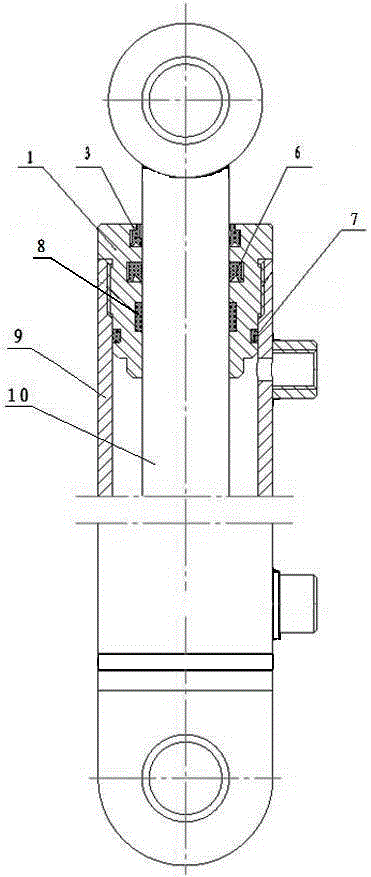

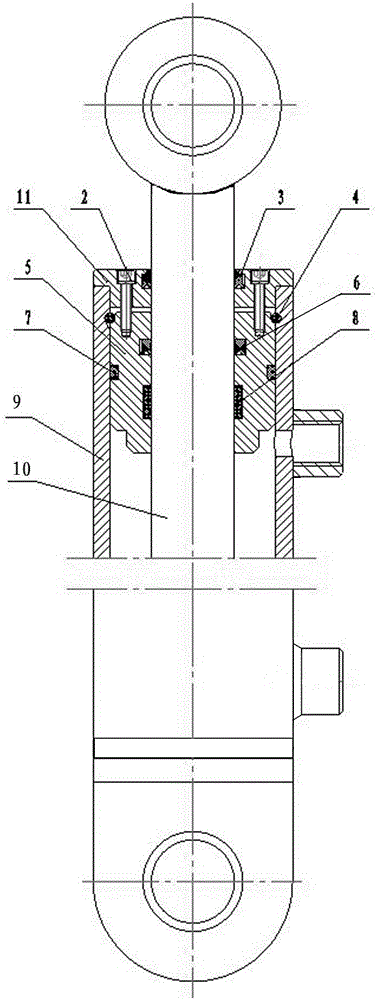

Double-acting piston type hydraulic cylinder

The invention discloses a double-acting piston type hydraulic cylinder and relates to the technical field of hydraulic instruments. The double-acting piston type hydraulic cylinder comprises a cylinder barrel and a piston rod. A piston rod guide sleeve is arranged between the inner wall of the cylinder barrel and the piston rod. A sealing ring I and a guide belt are arranged between the piston rod guide sleeve and the piston rod. A sealing ring II is arranged between the piston rod guide sleeve and the inner wall of the cylinder barrel. The piston rod guide sleeve is fixedly connected with an end cover arranged at the upper portion of the cylinder barrel through a bolt. A spring steel cable baffle ring is arranged between the piston rod guide sleeve and the cylinder barrel. A dustproof ring is arranged between the end cover and the piston rod. The sealing ring II is an O-shaped sealing ring. The problem that a double-acting piston type hydraulic cylinder is difficult to machine and assemble can be solved through the double-acting piston type hydraulic cylinder.

Owner:LIUZHOU SHUANGJI MACHINERY

Combined type press hydraulic cylinder

InactiveCN101135328ADoes not affect ascent speedIncrease pressureCylindersFluid-pressure actuatorsHydraulic pumpEngineering

The combined hydraulic cylinder of press has a tubular cylinder body with closed bottom, in the cylinder body there is a column-shape hydraulic cylinder internal chamber in which is matched with a column-shape piston. At side wall of the cylinder bottom there is a liquid inlet-outlet, there is a piston hydraulic cylinder which is used as a piston on the axis of which there is an opening toward to the internal chamber of the column-shape piston hydraulic cylinder with closed bottom. In the internal chamber of the piston hydraulic cylinder there is a tubular piston matching with the internal chamber, and the tubular piston is fixedly connected to the middle part of the cylinder bottom, the tube mouth of the tubular piston extends to outer of the cylinder. The diameter of internal chamber of the piston hydraulic cylinder is 10%- 20% of that of the hydraulic cylinder. Advantages: it can use high-pressure low-flow hydraulic pump with low power to realize quickly folding clamping device and applying high pressure to the clamping device, so it can save energy source.

Owner:祁胜

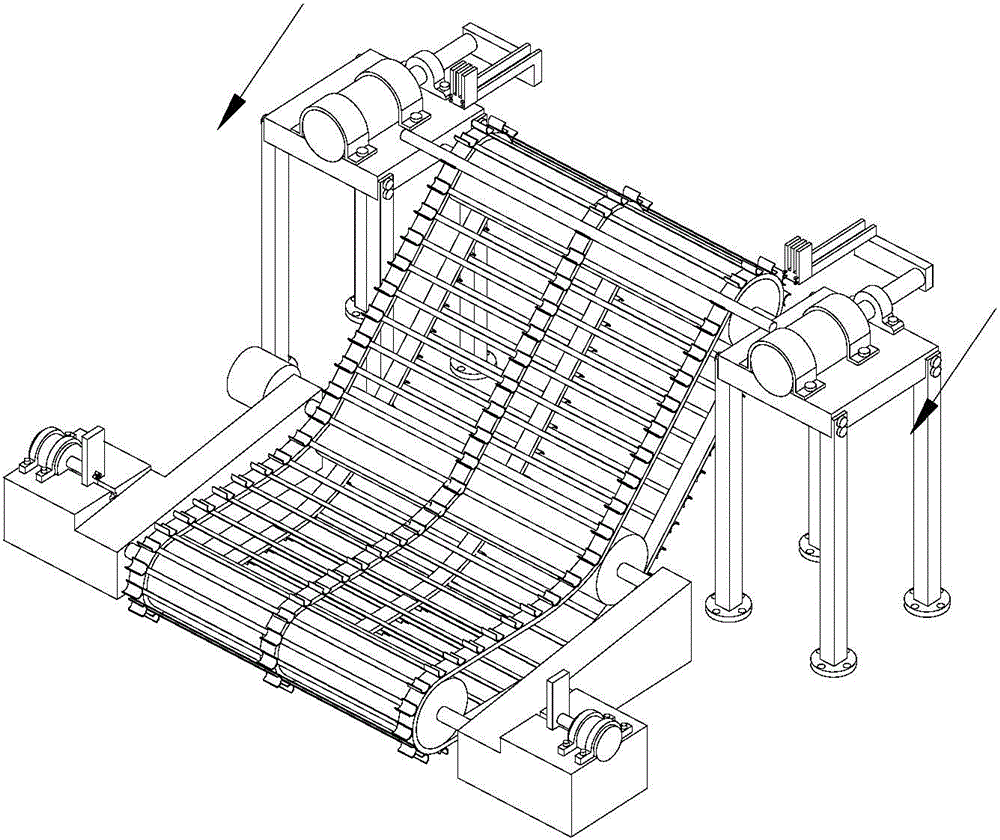

High temperature rod member unloading conveyer

InactiveCN104959868ARealize automatic transfer functionEasy to operateMetal working apparatusEngineeringSprocket

The invention discloses a high temperature rod member unloading conveyer. The high temperature rod member unloading conveyer is characterized by comprising high temperature rod member unloading mechanisms, a conveying mechanism and a positioning mechanism. Each unloading mechanism comprises a pedestal, a fixing support, an unloading hydraulic cylinder, a positioning support, a high temperature connecting rod member and an unloading claw. The conveying mechanism comprises a driving sprocket, a driving chain, a discharge hook, two pedestals and a motor. Each positioning mechanism comprises a hydraulic cylinder fixing support, a positioning hydraulic cylinder and a positioning slide block. The high temperature rod member unloading conveyer can cooperate with a robot to automatically unload, the work efficiency can be raised, and the labor force can be saved.

Owner:HEFEI UNIV OF TECH

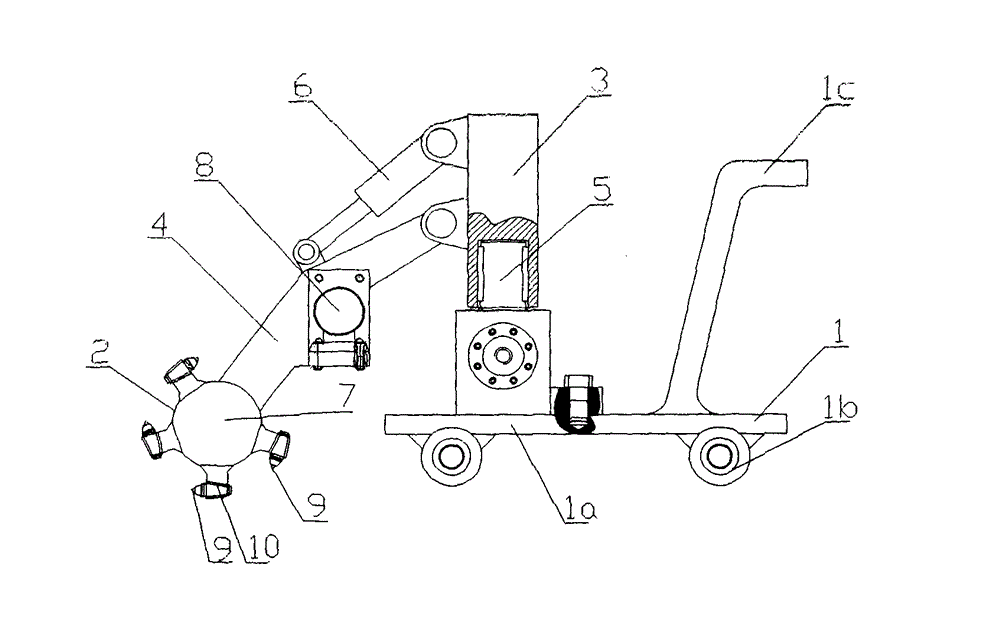

Mechanical arm for arranging and taking back road cone

InactiveCN105297649AImprove reliabilityIncreased durabilityTraffic signalsRoad signsPosition-sensing hydraulic cylinderManipulator

The invention provides a mechanical arm for arranging and taking back a road cone, and the mechanical arm is capable of arranging and taking back the road cone. The mechanical arm for arranging and taking back the road cone comprises a mechanical arm swing arm mechanism and a mechanical arm clamping mechanism; the mechanical arm swing arm mechanism comprises a mechanical arm swing arm, a swing type hydraulic cylinder, a position sensor and a supporting seat; the mechanical arm clamping mechanism comprises mechanical arm claws, a piston type hydraulic cylinder, the position sensor and a pull rod; the mechanical arm swing arm mechanism is connected to a base plate of an arranging box mechanism so as to be conveniently taken back to a compartment in a nonworking state together with the arranging box mechanism, so that over-width is avoided. The mechanical arm disclosed by the invention is capable of automatically arranging and taking back the road cone, simple in structure, convenient to operate, good in reliability and high in cost performance.

Owner:上海电控研究所有限公司

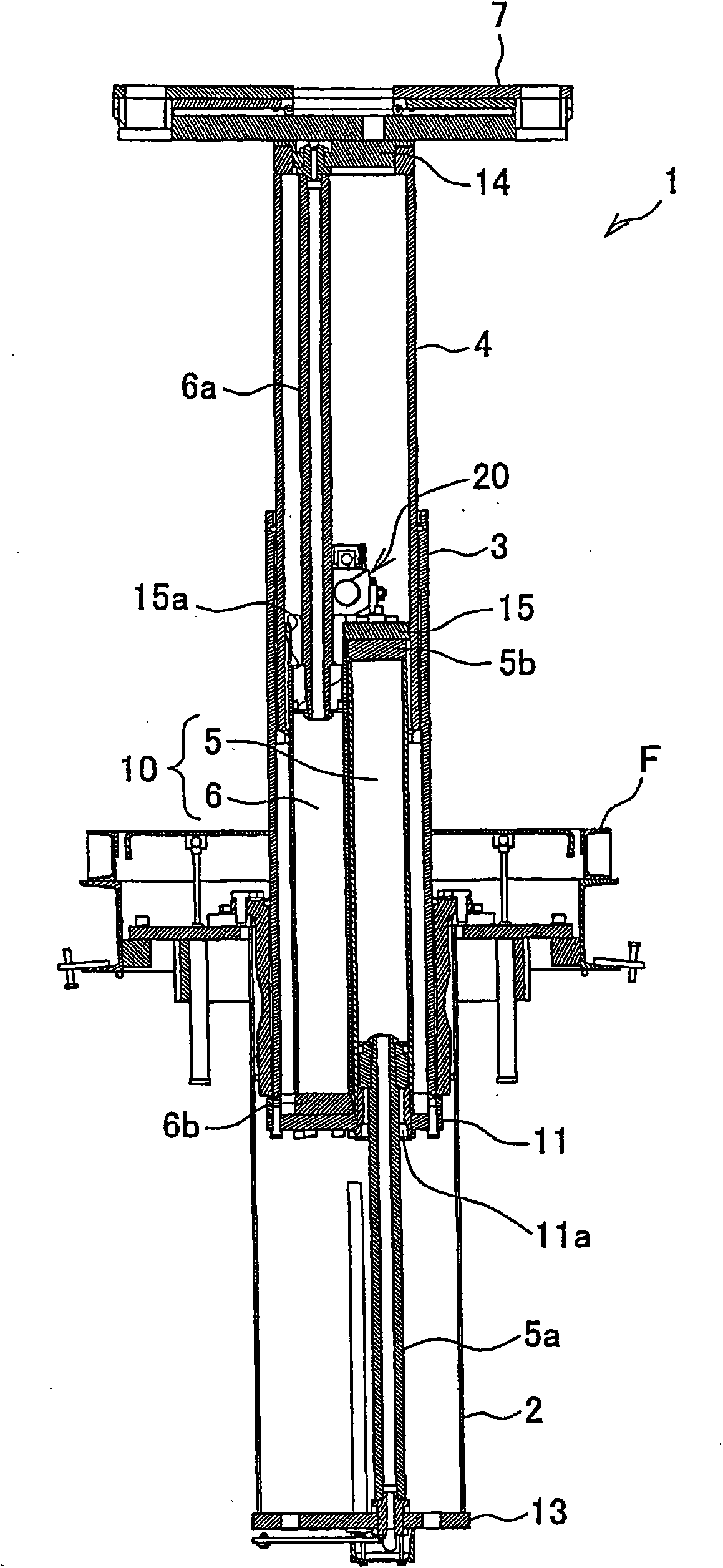

Extension sleeve type elevator and automobile maintenance elevator

InactiveCN101898737AReduced oil volumeSave setup spaceSafety devices for lifting equipmentsLifting framesEngineeringPosition-sensing hydraulic cylinder

The present invention provides an extension sleeve type elevator and an automobile maintenance elevator, capable of saving an additional space for a falling-prevention device, and preventing a bearing station from rotating by the falling-prevention device. An lower layer piston is arranged in an external cylinder in a mode of freely sliding, an upper layer piston is arranged in the lower layer piston in a mode of freely sliding, a juxtaposition hydraulic cylinder is arranged in the lower layer piston and includes a downward hydraulic cylinder with a downward cylinder rod and an upward hydraulic cylinder with an upward cylinder rod side by side, the falling-prevention device of the upper layer piston is arranged inside the upper layer piston, and the falling-prevention device of the lower layer piston is arranged on the side faces of the lower layer piston and the side faces of the external cylinder. The lower layer piston slides upwards in the external cylinder by means of the extension of the downward cylinder rod, and the upper layer piston slides upwards in the lower layer piston by means of the extension of the upward cylinder rod.

Owner:SUGIYASU

Residual oil recovery device for port loading arm

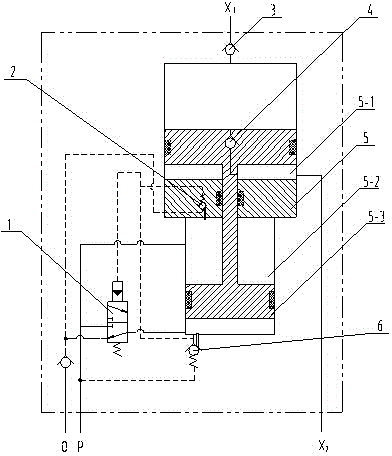

InactiveCN104555879ASolve the problem that cannot be recycledReduce economic lossLiquid transferring devicesReciprocating motionResidual oil

The invention relates to a residual oil recovery device for a port loading arm. The recovery device comprises a double-piston hydraulic cylinder, a two-position three-way hydraulic operated directional valve, two ejector rod type one-way valves and a group of suction and discharge one-way valves, wherein the two-position three-way hydraulic operated directional valve is mounted on the double-piston hydraulic cylinder. Automatic reciprocating movement of piston rods of the double-piston hydraulic cylinder is controlled by the two-position three-way hydraulic operated directional valve and the two ejector rod type one-way valves, and oil is sucked and discharged by the aid of the suction and discharge one-way valves. The device can realize residual oil recovery required by the port loading arm.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

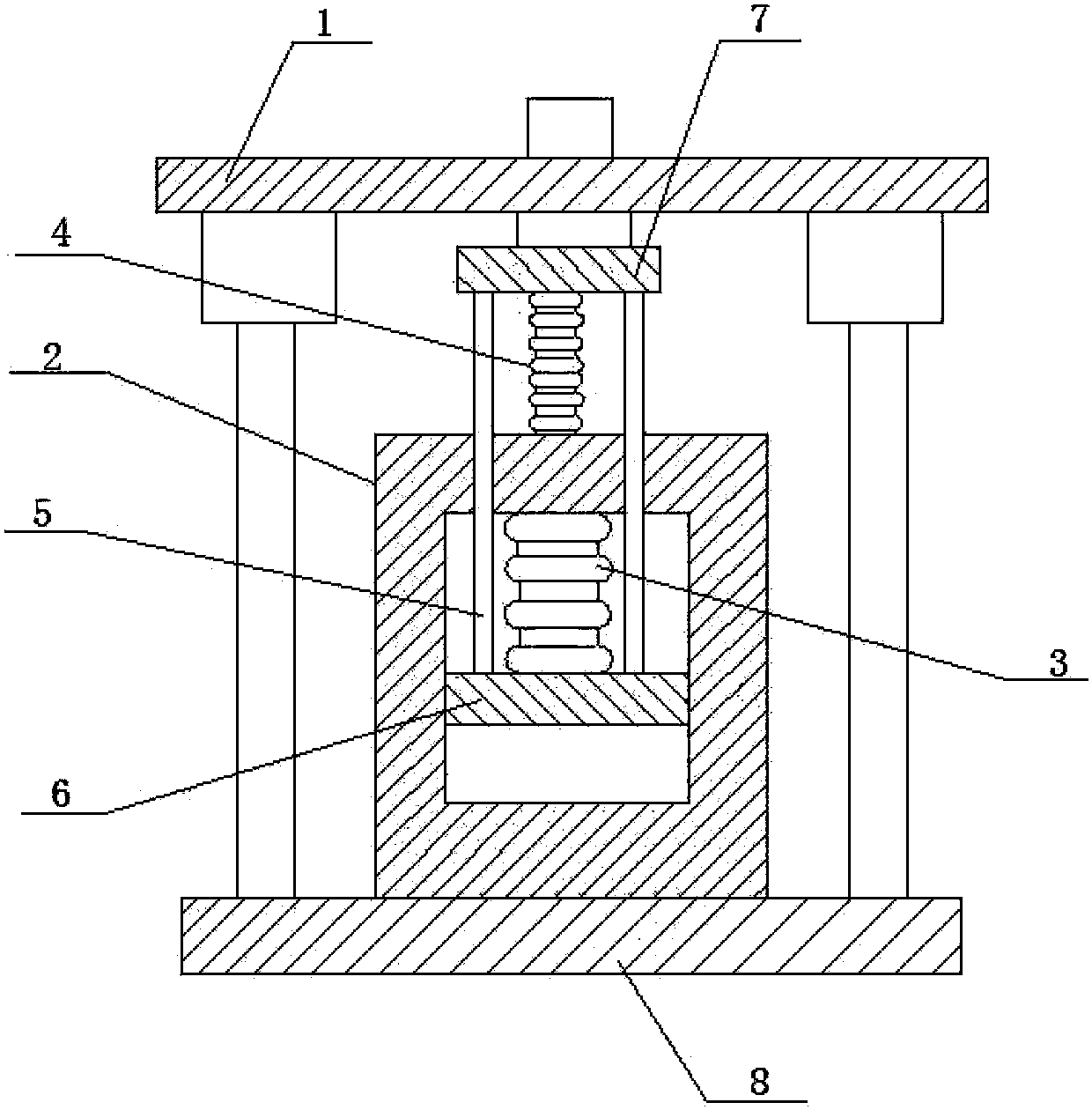

Novel air bag structure of pressure machine

InactiveCN103448283AOvercoming structural complexityOvercome maintenance inconvenienceForging press drivesPress ramEngineeringPosition-sensing hydraulic cylinder

The invention discloses a novel air bag structure of a pressure machine. The novel air bag structure is characterized in that a framework and an inner frame are connected onto a base, double-position guide columns are mounted on the inner frame and are connected with a top beam, a slider is connected with the bottom of the inner frame, a rotary lifting air bag is mounted between the lower portion of the top beam and the upper portion of the inner frame, and an air bag of the pressure machine is mounted between the inside of the inner frame and the upper portion of the slider. The novel air bag structure is provided with the pressure air bag and the lifting air bag which are used as working mechanisms of the pressure machine, and accordingly can be easily used with a product. Compared with a mechanical crank connecting rod structure and a piston hydraulic cylinder or air cylinder structure of a pressure machine, the novel air bag structure has the advantages of simple structure, convenience in maintenance and long service life.

Owner:XUZHOU KAILONG MINING SCI & TECH DEV

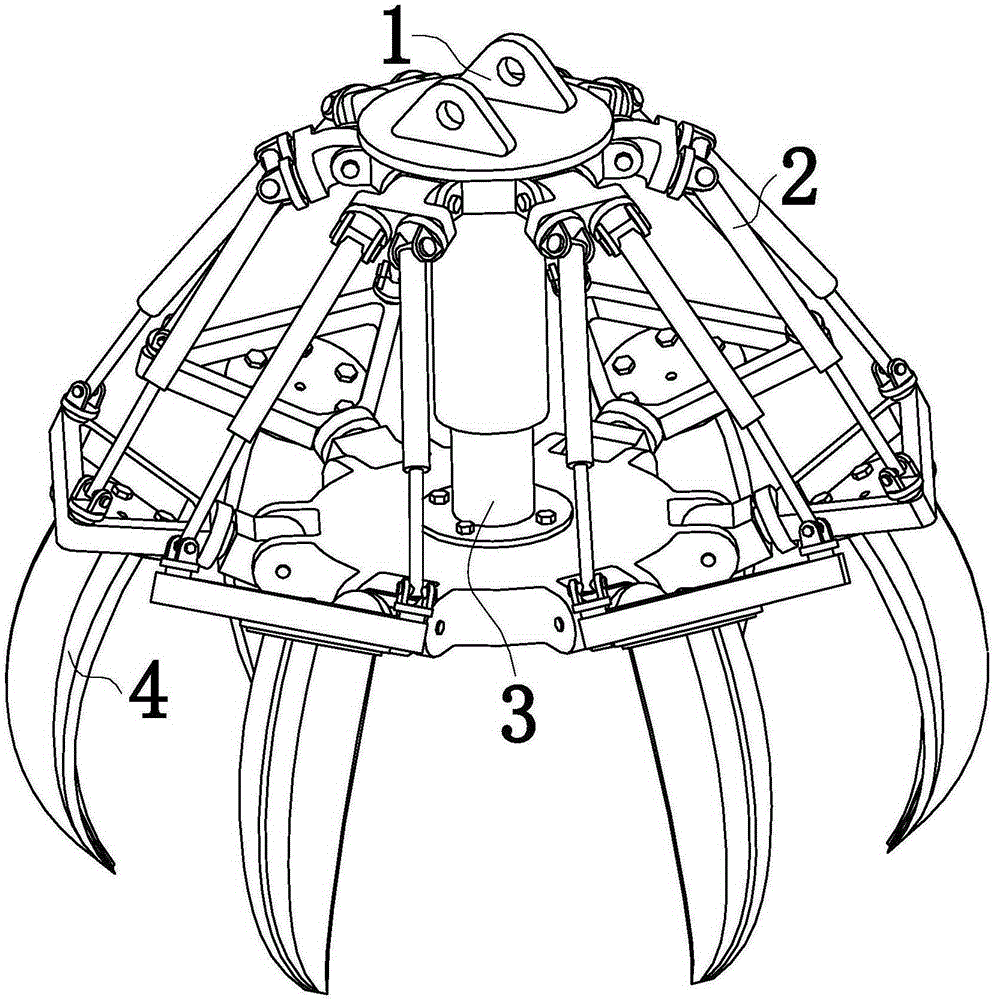

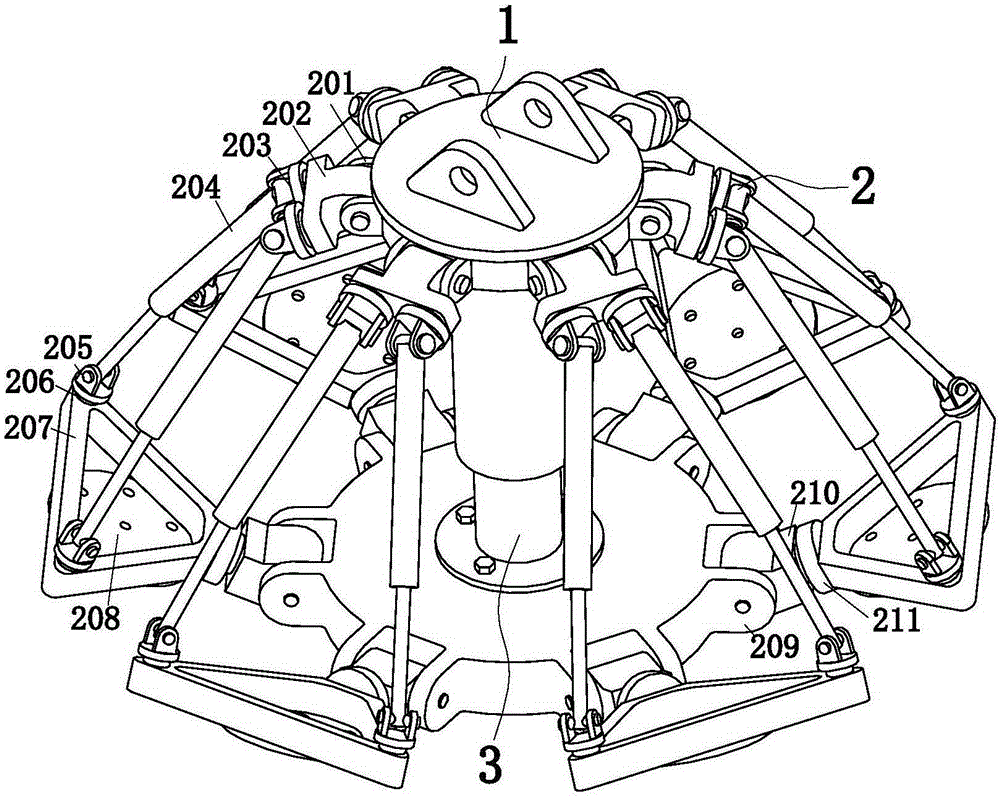

Adjustable grab bucket based on parallel mechanism control

ActiveCN105178373AQuality improvementImprove efficiencyMechanical machines/dredgersEngineeringPosition-sensing hydraulic cylinder

The invention relates to the field of hexagonal grab buckets, in particular to an adjustable grab bucket based on parallel mechanism control. The adjustable grab bucket comprises a connecting body, a parallel adjustment device, a position control hydraulic cylinder and grab bucket bodies. The connecting body is connected with the parallel adjustment device and used for connecting the grab bucket with the outside. The parallel adjustment device is located below the connecting body and used for adjusting the working positions of the grab bucket bodies. The position control hydraulic cylinder is located inside the parallel adjustment device and used for adjusting the positions of the grab bucket bodies in cooperation with the parallel adjustment device, and the two ends of the position control hydraulic cylinder are connected with the parallel adjustment device. The grab bucket bodies are installed on the lower portion of the parallel adjustment device and can be detached to be replaced. With a parallel mechanism as the design basis, adaptive adjustment can be performed according to different grab targets, and therefore the target grab quality and efficiency of an existing grab bucket can be obviously improved.

Owner:ENBEILI KUNSHAN MACHINERY

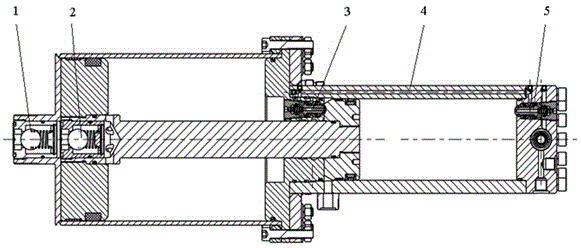

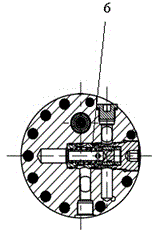

Novel linear reciprocating motion type hydraulic cylinder

InactiveCN105757037AImprove sealingSimple structureFluid-pressure actuatorsReciprocating motionEngineering

The invention discloses a novel linear reciprocating motion type hydraulic cylinder. The novel linear reciprocating motion type hydraulic cylinder comprises a cylinder barrel 1, a cylinder cover 2 and a piston 3, wherein an anti-corrosion coating 4 is sprayed on the outer surface of the cylinder barrel 1; the cylinder cover 2 is arranged on the cylinder barrel 1; a sealing ring 5 is arranged on the outer diameter of the piston 3; an oil draining hole 6 is formed in the cylinder barrel 1; an overflow valve 7 is arranged on the piston 3; a safety valve 8 is arranged on the cylinder cover 2; a spring 9 is arranged between the piston 3 and the cylinder barrel 1. The novel hydraulic cylinder is simple in structure and convenient to use, has better sealing performance, can eliminate a phenomenon of liquid leakage, works reliably and saves the cost, and the service life of a product is prolonged.

Owner:XIAN YIMU SOFTWARE TECH

Underground roadway dinting device

The invention discloses an underground roadway dinting device, which comprises a walking part and a cutting part hinged with the walking part, wherein the cutting part comprises a rocker arm hinged on an upper support frame of the walking part, the rocker arm realizes the transverse swinging operation through a swinging hydraulic cylinder arranged in the upper support frame, a height regulating hydraulic cylinder is hinged between the middle part of the upper end of the rocker arm and the upper support frame of the walking part, the height regulating hydraulic cylinder drives the rocker arm to realize the longitudinal height regulating operation, the top end of the rocker arm is provided with a cutting rolling tube, the cutting rolling tube is driven through a rolling tube transmission system and a hydraulic motor arranged at one side of the cutting rolling tube, the rotary operation at the top end of the rocker arm is realized, and cutting knives are uniformly distributed on the surface of the cutting rolling tube. The structure of the underground roadway dinting device is compact, the layout is reasonable, the rocker arm with the cutting part can be conveniently regulated in any position, the operation is simple, the application range is wide, and meanwhile, the walking part is designed, so the device has the advantages that the moving is convenient, and the moving along with the work surface can be realized.

Owner:ANHUI UNIV OF SCI & TECH

Hand wheel hydraulic pump

InactiveCN102312879AEasy to operateAdequate hydraulic powerFluid-pressure actuatorsInjection portHydraulic pump

The invention discloses a hand wheel hydraulic pump. A guide ring of which the outer ring is circular and the inner ring is oval and a rotary disk are arranged in a shell of the hand wheel hydraulic pump; the shell is provided with an oil injection port; a plurality of piston hydraulic cylinders are uniformly arranged on the rotary disk at intervals; the back end of a piston of the piston hydraulic cylinder is provided with a spring; the front end of the piston is provided with a steel ball which slides along the inner ring of the guide ring; a rotary shaft is inserted into the shell; one end of the rotary shaft is connected with the center of the rotary disk, and the other end of the rotary shaft is connected with a hand wheel; a flow distribution seat is arranged in the shell, and is provided with a plurality of oil grooves which are communicated with the hydraulic cylinders and two oil ports passing out of the shell; the two oil ports of the flow distribution seat are communicated with the oil grooves and the output ends of two one-way valves respectively; and the input ends of the two one-way valves are communicated with the shell. The hand wheel hydraulic pump has the advantages of convenience for operating, capabilities of supplying sufficient hydraulic power, greatly lowering the labor intensity and improving the conversion efficiency of labor force and hydraulic power, and suitability of driving hydraulic executing elements under multiple working conditions.

Owner:SHANGHAI RONGDE ENG EQUIP

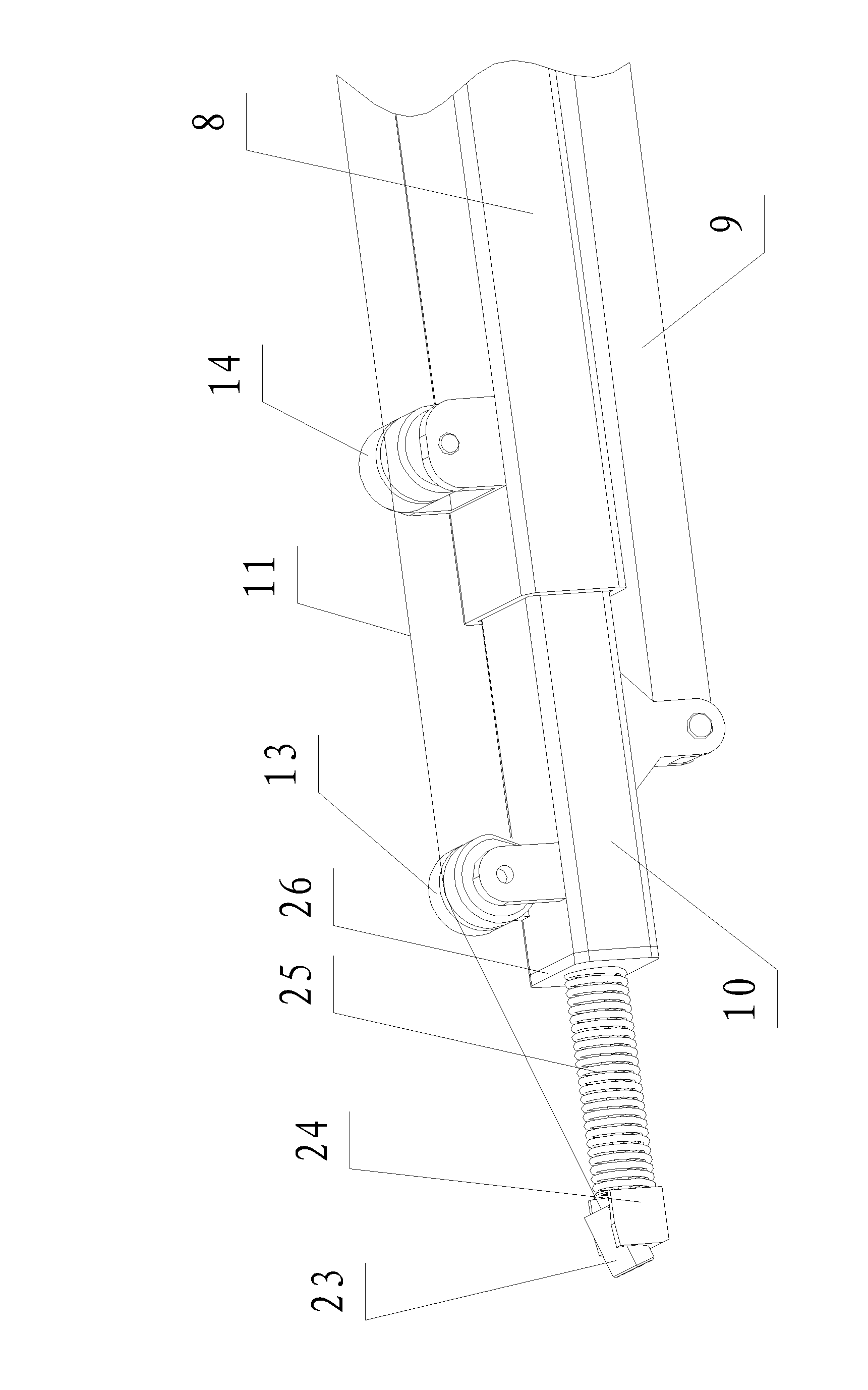

Racking platform bent arm pushing type drill rod discharging mechanical arm

InactiveCN104265206ACompact structureLight in massDrilling rodsDrilling casingsEngineeringPosition-sensing hydraulic cylinder

The invention relates to a racking platform bent arm pushing type drill rod discharging mechanical arm which comprises a track beam, a bottom chain, a sliding trolley, a power device, a sliding base, a small arm, a hydraulic clamp, a rotating rod, a hydraulic cylinder and a bent arm. A sliding way is arranged at an inner cavity of the track beam. Sliding wheels of the sliding trolley are connected to the sliding way of the inner cavity of the track beam in a clamping mode. The front end of the sliding base is fixedly connected to the sliding trolley through a screw. The power device is embedded to the inner cavity of the sliding base and is fixedly connected with the sliding base. The bottom chain is connected with the bottom of the track beam in a sliding mode. A gear of the power device is meshed with the bottom chain. The back end of the sliding base is in sliding connection with the front end of the bent arm through a pin shaft. One end of the hydraulic cylinder is in sliding connection with the back end of the sliding base through a pin shaft. The other end of the hydraulic cylinder is connected to the bent arm through a pin shaft. The bent arm is connected with a small arm through a pin shaft. The bottom of the small arm is provided with a swinging hydraulic cylinder. The other end of the swinging hydraulic cylinder is fixedly connected with the hydraulic clamp. The racking platform bent arm pushing type drill rod discharging mechanical arm is compact in structure, light in weight and high in reliability, working efficiency is improved, and labor intensity and potential safety hazards are lowered.

Owner:QINGDAO YONGTONG ELEVATOR ENG

A pipe multi-angle drilling equipment

ActiveCN105750937BRealize multi-angle drillingEasy to controlFeeding apparatusLarge fixed membersPosition-sensing hydraulic cylinderIndustrial engineering

Owner:江苏净傲机电科技有限公司

Double-piston hydraulic cylinder for winding drum of coiling machine

The invention relates to improvement on a hydraulic cylinder for a winding drum of a coiling machine for coiled plates made of strip steel, and discloses a double-piston hydraulic cylinder for a winding drum of a coiling machine. The double-piston hydraulic cylinder comprises a winding drum spindle. A connecting rod is mounted in a through hole in the axis of the winding drum spindle, a hydraulic cylinder is mounted at a spindle end of the winding drum spindle by the aid of a support frame, and an end of a piston rod of the hydraulic cylinder is connected with the connecting rod in the axis of the winding drum spindle by a connecting piece. The double-piston hydraulic cylinder is characterized in that a small cavity and a large cavity are arranged in a cylinder block of the hydraulic cylinder, a small piston is mounted in the small cavity, the root of the piston rod is connected with the small piston, and a large piston is mounted in the large cavity and sleeves the piston rod; an oil pipe port A, an oil pipe port B and an oil pipe port C are further respectively formed in the cylinder block. The double-piston hydraulic cylinder has the advantages that the problem of difficulty in rubber expansion sleeve replacing operation of a winding drum of an existing coiling machine for coiled plates made of strip steel can be solved, and the four-piston hydraulic cylinder for the winding drum of the existing coiling machine for the coiled plates made of the strip steel can be mainly improved.

Owner:HUANGSHI SUNNY XINGYE STRIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com