Underground roadway dinting device

An underground tunnel and undercover technology, which is applied in tunnels, mining equipment, earth-moving drilling and mining, etc., can solve the problems of low productivity, track deformation, high labor intensity, etc., and achieve the effect of convenient movement, convenient adjustment and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

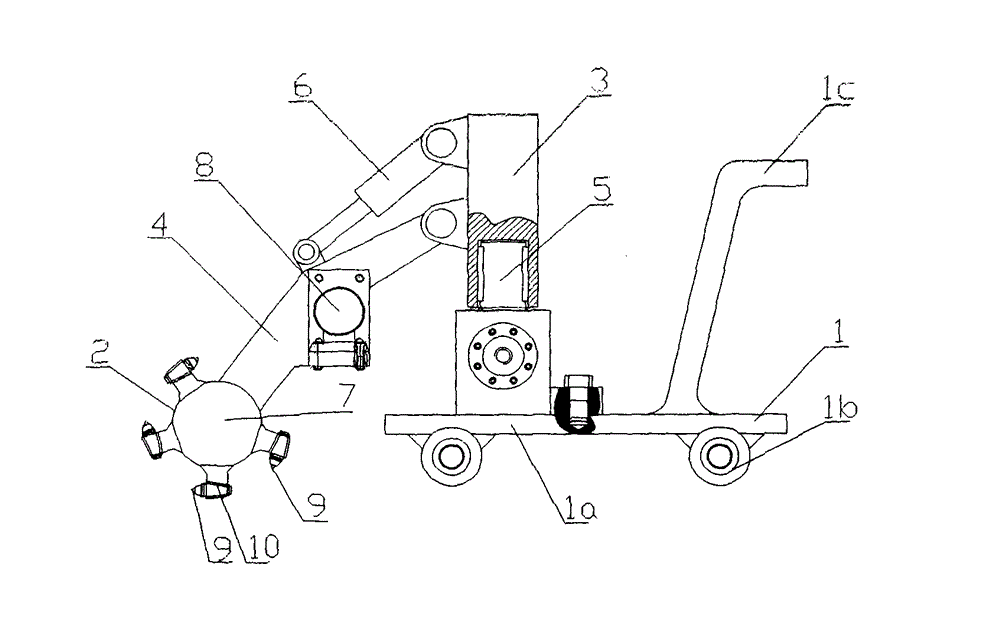

[0011] see figure 1 , an undercover device for an underground tunnel provided by the present invention includes a running part 1 and a cutting part 2 hinged with the running part 1, the cutting part 2 includes a rocker 4 hinged on the upper bracket 3 of the running part 1, The rocker arm 4 realizes lateral swing operation through the swing hydraulic cylinder 5 arranged in the upper bracket 3; the height adjustment hydraulic cylinder 6 is hinged between the middle part of the upper end of the rocker arm 4 and the upper bracket 3 of the walking part 1, and the height adjustment The hydraulic cylinder 6 drives the rocker arm 4 to realize vertical height adjustment operation; the top of the rocker arm 4 is provided with a cutting drum 7, and the cutting drum 7 is driven by the hydraulic motor 8 and the drum transmission system arranged on one side to realize the swinging The top end of the arm 4 rotates, and the surface of the cutting drum 7 is uniformly equipped with cutting kniv...

Embodiment 2

[0013] The walking part 1 includes a base plate 1a, at least two rollers 1b are provided at the bottom of the base plate 1a, and a push handle 1c is provided on the top of the base plate 1a, by pushing the push handle 1c, the whole machine can be moved.

Embodiment 3

[0015] The cutting knife 9 is detachably arranged in the knife seat 10 on the surface of the cutting drum 7. When the cutting knife 9 is used for a long time and is seriously worn, it can be replaced directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com