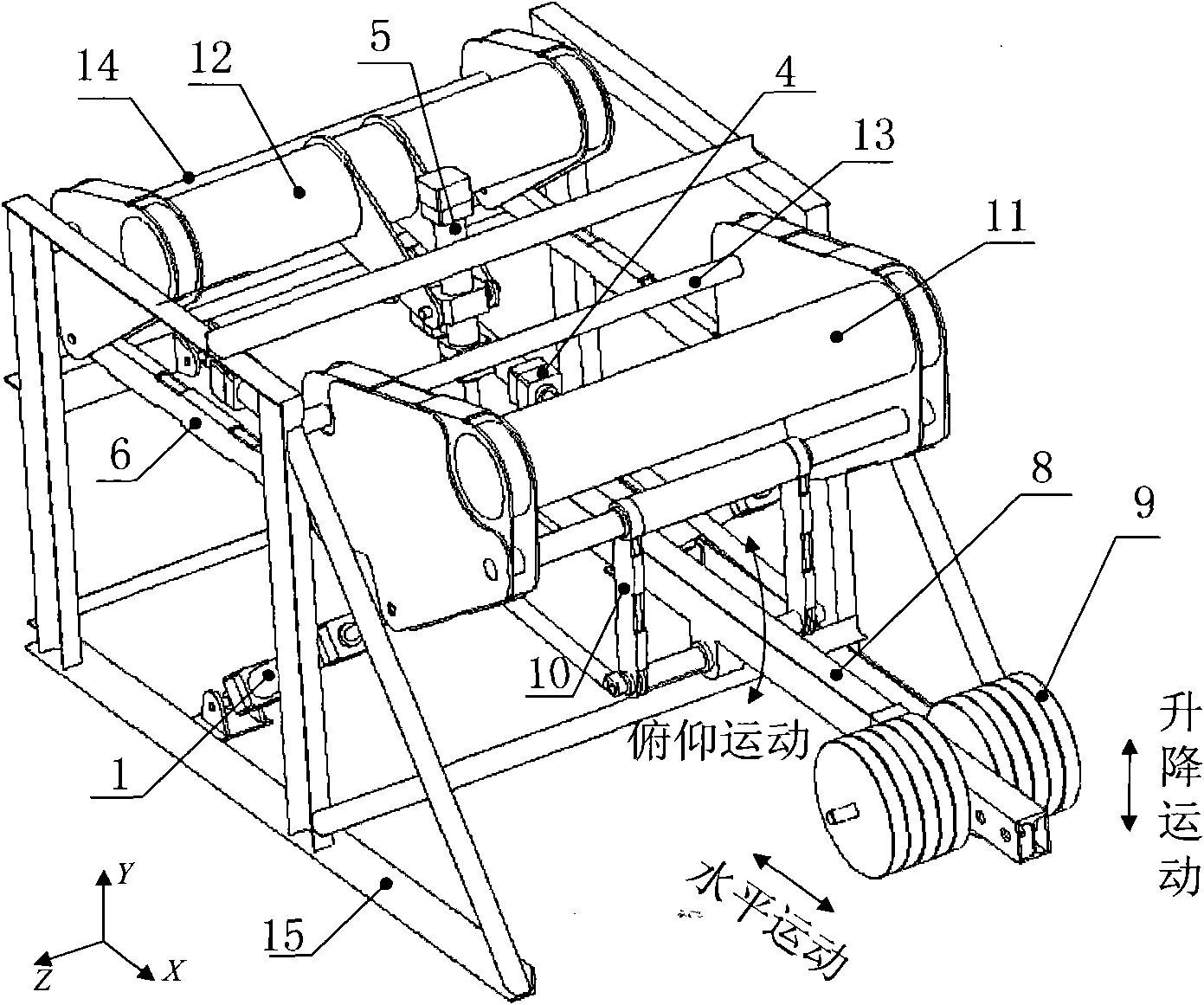

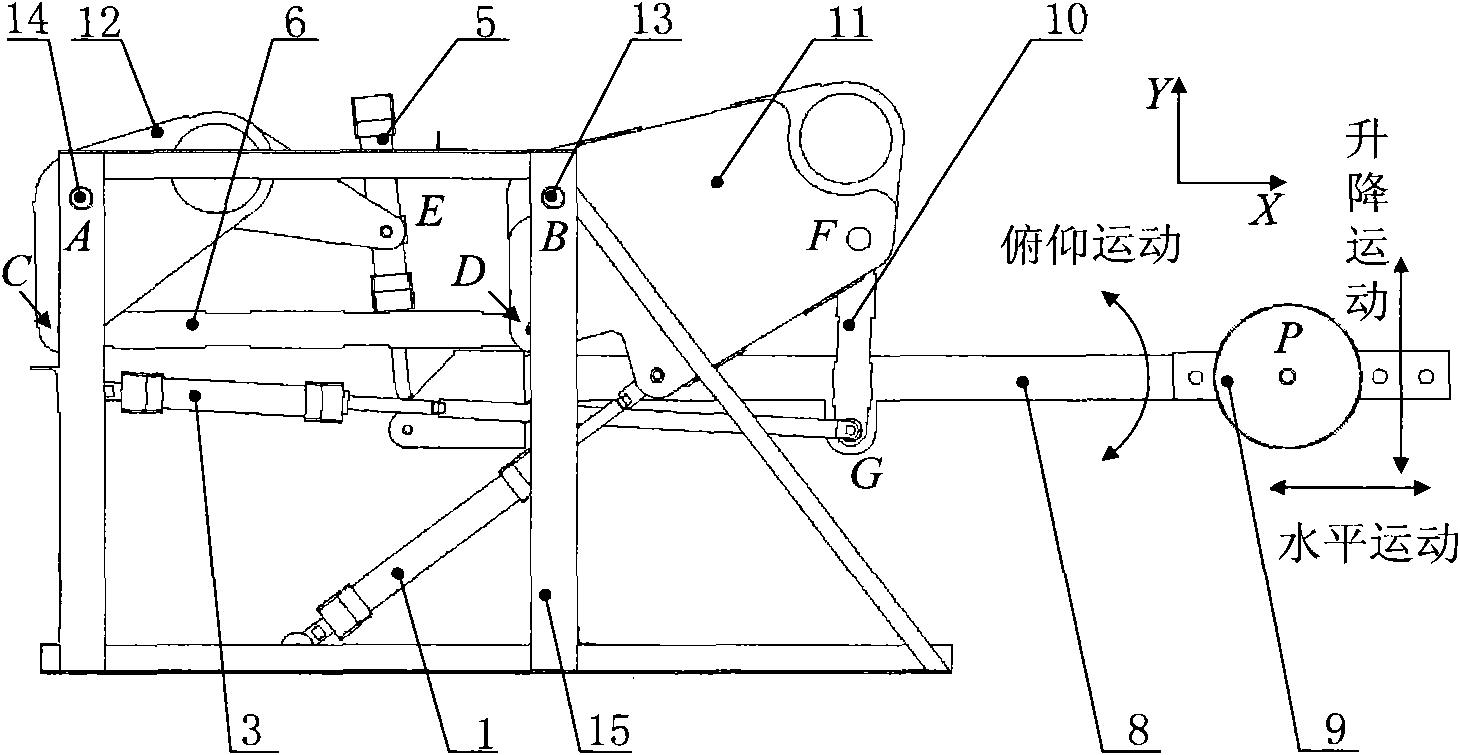

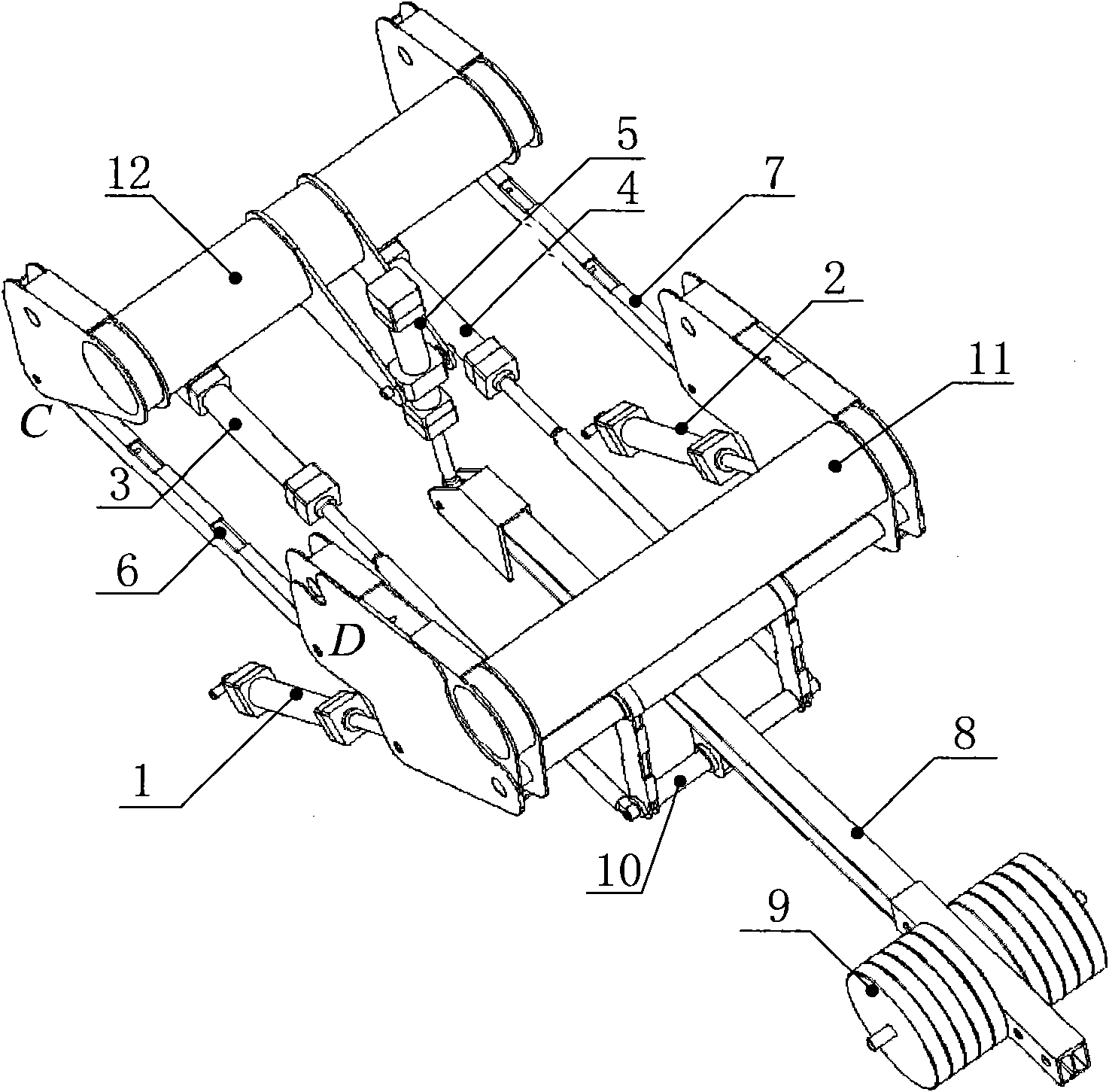

Experiment table for kinetic control of hydraulic servo driving system

A drive system and hydraulic servo technology, applied in the field of test benches, can solve the problems of high cost, danger, and risk of experiments, and achieve the effect of reducing experimental risks and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

[0032] Implementation plan 2: Install all hydraulic cylinders, and all hydraulic cylinders are activated. The vertical hydraulic cylinder 1 and the vertical hydraulic cylinder 2 are arranged in parallel and need synchronous control; the horizontal hydraulic cylinder 3 and the horizontal hydraulic cylinder 4 are arranged in parallel and need synchronous control. Study the position tracking control and output driving force of hydraulic cylinders arranged in parallel under different control strategies.

[0033] By using the experimental platform for dynamic control of the hydraulic servo system of the present invention, the dynamic control experiment that needs to be carried out on the actual forging machine can be moved to the laboratory, thereby greatly reducing the experiment cost and experiment risk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com