Physical simulation method and physical simulation device utilizing suction casting to research solidification of strip continuous casting

A technology of physical simulation and thin strip, which is applied in the field of physical simulation and device of using suction casting to study the solidification of thin strip continuous casting, can solve the problems of high cost, difficult research work, lack of directness, etc., and achieves reduction of scale and test. The effect of cycle time and experimental cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

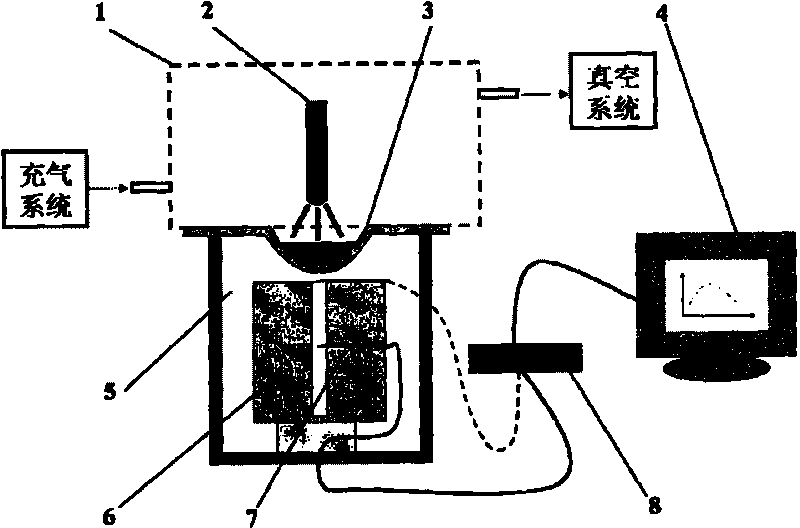

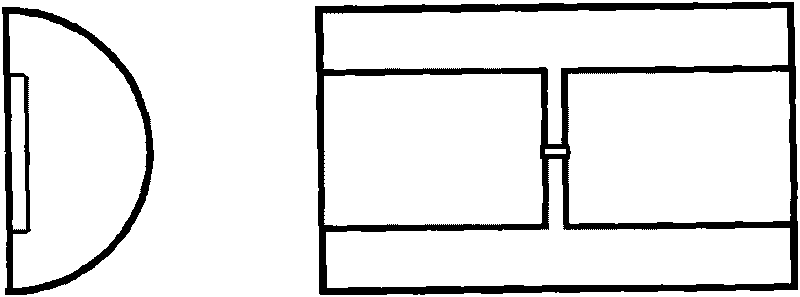

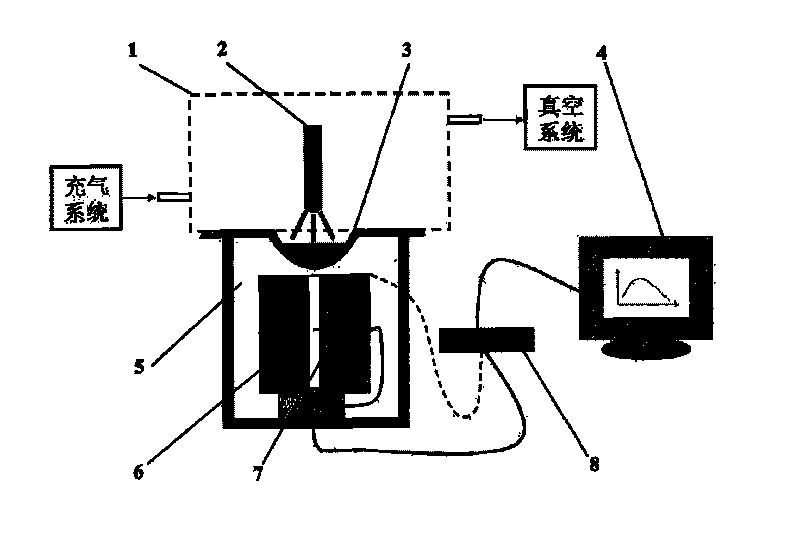

[0027] Specific embodiments of the present invention will be further described as follows in conjunction with the accompanying drawings.

[0028] Using silicon steel with a grade of 3.0wt% Si as the raw material, prepare a mold and a data acquisition system, mix the prepared raw materials and put them into the copper crucible of the electric arc melting furnace. Turn on the mechanical pump to pre-evacuate to 3-7Pa, and then turn on the molecular pump to evacuate until the vacuum degree is 5×10 -3 Pa, close the molecular pump valve, stop the molecular pump and mechanical pump. Fill the button furnace with high-purity argon to -0.08MPa (0.2 atmosphere). The raw material is melted into a liquid state by an electric arc, and then while the smelting is continued, the magnetic stirring is turned on to promote the uniform composition of the alloy, and the magnetic stirring current is about 0-8A. Melt and stir the alloy repeatedly for 3-5 times. Transfer the molten alloy to the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com