Patents

Literature

318results about How to "Save setup space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

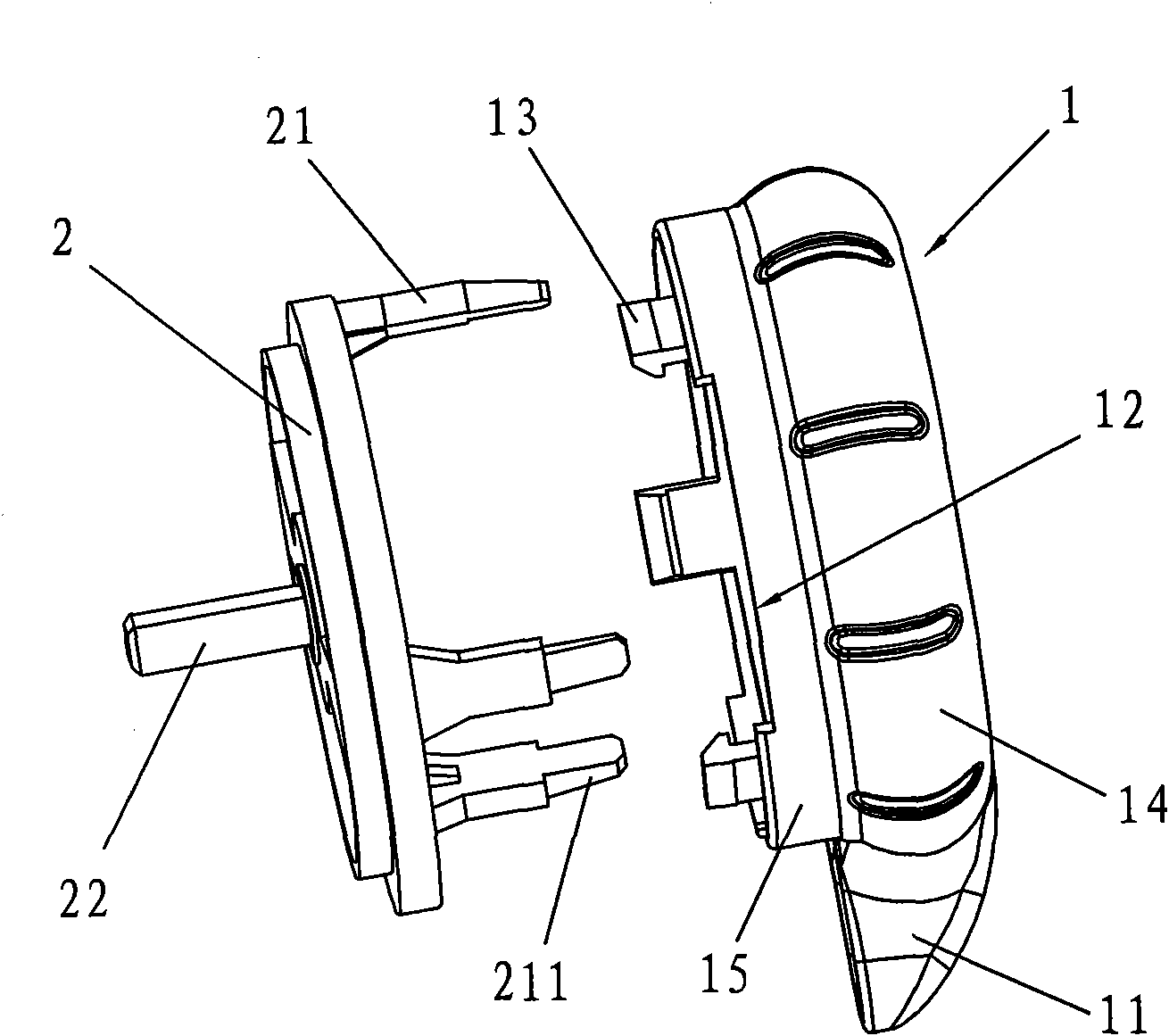

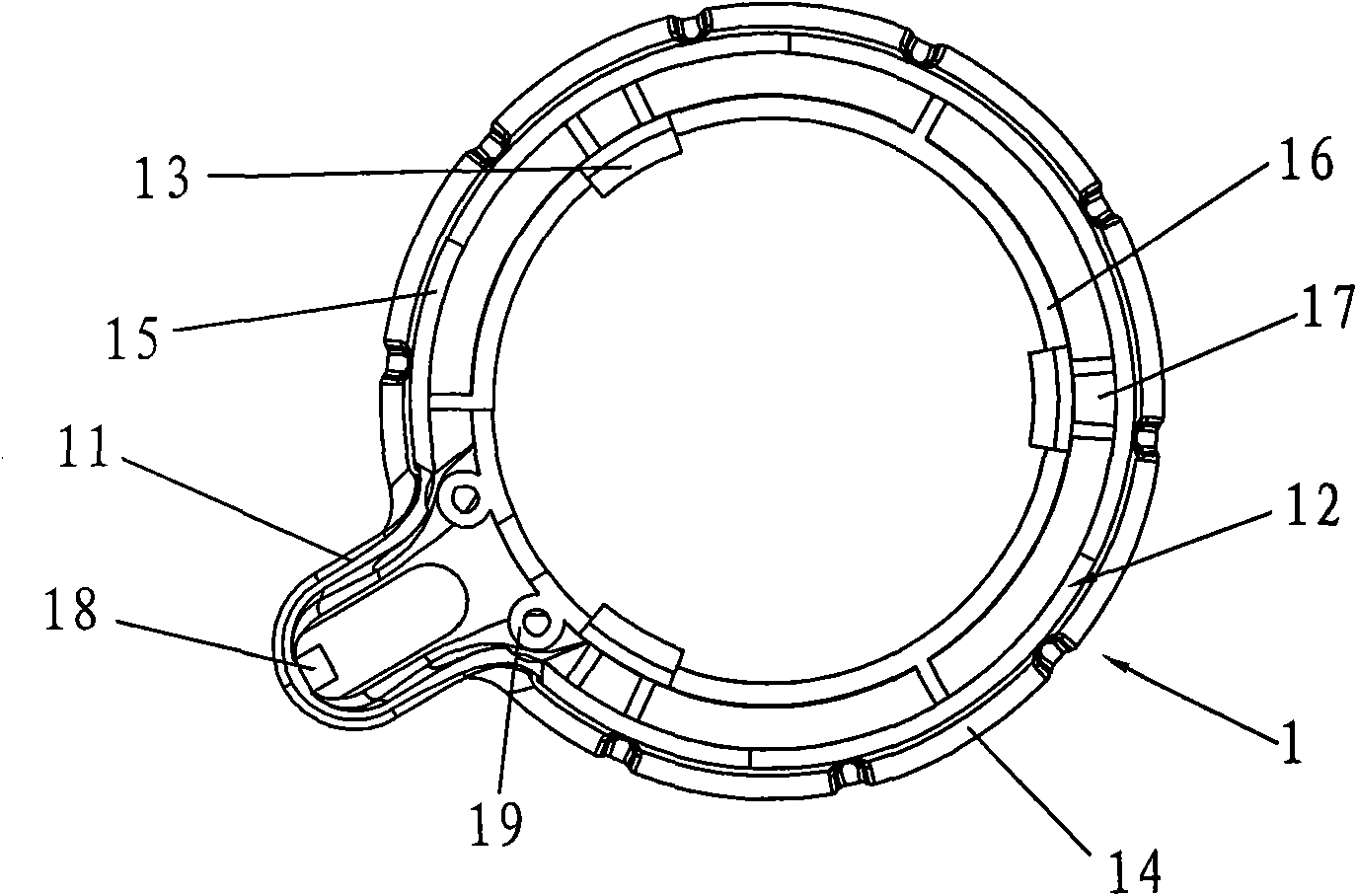

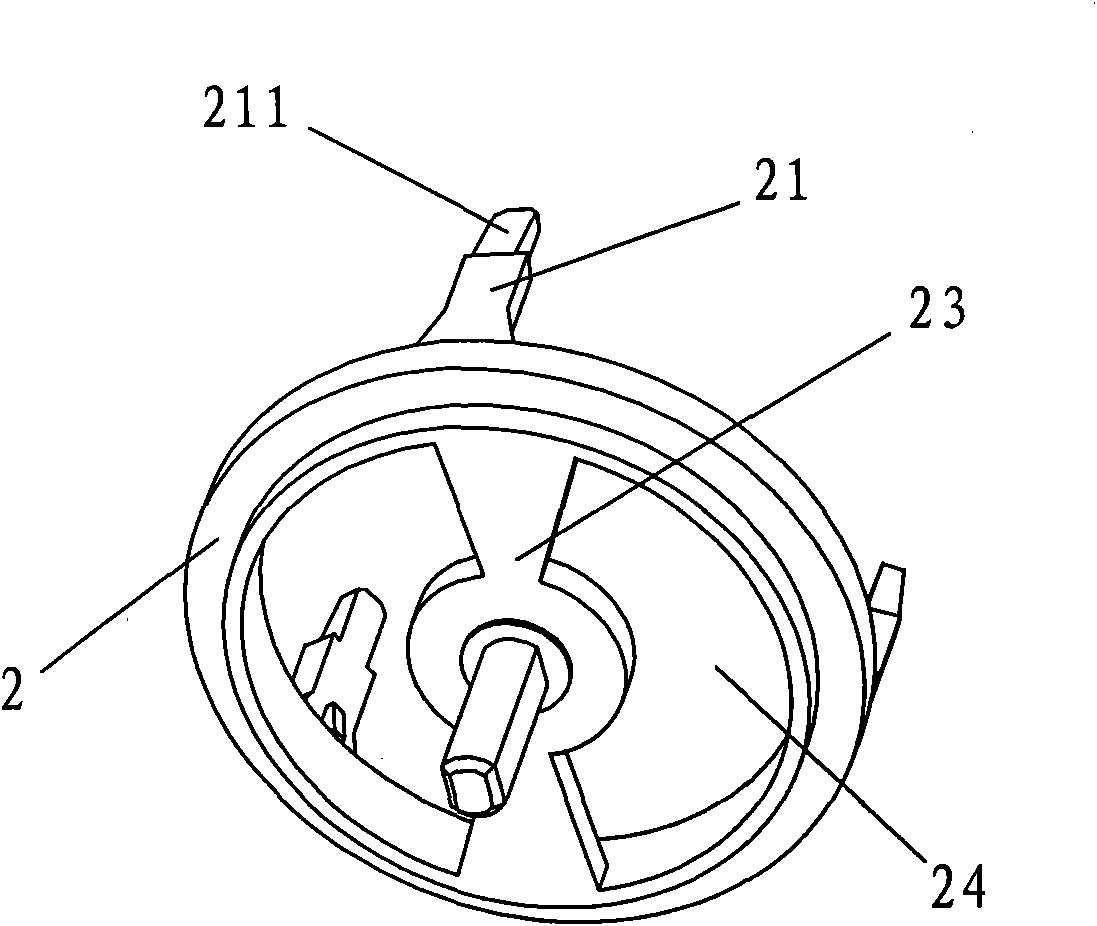

Knob structure

Owner:SHENZHEN CRASTAL TECH CO LTD

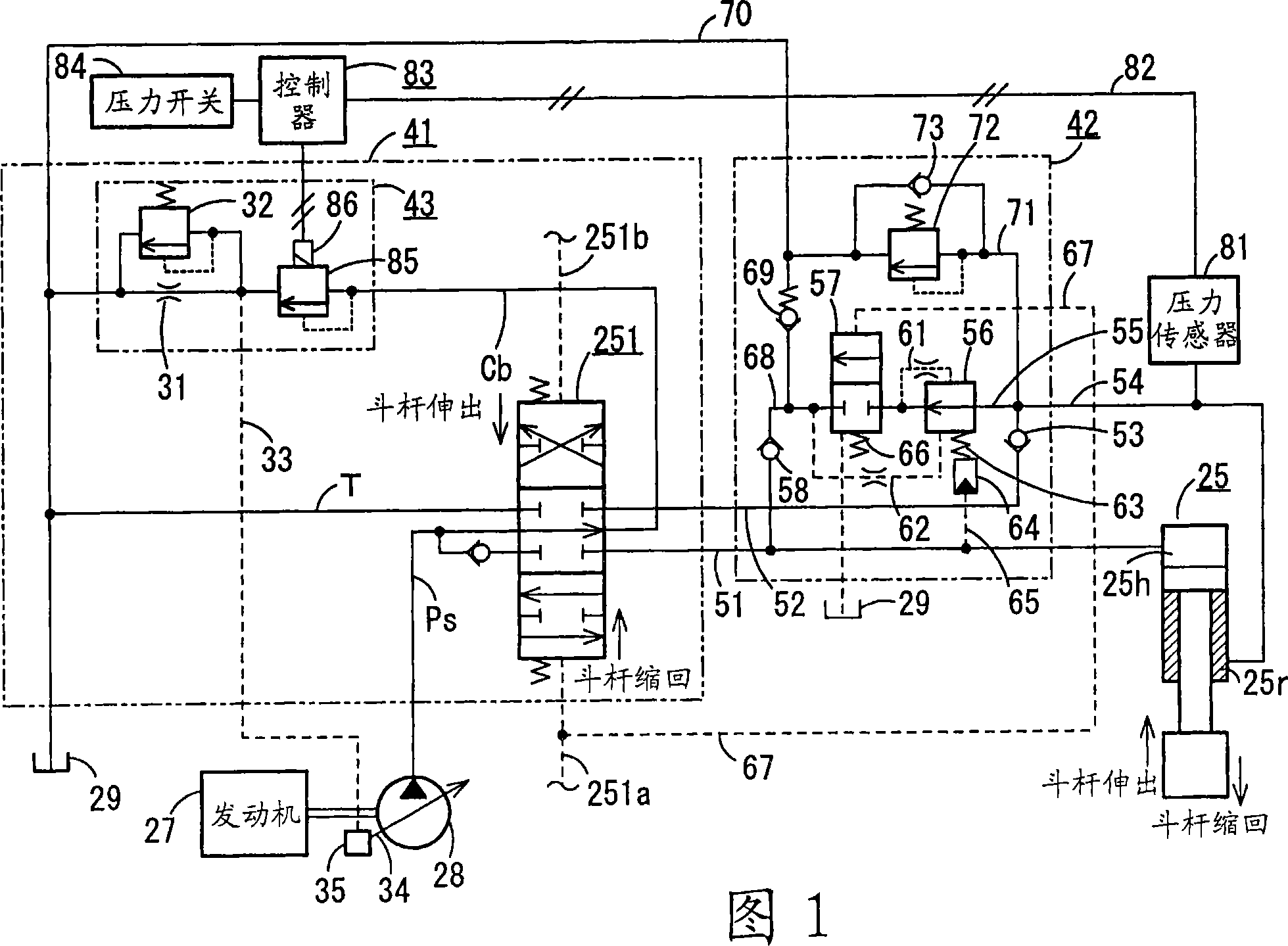

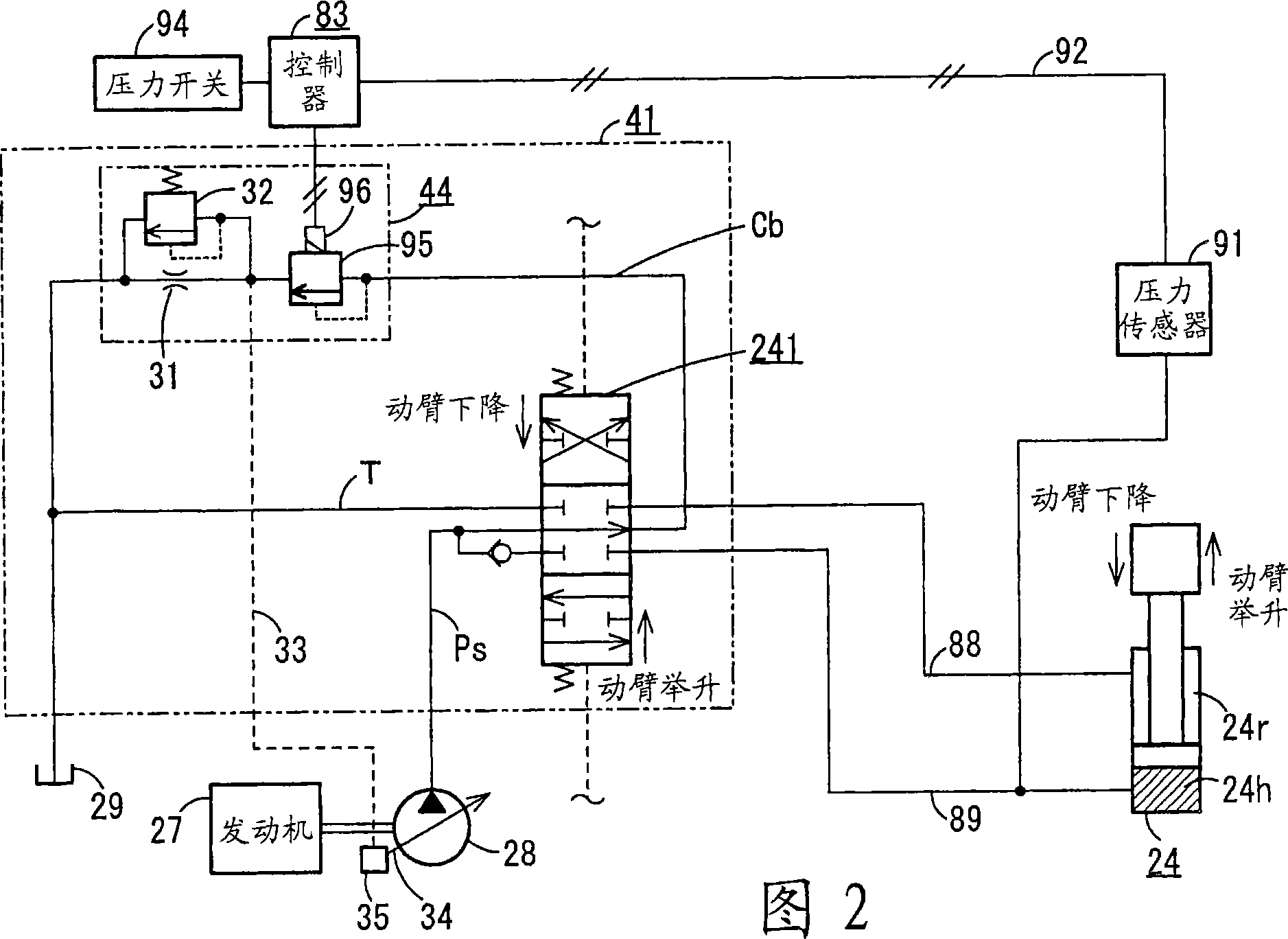

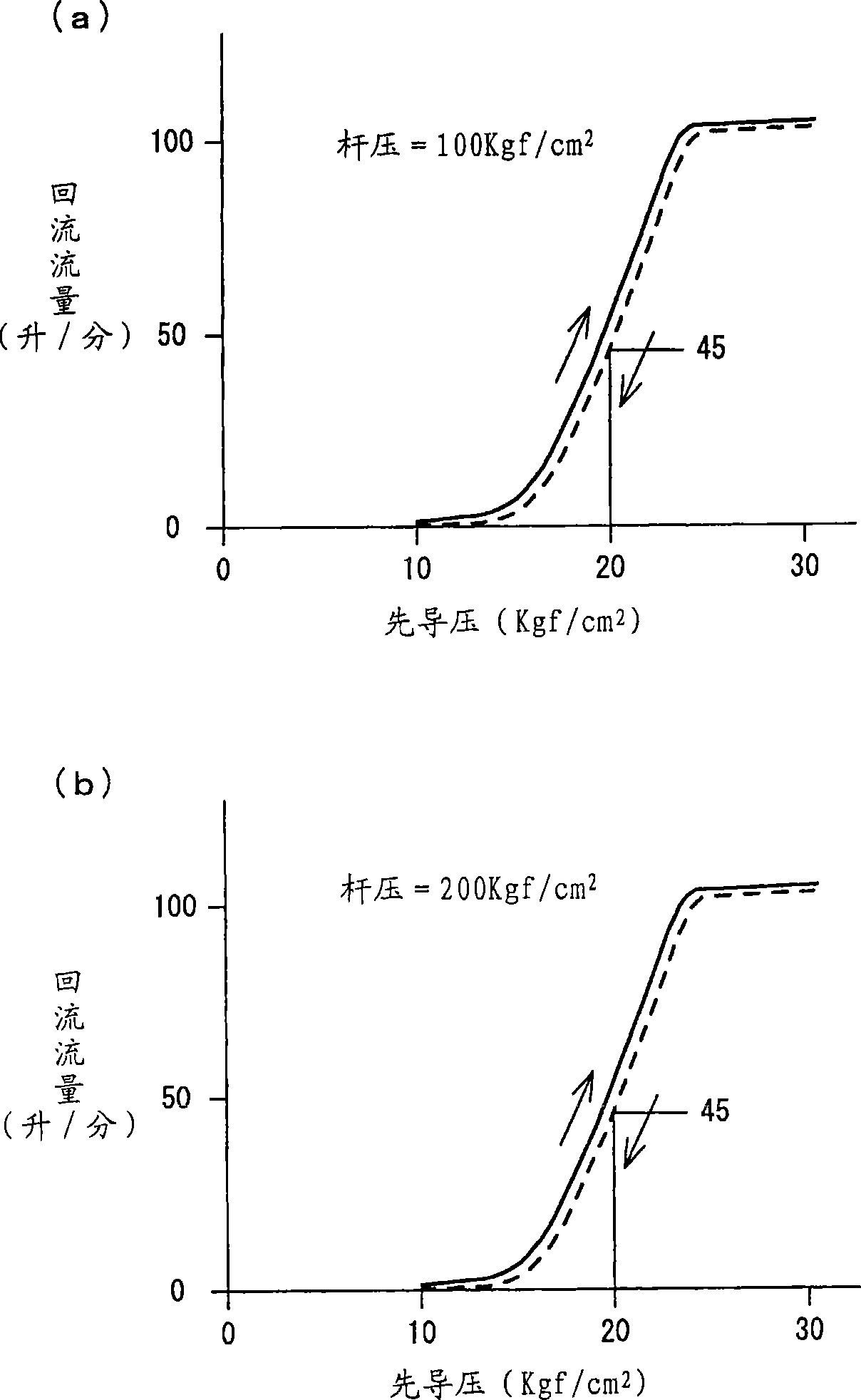

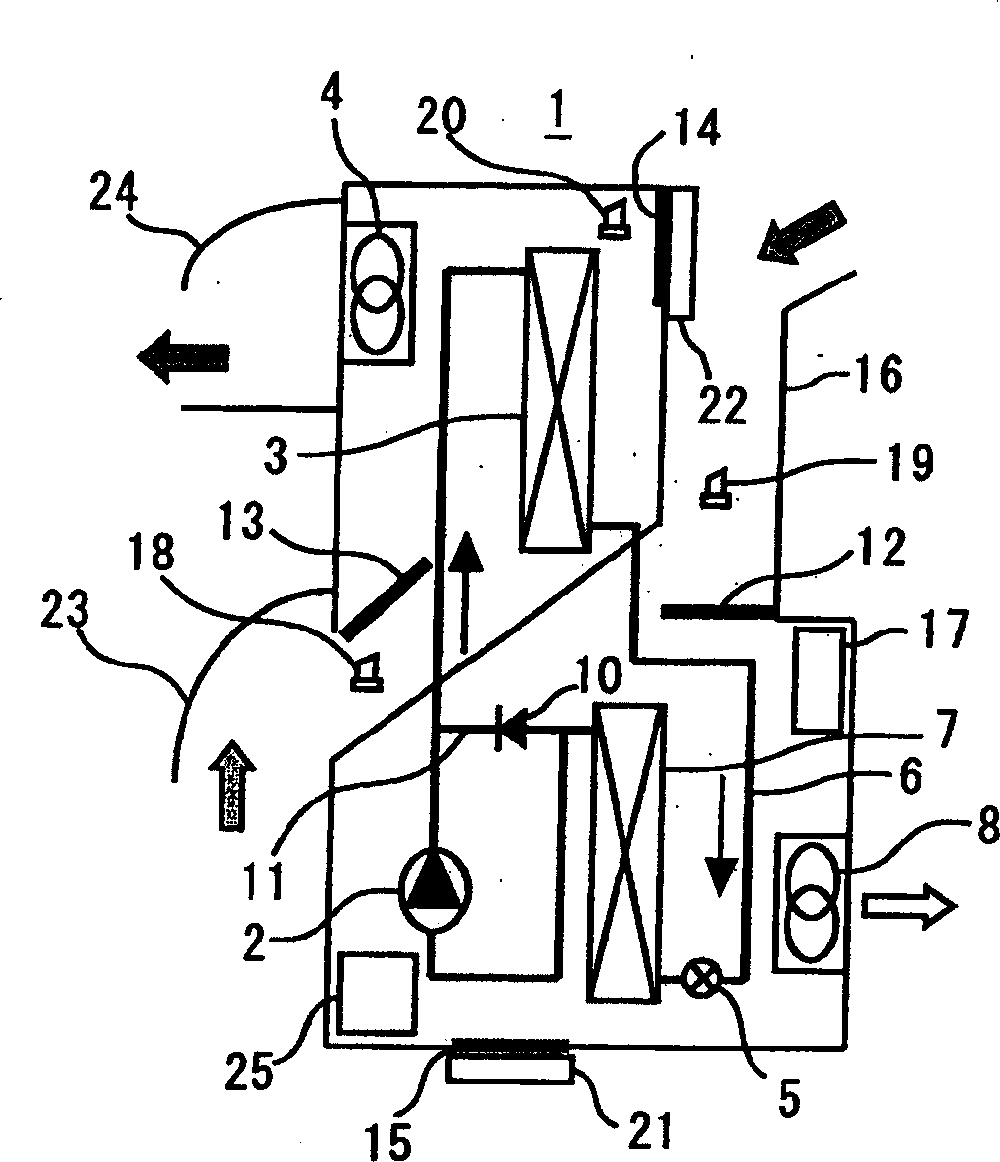

Control circuit of construction machine

InactiveCN1914384AStable flow characteristicsStable without changing flow characteristicsServomotorsSoil-shifting machines/dredgersHydraulic pumpControl engineering

A control circuit of a construction machine capable of securing a same operability as in a case where a hydraulic shovel having an open center circuit is tuned by using a standard bucket even when the bucket weight of the hydraulic shovel is changed. Center bypass lines (Cb) are installed for a boom operation valve and a stick operation valve (251) controlling an oil supplied from a hydraulic pump (28) to a boom cylinder and a stick cylinder (25). A stick-in meter-out load pressure compensating valve (42) is installed in a rod side return line (55) from the rod side (25r) of the stick cylinder (25) to a tank (29). A pressure sensor (81) detecting the pressure of the hydraulic oil supplied to the rod side (25r) is installed on the rod side (25r) of the stick cylinder (25). An electromagnetic proportional relief valve (85) controlling a center bypass line pressure on the downstream side of the stick operation valve (251) in an increasing direction according to the rise of the pressure detected by the pressure sensor (81) is installed in the center bypass line (Cb).

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

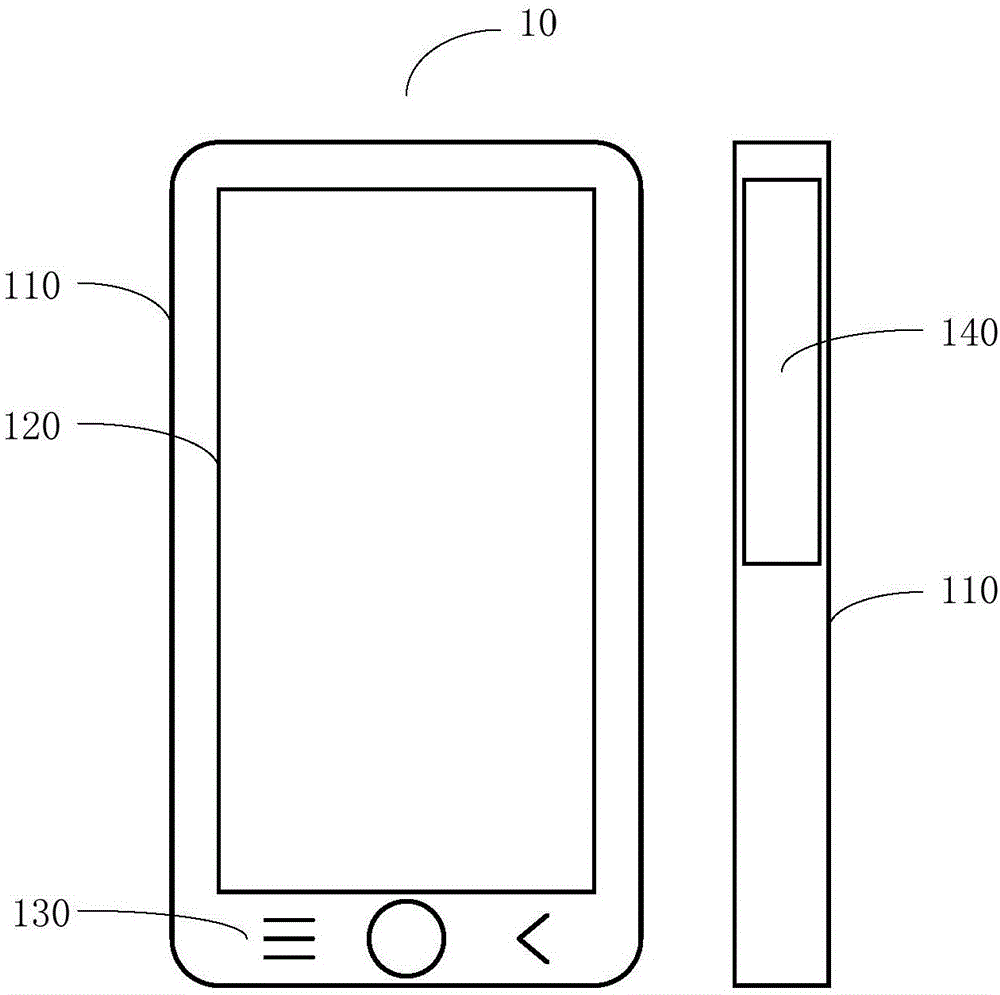

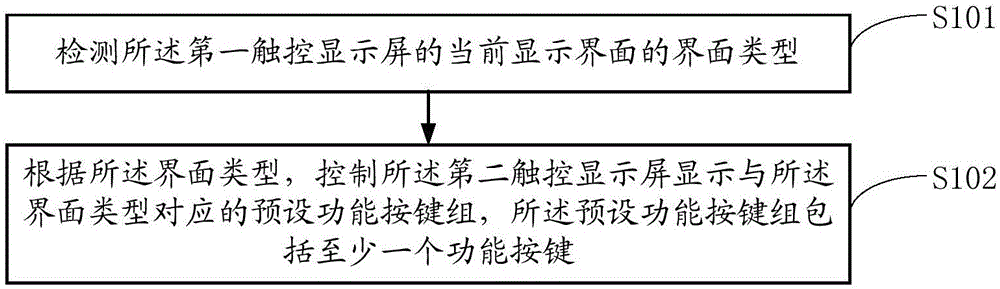

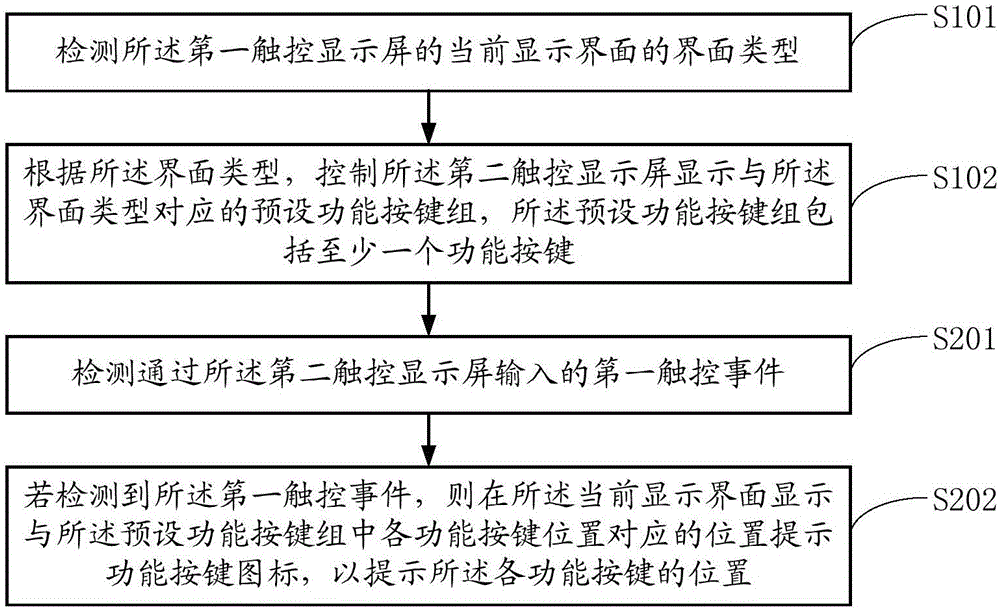

Terminal and function key display method thereof

InactiveCN106775425AImprove flexibility and convenienceSave key setting spaceInput/output processes for data processingControl functionKey pressing

An embodiment of the invention provides a terminal and a function key display method thereof. The terminal comprises a first touch control display screen arranged on the front side of the terminal and a second touch control display screen arranged on at least one lateral side of the terminal. The function key display method includes: detecting the interface type of the current display interface of the first touch control display screen; according to the interface type, controlling the second touch control display screen to display a preset function key set corresponding to the interface type, wherein the preset function key set comprises at least one function key. The terminal and the function key display method thereof have the advantages that by detecting the interface type of the current display interface of the main screen of the terminal, the function keys corresponding to the interface type are displayed on the lateral side of the terminal, and the flexibility and convenience of the fast control function of the terminal are increased effectively.

Owner:SHENZHEN GIONEE COMM EQUIP

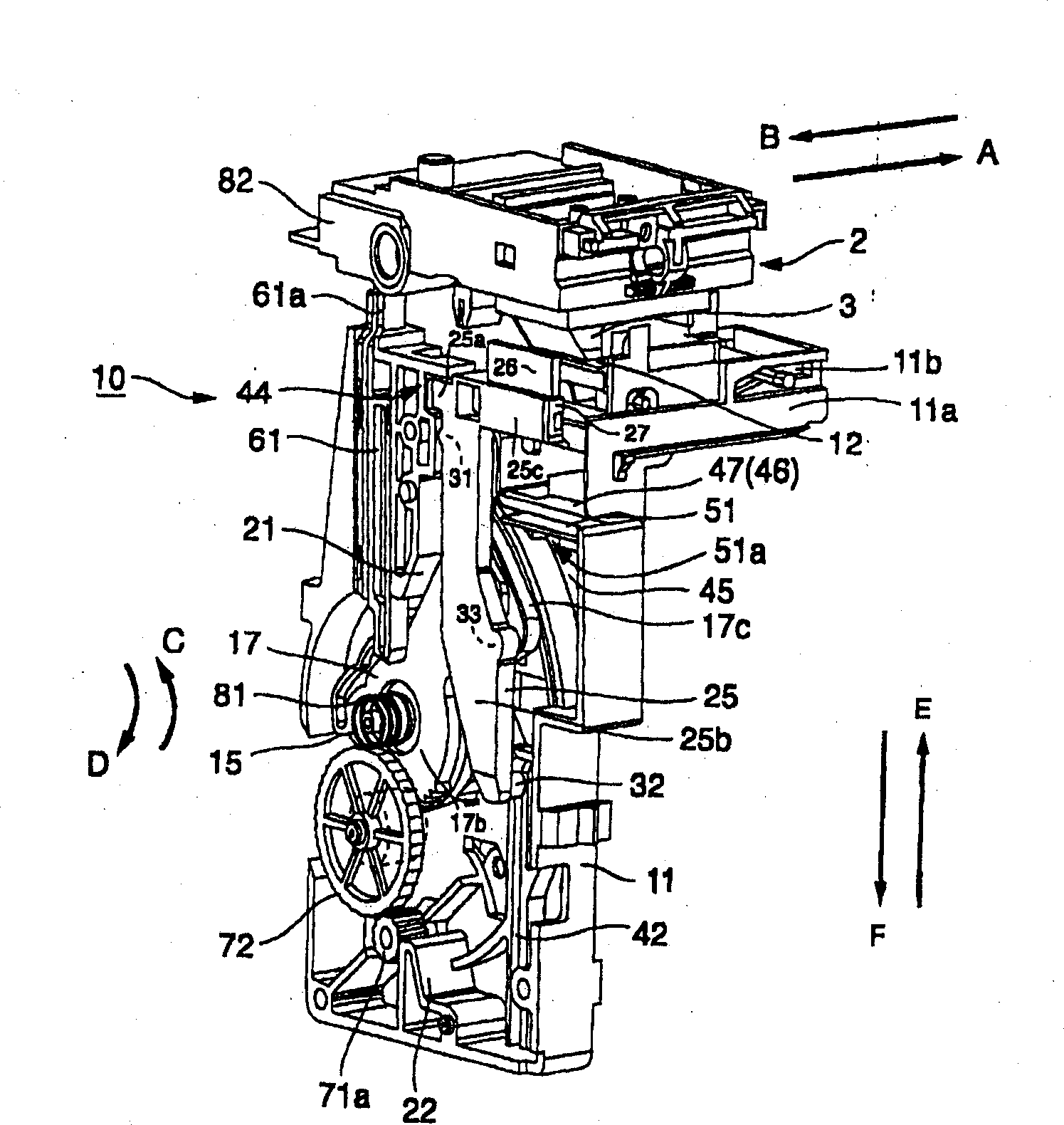

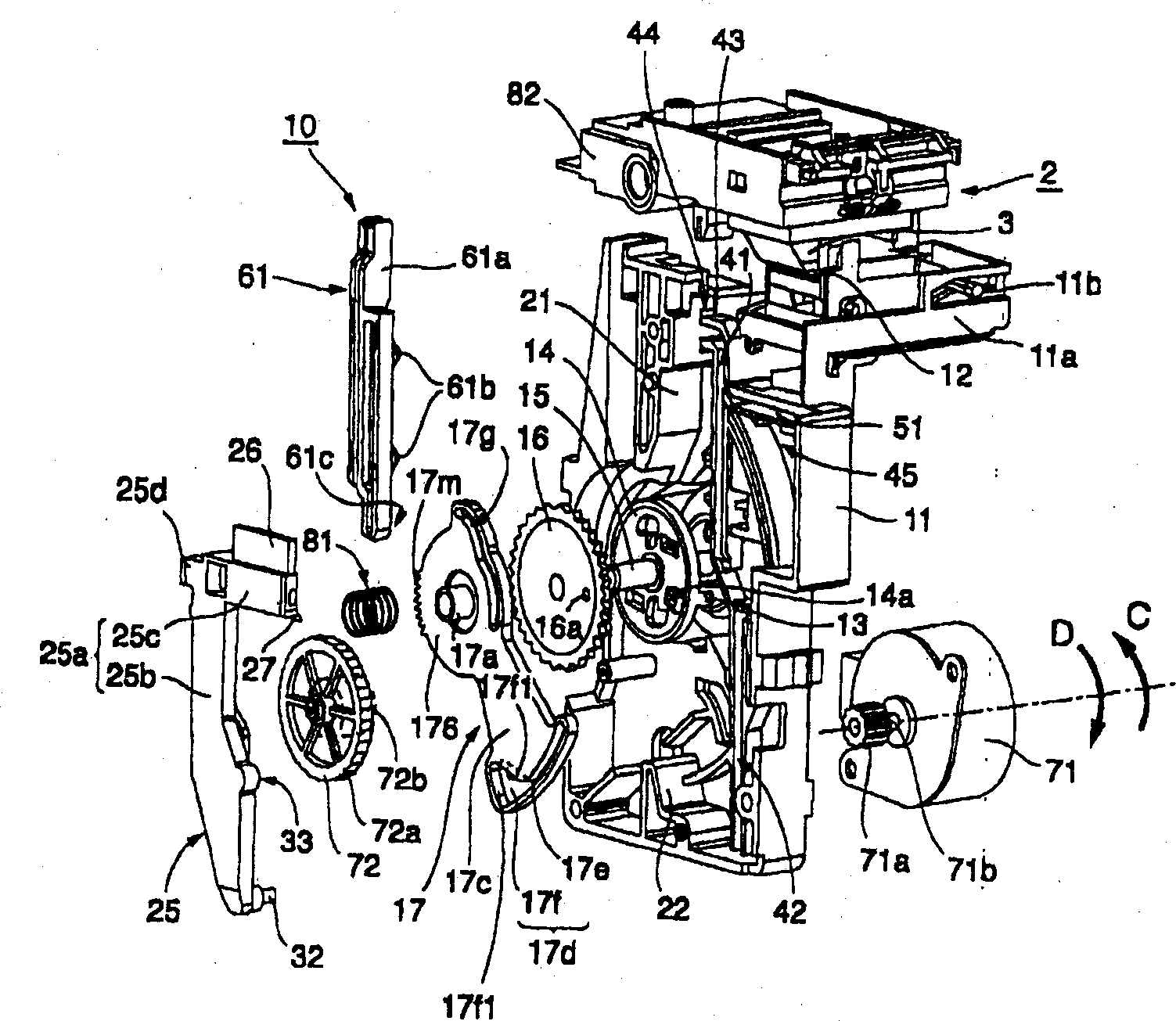

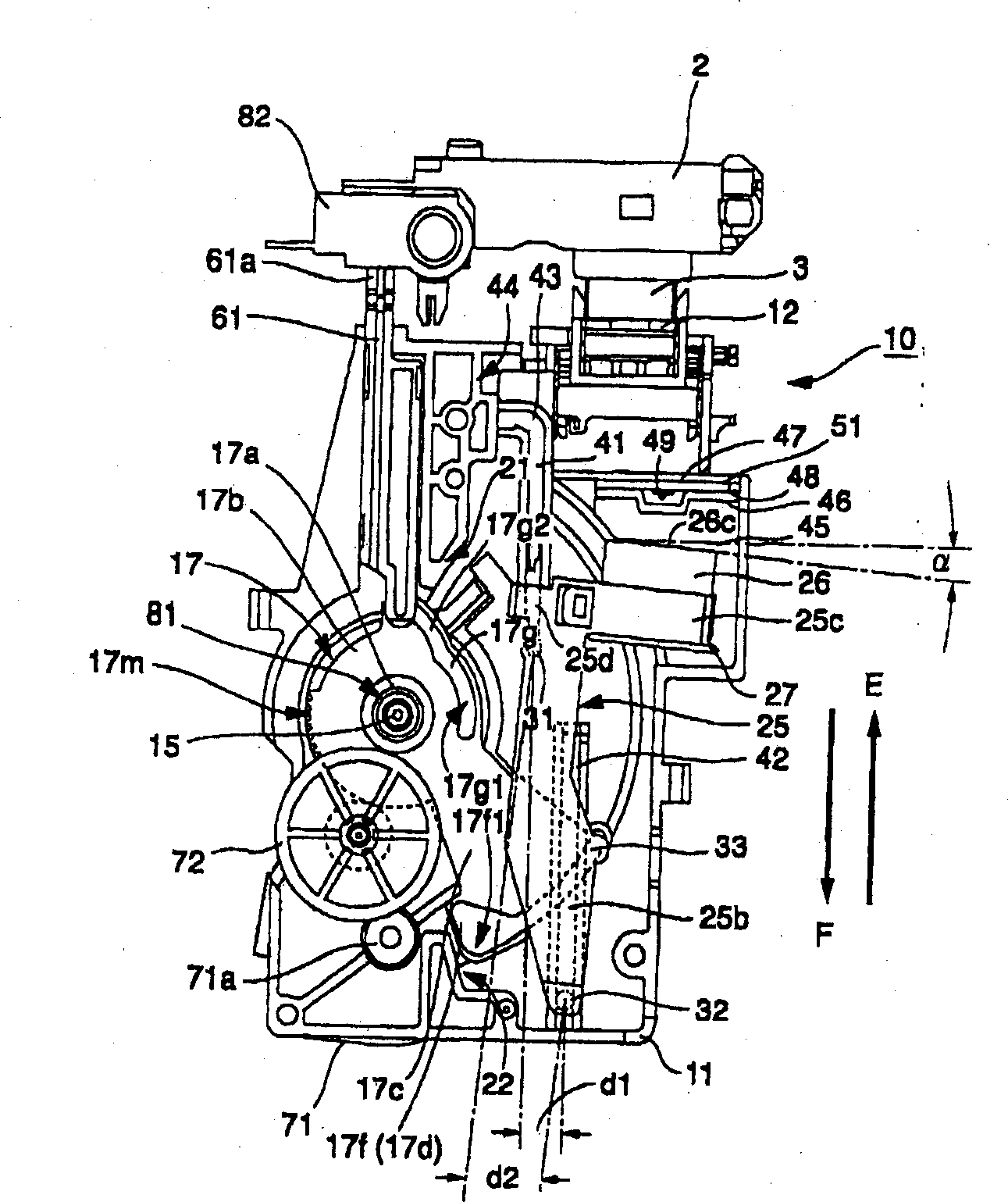

Cleaning device and ink jet printer

A cleaning device for cleaning an ink jet printer. The cleaning device includes the cleaner lever with an elastic blade which can reciprocate for wiping a nozzle surface of an ink-jet head, a lock lever for fixing the printing head and a clutch lever provided with a gear part engaging with the levers. A butting cam part can shift rotary movement of the clutch lever to reciprocating movement of the cleaner leverand the lock lever, at the same time, transfer motive power to the clutch lever by transfering routes of friction and gear engagement. Route of gear engagement is formed as follows: in one side of the gear, an elastic blade wipes the elastic blade wipes mounting on the front patr of the cleaner blade, and another side of the gear keeps moving. Due to the the sub-elastic blade wipes the elastic blade and based on the route of gear engagement, motive power can be transfered to the clutch lever. Thus, the elastic blade can move smoothly.

Owner:SEIKO EPSON CORP

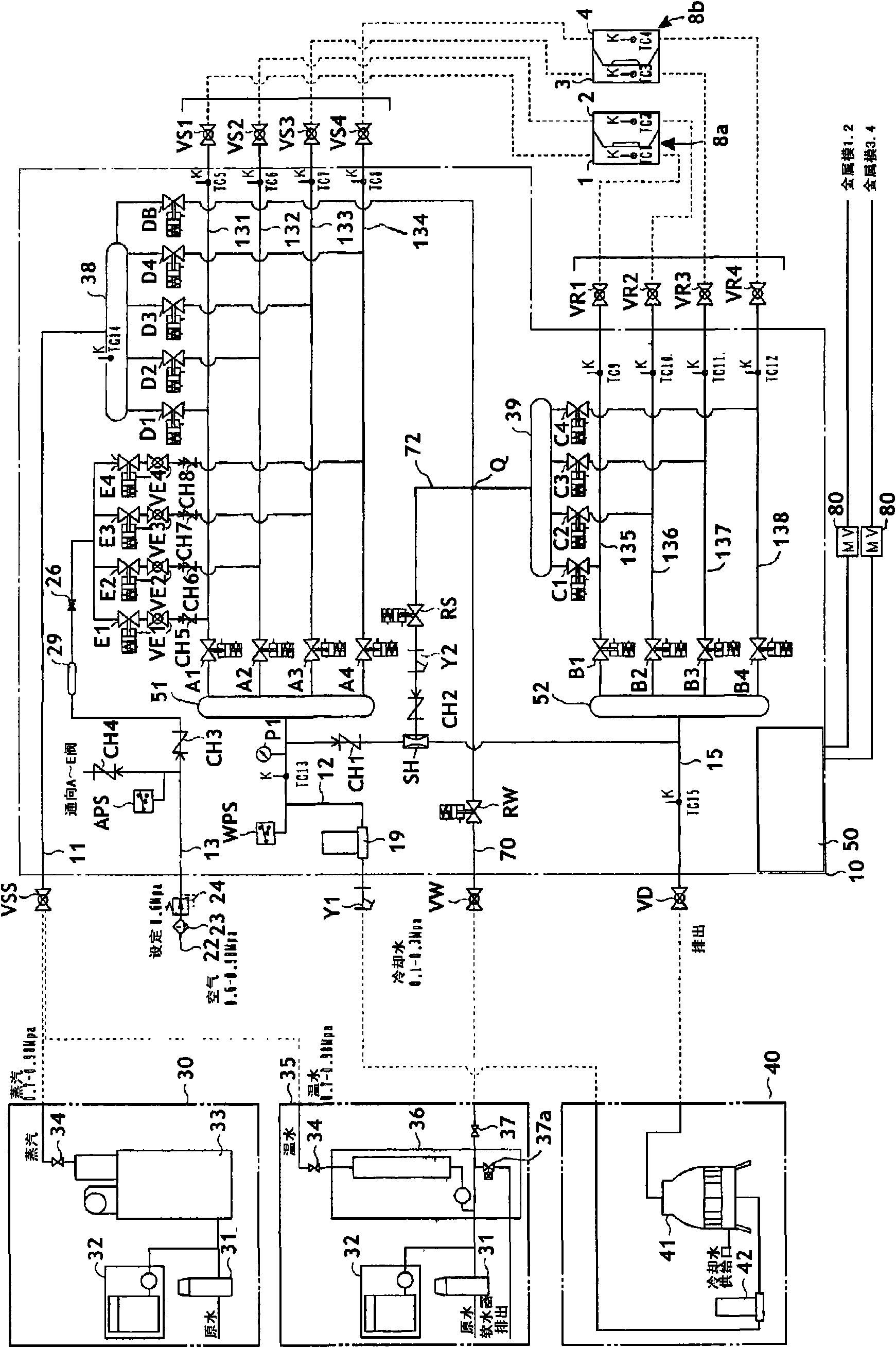

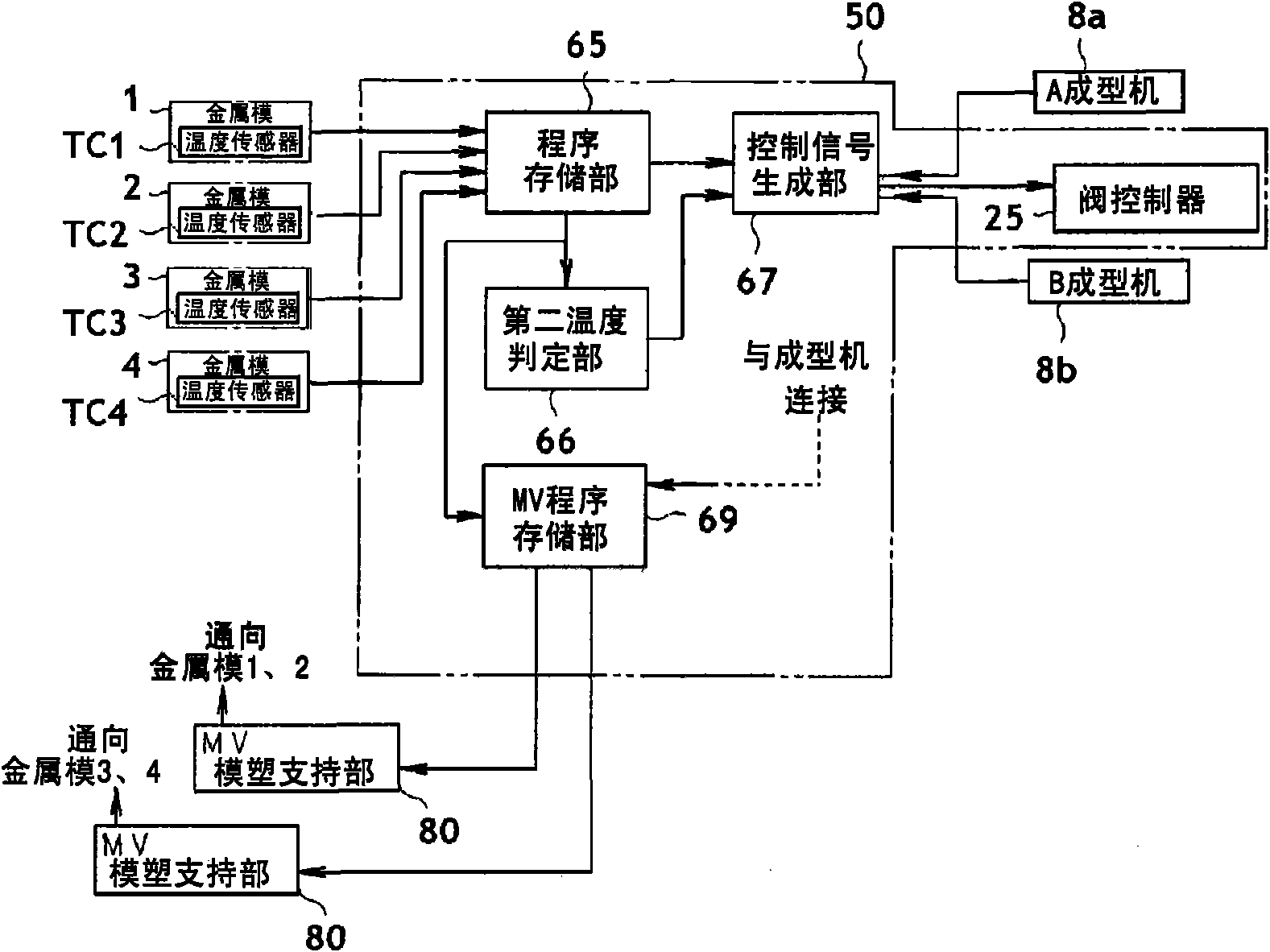

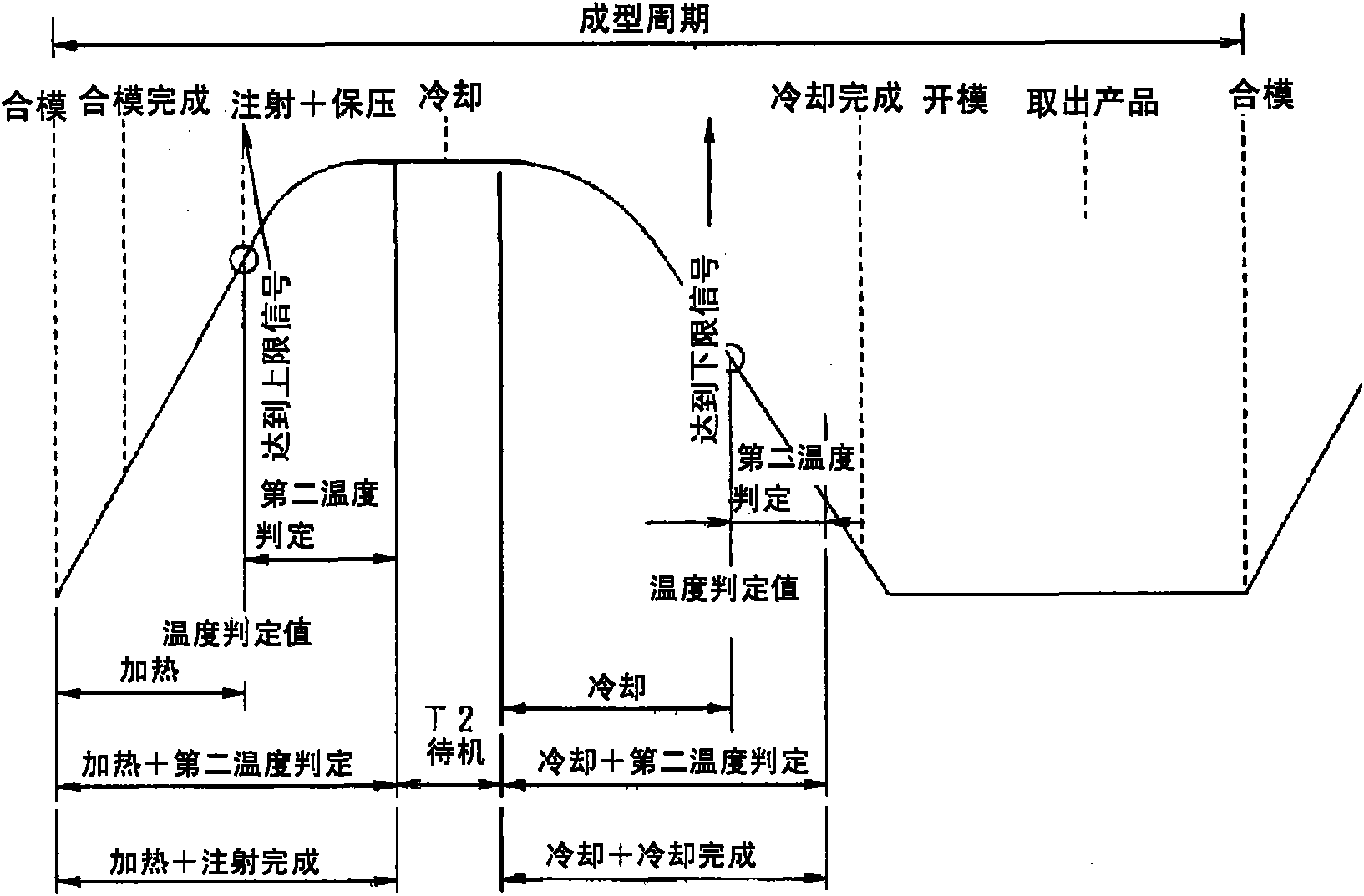

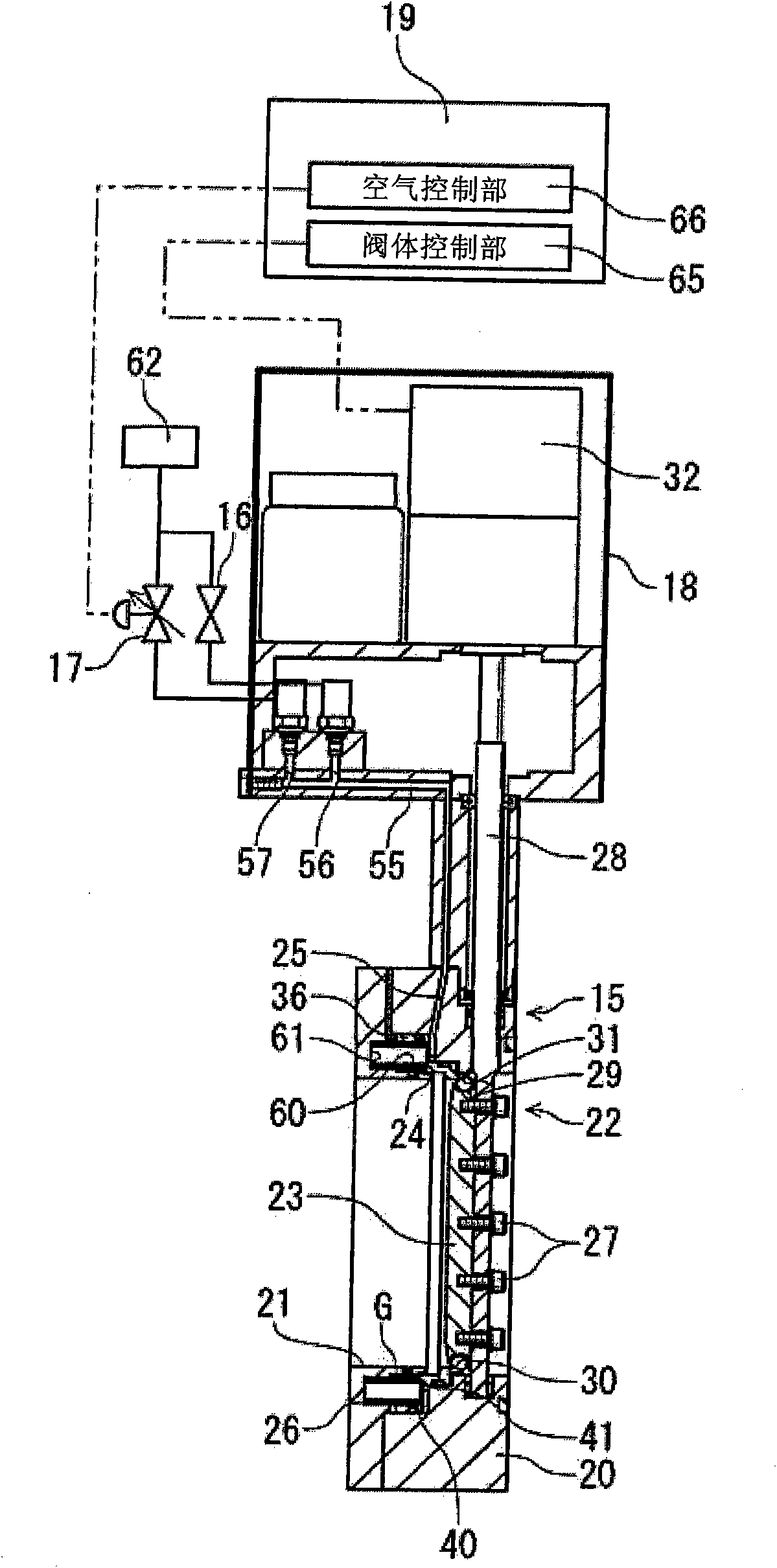

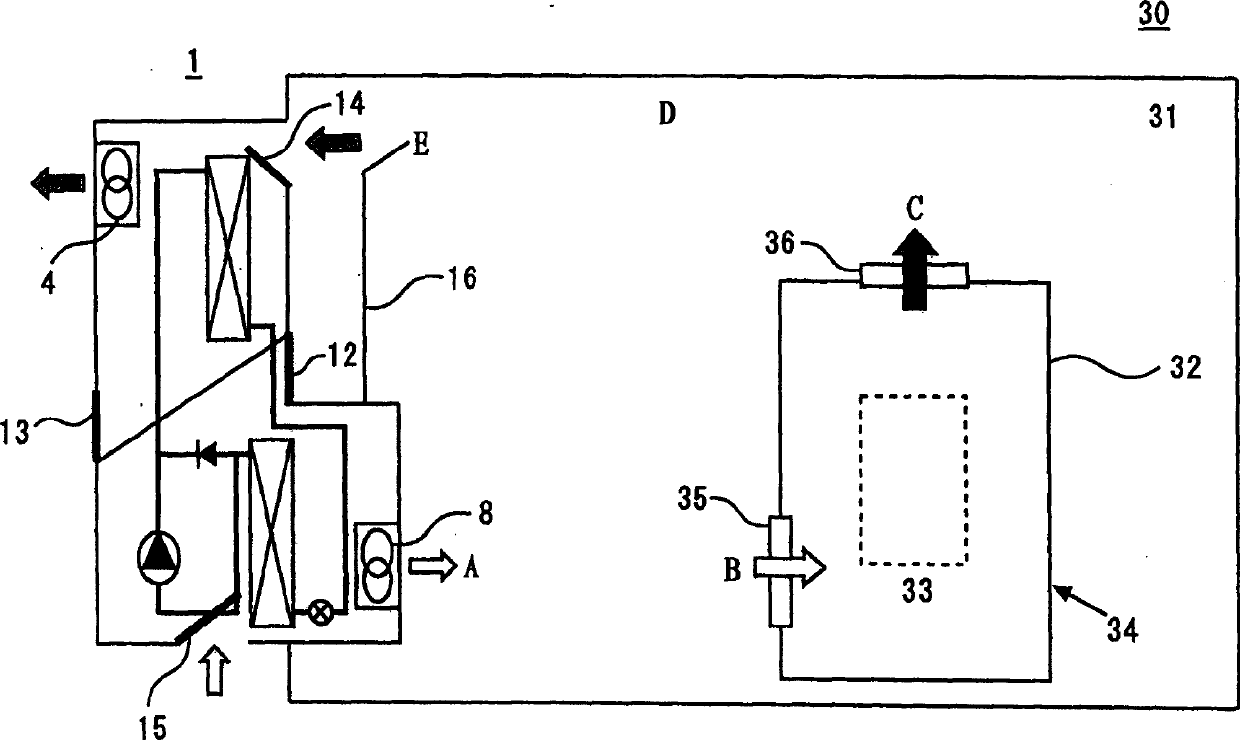

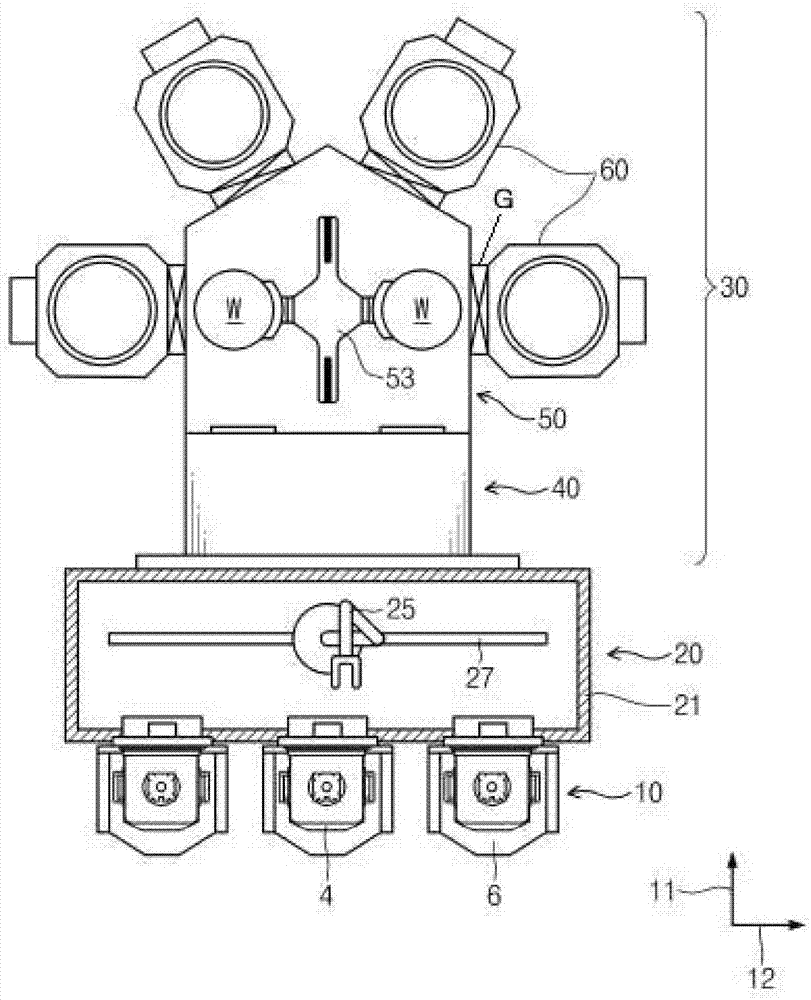

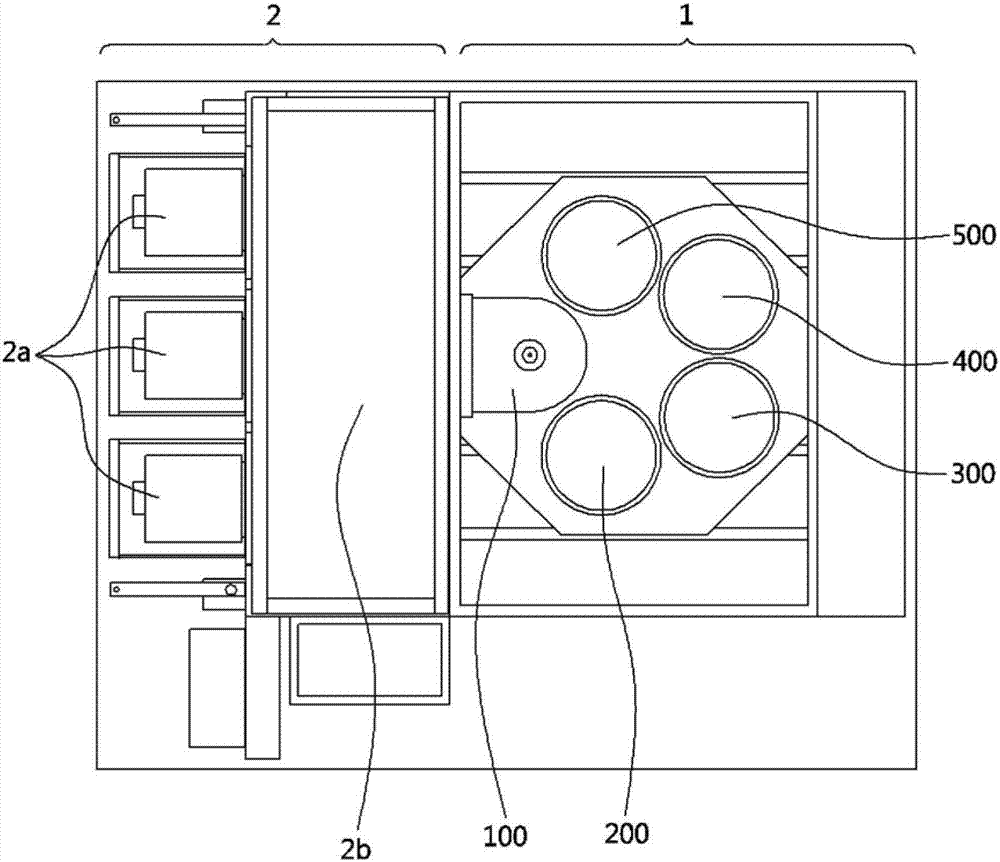

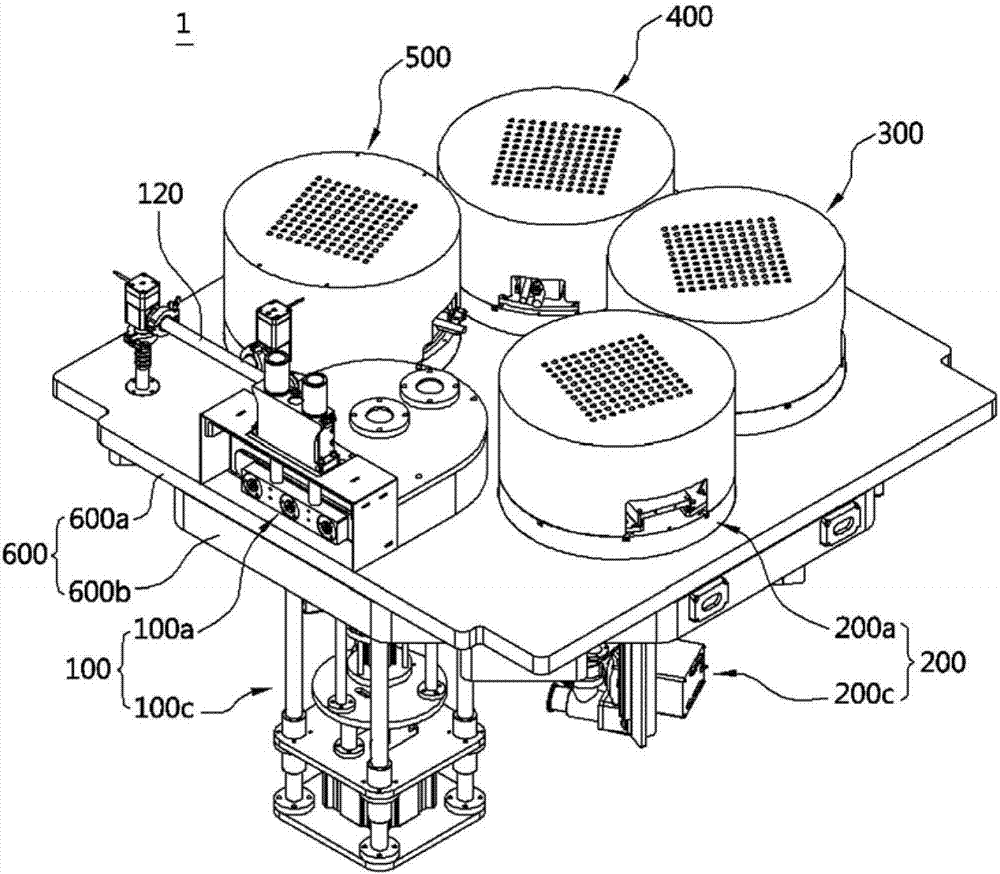

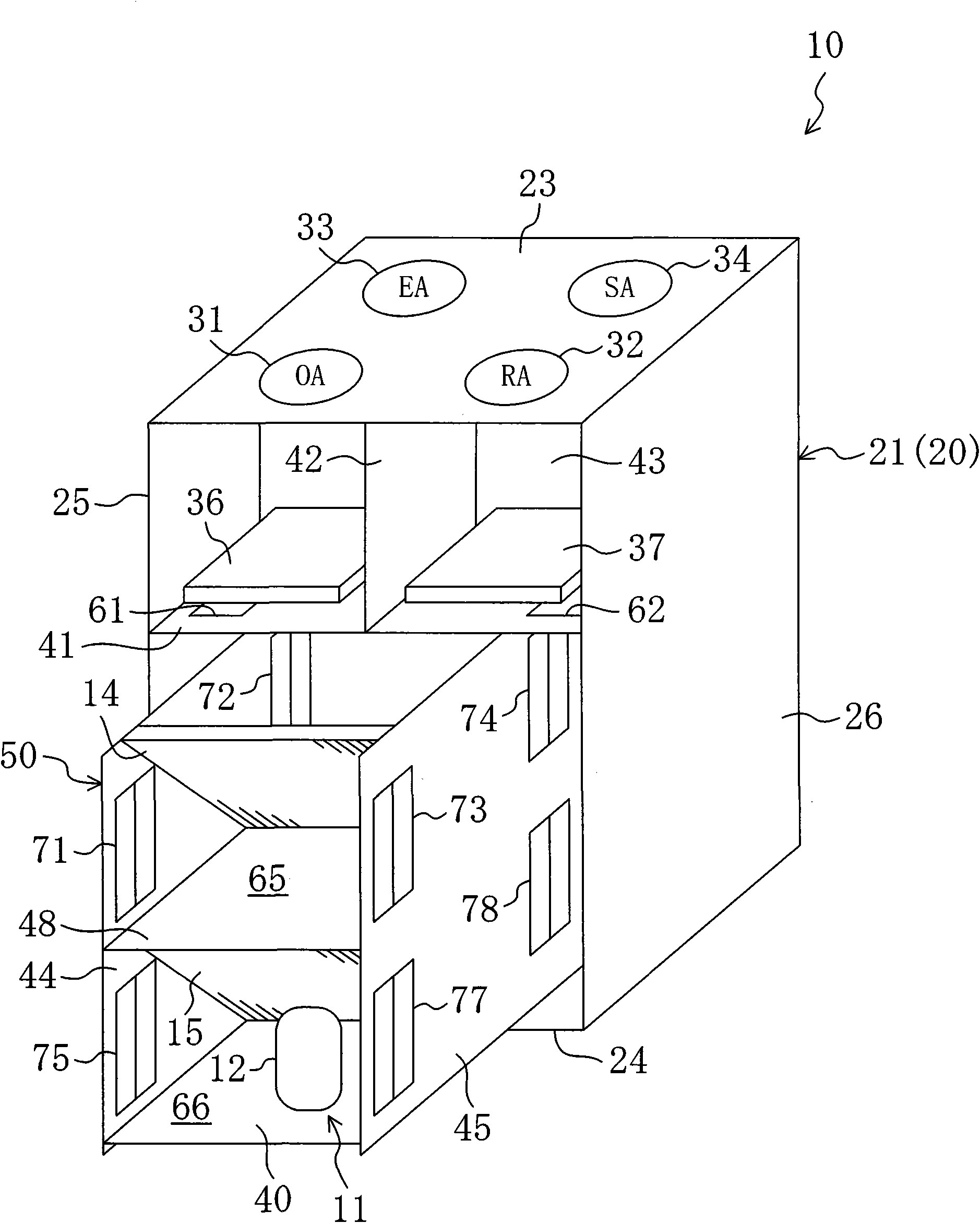

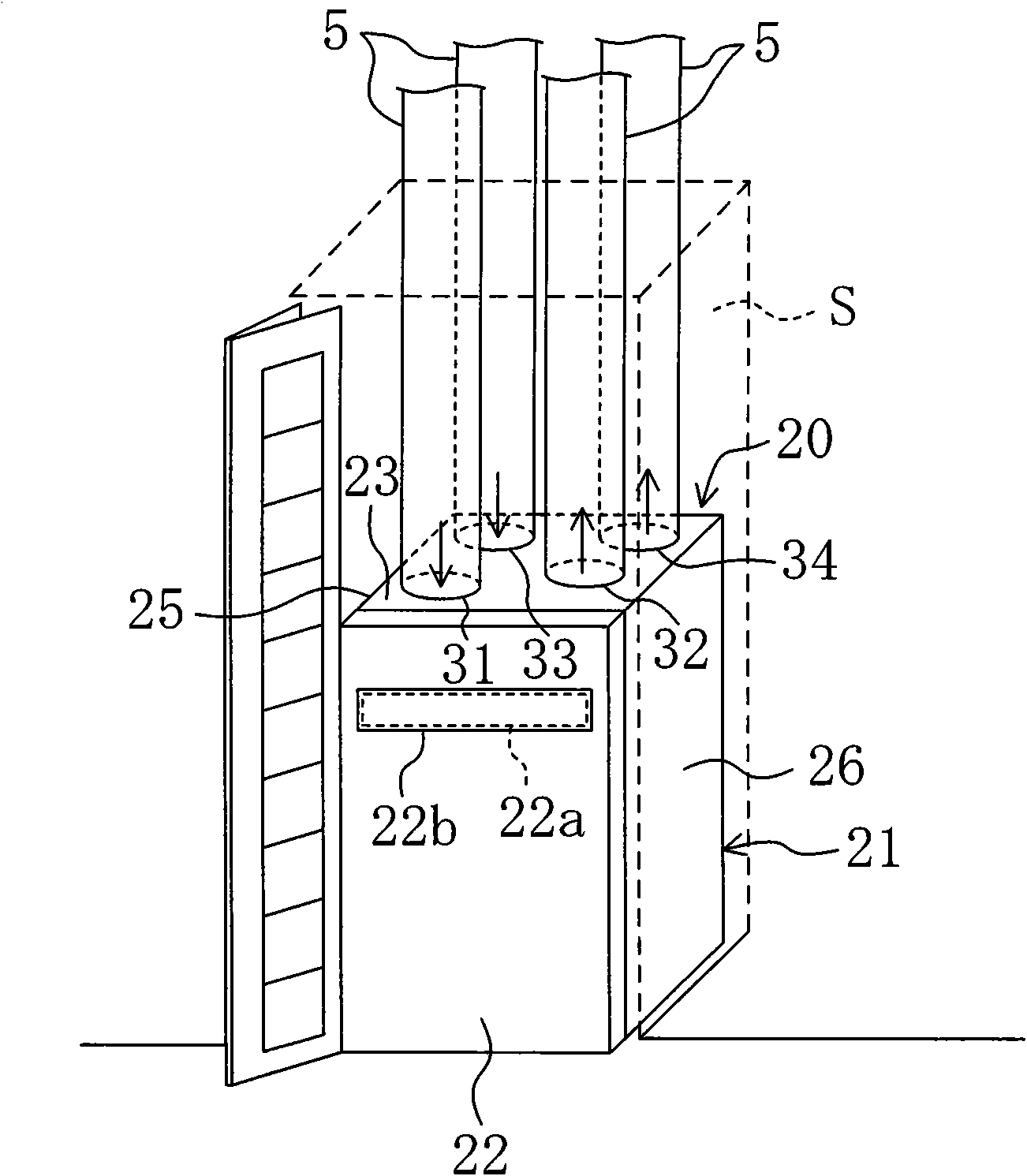

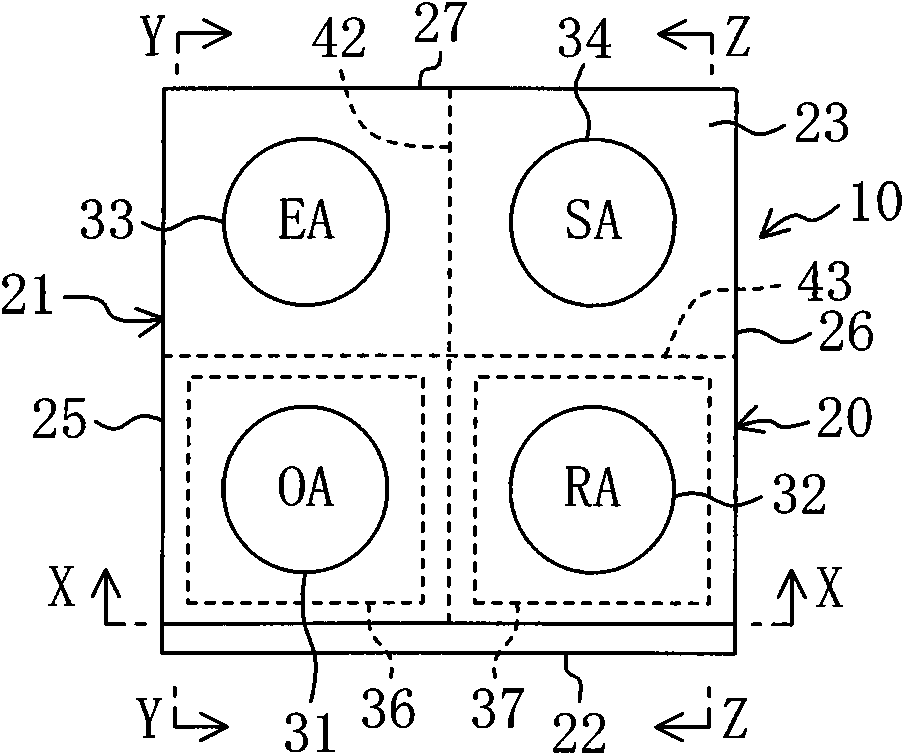

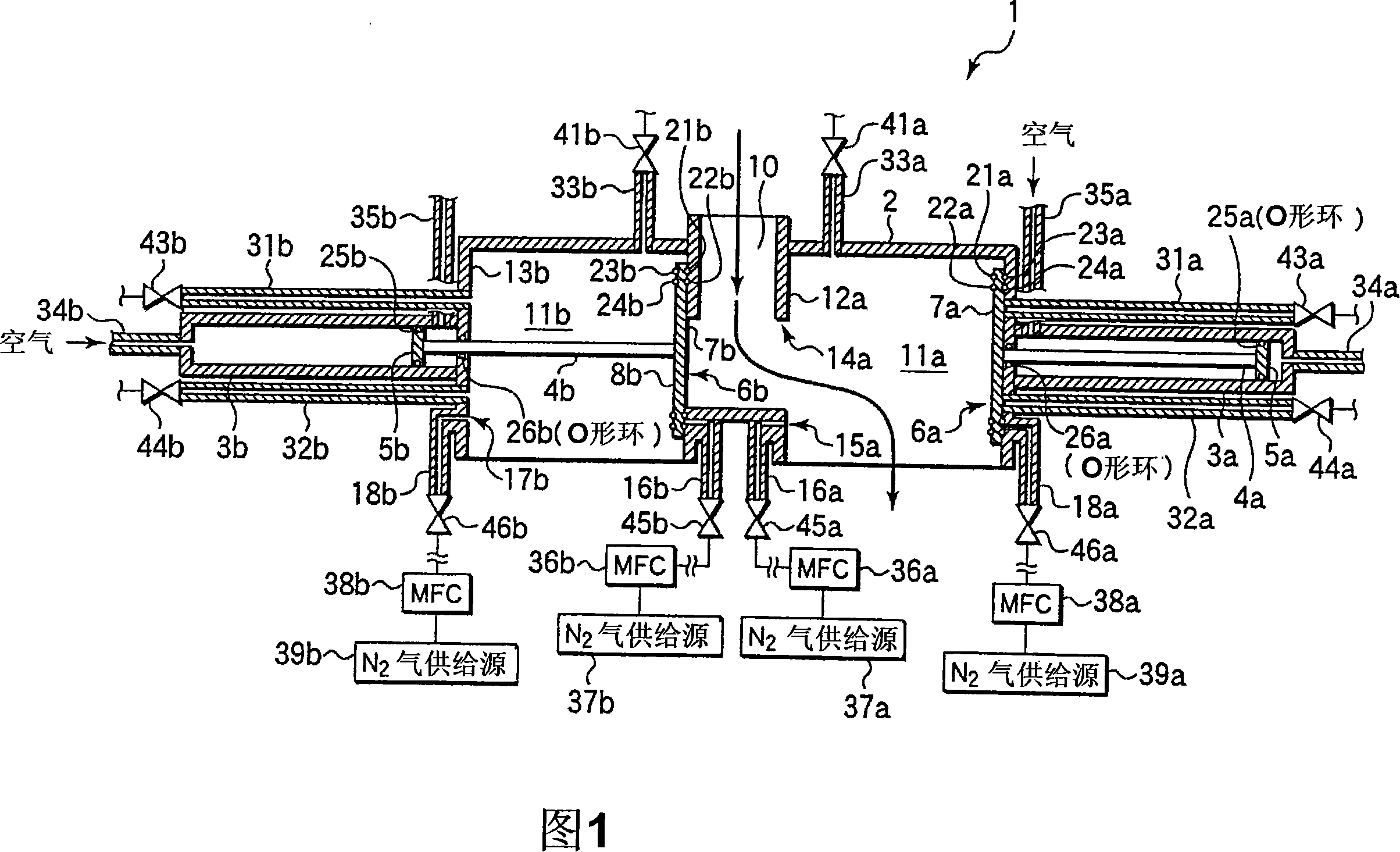

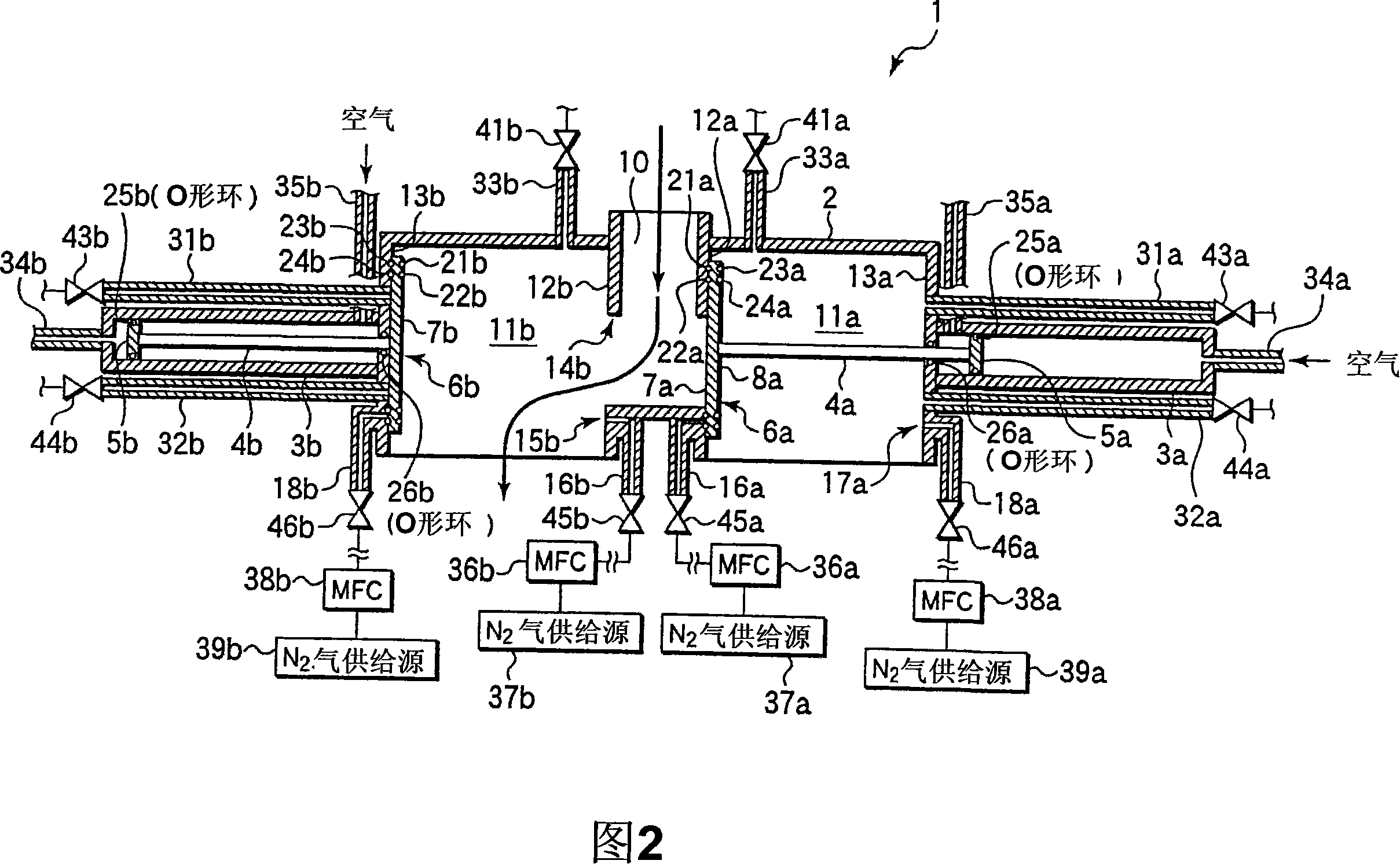

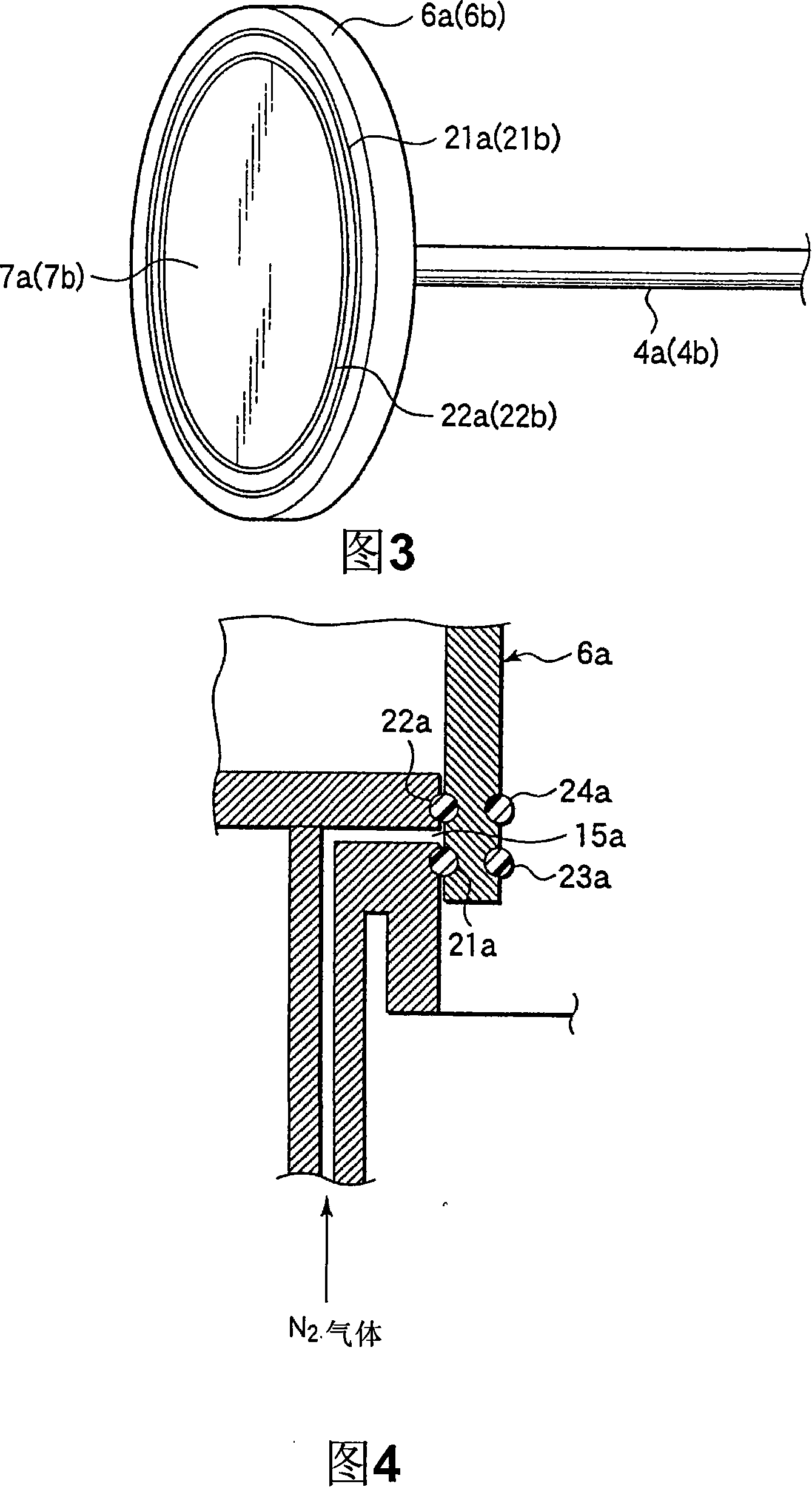

Mold multiple heating and cooling system

The present invention provides a mold multiple heating and cooling system which, for a plurality of molding machines (8a,8b), allows a single temperature control apparatus to be used to selectively supply steam or warm water, or cooling water for carrying out molding, and eliminates the need for separately installing a venting apparatus. The mold heating and cooling system pertaining to the present embodiment 1 includes a steam heating unit (30), a warm water heating unit (35), and a cooling unit (40) which feed steam, warm water, and cooling water, respectively, to molds (1 to 4) for two molding machines (8a,8b) that include an in-mold temperature sensor TC1 to TC4, respectively. A single temperature control apparatus (10) is disposed between the units and the respective molds (1 to 4) of the two molding machines (8a,8b), connected by a piping therebetween. Control means (50) which, on the basis of a temperature detected by each in-mold temperature sensor (TC1 to TC4) disposed in the respective molds (1 to 4), determines the temperature of the respective molds (1 to 4) on a previously stored temperature determination program for controlling selective supply and discharge of steam or warm water, or cooling water to / from the respective molds (1 to 4) of the two molding machines (8a,8b) according to a molding cycle for each molded article therefor. A mold vacuum system (80) carries out sucking and discharging of the gas and air inside the respective molds (1 to 4), and air blowing for the respective molds under the control of the control means (50).

Owner:SYSKO

Pressure control butterfly valve

ActiveCN101644338AReduced installation widthSave setup spacePressure relieving devices on sealing facesSemiconductor/solid-state device manufacturingHigh speed controlInternal pressure

Owner:KAISHI SCT CO LTD

Pipe bending device and pipe bending method

The invention provides a pipe bending device, which is simplified and miniaturized, and a pipe bending method. A pipe chuck assembly is mounted on a movable cart which carries out reciprocation in a rectilinear direction on a base table. The pipe chuck assembly includes a chunk supporter which rotates under the driving of a chunk rotating unit on the movable cart; right and left chuck holders mounted on the chunk supporter; and a pair of chunk moulds which moves close to or away from each other by drive units fixed on the chunk supporter, and are provided with grooves fitting a semi-circumference part of the pipe on opposite faces of the chunk moulds. The bending device has a bending roller mould and a fastening mould which are positioned in front of a front stop position of the movable cart. When the pipe is inserted from above and clamped by the pair of chunk moulds on the movable cart, the pipe is rotated by the chunk rotating unit, the moving cart is moved to the front stop position, and the pipe is clamped by the bending roller mould and the fastening mould so as to be subjected to bending processing in three dimensional directions, wherein during the bending processing, the movable cart returns to a preset position.

Owner:SUMITOMO WIRING SYST LTD

Band washing unit and band washing method

InactiveCN1824397AImprove cleanlinessEasy to removeWallsProjectorsMegasonic cleaningCleaning methods

Owner:MITSUI MINING & SMELTING CO LTD

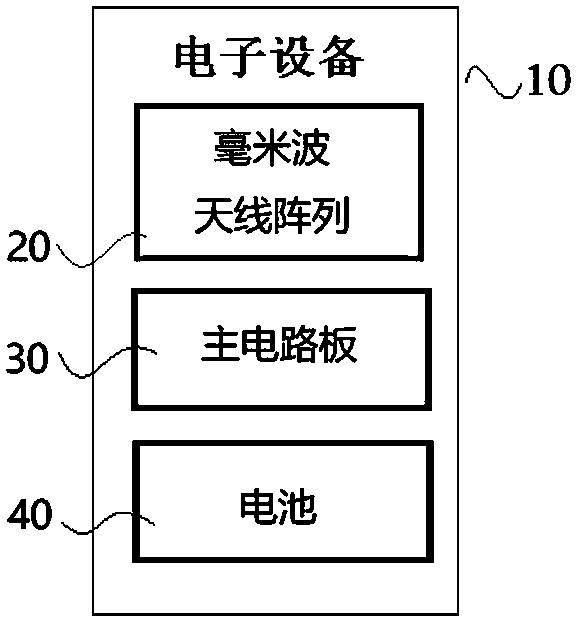

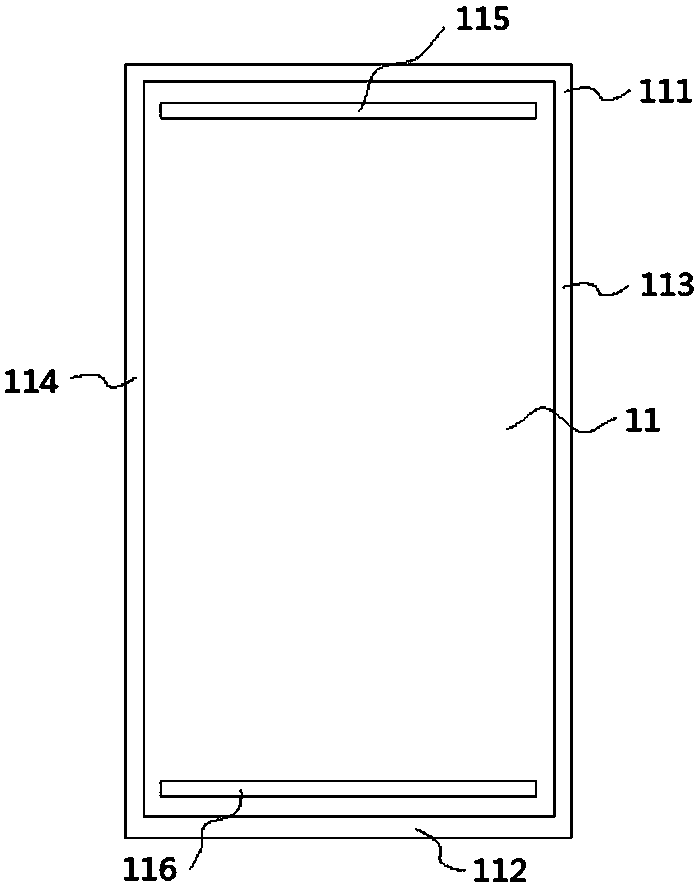

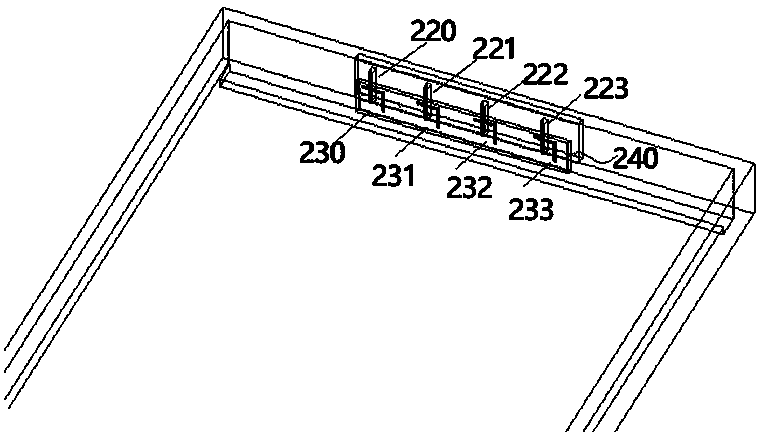

Electronic equipment integrated with millimeter wave array antenna

PendingCN110931944ABest Radiation DirectionReduce performanceAntenna supports/mountingsRadiating elements structural formsEngineeringMillimetre wave

The invention discloses electronic equipment integrated with a millimeter wave array antenna. The millimeter wave antenna comprises a millimeter wave antenna array, a main printed circuit board (PCB),a battery and a first metal middle frame, the method is characterized in that the first metal middle frame comprises a metal frame positioned on the appearance surface of the electronic equipment anda large-area metal block for supporting and grounding; the metal frames comprise a metal frame I, a metal frame II, a metal frame III and a metal frame IV; a first double-sided groove area is arranged in the metal frame I, grooves are formed in the front surface and the back surface of the first double-sided groove area, a metal partition is arranged in the middle of the first double-sided groovearea, the first groove area is used for arranging a millimeter wave antenna array, and the millimeter wave antenna array consists of more than two antenna units and is arranged in an array form. According to the invention, the optimal radiation direction of the millimeter wave array antenna can be realized, performance degradation caused by shielding of the millimeter wave array antenna by surrounding devices or the environment when consumers use the millimeter wave array antenna is avoided, the feeding and grounding realization mode is simple, and the realization cost is low.

Owner:天通瑞宏科技有限公司

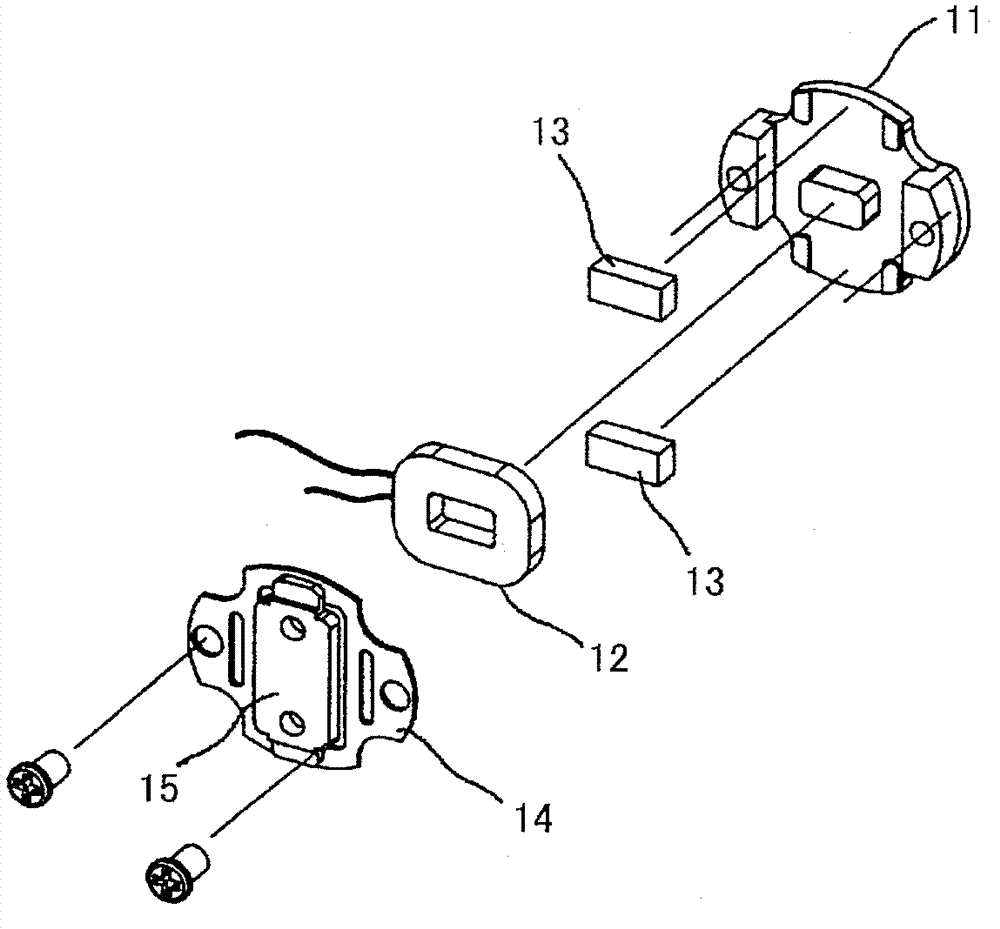

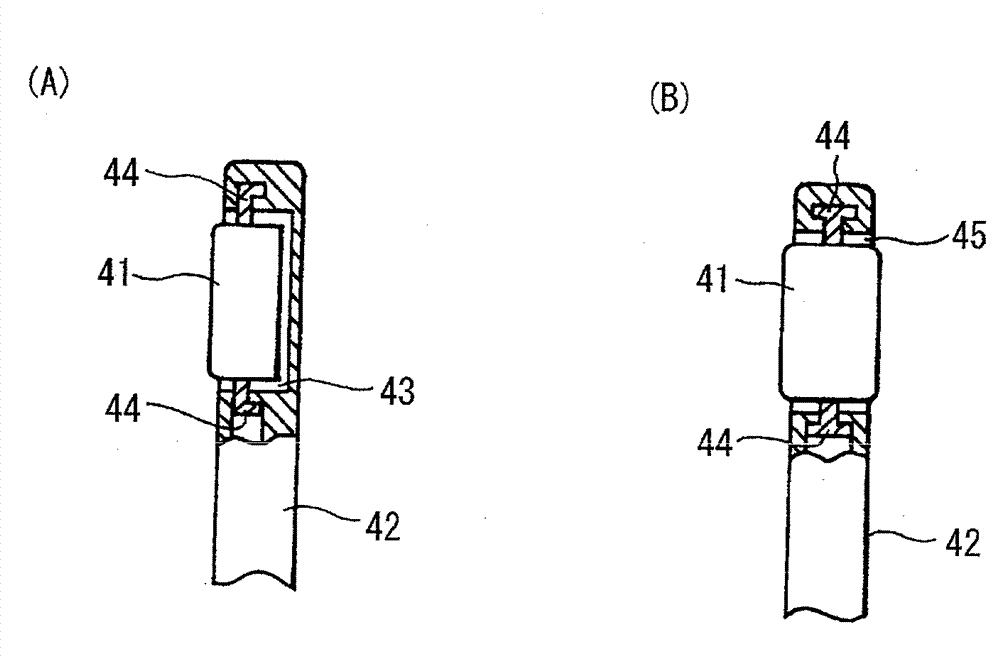

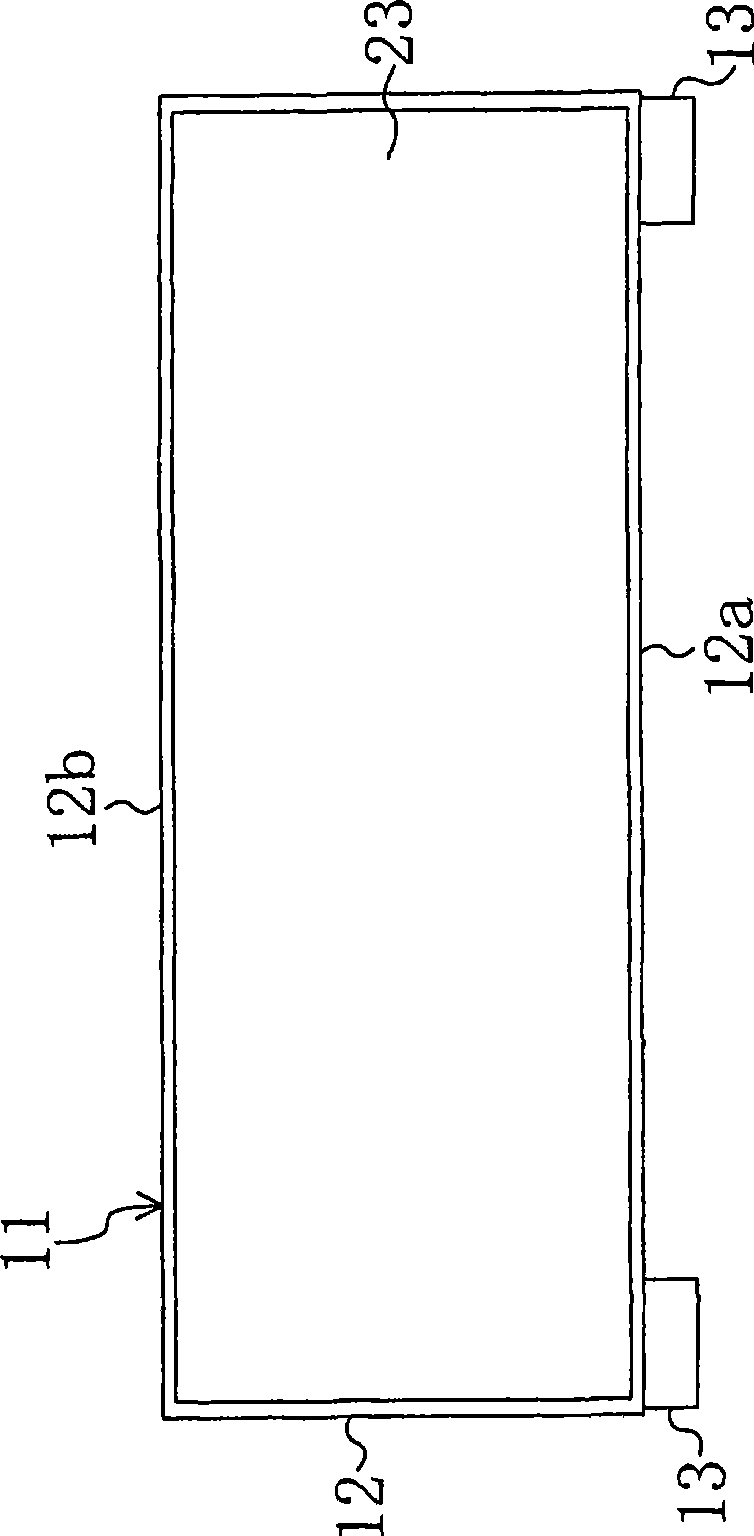

Mobile phone employing bone conduction device

InactiveCN103597803ASave setup spaceIncreasing the thicknessLoudspeaker transducer fixingBone conduction transducer hearing devicesCushioningEngineering

One surface of a housing (1) is furnished with an opening (2) larger in diameter than a bone conduction device (3) placed therein. A cushioning material (4) is arranged on the inside surface of the opening (2), and an abutting member (7) secured to a plate yoke (15) constituting the bone conduction device (3) is supported on the cushioning material (4), such that the top surface thereof is positioned slightly above the surface of the housing (1). The cushioning material (4) is an annular disk in which is formed a center hole (5) slightly smaller in diameter than the outside diameter of the bone conduction device (3). The outside peripheral half of the cushioning material (4) is secured resting on the upper edge of the opening (2) of the housing (1), and the outside edge of the abutting member (7) is secured resting on the upper edge of the center hole (5) of the cushioning material (4).

Owner:TEMCO JAPAN

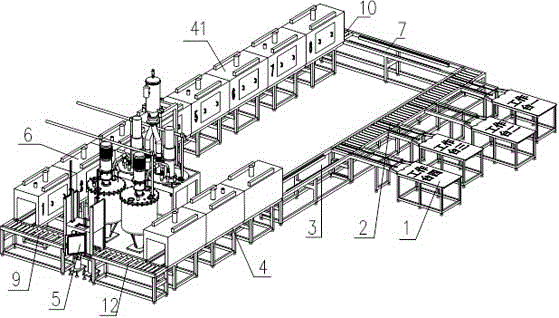

Casting assembly line and method for mutual inductors

ActiveCN106273138AHigh degree of automationSimple structureTransformersInductancesControl systemAssembly line

The invention discloses a casting assembly line and method for mutual inductors. The casting assembly line comprises a plurality of operating tables, an operating table roller line, a drying buffer area, a pre-drying area, a casting chamber, a curing area and a die releasing buffer area. The operating tables are connected to the outer side of the operating table roller line. The mutual inductors are mounted on dies through the operating tables and then conveyed onto the operating table roller line. The operating table roller line is connected with the drying buffer area. The mutual inductors mounted on the dies are conveyed into the pre-drying area according to a set takt through a takt control system arranged on the drying buffer area. The pre-drying area conveys the mutual inductors mounted on the dies into the casting chamber through a die inlet roller line connected with the pre-drying area. The cast mutual inductors mounted on the dies are conveyed into the curing area through a die outlet roller line connected with the casting chamber. The cured mutual inductors mounted on the dies are conveyed into the die releasing buffer area through a curing die outlet roller line connected with the curing area. The die releasing buffer area and the operating table roller line are connected, so that the cured mutual inductors mounted on the dies are conveyed onto the operating tables for die releasing.

Owner:重庆山城电器厂有限公司

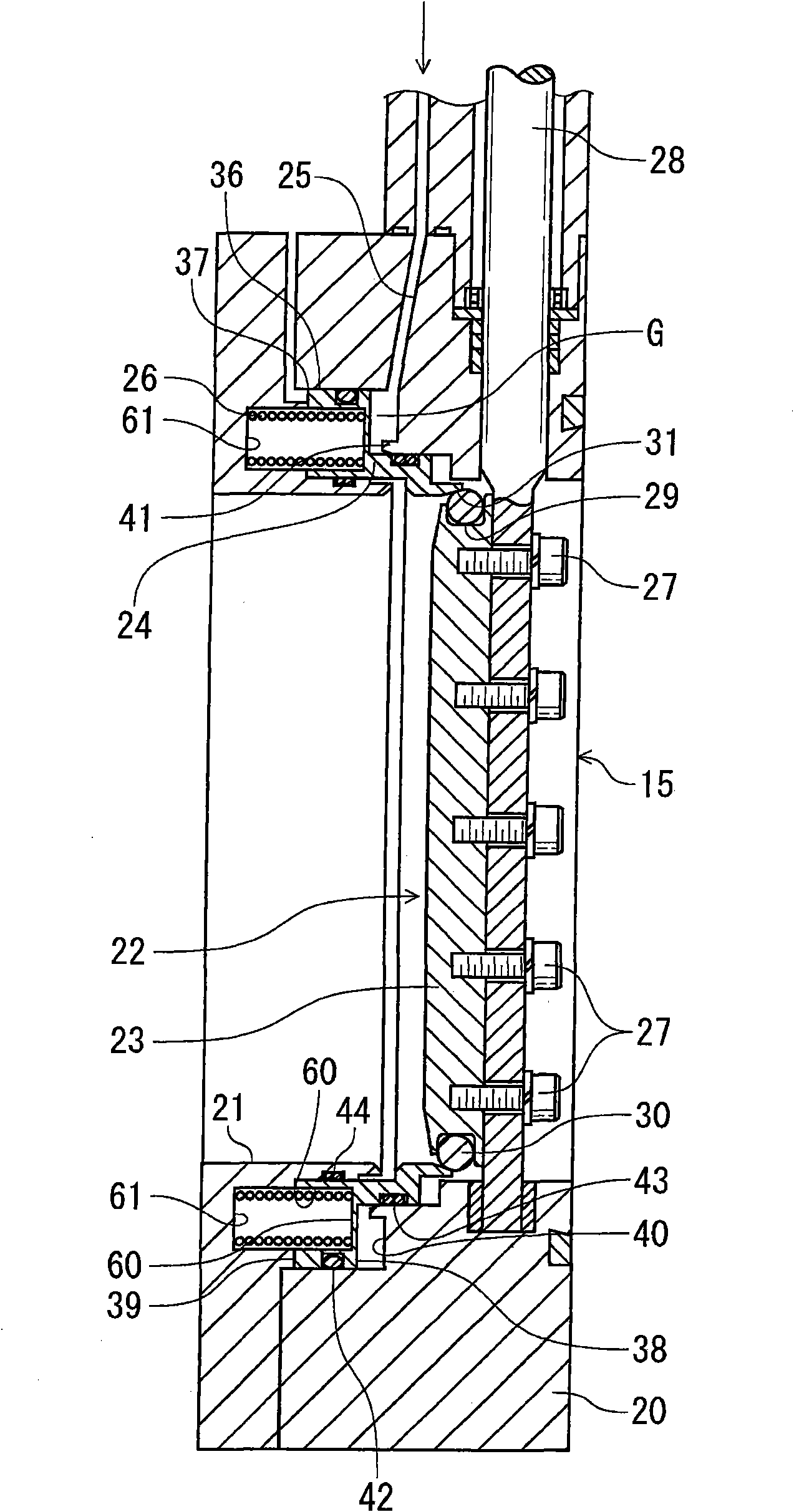

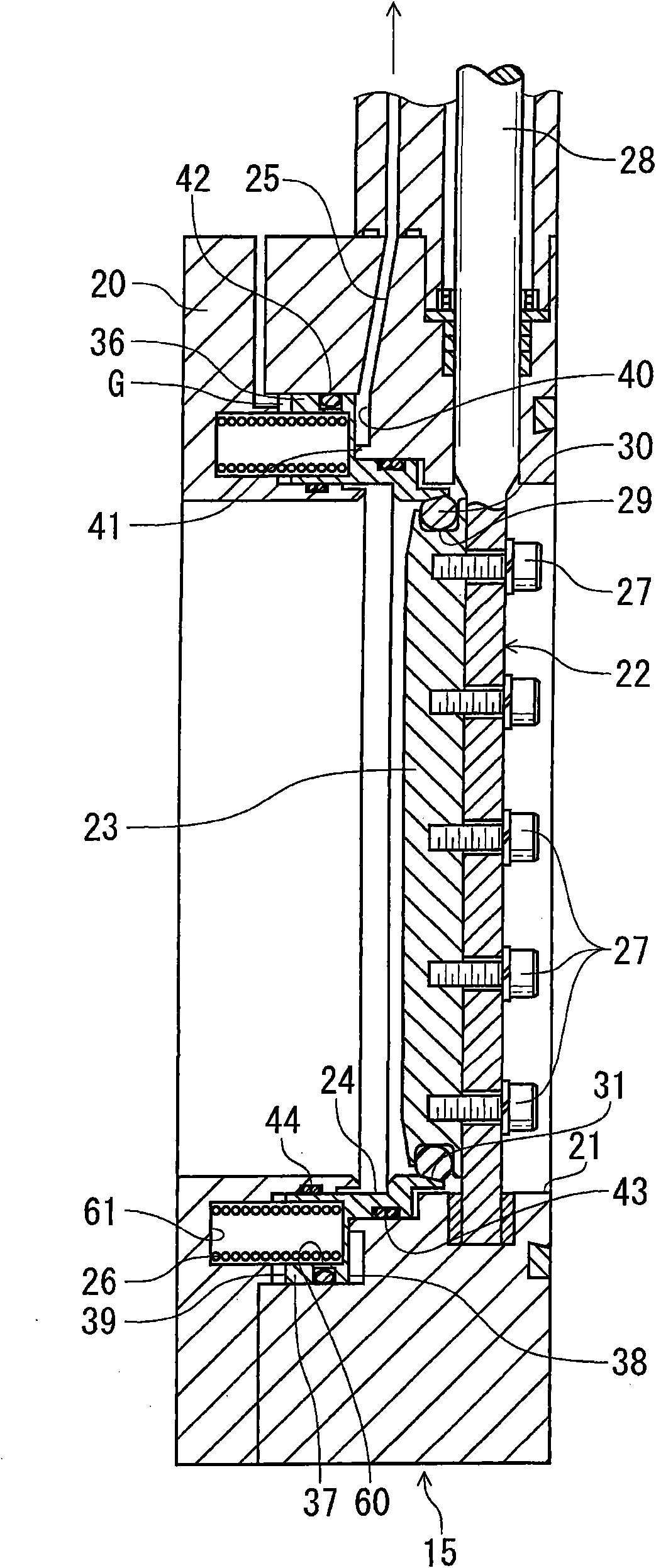

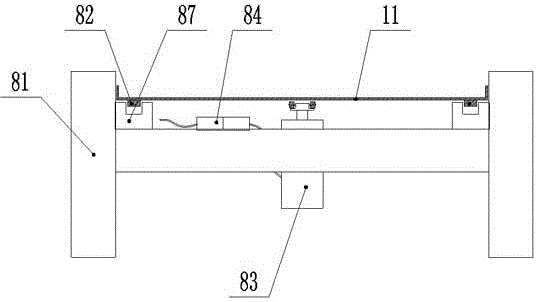

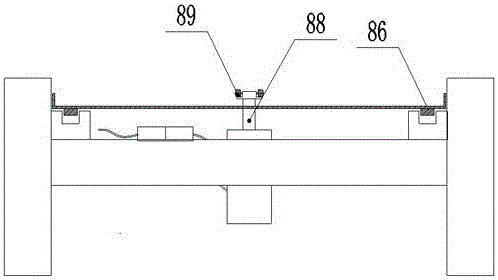

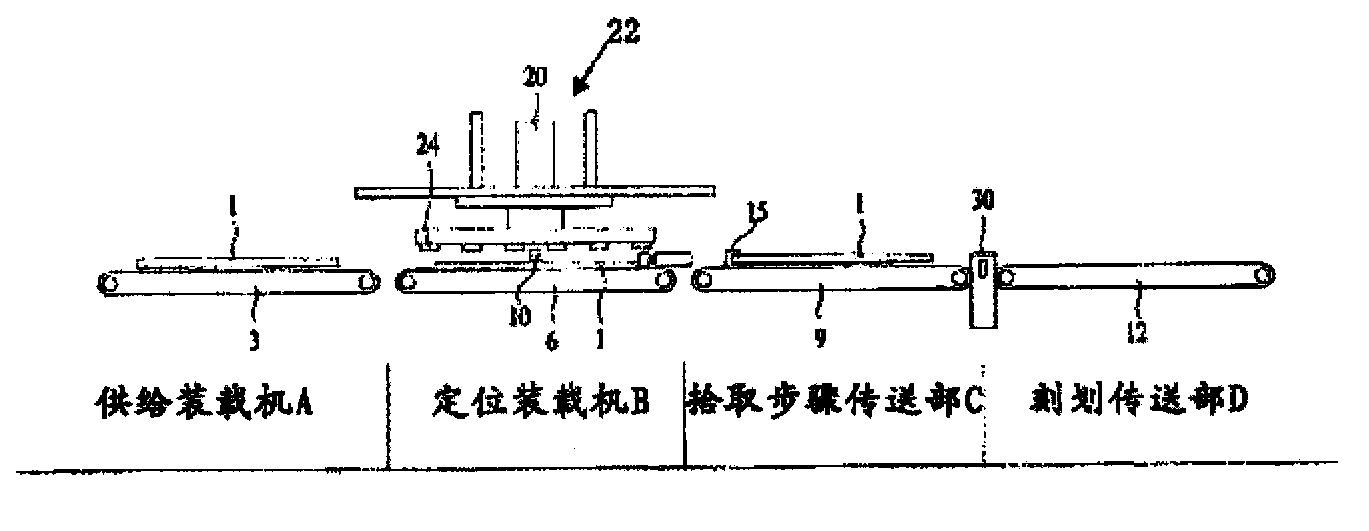

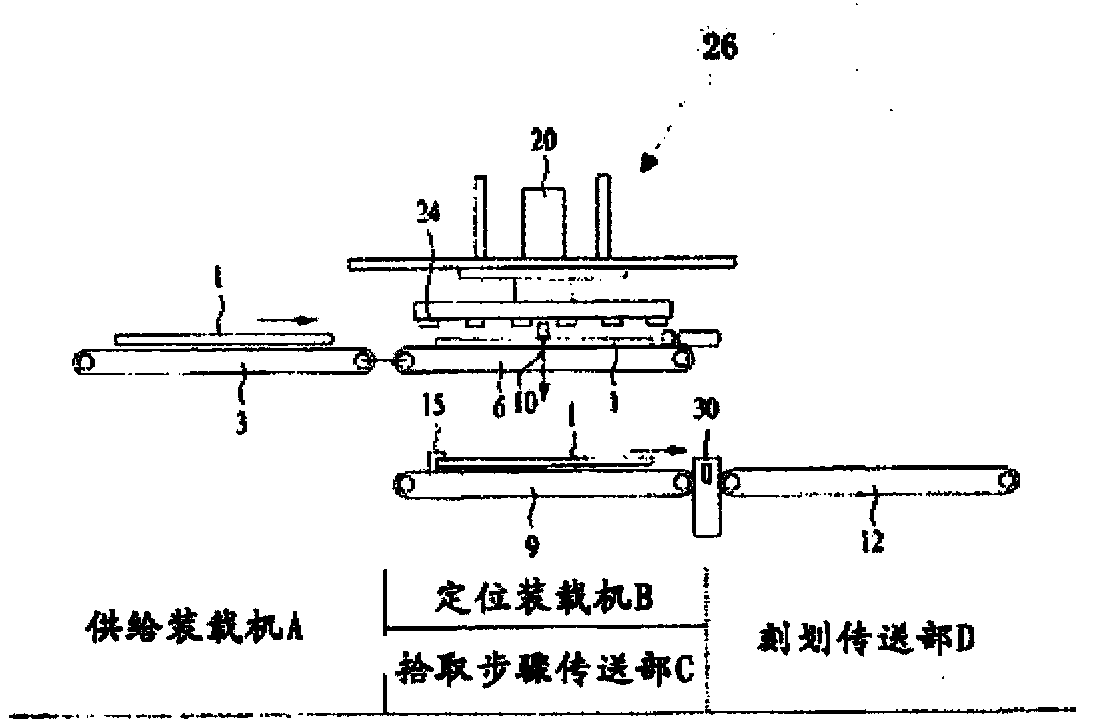

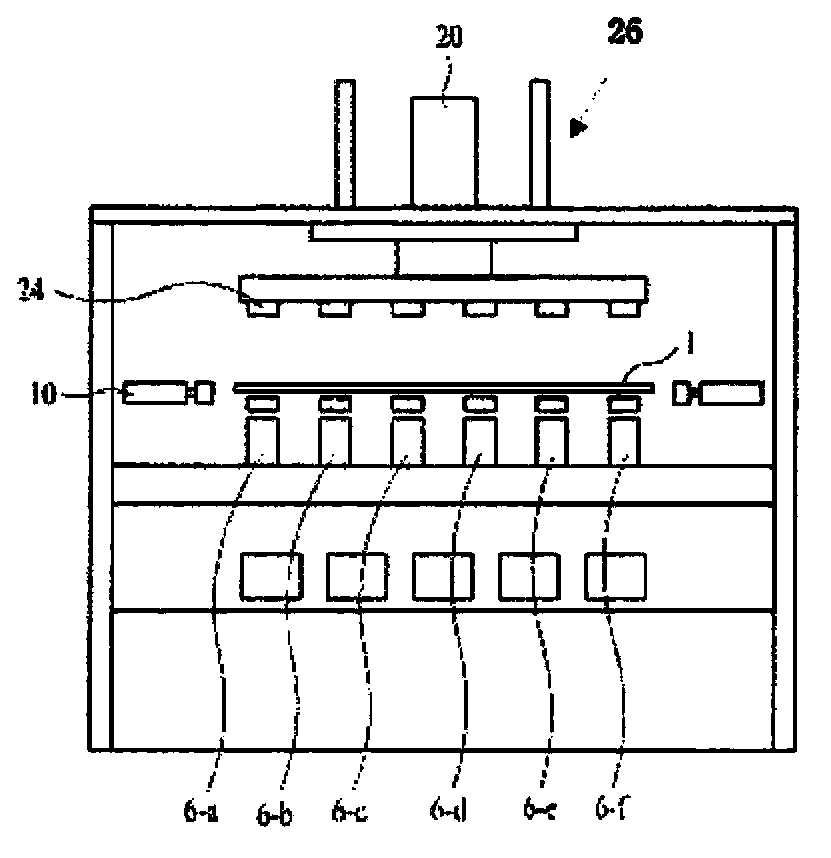

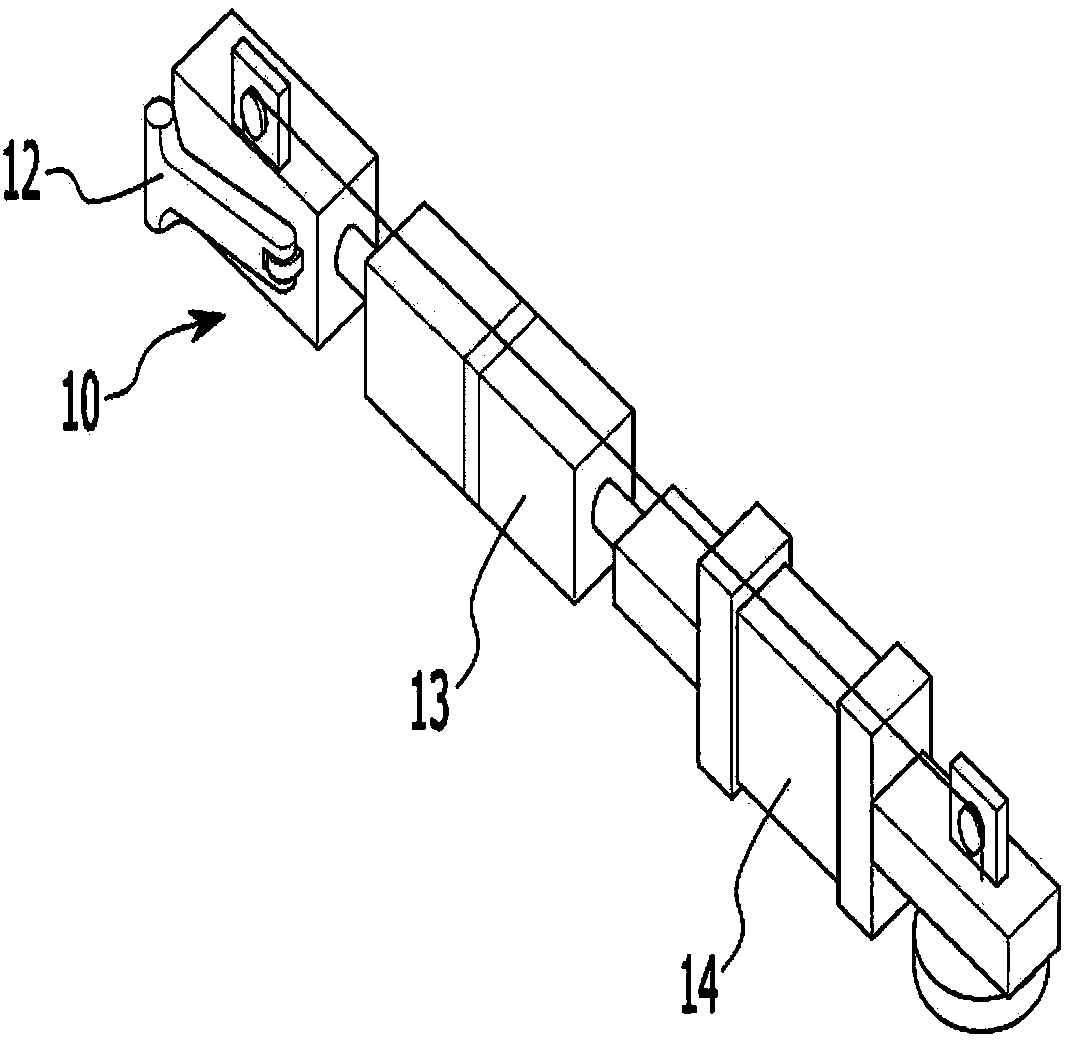

Vertical conveying device of substrate

InactiveCN103449179AReduce positional offsetSave setup spaceGlass transportation apparatusCharge manipulationEngineeringMechanical engineering

The invention discloses a vertical conveying device of a substrate capable of preventing the displacement of the substrate from the positioning part to the pick-up part during the weight shifting. The vertical conveying device is provided with a supporting member, a positioning loading machine used to adjusting a positioning part loaded on the substrate of the supporting member, and an absorbing elevating unit capable of absorbing and elevate the substrate of the supporting member, and a pick-up step transmitting part capable of conveying the substrate to the etching unit under the pick-up state of the pick-up member. With the help of the falling operation of the absorbing elevating unit, the weight shifting of the substrate from the positioning loading machine to the pick-up transmitting part can be finished.

Owner:MITSUBOSHI DIAMOND IND CO LTD

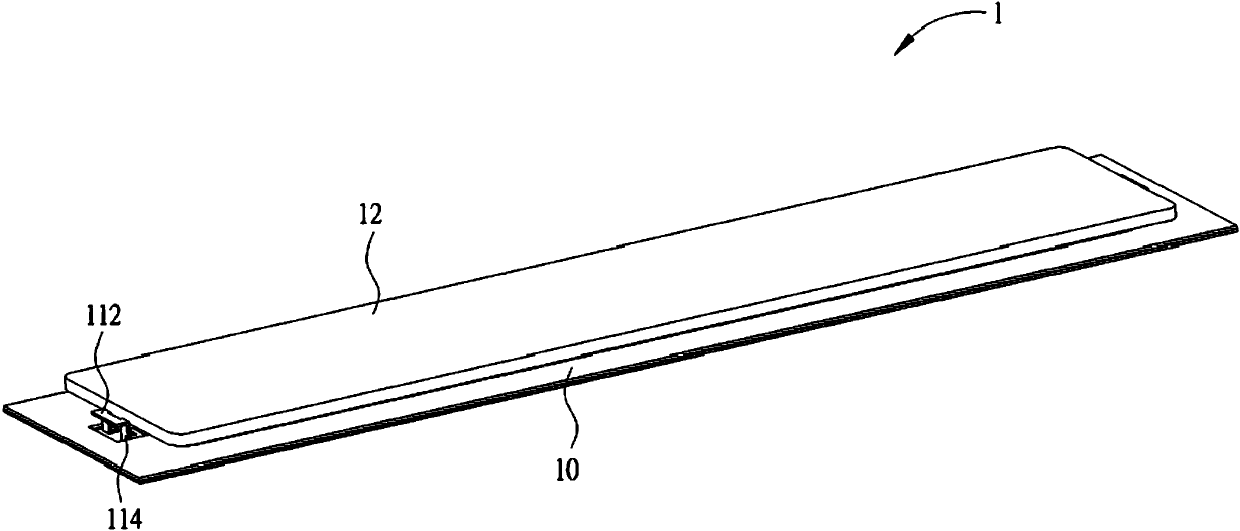

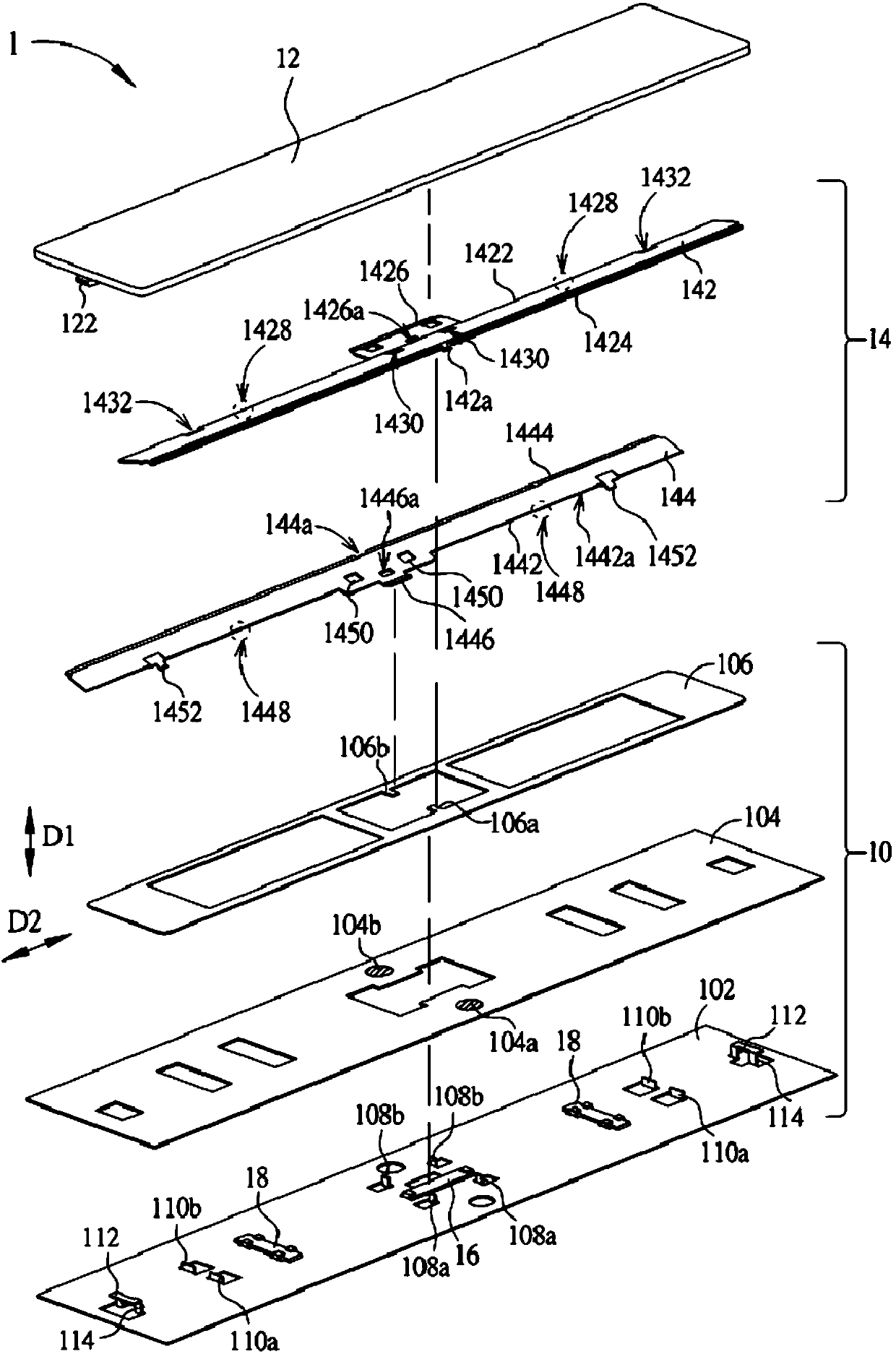

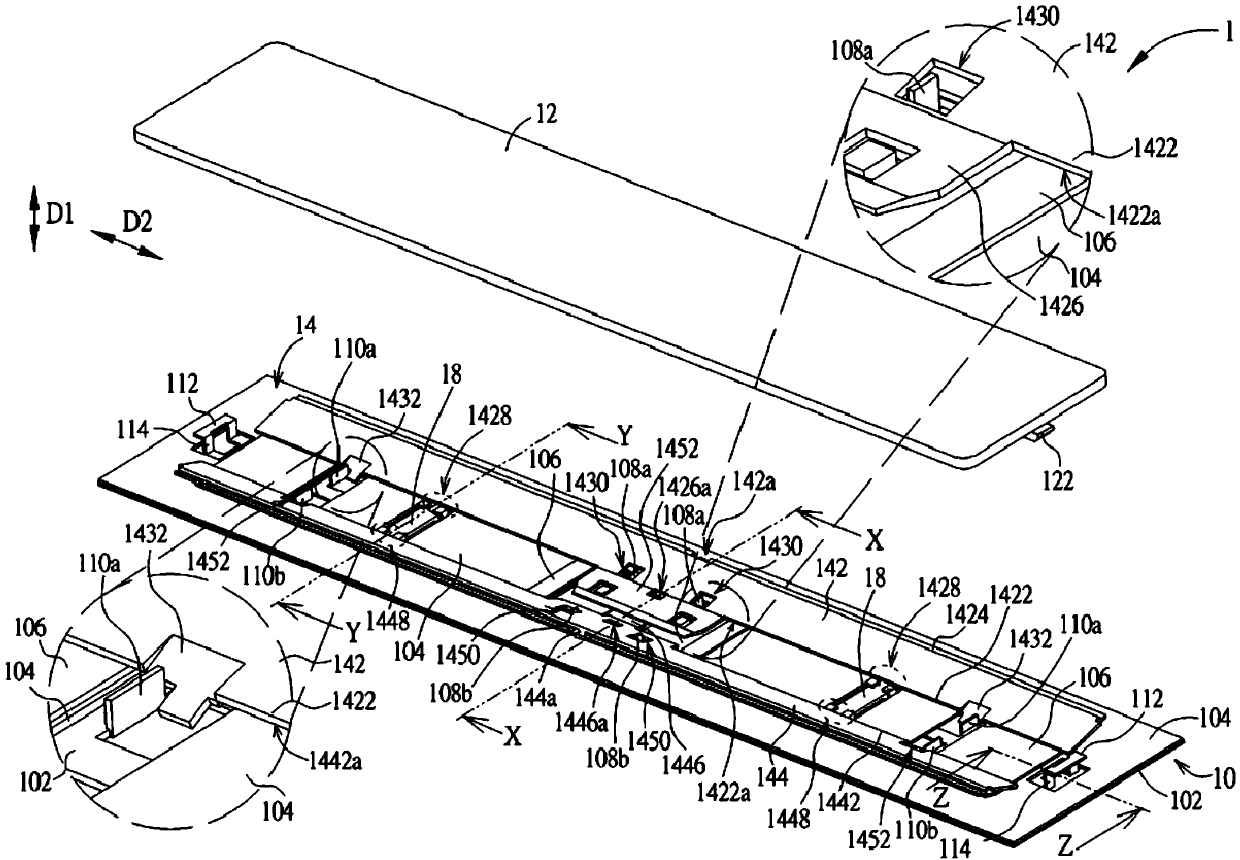

Key structure

ActiveCN104201029ALower the altitudeApproach steadilyElectric switchesTactile feedbackKey pressingSuction force

The invention relates to a key structure. The key structure comprises a base, a keycap, a lifting mechanism and a magnetic part; the keycap can move vertically relative to the base through the lifting mechanism; the lifting mechanism comprises a support; one lateral side portion of the support comprises a magnetic portion; the lateral side portion is in abutting joint with the base through a sharp edge; the magnetic portion extends outward from the lateral side portion; the support is flexibly connected with the keycap through an opposite lateral side portion; the magnetic part is arranged on the base corresponding to the magnetic portion; the magnetic suction force is produced between the magnetic part and the magnetic portion; when the keycap is pressed by the external force, the support rotates relative to the base through the sharp edge to enable the magnetic portion to be far away from the magnetic part and the keycap to be close to the base; when the external force is released, the support is driven by the magnetic suction force to rotate relative to the base through the sharp edge to enable the keycap to be far away from the base; the base can be provided with a magnetic part, wherein the magnetic suction force can be applied to the other magnetic portion of the support to drive the lateral side portion to be in abutting joint with the base.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

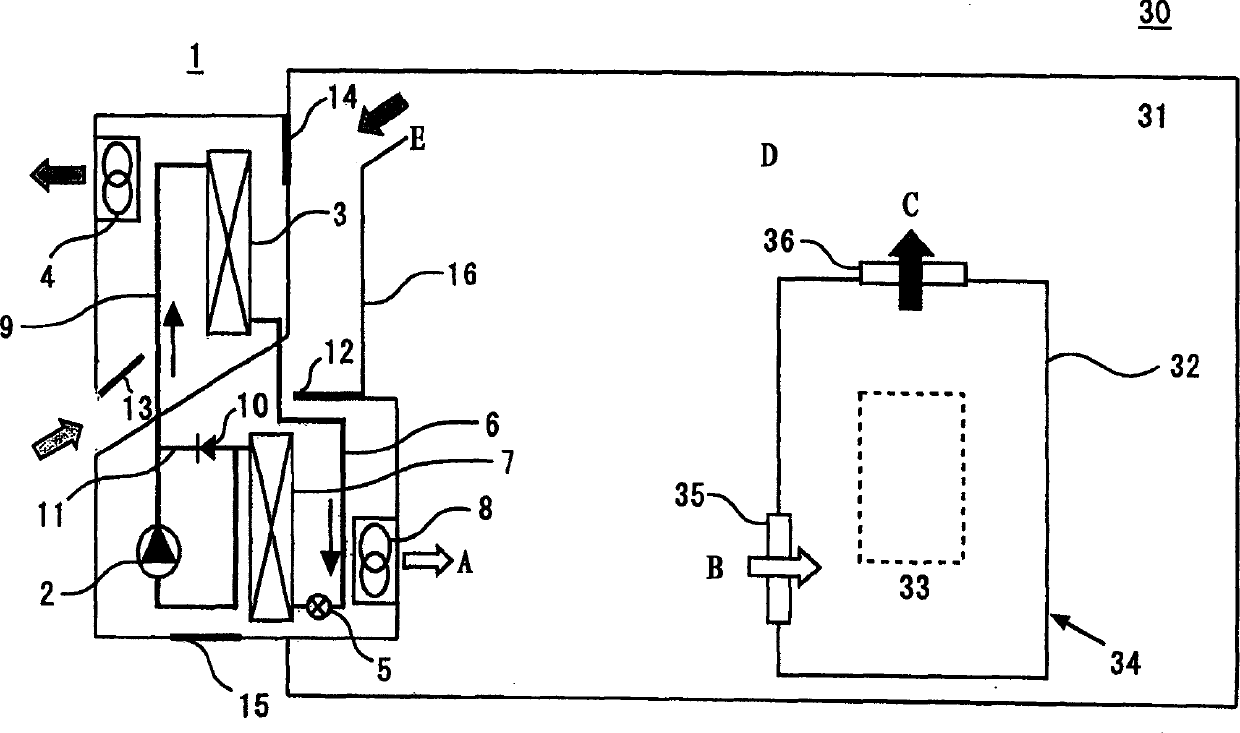

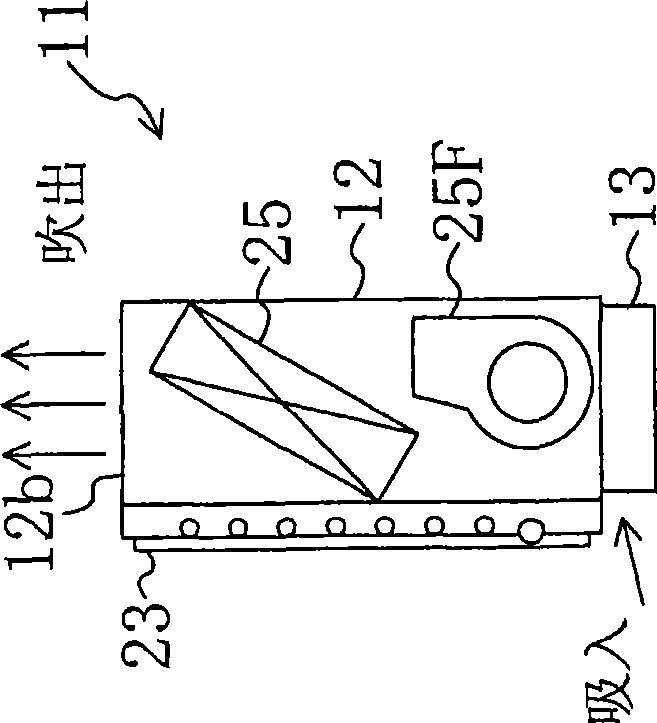

Cooling device

InactiveCN1511436ASave setup spaceReduce the number of setup devicesLighting and heating apparatusRefrigeration devicesEngineeringVentilation mode

A cooling system of the invention has heat exchange means which is housed in one enclosure (31) and is constituted of a plurality of heat exchange modes, and the heat exchange means includes a refrigerant forced circulation mode, a refrigerant natural circulation mode, and a ventilation mode. Temperature detection means performs switching to an optimal mode, to thereby cool the inside of the enclosure (31) of a housing (30) accommodating equipment (32) including a heat-generating component (33).

Owner:MITSUBISHI ELECTRIC CORP

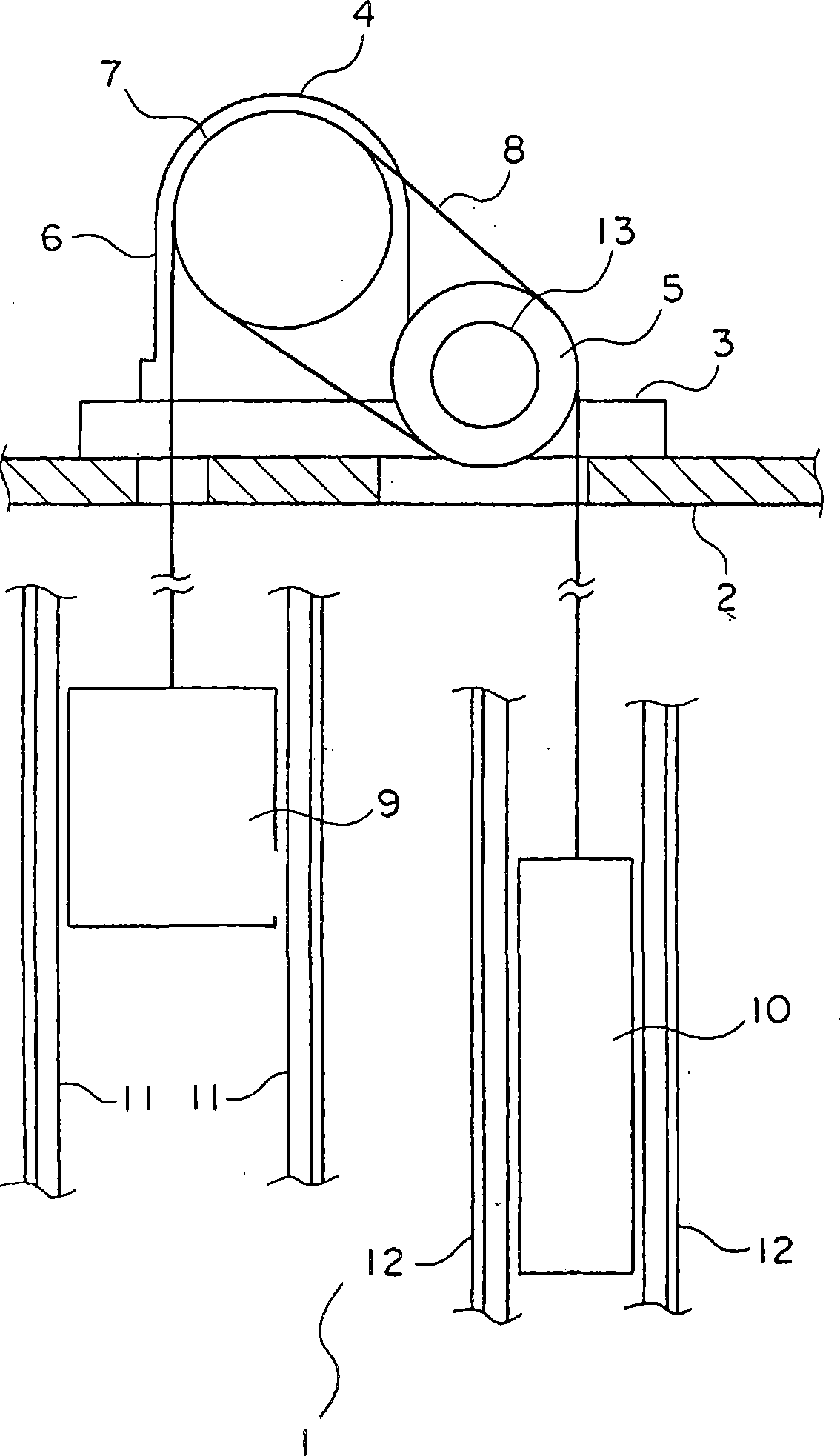

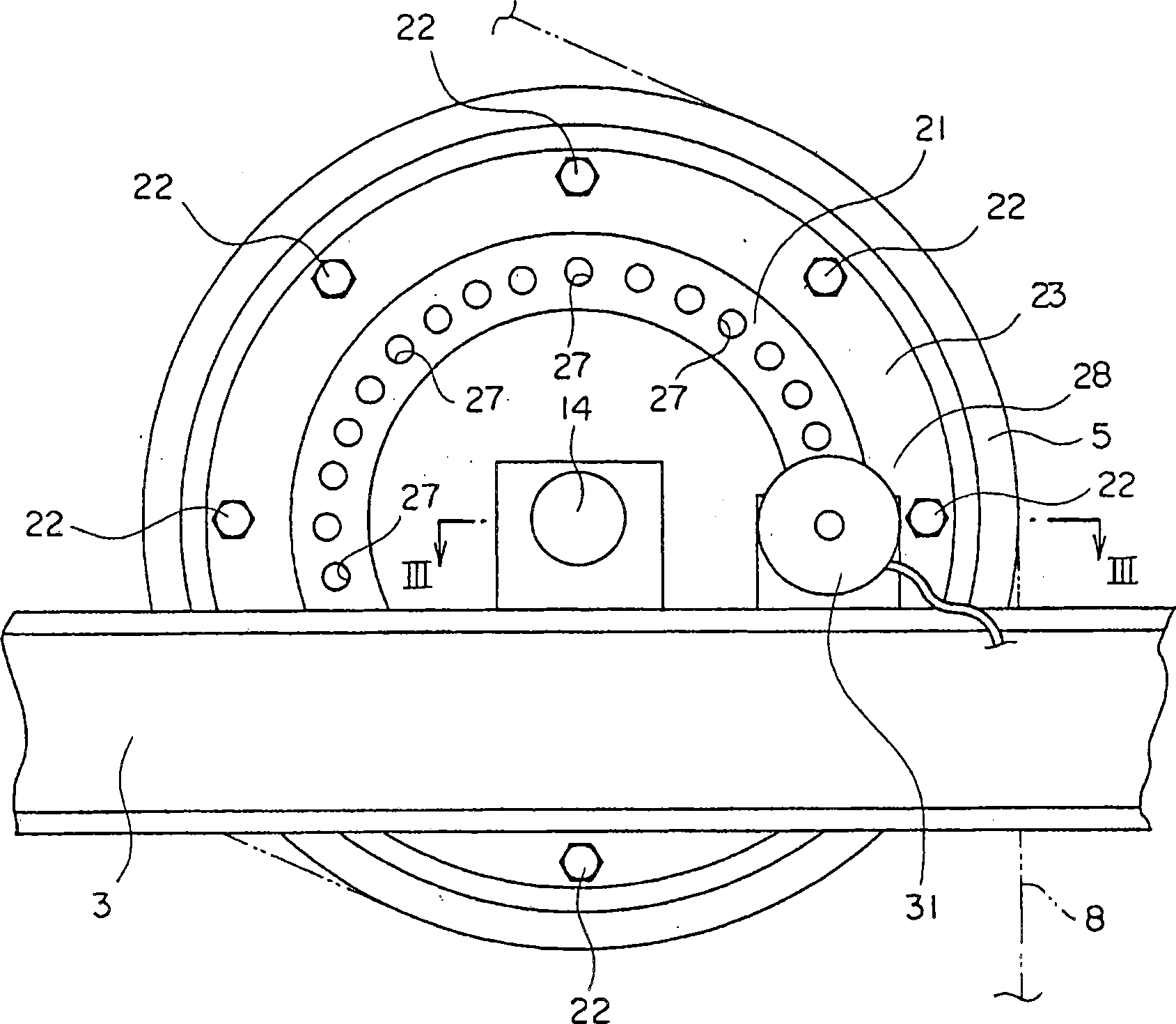

Brake device for elevator

InactiveCN1902122AAchieve long lifeSave setup spaceBrake typesElevatorsEngineeringMechanical engineering

In a brake device for an elevator, a hold-down device is provided on a sheave on which a main rope for suspending a cage and a balance weight runs. A brake disk on which engagement sections are arranged is pressed to the sheave by the hold-down device. An engagement device has a movable section displaceable between an engagement position at which the movable section is engaged with an engagement section is engaged and a release position at which the engagement of the movable section with the engagement section is released. The brake disk is rotatable together with the sheave when the movable section is in the release position, and the brake disk is stopped when the movable section is in the engagement position, braking the rotation of the sheave.

Owner:MITSUBISHI ELECTRIC CORP

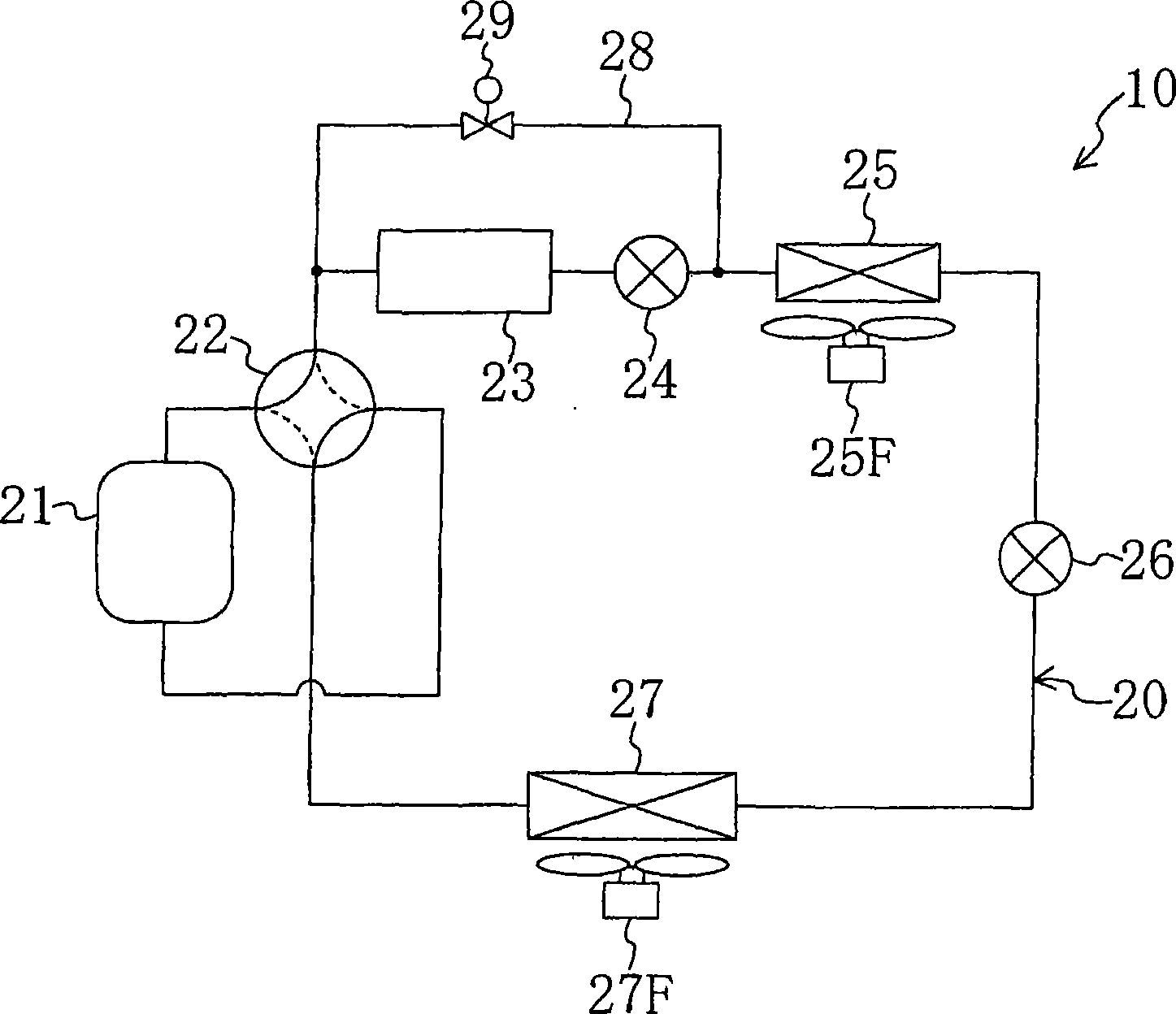

Air conditioning system

InactiveCN101479535ASuppress fluImprove comfortMechanical apparatusSpace heating and ventilation safety systemsRefrigerantCooling cycle

An air conditioning system includes a refrigerant circuit (20) in which a compressor (21), an indoor radiant panel (23), a first expansion valve (24), a room air heat exchanger (25), a second expansion valve (26) and an outdoor air heat exchanger (27) are connected in this order and which operates in a refrigeration cycle by reversibly circulating refrigerant therethrough. During a defrosting operation, the first expansion valve (24) is controlled to reduce the refrigerant pressure so that in a cooling cycle the refrigerant releases heat in the outdoor air heat exchanger (27) and the room airheat exchanger (25) and evaporates in the indoor radiant panel (23). Thus, the air conditioning system concurrently provides the defrosting of the outdoor air heat exchanger (27) and the room heating of the room air heat exchanger (25).

Owner:DAIKIN IND LTD

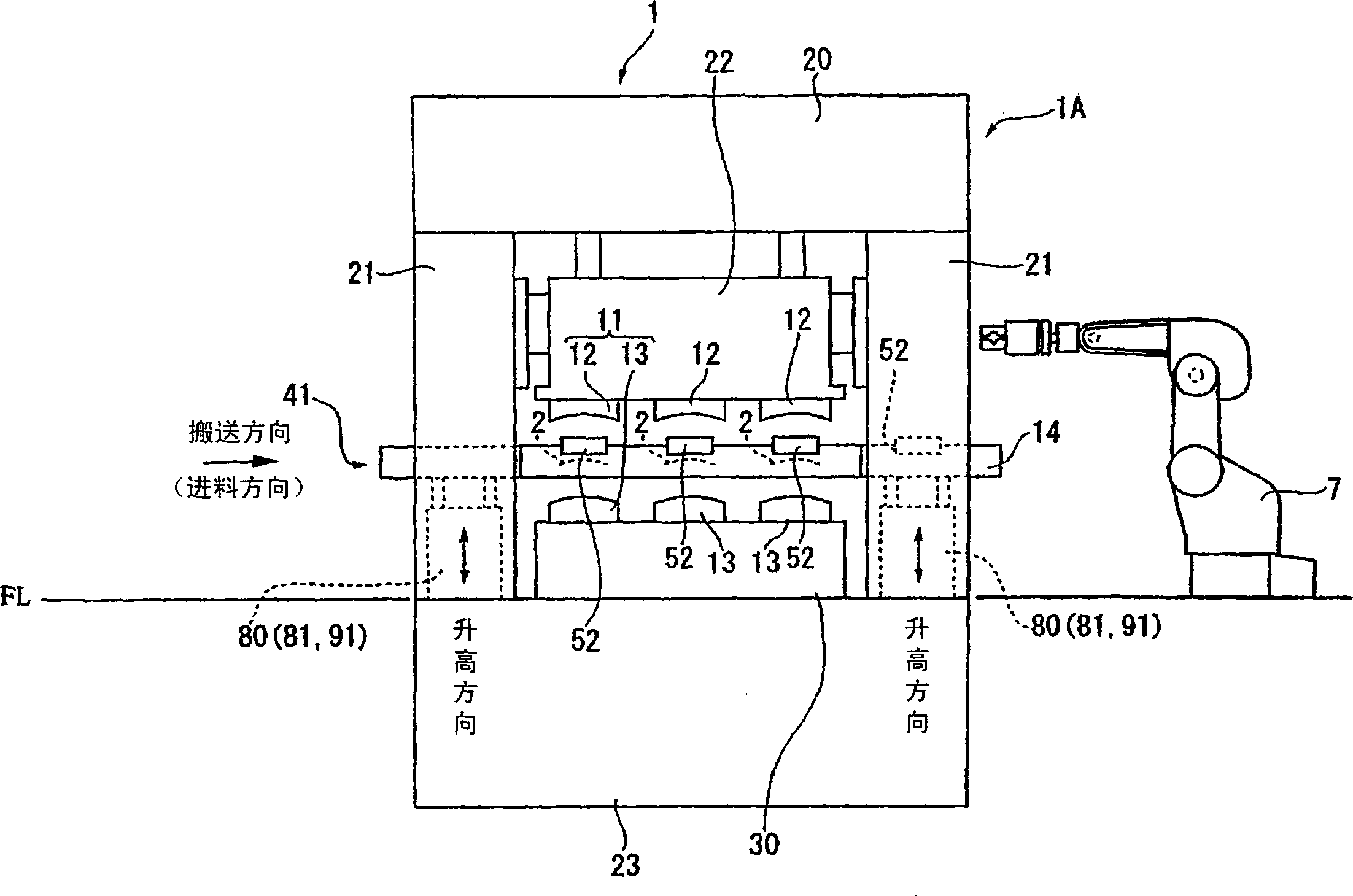

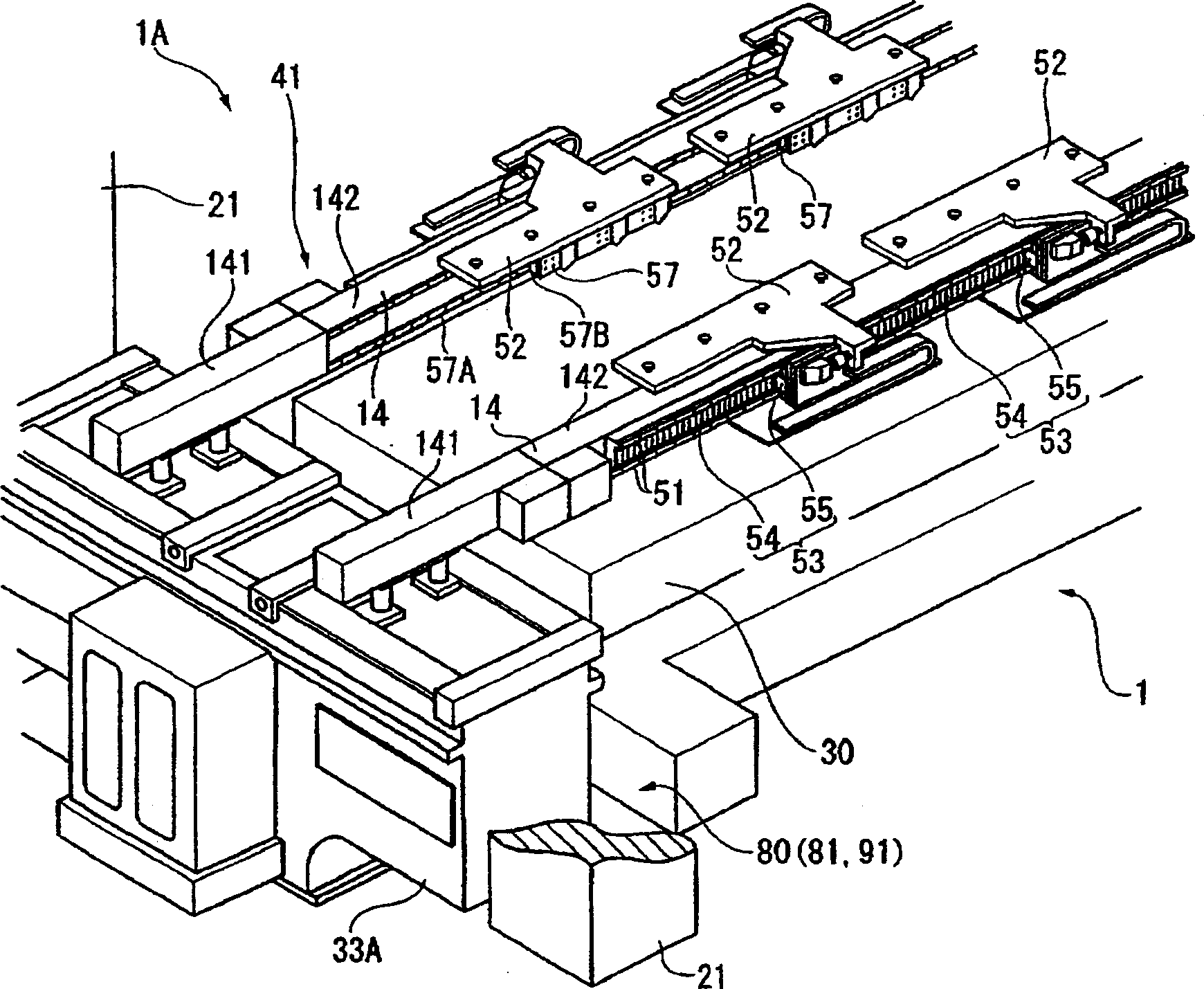

Work carrying device of pressing machine

ActiveCN1871078ALow costReduce the numberMetal-working feeding devicesPositioning devicesEngineeringLinear motor

A work carrying device of a pressing machine, comprising a transfer feeder (41) having a lift / clamp device (80) moving a bar (14) in the lift direction and the clamp direction, a plurality of feed carriers (52) installed on the bar (14), and feeding linear motors (53) driving the feed carriers (52) in the feed direction. An object driven by the feeding linear motors (53) can be formed small in size since the feed carriers (52) are installed on the bar (14), the feeding linear motors (53) having a small capacity can be adopted to simplify the structure of a transfer press (1).

Owner:KOMATSU LTD

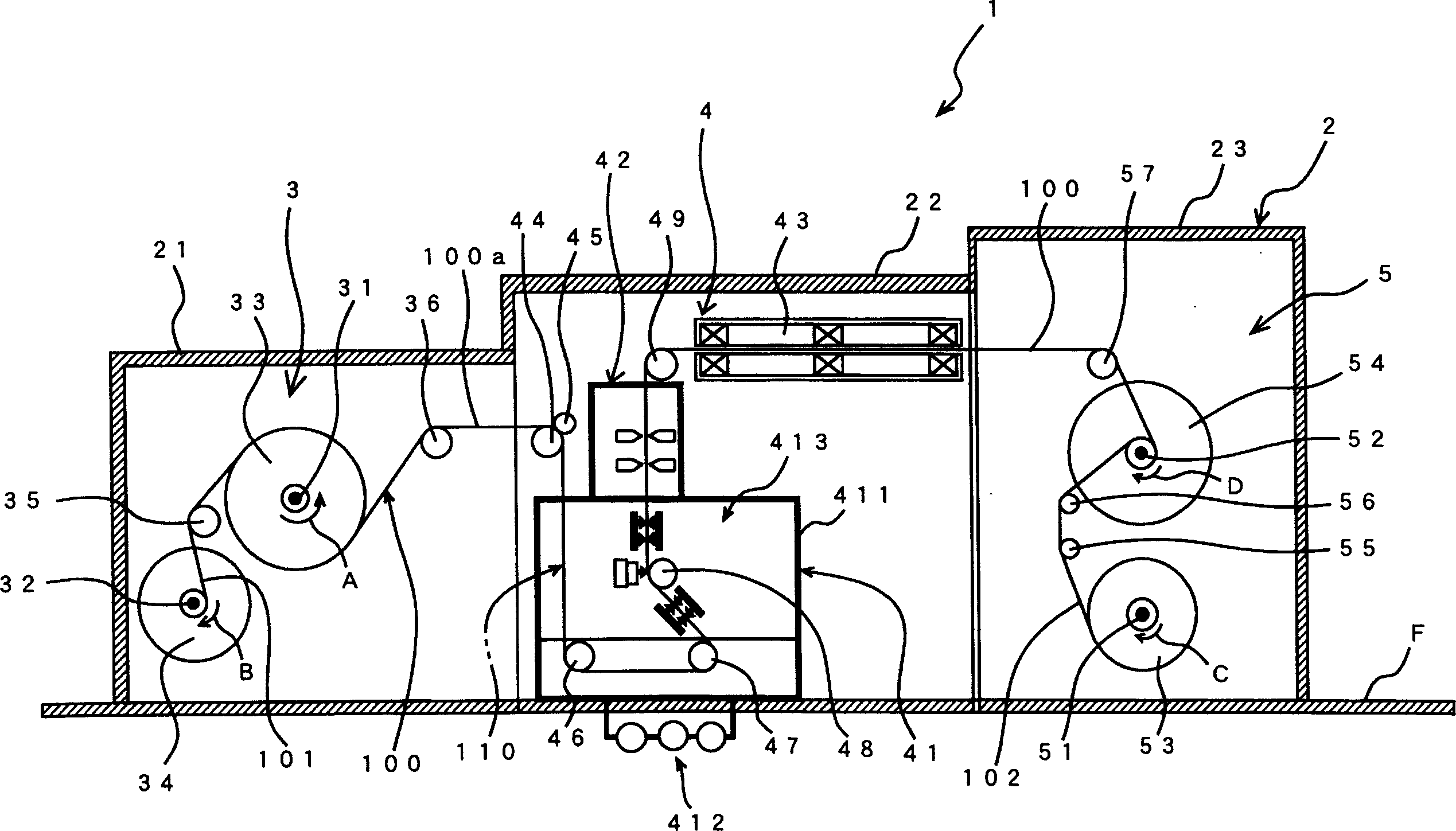

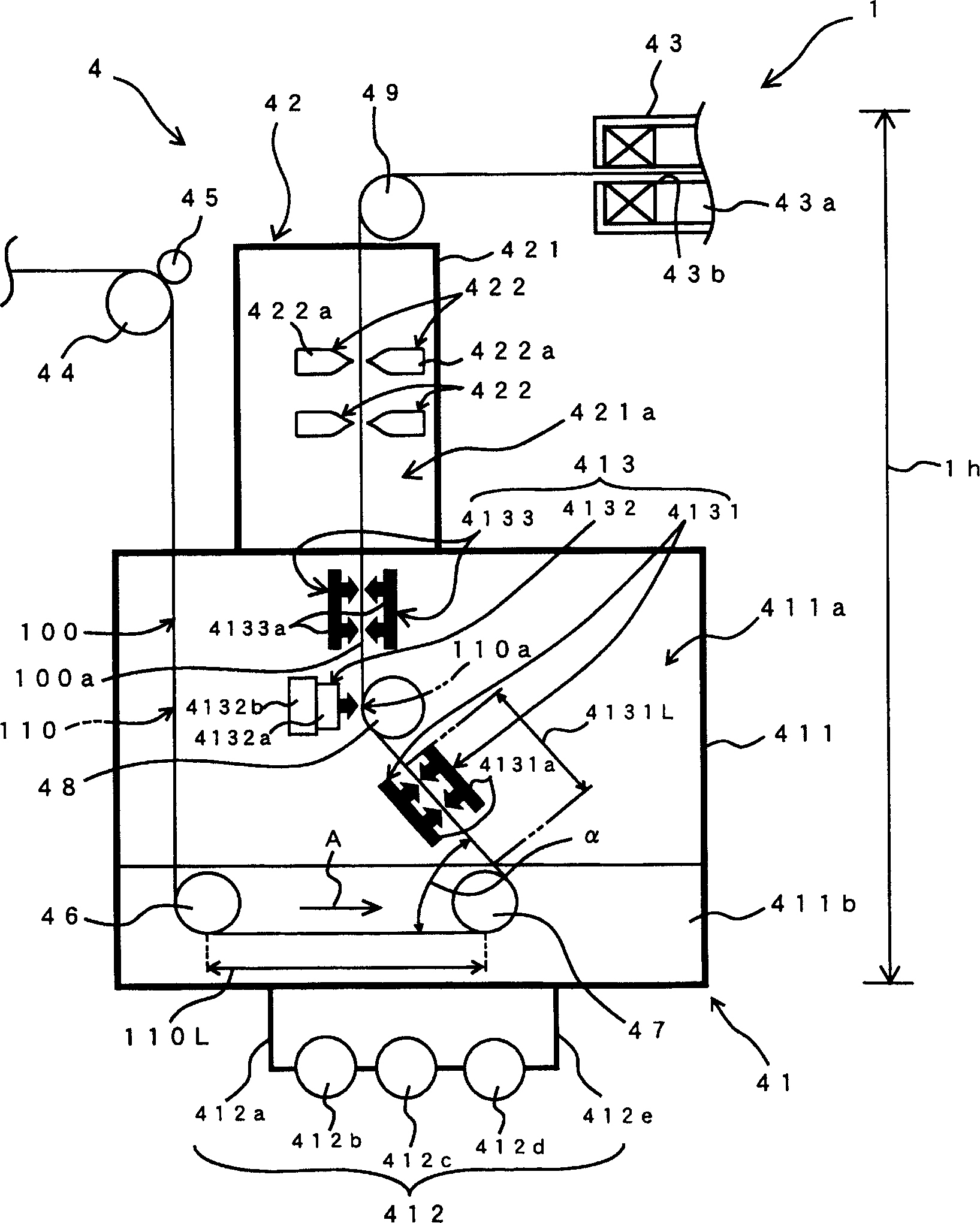

Substrate processing apparatus and substrate processing method

ActiveCN107342243ASimple structureSave setup spaceSemiconductor/solid-state device manufacturingConveyor partsComputer moduleEngineering

The present invention aims to provide a substrate processing apparatus and a substrate processing method which simplifies the structure of the apparatus, reduces the installation space, reduces steps of transferring the substrate, and improves the substrate processing speed by integrally forming a load-lock unit in a process chamber. In the substrate processing apparatus (1) of the present invention to implement this, a first chamber (100) among a plurality of chambers for processing a substrate in a vacuum state integrates a front end module with a load lock portion (100a) for loading and unloading the substrate therebetween. The loading and unloading of the substrate is performed in a state where a first space (S1) of the first chamber (100), where the load lock portion (100a) is located, and a second space (S2) of the first chamber (100), which is provided below the first space (S1) and communicates with the plurality of chambers, are spatially isolated from each other.

Owner:SUBARU TECNICA INTERNATIONAL

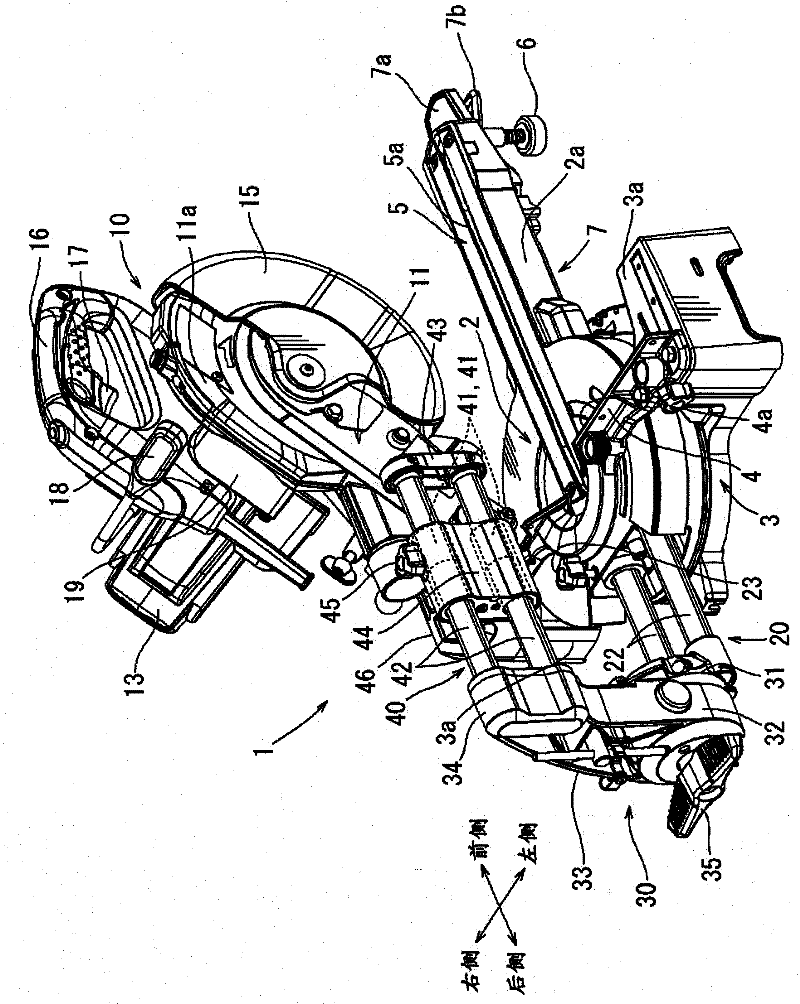

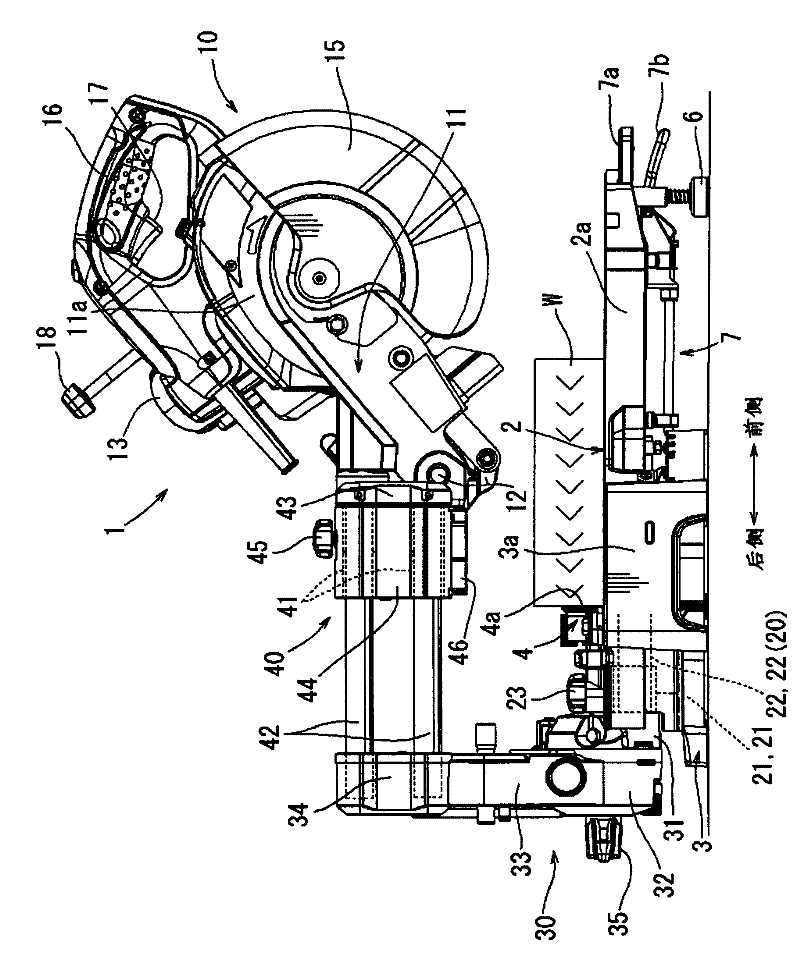

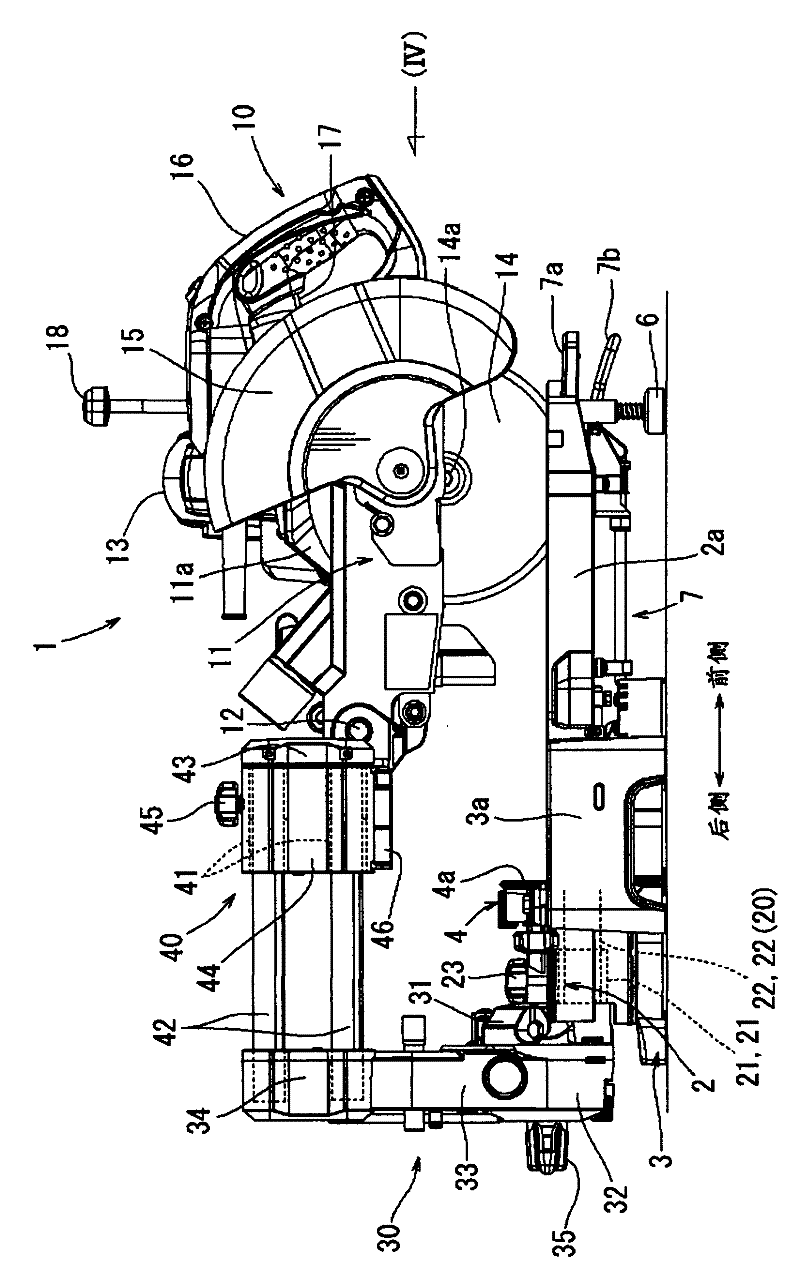

table cutting machine

In a table cutting machine capable of sliding a main body of the cutting machine in the backward and forward direction for the purpose of processing a large size material to be cut, a rearward installation space can be reduced by configuring the cutting machine in such a way that a slide bar of a slide mechanism for slidably supporting the main body of the cutting machine is fixed while a bearing side is adapted to be movable. However, this has caused a problem that the fixed slide bar obstructs an operation. In accordance with the present invention, the rearward installation space can be reduced and good visibility of the edge of a blade can be obtained, and thus an operational performance is improved. Slide mechanisms (20 and 40) arranged in two stages in the vertical direction are used for obtaining a long slide distance for a main body of a cutting machine (10). For the upper stage slide mechanism, there is adopted the slide mechanism (40) of a pattern 2 in which a slide bar (42) is fixed. This allows the rearward installation space of the slide mechanism (40) to be reduced, and ensures good visibility of the edge of a blade.

Owner:MAKITA CORP

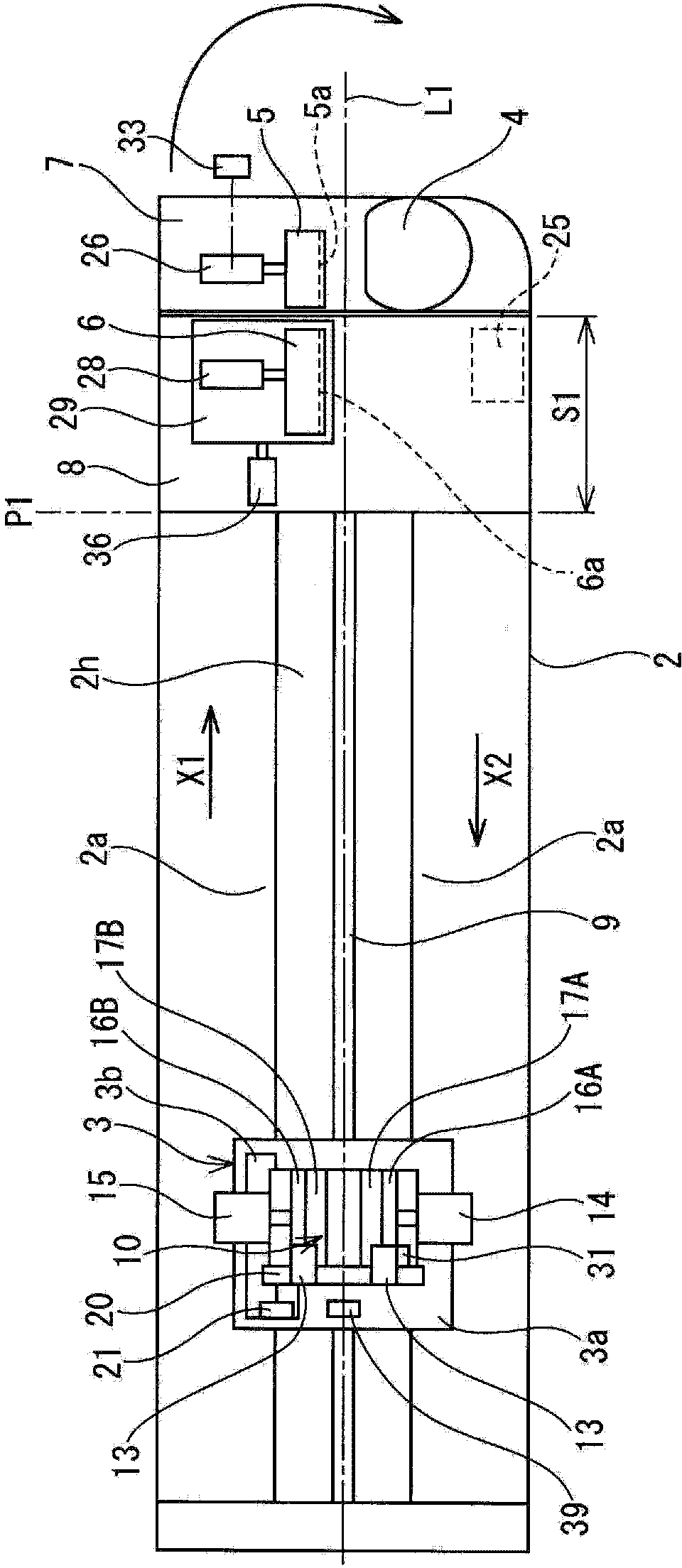

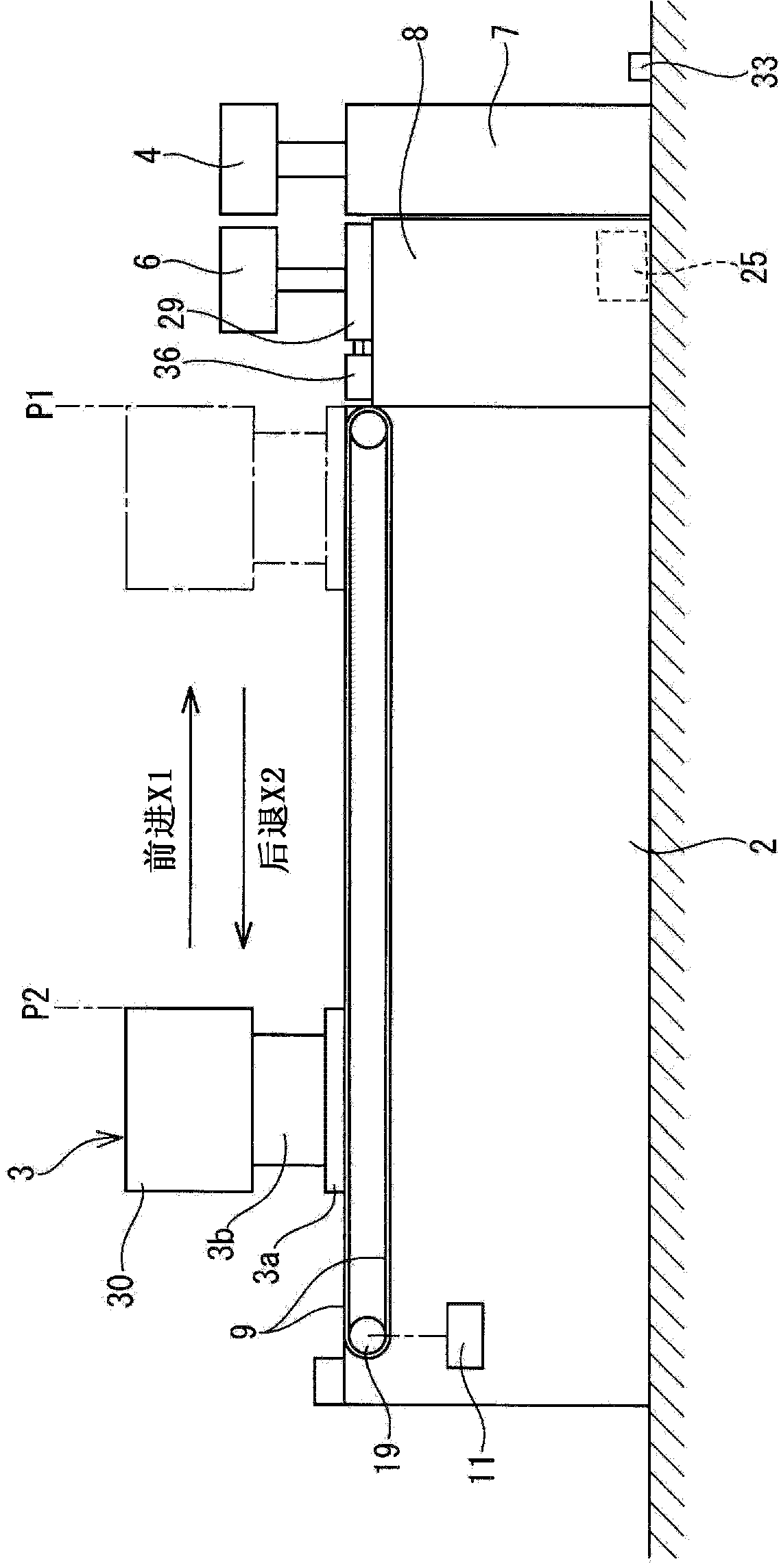

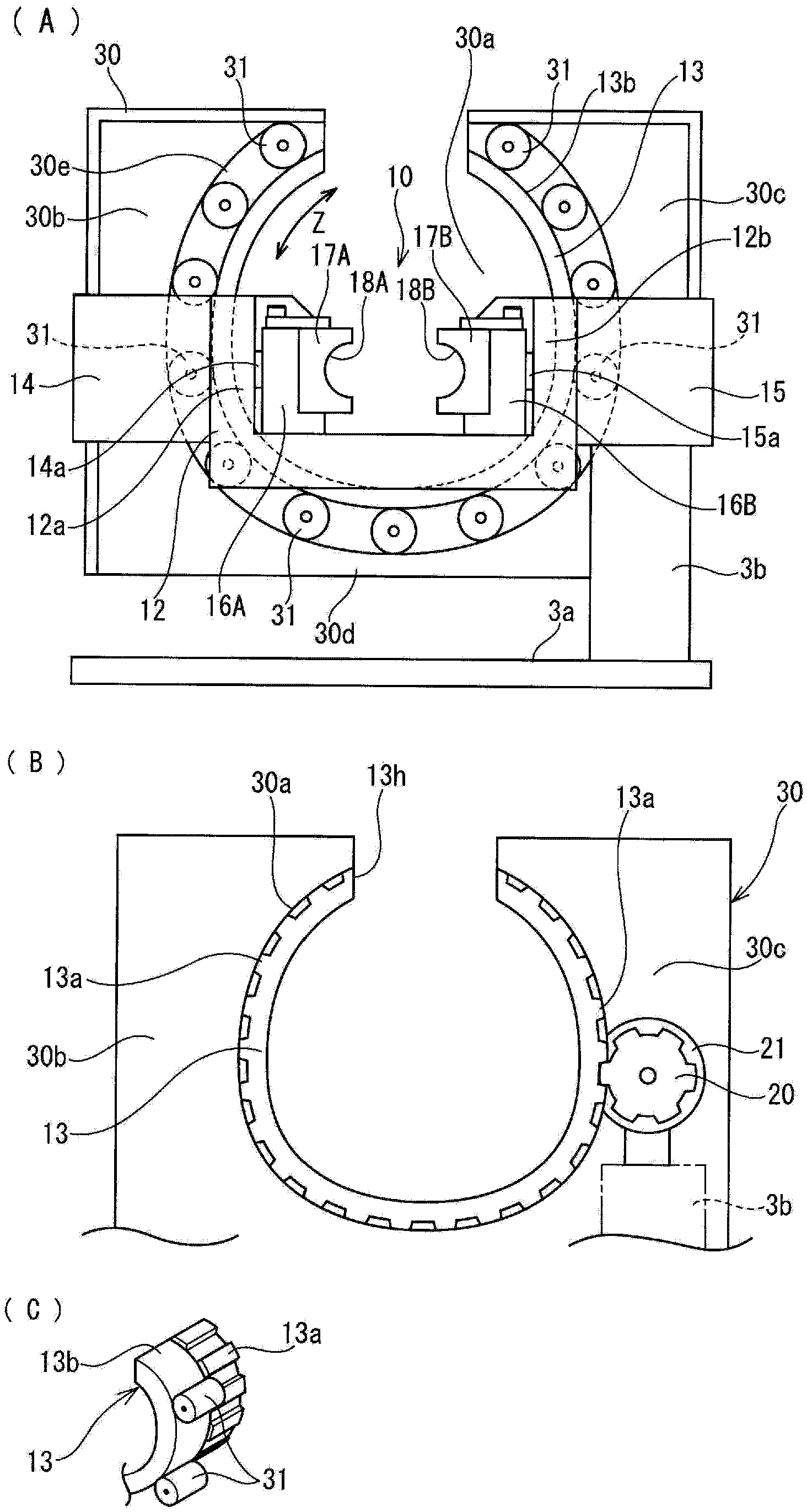

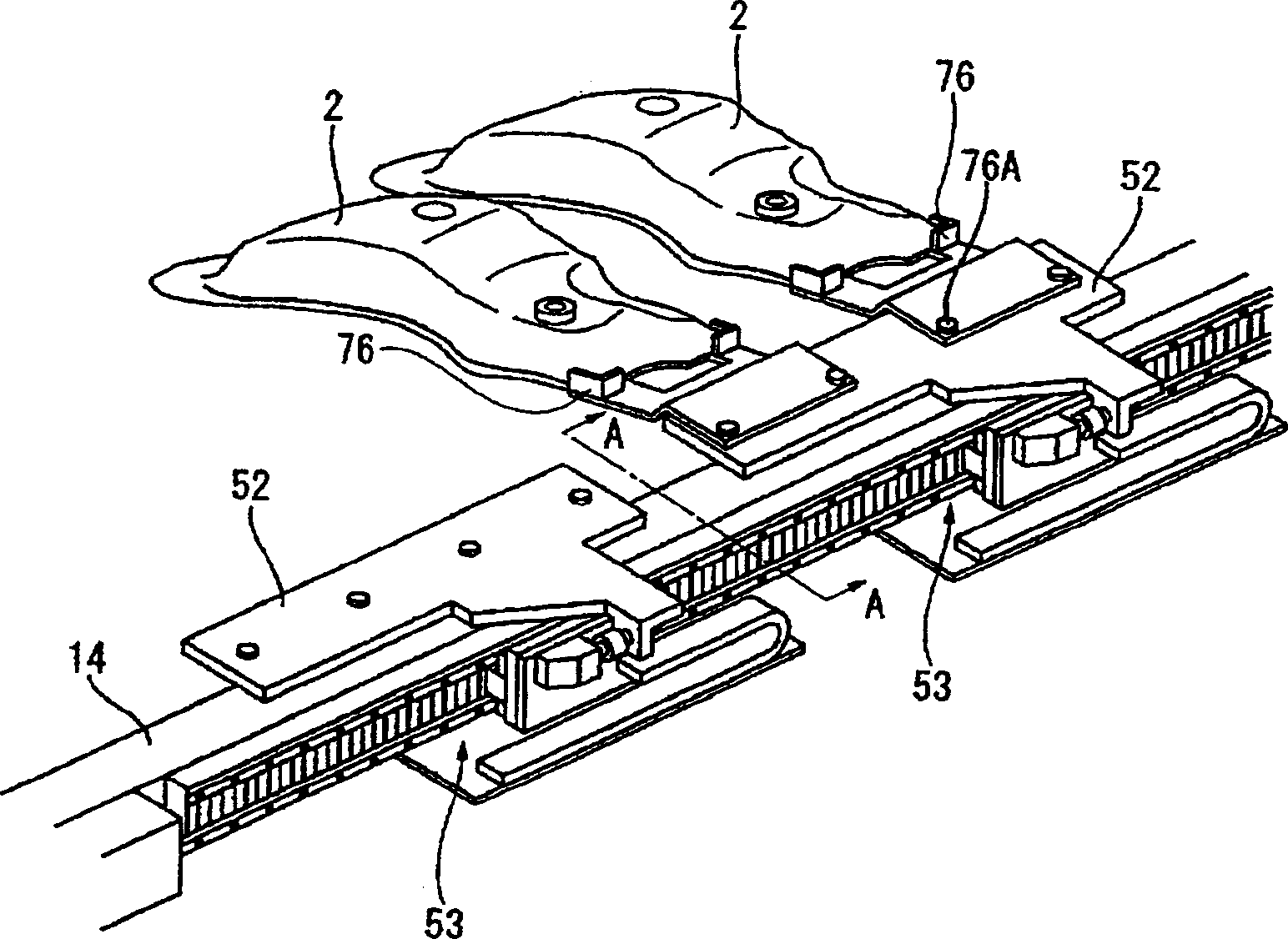

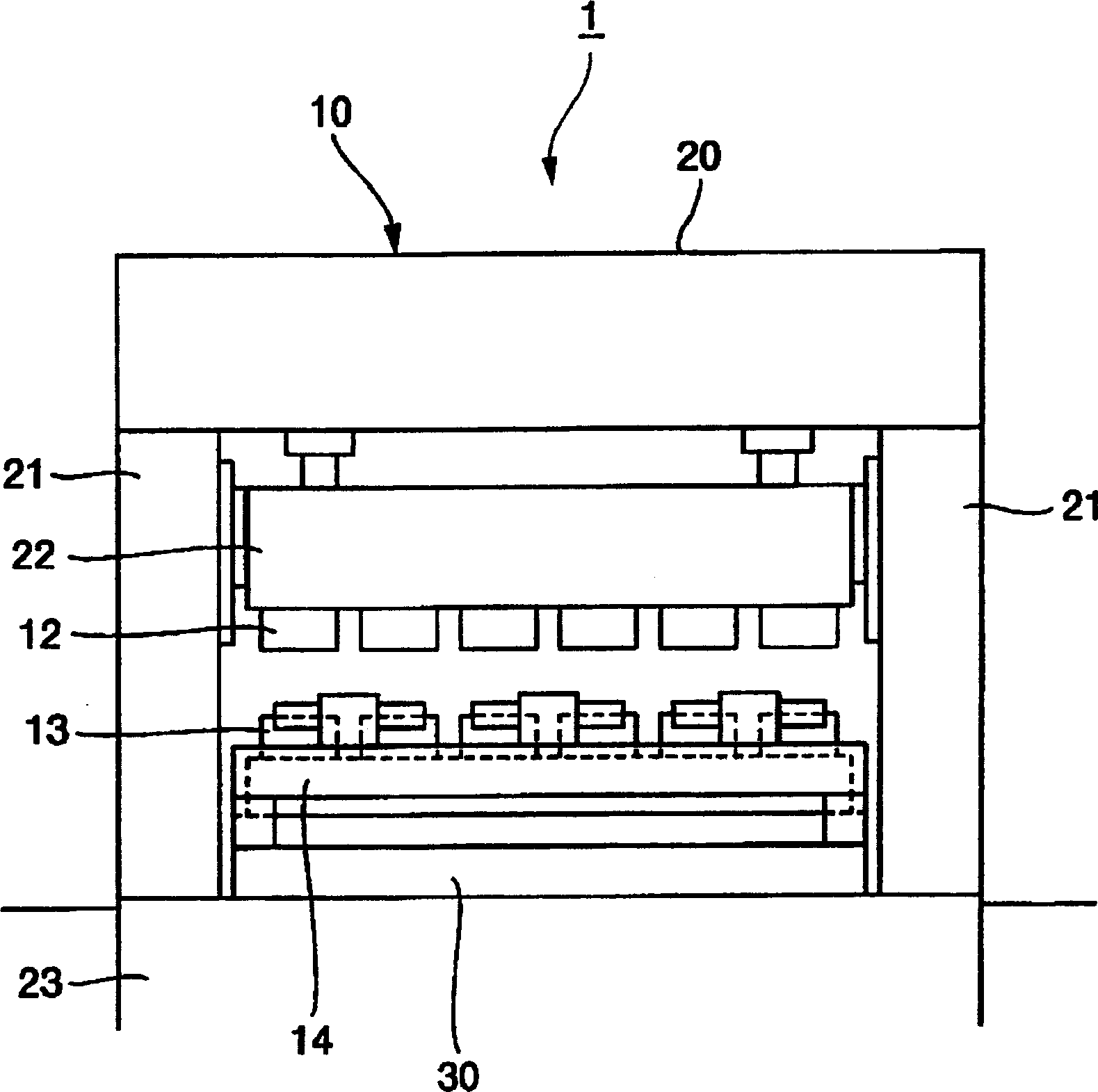

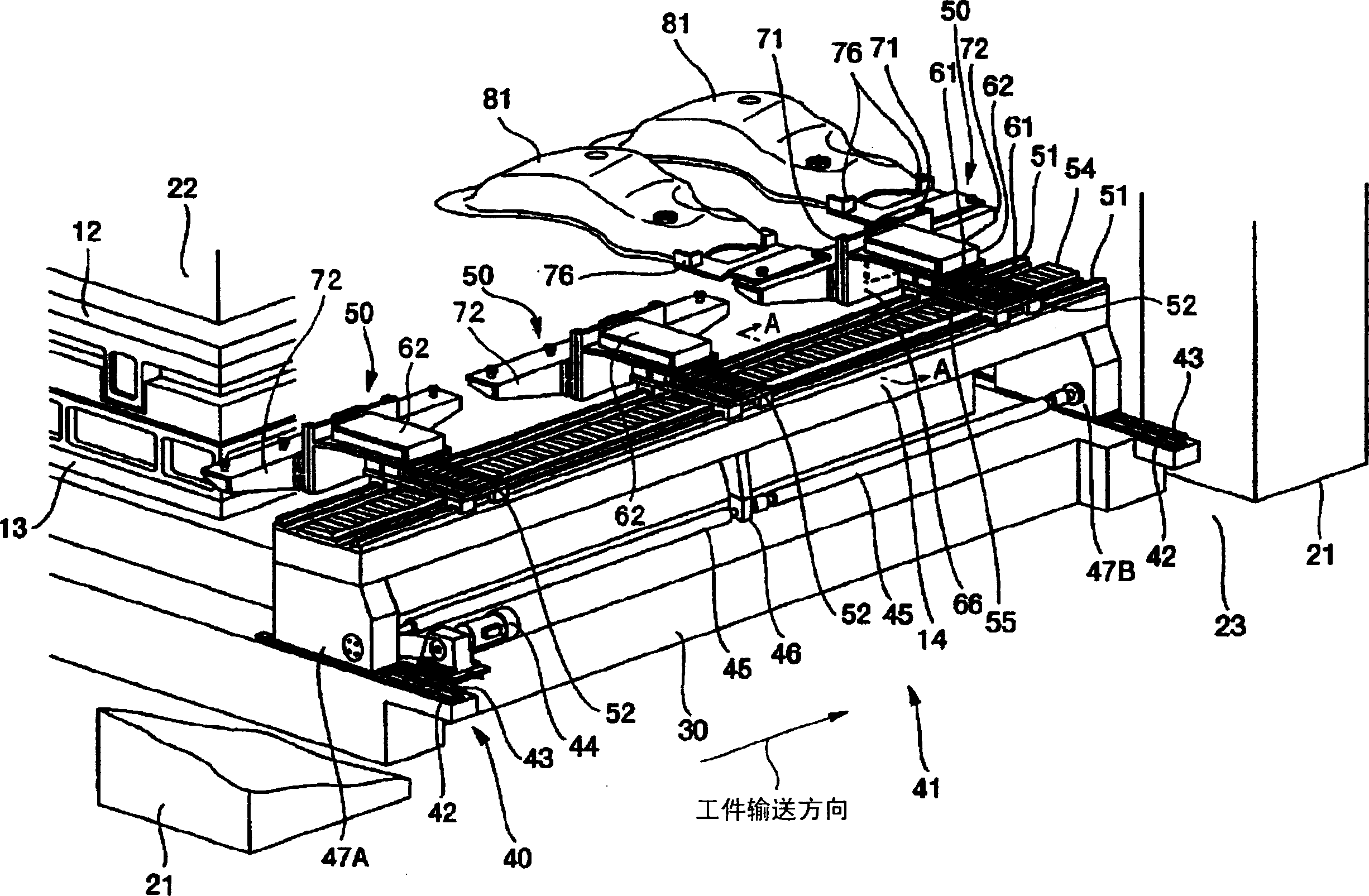

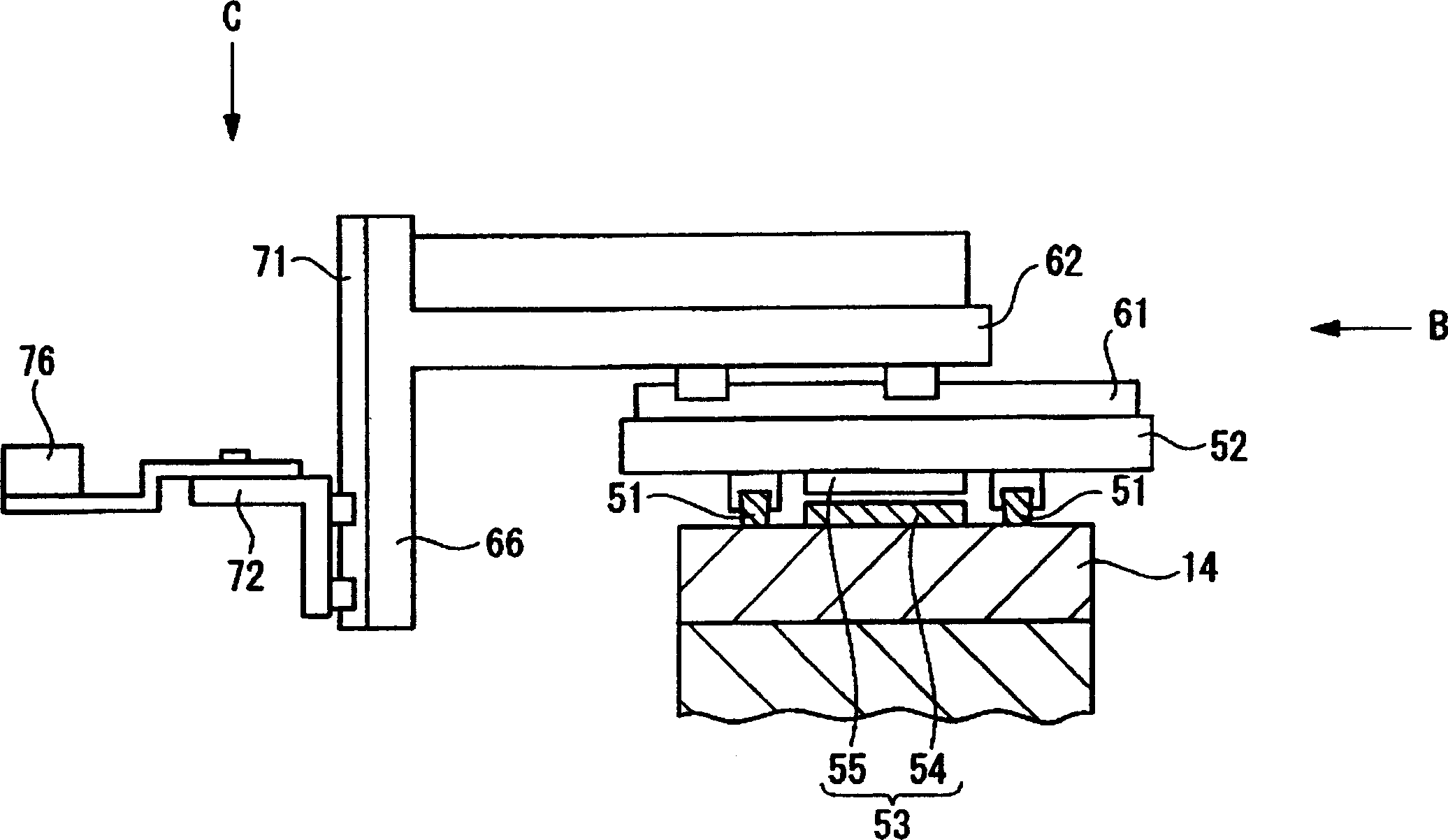

Work transfer device for press machines

InactiveCN1863616ALarge range of movementEasy replacement workShaping toolsMetal-working feeding devicesIndustrial engineeringMachine press

A transfer feeder (41) for a transfer press (1) comprises a pair of bars (14) disposed on a moving bolster (30) in parallel with the direction of work transfer, a feed carrier (52) supported by the bars (14) and movable in the direction of work transfer, a clamp carrier (62) supported by the feed carrier (52) and movable in the direction of clamp, and a lift carrier (72) supported by the clamp carrier (62) and movable in the direction of lift. Since a large drive mechanism is unnecessary, simplification of the construction can be enhanced. Further, since the whole of a transfer feeder (41) is disposed on a moving bolster (30), the moving bolster (30) in its entirety can be carried out of the transfer press (1), thus facilitating mold change operation.

Owner:KOMATSU LTD

Humidity control device and ventilation device

InactiveCN101815906AImprove maintainabilityEasy to take outEnergy recovery in ventilation and heatingGas treatmentMoistureElectrical and Electronics engineering

Owner:DAIKIN IND LTD

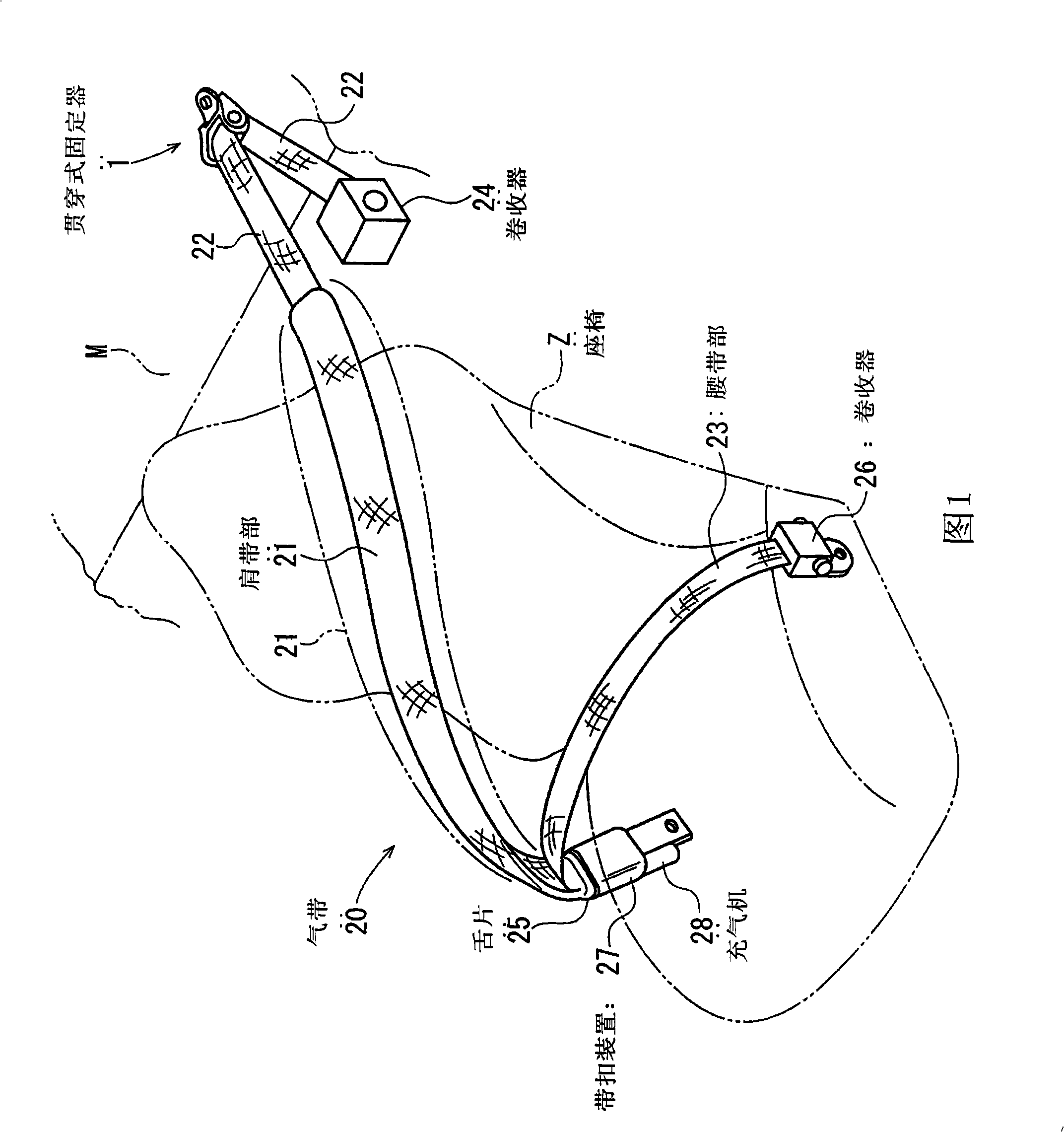

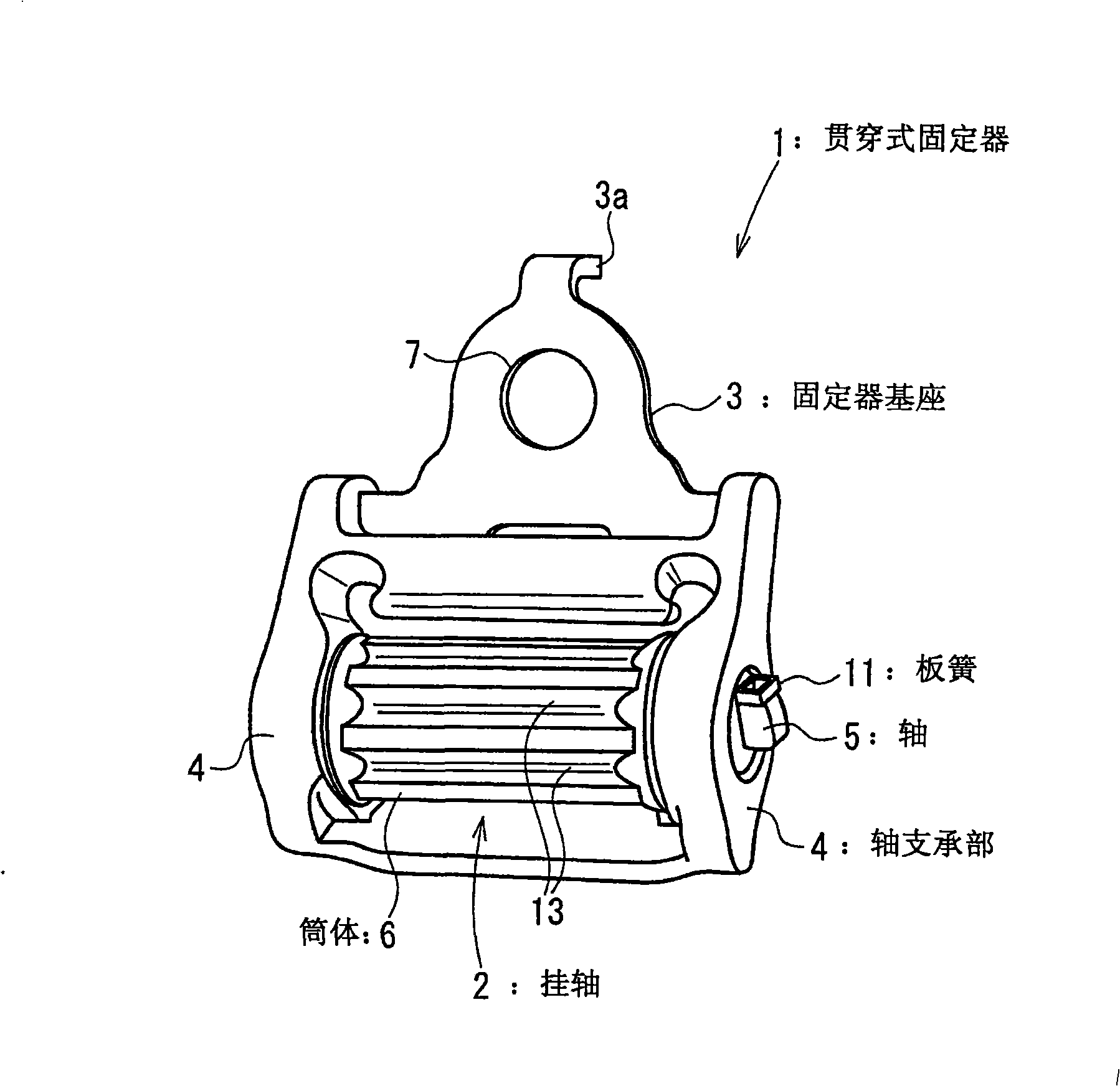

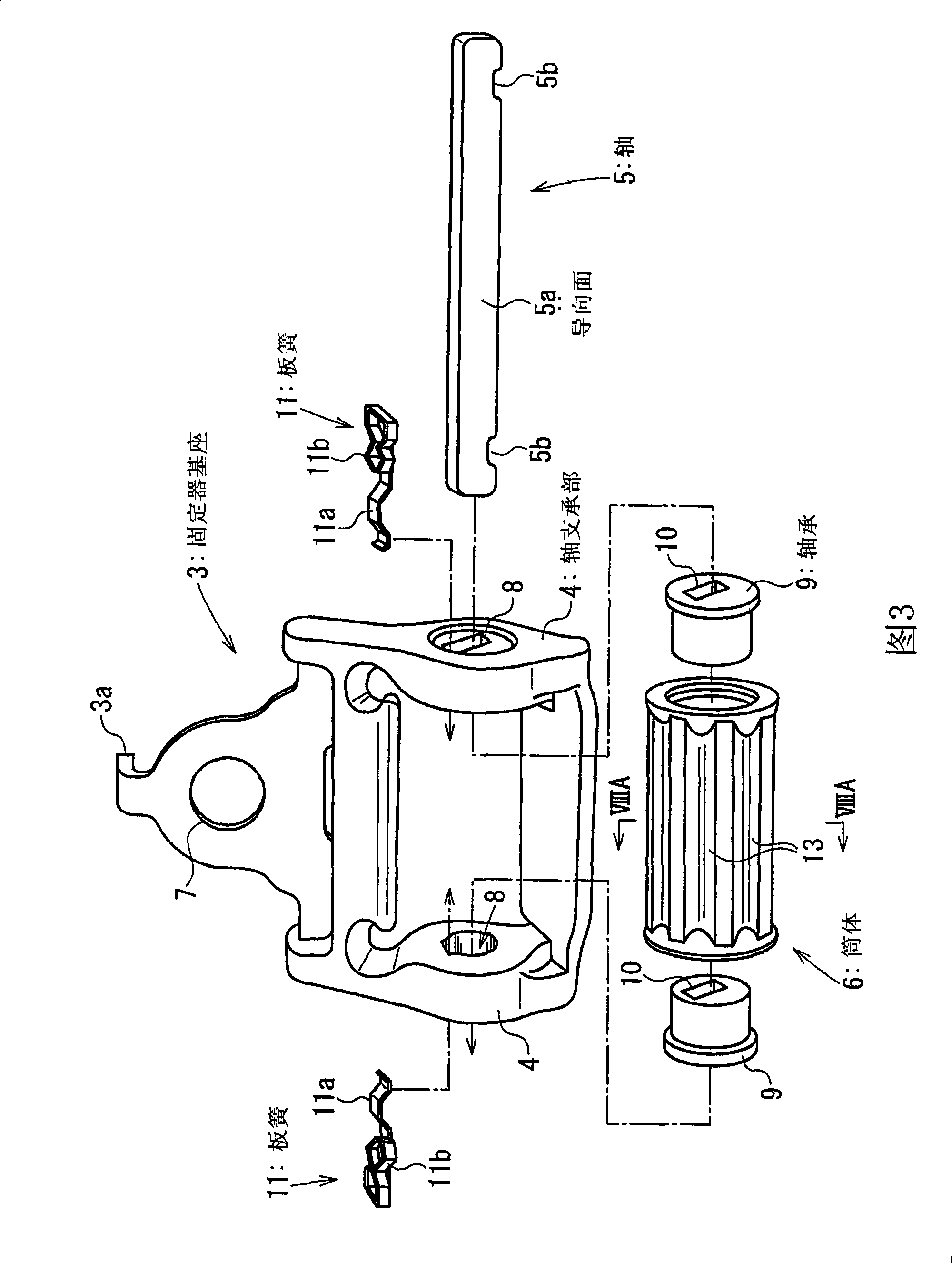

Seat belt through anchor, seat belt apparatus and vehicle

InactiveCN101402346AIncreased durabilityLow costBelt retractorsBelt anchoring devicesSeat beltActive force

The invention provides a penetrating fixer for safety belt with good cylinder durability and low cost. A shaft (5) is supported on a fixer base (3) by a nonrotatable way, and a cylinder (6) is externally embedded on the shaft (5) by a rotatable way. A recessed portion (12) buckled with a convex angle portion (5t) of the shaft (5) is arranged on inner circumferential surface of the cylinder (6). The cylinder (6) is supported on the shaft (5) up-and-down movably by a bearing (9). A leaf spring (11), which applies force upwards to the bearing (9) for separating the recessed portion (12) of the cylinder (6) and the convex angle portion (5t) of the shaft (5), is arranged between the bearing (9) and the shaft (5). When the safety belt applies press force more than specified value to the cylinder (6), active force of the cylinder (6) antagonized to the leaf spring (11) moves downwards, So that, the recessed portion (12) of the cylinder (6) is buckled with the convex angle portion (5t) of the shaft (5) to prevent the cylinder (6) from rotating.

Owner:TAKATA CORPORATION

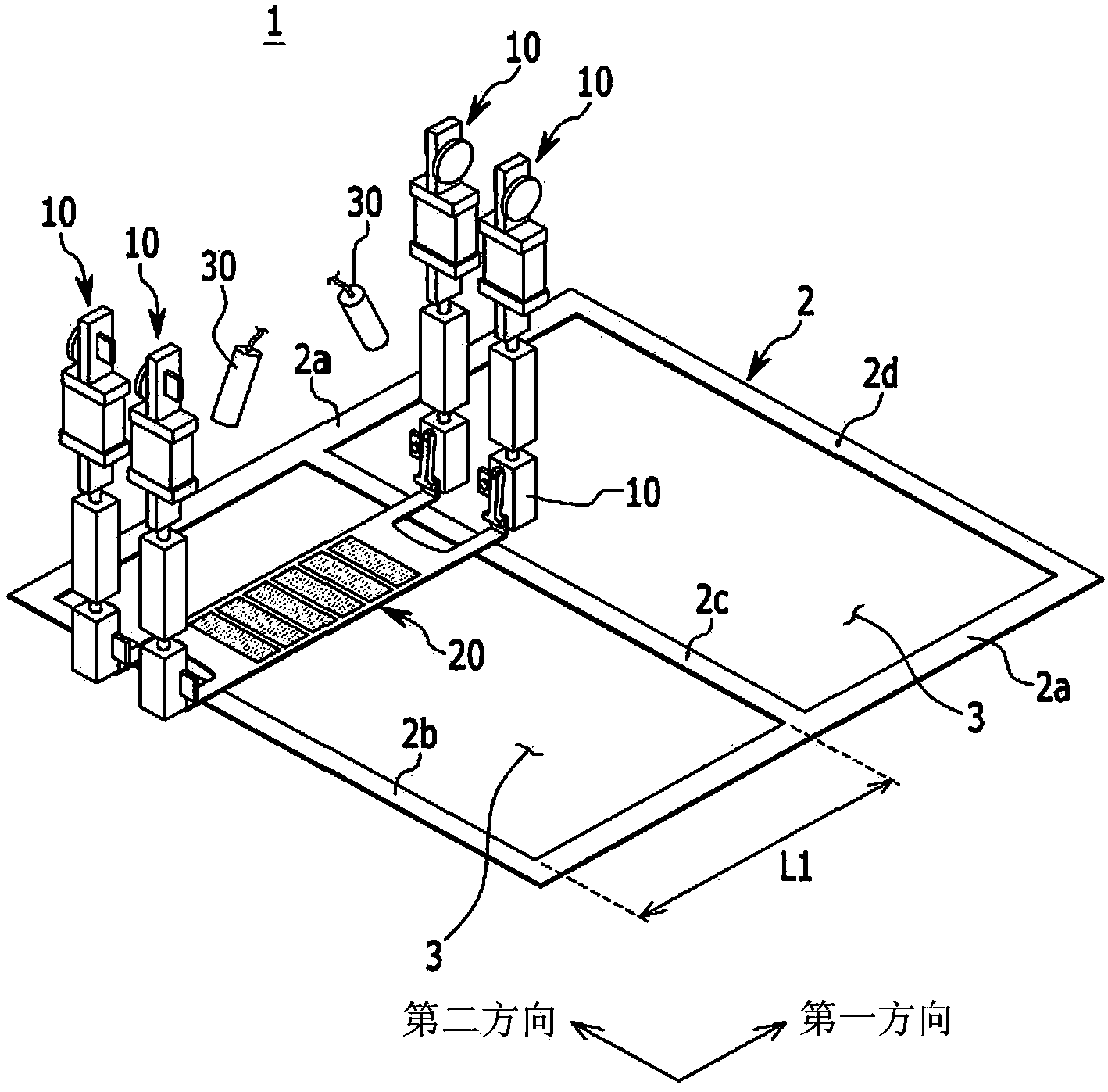

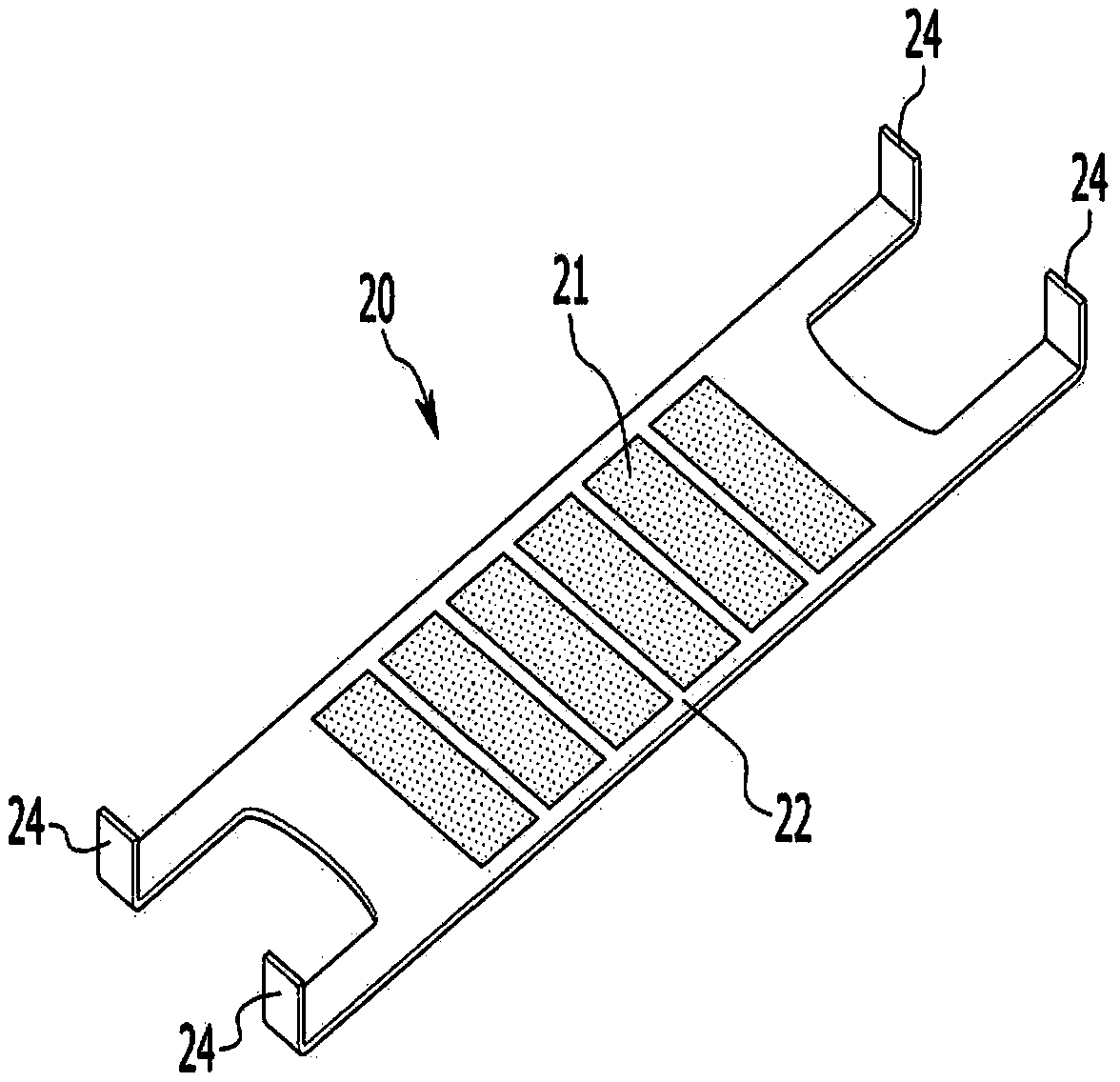

Tensioning apparatus for mask, mask sheet, and manufacturing system for mask

ActiveCN103451597ASave setup spaceLiquid surface applicatorsVacuum evaporation coatingBiomedical engineeringManufacturing systems

A mask tensioning apparatus is disclosed. In one embodiment, the mask tensioning apparatus includes: i) a clamp supporting a mask sheet disposed on the mask frame to couple the mask sheet to the mask frame and ii) a tensioner connected to the clamp and applying a tensioning force to the clamp to fix the mask sheet fixed by the clamp to the mask. The clamp may be arranged in a substantially vertical or oblique direction with regard to the elongation direction of the mask sheet, thereby supporting the mask sheet.

Owner:SAMSUNG DISPLAY CO LTD

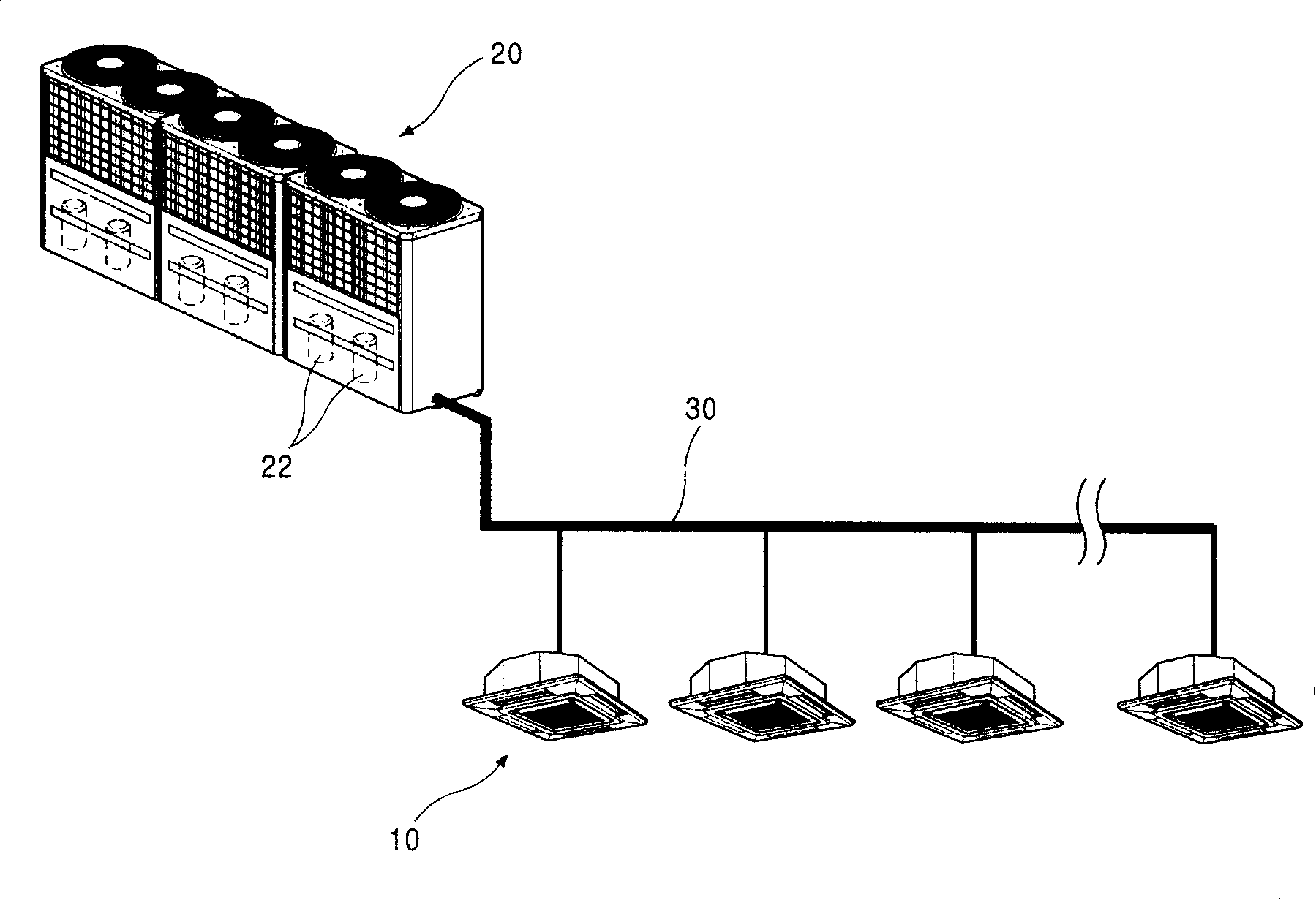

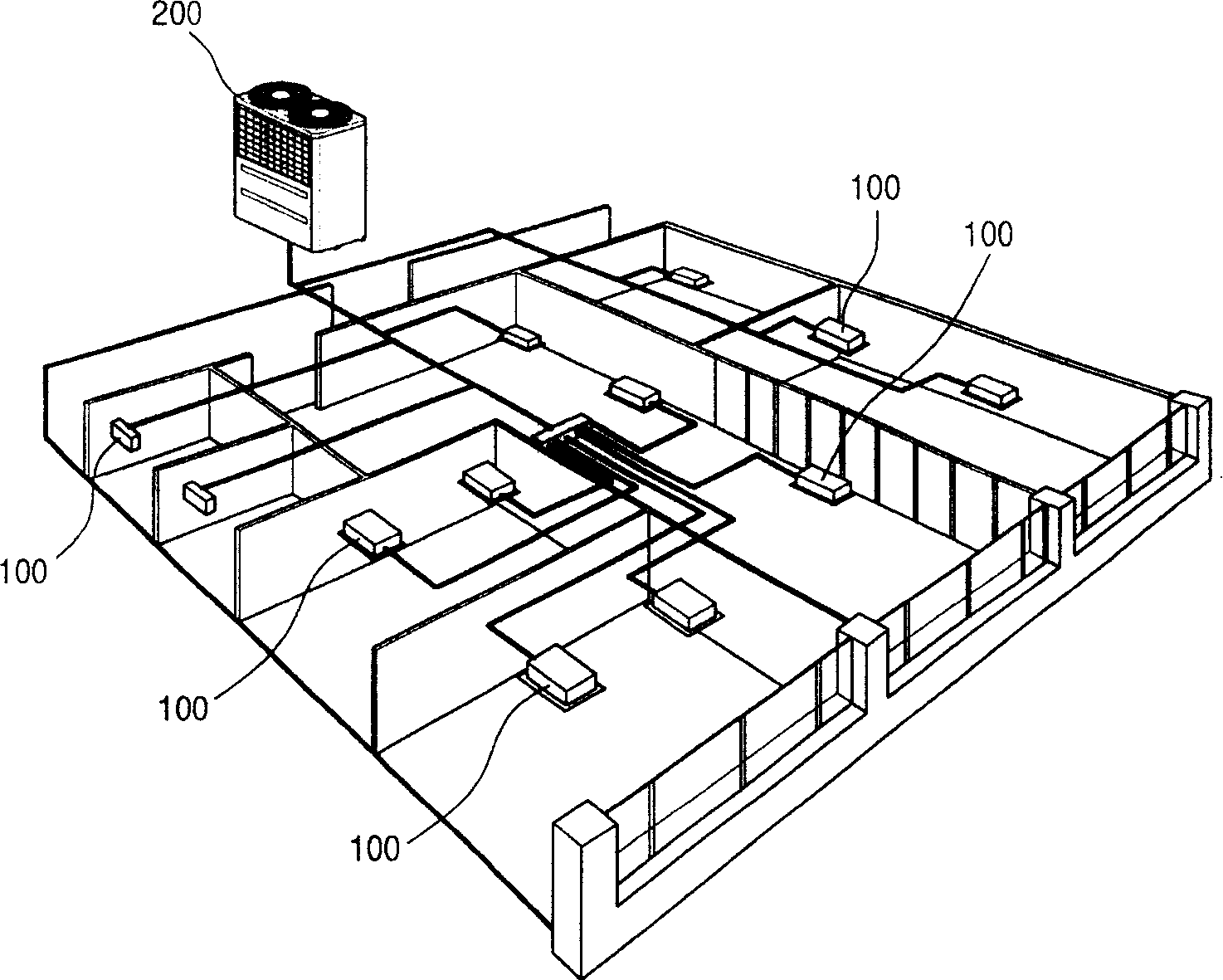

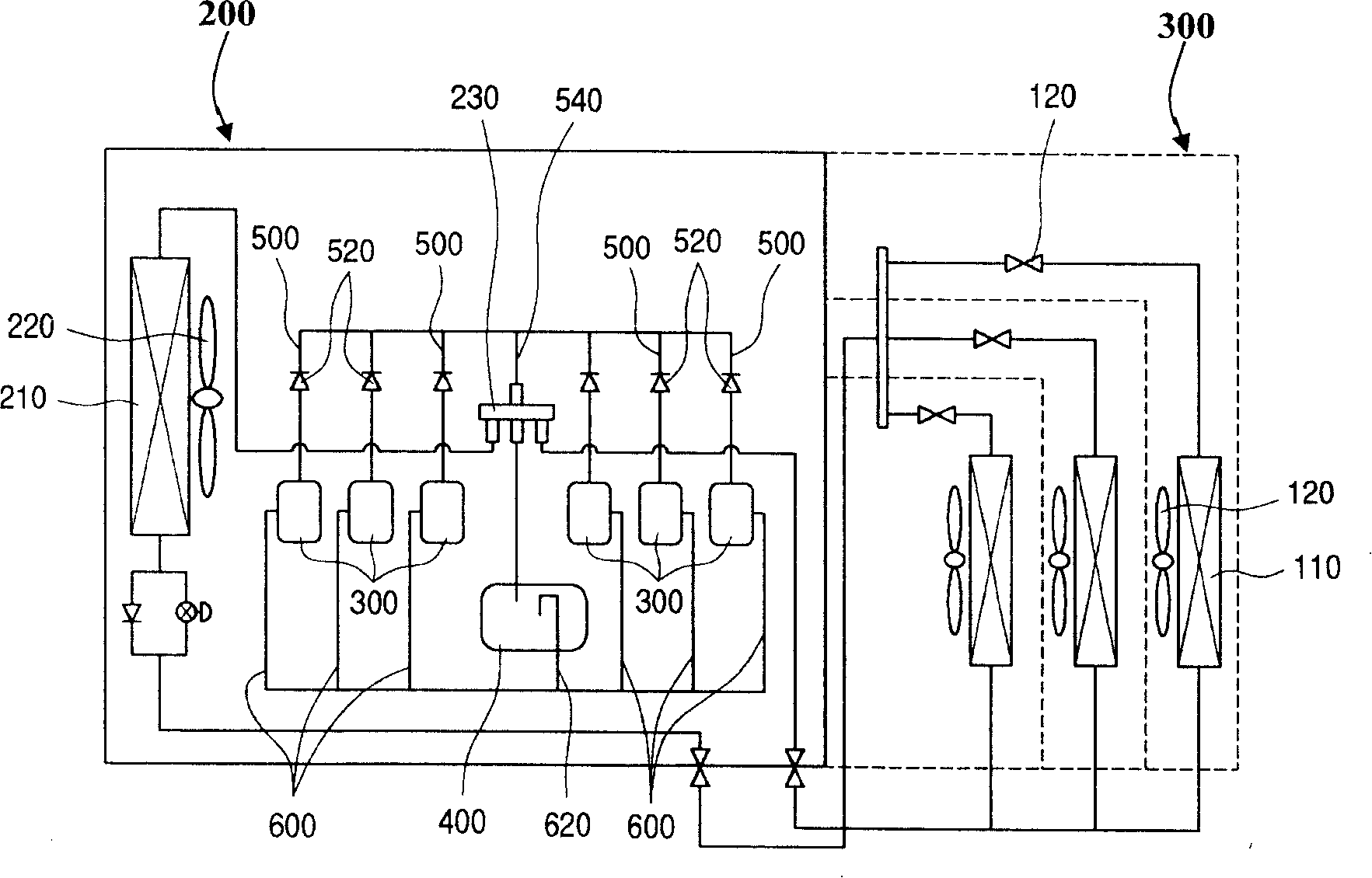

Multistage compression air-conditioner

InactiveCN101178192ALoad capacity meetsLow composition costCompression machines with non-reversible cycleAir conditioning systemsLiquid storage tankEngineering

The invention relates to a multi-compression air-condition device, comprising a plurality of compressors which are arranged in an annular structure and connected with each other, and more than one of which are combined with each other; a liquid storage tank which is communicated with a plurality of compressors; a check valve which is respectively arranged at the exit sides of a plurality of compressors; and a control part which is connected on the compressors and the check valve and is used for adjusting the actions of the compressors and the check valve. The combinations of more than one of the compressors which are combined with each other are in sequence changed at each preset time along the array direction of a plurality of compressors in the control of the control part, so that a plurality of compressors can operate alternately according to the preset time alternation. The invention can satisfy the load capacity of a compound air-condition device which is provided with a plurality of indoor units only through one outdoor unit. A plurality of compressors can operate alternately, thereby preventing the load from concentrating on a certain compressor among a plurality of compressors in the operation of continuous refrigeration or heating, and avoiding the over operation event of a certain compressor. Besides, the invention has the advantages of increasing the durability of the compressor and prolonging the service life of the compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

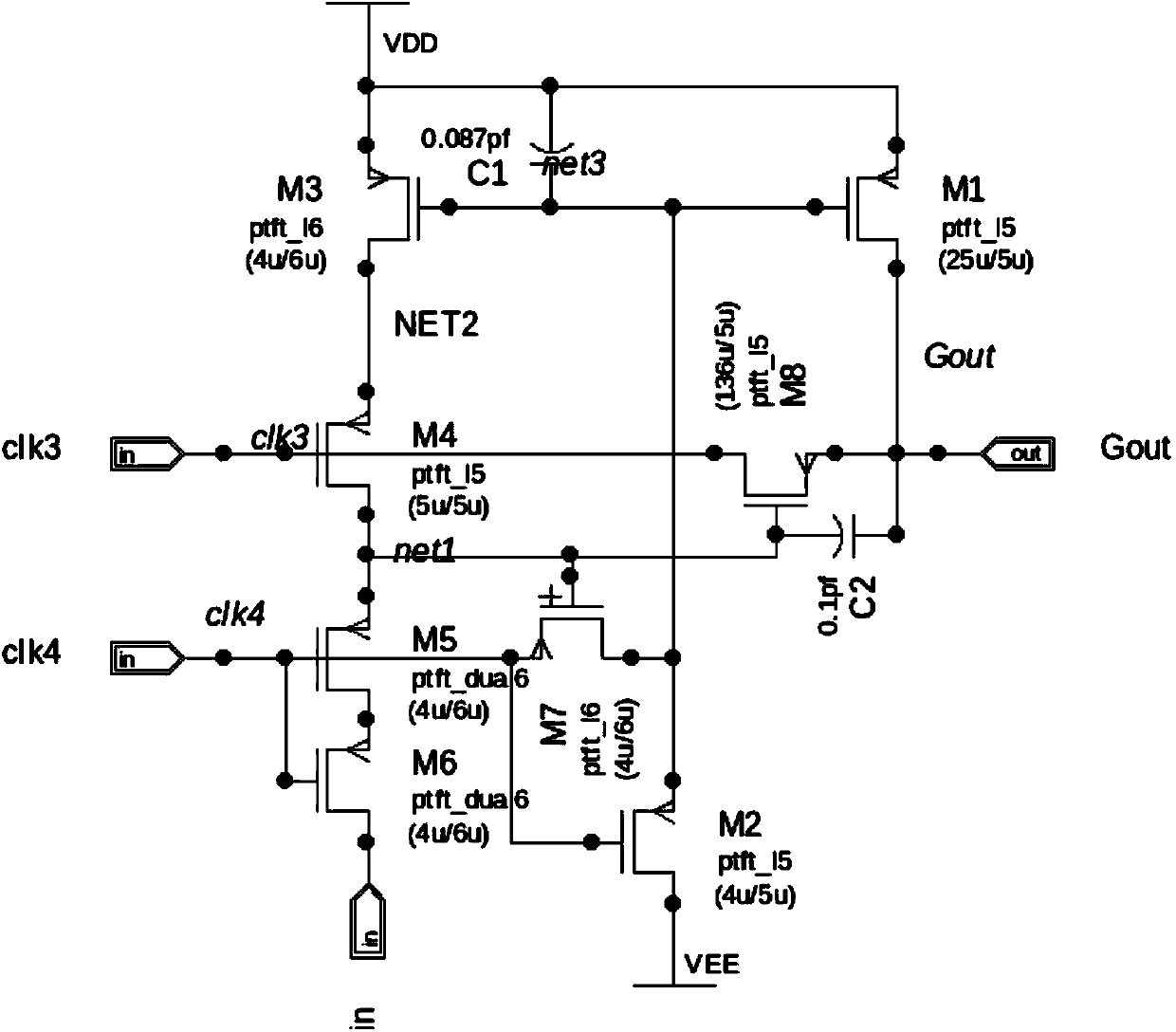

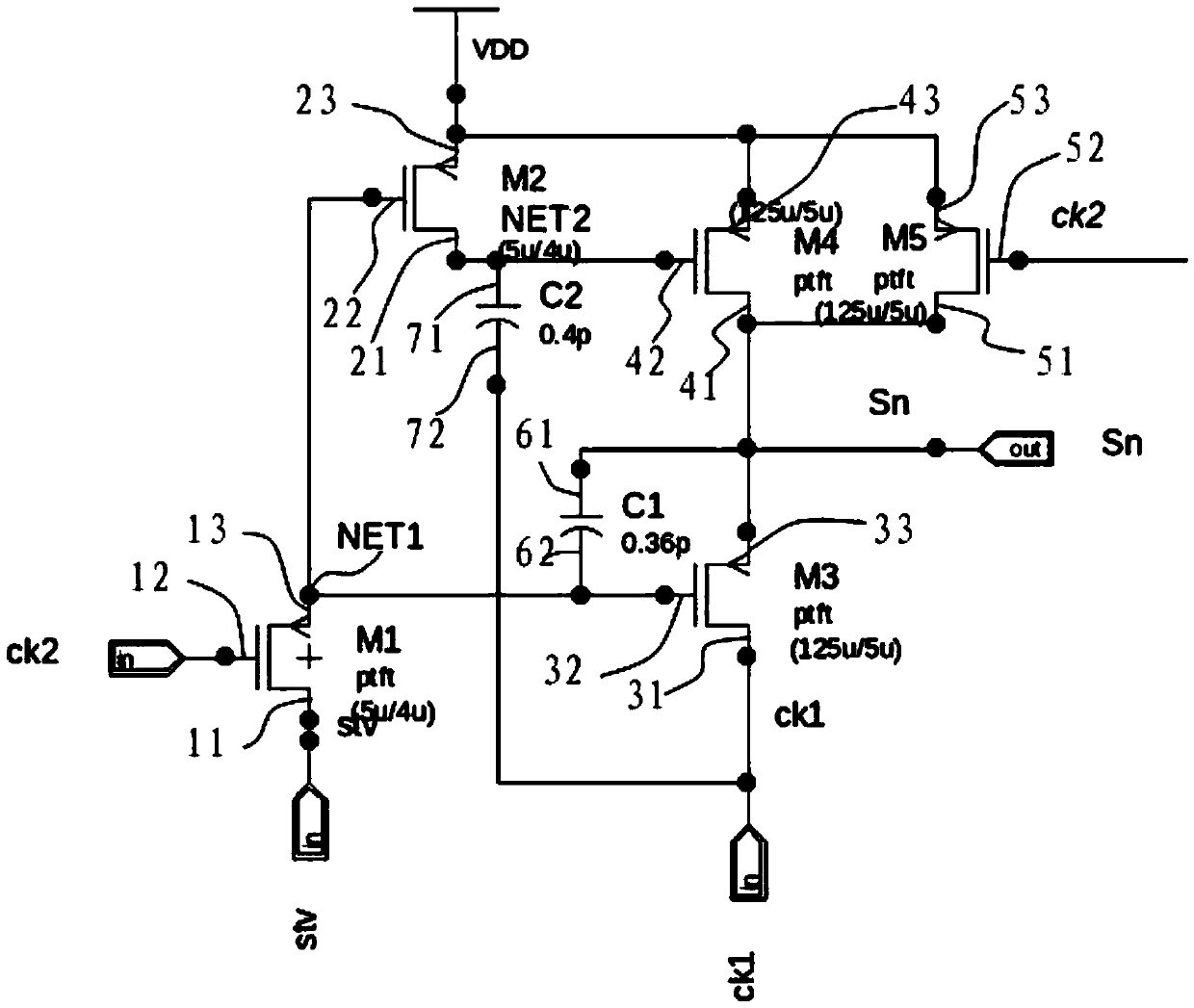

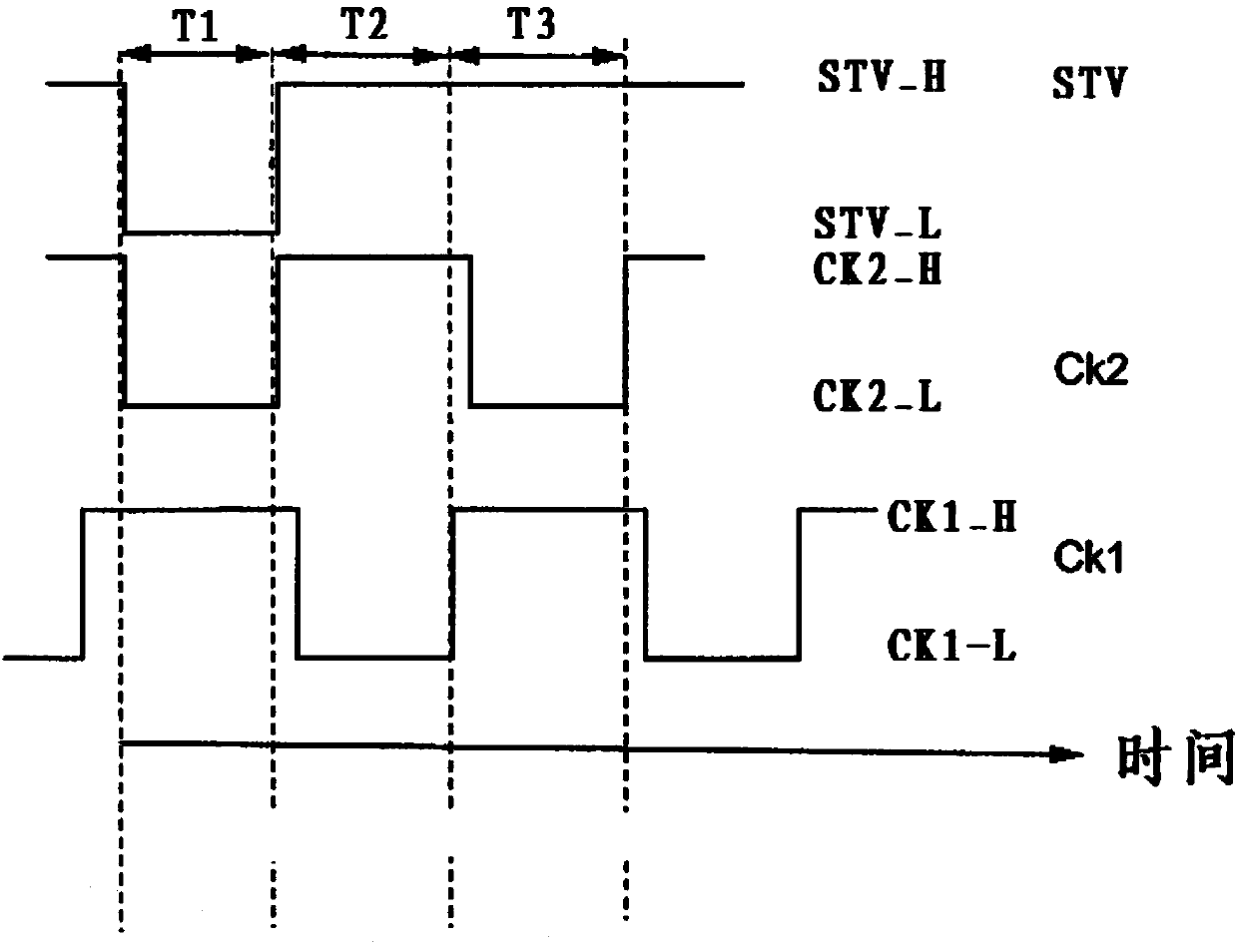

Scanning signal producing circuit

ActiveCN104200769AImprove stabilitySave setup spaceStatic indicating devicesCapacitanceTelecommunications

The invention discloses a scanning signal producing circuit. The scanning signal producing circuit is mainly formed by five transistors which are matched with two capacitors, a scanning signal can be produced by means of few transistors, the setting space of the scanning signal producing circuit can be reduced so that the requirement of a narrow bezel design of a displayer can be met, meanwhile, two transistors of the scanning signal producing circuit perform outputting of the scanning signal by turns, and therefore, the stability of the scanning signal producing circuit can be improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Valve element, valve, selector valve, and trap device

InactiveCN101107467ASimple structureSave setup spaceSolidificationPressurized chemical processVALVE PORT

Owner:TOKYO ELECTRON LTD

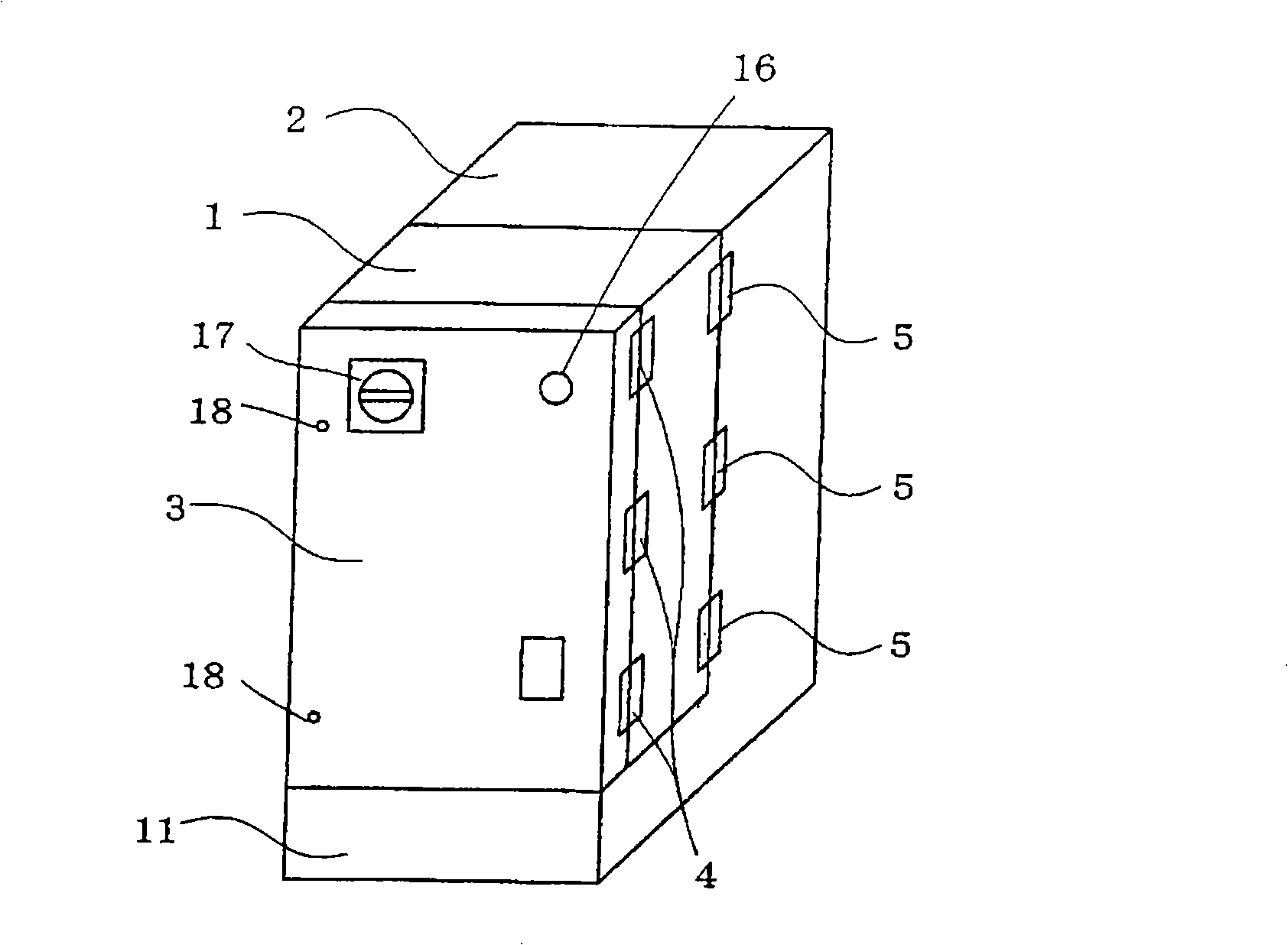

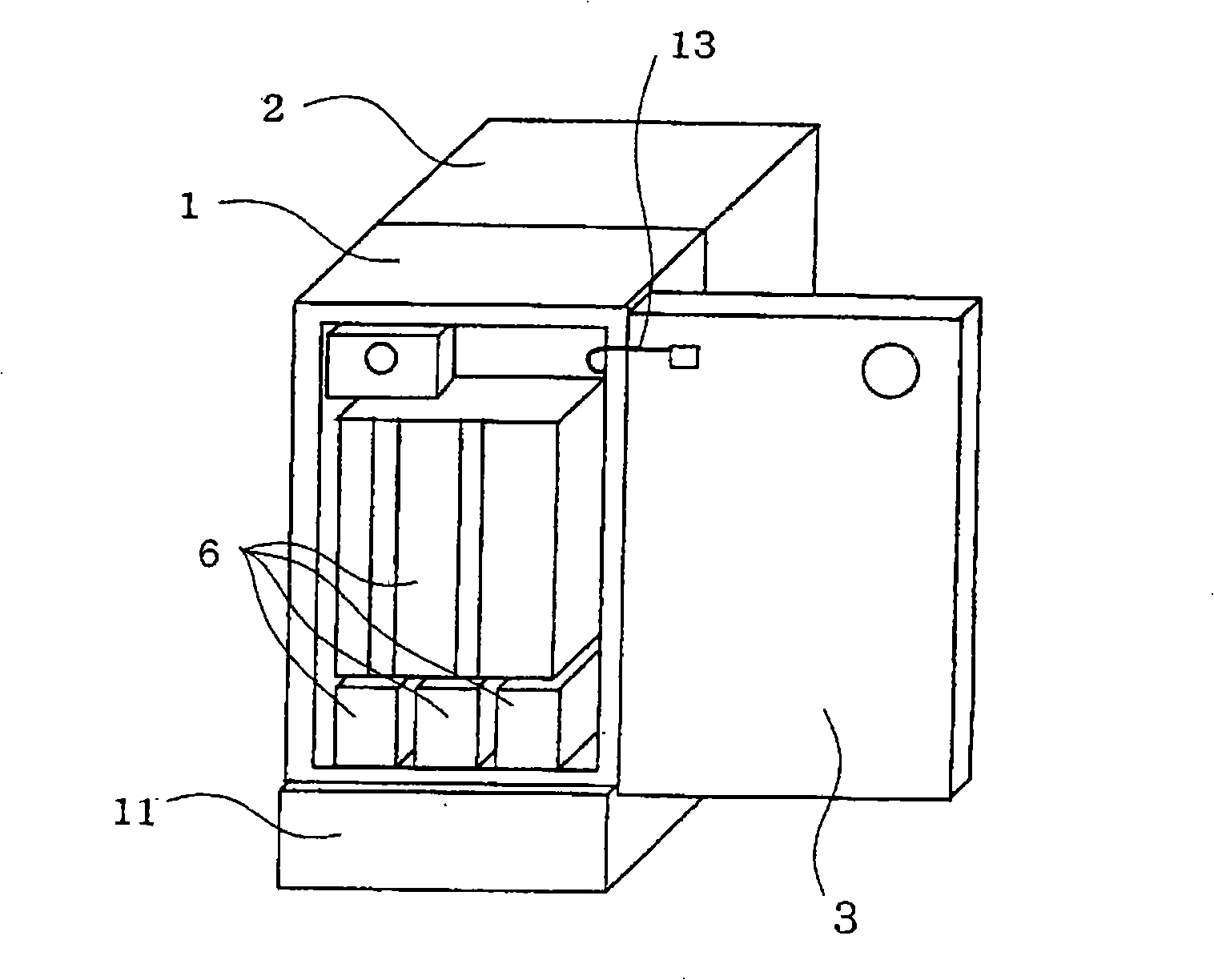

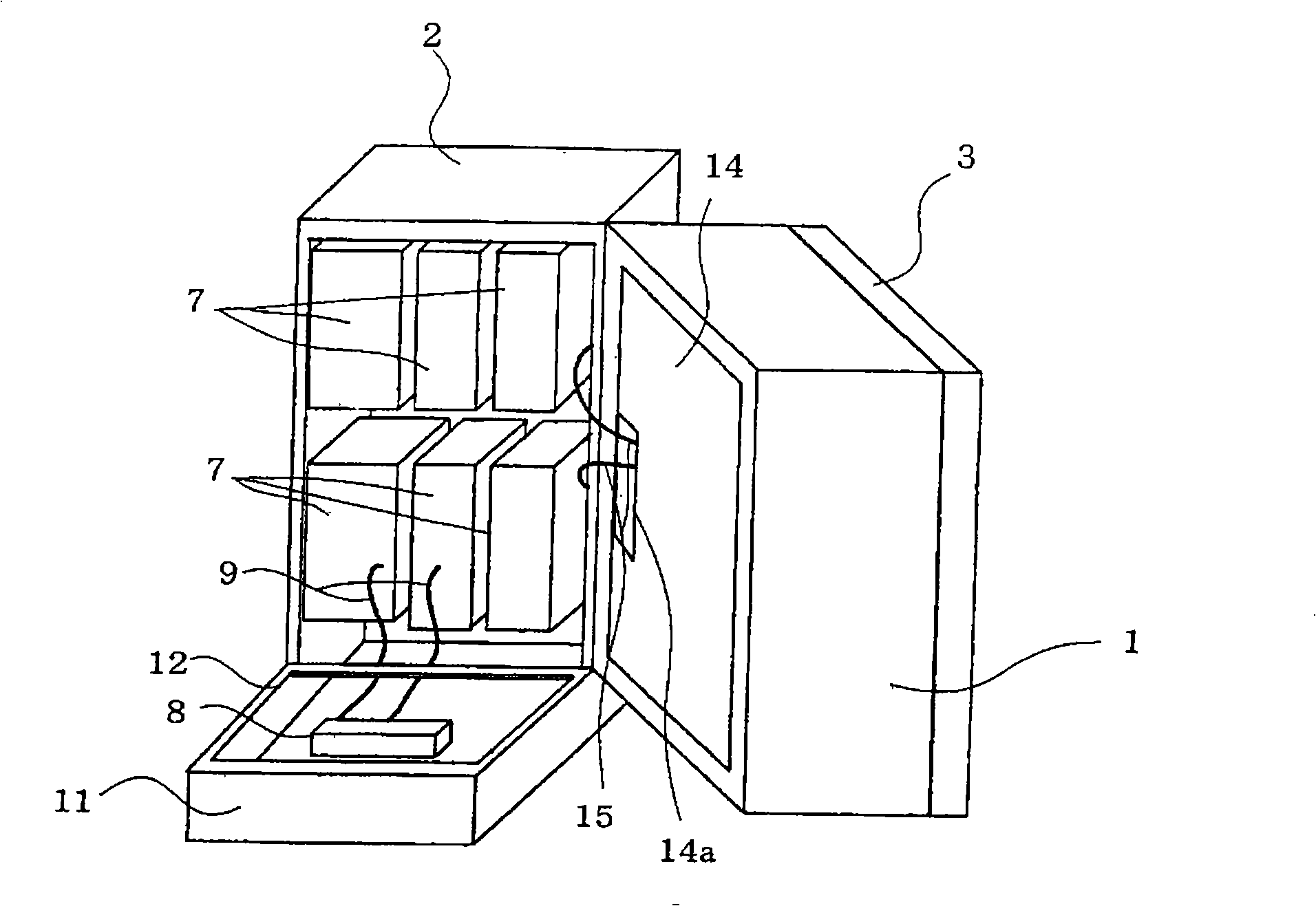

Controller for industrial robot

InactiveCN101406115AImprove containment capacityReduce sheddingPLC for automation/industrial process controlCasings/cabinets/drawers detailsControl theoryRobot controller

The present invention provides a robot controller that has excellent maintenance workability and safety and where the space in a robot controller housing is sufficiently utilized. The robot controller has a first housing (1) where a first internal device (6) is received, a second housing (2) where a second internal device (7) is received, and a front door (3) openably / closably supported by a first hinge (4) provided at a side face of the first housing (1). A second hinge (5) is provided at side faces of the first housing (1) and the second housing (2) to allow the entire first housing (1) to be openably / closably supported at the second housing (2).

Owner:YASKAWA DENKI KK

Apparatus for forming tires utilizing rotary base

An apparatus is invented for forming a tire tread on the surface of a prototype tire that is pre-fabricated during the tire manufacturing processes. The apparatus for forming the tire comprises six forming devices disposed above the circular rotary base for securing the prototype tire, a transporting compression ring disposed around the rotary base for supplying and compressing an iron core belt onto the prototype tire of the forming device, and a first extruder, a second extruder, a third extruder, and a fourth extruder for extruding a ribbon-shaped rubber band to form a tire tread on the surface of the prototype tire. Accordingly, by constructing a plurality of extruders around the circular rotary base, the installation space can be smaller than the conventional prototype tire forming apparatus, the device fabricating cost can be reduced, and various shaped tires can be fabricated.

Owner:株式会社宇星机工

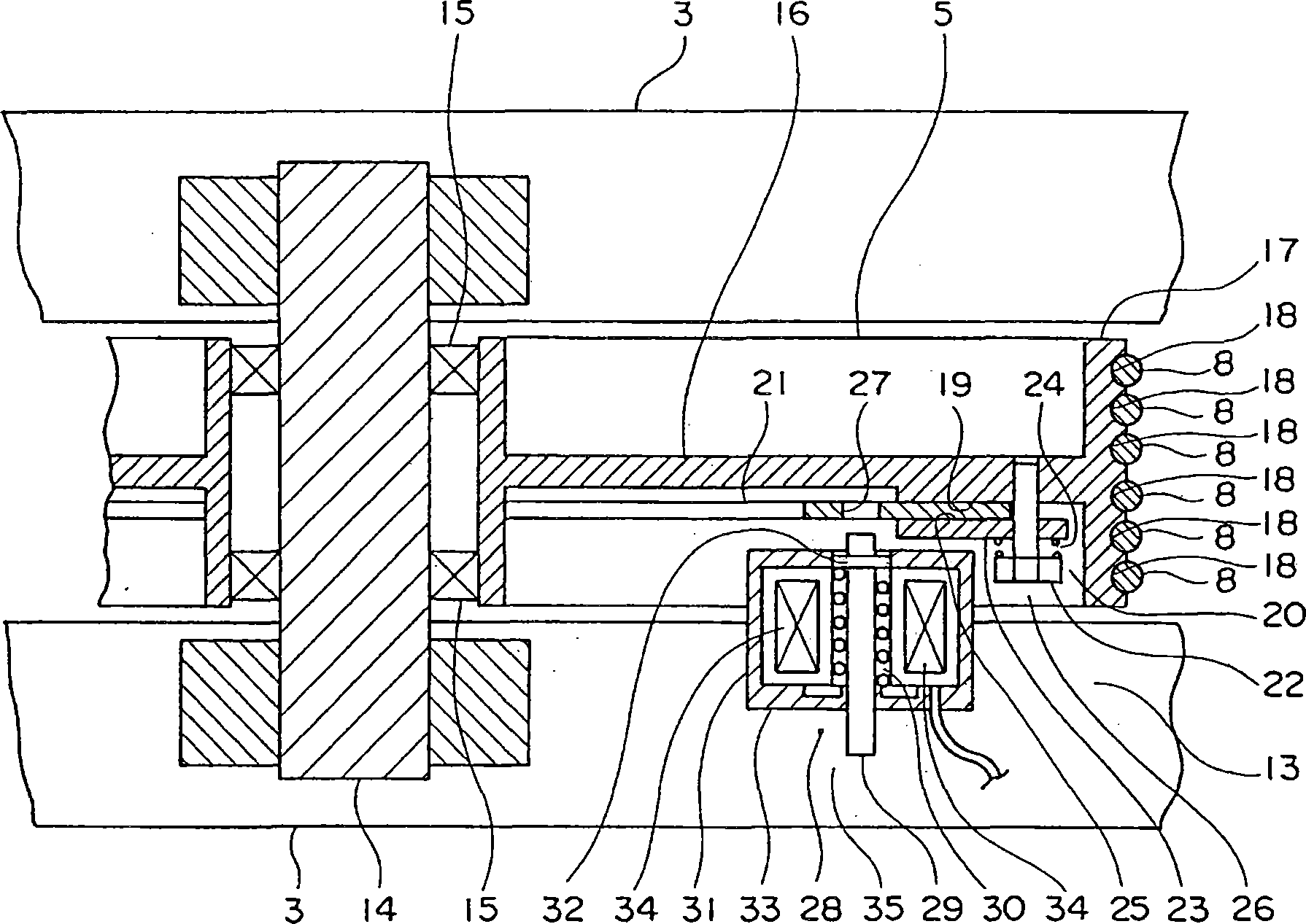

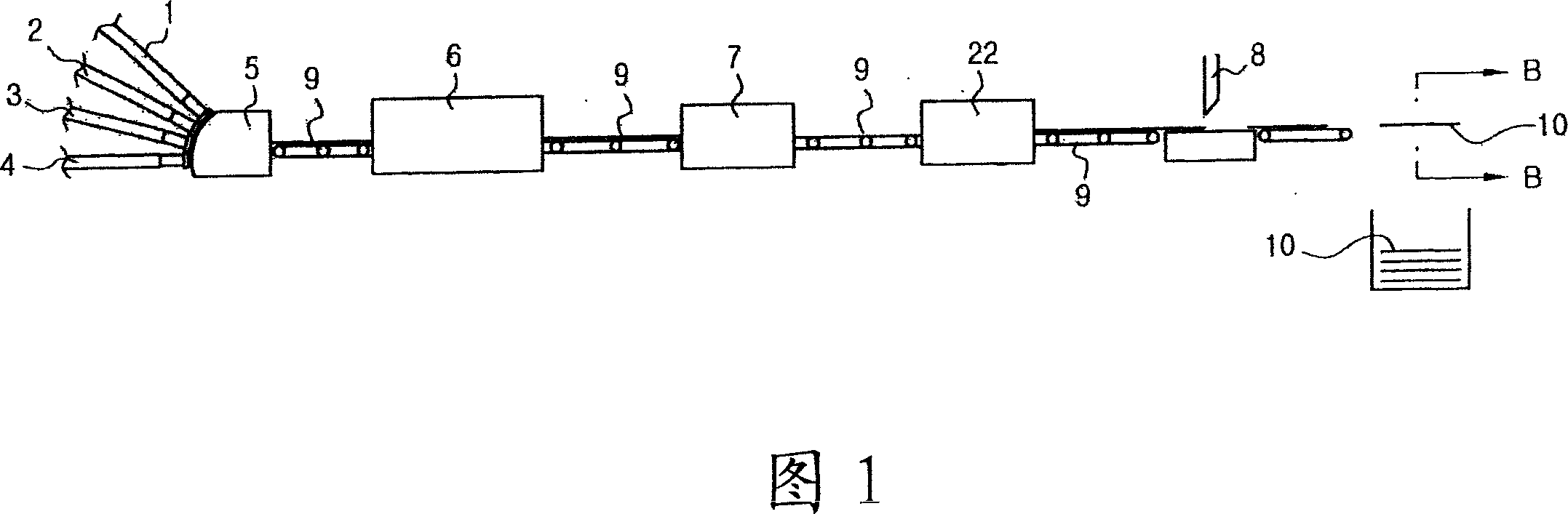

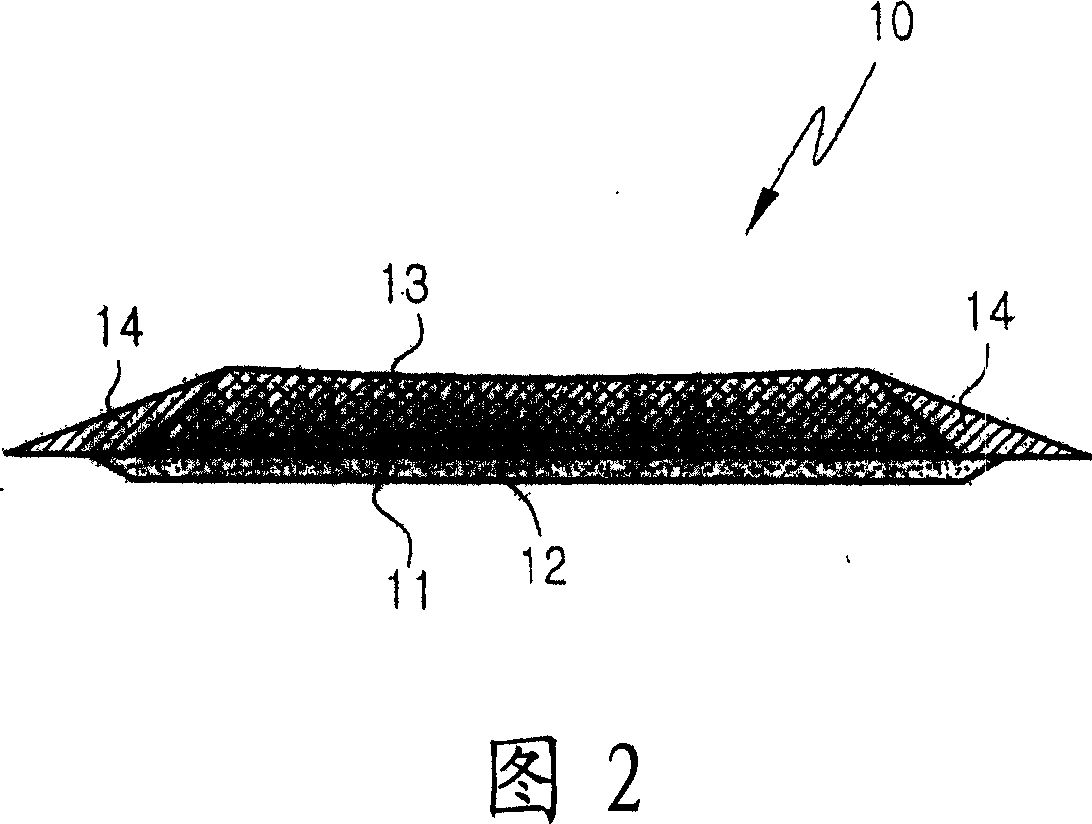

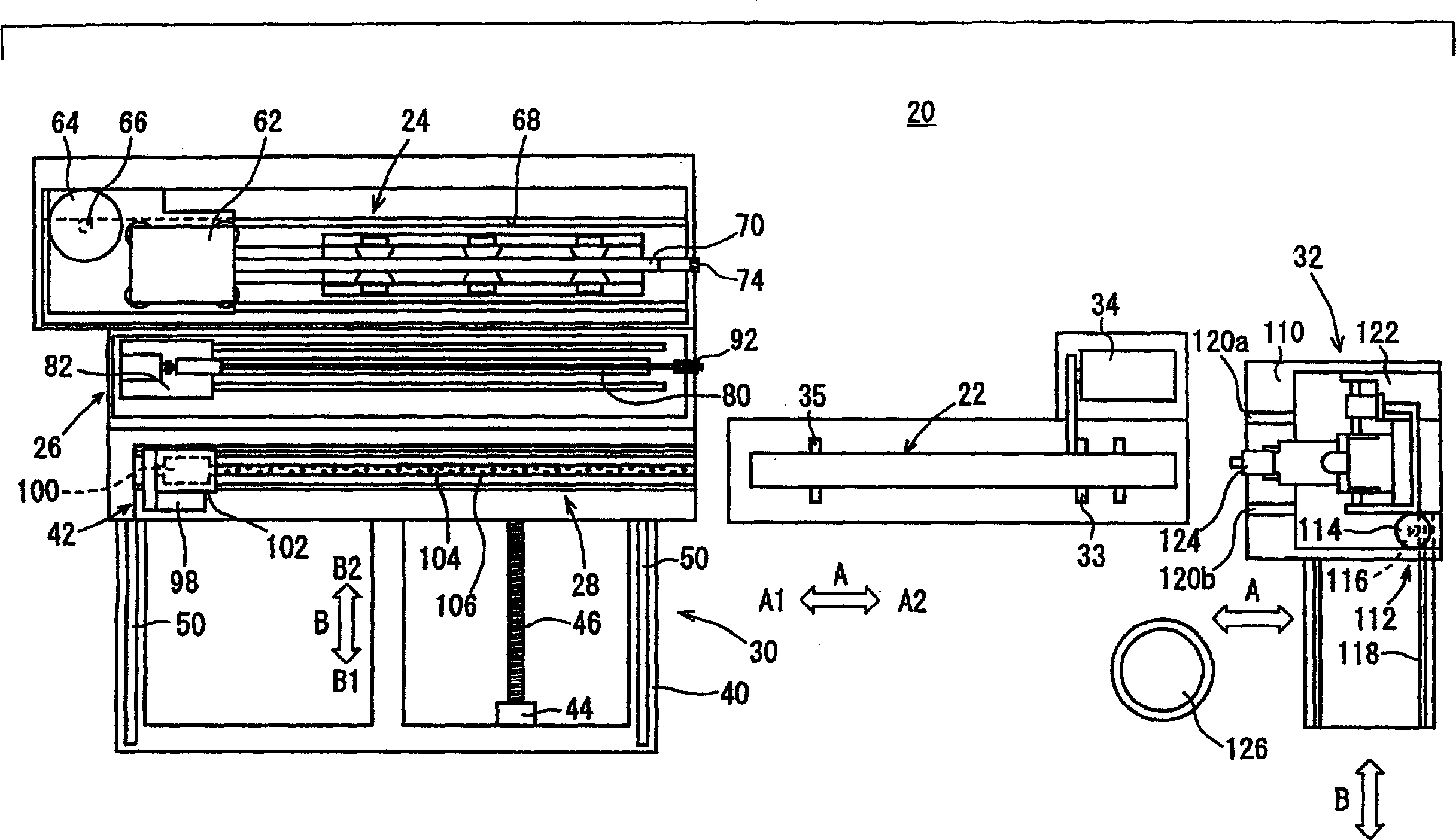

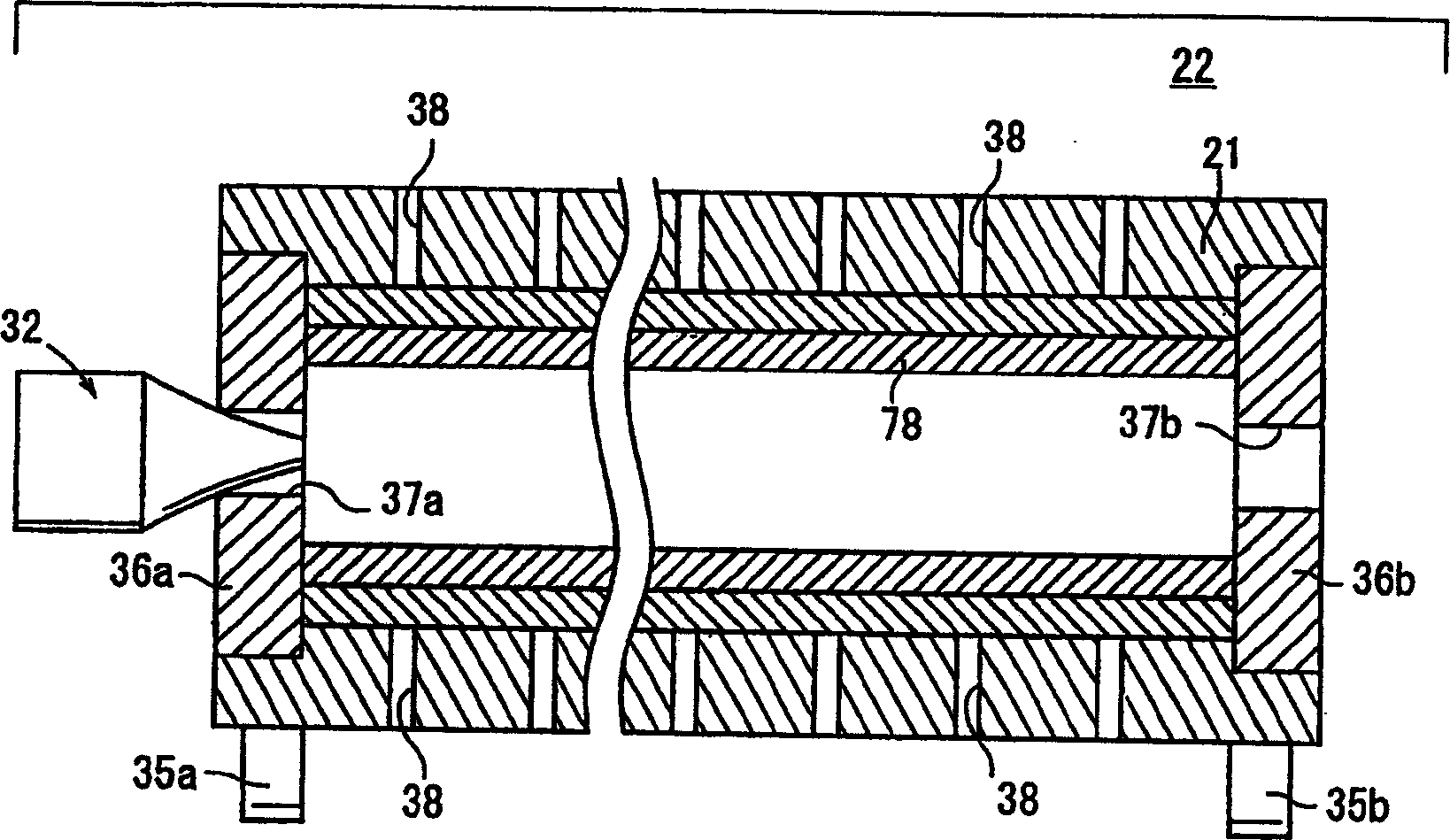

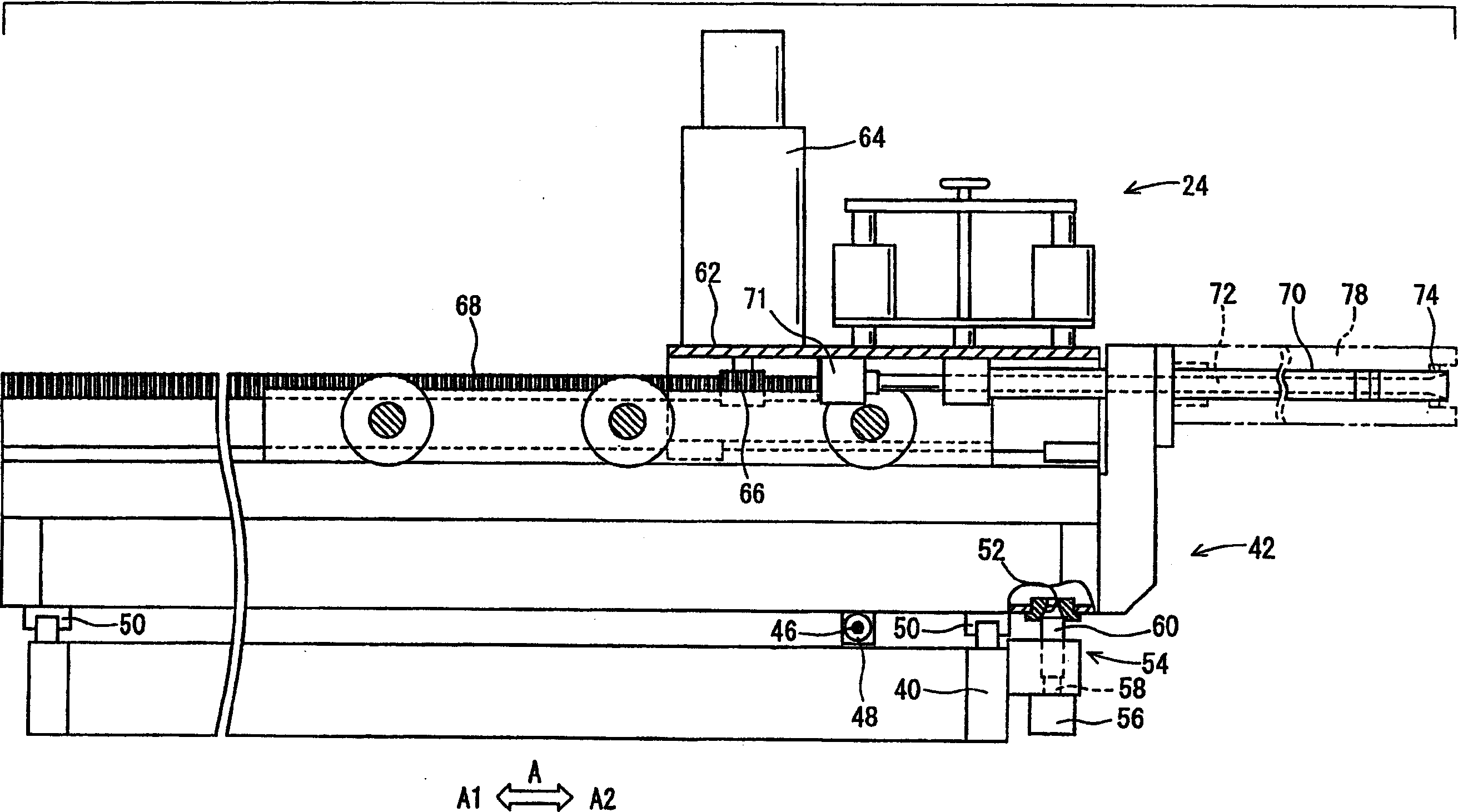

Centrifugal casting equipment

A centrifugal casting equipment, comprising a work extraction mechanism (24), a cleaning mechanism (26), and a facing coating mechanism (28) disposed parallel with each other on one side of a centrifugal casting metal mold (22), a unit drive mechanism (30) for integrally moving the work extraction mechanism (24), cleaning mechanism (26), and facing coating mechanism (28) in the direction of arrow (B) crossing the direction of arrow (A), and a molten metal filling mechanism (32) disposed on the other side of the centrifugal casting metal mold (22).

Owner:HONDA MOTOR CO LTD

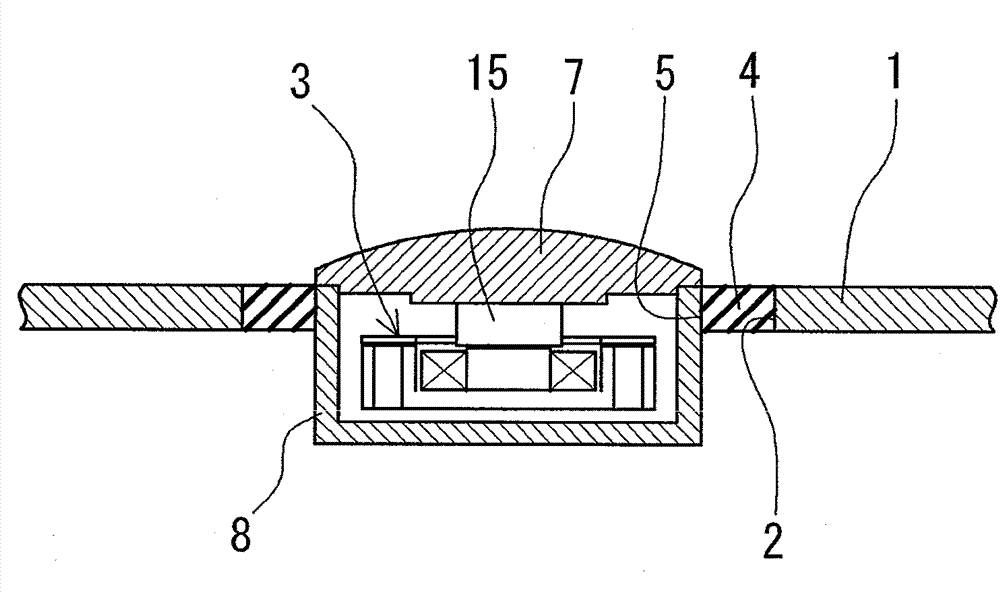

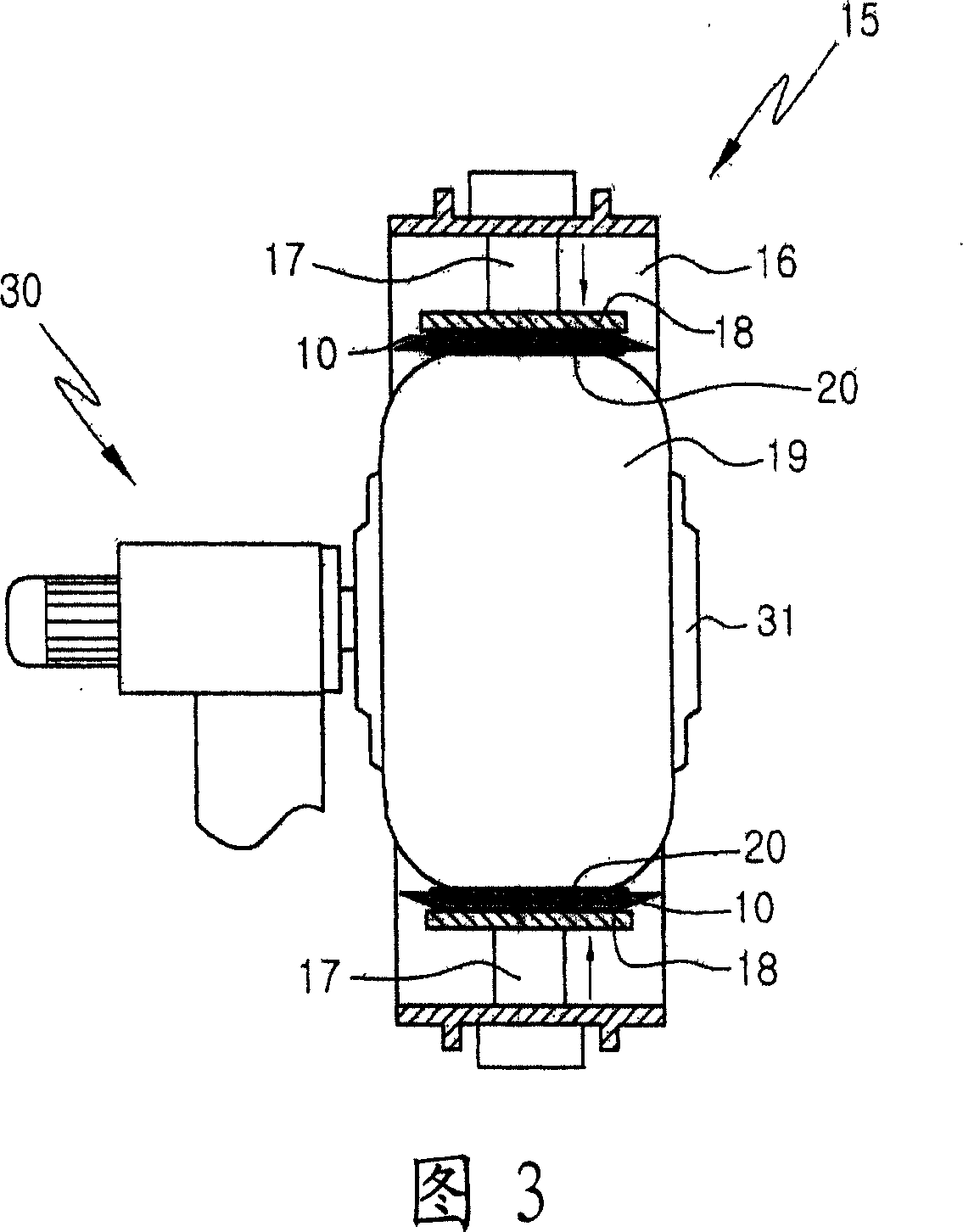

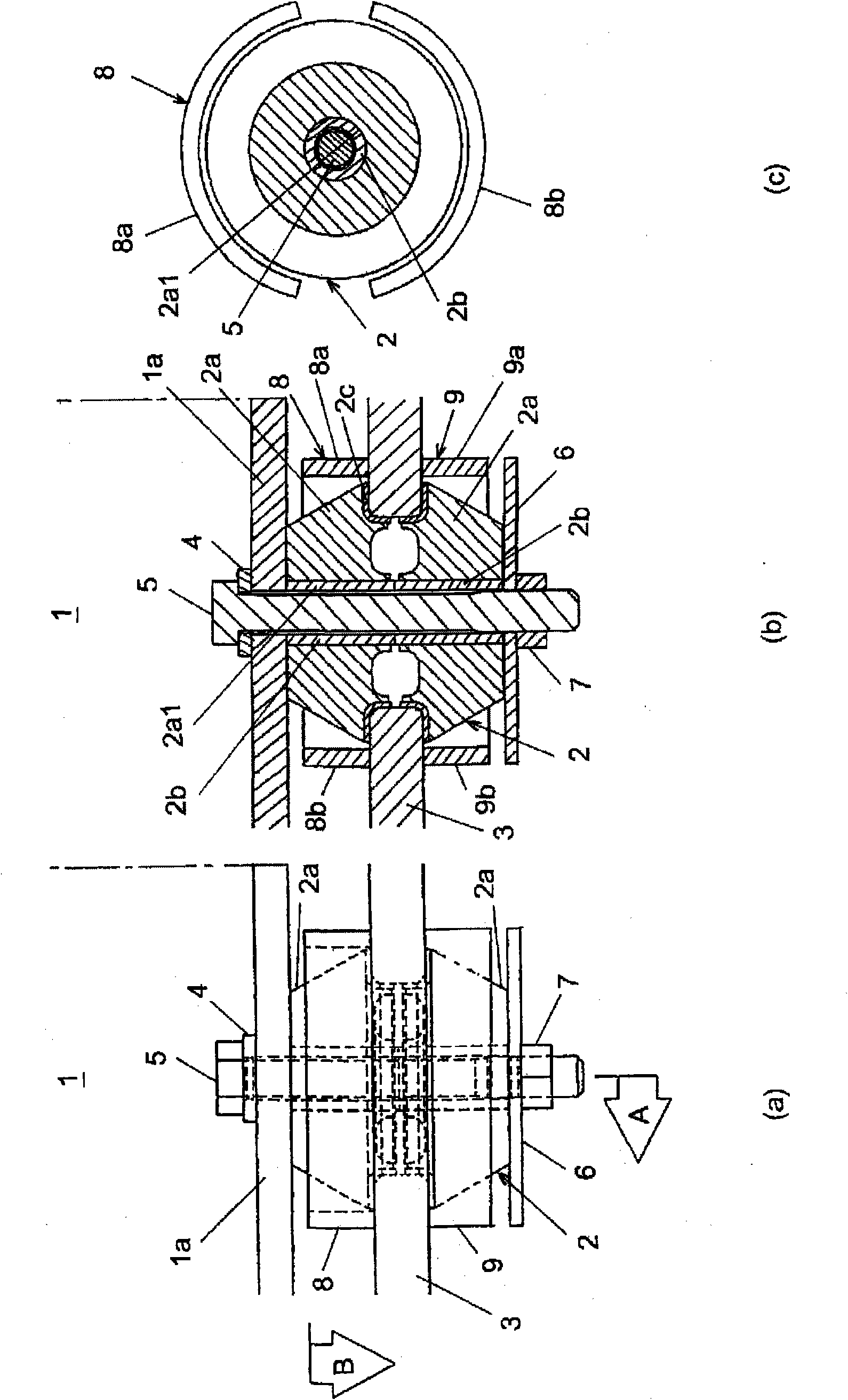

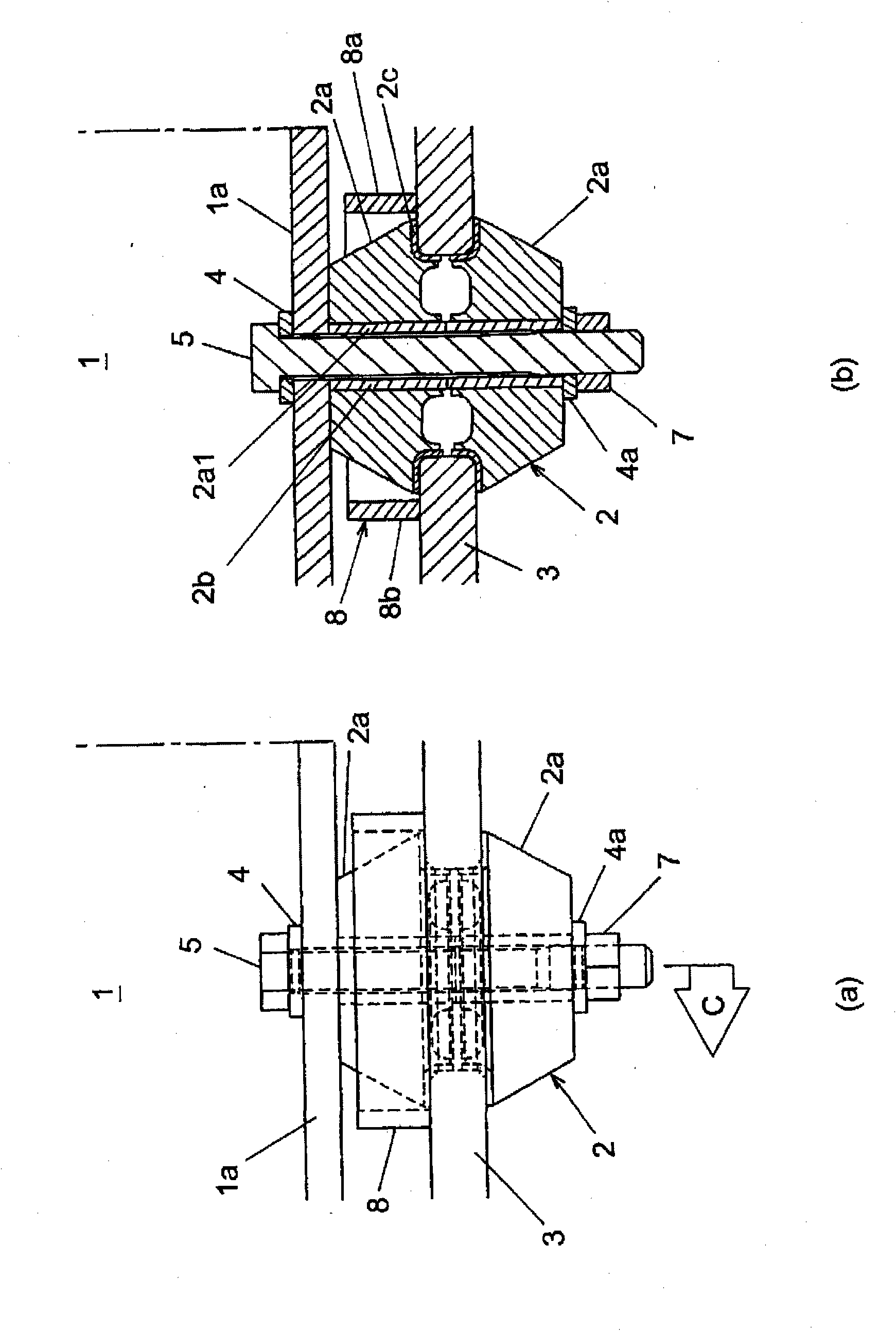

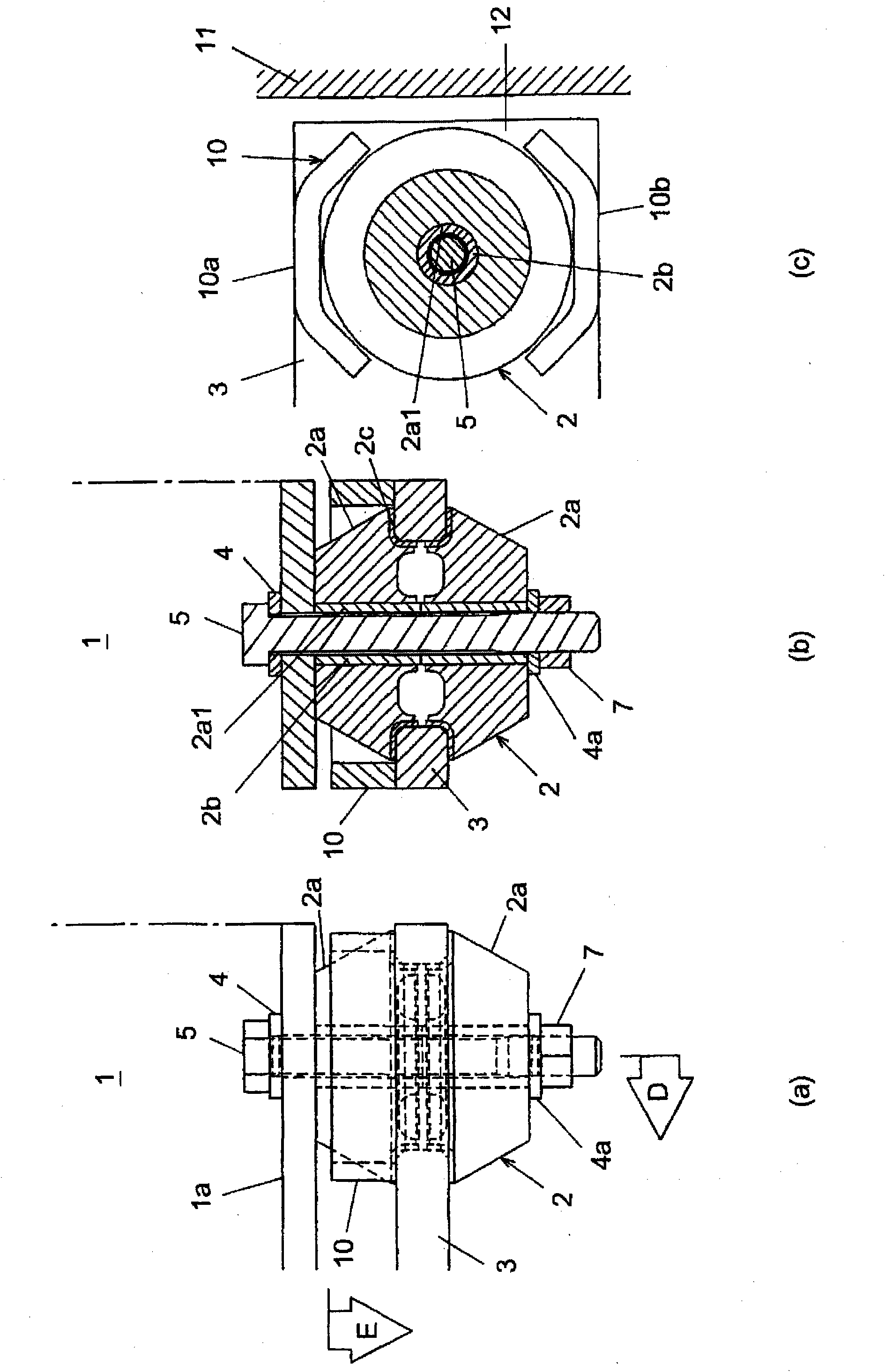

Vibration-damping support device

ActiveCN101952616ASmall outer diameterSave setup spaceNon-rotating vibration suppressionJet propulsion mountingExcavator

A vibration-damping support device occupies a less installation space. The vibration-damping support device has a rubber mount (2) which is fitted to a mounting section (1a) for mounting thereon an object, such as an engine (1) vibrating in the vertical and horizontal directions, mounted on a hydraulic excavator and to be isolated from vibration and which has an elastic member made of rubber or the like for absorbing vibration of the engine (1); a support bracket (3) which is fixed to a support member, such as a rotating frame (not shown), for supporting the rubber mount (2); and stoppers (8,9) which are mounted integrally on the support bracket (3) and prevent excessive deformation of the elastic member of the rubber mount (2) caused by vibration of the engine (1). The stopper (8) is placed above the support bracket (3), and the stopper (9) is placed below the support bracket (3). The stoppers (8, 9) are constructed from plate-like members (8a, 8b, 9a, 9b) having a circular arc-shape in a plan view.

Owner:NIHON KENKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com