Patents

Literature

151results about How to "Reduce positional offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

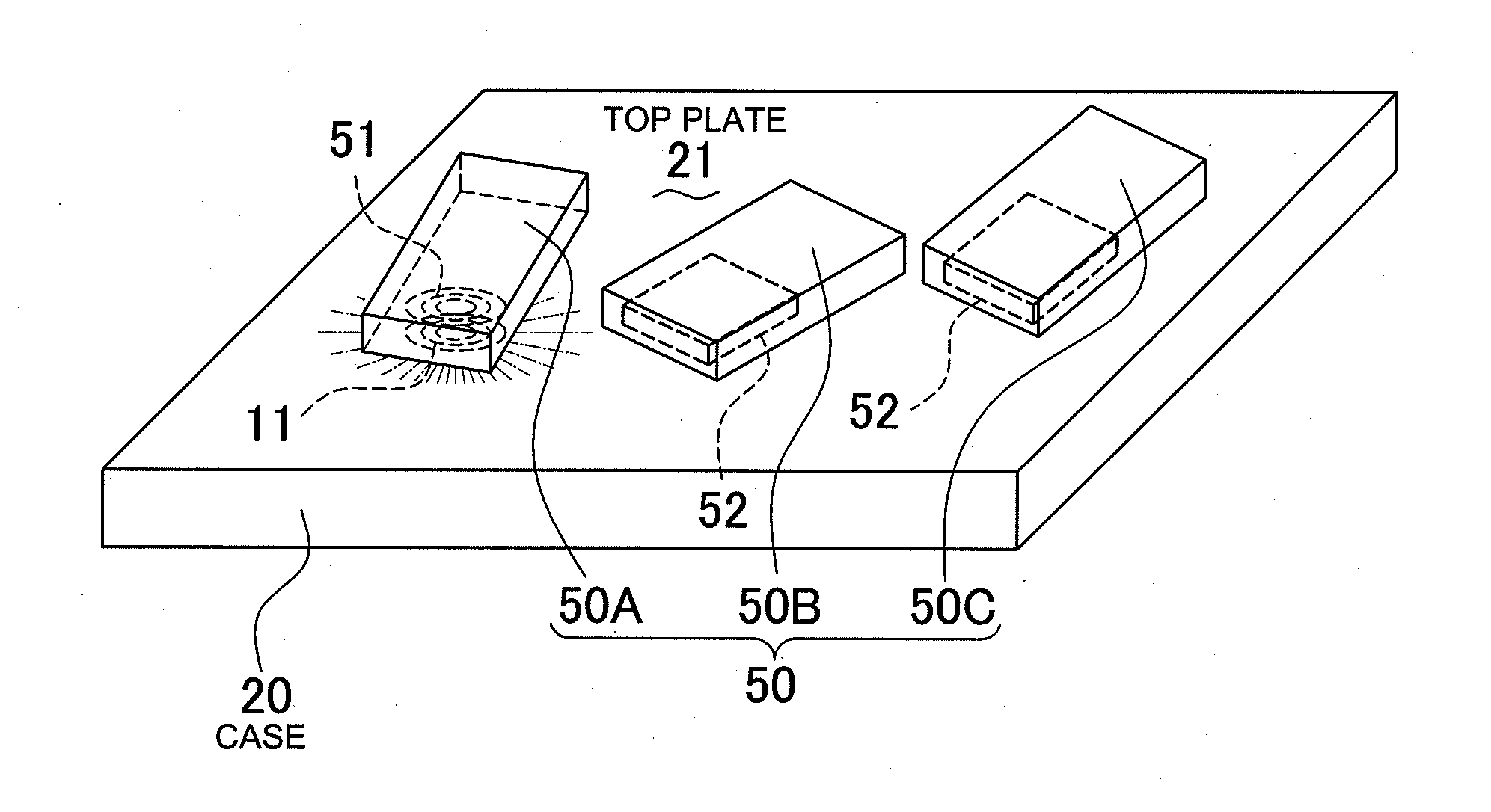

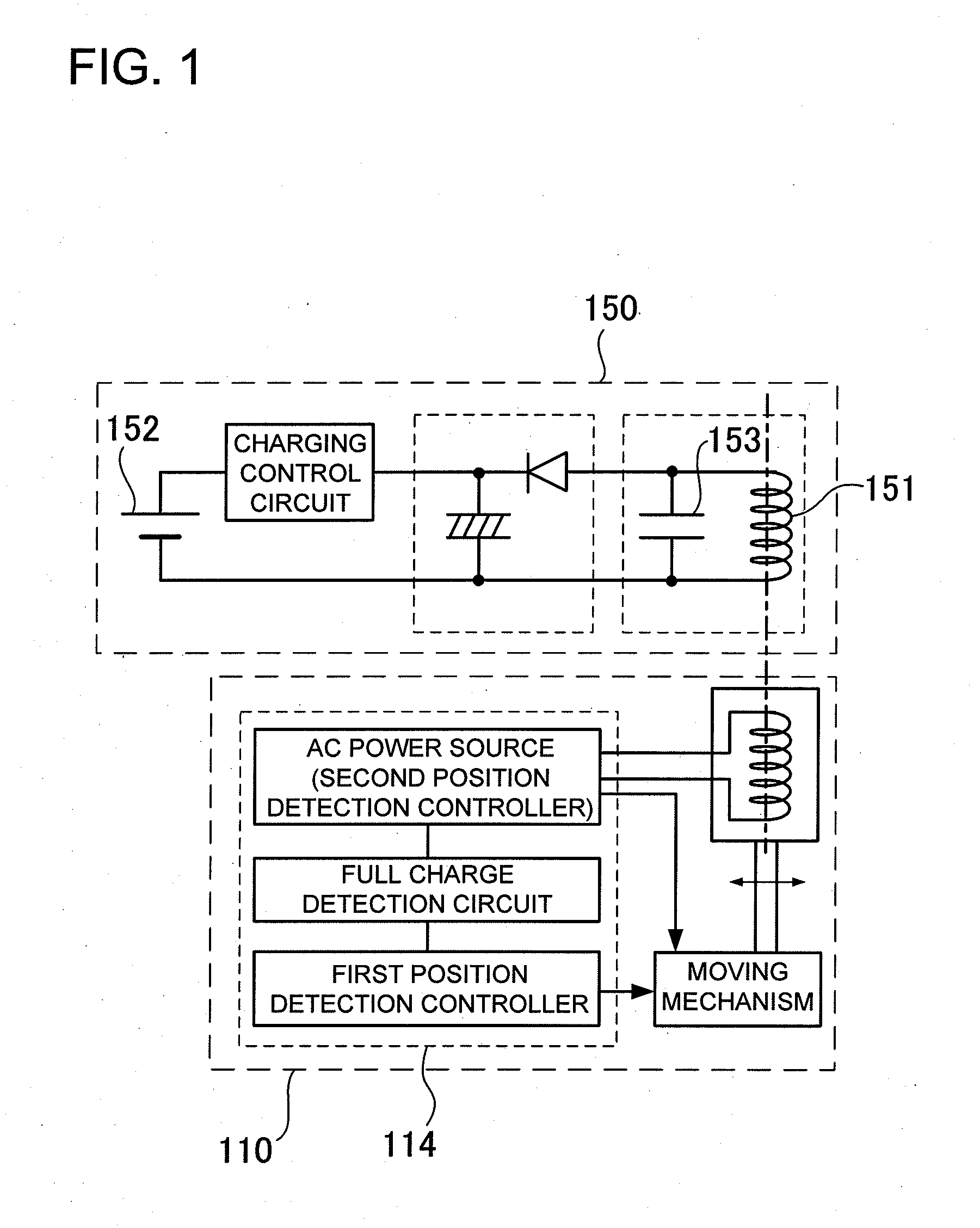

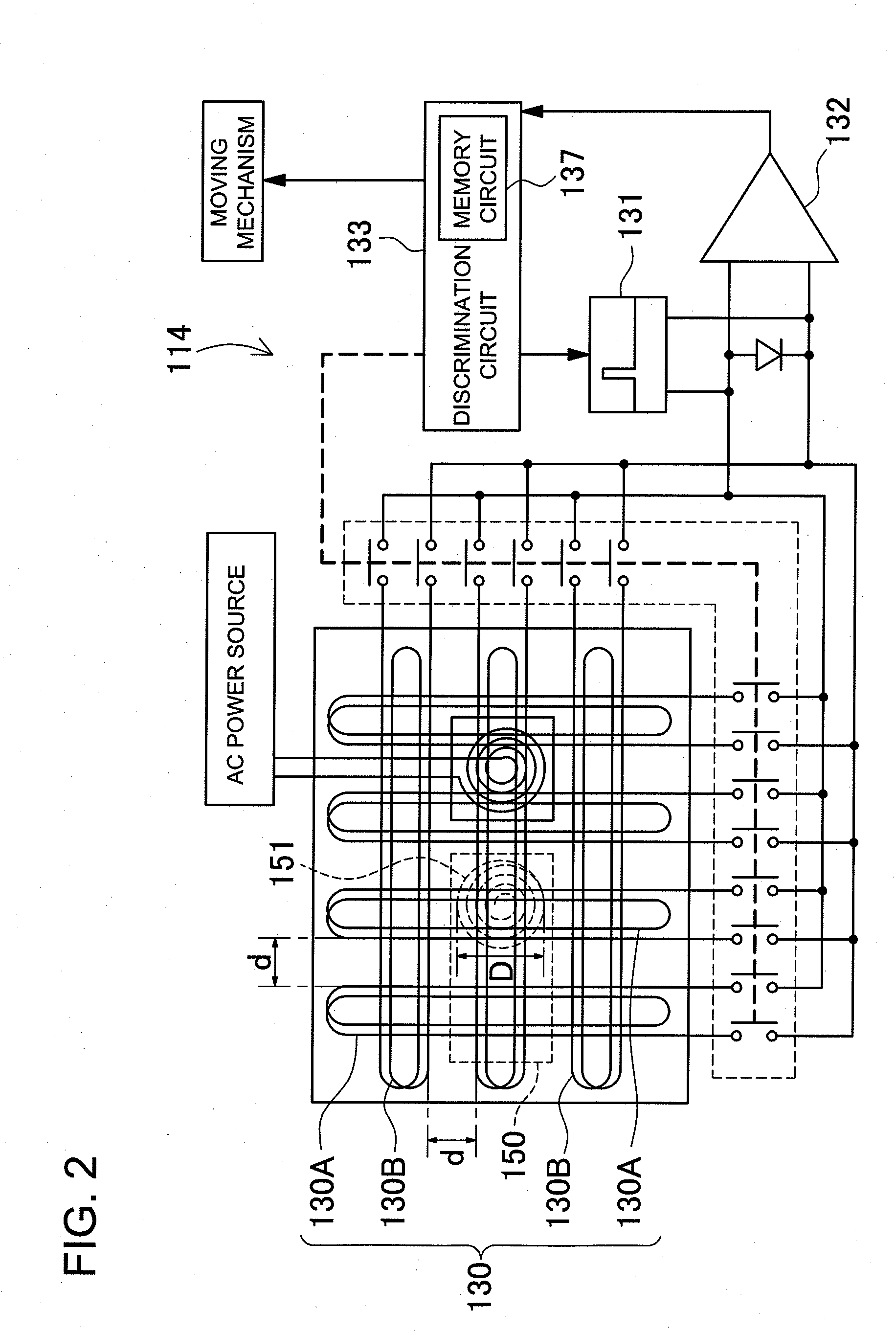

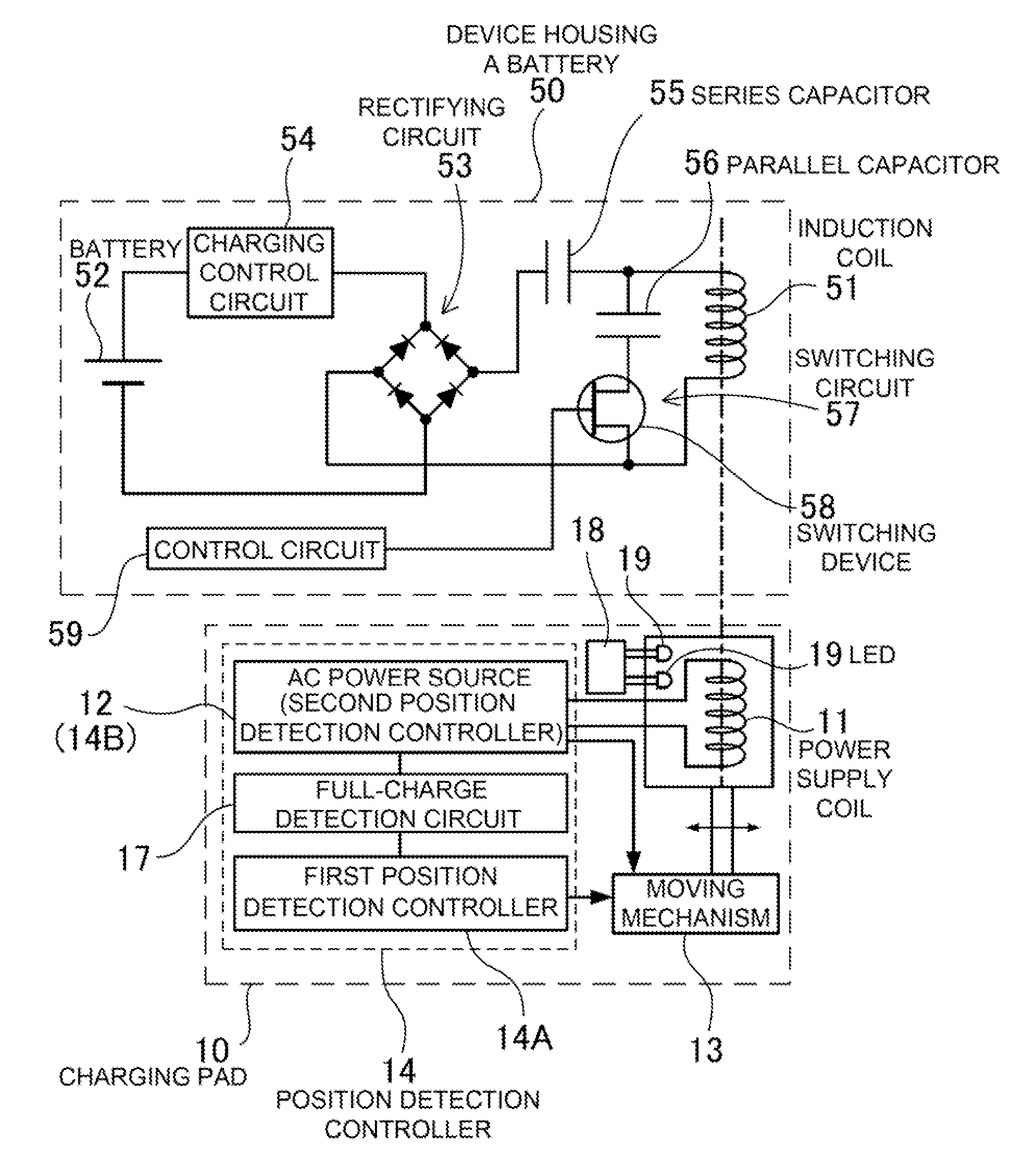

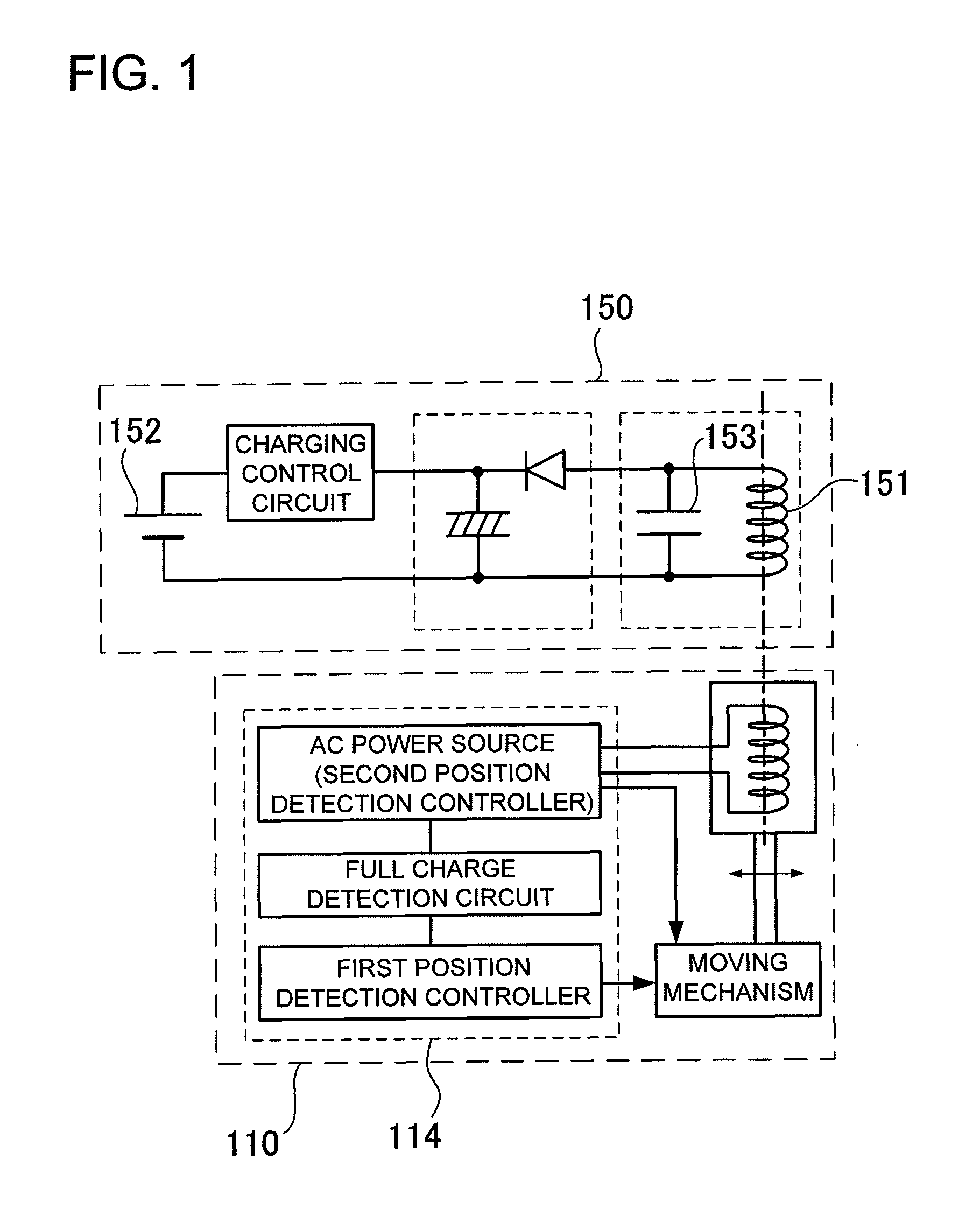

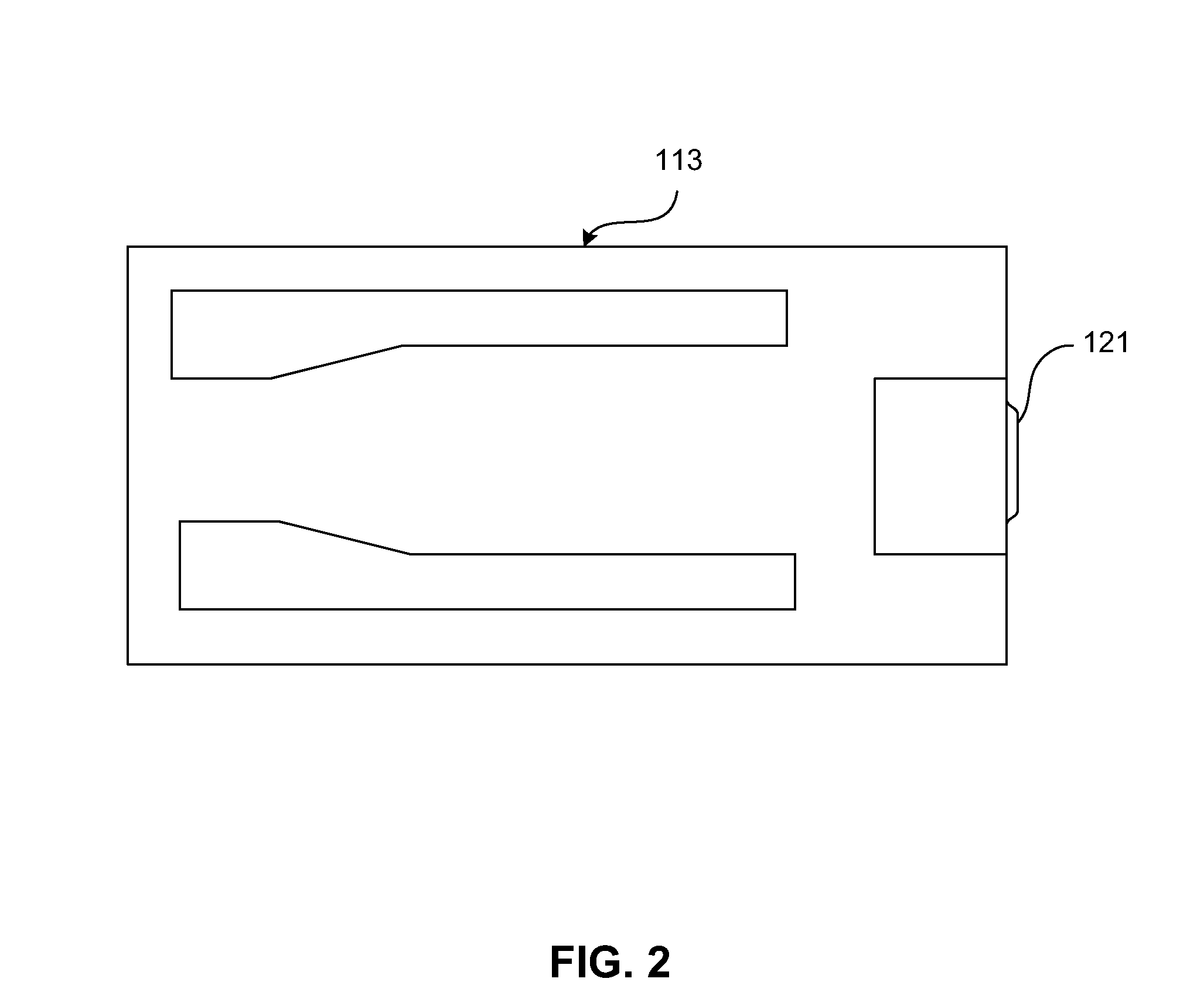

Device housing a battery and charging pad

InactiveUS20100270970A1Accurately determineMove quicklyMobile unit charging stationsElectric powerEngineeringCapacitor

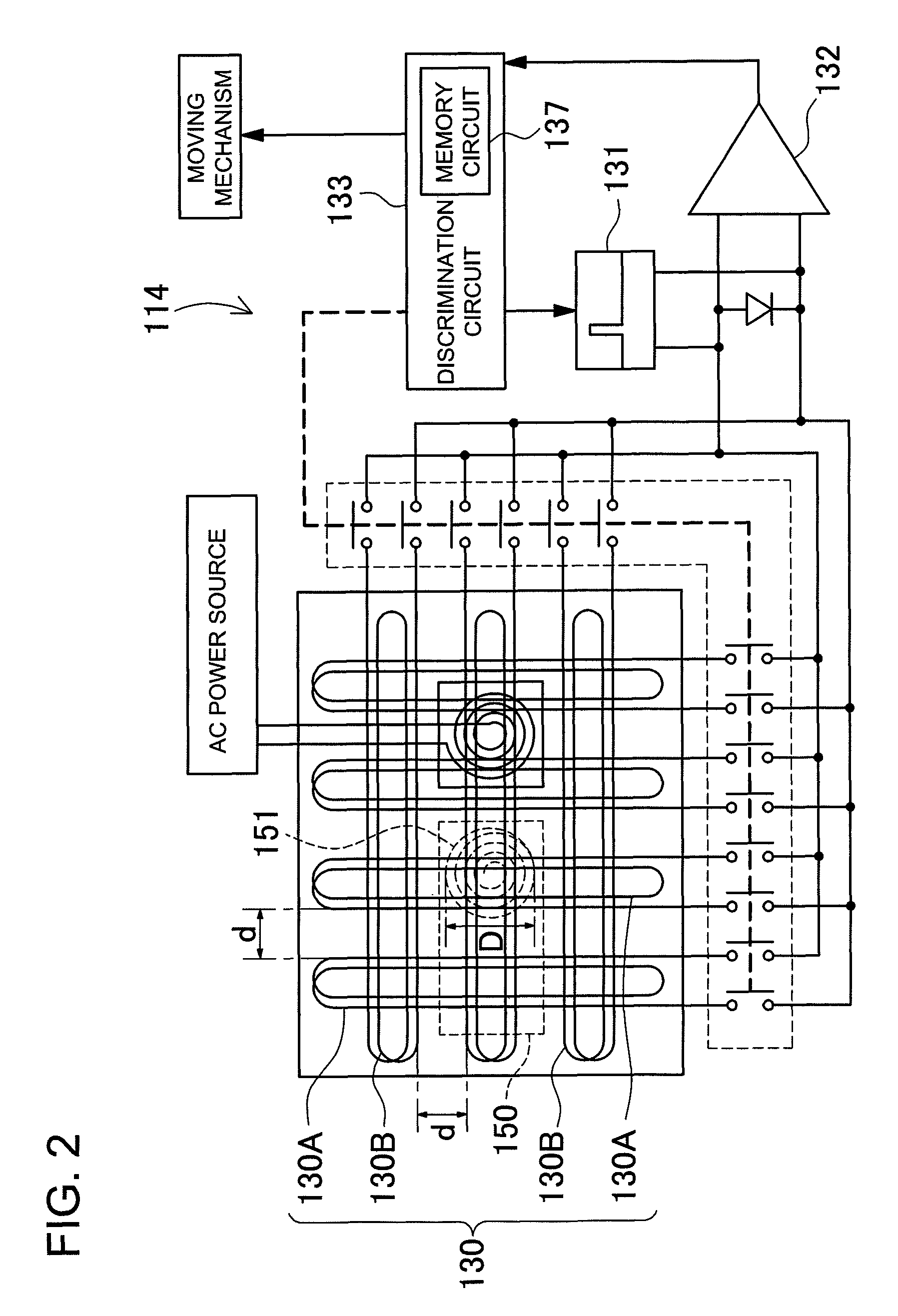

The charging pad 10 is provided with a position detection controller 14 that supplies position detection signals to position detection coils 30, and detects induction coil 51 position from echo signals output from the induction coil 51. The device housing a battery 50 is provided with a series capacitor 55 connected in series with the induction coil 51, a parallel capacitor 56 connected in parallel with the induction coil 51, and a switching circuit 57. When the position detection controller 14 is issuing position detection signals, the parallel capacitor 56 is connected to the induction coil 51. When power is transmitted from the power supply coil 11 to the induction coil 51, the parallel capacitor 56 is not connected to the induction coil 51 and induction coil 51 AC is output to a rectifying circuit 53 through the series capacitor 55.

Owner:SANYO ELECTRIC CO LTD

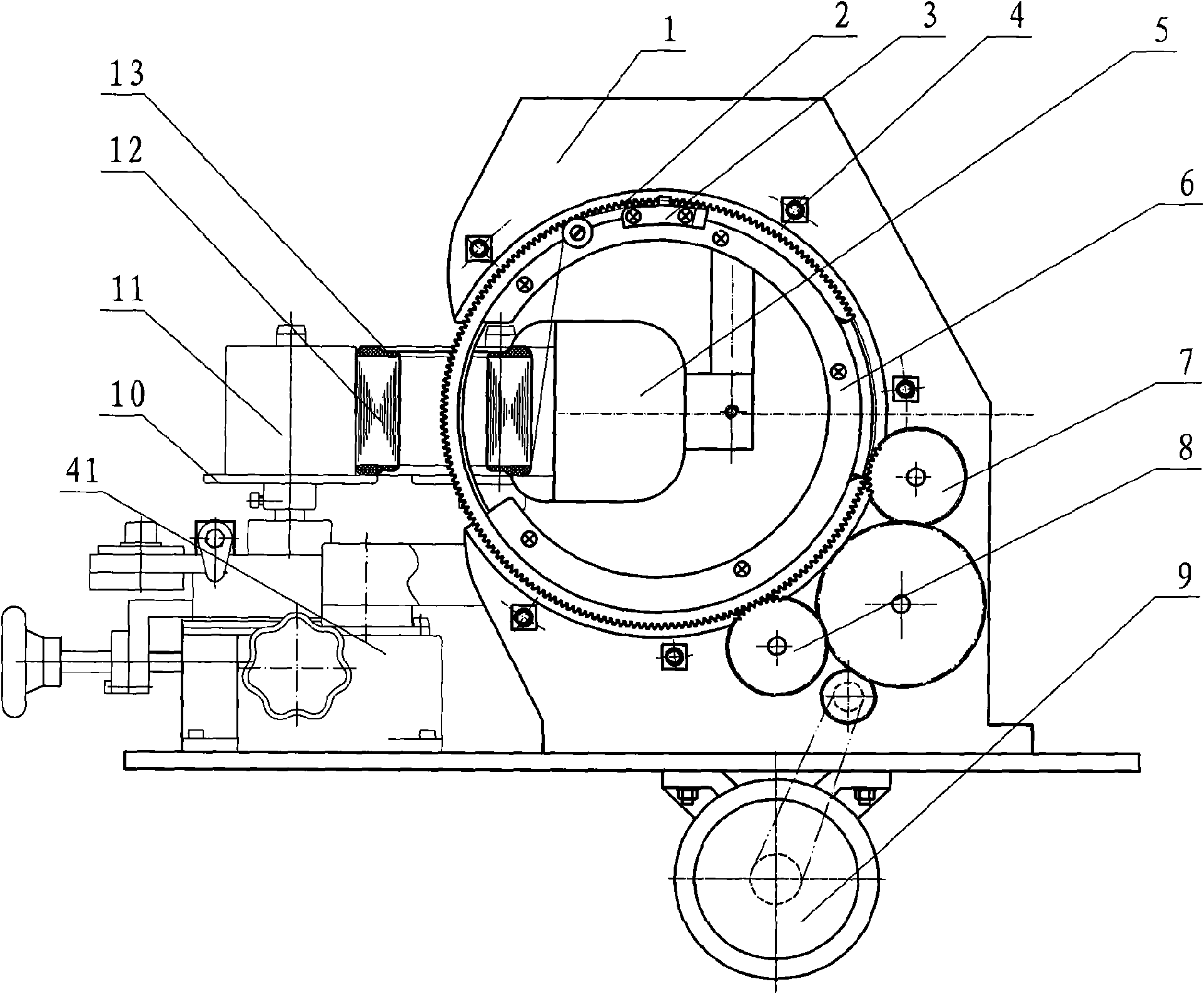

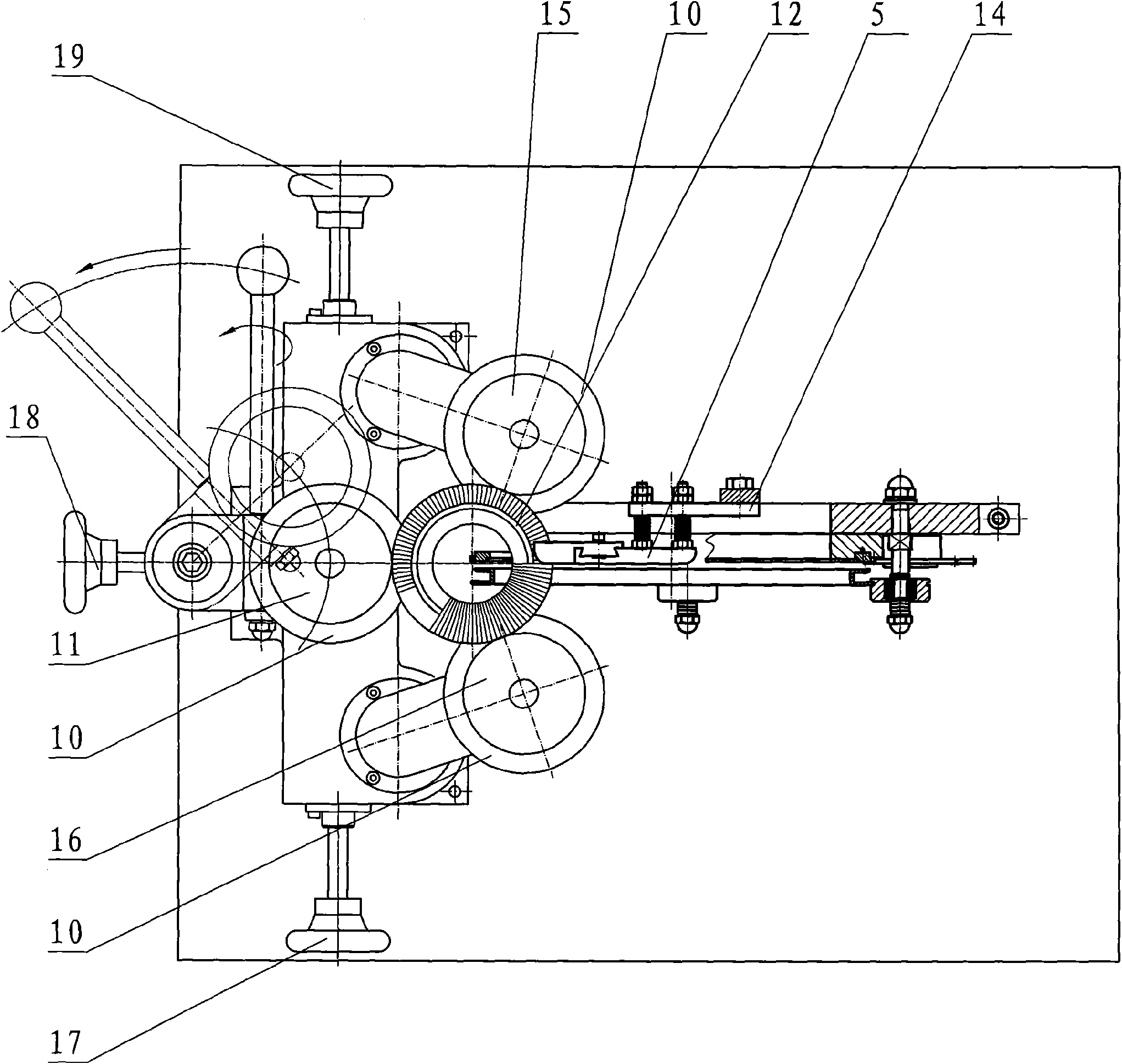

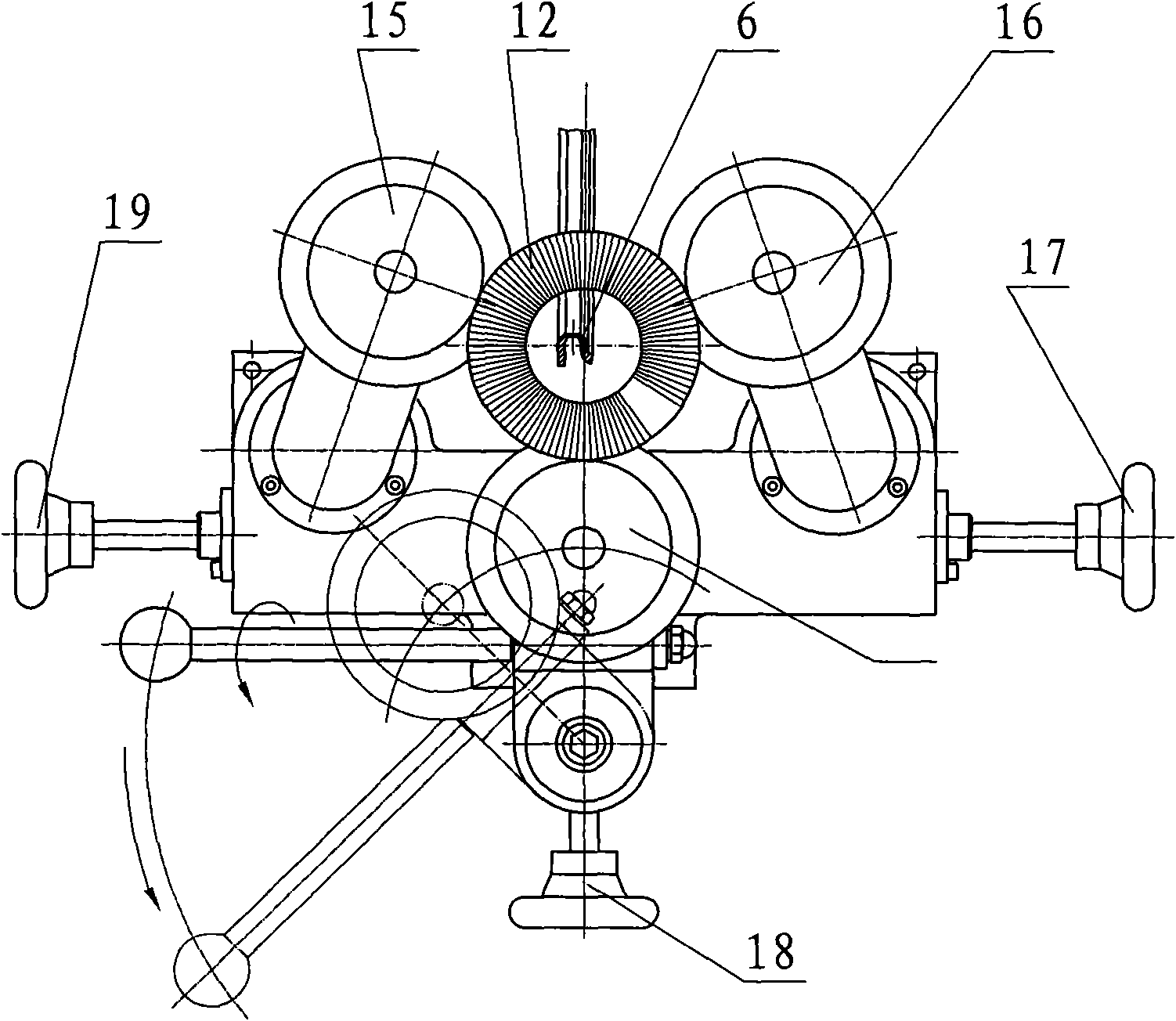

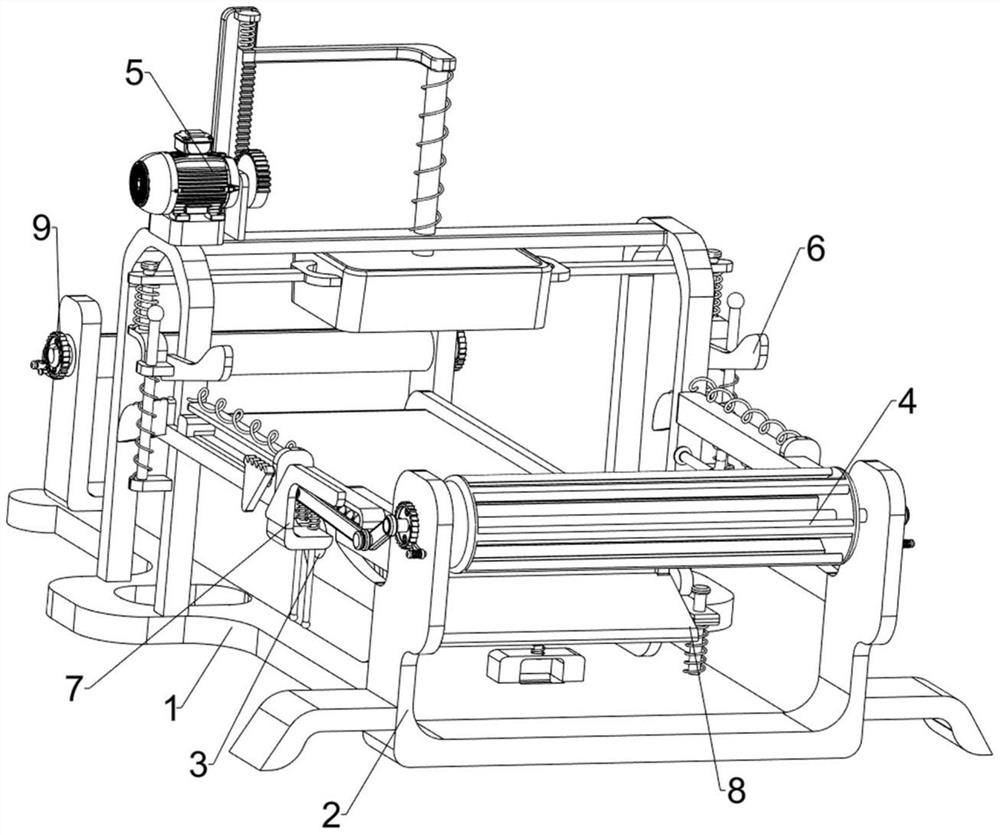

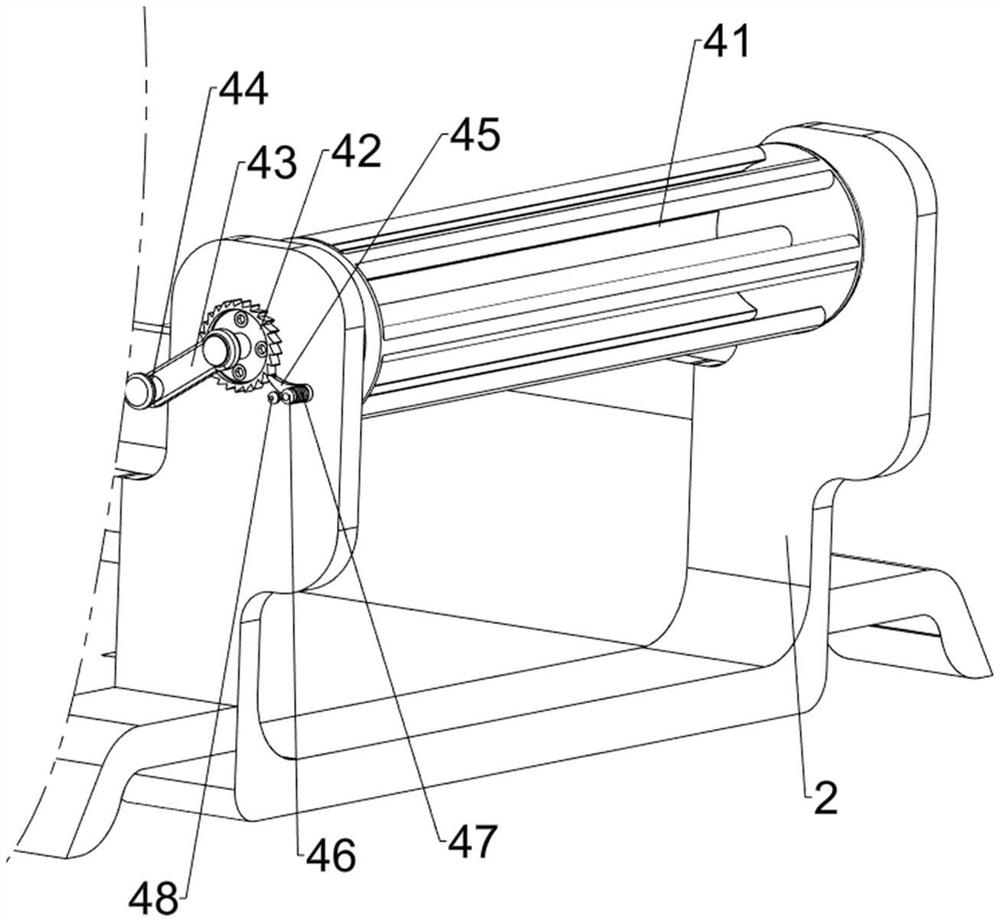

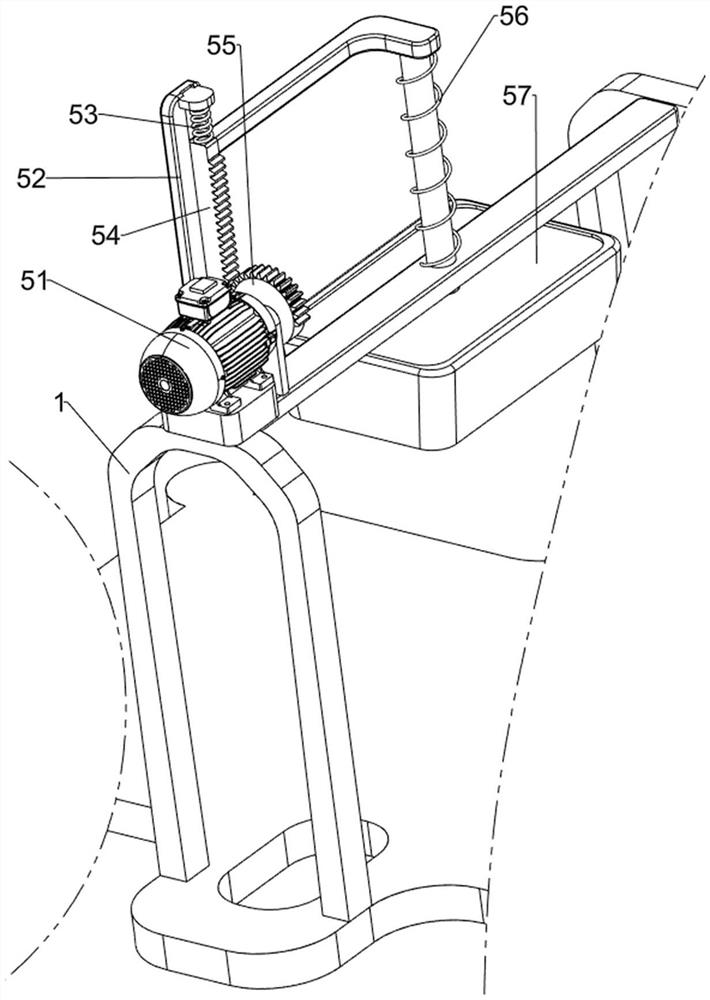

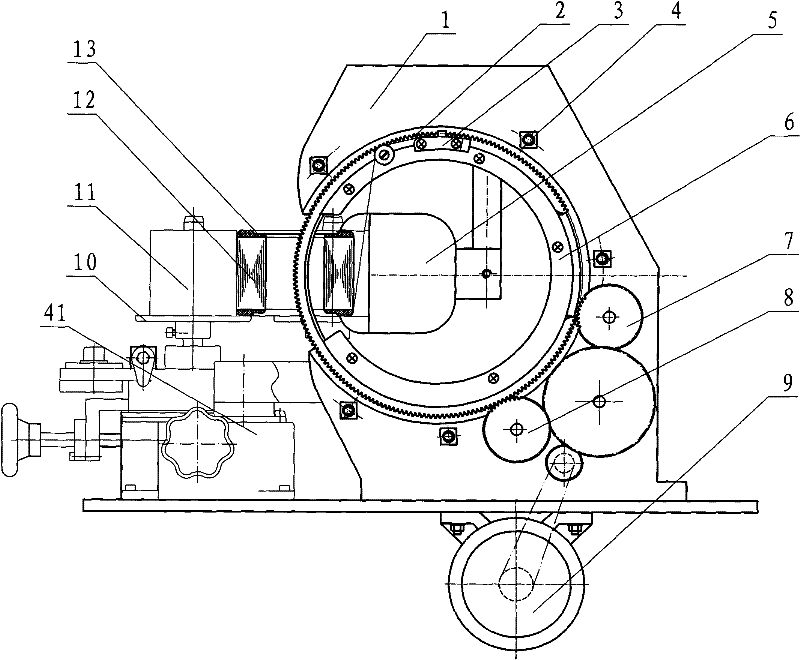

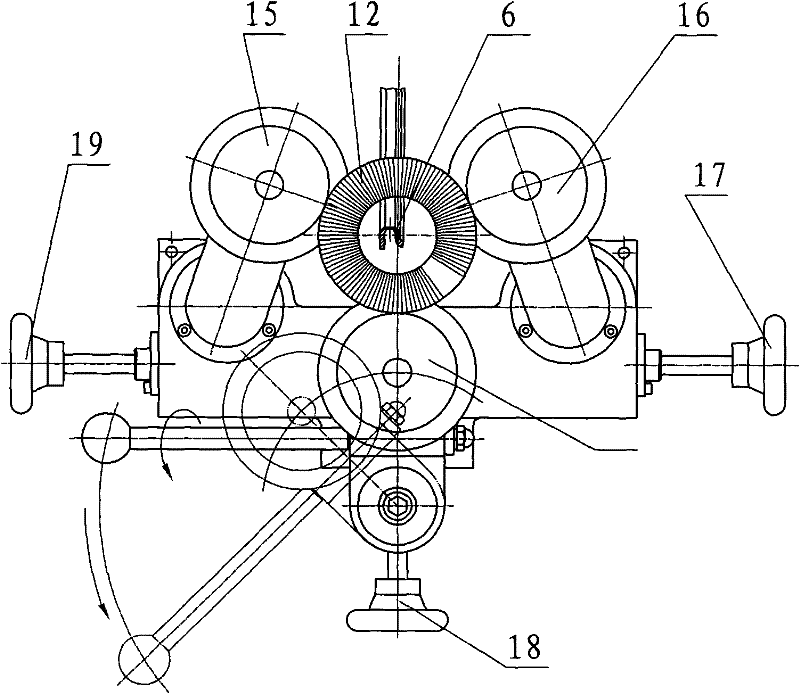

Ring-shaped winding machine

The invention discloses a ring-shaped winding machine which comprises an open-type machine head, an electric cabinet, a transmission mechanism, a wire storage mechanism, a winding mechanism and a wire arranging mechanism, wherein the wire arranging mechanism comprises a mounting seat, a driving rubber wheel provided with a tray and a driven rubber wheel, and the driving rubber wheel provided with the tray is connected with a second transmission mechanism in a transmission way; the wire storage mechanism is provided with a wire storage ring, the winding mechanism is provided with a gear provided with an opening, and the gear provided with the opening is connected with a first transmission mechanism in a transmission way and connected with the wire storage ring when rotating clockwise. The ring-shaped winding machine is characterized in that the second transmission mechanism is driven by a stepper motor, the electric cabinet is internally provided with a singlechip control system, a wire distance amending button is arranged on the electric cabinet, the stepper motor is controlled by a singlechip, and the wire distance amending button is electrically connected with the singlechip. The ring-shaped winding machine can increase or reduce the number of wire distance pulse by the control of the wire distance amending button and the singlechip, so that enamelled wires can be accurately wound into a wire groove all the time, and the phenomenon of wire jumping or overlapping can be stopped.

Owner:温州市南方机械制造有限公司

Device housing a battery and charging pad

InactiveUS8248028B2Reduce positional offsetMobile unit charging stationsElectric powerEngineeringCapacitor

The charging pad 10 is provided with a position detection controller 14 that supplies position detection signals to position detection coils 30, and detects induction coil 51 position from echo signals output from the induction coil 51. The device housing a battery 50 is provided with a series capacitor 55 connected in series with the induction coil 51, a parallel capacitor 56 connected in parallel with the induction coil 51, and a switching circuit 57. When the position detection controller 14 is issuing position detection signals, the parallel capacitor 56 is connected to the induction coil 51. When power is transmitted from the power supply coil 11 to the induction coil 51, the parallel capacitor 56 is not connected to the induction coil 51 and induction coil 51 AC is output to a rectifying circuit 53 through the series capacitor 55.

Owner:SANYO ELECTRIC CO LTD

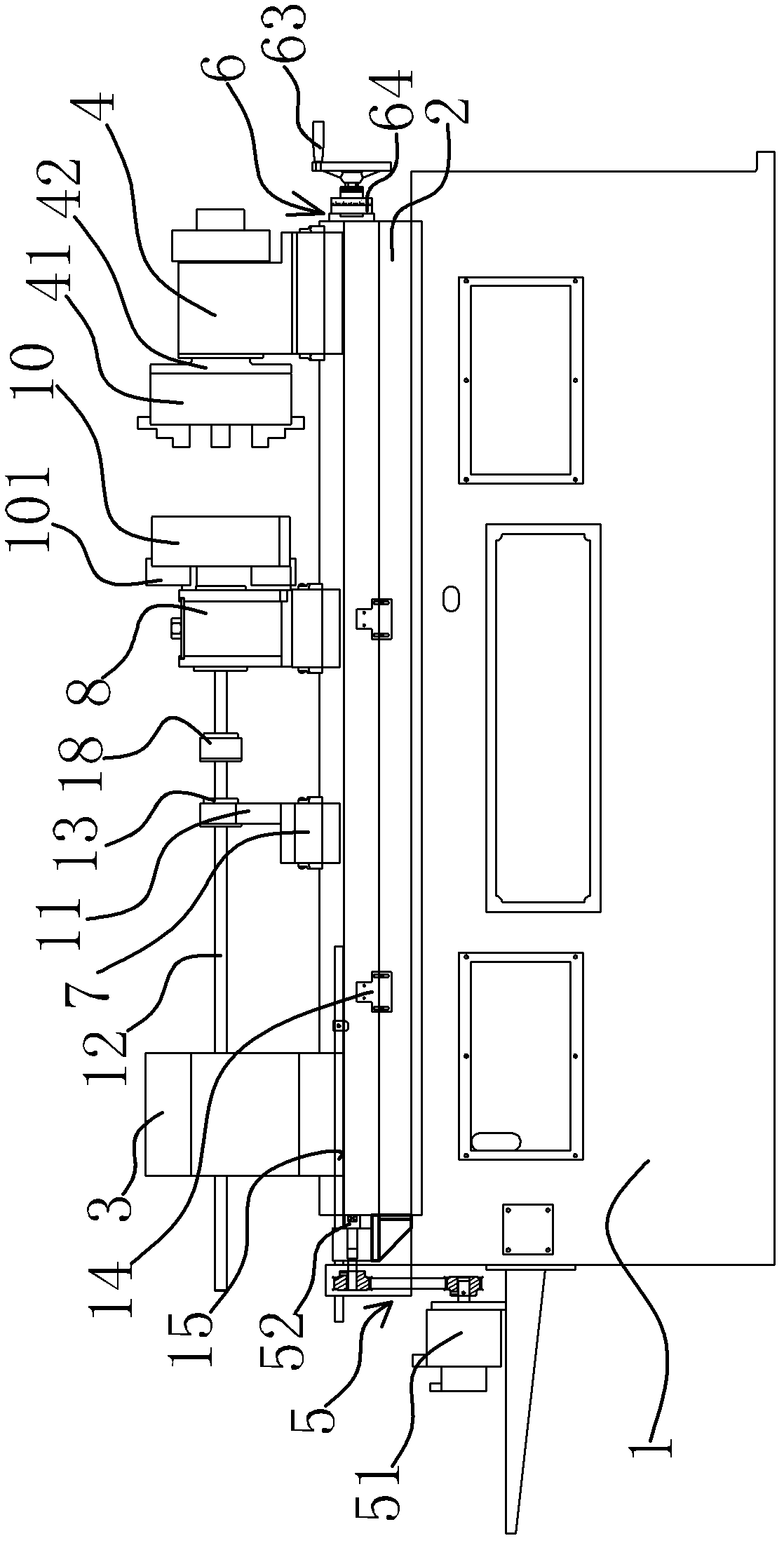

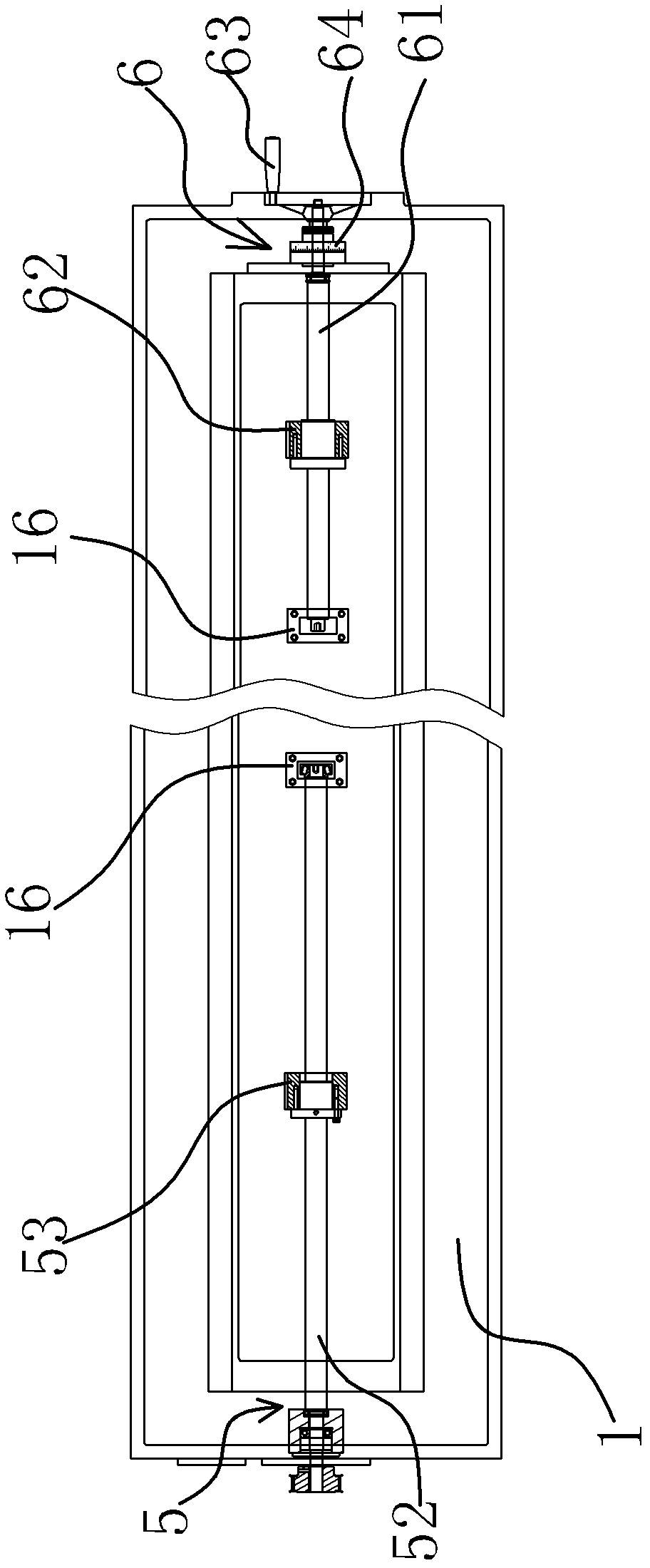

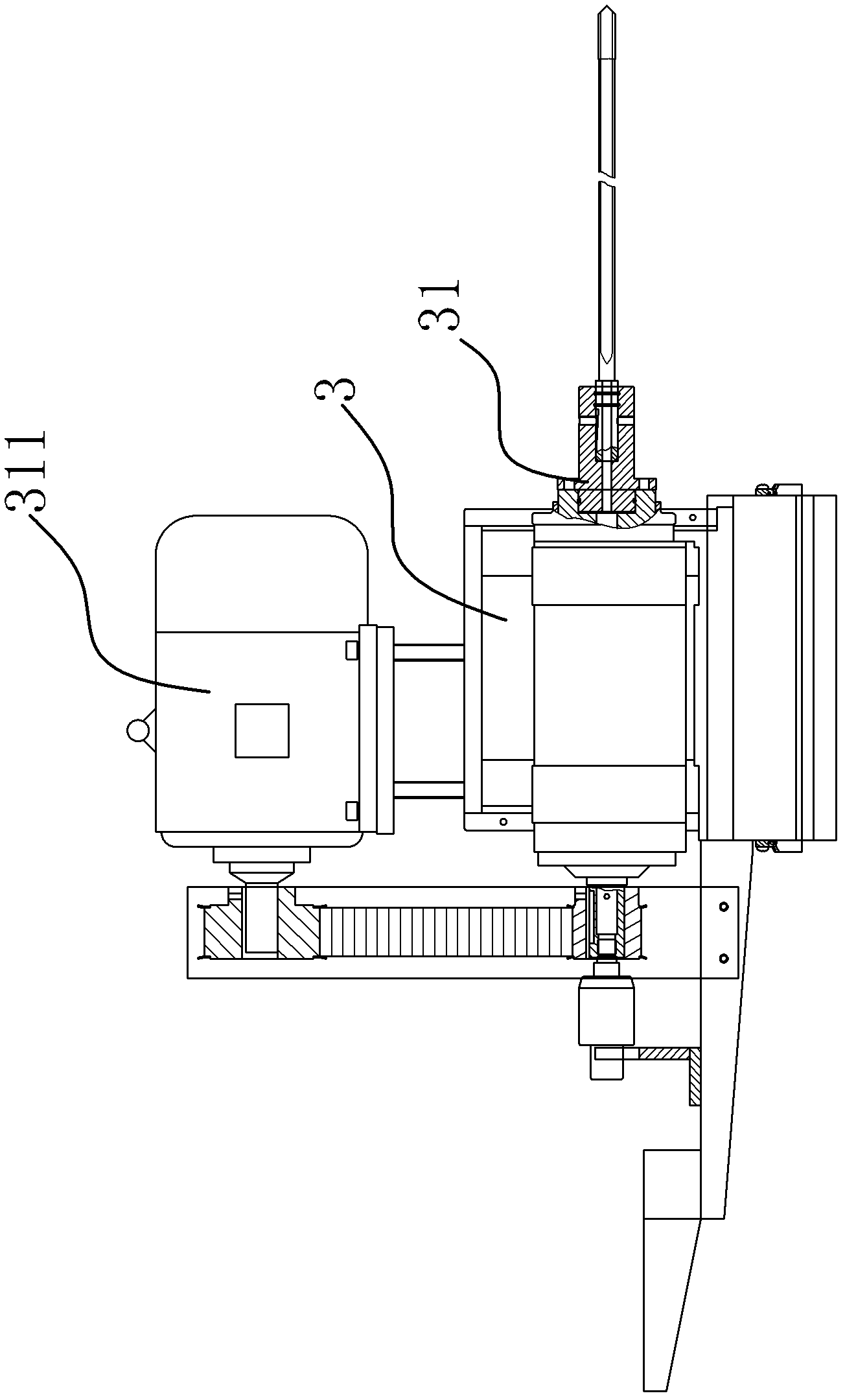

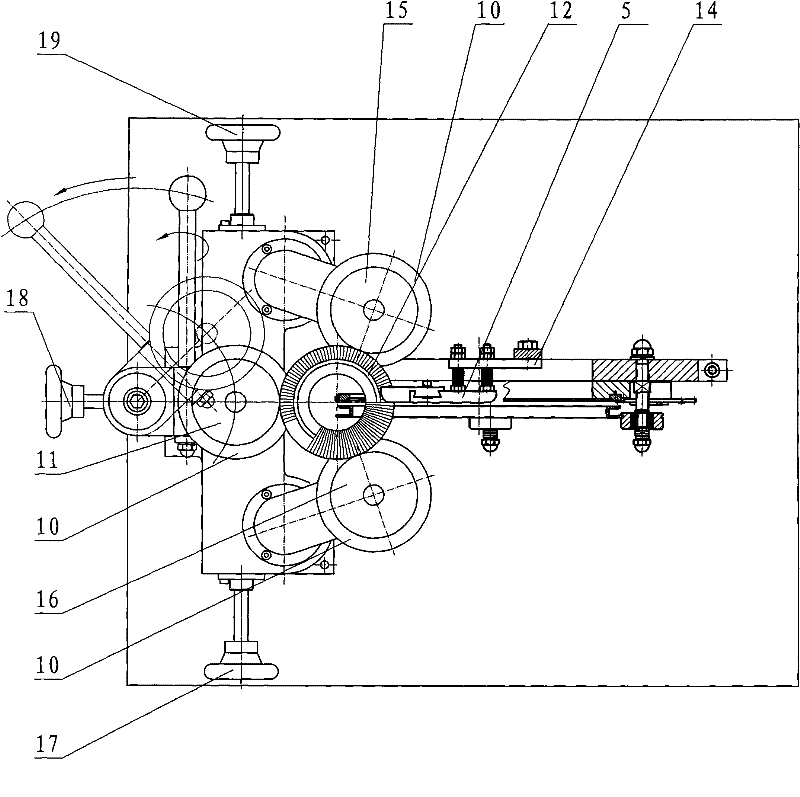

Deep hole drilling machine

ActiveCN102198529AReasonable designCompact structureBoring/drilling componentsBoring/drilling machinesEngineeringTailstock

The invention provides a deep hole drilling machine which belongs to the technical field of machining equipment. The drilling machine solves the problems that the traditional deep hole drilling machine has poor guidance, poor stability, no high machining precision, no high efficiency and a not enough compact structure. The deep hole drilling machine comprises a lathe bed, a power head and a tailstock, wherein the lathe bed is provided with a horizontally arranged slide rail ; the tailstock and the power head are arranged on the slide rail; the power head is provided with a horizontally arranged feed main shaft and a driving motor I for driving the feed main shaft to rotate; one end of the feed main shaft can be connected with a cutting tool; a driving mechanism I is arranged between the power head and the lathe bed and can drive the power head to slide along the slide rail; the tailstock is provided with a jig; and a driving mechanism II is arranged between the tailstock and the lathe bed and can drive the tailstock to slide along the slide rail. The lathe bed of the deep hole drilling machine is provided with the driving mechanism I for driving the power head to slide along the slide rail and the driving mechanism II for driving the tailstock to slide along the slide rail, so that the design is reasonable and the structure is compact; moreover, the lathe bed is provided withthe guide rail and a guide holder, thereby the machining precision of deep holes is improved.

Owner:ZHEJIANG XILING

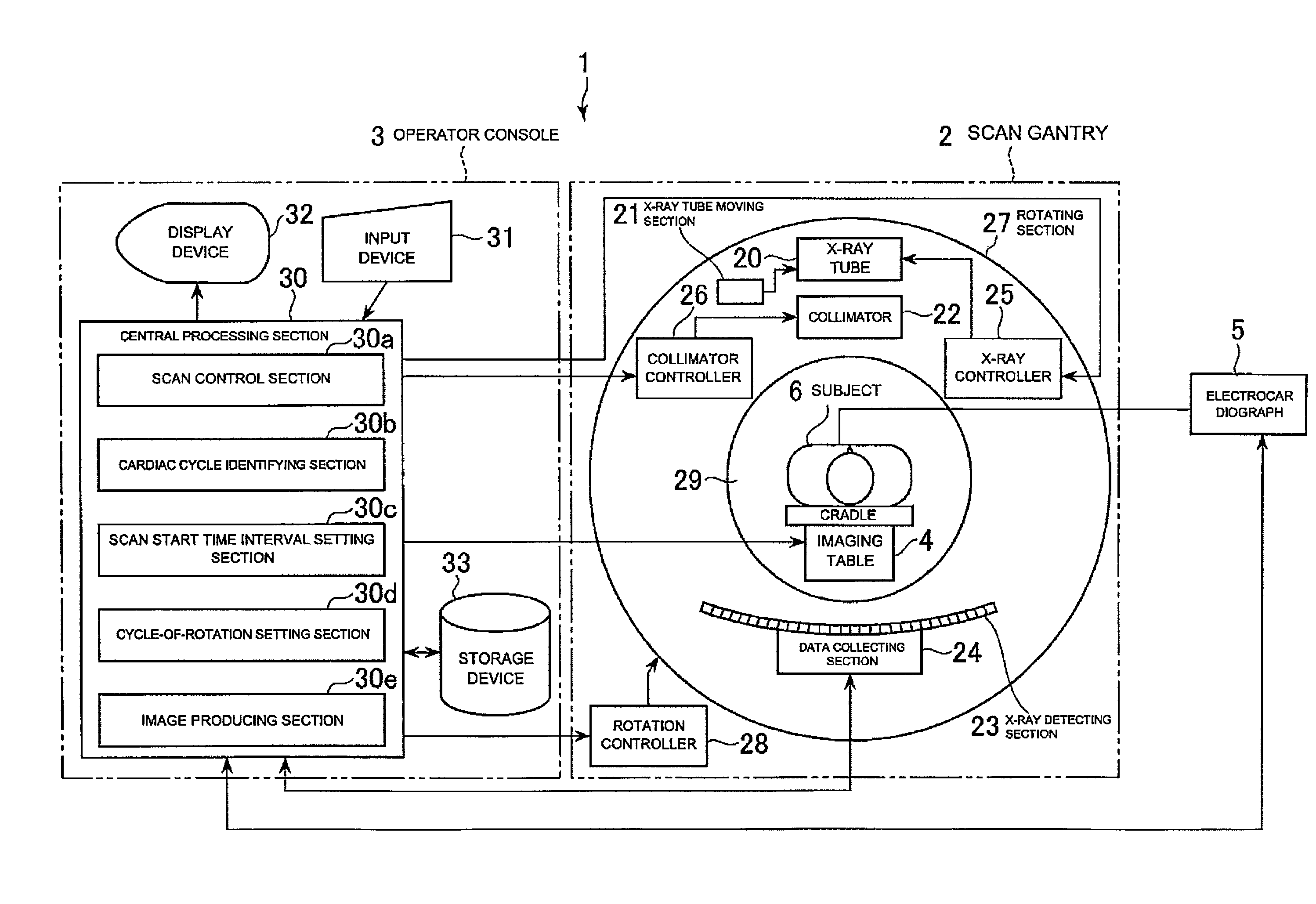

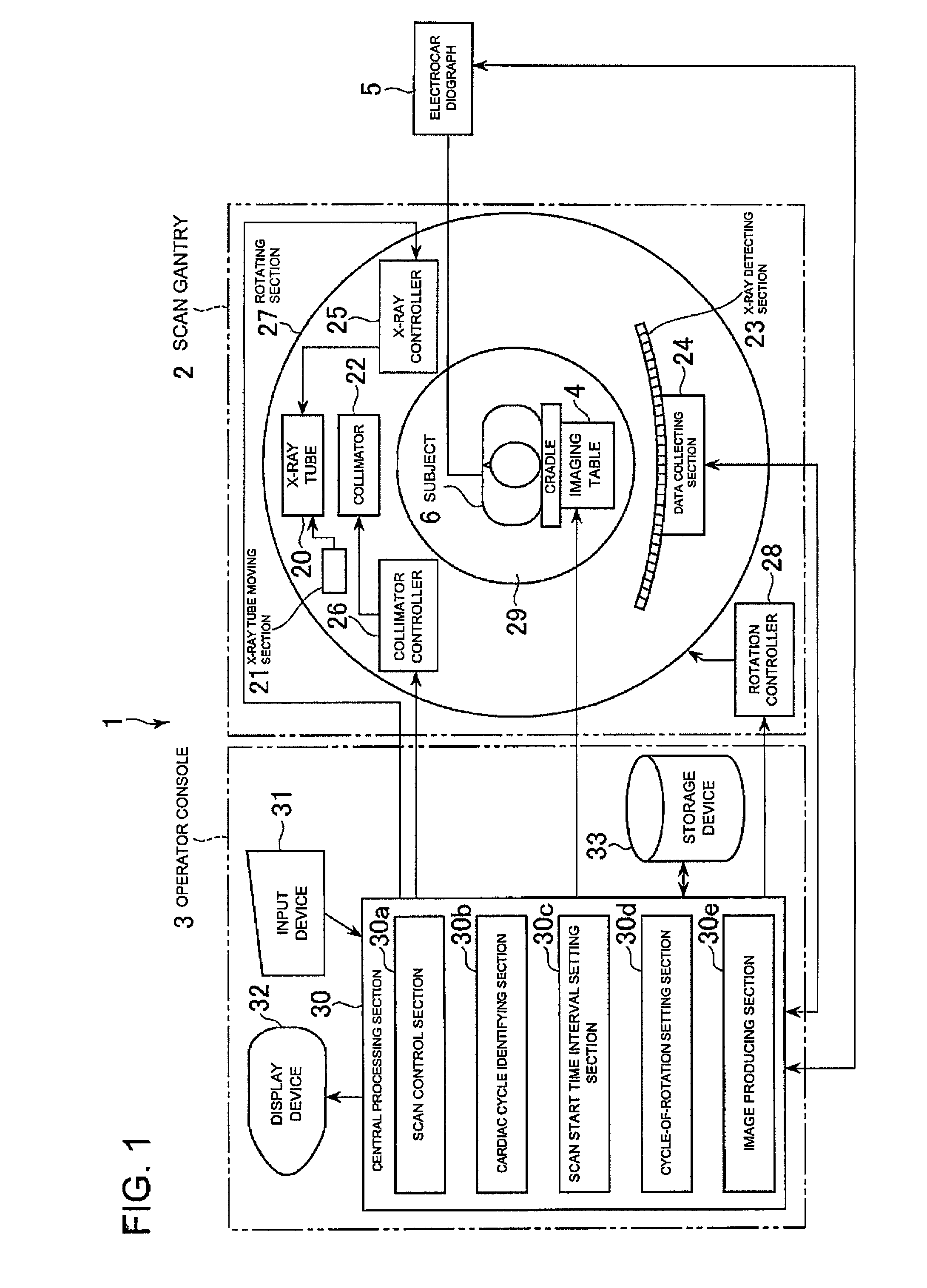

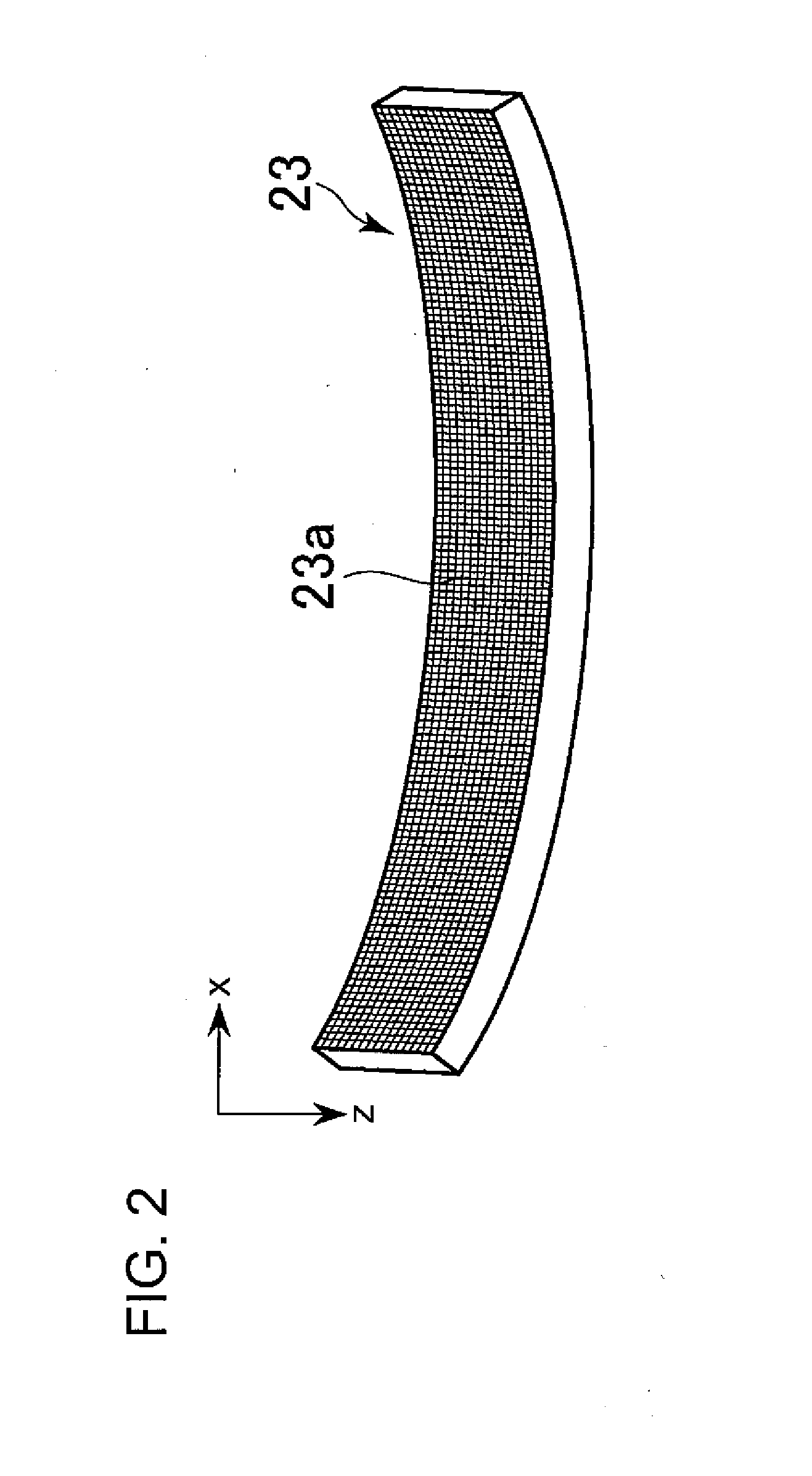

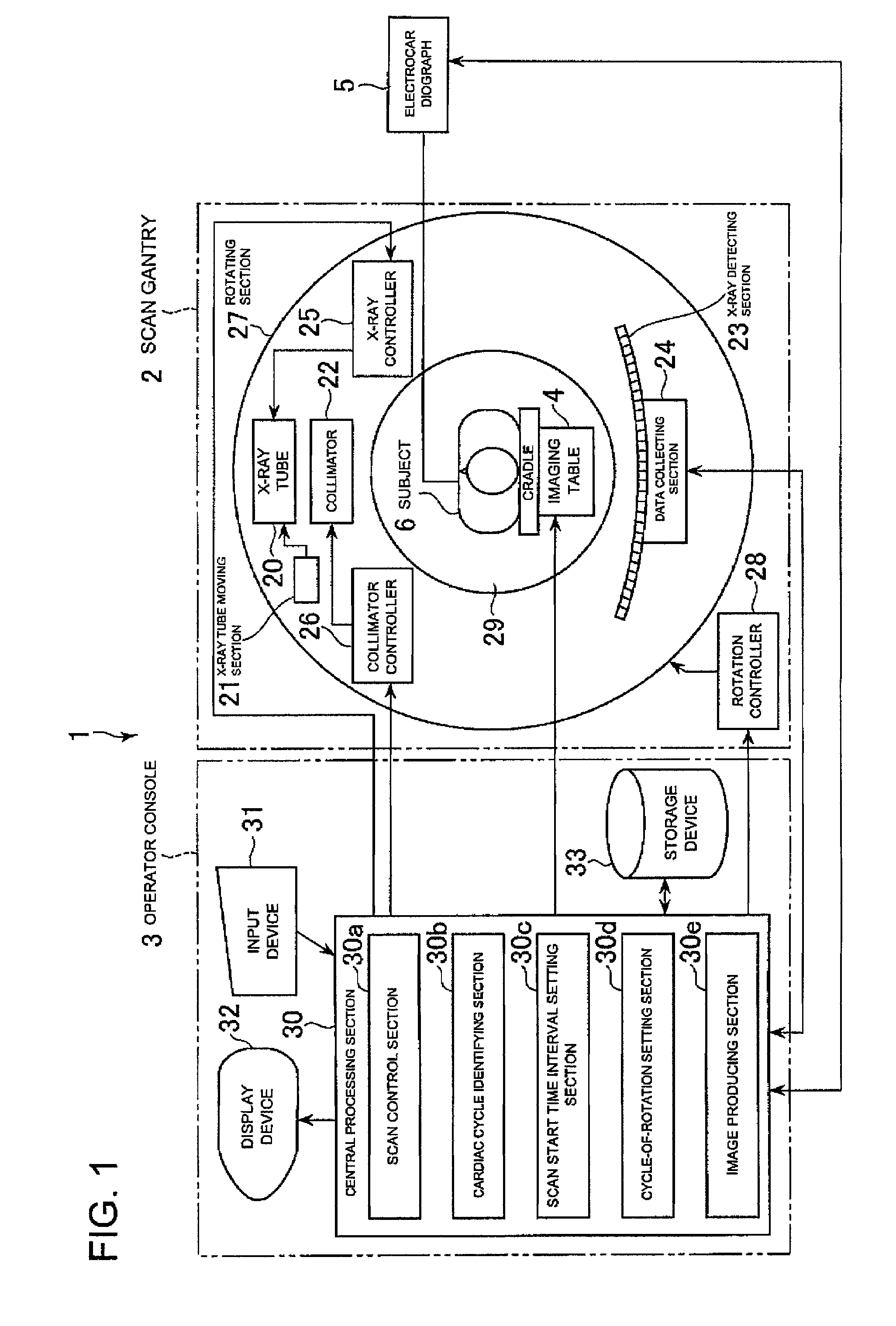

X-ray ct apparatus

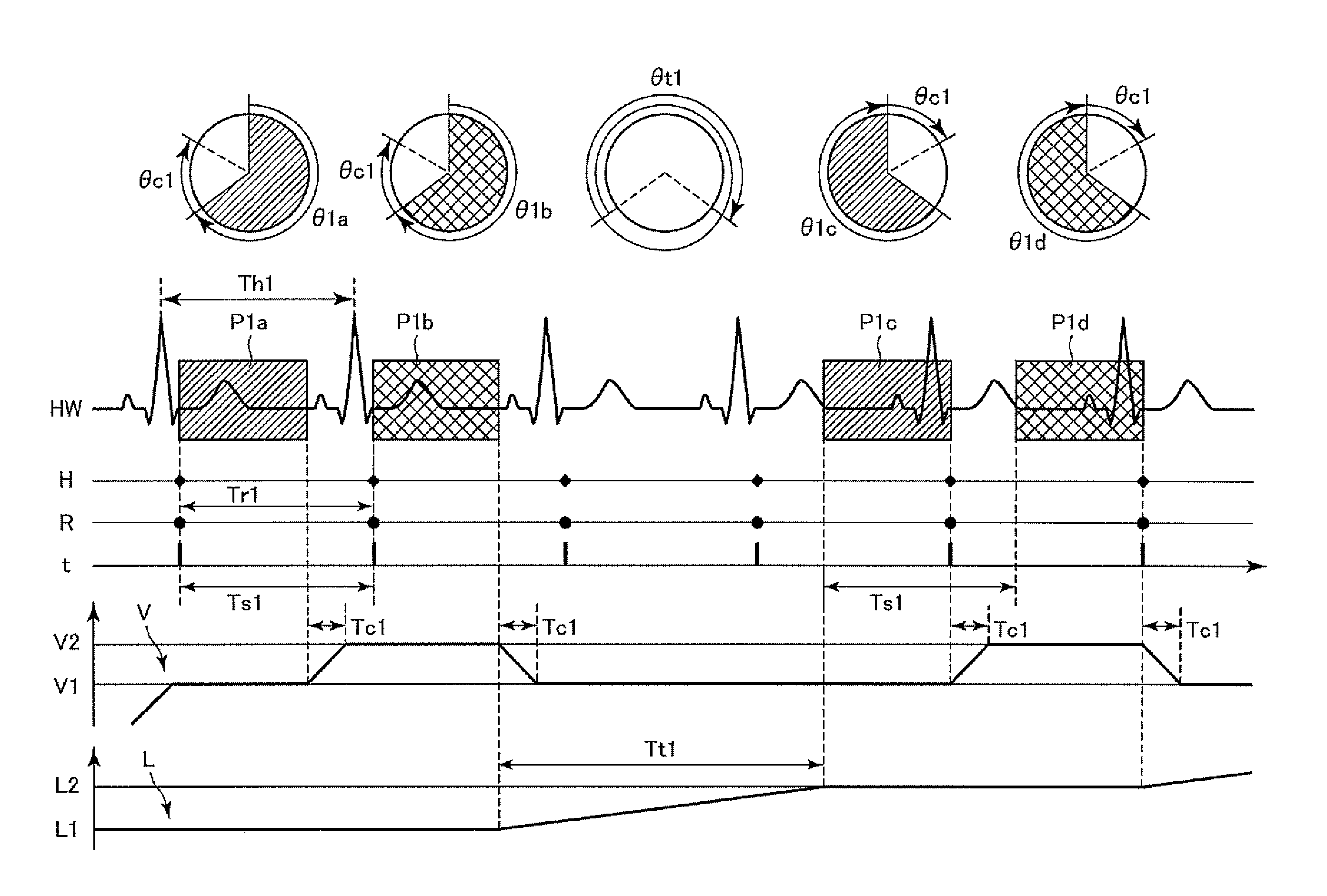

InactiveUS20080317196A1Complicating control of X-rayIncrease exposureMaterial analysis using wave/particle radiationRadiation/particle handlingStart timeCardiac cycle

In X-ray CT imaging for scanning a subject in the same anatomical region with two kinds of X-rays having different energy distributions, for the purpose of reducing a subject's positional offset between two kinds of tomographic images representing the same slice by a simple control scheme while reducing stress on the subject, a cardiac cycle identifying section 30b identifies a cardiac cycle of a subject 6 by an electrocardiograph 5 or the like, and a scan start time interval setting section 30c sets a time interval from the start of a first scan with first X-rays to the start of a second scan with second X-rays to a time approximately the same as the aforementioned cardiac cycle. A scan control section 30a controls several sections to keep a constant rotation speed of a rotating section 27 and start the scans at the aforementioned time interval. In each scan, projection data over a given view angle sufficient for reconstruction processing for a tomographic image are collected at once.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

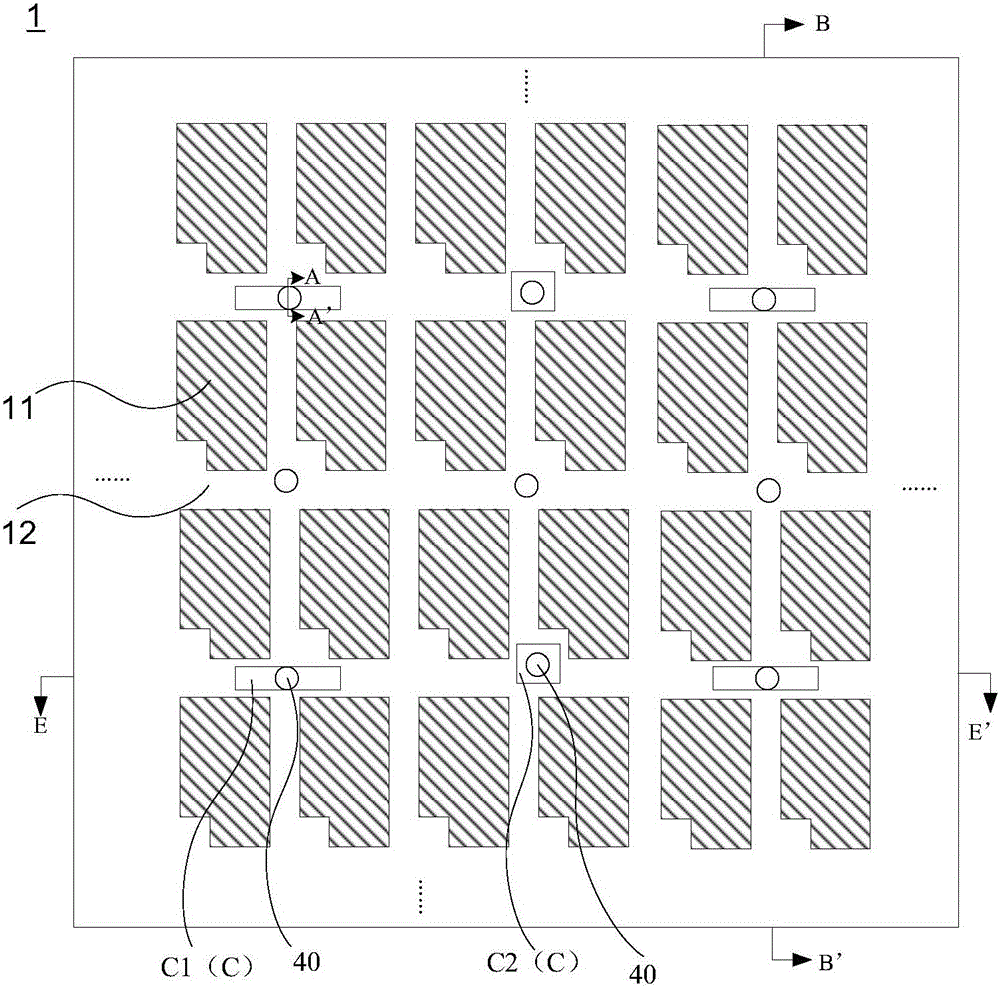

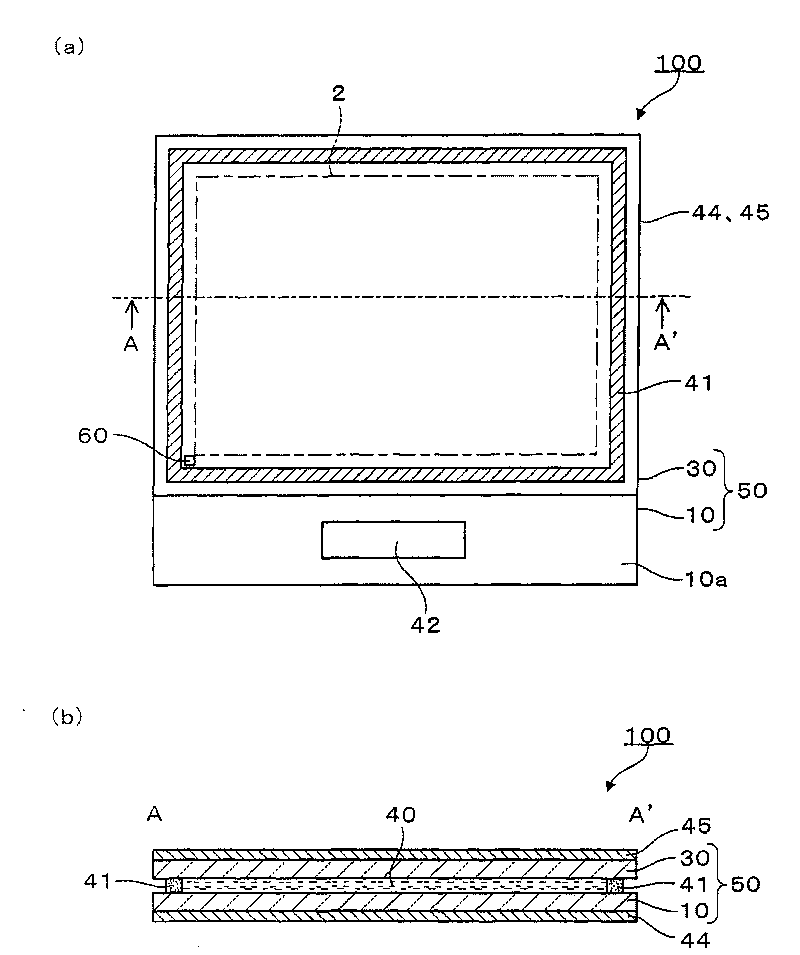

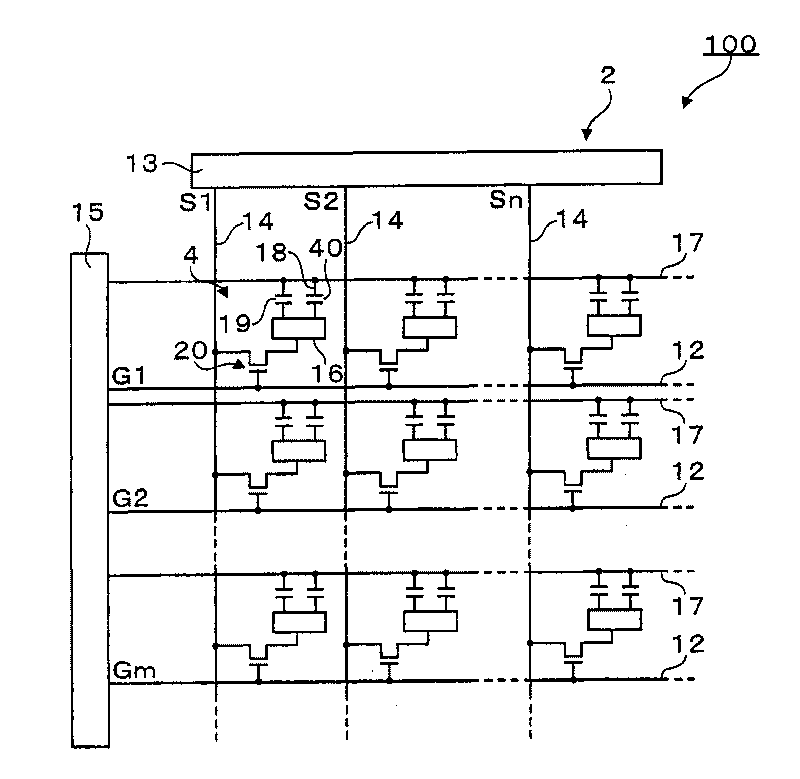

Liquid crystal display panel and manufacturing method thereof as well as display device

InactiveCN105929607AReduce positional offsetReduced contact area densityNon-linear opticsLiquid-crystal displayDisplay device

The embodiment of the invention discloses a liquid crystal display panel and a manufacturing method thereof as well as a display device, and relates to the technical field of display, so as to solve the problem that pixel region position offset easily occurs to the top end of a columnar spacer. The liquid crystal display panel is provided with a pixel region and a pixel definition region surrounding the pixel region; the liquid crystal display panel comprises a first substrate and a second substrate which are oppositely arranged; in the pixel definition region, the upper surface of the first substrate is provided with a spacer limiting slot; the second substrate is provided with a columnar spacer; the top end of the columnar spacer props against the spacer limiting slot of the first substrate; under a condition that the liquid display panel is in the absence of external force, a clearance is reserved between the top end of the spacer and the bottom end of the spacer limiting slot.

Owner:BOE TECH GRP CO LTD

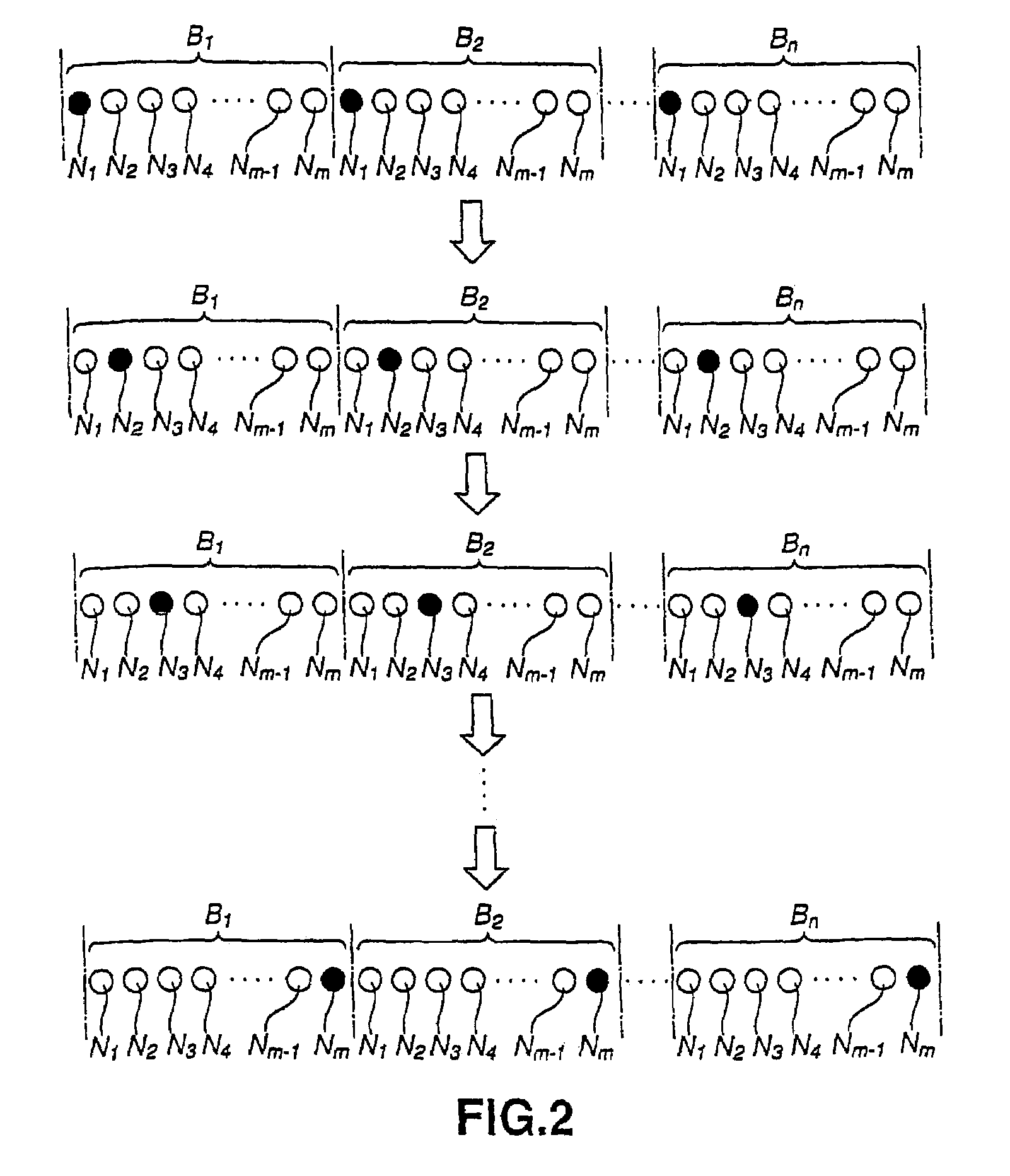

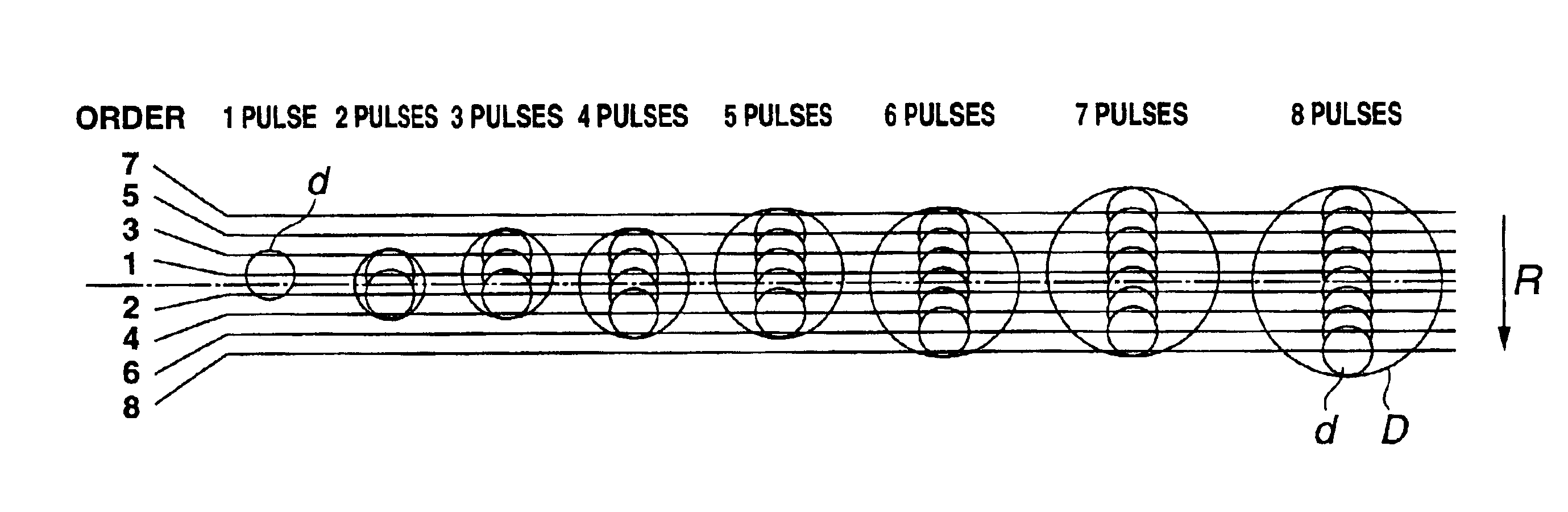

Method for driving recording head, recording head, and ink jet printer

InactiveUS7165823B2Reduce positional offsetMaximum dissipation powerInking apparatusOther printing apparatusEngineeringPaper sheet

Owner:SONY CORP

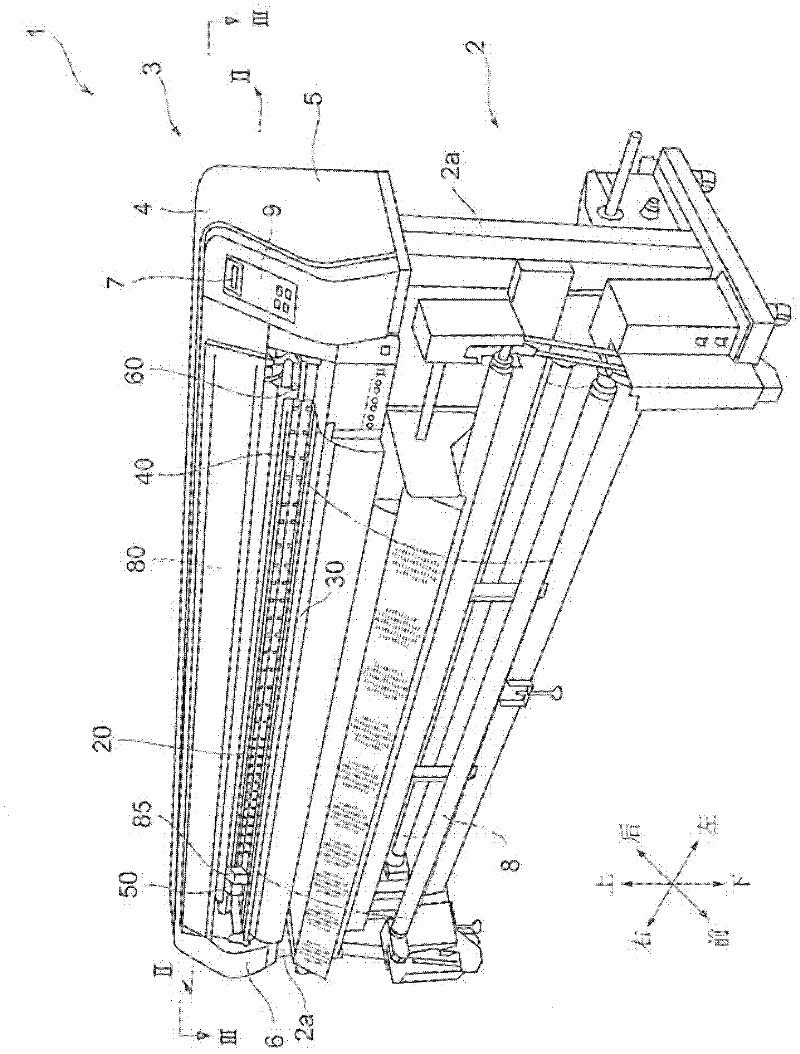

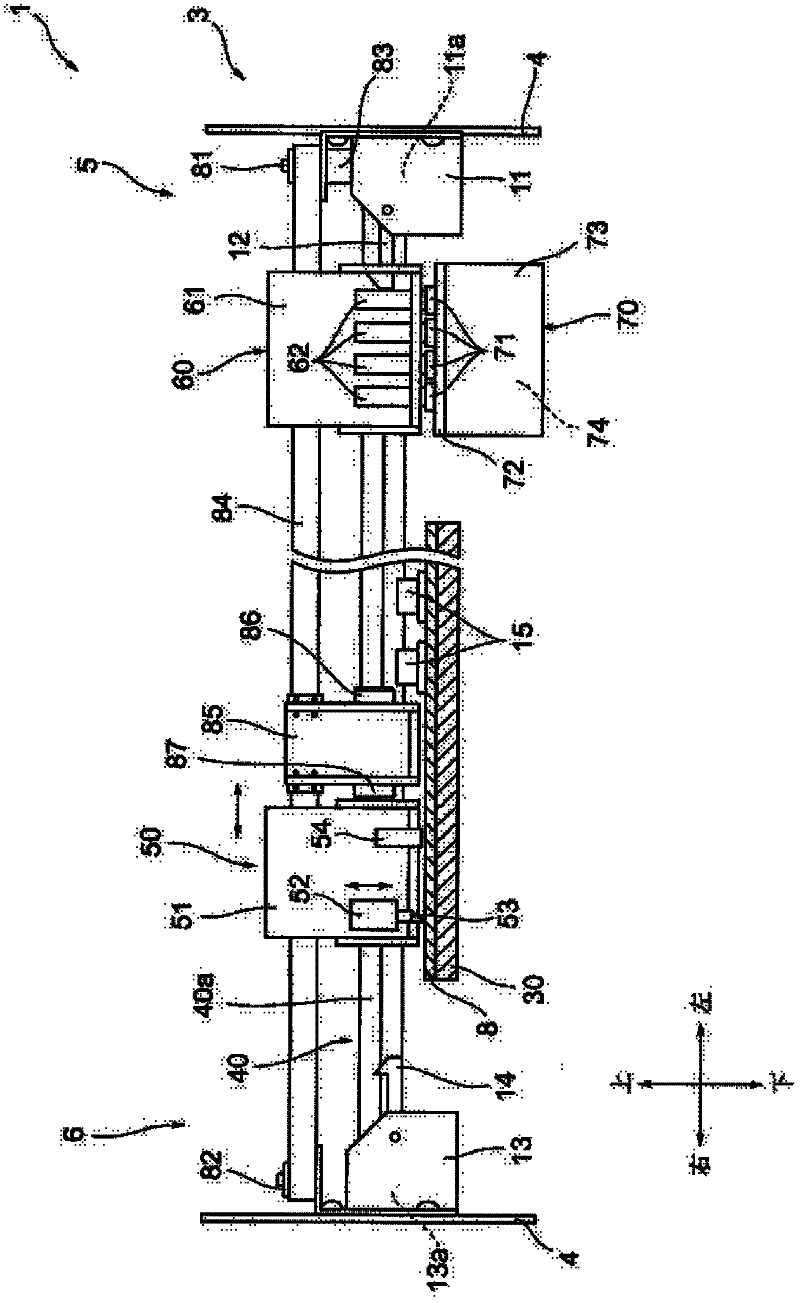

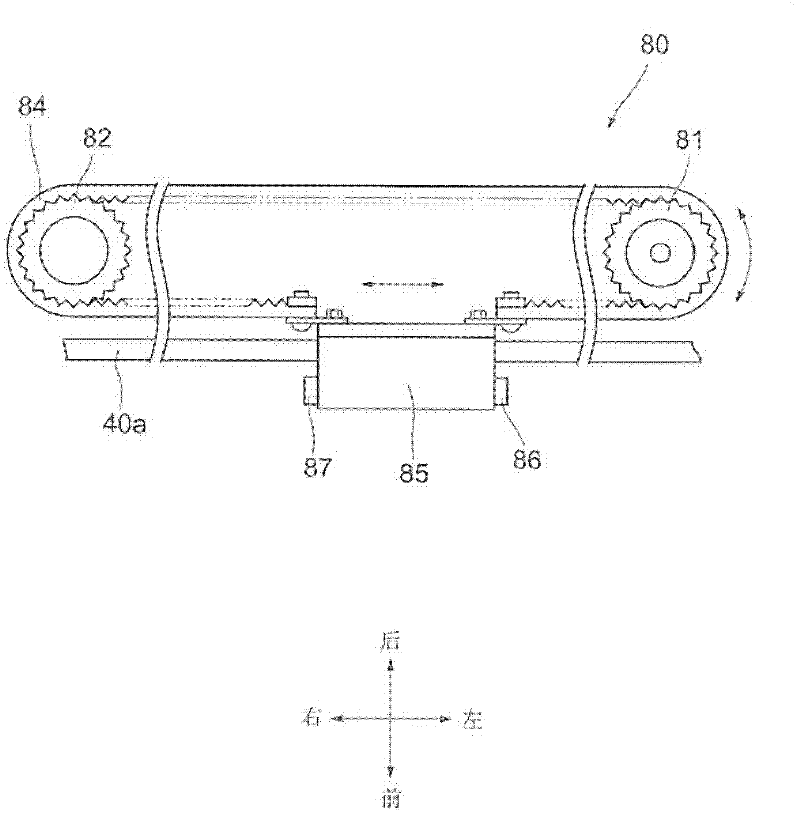

Cutting device and cutting method thereof

ActiveCN102481793AReduce frequencyGuaranteed positioning accuracyOther printing apparatusMetal working apparatusEngineeringFlat panel

Provided is a cutting device capable of performing a cutting process under the conditions that accurate positioning between a cutting head and an object can be reliably obtained. A cutting device (1) comprises a guide rail (40a) which is opposed to a platen (30), a printer head (62) for printing an image and register marks on a sheet material (8), a cutter blade (53) for performing a cutting process to the sheet material (8), an object feeding mechanism for feeding the sheet material (8) forward and backward, a register mark detection unit (54) which detects positions of the register marks, and a controller which sets a cutting position corresponding to a print position of the image, wherein the image and the register marks are printed while the sheet material (8) is fed forward, positions of the register marks are detected by the register mark detection unit (54), and a cutting process is performed by the cutter blade (53) to the cutting position set by the controller. Before starting the cutting process, positions of the register marks printed around an image which has been printed at the rear-most side among the plurality of images, are detected, and the cutting process of the image is performed.

Owner:MIMAKI ENG

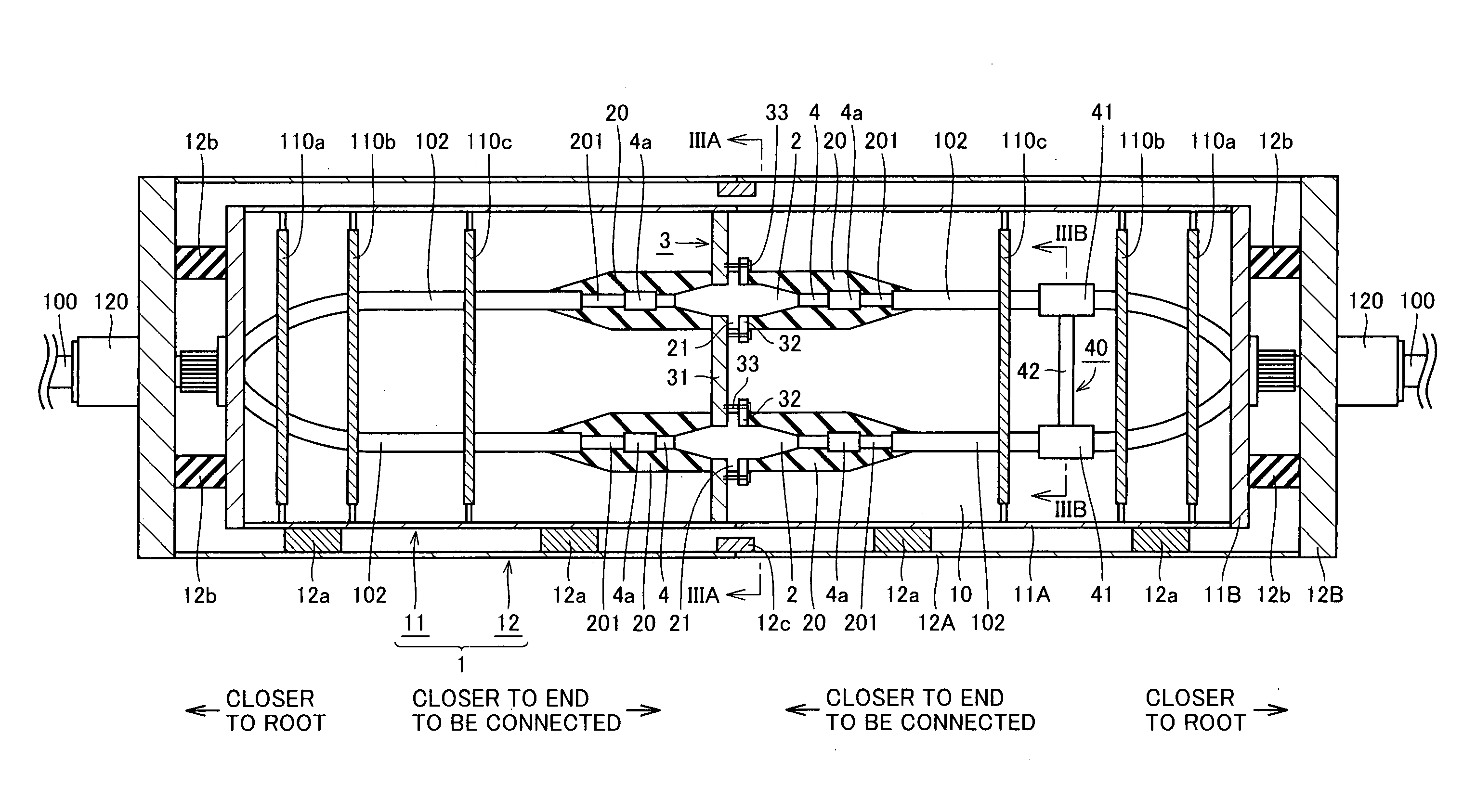

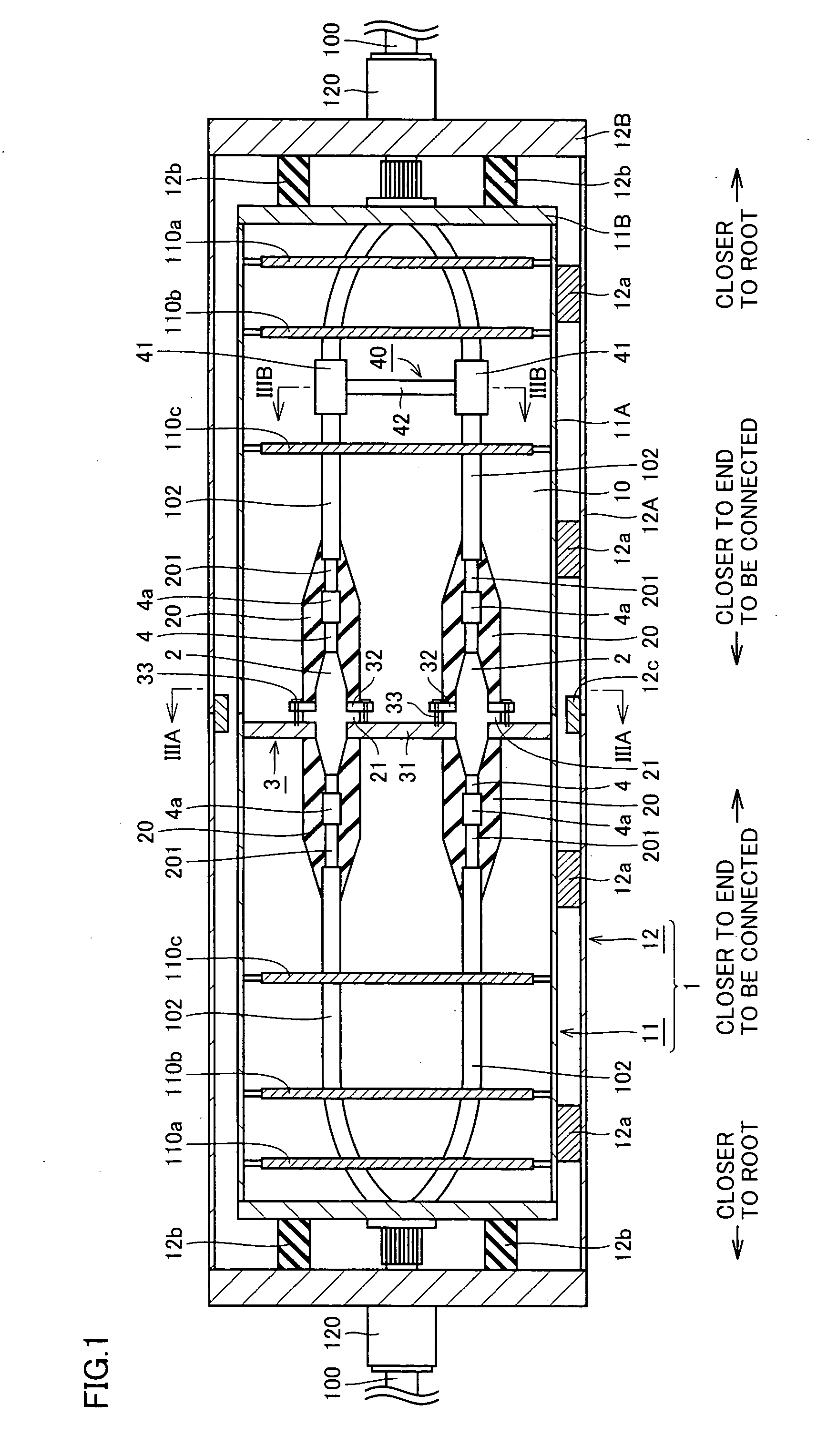

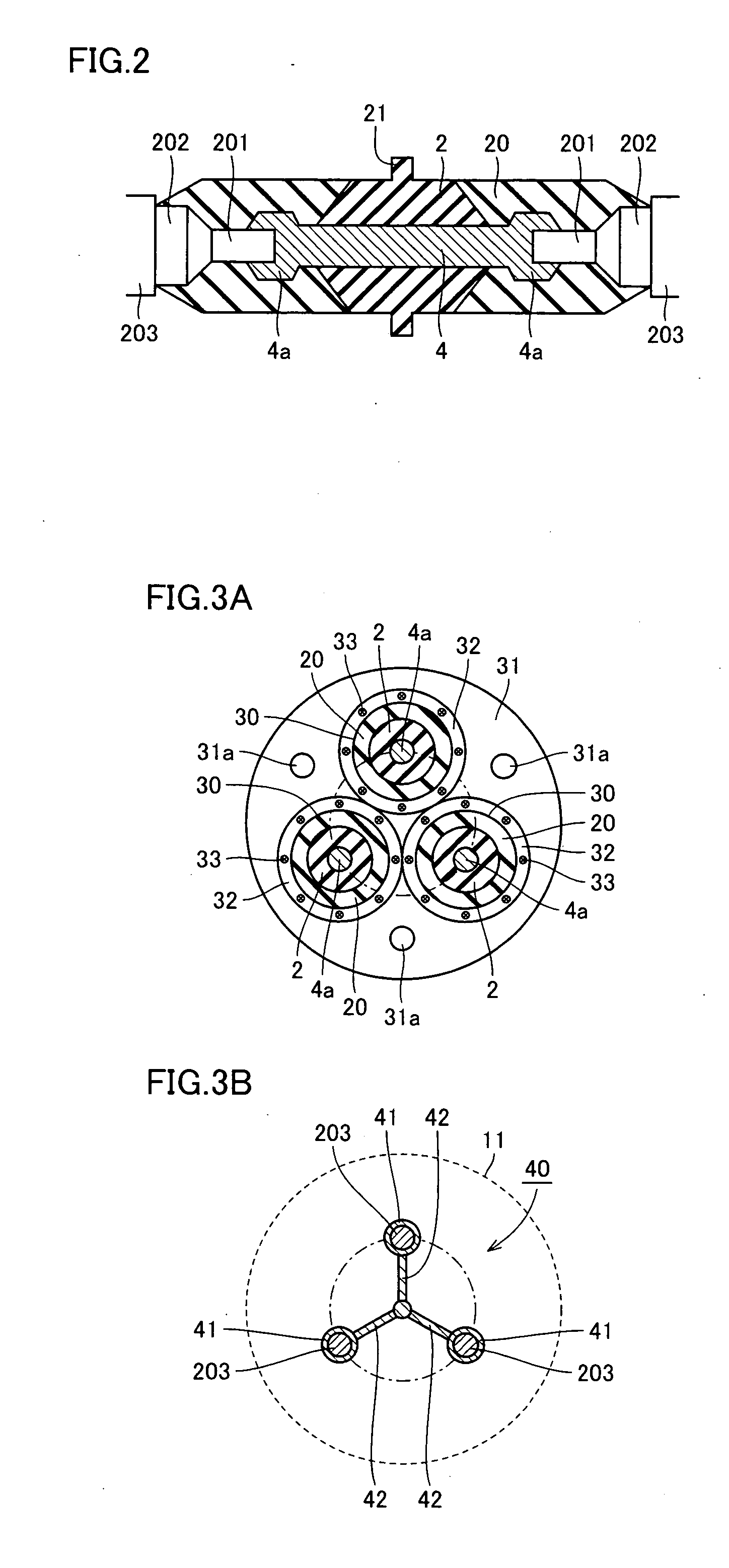

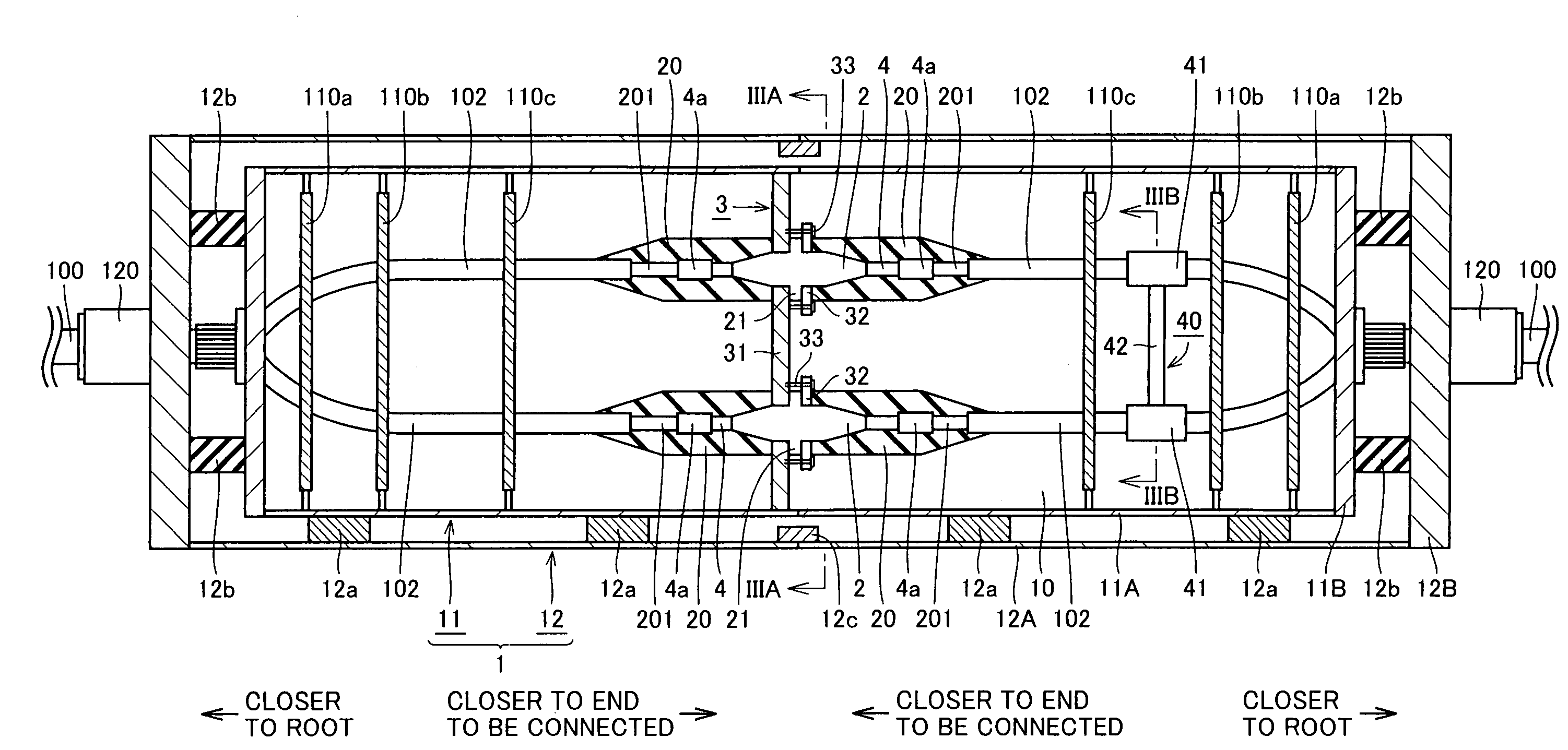

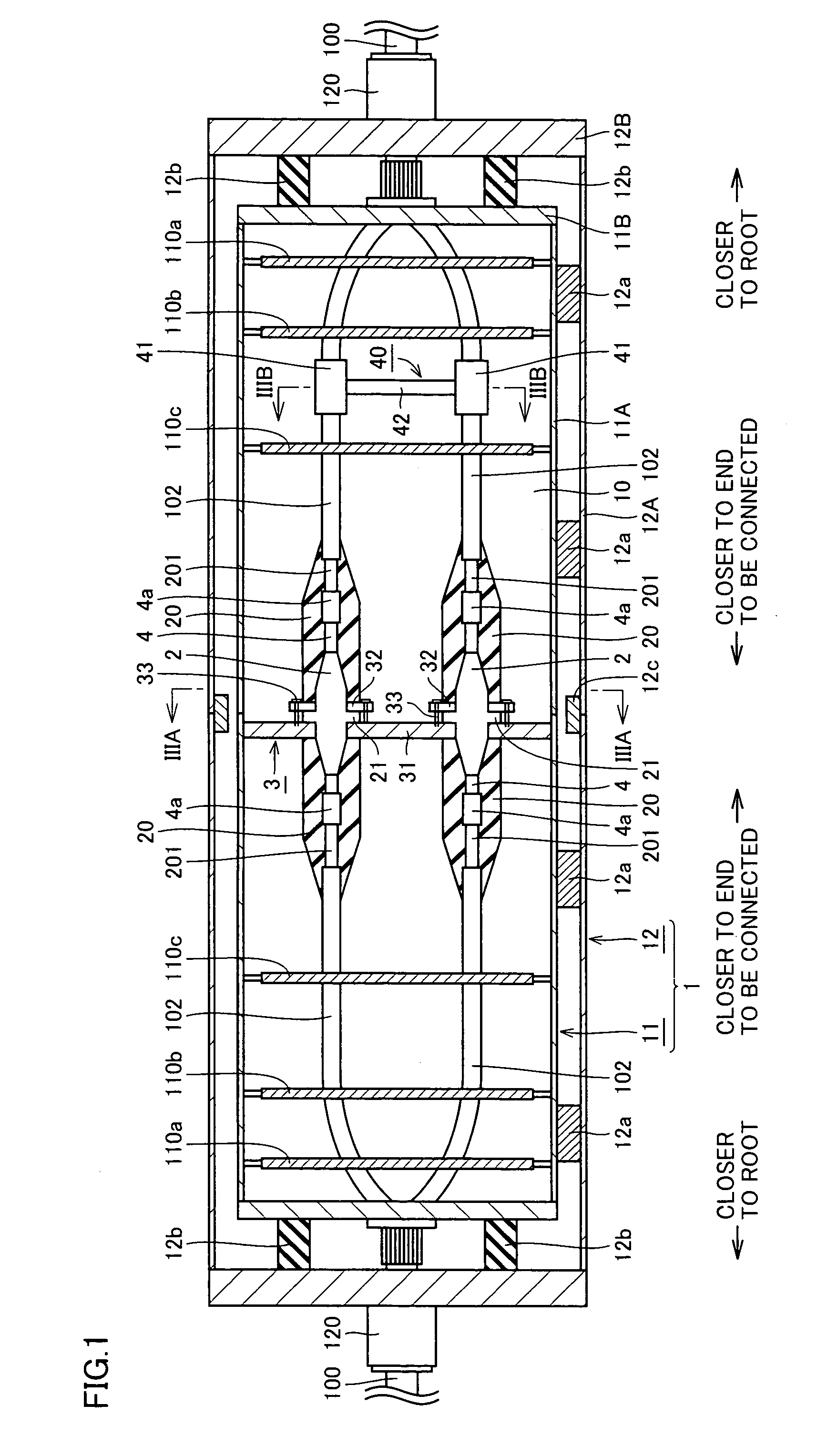

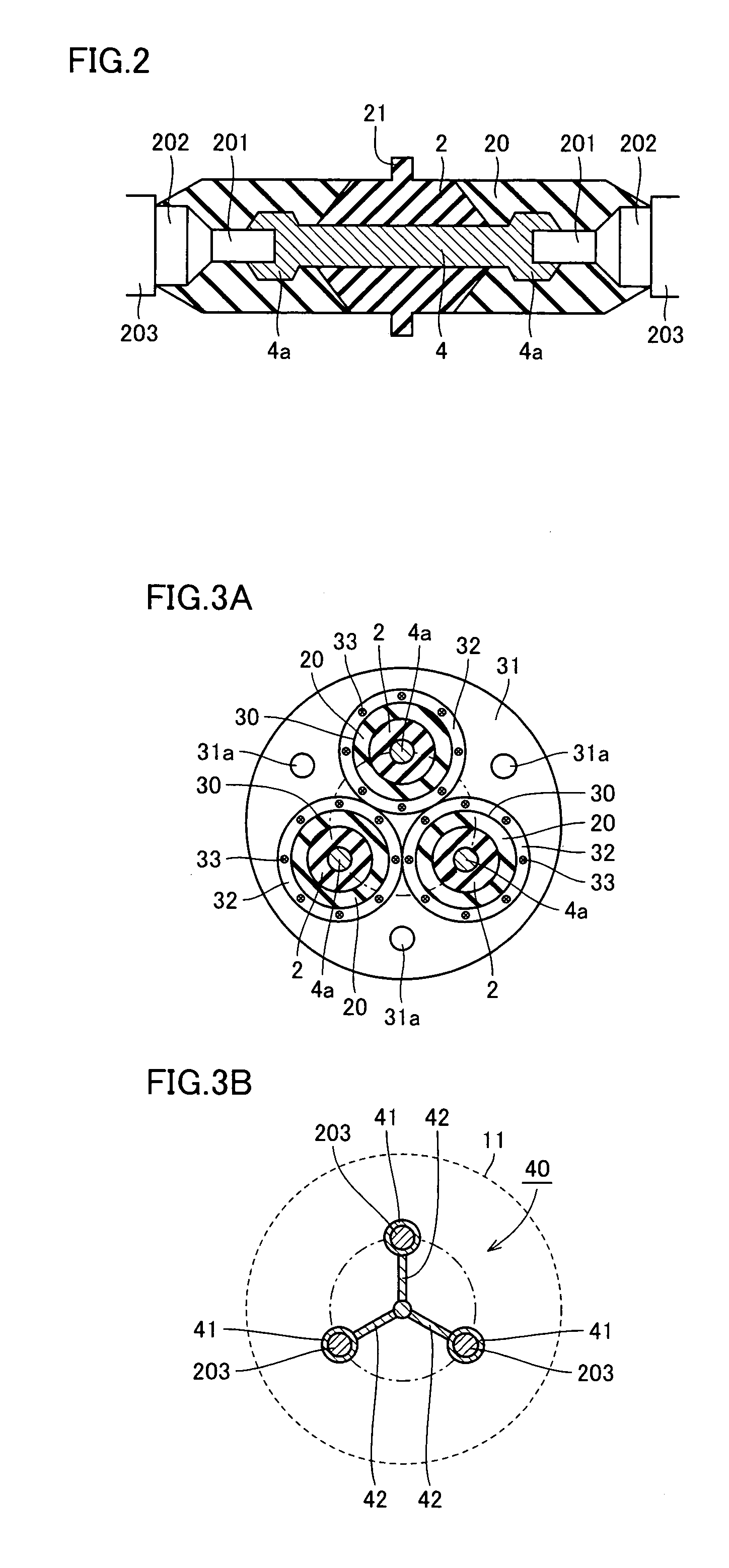

Multiphase superconducting cable connection structure and multiphase superconducting cable line

InactiveUS20050217878A1Help positioningHigh strengthSuperconductors/hyperconductorsCable fittings for cryogenic cablesElectrical conductorEngineering

A multiphase superconducting cable connection structure includes a connection box accommodating three conductor connects connecting a superconductor of a cable core of each phase extracted from a pair of 3-phase superconducting cables, a solid insulation member fixed to an outer circumference of each conductor connect, and a metal flange fixing the solid insulation member to the connection box. By fixing the metal flange to the connection box (a refrigerant vessel), the conductor connect can be positioned and the conductor connector's movement caused as the cable core thermally contracts can be reduced. The structure can help to position the conductor connect in the connection box and reliably hold it at a prescribed position.

Owner:SUMITOMO ELECTRIC IND LTD

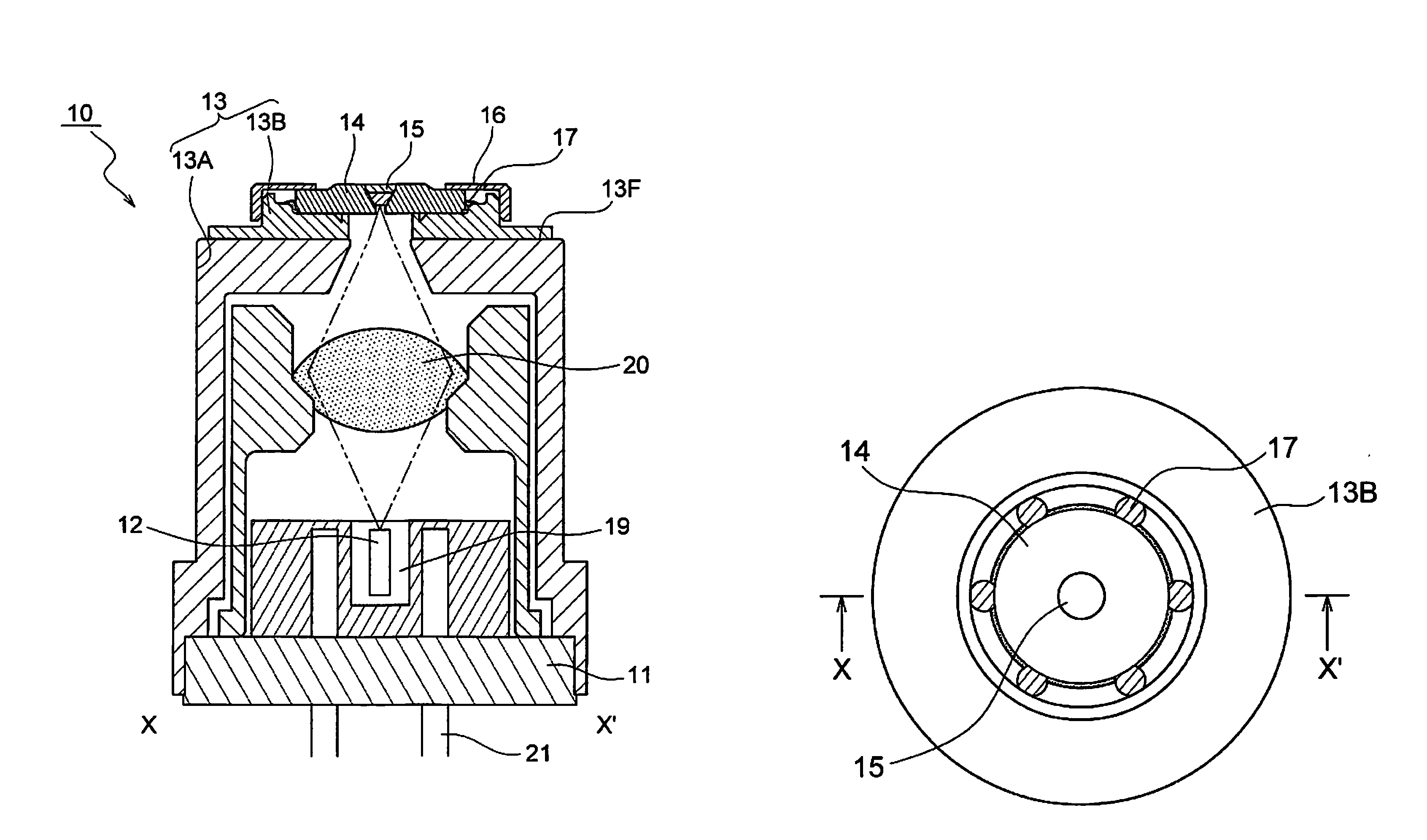

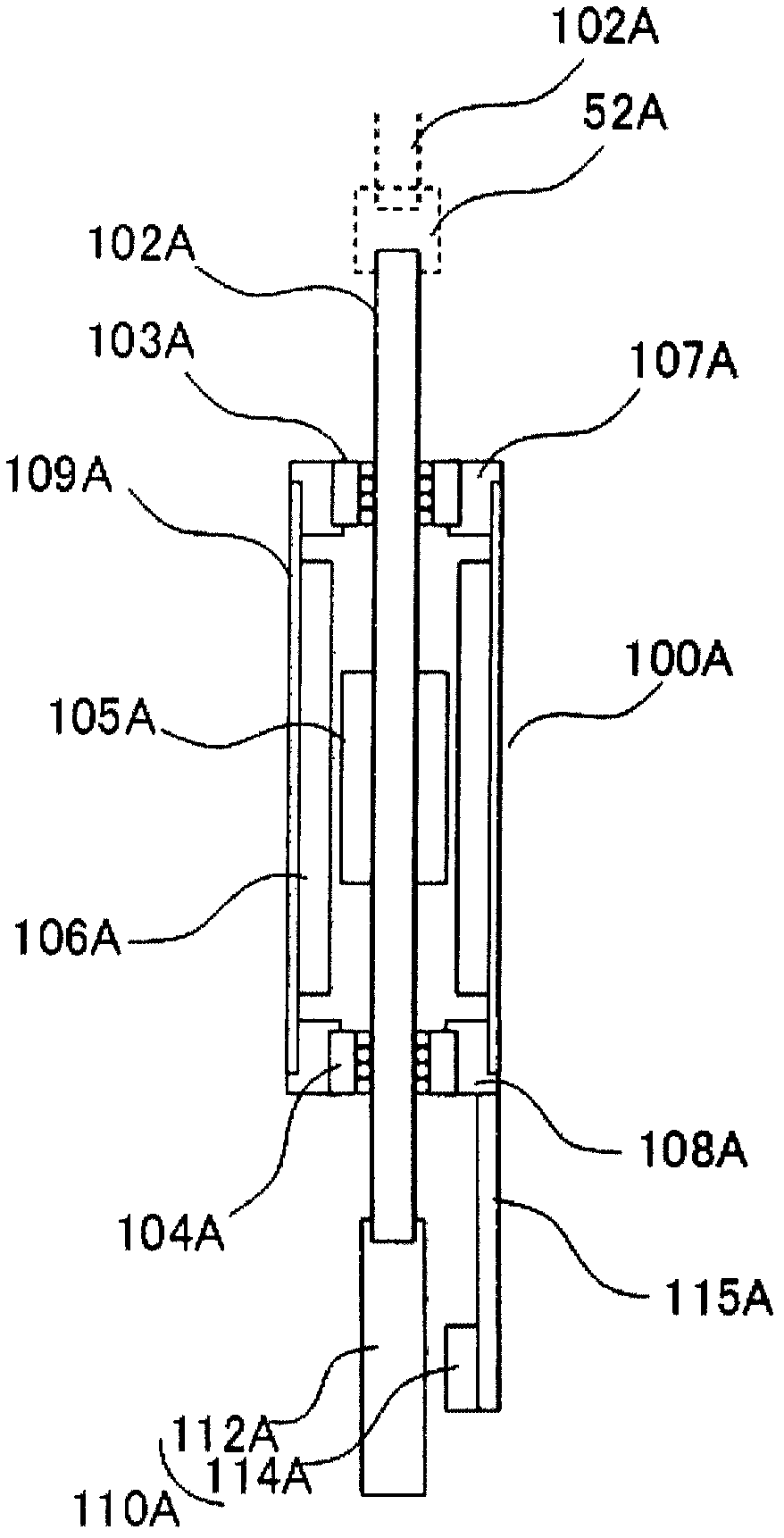

Semiconductor laser device

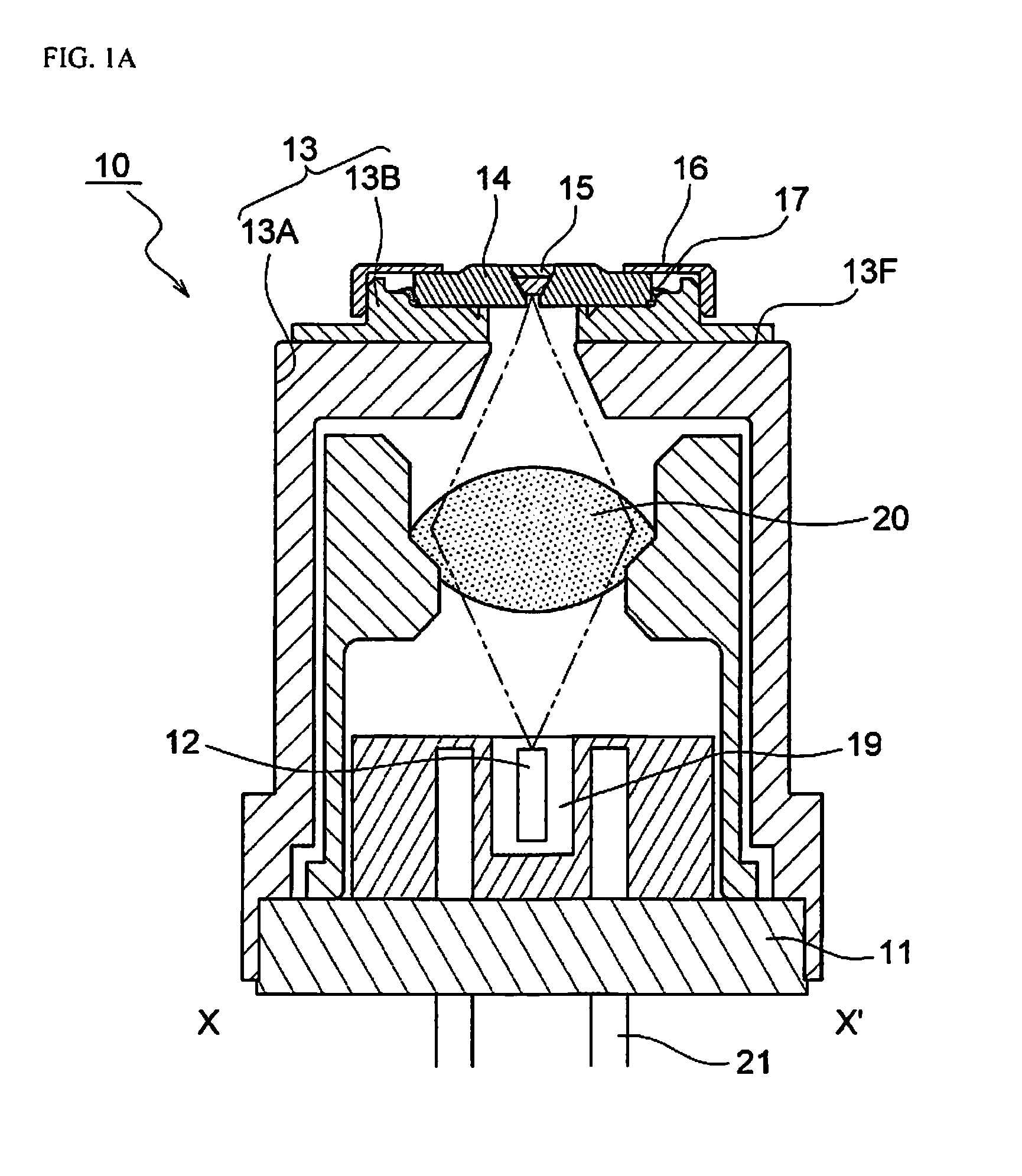

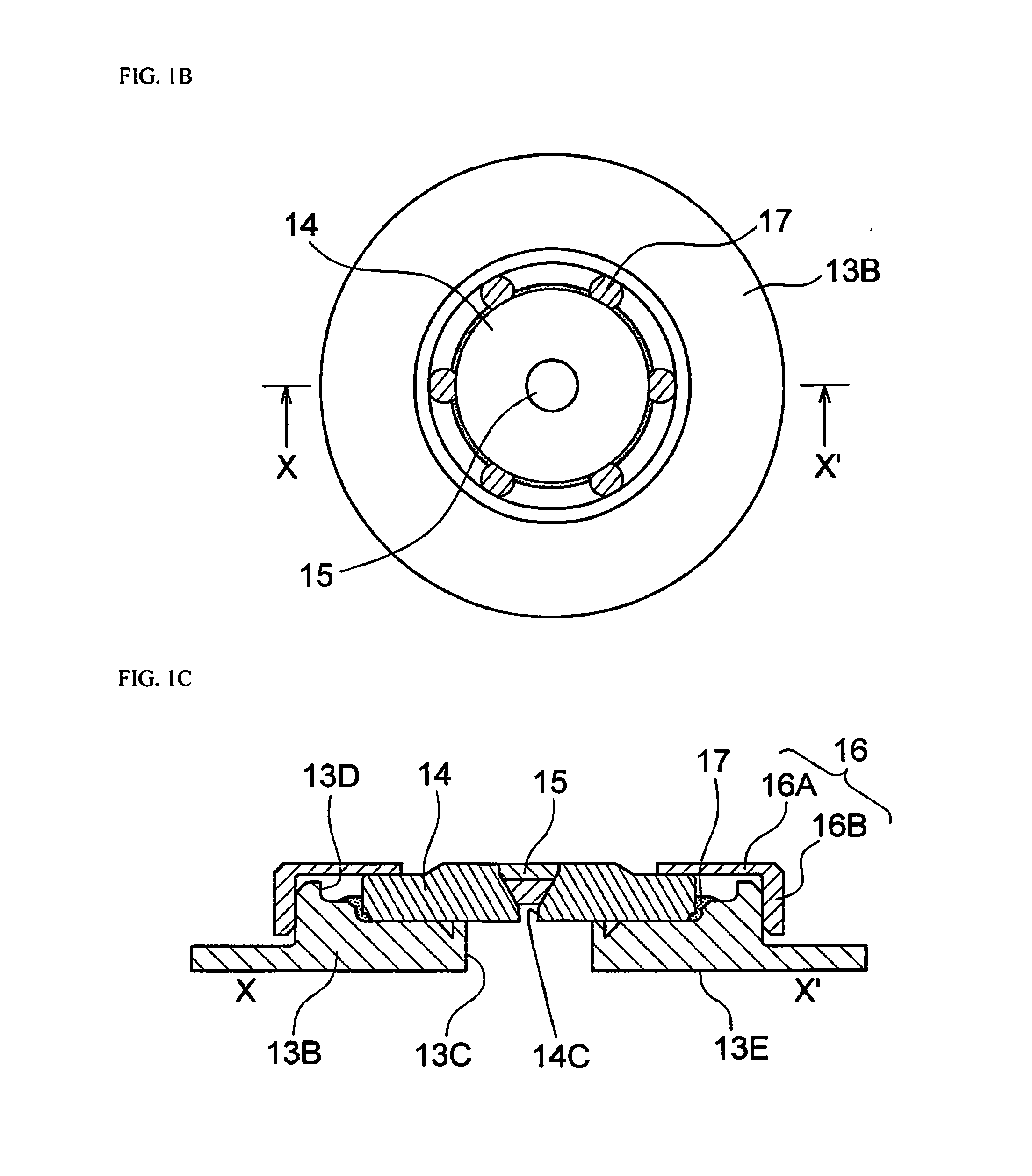

ActiveUS20170063032A1Less position shiftLess misalignmentLaser detailsVehicle headlampsThermal expansionEngineering

A semiconductor laser device includes a base, a semiconductor laser element, a lid, a support member, a wavelength converting member, a holding member, and a buffer material. The lid has a recess formed in an upper portion of the lid, and a through-hole formed in the bottom of the recess. The support member is disposed in the recess and has a through-hole. A diameter of the through-hole of the support member is smaller than that of the through-hole of the lid. A coefficient of thermal expansion of the support member is different from that of the lid. The wavelength converting member is supported in the through-hole of the support member. The holding member is fixed to the lid and holds the support member. The buffer material is disposed in at least a part of a space to between the lateral surfaces of the recess and the support member.

Owner:NICHIA CORP

X-ray CT apparatus

InactiveUS7684537B2Complicating control of X-rayIncrease exposureMaterial analysis using wave/particle radiationRadiation/particle handlingStart timeCardiac cycle

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

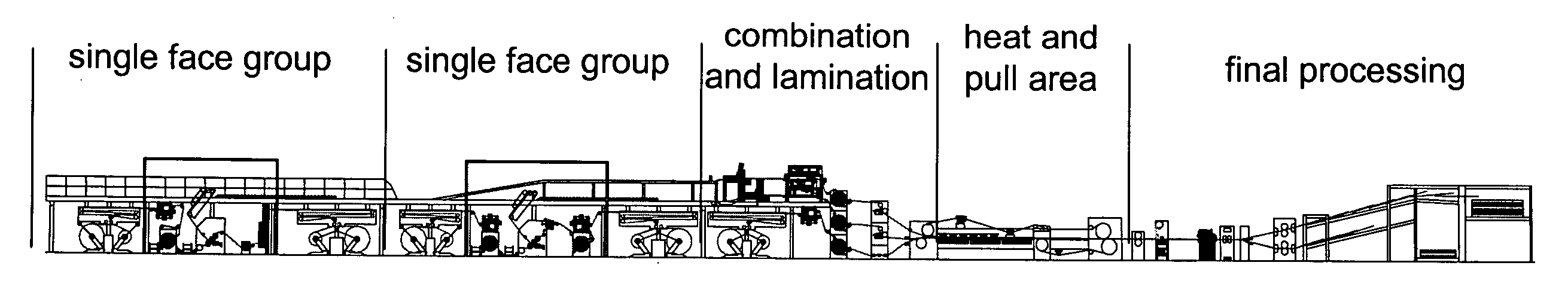

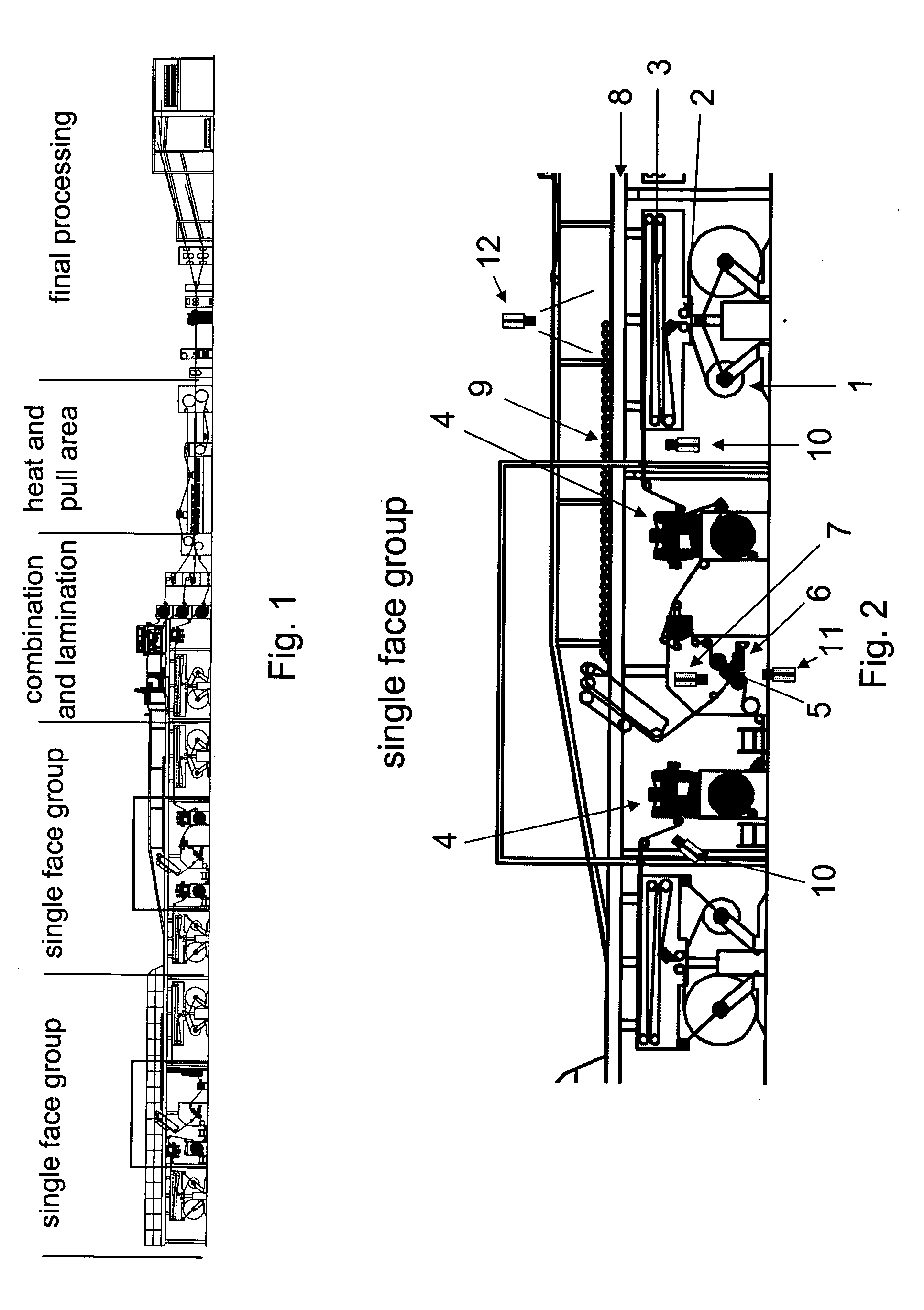

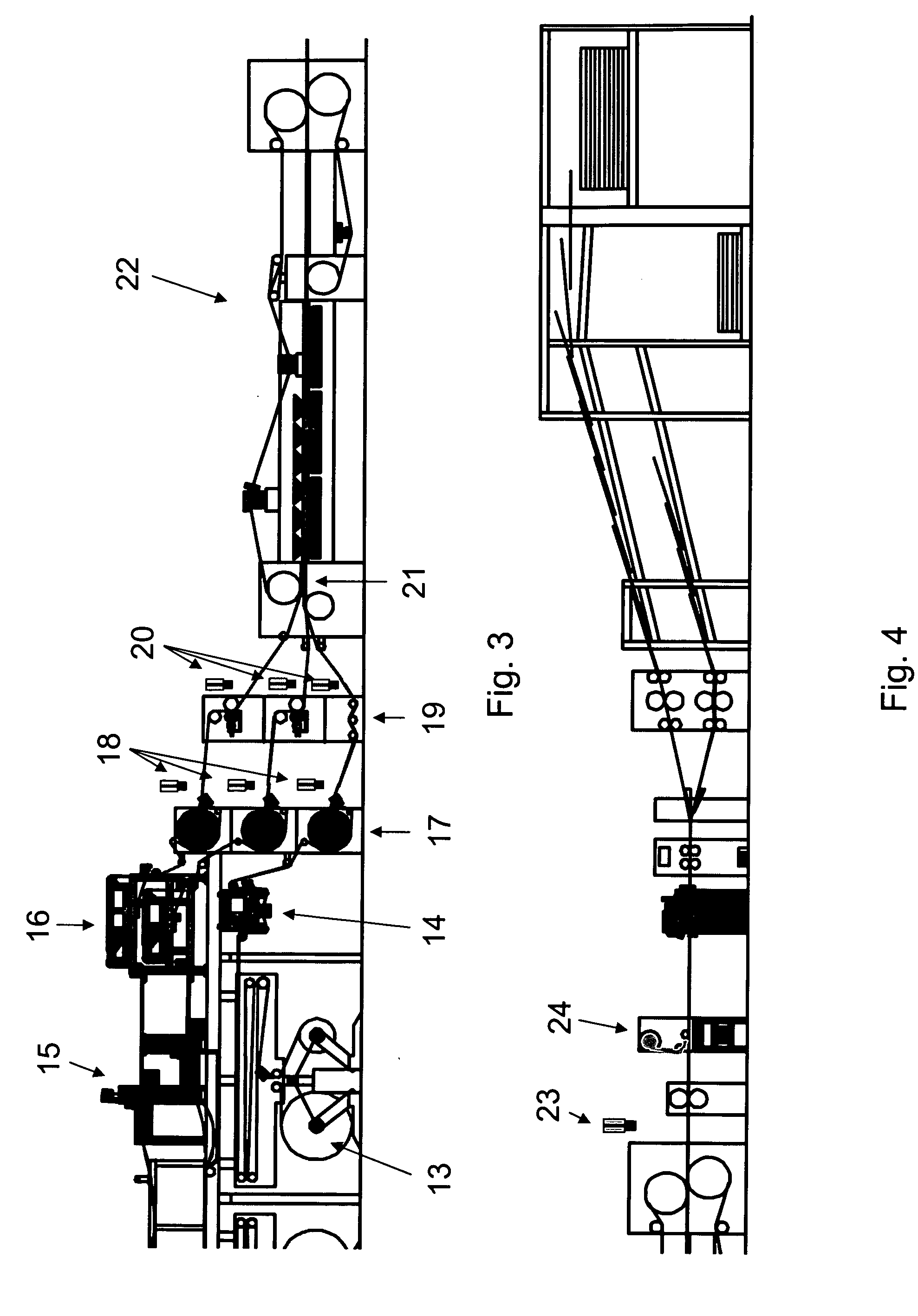

Method and system for position control of webs and corrugated board with a natural edge

InactiveUS20070137788A1Improve manufacturing precisionEasy to controlAdhesive processesMechanical working/deformationPosition controlElectrical and Electronics engineering

The invention relates to a method and a system for position control of one or more webs, particularly of paper-like or board-like webs, which are preferably used in manufacturing corrugated board and corrugated board which has a natural edge. For controlling the web position by means of position manipulation apparatuses, position information is used, which is detected downstream by position detection means.

Owner:TEXMAG GMBH VERTRIEBS

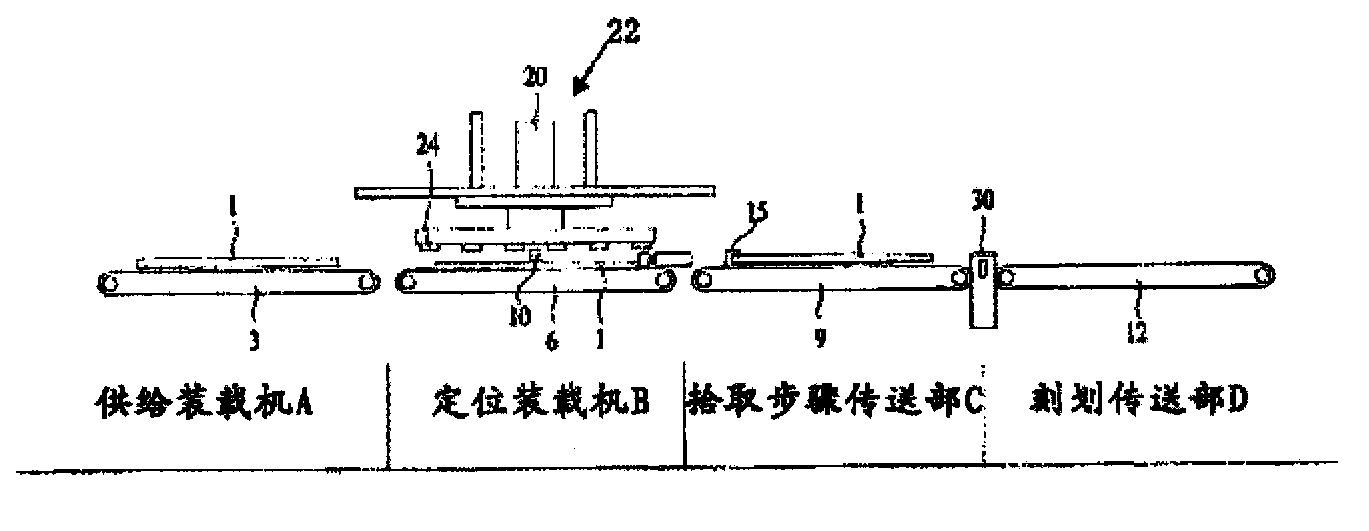

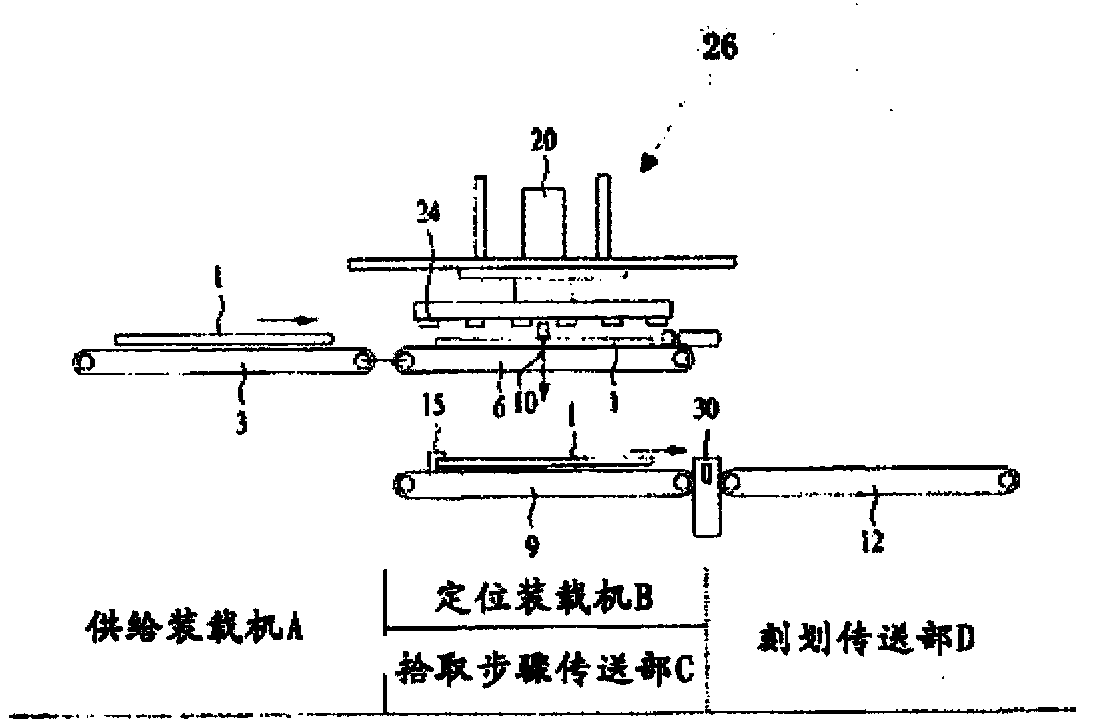

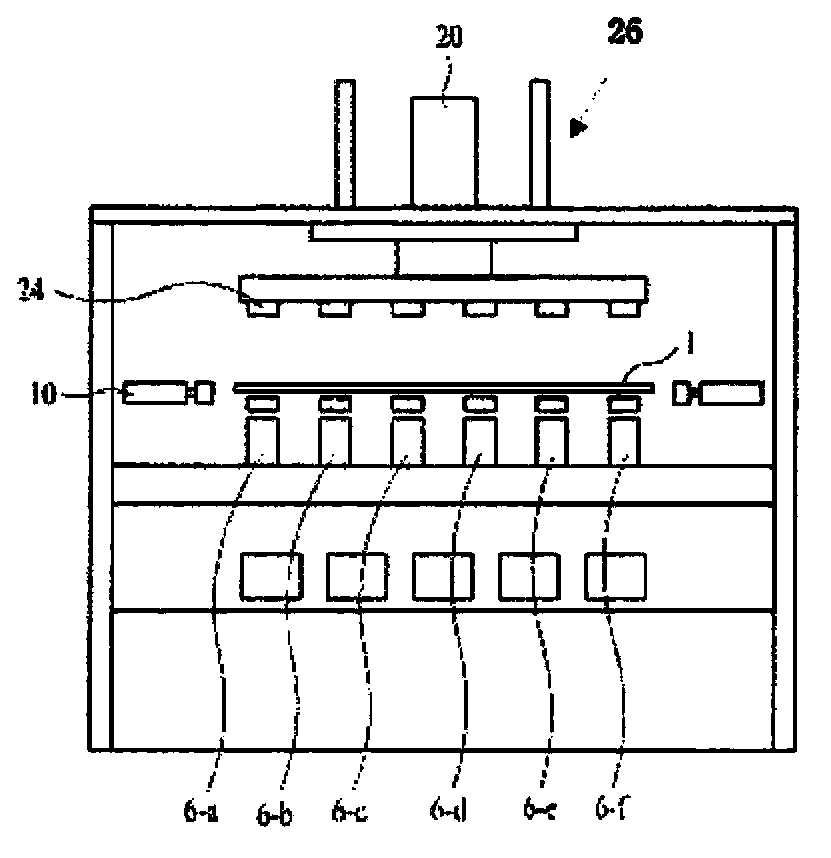

Vertical conveying device of substrate

InactiveCN103449179AReduce positional offsetSave setup spaceGlass transportation apparatusCharge manipulationEngineeringMechanical engineering

The invention discloses a vertical conveying device of a substrate capable of preventing the displacement of the substrate from the positioning part to the pick-up part during the weight shifting. The vertical conveying device is provided with a supporting member, a positioning loading machine used to adjusting a positioning part loaded on the substrate of the supporting member, and an absorbing elevating unit capable of absorbing and elevate the substrate of the supporting member, and a pick-up step transmitting part capable of conveying the substrate to the etching unit under the pick-up state of the pick-up member. With the help of the falling operation of the absorbing elevating unit, the weight shifting of the substrate from the positioning loading machine to the pick-up transmitting part can be finished.

Owner:MITSUBOSHI DIAMOND IND CO LTD

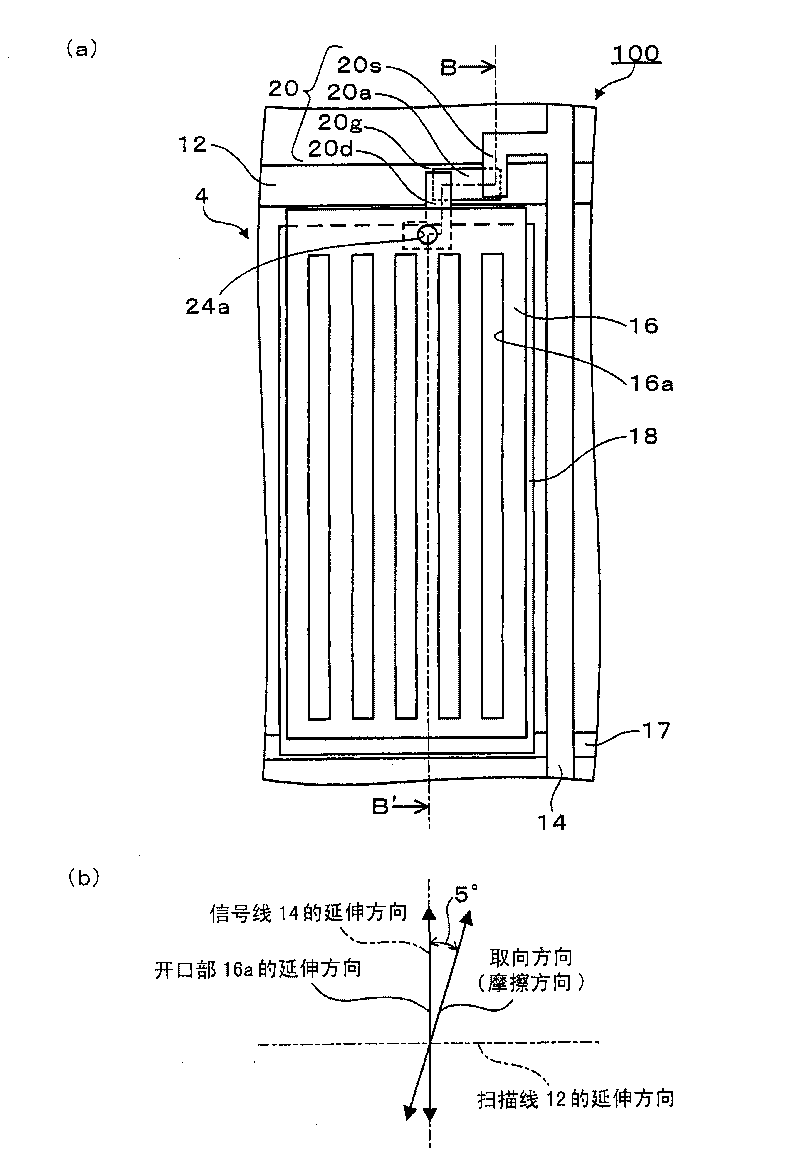

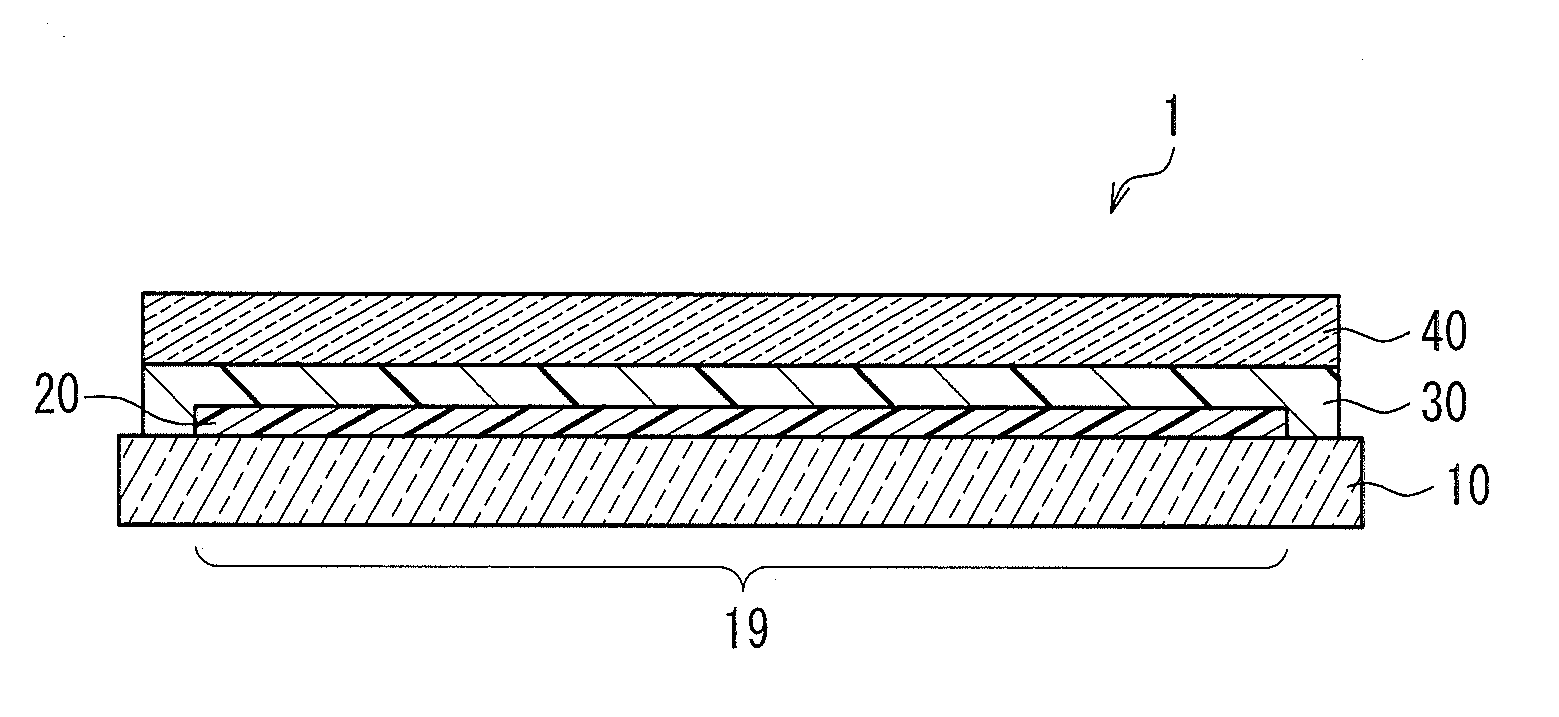

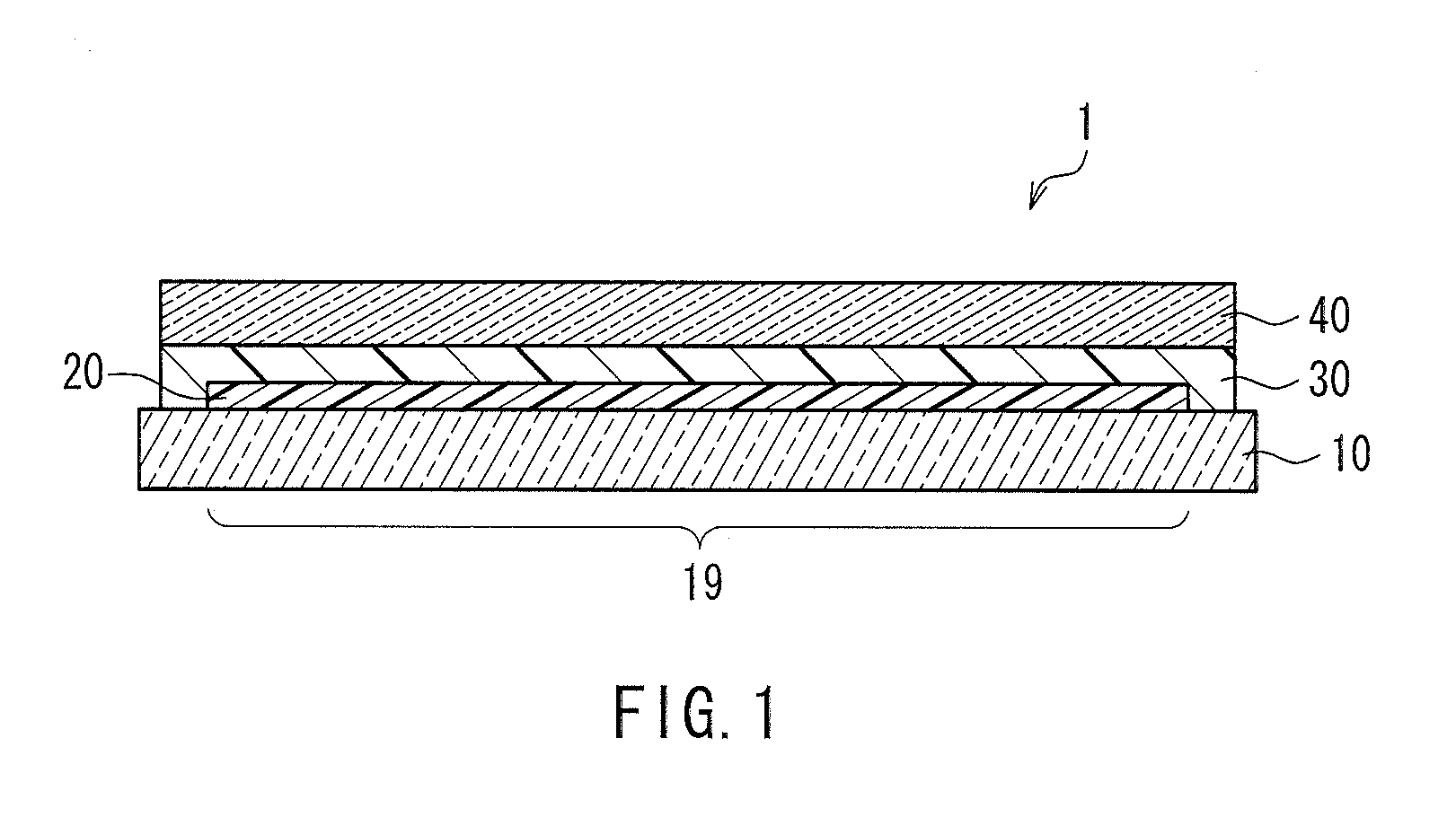

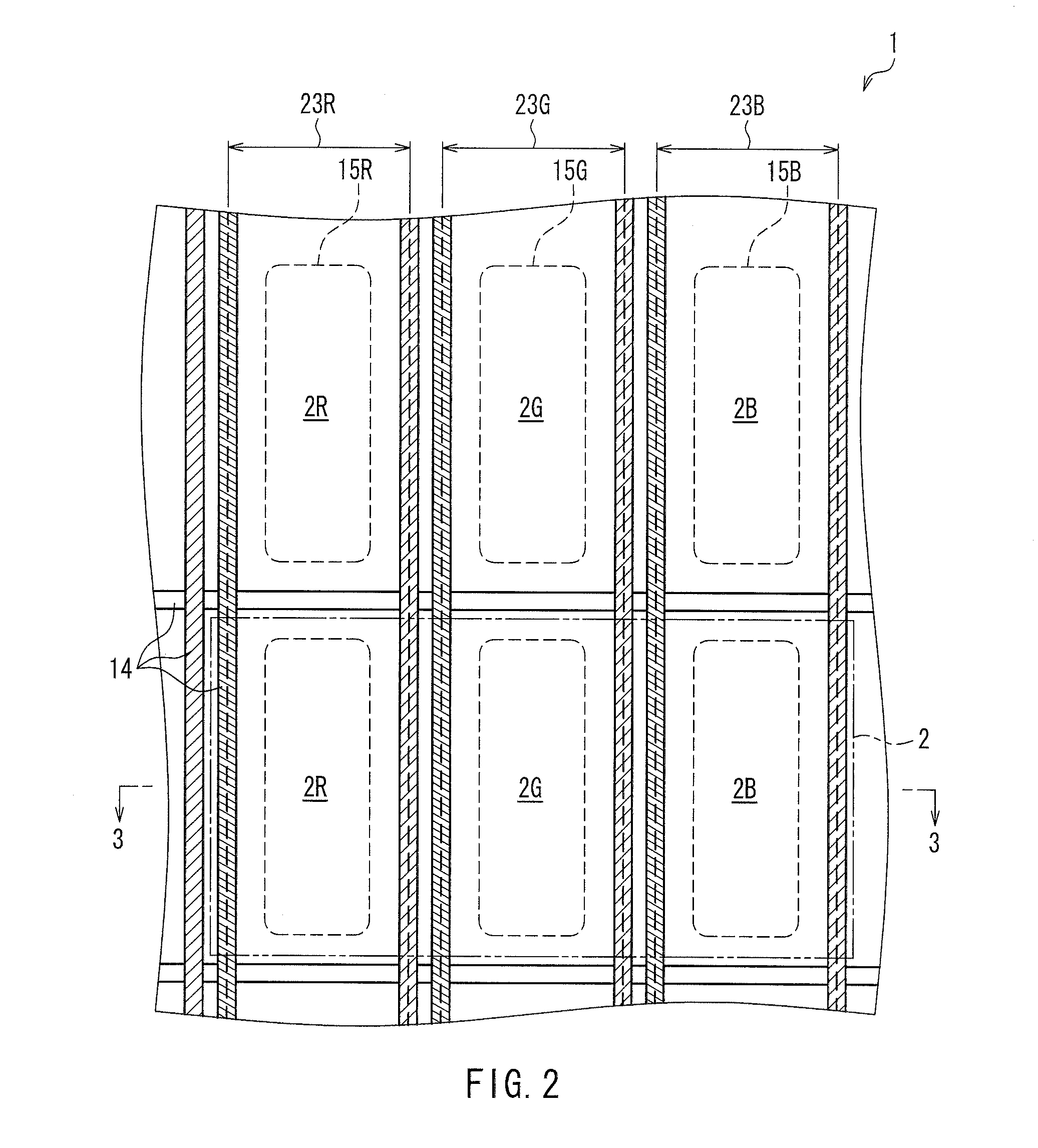

Method of manufacturing liquid crystal device and liquid crystal device

InactiveCN101718924AReduce positional offsetPolarising elementsNon-linear opticsLiquid-crystal displayOptical axis

The present invention provides a liquid crystal device manufacturing method for reducing the position deviation of an optical shaft of a liquid crystal unit and an optical shaft of a polarization optical plate and a liquid crystal device. The liquid crystal device manufacturing method includes: a working procedure for preparing the liquid crystal unit having a liquid crystal layer clamped between an element substrate and a contraposition substrate which are opposite to each other, at least one position arranged at the element substrate, and a wire grating polariscope with polarized light separating function; a first working procedure, under the state of contraposition of a polarized light plate with the outer side of the element substrate of the liquid crystal unit, at least one of the liquid crystal unit and the polarized light plate rotates in the contraposition surface, for detecting the intensity of light which passes through a region arranged with wire grating polariscope of the liquid crystal unit and the polarized light plate; and a second working procedure, according to the detection result of the intensity of the light, for determining the position relationship of the polarized light plate relative to the wire grating polariscope in the opposite surfaces, and adhering the polarized light plate on the element substrate of the liquid crystal unit.

Owner:SEIKO EPSON CORP

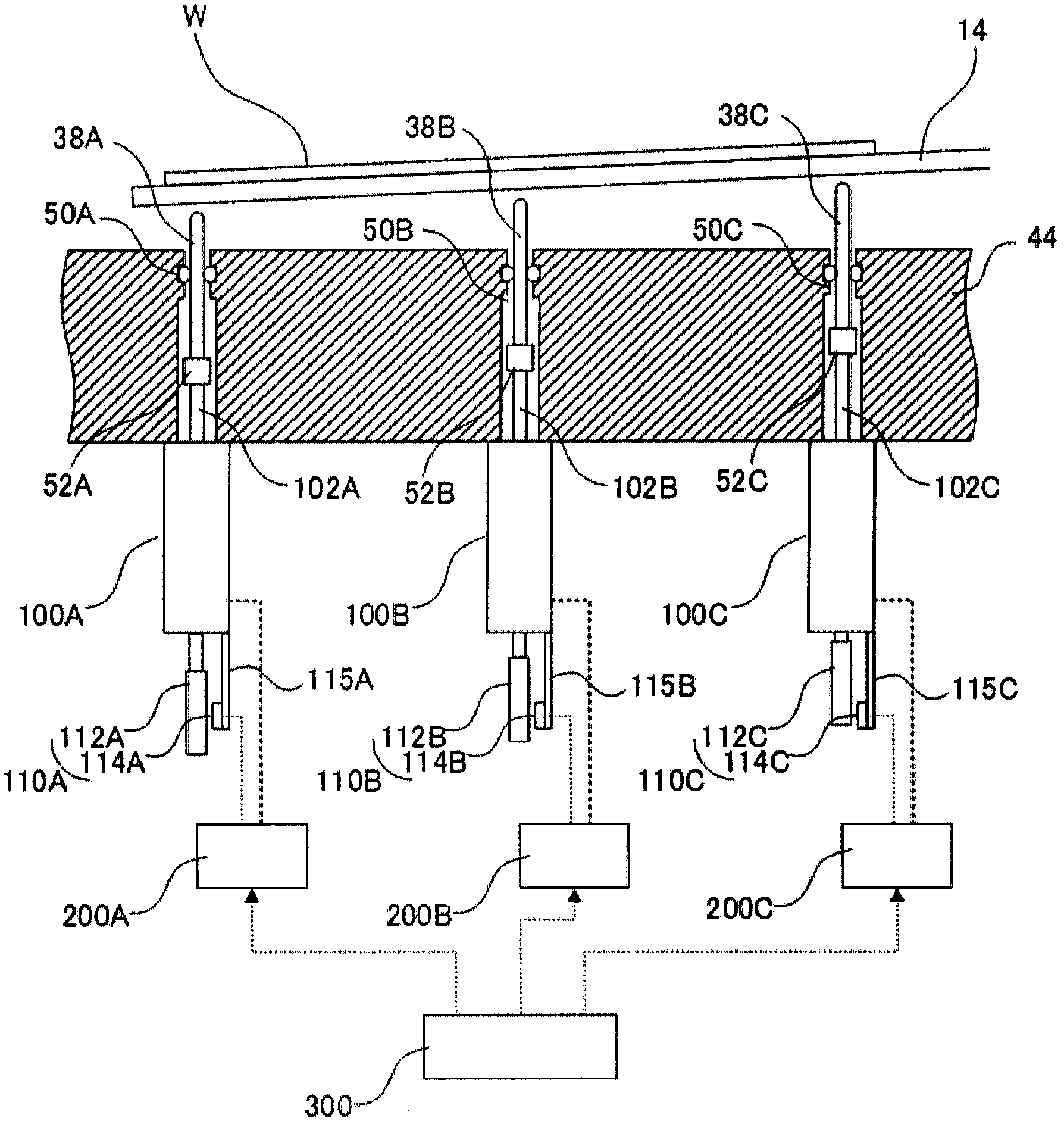

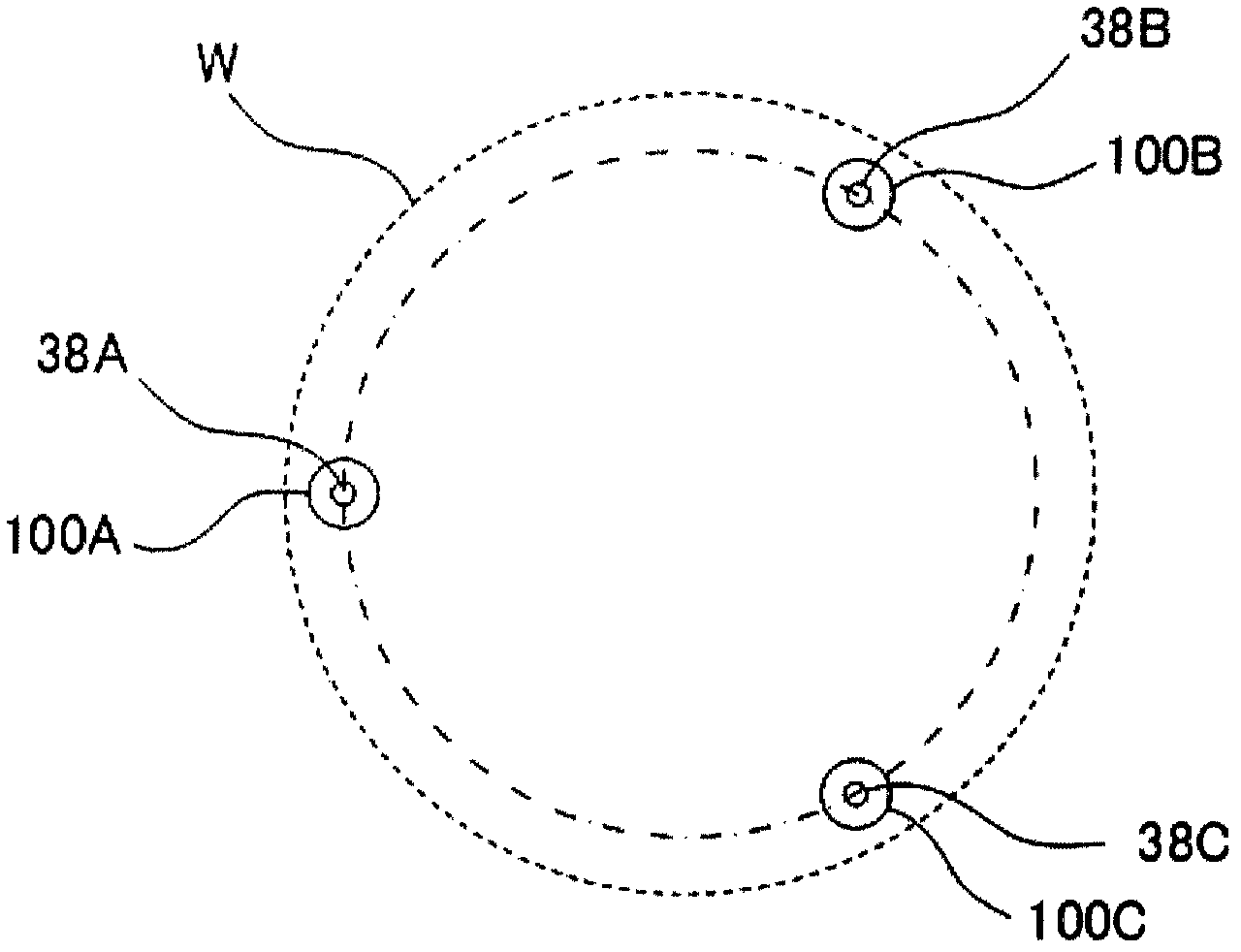

Processing-object-supporting mechanism, supporting method, and conveying system including the mechanism

InactiveCN102214593AReduce positional offsetPosition control does not changeSemiconductor/solid-state device manufacturingConveyor partsDrive motorControl theory

The invention provides a processing-object-supporting mechanism and supporting method for minimizing the configuration space of the supporting mechanism so as to benefit downsizing of the whole processing device and substantially reduce the position offset of the processing object in moving between the carrying arms. Particularly, the processing-object-supporting mechanism is characterized by having N (N is an integer of more than 3) groups of lift pins (38) in contact with the processing object (W) for supporting, a motor (100) making the lift pins (38) to lift, and a unit composed of a drive controller (200) of the drive motor (100). The drive controller (200) of each of the N groups of units is configured to control the motor (100) of each of the unit independently.

Owner:YASKAWA DENKI KK

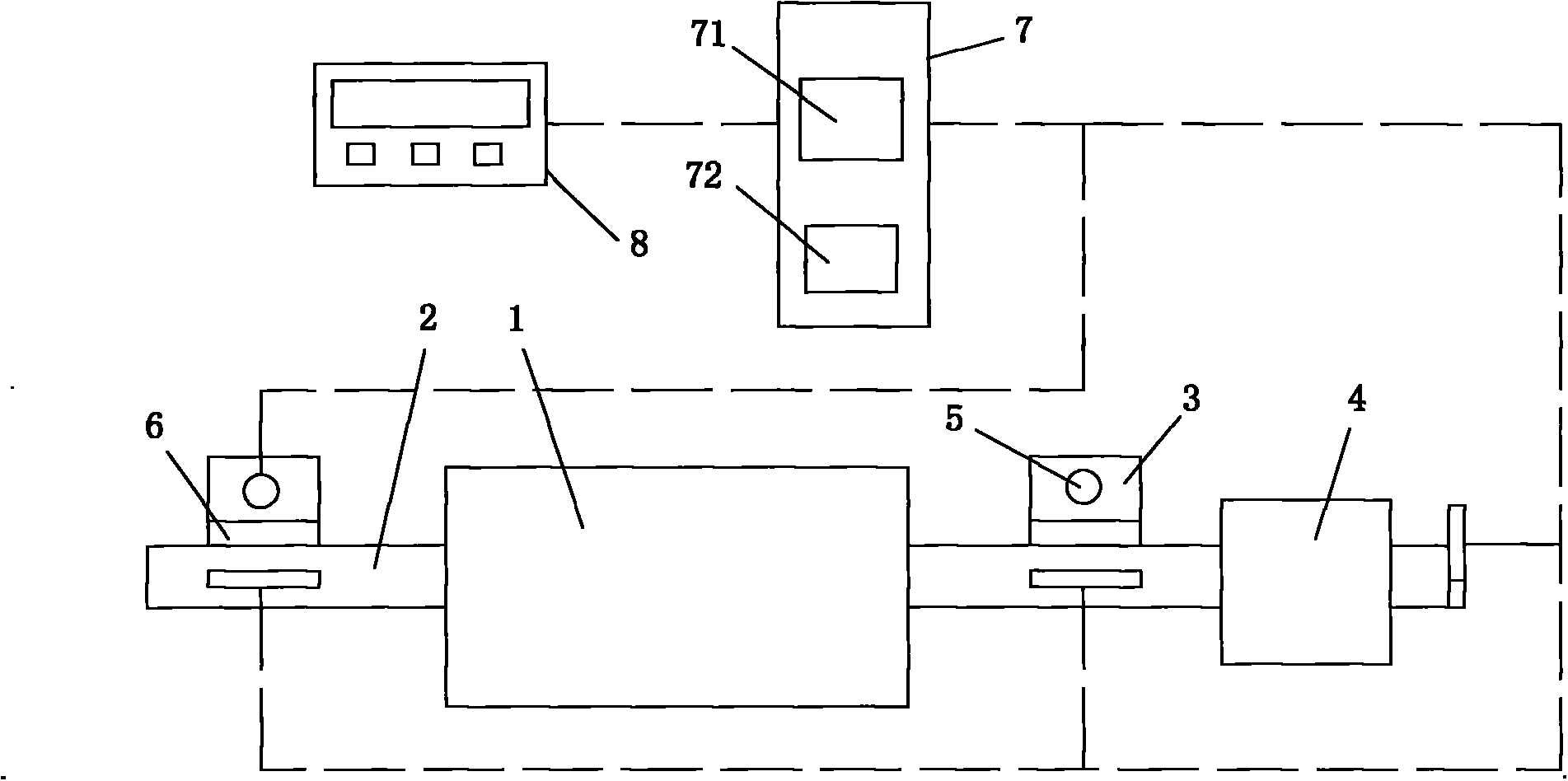

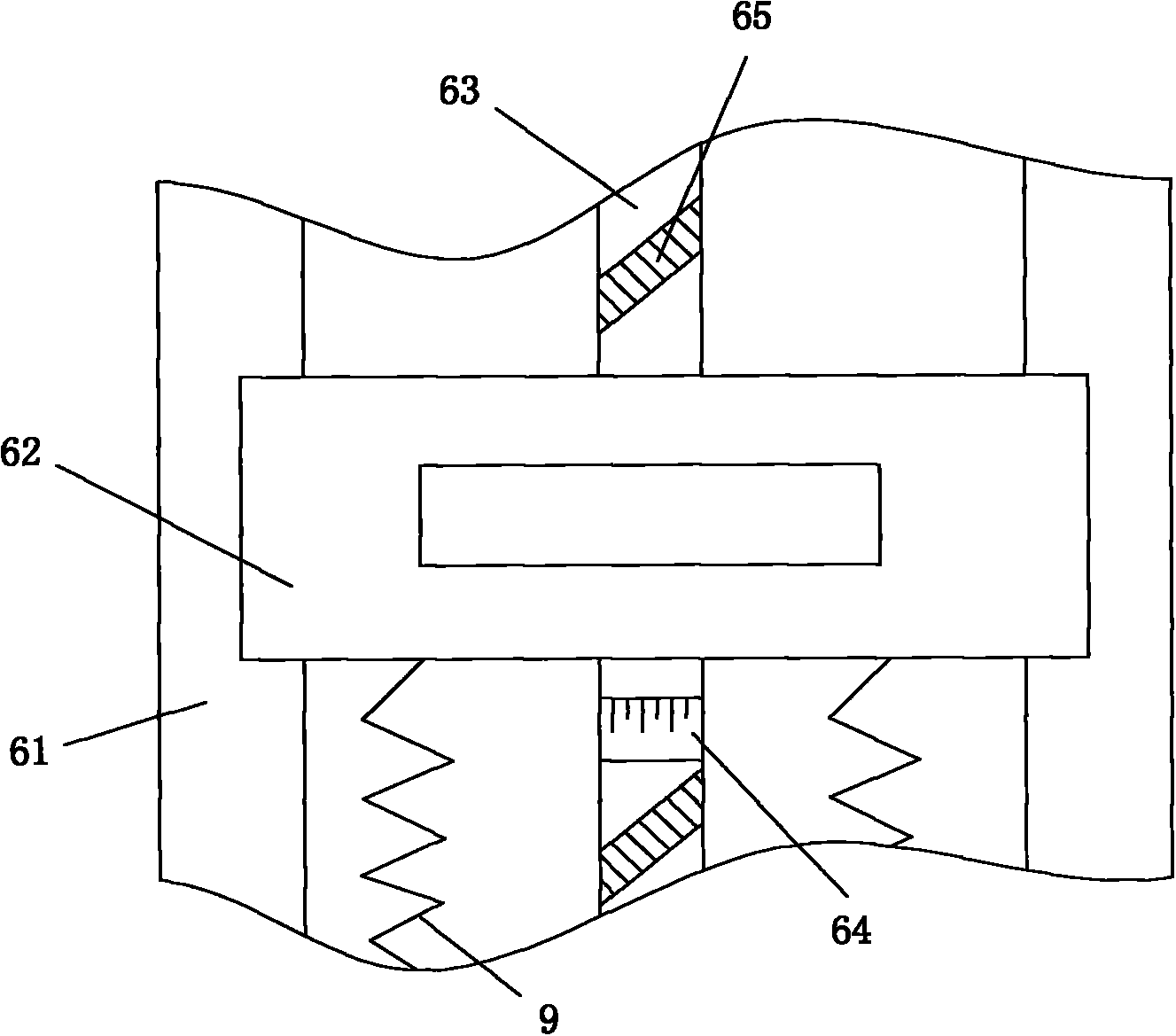

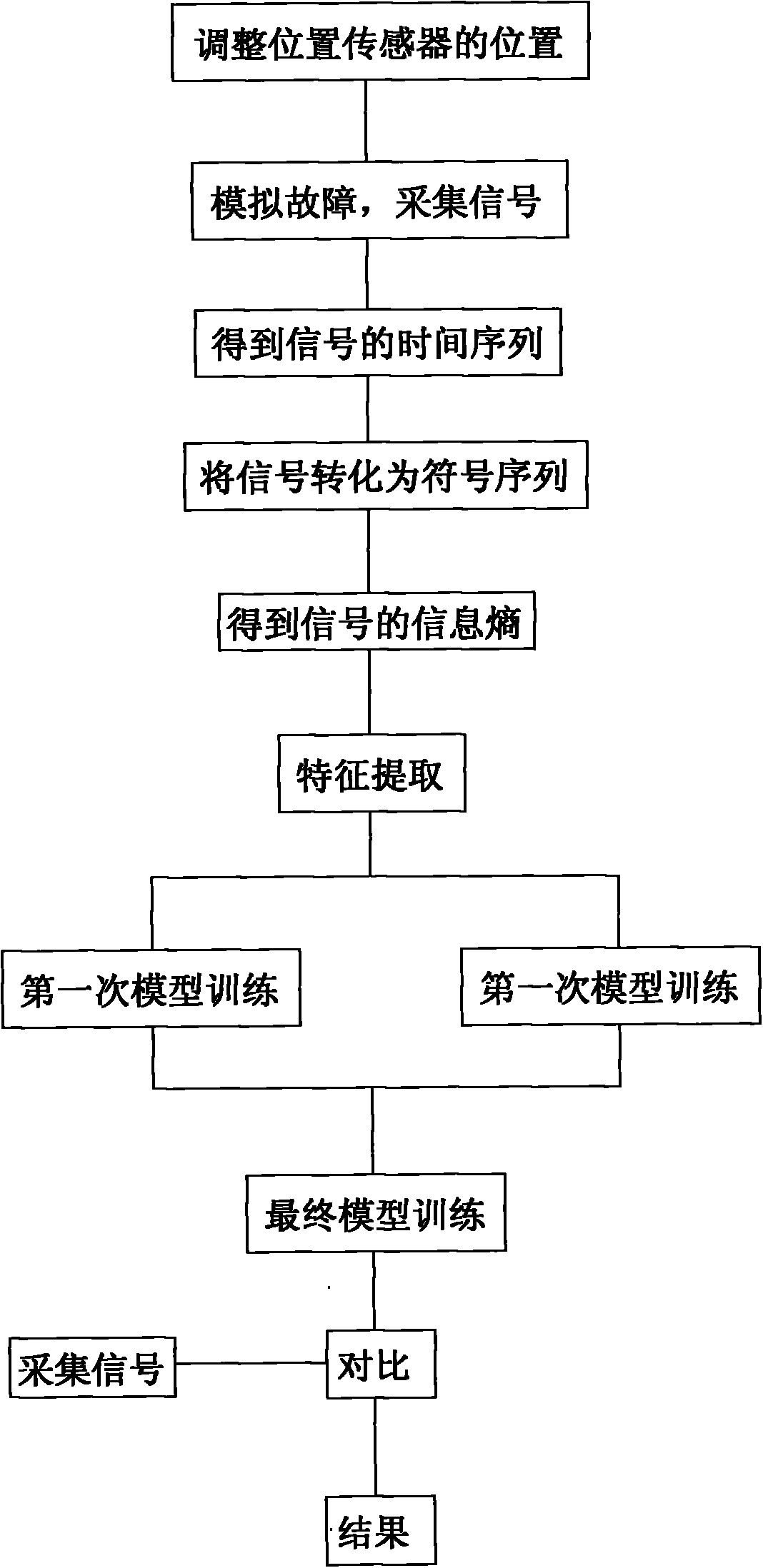

Draught fan failure detection apparatus and method

InactiveCN104343709AAvoid position shiftReduce the effects of noiseEngine fuctionsPump controlEngineeringTime series

The invention discloses a draught fan failure detection apparatus and method. The draught fan failure detection apparatus structurally comprises a position adjusting unit and a vibration acquisition frame arranged on the position adjusting unit. A displacement sensor connected to a processing host is arranged on the vibration acquisition frame. The draught fan failure detection method with the draught fan failure detection apparatus includes the steps of A adjusting the position of the displacement sensor; B, simulating draught fan failure and collecting a failure signal; C, obtaining a time series of the failure signal; D, converting the time series into a symbol sequence; E, calculating information entropy of the symbol sequence; F, extracting a feature vector; G, performing a first model training; H, performing a second model training; I, obtaining a final training model; J, formally running a draught fan and comparing the signal with the final training model to obtain failure information. According to the draught fan failure detection apparatus and method, a vibration acquisition device is arranged reasonably and symbolization processing is performed on the acquired vibration signal to obtain a comparative database and reduce the impact of noise, so that the computation speed is greatly improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Multiphase superconducting cable connection structure and multiphase superconducting cable line

InactiveUS7265297B2High strengthAvoid Positioning OffsetSuperconductors/hyperconductorsCable fittings for cryogenic cablesElectrical conductorMulti phase

A multiphase superconducting cable connection structure includes a connection box accommodating three conductor connects connecting a superconductor of a cable core of each phase extracted from a pair of 3-phase superconducting cables, a solid insulation member fixed to an outer circumference of each conductor connect, and a metal flange fixing the solid insulation member to the connection box. By fixing the metal flange to the connection box (a refrigerant vessel), the conductor connect can be positioned and the conductor connector's movement caused as the cable core thermally contracts can be reduced. The structure can help to position the conductor connect in the connection box and reliably hold it at a prescribed position.

Owner:SUMITOMO ELECTRIC IND LTD

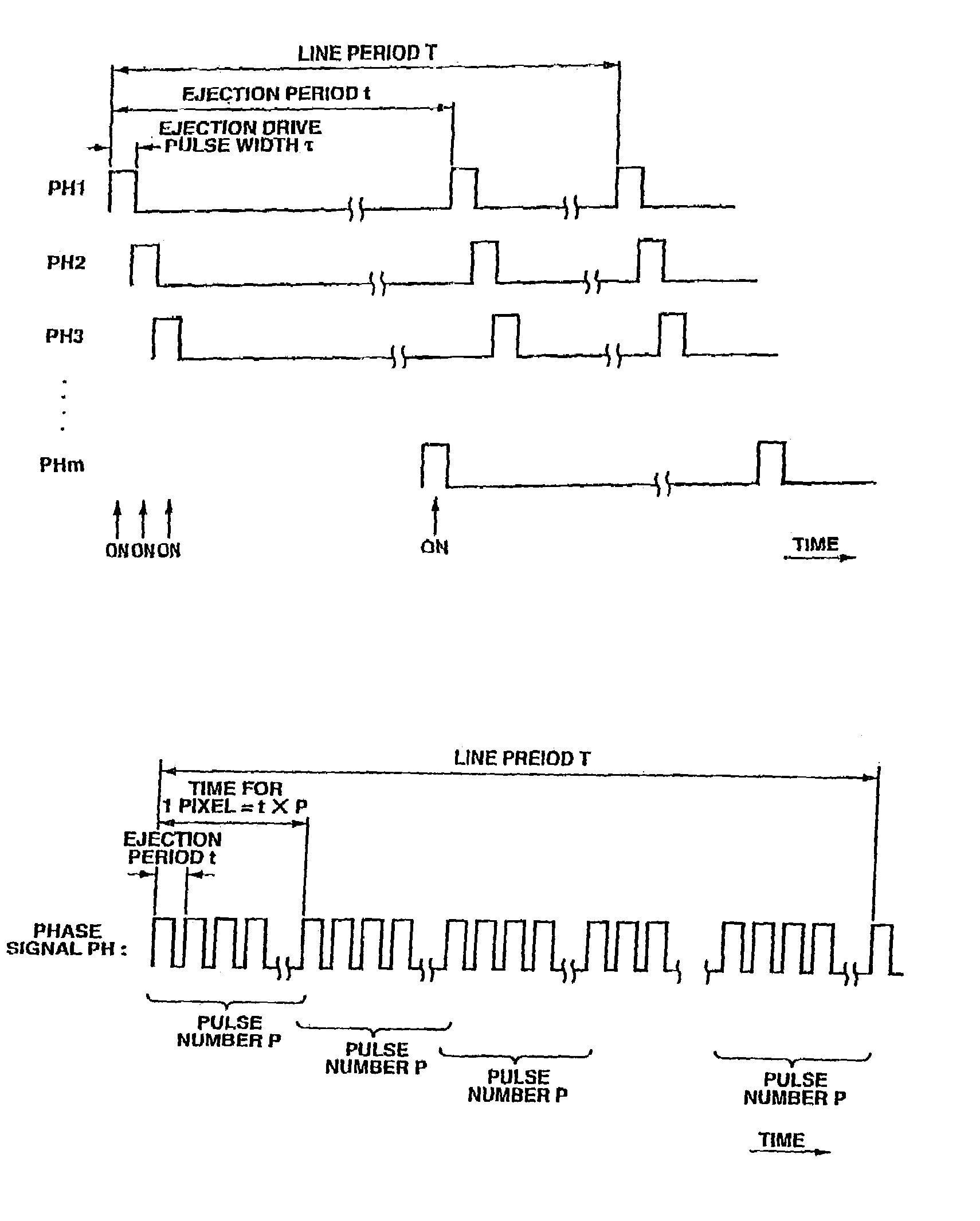

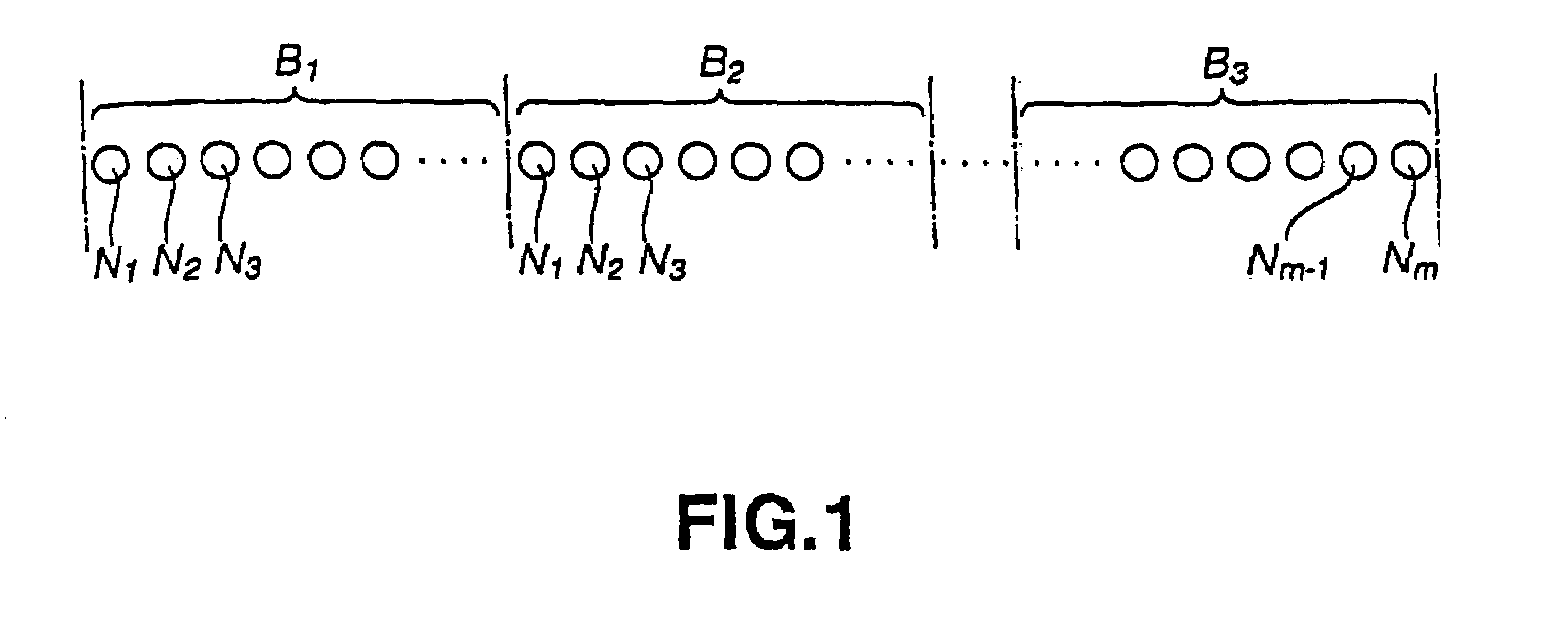

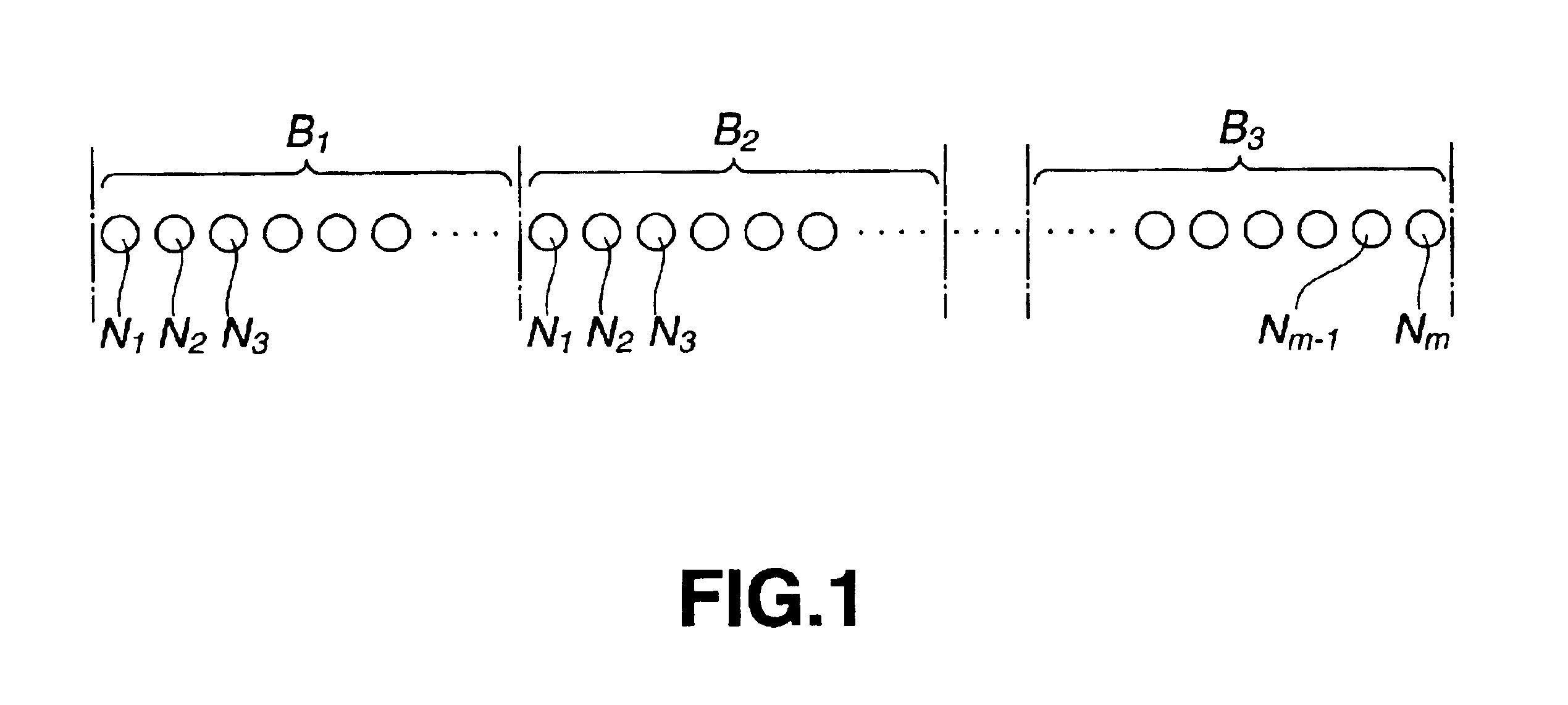

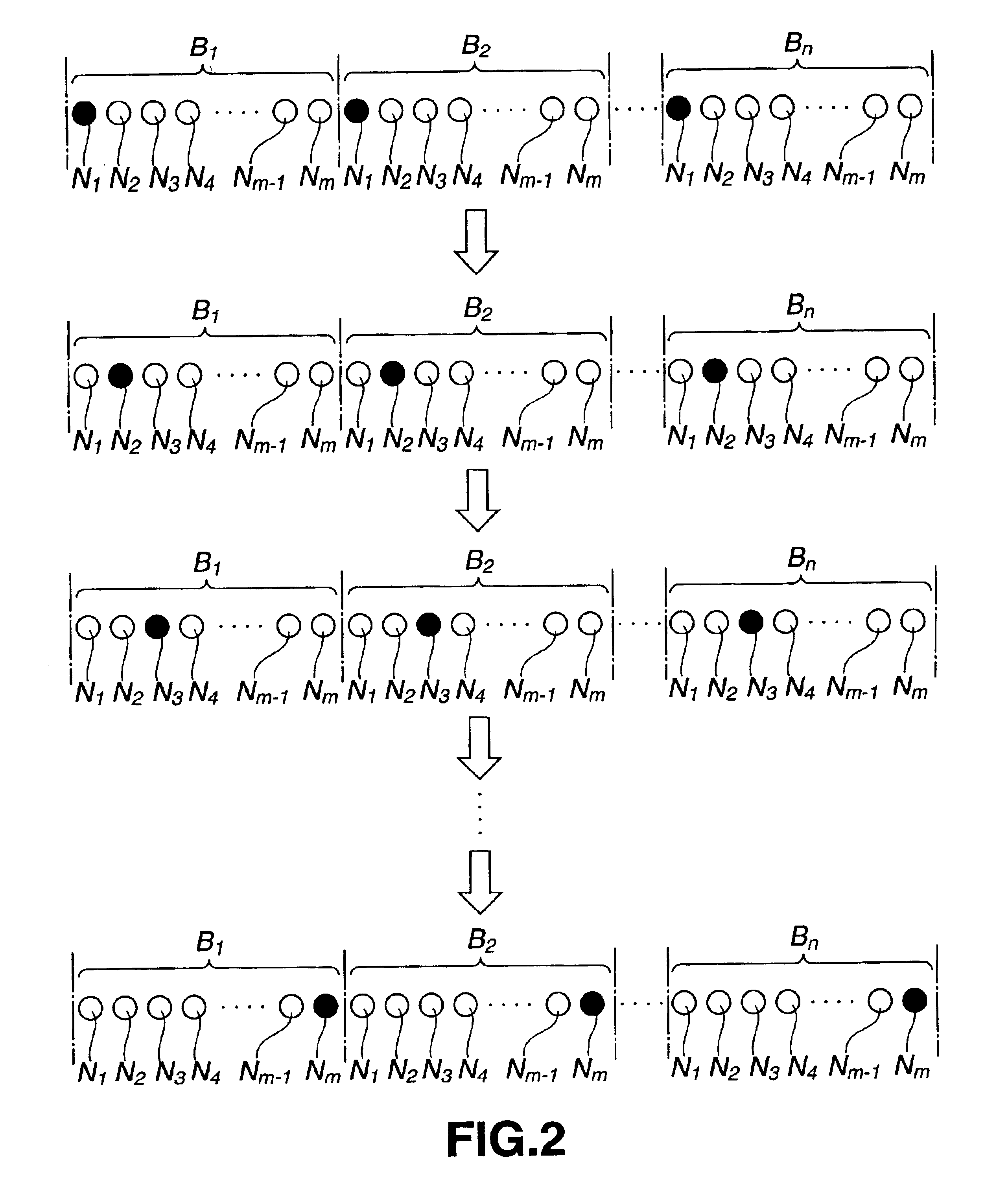

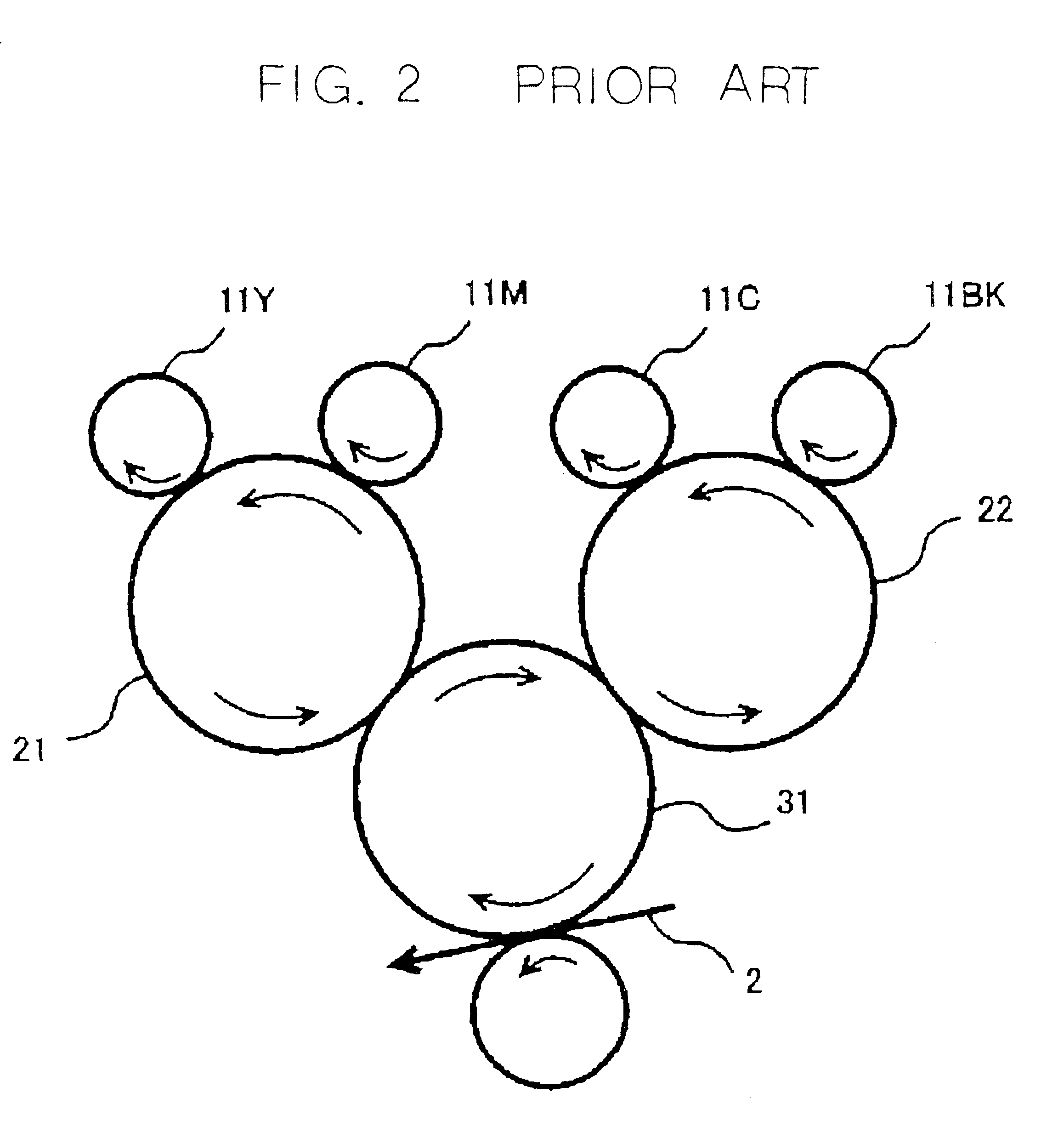

Recording head driving method, recording head, ink-jet printer

InactiveUS6890060B2Reduce positional offsetMaximum dissipation powerElectric signal transmission systemsInking apparatusPaper sheetHeating element

An ink jet printer has a line head having heating elements (121d) for ejecting ink droplets from nozzles, in which the plurality of heating elements (121d) are arrayed in a direction substantially perpendicular to the paper feed direction. In the line head, the plurality of heating elements (121d) are divided into a plurality of blocks, with each block consisting of a predetermined number of spatially arrayed heating elements of the plurality of heating elements (121d) corresponding to the plurality of nozzles, and a phase signal PH is sequentially supplied to a set of heating elements (121d) simultaneously driven over the respective blocks, thus sequentially driving the respective heating elements (121d) by each set as a unit in a time-divisional manner. Thus, the ink jet printer can reduce the positional shift of dots on the paper and can reduce the instantaneous maximum dissipation power in time-division drive.

Owner:SONY CORP

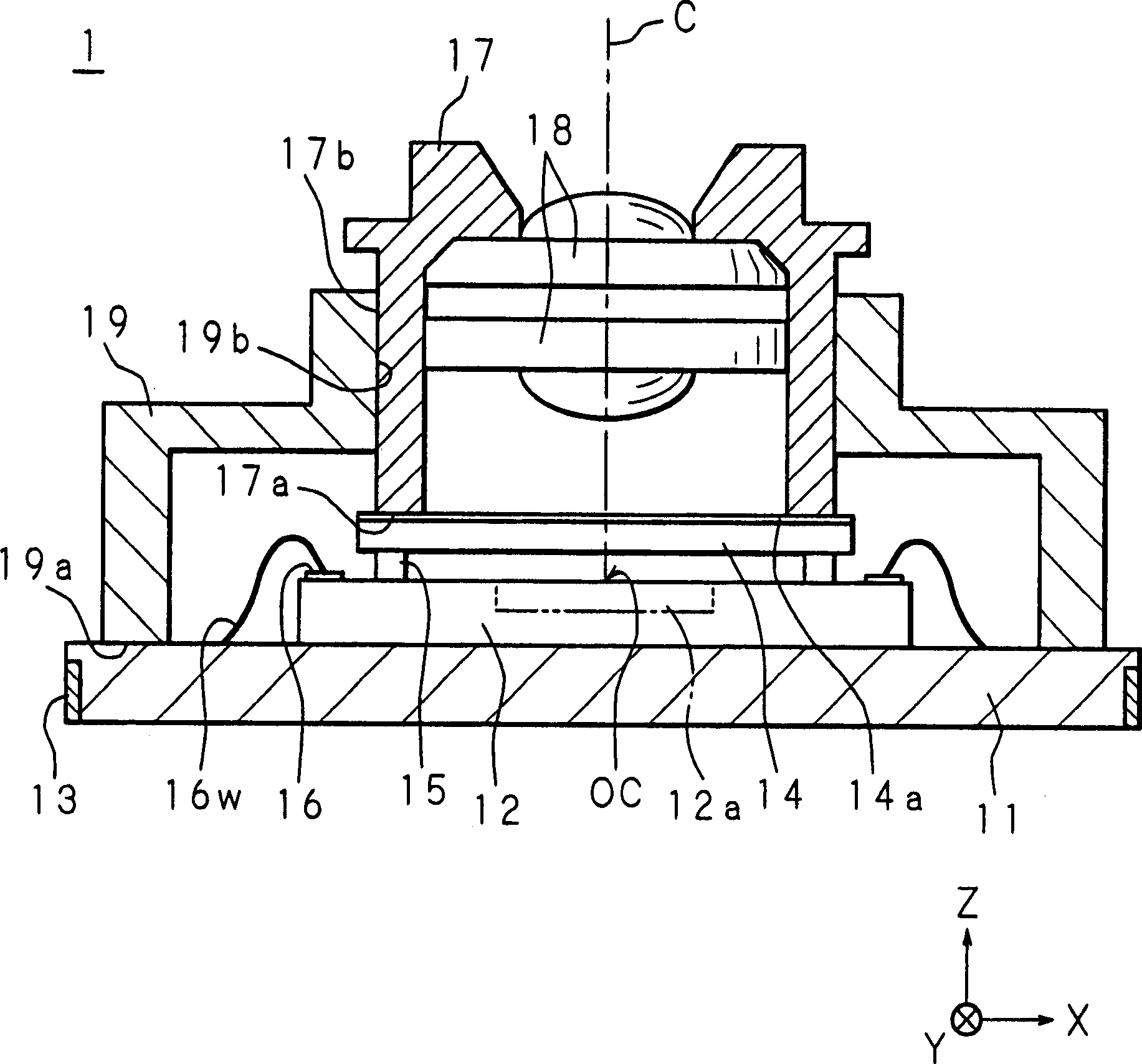

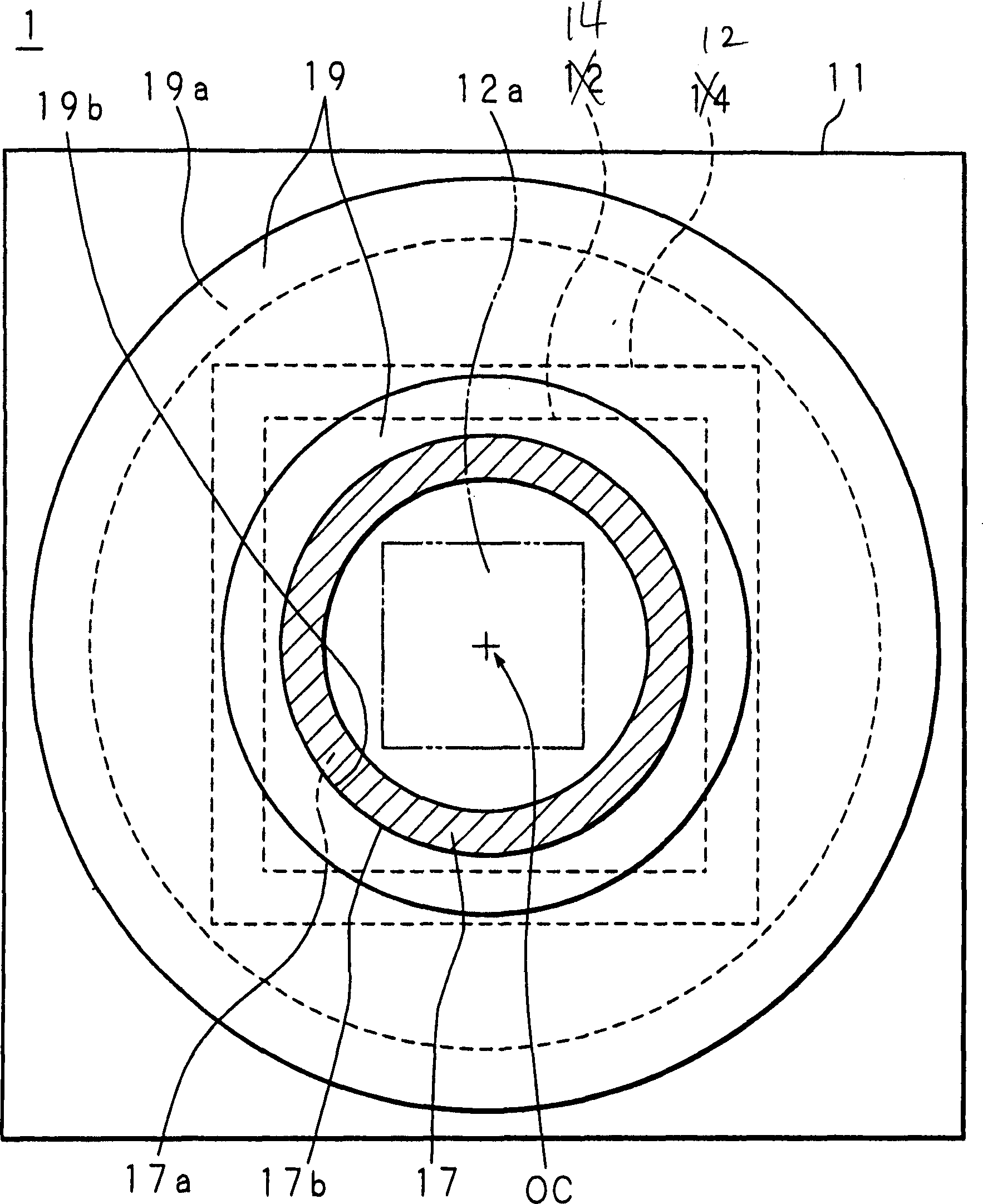

Image pickup module and manufacturing method of image pickup module

InactiveCN1783953AReliable focusReduce manufacturing costTelevision system detailsSolid-state devicesEngineeringMethod of images

The camera module (1) of the present invention is provided with a tubular cover (19) and a lens holder (17). The cover (19) is fixed (bonded) to the substrate (11) with its legs (19a) in contact with the surface of the substrate (11). Moreover, the lens holder (17) is inserted into the inner surface (19b) of the cover (19), the lens holder (17) is in contact with the transparent plate (14) at its foot (17a) and its outer surface (17b) is in contact with the inner surface of the cover In the state, the outer surface (17b) of the lens holder (17) is fixed (bonded) on the inner surface (19b) of the cover (19). A lens (18) guiding the path of incident light to the light receiving portion (12a) of the imaging element (12) is fixed at a predetermined position on the lens holder (17).

Owner:SHARP KK

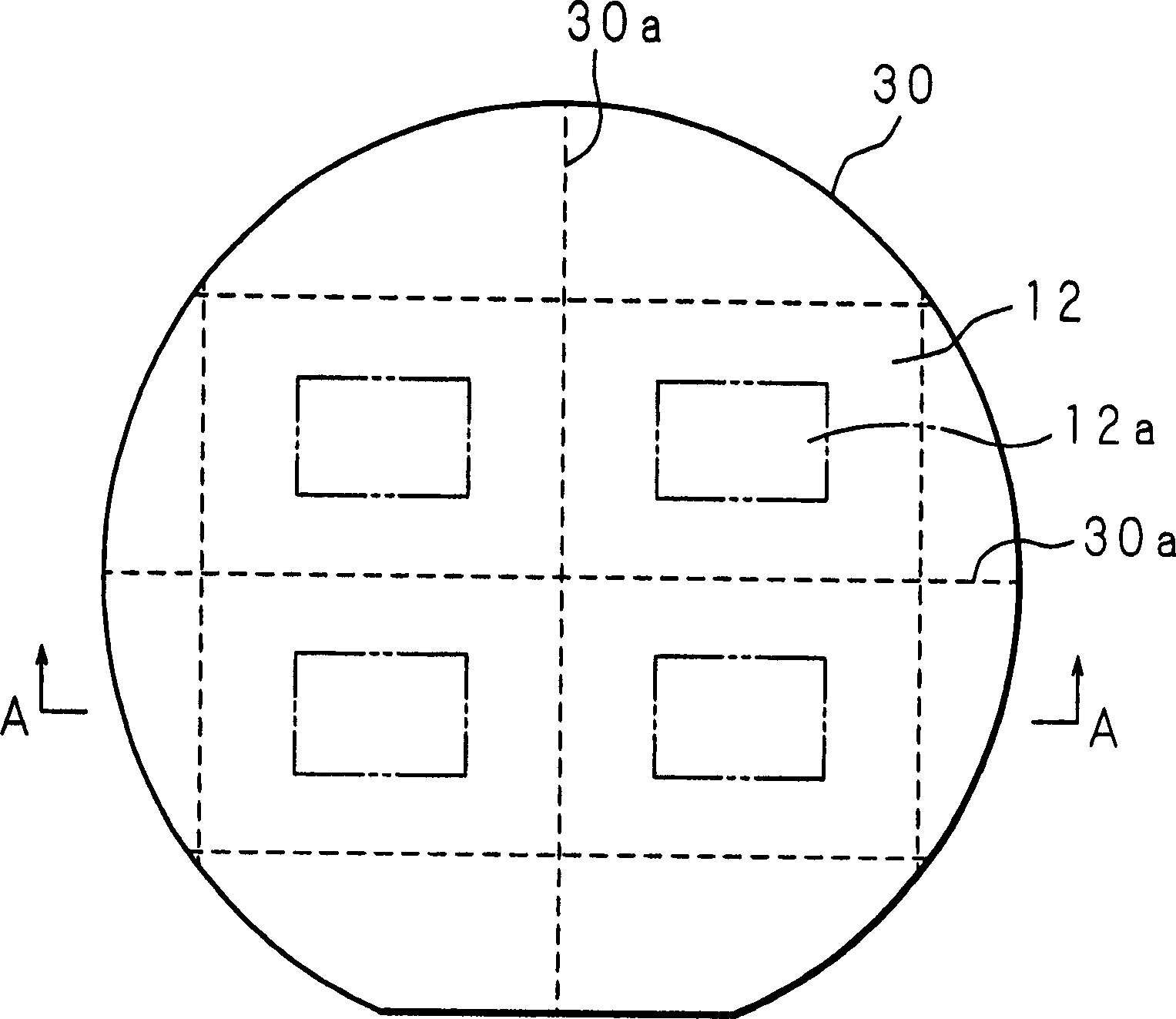

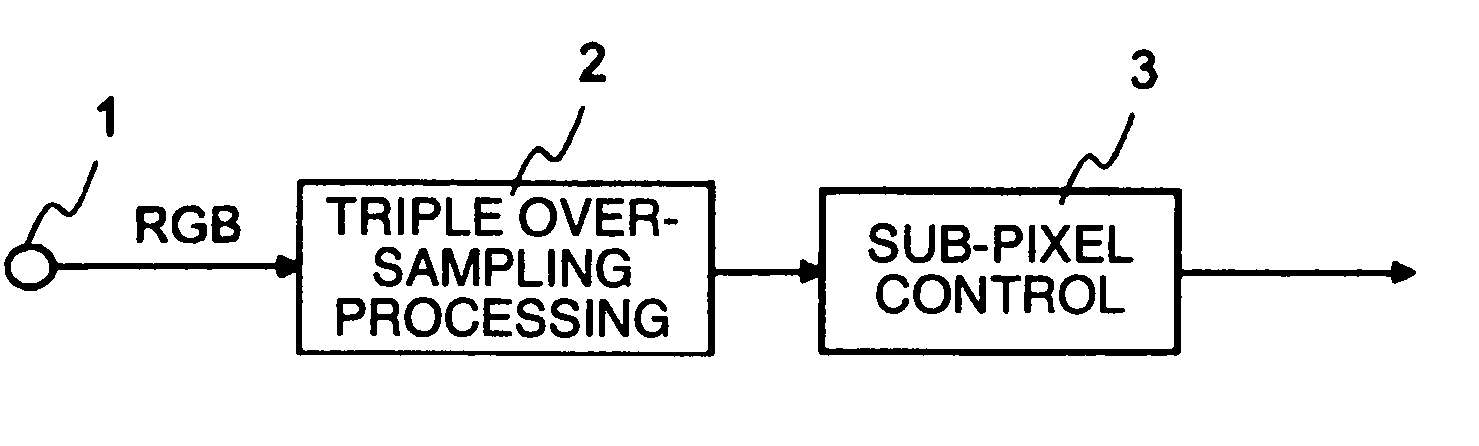

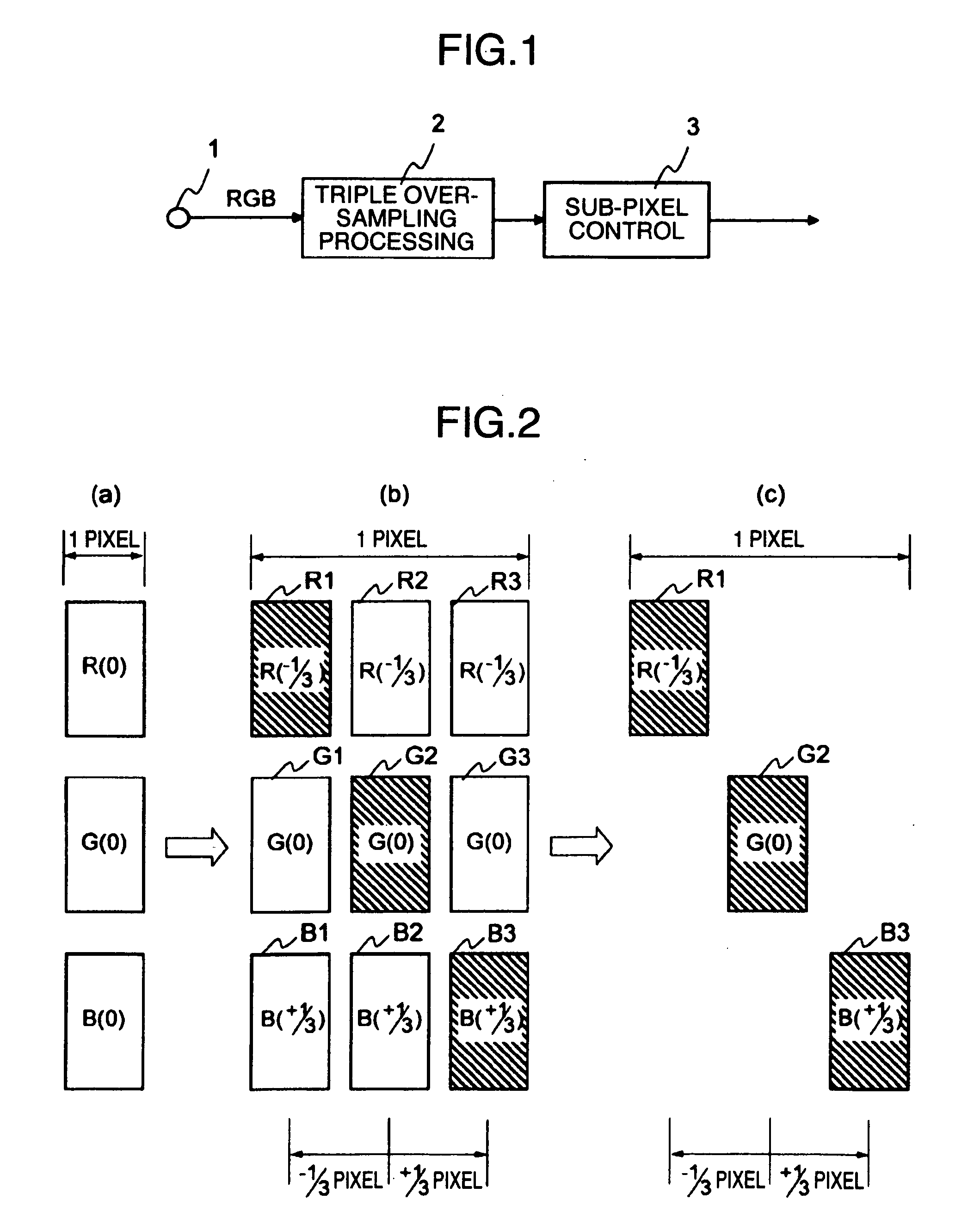

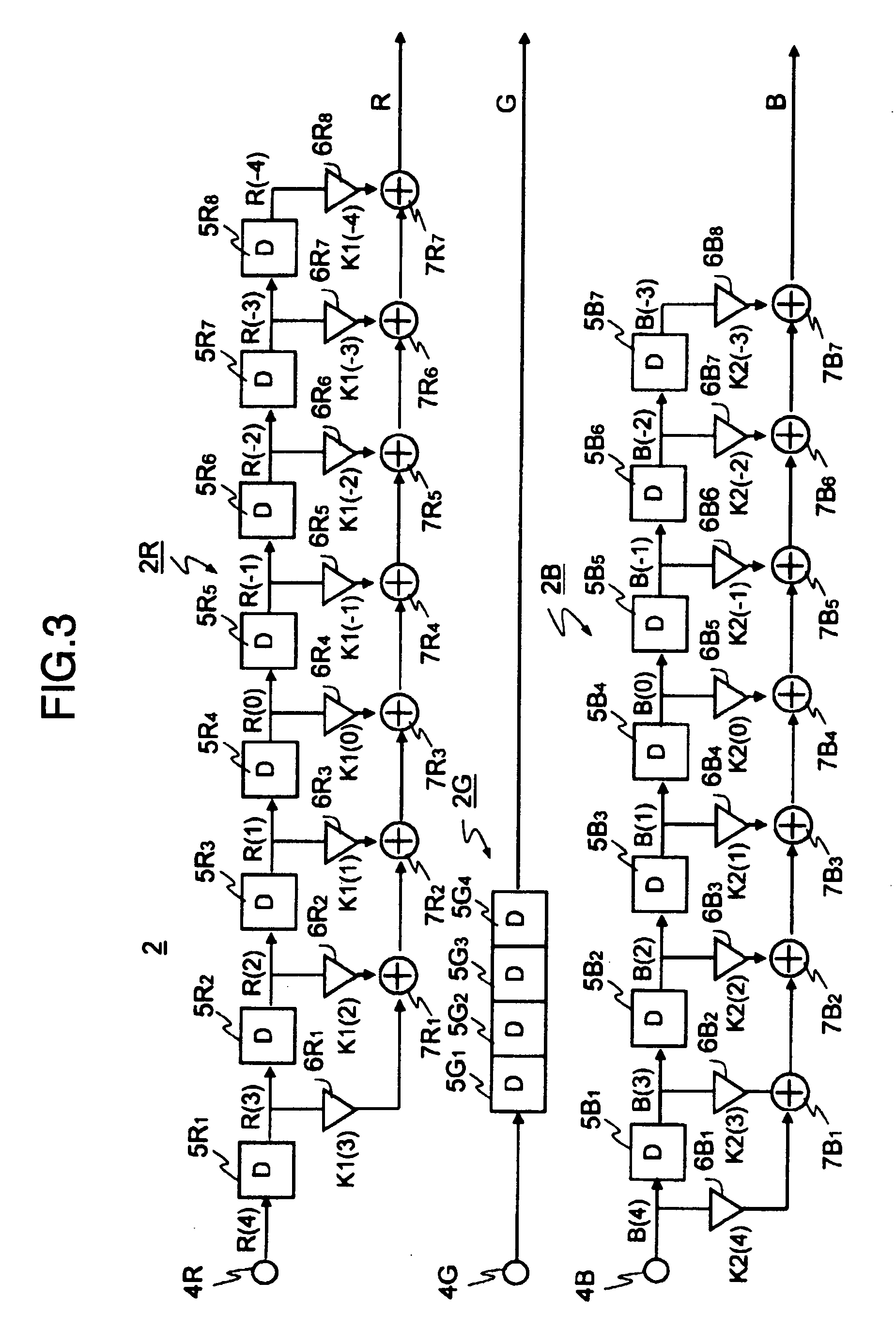

Image processing apparatus and image displaying device

ActiveUS20080180455A1Reduce color position shiftIncrease display resolutionCathode-ray tube indicatorsImaging processingBrightness perception

An RGB signal from an input terminal is supplied to a triple over-sampling / sub-pixel control processing unit and a brightness signal generating circuit in which a brightness signal is generated. A brightness edge detection / judgment unit detects an edge from this brightness signal, judges the kind of the edge, fetches a coefficient select signal corresponding to the judgment result from a memory and supplies the signal to the control processing unit. A tap coefficient corresponding to this coefficient select signal is set in the control processing unit and a triple over-sampling processing is executed for each of RGB. For edge parts, R and B sub-pixels the timings of which are displaced by ±1 / 3 pixel from the input R and B sub-pixels and the pixel gravitys of which are displaced by ±1 / 3 or ±1 / 8 pixel in accordance with the kind of the edge are generated.

Owner:MAXELL HLDG LTD

Automatic cloth edge cutting equipment for garment production

ActiveCN112647273ARealize windingAchieve normal workSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to edge cutting equipment, in particular to automatic cloth edge cutting equipment for garment production. According to the automatic cloth edge cutting equipment for garment production, cloth for garment production can be wound, meanwhile, the cloth for garment production can be quickly cut into the specified width, and redundant cloth for garment production can be shaken off at intervals. The automatic cloth edge cutting equipment for garment production comprises a base, supporting frames and rolling columns, the supporting frames are fixedly connected to the base, the rolling columns are rotationally connected between the upper portions of the supporting frames, a material rolling mechanism is installed between the upper portions of the supporting frames, a cutting mechanism is arranged at the top of the base, and the material rolling mechanism is matched with the cutting mechanism. By arranging the material rolling mechanism, the material rolling mechanism is matched with the cutting mechanism, and cloth rolling and edge cutting for garment production can be achieved; through cooperation of a reciprocating mechanism and the material rolling mechanism, rolling of cloth for garment production can be achieved; and through cooperation of a material conveying mechanism and the reciprocating mechanism, cloth for garment production can be conveyed at intervals.

Owner:江西美硕实业有限公司

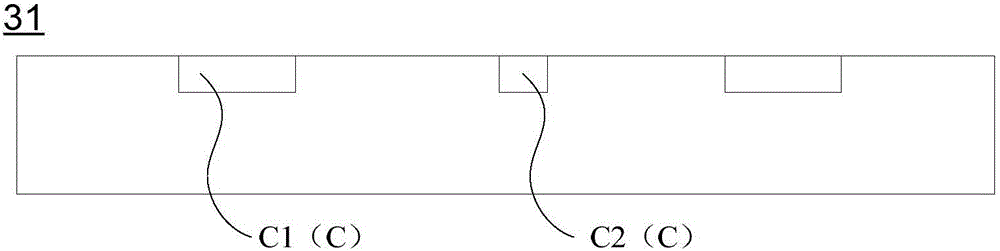

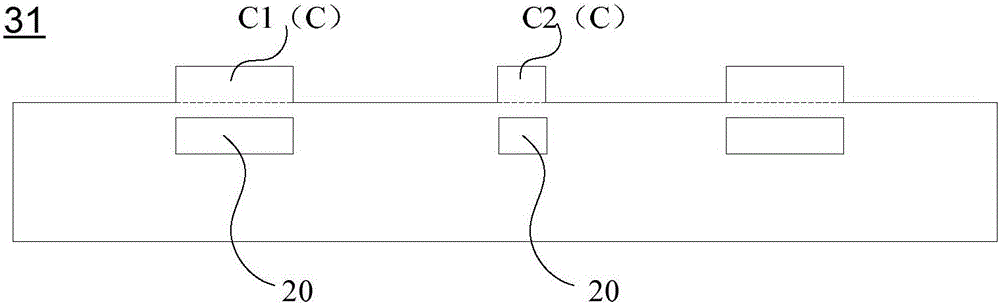

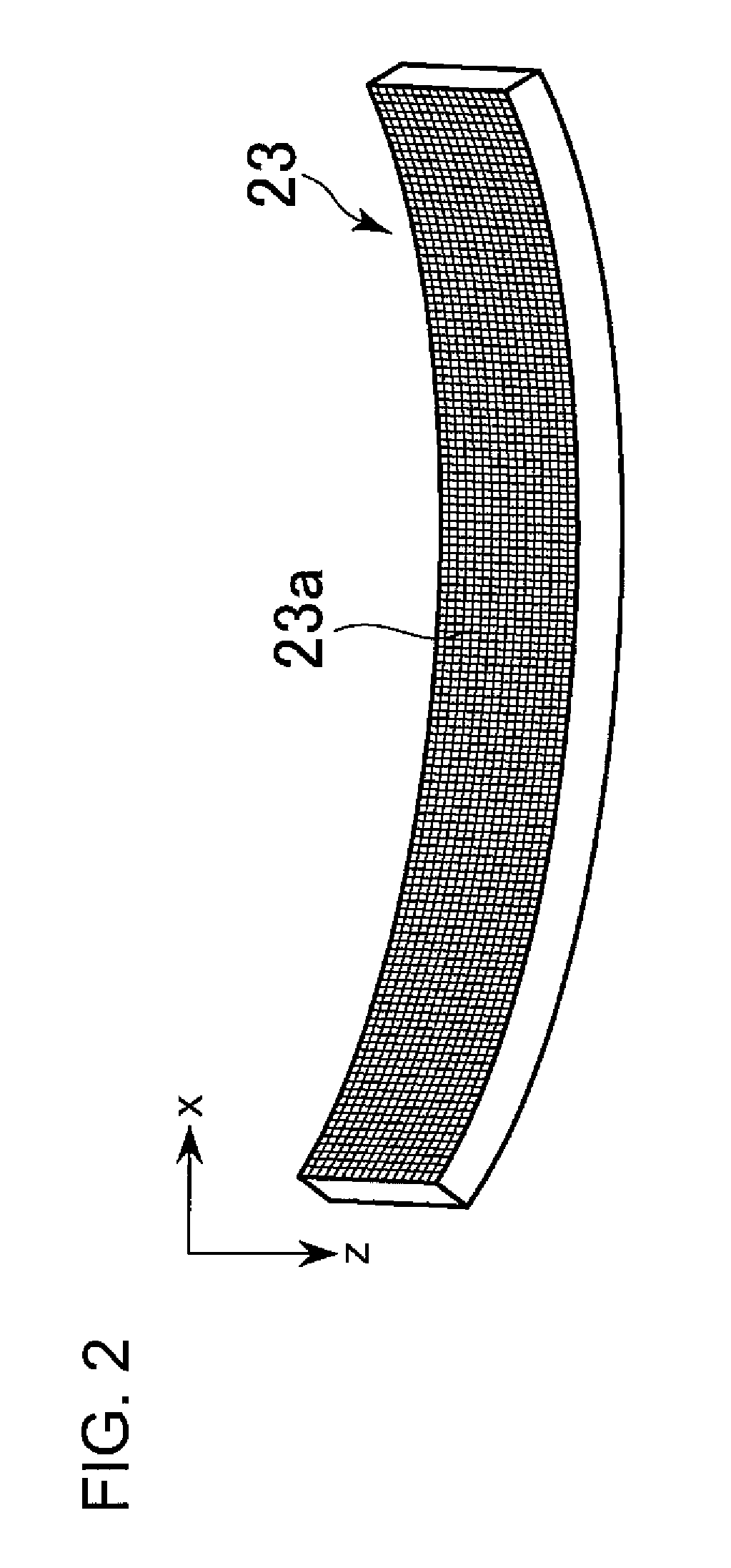

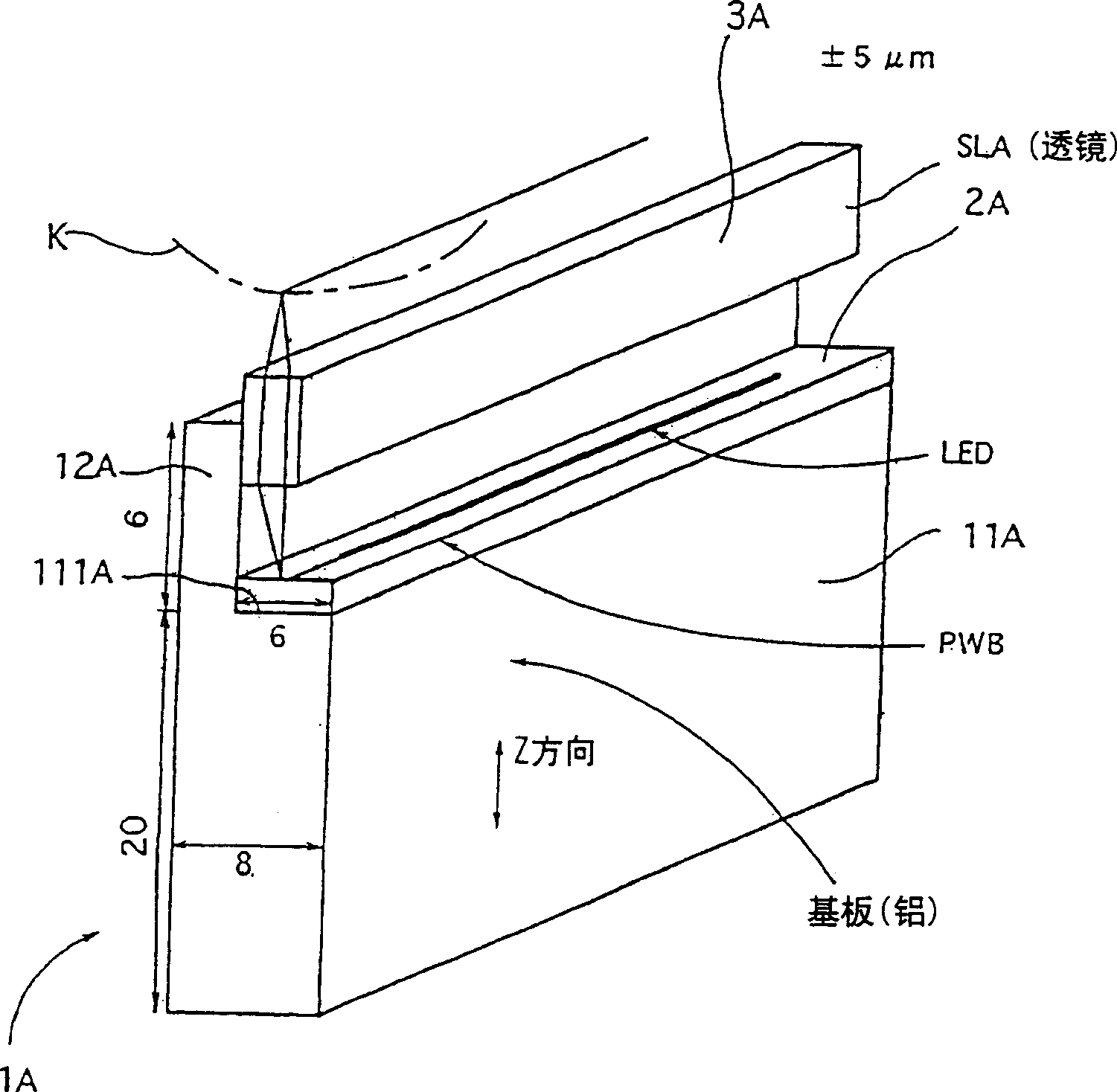

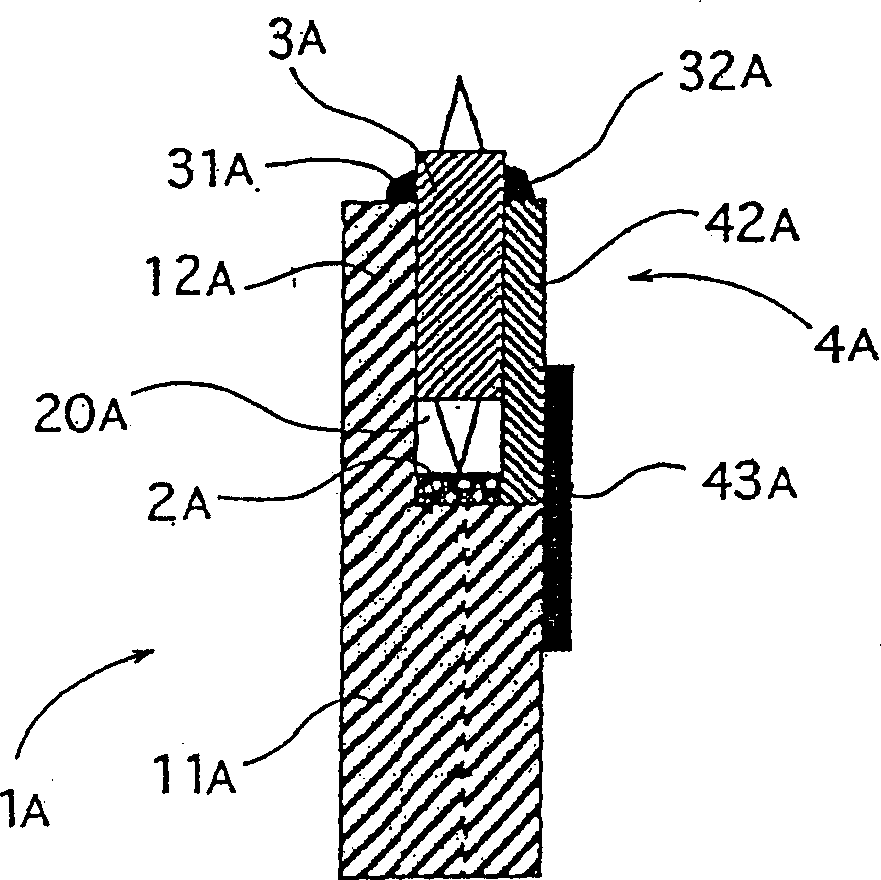

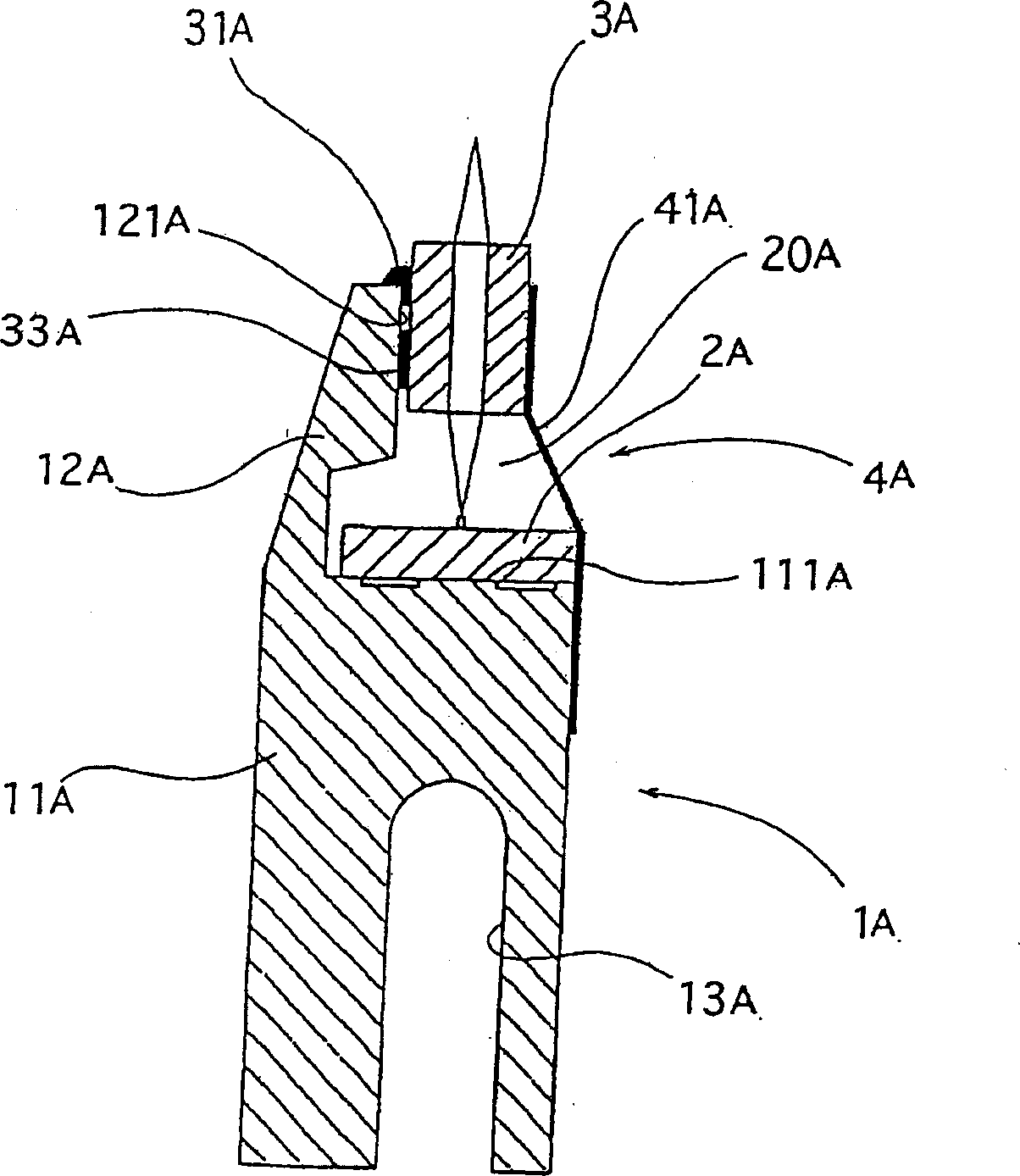

LED print-head and producing method thereof, and methof for producing LED substrate and pasting method thereof

InactiveCN1509236AReduce positional offsetCurb bendingPrintingPictoral communicationPhysical chemistryEngineering

An LED print head comprising a base body (1) consisting of a large-capacity base unit (11) disposed to extend in parallel to the axis direction of a photosensitive element (K) and formed with a facing upper surface (111) facing the photosensitive element, and a small-capacity projection (12) projecting from a part of the facing upper surface of the base unit to extend and be formed integrally therewith and having a small width in the moving direction of the photosensitive element, an LED substrate (2) disposed on the facing upper surface of the base unit, and lens array (3) disposed at a portion between the facing surface (111) of the element (K) and the upper surface of the LED substrate (2) at one end of the projection (12); and a production method of the LED print head; and a method of producing an LED substrate and a method of pasting an LED substrate.

Owner:SUZUKA FUJI XEROX CO LTD

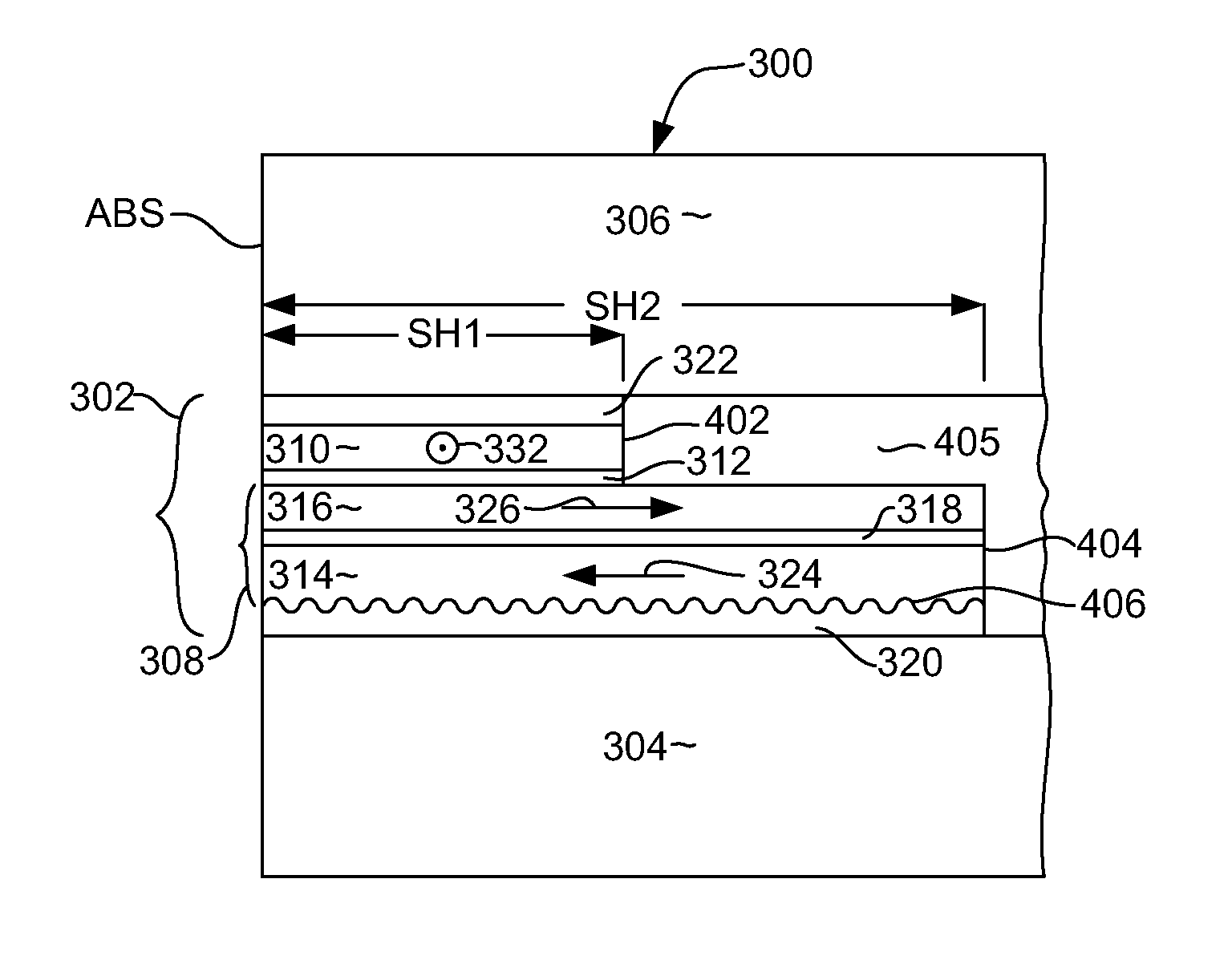

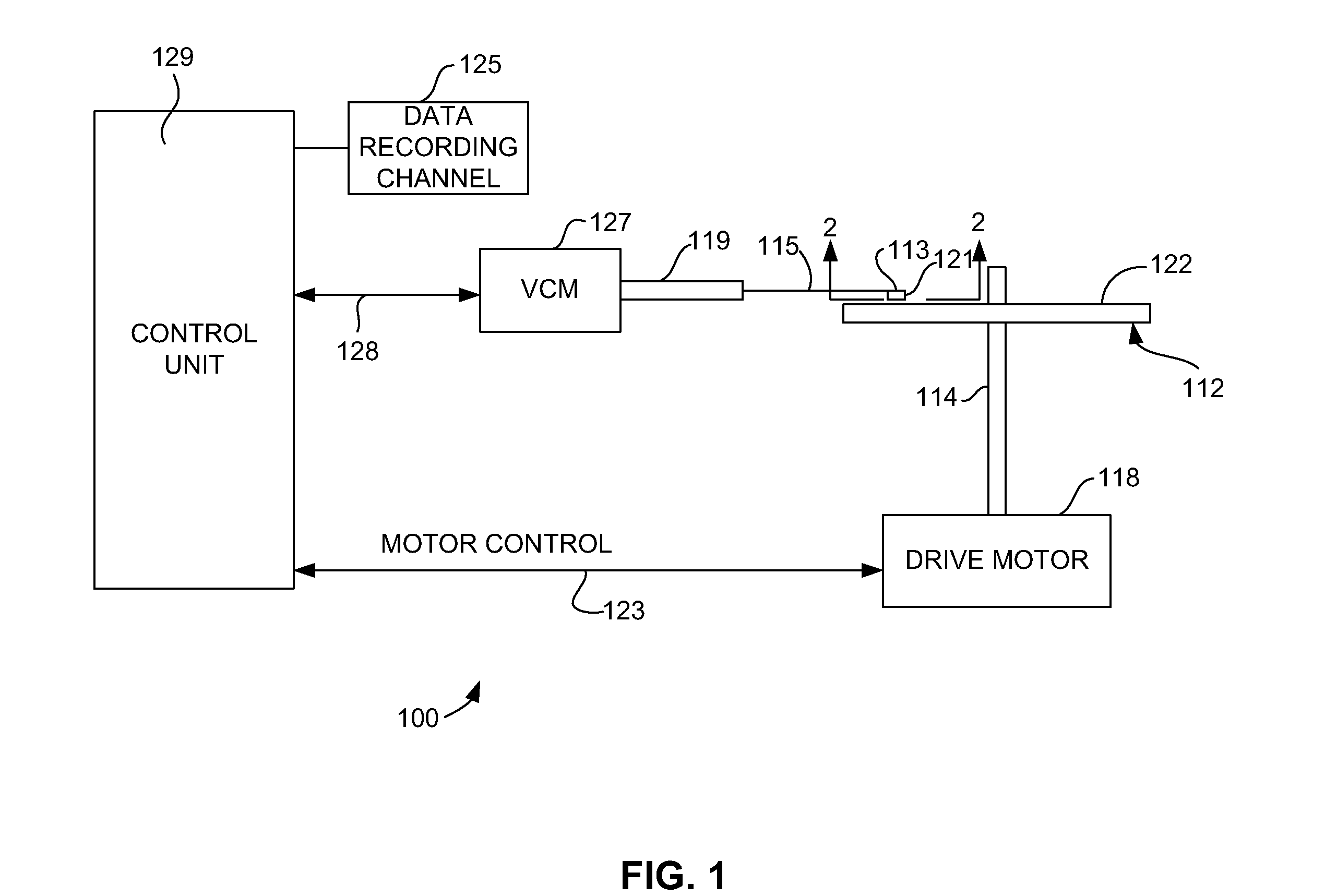

Magnetoresistive sensor having reduced read gap and strong pinned layer stability

InactiveUS20140133052A1High aspect ratioReduce degradationDecorative surface effectsRecord information storageMagnetic anisotropyOptoelectronics

A magnetic read head having a reduced read gap and a stable magnetic pinned layer structure. The sensor includes a seed layer that has a surface formed with an anisotropic texture. A magnetic pinned layer formed over the seed layer has a body centered cubic structure which causes the pinned layer structure to have a magnetic anisotropy with an easy axis oriented perpendicular to the air bearing surface when deposited over the textured seed layer. A magnetic free layer structure formed over the pinned layer structure and over a non-magnetic barrier layer has a face centered cubic structure which causes the magnetic free layer to have a magnetic anisotropy with an easy axis oriented parallel with the air bearing surface.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Vapor deposition method, vapor deposition device and organic el display device

InactiveUS20130252353A1Suppress blurReduce positional offsetSemiconductor/solid-state device testing/measurementElectroluminescent light sourcesGas phaseDisplay device

A coating film (90) is formed by causing vapor deposition particles (91) discharged from a vapor deposition source opening (61) of a vapor deposition source (60) to pass through a space (82) between a plurality of limiting plates (81) of a limiting plate unit (80) and a mask opening (71) of a vapor deposition mask in this order and adhere to a substrate while the substrate is moved relative to the vapor deposition mask in a state in which the substrate (10) and the vapor deposition mask (70) are spaced apart at a fixed interval. It is determined whether or not it is necessary to correct the position of at least one of the plurality of limiting plates in the X axis direction, and in the case where it is necessary to correct the position, the position of at least one of the plurality of limiting plates in the X axis direction is corrected. Accordingly, a coating film whose edge blur is suppressed can be stably formed at a desired position on a large-sized substrate.

Owner:SHARP KK

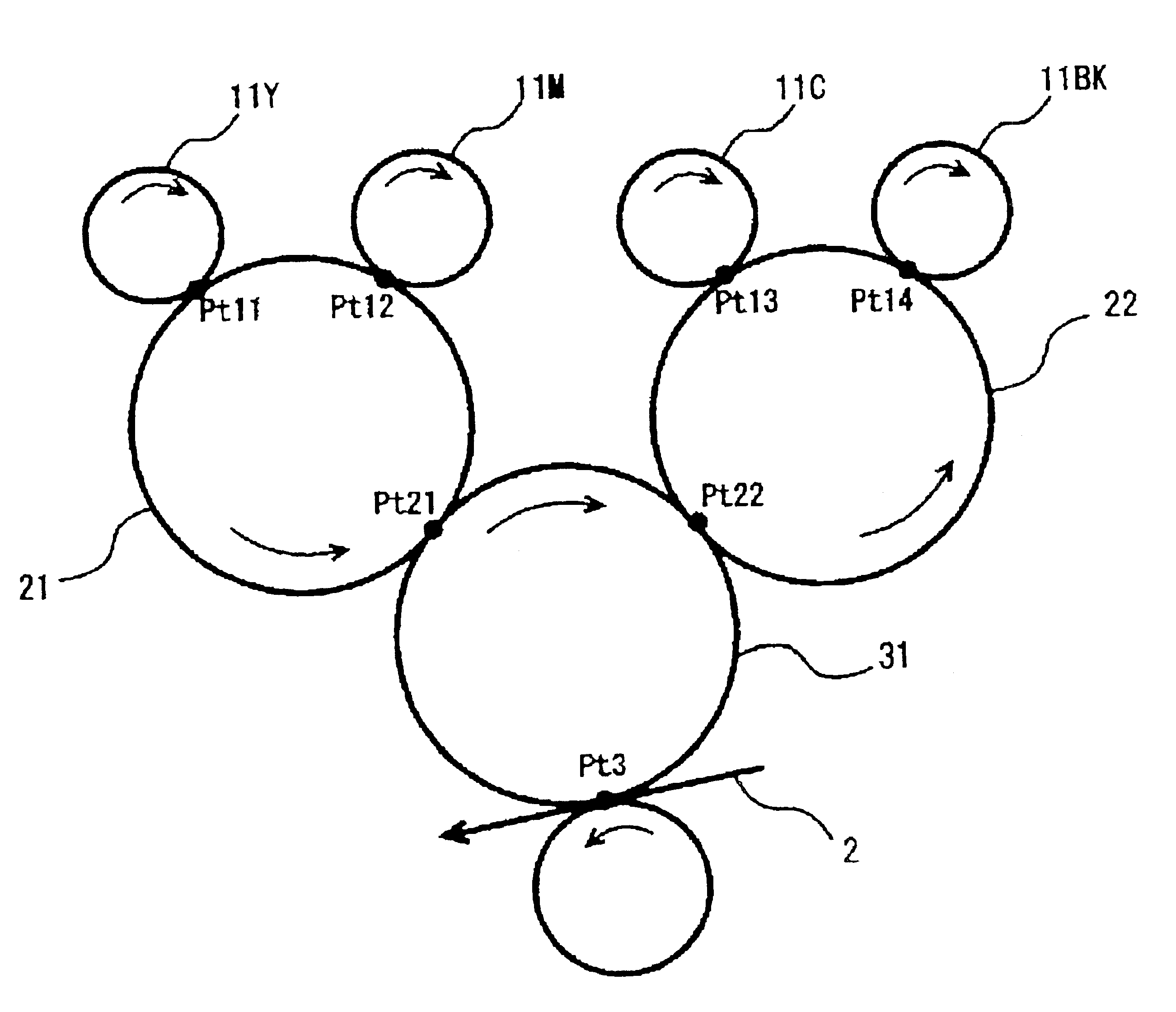

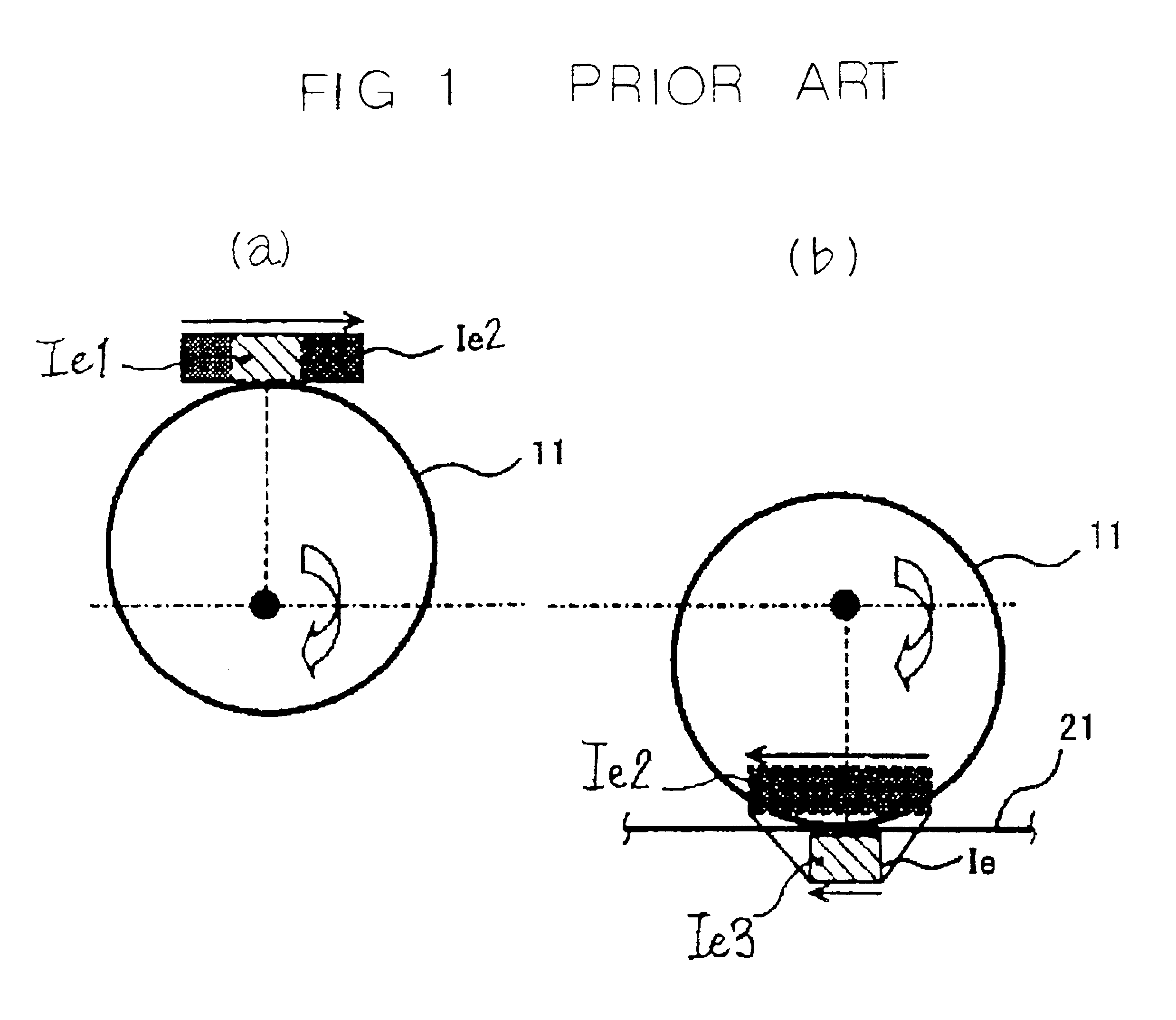

Image forming apparatus with an intermediate image transfer body and provisions for correcting image transfer distortions

InactiveUS6889030B2Improve image qualityImage formingElectrographic process apparatusIntermediate imageImage transfer

An image forming apparatus of the present invention includes at least one rotatable image carrier, an image forming device for forming different images on the image carriers, a first image transferring device for transferring the images from the image carriers to a first image transfer body driven to move via a first image transfer position where it faces the image carriers, and a second image transferring device for transferring the resulting composite image from the first image transfer body to a second image transfer body driven to move via a second image transfer position where it faces the first image transfer body. The moving speed of each image carrier is equal to the moving speed of the second image transfer body. A period of time necessary for the surface of the first image transfer body to move from the first image transfer position to the second image transfer position is a natural number multiple of the period of speed variation occurring on the above surface.

Owner:RICOH KK

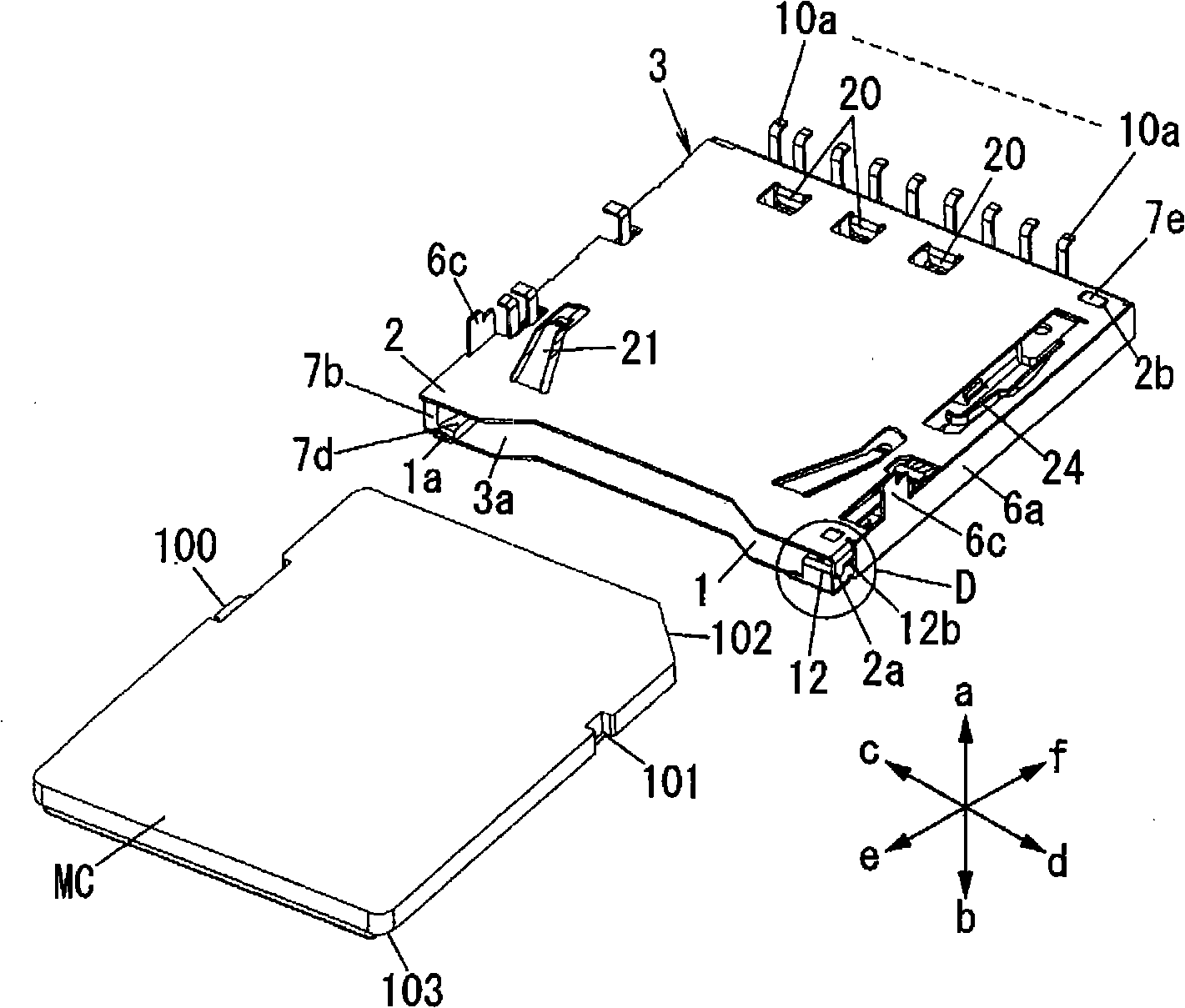

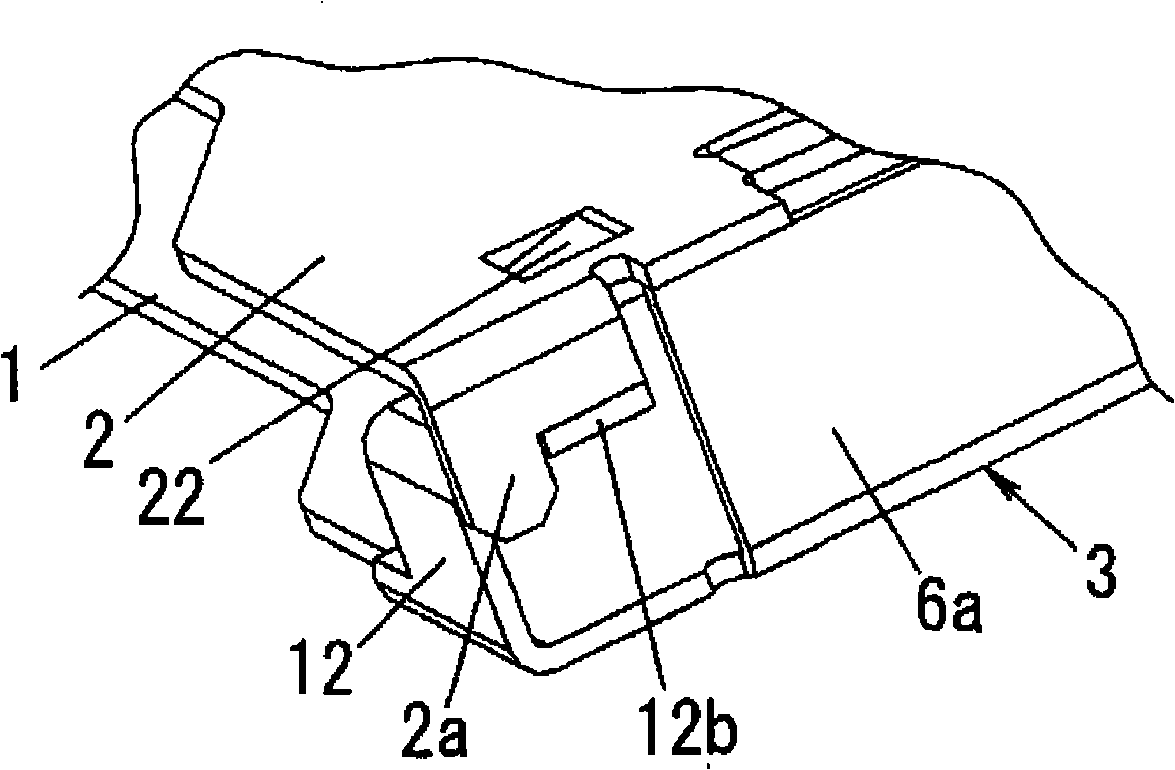

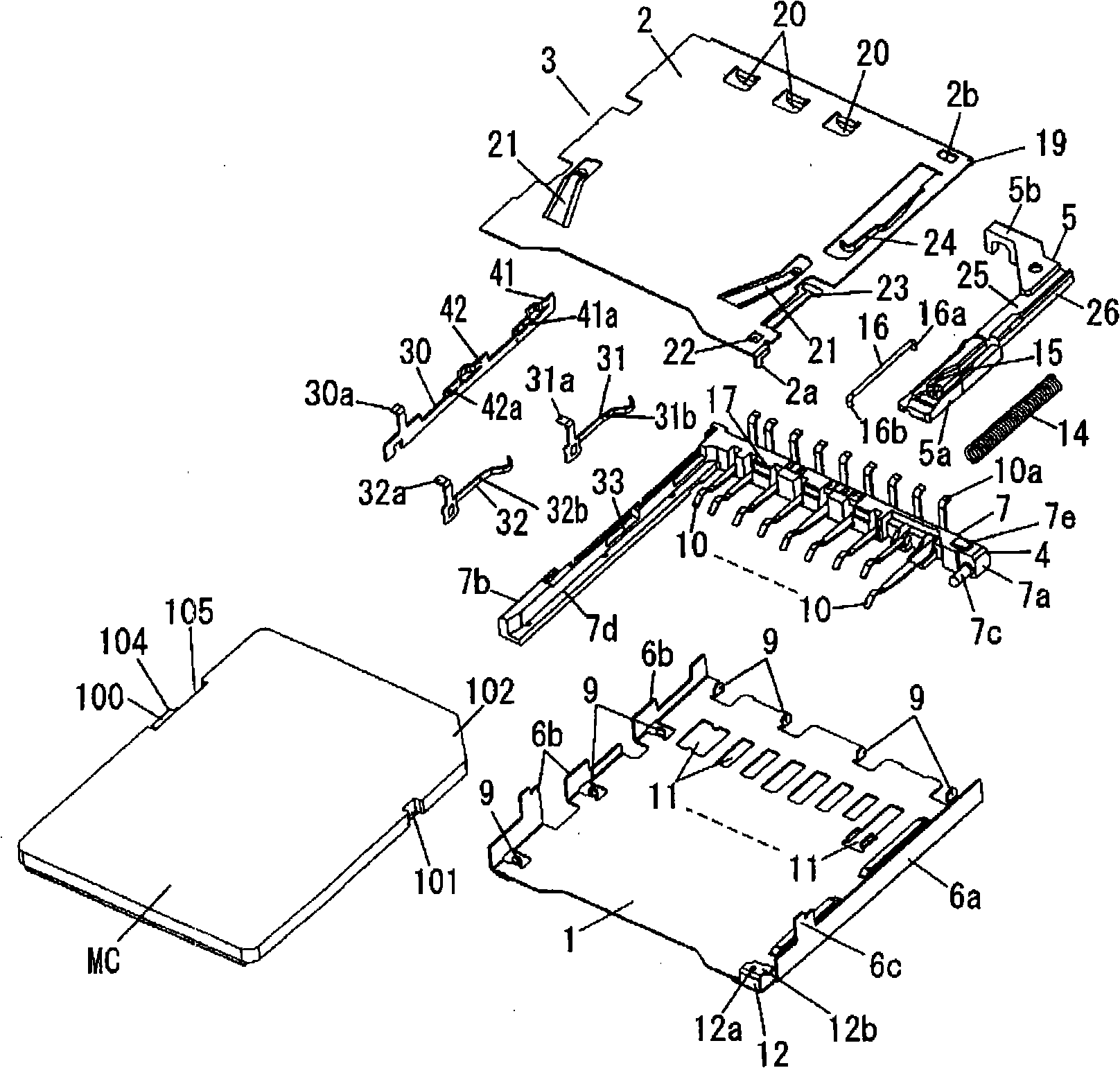

Socket for storage card

A memory card socket is provided, the main body (3) of which is composed of a first metal shell (1) and a second metal shell (2), wherein only the first metal shell (1) is pressed on a base (7) fixed on a contact block (4), and the second metal shell (2) is combined on the first metal shell (1) by the methods such as laser welding in order to prevent the main body (3) of the socket from deforming caused by the external force applied when inserting and pulling. Therefore, the second metal shell (2) is provided with a first abut piece (20) and a second abut piece (19), wherein the first abut piece (20) is abutted with the front of the base (7) from the front side, and the second abut piece (19) is projecting from the base (7) in the rear side and is abutted with the rear part of the base (7) from the rear side.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Ring-shaped winding machine

The invention discloses a ring-shaped winding machine which comprises an open-type machine head, an electric cabinet, a transmission mechanism, a wire storage mechanism, a winding mechanism and a wire arranging mechanism, wherein the wire arranging mechanism comprises a mounting seat, a driving rubber wheel provided with a tray and a driven rubber wheel, and the driving rubber wheel provided withthe tray is connected with a second transmission mechanism in a transmission way; the wire storage mechanism is provided with a wire storage ring, the winding mechanism is provided with a gear provided with an opening, and the gear provided with the opening is connected with a first transmission mechanism in a transmission way and connected with the wire storage ring when rotating clockwise. The ring-shaped winding machine is characterized in that the second transmission mechanism is driven by a stepper motor, the electric cabinet is internally provided with a singlechip control system, a wire distance amending button is arranged on the electric cabinet, the stepper motor is controlled by a singlechip, and the wire distance amending button is electrically connected with the singlechip. The ring-shaped winding machine can increase or reduce the number of wire distance pulse by the control of the wire distance amending button and the singlechip, so that enamelled wires can be accuratelywound into a wire groove all the time, and the phenomenon of wire jumping or overlapping can be stopped.

Owner:温州市南方机械制造有限公司

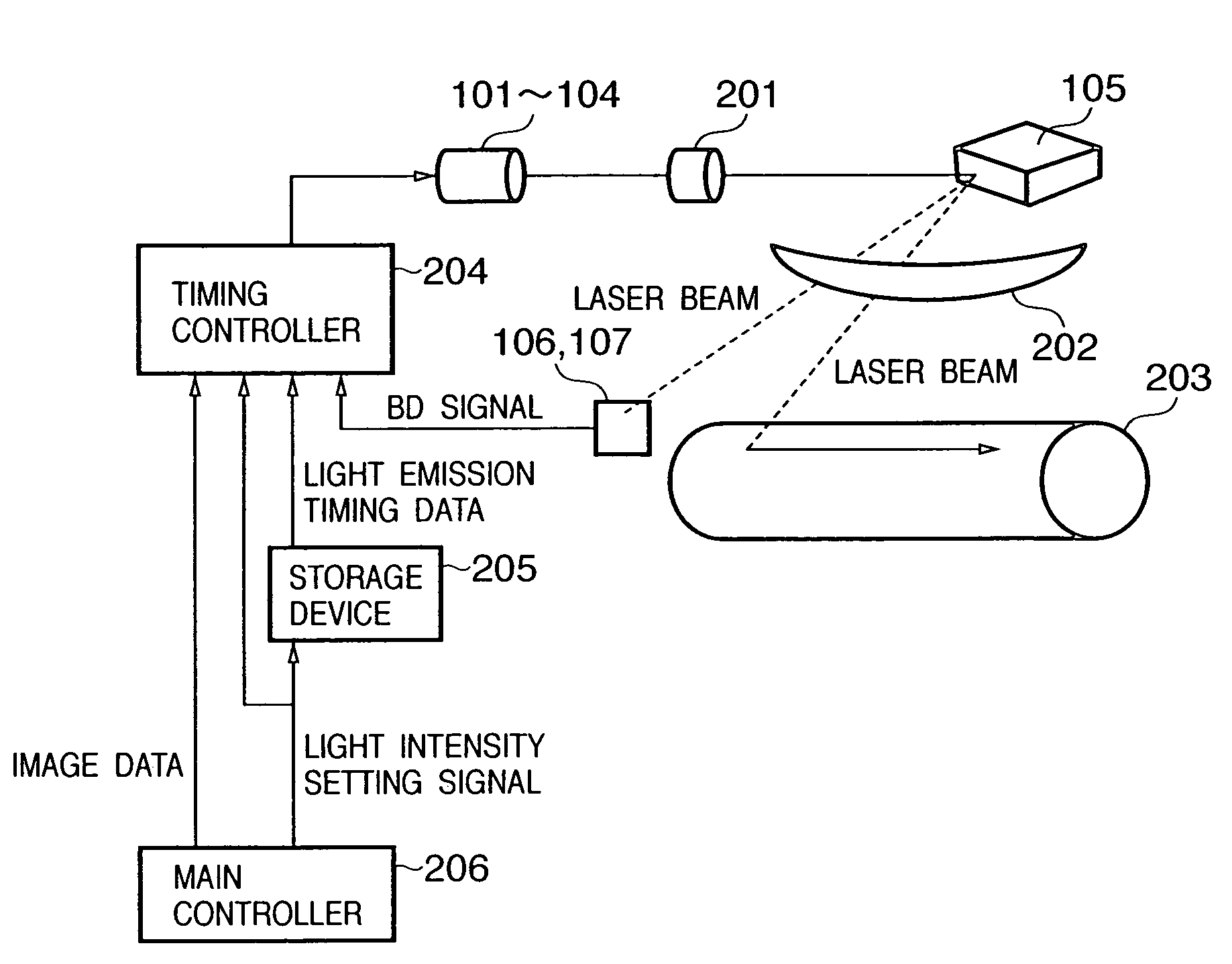

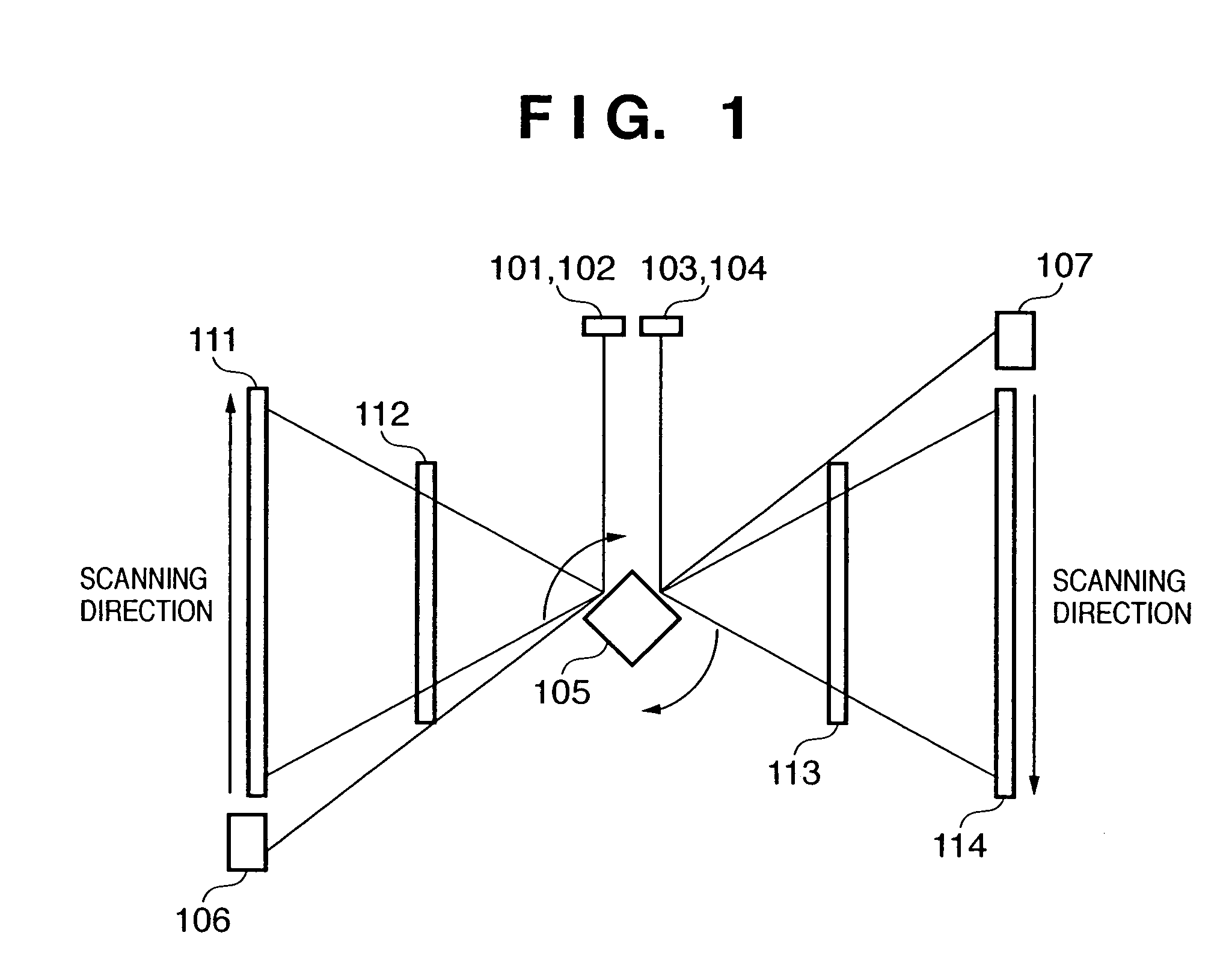

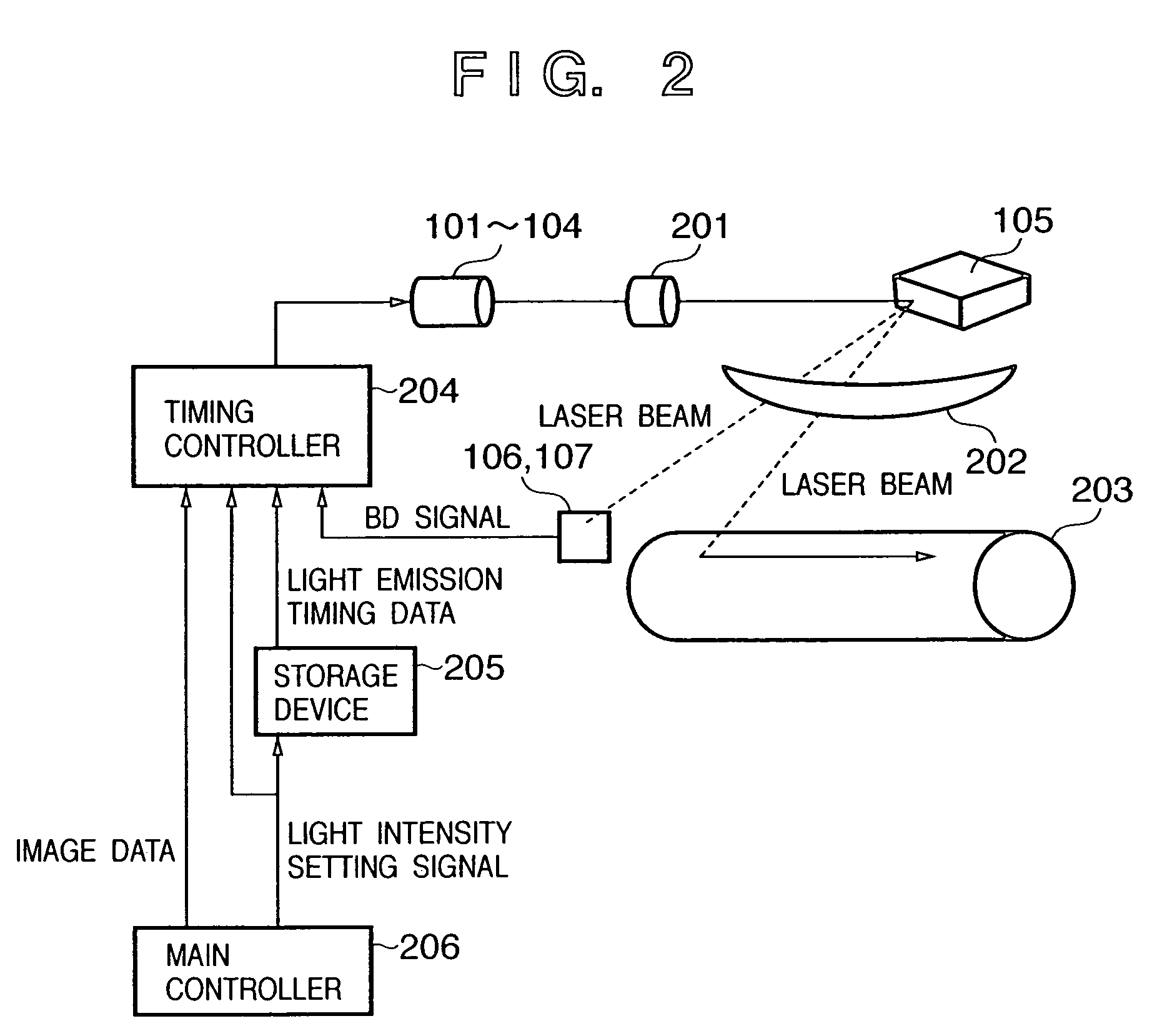

Method and apparatus for image forming

InactiveUS7277113B2Reduce positional offsetLow costVisual representatino by photographic printingPrintingImage resolutionLatent image

An image forming apparatus in which the intensity of a light beam used to form a latent image is switched in response to a change in resolution. A laser emits a light beam for forming a latent image on a photosensitive drum. A polygon mirror scans the emitted light beam. BD sensors detect the scanned beam. A timing controller selects the preferable timing from a storage device table according to the intensity of the light beam or the resolution when controlling the light emission timing of the lasers in response to a detection of timing of the detected light beam.

Owner:CANON KK

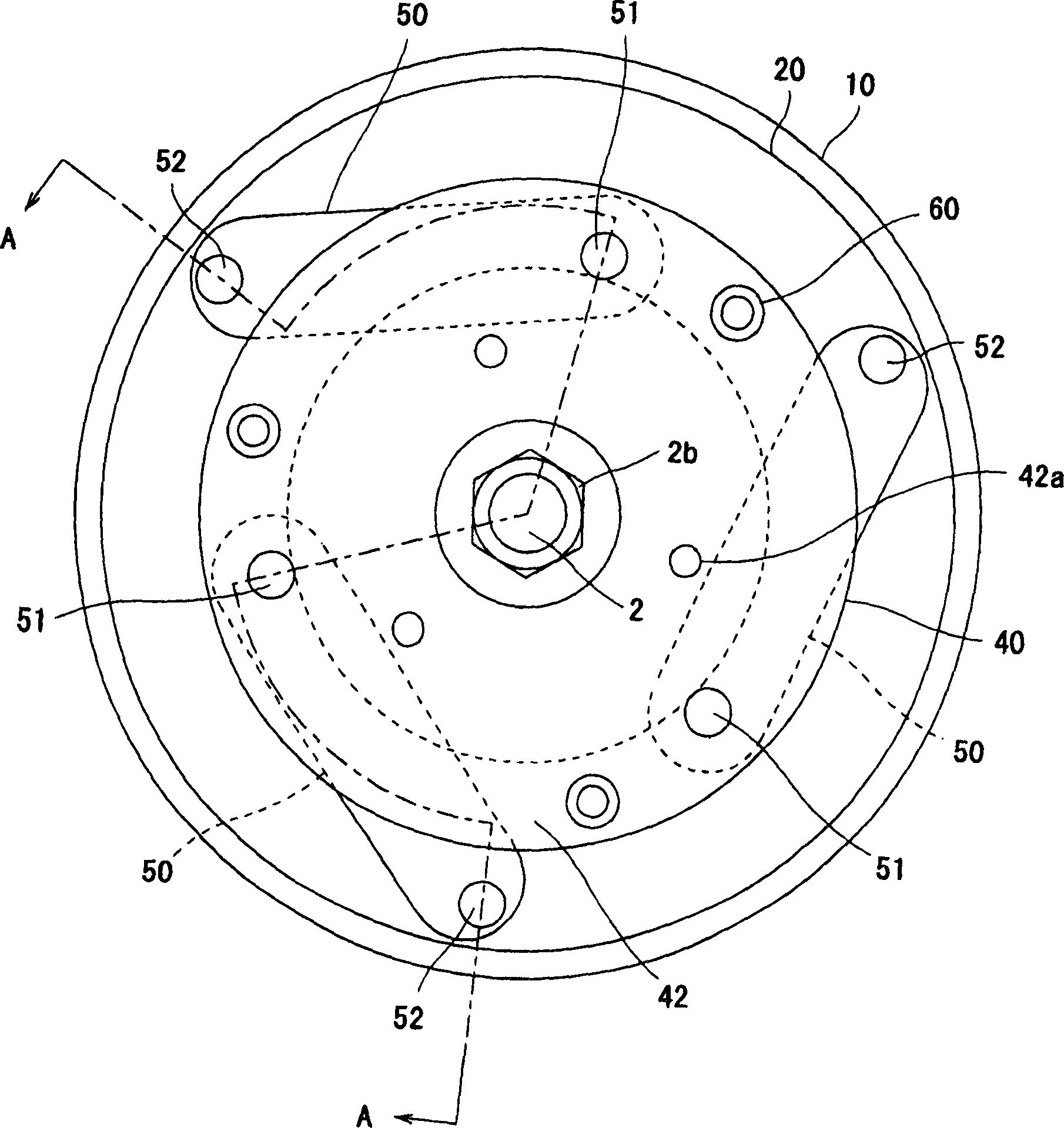

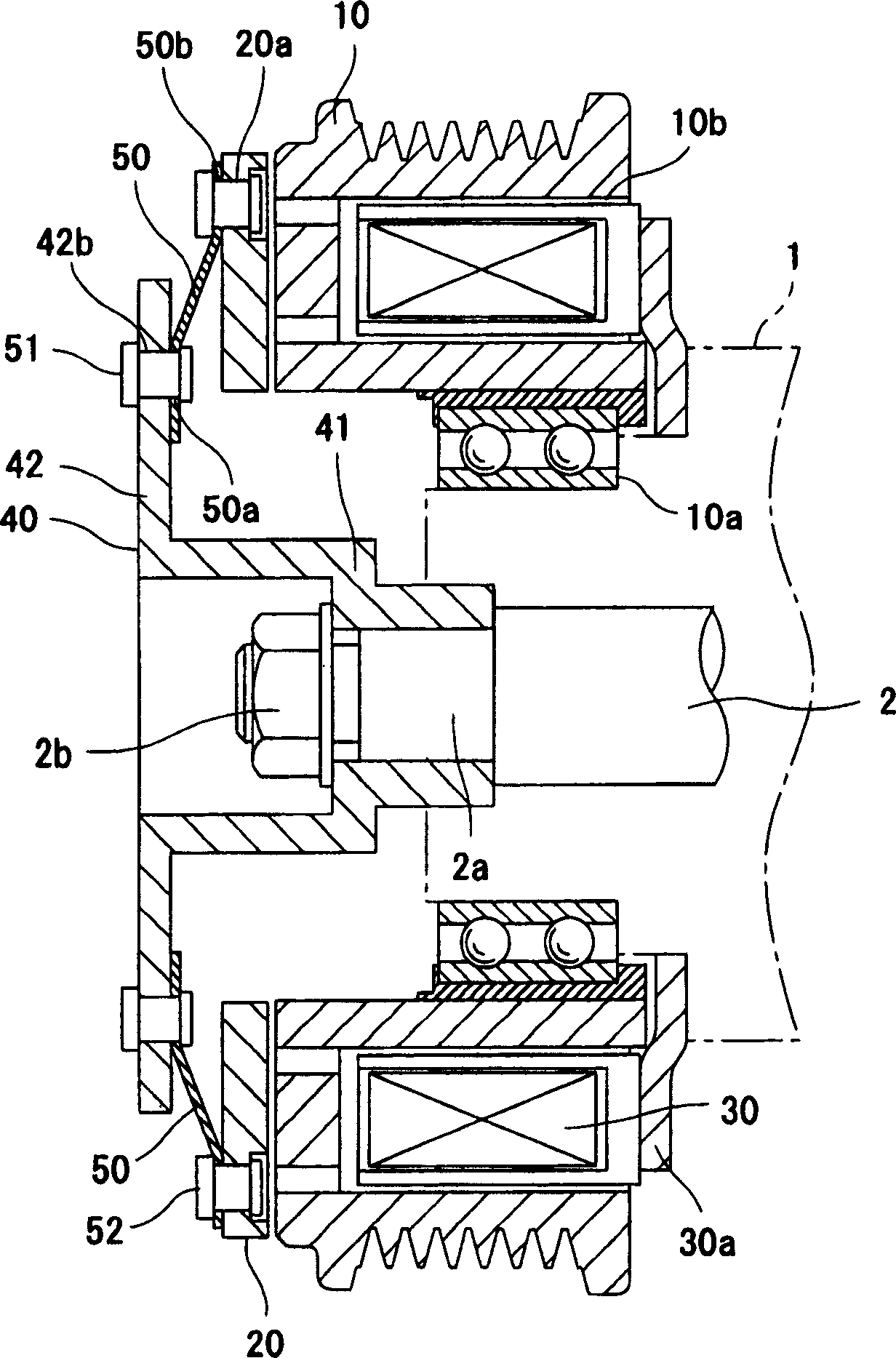

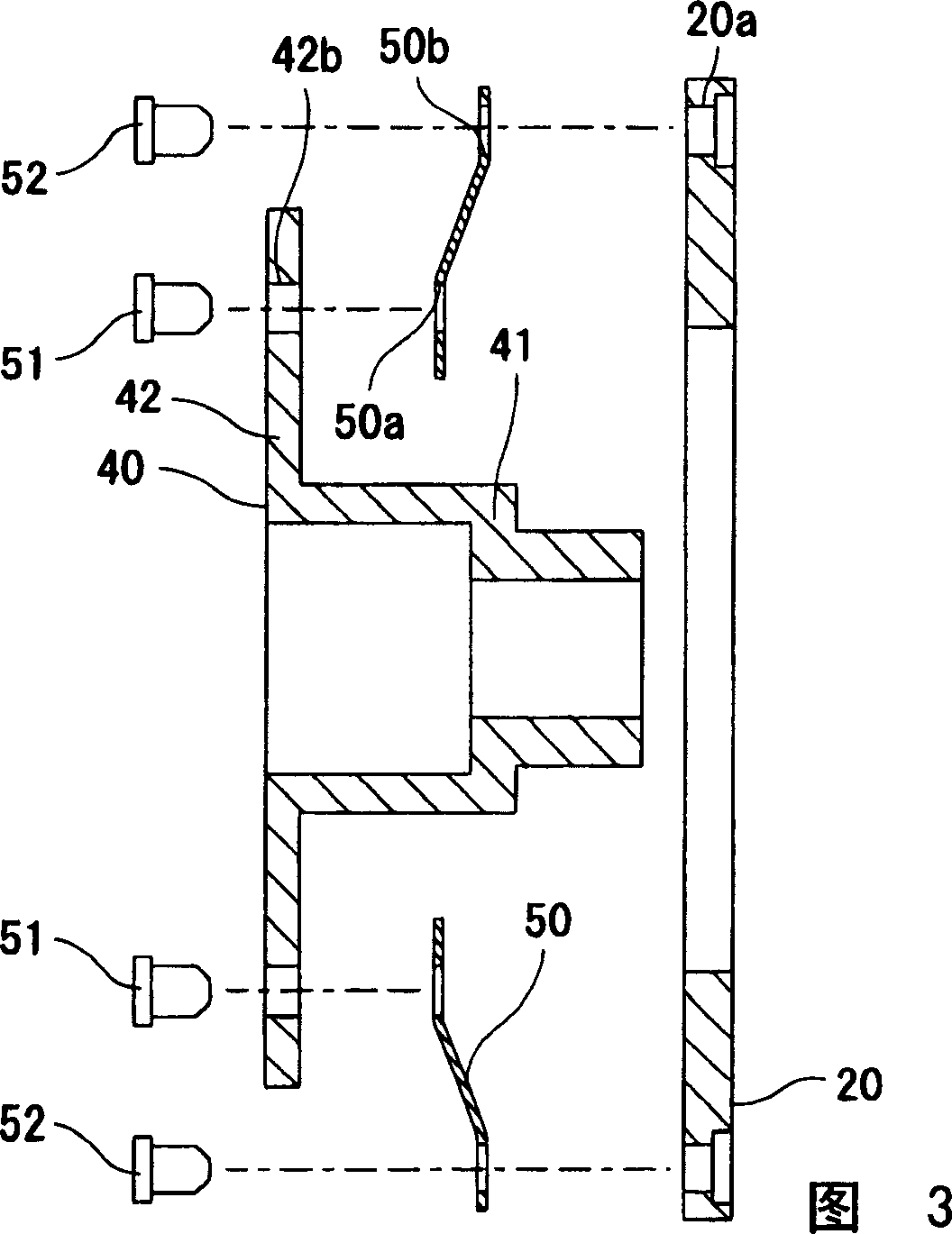

Electromagnetic clutch

InactiveCN1840927ASmall inner diameterIncrease the adsorption areaMagnetically actuated clutchesElectromagnetic clutchEngineering

In this electromagnetic clutch, only each of the plate springs is connected to the second rotor by first connecting members. Therefore, each of the first holes of the plate springs is accurately positioned to the position of each of the second holes of the extended portion. That is, it is not necessary to provide a useless gap between the first connecting members and the each of the holes. Also, the extended portion of the second rotor is opposed to the armature plate in the axial direction. Therefore, the inner diameter of the armature plate can be formed small irrespective of the extended portion.

Owner:SANDEN CORP

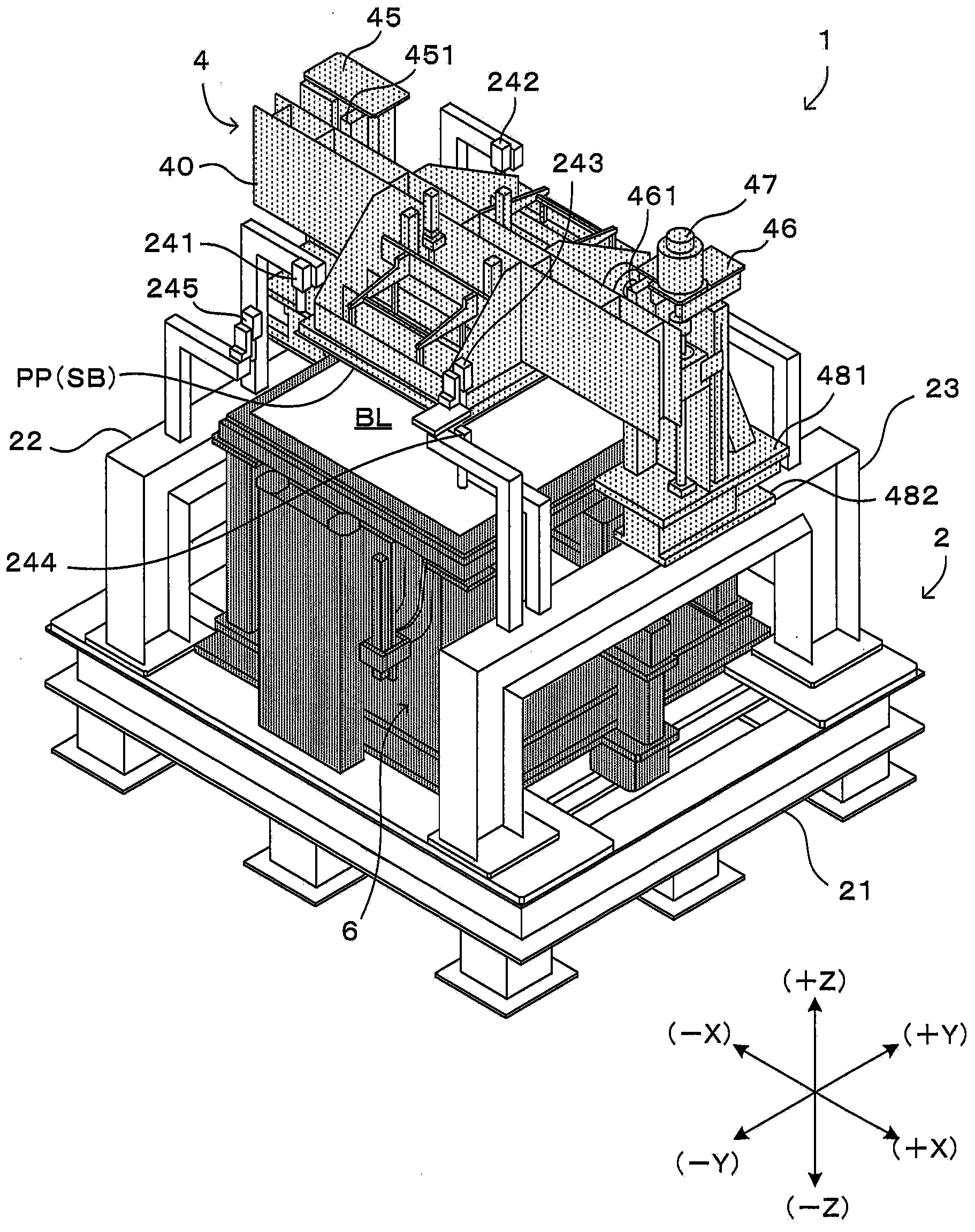

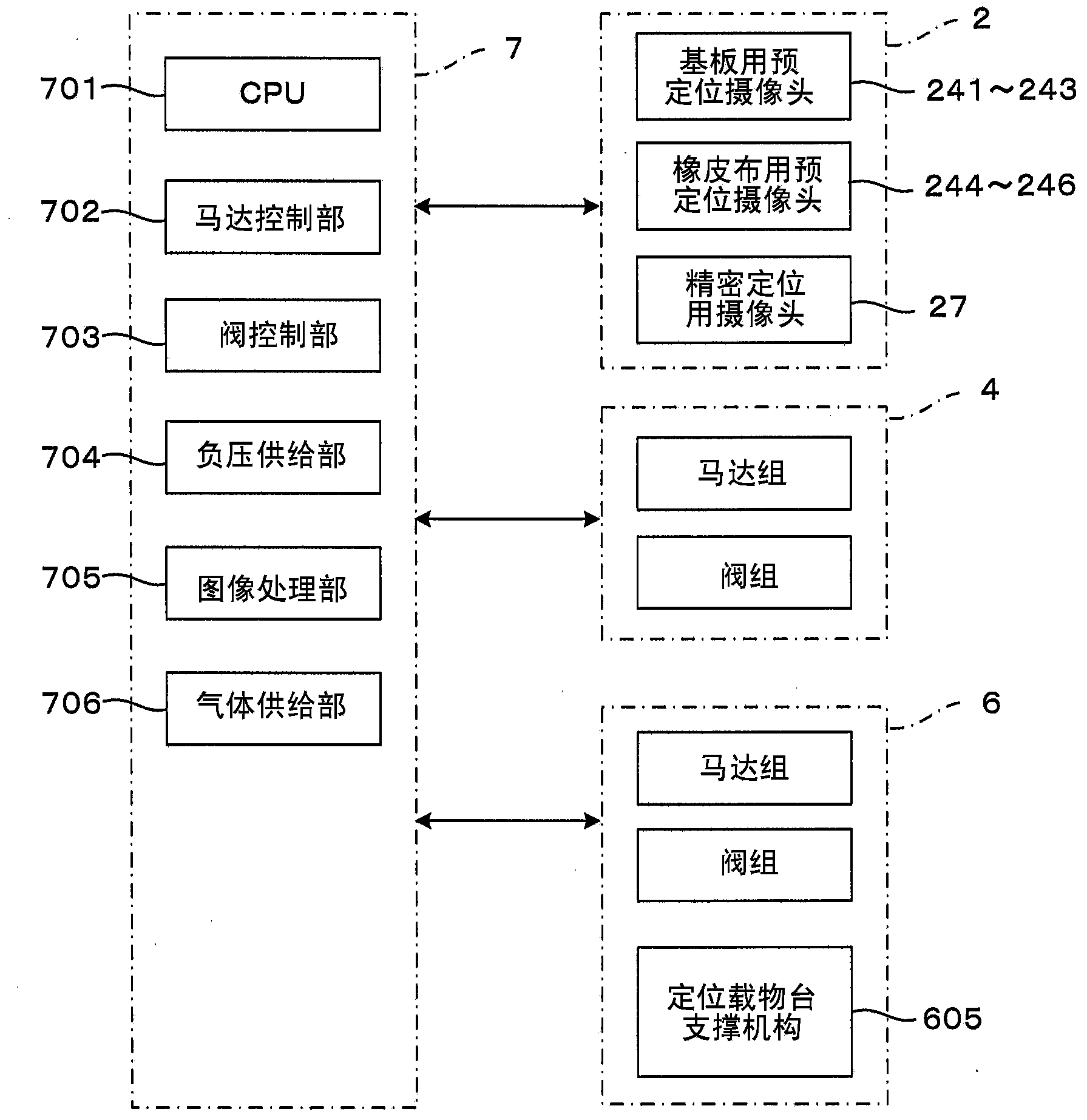

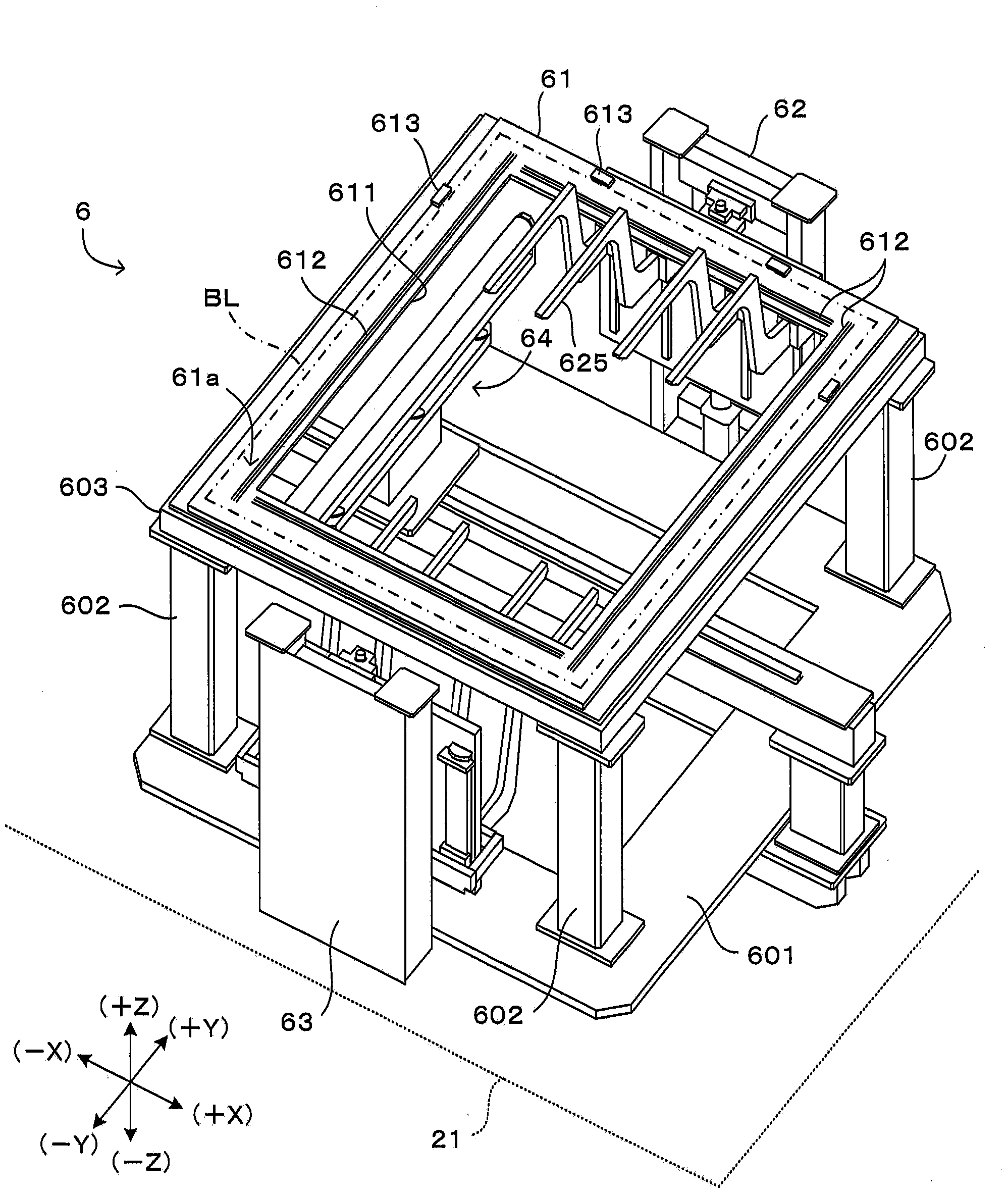

Pattern forming apparatus and pattern forming method

ActiveCN103963425AReduce voidsReduce positional offsetTransfer printingDuplicating/marking methodsEngineeringMechanical engineering

The invention relates to a pattern forming apparatus and a pattern forming method. The pattern forming apparatus comprises: a first holder unit (61) which holds a rubber blanket (BL) carrying a pattern forming material (PT) on one surface in a horizontal posture with a carrying surface for the pattern forming material faced up; a second holder unit (41) which holds a plate (PP) for patterning the pattern forming material or a substrate (SB), to which a pattern is transferred, as a processing object such that the processing object is proximate to and facing the carrying surface of the rubber blanket (BL) held on the first holder unit (61); and a push-up unit (641) which partially pushes up an effective area in a central part of the rubber blanket (BL) from a lower surface side of the rubber blanket (BL) to bring the effective area into contact with the processing object held on the second holder unit (41) and moves along the lower surface of the rubber blanket (BL) to change a push-up position of the rubber blanket (BL).

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com