Processing-object-supporting mechanism, supporting method, and conveying system including the mechanism

A technology of the object to be processed and the supporting mechanism, which is applied in the directions of conveyor objects, transportation and packaging, semiconductor/solid-state device manufacturing, etc. The effect of position offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

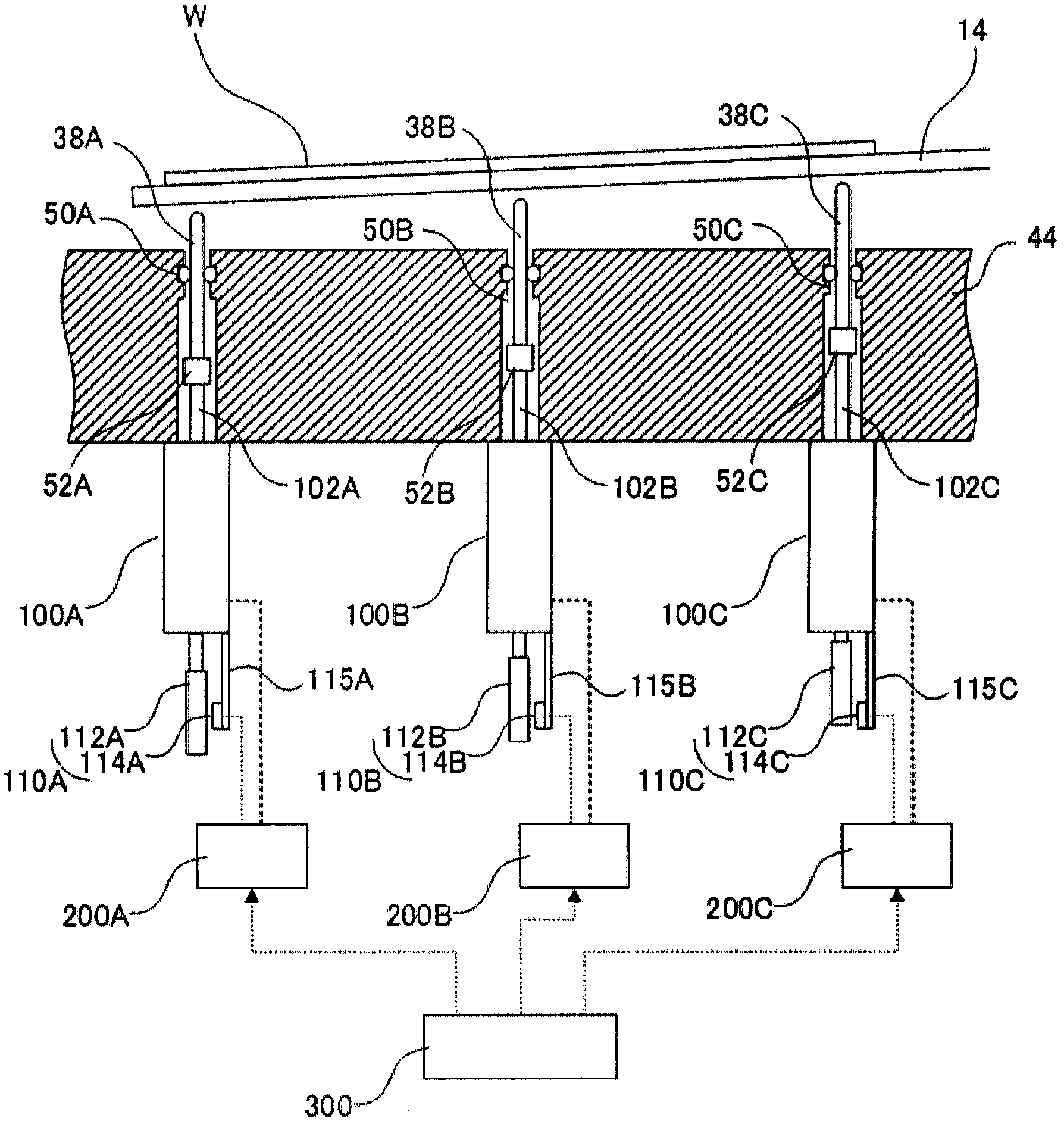

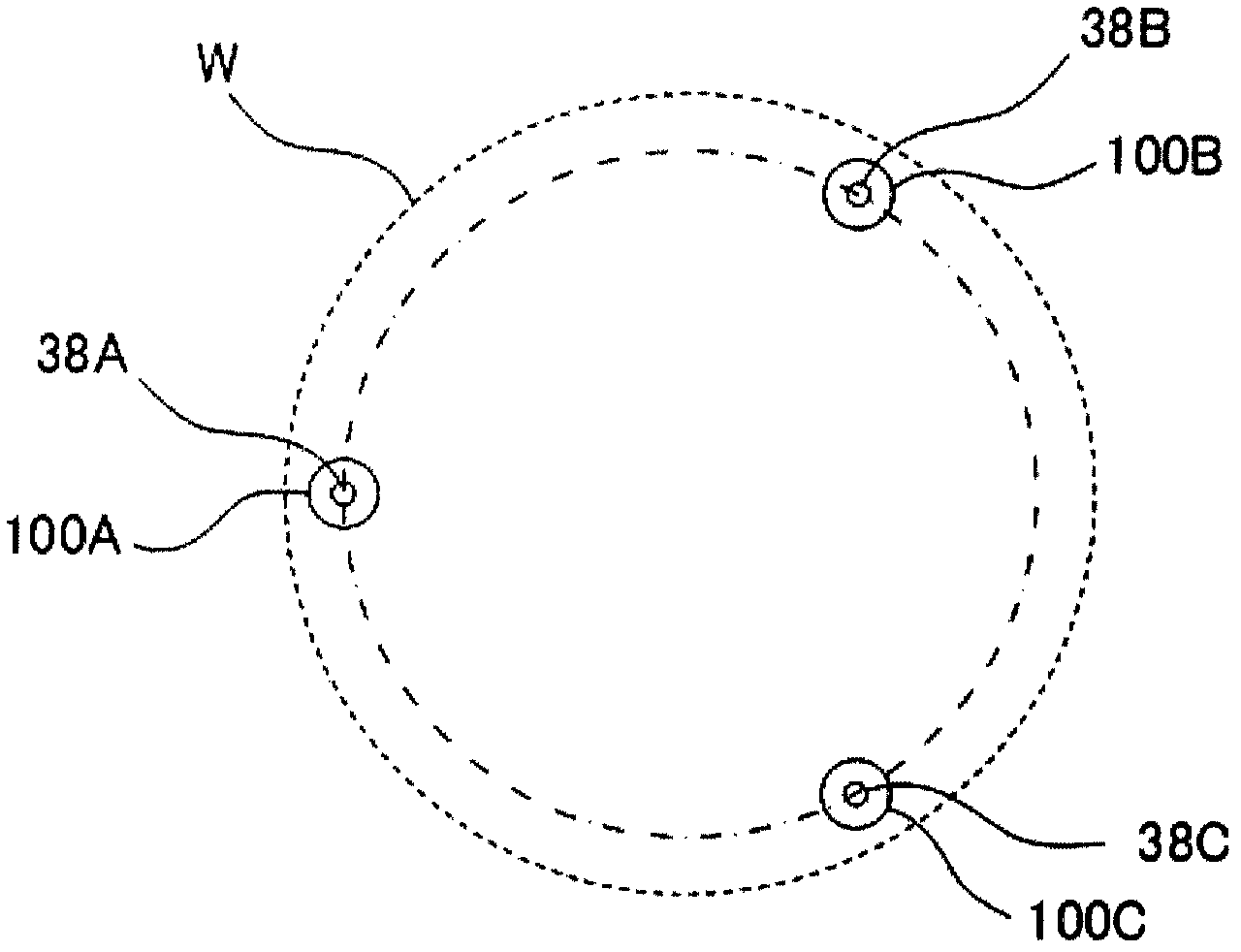

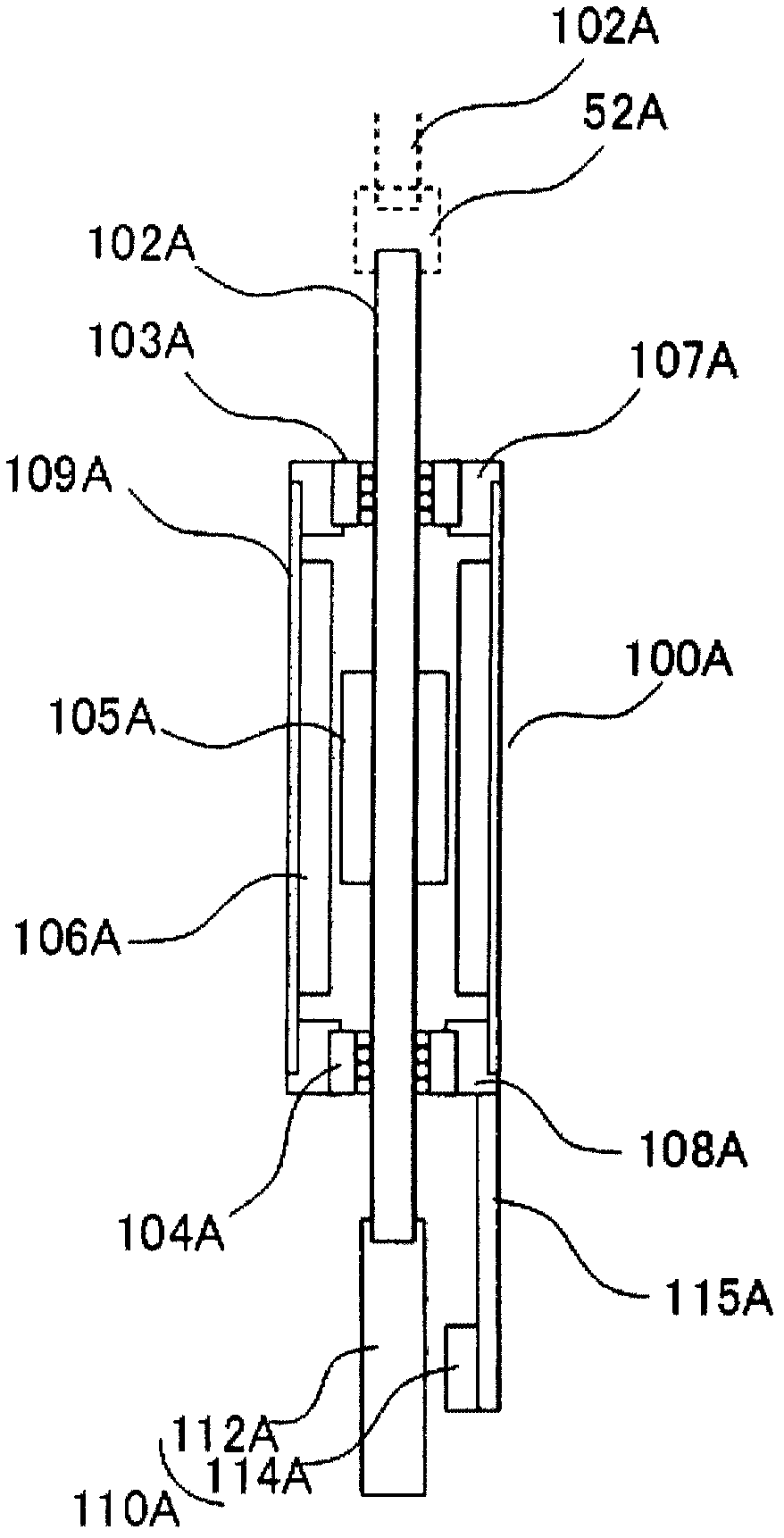

[0049] figure 1 is a schematic diagram of a support mechanism of an object to be processed (a wafer in this embodiment) in the first embodiment of the present invention, figure 2 It corresponds to the top view of the first embodiment, and is a layout diagram of lift pins and linear motors, image 3 It is a block diagram of a linear motor and a position detector. In the above figure, W is the wafer to be processed, 14 is the transfer arm, 44 is the bottom of the airtight chamber, 38A~38C are lift pins, 50A~50C are O-rings, 52A~52C are couplings, 100A~ 100C is a linear motor, 102A~102C is a movable shaft, 110A~110C is a position detector, 112A~112C is a grating scale, 114A~114C is a detection head, 200A~200C is a drive control device, 300 is a position command device, 103A 104A and 104A are linear motion guide parts, 105A is a field magnet part, 106A is an armature part, 107A and 108A are brackets, 109A is a frame, and 115A is a detection head mounting member. In addition, ...

Embodiment 2

[0062] Figure 4 It is a block diagram of the linear motor and the position detector in the second embodiment. In the figure, 116A is a scale mounting member.

[0063] The difference between the second embodiment and the first embodiment is that one end of the L-shaped grating scale mounting member 116A is mounted on the movable shaft 102A, and the grating scale 112A is mounted on the other end, while being separated from the grating scale 112A. The detection head 114A is attached to the frame body 109A with a predetermined gap. That is, the position detector 110A has a scale attachment portion 116A formed so as to be located on the outer peripheral portion of the housing 109A. That is, in contrast to the arrangement in which the position detector 110A and the linear motor 100A are coaxially arranged in the first embodiment, they are arranged in parallel in the second embodiment. By configuring in this way, it is possible to reduce the unit height of the support mechanism a...

Embodiment 3

[0065] Figure 5 It is a diagram showing the method of supporting the object to be processed (wafer) in the third embodiment, showing the flow of the method of supporting the wafer W carried by the transfer arm to the lift pins 38A to 38C. In addition, for ease of understanding and description, the lift pins 38A to 38C that are actually arranged on the circumference are arranged horizontally in a row, and the lift pins 38A to 38C are located in front of the transfer arm 14 . Figure 5 (a) is a case where the transfer arm 14 on which the wafer W is mounted enters the airtight chamber. The wafer W is tilted from the reference plane as the transfer arm 14 is deflected. In addition, before the transfer by the transfer arm 14, the inclination of the wafer at the positions of the three lift pins 38A-38C, that is, the distance from the front end of each lift pin to the bottom of the wafer, for example, is measured in advance, so that it can be used for position command. value gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com