Ring-shaped winding machine

A technology of winding machine and winding mechanism, which is applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc. It can solve the problems of coil scrapping, jumping wires, overlapping wires, etc., and eliminate the phenomenon of jumping wires and overlapping wires , to avoid the effect of crossover phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

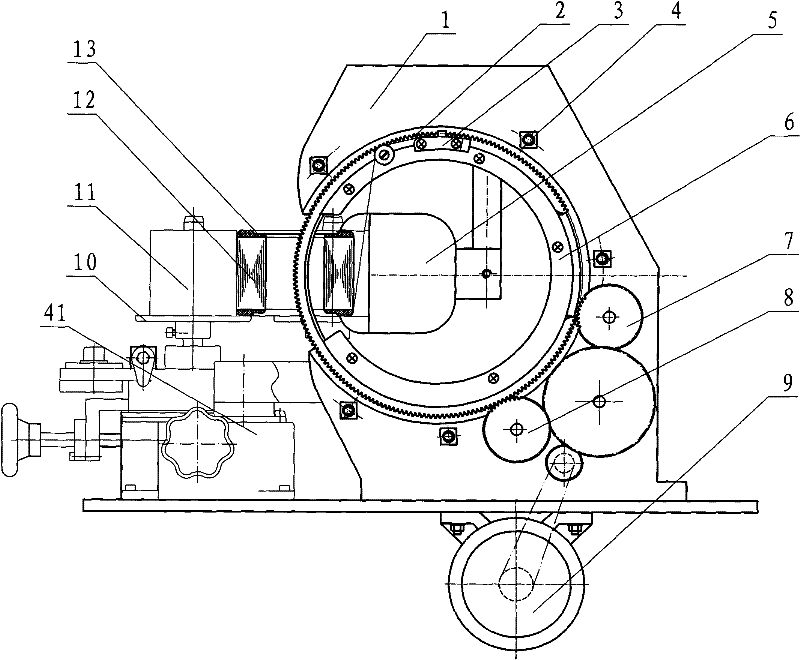

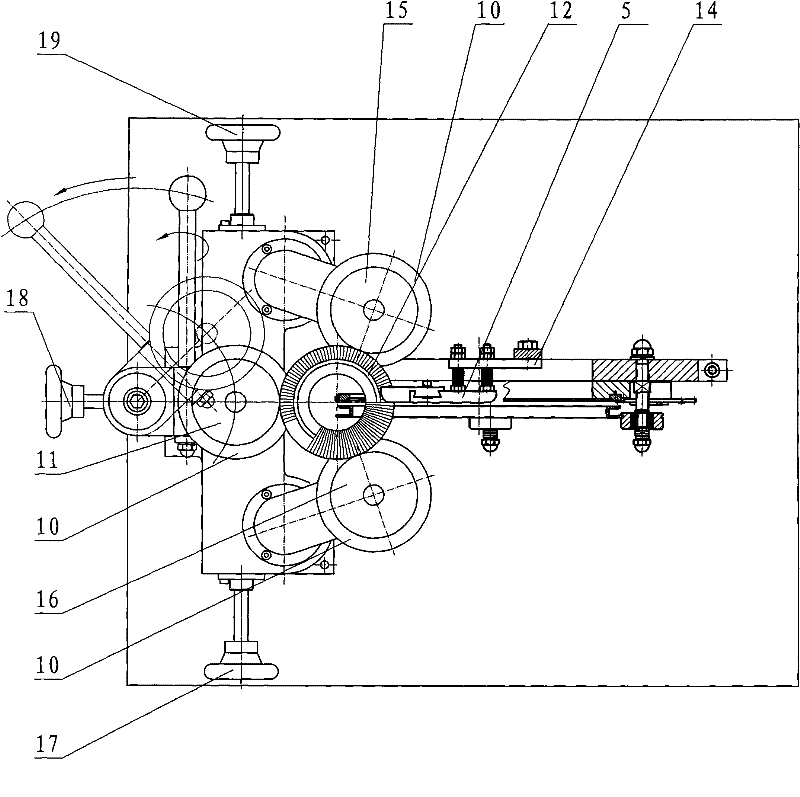

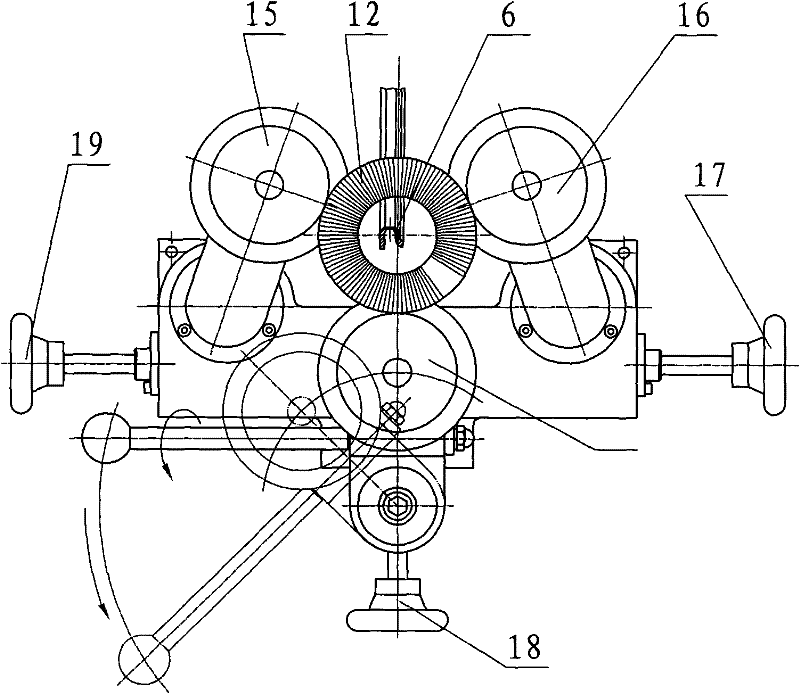

[0019] Referring to the accompanying drawings, this ring winding machine includes an open machine head 1, an electric control box, a transmission mechanism, a storage mechanism, a winding mechanism and a winding mechanism, and the transmission mechanism includes a first transmission mechanism and a second transmission mechanism. mechanism, wherein the first transmission mechanism drives the winding mechanism, and the second transmission mechanism drives the cable arrangement mechanism. The first transmission mechanism is composed of a frequency conversion motor 9 and transmission gears 7 and 8. The cable arrangement mechanism includes a mounting seat 41, two A driving rubber wheel 15, 16 with a tray 10 and a passive rubber wheel 11 with a tray 10, the driving rubber wheels 15, 16 with a tray 10 are in transmission connection with the second transmission mechanism, and the wire storage mechanism has The wire storage ring 6, wherein a small circular arc portion 6b of the wire sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com