Cutting device and cutting method thereof

A cutting device and cutting processing technology, applied in printing devices, printing, metal processing, etc., can solve the problems of position deviation, difficulty in ensuring the position accuracy of the cutting head and the target medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the following, for convenience of explanation, the arrow directions shown in each figure are respectively defined as front and rear, left and right, and up and down.

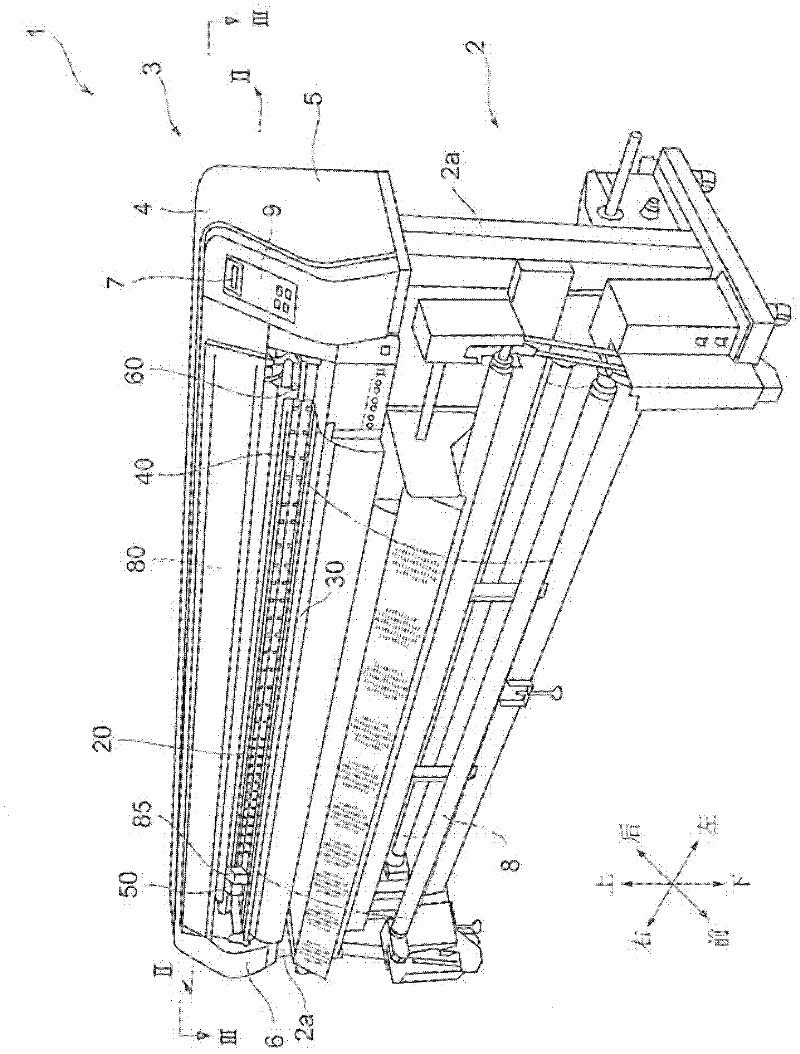

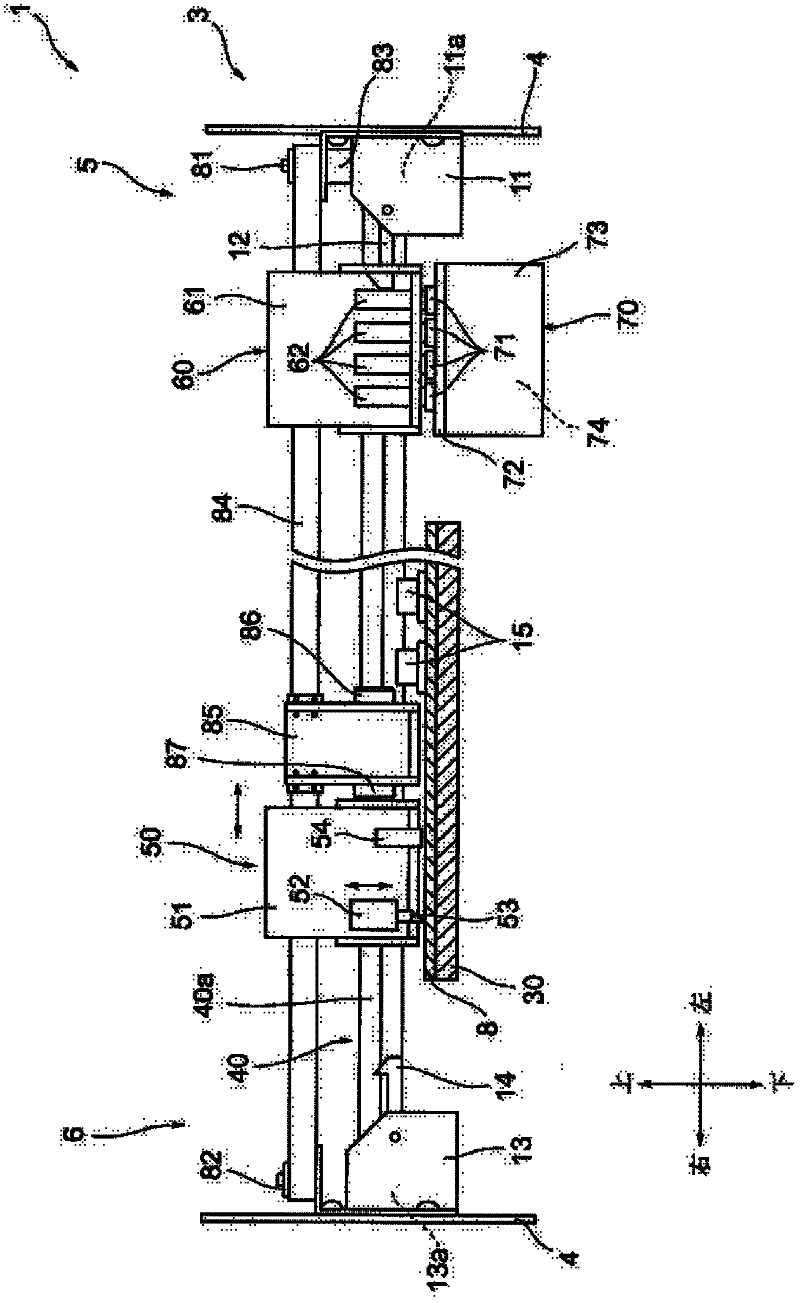

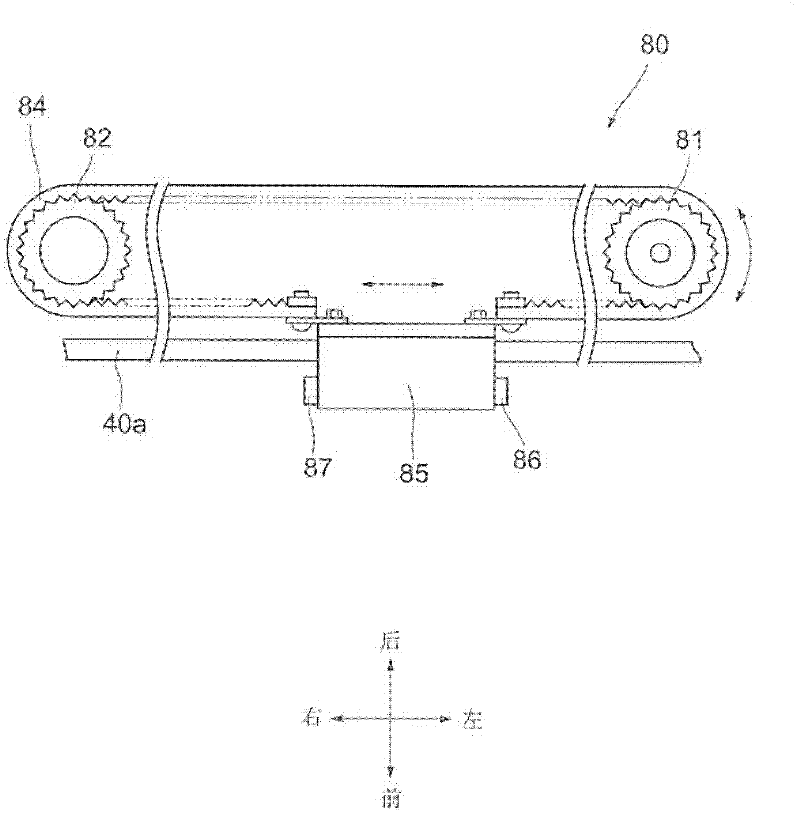

[0030] while referring to Figure 1 to Figure 5 , and the structure of the cutting device 1 to which the present invention is applied will be described. figure 1 A perspective view of the cutting device 1 is shown. figure 2 The internal structure of the main body part 3 mentioned later is shown. image 3 A plan view of a unit driving device 80 described later is shown. Figure 4 A perspective view showing the periphery of the printing unit 60 described later. Figure 5 A control system diagram of the cutting device 1 is shown.

[0031] Such as figure 1 As shown, the main body of the cutting device 1 includes: a support part 2 having a pair of left and right support legs 2a, 2a, and a main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com