Image pickup module and manufacturing method of image pickup module

The technology of a camera module and manufacturing method is applied in the direction of optical filter for photography, image communication, radiation control device, etc. It can solve the problems of poor impact resistance, blurred focus of incident light, and no installation process, etc., and achieves Effect of improving impact resistance and improving path accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

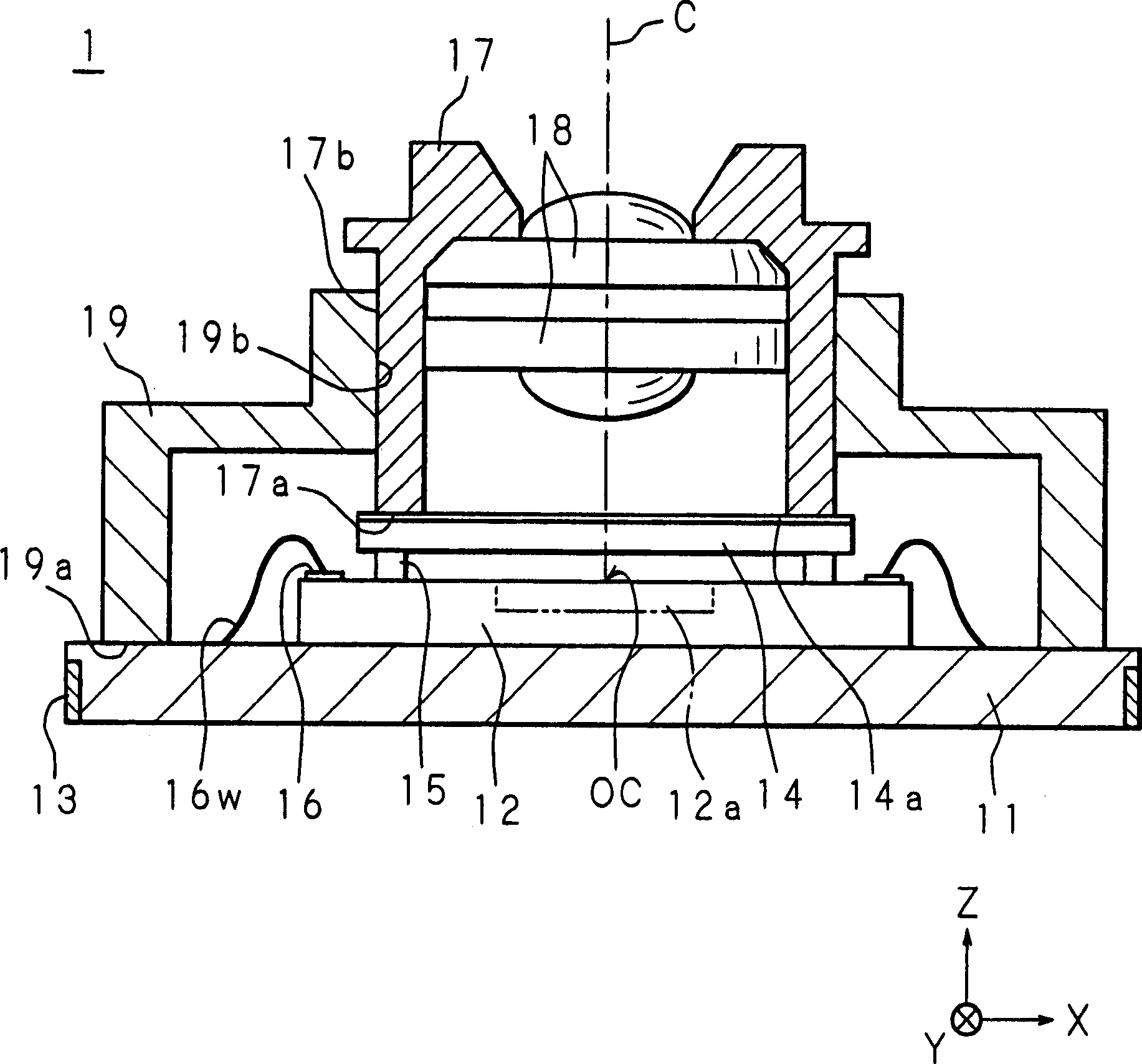

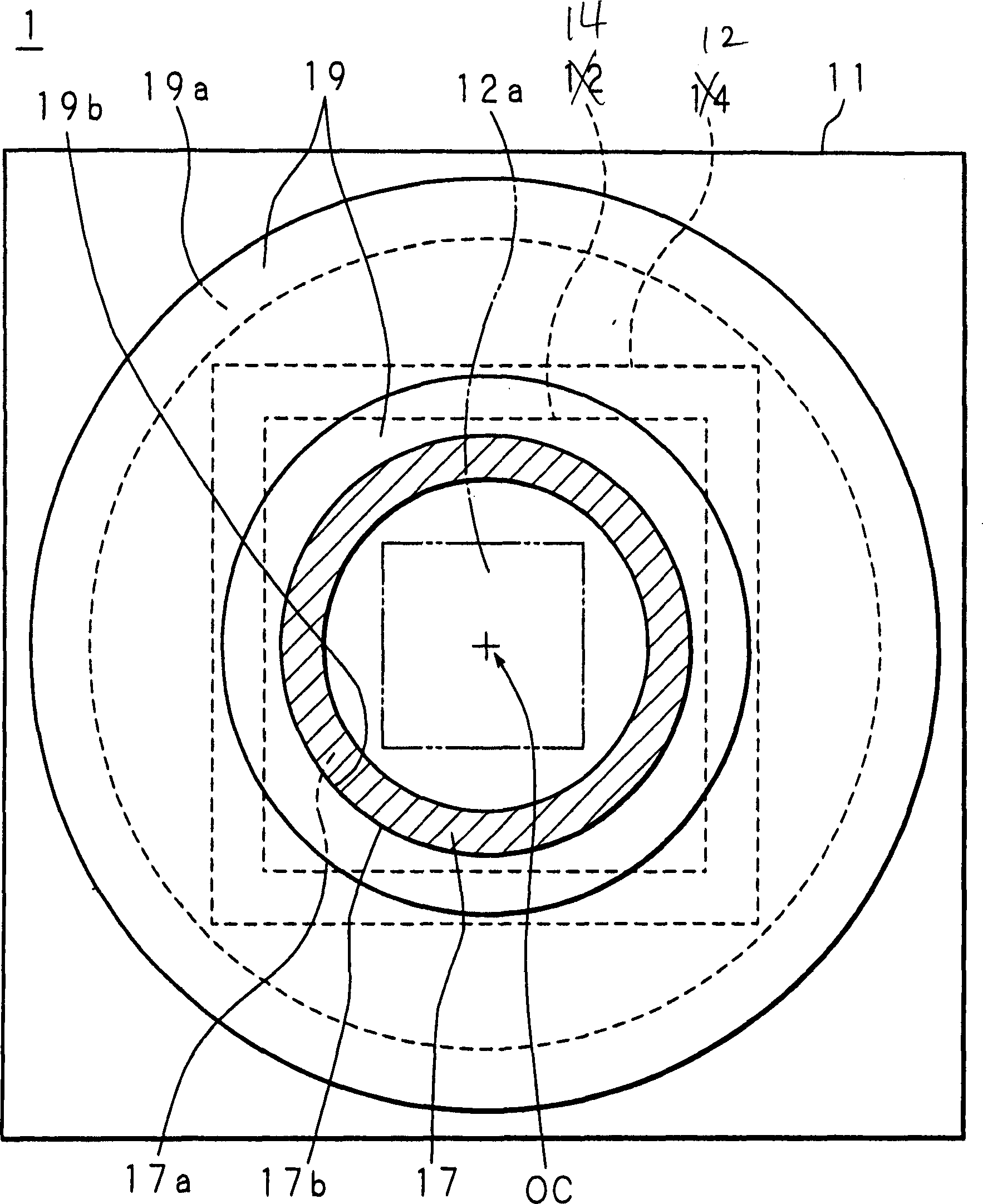

[0060] figure 1 is a side sectional view showing the structure of the camera module according to Embodiment 1 of the present invention, figure 2 It is a plan view of the camera module according to Embodiment 1 of the present invention viewed from the light incident side. In order to easily understand the positional relationship of the imaging element, the lens holder and the cover which are the features of the present invention, in figure 2 Some structural elements are omitted for representation.

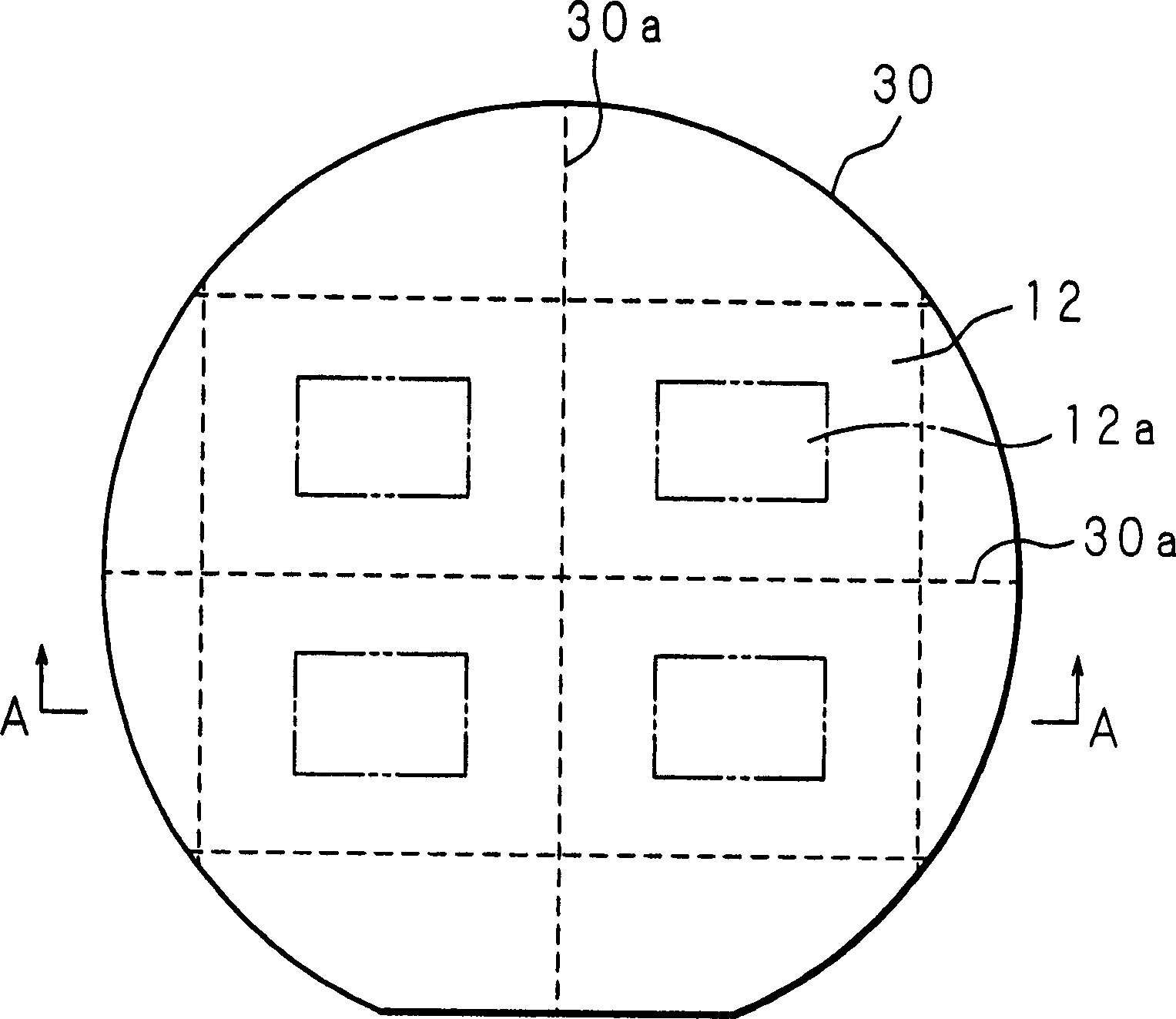

[0061] In the camera module 1 according to Embodiment 1 of the present invention, the camera element 12 is diced and bonded to the substrate ( Substrate )11 on one surface. The imaging element 12 is a semiconductor device such as a CCD or a CMOS imager, and its structure is such that the light receiving unit 12a is placed in the center of the chip, and peripheral circuits such as a readout circuit for reading out a signal based on the amount of light detected by the light rece...

Embodiment approach 2

[0083] In Embodiment 1, a method was described in which the optical position of the lens in the XY direction and the Z direction is restricted by a cover and a lens holder, but a lens holder functioning as a cover may also be used, as is the case in Embodiment 2.

[0084] Figure 7 It is a side sectional view showing the structure of the camera module according to Embodiment 2 of the present invention.

[0085] The camera module 2 according to Embodiment 2 of the present invention is provided with: the lens holder ( fixed part )27. A lens 28 that guides the path of incident light to the light receiving portion 12 a of the imaging element 12 is fixed at a predetermined position on the lens holder 27 . The lens holder 27 has a stepped portion 27b having the function of the contact portion of the present invention, the stepped portion 27b engages with the edge of the transparent plate 14, and the foot portion 27a is fixed with an adhesive 63 in a state where the stepped portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com