High-stress large-deformation roadway supporting system and method

A roadway support and large deformation technology, which is applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of poor effect and easy failure, and achieve the goal of improving pull-out resistance, reducing anchor loss rate, and enhancing overall bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

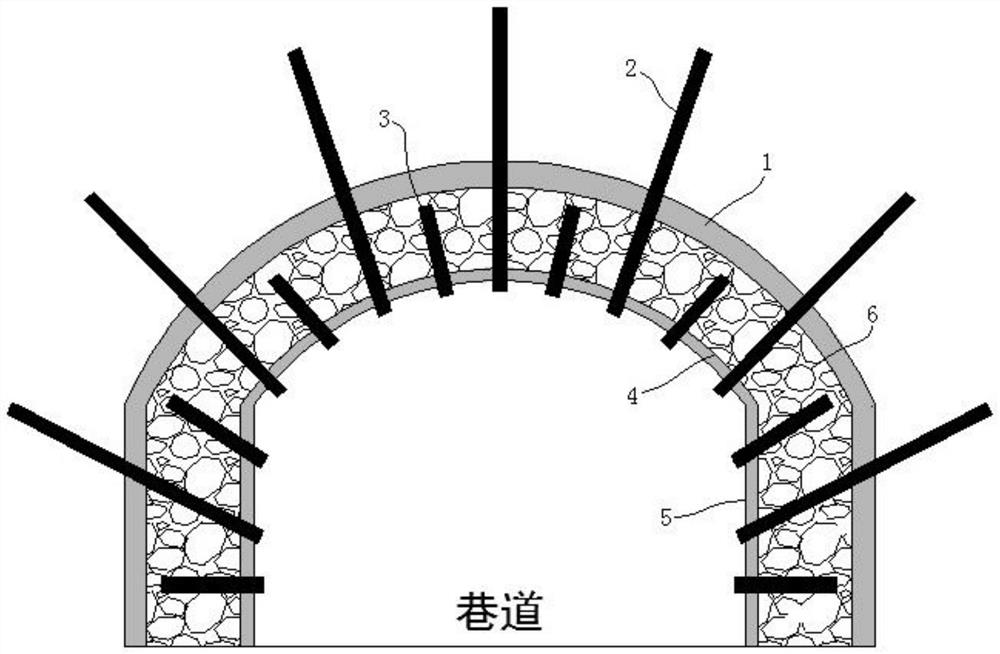

[0028] A high stress and large deformation roadway support method, comprising the following steps:

[0029] S1. Arrange the reinforced shell bracket 1 close to the inner wall of the roadway, install the anchor cable 2 on the reinforced shell bracket 1, and fix it on the inner wall of the roadway;

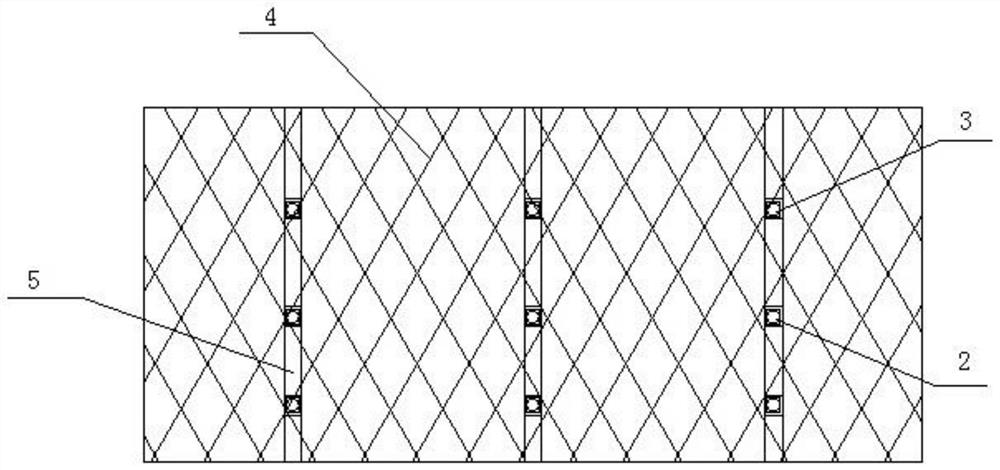

[0030] S2. Install the anchor cable 2 and the anchor rod 3 at intervals between the two sides and the arch of the soft rock roadway, and lay a metal mesh 4 on the ends of the anchor cable 2 and the anchor rod 3 for hanging and fixing;

[0031] S3. A retractable metal bracket 5 is installed on one side of the metal mesh 4, and the legs of the retractable metal bracket 5 are supported by double-row anchor piles;

[0032] S4. Concrete is poured through the grouting hole, so that the flexible concrete spray layer 6 is covered in the gap formed by the metal mesh 4, the shrinkable metal bracket 5, the steel shell bracket 1 and the inner wall of the roadway.

[0033] like figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com