Patents

Literature

37results about How to "Prevent inward movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

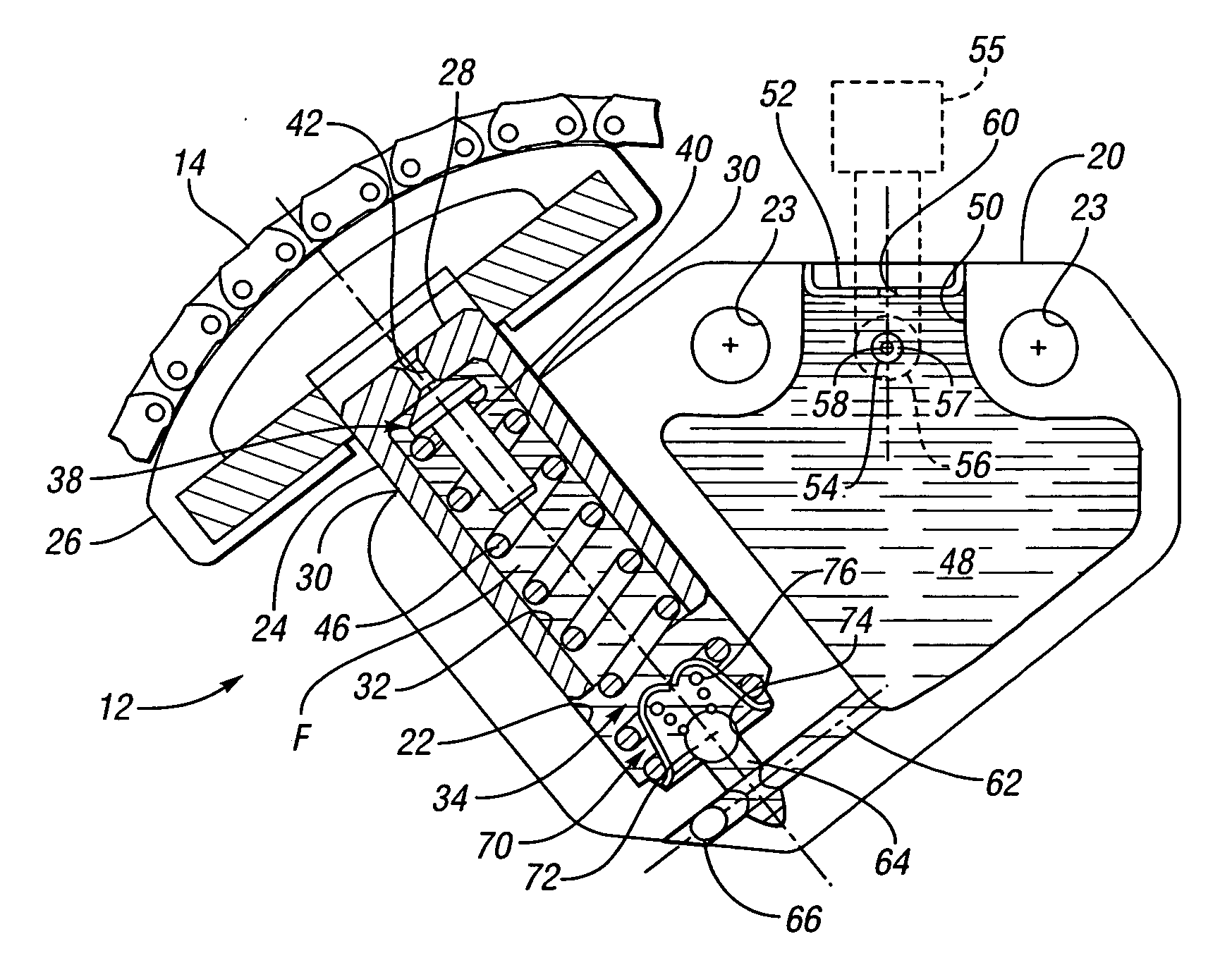

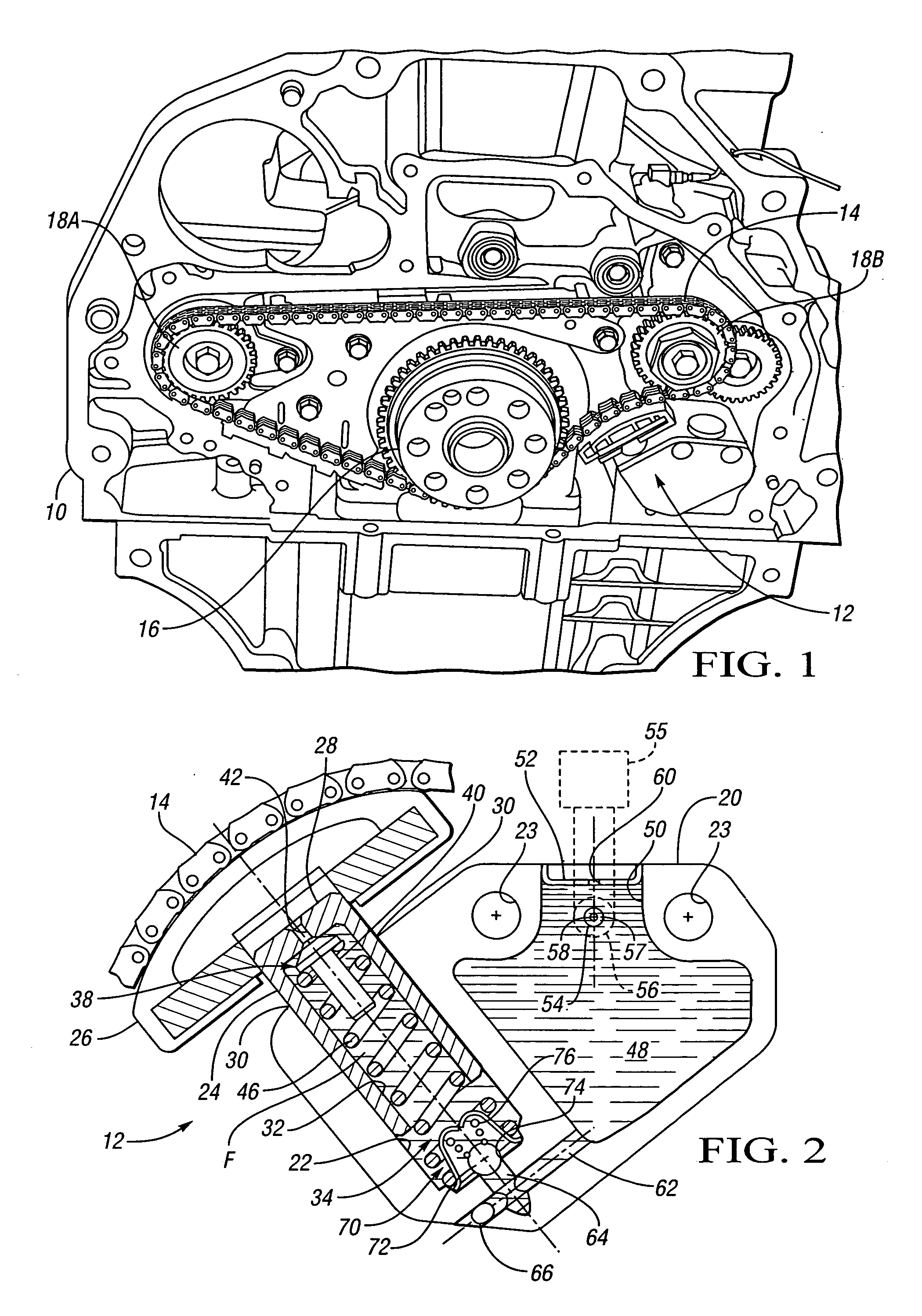

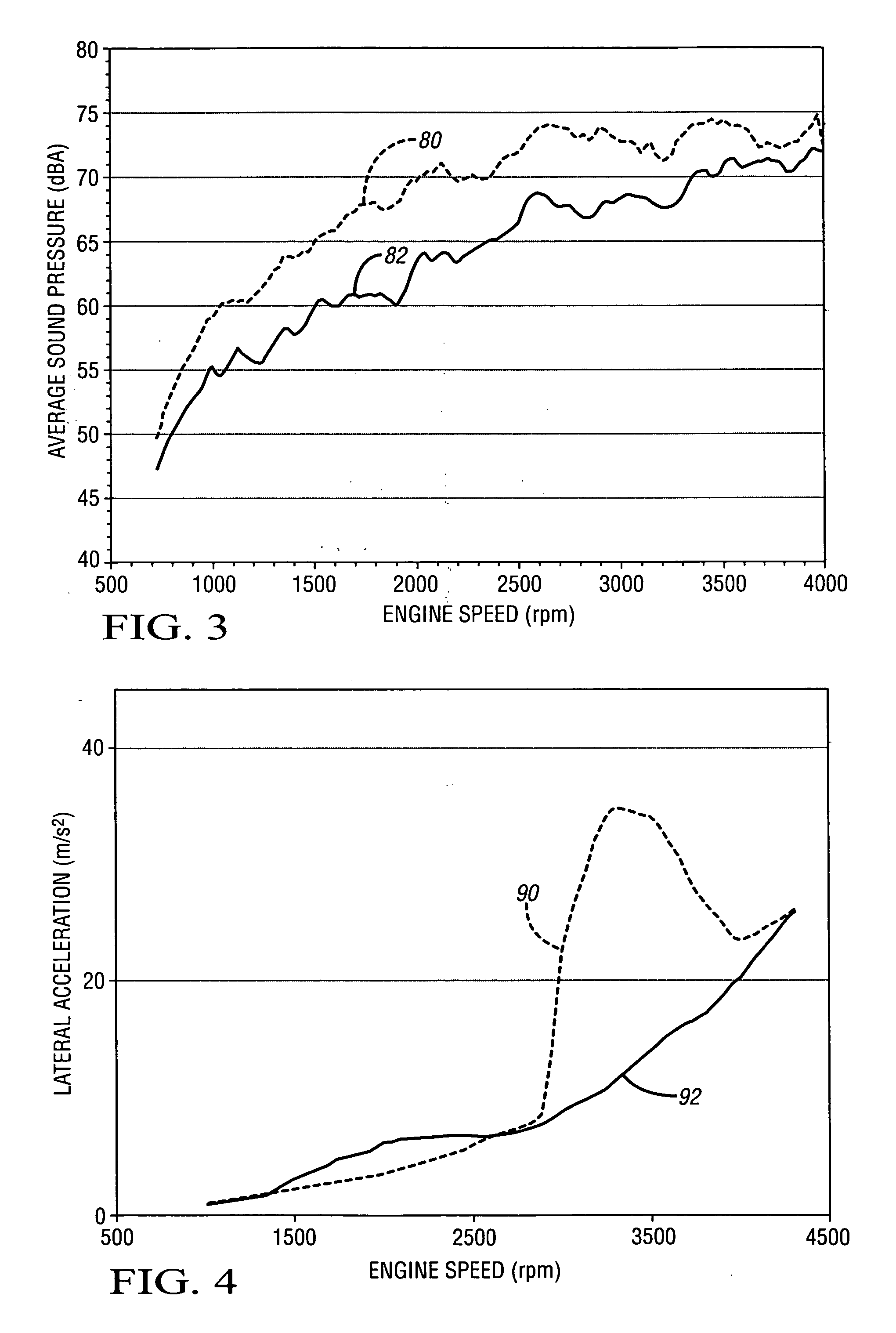

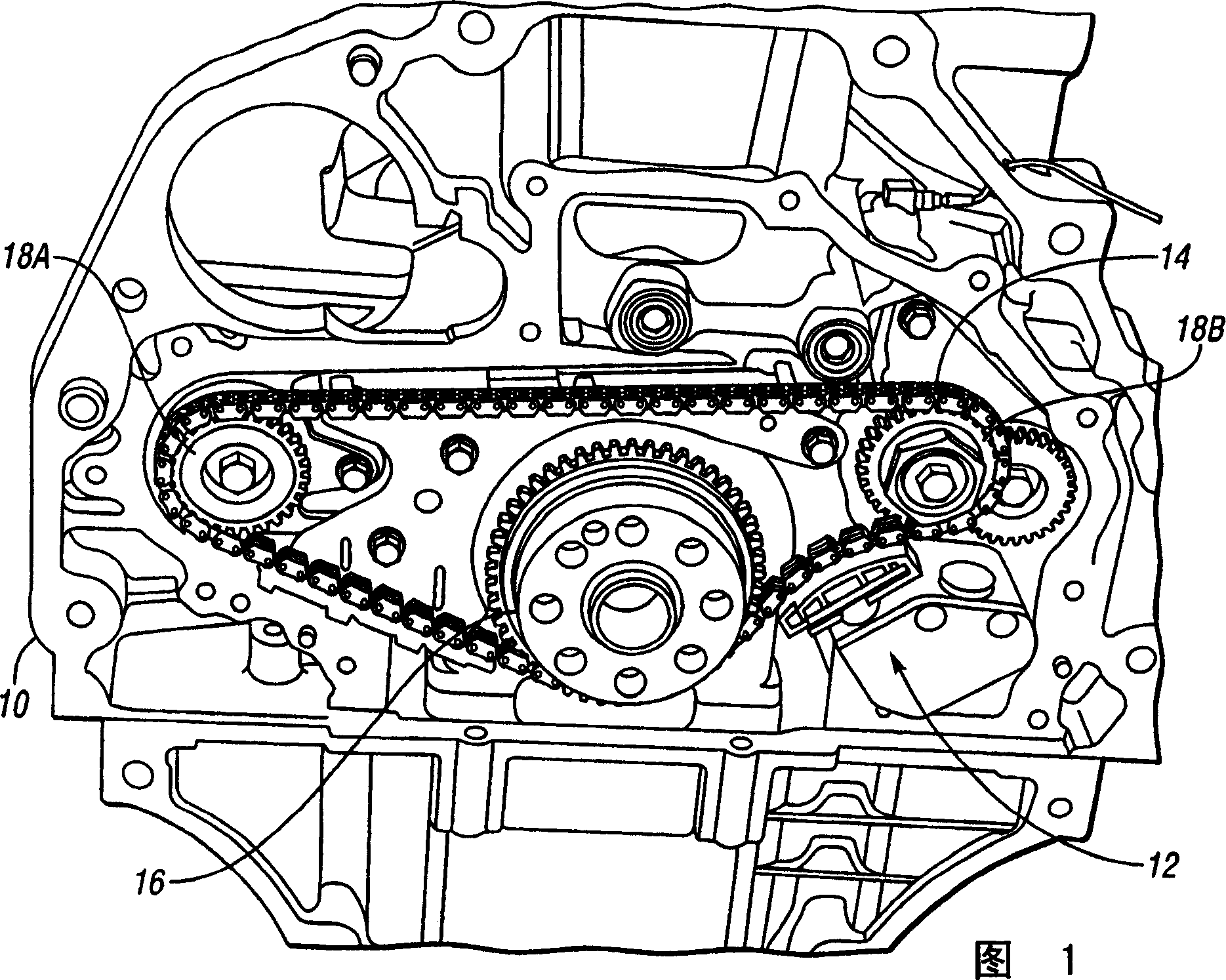

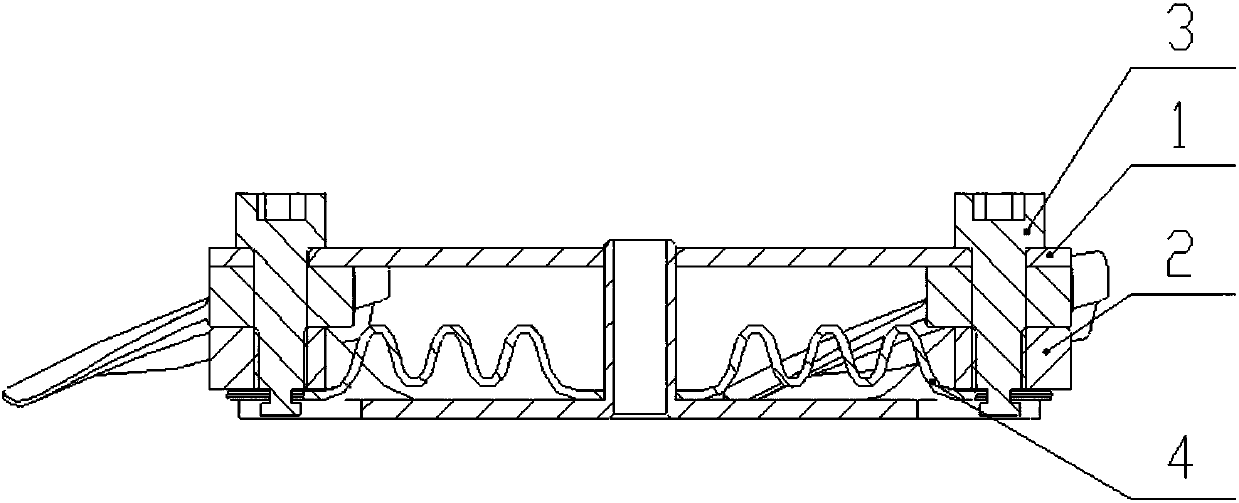

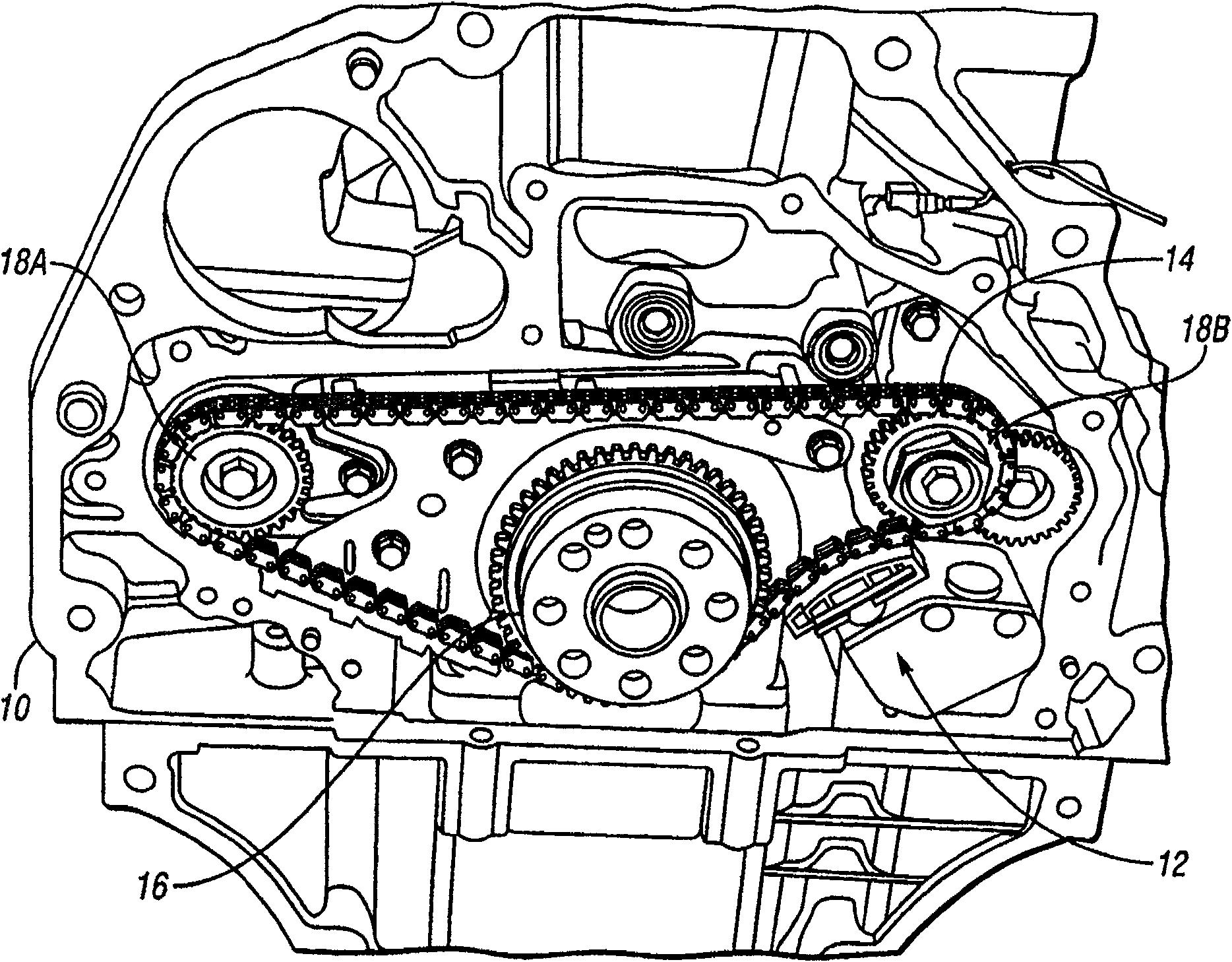

Hydraulic chain tensioner assembly

A hydraulic chain tensioner assembly includes a plunger slider received within an opening in a tensioner body to define a controlled clearance and a substantially fluid-tight chamber. Pressure in a supply reservoir that is in fluid communication with the fluid-tight chamber is controlled to a relatively low level by appropriate sizing of the feed orifice and a bleed orifice in communication with the supply reservoir. Thus, apply force of a shoe connected to a plunger on a chain is a function of stiffness of a main spring that biases the plunger outward, and is not substantially affected by pressure of a fluid source supplying fluid to the reservoir. A method of manufacturing a hydraulic chain tensioner assembly is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

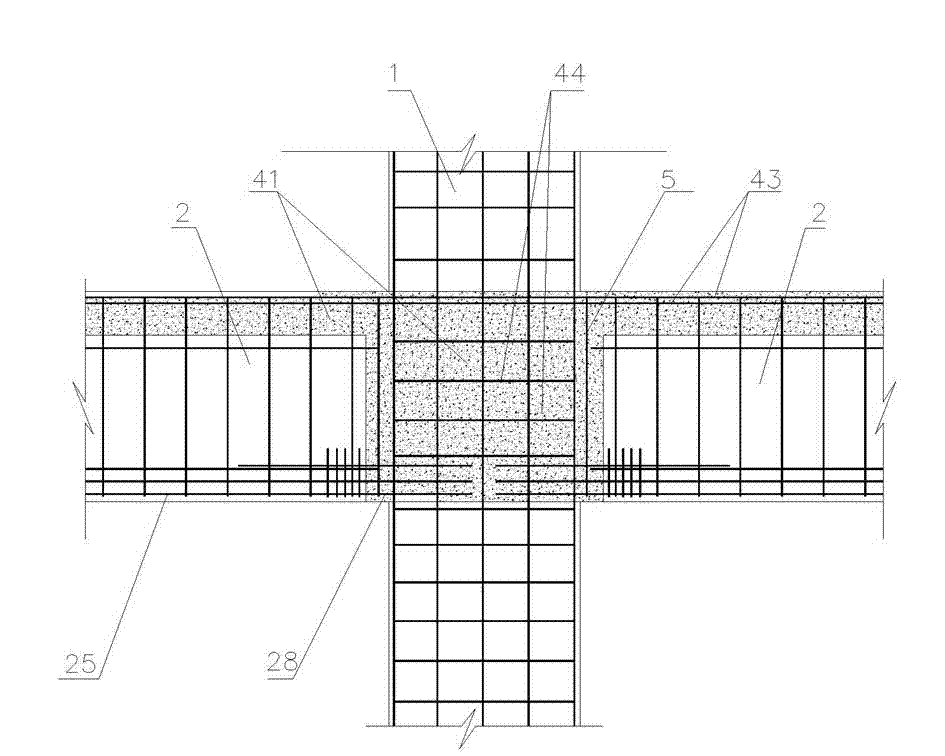

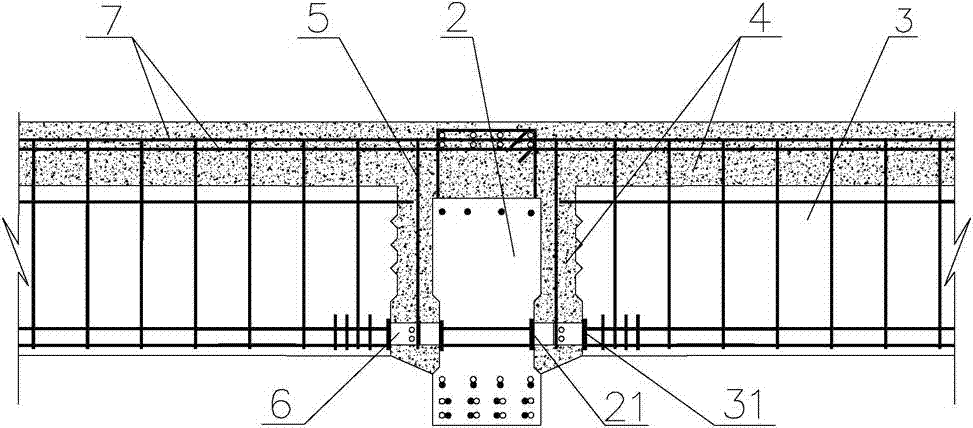

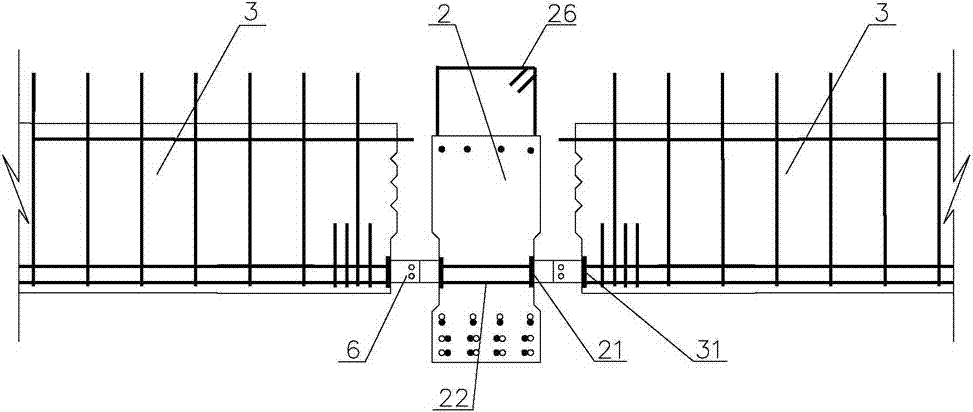

Pre-tensioning prestressed composite beam structural system and construction method thereof

The invention relates to a pre-tensioning prestressed composite beam structural system and a construction method of the pre-tensioning prestressed composite beam structural system. Lower longitudinal reinforcements are bound and lapped on lower longitudinal prestress wires in composite frame beam prefabricated components; the lower longitudinal reinforcements are inserted into frame pillars; second pre-buried steel plates are buried in the lower end portions of the composite frame beam prefabricated components; lower portion longitudinal prestress wires are buried in the composite frame beam prefabricated components; secondary beam longitudinal reinforcements are lapped and bound on the lower portion longitudinal prestress wires; the second pre-buried steel plates are welded with the secondary beam longitudinal reinforcements; first pre-buried steel plates opposite to the second pre-buried steel plates are arranged on the composite frame beam prefabricated components; pitch point steel plates are respectively welded on the first pre-buried steel plates and the second pre-buried steel plates; and the pitch point steel plates are connected through bolts, which enables the composite frame beam prefabricated components to connect with composite secondary beam prefabricated components. Wires and longitudinal reinforcements are lapped to use in the pre-tensioning prestressed composite beam structural system, and therefore the connecting mode of the pre-tensioning prestressed composite beam structural system is scientific and reasonable, and quality is safe and reliable.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

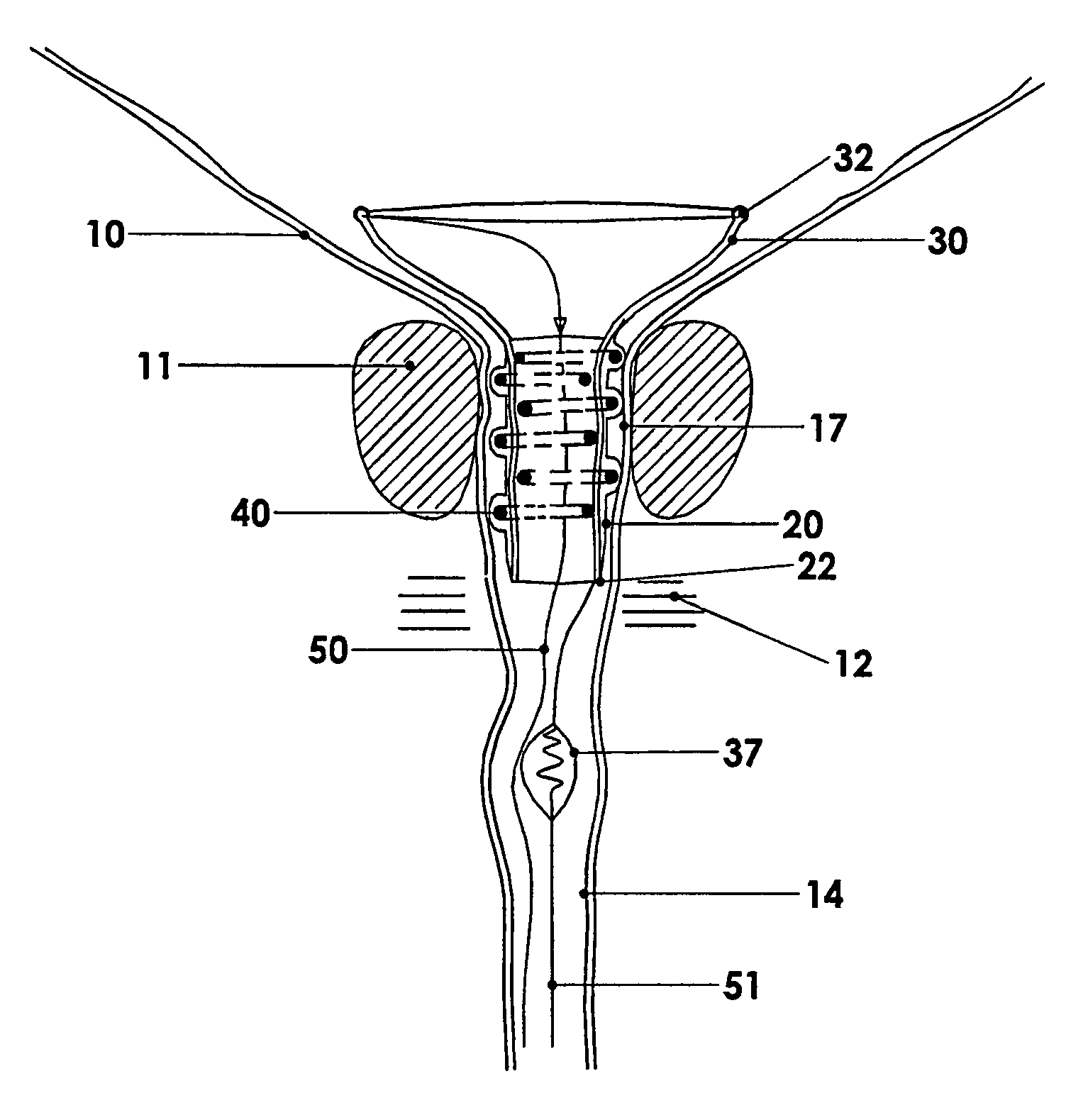

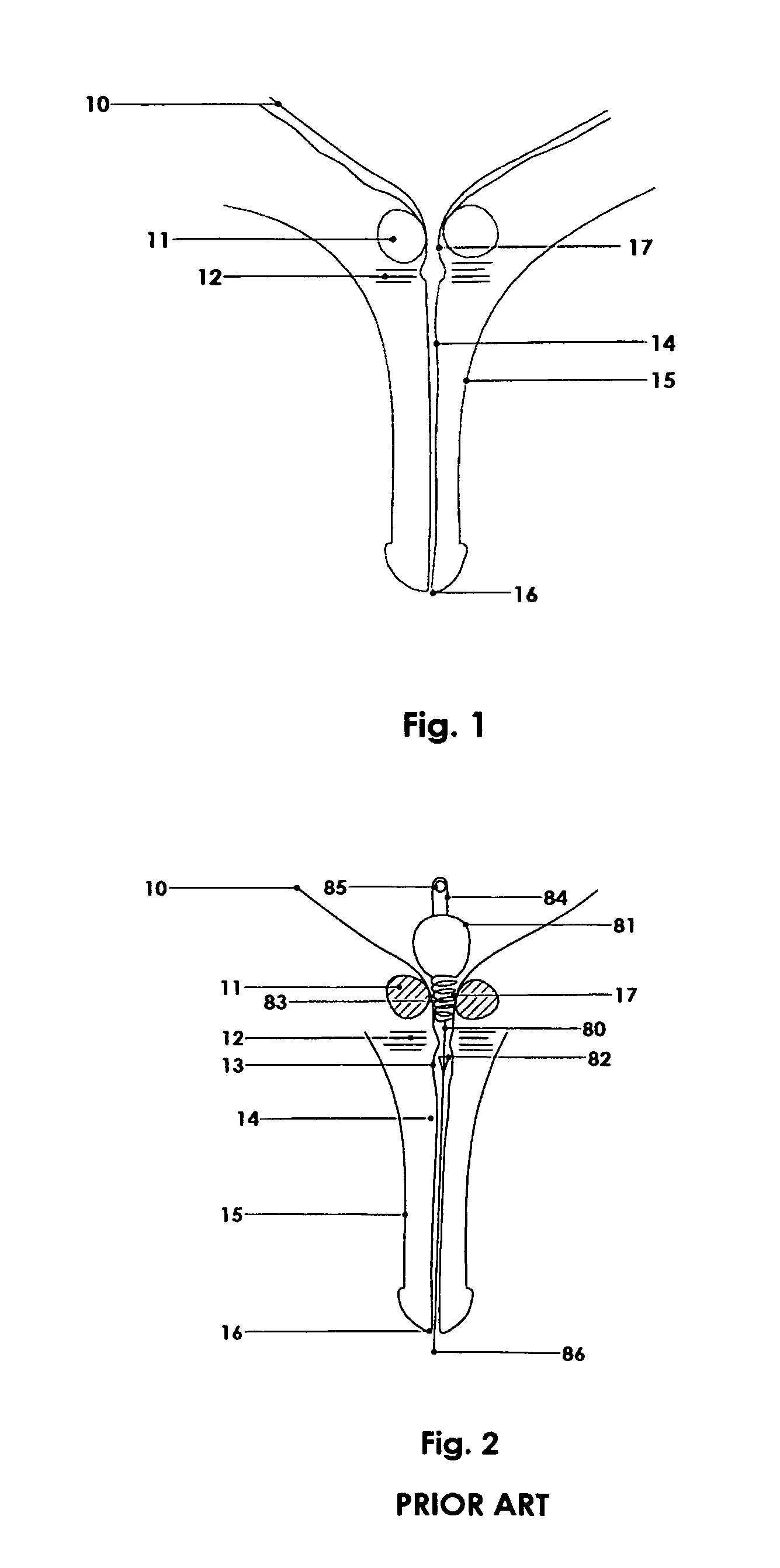

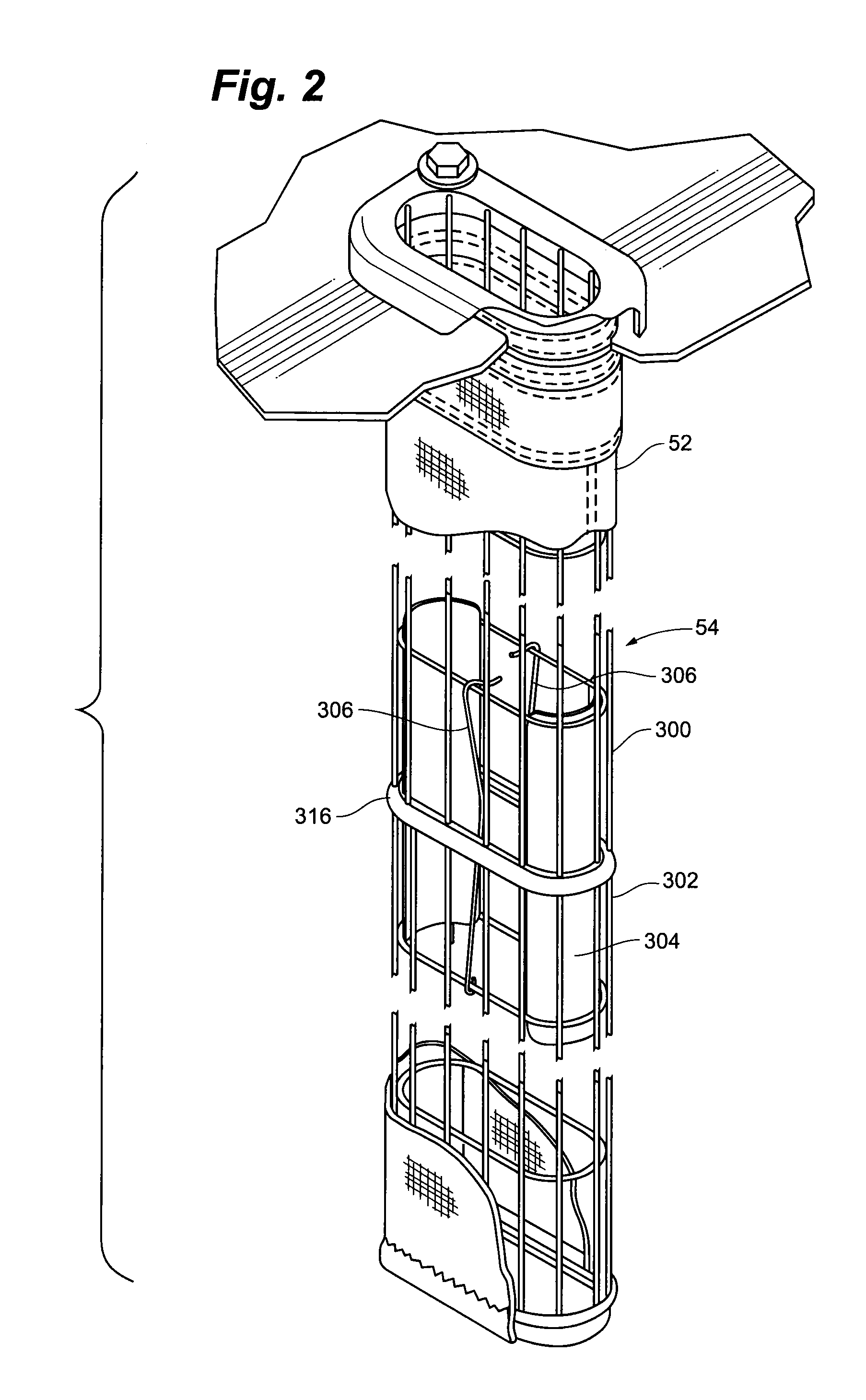

Temporary prostatic stent for benign prostatic hyperplasia

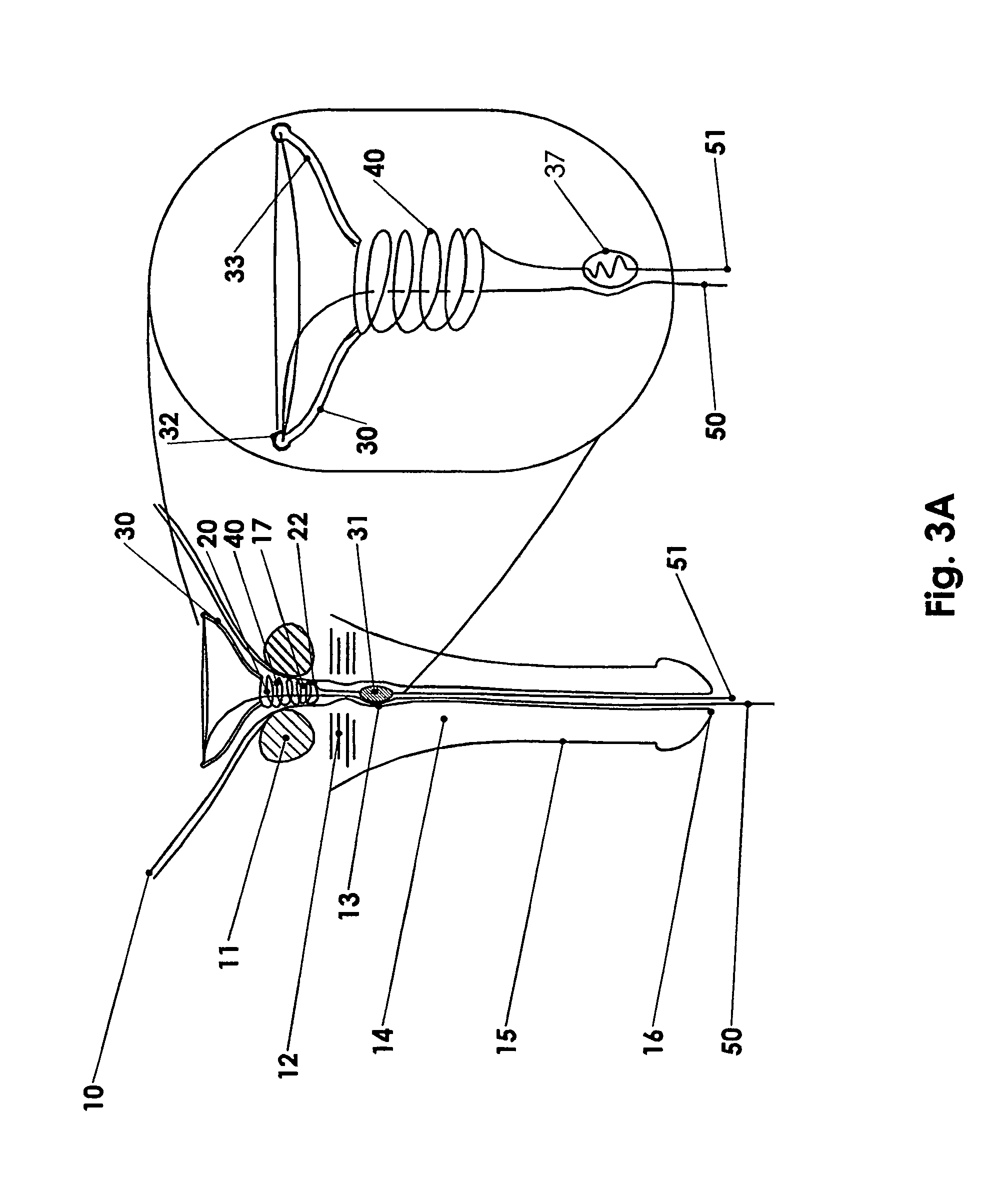

InactiveUS8465551B1Easy to drainPrevent inward movementStentsCatheterInsertion stentProstate hyperplasia

This invention relates to a temporary indwelling prostatic stent which provides a passage for urine through the prostatic urethra and which enable the patient to void the bladder at will. This temporary prostatic stent consists of a coiled or braided made out of metal or plastic section which spans the prostatic urethra, wings composed of memory alloy allowing an anchoring means in the bladder, and an anchoring means below the external sphincter, and a retrieval string to facilitate removal of the stent from the patient.

Owner:WIJAY BANDULA +2

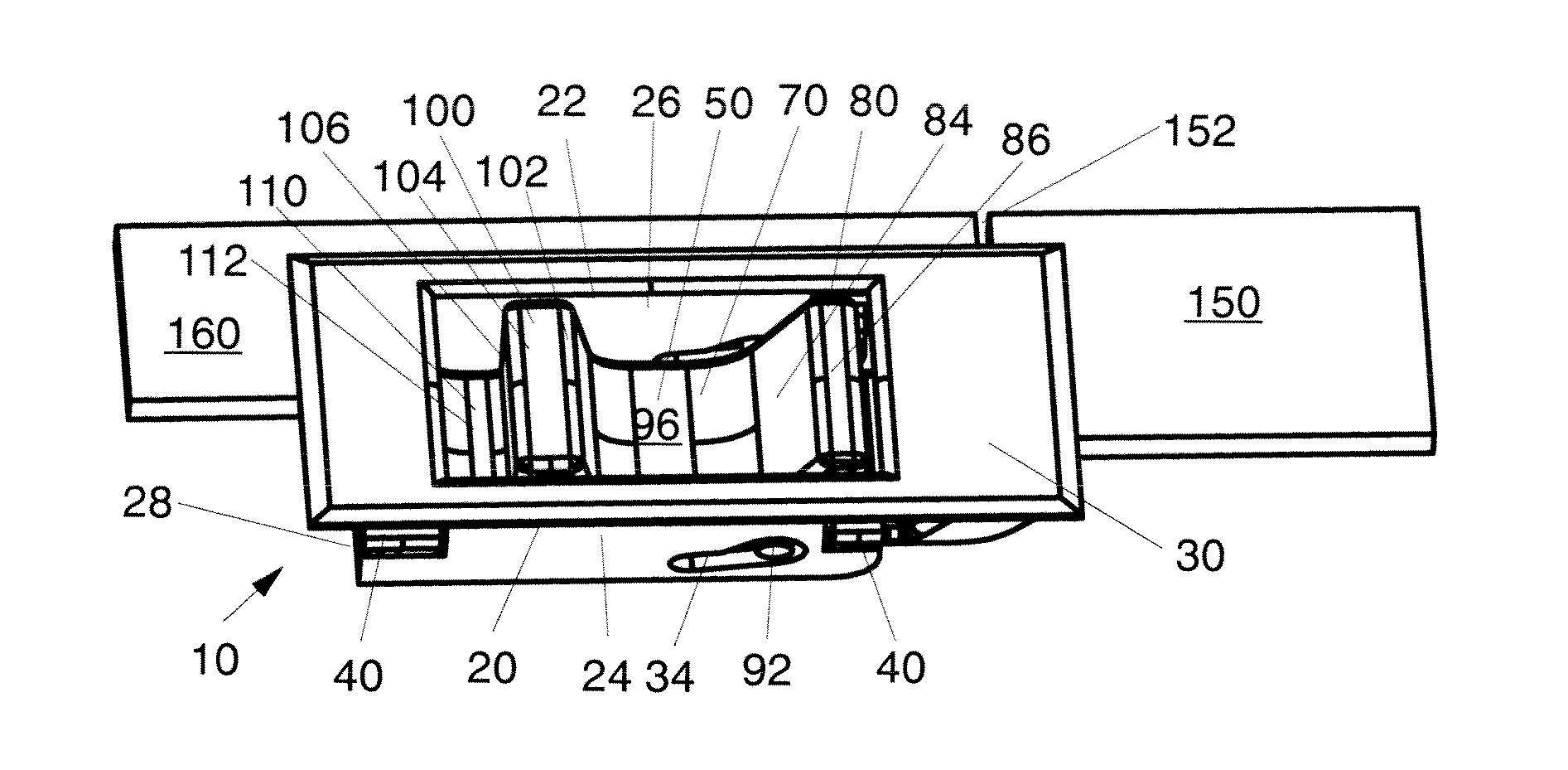

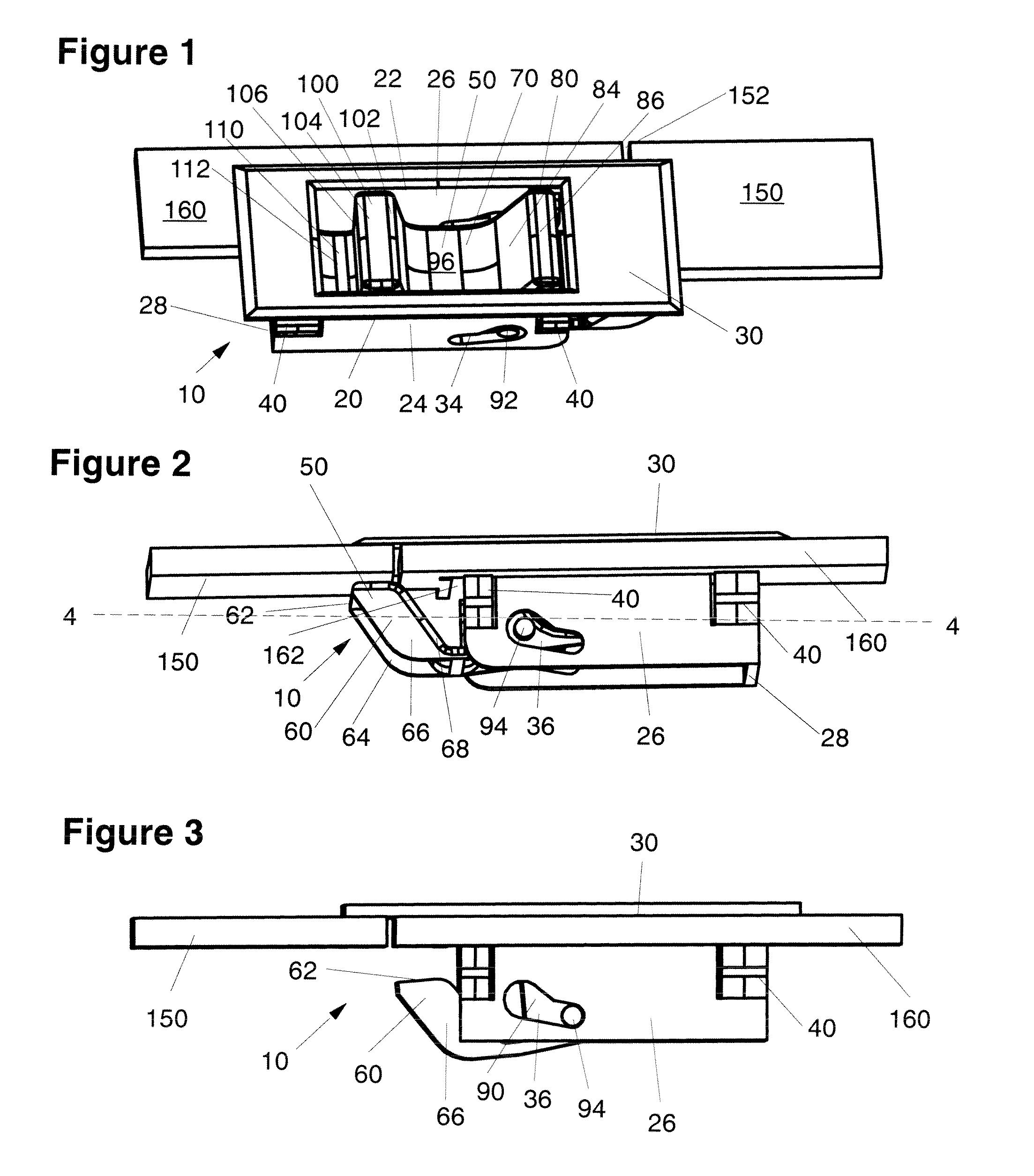

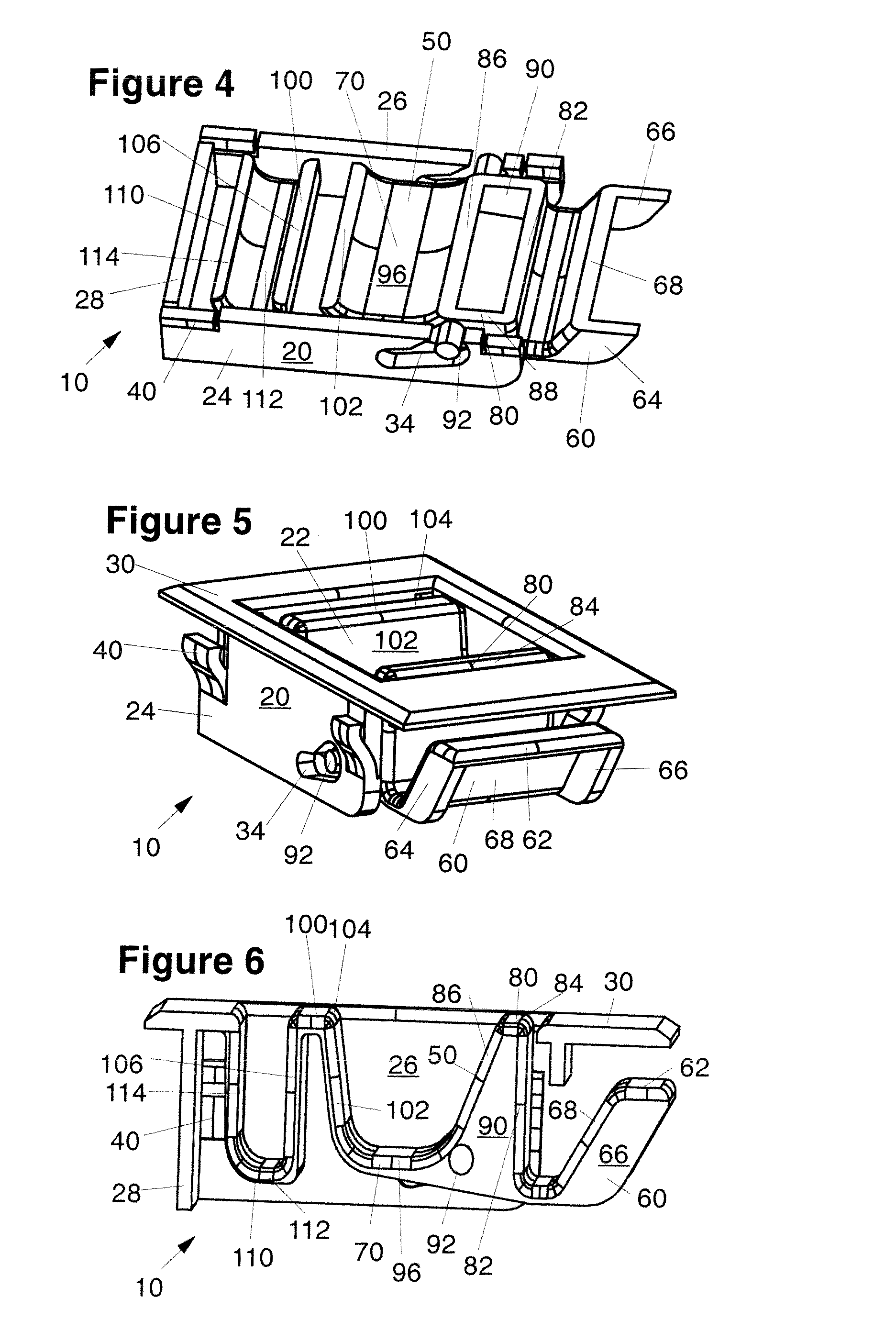

Slide latch

A sliding-action slam latch includes an integrally molded actuator having a rigid portion and an flexible portion, the flexible portion serving to bias the actuator closed. Pins extending from the rigid portion of the actuator contact guide surfaces on the latch body to limit travel of the actuator.

Owner:SOUTHCO

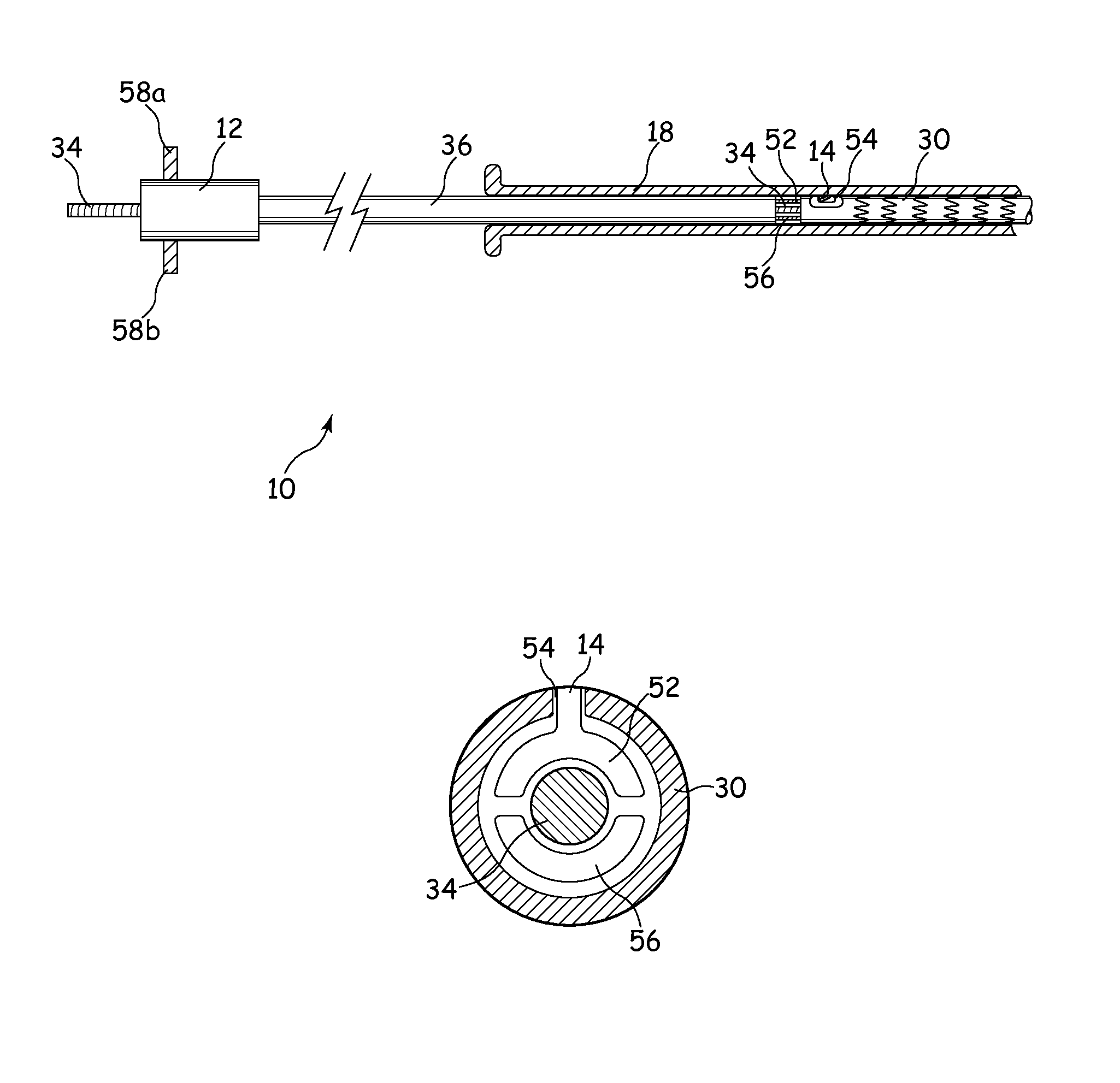

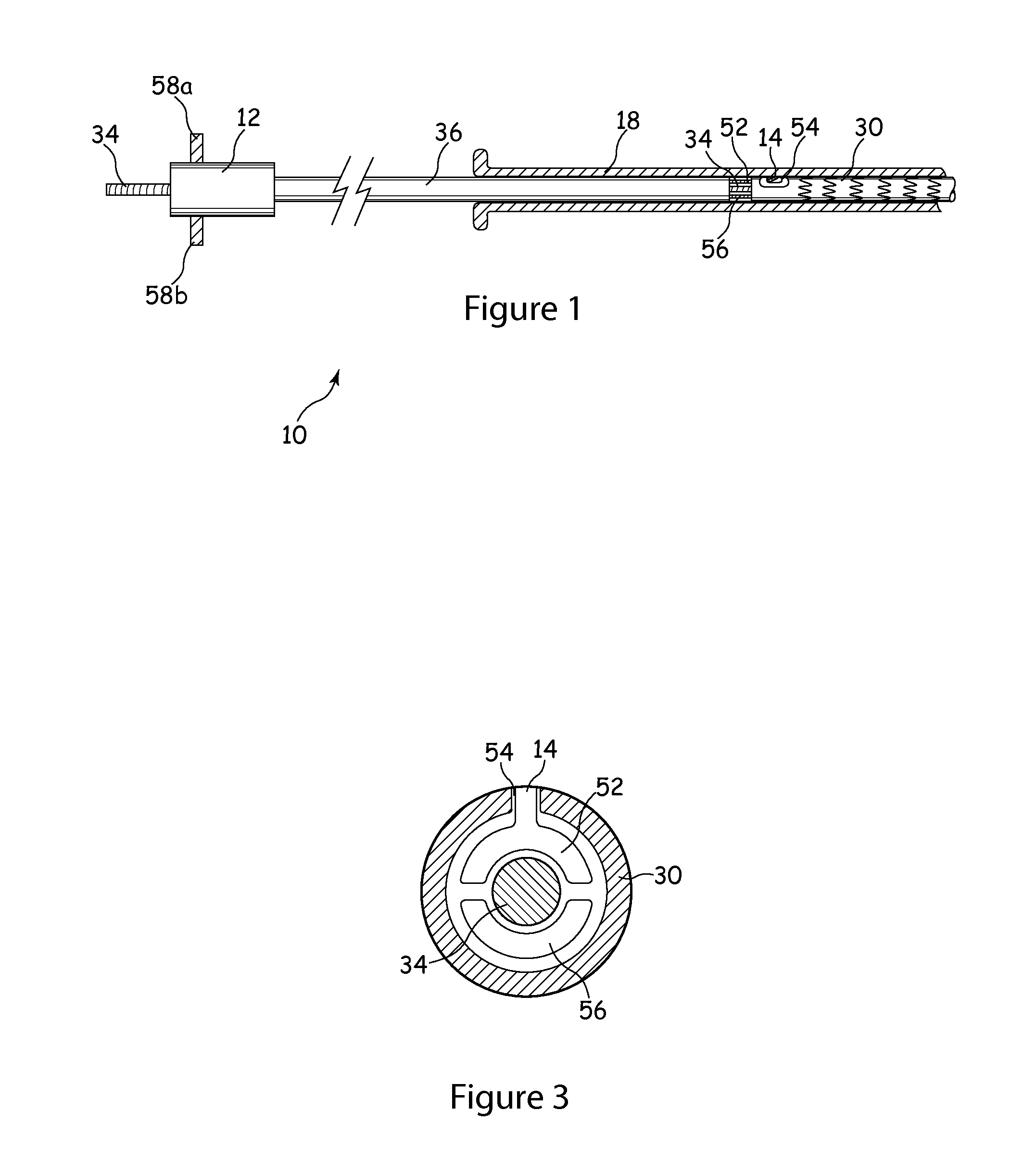

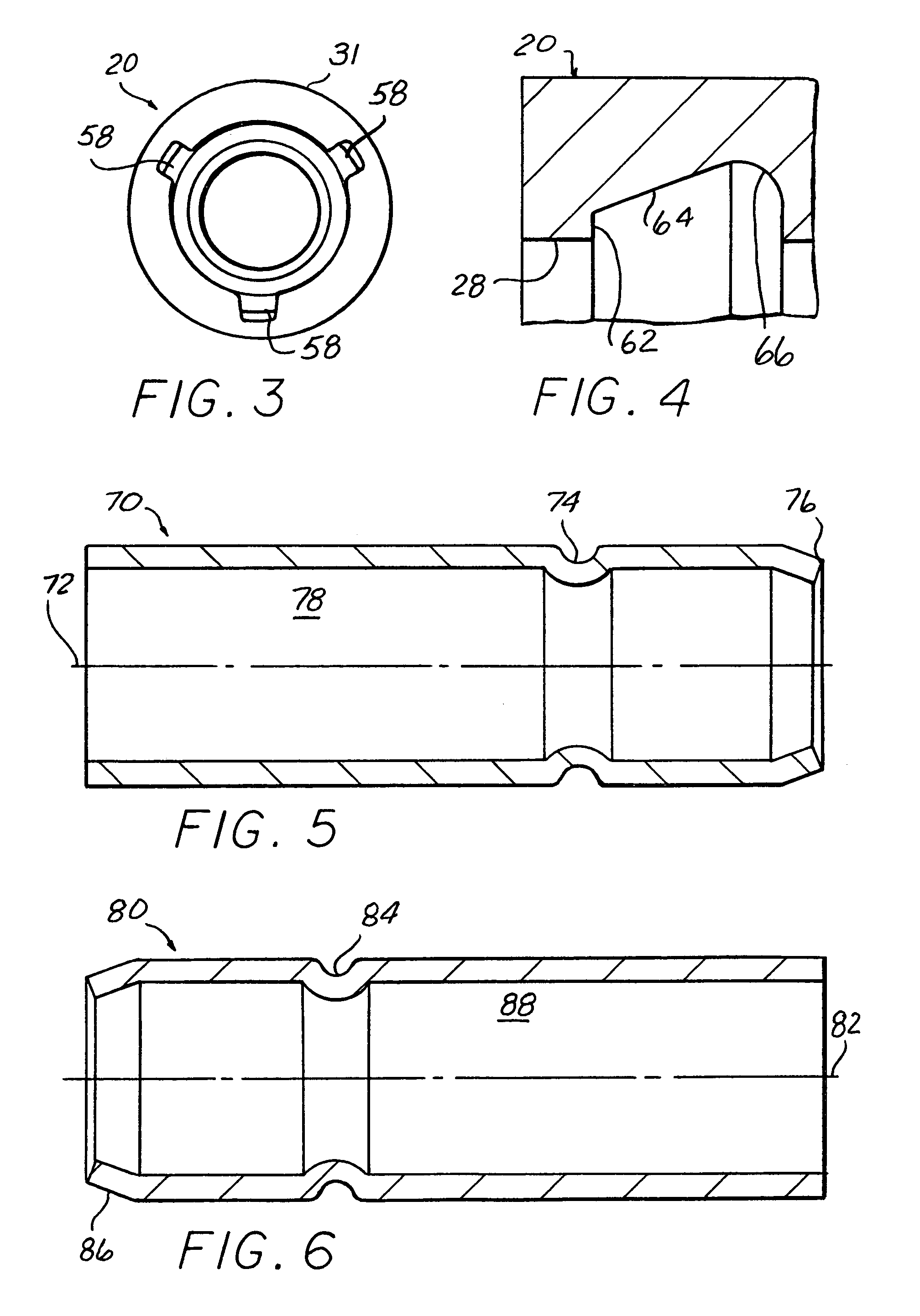

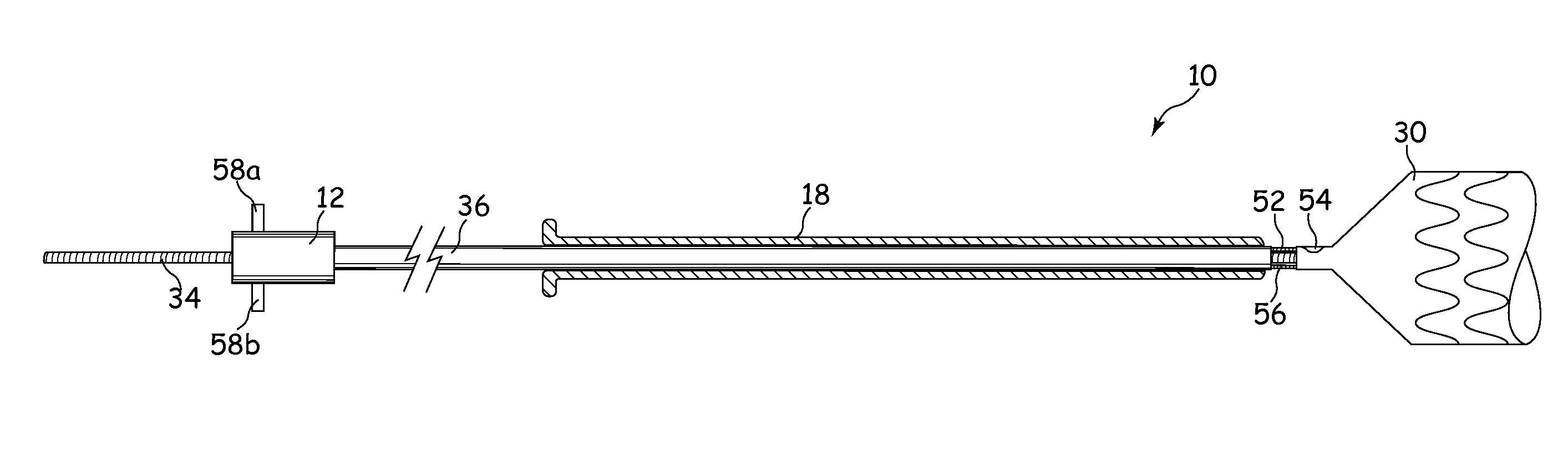

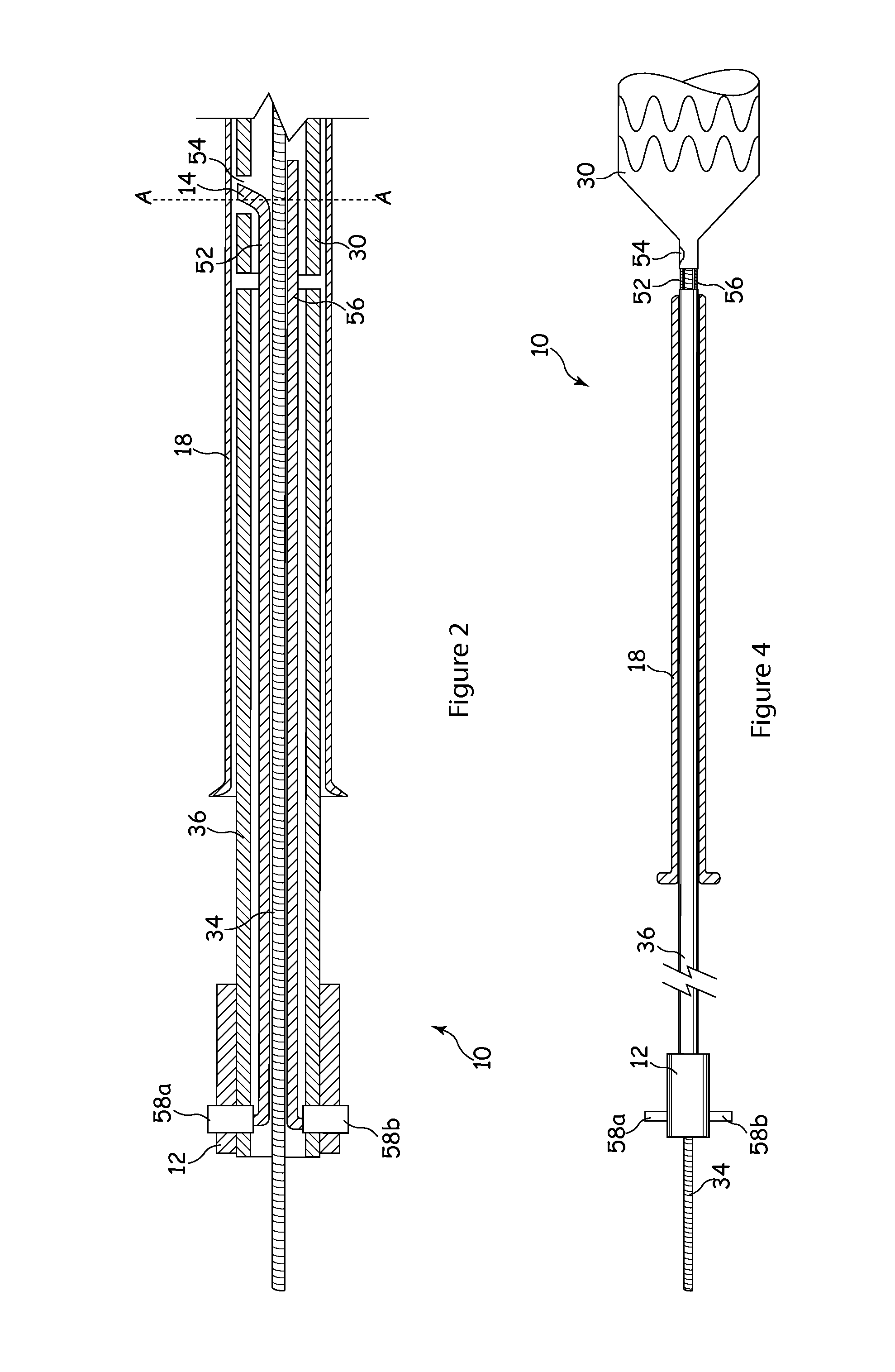

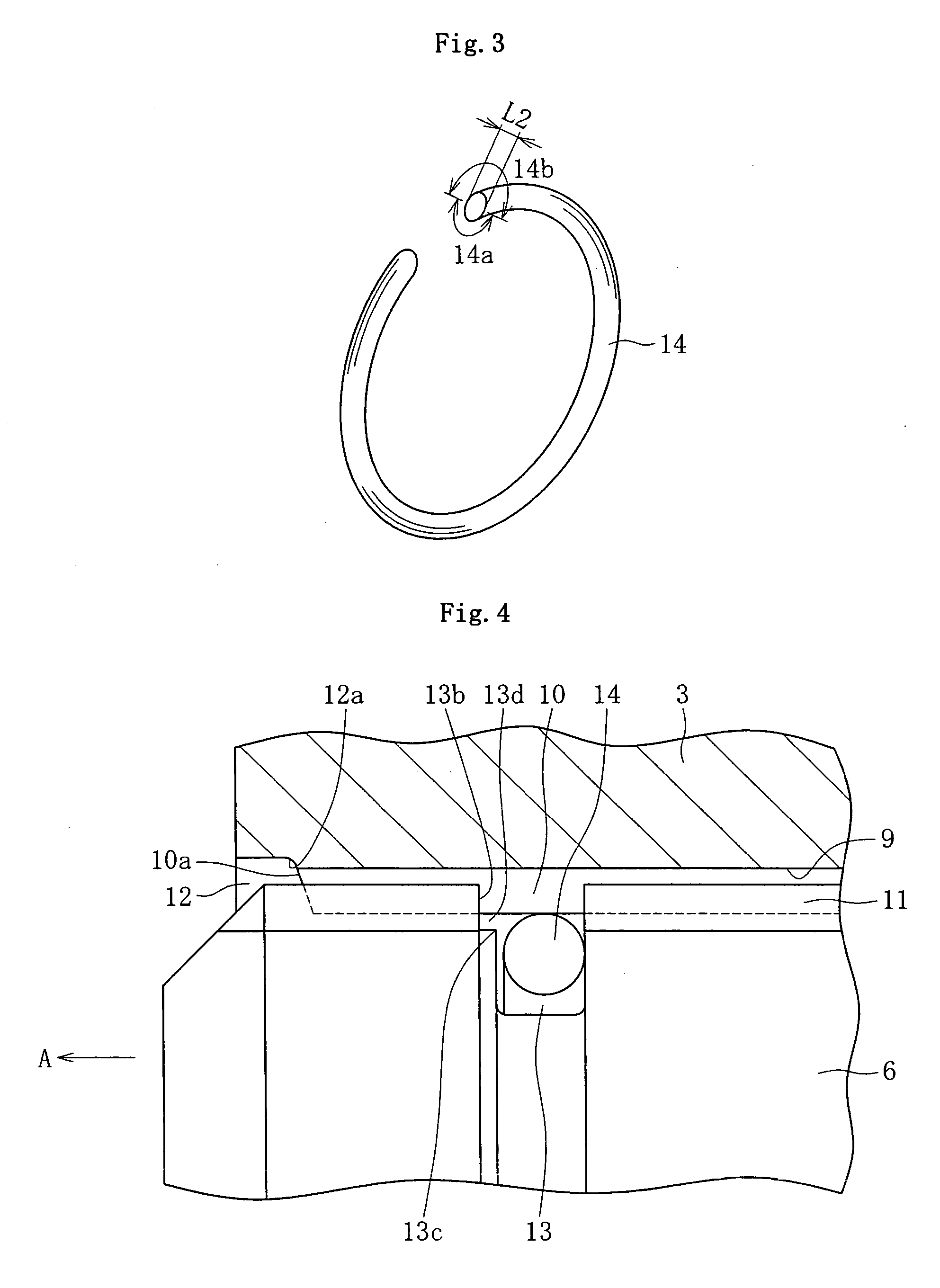

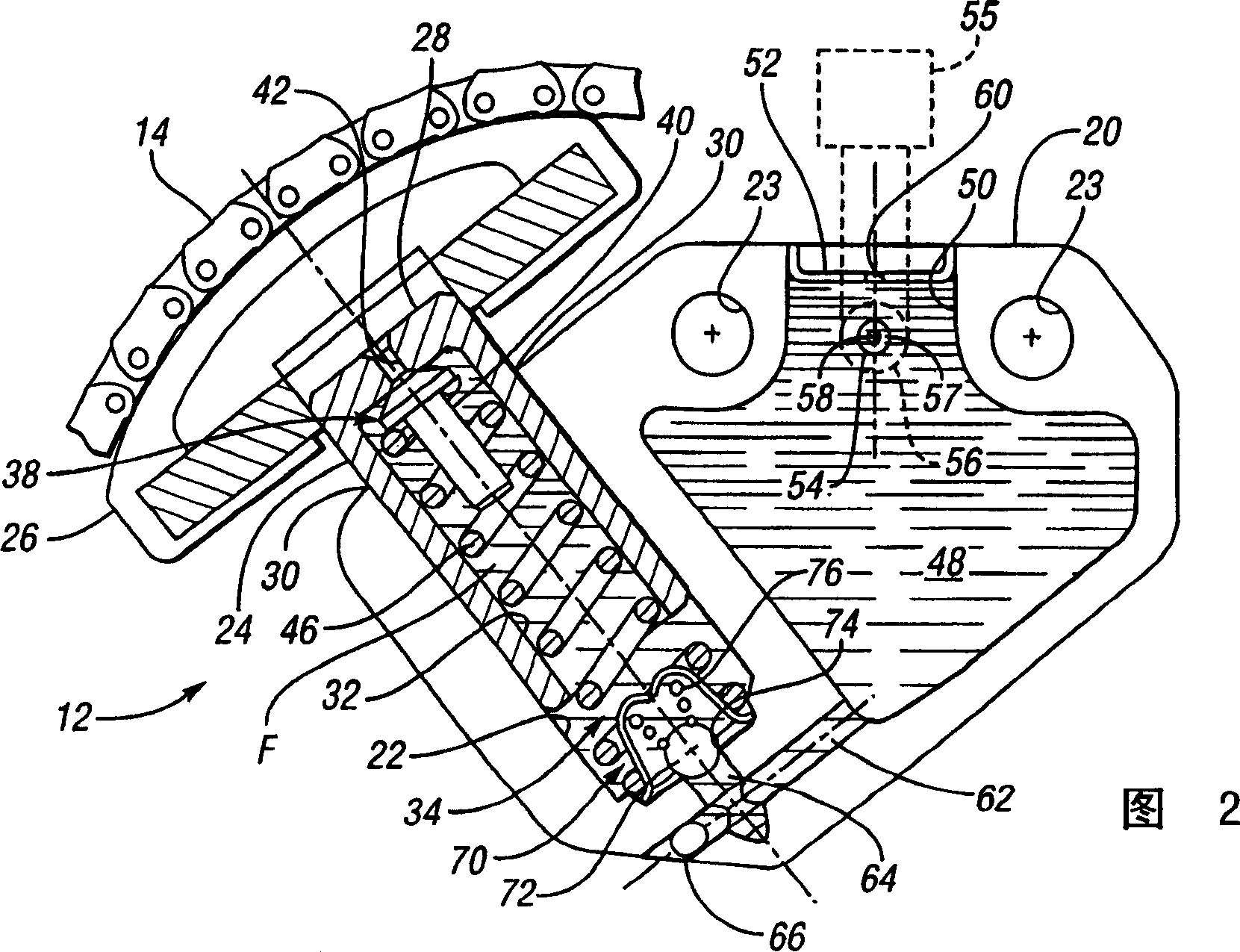

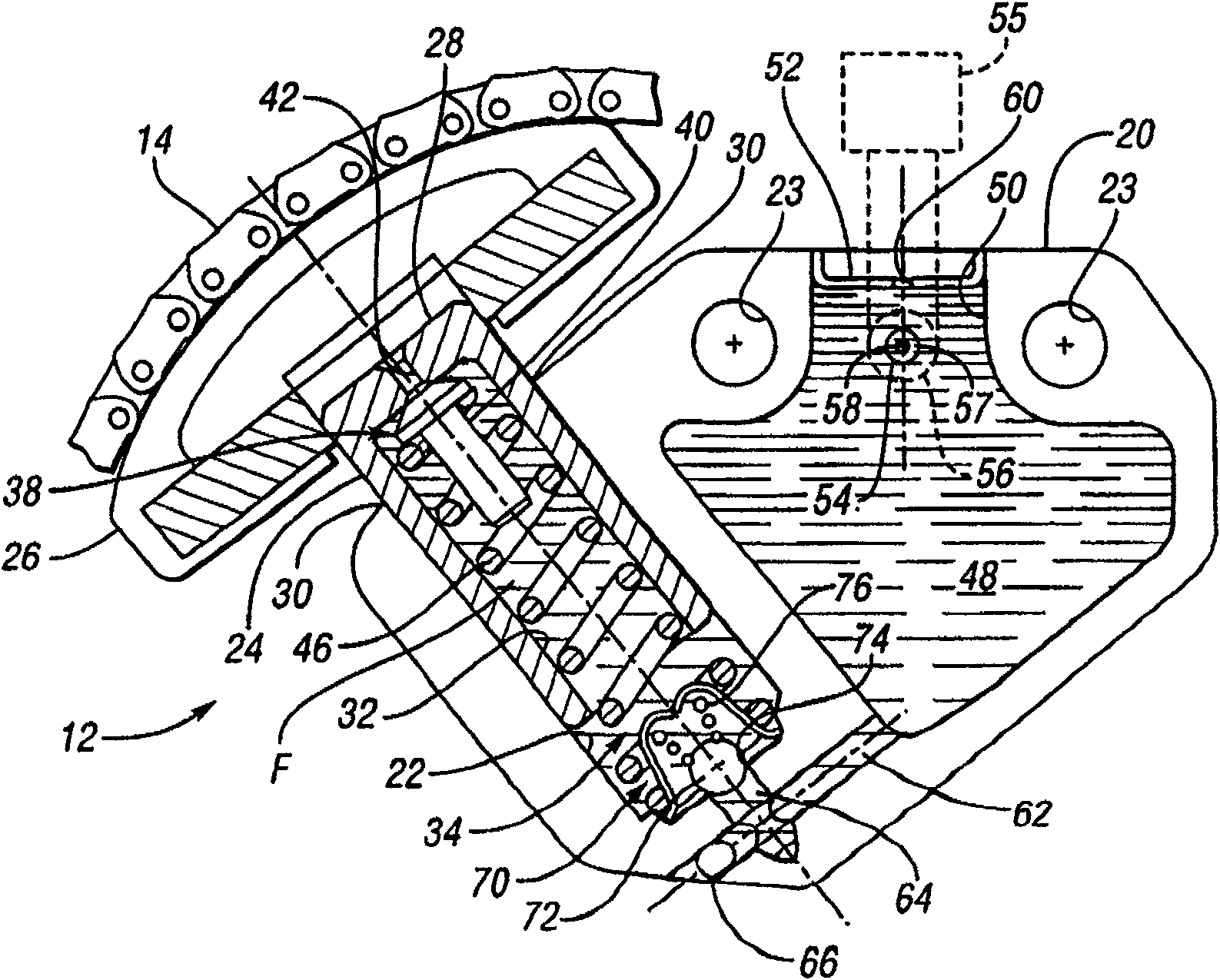

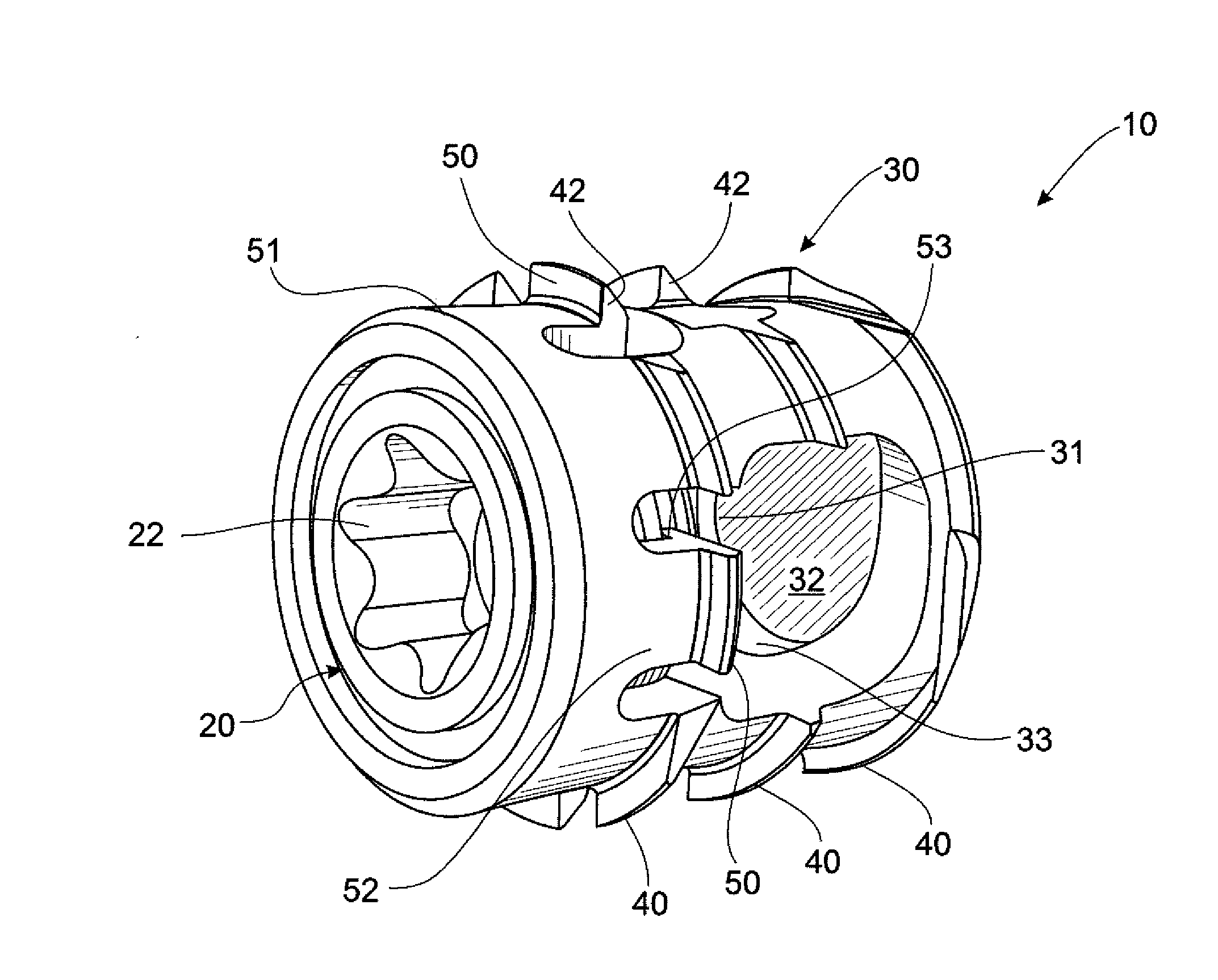

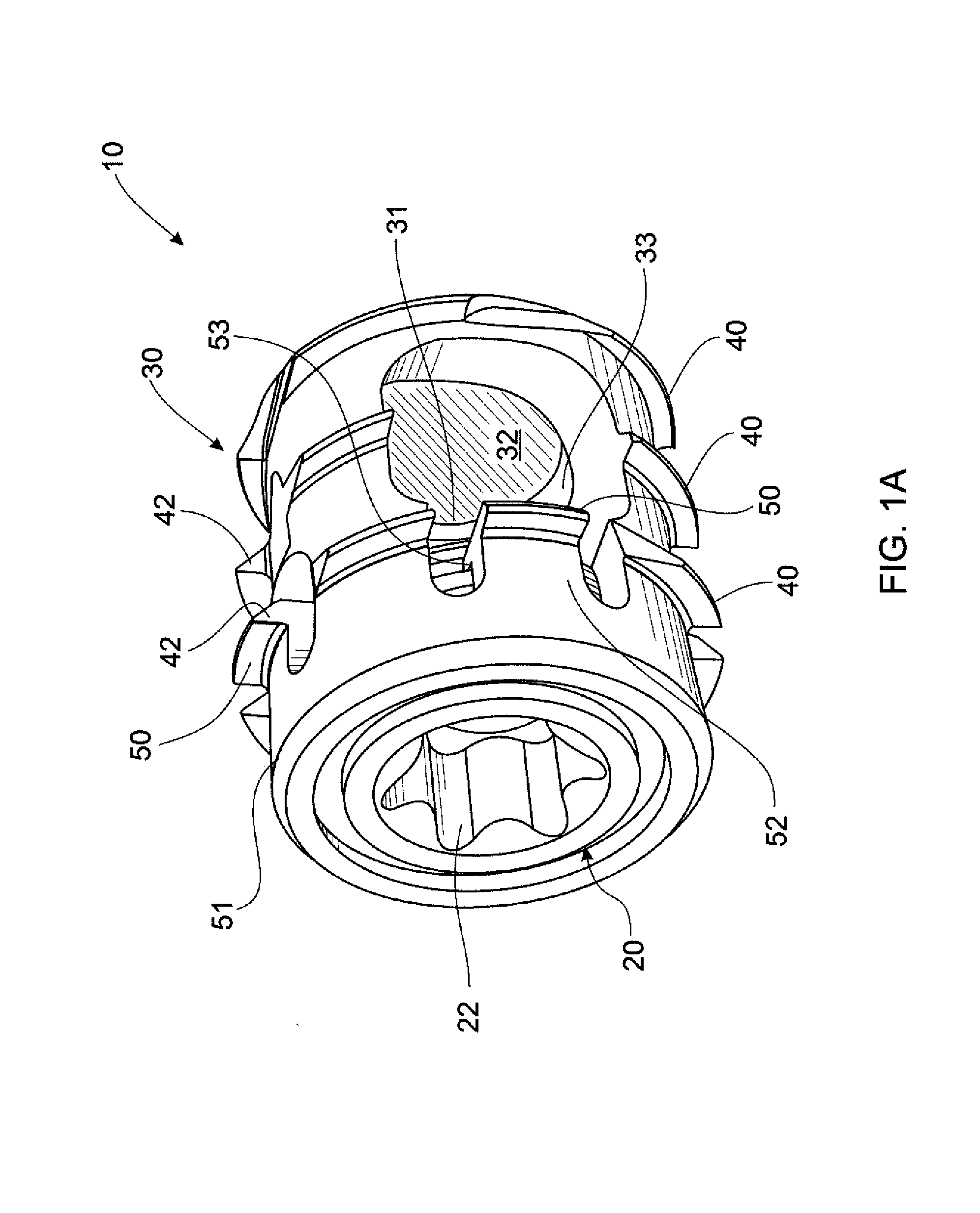

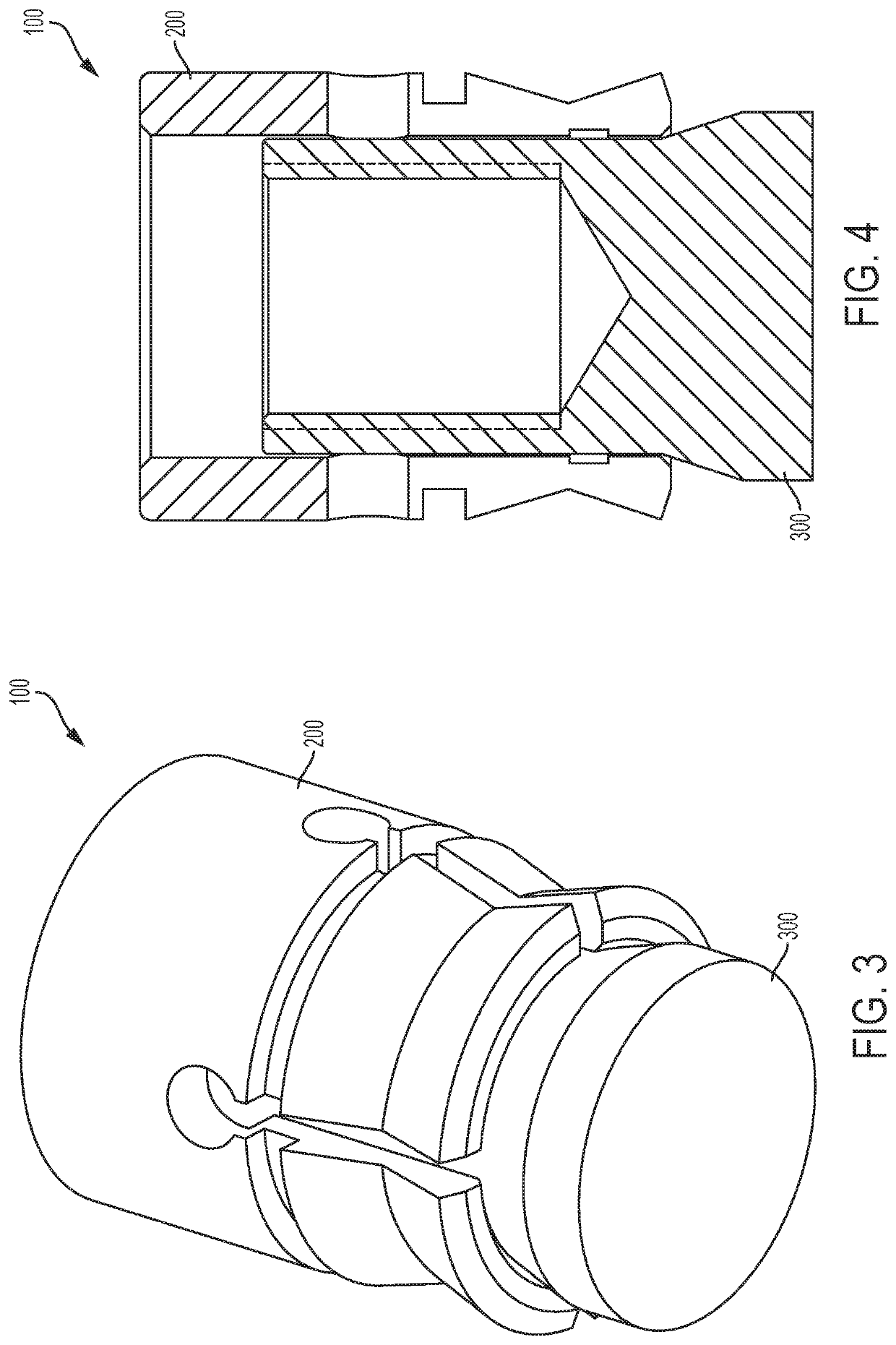

Implant release mechanism

A delivery assembly (10) for an implant (30) includes a release mechanism with a locking element (52) and a blocking member (56). The locking element (52) includes a latching pin (14) that engages with an eyelet (54) in the implant (30) to attach the implant (30) to a distal end of an inner catheter (36). The blocking member (56) prevents premature disengagement of the latching pin (14) from the implant (30). Withdrawal of the blocking member (56) allows disengagement of the latching pin (14). The locking pin (52) and the blocking member (56) extend along the lumen of the inner catheter (36) from a handle (12) such that a guide wire (34) is also able to extend through the lumen of the inner catheter (36). The locking pin (52) and the blocking member (56) preferably have a crescent-shaped transverse cross section. The release mechanism allows retrieval of the implant (30).

Owner:COOK MEDICAL TECH LLC

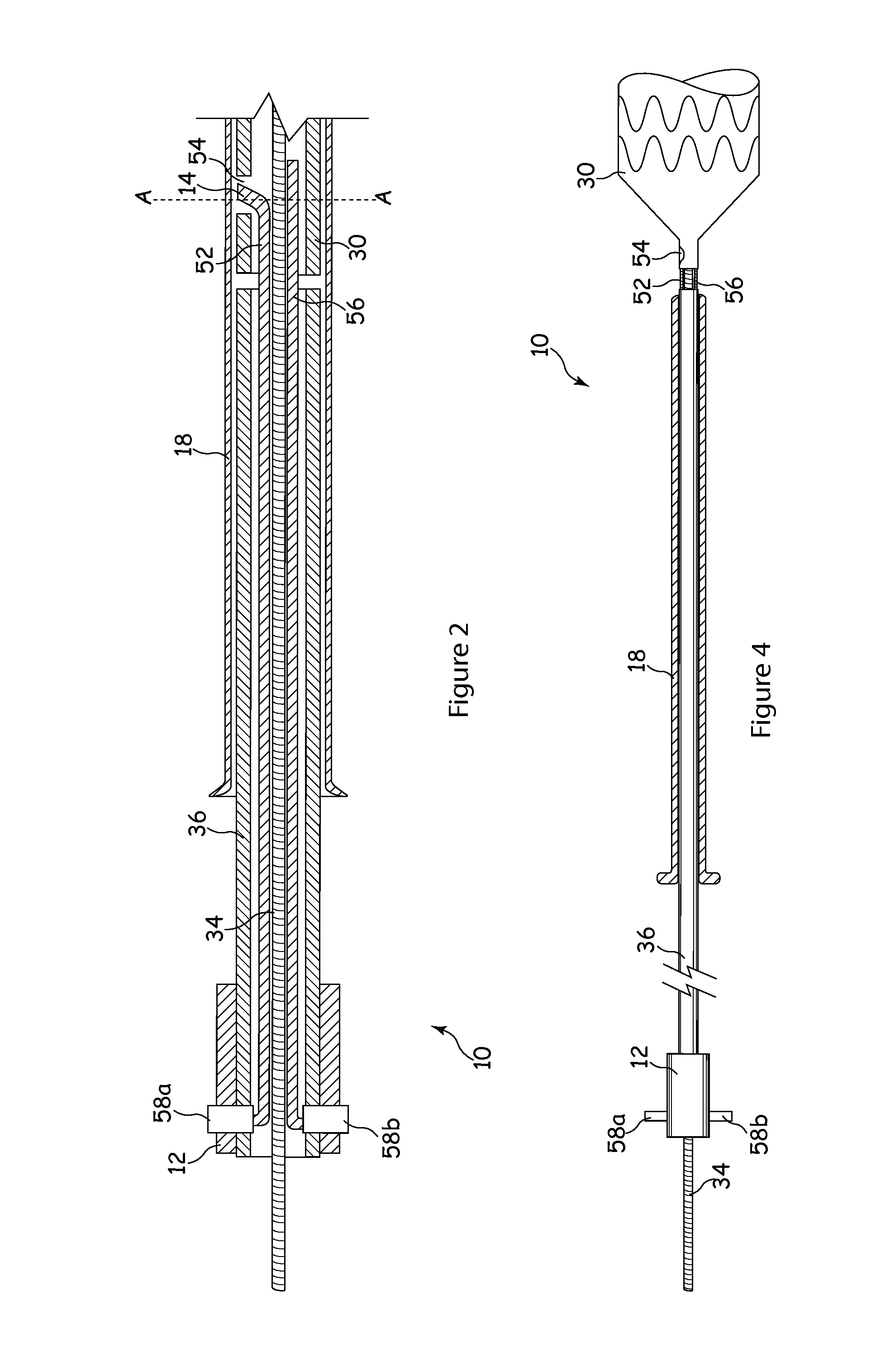

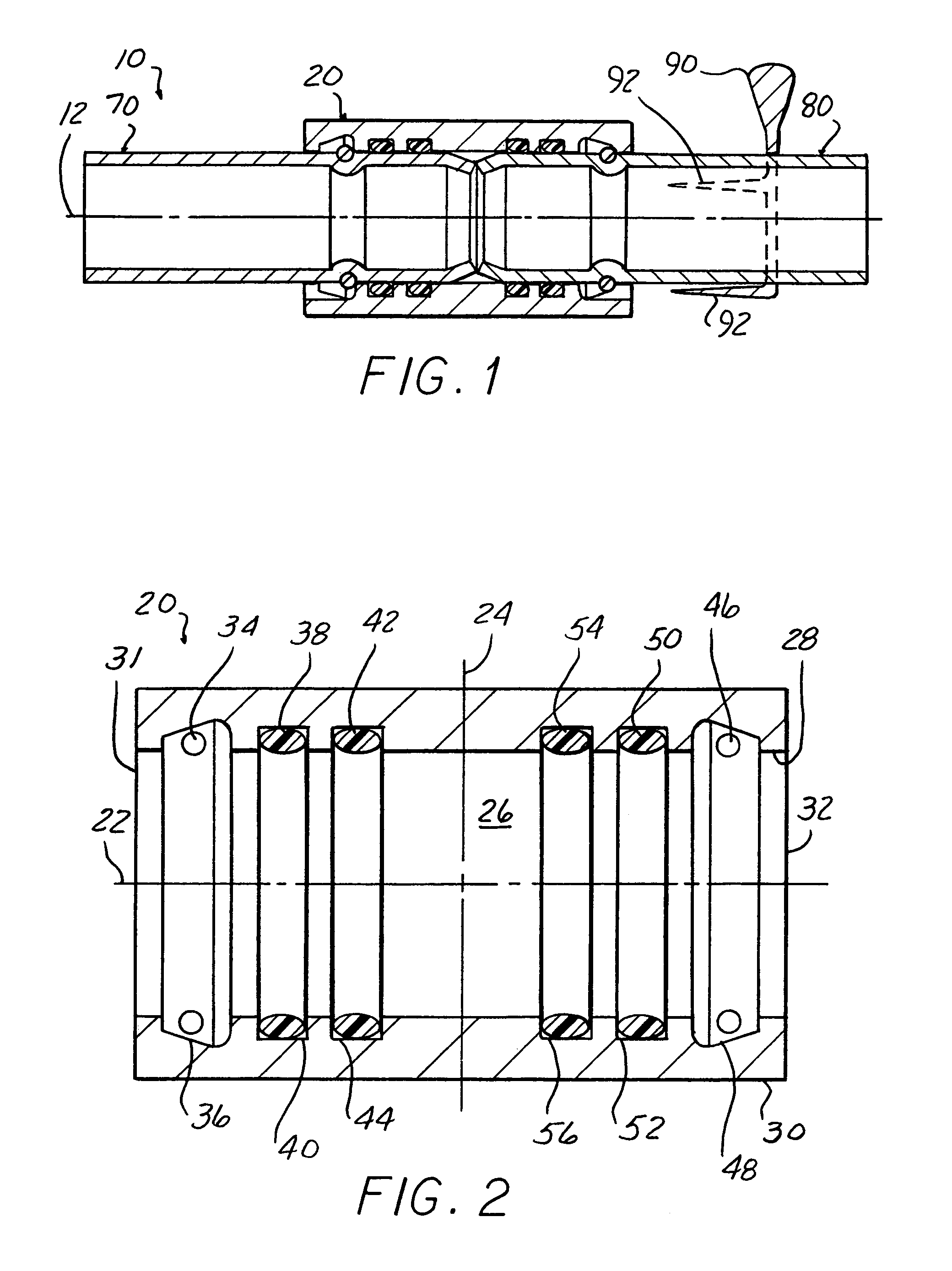

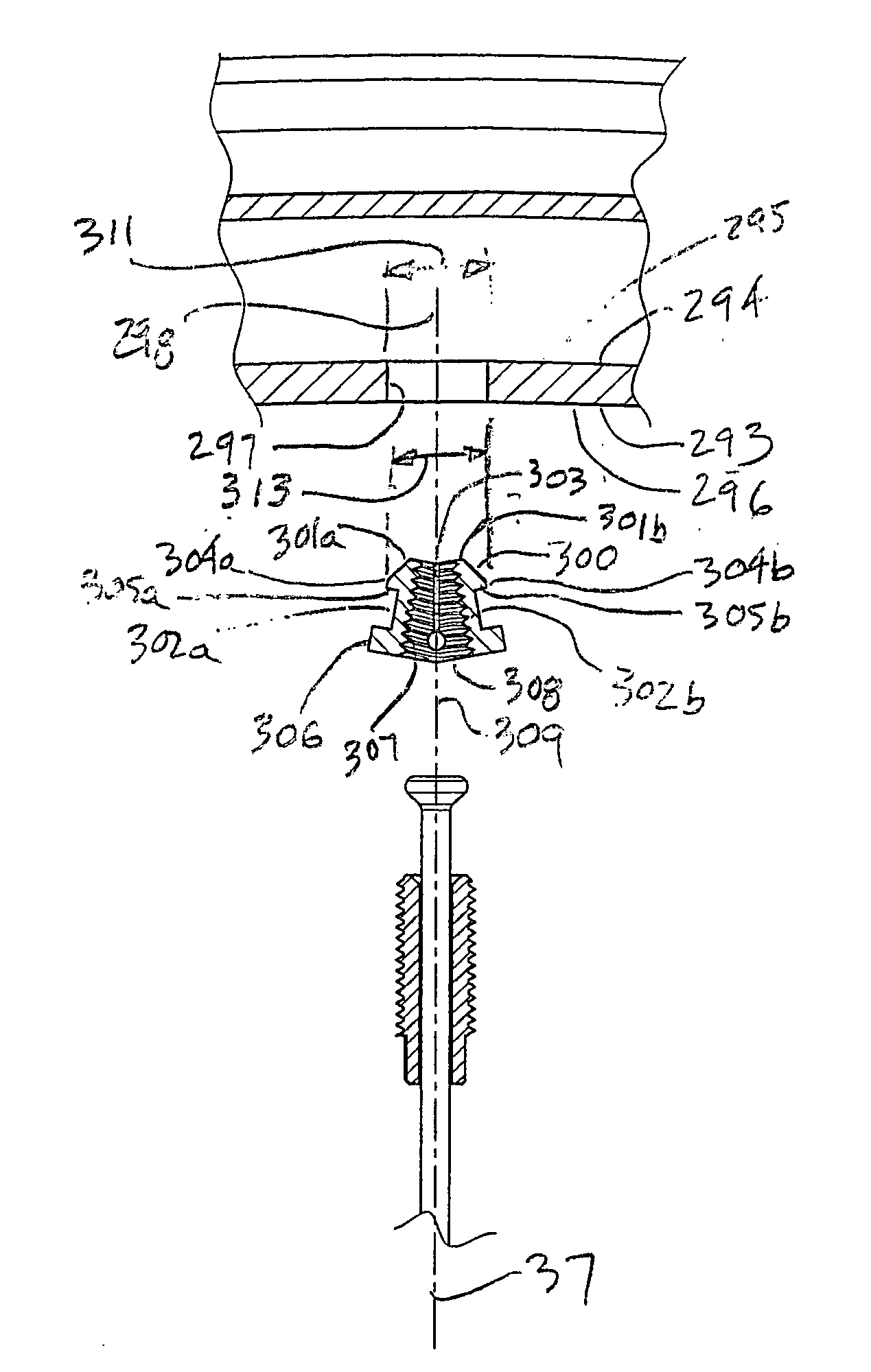

Union coupler assembly for coolant lines

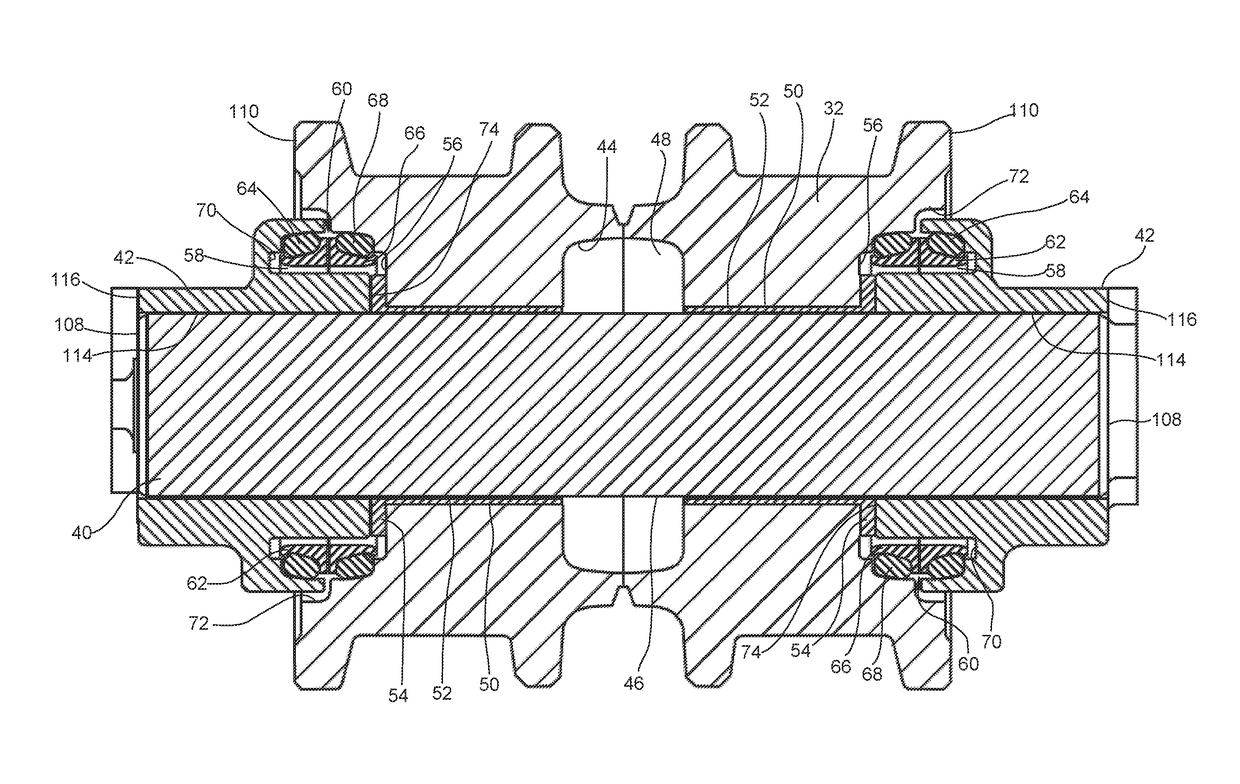

InactiveUS7273237B1Prevent inward movementSleeve/socket jointsFluid pressure sealed jointsEngineeringCooling fluid

A union coupler assembly for coolant lines comprising a coupler body, a first coolant line end portion, and a second coolant line end portion. The coupler body has a passageway extending between first and second ends, two tapered annular grooves, a snap ring disposed within each tapered annular groove, and a plurality of o-rings seated in corresponding annular grooves. The coolant line end portions are fabricated from metal and have tapered ends and grooves formed in their outer surfaces. The coolant line end portions are movable between an engaged position, wherein the snap rings engage the grooves in the coolant line end portions, and a disengaged position, wherein the snap rings do not engage the grooves in the coolant line end portions. When the coolant line end portions are in the engaged position, the tapered end of the first coolant line end portion abuts the tapered end of the second coolant line end portion to prevent inward movement of the coolant line end portions, and at least one o-ring seals each coolant line end portion with respect to the coupler body.

Owner:PLATTNER WESLEY M

Implant release mechanism

A delivery assembly (10) for an implant (30) includes a release mechanism comprising a locking element (52) and a blocking member (56). The locking element (52) includes a latching pin (14) that engages with an eyelet (54) in the implant (30) to attach the implant (30) to a distal end of an inner catheter (36) of the deployment of the delivery assembly (10). The blocking member (56) prevents premature disengagement of the latching pin (14) from the implant (30). Withdrawal of the blocking member (56) allows disengagement of the latching pin (14) once the implant (30) has been correctly positioned within a patient's vasculature. The locking pin (52) and the blocking member (56) extend along the lumen of the inner catheter (36) from a handle (12) at the proximal end thereof, and are arranged such that a guide wire (34) is also able to extend through the lumen of the inner catheter (36). The locking pin (52) and the blocking member (56) preferably have a crescent-shaped transverse cross section. The release mechanism allows an implant (30) to be retrieved either during deployment of the implant (30) to allow the surgeon to correct any mislocation of the implant (30), or in order to remove a previously deployed temporary implant (30) from a patient.

Owner:COOK MEDICAL TECH LLC

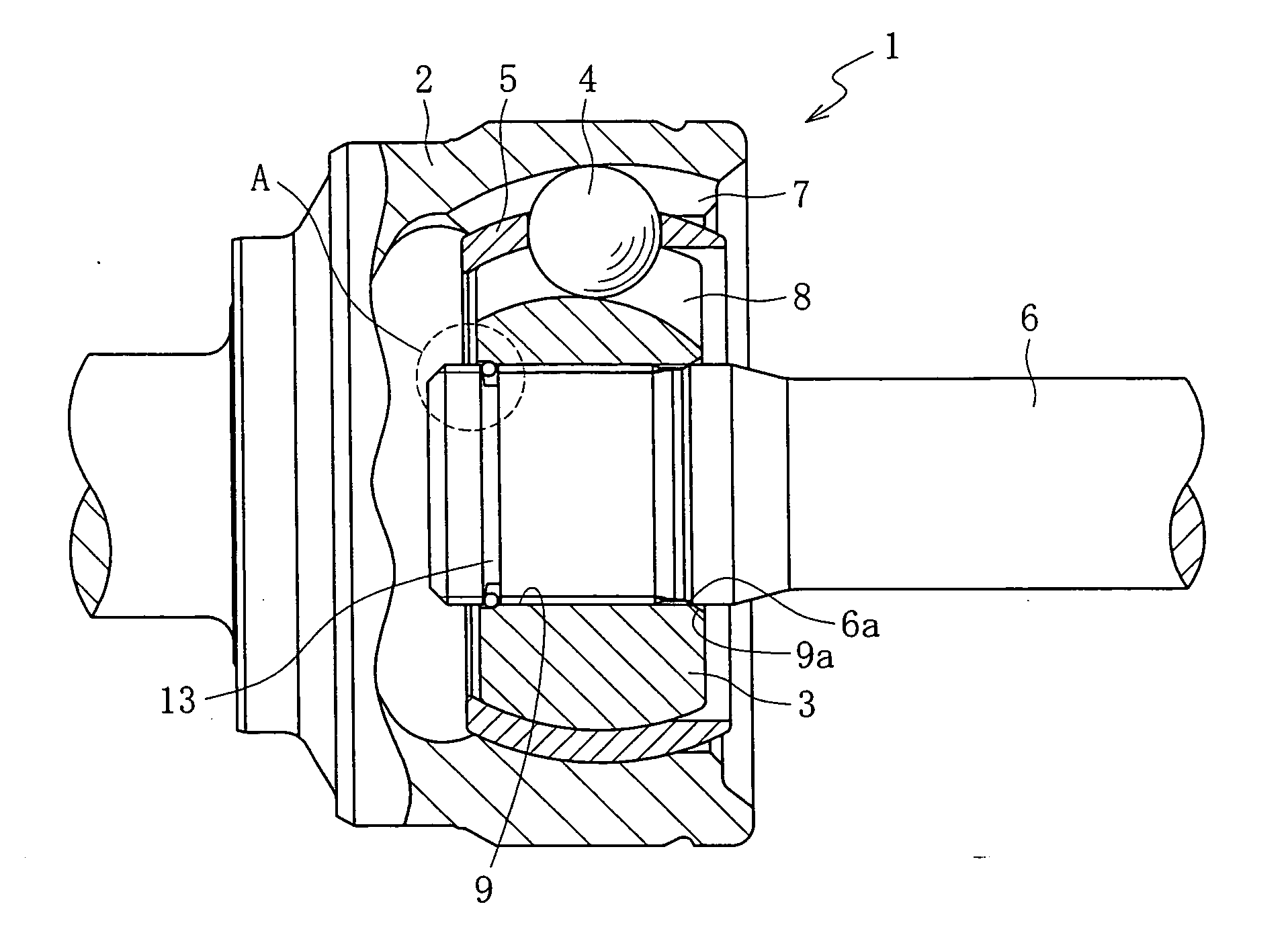

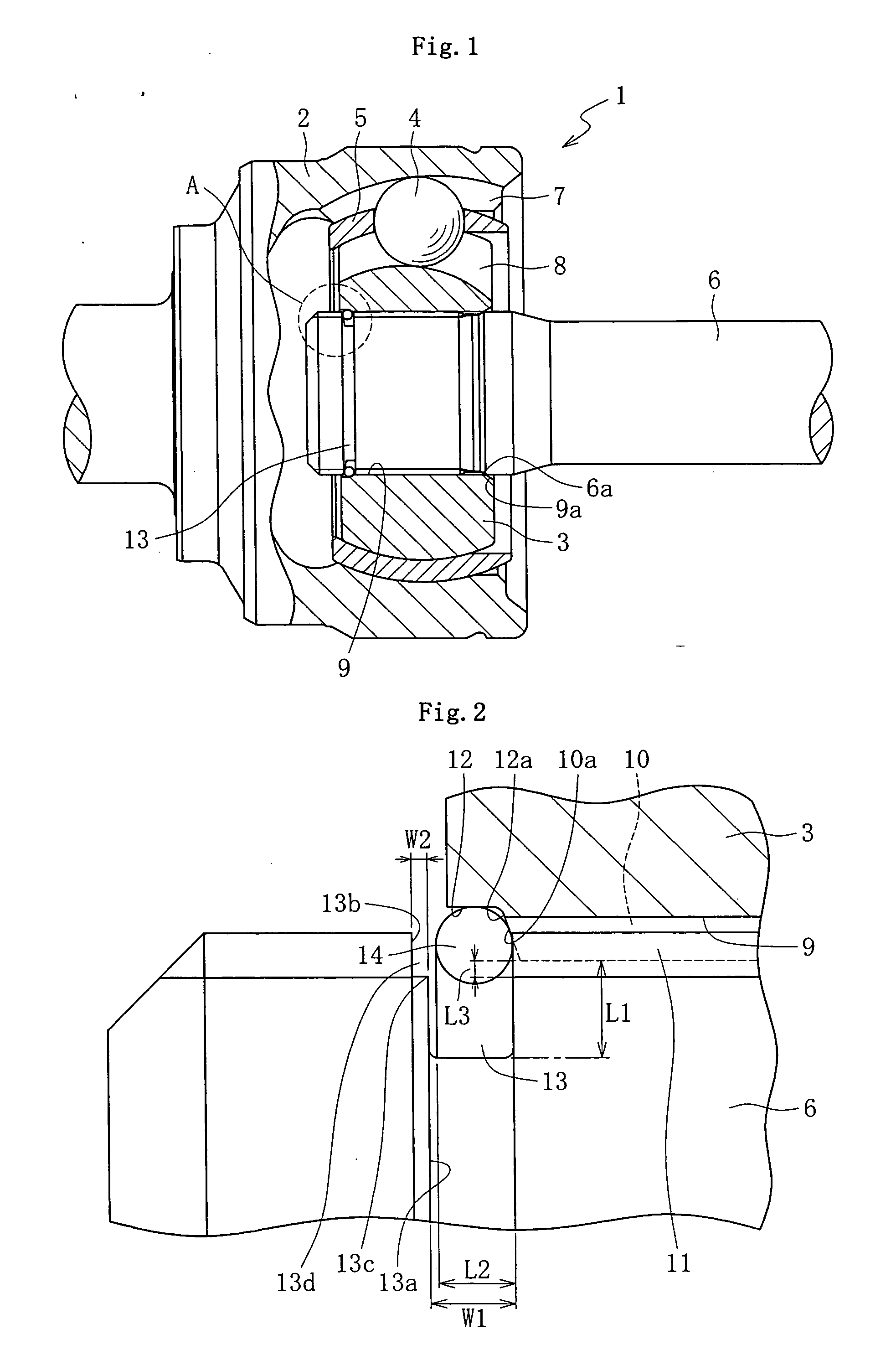

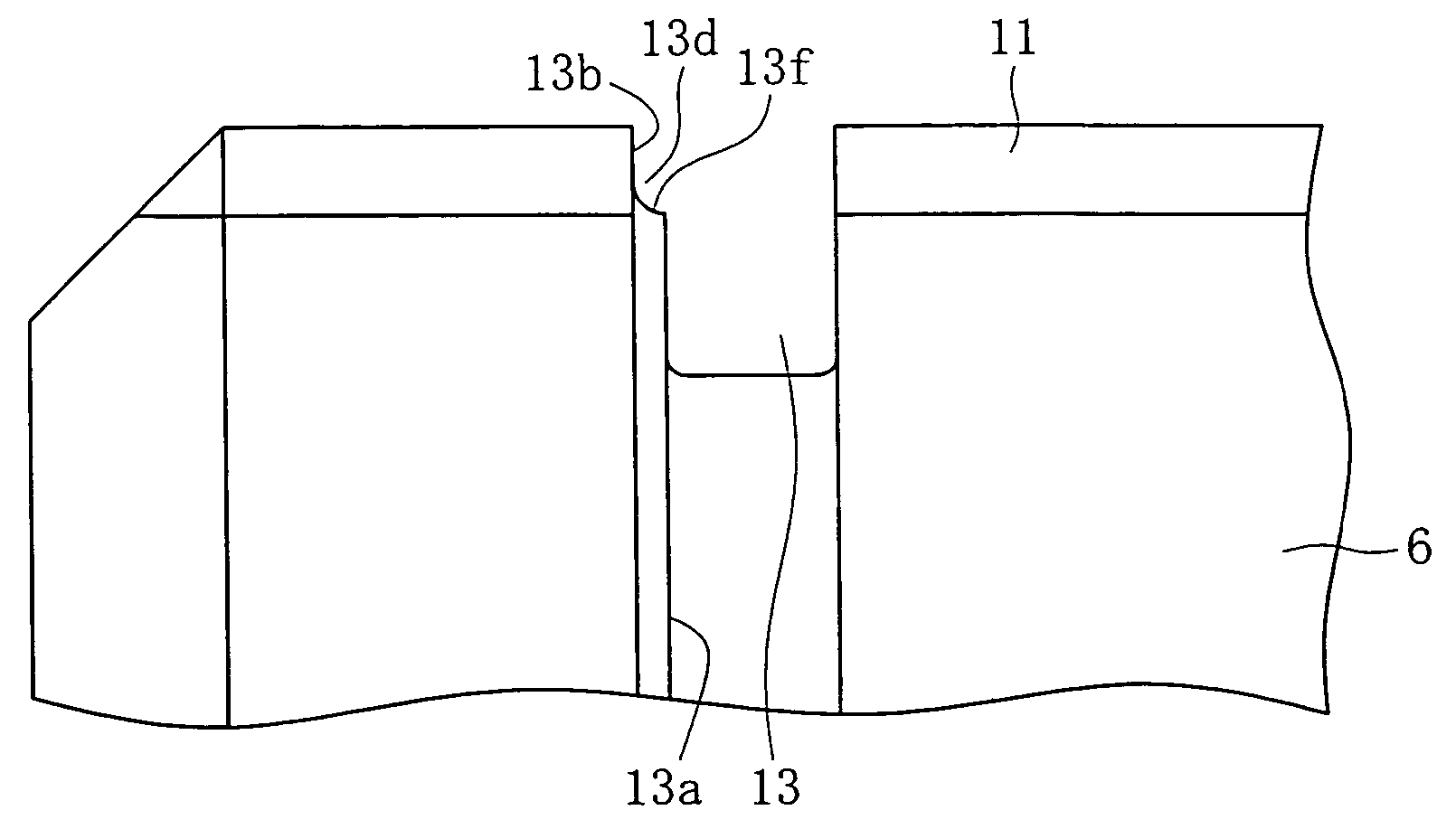

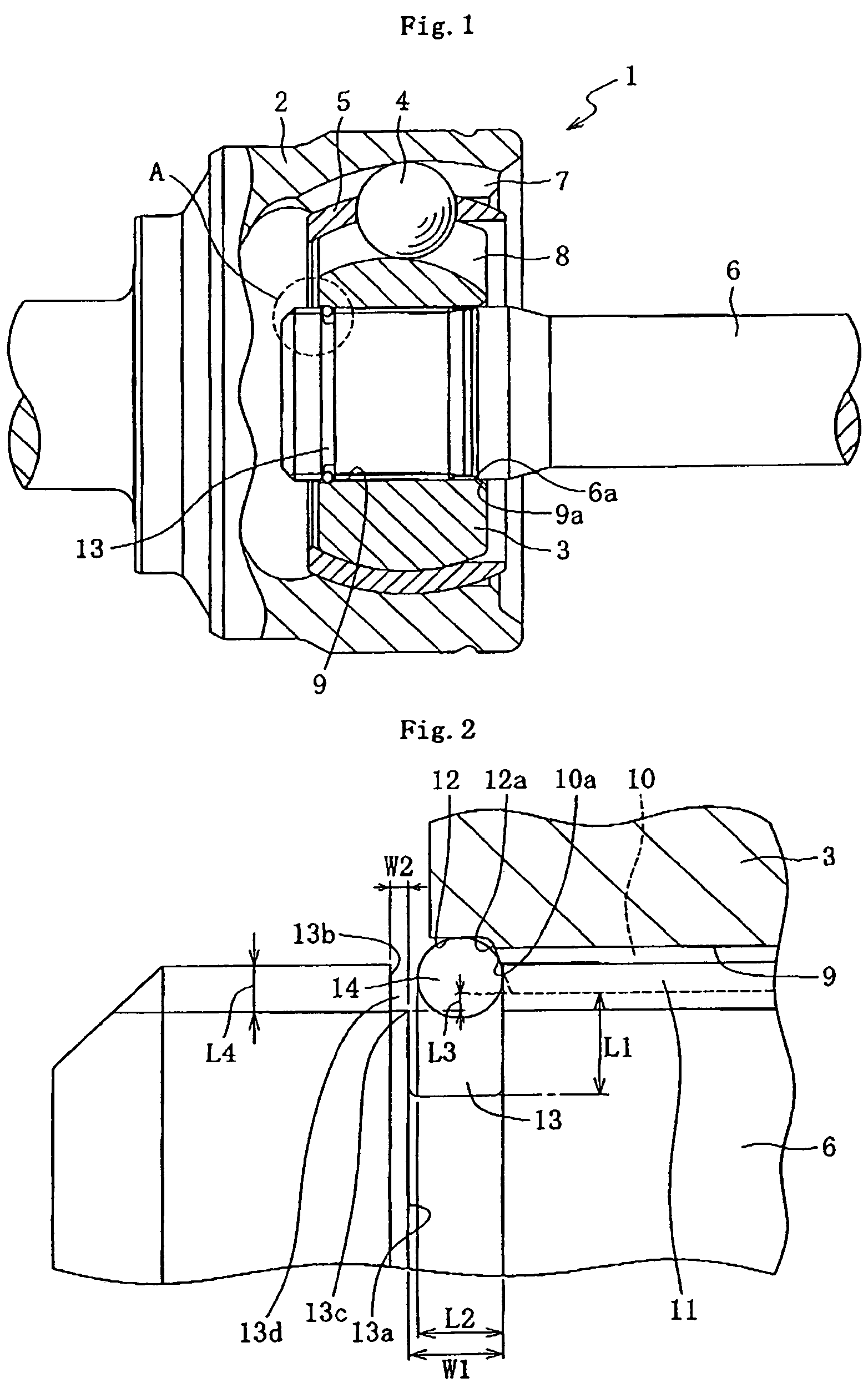

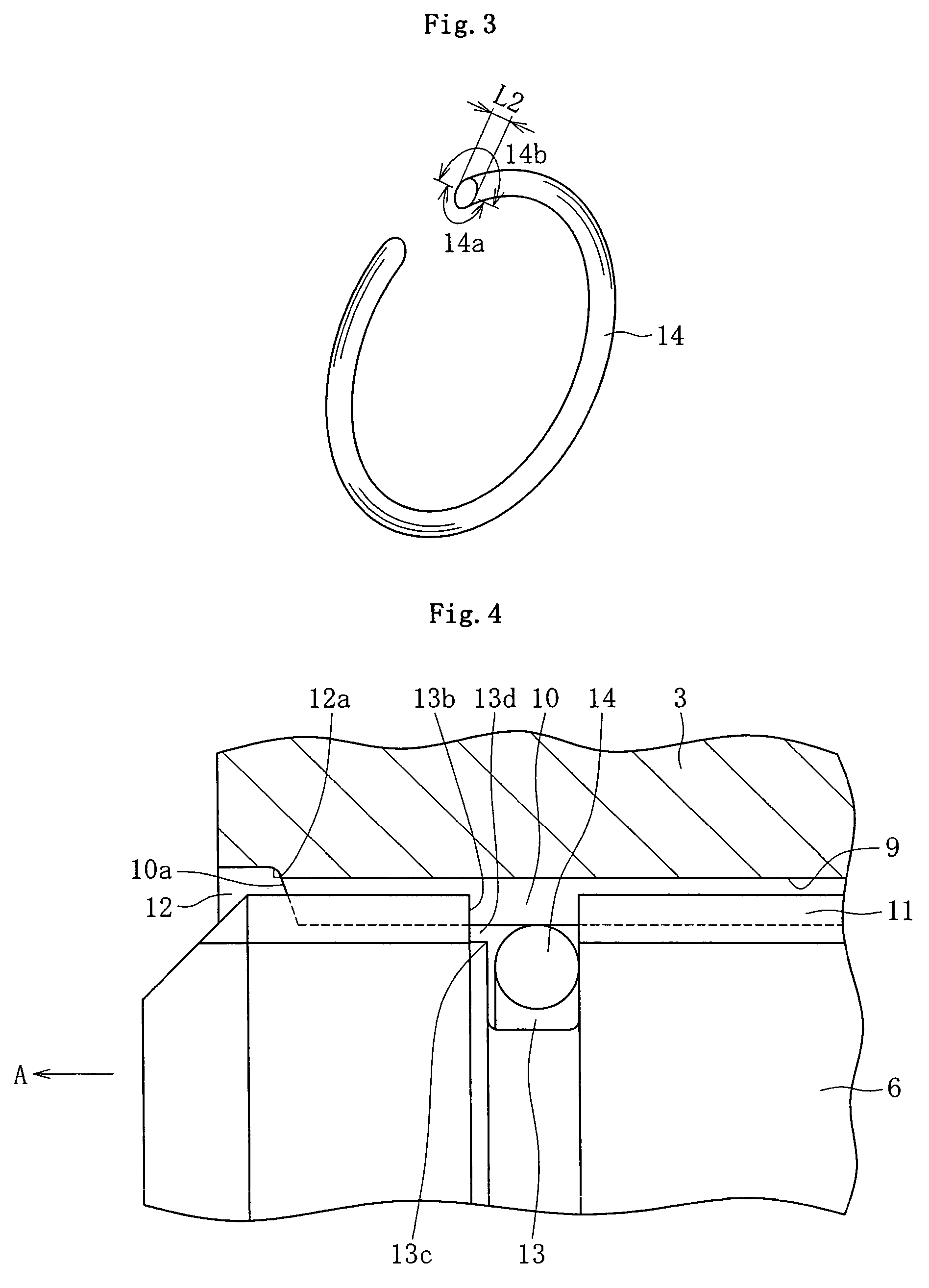

Structure for preventing shaft of constant velocity joint from coming off

InactiveUS20060211505A1Reduce overall man-hoursPossible to useClutchesFurniture joining partsJoint componentEngineering

The present invention presents a structure for preventing a shaft of constant velocity joint from coming off which allows changing design of connection between the shaft and an inner joint member to a type for disassembly or anti-disassembly. The anti-disassembly type is realized in such a manner that a wall at an opposite side to a shaft pulling out direction of a retaining ring groove of the shaft is used as a contacting part to a retaining ring, wherein at least two points are formed on the contacting part, one of which is on a perpendicular surface and the other is a corner of the contacting part, these two points are contacted with an inner surface of the retaining ring thereby provides the anti-disassembly type for preventing the ring from being contracted in a radial direction.

Owner:NTN CORP

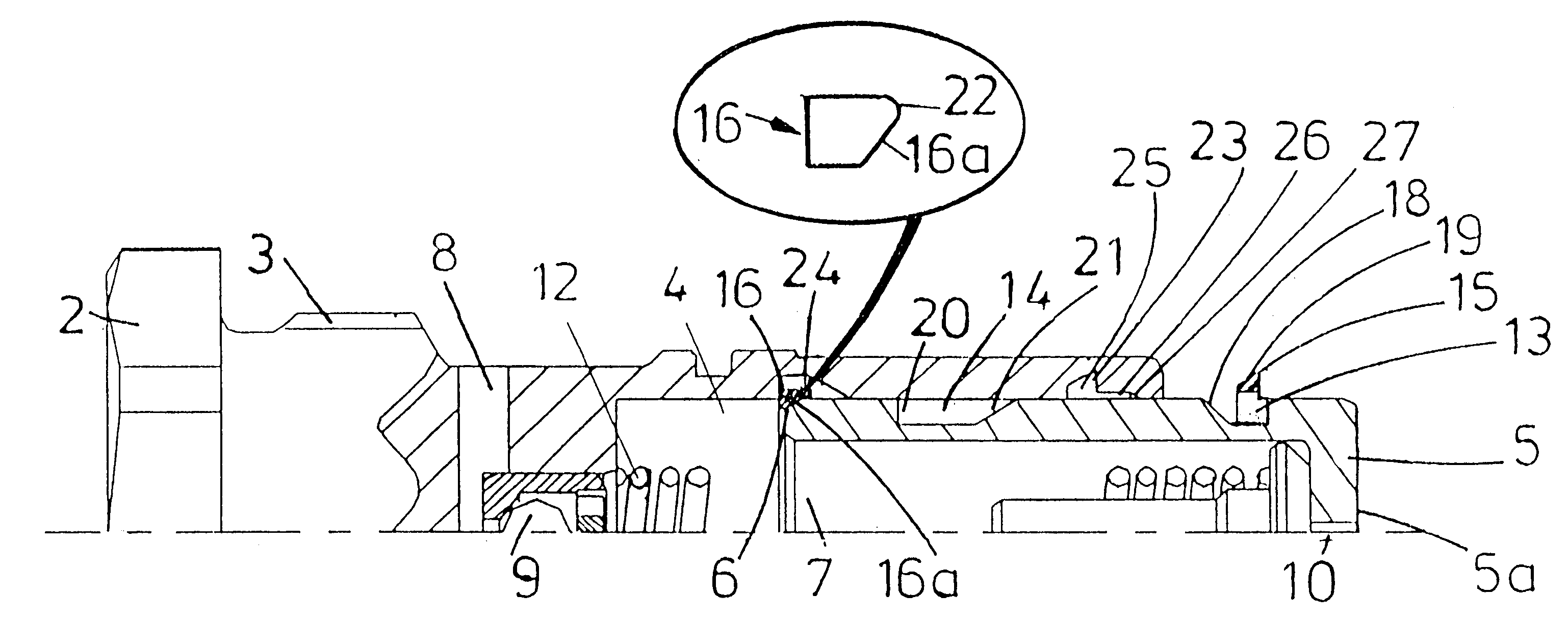

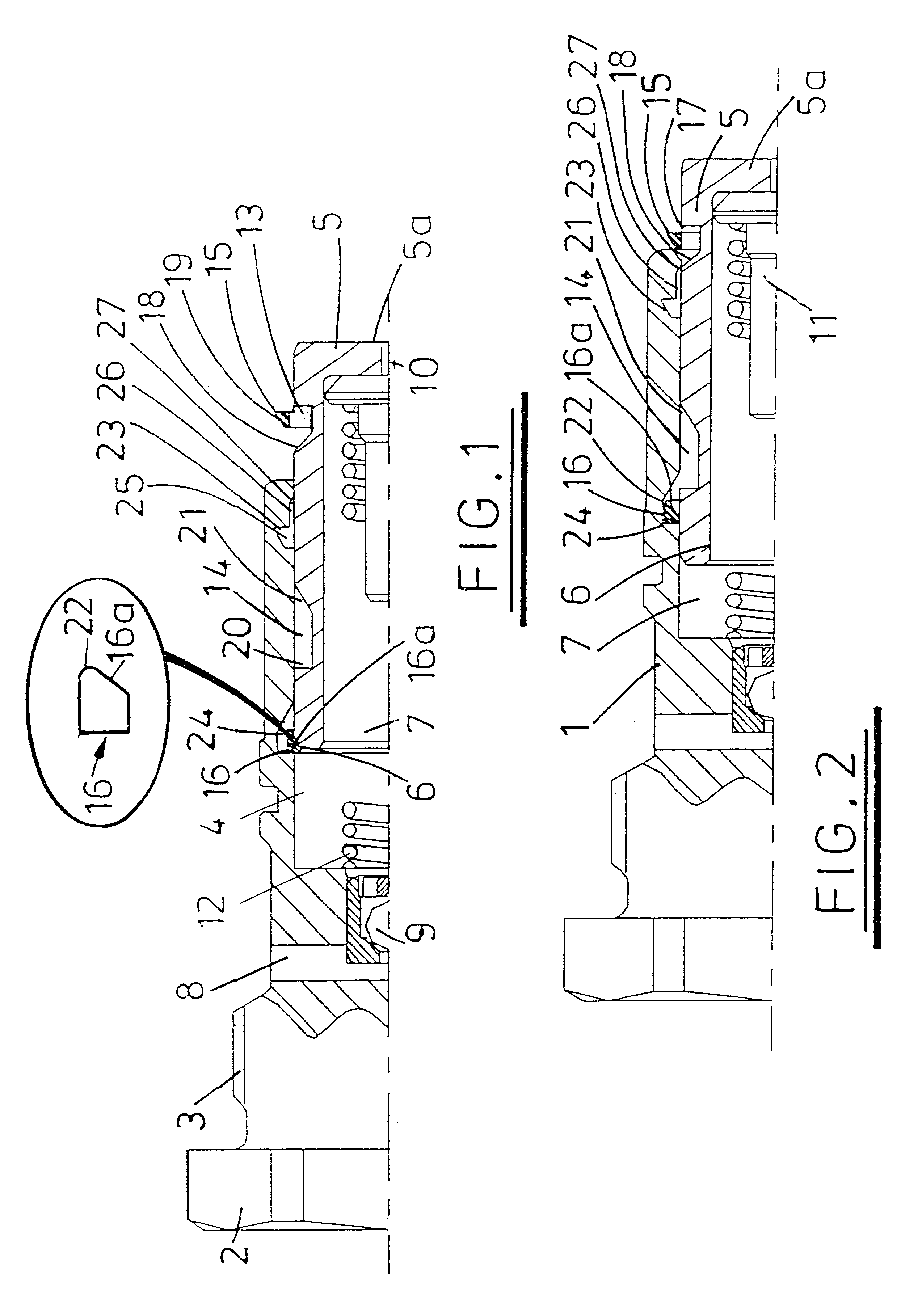

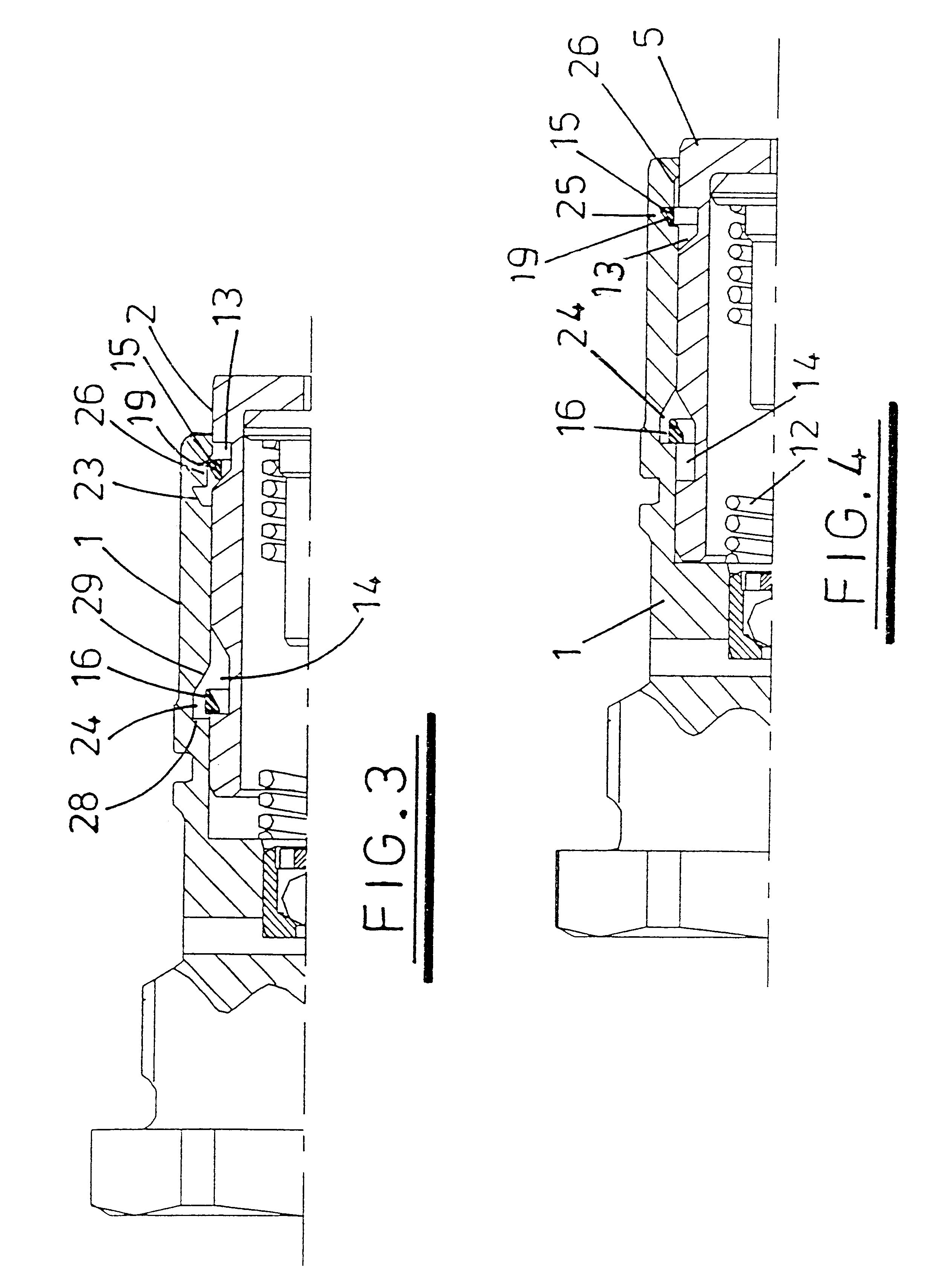

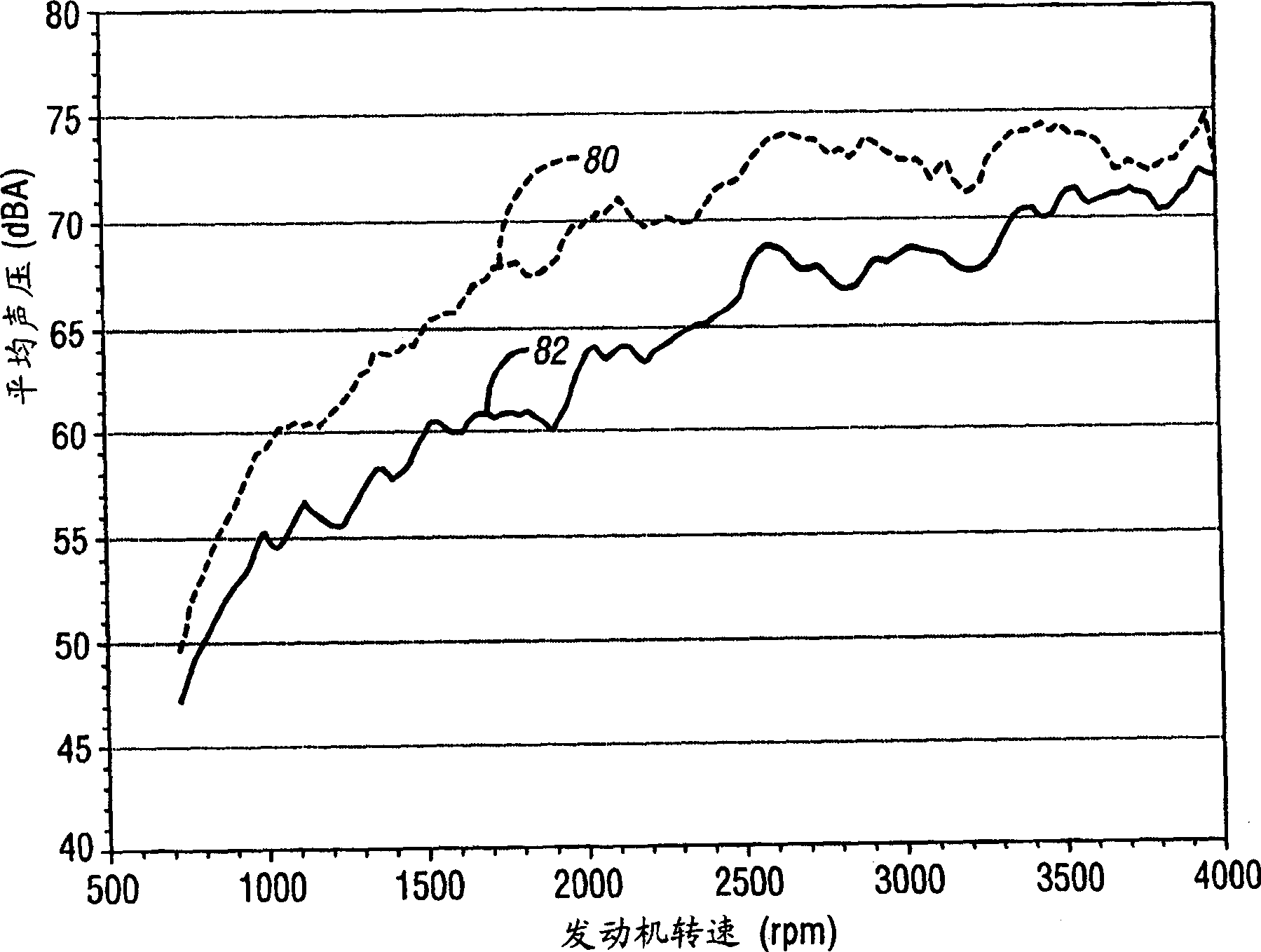

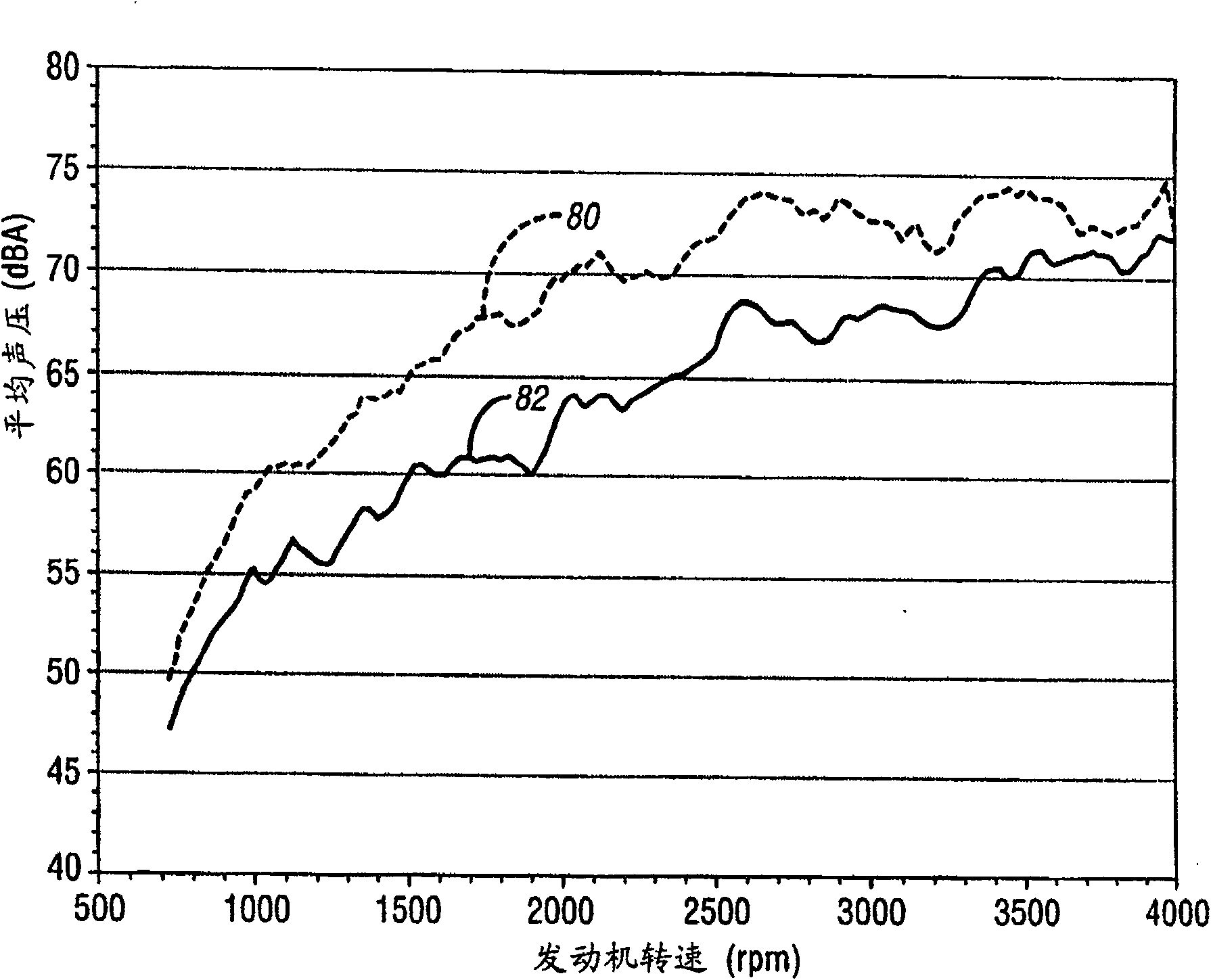

Tensioner for a chain or belt

A chain or belt tensioner comprises a plunger displaceable in a housing between retracted and extended positions. A stop ring between the plunger and housing frictionally contacts a smooth surface of the housing. A recess in the plunger has a tapered face for engagement with a bevelled surface of the stop ring. Inward movement of the plunger causes the tapered face to engage the stop ring and to force it to deform outwardly to a wedging position in which the stop ring is wedged between the tapered face and the surface thus preventing further inward movement of the plunger. The recess has a second face that engages the stop ring when the plunger moves out of the housing so as to slide it over the surface. The invention provides for a stop mechanism that enables retraction of the plunger to be prevented at an infinite number of positions.

Owner:SCHAEFFLER KG

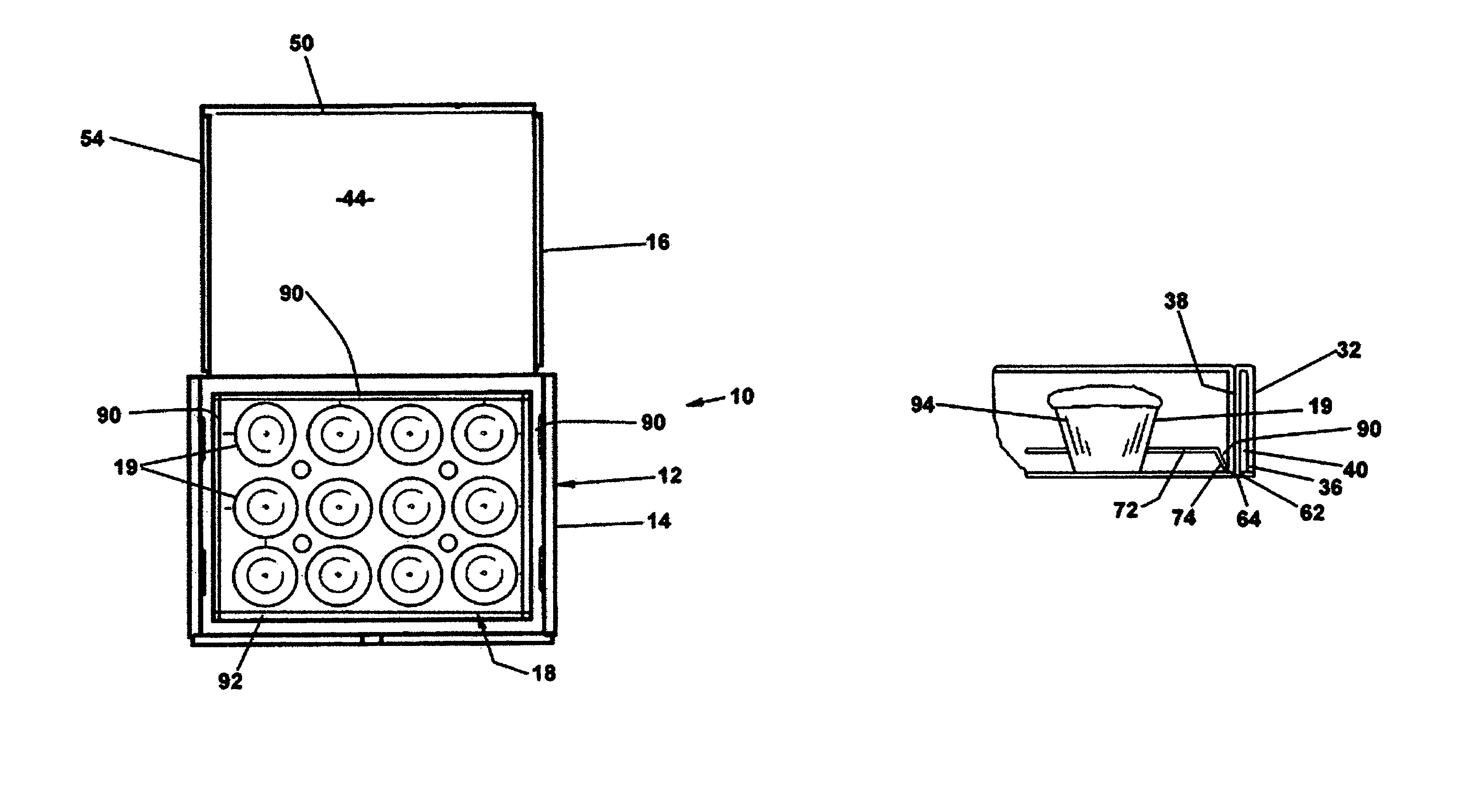

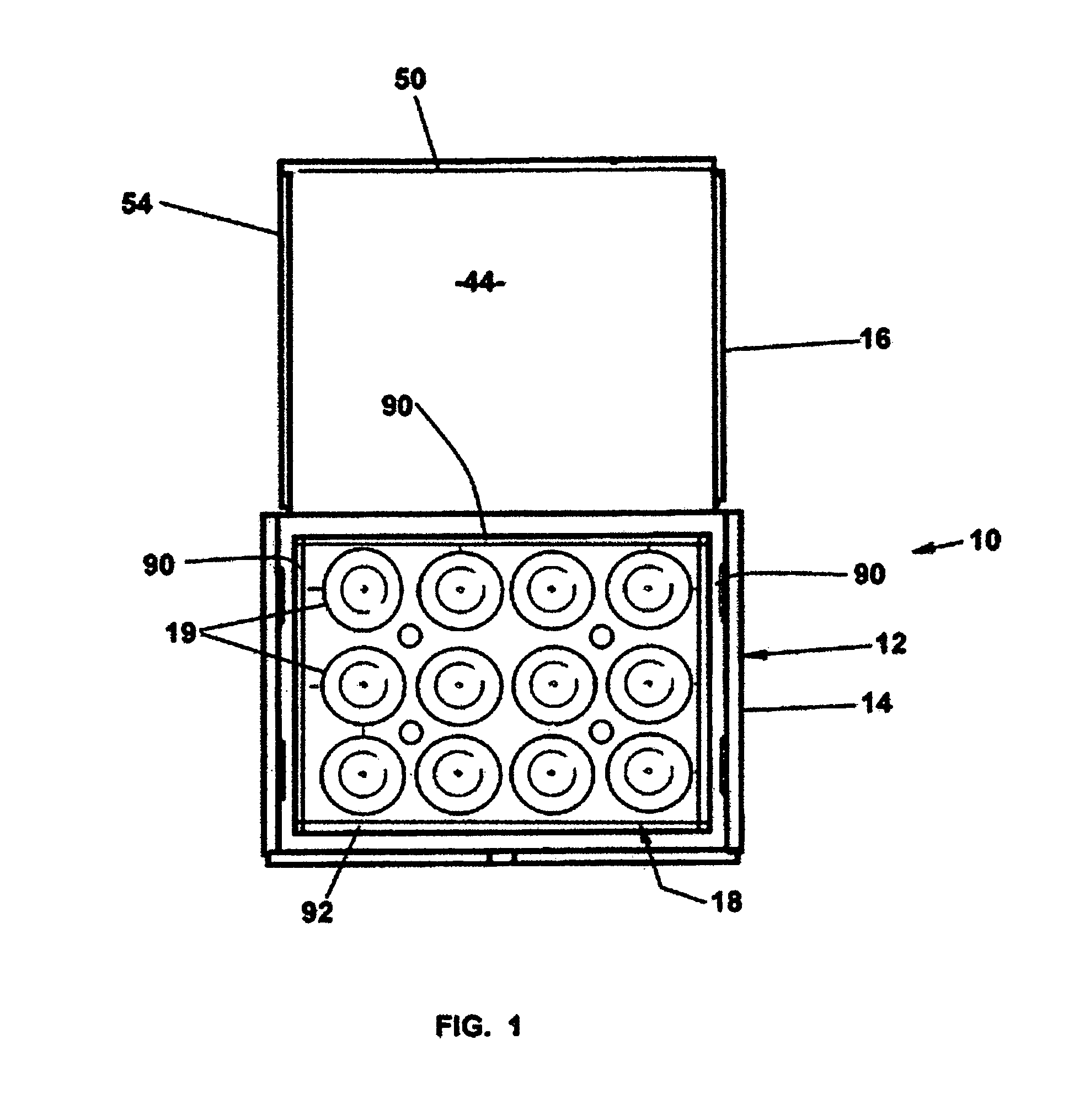

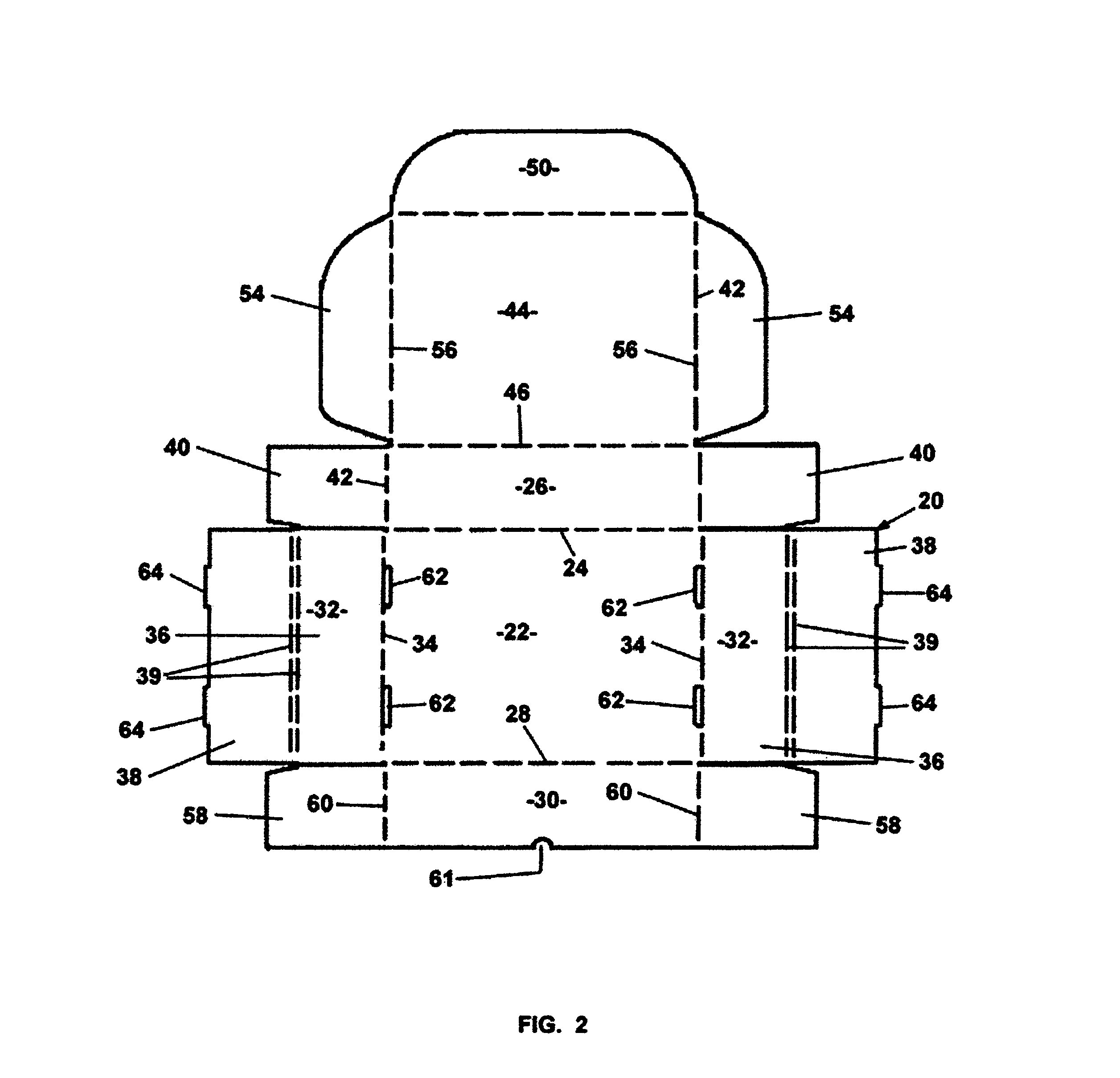

Cupcake crate

InactiveUS7303115B1Safely discardedGuaranteed safe reusePaper/cardboardOther accessoriesSized smallCrate

A cupcake carrier for organizing and protecting cupcakes during storage and transit includes a container formed of a singled sheet of planar material and having flaps folded in assembly to form an upwardly opening cavity carrying an insert tray formed of a single sheet of planar material and having circular openings for lightly compressively holding the cupcakes in a grid array. The insert is sized smaller than the base of the container to provide slots about the periphery. The container includes a hinged lid having flaps that enter the slots in the closed position to reinforce the outer walls and prevent inner movement of the flaps during transit and storage.

Owner:MCCLYMONT LEE ANNE

Structure for preventing shaft of constant velocity joint from coming off

InactiveUS7481711B2Preventing contracting movementPrevent inward movementClutchesFurniture joining partsPull forceEngineering

A constant velocity joint structure including an inner joint member, a retaining ring, and a shaft which are configured to prevent the shaft from being withdrawn from the inner joint member when a pulling force is applied to one side of the shaft is disclosed. A retaining ring groove is disposed at an opposite side of the shaft. In a preferred embodiment, the retaining groove has at least two points which contact an inner surface of the retaining ring when the pulling force is applied to prevent the retaining ring from contracting in a radial direction, thereby preventing the shaft from being withdrawn from the inner joint member.

Owner:NTN CORP

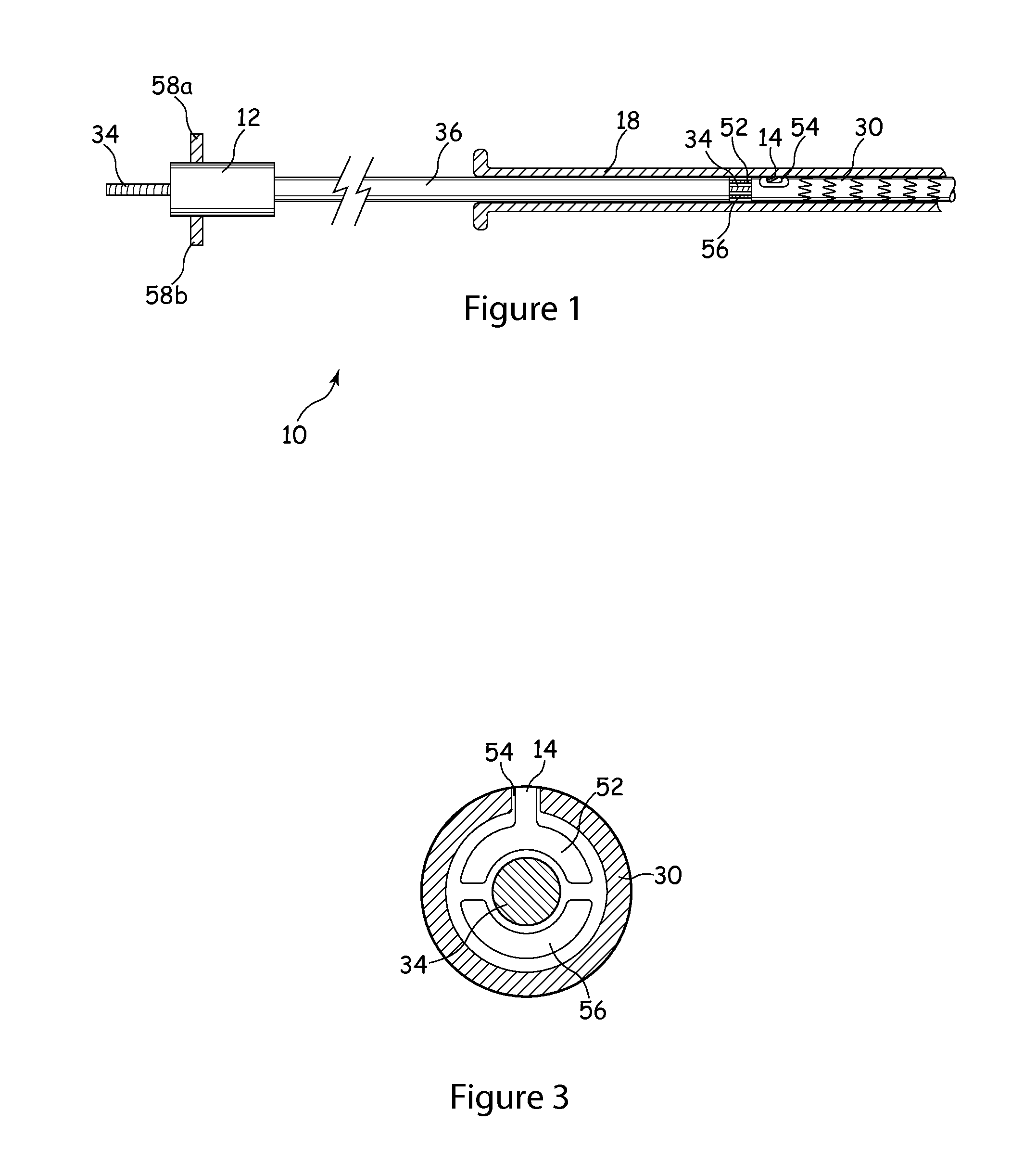

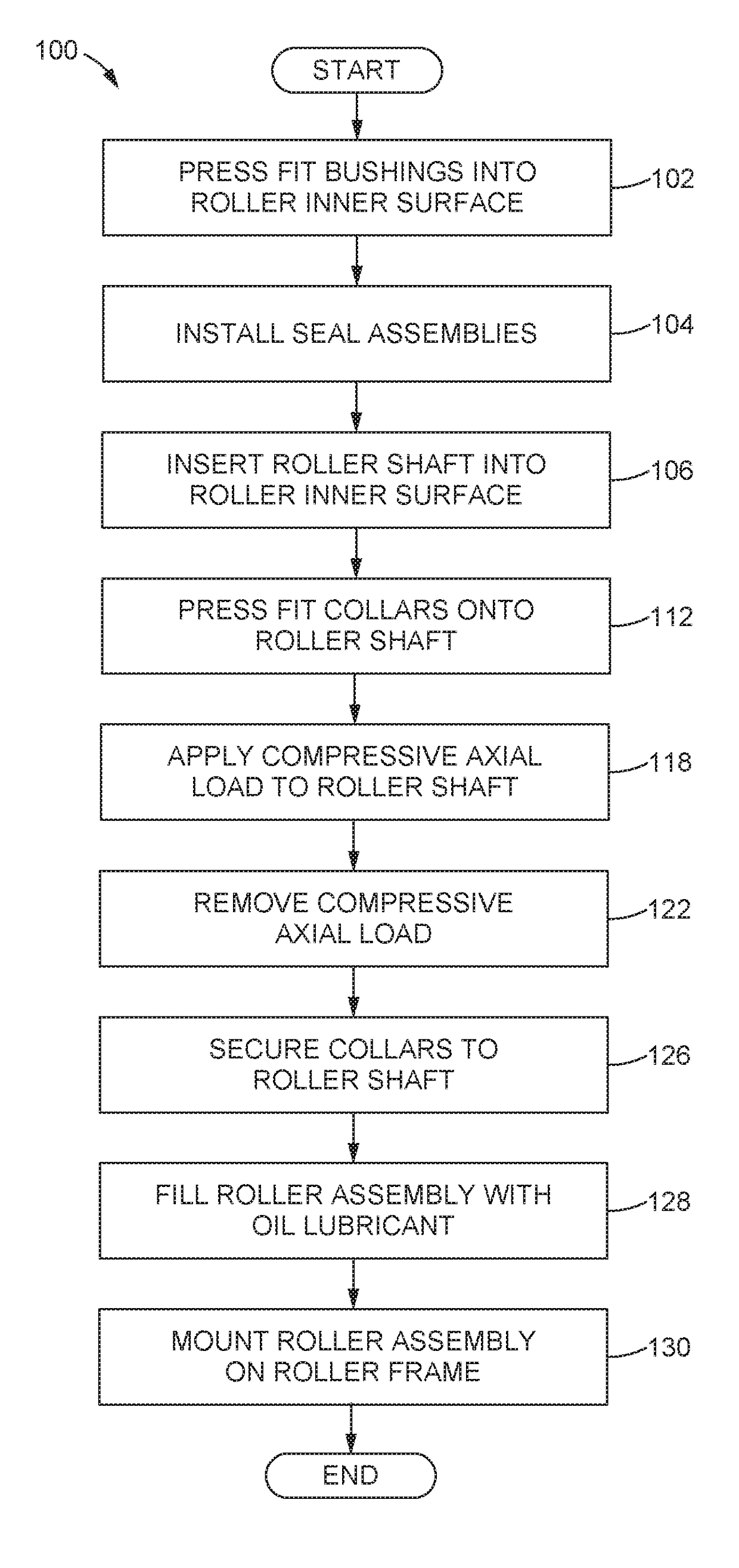

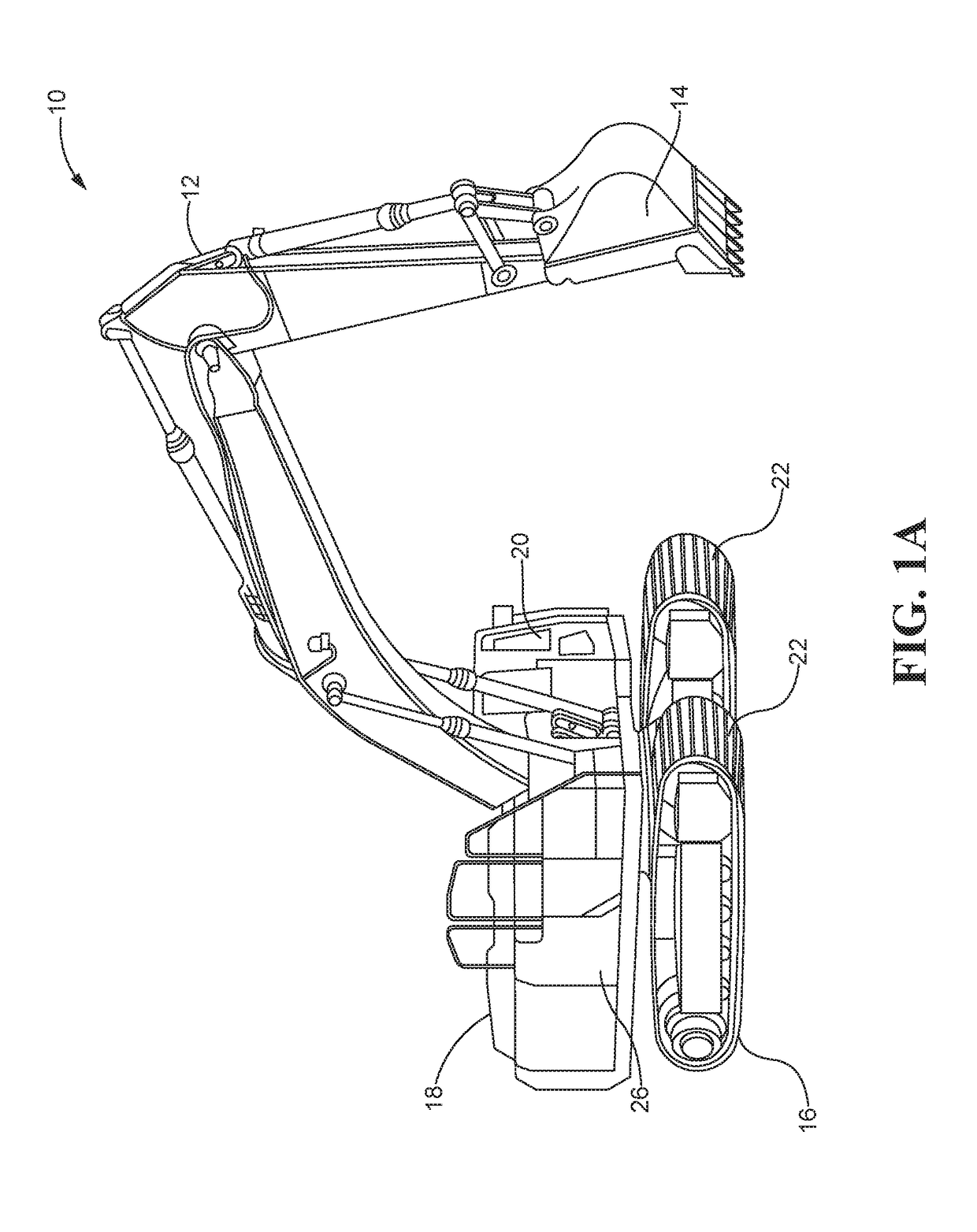

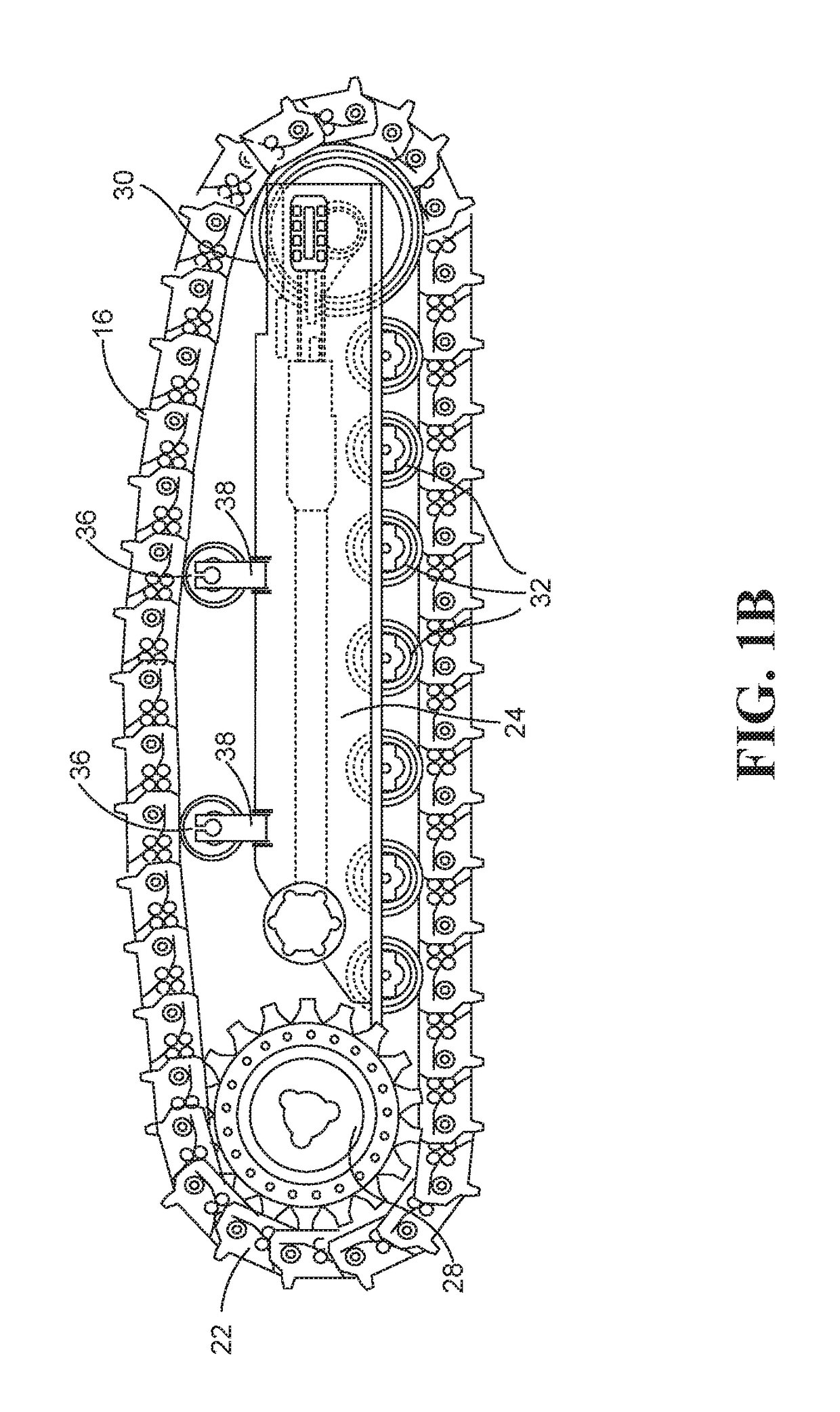

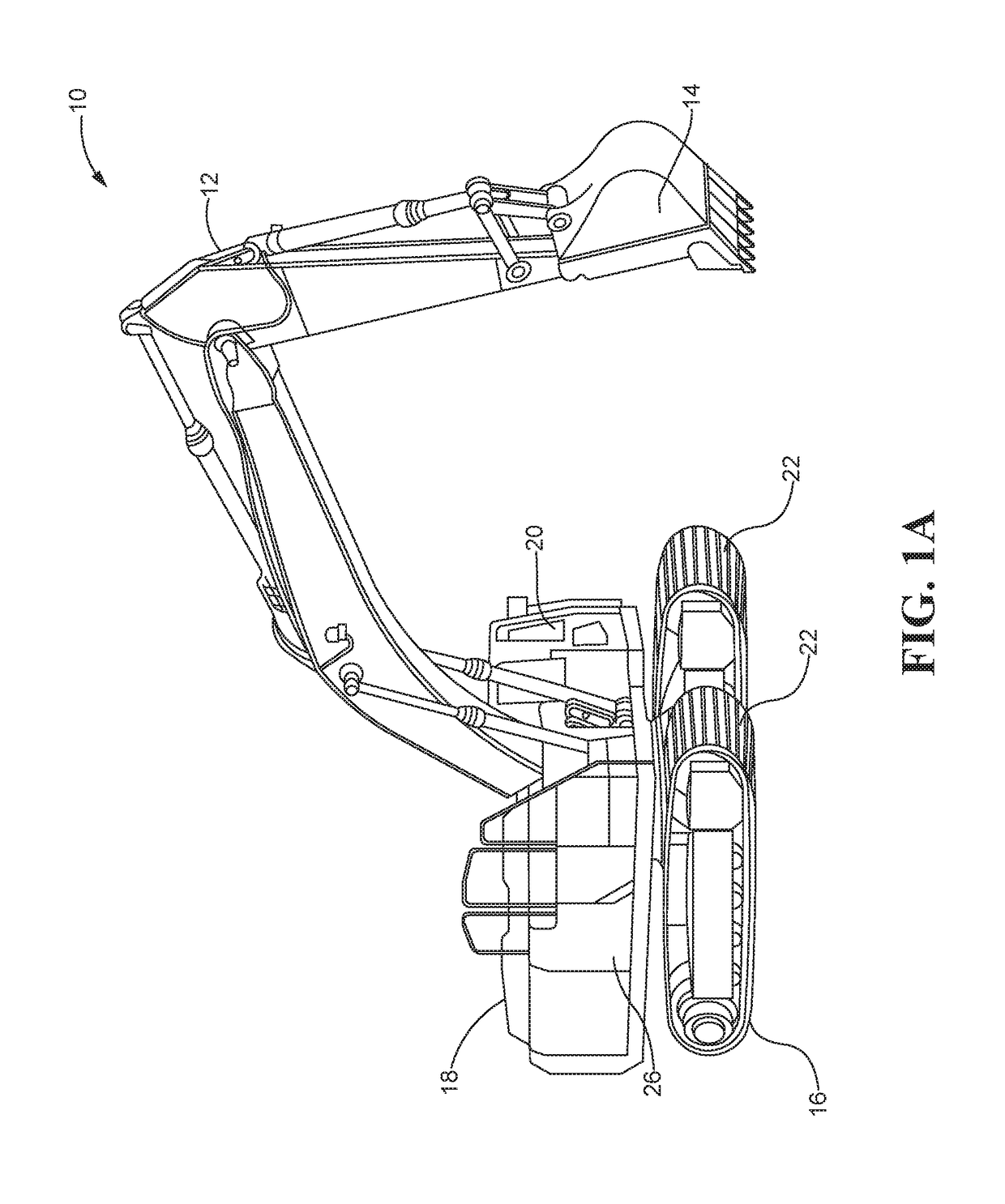

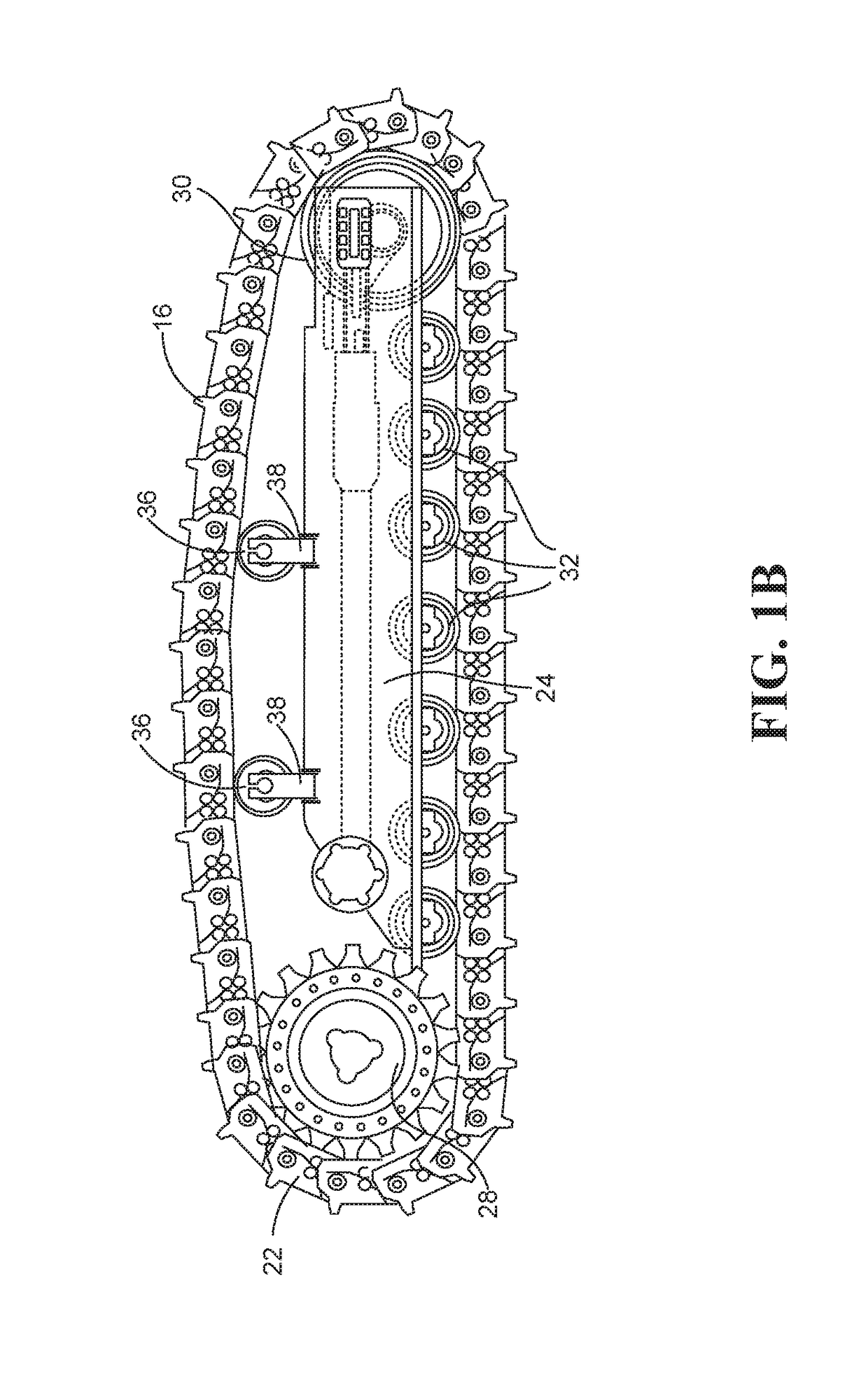

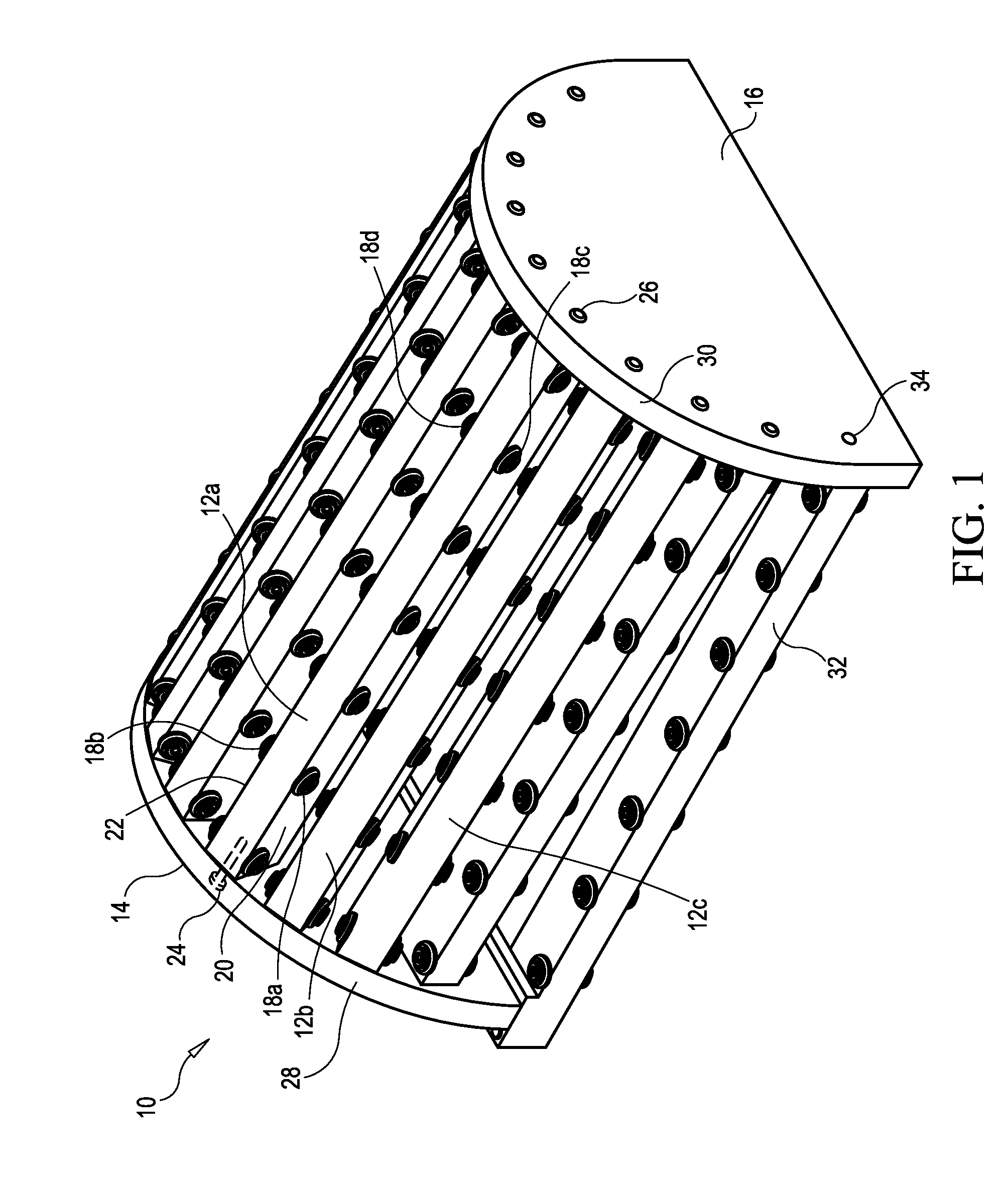

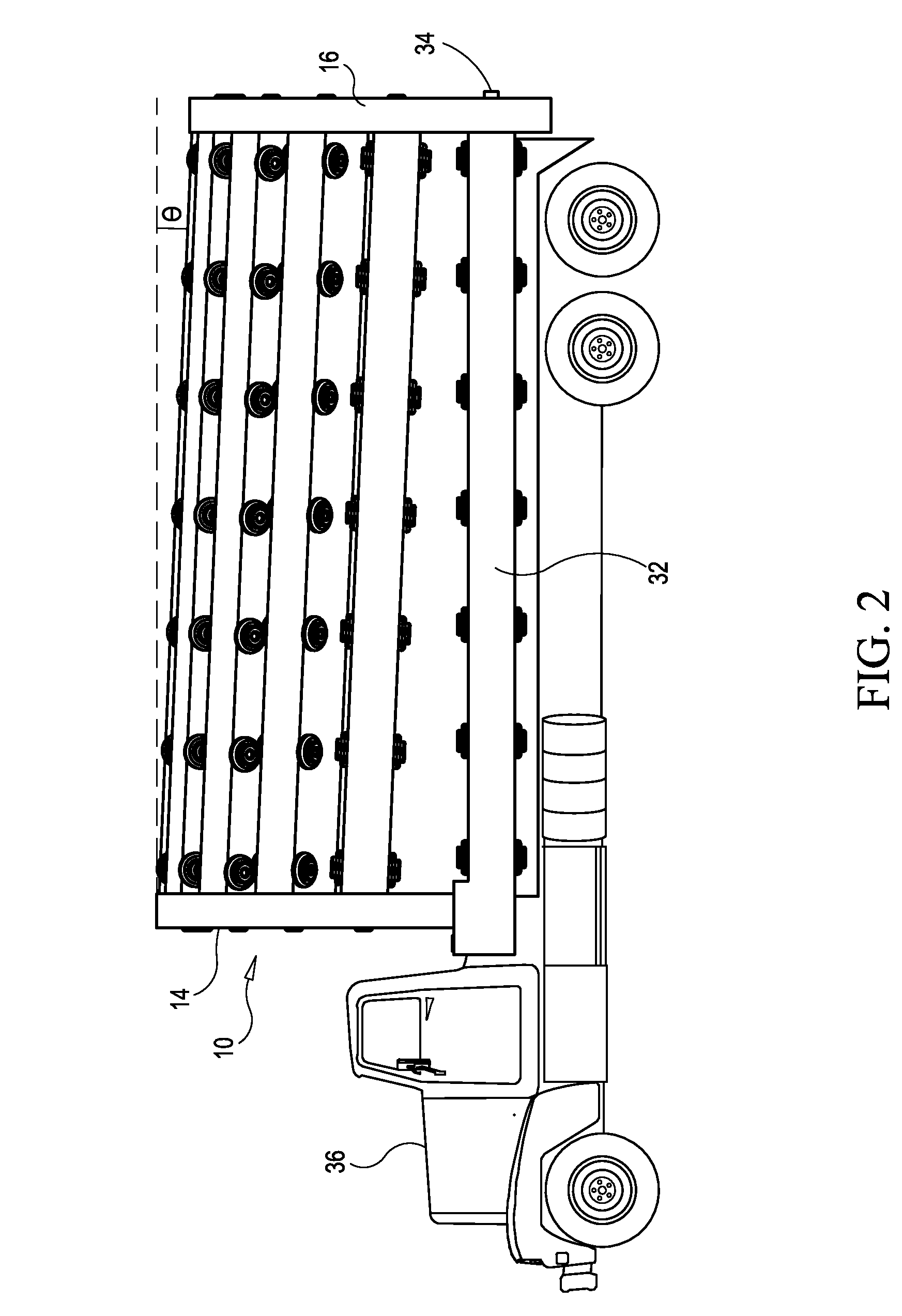

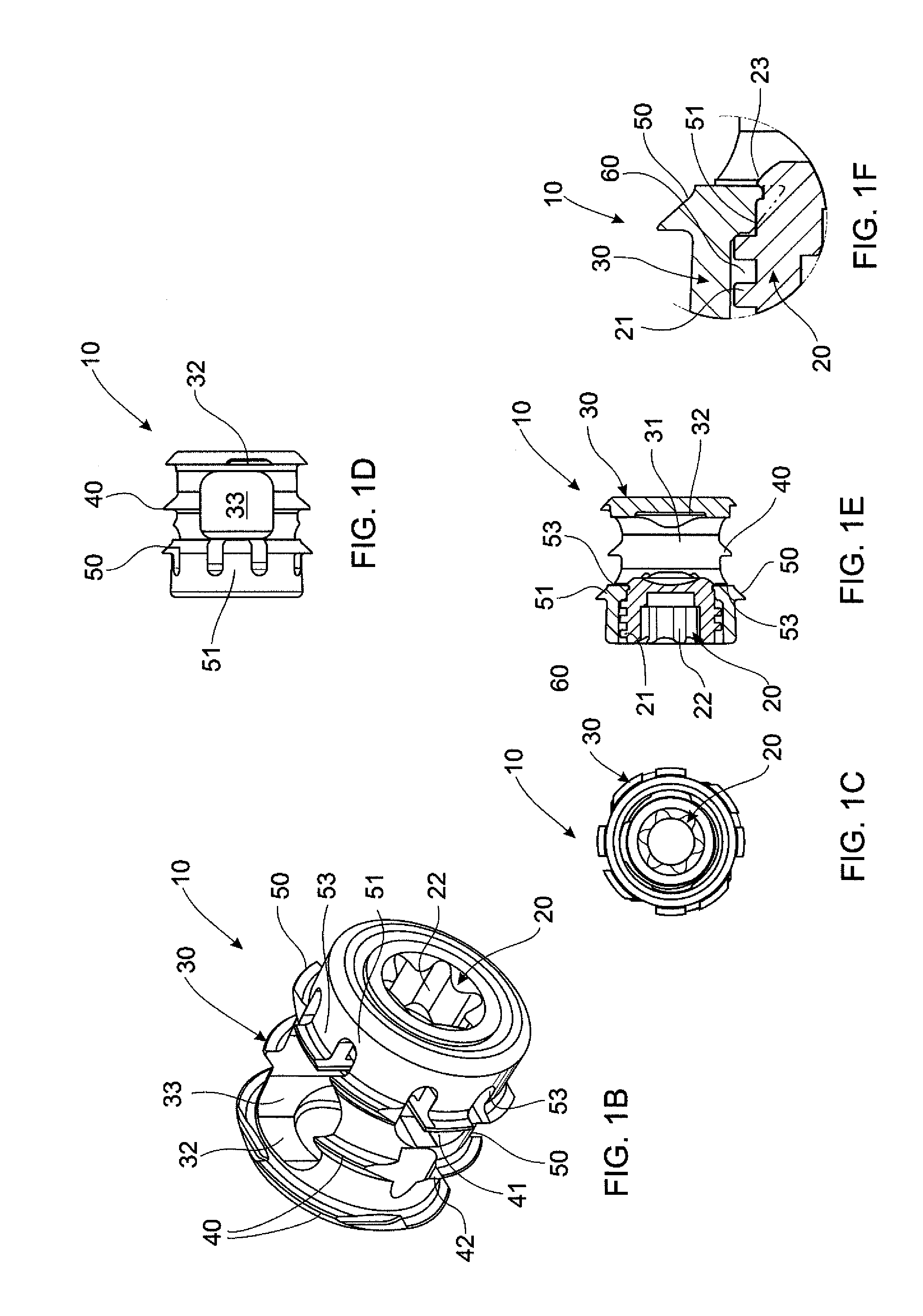

Track Roller Assembly and Method

ActiveUS20170369111A1Shorten shaft lengthPrevent inward movementMechanical machines/dredgersEndless track vehiclesEngineeringMechanical engineering

A track roller assembly may have a track roller, a roller shaft and collars press fit onto either end of the roller shaft to retain the track roller on the roller shaft with an axial clearance between the collars and the track roller. During assembly, the collars may be press fit onto the shaft ends and forced axially inwardly until further axial movement of the collars is prevented by engagement shoulders of the track roller. A compressive axial load may be applied to the roller shaft to reduce a shaft length of the roller shaft and to cause the roller shaft to slide inwardly relative to the collars. The compressive axial load is removed from the roller shaft so that the roller shaft extends back to the normal shaft length and the collars move axially farther apart as the roller shaft extends back to the normal shaft length.

Owner:CATERPILLAR INC

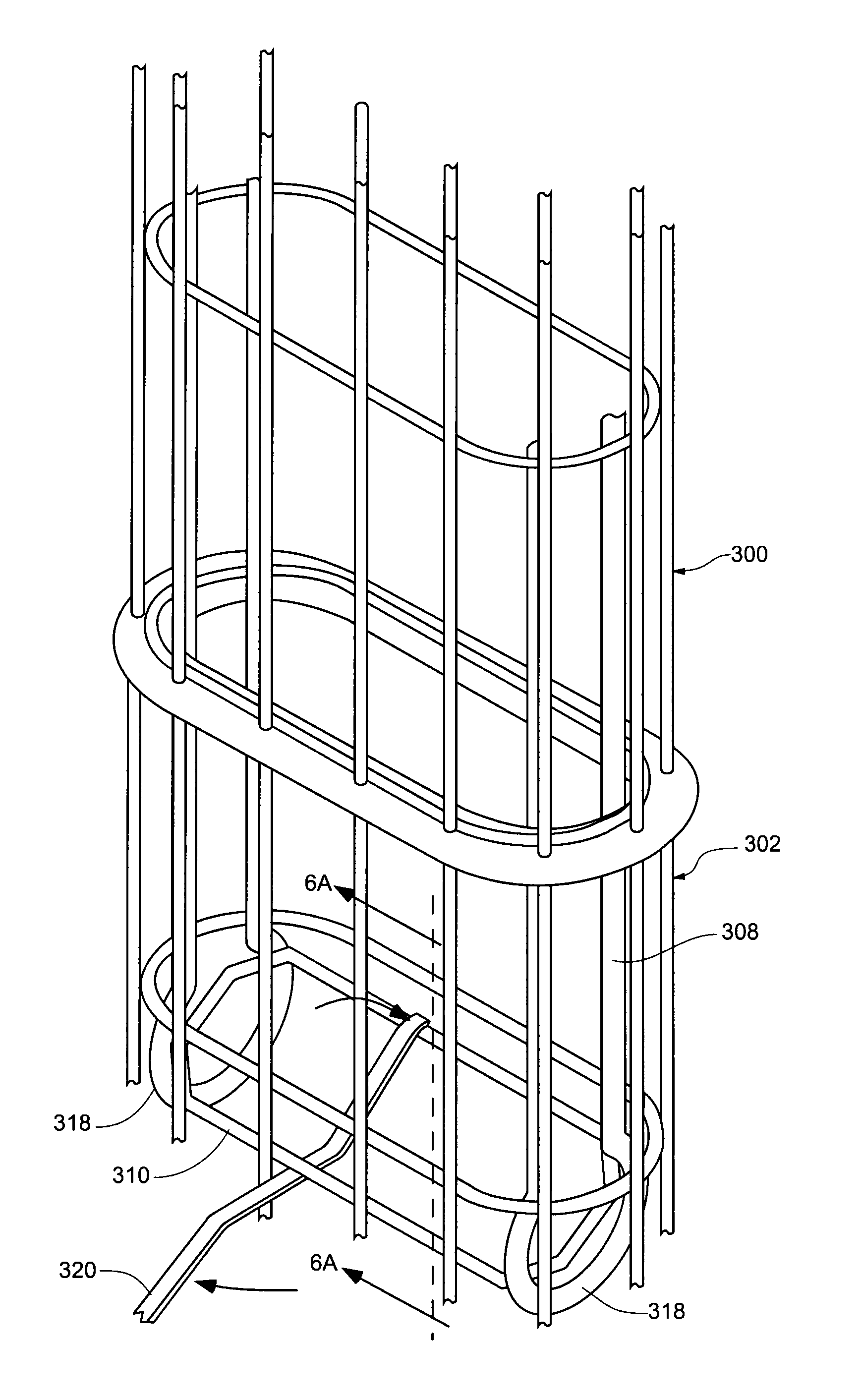

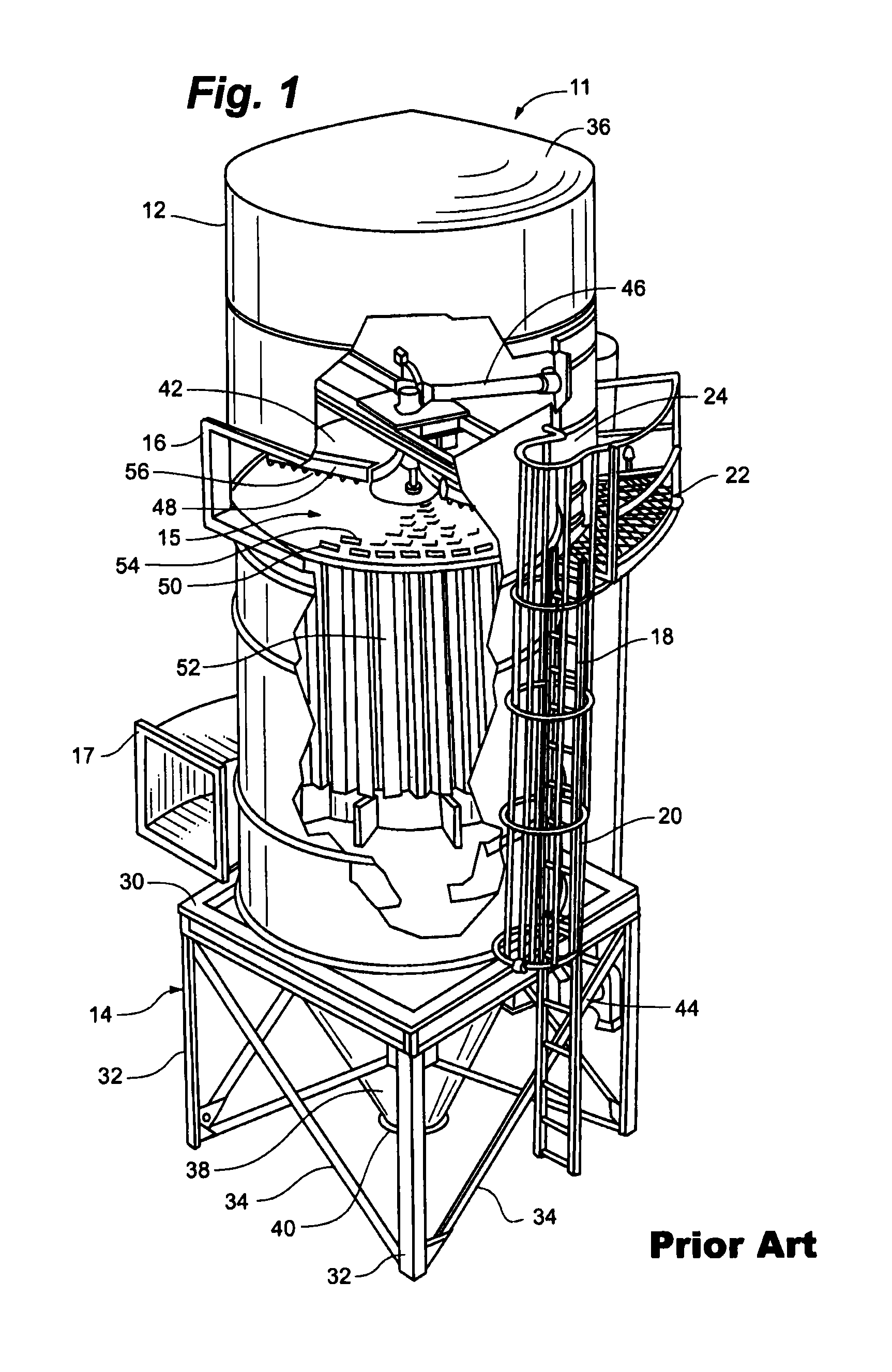

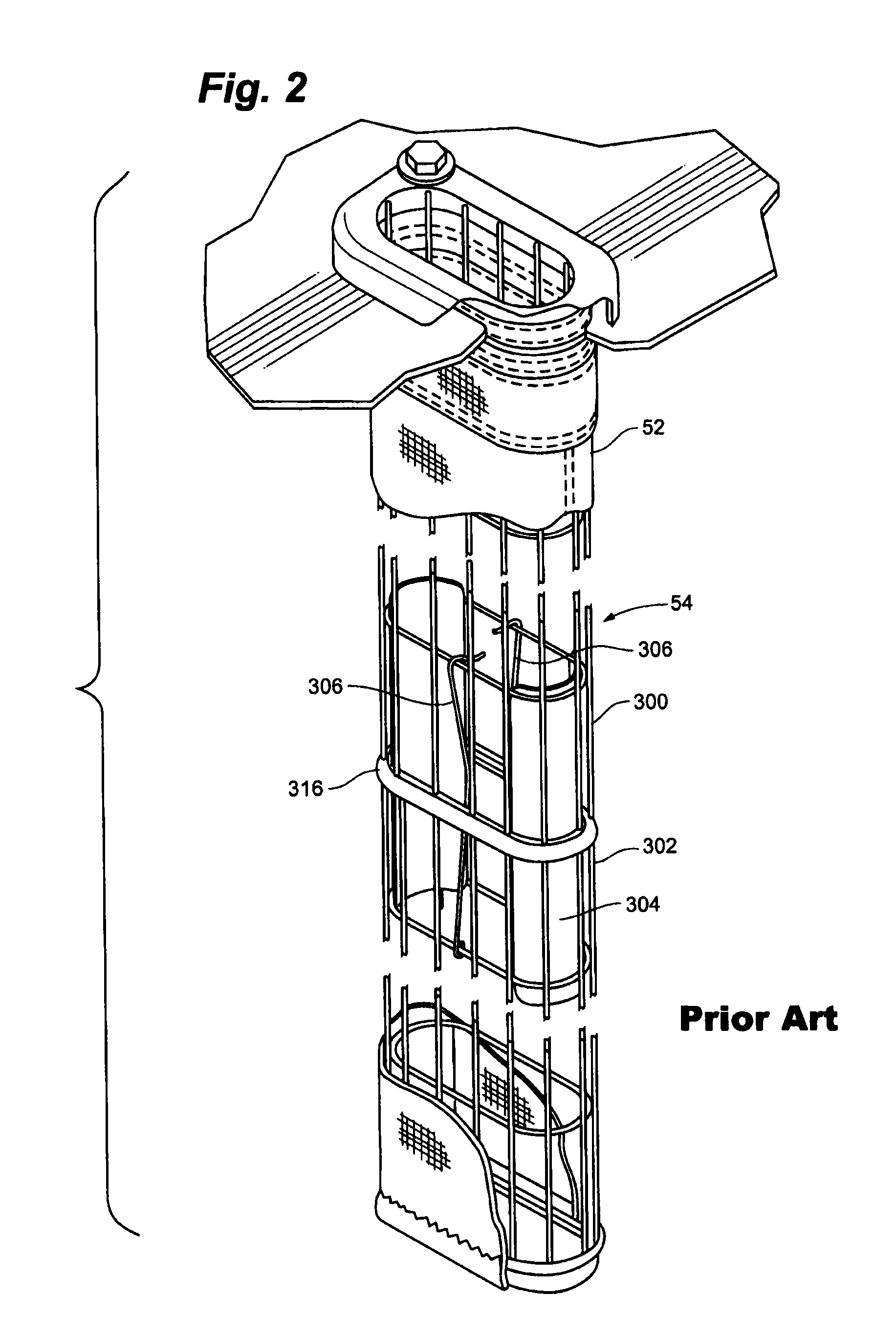

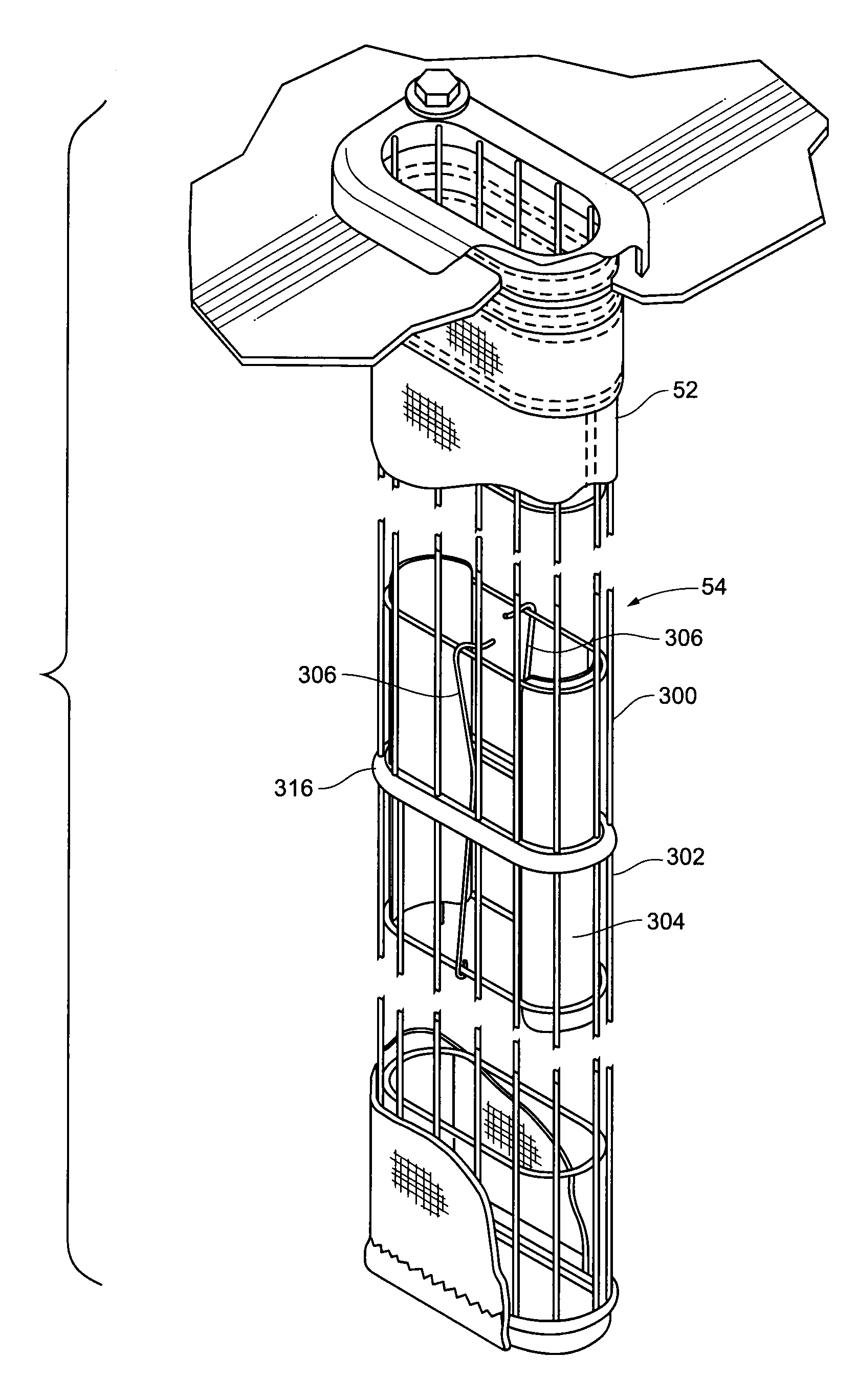

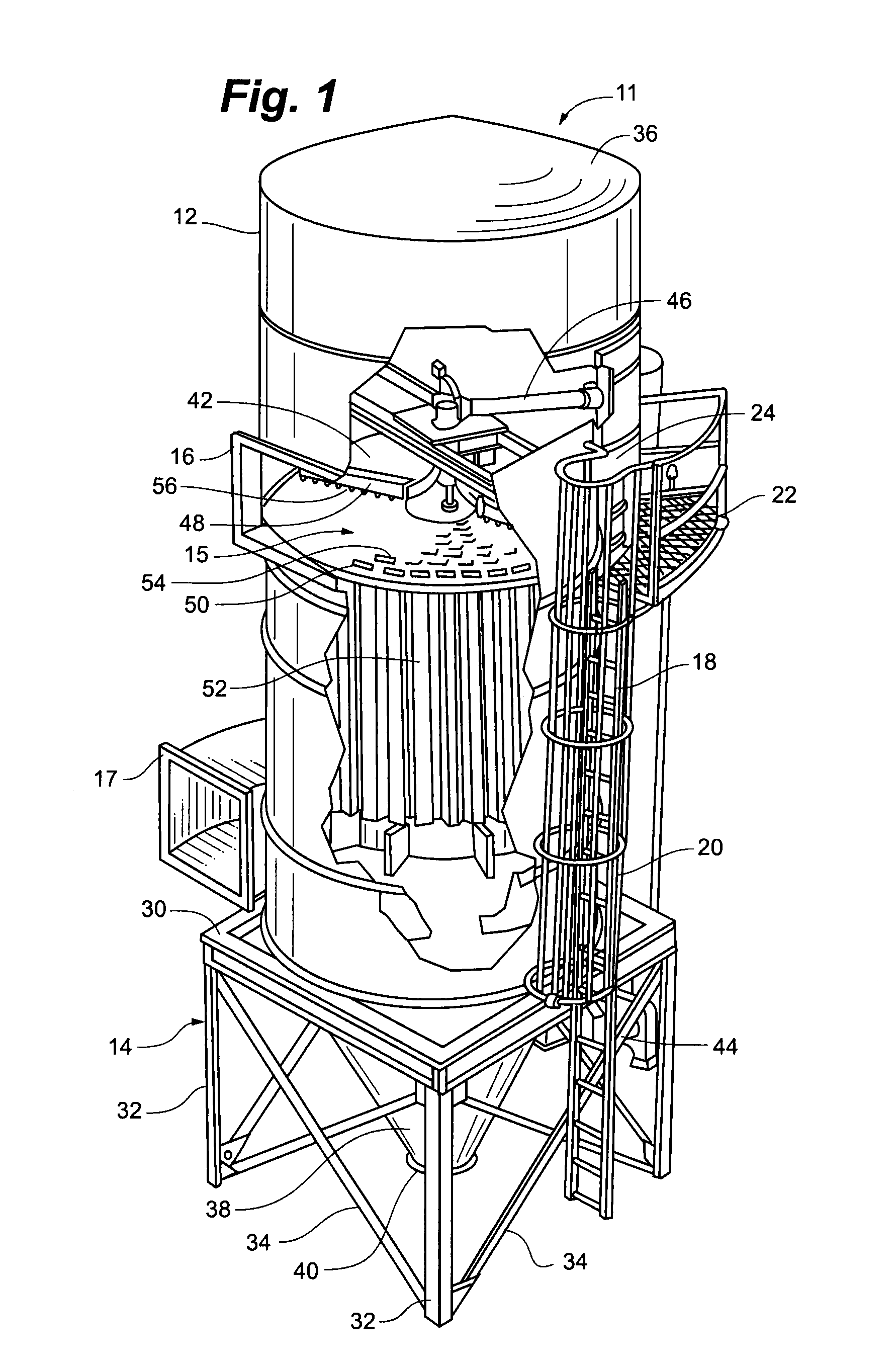

Wire filter cage locking mechanism

ActiveUS8226738B2Easy to disassembleAvoid bendingDispersed particle filtrationUsing liquid separation agentLocking mechanismEngineering

A filter bag support structure, including a first section and a second section. The first section includes a pair of opposed alignment members located partially internal to the first section and extending outwardly away from the first section aligned to insert into the second section. The second section includes at least one annular member. The alignment members are receivable within the second section and have engagement members near a distal end. A locking member is removeably insertable between the opposed alignment members and inhibits the alignment members from flexing inwardly when the locking member is inserted and causes the alignment members to resist being removed from the at least one annular member when a tension load is applied that would tend to separate the first section from the second section to a greater degree than when the locking member is not present.

Owner:AIR CURE

Wire filter cage locking mechanism

ActiveUS20110277428A1Easy to disassembleAvoid bendingDispersed particle filtrationUsing liquid separation agentLocking mechanismEngineering

A filter bag support structure, including a first section and a second section. The first section includes a pair of opposed alignment members located partially internal to the first section and extending outwardly away from the first section aligned to insert into the second section. The second section includes at least one annular member. The alignment members are receivable within the second section and have engagement members near a distal end. A locking member is removeably insertable between the opposed alignment members and inhibits the alignment members from flexing inwardly when the locking member is inserted and causes the alignment members to resist being removed from the at least one annular member when a tension load is applied that would tend to separate the first section from the second section to a greater degree than when the locking member is not present.

Owner:AIR CURE

Hydraulic chain tensioner assembly

A hydraulic chain tensioner assembly includes a plunger slider received within an opening in a tensioner body to define a controlled clearance and a substantially fluid-tight chamber. Pressure in a supply reservoir that is in fluid communication with the fluid-tight chamber is controlled to a relatively low level by appropriate sizing of the feed orifice and a bleed orifice in communication with the supply reservoir. Thus, apply force of a shoe connected to a plunger on a chain is a function of stiffness of a main spring that biases the plunger outward, and is not substantially affected by pressure of a fluid source supplying fluid to the reservoir. A method of manufacturing a hydraulic chain tensioner assembly is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

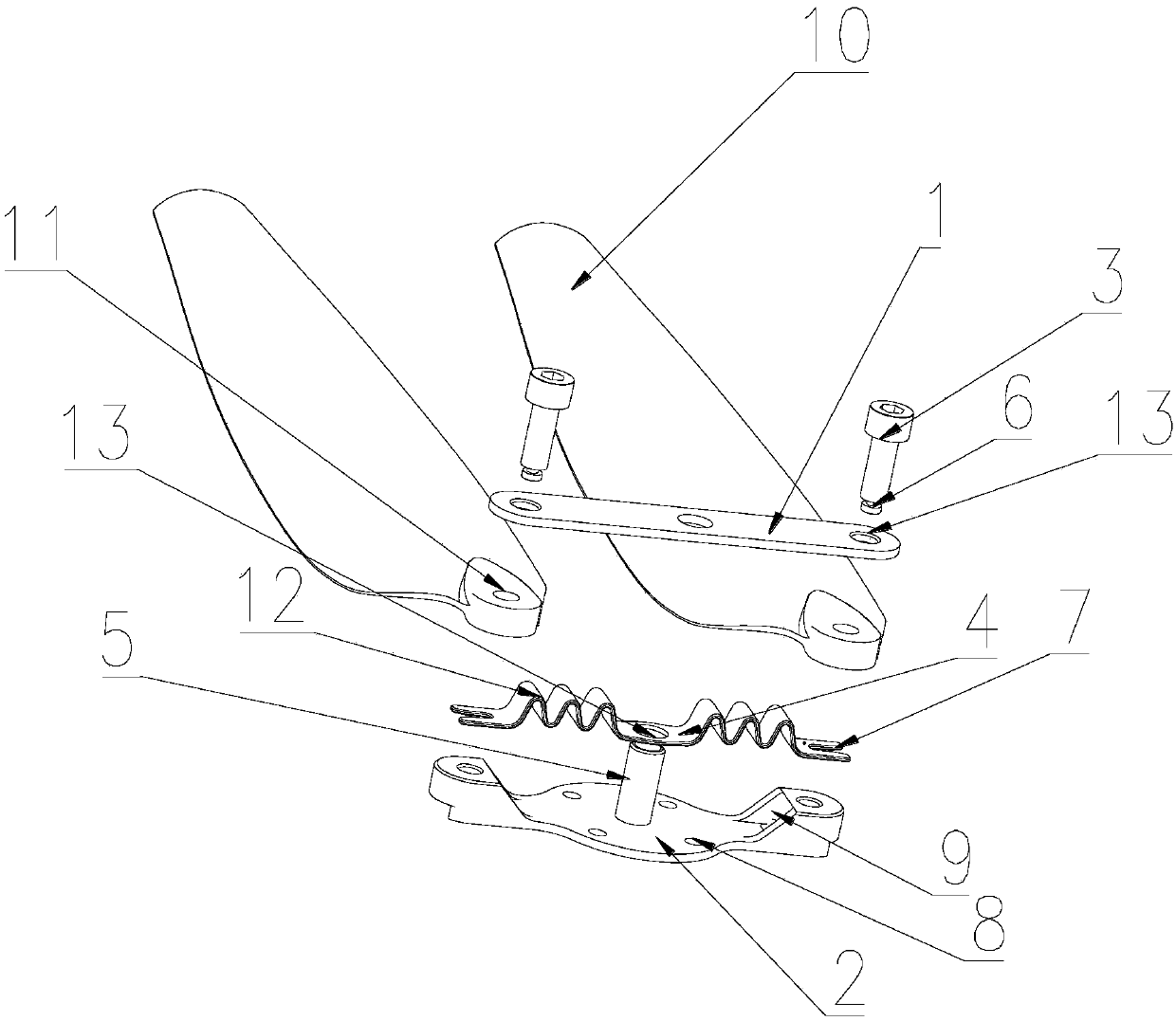

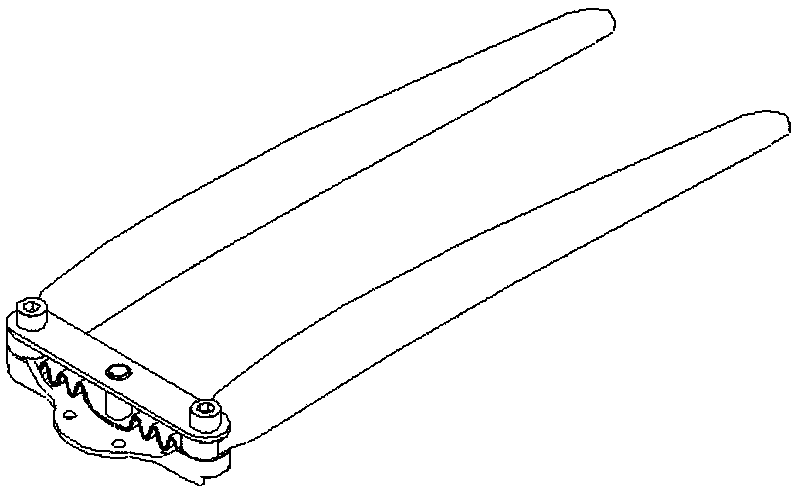

Propeller clamp and foldable propeller

The invention discloses a propeller clamp and a foldable propeller and relates to the field of unmanned aerial vehicles. The propeller clamp comprises a propeller seat, a propeller cover arranged on the propeller seat and an elastic piece arranged between the propeller seat and the propeller cover through a connecting mechanism and further comprises a limiting mechanism, the connecting mechanism comprises a connecting hole formed in the middle portion of the elastic piece and a connecting piece arranged on the propeller seat and matched with the connecting hole; and the limiting mechanism comprises limiting grooves formed in the tail ends of the elastic piece and limiting pieces arranged on the propeller seat and matched with the limiting grooves. An integrated spring leaf anti-loosening measure is adopted by the propeller clamp, screws can be effectively prevented from being loosened, anti-loosening operation is reliable, detachment and installation are easy, maintenance is easy, andan unmanned aerial vehicle propeller is convenient to replace and can be reused.

Owner:丰翼科技(深圳)有限公司

Track roller assembly and method

ActiveUS10023251B2Shorten shaft lengthPrevent inward movementMechanical machines/dredgersEndless track vehiclesEngineeringShaft collar

A track roller assembly may have a track roller, a roller shaft and collars press fit onto either end of the roller shaft to retain the track roller on the roller shaft with an axial clearance between the collars and the track roller. During assembly, the collars may be press fit onto the shaft ends and forced axially inwardly until further axial movement of the collars is prevented by engagement shoulders of the track roller. A compressive axial load may be applied to the roller shaft to reduce a shaft length of the roller shaft and to cause the roller shaft to slide inwardly relative to the collars. The compressive axial load is removed from the roller shaft so that the roller shaft extends back to the normal shaft length and the collars move axially farther apart as the roller shaft extends back to the normal shaft length.

Owner:CATERPILLAR INC

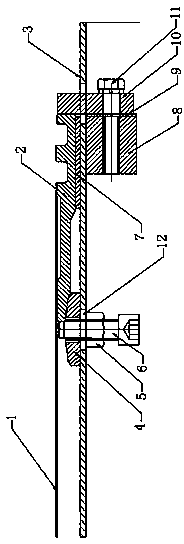

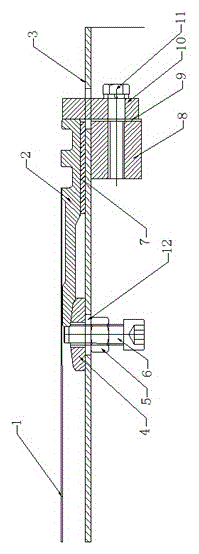

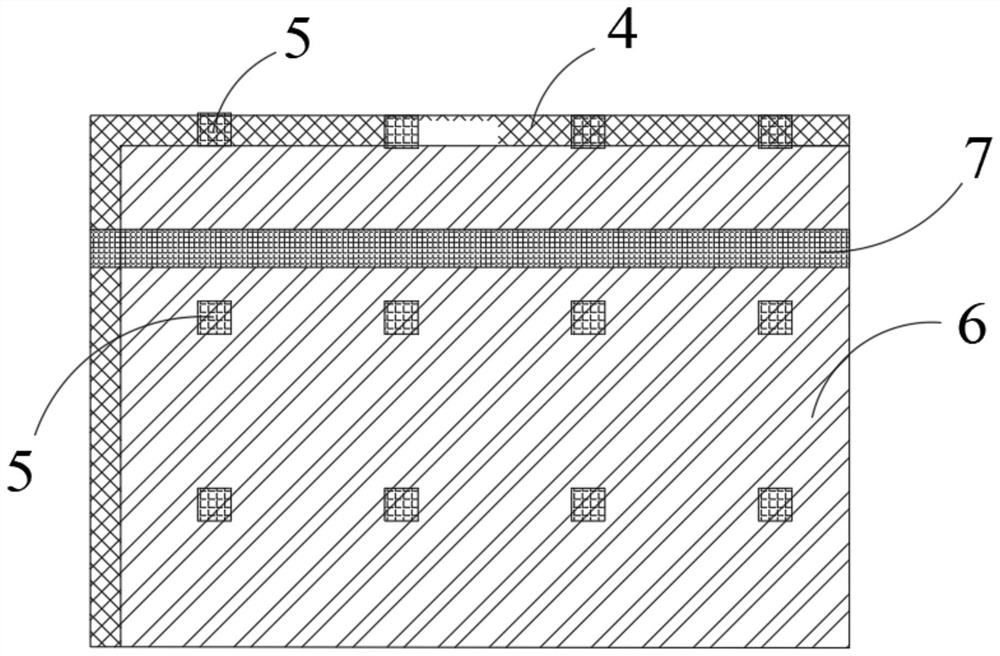

Spiral pipe welder spigot ring positioning device

ActiveCN104057235ASimple structureEasy to produceWelding/cutting auxillary devicesAuxillary welding devicesCoaxial lineSteel plates

The invention relates to a spiral pipe welder spigot ring positioning device and belongs to the technical field of spiral reel pipe welders. The device comprises a spigot ring, an outer positioning block, a core mould cylinder body, a limit special nut, an inner hexagonal limit bolt, a hexagonal nut, a spigot ring positioning block, an adjusting gasket, a hexagonal head bolt and a cushion block, wherein a spigot ring front adjustable device is formed by the limit special nut, the inner hexagonal limit bolt and the hexagonal nut and is fixedly arranged on the core mould cylinder body through the limit special nut and the hexagonal nut, a spigot ring back positioning device is formed by the spigot ring positioning block, the adjusting gasket and the outer positioning block, the spigot ring positioning block is welded on the core mould cylinder body, and the cushion block is arranged between the front upper end surface of the spigot ring and the core mould cylinder body. The spigot ring can be accurately positioned and tightly clamped through the spigot ring front adjustable device and the spigot ring back positioning device. The spiral pipe welder spigot ring positioning device avoids the inward movement of the spigot ring due to mechanical vibration when a spiral welded pipe is produced, the coaxial line of the spigot ring and the core mould cylinder body is guaranteed, a steel plate and the spigot ring are firm in welding, and the quality of a product is improved.

Owner:JIANGSU JIANGYANG BUILDING MATERIAL MACHINERY

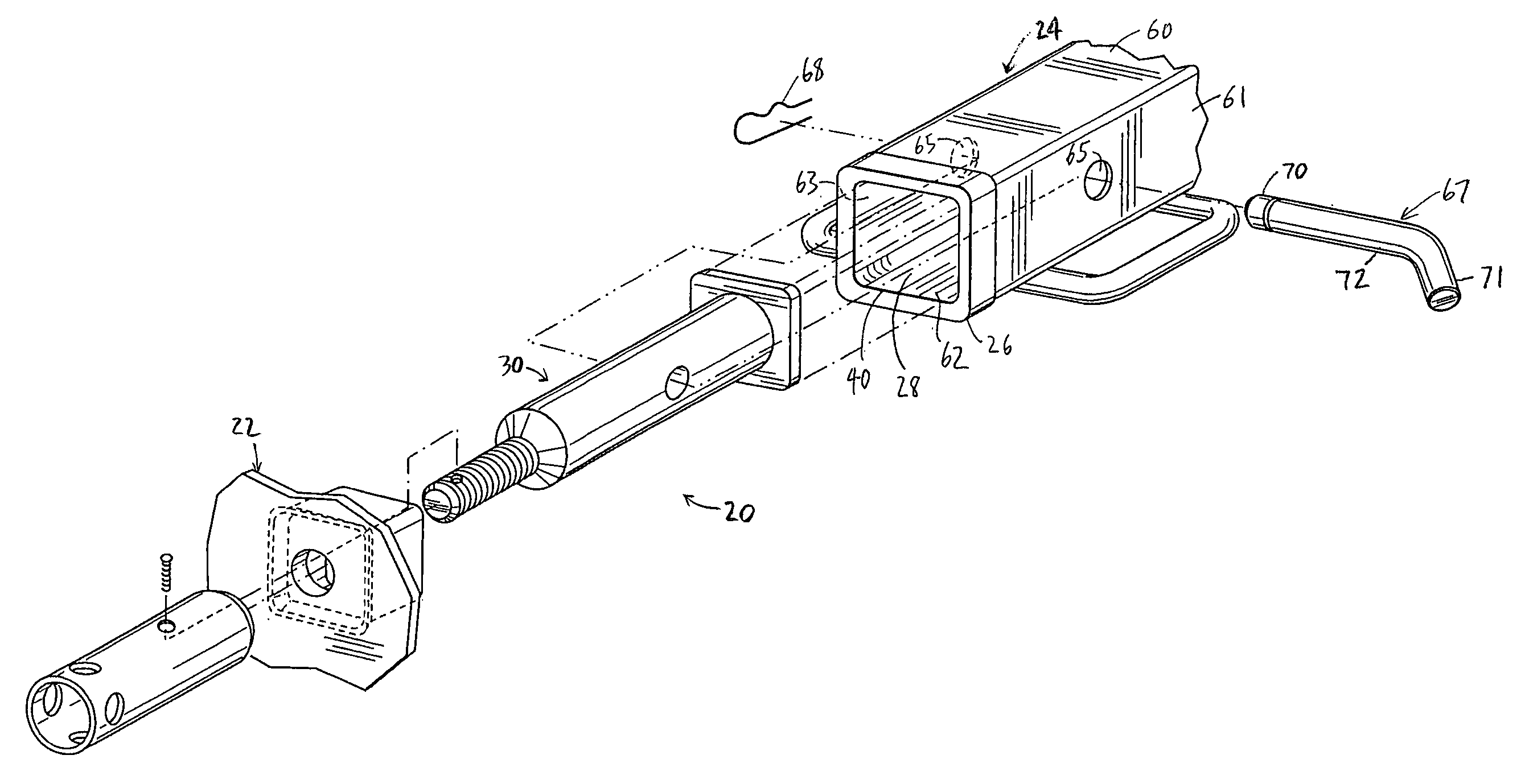

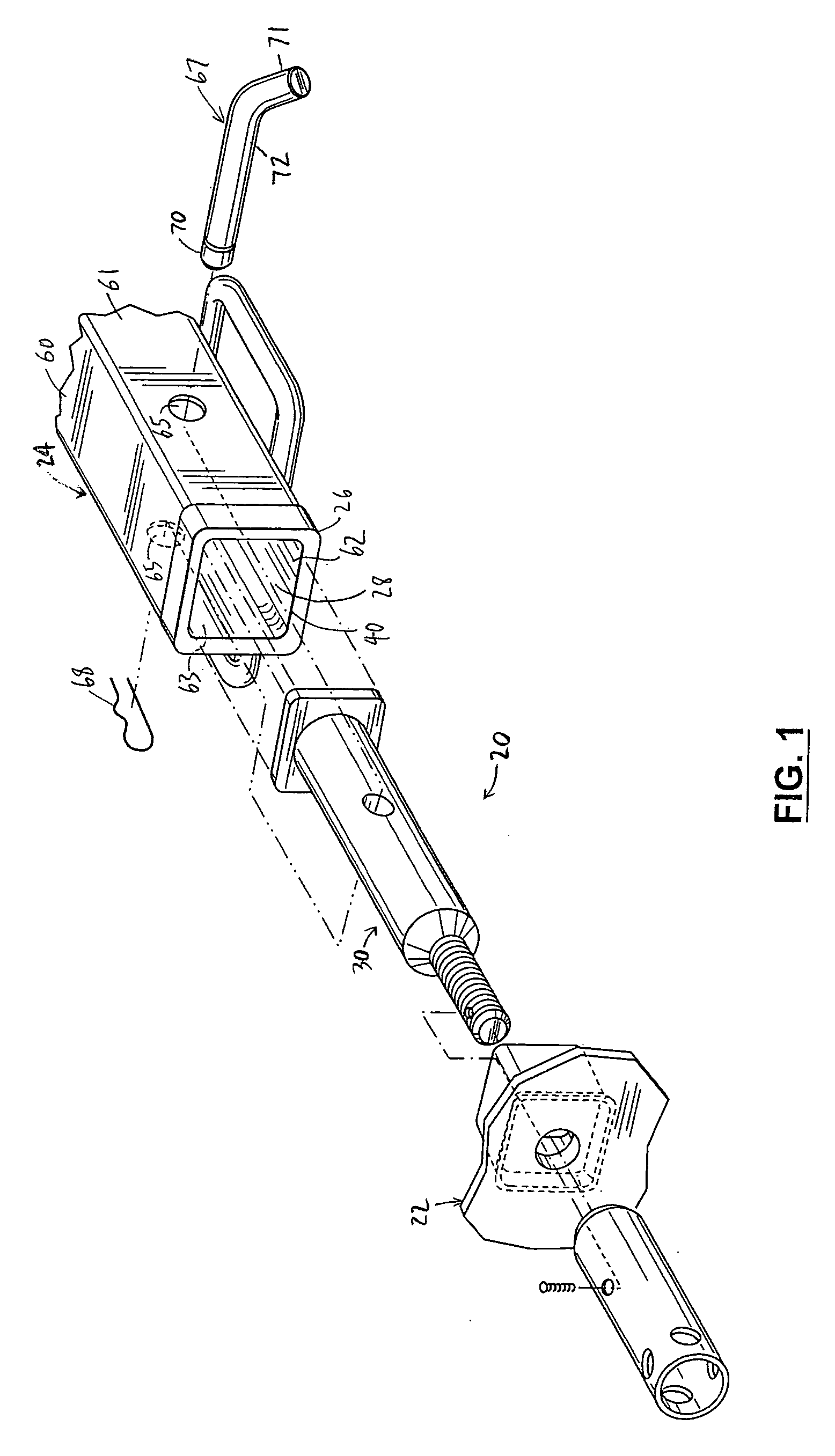

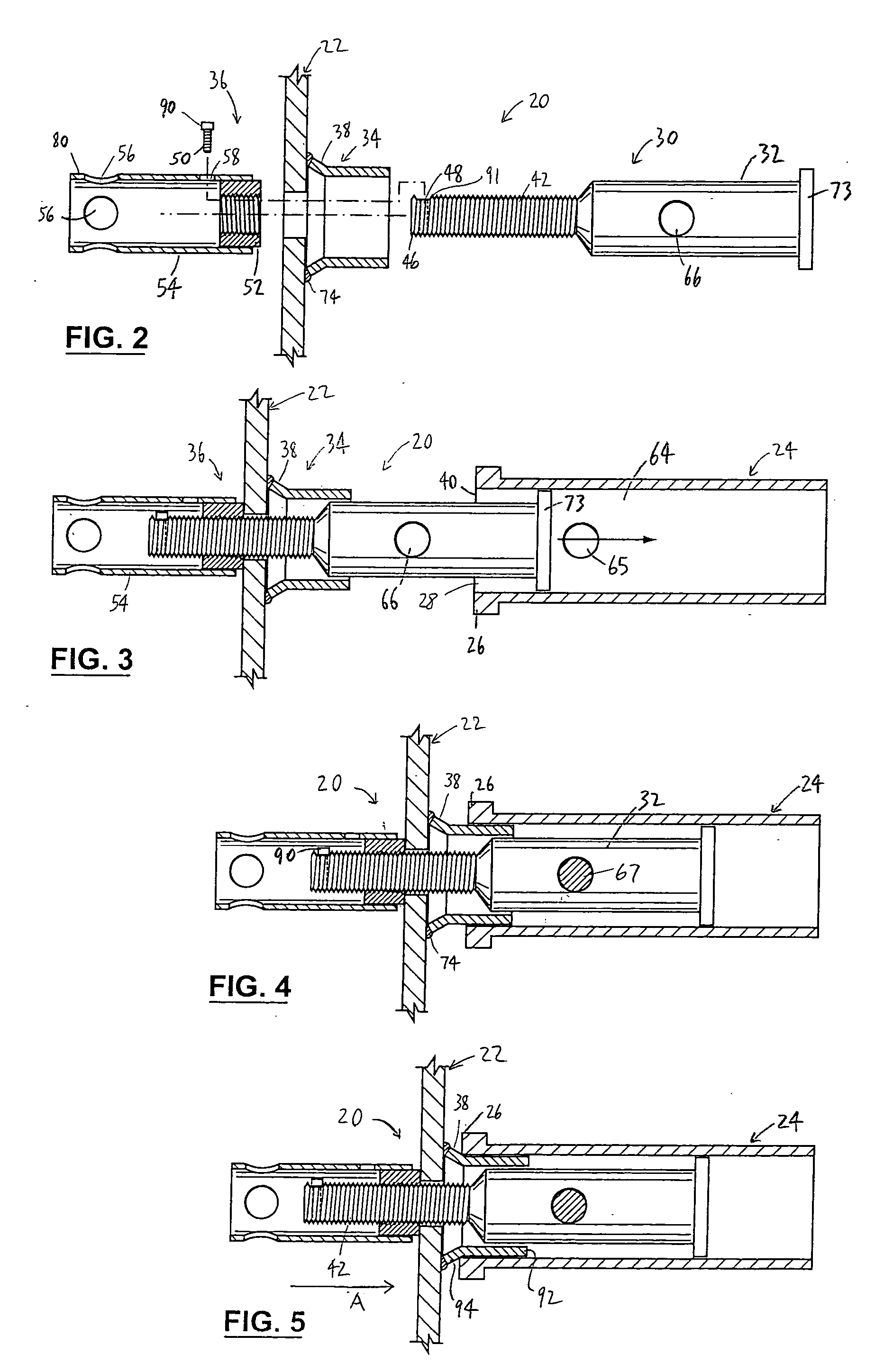

Connecting device

InactiveUS20060006627A1Prevent inward movementTowing devicesInterference fitElectrical and Electronics engineering

A connecting device for connecting an accessory to a hitch receiver with an outward end defining an opening. The connecting device has a base with a body portion receivable in the hitch receiver. The body portion is adapted for coupling with the hitch receiver to locate the base in a predetermined position thereon. The connecting device also has a collar for engaging the outward end of the hitch receiver in an interference fit upon engagement of the collar with the outward end, the collar being coupled with the accessory. In addition, the connecting device includes a fastener operatively connected with the base for urging the collar against the outward end to cause the collar to engage the outward end. The connecting device connects the accessory to the hitch receiver upon engagement of the collar with the outward end of the hitch receiver.

Owner:IRON CONCEPTS

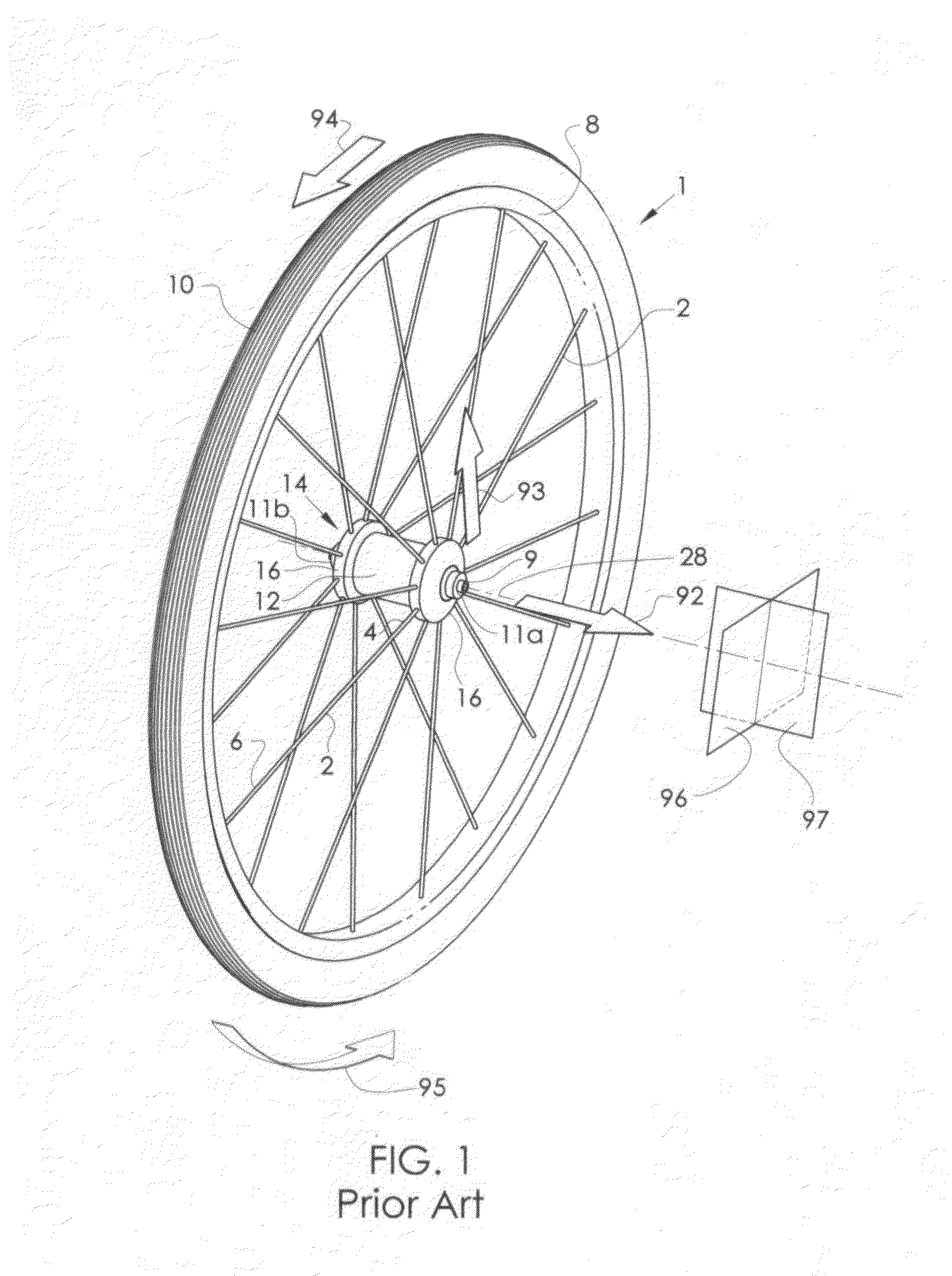

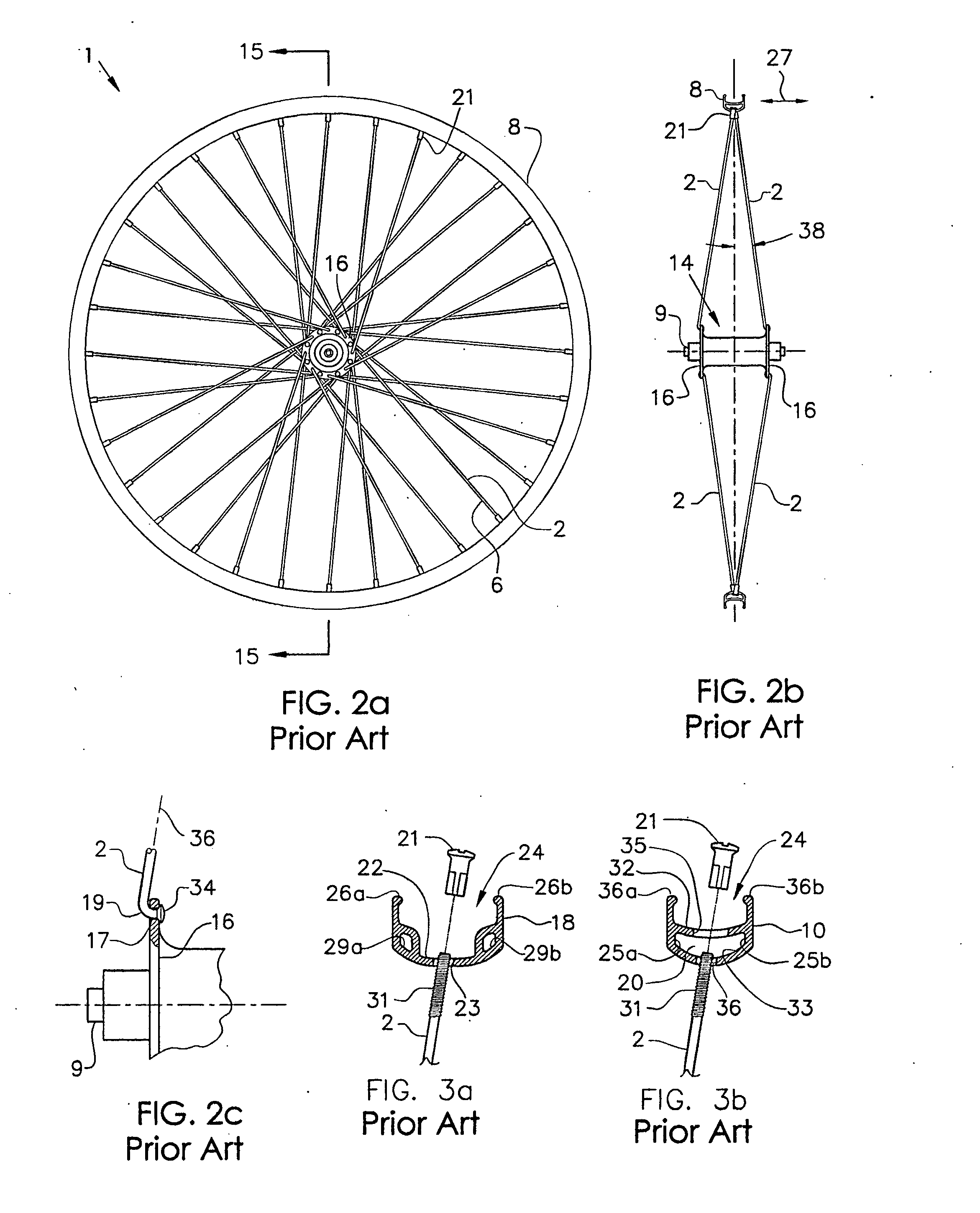

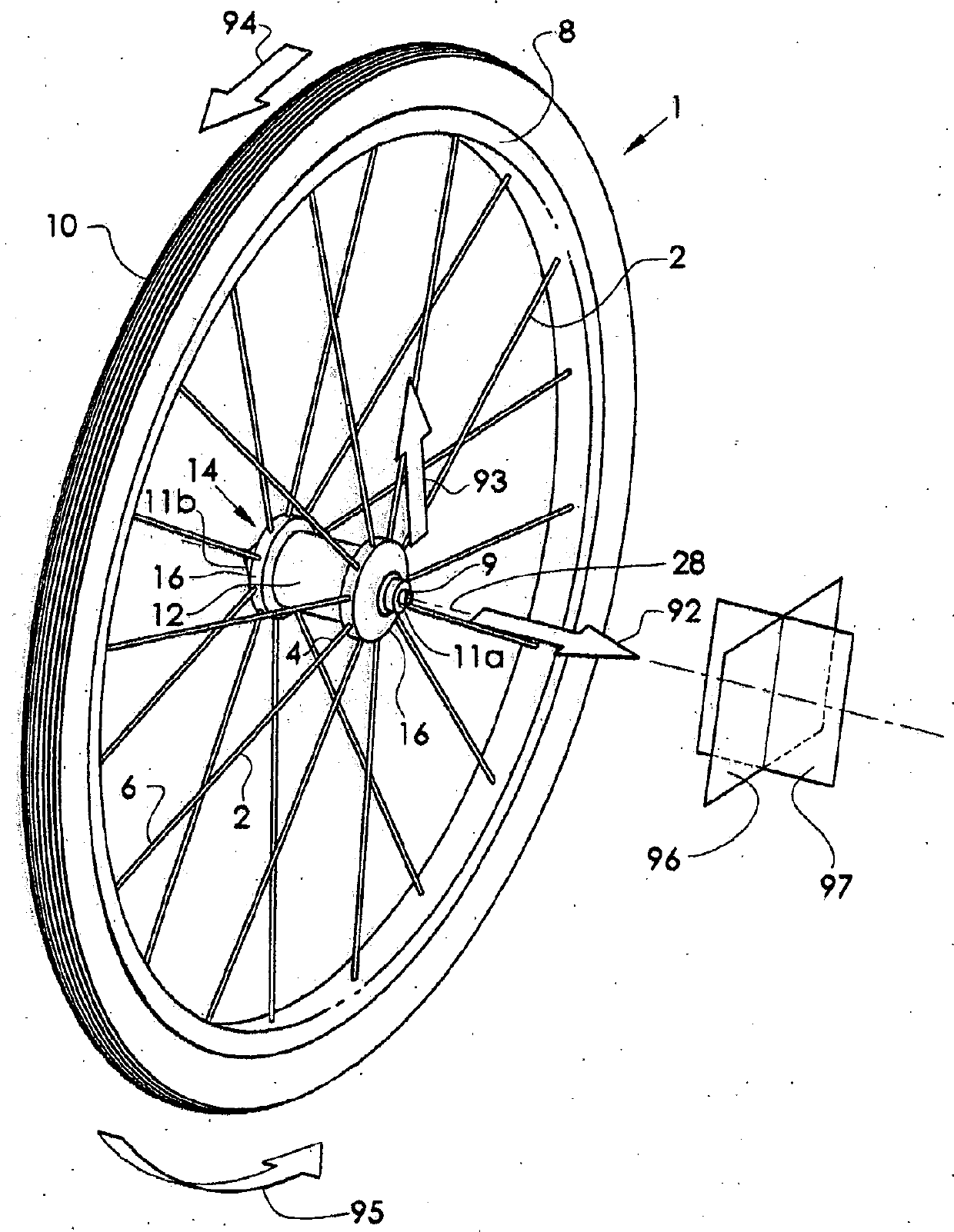

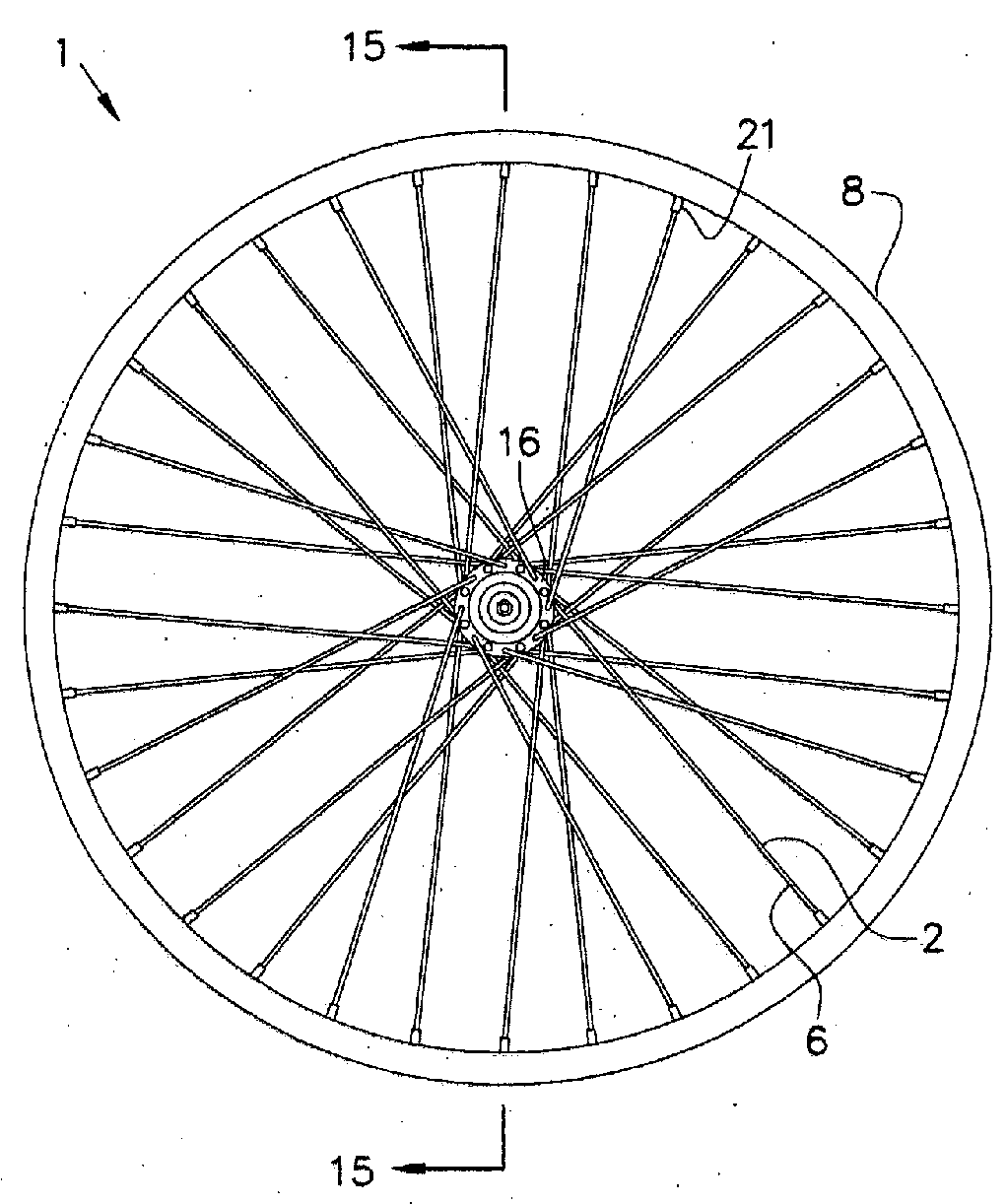

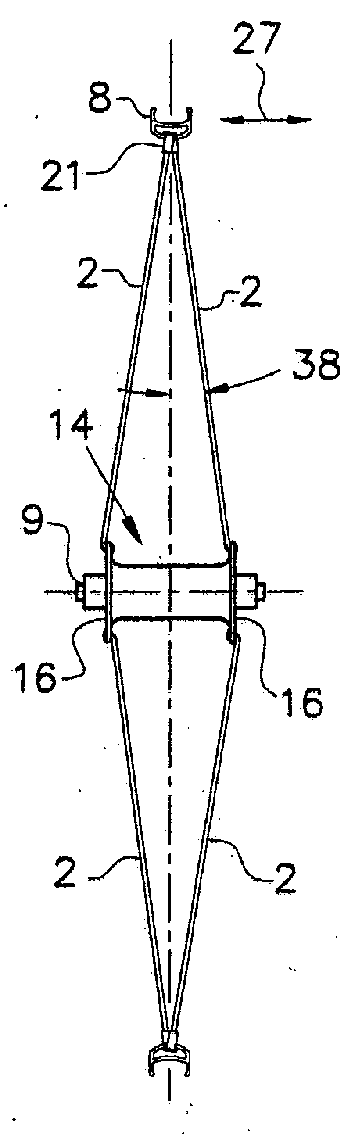

Vehicle wheel spoke connection

A vehicle wheel, comprising a rim, a hub, a plurality of spokes extending between the rim and hub, a bracing element including a hole with a central axis, a sidewall, a longitudinally inward entrance, and at least one of an engagement surface and an engagement edge outward of the entrance, a connecting element connected to the bracing element, including an opening extending along an opening axis, and a multiplicity of prongs, with at least one of the prongs including a lateral overhang surface. The connecting element is resilient and may be flexed between collapsed and expanded orientations and is positioned within the hole, with the overhang surface overlying one of the engagement surface and engagement edge. The spoke is connected to the connecting element by a threaded engagement with the central opening.

Owner:SCHLANGER RAPHAEL

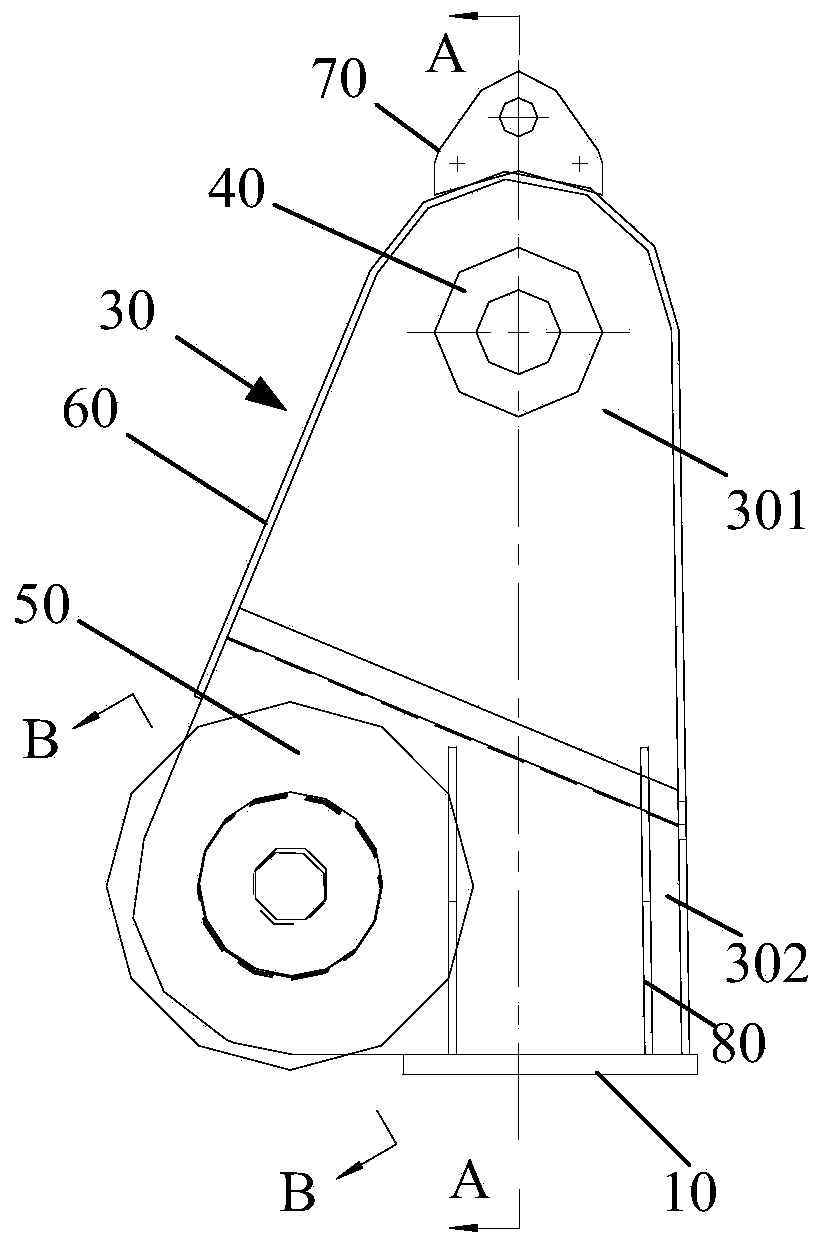

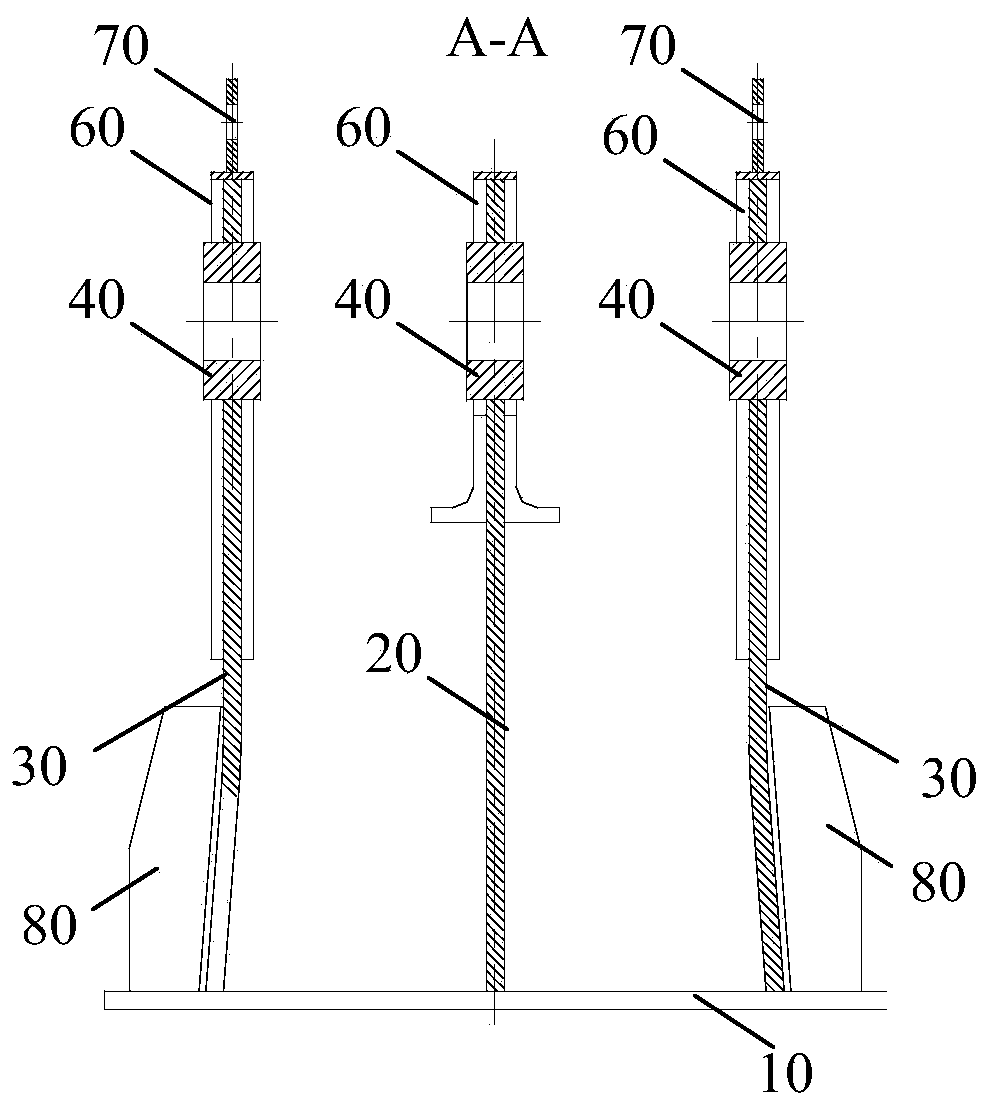

Manufacturing tool and manufacturing method of crane top structural part

The invention discloses a manufacturing tool and manufacturing method of a crane top structural part, and belongs to the field of machining. Firstly, a middle vertical plate is welded on a bottom plate, a cylindrical bulge of a first positioning shaft is inserted into a pulley flange of the middle vertical plate, a second positioning shaft is inserted into a pulley flange of a side plate, a positioning ring is supported on the pulley flange of the side plate, a positioning plate abuts against the plate surface of one side plate, the second positioning shaft is in threaded connection to the first positioning shaft, and a positioning bolt is rotated to enable one end of the positioning bolt to abut against the pulley flange of the side plate; the position of one side plate relative to the middle vertical plate is fixed by one positioning unit, and the position of the other side plate relative to the middle vertical plate is positioned by another positioning unit, so that the position accuracy of the two side plates relative to the middle vertical plate is ensured; the positions of the two side plates relative to the middle vertical plate are further guaranteed through a supporting unit; and finally, the two side plates and the bottom plate are welded. The size precision of the obtained crane structural part is high, and the rejection rate of the crane structural part can be reduced.

Owner:WUHAN MARINE MACHINERY PLANT

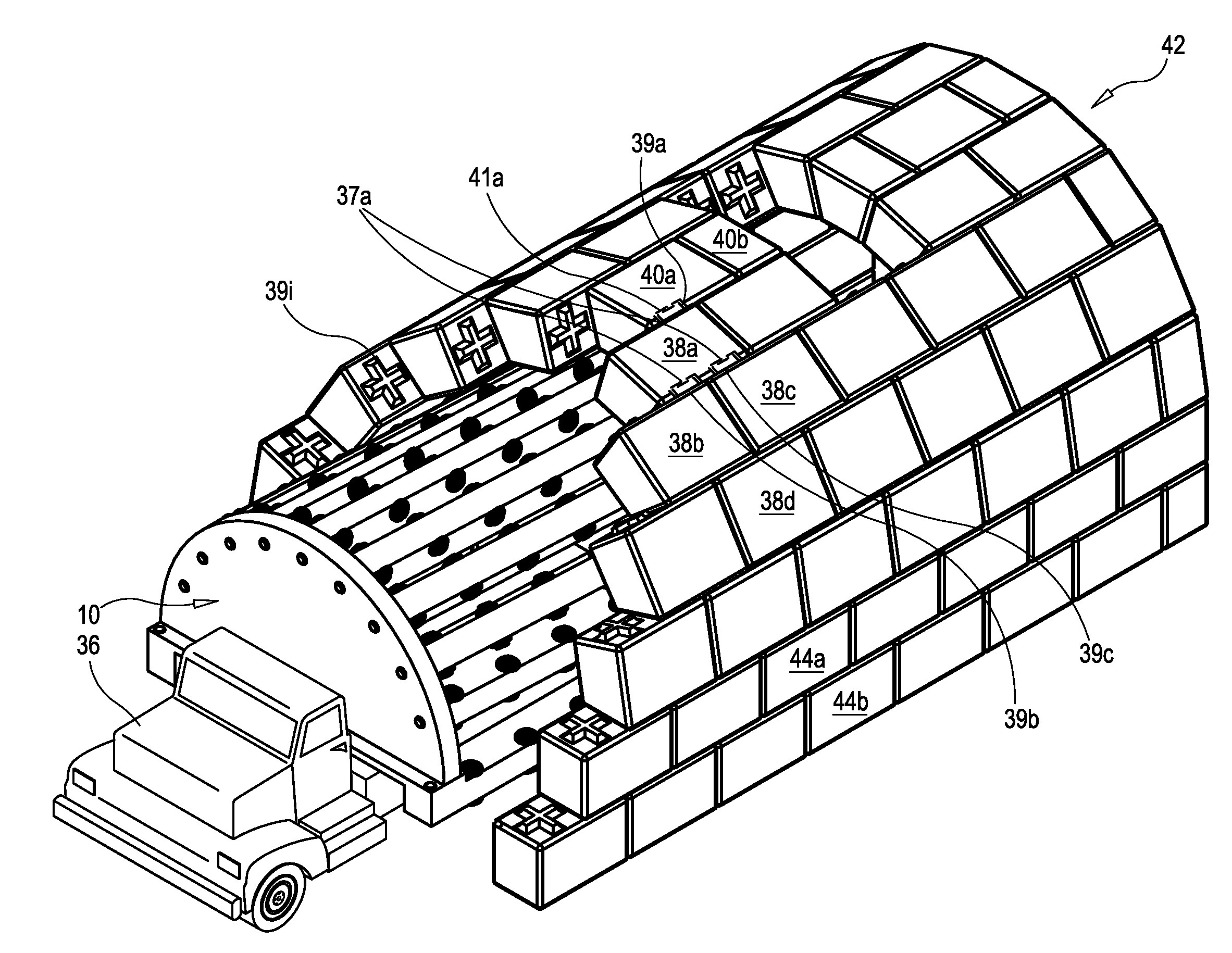

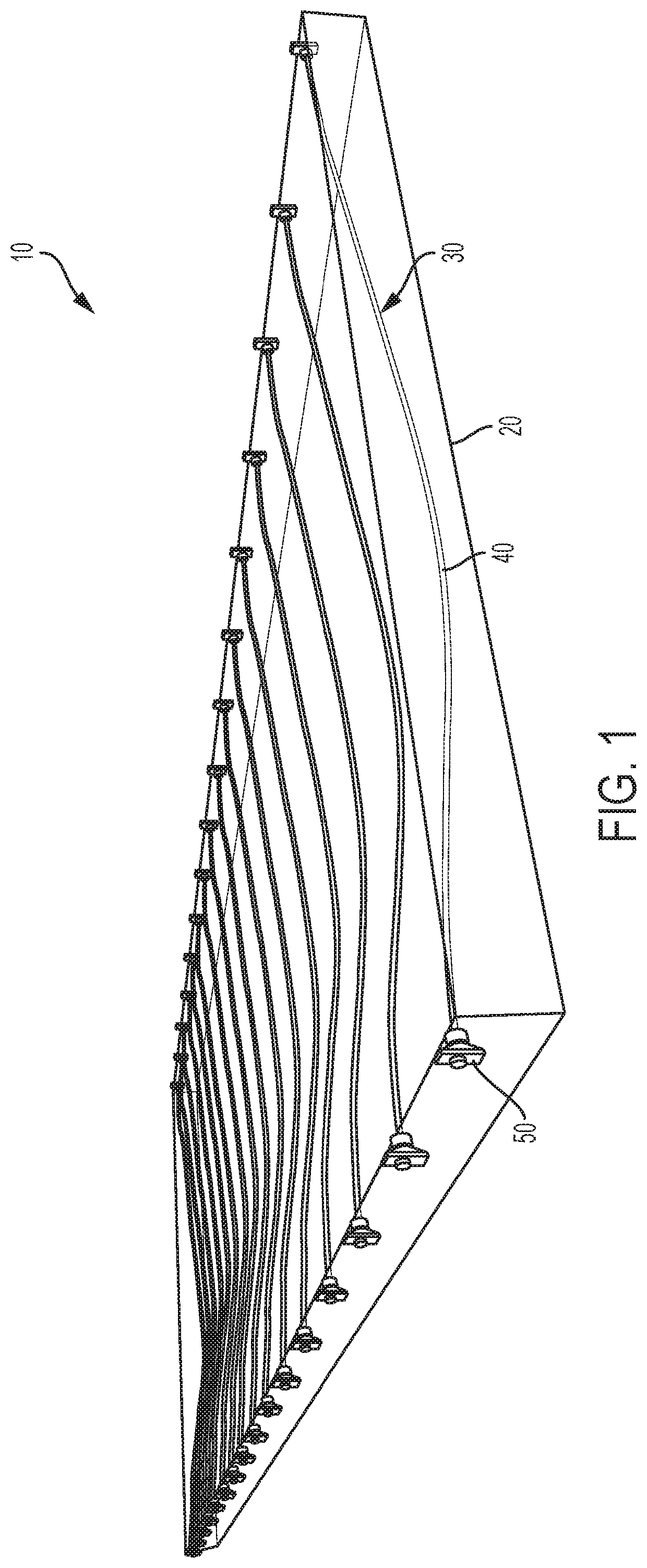

Formwork for use in the construction of arched structures and a method of constructing arched structures

ActiveUS20120233934A1Prevent outward movementPrevent inward movementGround-workArched structuresEngineeringBuilding construction

Owner:LOCK BLOCK LTD

Vehicle wheel spoke connection

A vehicle wheel, comprising a rim, a hub, a plurality of spokes extending between the rim and hub, a bracing element including a hole with a central axis, a sidewall, a longitudinally inward entrance, and at least one of an engagement surface and an engagement edge outward of the entrance, a connecting element connected to the bracing element, including an opening extending along an opening axis, and a multiplicity of prongs, with at least one of the prongs including a lateral overhang surface. The connecting element is resilient and may be flexed between collapsed and expanded orientations and is positioned within the hole, with the overhang surface overlying one of the engagement surface and engagement edge in a first overlie engagement. The spoke includes a laterally projecting surface to overlie the connecting element in a second overlie engagement that is preferably located longitudinally outwardly of the first overlie engagement.

Owner:SCHLANGER RAPHAEL

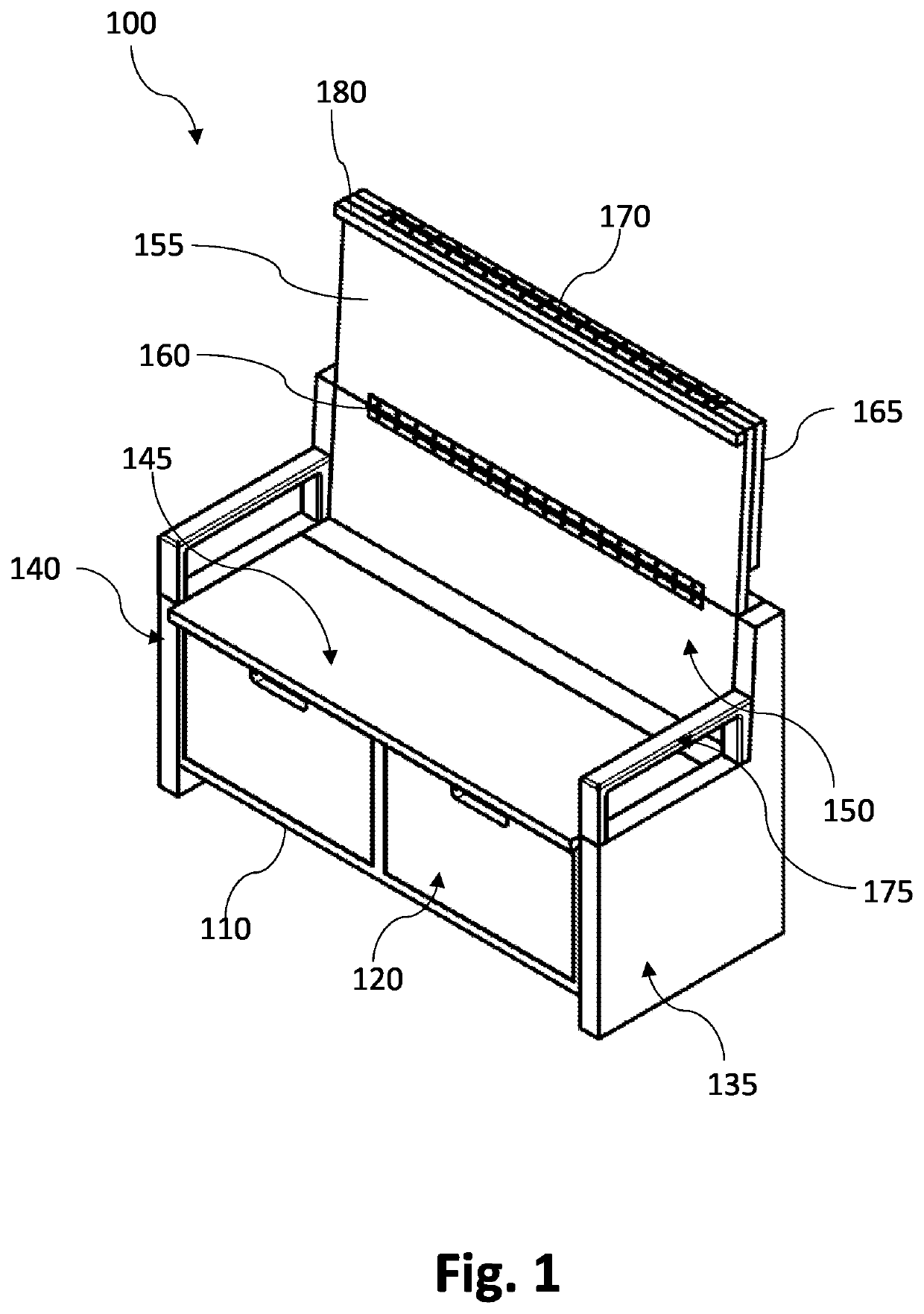

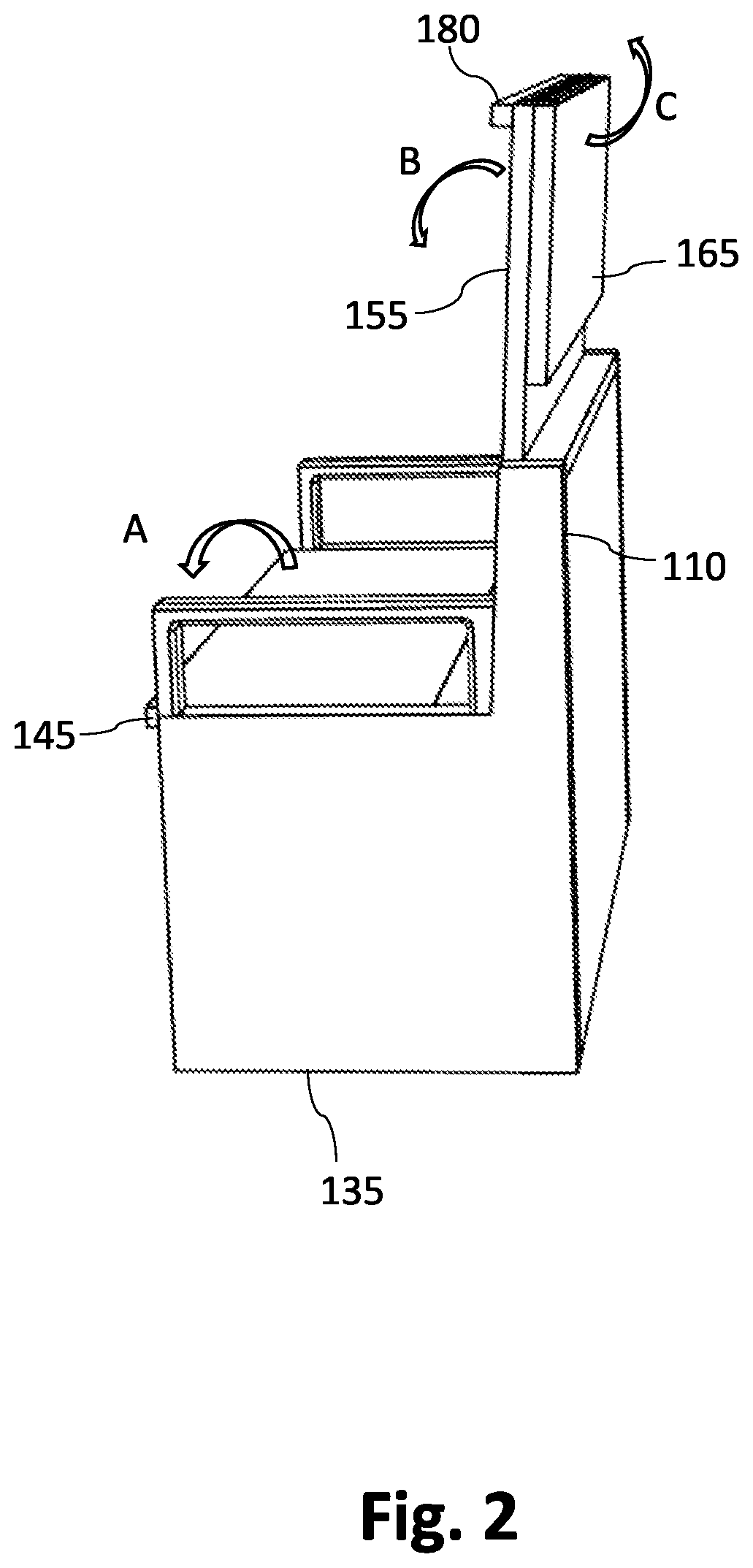

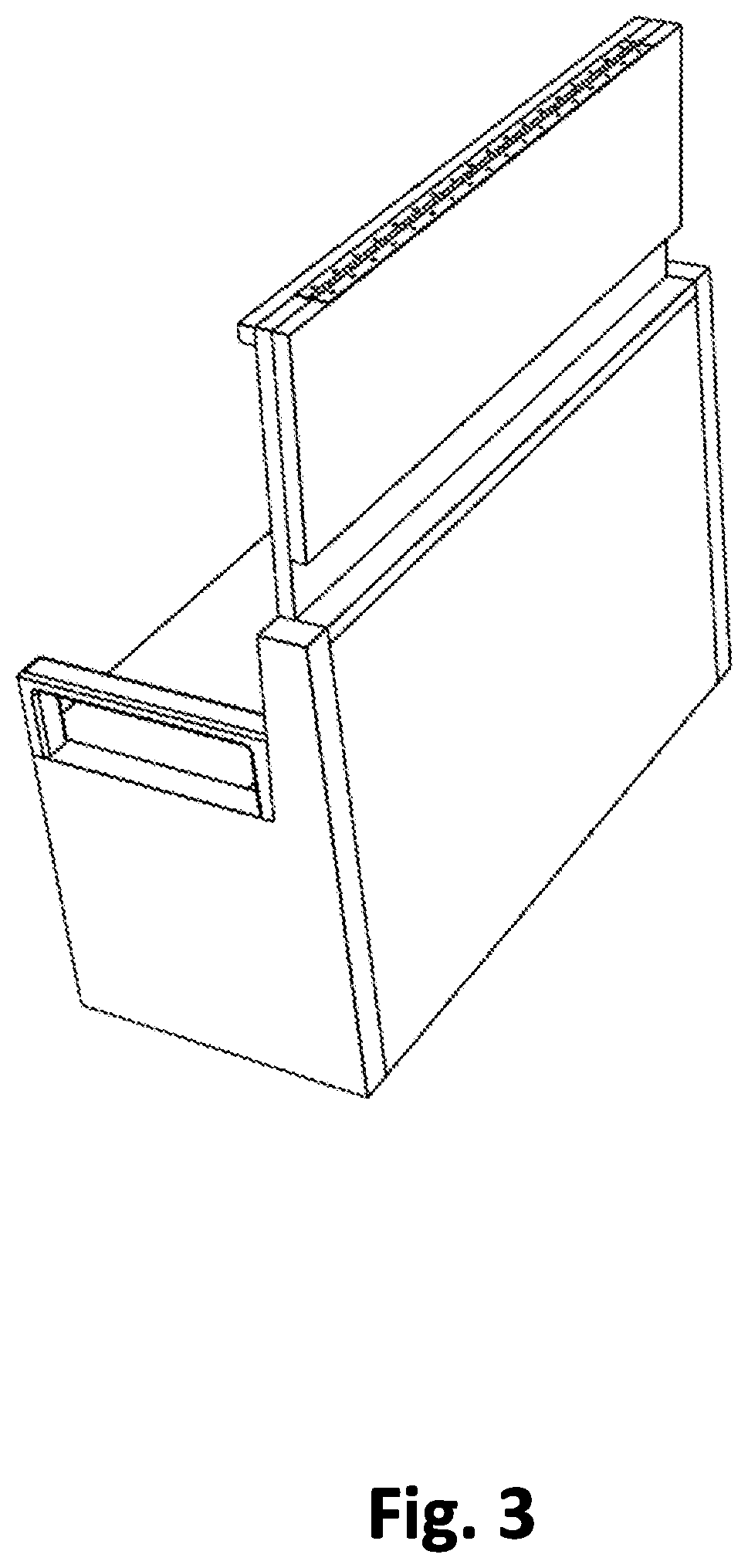

Integral furniture item convertible between a sitting bench and a table

PendingUS20220248844A1Large tabletop areaWithout any strainConvertible furnitureStructural engineeringIndustrial engineering

A multi-functional, space-saving, and economical furniture item, made of wood, that converts shape and function to provide storage, seating, a desk-top workspace, and a countertop-height workspace. The furniture item is a bench that provides seating and has a flap that can be “actioned” (folded down) to provide a table for writing. The bench is integrally formed in a unitary structure that affords multimodal transformation and practicality for ease-of-use and desired functional range. By lifting the bench seat clockwise and lowering the backrest, the furniture item transforms into a countertop or a desktop workspace. Undoing the said steps transforms the countertop back to the bench.

Owner:SILVERMAN DAVID +1

Spiral welded pipe machine socket ring positioning device

ActiveCN104057235BSimple structureReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesCoaxial lineEngineering

The invention relates to a spiral pipe welder spigot ring positioning device and belongs to the technical field of spiral reel pipe welders. The device comprises a spigot ring, an outer positioning block, a core mould cylinder body, a limit special nut, an inner hexagonal limit bolt, a hexagonal nut, a spigot ring positioning block, an adjusting gasket, a hexagonal head bolt and a cushion block, wherein a spigot ring front adjustable device is formed by the limit special nut, the inner hexagonal limit bolt and the hexagonal nut and is fixedly arranged on the core mould cylinder body through the limit special nut and the hexagonal nut, a spigot ring back positioning device is formed by the spigot ring positioning block, the adjusting gasket and the outer positioning block, the spigot ring positioning block is welded on the core mould cylinder body, and the cushion block is arranged between the front upper end surface of the spigot ring and the core mould cylinder body. The spigot ring can be accurately positioned and tightly clamped through the spigot ring front adjustable device and the spigot ring back positioning device. The spiral pipe welder spigot ring positioning device avoids the inward movement of the spigot ring due to mechanical vibration when a spiral welded pipe is produced, the coaxial line of the spigot ring and the core mould cylinder body is guaranteed, a steel plate and the spigot ring are firm in welding, and the quality of a product is improved.

Owner:JIANGSU JIANGYANG BUILDING MATERIAL MACHINERY

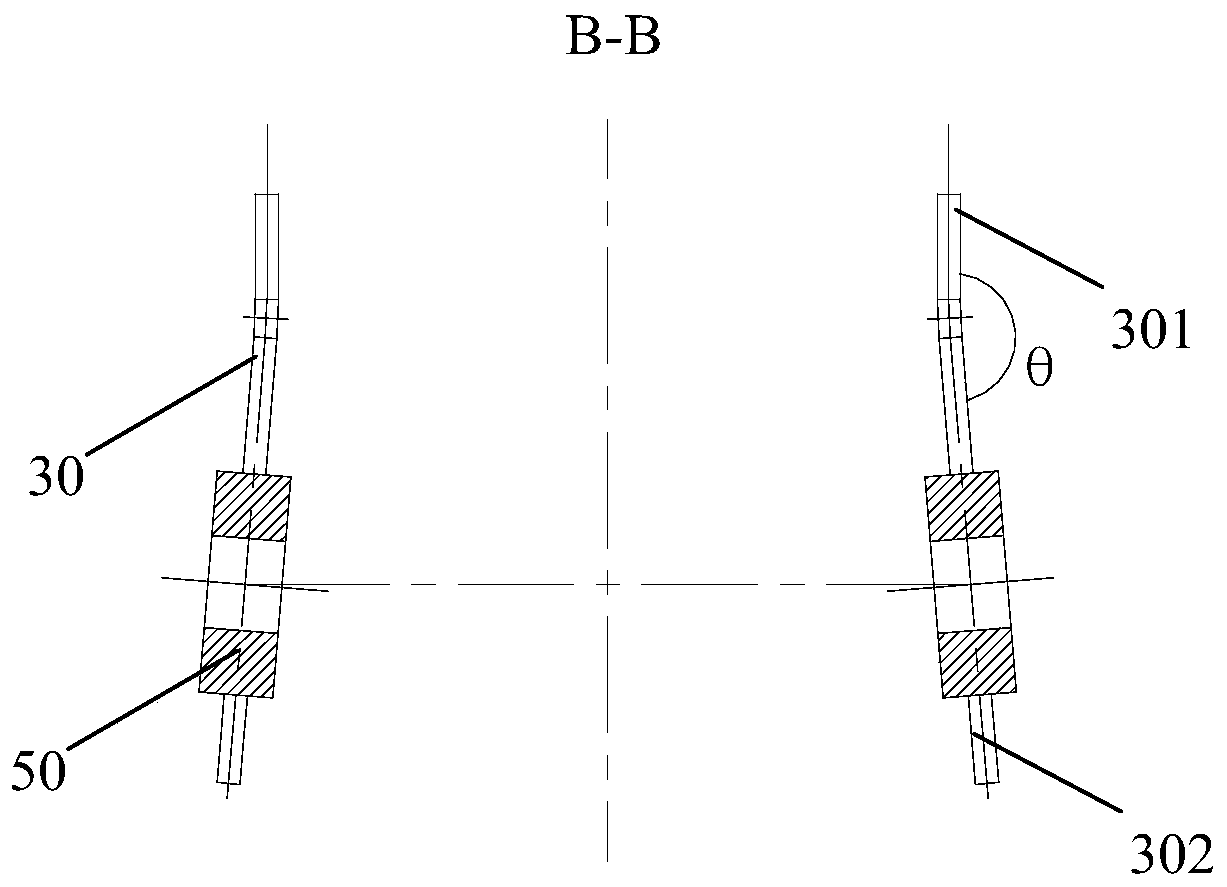

Lateral displacement resisting horizontal supporting structure for post-cast strip of super high-rise underground wall

PendingCN114482302APlay a supporting rolePrevent inward movementWallsAuxillary members of forms/shuttering/falseworksEngineeringStructure support

The invention provides a lateral displacement resisting horizontal supporting structure for a post-cast strip of a super high-rise underground wall. The lateral displacement resisting horizontal supporting structure comprises an outer wall, frame columns and a top plate installed on the outer wall and the frame columns. The structure further comprises a post-cast strip and a supporting structure installed on the post-cast strip, the supporting structure comprises a mother plate, an inserting plate and a locking piece, an inserting groove is formed in the mother plate, the inserting plate partially extends into the inserting groove and is locked through the locking piece, and the supporting structure tightly abuts against the two sides of the post-cast strip. According to the scheme, the inserting groove is formed in the mother plate, the mother plate and the inserting plate are placed into the post-cast strip after the inserting plate is inserted into the mother plate, then the inserting plate and the mother plate are locked through the locking piece, the inserting structure abuts against the two sides of the post-cast strip to provide a supporting effect, and equivalently, horizontal supporting force is provided; the effect of preventing the outer wall from moving inwards and even collapsing can be achieved. The lateral displacement resisting horizontal supporting structure for the post-cast strip of the super high-rise underground wall has the advantage of being capable of preventing an outer wall from moving inwards and even collapsing.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Hydraulic chain tensioner assembly

The hydraulic chain tensioner assembly includes a sliding plunger received within an opening in the tensioner body so as to define a controlled clearance and a substantially fluid-tight chamber. The pressure in the supply reservoir, which is in fluid communication with the fluid-tight chamber, is controlled to a lower level by the size of the inlet and outlet holes in communication with the supply reservoir. Thus, the force of the shoe on the chain connected to the plunger is a function of the stiffness of the main spring biasing the plunger outward and is substantially independent of the fluid source supplying fluid to the reservoir. A method of making a hydraulic chain tensioner assembly is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

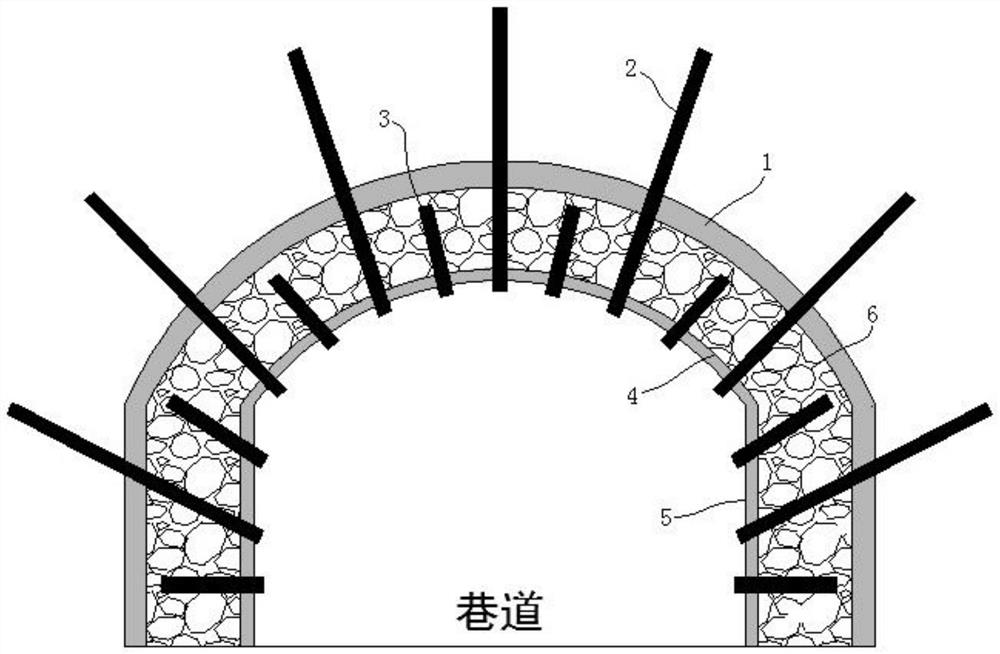

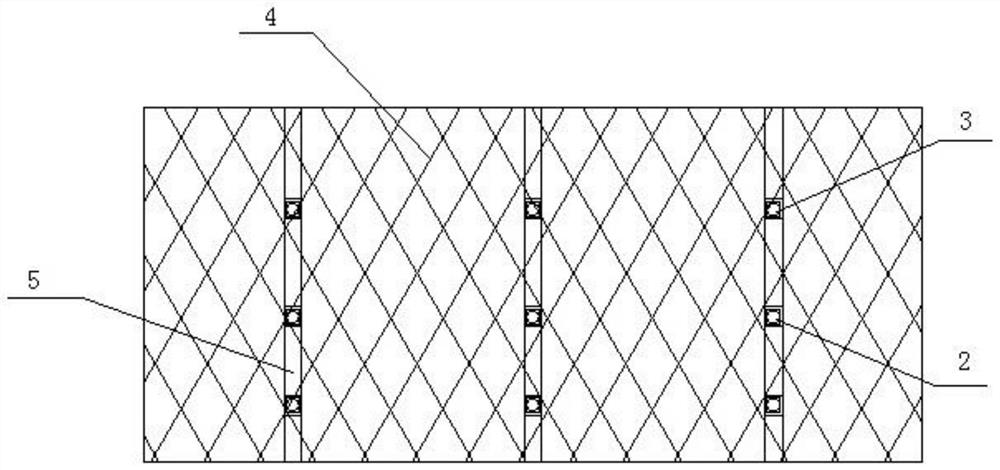

High-stress large-deformation roadway supporting system and method

PendingCN114673529AImprove mechanical propertiesImprove self-supporting capacityUnderground chambersTunnel liningSupporting systemRebar

The invention discloses a high-stress large-deformation roadway supporting system and method, and relates to the technical field of roadway supporting. The steel bar shell support is tightly attached to the inner wall of the roadway, and the anchor cable is installed on the steel bar shell support and fixed to the inner wall of the roadway; anchor cables and anchor rods are installed on the two sides and the arch portion of the soft rock roadway at intervals, and metal nets are laid on the anchor cables and the anchor rods for net hanging and fixing; a retractable metal bracket is mounted on one side of the metal net, and legs of the retractable metal bracket are supported by using double rows of anchor rod piles; concrete is poured through the grouting holes, so that the flexible concrete spraying layer covers gaps formed by the metal net, the retractable metal support, the steel bar shell support and the inner wall of the roadway. The supporting method and system can effectively improve the stability and the supporting strength of the surrounding rock of the high-stress large-deformation soft rock roadway, have the advantages of being safe, reliable, low in construction cost, easy to popularize in a large range and the like, and can greatly improve the stability of the soft rock roadway and achieve roadway supporting.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP +1

Joint implant and a surgical method associated therewith

InactiveUS20140012381A1Lower the volumePromote bone growthBone implantSpinal implantsSacroiliac jointJoint spaces

An implant able to be inserted into a surgically prepared joint space includes a body having a central cavity extending longitudinally through the body and at least one movable barb, and a cap for location within the central cavity at an end of the body. The location of the cap within the central cavity of the body causes outward movement of the barb.

Owner:OTB SURGICAL DESIGNS

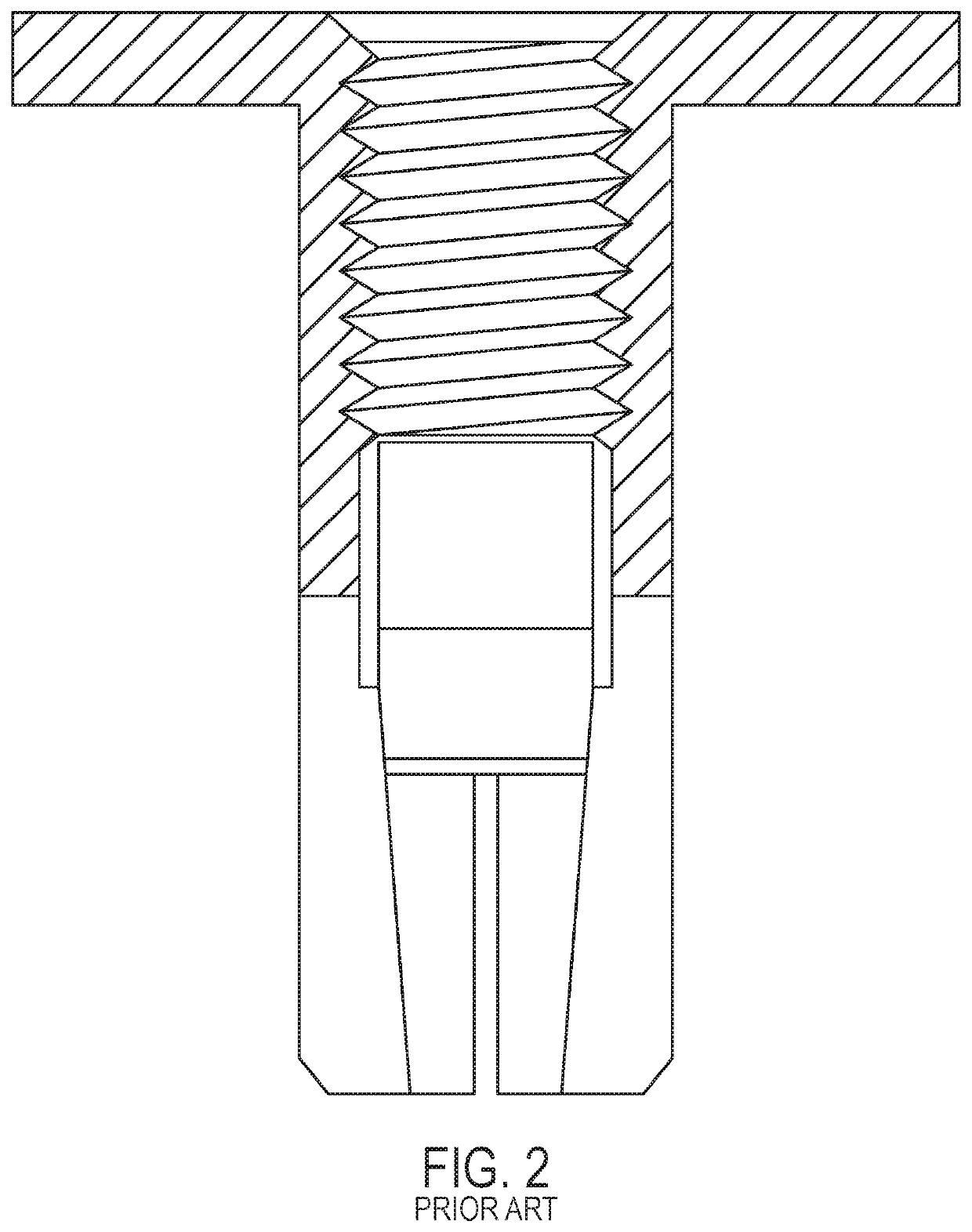

Shallow undercut concrete anchor

ActiveUS11111941B2Prevent inward movementPipe supportsConstruction materialArchitectural engineeringEmbedment

A concrete anchor capable of resisting large loads while requiring minimal embedment depth. The system includes a concrete structure including a cylindrical opening in the concrete surface thereof. The system also uses an anchor which includes a sleeve and a plug. The sleeve includes at least two legs extending toward a first end of the sleeve. The plug includes an increasing diameter portion disposed toward a first end of the plug. The plug includes a locking opening. After installation, legs of the sleeve extend radially outward past the wall and the increasing diameter portion prevents inward movement of the legs to lock the sleeve and the plug in turn in the concrete cylindrical opening. Furthermore, dynamic loading on the plug via the locking opening when the anchor is in use generates a dynamic radially outward force on the legs to secure the anchor in the concrete hole.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com