Hydraulic chain tensioner assembly

A chain tensioning device, hydraulic technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as loose chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

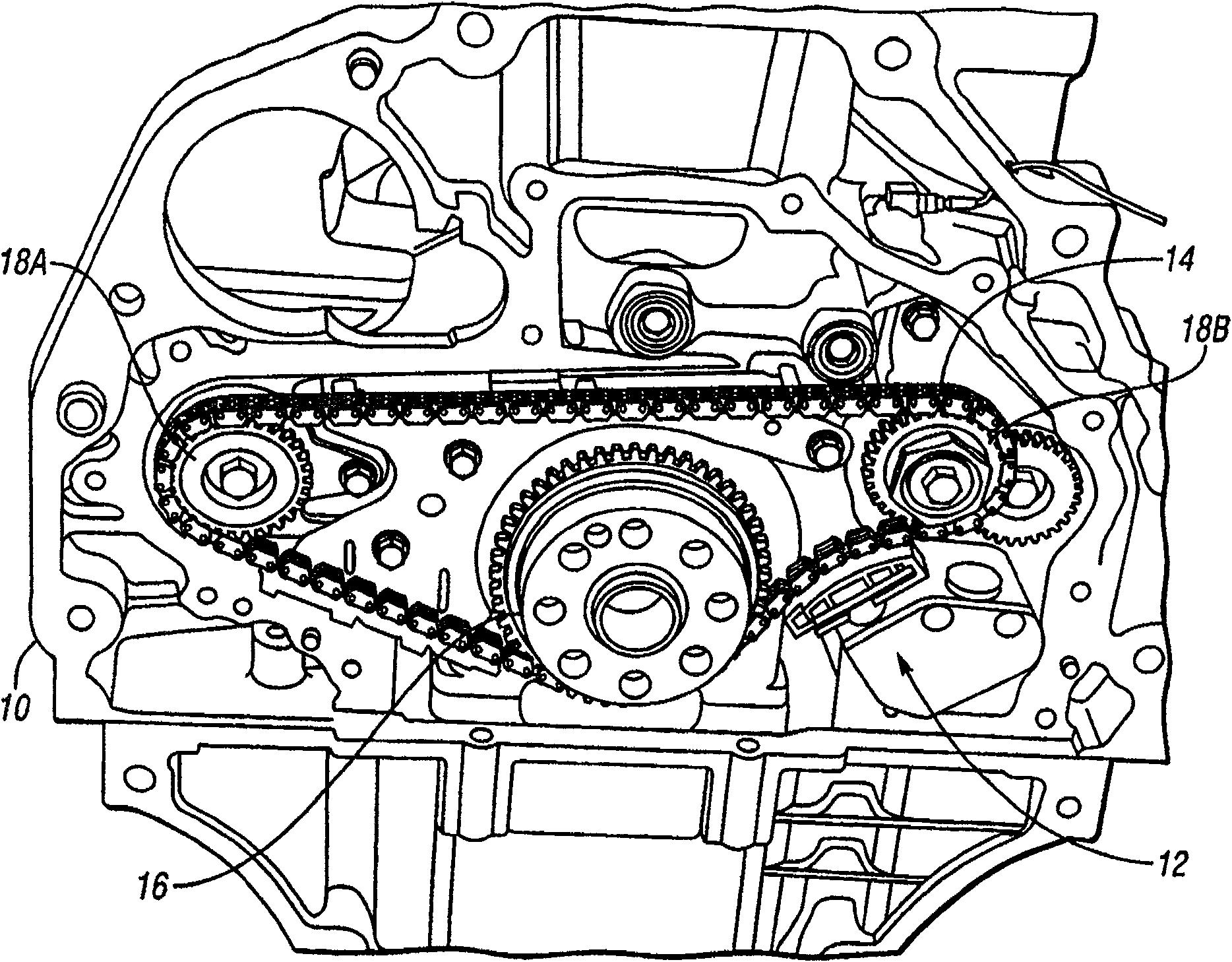

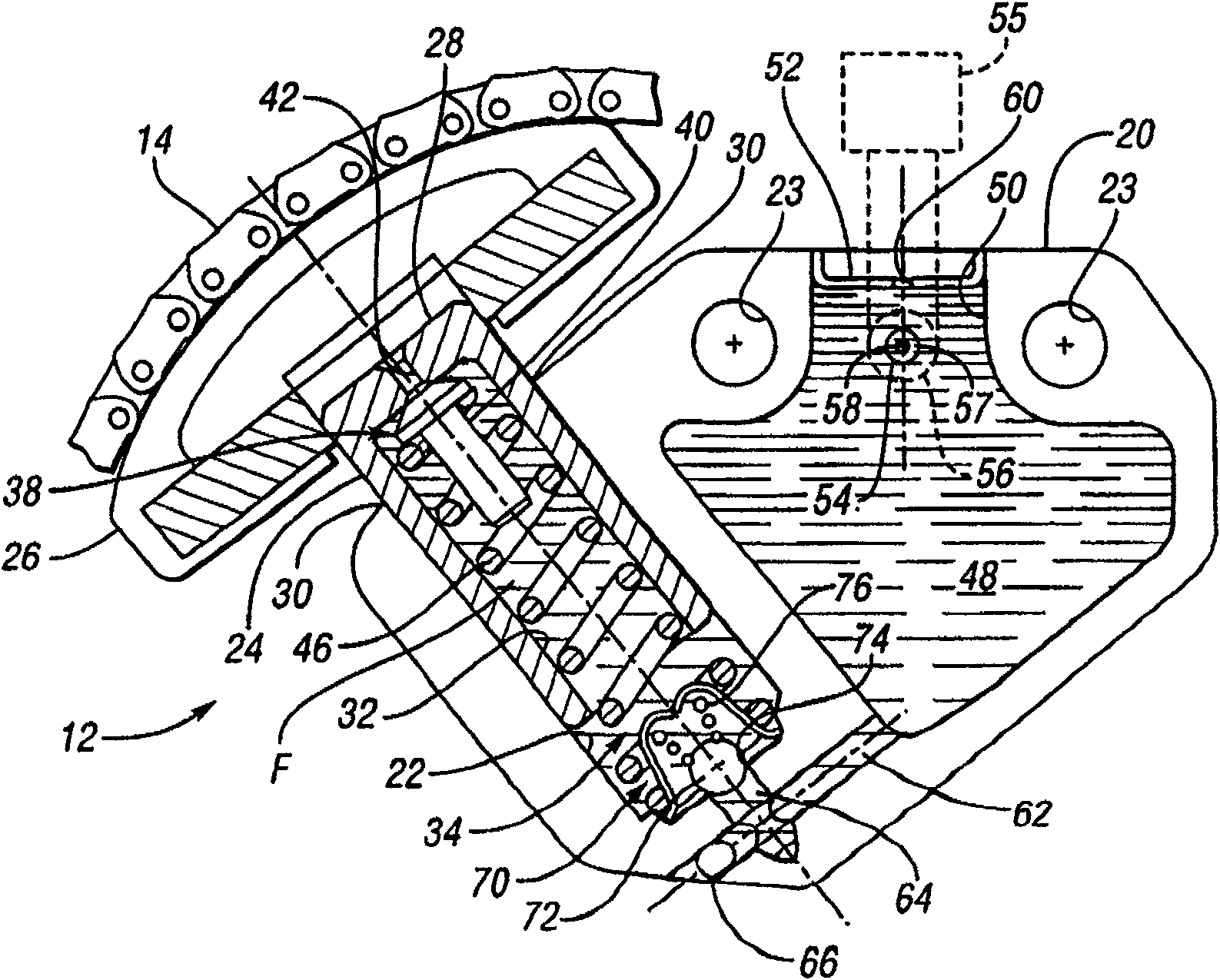

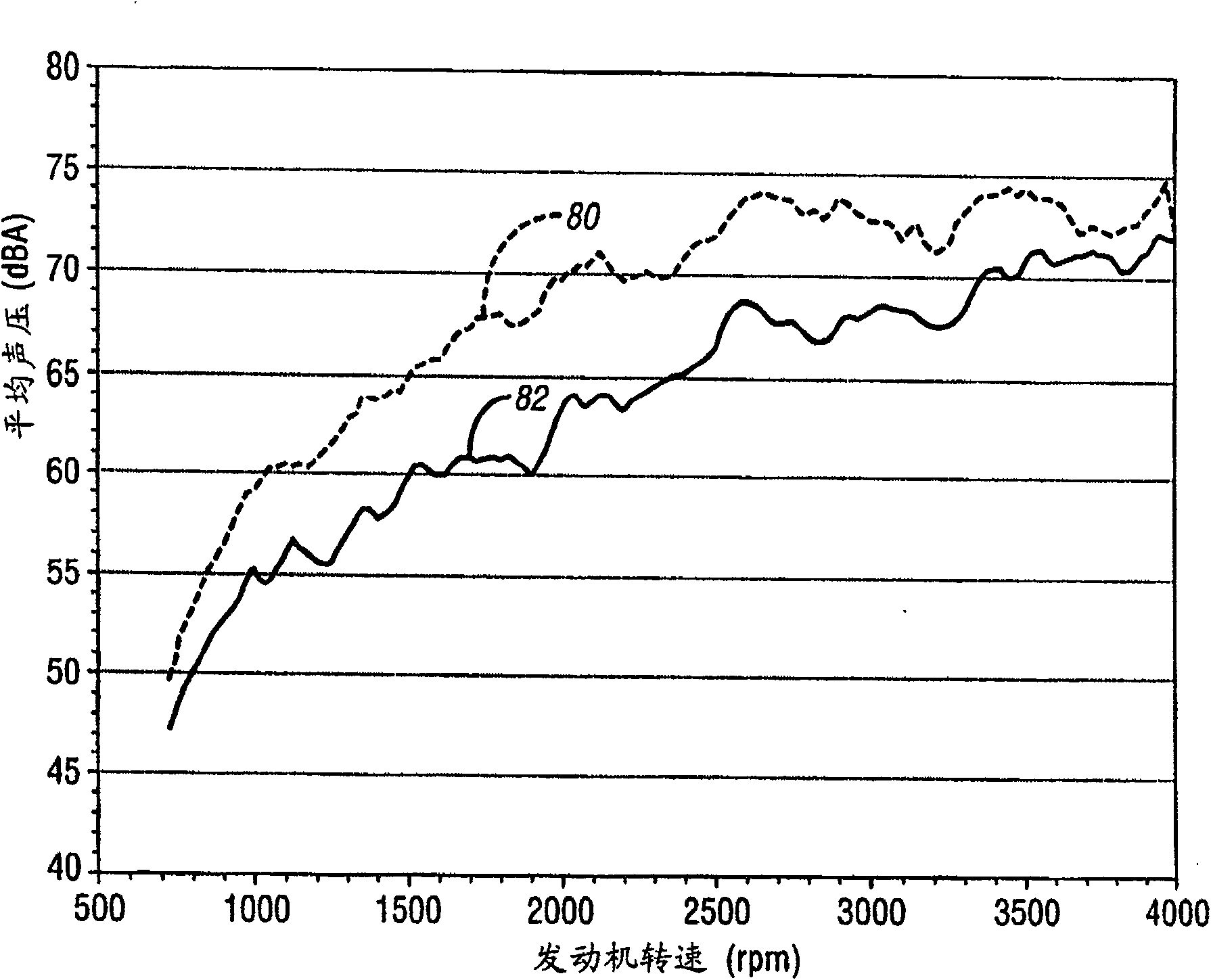

[0019] Referring to the drawings, wherein like reference numerals refer to like parts, figure 1 An engine 10 is shown having a hydraulic chain tensioner assembly 12 tensioning a balancer drive chain 14 . It should be noted that although the hydraulic chain tensioner assembly 12 is used in figure 1 However, those of ordinary skill in the art will appreciate that such a hydraulic chain tensioner assembly 12 could alternatively be applied to a tensioning valve train drive. Crank sprocket 16 powered by engine 10 and rotating at engine speed drives balancer chain 14 which rotates countershaft sprockets 18A and 18B to drive a balance shaft connected thereto (balance shaft not shown). out). The arrangement of the crank sprocket 16 and balance sprockets 18A, 18B requires encapsulation of the hydraulic chain tensioner assembly 12 as shown, which means that it contacts the chain 14 in a short span. Tensioning the chain 14 over such a short span increases the noise caused by the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com