Propeller clamp and foldable propeller

A technology of propeller clamp and propeller seat, which is applied to propellers, rotorcraft, aircraft parts, etc., can solve the problems of reduced connection reliability, failure of thread fastening glue, and easy loosening of screws, so as to ensure the reliability of anti-loosening, Guaranteed reliability and easy paddle replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

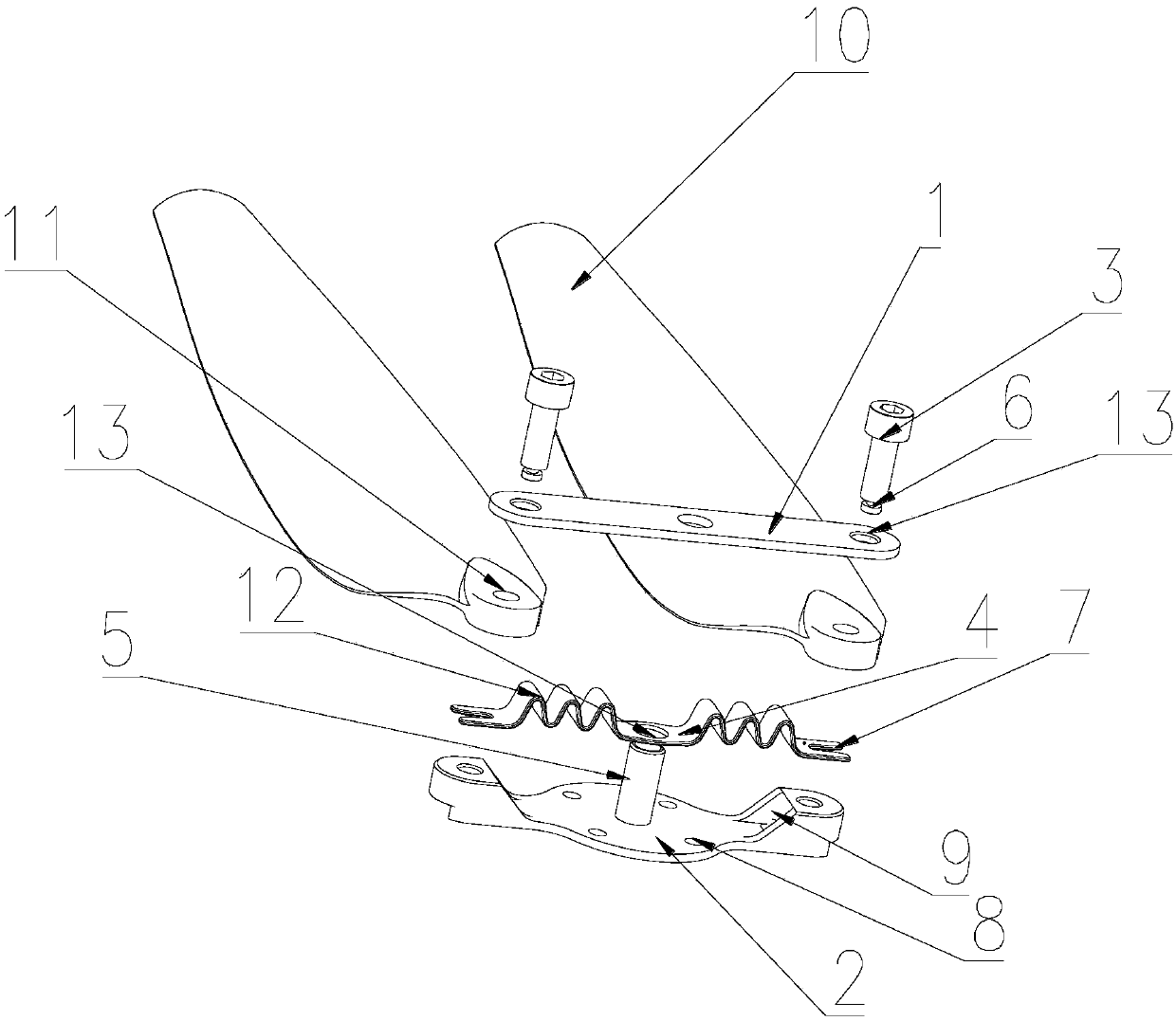

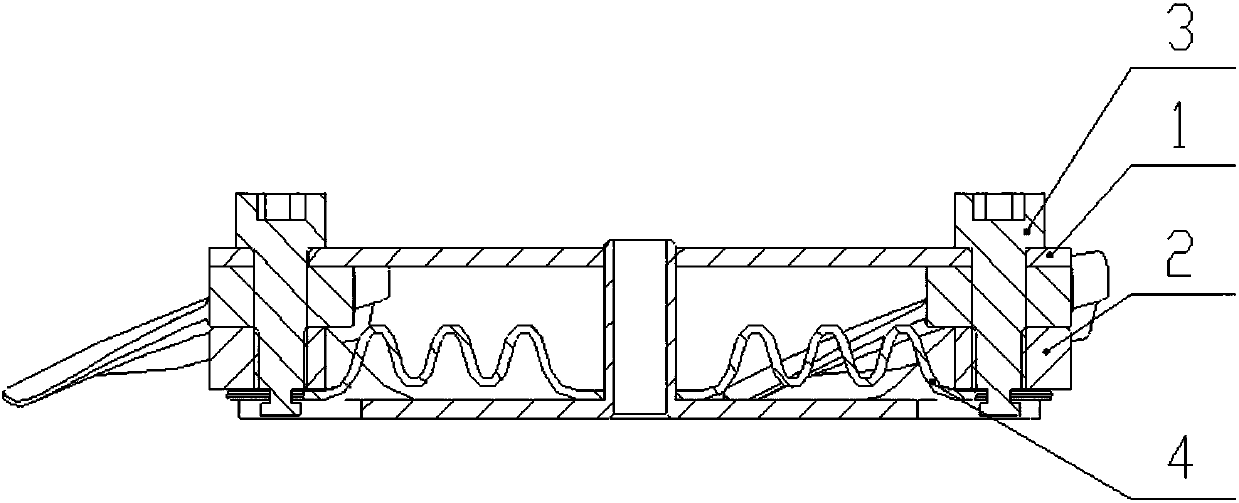

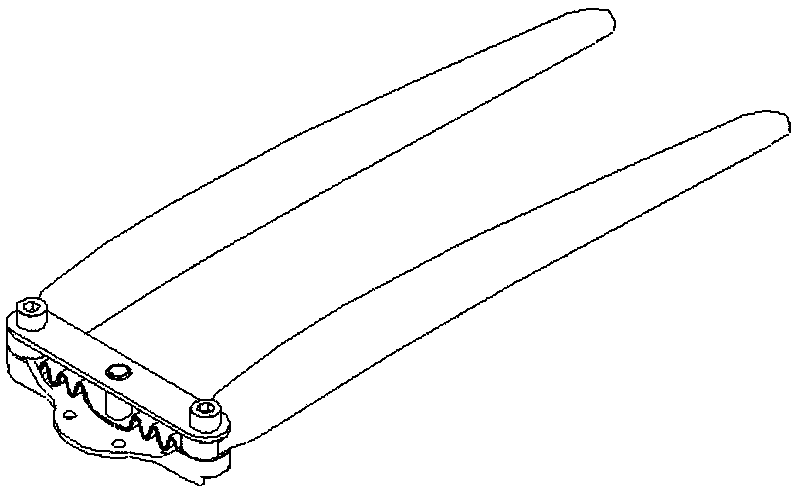

[0035] Please refer to figure 1 , a paddle clip provided by the embodiment of the present invention includes a paddle base 2, a paddle cover 1 arranged on the paddle base 2, and an elastic member 4 arranged between the paddle base 2 and the paddle cover 1 through a connecting mechanism, and also includes a limit organization,

[0036] The connecting mechanism includes a first connecting hole 13 arranged in the middle of the elastic member 4 and a connecting piece 5 arranged on the paddle seat 2 to fit the first connecting hole 13;

[0037] The limiting mechanism includes a limiting groove 7 arranged at the end of the elastic member 4 and a limiting member 3 arranged on the oar seat 2 and matched with the limiting groove 7 .

[0038] As mentioned in the background technology, most of the current propellers are fixed on the propeller clamp by screws, and the thread fastening glue is applied to prevent loosening. During use, due to factors such as vibration caused by the high sp...

Embodiment 2

[0043] The same features of this embodiment and Embodiment 1 will not be repeated. The difference between this embodiment and Embodiment 1 is that: the limiting member 3 includes a rod member and a card slot 6 opened in the radial direction, and the limiting groove 7 is adapted to the card slot 6, so that the elastic member 4 can be limited in the card slot 6 when the paddle clamp 10 rotates.

Embodiment 3

[0045] The features of this embodiment that are the same as those of Embodiment 2 will not be described in detail here. The difference between this embodiment and Embodiment 2 is that: the limiting member 3 is a threaded limiting member, and the card slot 6 is opened on the threaded limiting member. on the screw of the piece.

[0046] The thread limiter is easy to assemble and disassemble, can be used repeatedly, and is tightly connected. The upper end of the threaded connector can be provided with an anti-falling head. In addition, the head can be provided with a cross groove or a slot, which also effectively avoids the limit. The spacer 3 is loosened from the upper part of the paddle cover 1, and the setting of different groove types facilitates the installation of the spacer 3 with different tools. Here, it is not limited to a straight groove and a cross groove, but other groove types are also possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com