Spiral pipe welder spigot ring positioning device

A technology of positioning device and socket ring, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of affecting product quality, weak welding of steel plate and socket ring, and deviation of the axis of socket plate and mandrel cylinder, etc. To achieve the effect of simple structure, convenient operation and improved positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings.

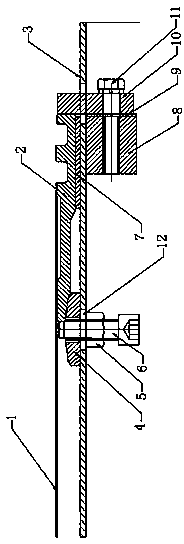

[0017] Such as figure 1 Shown:

[0018] The socket ring positioning device of the spiral welded pipe machine consists of socket ring 2, outer positioning block 10, core mold cylinder body 3, special limit nut 4, inner hexagonal limit bolt 6, hexagon nut 5, socket ring positioning block 8, and adjusting gasket 9. Composed of hexagonal head bolts 11, etc., the mandrel shell is provided with a horse trough 12, the special limit nut, the inner hexagonal limit bolt, and the hexagonal nut form the forward adjustable device of the socket ring, and the inner hexagonal limit bolt is sleeved on the In the trough set on the core mold cylinder, the special limit nut and the hex nut are fixed on the core mold cylinder. The special limit nut is in contact with the front and lower end surface of the socket ring. The upper plane of the special limit nut is inclined. The wedge surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com