Patents

Literature

156results about How to "Avoid brittle failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

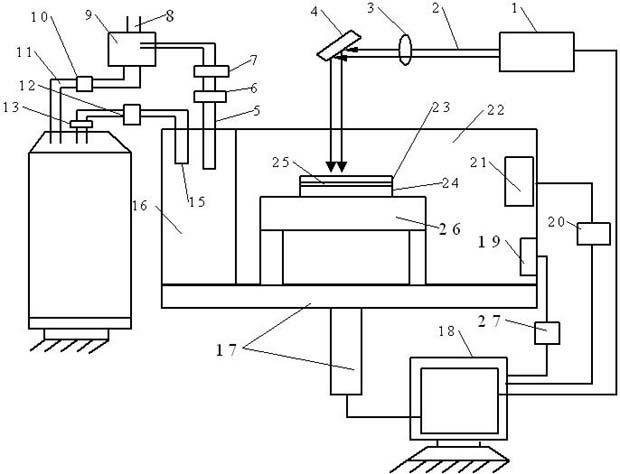

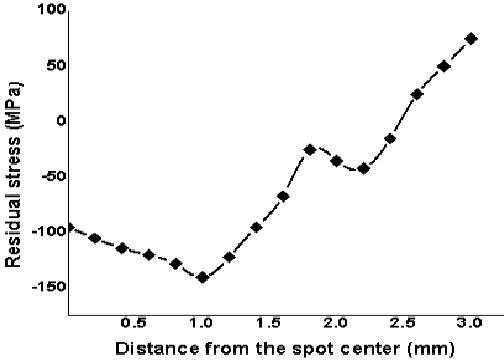

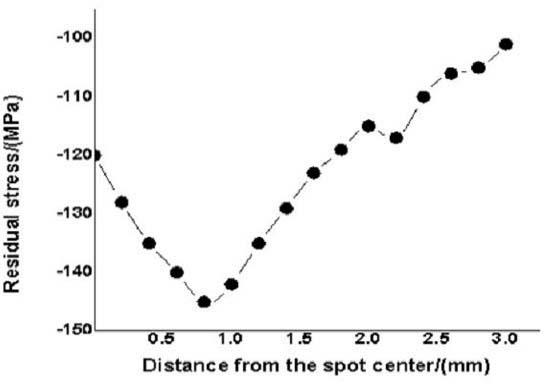

Method and device for processing metal materials with cryogenic laser shock

A method and a device for processing metal materials with cryogenic laser shock belong to the fields of laser processing and subzero treatment. The device comprises a cryogenic treatment cavity, a laser, a liquid nitrogen tank, a temperature sensor and the like. The method is used for strengthening the materials in an ultra-low temperature environment by adopting the laser shock processing technology, insulating the materials for a period after the strengthening process, and heating the materials to be as hot as the ambient temperature. In the ultra-low temperature environment, the metal materials shrink, and a large quantity of dislocation is generated in the materials; due to the instant impact effect of the laser shock processing technology, the high-density dislocation in the materials moves at a high speed, so as to induce high-density nano twin crystal, which ensures that the materials have superior tenacity as well as high intensity, and brittle failure of the metal materials in the low-temperature environment can be avoided effectively; and a large quantity of nano educt is dissolved out from the materials, and the conversion of residual austenite as well as the thinning of martensite and crystal can be promoted effectively, which remarkably improves the mechanical properties and the mechanical properties of the materials.

Owner:JIANGSU UNIV

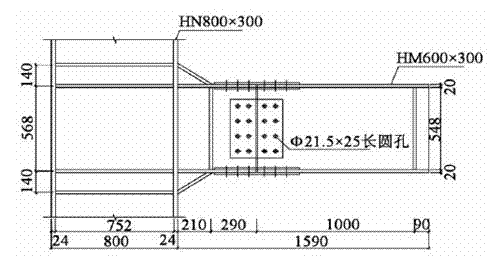

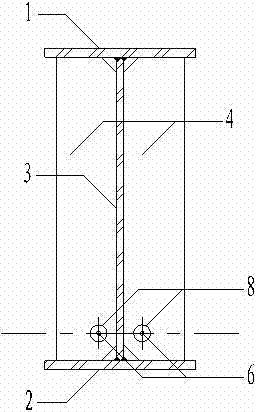

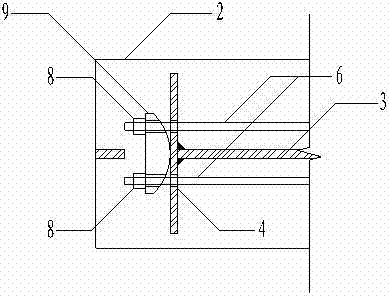

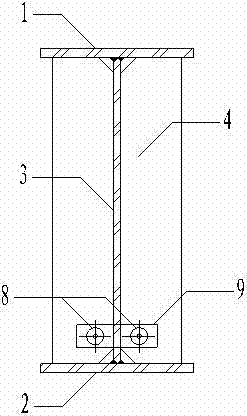

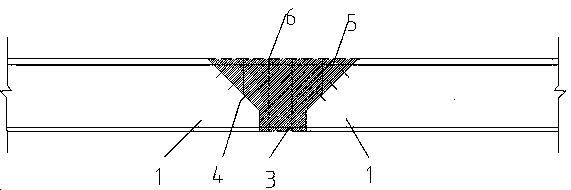

High-ductility steel structure beam column node in angle steel connection and construction method of high-ductility steel structure beam column node

ActiveCN102363979AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingHigh intensitySteel columns

The invention relates to a high-ductility steel structure beam column node in angle steel connection and a construction method of the high-ductility steel structure beam column node. The invention is characterized in that: upper and lower flange plates of an H-shaped steel beam are respectively connected with a steel column by using flange angle steel, a flange steel cushion plate and a friction type high-strength bolt; a web plate of the H-shaped steel beam is connected with the steel column by using web plate angle steel, a web plate steel cushion plate and the friction type high-strength bolt; bolt holes in a flange angle steel branch and a web plate angle steel branch, which are connected with the H-shaped steel beam, are long circular holes; horizontal reinforcing ribs are arranged, at a joint of the steel column and the H-shaped steel beam, inside the steel column; and a gap is reserved between an end head of the H-shaped steel beam and the steel column. The high-ductility steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and connection welded beams are not formed on beam column members, so that the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake is avoided. Furthermore, the high-ductility steel structure beam column node has the advantages of convenience for construction, simple and quick in repair operation after the earthquake, low in repair cost and the like.

Owner:FUZHOU UNIV

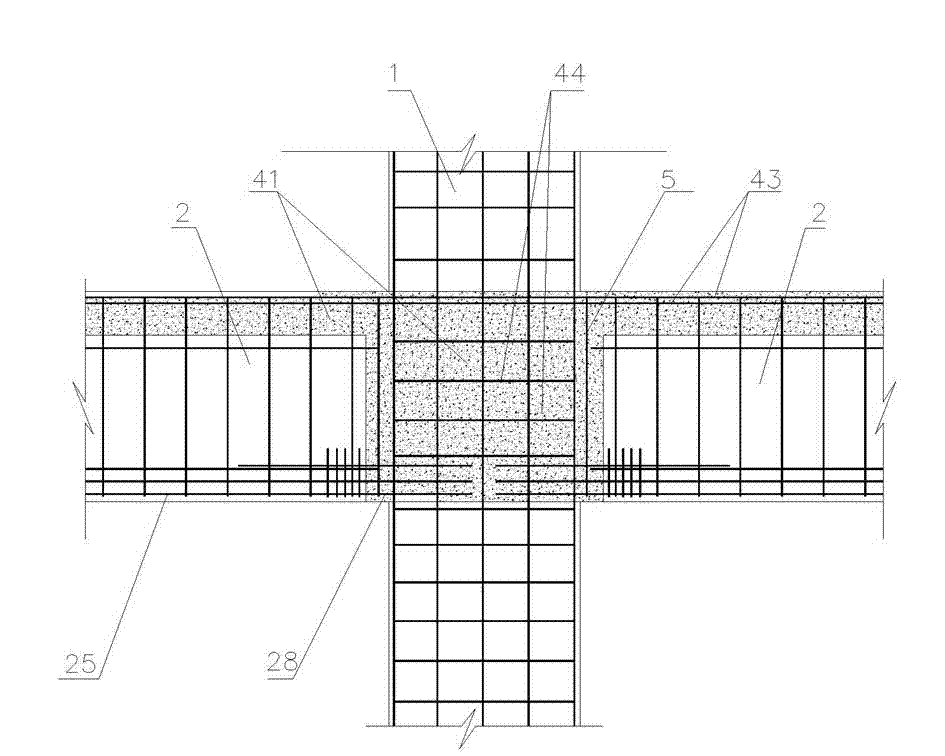

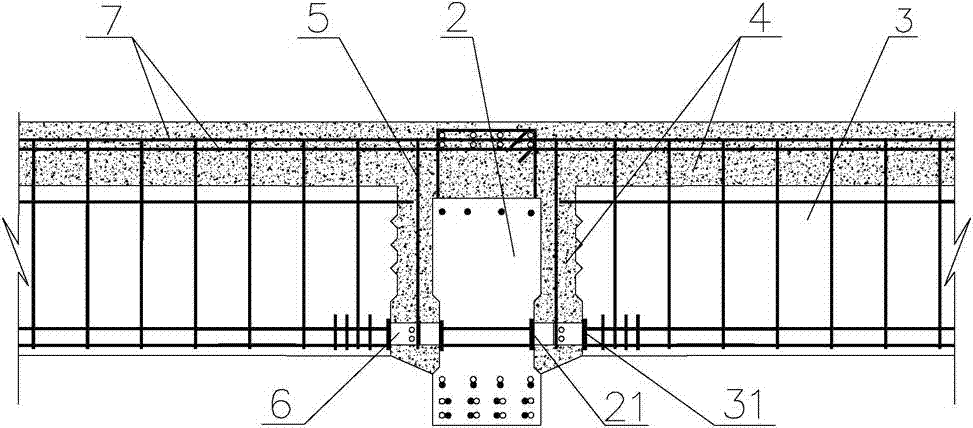

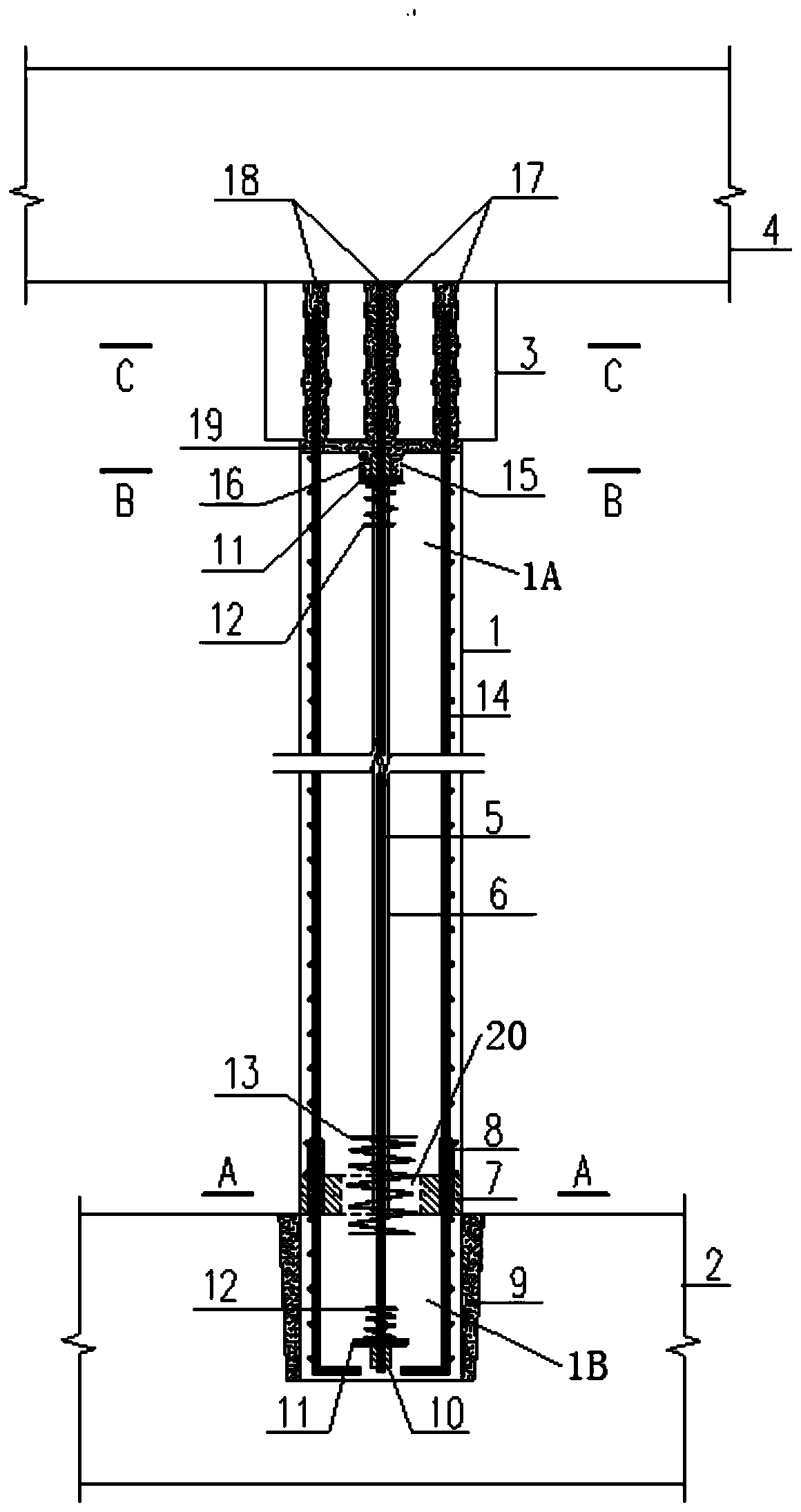

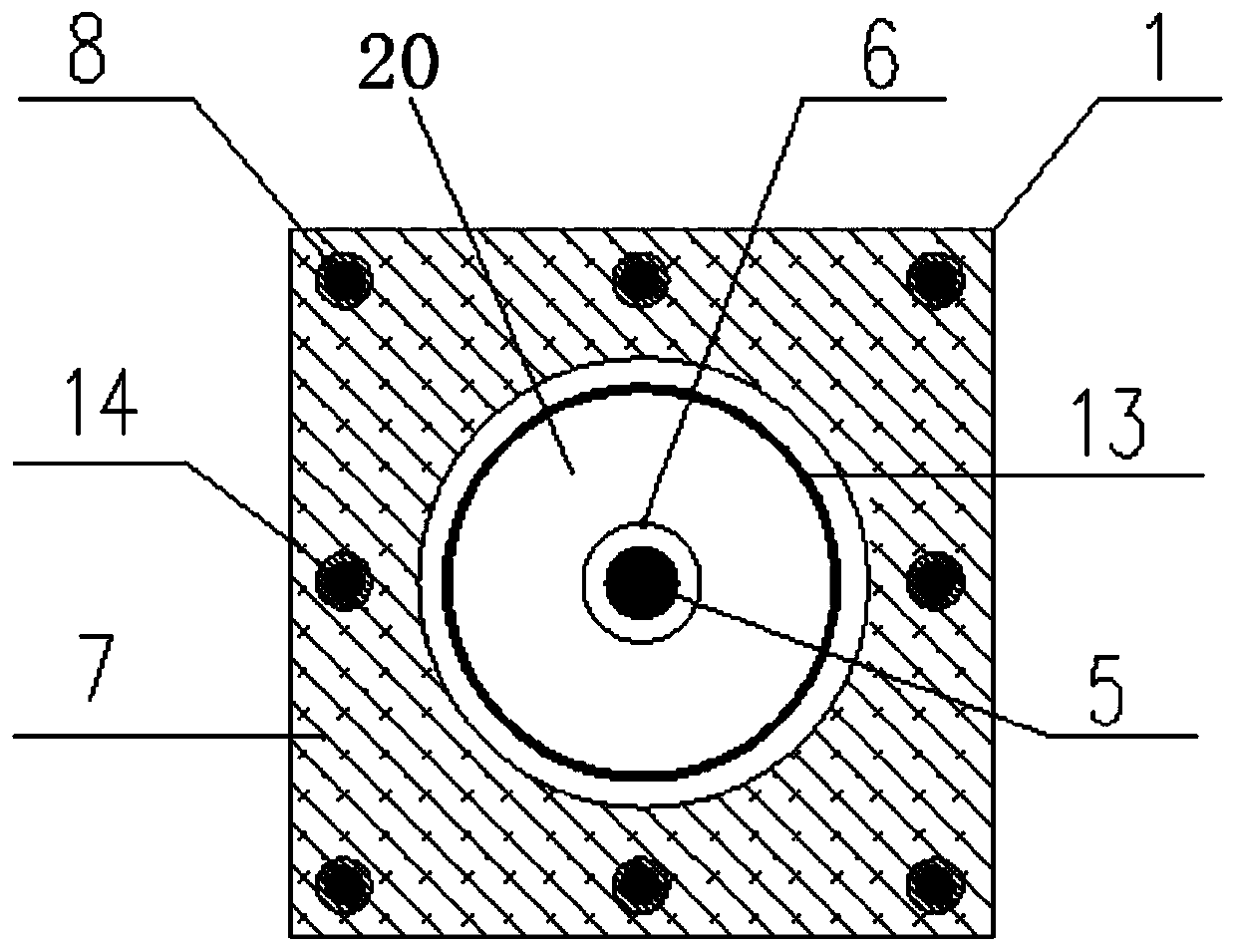

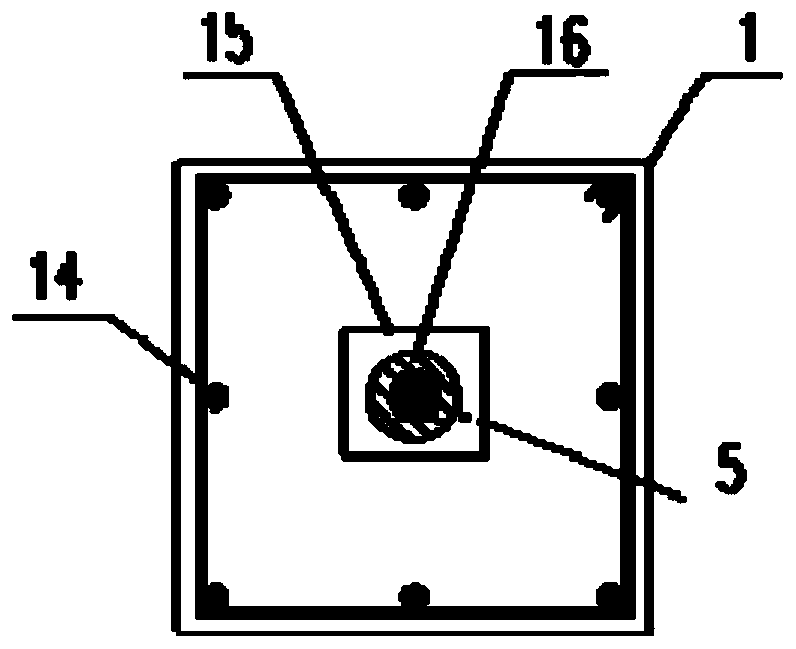

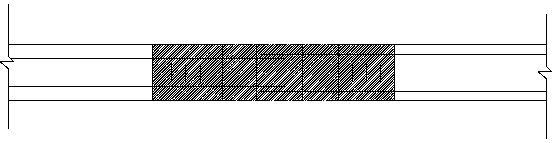

Pre-tensioning prestressed composite beam structural system and construction method thereof

The invention relates to a pre-tensioning prestressed composite beam structural system and a construction method of the pre-tensioning prestressed composite beam structural system. Lower longitudinal reinforcements are bound and lapped on lower longitudinal prestress wires in composite frame beam prefabricated components; the lower longitudinal reinforcements are inserted into frame pillars; second pre-buried steel plates are buried in the lower end portions of the composite frame beam prefabricated components; lower portion longitudinal prestress wires are buried in the composite frame beam prefabricated components; secondary beam longitudinal reinforcements are lapped and bound on the lower portion longitudinal prestress wires; the second pre-buried steel plates are welded with the secondary beam longitudinal reinforcements; first pre-buried steel plates opposite to the second pre-buried steel plates are arranged on the composite frame beam prefabricated components; pitch point steel plates are respectively welded on the first pre-buried steel plates and the second pre-buried steel plates; and the pitch point steel plates are connected through bolts, which enables the composite frame beam prefabricated components to connect with composite secondary beam prefabricated components. Wires and longitudinal reinforcements are lapped to use in the pre-tensioning prestressed composite beam structural system, and therefore the connecting mode of the pre-tensioning prestressed composite beam structural system is scientific and reasonable, and quality is safe and reliable.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

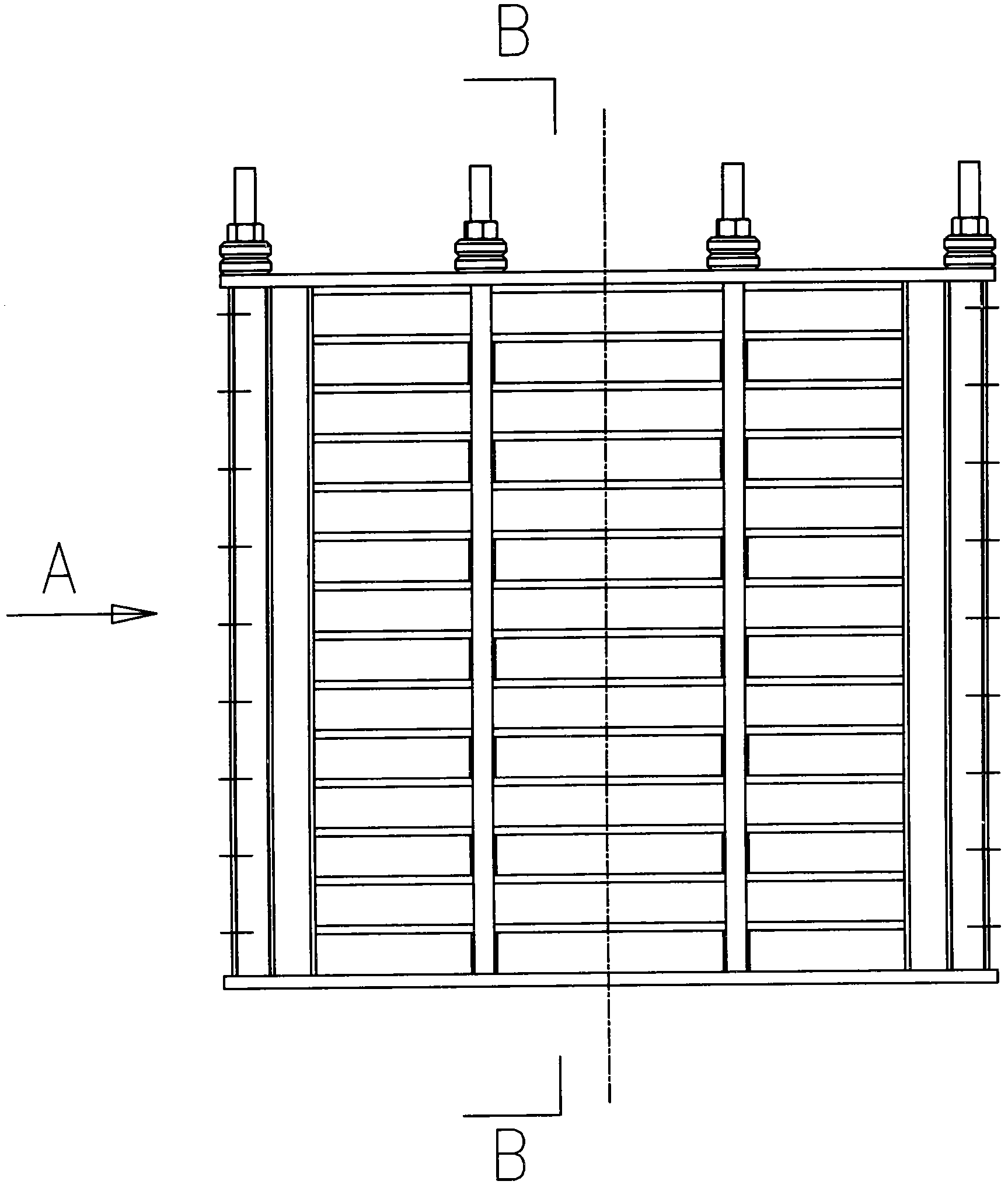

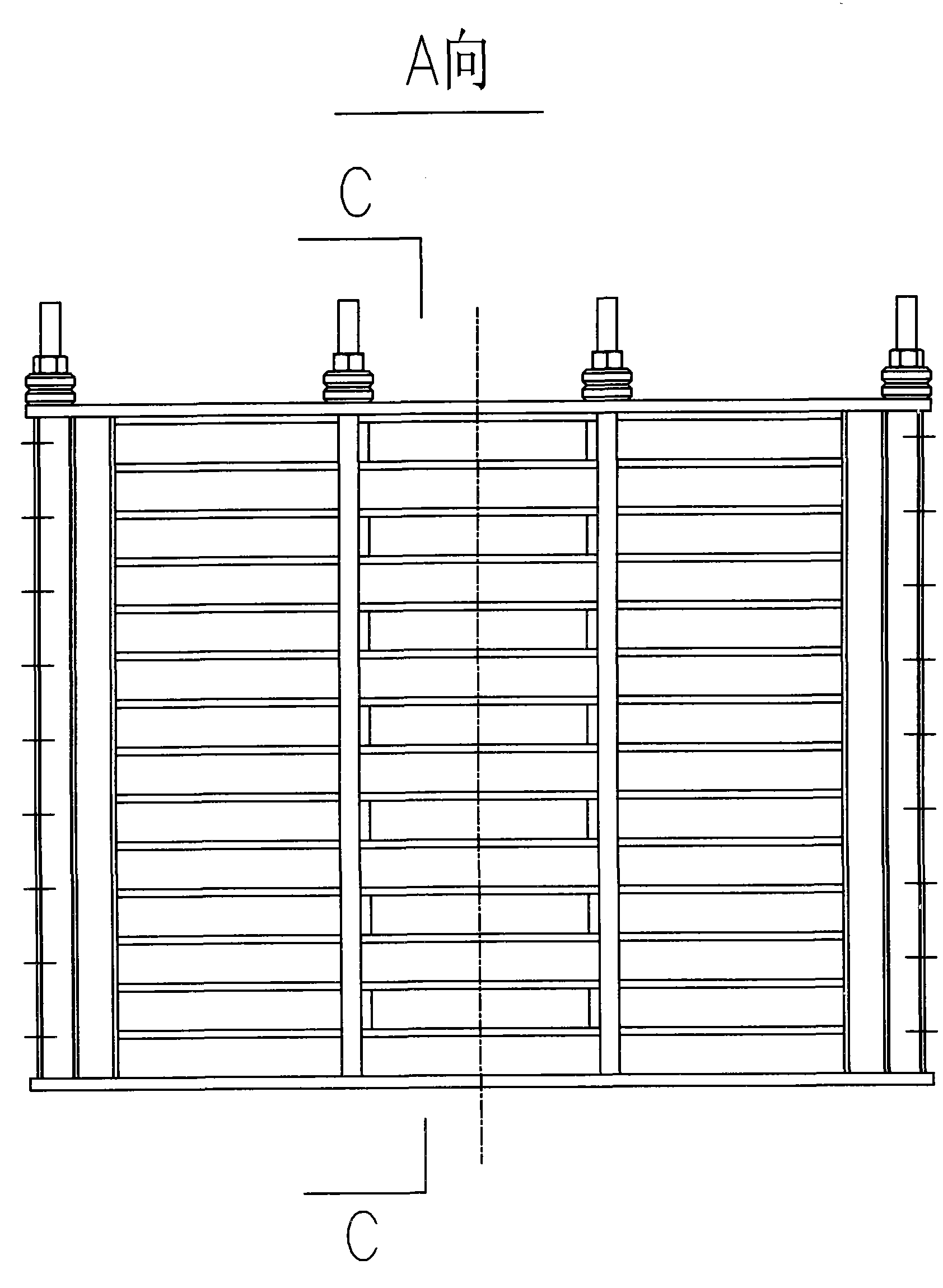

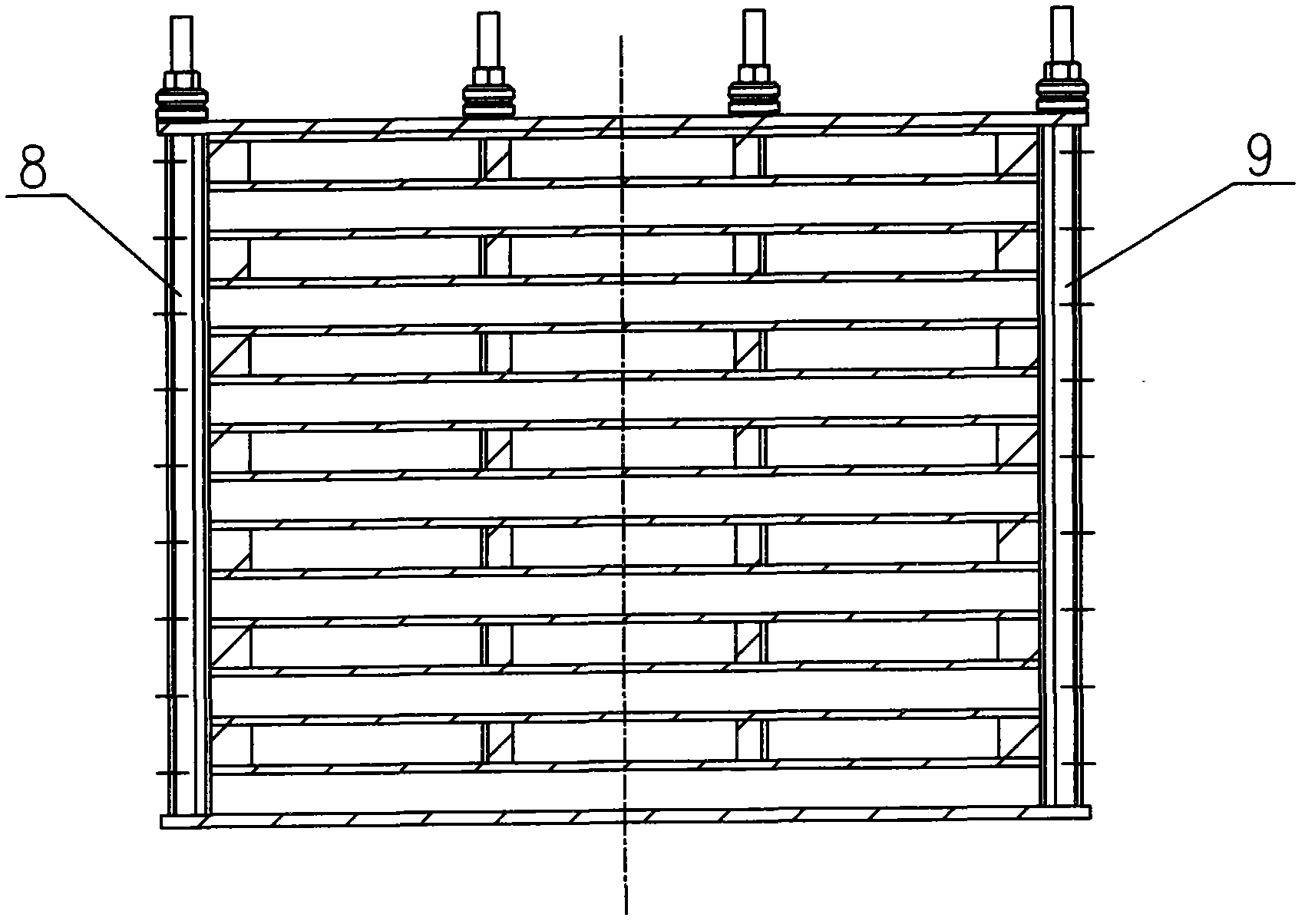

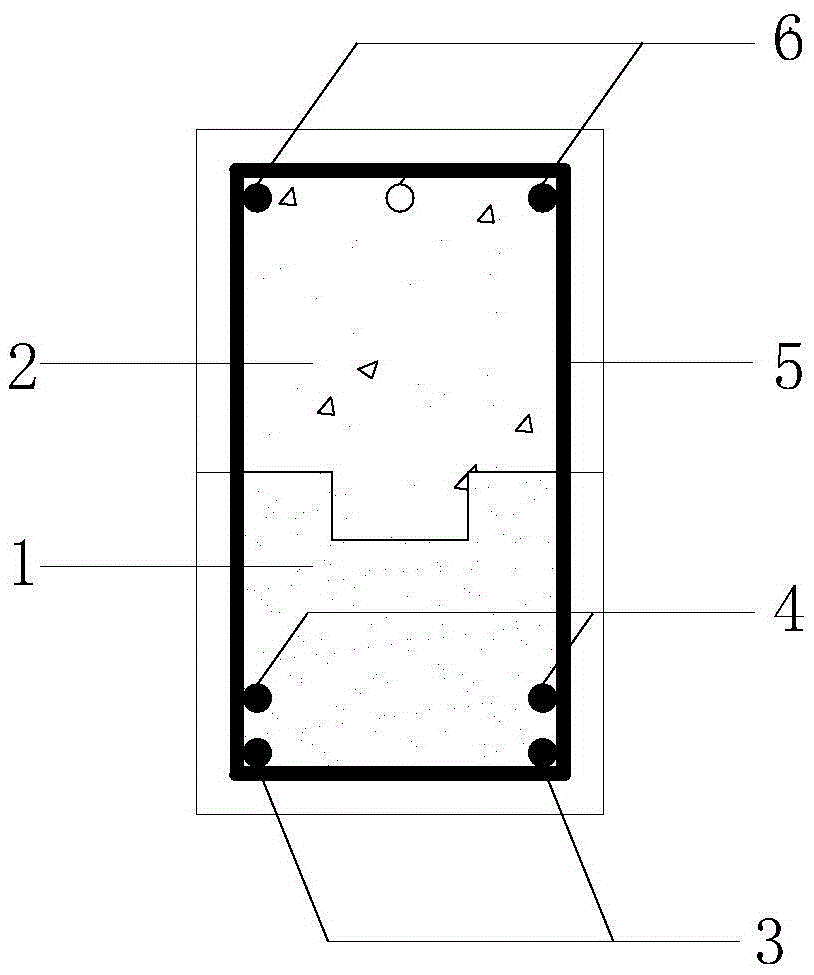

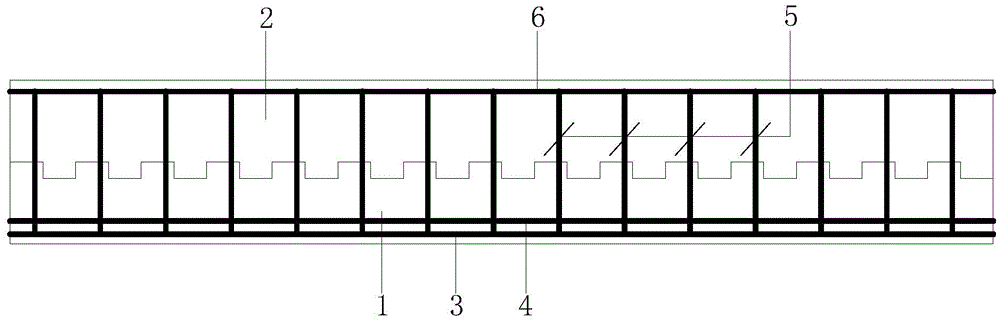

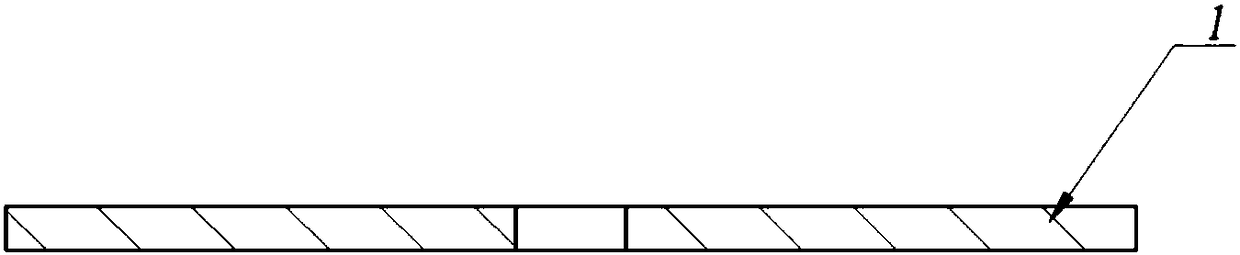

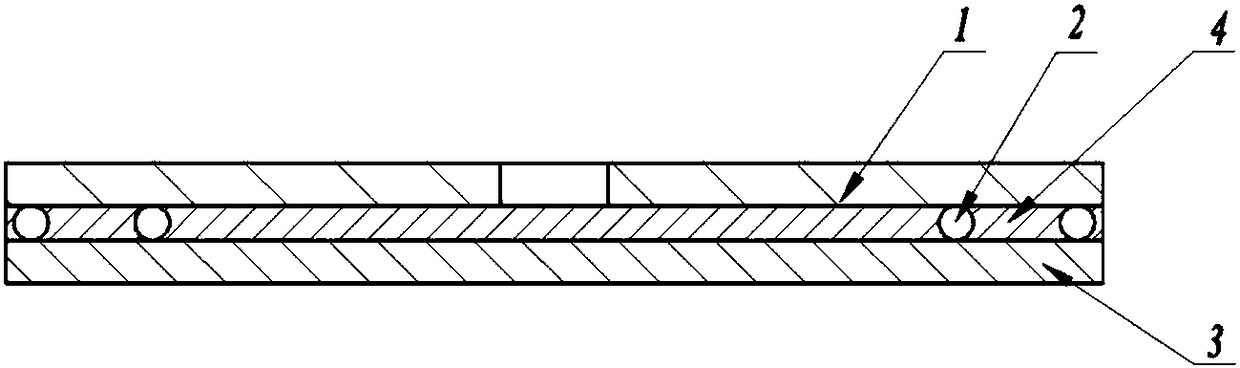

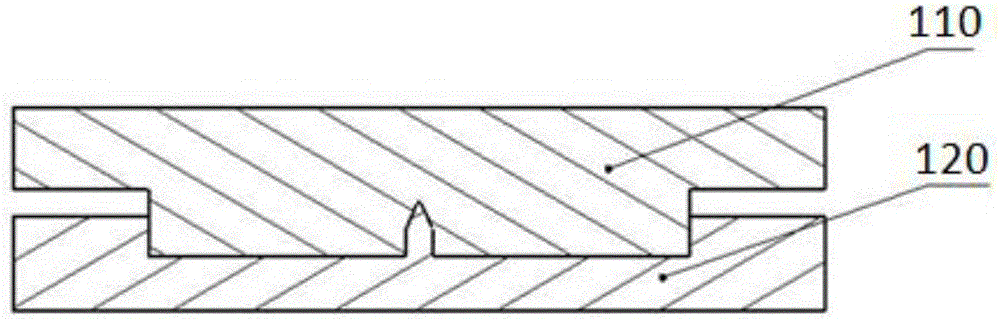

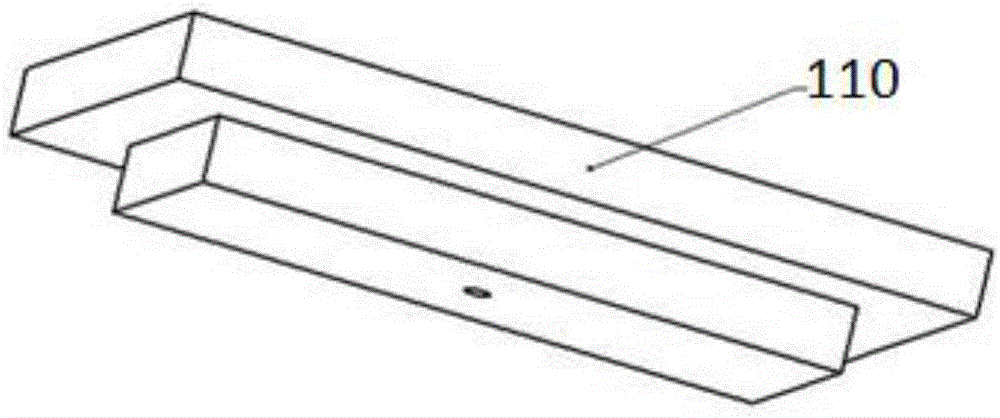

Plate type air preheater with glass as heat exchange plate

ActiveCN102032587AStrong corrosion resistanceGood energy saving effectIndirect carbon-dioxide mitigationHeat exchanger casingsDew pointCorrosion

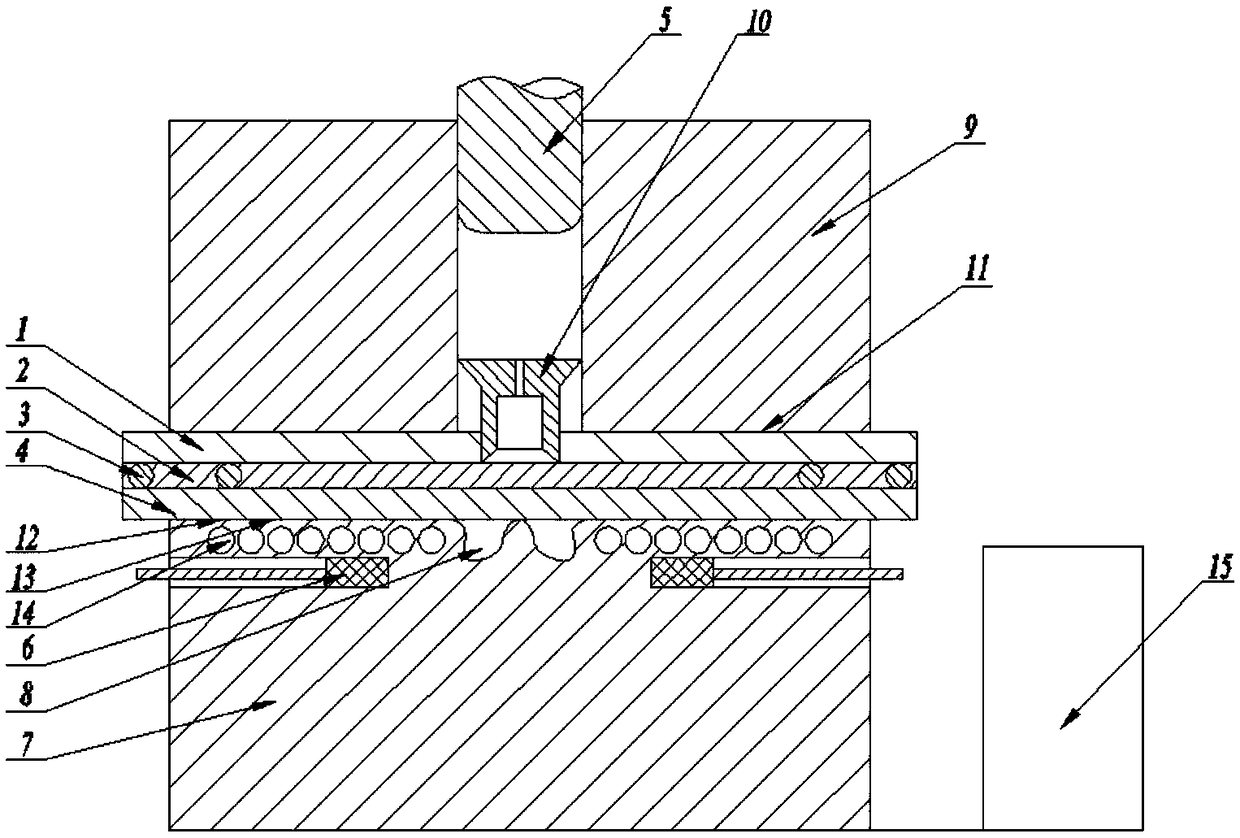

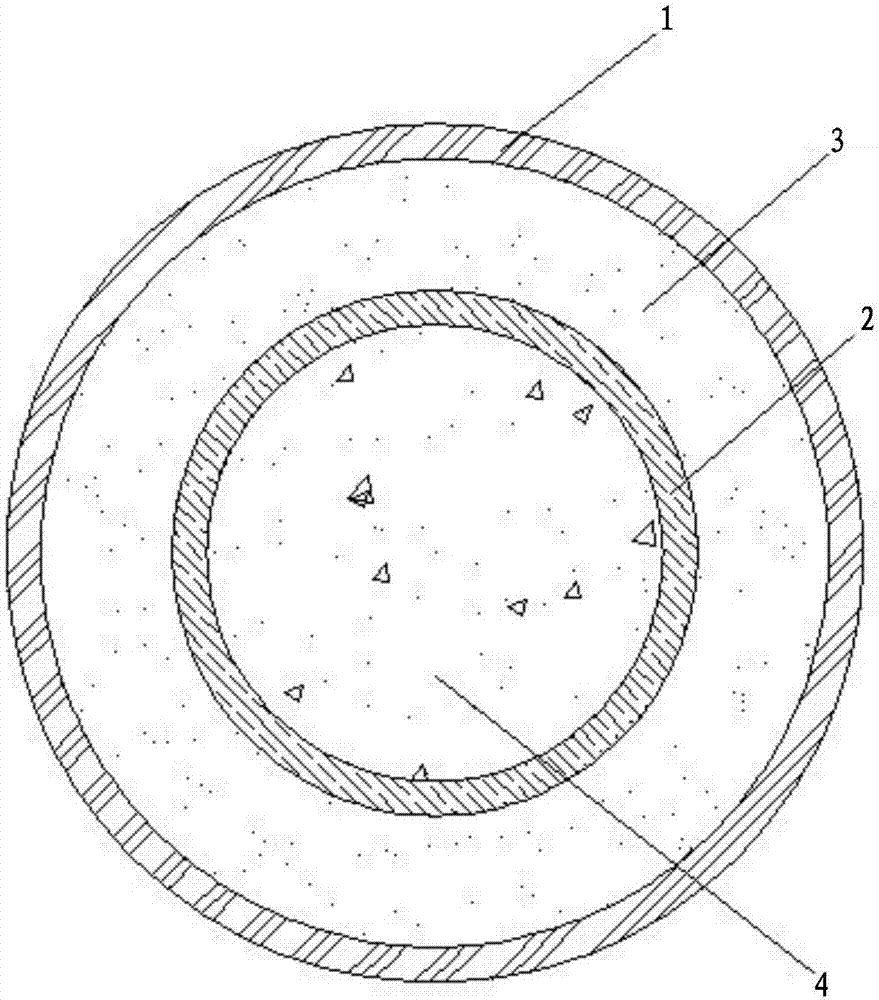

The invention provides a plate type air preheater with glasses as heat exchange plates, belonging to the technical field of heat exchangers. The plate type air preheater comprises an air preheater frame, the air preheater frame comprises an upper cover plate (10), a lower bottom plate (11) and a stand column (5) and is internally provided with a plurality of heat exchange plates (1) which are correspondingly placed in vertical direction; a sealing strip (4) is arranged between every two heat exchange plates (1) which are adjacent in vertical direction; the sealing strips (4) are mutually staggered at 90 degrees and form a plurality of sealing fluid channels which are adjacent and mutually staggered at 90 degrees by being placed in a staggered way so as to respectively form hot fluid channels and cold fluid channels; rectangular glass plates are adopted as the heat exchange plates (1), and the glass can be silicon-boron glass and boron-free low-alkali glass or quartz glass; and supporting strips (2) which are rectangular or S-shaped nonmetal plate bars are arranged among the fluid channels formed by the upper and lower heat exchange plates (1). The invention has dew point corrosion resistance, efficiently recovers the low-temperature exhaust heat of smoke and can reduce the temperature of discharged smoke and enhance the efficiency of a heating furnace.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

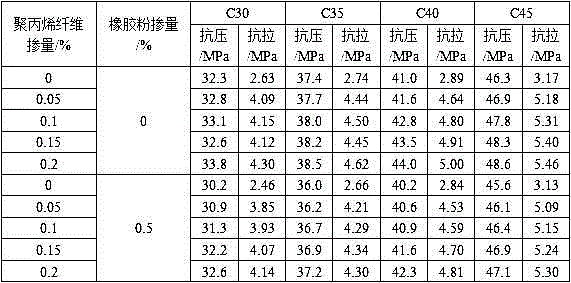

Waste polypropylene fiber rubber recycled concrete and preparation method thereof

ActiveCN105060785AStir wellShorten mixing timeSolid waste managementEnvironmental resistanceRoad surface

The invention discloses waste polypropylene fiber rubber recycled concrete and a preparation method thereof. The waste polypropylene fiber rubber recycled concrete is prepared from the components in parts by weight: 1-10 parts of polypropylene fiber, 5-20 parts of a rubber powder, 0-1600 parts of a recycled coarse aggregate, 0-1600 parts of gravels, 300-500 parts of sand, 300-500 parts of cement, 150-300 parts of water, and 50-100 parts of an additive. The waste polypropylene fiber rubber recycled concrete can be applied in road construction, reduces road noise and vibration, increases the collision buffer distance between automobile tires and roads, and increases the elasticity and toughness of a concrete pavement. At the same time, the used polypropylene fiber and the used rubber powder are mostl.y polypropylene fiber clothing, discarded tires and the like, not only are the pollution of the wastes to the environment and the occupied cultivated land area reduced, but also the elasticity and toughness of the concrete can be improved, concrete pavement cracks generated due to temperature change are reduced, and thus the waste polypropylene fiber rubber recycled concrete is not only environmentally friendly but also has relatively high practical value during application.

Owner:TAIYUAN UNIV OF TECH

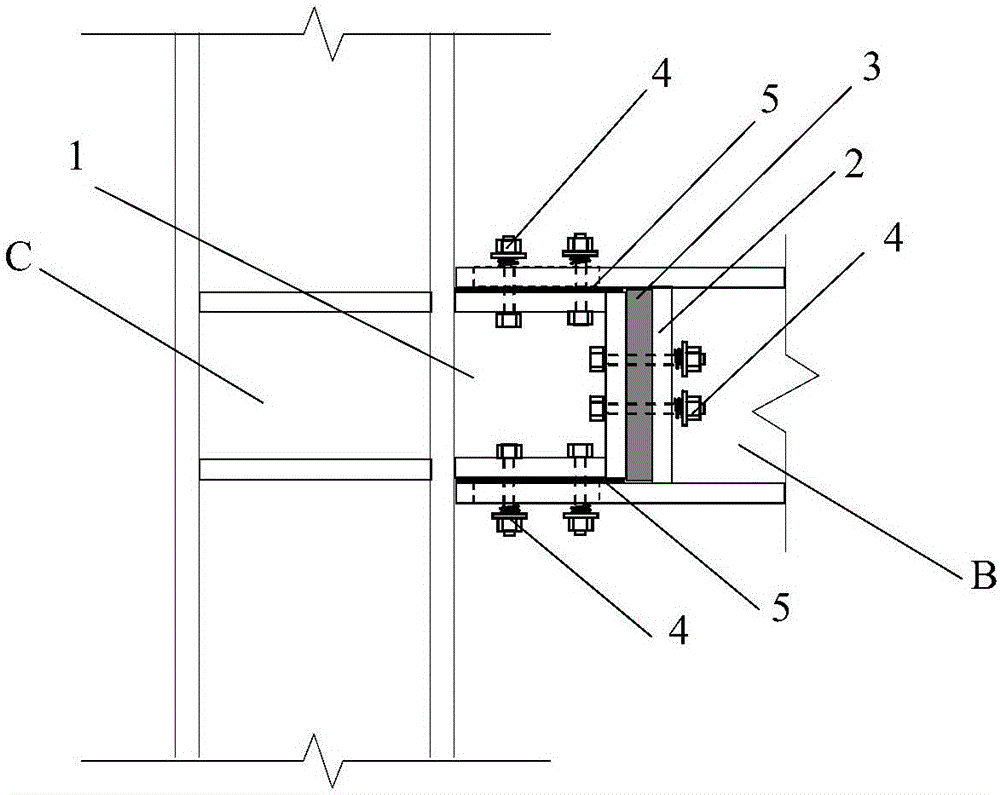

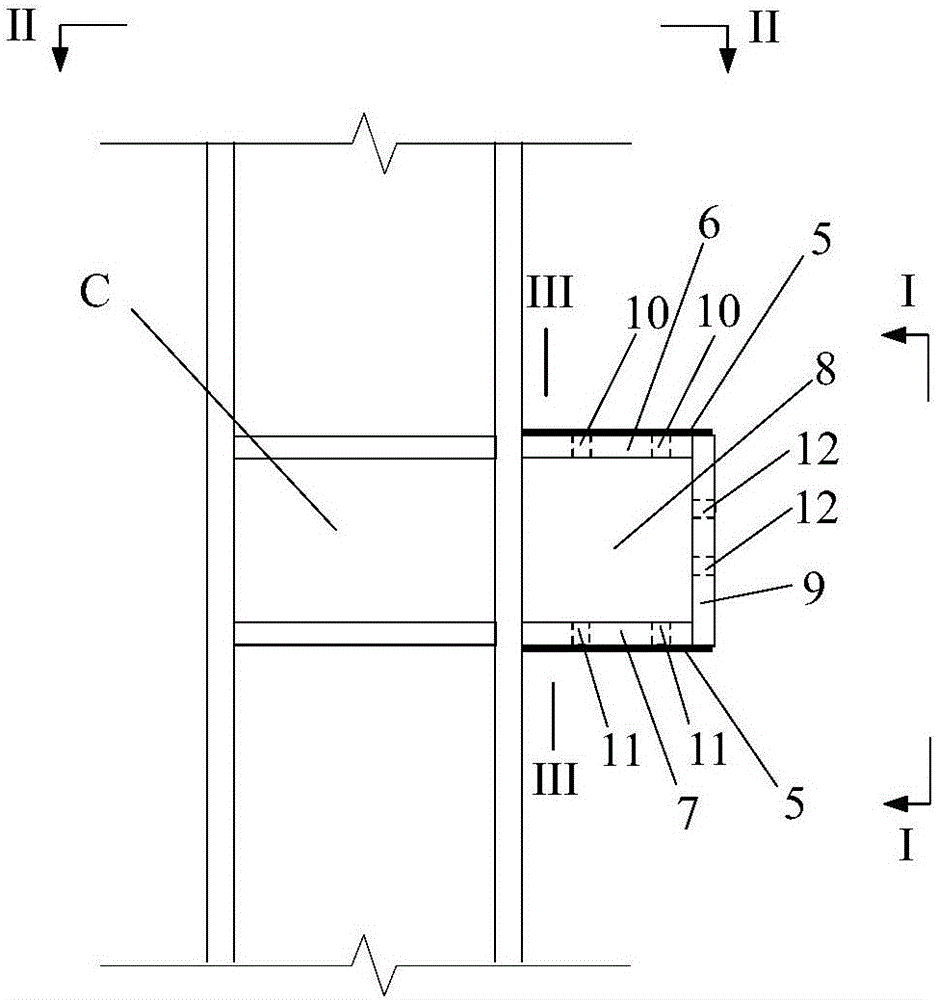

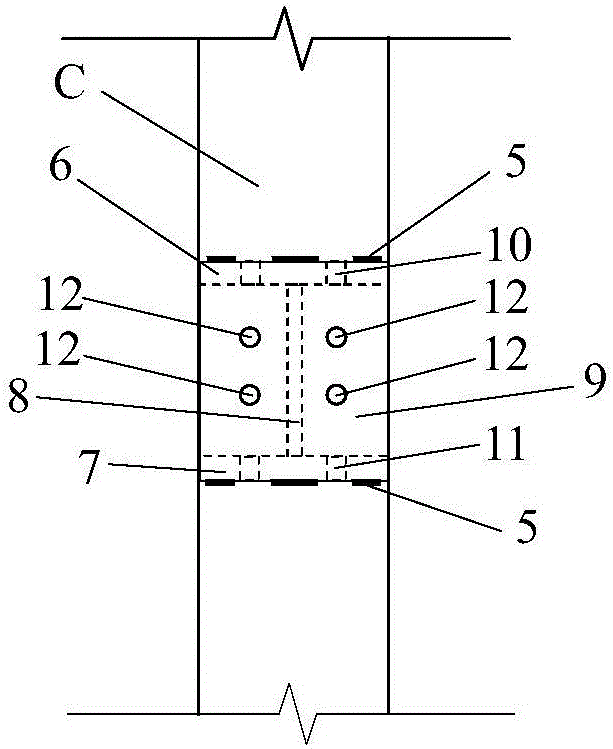

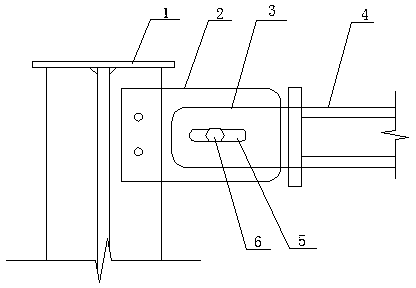

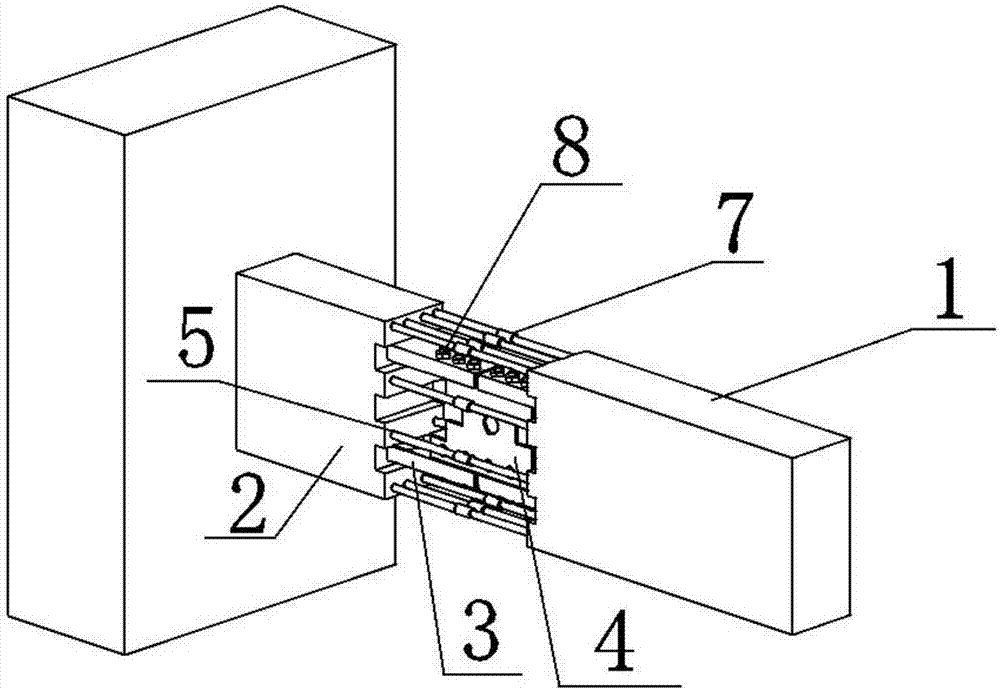

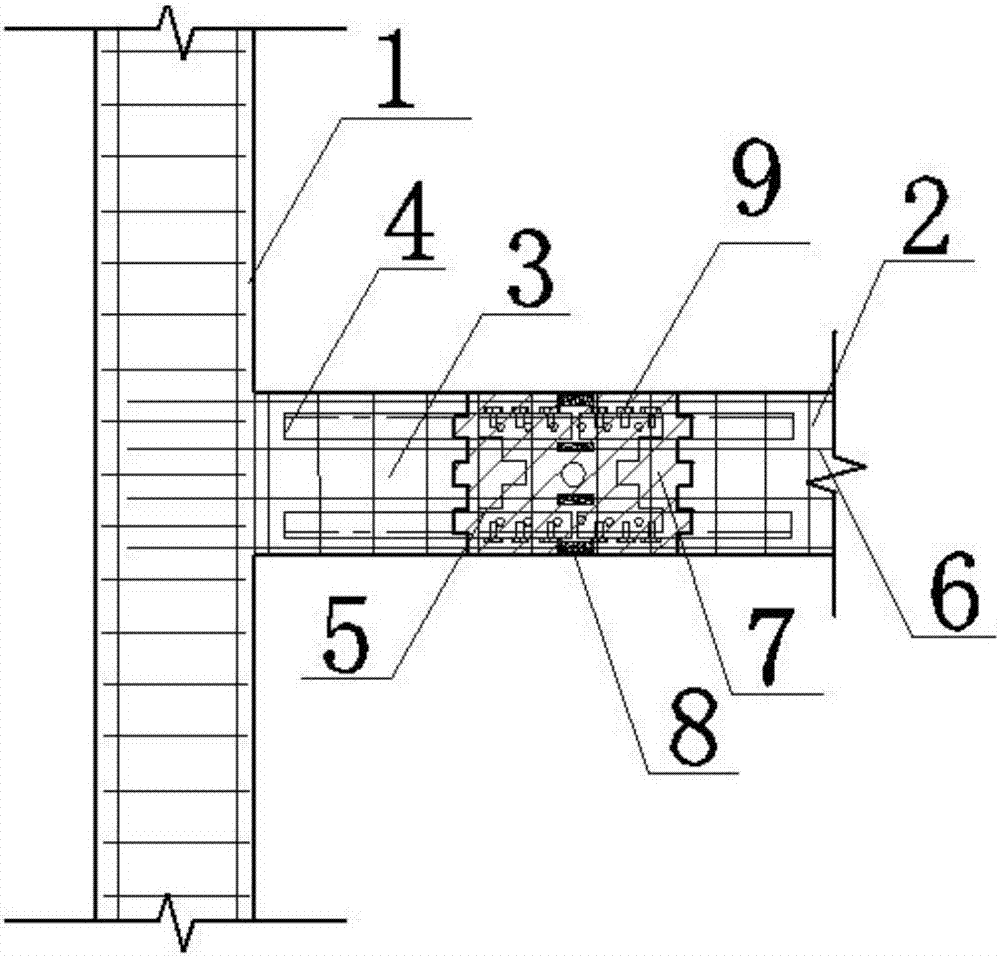

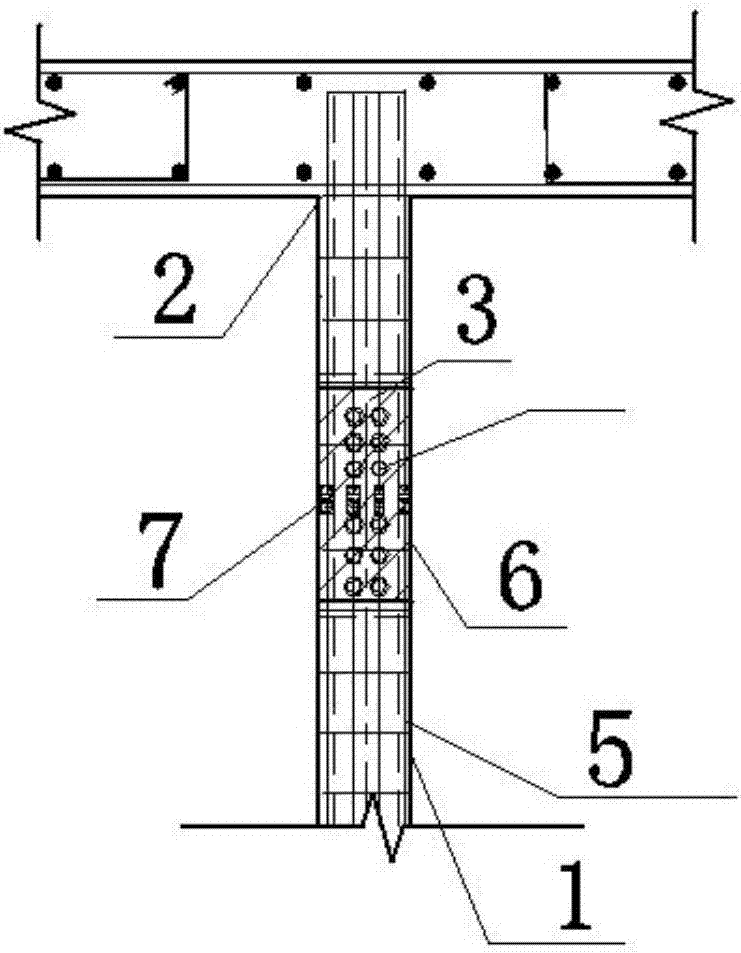

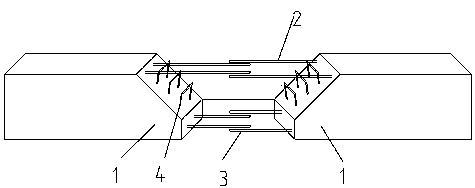

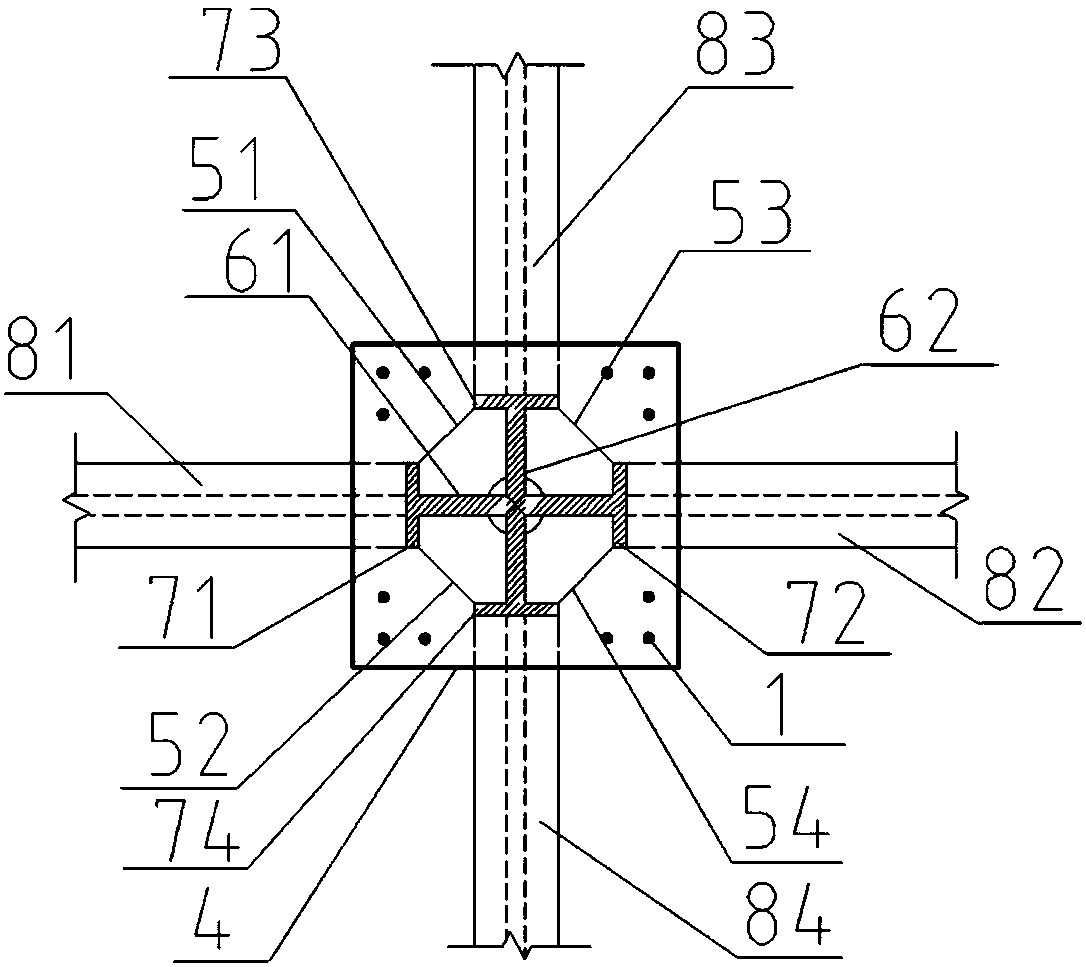

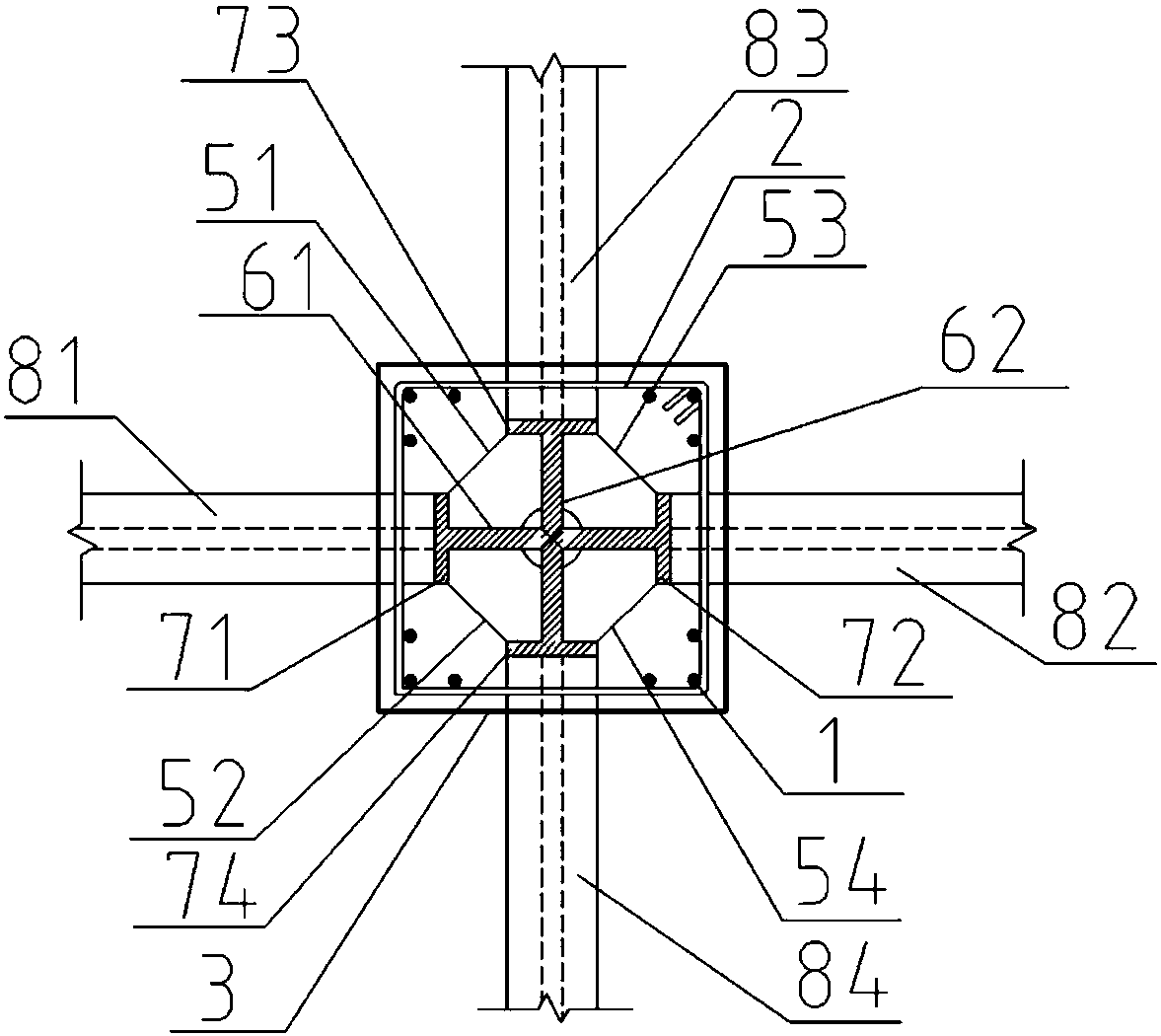

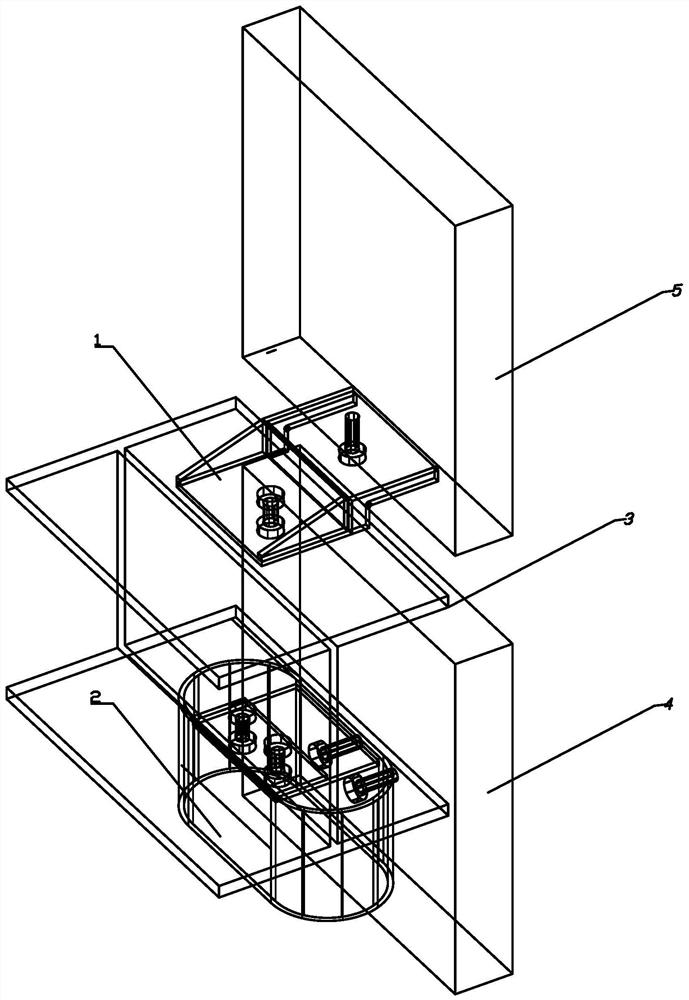

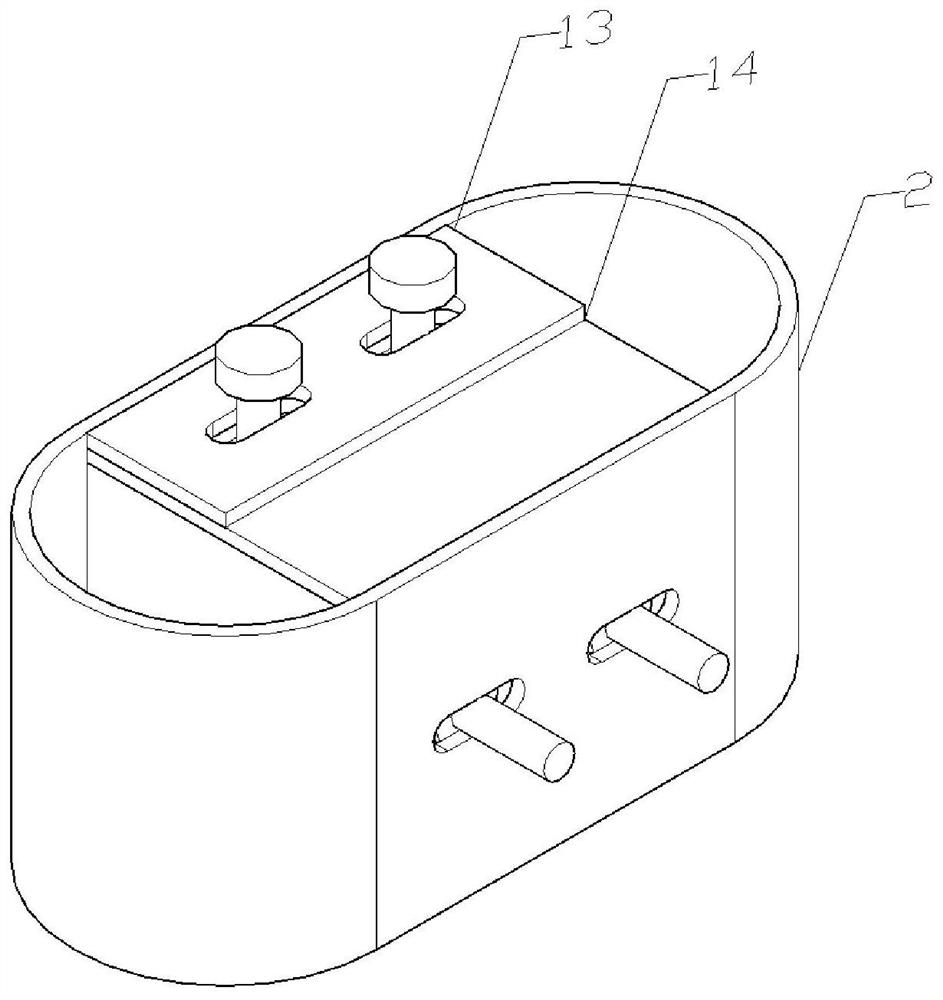

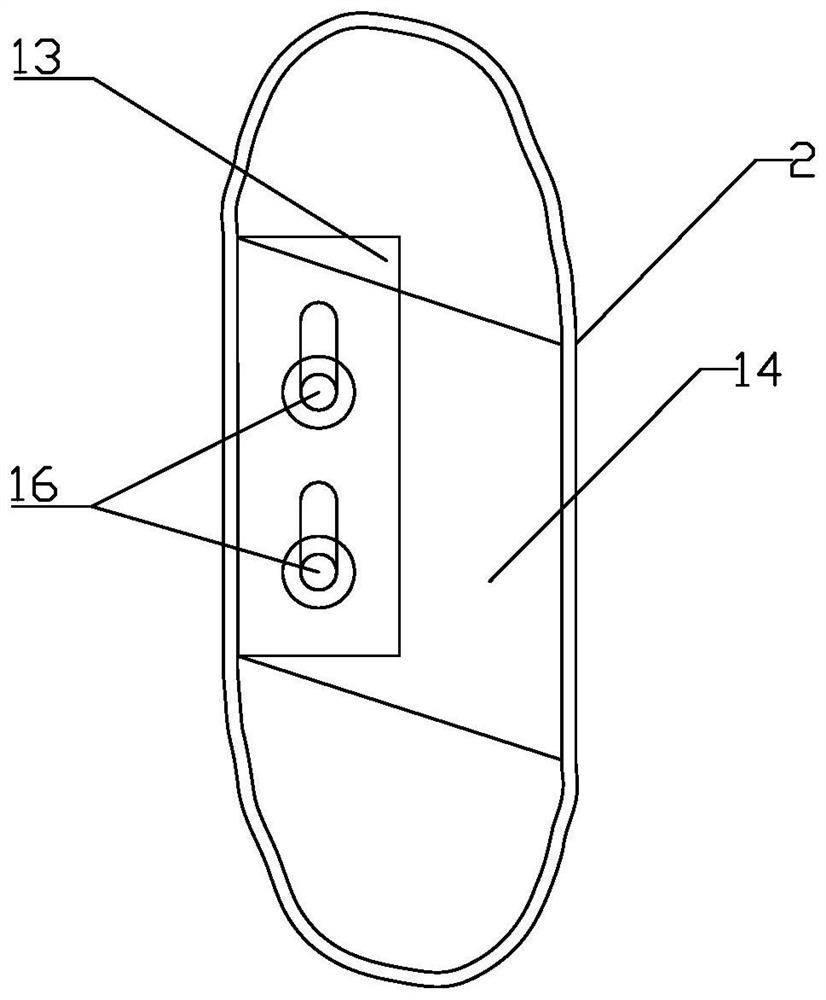

Assembly type energy consumption beam column node

ActiveCN106638991AStable and efficient reciprocating energy consumptionAvoid brittle failureProtective buildings/sheltersShock proofingFire - disastersCantilever

The invention discloses an assembly type energy consumption beam column node, comprising a cantilever convex section, a beam end concave opening, a rubber cushion block, and a bolt connecting pair which are welded to the column; the cantilever convex section, the beam end concave opening, and the rubber cushion block are connected to be one body through the bolt connecting pair; the cantilever convex section consists of an upper wing edge, a lower wing edge, a web plate, an end plate, and a friction element bonded to the upper surface of the upper wing edge and the lower surface of the lower wing edge; the upper wing edge, the lower wing edge, and the web plate are formed to be a transverse-H shaped section; circular bolt holes are arranged on the upper wing edge, the lower wing edge and the end plate; the beam end concave opening consists of an upper overhanging wing edge, a lower overhanging wing edge, and a bottom plate of the transverse-H shaped section beam; waist bolt holes are formed on the upper overhanging wing edge and the lower overhanging wing edge, and the circular bolt hole is formed on the bottom plate. The assembly type energy consumption beam column node can automatically reset and slip in earthquake or fire disaster, so ass to realize the reciprocating friction and energy consumption, guarantee that node has stable and high-efficient energy consumption ability in the whole disaster process, avoid brittle failure of the rigid node, and thereby reducing the repair cost after disaster.

Owner:HUNAN UNIV

Prestressed anti-fatigue steel beams

InactiveCN102296751AIncreased design fatigue stress amplitudeIncreased fatigue stress amplitudeGirdersJoistsFatigue ProblemEngineering

The invention belongs to the technical field of civil engineering, and specifically relates to a prestressing anti-fatigue girder. The prestressing anti-fatigue girder comprises a top flange, a bottom flange, a web, a bearer stiffening plate and prestressing anchor slab, anchor holes, a high-strength prestressing steel strand, an anchoring stiffening plate, an anchor head, an arc plate, a bearer steel bracket and lateral movement proof cushion block. The prestressing steel strand is penetrated into anchor holes which are near to a tensile flange and are symmetrical on two sides of the web, and is anchored by the anchor head after stretch-draw, so as to generate a precompression on a girder tensile area. After prestressing relaxation, the prestressing steel strand has a pressure stress larger than amplitude of a self-weight stress and a fatigue tensile stress; and the girder bottom flange will not be subjected to tension under compound effects of deadweight and fatigue load. Therefore,a fatigue problem id solved. According to the invention, a design fatigue stress amplitude of the bottom flange is increased from a former one limited in an allowed fatigue stress amplitude to one approaching a design strength f, so as o substantially increase anti-fatigue capability and change a fatigue brittle failure to a ductility strength problem. An ultimate strength of the bottom flange isincreased by one time, so as to substantially increase material utilization rate of high-strength steel.

Owner:马人乐

Composite bar-reinforced ECC and concrete composite beam and construction method thereof

InactiveCN105464288ASmall sizeReduce the weight of the structureClimate change adaptationGirdersSteel barMaterials science

The invention discloses a composite bar-reinforced ECC and concrete composite beam and a construction method thereof. The whole cross section of the composite beam is in a rectangular shape, and the composite beam comprises a fiber-reinforced cement-based composite material with concrete on the upper portion and interval grooves in the lower portion and an FRP bar-steel bar framework; in the FRP bar-steel bar framework, longitudinally-tensioned FRP bars are placed at the bottom of the beam, located on the inner sides of steel bar stirrups and bound together with the steel bar stirrups, longitudinally-tensioned steel bars are placed on the upper sides of the longitudinally-tensioned FRP bars, and a steel bar framework stud is placed on the top of the beam, located on the inner sides of the steel bar stirrups and bound together with the steel bar stirrups. According to the composite bar-reinforced ECC and concrete composite beam and the construction method thereof, on one hand, through the superior tensile property of the ECC material and the tiny crack mechanism, the dampproof and rustproof purposes are achieved while the bearing capacity and ductility of the composite beam are significantly improved; on the other hand, by mixing the FRP bars with the steel bar, the high strength and the corrosion resistance of the FRP bars and the ductility of the steel bar are fully utilized. The composite bar-reinforced ECC and concrete composite beam can be applied to beam components in building and bridge structures.

Owner:SOUTHEAST UNIV

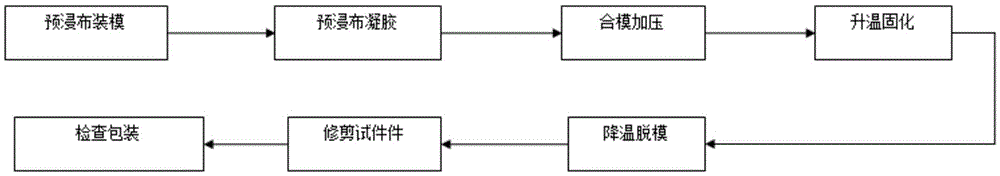

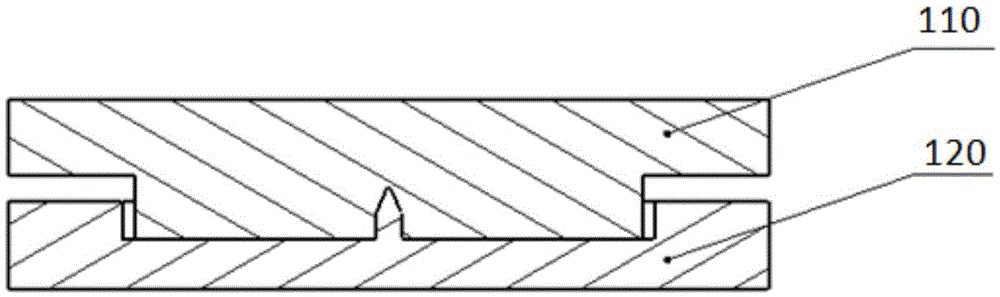

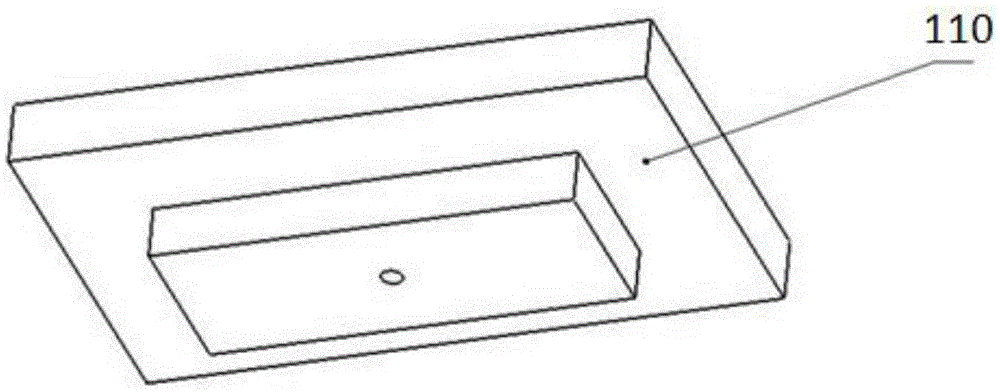

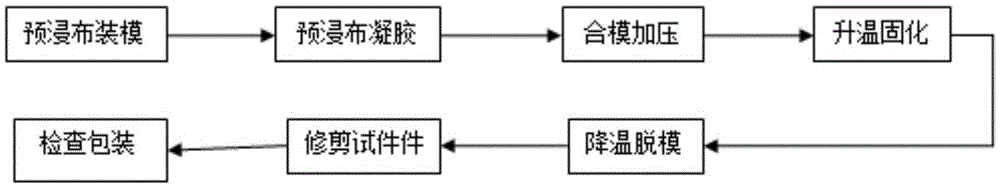

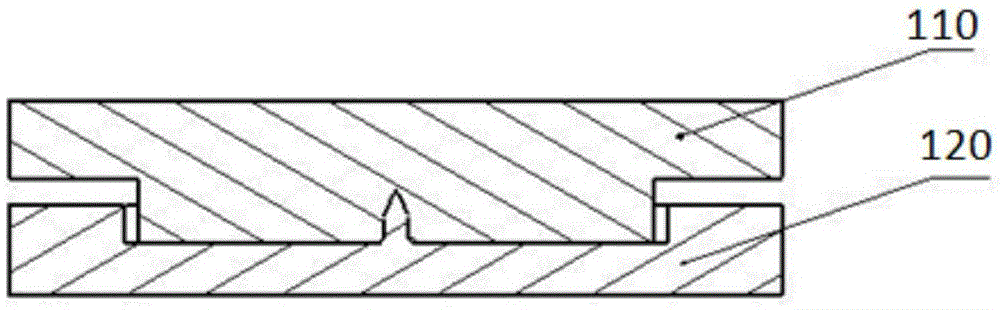

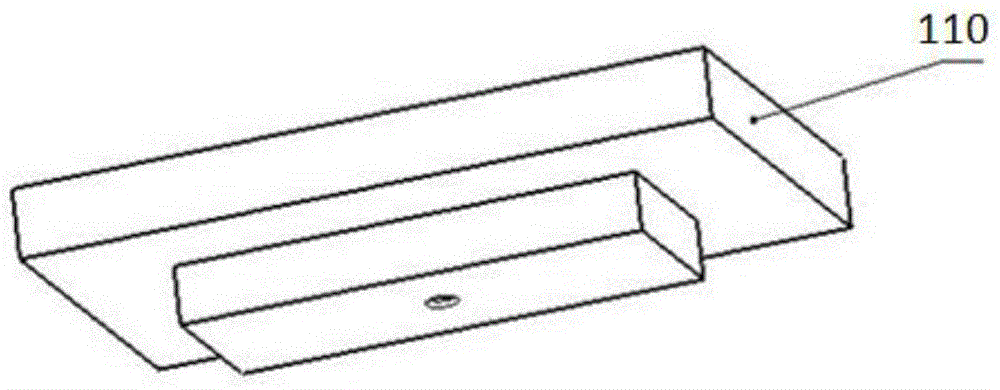

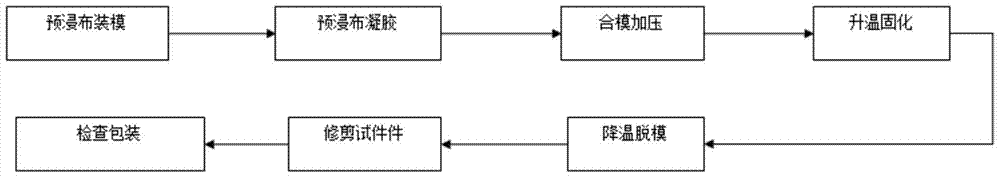

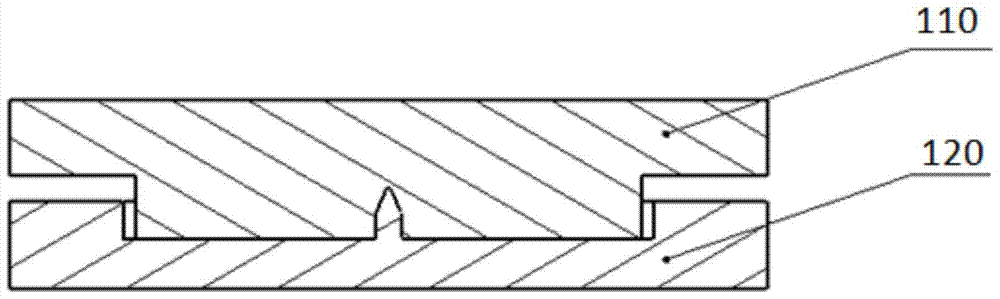

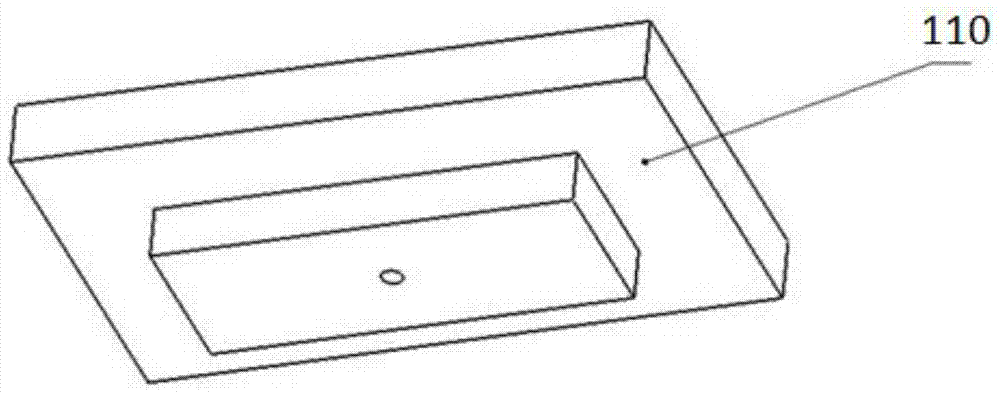

Manufacturing method for carbon fiber composite plate and self-punching riveting die and method for carbon fiber composite plate and aluminum alloy plate

The invention discloses a self-punching riveting die for a carbon fiber composite plate and an aluminum alloy plate. The self-punching riveting die comprises a rivet which is used for riveting the carbon fiber composite plate and the aluminum alloy plate, a punch which can reciprocate vertically in a through hole of a blank holder, and a female die body. Female die cavities in the center position of the female die body are concentrically formed with the punch. The side walls of the female die cavities are unthreaded hole cylindrical side walls, and cone bosses are arranged in the centers of the female die cavities. Unthreaded holes and the conical bosses are riveted and matched. The punch and the female die body are connected with a sensor, and height adjusting coefficients, speed adjusting coefficients and timing adjusting coefficients of the punch are obtained by collecting data. The invention further discloses a preparing method for the carbon fiber composite plate and a self-punching riveting method for the carbon fiber composite plate and the aluminum alloy plate. The self-punching riveting die and method for the carbon fiber composite plate and the aluminum alloy plate have the characteristics that large impact force can be borne, technology steps are simple, cost is low, and tensile, shearing resistance and fatigue resisting performance of a riveting connector are superior.

Owner:JILIN UNIV

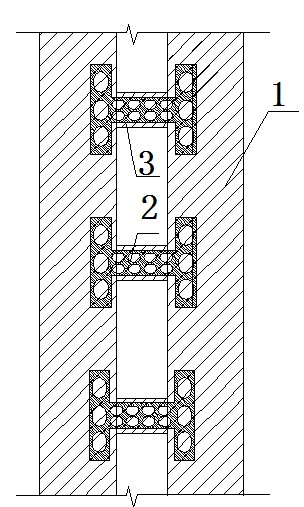

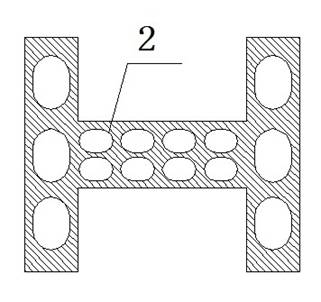

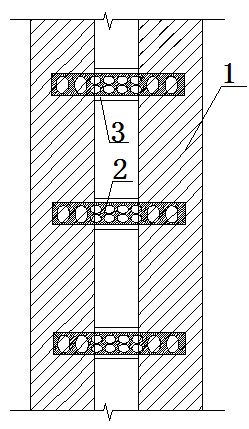

Shear wall and connecting beam damping system with internally embedded energy consumption steel plate damping devices

InactiveCN102011438AReduce out-of-plane deformationExpand energy consumption areaWallsShock proofingArchitectural engineeringSteel bar

The invention discloses a shear wall and connecting beam damping system with internally embedded energy consumption steel plate damping devices and relates to an energy consumption device for a building structure. The shear wall and connecting beam damping system is characterized in that a main body part of the system consists of shear walls, a connecting beam and a high-ductility steel plate with a hole; the whole steel plate has an H shape or a horizontal straight line shape; the installation of the steel plate in construction engineering is carried out together with the binding of the shear walls and a connecting beam steel bar and the position of the steel plate is calibrated before concreting; and steel plate energy consumption dampers are arranged on the connecting beam and the shear walls at both ends of the connecting beam. The steel plate energy consumption dampers serving as non load bearing elements can increase the integral rigidity of the building structure. In case of an earthquake, the steel plate energy consumption dampers can effectively prevent the connecting beam from being damaged under the action of repeated load and make the energy consumption effect of the connecting beam more obvious so as to well protect the building structure.

Owner:SHENYANG JIANZHU UNIVERSITY

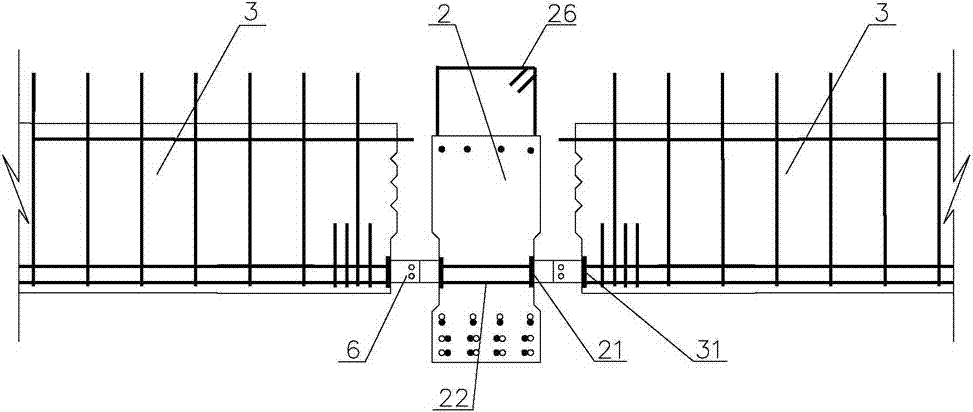

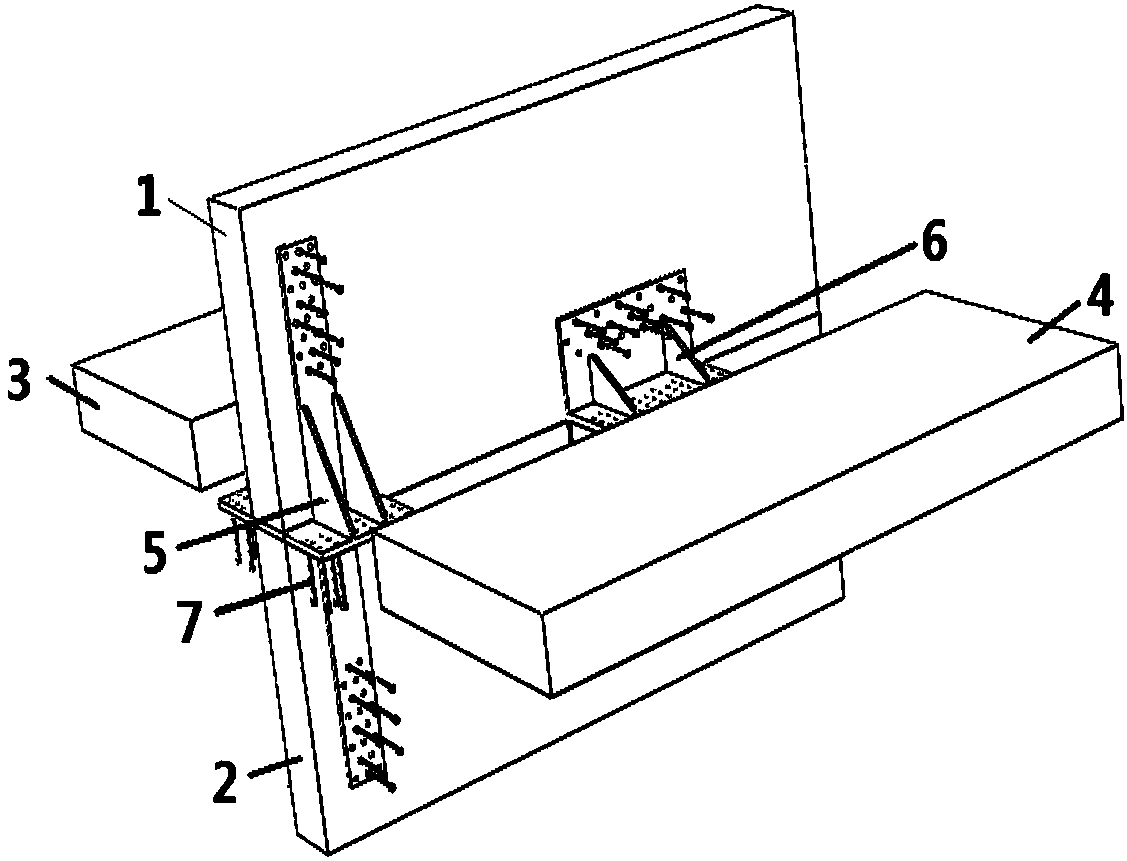

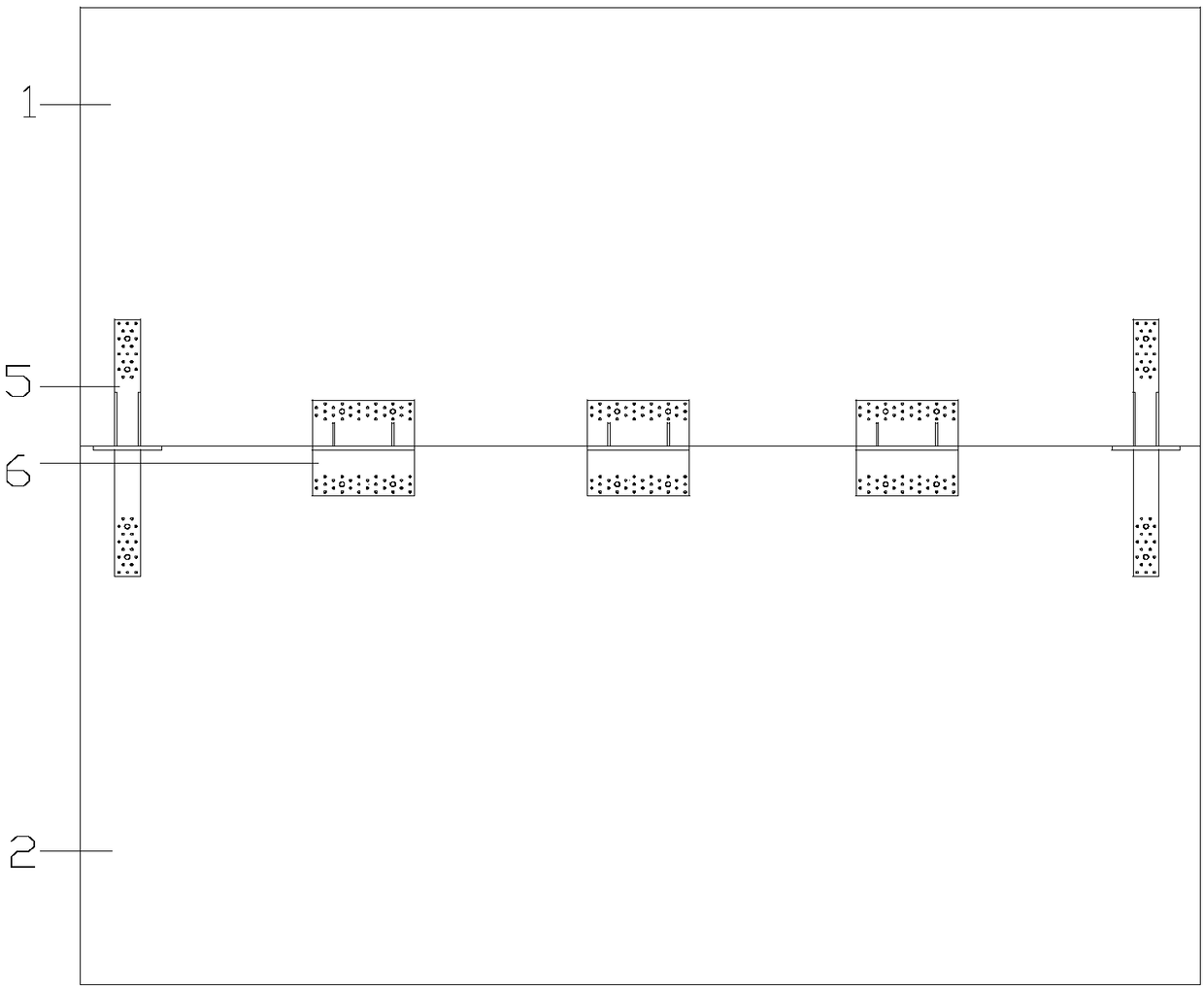

Temperature stress releasing structure of large-size steel structure building

InactiveCN103132603AEasy to makeEasy to installBuilding constructionsTemperature stressExpansion joint

The invention relates to a large-size steel structure building, in particular to a temperature stress releasing structure of a large-size steel structure building. Members of the structure comprise a steel beam, and a longitudinal member. A connected node between the longitudinal member and the steel beam is a slidable slotted hole structure node. Under the condition that a temperature expansion joint is not arranged, a slotted hole variant high strength bolt node is utilized to effectively release the temperature stress of a steel structure system. The problem of brittle failure of a large number of beam-column nodes of the steel structure is avoided. A door type steel beam and corresponding foundation are reduced and a complex joint structure is avoided. Slotted hole technology is simple in manufacture in a factory, and convenient to assemble, an opening is in the shape of a long circle. Bolt is hardly in need of repair after slide deformation.

Owner:TANGSHAN COLLEGE

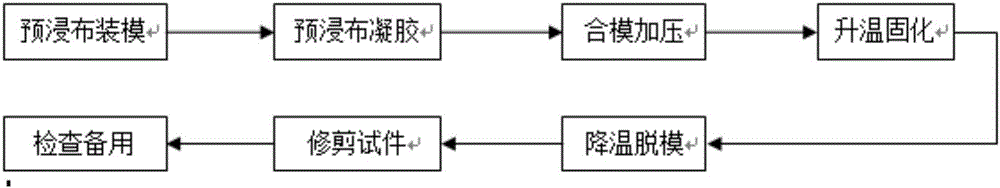

Preparing method of carbon fiber composite board and non-rivet riveting die and method of carbon fiber composite board and aluminum alloy board

The invention discloses a non-rivet riveting die of a carbon fiber composite board and an aluminum alloy board. The non-rivet riveting die comprises an upper punch needle and a rivet overturning needle. The upper punch needle can vertically reciprocate in a blank holder through hole, the rivet overturning needle and the upper punch needle are concentrically arranged, and the rivet overturning needle vertically reciprocates in a lower die through hole. The upper punch needle and the rivet overturning needle are connected with a sensor. By means of data collection, the height adjusting coefficient and the speed adjusting coefficient of the upper punch needle and the rivet overturning needle are obtained, and the height and the running speed of the upper punch needle and the rivet overturning needle are controlled. The invention further discloses a preparing method of the carbon fiber composite board and a non-rivet riveting method of the carbon fiber composite board and the aluminum alloy board. The non-rivet riveting die, the preparing method and the non-rivet riveting method have the characteristics that the large impact force can be borne, the technology step is simple, cost is low, and a riveting connector is superior in pulling resisting, shearing resisting and fatigue resisting performance.

Owner:JILIN UNIV

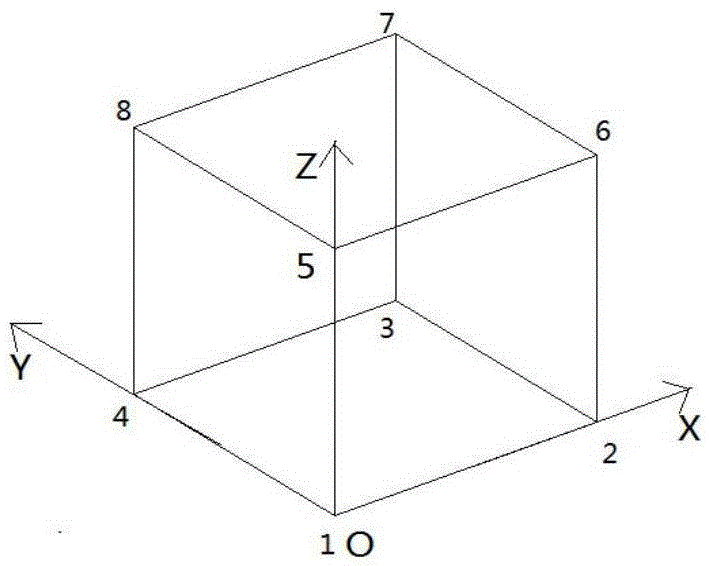

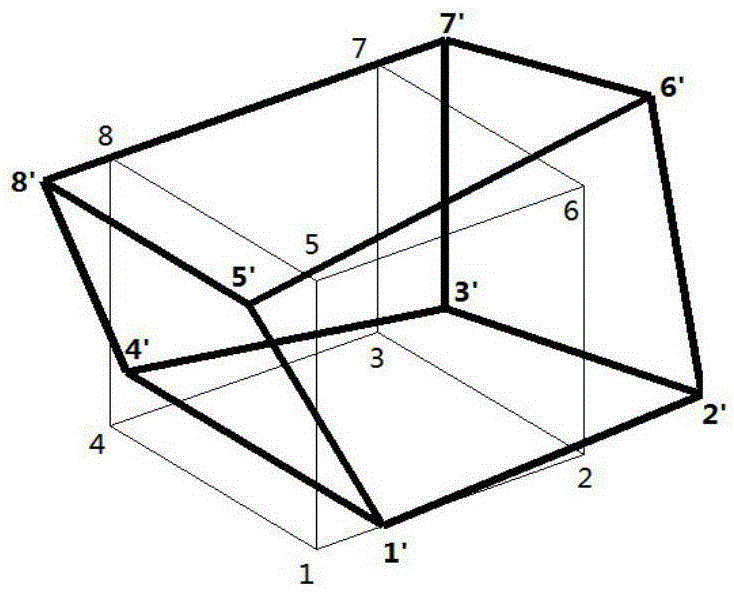

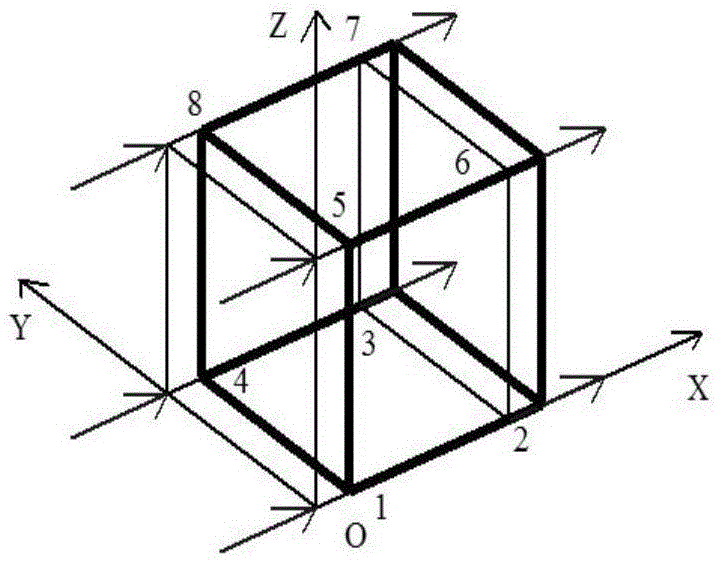

Cube unit deformation decomposition method meeting complete orthogonality and mechanical equilibrium conditions

ActiveCN105677971ARealize deformation quantitative recognitionRealization of vibration mode recognitionDesign optimisation/simulationSpecial data processing applicationsElement analysisMechanical equilibrium

A cube unit deformation decomposition method meeting complete orthogonality and mechanical equilibrium conditions comprises the first step that spatial deformation of a 8-node cube unit is composed of rigid body displacement in the X direction, rigid body displacement in the Y direction, rigid body displacement in the Z direction, tension and compression deformation in the X direction, tension and compression deformation in the Y direction, tension and compression deformation in the Z direction, X-axis bending deformation in an XOY plane, Y-axis bending deformation in the XOY plane, Y-axis bending deformation in a YOZ plane, Z-axis bending deformation in the YOZ plane, X-axis bending deformation in an XOZ plane, Z-axis bending deformation in the XOZ plane, shear deformation in the XOY plane, shear deformation in the YOZ plane, shear deformation in the XOZ plane, rigid body rotation displacement in the XOY plane, rigid body rotation displacement in the YOZ plane, rigid body rotation displacement in the XOZ plane and X-axis reverse bending deformation. Based on the method, an engineering designer can conveniently decompose ductile deformation (such as tension and compression deformation and bending deformation) and brittle deformation (such as shear deformation and torsion deformation) of a structure according to finite element analysis and laboratory test and field test data.

Owner:ZHENGZHOU UNIV

Bonding and riveting method between carbon fiber composite material plate and aluminum alloy plate

The invention discloses a bonding and riveting method between a carbon fiber composite material plate and an aluminum alloy plate. The bonding and riveting method adopts the carbon fiber composite material plate with a through hole and the aluminum alloy plate for gluing; and riveting is performed before adhesive is not cured; a half-hollow rivet is tapped; air in a hollow part of the half-hollowrivet is exhausted in the riveting process under a punch effect; the adhesive flows into the hole of the rivet for closing; and curing is performed after completion of self-punching riveting process to finish bonding and riveting connection. The bonding and riveting method can improve the strength of a traditional carbon fiber composite material connecting process, and solves the damage problem ofa glue layer by riveting in a traditional bonding and riveting technology; and meanwhile, the air in the hollow part can be emptied in the riveting process, and the hole of the rivet is closed afterthe adhesive flows in, so that the corrosion resistance of a joint is improved.

Owner:JILIN UNIV

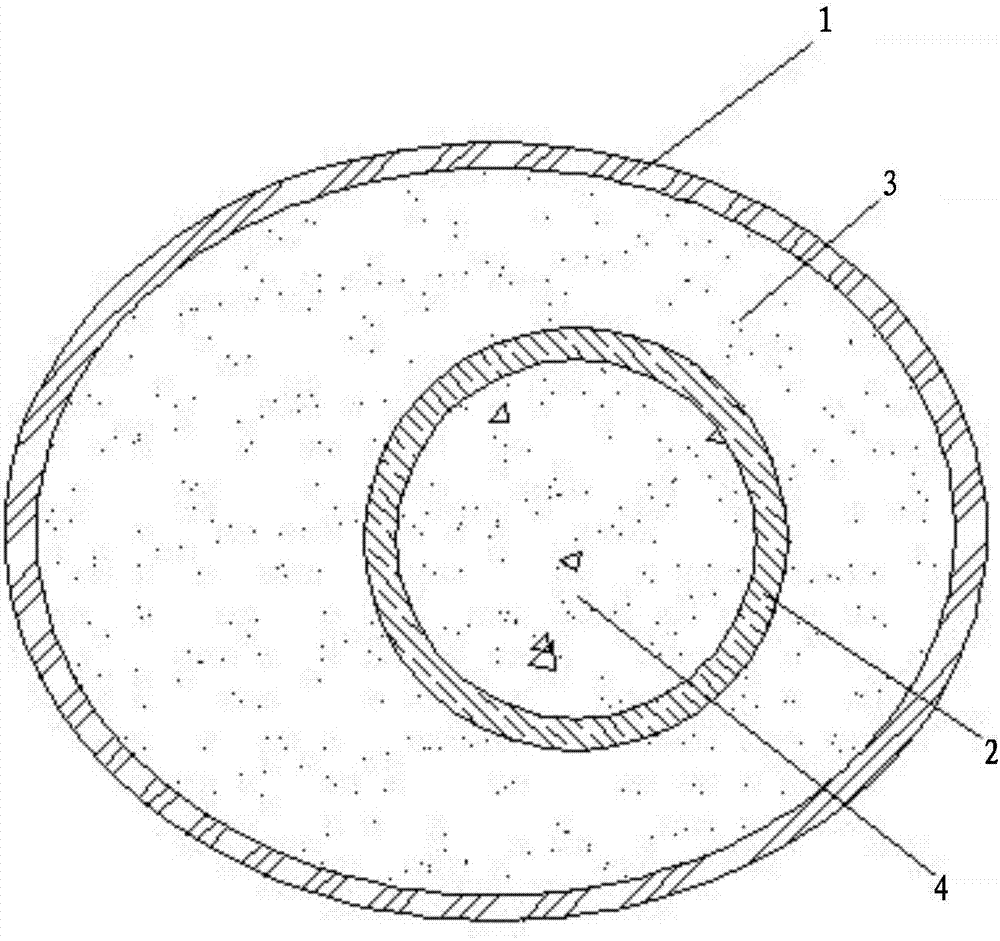

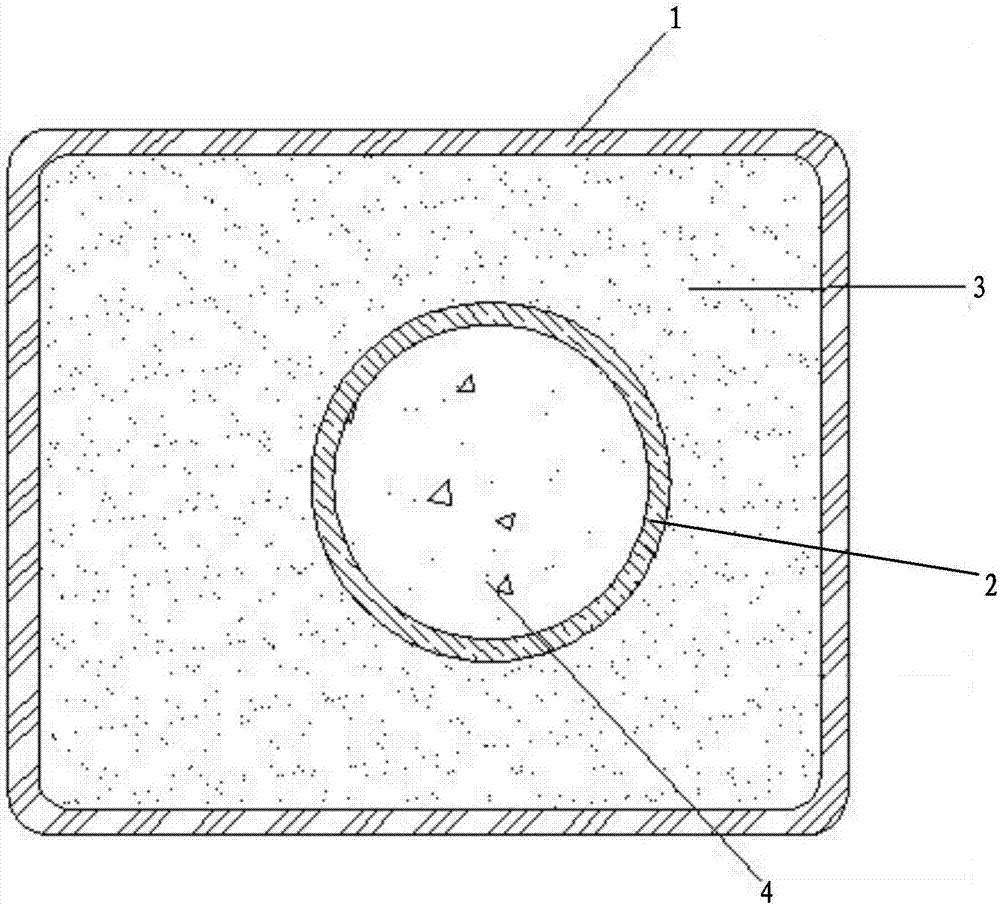

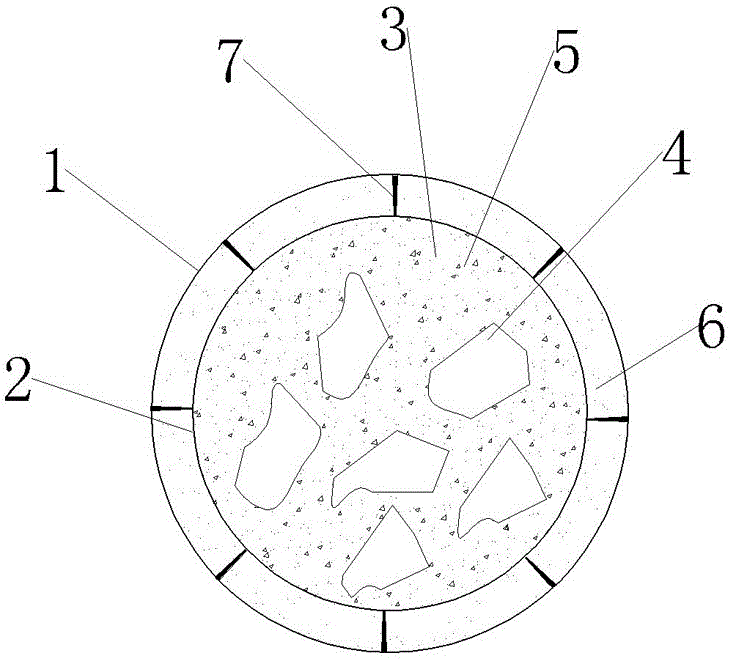

Concrete column with sea sand concrete and core rubber concrete

PendingCN107035071AAvoid odorExpand the applicable field of engineeringStrutsPillarsFiberFresh water

The invention discloses a concrete column with sea sand concrete and core rubber concrete. The concrete column with the sea sand concrete and the core rubber concrete comprises an outer-layer FRP pipe, an FRP-steel composite pipe, the sea sand concrete and the rubber concrete, the FRP-steel composite pipe is arranged in the outer-layer FRP pipe, and the position between the FRP-steel composite pipe and the outer-layer FRP pipe is filled with the sea sand concrete; the FRP-steel composite pipe is filled with the rubber concrete; and the FRP-steel composite pipe comprises a steel pipe body and FRP fiber cloth covering the external surface of the steel pipe body. According to the concrete column with the sea sand concrete and the core rubber concrete, original sea sand which is not subjected to desalting treatment can be directly used, the fresh water resource is saved, the desalting working procedure is omitted, and the utilization rate of the sea sand is greatly increased. In addition, the defects that a rubber concrete column is low in compressive strength, and peculiar smell is released are overcome, the engineering application fields of the rubber concrete are expanded, the utilization rate of rubber is greatly increased, and the concrete column with the sea sand concrete and the core rubber concrete has the beneficial effects of being high in bearing capacity, good in shock resistance and damping capacity, excellent in seismic performance and environmentally friendly.

Owner:GUANGDONG UNIV OF TECH

Partially bonded prestress assembly self-reset bridge pier column node and method

ActiveCN110359363ABuild fastImprove construction qualityBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention relates to a partially bonded prestress assembly self-reset bridge pier column node and a method. The node comprises a pier column, wherein a main body of the pier column is fabricated by concrete; the lower end of the pier column is inserted into a foundation and fixedly connected with the foundation; the upper end of the pier column is fixedly connected with a capping beam; a prestressed reinforcement is arranged in the pier column; a central axis of the pier column is coincided with that of the prestressed reinforcement; the lower end of the prestressed reinforcement is inserted into the foundation along with the pier column; the middle of the prestressed reinforcement is arranged in the pier column; the upper end of the prestressed reinforcement penetrates out of the piercolumn and is inserted into the capping beam; the lower end of the prestressed reinforcement is bound and fixed to the pier column; the upper end of the prestressed reinforcement is bound and fixed to the capping beam; the middle of the prestressed reinforcement is arranged in a prestressed reinforcement duct of the pier column; the upper end of the prestressed reinforcement duct penetrates through the pier column; the lower end of the prestressed reinforcement duct is positioned in the pier column; and the lower end of the prestressed reinforcement is fixedly connected with the pier column through an anchor piece. The disadvantages of long construction cycle and high cost due to adoption of an external dissipative element and post tensioned application of prestress can be avoided, and the probability of brittle failure of the pier column is reduced.

Owner:SHANDONG JIANZHU UNIV

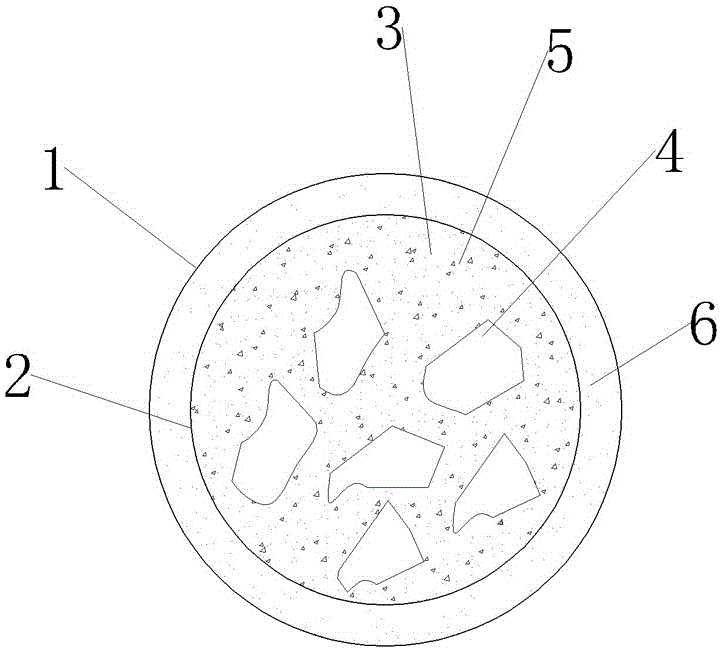

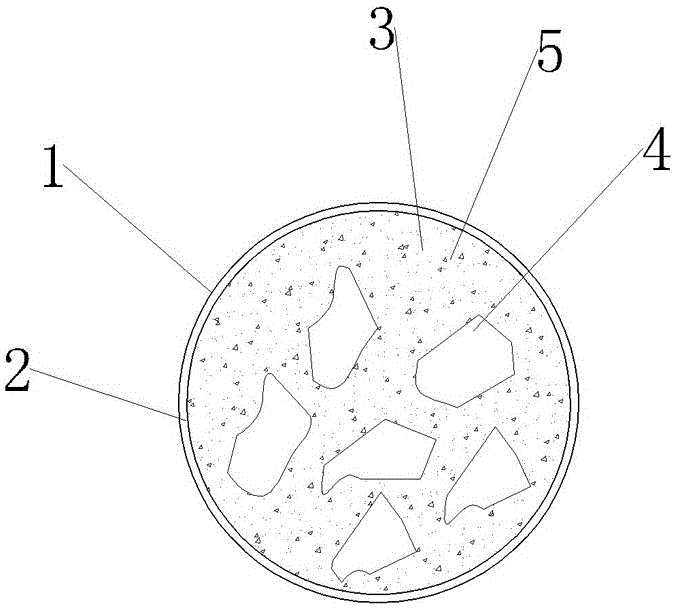

FRP restrained pipe regenerated mixed concrete combination column

InactiveCN105003027AOvercoming the weakness of low elastic modulusAvoid brittle failureStrutsPillarsFiberCompressive strength

The invention discloses an FRP (Fiber Reinforced Plastic) restrained pipe regenerated mixed concrete combination column, which comprises an FRP pipe, a steel pipe and a mixture inner core, wherein the mixture inner core comprises regenerated concrete blocks and fresh concrete which are mutually stirred into a whole; the mixture inner core is positioned in the steel pipe; and the steel pipe is positioned in an inner hole of the FRP pipe. The combination column has the following advantages that 1, the compressive strength and the ductility are high; 2, the bending strength and the ductility are high; 3, the durability is high; and 4, the construction is convenient.

Owner:WENZHOU UNIVERSITY

Shear wall-support structure system

InactiveCN102767251AImprove earthquake resistance and energy dissipation capacityImprove the level of earthquake resistanceWallsShock proofingFiberSupporting system

The invention relates to a shear wall-support structure system. Support systems are arranged among shear wall limbs to form the shear wall-support structure system. The support systems can utilize steel rod pieces, concrete-filled steel tube rod pieces and fiber reinforce plastic (FRP) confined concrete rod pieces, and damping members or damping devices can be arranged in the support systems. According to the structure system, anti-seismic and energy dissipation capabilities of concrete shear wall structures can be improved, material performances are played fully, the brittle failure of the structure can be prevented, and the shear wall-support structure system has the advantages of being convenient to construct and easy for restoration after shaking.

Owner:CHANGCHUN INST OF TECH

Method for bonding metallization modification on semiconductor unpacked chip

InactiveCN106835084AMeet application needsMeeting Reliability NeedsSolid-state devicesSemiconductor/solid-state device manufacturingBiological activationAdhesion strength

The invention discloses a method for bonding metallization modification on a semiconductor unpacked chip. The method comprises the following steps: putting a deoiled semiconductor unpacked chip surface or a wafer into a mixed solution of sulfuric acid and hydrogen peroxide, performing reaction for 60-90 seconds at 30-40 DEG C, dehydrating, performing primary zinc activation, performing acid corrosion, performing secondary zinc activation, performing deposition on the surface of the unpacked chip or the wafer after secondary zinc activation so as to form an Ni layer; depositing a Pd layer on the Ni layer; depositing an Au layer on the Pd layer. By using a chemical nickel and palladium plating gold leaching process, three layers of metallization layers of nickel, palladium and gold compatible with gold thread bonding are prepared on the surface of the deoiled semiconductor unpacked chip, the adhesion strength and the stability of a membrane layer meet application requirements of packaging processes, various electric parameters of the modified chip are not greatly different from those before modification, and gold thread bonding implemented on the surface of the modified nickel, palladium and gold layer can meet high-temperature environment application and reliability requirements of long-service life application of devices.

Owner:XIAN MICROELECTRONICS TECH INST

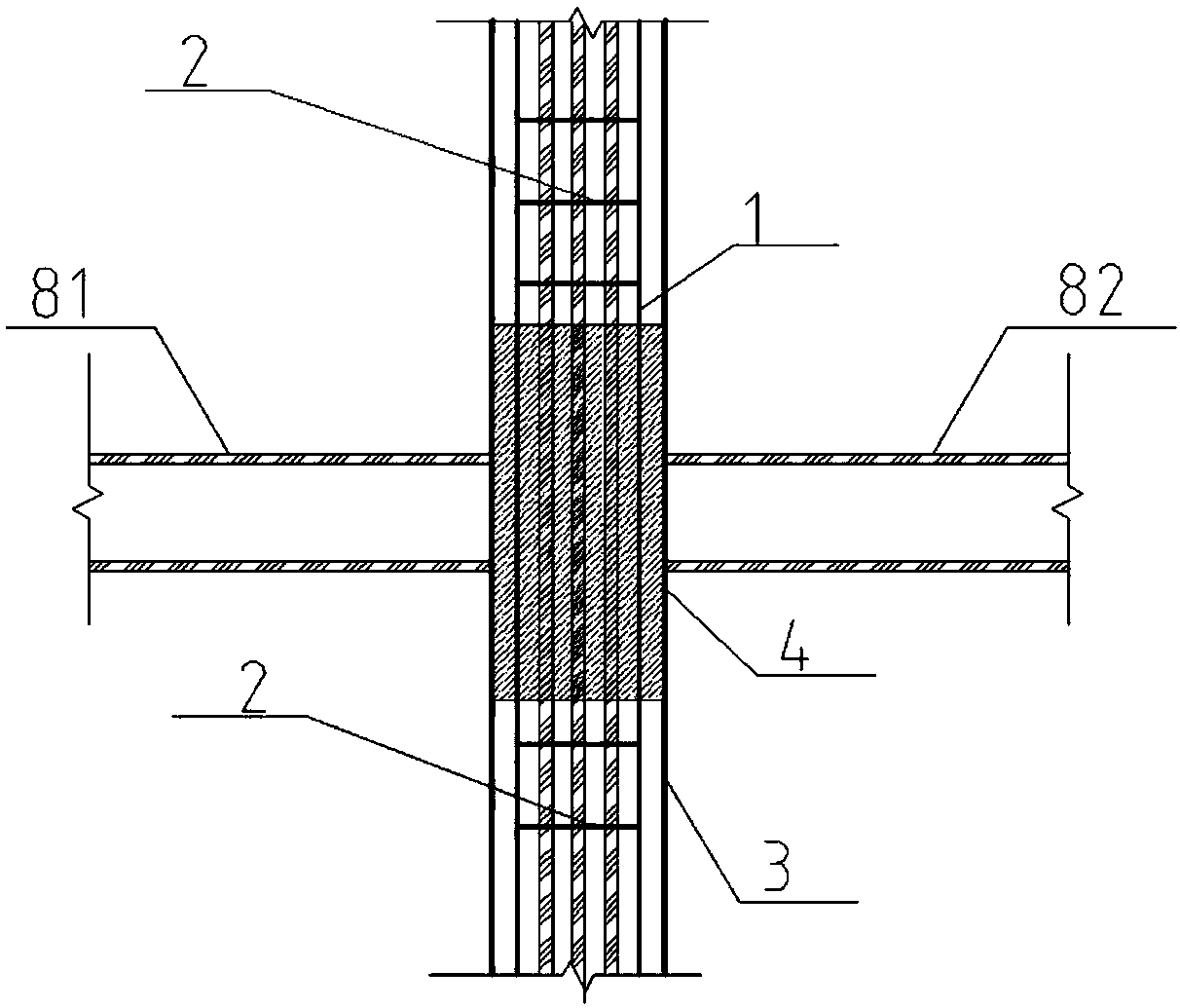

Assembled active beam node of built-in X-shaped low-yield-point type steel connecting piece

ActiveCN107254937AImprove interface shear performanceImprove shear resistanceGirdersProtective buildings/sheltersArchitectural engineeringRebar

The invention discloses an assembled active beam node of a built-in X-shaped low-yield-point type steel connecting piece. The assembled active beam node mainly comprises a prefabricated beam, a beam end connecting section, a connecting channel steel, a common stressed reinforcement, a profile steel connecting piece, a post-cast node and a connecting sleeve. One connecting section of the prefabricated beam which is produced on site and provided with a combed joint is arranged, the prefabricated beam is transported to the site after being manufactured in a factory and positioned through a high-strength bolt and the profile steel connecting piece on site, then the prefabricated beam and the reserved connecting reinforcement of the connecting section are connected through a grouting sleeve and poured with ultrahigh-tenacity cement-based composite materials, thus being capable of forming a reliable connecting node. Through the assembled active beam node, the on-site construction difficulty can be reduced, the energy consumption capability and deformation capability of the shearing wall-beam node can be improved, and the overall anti-seismic property of the wall-beam node can be guaranteed.

Owner:BEIJING UNIV OF TECH

Preparation method of carbon fiber composite material plate and its self-piercing riveting mold and method with aluminum alloy plate

The invention discloses a self-piercing riveting die for a carbon fiber composite material plate and an aluminum alloy plate, comprising: a rivet, which is used for riveting a carbon fiber composite material plate and an aluminum alloy plate; Reciprocating motion; the main body of the concave mold, the concave mold cavity in the center is set concentrically with the punch, the side wall of the concave mold cavity is a light hole cylindrical side wall, and the center is a conical boss, and the light hole and the cone boss are matched with riveting , the punch and the main body of the die are connected with sensors, and the height adjustment coefficient, speed adjustment coefficient and timing adjustment coefficient of the punch are obtained through data collection. The invention also discloses a preparation method of the carbon fiber composite material plate and a self-piercing riveting method of the carbon fiber composite material plate and the aluminum alloy plate. The invention has the characteristics of being able to withstand relatively large impact force, simple process steps, low cost, and superior tensile, shearing and fatigue resistance performances of riveted joints.

Owner:JILIN UNIV

Rivetless riveting device and riveting method for dissimilar materials based on hot melting principle

The invention discloses a rivetless riveting device for dissimilar materials based on a hot melting principle. The rivetless riveting device comprises an edge pressing ring, a hot melting drill bit, a rivet overturning needle and a lower die, wherein the edge pressing ring is provided with a through hole and used for fixing an aluminum alloy plate and a carbon fiber composite plate; the hot melting drill bit is capable of doing up-down reciprocating motion in the through hole in the edge pressing ring; the rivet overturning needle and the hot melding drill bit are concentrically arranged; the lower die is provided with a through hole and used for positioning the rivet overturning needle; the rivet overturning needle does up-down reciprocating motion in the through hole in the lower die; and the auxiliary alloy plate and the carbon fiber composite material plate are concentrically arranged on the lower die, and the aluminum alloy plate, the carbon fiber composite plate, the hot melting drill bit and the rivet overturning needle are concentrically arranged. The hot melting drill bit and the rivet overturning needle act on the through hole position of the aluminum alloy plate and the carbon fiber composite plate in the moving process, and the rivetless riveting piece is formed. The invention further discloses a rivetless riveting method for the dissimilar materials based on the hot melt principle.

Owner:JILIN UNIV

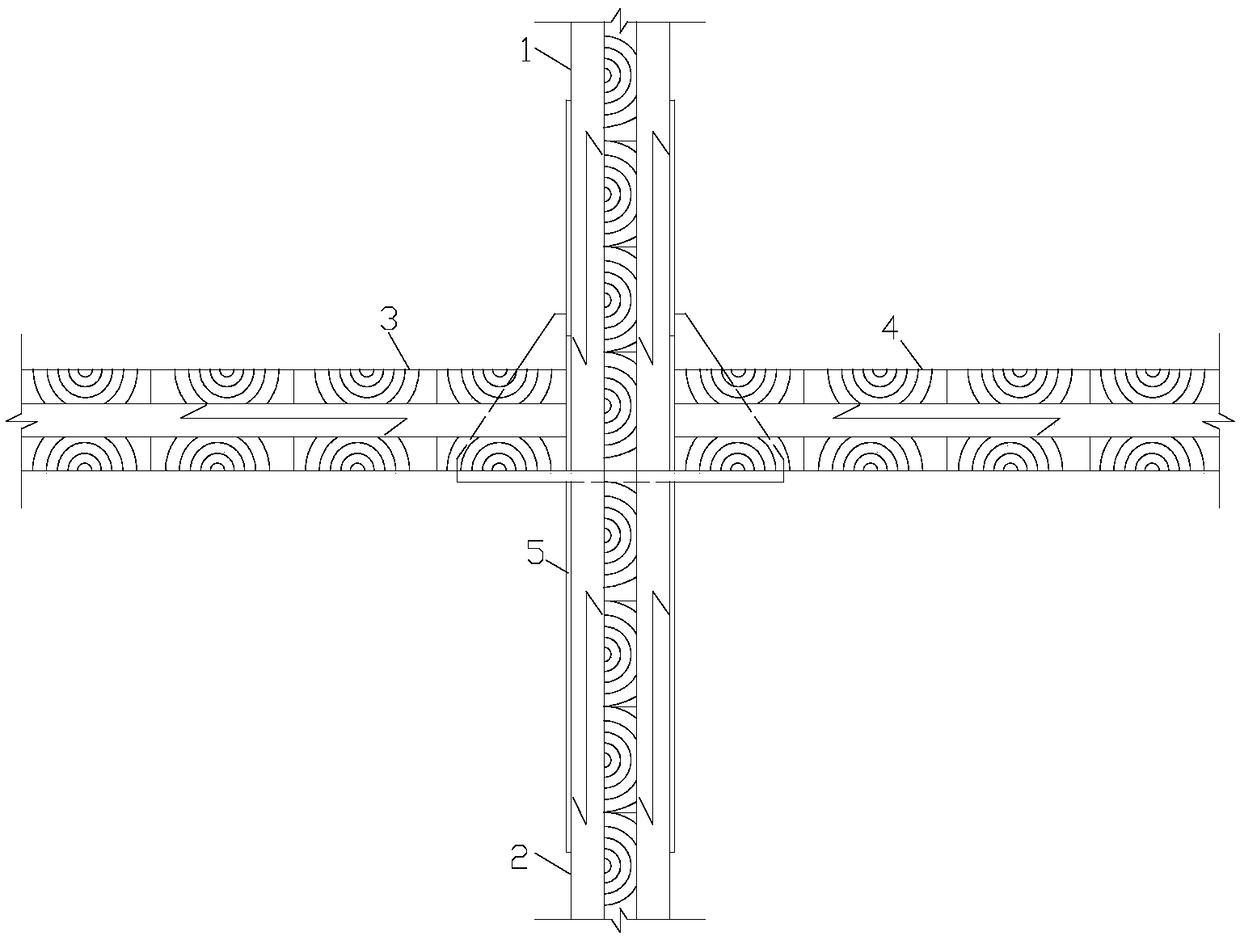

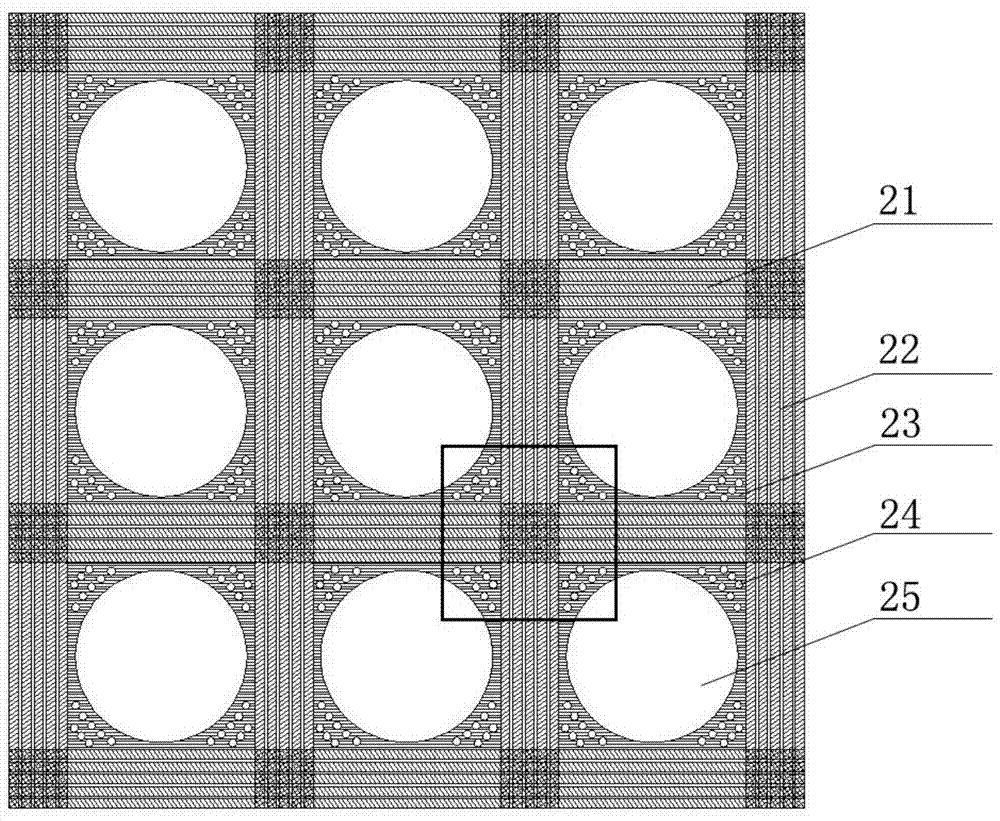

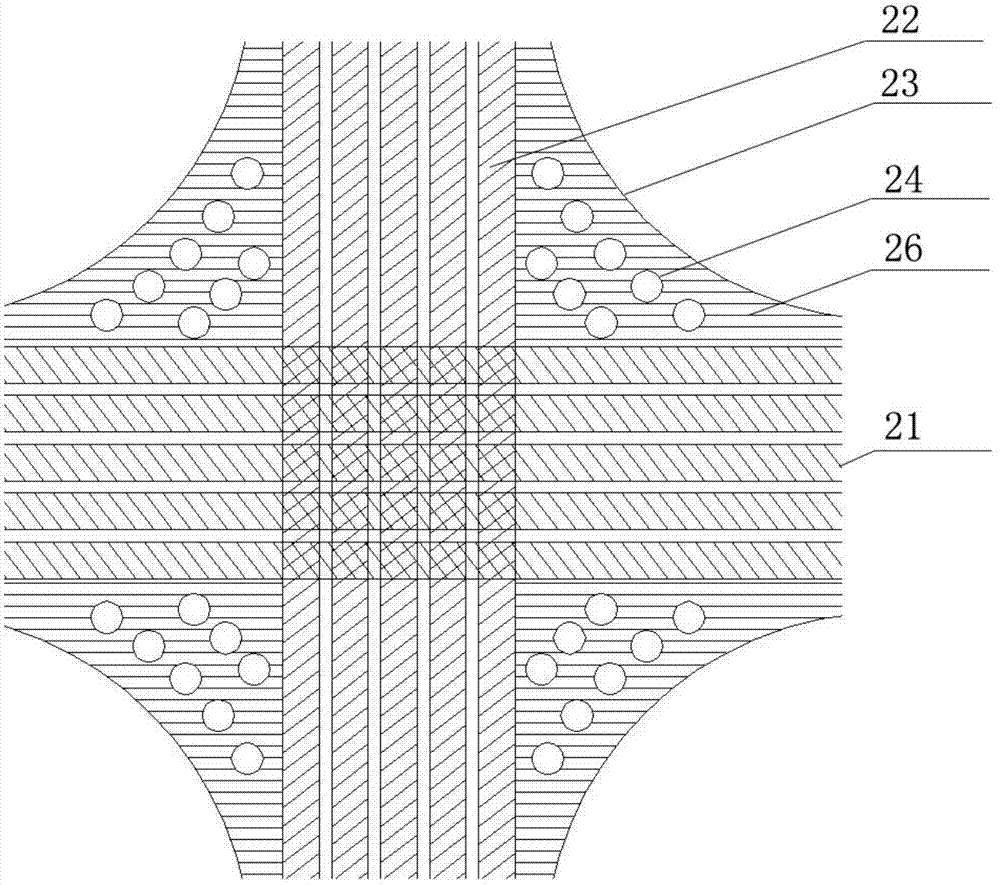

Multi-storey and high-rise CLT wallboard and floorslab connecting structure and method

InactiveCN108316484AAvoid pressure damageAvoid pressure damage, fromBuilding constructionsHigh riseWall plate

The invention discloses a multi-storey and high-rise CLT wallboard and floorslab connecting structure and method. The multi-storey and high-rise CLT wallboard and floorslab connecting structure comprises an orthogonal glued wood upper wallboard, an orthogonal glued wood lower wallboard, orthogonal glued wood floorslabs, pulling-resisting connecting pieces and shear-resisting connecting pieces, anorthogonal glued wood upper wall body and an orthogonal glued wood lower wall body are connected by the two shear-resisting connecting pieces, and two upper steel plates and two lower steel plates ofthe pulling-resisting connecting pieces through wood screws, the orthogonal glued wood floorslabs are overlapped on horizontal steel plates on the two sides of the pulling-resisting connecting piecesand the shear-resisting connecting pieces and are fixed through wood screws, the bearing capability of the horizontal steel plates on the outer sides are additionally increased through the fact that stiffened ribs are embedded into groove ports formed in the orthogonal glued wood floorslabs. The metal connecting structure of the multi-storey and high-rise CLT wallboard and floorslab connecting structure is simple in structure and low in cost, construction is convenient and rapid, compared with a traditional CLT building connecting structure, the situation that wood transverse grains are pressed and damaged can be effectively avoided, and the good mechanical performance of a CLT building can also be ensured.

Owner:NANJING UNIV OF TECH

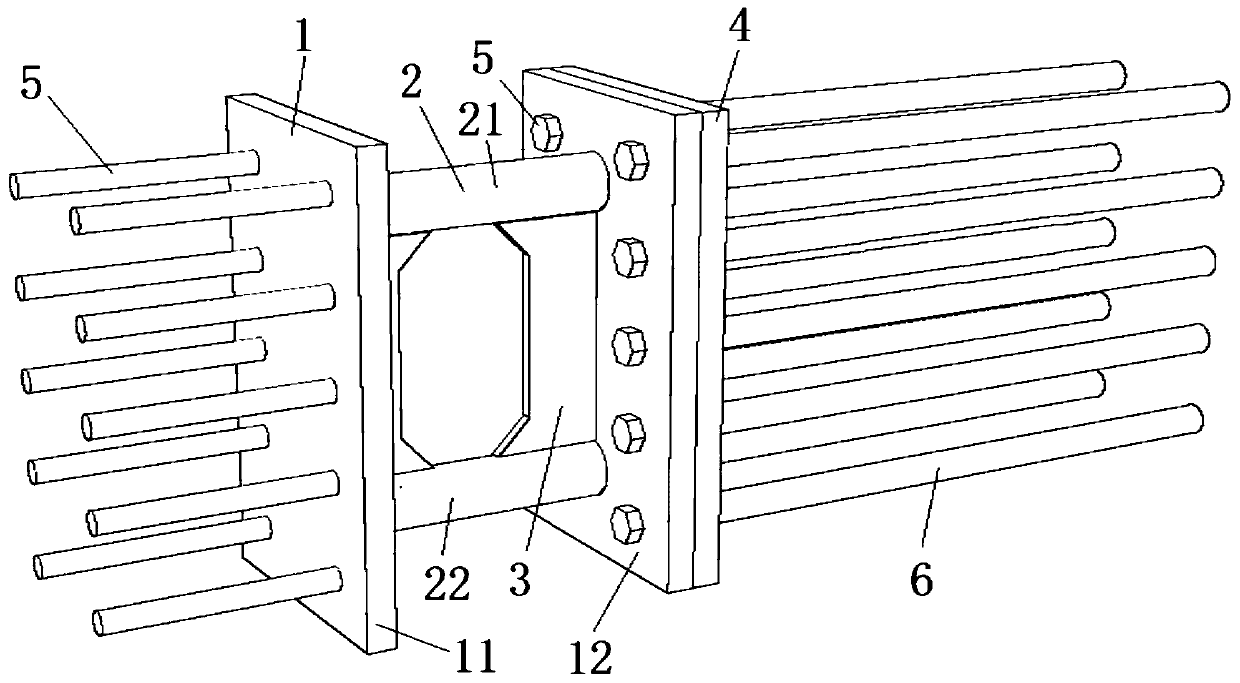

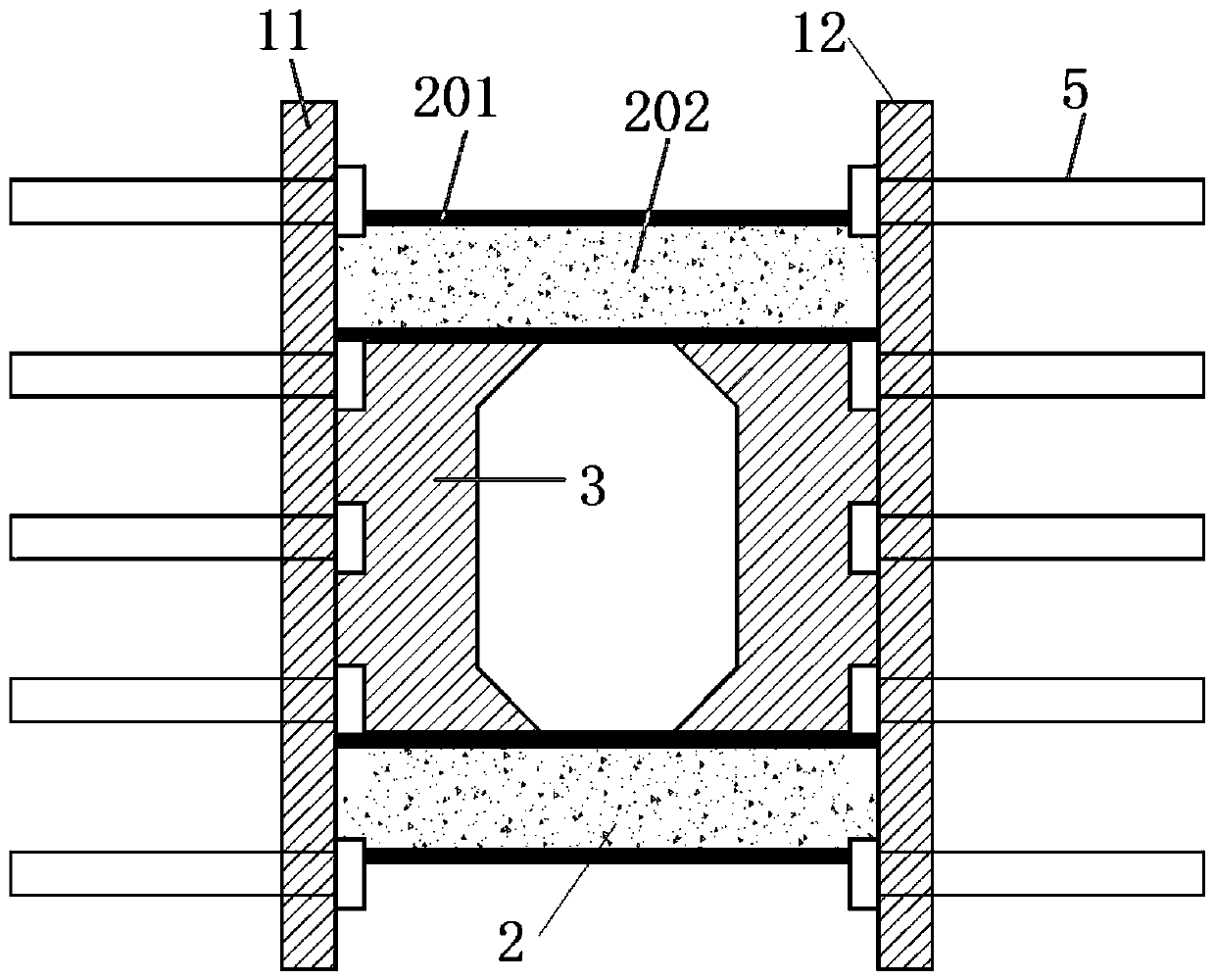

Assembled frame structure beam-column energy-consumption connecting key

PendingCN110359554AAchieve controllabilityGuaranteed uniformityProtective buildings/sheltersShock proofingSteel tubePlastic property

The invention discloses an assembled frame structure beam-column energy-consumption connecting key. End plates include the first end plate and the second end plate which are parallel to each other inthe vertical direction; the first end plate and the second end plate are detachably fixed to a frame concrete beam and a frame concrete column correspondingly; steel tube concrete connectors are perpendicularly fixedly arranged between the first end plate and the second end plate; the steel tube concrete connectors include the first steel tube concrete connector and the second steel tube concreteconnector which are parallel to each other in vertical direction; webs are vertically disposed between the first steel tube concrete connector and the second steel tube concrete connector; and the webs are perpendicularly welded and fixed to the steel tube concrete connectors and the end plates. The two steel tube concrete connectors and the webs are arranged between end plates, and then the energy-consumption connecting key is formed; the end plates and the steel tube concrete are combined to form the connecting key so as to improve the bearing force as much as possible, the steel tube concrete has high plastic deformation and energy-consumption property after yielding; and the end plates are detachably fixedly connected to the frame concrete beam and column, and timely replacement and repair of the energy-consumption connecting key are guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

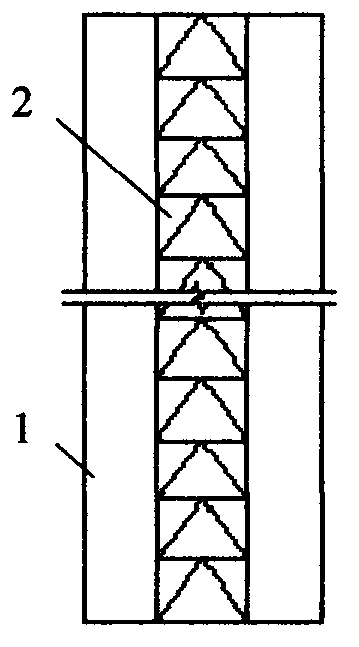

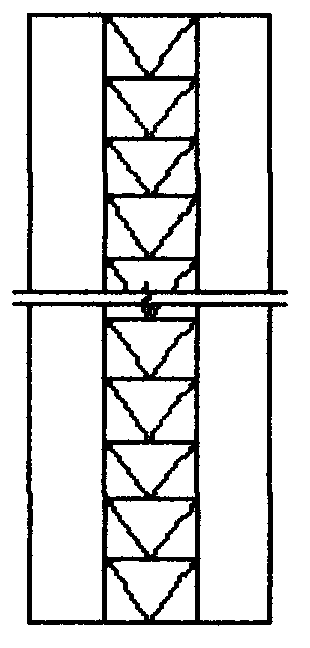

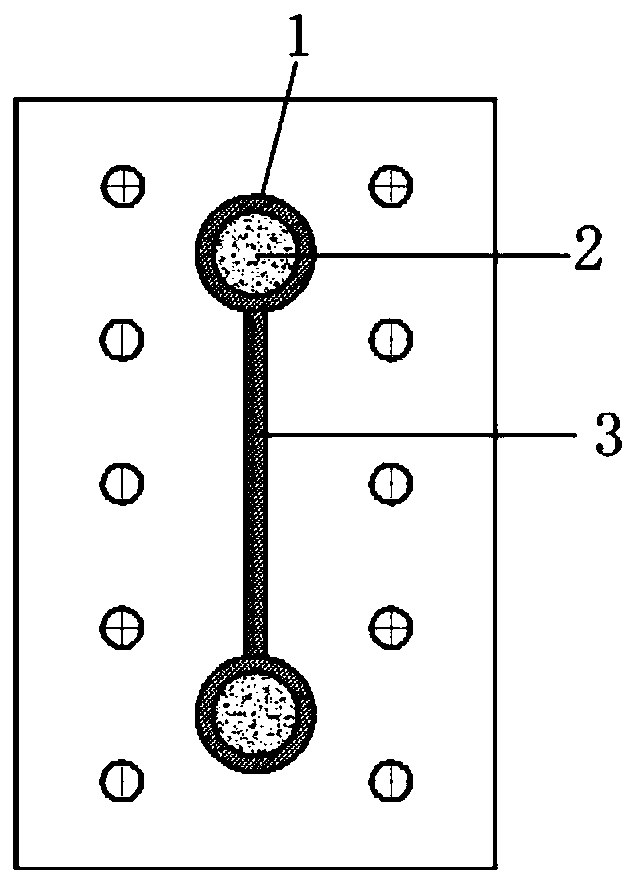

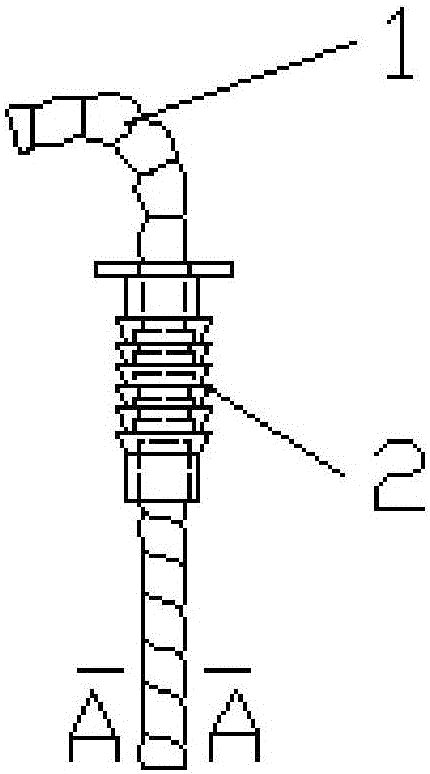

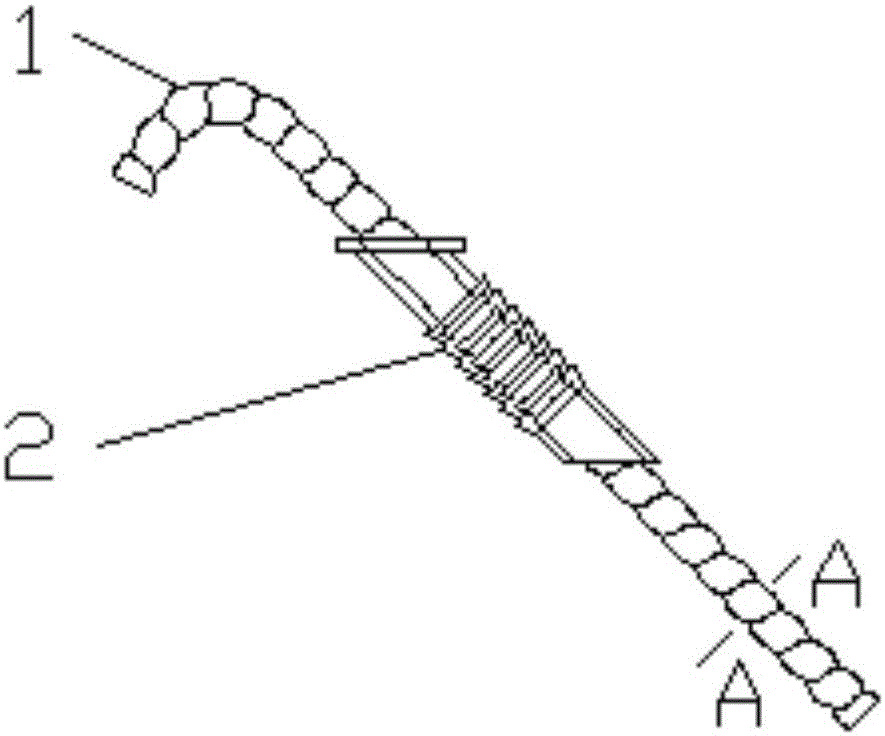

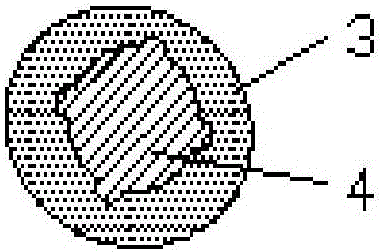

Hook-shaped reinforcing bar core continuous fiber composite connection piece for prefabricated sandwich heat insulation wall body

ActiveCN105780948AIncreased durabilityGood heat insulationWallsHeat proofingPlastic injection moldingWave form

The invention discloses a hook-shaped reinforcing bar core continuous fiber composite connection piece for a prefabricated sandwich heat insulation wall body. The connection piece consists of a hook-shaped reinforcing bar core continuous fiber composite bar and a bushing, wherein a main body of the hook-shaped reinforcing bar core continuous fiber composite bar is a novel composite material which takes a reinforcing bar as a ductile inner core wrapped by a rigid continuous fiber and is prepared by wrapping the surface of the reinforcing bar with a longitudinal continuous fiber through an integrated pultrusion process, then winding the outer surface of the longitudinal continuous fiber with a transverse fiber to form a wave-form continuous fiber covering layer, bending one end of the reinforcing bar into a hook after the fibers are cooled and heating and forming the reinforcing bar; the bushing is molded by a plastic injection molding process. The connection piece disclosed by the invention is simple in structure, low in manufacturing cost, low in heat conduction coefficient, high in durability and high in safety stock, and is suitable for connection of concrete plates inside and outside the prefabricated sandwich heat insulation wall body.

Owner:SOUTHEAST UNIV

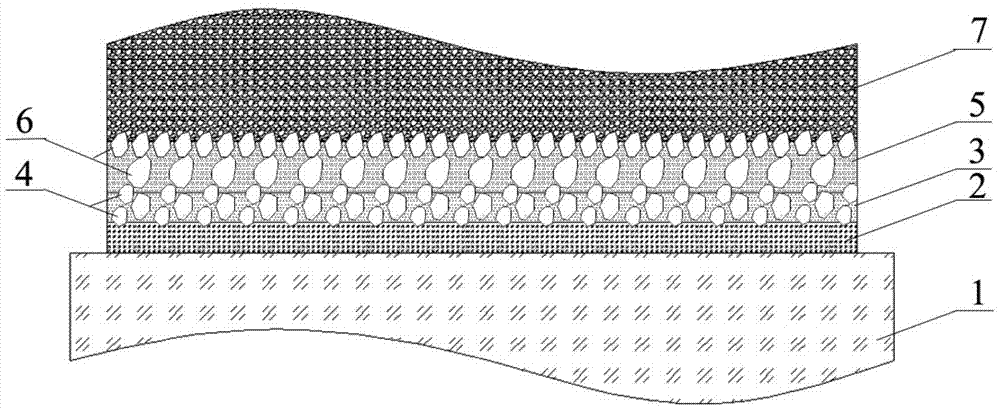

Ultrathin composite structure layer for preventing reflection cracks and preparation method of ultrathin composite structure layer

ActiveCN104499399AHigh tensile strengthEnhanced resistance to peelingIn situ pavingsEpoxyLower grade

The invention discloses an ultrathin composite structure layer for preventing reflection cracks and a preparation method of the ultrathin composite structure layer. The ultrathin composite structure layer comprises an anti-sliding high-strength geogrid layer, a lower toughening type epoxy asphalt layer, a lower graded macadam layer, an upper reinforced type epoxy asphalt layer and an upper graded macadam layer which are arranged on a cement pavement from bottom to top in sequence. The composite structure layer disclosed by the invention is a complex and solid interlocking system which is excellent in anti-pull, anti-shearing, adhesive and waterproof property, has very good tensile, anti-shearing and stress absorption functions when strain is relatively small, is capable of effectively reducing reflection cracks of an additionally paved asphalt concrete layer on the cement pavement and effectively reducing the self-weight, and is relatively low in thickness, good in stability, high in anti-sliding property and relatively long in service life, the preparation method of the composite structure layer is high in mechanical degree and high in feasibility, and the additionally paved asphalt concrete layer can be directly constructed on the prepared ultrathin composite structure layer.

Owner:SOUTHEAST UNIV

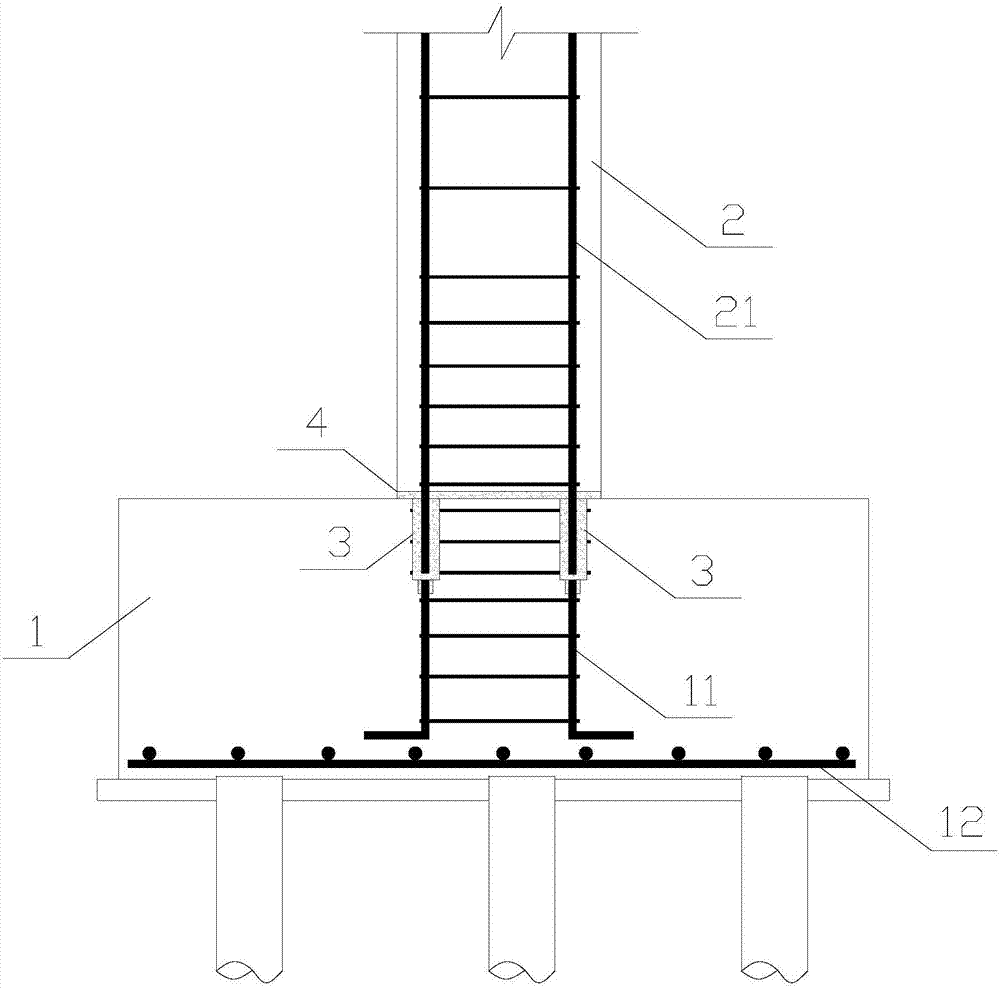

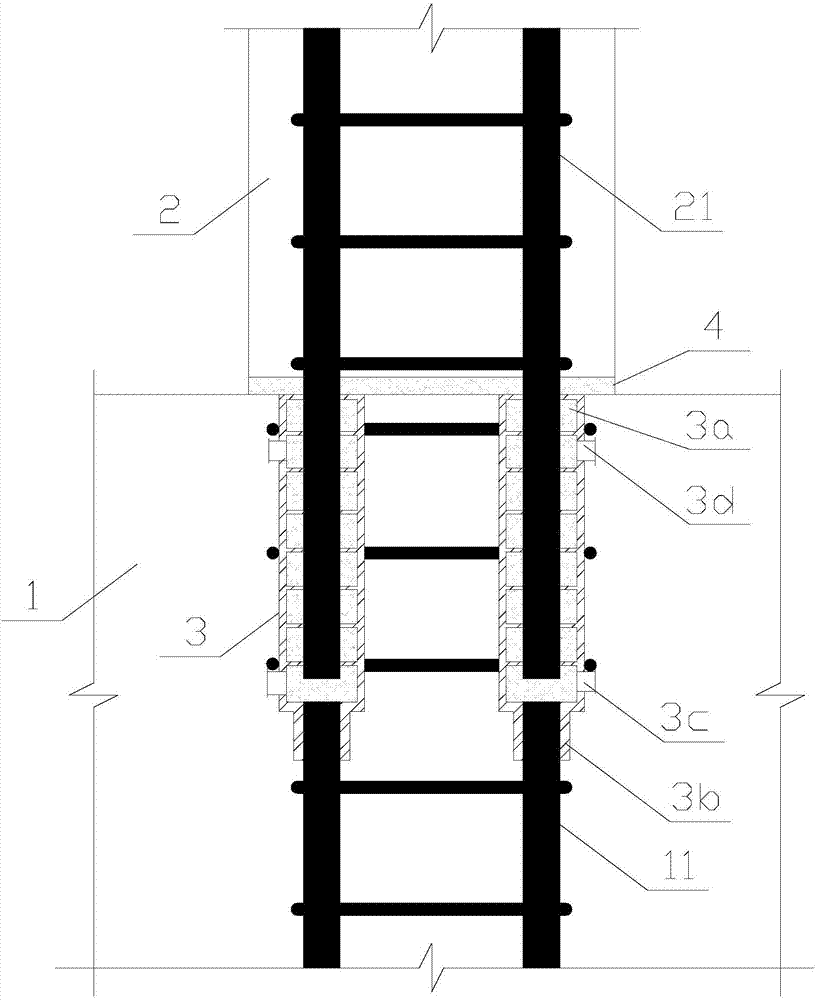

Ductile connection construction and construction method for assembly type vertical component and foundation

PendingCN108005101ADuctile Connection RealizationEfficient deliveryFoundation engineeringRebarPlastic hinge

The invention discloses a ductile connection construction and construction method for an assembly type vertical component and a foundation. A grout sleeve is embedded in concrete of the cast-in-placereinforced concrete foundation, thus ductile connection of connection nodes between the cast-in-place reinforced concrete foundation and the reinforced concrete precast vertical component is achievedon the premise that a connecting rebar of the cast-in-place reinforced concrete foundation can be connected with a longitudinal bar of the reinforced concrete precast vertical component through the grout sleeve, the effect that rebar internal force in the connection node area can be effectively transmitted is ensured so that when a building encounters a rare earthquake, a plastic hinge can be generated in the column bottom area above the connection nodes, the problems that when the grout sleeve is embedded in the column bottom, the bottom of the vertical component is connected with the foundation, thus the plastic hinge is difficult to generate, and consequently when the rare earthquake occurs, brittle failure occurs are avoided, and the effect that damage to the bottom of the vertical component is ductile damage is ensured. The ductile connection construction and the construction method for the assembly type vertical component and the foundation have the advantages that overall stressed performance of a frame structure and ductile anti-seismic performance can be improved.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

Novel fabricated building joint and construction form thereof

PendingCN110130488AFirmly connectedHas self-compacting propertiesBuilding constructionsSafety indexEngineering

The invention discloses a novel fabricated building joint and a construction form thereof. The novel fabricated building joint mainly comprises reinforcement, normal concrete or high-performance concrete or reactive powder concrete (RPC), and is characterized in that a special-shaped normal concrete structure factory is adopted to pre-embed U-shaped or T-shaped reinforcement, and stagger arrangement is carried out; and the reinforcement at the upper part and lower part adopts overlapped part reinforcement lap-jointing, welding, grouting or sleeve connection, and the RPC or normal concrete or high-performance concrete is poured at the post-casting section. The joint is suitable for beam-beam joint, beam-column joint and shear wall joint connection, and is excellent in stress form, the U-shaped reinforcement or T-shaped reinforcement is added, shear resisting performance is high, the interface contact area between old and new concrete is large, connection is reliable, the work efficiencyis improved greatly, and the length of reinforcement anchoring is also decreased, safety is high, adhesion is high, anti-seismic performance is good, and the novel fabricated building joint can be widely applied to prefabricated parts and has the advantages of being efficient in fabricated building and high in safety index.

Owner:XIANGTAN UNIV

Steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete

PendingCN107842107AAvoid brittle failureIncreased shear capacityProtective buildings/sheltersShock proofingReinforced concrete columnMetallurgy

The invention discloses a steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete. The steel reinforced concrete column-steel beam joint comprises core profile steel, the fiber reinforced concrete, a first steel beam, a second steel beam, a third steel beam and a fourth steel beam; the core profile steel comprises a first profile steel web and a second profilesteel web which are welded to form cross-shaped profile steel, the two ends of the first profile steel web are correspondingly provided with a first profile steel flange and a second profile steel flange, and the two ends of the second profile steel web are correspondingly provided with a third profile steel flange and a fourth profile steel flange; and the first profile steel flange, the second profile steel flange, the third profile steel flange and the fourth profile steel flange are correspondingly connected with the first steel beam, the second steel beam, the third steel beam and the fourth steel beam. The steel reinforced concrete column-steel beam joint locally adopting the fiber reinforced concrete has the characteristics that the fiber reinforced concrete is adopted at a joint core zone, the using amount of stirrups in the core zone can be reduced or even eliminated, the shear resistance capacity of the joint, the rotating capability of the joint and the energy dissipation capability can be remarkably improved, and meanwhile, construction complexity is reduced.

Owner:CHANGAN UNIV

Annular steel-steel support connecting joint structure for steel structure and externally-hung wall plate

PendingCN112663797AAvoid wet work such as grouting on siteReduce labor costsProtective buildings/sheltersShock proofingUpper jointRebar

The invention discloses an annular steel-steel support connecting joint structure for a steel structure and an externally-hung wall plate. The annular steel-steel support connecting joint structure comprises a lower-layer externally-hung wall plate and an upper-layer externally-hung wall plate, the lower-layer externally-hung wall plate is connected with the upper-layer externally-hung wall plate through a frame beam, and the frame beam is provided with an upper joint connecting device and a lower joint connecting device; the upper joint connecting device comprises an upper joint annular steel plate, a connecting steel plate and an embedded part; at least more than one energy dissipation steel sheet is arranged on the upper joint annular steel plate; the connecting steel plate is located on the inner surface of the upper joint annular steel plate and makes contact with a lower flange of the frame beam; the embedded part is located in the lower layer externally-hung wall plate and connected with the upper joint annular steel plate; and the embedded part comprises a bolt sleeve, an anchoring steel bar and an embedded part steel plate, the lower joint connecting device comprises a steel support, a first long hole is formed in the position, connected with the steel support, of the frame beam, and the steel support is connected with the frame beam in a fastened mode through a first bolt.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com