Plate type air preheater with glass as heat exchange plate

A technology of air preheater and heat exchange plate, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of low exhaust gas temperature, high price, energy waste, etc., and achieve exhaust The effect of lowering the temperature of smoke, preventing brittle glass damage, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] Embodiment 2: Its main structure is the same as that of Embodiment 1. In this embodiment, the sealing gasket 4 placed between the adjacent upper and lower glass heat exchange plates 1 is a silicone rubber gasket.

Embodiment 3

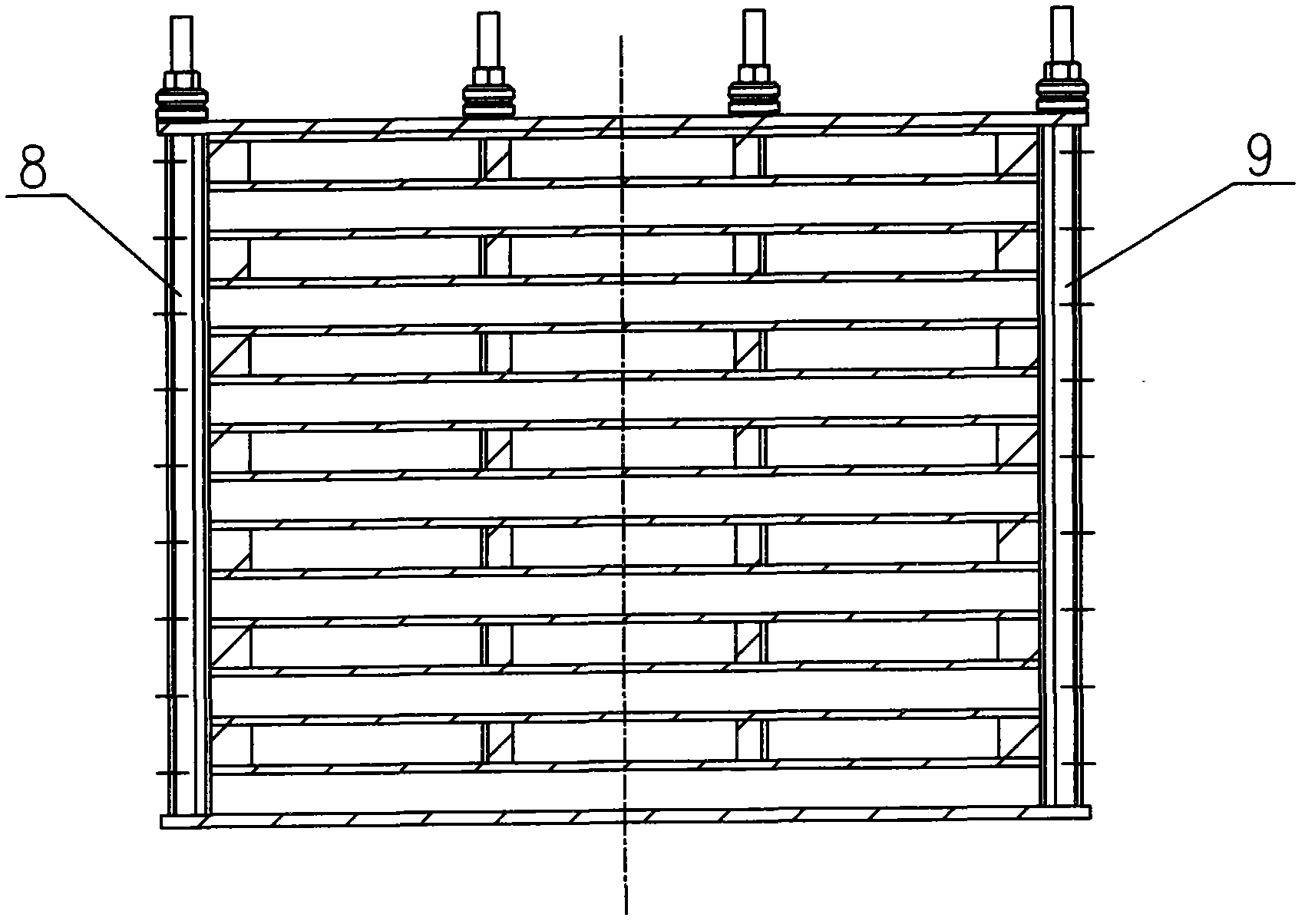

[0029] Embodiment 3: Its main structure is the same as that of Embodiment 1. In this embodiment, the glass heat exchange plate 1 is a glass plate processed with corrugations, so as to achieve the purpose of improving heat transfer efficiency. Several S-shaped support bars are arranged between the heat exchange plates, so as to achieve the purpose of improving heat transfer efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com