Patents

Literature

44results about How to "Achieving long-term operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

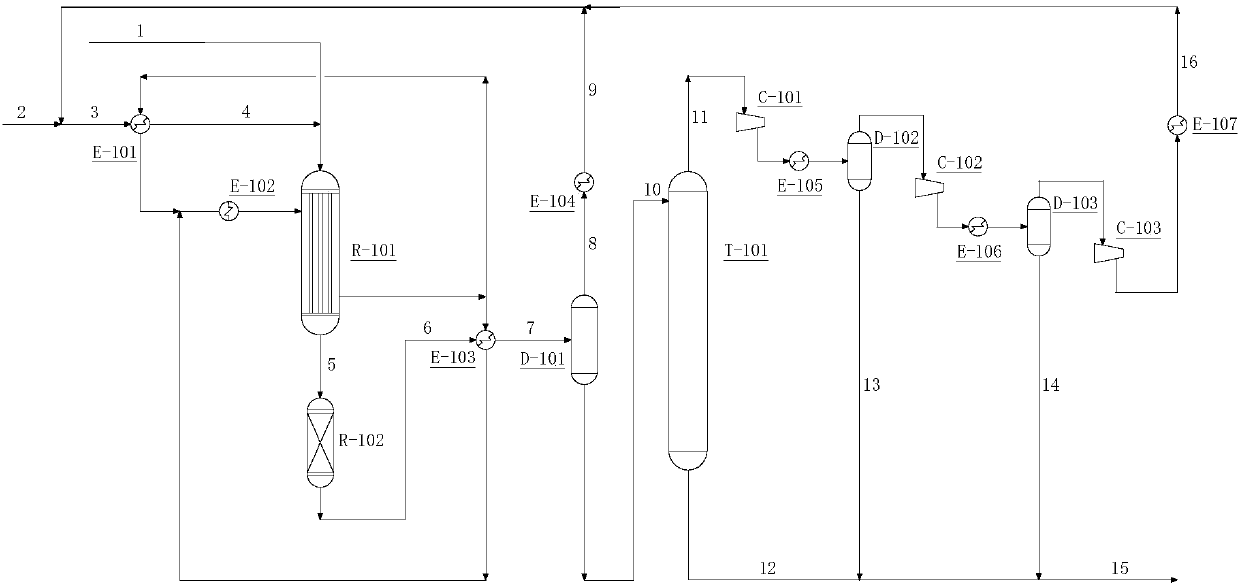

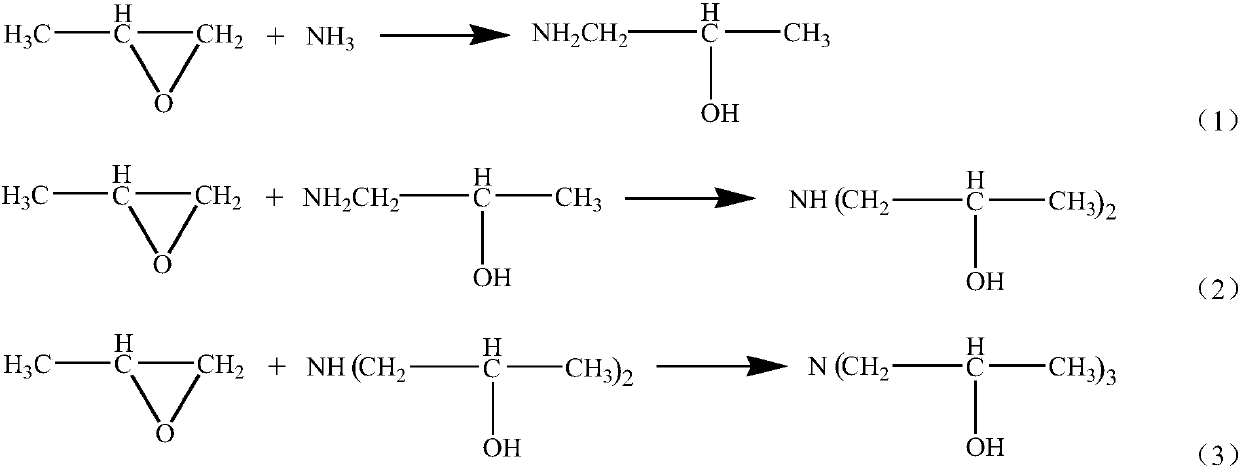

Method for producing isopropanolamine by liquid ammonia process

ActiveCN109748805AGuaranteed conversionReduce volumeOrganic compound preparationAmino-hyroxy compound preparationHigh energyTower

The invention relates to a method for producing isopropanolamine by a liquid ammonia process, mainly solving the problems such as high device investment, high energy consumption in dehydration and many by-products due to the fact that water is used as a catalyst in the prior art. The method has the advantages that anhydrous liquid ammonia and propylene oxide are used as raw materials for reaction,a tubular fixed bed reactor and an adiabatic fixed bed reactor are provided to ensure complete conversion of the propylene oxide, and the tubular fixed bed reactor removes heat of the hot water preheated reaction raw materials and reaction products under reduced pressure through heat removal of circulating hot water, so that most of reaction heat can be recycled; most of ammonia of the reaction products is recycled through a flash tank, and residual ammonia is recycled by an ammonia stripping tower with an compressor at the top; few by-products are generated, equipment investment and device energy consumption can be reduced, and the method can be applied to industrial production of the isopropanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

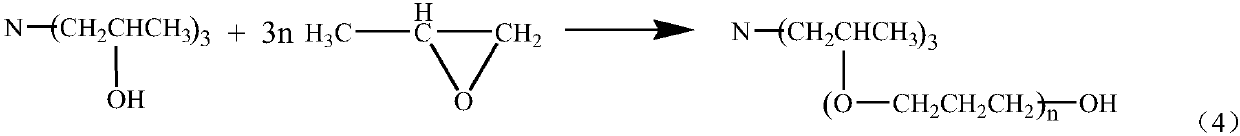

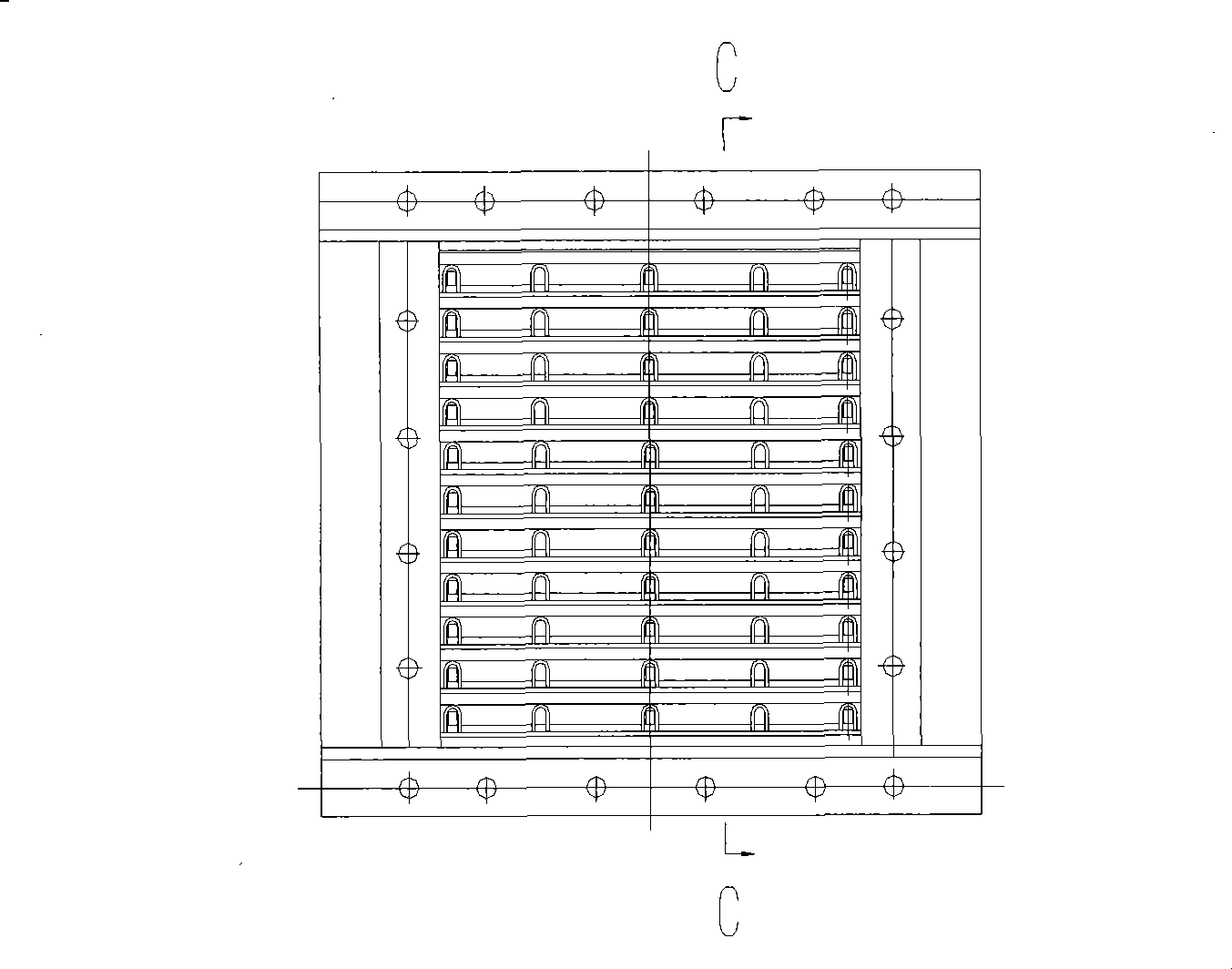

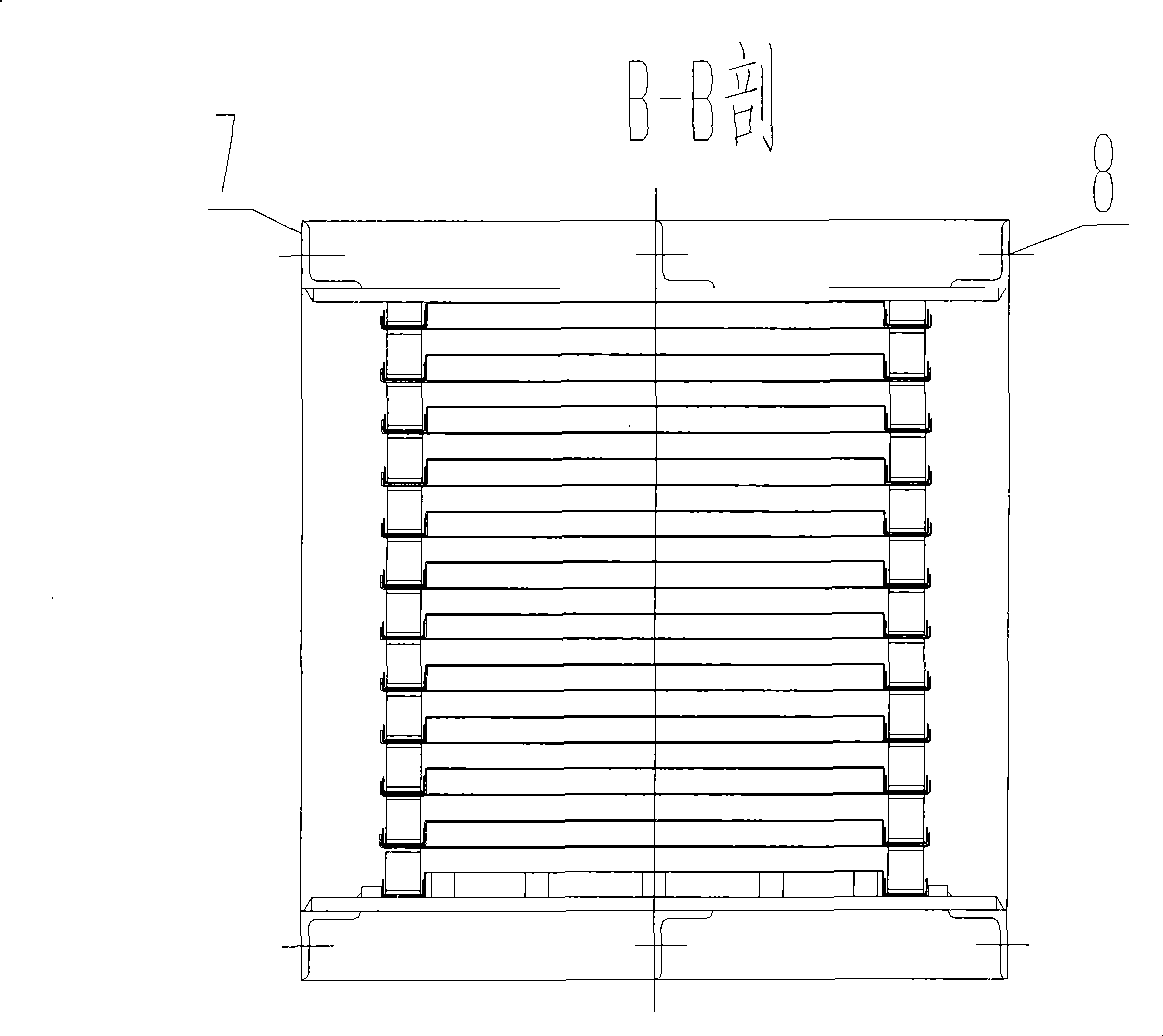

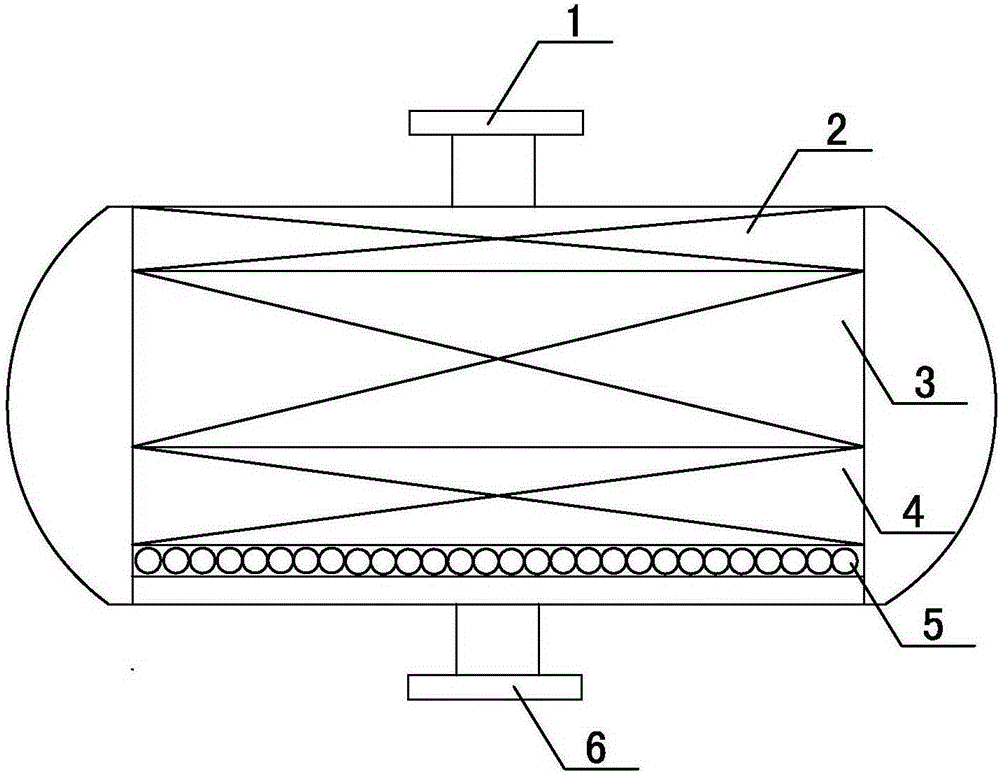

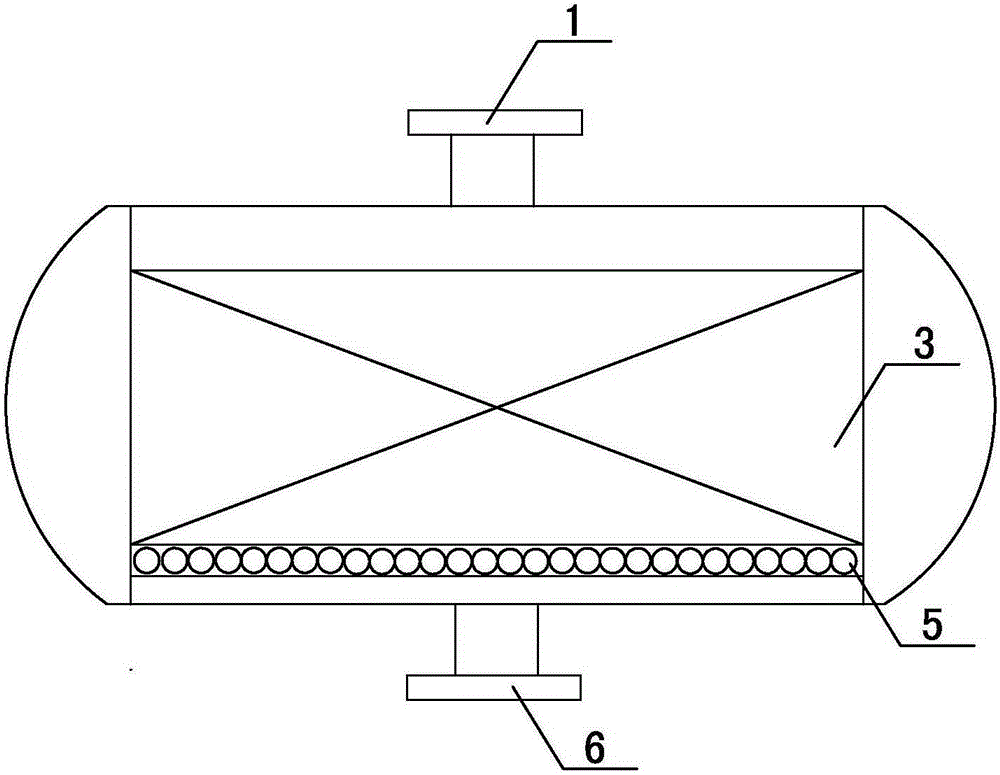

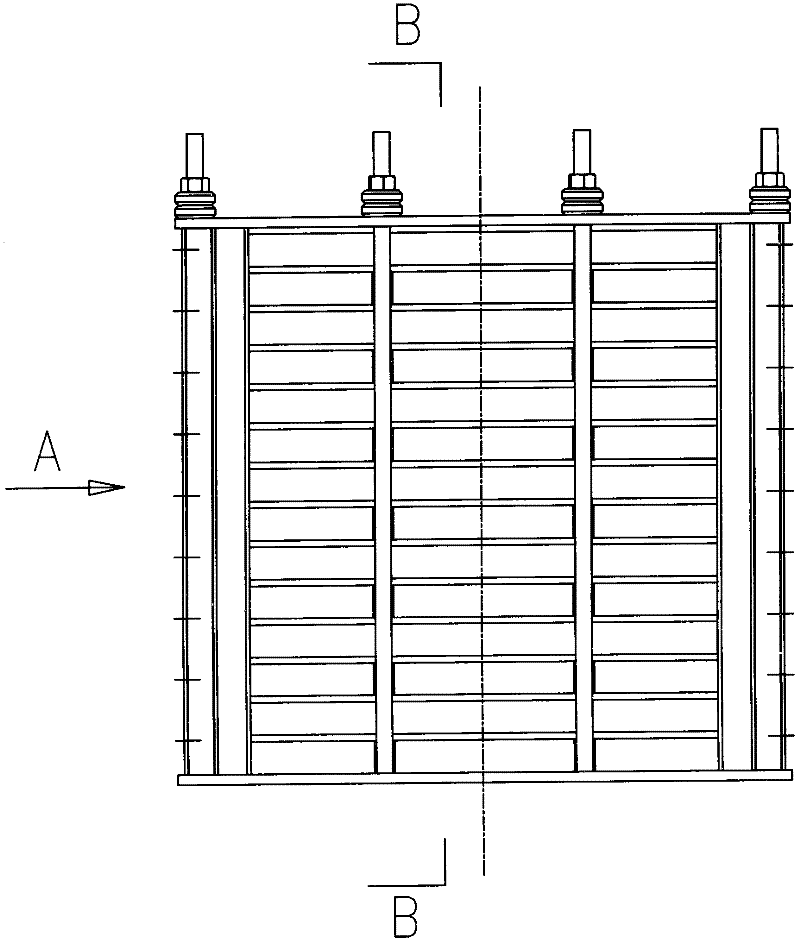

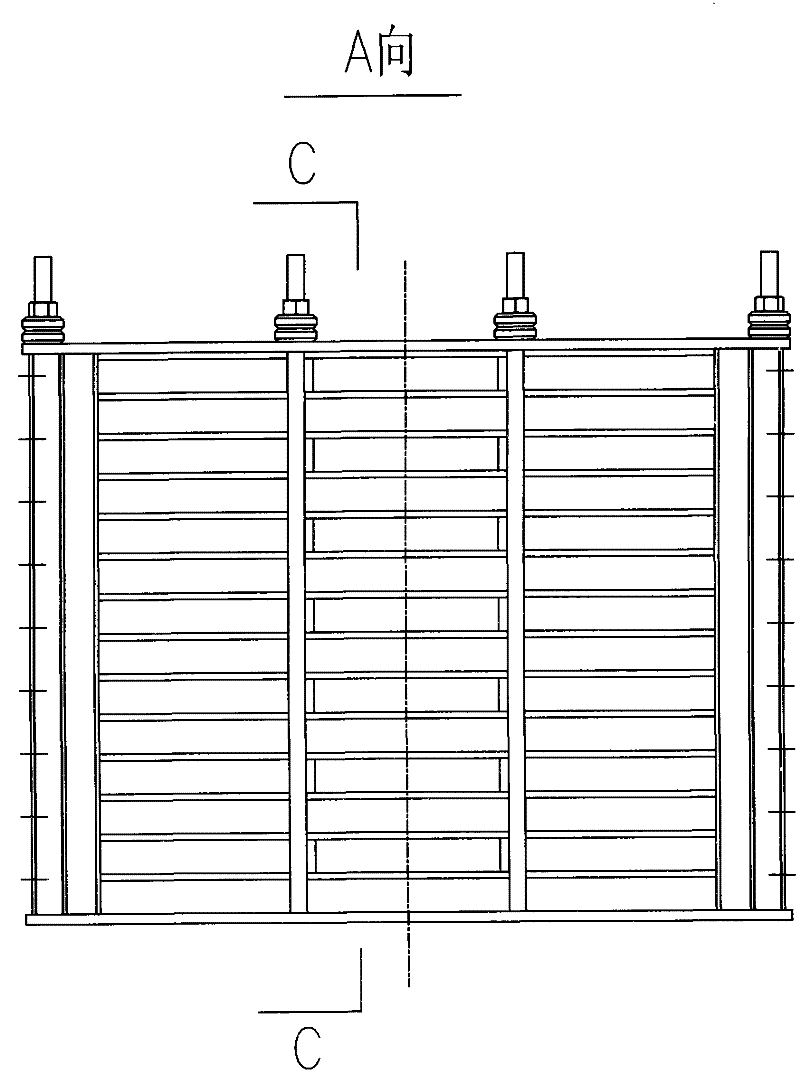

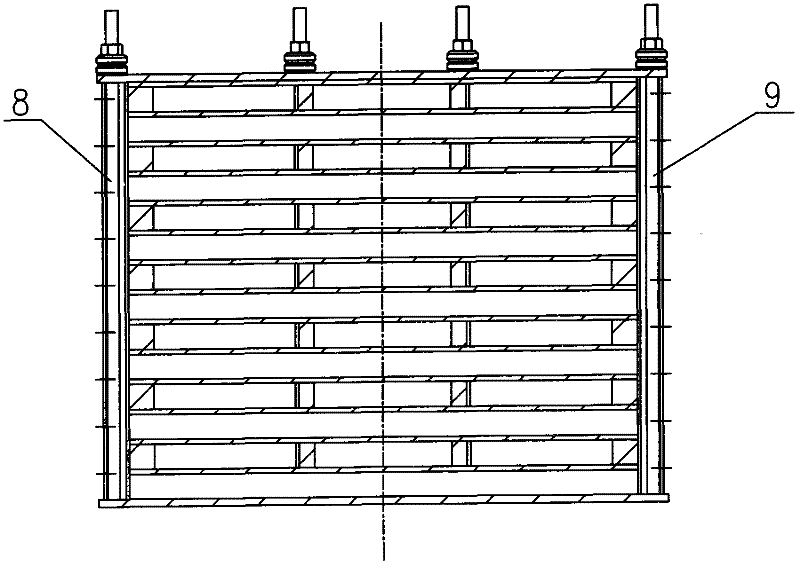

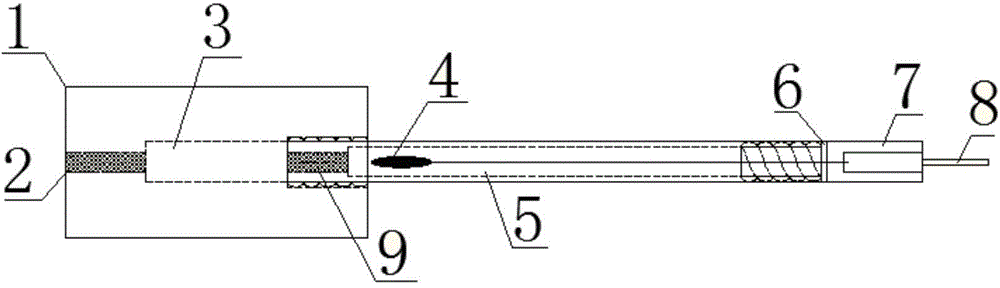

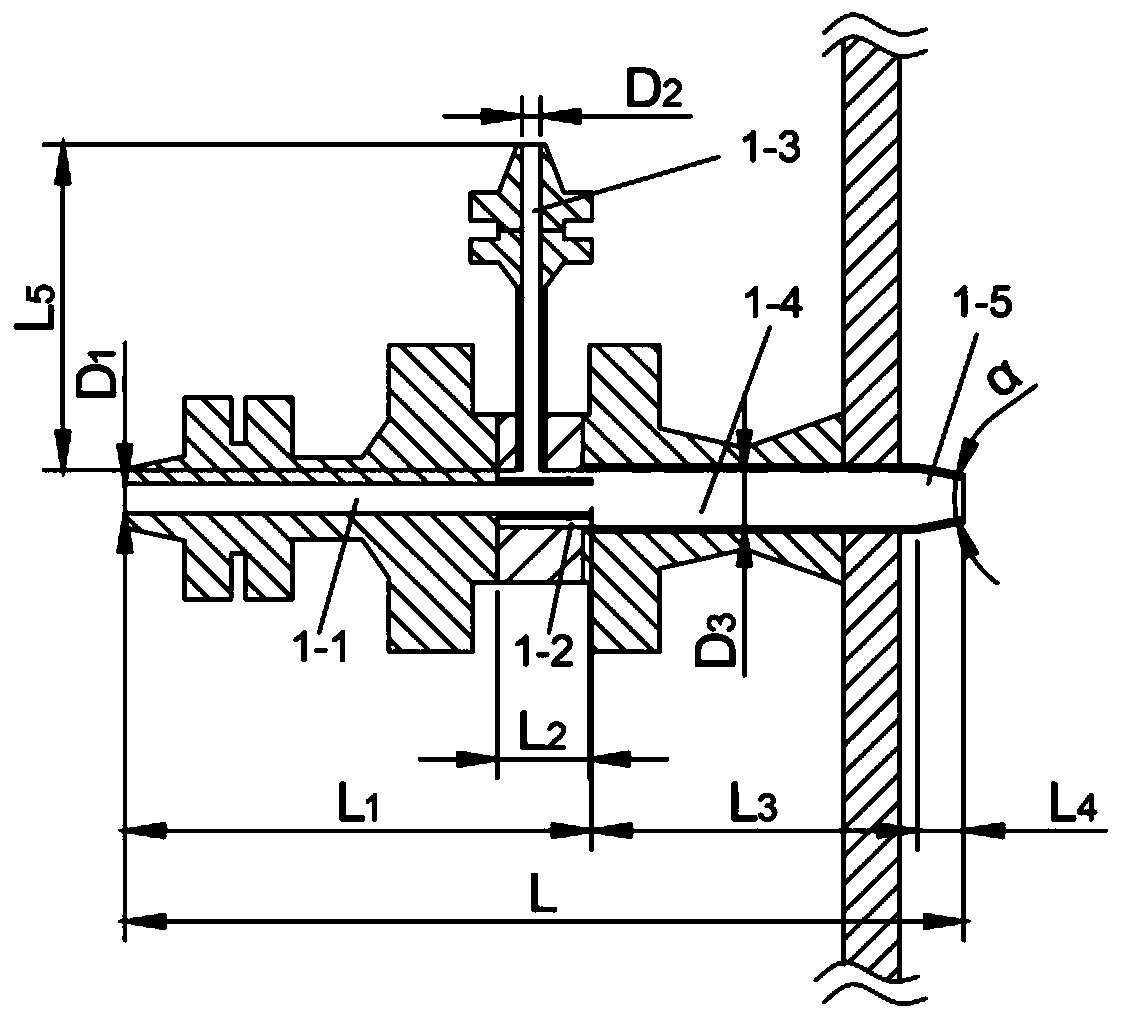

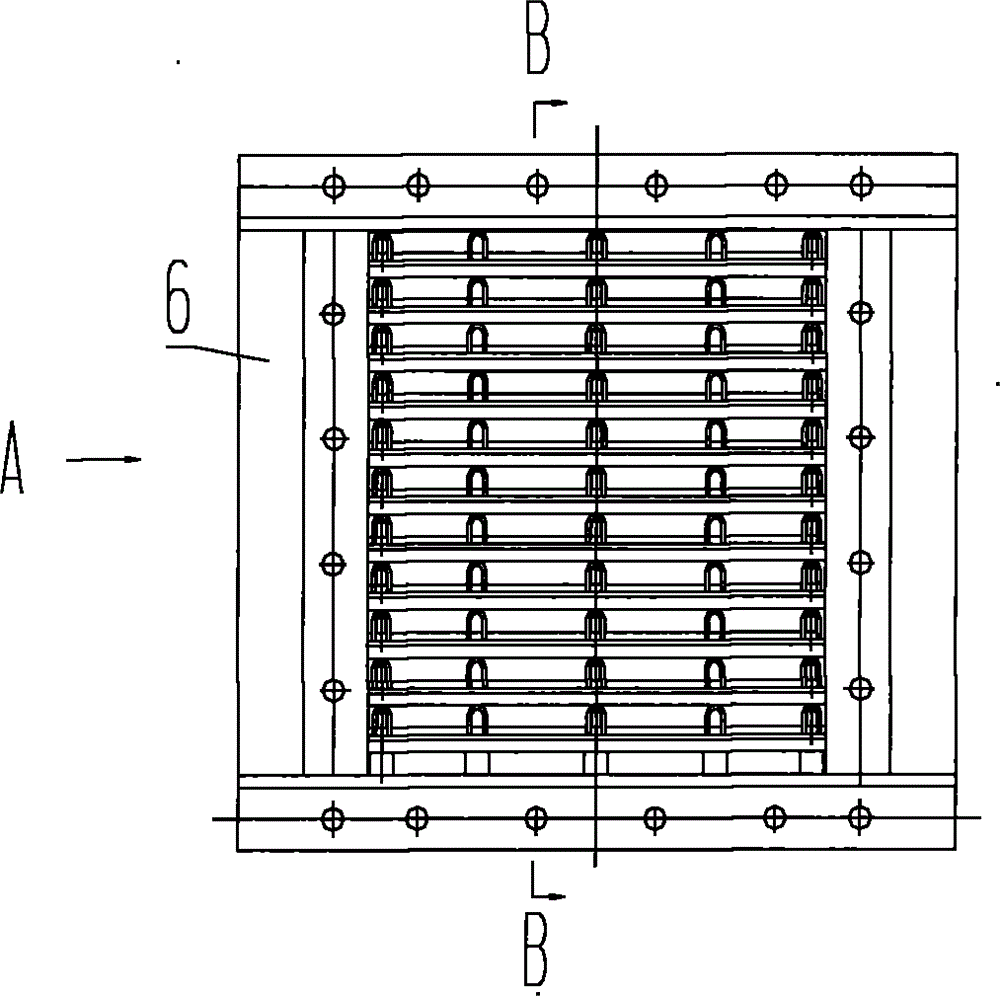

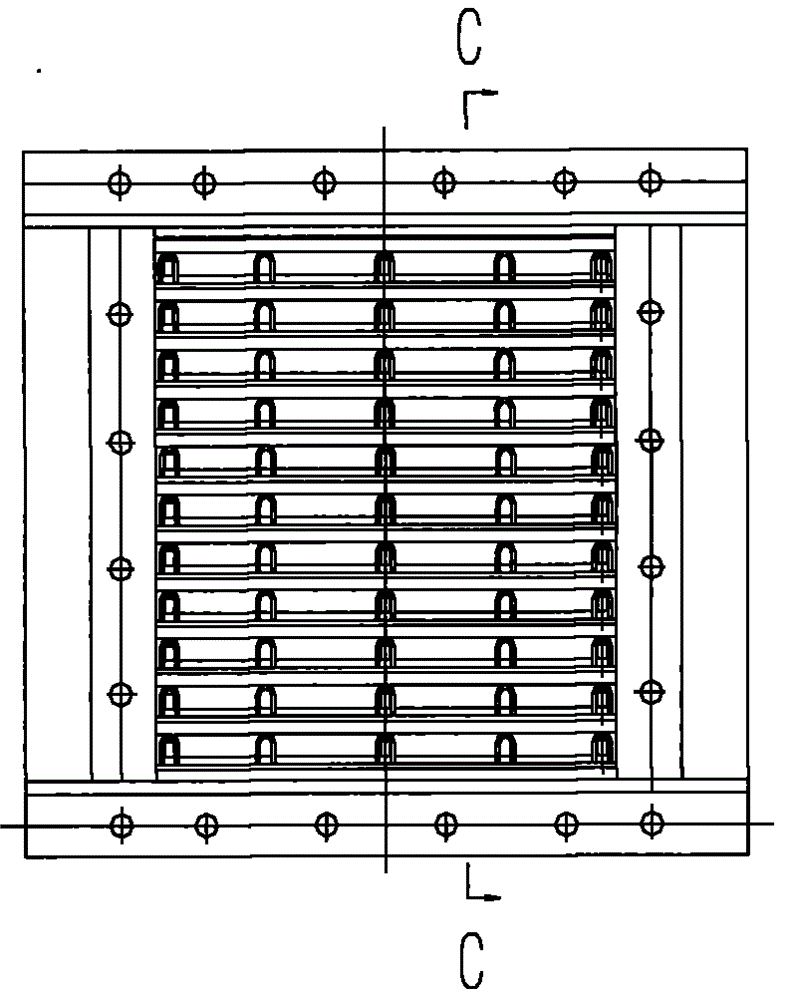

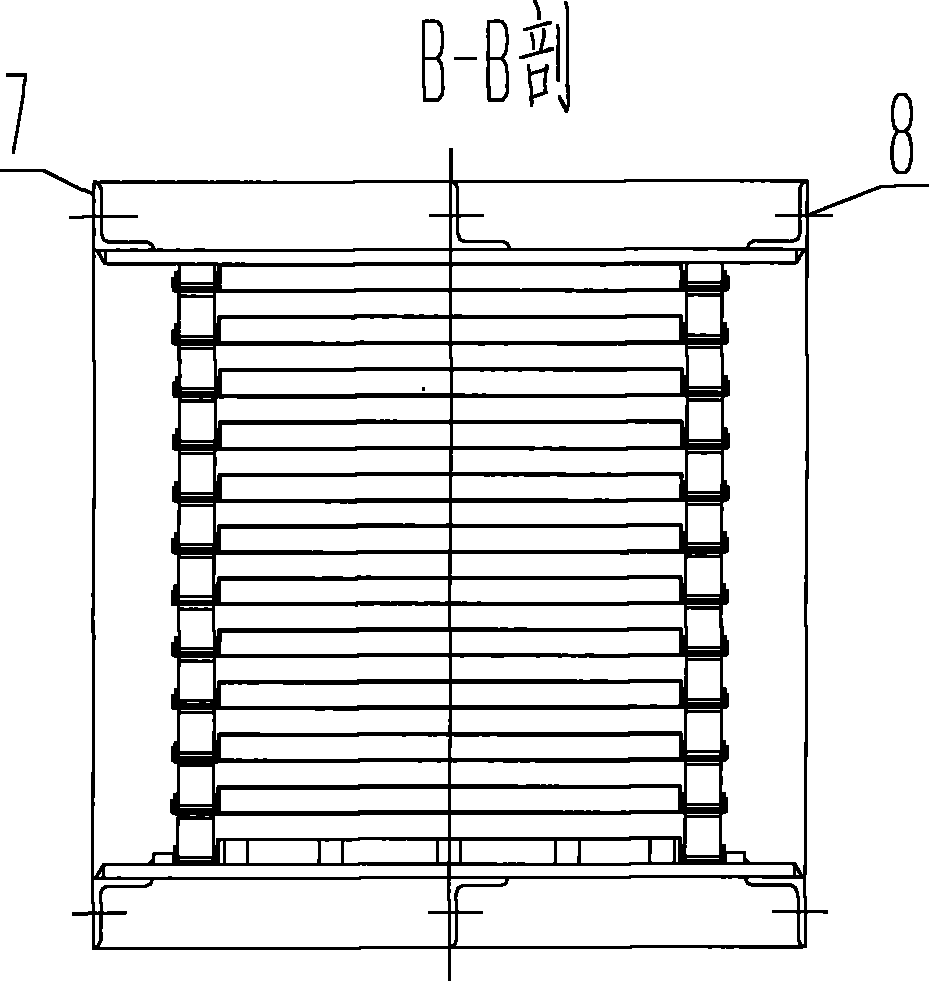

Non-welded plate type heat exchanger

ActiveCN101464105AEasy to manufactureLow costStationary plate conduit assembliesEngineeringHeat exchanger

The invention relates to the technology of heat exchangers, particularly a weldless plate-type heat exchanger. A plurality of fluid passages are formed by a plurality of heat exchange plates 1 which are vertically placed in a rectangularly (90 DEG) staggered manner, wherein, the openings of adjacent fluid passages among the fluid passages are mutually staggered at an angle of 90 DEG to form hot fluid passages and cold fluid passages; upward right-angled fold edges are formed on the two symmetric sides of each heat exchange plate 1, and right-angled double-fold edges are formed on the other two corresponding sides so as to form L-shaped fold edges; each two vertically adjacent heat exchange plates are placed in a rectangularly (90 DEG) staggered manner, that is, the downward L-shaped fold edge of an upper heat exchange plate is correspondingly placed between the upward right-angled fold edges of a lower heat exchanges plate, and the upward rectangular (90 DEG) fold edge of the lower heat exchange plate serves the function of limiting to the L-shaped fold edge of the upper heat exchange plate; a sealing gasket 5 is arranged between the lower heat exchange plate and the upper exchange plate; a flexible sealing layering 3 is arranged between each two adjacent heat exchange plates; and a support strip 2 is arranged between the passage formed by the upper heat exchange plate and thelower heat exchange plate.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

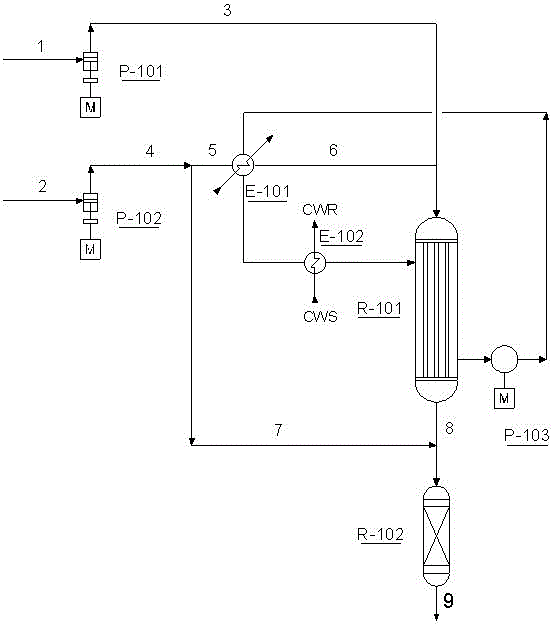

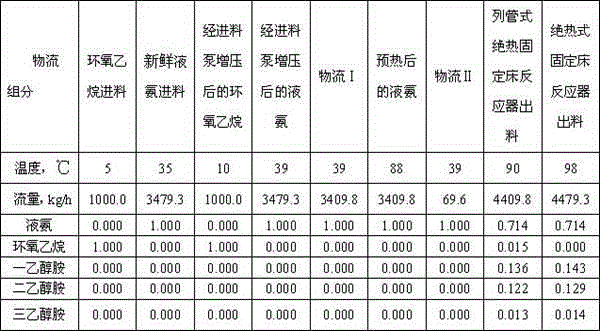

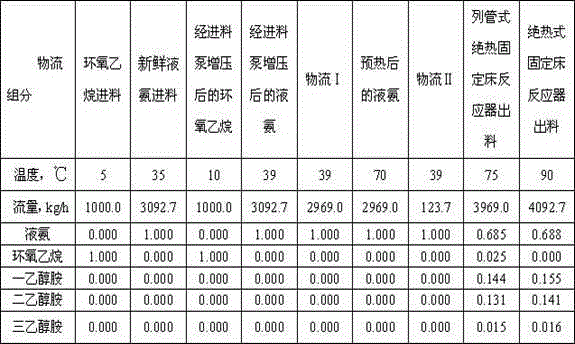

Method of producing ethanolamine from liquid ammonia

ActiveCN104557571AGuaranteed conversionReduce volumeOrganic compound preparationAmino-hyroxy compound preparationMolecular sieveState of art

The invention relates to a method of producing ethanolamine from liquid ammonia and mainly aims to solve the technical problems of a large amount of byproducts, low security, high investment in equipment and high energy consumption in the prior art. According to the technical scheme, ethylene oxide and fresh liquid ammonia are respectively added into a tubular fixed-bed reactor by a feeding pump, the product of reaction is added into an adiabatic fixed-bed reactor, and the tubular fixed-bed reactor and the adiabatic fixed-bed reactor are both filled with a binder-free ZSM-5 zeolite molecular sieve catalyst so as to catalyze ammoniation to generate ammonia-containing ethanolamine. By adopting the technical scheme, the problems can be well solved. The method provided by the invention can be applied to the industrial production of ethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

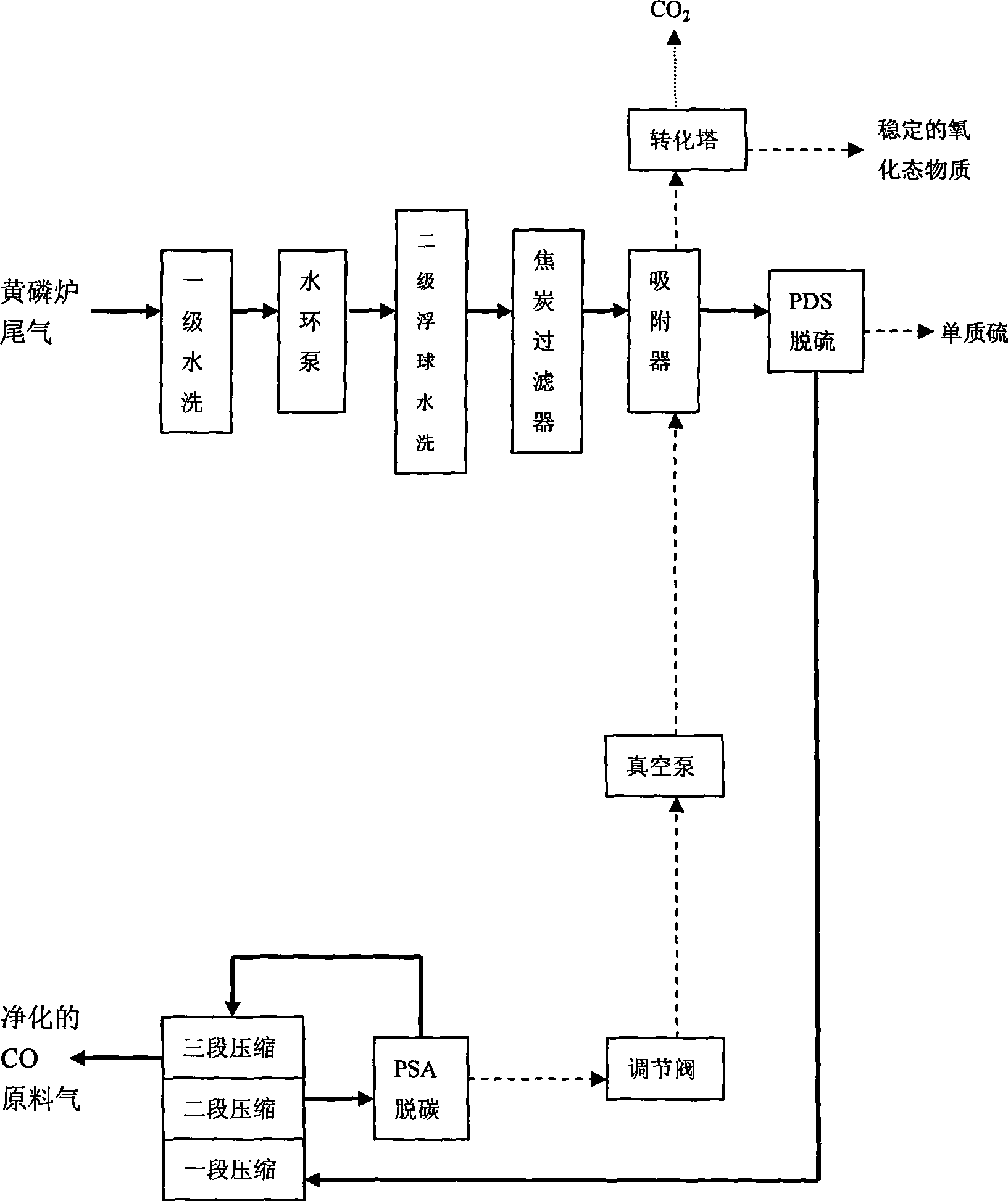

Method for preparing high-purity sodium formate with tail gas of yellow phosphorus stove

InactiveCN101367718AOvercoming poor exhaust gas purificationHigh purityCarboxylic acid salt preparationExhaust gasDecarburization

The invention discloses a method for preparing high purity sodium formate with the tail gas of a yellow phosphorus furnace; the tail gas of the yellow phosphorus furnace is firstly purified, and then reacts with alkali liquor to synthesize sodium formate. The invention is characterized in that the wet PDS is adopted for desulphurization; the desulphurized tail gas enters into a decarburization device, and PSA variable pressure is used for adsorption and decarburization; the purified tail gas reacts with alkali liquor under the conditions of 2.3-2.5 Mpa and 230 DEG C to synthesize sodium formate. The process can be described as follows: firstly the tail gas of the yellow phosphorus furnace is washed with first class water, pumped out by a water ring pump, and delivered to a second class water washing tower and a floating ball type water washing tower, and then delivered to a coke filter to filter the solid impurities and enters into a adsorber and a desulphurization tower; the desulphurized gas is delivered to the first part and the second part of a compressor, and then delivered to the decarburization device after being pressurized; the decarburized gas is delivered to the third part of the compressor, and pressurized to obtain purified feed gas which can react with the alkali liquor in a synthesizer to synthesize the sodium formate. The invention can realizes that the device for preparing high purity sodium formate with the tail gas of a yellow phosphorus furnace can run in large-scale, cleaning and long period, and is suitable to be used for the enterprises preparing high purity sodium formate with the tail gas of the yellow phosphorus furnace.

Owner:贵州青利集团有限公司

Preparation method of low carbon olefin

ActiveCN109651041AHigh operating temperatureEmission reductionBulk chemical productionHydrocarbon by hydrocarbon crackingPetrochemicalFuel oil

The invention relates to the field of petrochemical production and discloses a preparation method of low carbon olefin. The method comprises the following steps of: (1) heavy oil is contacted with andseparated from supercritical carbon dioxide to obtain a light fluid phase containing light oil and carbon dioxide, and a heavy fluid phase containing heavy oil; (2) the light fluid phase containing the light oil and carbon dioxide undergoes component separation to obtain light oil and carbon dioxide; and (3) the light oil is subjected to steam thermal cracking to obtain low carbon olefin. Throughthe above method, the heavy oil can be fully utilized, the problem of the shortage of the petrochemical raw material can be alleviated, and a cracking device can be operated for a long time. Moreover, in the preparation method of the invention, carbon dioxide is used, which not only avoids the greenhouse effect caused by the emission of carbon dioxide into the atmosphere but also recycles the carbon dioxide to achieve the effect of synergistic emission reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

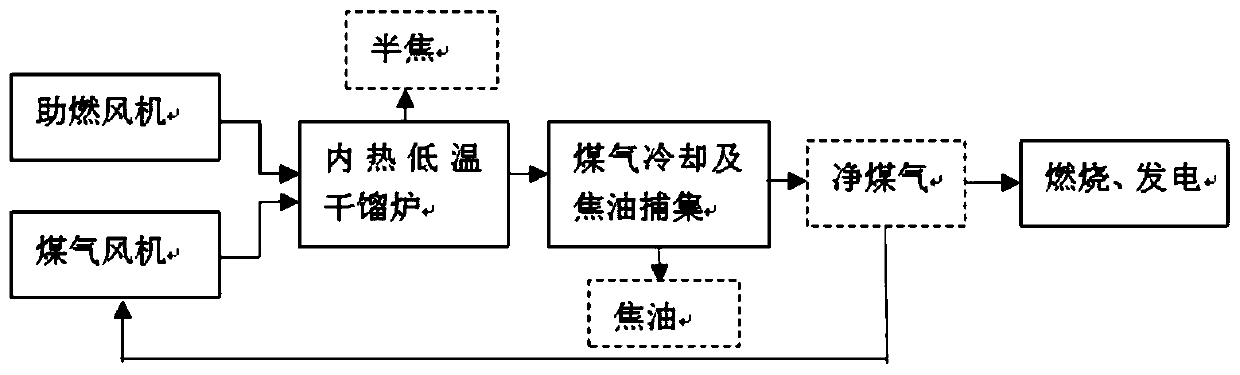

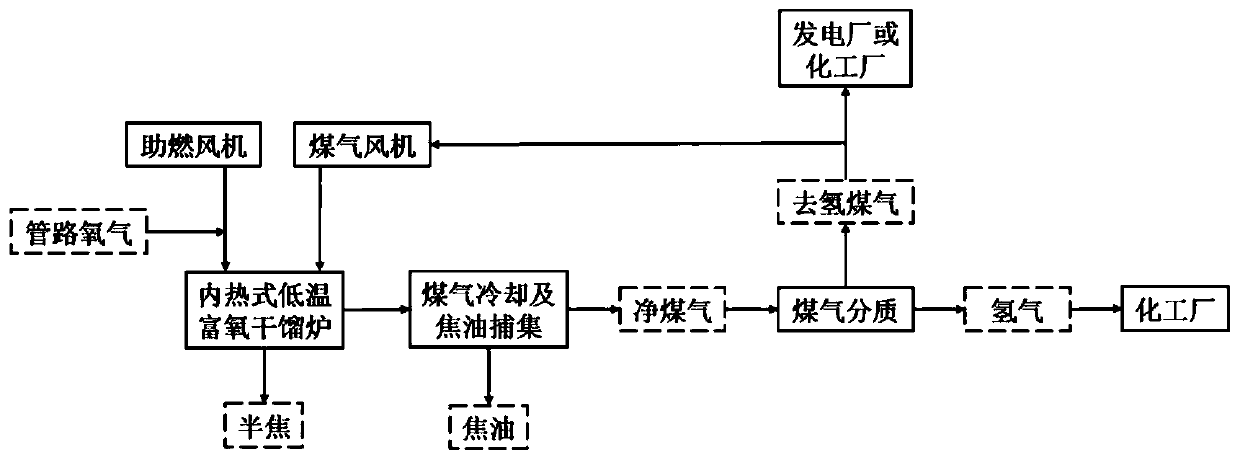

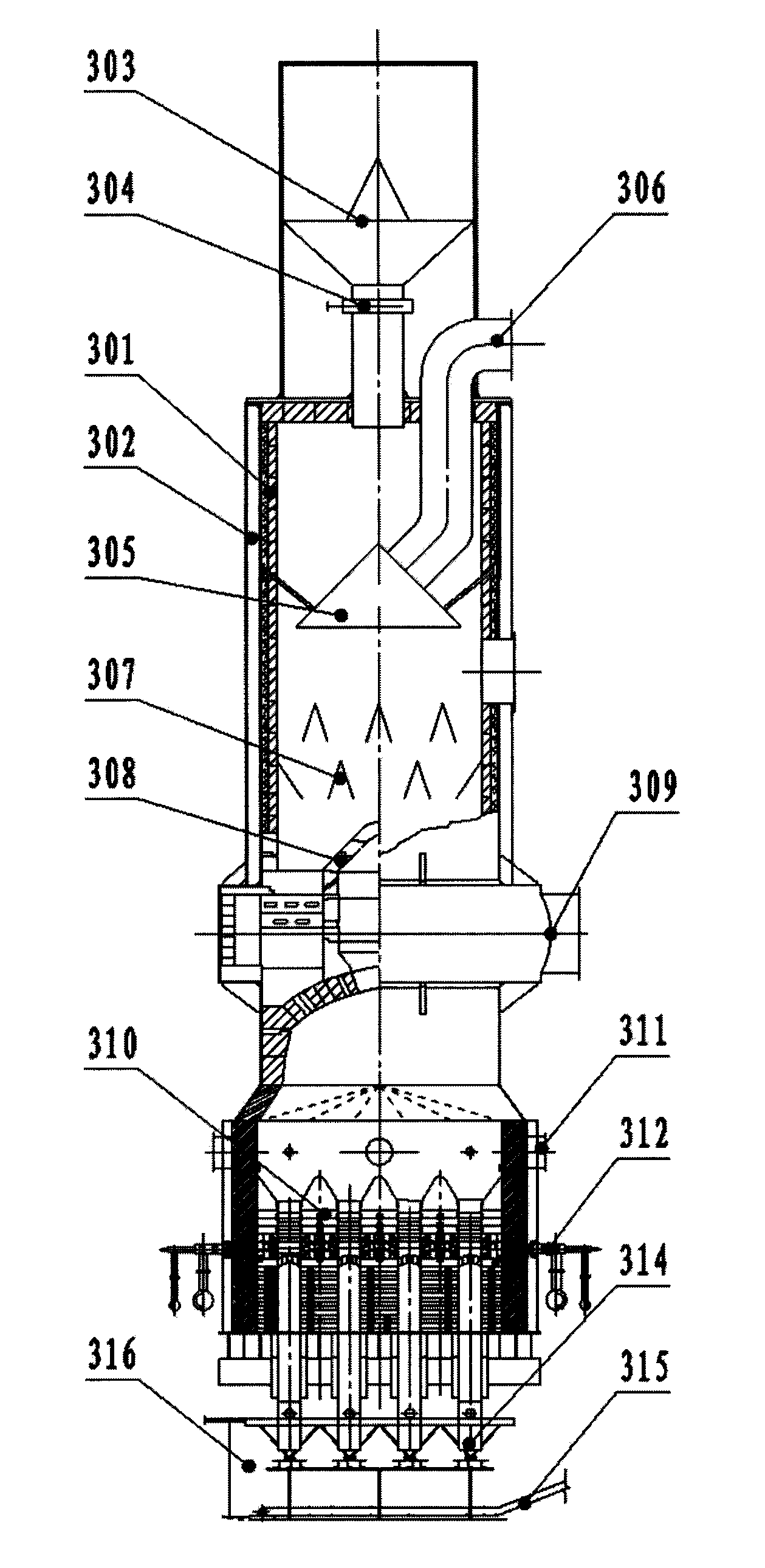

Internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas

ActiveCN111187632AAchieving long-term operationQuality improvementSpecial form destructive distillationThermodynamicsProcess engineering

The invention discloses an internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas. The process comprises the following steps: introducing dehydrogenated coal gas, air and oxygen into an internal heating type low-temperature destructive coal distillation furnace; mixing the air and the oxygen to form oxygen-enriched combustion-supporting gas; and subjecting the dehydrogenized coal gas and the oxygen-enriched combustion-supporting gas to oxygen-enriched combustion in the internal heating type low-temperature destructive coal distillation furnace, wherein the volume fraction of oxygen in the oxygen-enriched combustion-supporting gas is greater than or equal to 30%. A step of acquiring the dehydrogenated coalgas comprises the following sub-steps: carrying out coal gas cooling and tar trapping on coal gas generated by the internal heating type low-temperature destructive coal distillation furnace to obtain purified coal gas; separating and removing hydrogen in the purified gas so as to obtain the dehydrogenated gas. According to the invention, the flame length and the flame temperature of a flame pathcan better meet the requirements of a low-temperature destructive distillation process, the influence of too high combustion speed of oxygen-enriched destructive distillation high-hydrogen-content coal gas is reduced, the long-period operation of an oxygen-enriched destructive distillation process device and the stable quality of dry distillation products are realized, and the high-added-value gradient utilization of the coal gas can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

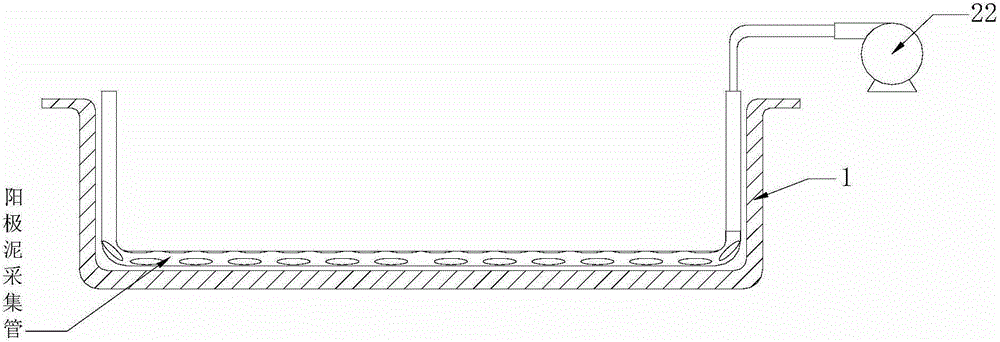

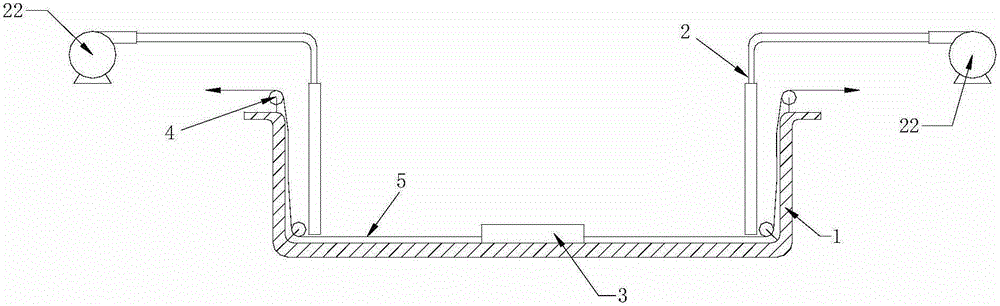

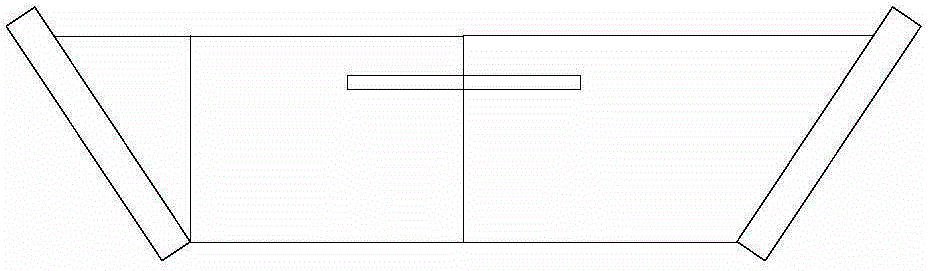

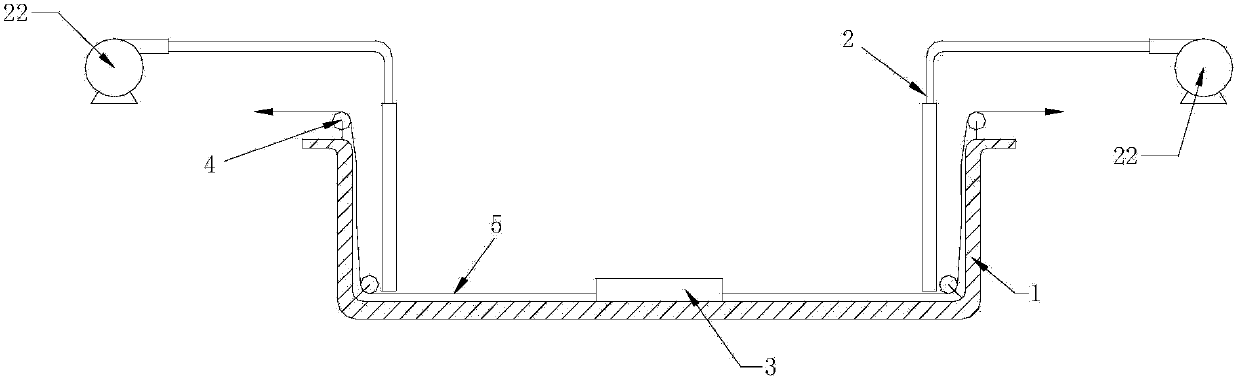

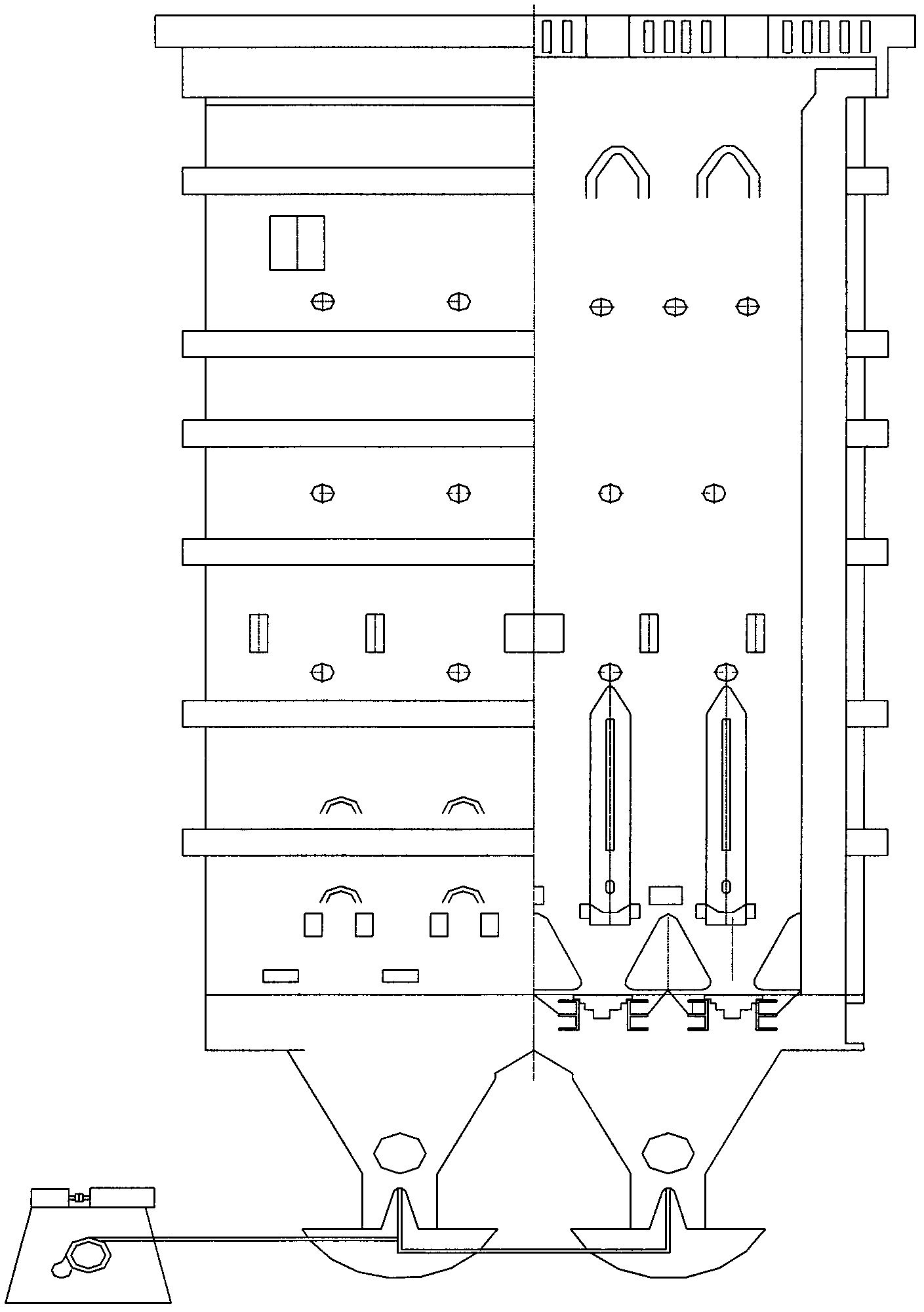

A device for collecting anode slime at the bottom of an electrolytic tank in a zinc electrolytic refining process

ActiveCN103469250BRealize online suctionIncreased suction rateElectrolysis componentsPhotography auxillary processesOperational stabilityVacuum pump

The invention relates to a device for collecting anode slime from the bottom of an electrolytic cell in a zinc electrolytic refining process. The device mainly comprises an electrolytic cell body and two vacuum sucking devices, wherein the bottom of the electrolytic cell is trapezoidal, an anode slime gathering device is arranged at the bottom of the electrolytic cell body, and two ends of the electrolytic cell body are provided with transmission mechanisms; the anode slime gathering device is connected to the transmission mechanisms through a corrosion-resistant drag rope; the vacuum sucking devices are arranged at two sides of the electrolytic cell body; vacuum sucking pipes in the vacuum sucking devices are inserted into the bottom end of the electrolytic cell body, and the vacuum sucking pipes suck the anode slime through a vacuum pump. The device has the following beneficial effects that the device is easy to operate and is liable to the realization of industrialized application, the stability in operation is good, not only is the on-line sucking of the anode slime realized, but also the sucking rate of the anode slime is greatly improved, and furthermore, the anode slime is prevented from accumulating.

Owner:HANGZHOU SANAL ENVIRONMENTAL TECH

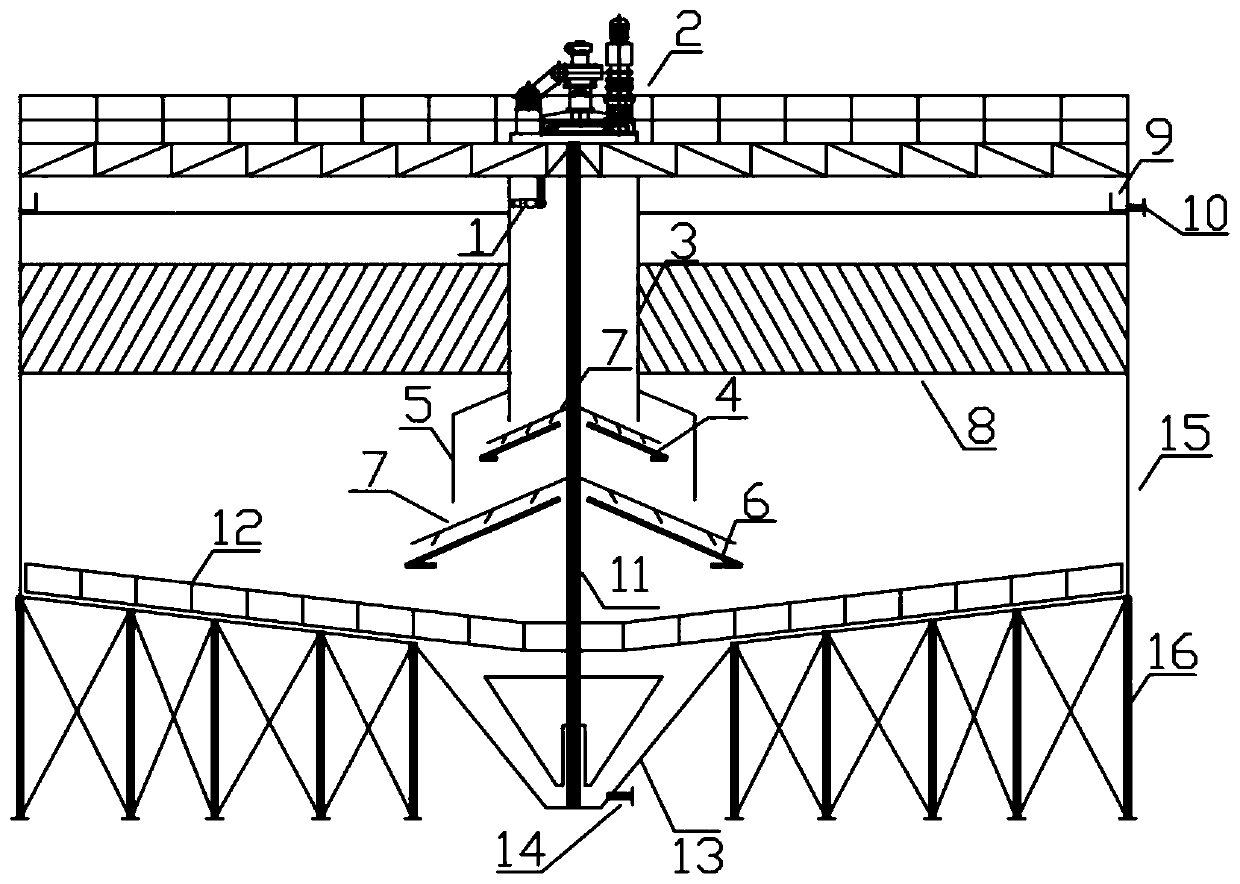

High-efficiency solid-liquid clarification and separation device

PendingCN111450581AReduce processing sizeReduce effluxSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationSludgeEngineering

The invention discloses a high-efficiency solid-liquid clarification and separation device. The device comprises a bottom bracket, a cylinder body, a flow guide device, an inclined plate, a mud scraping mechanism and a speed reducer, wherein the cylinder body is mounted on the bottom bracket, the speed reducer is arranged on the cylinder body, the flow guide device comprises a flow guide barrel and a reflecting plate, the reflecting plate is arranged below the flow guide barrel, the top of a first-stage flow guide barrel is communicated with a sewage / grey water inlet, the top of a second-stageflow guide barrel is connected to the outer side of a lower end opening of a first-stage flow guide barrel, and auxiliary scraping arms are arranged on the upper surface of a first-stage reflecting plate and the upper surface of a second-stage reflecting plate respectively, a slag / sludge concentration hopper is arranged at the bottom of the cylinder body, a scraping arm is arranged on a bottom plate of the cylinder body, and the scraping arm and auxiliary scraping arms jointly form the sludge scraping mechanism. According to the invention, the specific surface area is increased, the treatmentload is increased, the diffusion flow is enhanced by the flow guide reflection device, the water distribution is more uniform, the flow velocity is more stable, the liquid medicine is more fully mixed, and the clarification and separation efficiency is greatly improved.

Owner:宜兴市荣盛达环保有限公司

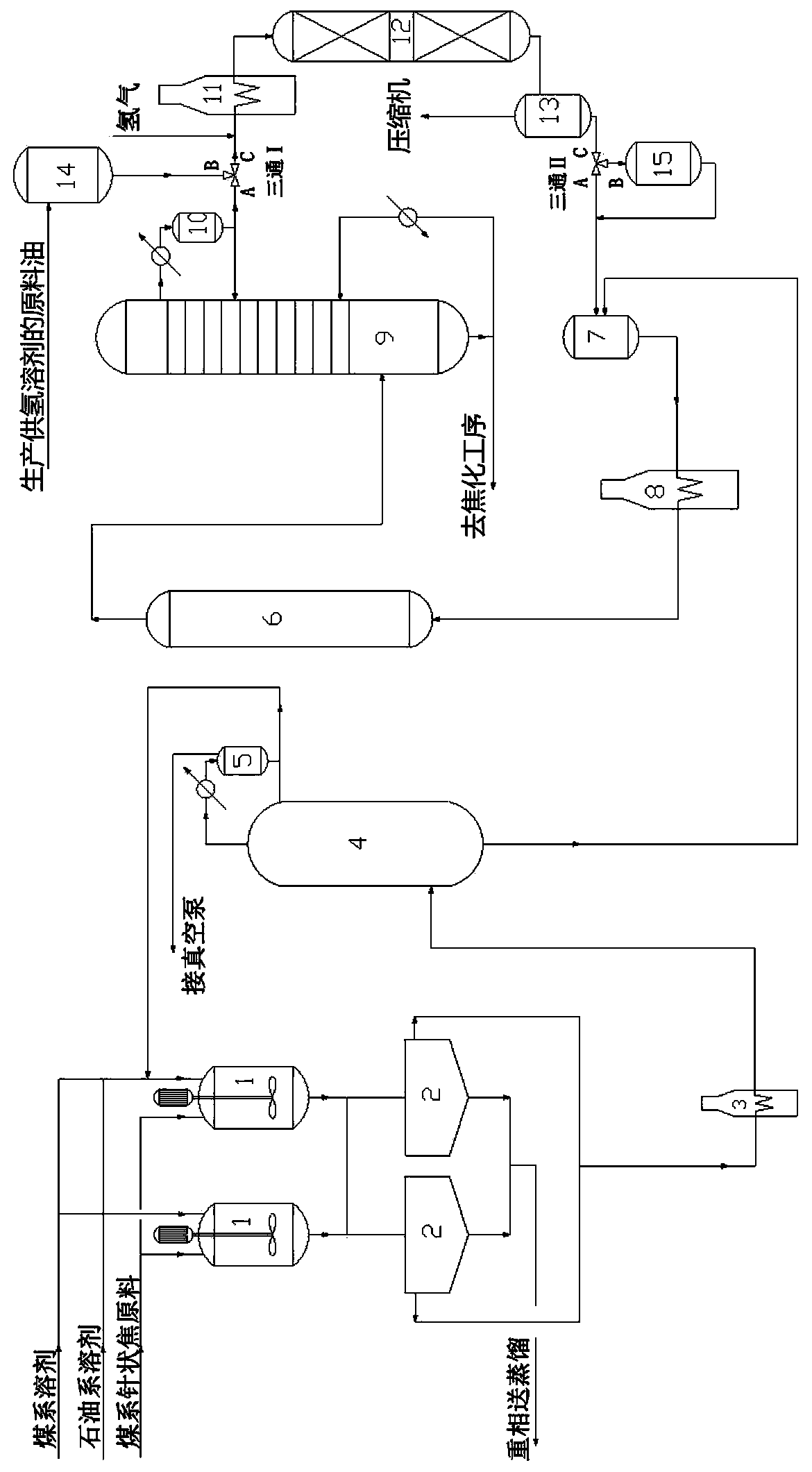

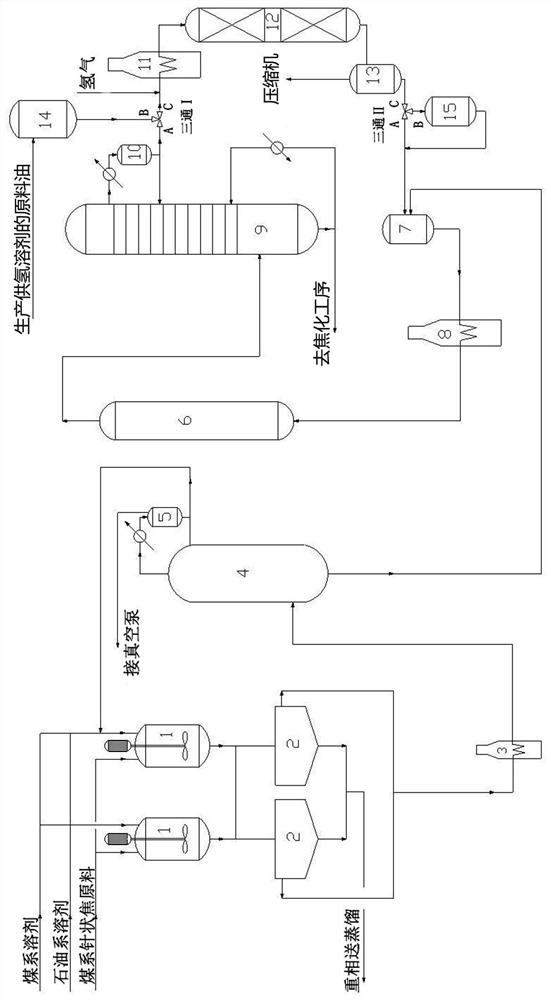

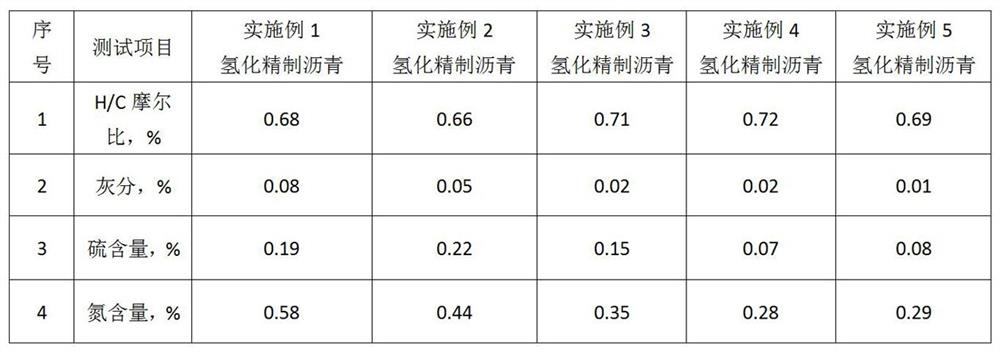

Coal based needle coke material pretreatment process

The invention belongs to the technical field of preparation of coal based needle coke, and particularly relates to a coal based needle coke material pretreatment process, comprising the following steps: jointly stirring the cola based needle coke material, coal based solvent and petroleum based solvent, settling, dividing into a heavy phase and a light phase, pumping out the heavy phase and sending to the outside, distilling the light phase, wherein one part of gaseous phase after distillation is taken as overhead reflux, the other part is taken as a circulating solvent and returns to a mixingtank; enabling quinoline insoluble pitch and hydrogen-donor solvent to generate hydrogenation reaction in a hydrogenation reactor, sending the material after hydrogenation into a rectifying tower, wherein one part is taken as tower bottom reflux, and the other part is sent into the mixing tank at the bottom of the rectifying tower; cooling part of dehydrogenation solvent gaseous phase by a condenser at the top of the rectifying tower and then flowing into a tank at the top of the rectifying tower, wherein one part is taken as rectifying tower top reflux, the other part is heated by a heatingfurnace together with hydrogen and then sent into a hydrogen-donor solvent hydrogenation reactor, the hydrogen-donor solvent after re-hydrogenation is divided into gaseous phase circulating hydrogen and liquid phase circulating hydrogen-donor solvent by a gas-liquid separator.

Owner:山西中科化美科技有限责任公司

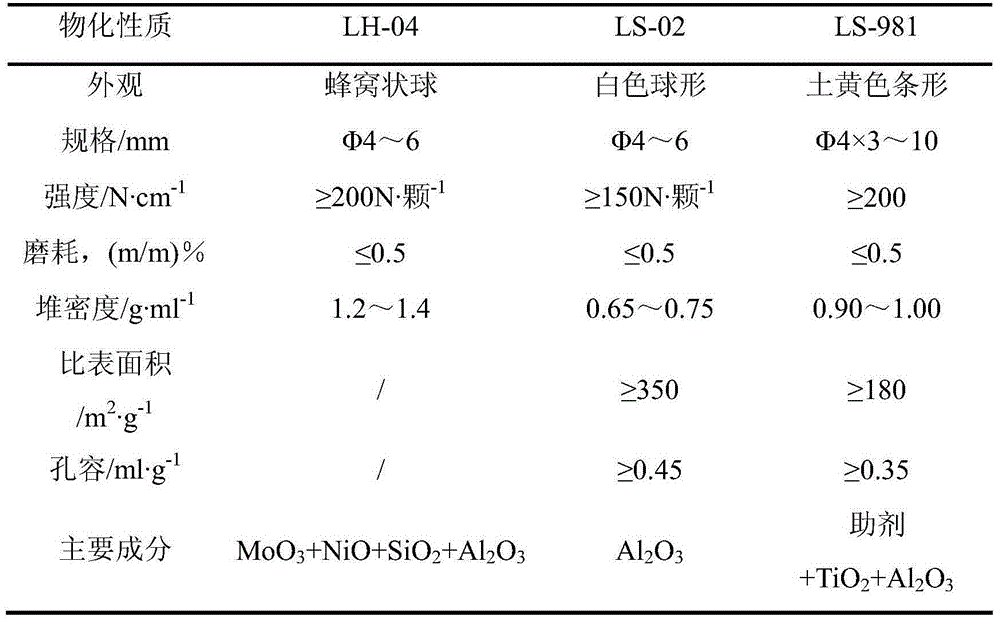

Technology for processing alkylated waste acid by using sulphur apparatus

ActiveCN106256760AImprove conversion rateIncrease the ability to remove iron scaleSulfur preparation/purificationCarbon depositMass content

The invention belongs to the technical field of petroleum processing, and concretely relate to a technology for processing alkylated waste acid by using a sulphur apparatus. In the technology, the upper part of a primary converter is filed with a catalysis protective agent, the lower part is filled with a multifunctional sulfur recovery catalyst; and the whole part of a secondary converter is filled with an alumina-based sulfur recovery catalyst. The technology realizes the low investment and high efficiency processing of the alkylated waste acid; SO3 in the high-temperature process gas can be processed in a reasonable mode, the apparatus corrosion problem is avoided, the SO3 conversion rate can reach 97% or more; influence of remainder iron in the waste acid is eliminated, the iron mass content in the sulphur product is less than 0.005%; the influence of carbon deposit on the catalyst is eliminated, and a claus catalyst is effectively protected. The catalyst can keep high claus catalytic activity and organic sulfur hydrolysis activity, the total sulfur conversion rate of the apparatus can reach 96.5% or more. The catalyst service life is prolonged, and the long-period operation of the sulphur recovery device is achieved.

Owner:CHINA PETROLEUM & CHEM CORP

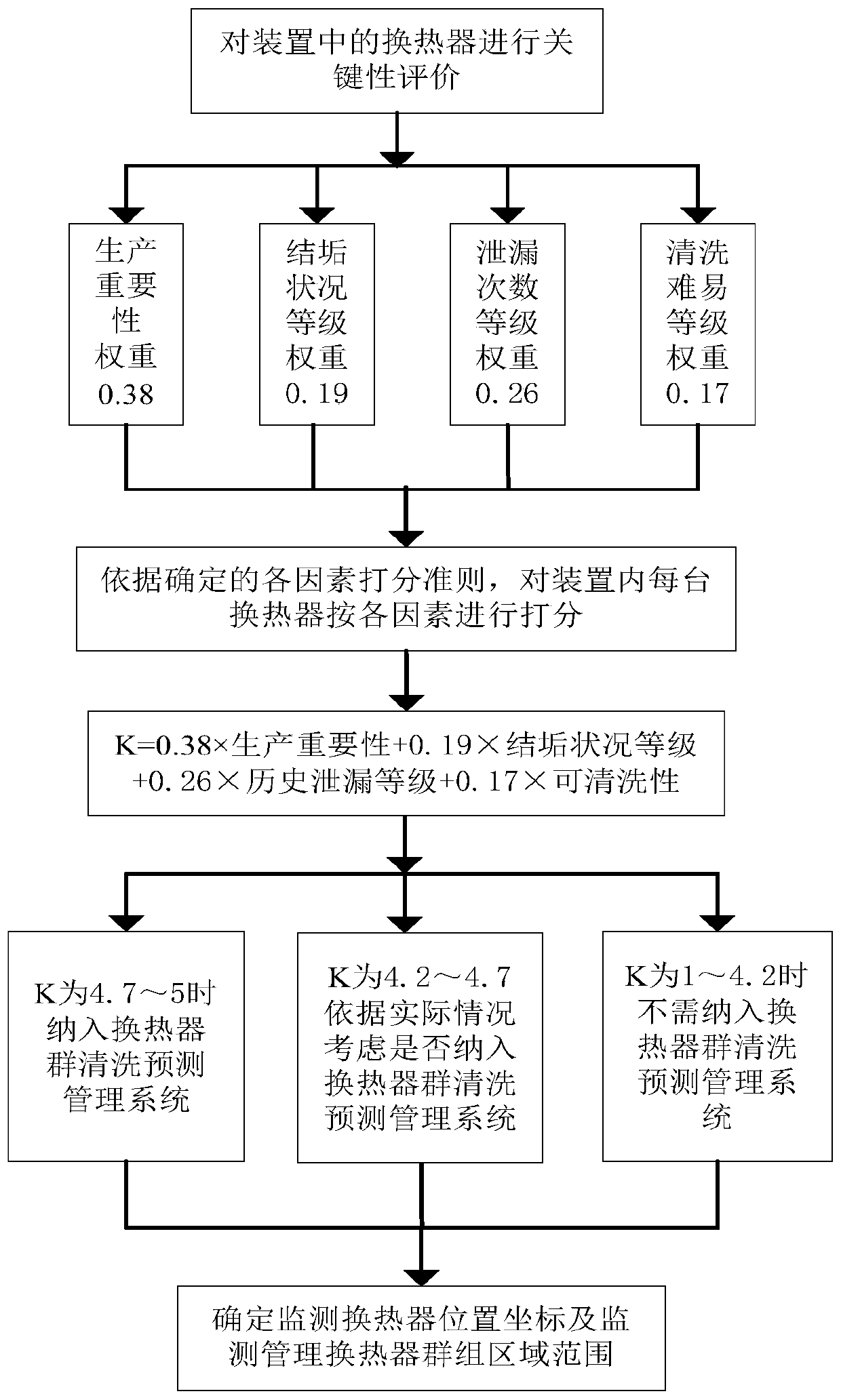

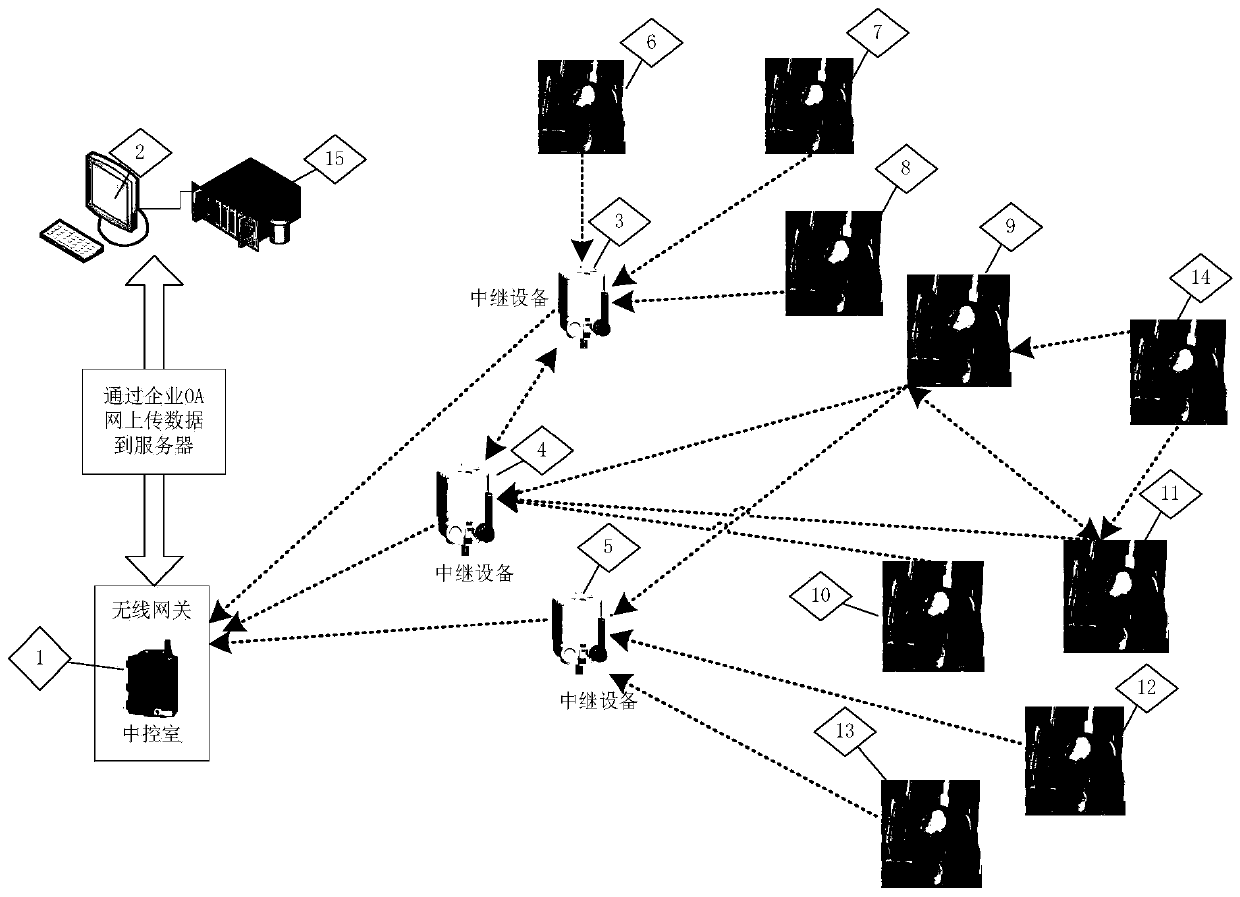

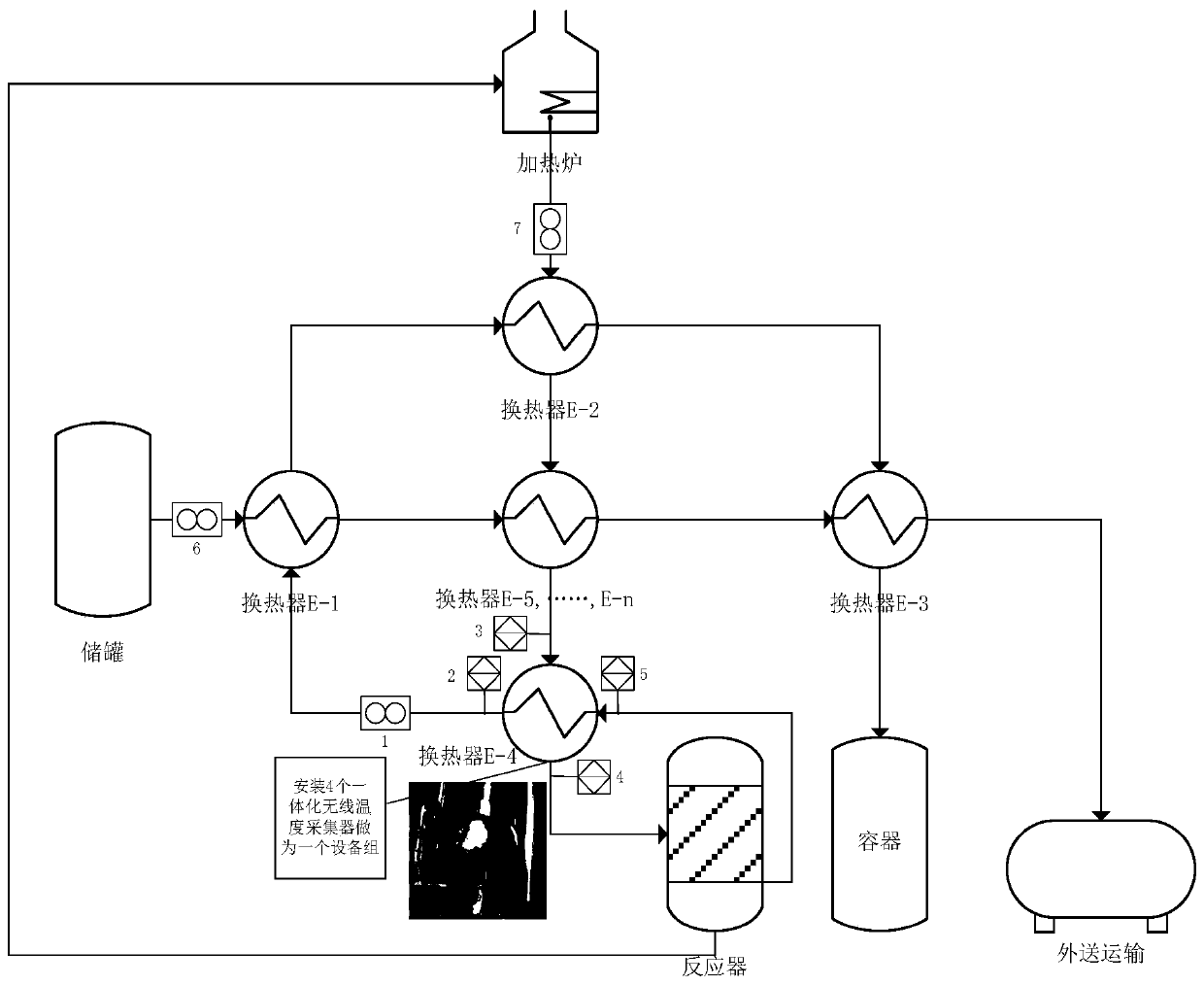

Heat exchanger group operation condition monitoring, cleaning and early warning method based on dynamic envelope line method

ActiveCN110991692AThe evaluation procedure is concise and reasonableEasy to useForecastingDesign optimisation/simulationMonitoring systemProcess engineering

A heat exchanger group operation state monitoring, cleaning and early warning method based on a dynamic envelope line method comprises the steps of establishing an in-service heat exchanger key evaluation standard, performing key evaluation on an in-service heat exchanger, and according to an evaluation result, performing operation state monitoring and cleaning prediction control on a heat exchanger group; selecting heat exchanger detection points, and installing integrated wireless temperature collectors on a tube pass inlet pipeline, a tube pass outlet pipeline, a shell pass inlet pipeline and a shell pass outlet pipeline of a selected heat exchanger; building a heat exchanger group operation state wireless monitoring system network; building an online monitoring system platform, and outputting a real-time dynamic oscillogram of the heat load, the heat transfer coefficient and the heat exchange efficiency of the heat exchanger; drawing a heat exchange efficiency trend value point diagram of the heat exchanger, and drawing a heat exchange efficiency dynamic envelope diagram on the diagram; and performing heat exchanger scaling condition analysis and heat exchanger cleaning early warning according to the heat exchanger heat exchange efficiency dynamic envelope diagram. According to the method, the operation condition of the heat exchanger can be monitored, and faults can be diagnosed in the early stage of scaling of the heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP

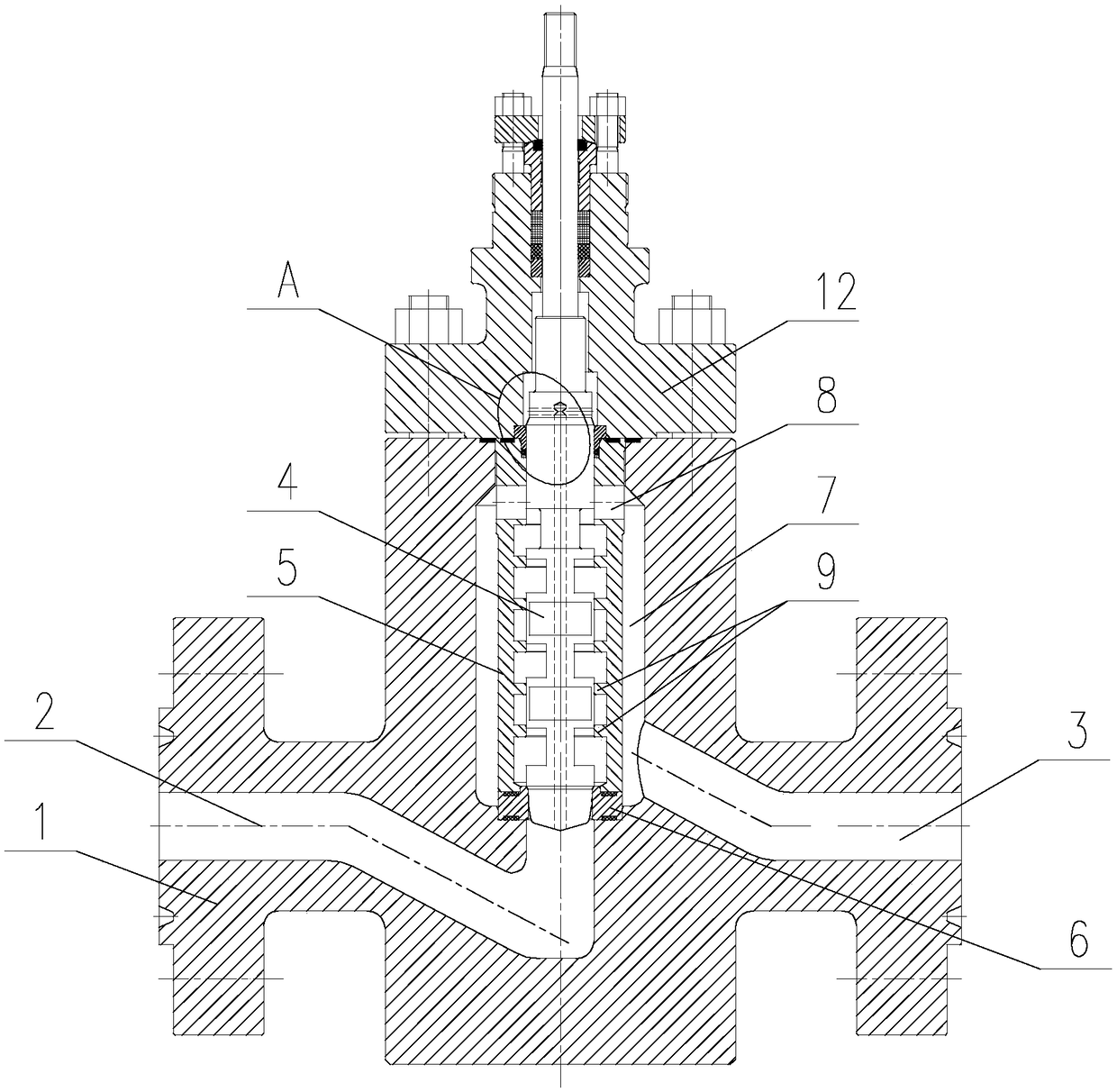

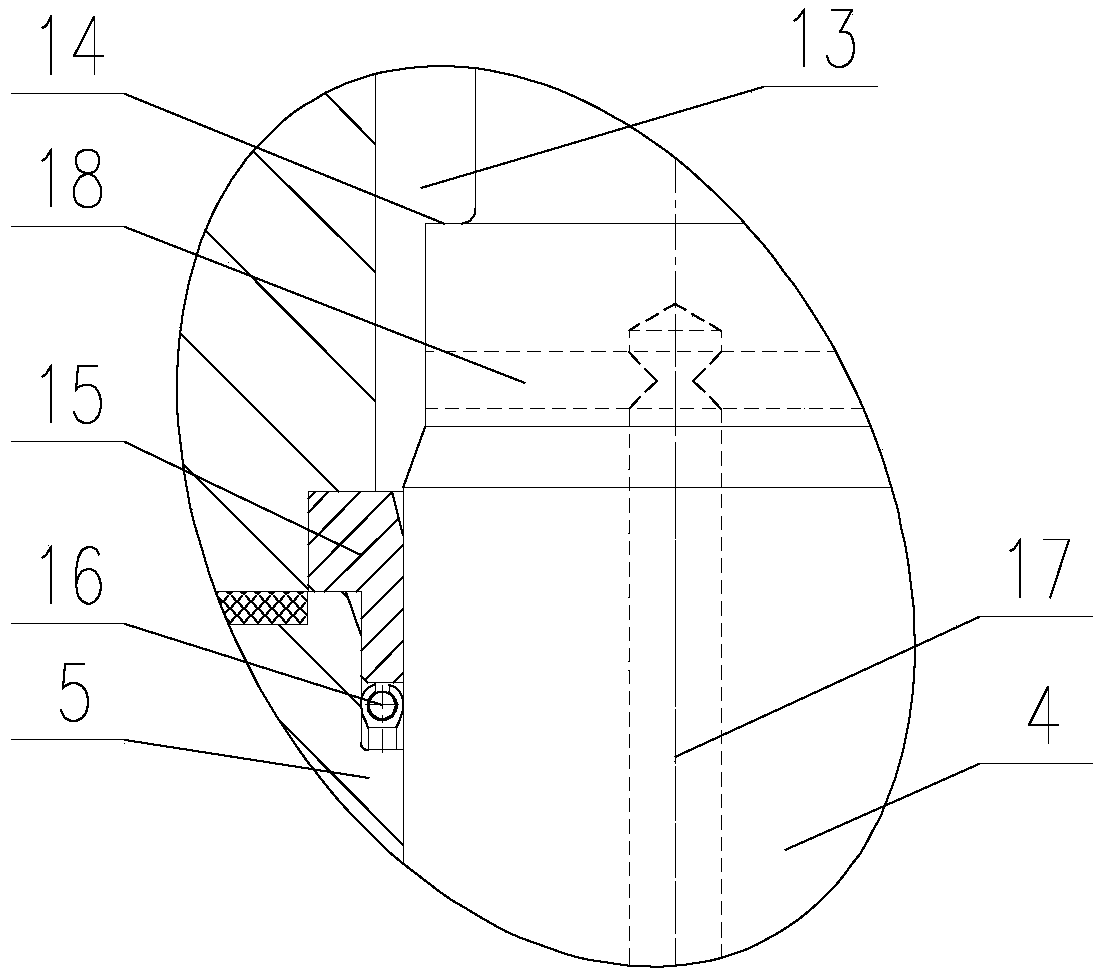

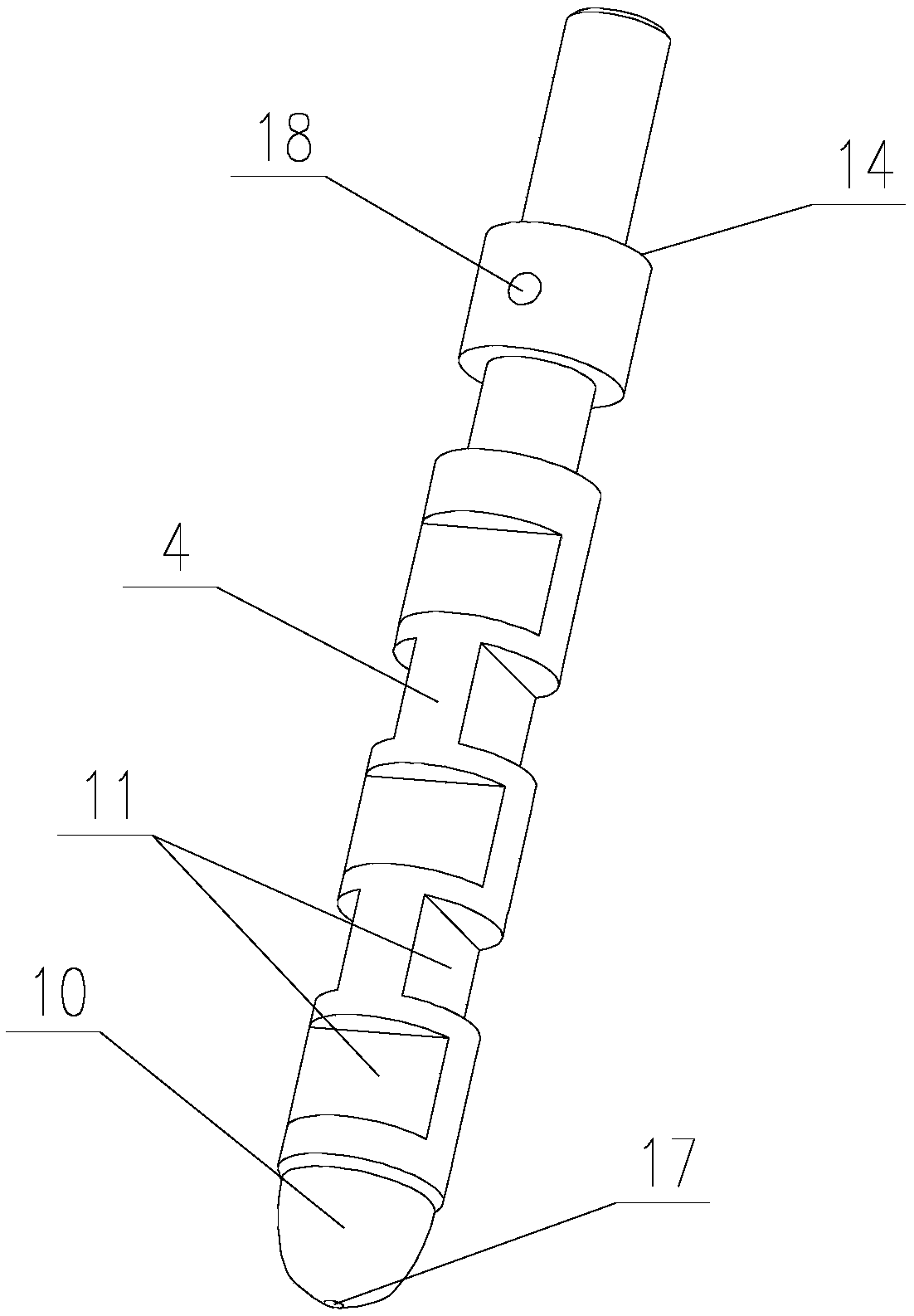

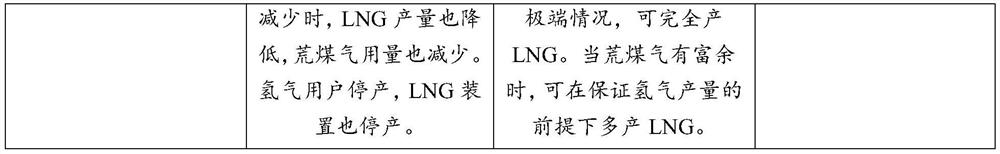

Pressure balancing type high-precision high-pressure-difference control valve

PendingCN109404606ALong runAchieving long-term operationPressure relieving devices on sealing facesValve members for absorbing fluid energyMultiple bufferingEngineering

The invention provides a pressure balancing type high-precision high-pressure-difference control valve which comprises a valve body and a pressure reducing channel. An inlet and an outlet are formed in the two sides of the valve body. The pressure reducing channel is composed of a valve core, a valve core sleeve and a valve base. A drainage runner is arranged between the valve core sleeve and thevalve body. A drainage opening communicating with the drainage runner is formed in the upper end of the valve core sleeve. The drainage runner communicates with the outlet. Multiple ring-shaped bossesare arranged on the inner wall face of the valve core sleeve at intervals. The valve base is arranged at the lower end of the valve core sleeve and communicates with the inlet. The valve core is arranged in the valve core sleeve and connected with the valve core sleeve in a sliding manner. A curved surface sealing face matched with the valve base is arranged at the lower end of the valve core. The valve core is provided with multiple buffering sets at intervals in the axial direction. Each buffering set comprises two buffering grooves arranged symmetrically. The adjacent buffering sets are arranged in a staggering manner. When the curved surface sealing face is matched with the valve base, the buffering grooves and the ring-shaped bosses are partially overlapped. According to the controlvalve, the valve core, the valve core sleeve and the valve base are adopted, control over high-pressure-difference media is achieved, adjusting performance is good, and adjusting precision is high.

Owner:WUZHONG INSTR +1

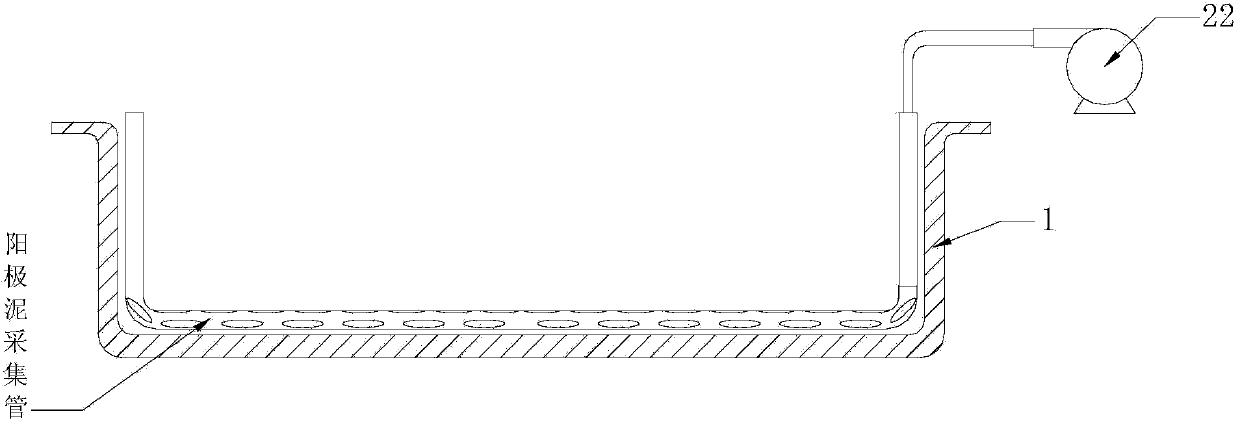

Device for collecting anode slime from bottom of electrolytic cell in zinc electrolytic refining process

ActiveCN103469250ARealize online suctionIncreased suction rateElectrolysis componentsPhotography auxillary processesOperational stabilityZinc

The invention relates to a device for collecting anode slime from the bottom of an electrolytic cell in a zinc electrolytic refining process. The device mainly comprises an electrolytic cell body and two vacuum sucking devices, wherein the bottom of the electrolytic cell is trapezoidal, an anode slime gathering device is arranged at the bottom of the electrolytic cell body, and two ends of the electrolytic cell body are provided with transmission mechanisms; the anode slime gathering device is connected to the transmission mechanisms through a corrosion-resistant drag rope; the vacuum sucking devices are arranged at two sides of the electrolytic cell body; vacuum sucking pipes in the vacuum sucking devices are inserted into the bottom end of the electrolytic cell body, and the vacuum sucking pipes suck the anode slime through a vacuum pump. The device has the following beneficial effects that the device is easy to operate and is liable to the realization of industrialized application, the stability in operation is good, not only is the on-line sucking of the anode slime realized, but also the sucking rate of the anode slime is greatly improved, and furthermore, the anode slime is prevented from accumulating.

Owner:HANGZHOU SANAL ENVIRONMENTAL TECH

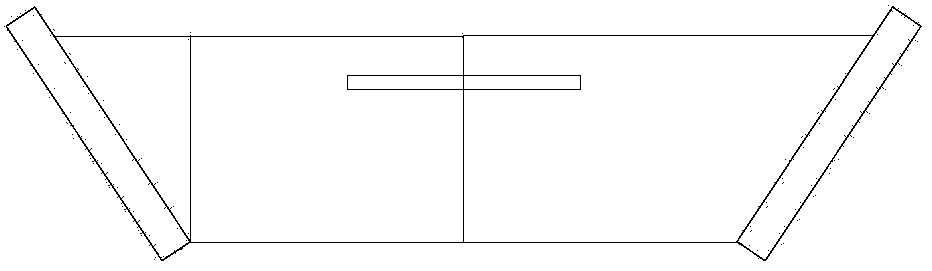

Anti-jamming method for sludge scraper of power-plant wastewater concentration treatment pond

InactiveCN113041668AGuaranteed reliabilityGuaranteed degree of aggregationSettling tanks feed/dischargeSludgeTreatment pond

The invention provides an anti-jamming method for a sludge scraper of a power-plant wastewater concentration treatment pond. The method comprises the following steps: continuously measuring the moment of force in a rotary sludge scraping process of a rotary rake of the sludge scraper, judging the aggregation degree of sludge in the treatment pond according to the continuously measured moment of force, and discharging the sludge according to the aggregation degree of the sludge. According to the invention, an original complex and low-reliability mechanical torque mechanism is simplified, measurement precision is improved, and the reliability of judging the aggregation degree of sludge in the treatment tank according to the measured torque is ensured; the functions of automatic sequential control of sludge discharging and flushing according to gyroscopic moment are achieved, stepping rake lifting of a scraper rake machine can be achieved based on moment control, and meanwhile, overload of a sludge-scraping rotary motor and a transmission shaft system is avoided through frequency conversion speed regulation; sludge treatment effect is improved, and the power consumption of a sewage pump is reduced; the long-period operation of a slag water system and a desulfurization wastewater concentration tank is realized, the risk of environmental pollution caused by manual desilting due to system shutdown is avoided, and labor cost generated by pool cleaning due to shutdown is also saved.

Owner:HUANENG NANJING JINLING POWER GENERATION

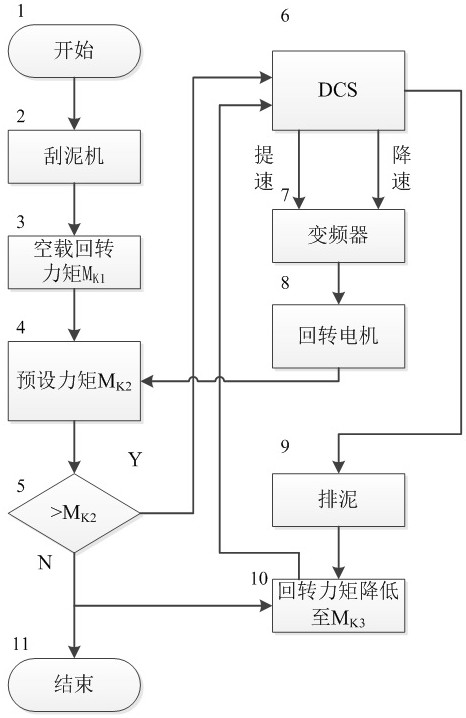

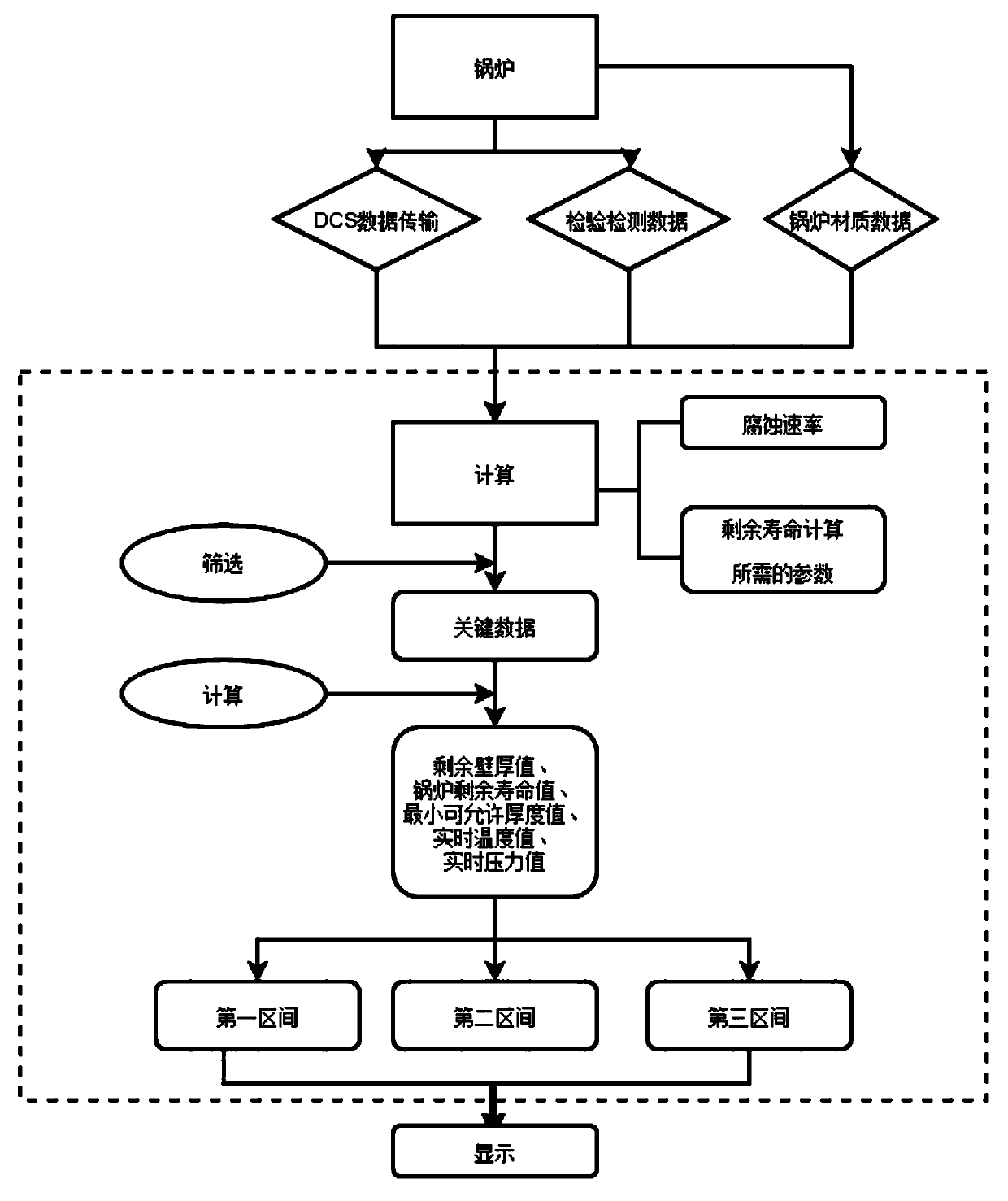

Digital representation method of coal-fired boiler operation state

ActiveCN108644753AAvoid the problems of low efficiency and low accuracyImprove real-time practical functionsBoiler indication operationsBoiler furnaceEngineering

The invention discloses a digital representation method of a coal-fired boiler operation state. The method comprises the steps that data is collected from four main tubes of a boiler; according to thecollected data, the corrosion rate of the boiler and parameters needed by the residual service life are calculated respectively; key data affecting boiler operation is screened out from the collecteddata according to corresponding boiler operation safety requirements; the residual wall thickness value of the boiler tubes, the residual service life value of the boiler and the smallest allowable thickness value of the boiler tubes are calculated respectively; the residual wall thickness valve, the residual service life value and real-time temperature and pressure values of the boiler are compared with specified allowable operation parameters of the boiler; the overall operation state of the boiler is judged; three state intervals are represented by different colors; different serial numbers are given to different boilers, and the serial numbers corresponding to the boilers are displayed through green, yellow and red on a display interface. The analysis accuracy of collected mass data is high, boiler real-time operation state health values can be visual, the tube burst frequency can be reduced, and long-period operation of the boiler is achieved.

Owner:CHINA PETROLEUM & CHEM CORP

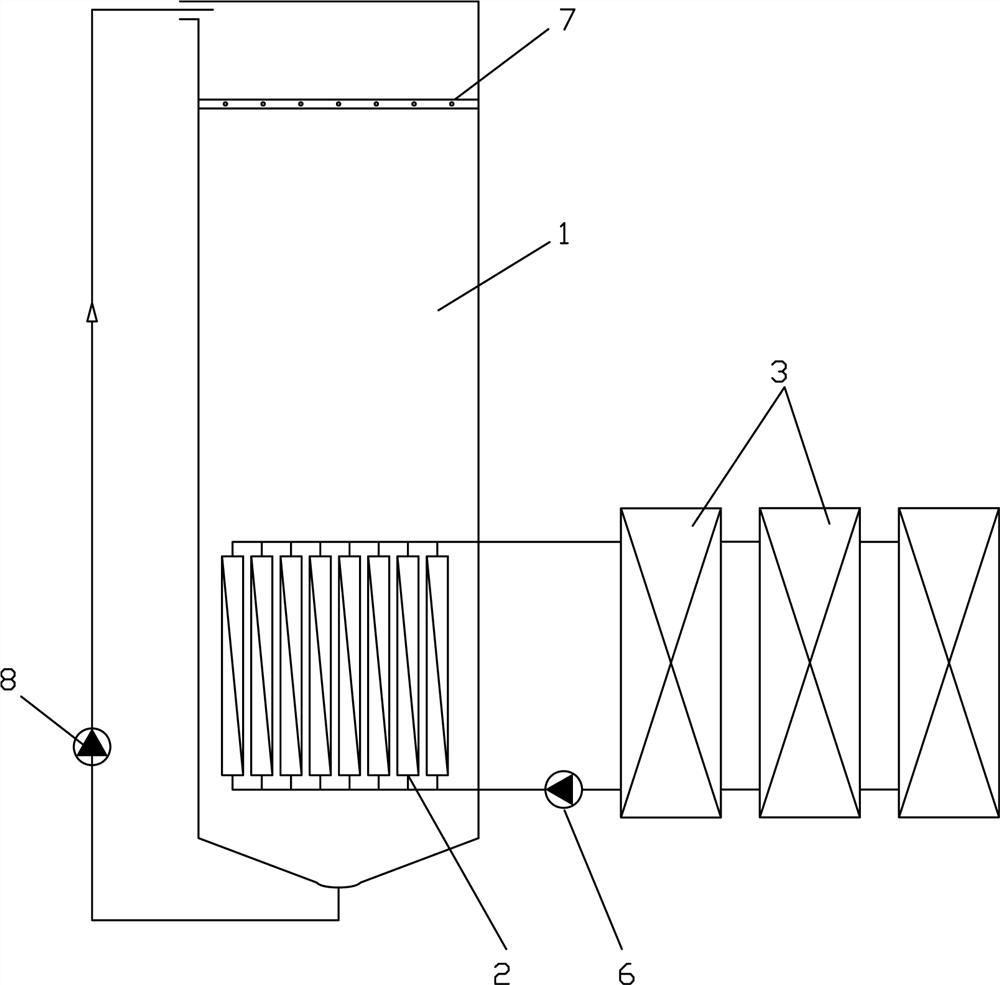

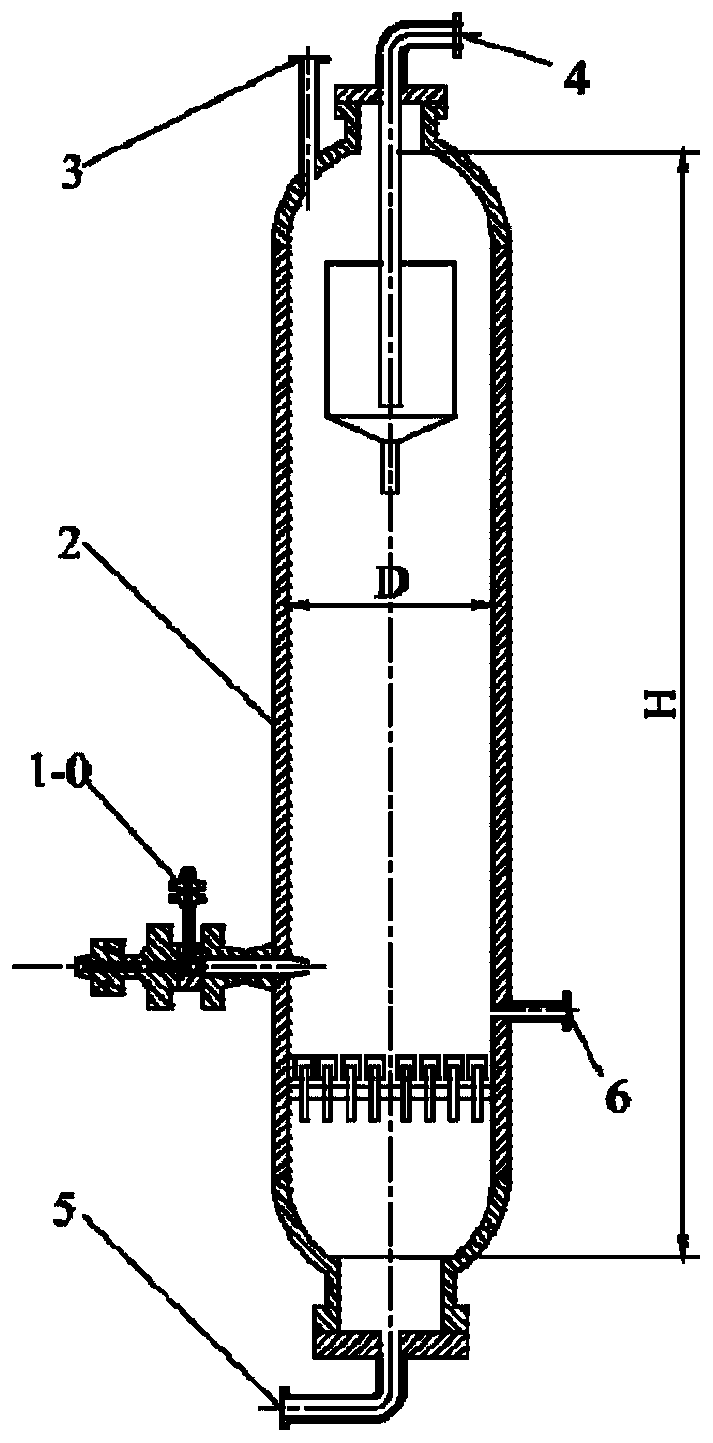

Plate type air preheater with glass as heat exchange plate

ActiveCN102032587BImprove corrosion resistanceGuaranteed long-term stable operationIndirect carbon-dioxide mitigationHeat exchanger casingsAir preheaterEngineering

The invention provides a plate type air preheater with glasses as heat exchange plates, belonging to the technical field of heat exchangers. The plate type air preheater comprises an air preheater frame, the air preheater frame comprises an upper cover plate (10), a lower bottom plate (11) and a stand column (5) and is internally provided with a plurality of heat exchange plates (1) which are correspondingly placed in vertical direction; a sealing strip (4) is arranged between every two heat exchange plates (1) which are adjacent in vertical direction; the sealing strips (4) are mutually staggered at 90 degrees and form a plurality of sealing fluid channels which are adjacent and mutually staggered at 90 degrees by being placed in a staggered way so as to respectively form hot fluid channels and cold fluid channels; rectangular glass plates are adopted as the heat exchange plates (1), and the glass can be silicon-boron glass and boron-free low-alkali glass or quartz glass; and supporting strips (2) which are rectangular or S-shaped nonmetal plate bars are arranged among the fluid channels formed by the upper and lower heat exchange plates (1). The invention has dew point corrosionresistance, efficiently recovers the low-temperature exhaust heat of smoke and can reduce the temperature of discharged smoke and enhance the efficiency of a heating furnace.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

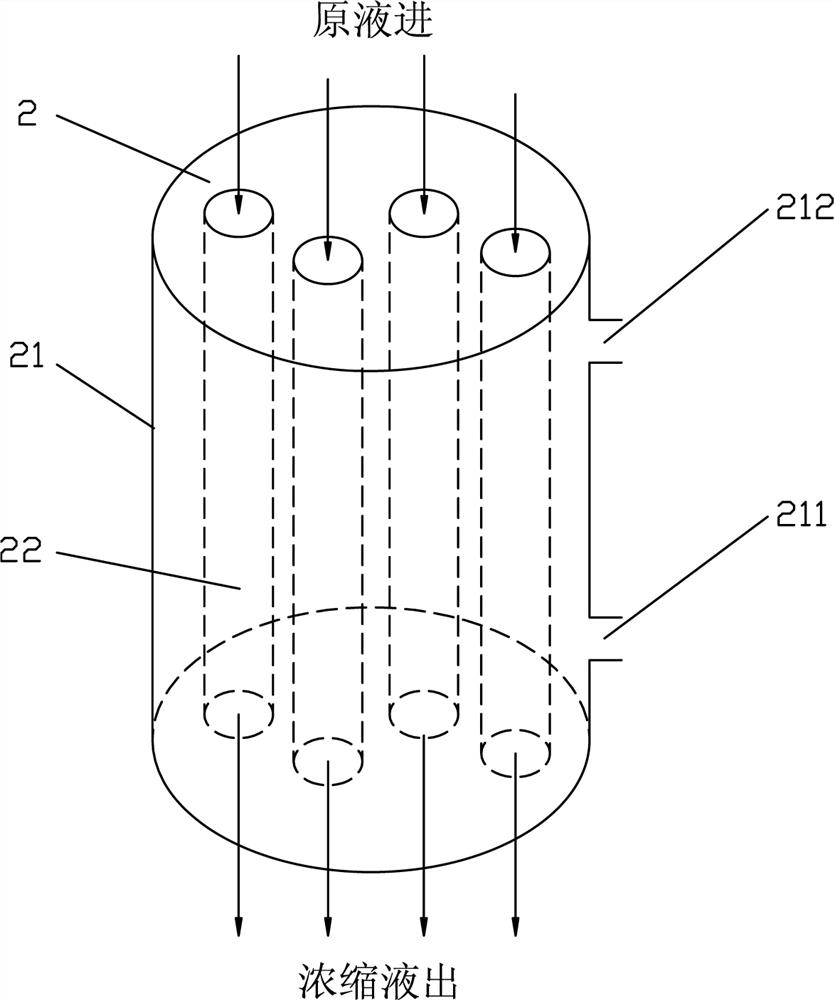

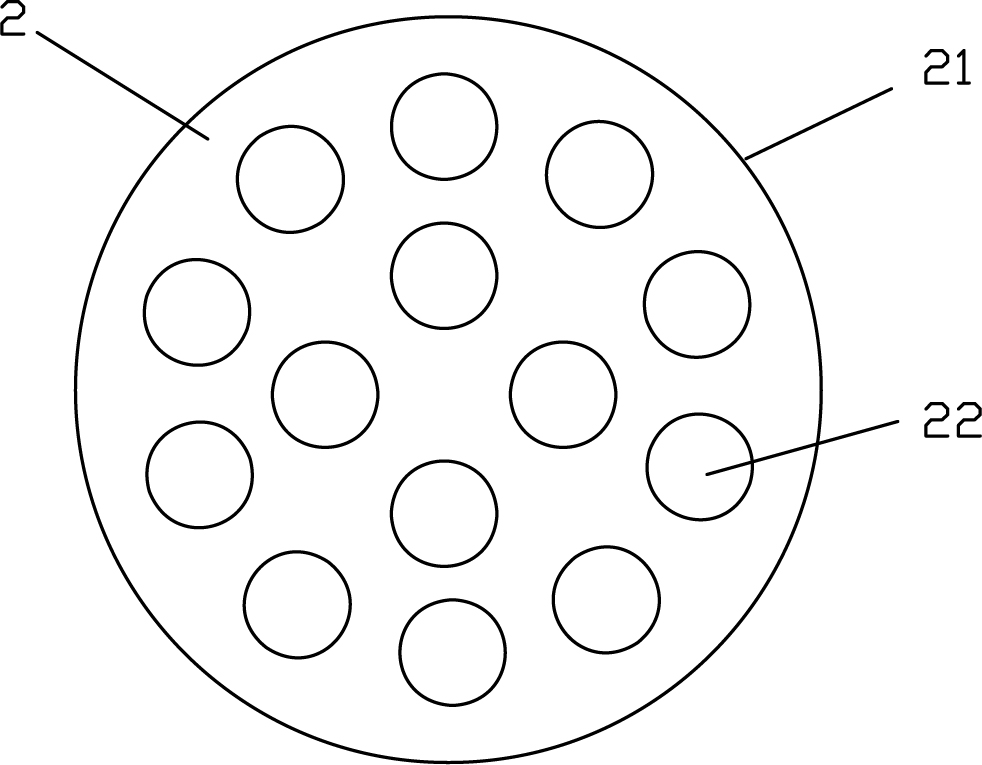

Concentration device for high-concentration and high-viscosity liquid

The invention discloses a concentration device for a high-concentration and high-viscosity liquid. The concentration device mainly comprises a liquid storage tank, an osmosis device, an extracting solution storage tank and a circulating pump. According to the concentration device, a forward osmosis membrane is adopted as the osmosis device and matches an extracting solution, osmotic pressure difference is generated on the two sides of the forward osmosis membrane, heating and mechanical external pressure applying are not needed when high-concentration and high-viscosity liquid is concentrated, loss of nutritional ingredients is reduced, energy is saved, and the production cost is reduced; the osmosis device is arranged in the liquid storage tank, the surface of the osmosis membrane element can be kept clean for a long time, the service life is prolonged, and cleaning and maintenance are convenient; and the extracting solution can be replaced under the condition of not influencing the normal operation of the device, so that the long-period operation of the device is ensured.

Owner:苏州诺津环保科技有限公司

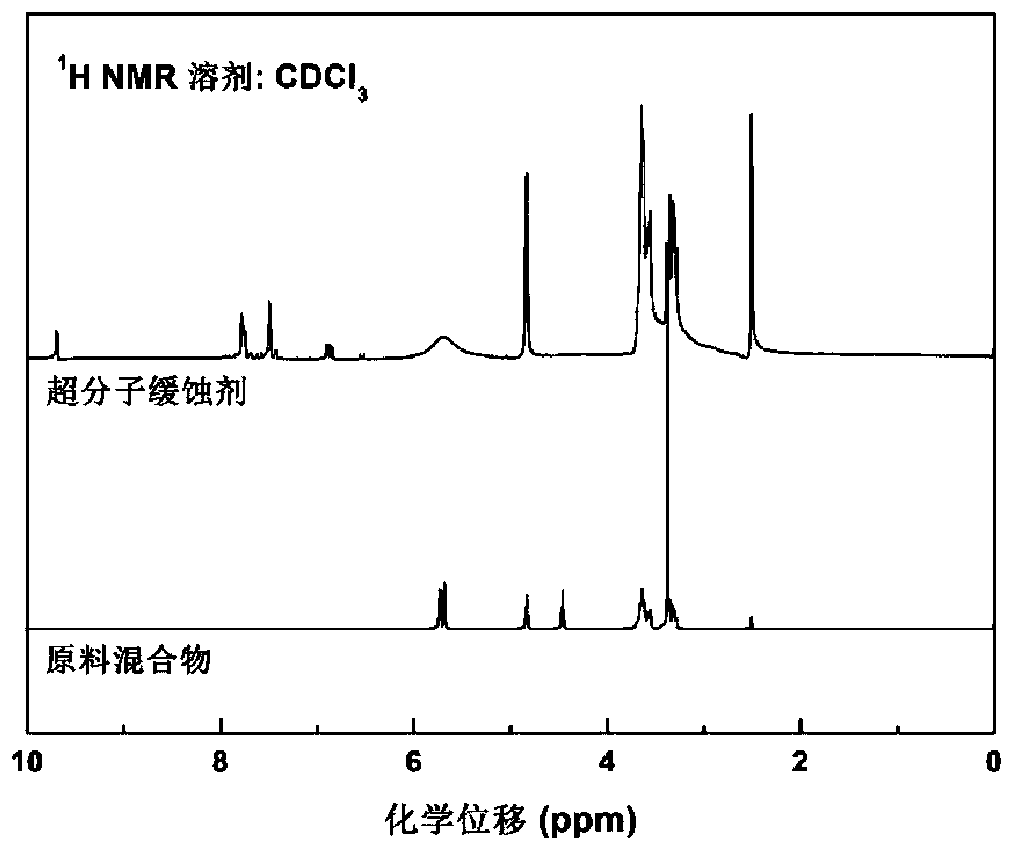

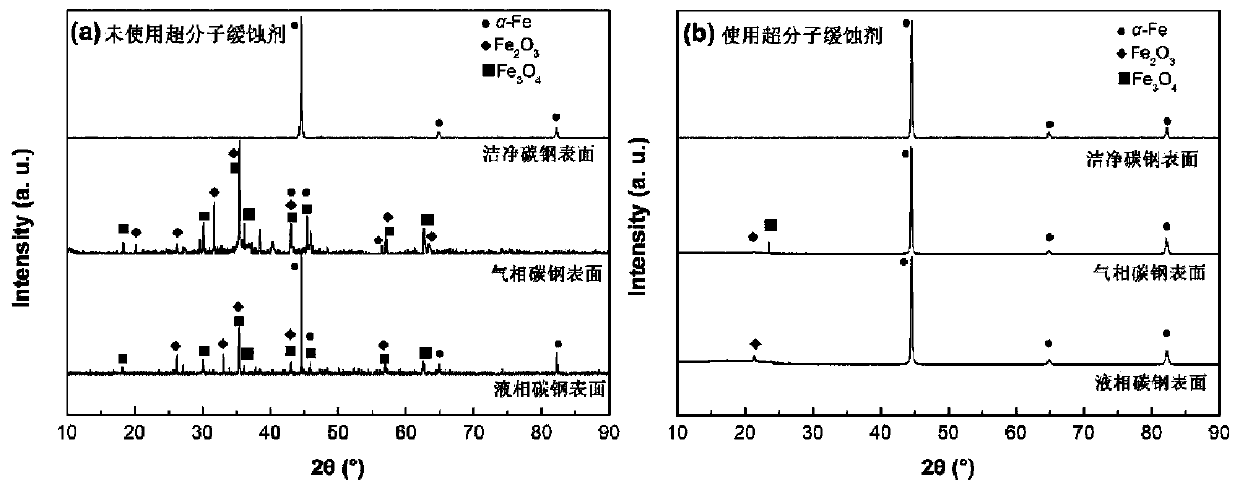

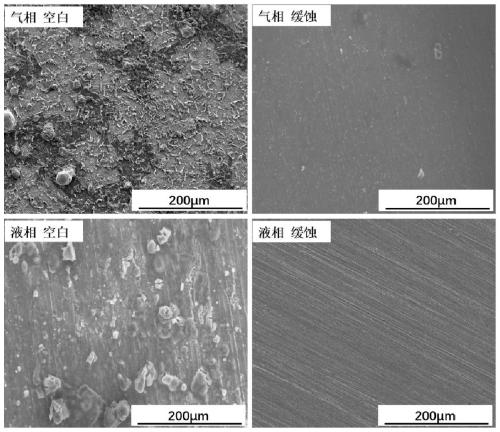

A gas-liquid double-effect supramolecular corrosion inhibitor for protecting condensate pipeline steel and its preparation method

ActiveCN107059015BSolve the problem of gas-liquid two-phase corrosionVolatileObject structureGas phase

The invention relates to a gas-liquid double-effect supramolecular corrosion inhibitor used for protecting condensate water pipe line steel and a preparation method thereof. The preparation method comprises the following steps: 30-70 parts by mass of cyclodextrin and derivatives form a network-like body under the effect of 10-20 parts by mass of an inductive bridging agent, and the network-like body is then subjected to noncovalent interaction with 20-40 parts by mass of oily corrosion inhibition components to form a supramolecular system with a subject and object structure. According to the gas-liquid double-effect supramolecular corrosion inhibitor used for protecting condensate water pipe line steel and the preparation method thereof, the preparation method of the supramolecular corrosion inhibitor is simple and convenient, the reaction condition is mild, the parts, being exposed to gas phase and immersed in liquid phase, of the condensate water pipe line steel are effectively protected.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

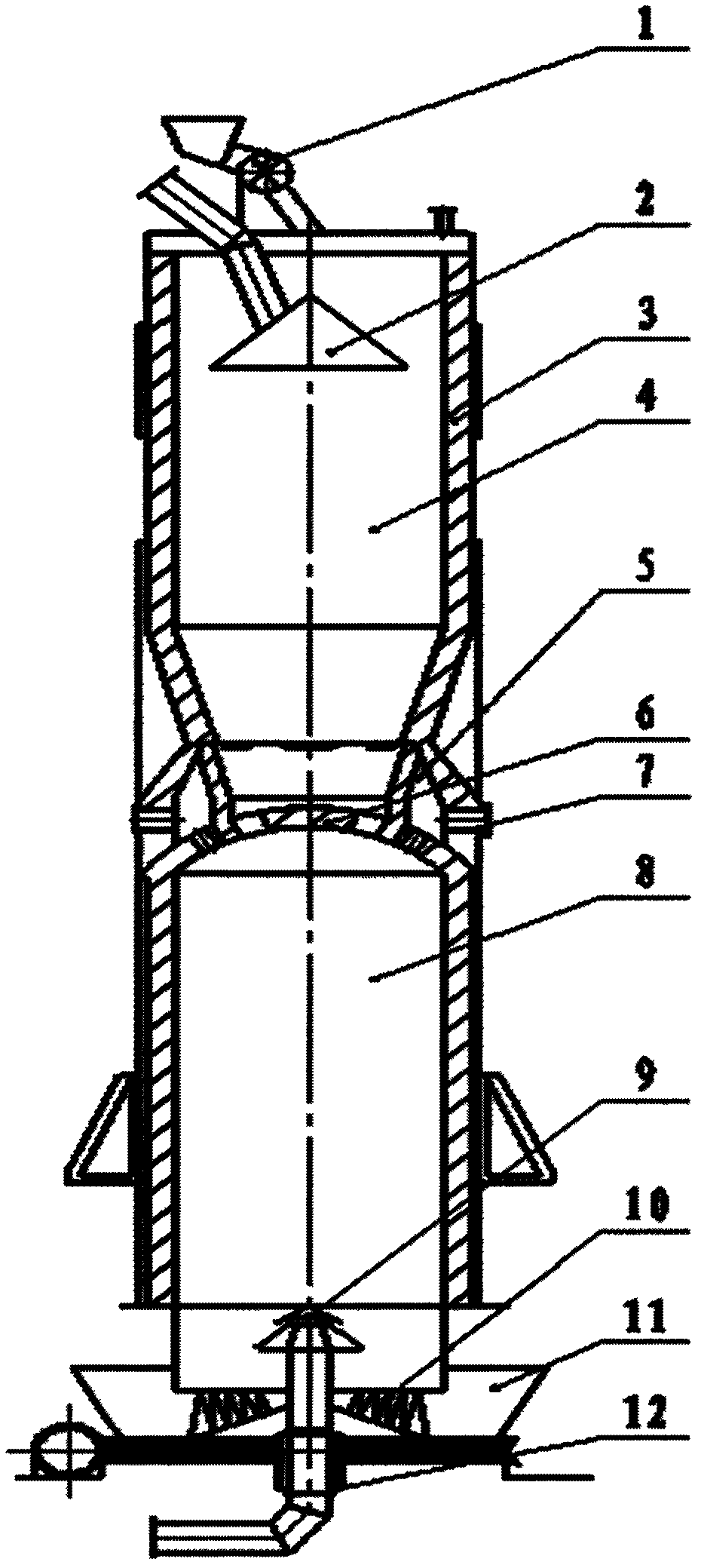

Combined type gas full-cycle gas retort

InactiveCN102492446BContact mix evenlyReduce distanceDirect heating destructive distillationEnergy inputShaped beamHeat carrier

The invention discloses a gas retort, which comprises a plurality of retorting sub units and performs retorting and oil-refining to oil shale by the gas full-cycle technology. The combined type gas full-cycle gas retort is characterized by using gas generated in the retorting process of the oil shale as heat carrier to retort the oil shale, using cold gas to recycle semi-coke waste heat generated by the retorting of the oil shale, and using tracery walls to distribute the heat carrier, wherein a gas chamber, an inverted V-shaped beam, an inverted V-shaped baffle plate, tracery walls, a cooling water sleeve, a coke exhausting passage, a coke pusher, a scraper blade conveyor and a water sealing pond are arranged inside each retorting sub unit of the gas retort from top to bottom in sequence. The tracery walls of the retorting sub units are arranged vertical to the bottom part, and a passage is formed between every two tracery walls; spray holes for cold and heat recycle gases are arranged on the tracery walls. The actual daily capacity, which can reach more than 6000 tons, of the gas retort is in a direct proportion with the number of the retorting sub units. The combined type gas full-cycle gas retort is applicable to performing retorting and oil-refining to various oil shale with grain sizes of 5-75mm, low gas content, low fixed carbon content and low moisture content, and the oil recovery rate of the gas retort reaches about 90%.

Owner:沈阳海源干馏设备技术开发有限公司

Chloroform rectification device and rectification process

PendingCN113813633ARealize natural settlementLess quantityChemical industryHalogenated hydrocarbon preparationReboilerProcess engineering

The invention belongs to the technical field of energy conservation and environmental protection, and relates to an energy-saving heat exchange device in a chloroform rectification process, in particular to a chloroform rectification device and a rectification process. The chloroform rectification device comprises a chloroform rectifying tower, the bottom of the chloroform rectifying tower is provided with at least two reboilers, the reboilers are vertically arranged, the reboilers are tube type heat exchangers, lower end sockets of the reboilers are provided with settlement areas, the settlement areas are spaces capable of carrying out settlement, shell pass inlets of the reboilers are connected with a steam source, and the steam of the steam source is lower than 0.4 MPa. The problem of frequent blockage of the reboiler of the rectifying tower can be solved, so that long-period operation of the chloroform rectifying tower is realized, meanwhile, the energy consumption can be greatly reduced, and the production cost is saved.

Owner:聊城鲁西氯甲烷化工有限公司

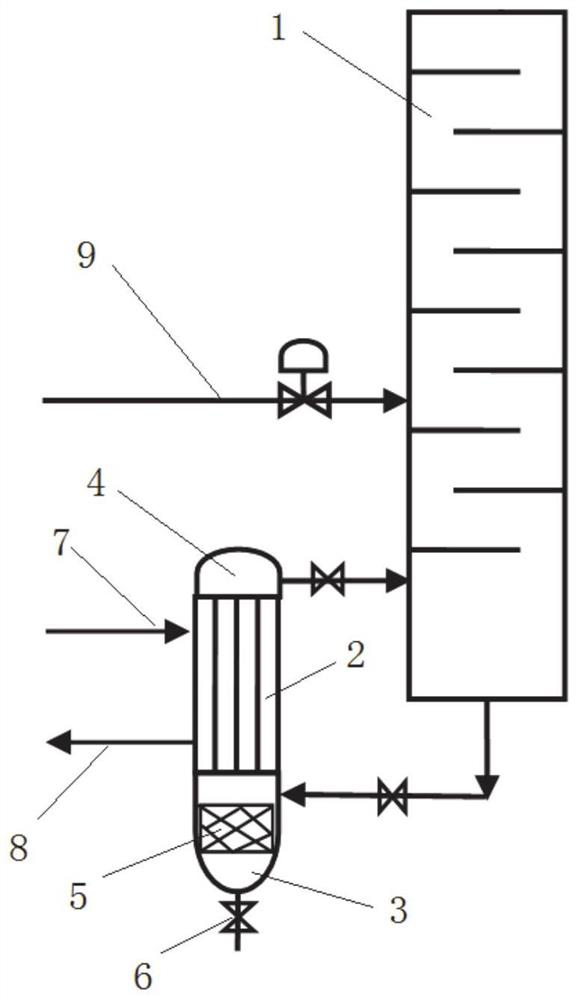

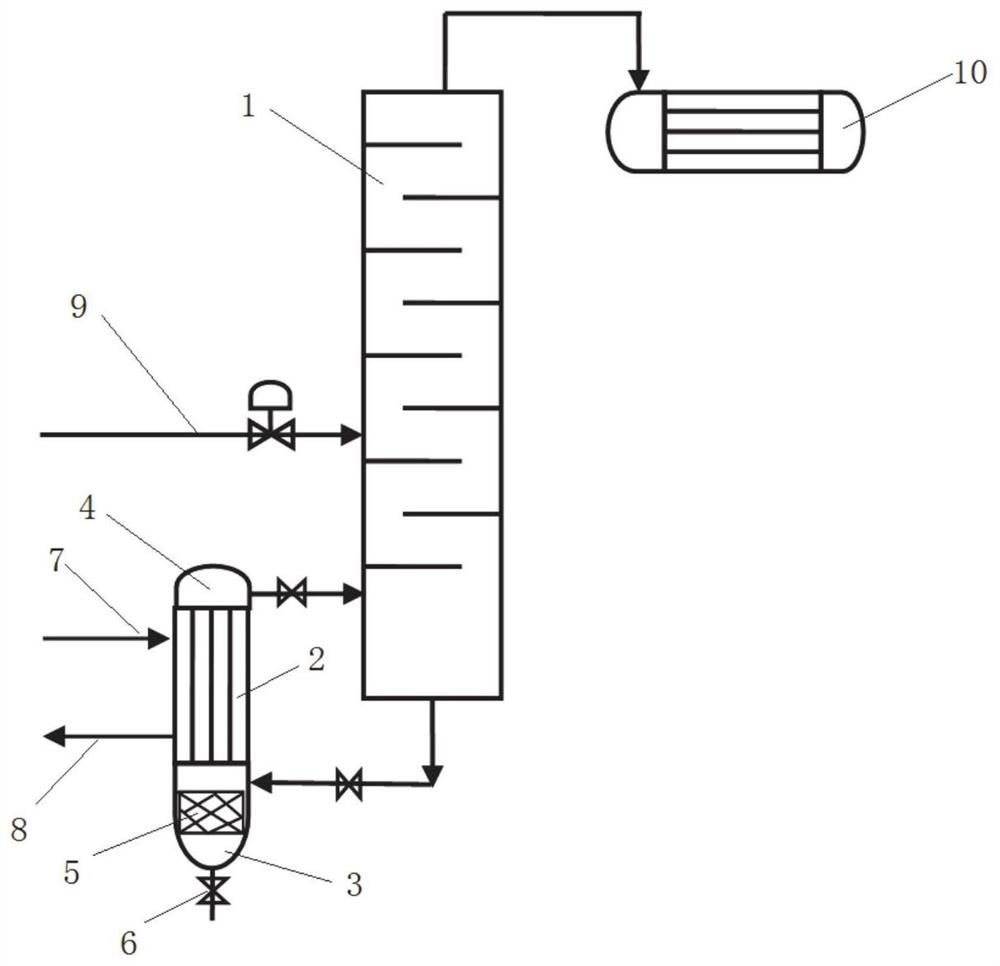

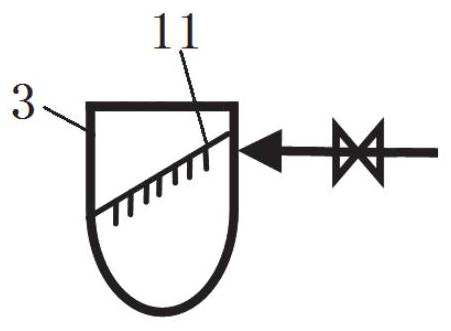

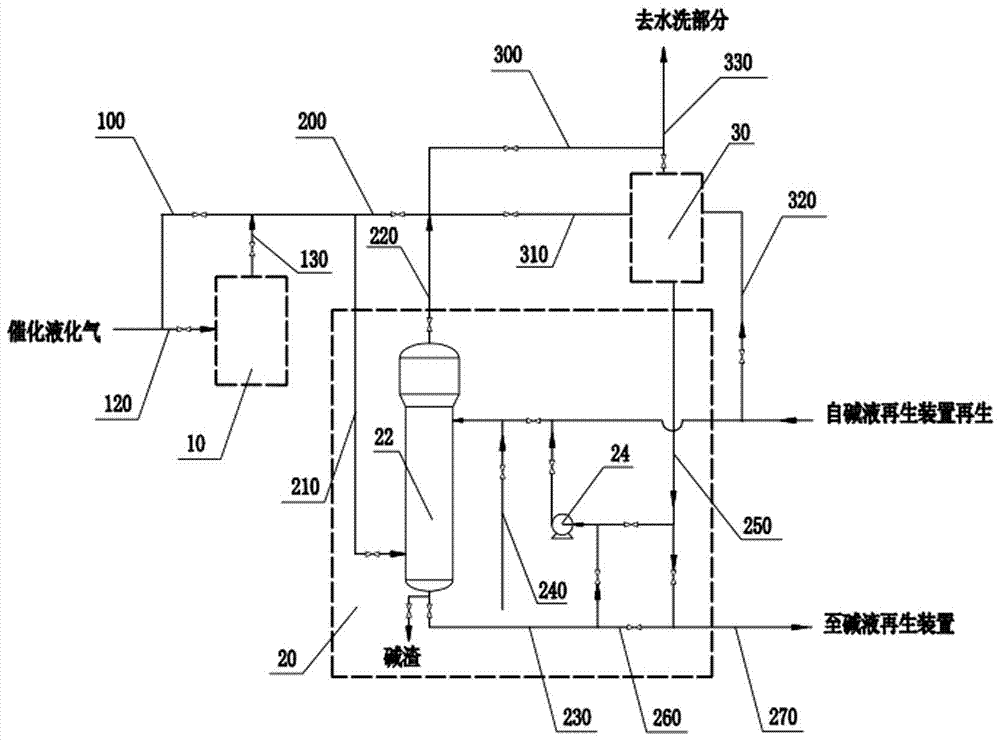

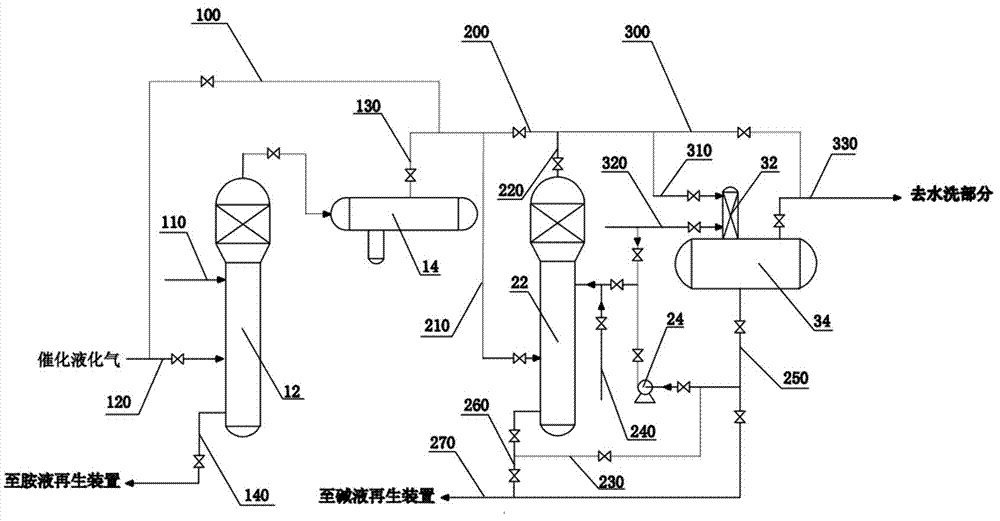

Combined device for catalyzing deep desulfurization of liquefied gas

InactiveCN107227173AImprove anti-accident interference abilityAchieving long-term operationGaseous fuelsGaseous mixture working upLiquid gasLongest cycle

The invention provides a combined device for catalyzing deep desulfurization of liquefied gas. The combined device comprises a hydrogen sulfide removing unit, a stand-by unit, a thioalcohol removing unit, a plurality of pipelines and a plurality of valves, wherein the hydrogen sulfide removing unit is used for removing hydrogen sulfide from catalyzed liquefied gas, the thioalcohol removing unit is used for removing thioalcohol from the catalyzed liquefied gas, the stand-by unit is used for removing the hydrogen sulfide or thioalcohol from the catalyzed liquefied gas, the pipelines and the valves are used in a matched manner, and then, at least two of the hydrogen sulfide removing unit, the stand-by unit and the thioalcohol removing unit can communicate with each other so as to remove the hydrogen sulfide and thioalcohol from the catalyzed liquefied gas. The combined device for catalyzing the deep desulfurization of the liquefied gas can adapt to a variety of abnormal conditions, the capability against fault disturbance is improved, and long-cycle operation is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cryogenic separation process for preparing propylene through propane dehydrogenation in Olflex process

ActiveCN113121299AReduce dosageReduce partial pressureSolidificationLiquefactionDehydrogenationPhysical chemistry

A cryogenic separation process for preparing propylene through propane dehydrogenation of an Olflex process is mainly suitable for an Olflex propane dehydrogenation (PDH) project of UOP, cryogenic separation is carried out on a dehydrogenation reaction product gas-phase product, potential cooling capacity of liquid raw material propane gasification, circulating hydrogen and other energy are recycled, and the whole cryogenic separation process does not need external refrigeration, and is more energy-saving and environment-friendly. High-purity hydrogen is adopted as circulating hydrogen, so that cryogenic separation of reaction gas with a low hydrogen-hydrocarbon ratio can be realized, reduction of carbon deposition in a reaction zone of a propane dehydrogenation device is facilitated, and long-period operation of the device is realized.

Owner:ZHEJIANG SATELLITE ENERGY CO LTD

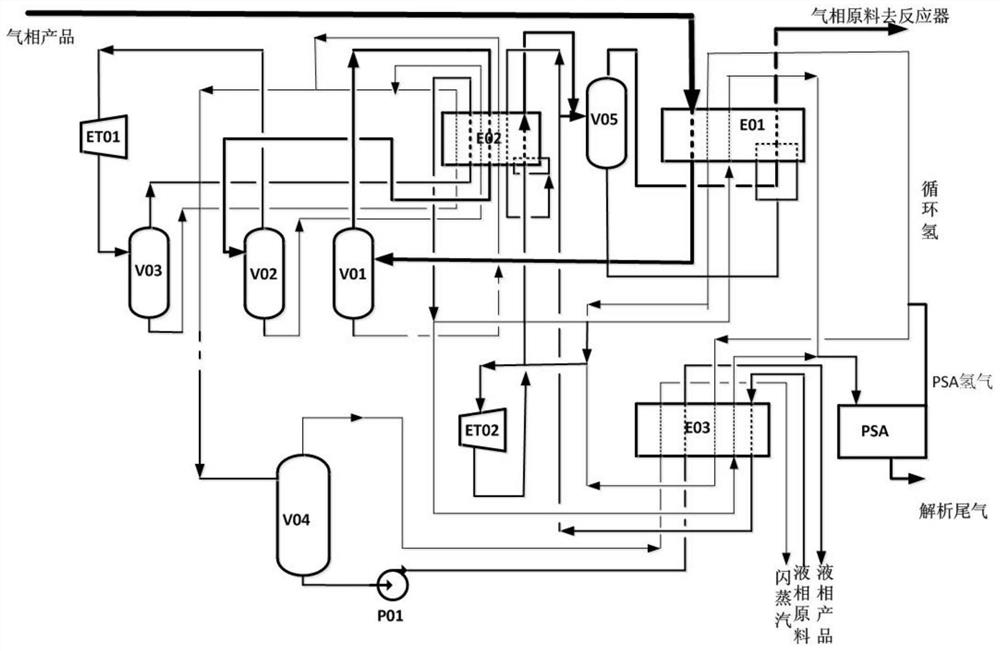

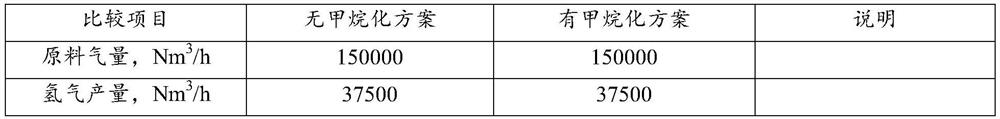

A co-production lng process of hydrogen production from raw coal gas with methanation

ActiveCN112897464BSimple purification processEfficient removalHydrogen separationGaseous fuelsMethanationCoal pyrolysis

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

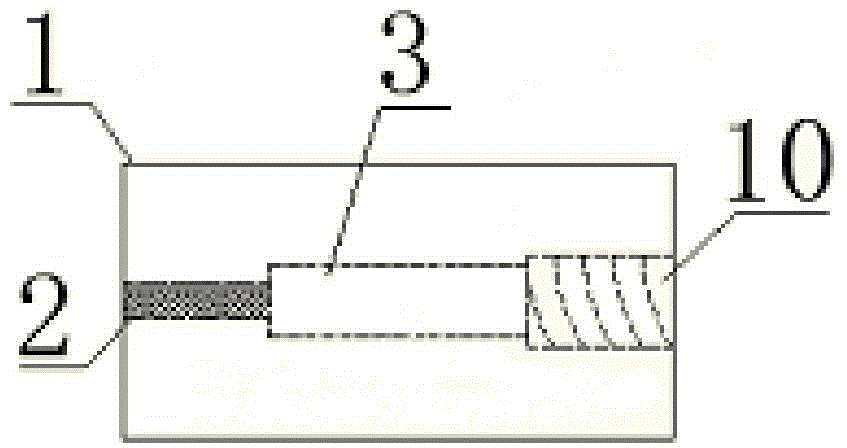

Semisolid reference electrode used for metal soil corrosion electrochemical system

InactiveCN104931412AImprove sealingAchieving long-term operationWeather/light/corrosion resistancePotassium nitrateSalt bridge

The invention discloses a semisolid reference electrode used for a metal soil corrosion electrochemical system. The semisolid reference electrode comprises a salt bridge, an electrode cavity and an electrode inner core, the salt bridge comprises a polytef shell of a cylindrical structure, a saturated electrolyte chamber is arranged in the middle of the salt bridge longitudinally, a saturated electrolyte is a semisolid saturated potassium nitrate or saturated potassium chloride, a porous sand core A is arranged at the end of the saturated electrolyte chamber, the top end of the porous sand core A directly contacts with soil, the electrode cavity is connected with the polytef shell through a thread, and the electrode inner core is connected with the electrode cavity through a thread. Medium-long-term running of the semisolid reference electrode in a soil medium is realized while good sealing effect of the electrolyte in the reference electrode and the salt bridge is guaranteed with temperature conditions changed constantly, so that accuracy and smoothness of metal corrosion electrochemical experiments in the soil medium are guaranteed.

Owner:TIANJIN UNIV

A digital characterization method of coal-fired boiler operating state

ActiveCN108644753BIntuitive real-time running status health valueReal-time push alarm technologyBoiler indication operationsEngineeringBurst frequency

The invention discloses a digital representation method of a coal-fired boiler operation state. The method comprises the steps that data is collected from four main tubes of a boiler; according to thecollected data, the corrosion rate of the boiler and parameters needed by the residual service life are calculated respectively; key data affecting boiler operation is screened out from the collecteddata according to corresponding boiler operation safety requirements; the residual wall thickness value of the boiler tubes, the residual service life value of the boiler and the smallest allowable thickness value of the boiler tubes are calculated respectively; the residual wall thickness valve, the residual service life value and real-time temperature and pressure values of the boiler are compared with specified allowable operation parameters of the boiler; the overall operation state of the boiler is judged; three state intervals are represented by different colors; different serial numbers are given to different boilers, and the serial numbers corresponding to the boilers are displayed through green, yellow and red on a display interface. The analysis accuracy of collected mass data is high, boiler real-time operation state health values can be visual, the tube burst frequency can be reduced, and long-period operation of the boiler is achieved.

Owner:CHINA PETROLEUM & CHEM CORP

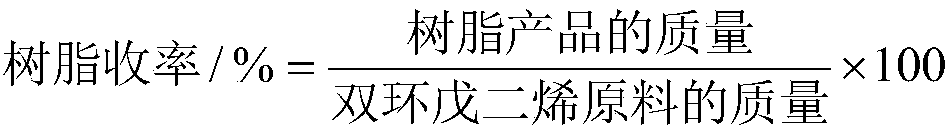

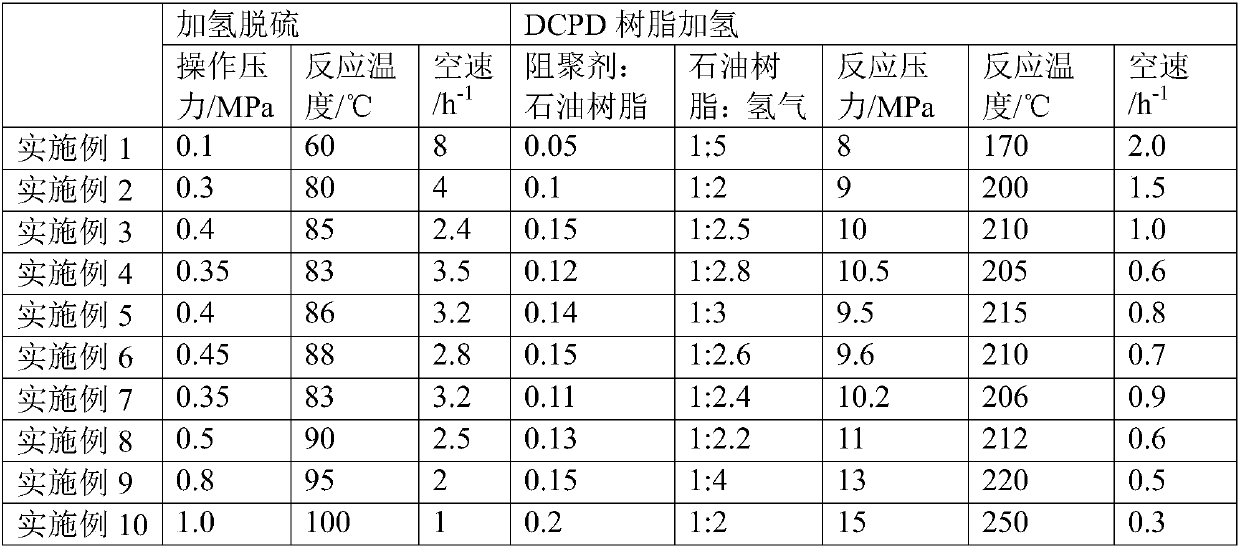

Method for preparing hydrogenated petroleum resin by using dicyclopentadiene as a raw material

The invention discloses a method for preparing a hydrogenated petroleum resin by using dicyclopentadiene as a raw material. According to the present invention, the influence of gel, sulfur and other impurities on hydrogenated petroleum resins is eliminated by adopting the desulfurization and hydrogenation process, the service lives of the pretreatment catalyst and the hydrogenation catalyst are improved, the operating cost and the equipment investment are reduced, the high-quality hydrogenated petroleum resin is obtained, the product quality stability can be maintained, and the benefits can beincreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

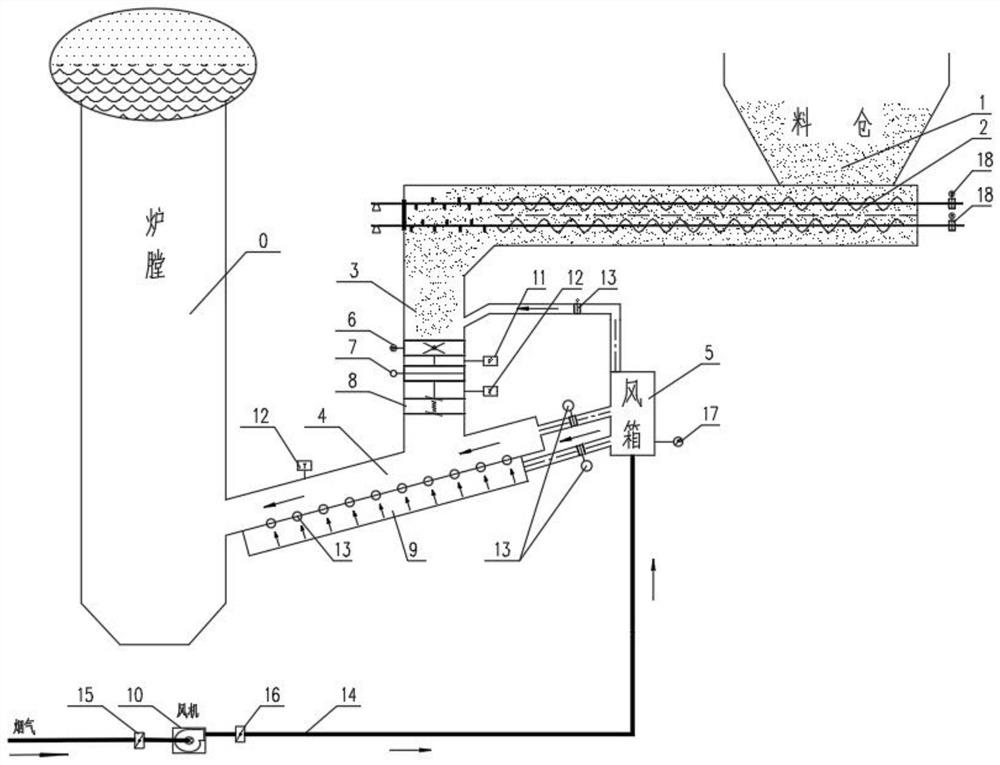

Biomass boiler feeding system

PendingCN113339834AReduce labor intensitySave one investment feeFuel supply regulationSolid fuel combustionProcess engineeringBiomass boiler

The invention discloses a biomass boiler feeding system, and belongs to the field of biomass boilers. According to the biomass boiler feeding system, the bottom of a stock bin and a secondary spiral feeder are installed in a communicating and matched mode, the secondary spiral feeder and a feeding pipe are installed in a communicating and matched mode, the feeding pipe and a discharging pipe are installed in a communicating and matched mode, the discharging pipe and a hearth are installed in a communicating and matched mode, an air bellow is installed in a communicating and matched mode with the feeding pipe and the discharging pipe, a pneumatic quick shut-off valve, a heavy hammer type lever valve and a metal expansion joint are sequentially installed on the feeding pipe in a matched mode from top to bottom, a fluidization air bellow is installed at the bottom of the discharging pipe in a matched mode, the fluidization air bellow and an air bellow communicate and are installed in a matched mode, and the air bellow and a draught fan are installed in a matched mode. The biomass boiler feeding system aims to solve the problem that a unit cannot run for a long period due to material blockage, shaft breakage and shaftless spiral breakage of a stokehole feeding system of a power plant in the current biomass industry, reduce the labor intensity of operators, save electricity and reduce the production cost, the one-time investment cost, the repeated investment cost and the maintenance cost are saved, and meanwhile the target of long-period operation of the unit is achieved.

Owner:黑龙江华热能源有限公司

A coal-based needle coke raw material pretreatment process

The invention belongs to the technical field of preparation of coal based needle coke, and particularly relates to a coal based needle coke material pretreatment process, comprising the following steps: jointly stirring the cola based needle coke material, coal based solvent and petroleum based solvent, settling, dividing into a heavy phase and a light phase, pumping out the heavy phase and sending to the outside, distilling the light phase, wherein one part of gaseous phase after distillation is taken as overhead reflux, the other part is taken as a circulating solvent and returns to a mixingtank; enabling quinoline insoluble pitch and hydrogen-donor solvent to generate hydrogenation reaction in a hydrogenation reactor, sending the material after hydrogenation into a rectifying tower, wherein one part is taken as tower bottom reflux, and the other part is sent into the mixing tank at the bottom of the rectifying tower; cooling part of dehydrogenation solvent gaseous phase by a condenser at the top of the rectifying tower and then flowing into a tank at the top of the rectifying tower, wherein one part is taken as rectifying tower top reflux, the other part is heated by a heatingfurnace together with hydrogen and then sent into a hydrogen-donor solvent hydrogenation reactor, the hydrogen-donor solvent after re-hydrogenation is divided into gaseous phase circulating hydrogen and liquid phase circulating hydrogen-donor solvent by a gas-liquid separator.

Owner:山西中科化美科技有限责任公司

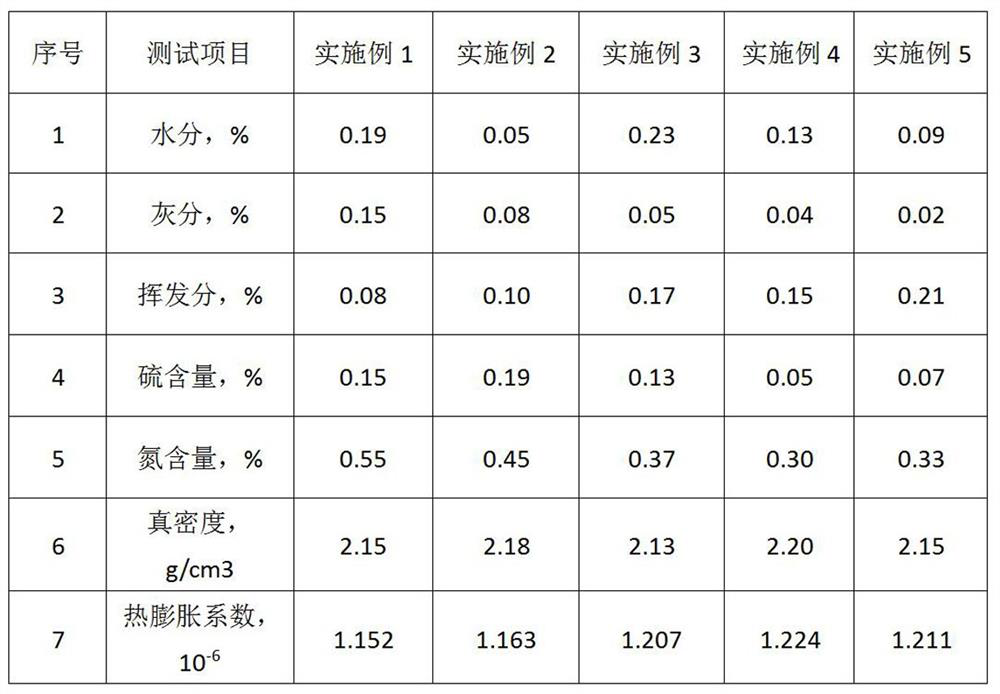

Method and device for feeding rotational flow cushion layer of hydrogenation reactor

ActiveCN110003936AAvoid cloggingEffective insulationRefining to eliminate hetero atomsHydrogen supplyRotational flow

The invention relates to a method and a device for feeding a rotational flow cushion layer of a hydrogenation reactor, and provides a method for feeding the rotational flow cushion layer of the hydrogenation reactor, which comprises the following steps: (a) enabling raw oil to enter a rotational flow cushion layer feeder to form a raw material oil flow which flows linearly in the axial direction of the rotational flow cushion layer feeder; (b) enabling a circulating hydrogen supply agent to enter the rotational flow cushion layer feeder to form a circulating hydrogen supply agent flow which istightly attached to the inner wall surface of the rotational flow cushion layer feeder to perform rotational flow movement; (c) enabling the circulating hydrogen supply agent to be in close contact with the inner wall of the rotational flow cushion layer feeder and in swirling motion; enabling the raw oil to flow linearly along the axial direction of the rotational flow cushion layer feeder so that the circulating hydrogen supply agent can wrap the raw oil; (d) shear-mixing the circulating hydrogen supply agent obtained in the step (c) with the raw oil; (e) spraying the mixed stream of the raw oil obtained in the step (d) and the circulating hydrogen supply agent into the hydrogenation reactor in an umbrella form. The invention further provides the device for feeding the rotational flow cushion layer of the hydrogenation reactor.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Non-welded plate type heat exchanger

ActiveCN101464105BEasy to manufactureLow costStationary plate conduit assembliesEngineeringHeat exchanger

The invention relates to the technology of heat exchangers, particularly a weldless plate-type heat exchanger. A plurality of fluid passages are formed by a plurality of heat exchange plates 1 which are vertically placed in a rectangularly (90 DEG) staggered manner, wherein, the openings of adjacent fluid passages among the fluid passages are mutually staggered at an angle of 90 DEG to form hot fluid passages and cold fluid passages; upward right-angled fold edges are formed on the two symmetric sides of each heat exchange plate 1, and right-angled double-fold edges are formed on the other two corresponding sides so as to form L-shaped fold edges; each two vertically adjacent heat exchange plates are placed in a rectangularly (90 DEG) staggered manner, that is, the downward L-shaped fold edge of an upper heat exchange plate is correspondingly placed between the upward right-angled fold edges of a lower heat exchanges plate, and the upward rectangular (90 DEG) fold edge of the lower heat exchange plate serves the function of limiting to the L-shaped fold edge of the upper heat exchange plate; a sealing gasket 5 is arranged between the lower heat exchange plate and the upper exchange plate; a flexible sealing layering 3 is arranged between each two adjacent heat exchange plates; and a support strip 2 is arranged between the passage formed by the upper heat exchange plate and thelower heat exchange plate.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com