Patents

Literature

45 results about "Sulphur product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulphur that is mined or recovered from oil and gas production is known as brimstone, or elemental sulphur. Sulphur produced as a by-product of ferrous and non-ferrous metal smelting is produced in the form of sulphuric acid.

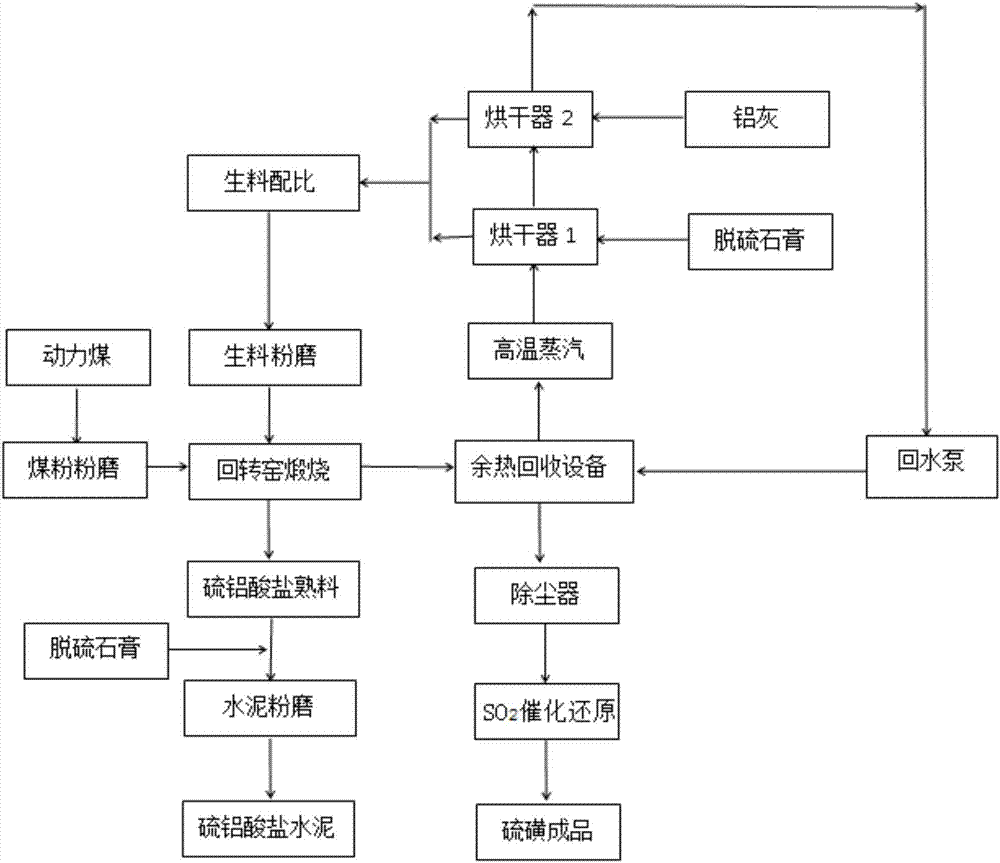

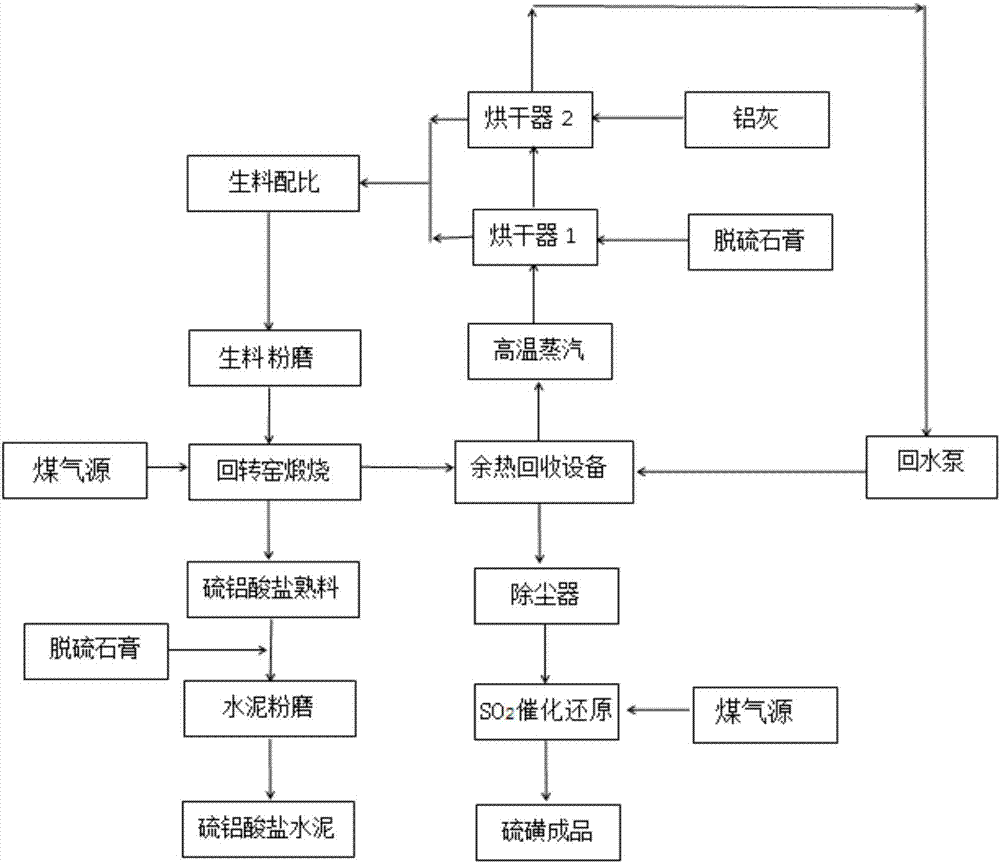

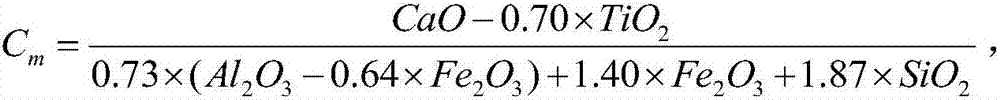

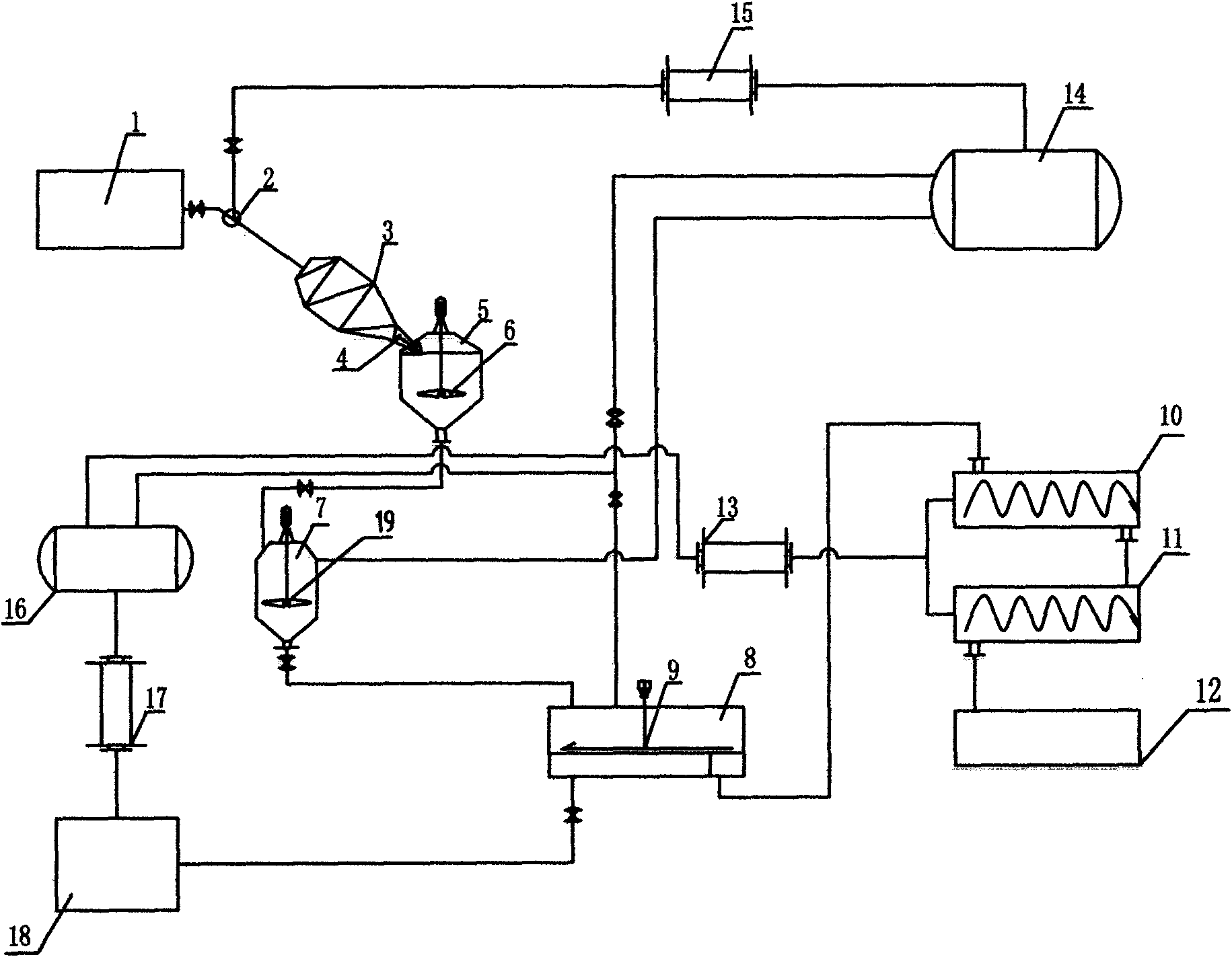

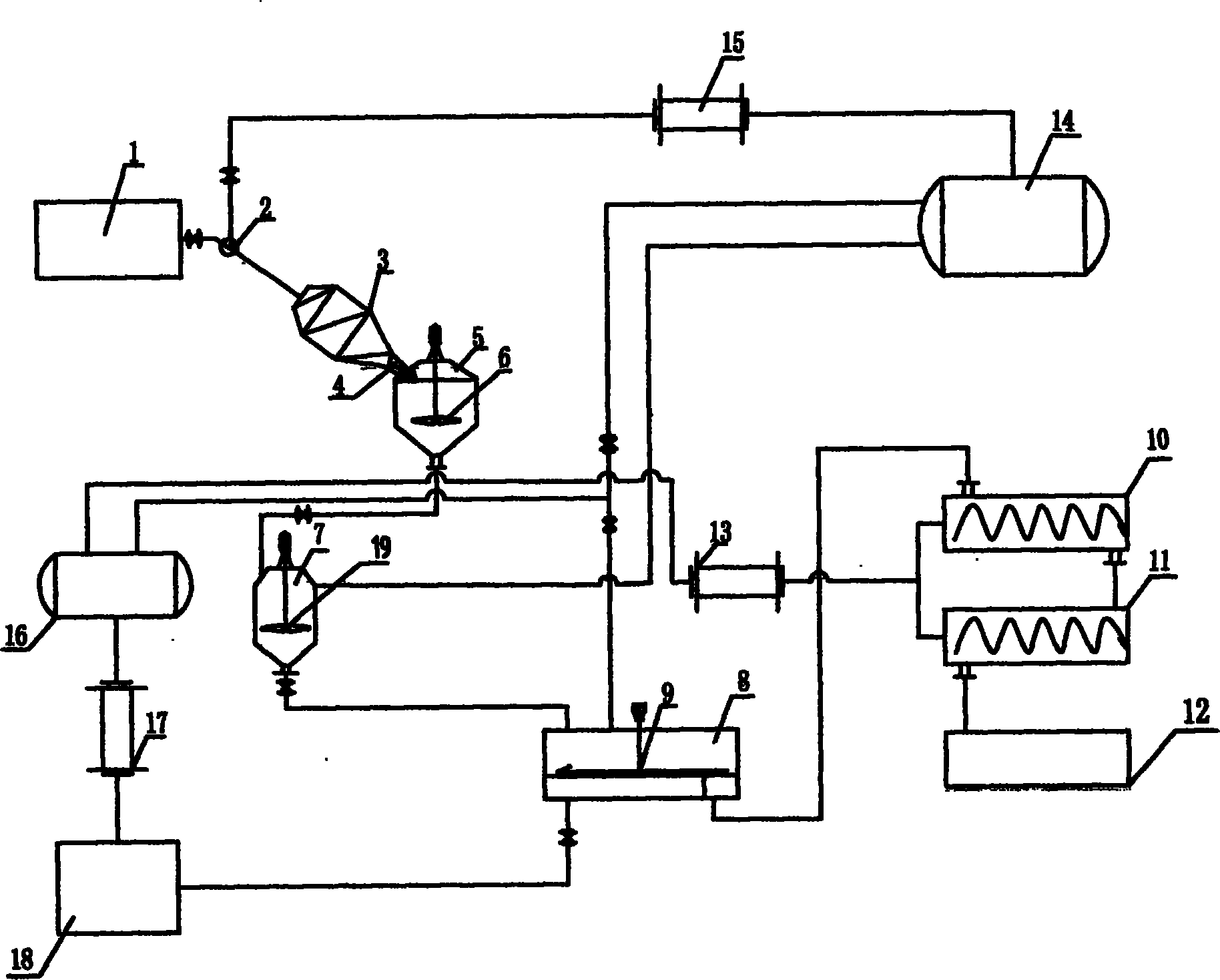

System and method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash

ActiveCN107056102AReduce usageMeet the formulation requirementsSulfur preparation/purificationCarbon monoxideCombustionSulfur product

The invention discloses a system and a method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash. The method comprises the following steps: (1) drying aluminum ash, and heating desulfurized gypsum for dehydration to obtain semi-hydrated gypsum; (2) mixing aluminum ash with semi-hydrated gypsum according to a preset ratio, pulverizing, and homogenizing; (3) calcining the pulverized and homogenized mixture of aluminum ash and semi-hydrated gypsum while adding coal dust to the mixture, and carrying out oxygen enriched combustion to obtain sulfo-aluminate cement clinker and sulfur dioxide-containing flue gas; (4) mixing sulfo-aluminate cement clinker and desulfurized gypsum according to a ratio, and pulverizing to obtain sulfo-aluminate cement; and (5) dedusting the sulfur dioxide-containing flue gas, and carrying out catalytic reduction to obtain a sulfur product, wherein the mass ratio of aluminum ash to desulfurized gypsum to carbon powder is (33-39):(61-66):1.

Owner:中芈(山东)环保科技有限公司

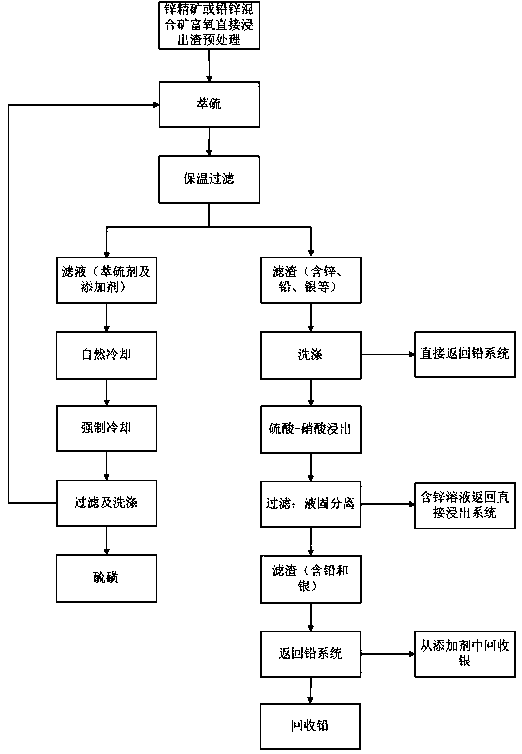

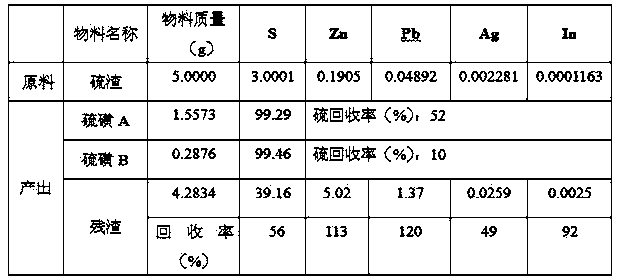

Process for recovering sulfur, lead, zinc and silver from oxygen-enriched directly leached residues of zinc concentrates or lead-zinc mixed ores

ActiveCN104195345AHigh recovery rateQuality improvementSulfur compoundsProcess efficiency improvementLead systemPre treatment

The invention discloses a process for recovering sulfur, lead, zinc and silver from oxygen-enriched directly leached residues of zinc concentrates or lead-zinc mixed ores, which comprises the following steps: adding the oxygen-enriched directly leached residues of zinc concentrates or lead-zinc mixed ores, which are not processed or subjected to drying, grinding and screening pretreatment, into a heating device in which mixed liquid of a sulfur extracting agent and an additive metered in a liquid-solid ratio of 8-15 is filled, after heating for reaction, filtering the obtained object while the obtained object is hot, and cooling and then filtering filter liquor so as to obtain a sulphur product; after filter residues are washed by using a sulfur extracting agent and ethanol, returning the obtained product to a lead system to recover lead and silver; after washing liquid is volatilized, cooled and recovered, returning the obtained object to use; after the sulfur extracting agent is filtered, regenerating, and returning the obtained object to a sulfur extracting process so as to cyclically participate in the reaction; and after a zinc-containing solution is filtered, returning the obtained product to a direct leaching system. The process is simple in process and equipment and high in sulfur recovery rate and product quality, has no pollution to the environment, both can realize the efficient and economic extraction of sulfur in floating sulfur residues, and can realize the respective efficient and economic recovery of zinc, lead and silver in floating sulfur residues.

Owner:株洲起源科技有限责任公司

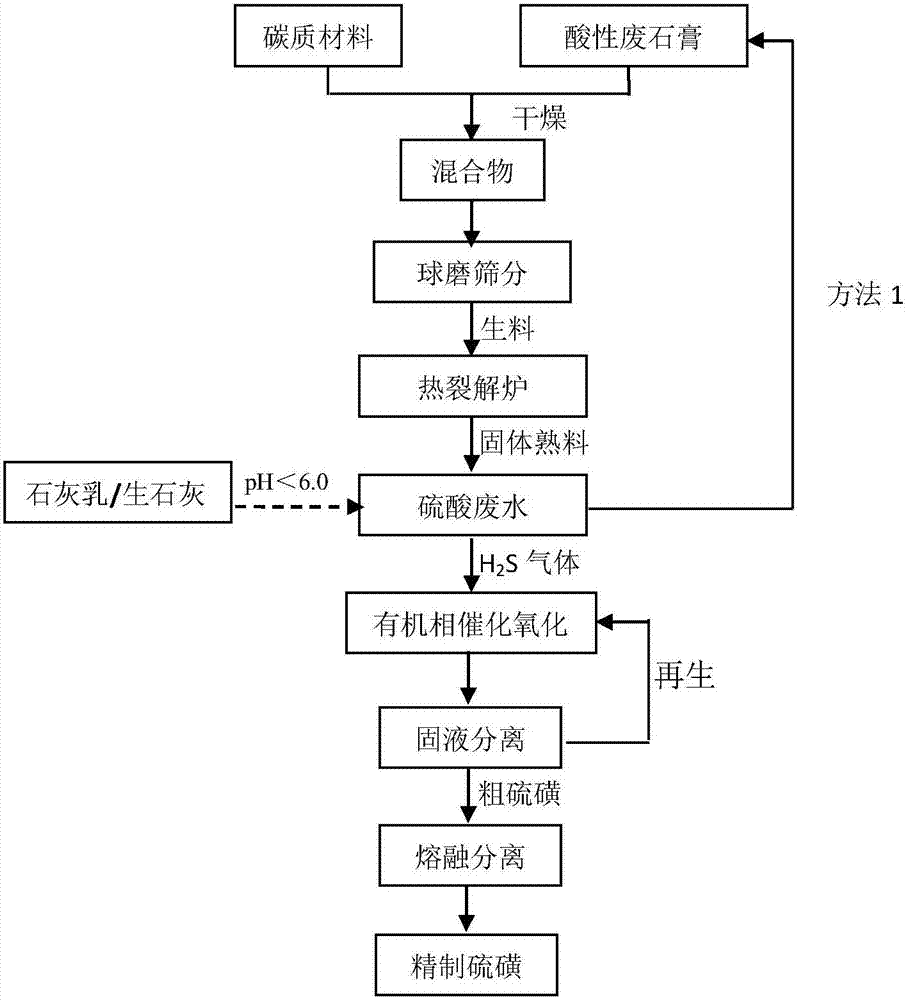

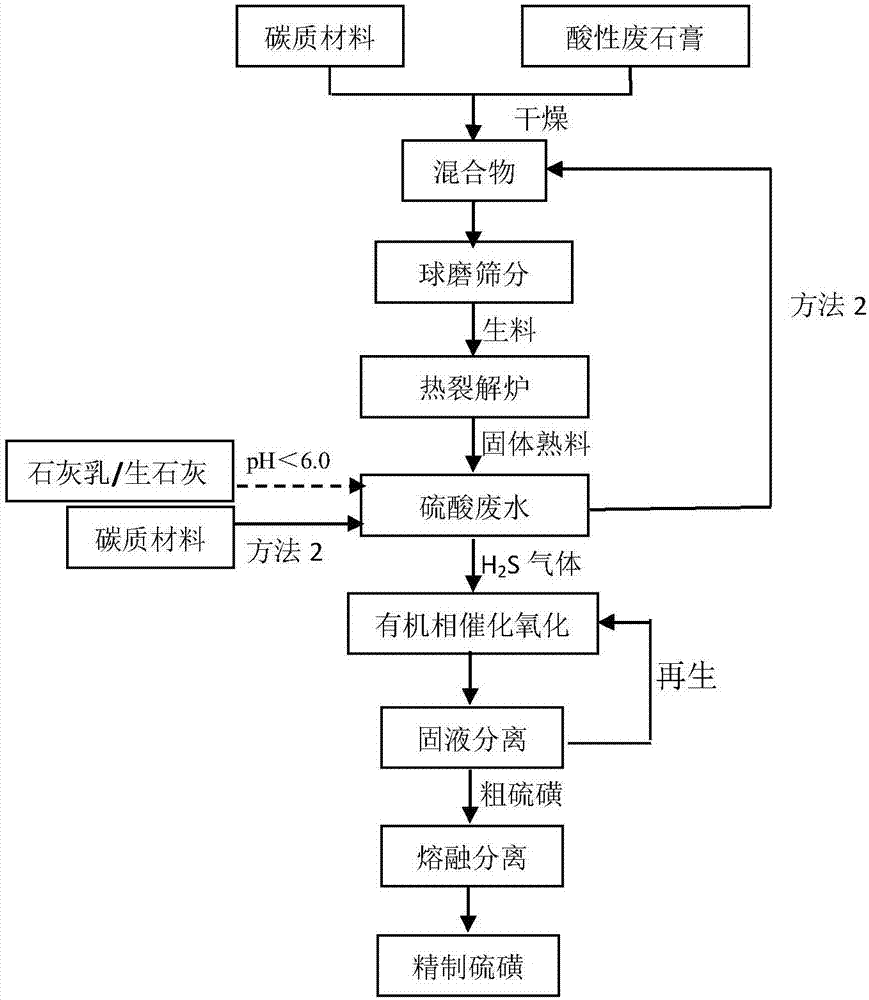

Process for comprehensively treating and recycling acid waste gypsum

ActiveCN107324288AMake full use of resourcesImprove adsorption capacityTreatment involving filtrationSulfur preparation/purificationSulfur productWastewater

The invention discloses a process for comprehensively treating and recycling acid waste gypsum and belongs to the fields of environmental protection as well as chemistry and chemical engineering. The process comprises the following steps: firstly mixing a carbonaceous material and acid waste gypsum in a certain ratio, and carrying out thermal cracking under anoxic condition, so that solid clinker is obtained; treating wastewater containing sulfuric acid with the solid clinker, so that waste gypsum and hydrogen sulfide gas are produced, carrying out organic phase catalytic treatment on the hydrogen sulfide gas to obtain a sulfur product, and recycling the waste gypsum again. The technology also comprises the steps of mixing one or more of the carbonaceous material, lime milk and quicklime when the solid clinker is recycled, putting acid wastewater, obtaining a mixture of the carbonaceous material and the acid waste gypsum and then participating in recycling. The process disclosed by the invention has the advantages that treatment efficiency is high, operation is stable, discharge is reduced, recycling is realized and a sulfur resource is obtained, so that wastewater-containing gypsum is subjected to harmless treatment, reduction and recycling.

Owner:海若斯(北京)环境科技有限公司

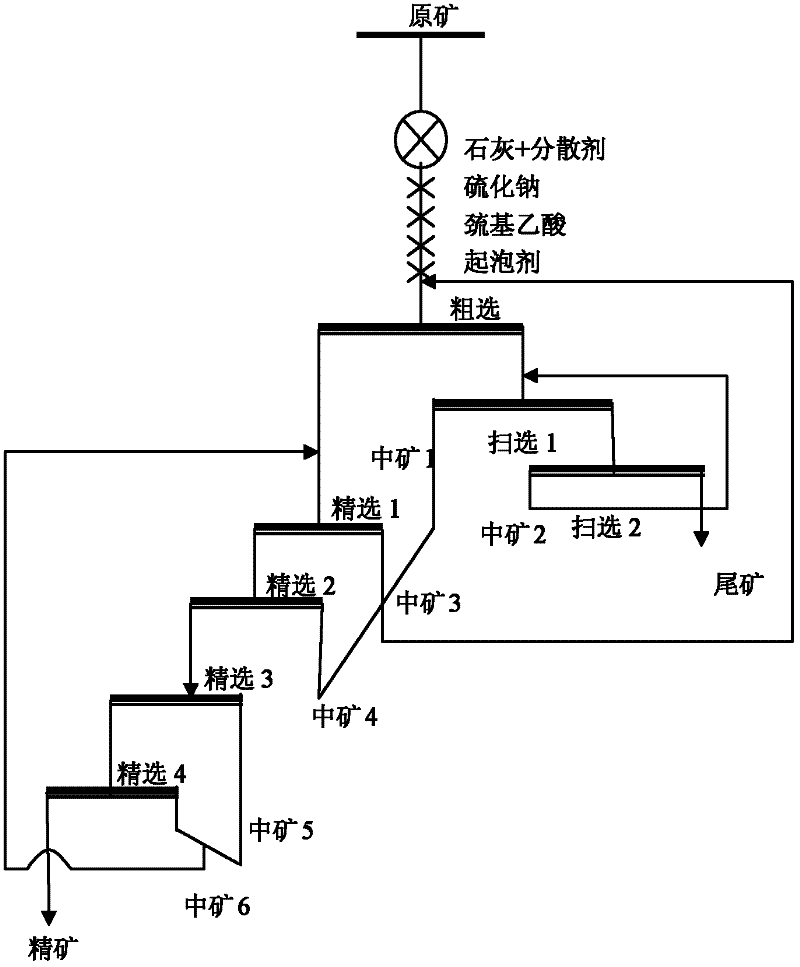

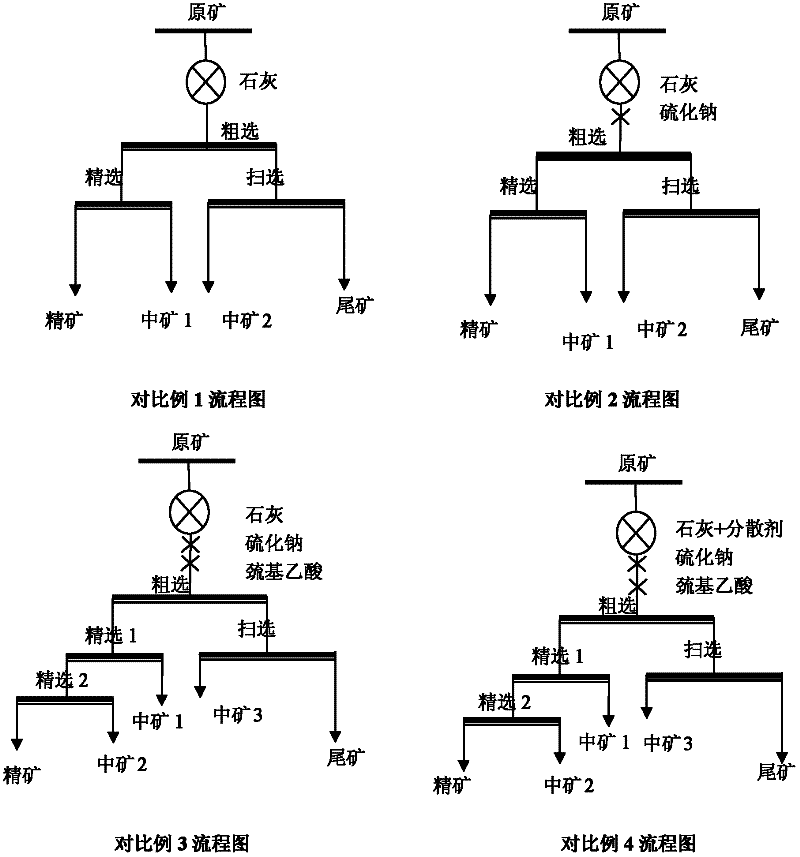

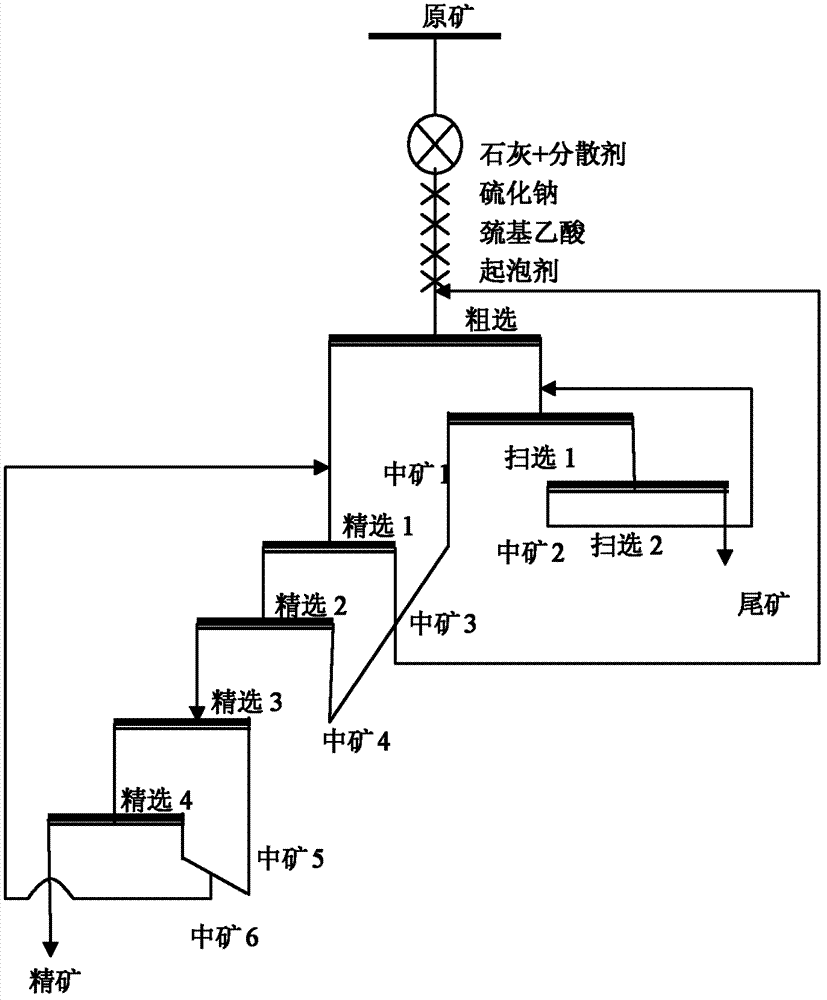

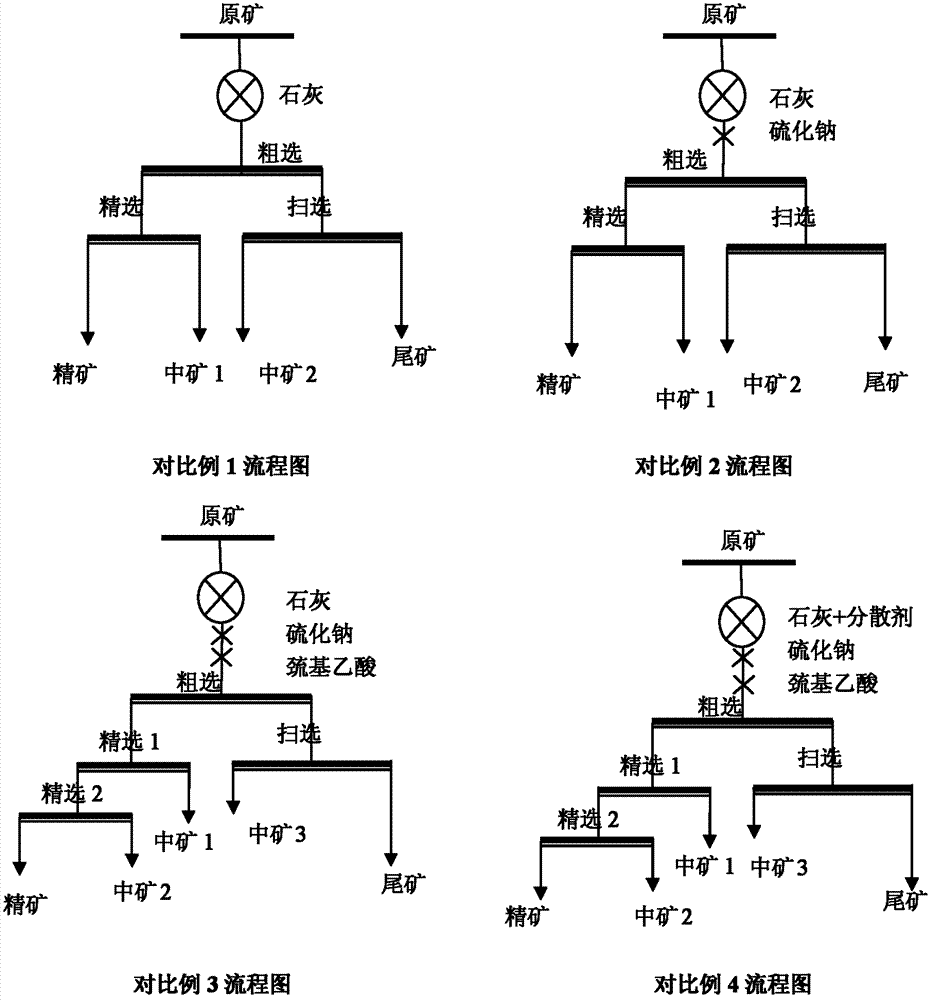

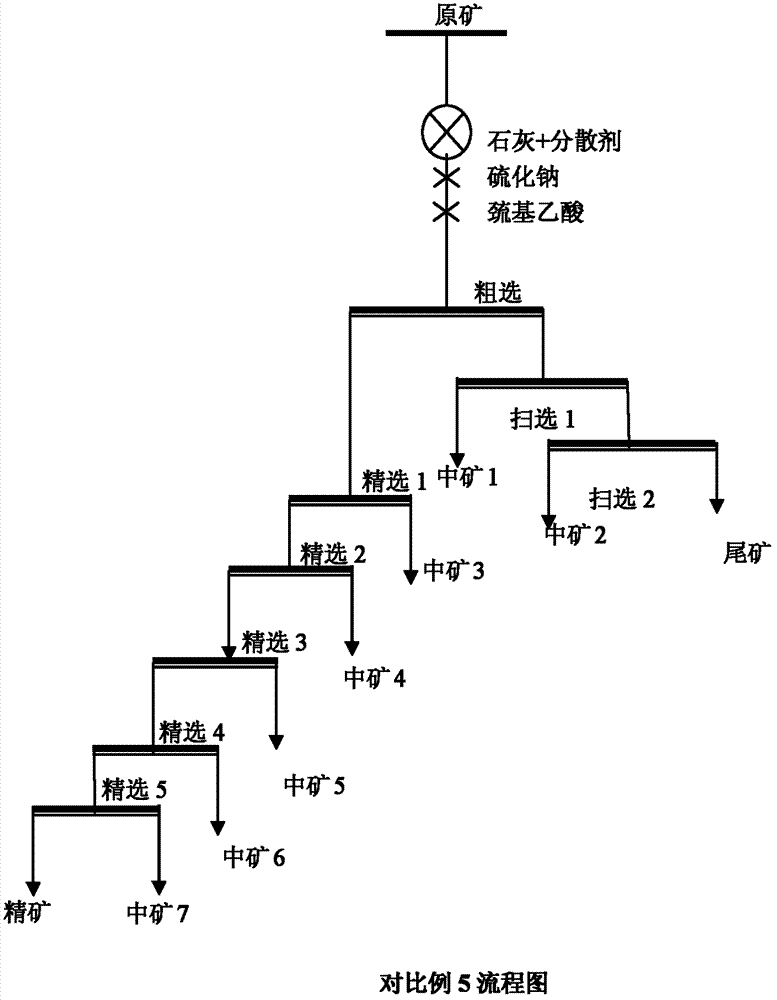

Beneficiation method for separating zinc sulfide ores from sulphur in wet-method zinc smelting slag

The invention provides a beneficiation method for separating ores from sulphur in wet-method zinc smelting slag. The beneficiation method includes firstly, realizing fine grinding of the wet-method zinc smelting slag while adding dispersing agent and realizing separation and dispersing of the sulphur and the zinc sulfide ores; secondly, utilizing combined suppressant to suppress the zinc sulfide ores in leaching slag in a floatation process after the leaching slag is ground, realizing floatation separation of the zinc sulfide ores and the sulphur via once roughing, twice scavenging and four times of concentration under the condition of adding a small quantity of foaming agent, and obtaining high-quality sulphur products and zinc concentrate capable of returning to a wet-method zinc smelting process; and thirdly, leading ores in first concentration, second concentration and first scavenging to return to roughing in a centralized manner and leading ores in third concentration and fourth concentration to return to the first concentration in a centralized manner in a floatation technical process. The beneficiation method effectively realizes separation of the sulphur and the zinc sulfide ores in the zinc sulfide concentrate wet-method leaching slag, the quality of the sulphur products is improved, zinc elements are recycled effectively, and comprehensive utilization rate of the wet-method zinc smelting process is improved.

Owner:CENT SOUTH UNIV

Comprehensive utilization method of sulfur slag generated in hyperbaric oxygen leaching of zinc concentrate

InactiveCN104120272AReduce pressure on environmental protectionReduce pollutionSulfur preparation/purificationProcess efficiency improvementSlagDistillation

The invention relates to a comprehensive utilization method of sulfur slag generated in hyperbaric oxygen leaching of zinc concentrate, belonging to the field of comprehensive utilization of industrial residues in metallurgical industry. The method disclosed by the invention comprises the following steps: adding sulfur slag to a leaching tank containing water and carbon disulfide, wherein the water plays a sealing role, and prevents carbon disulfide from volatilizing in the leaching process; obtaining a high-quality sulfur product by vacuum filtration and distillation after reaction under stirring; obtaining enrichment slag of gathering zinc-mercury from filter residues after washing and drying. The sulfur content of the sulfur product obtained by adopting the method is more than 99.5%, Hg content is smaller than 0.02mg / kg, the Zn content in the enrichment slag can be up to about 25%, Ag content is more than 1600g / t, and the Hg content is about 0.5%. By adopting the technique, industrial waste sulfur slag can be fully utilized, a new application way is developed for utilization of the sulfur slag, waste materials are changed into treasures, meanwhile, the environmental protection pressure of a smelting plant can be relieved, the environmental pollution can be reduced, and the economic benefits of enterprises are improved.

Owner:KUNMING UNIV OF SCI & TECH

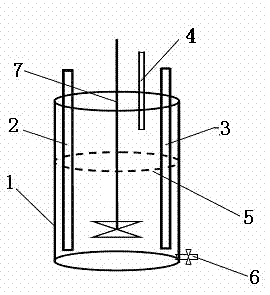

Integrated method for wet-process desulfurization, denitrification demercuration and dearsenification of complexing ferroporphyrin smoke based on supergravity

InactiveCN103432878AEasy to removeImprove regeneration efficiencyDispersed particle separationAir quality improvementToxicantSulfide

The invention discloses an integrated method for wet-process desulfurization, denitrification demercuration and dearsenification of complexing ferroporphyrin smoke based on supergravity. The method comprises the following steps of firstly, absorbing SOx by utilizing inorganic sulfide, desulfurating, meanwhile, reacting inorganic sulfide with toxic heavy metals such as mercury and arsenic in the smoke so as to generate an insoluble vulcanized salt; utilizing a complexing ferroporphyrin to absorbing NOx by utilizing complexing ferroporphyrin for denitration; and regenerating ab absorber by utilizing inorganic sulfide as a reducing agent. The method provided by the invention has the advantages that a supergravity machine is adopted as gas-liquid mass transfer strengthening equipment, the method is beneficial to removal of toxicants such as SOx, NOx, mercury and arsenic, the regeneration efficiency of the absorbent is high, an absorption liquid is applied in a circulating manner, a reducing agent inorganic sulfide is oxidized so as to generate sulphur which can be recovered, sulphur is processed into a high quality sulphur product, and the secondary pollution is not generated; the process is simple, the absorption efficiency is high, the dust is thoroughly removed, the desulfurization degree is more than 99%, the denitration rate is more than 96%, and mercury and arsenic in the smoke are fully basically removed.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Method for continuously preparing poly-sulphur

InactiveCN102145878AReduce consumptionImprove qualitySulfur preparation/purificationSolventVacuum drying

Owner:胡学军

Technology for processing alkylated waste acid by using sulphur apparatus

ActiveCN106256760AImprove conversion rateIncrease the ability to remove iron scaleSulfur preparation/purificationCarbon depositMass content

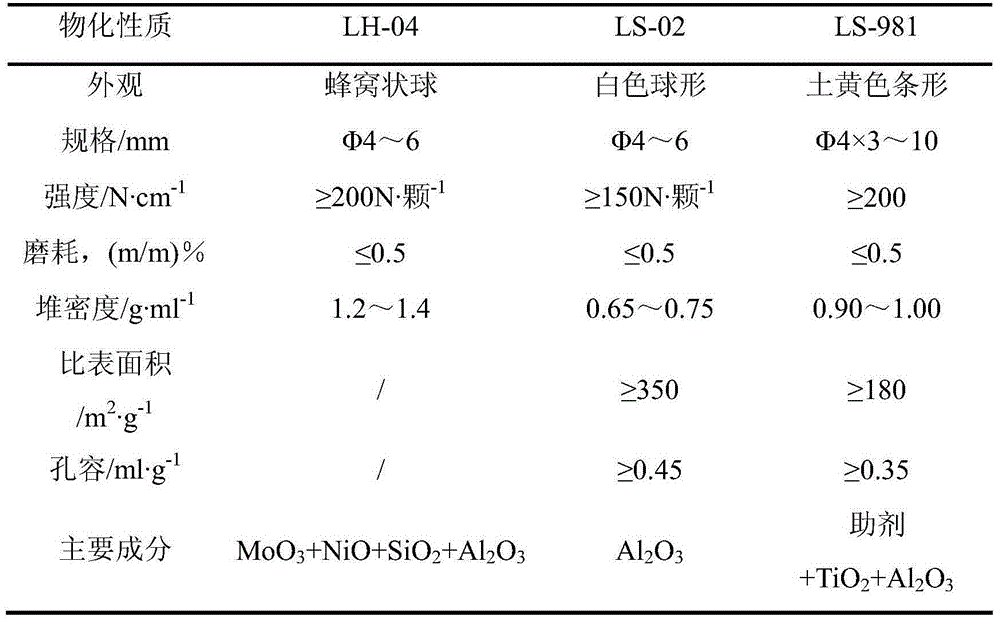

The invention belongs to the technical field of petroleum processing, and concretely relate to a technology for processing alkylated waste acid by using a sulphur apparatus. In the technology, the upper part of a primary converter is filed with a catalysis protective agent, the lower part is filled with a multifunctional sulfur recovery catalyst; and the whole part of a secondary converter is filled with an alumina-based sulfur recovery catalyst. The technology realizes the low investment and high efficiency processing of the alkylated waste acid; SO3 in the high-temperature process gas can be processed in a reasonable mode, the apparatus corrosion problem is avoided, the SO3 conversion rate can reach 97% or more; influence of remainder iron in the waste acid is eliminated, the iron mass content in the sulphur product is less than 0.005%; the influence of carbon deposit on the catalyst is eliminated, and a claus catalyst is effectively protected. The catalyst can keep high claus catalytic activity and organic sulfur hydrolysis activity, the total sulfur conversion rate of the apparatus can reach 96.5% or more. The catalyst service life is prolonged, and the long-period operation of the sulphur recovery device is achieved.

Owner:CHINA PETROLEUM & CHEM CORP

Sulphur cement products

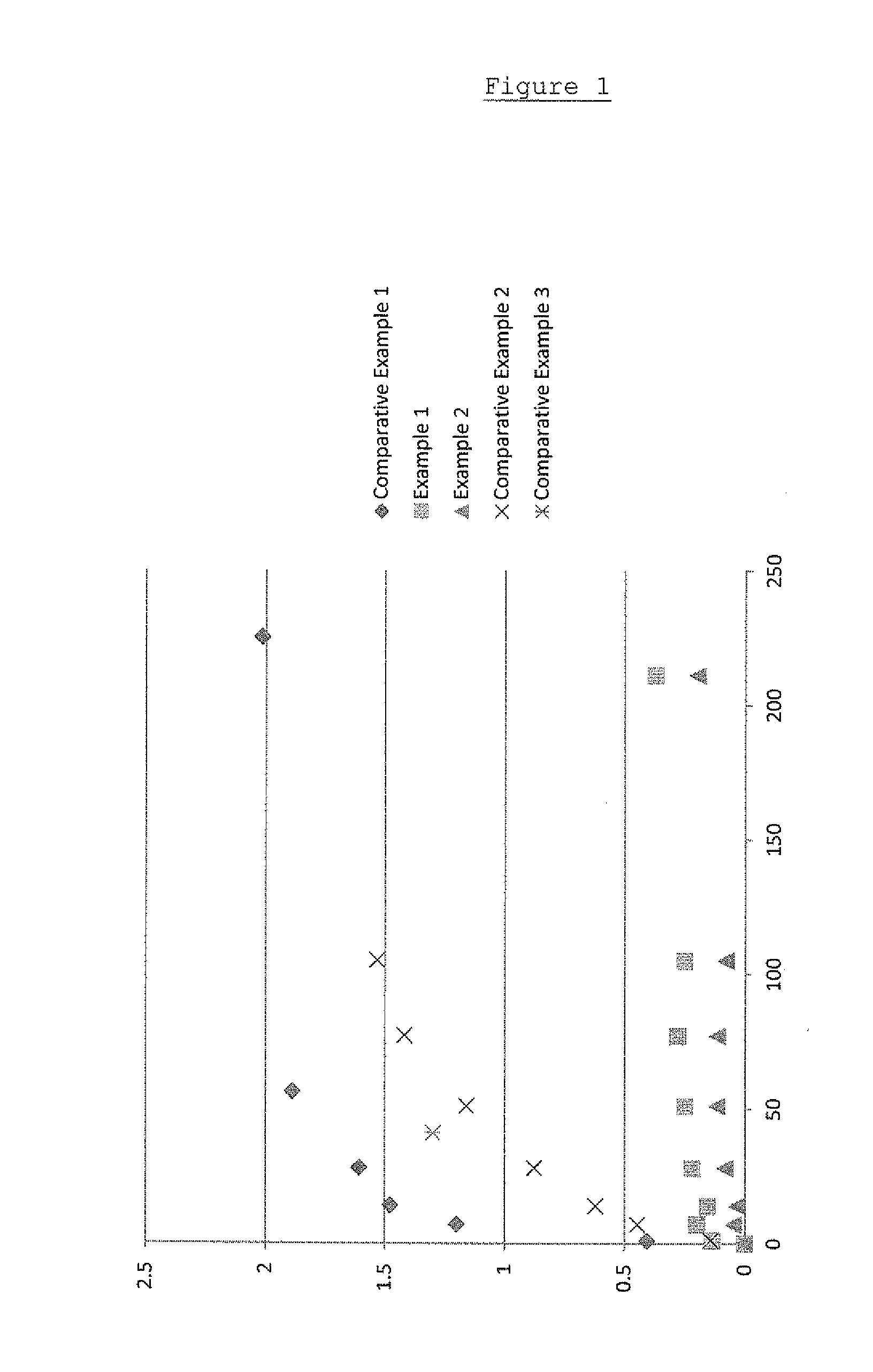

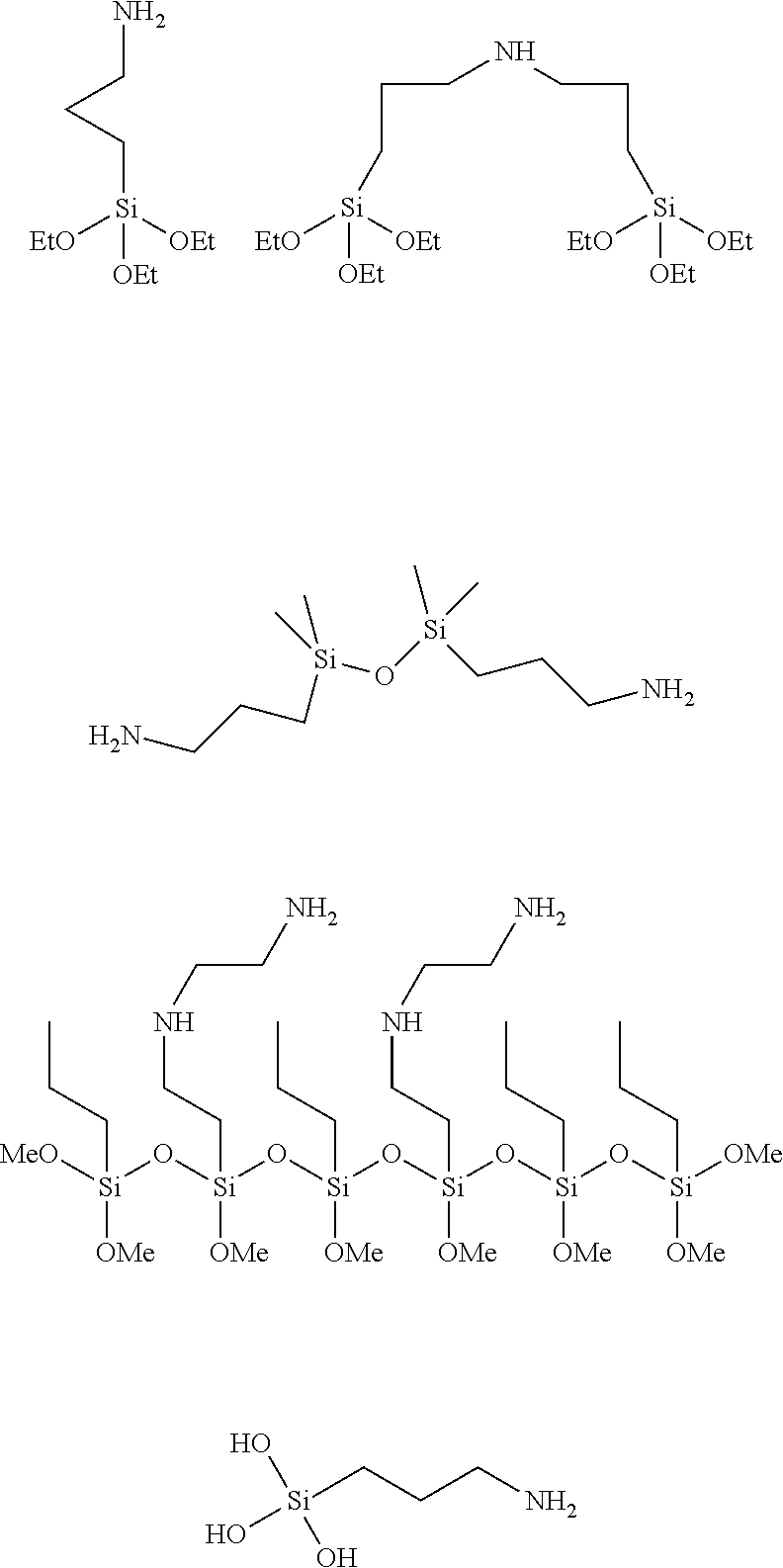

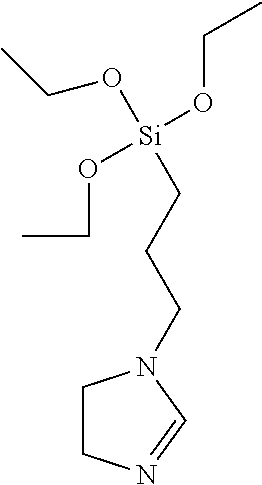

ActiveUS20140007792A1Improve water stabilityLarge specific surface areaFibre treatmentMaterials scienceSulphur product

A sulphur cement product comprising sulphur, filler, sand having a surface area of greater than 0.5 m2 / g, and an organosilane having at least one amino functional group is disclosed. Further, a process for the preparation of such cement sulphur product is disclosed.

Owner:SHELL USA INC

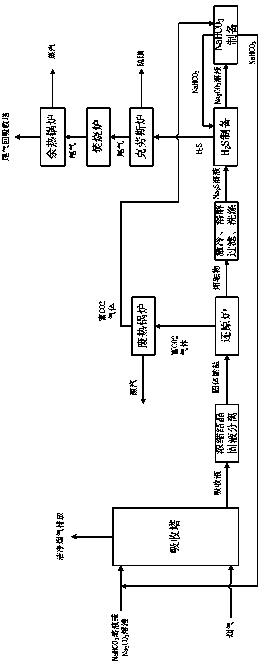

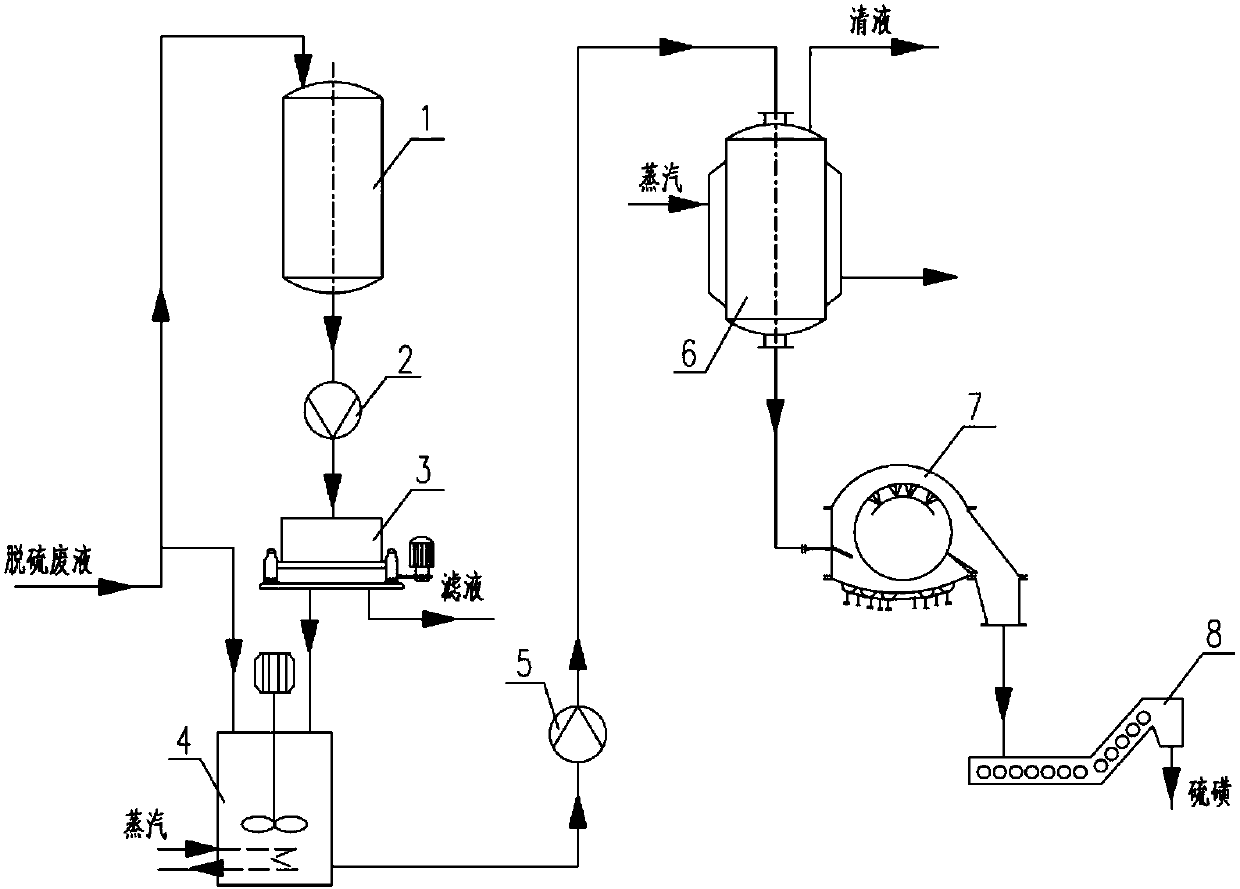

Production process for preparing sulfur by recovering sulfur dioxide from flue gas

ActiveCN103879970ANo emissionsNo cloggingEnergy inputSulfur preparation/purificationSodium saltSodium sulphide

The invention provides a production process for preparing sulfur by recovering sulfur dioxide from flue gas. The production process comprises the following specific steps of: (A) carrying out desulfurization on the flue gas by sodium carbonate or sodium bicarbonate solution in an absorbing tower, concentrating and crystallizing absorbing solution after reacting with the flue gas, and separating out solid sodium salt; (B) feeding the solid sodium salt into a reducer, and under the action of a reducing agent, reducing the solid sodium salt into sodium sulfide; carrying out chilling, dissolving, filtering and washing on molten mixture from the reducer to obtain clean liquid which is aqueous solution of sodium sulfide; recovering the heat of gas with rich CO2 discharged by the reducer by a waste heat boiler to generate steam, and feeding the steam to next step for treatment; and (C) adding sodium bicarbonate into the aqueous solution of sodium sulfide obtained in the step (B), feeding H2S obtained by reaction into a claus furnace, and manufacturing a sulfur product; and feeding sodium carbonate solution obtained by reaction to react with the rich CO2 in the step (B), and obtaining sodium bicarbonate which can be recycled.

Owner:CHENGDU HUAXITANG INVESTMENT

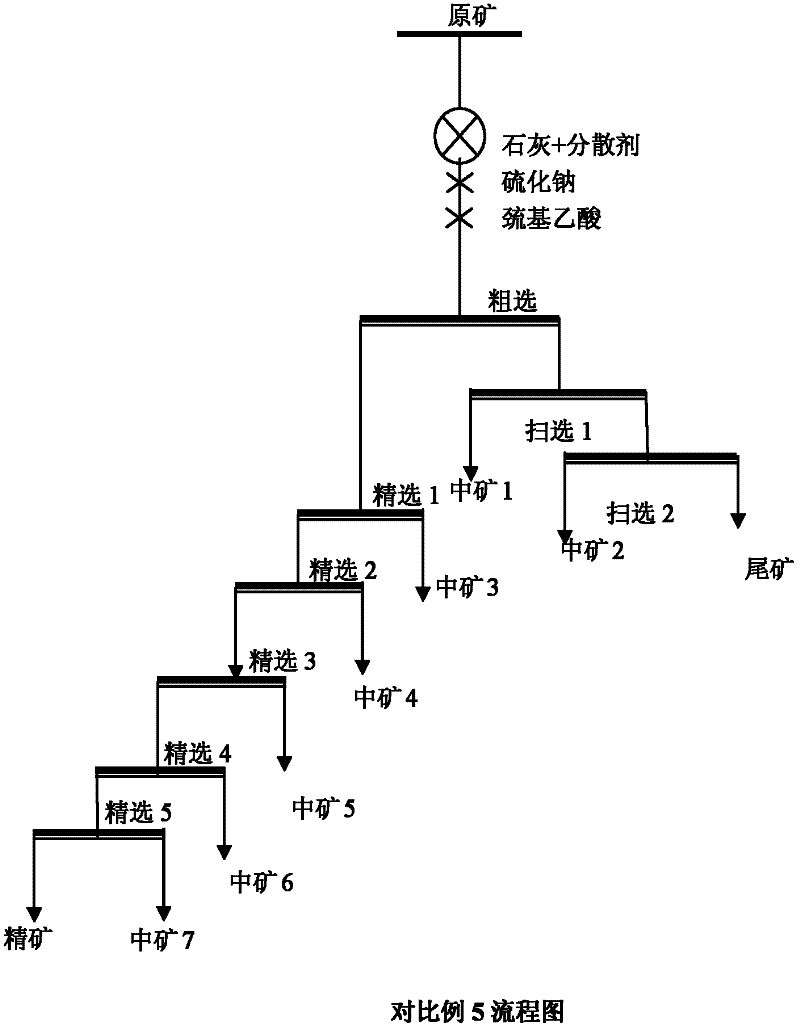

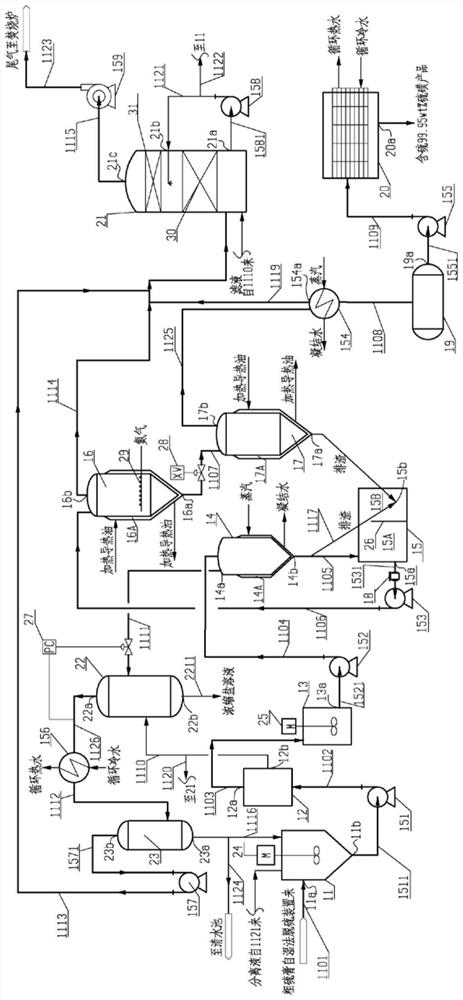

Method and device for refining sulfur from desulfurized sulfur paste

The invention discloses a method and a device for refining sulfur from desulfurized sulfur paste. A sulfur paste pulping tank is connected with wet desulfurized sulfur paste through a first pipeline, and is communicated with a sulfur paste concentration filter through a second pipeline; the sulfur slurry concentration filter is connected and communicated with the sulfur slurry buffer tank through a third pipeline, is connected and communicated with the vacuum evaporation crystallization tank through a tenth pipeline, and is connected and communicated with the tail gas washing tower through a twentieth pipeline; slurry in the sulfur slurry buffer tank is communicated with the sulfur melting kettle through a fourth pipeline; the sulfur melting and sublimation combined device for refining sulfur from sulfur paste is adopted, the sulfur product obtained by refining and recycling the sulfur paste reaches the superior grade of industrial sulfur, and meanwhile, the whole device for refining sulfur from sulfur paste is automatic, continuous and free of secondary pollution; the method is particularly suitable for treating a large amount of sulfur paste as a byproduct of a wet oxidation desulfurization device in the fields of coal coking gas, petrochemical gas and the like.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

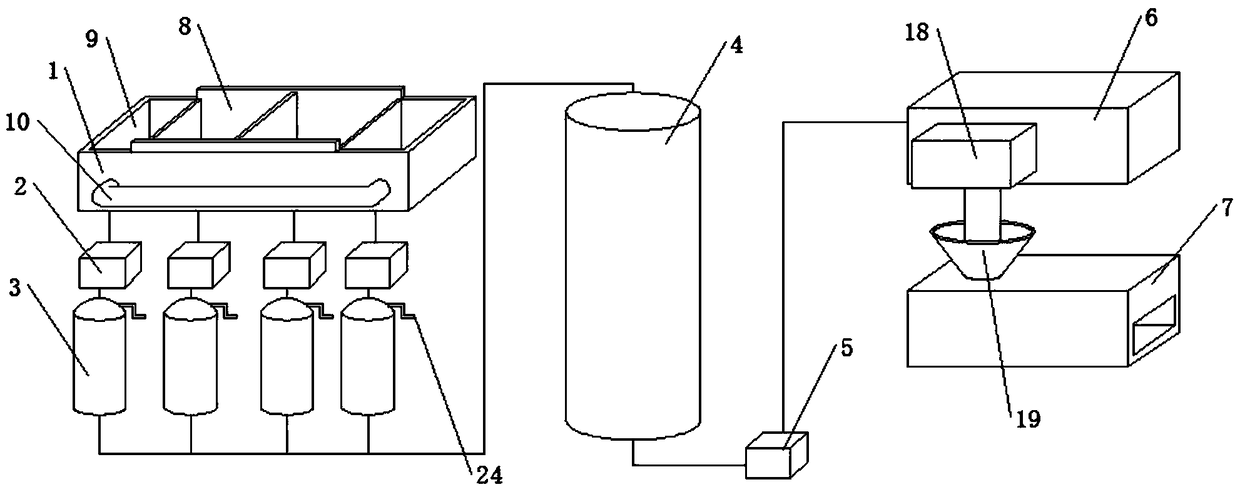

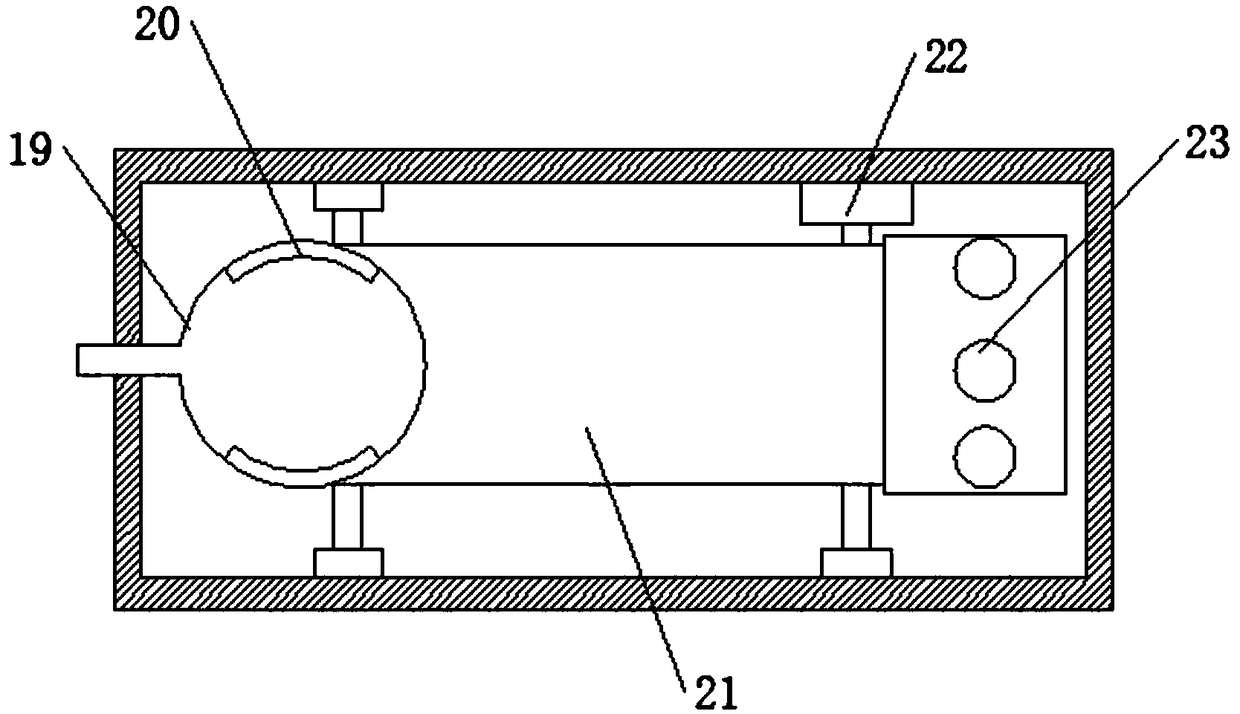

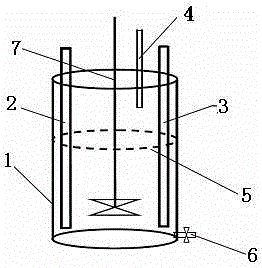

Sulphur refining equipment system

PendingCN109455673AReduce wasteImprove resource utilization efficiencySulfur compoundsChemistryClear liquid

The invention discloses a sulphur refining equipment system, comprising a sulphur slurrying basin, a plurality of sulphur foam pumps, sulphur melting kettles, a liquid sulphur tank, a liquid sulphur pump, a granulator and a packaging machine. The sulphur slurrying basin is divided into two big chambers and two small chambers and the small chambers are communicated through a connecting pipe; the sulphur foam pumps are arranged at the bottom of the sulphur slurrying basin; the sulphur melting kettles are arranged at the bottom of the sulphur slurrying basin and are communicated with the sulphurfoam pumps; clear liquid discharge pipelines are respectively arranged at the bottom of the sulphur melting kettles; the liquid sulphur tank is arranged beside the sulphur melting kettles and communicated with the sulphur melting kettles; the liquid sulphur pump is arranged on one side of the liquid sulphur tanks. The sulphur refining equipment system is stable and efficient in running and provides a guarantee to full refining of sulphur; sulphur products prepared by the system have high good quality and high purity. Compared with the other processes for producing sulphur cream or blocks only,the system is much environmentally friendly and has remarkable benefit.

Owner:HUANENG TIANJIN COAL GASIFICATION POWER CO LTD

Method for recovering sulfur from zinc oxygen pressure leached high-sulfur slag

The invention discloses a method for recovering sulfur from zinc oxygen pressure leached high-sulfur slag, and belongs to the field of non-ferrous metal metallurgy. The method comprises the steps of firstly, performing blank roughing; adding lime into roughing tailings for size mixing, then adding a combined inhibitor of sodium sulfide, zinc sulfate and sodium sulfite, a collecting agent and a foaming agent, and carrying out two-stage dosing roughing; and after the concentrates I, II and III obtained through roughing are combined and mixed with lime, adding an inhibitor for second-stage concentration, wherein the concentrate II obtained through concentration is sulfur concentrate. According to the invention, separation of sulfur from minerals such as zinc sulfide, sulfate and silicate in the zinc oxygen pressure leaching high-sulfur slag is effectively achieved, the grade of sulfur products is improved, stockpiling of the zinc oxygen pressure leaching slag is reduced, favorable conditions are provided for comprehensive recovery of various elements, valuable elements such as lead, zinc and silver enter the tailing slag, the flotation tailings and the lead concentrate can be subjected to lead smelting together after ore blending, and then valuable elements such as lead, zinc and silver in the flotation tailings are further recycled.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST

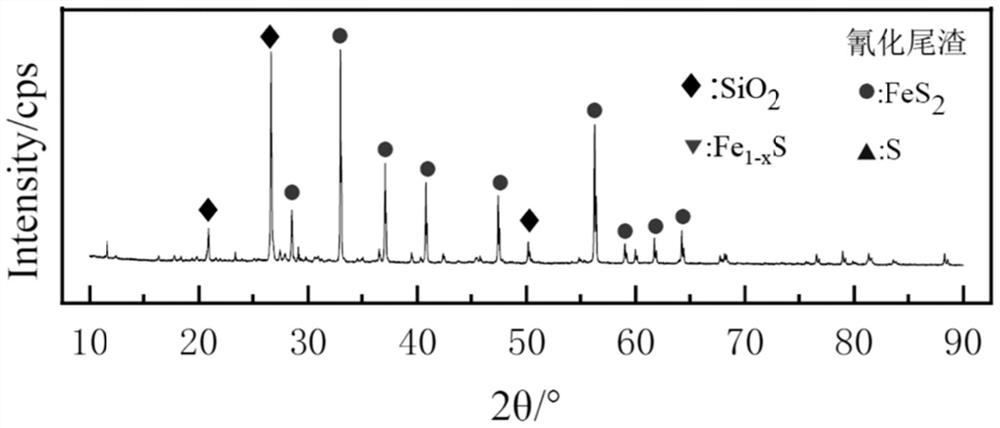

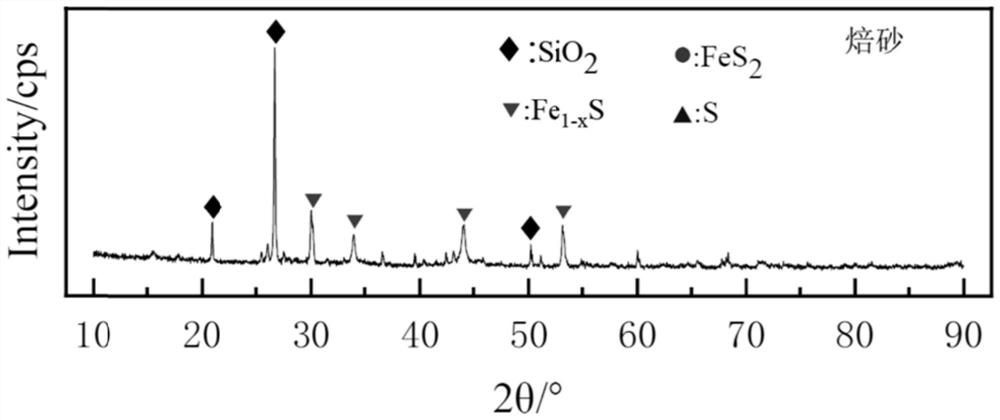

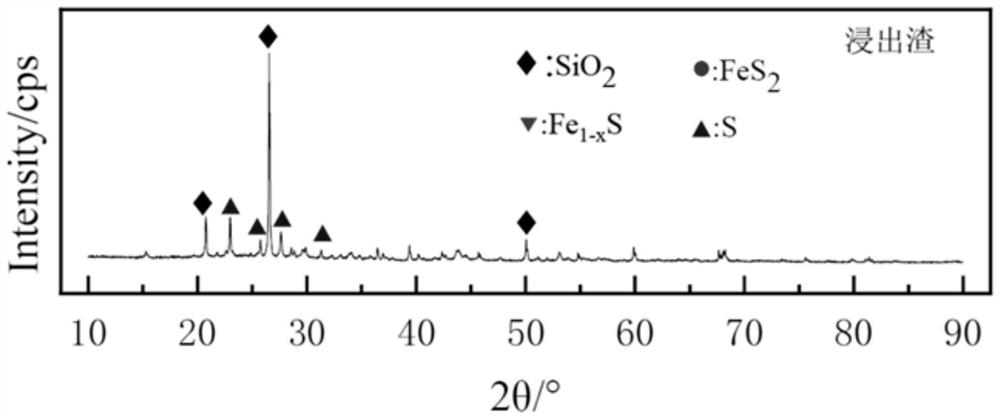

Method for treating cyanidation tailings by adopting anaerobic roasting-persulfate leaching combined technology

PendingCN114737059ARealize resource utilizationChemically stableOrganic compound preparationSulfur preparation/purificationSlagSulphur product

The invention discloses a method for treating cyanidation tailings by adopting an anaerobic roasting-persulfate leaching combined technology, which comprises the following steps: roasting dried cyanidation tailings in an anaerobic environment, controlling the temperature to pyrolyze pyrite to remove part of sulfur and convert the part of sulfur into pyrrhotite, and condensing sulfur steam to directly recover a sulfur product. Roasting slag is prepared into ore pulp, the ore pulp is oxidized and leached through persulfate, pyrrhotite in roasted sand can effectively activate the persulfate to generate SO4 <-> and OH <->, iron is leached through self-activation of the persulfate under the condition that an activating agent is not additionally added, and Fe ions in leachate are prepared into ferrous oxalate through the extraction-reverse extraction-photocatalysis technology. And after the gold-containing cyanidation tailings are treated, wrapping gold can be exposed and enriched to a great extent and can be further leached and recycled. According to the technology, pollution caused by SO2 emission in the cyanidation tailing treatment process is completely eradicated, meanwhile, enrichment and recovery of residual gold and value-added utilization of iron can be achieved, and the technology has important significance on recycling and reduction of the cyanidation tailings.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

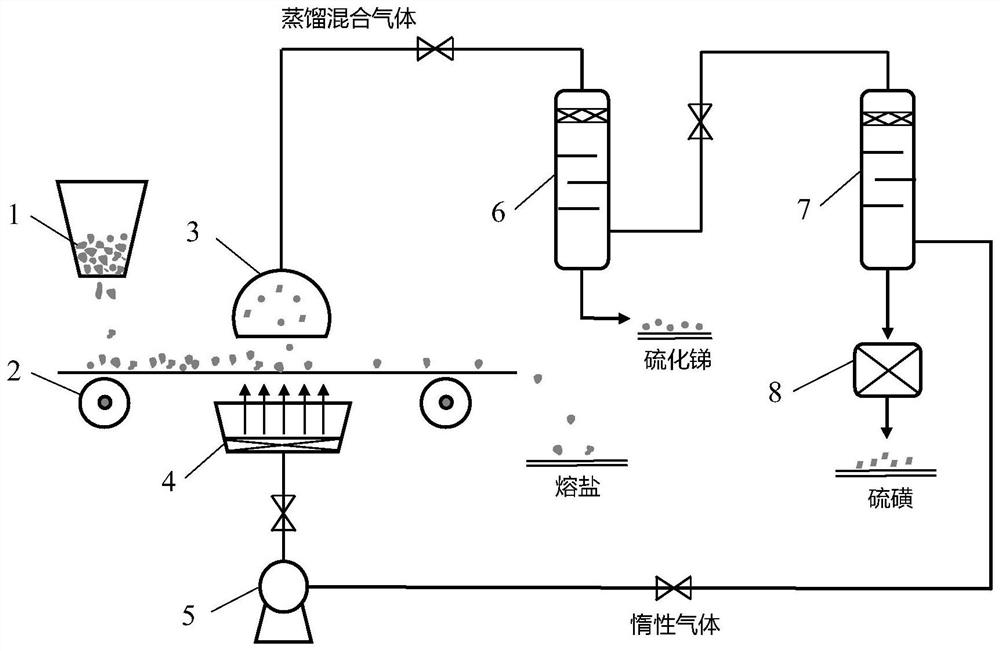

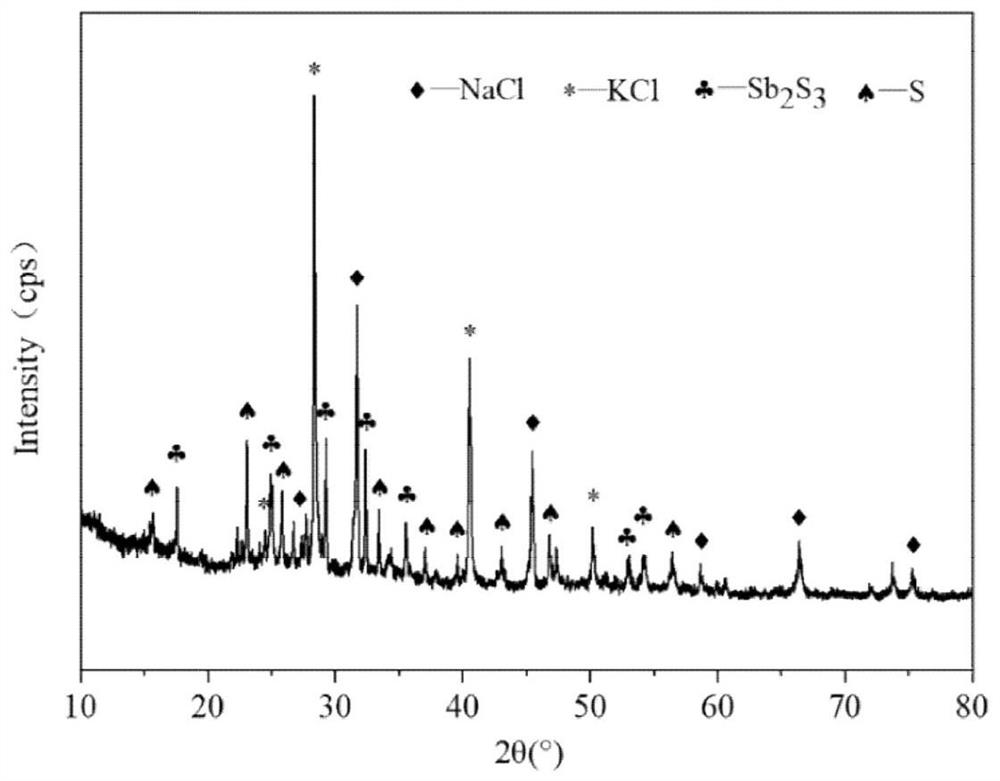

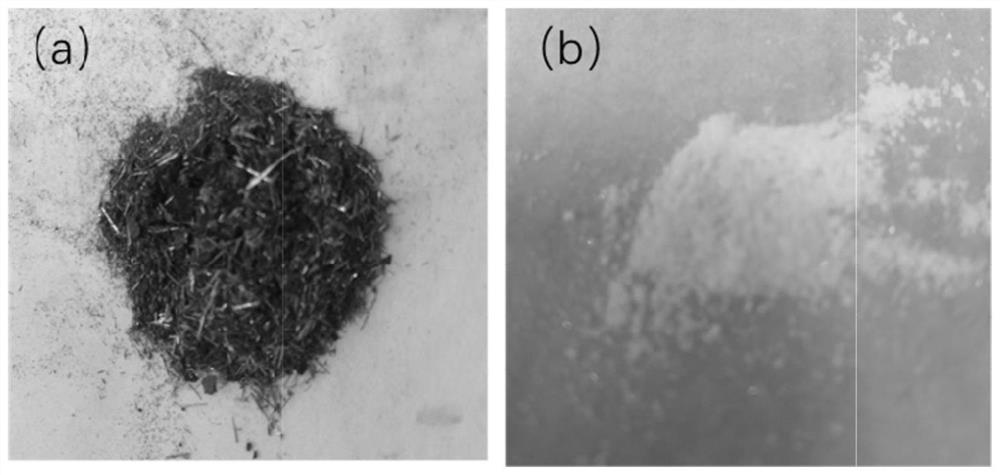

Method and system for purifying antimony sulfide concentrate molten salt electrolysis smoke dust and preparing sulfur

PendingCN114702070AEfficient separationImprove applicabilitySulfur preparation/purificationProcess efficiency improvementElectrolysisDistillation

The invention discloses a method and a system for purifying antimony sulfide concentrate molten salt electrolysis smoke dust and preparing sulfur. The method comprises the following steps: uniformly spreading the antimony sulfide concentrate molten salt electrolysis sulfur-containing smoke dust on a belt conveyor through a feeding funnel, transporting to a distillation area, and distilling volatile antimony sulfide and elemental sulfur in the smoke dust into a gas phase by high-temperature inert gas with a certain flow rate; then distilled mixed gas sequentially passes through a first condensing tower and a second condensing tower to be subjected to two-stage condensation, and antimony sulfide and elemental sulfur are separately separated out. The antimony sulfide and the molten salt are returned to the electrolysis process again, and the liquid sulfur is prepared into a high-grade sulfur product by a pelletizer. In addition, inert gas is recycled through the gas pressurizing machine and the heater. The method disclosed by the invention is simple and practical, and good effects can be obtained on purification of the flue gas generated by electrolysis of the antimony sulfide molten salt and preparation of sulfur.

Owner:CENT SOUTH UNIV

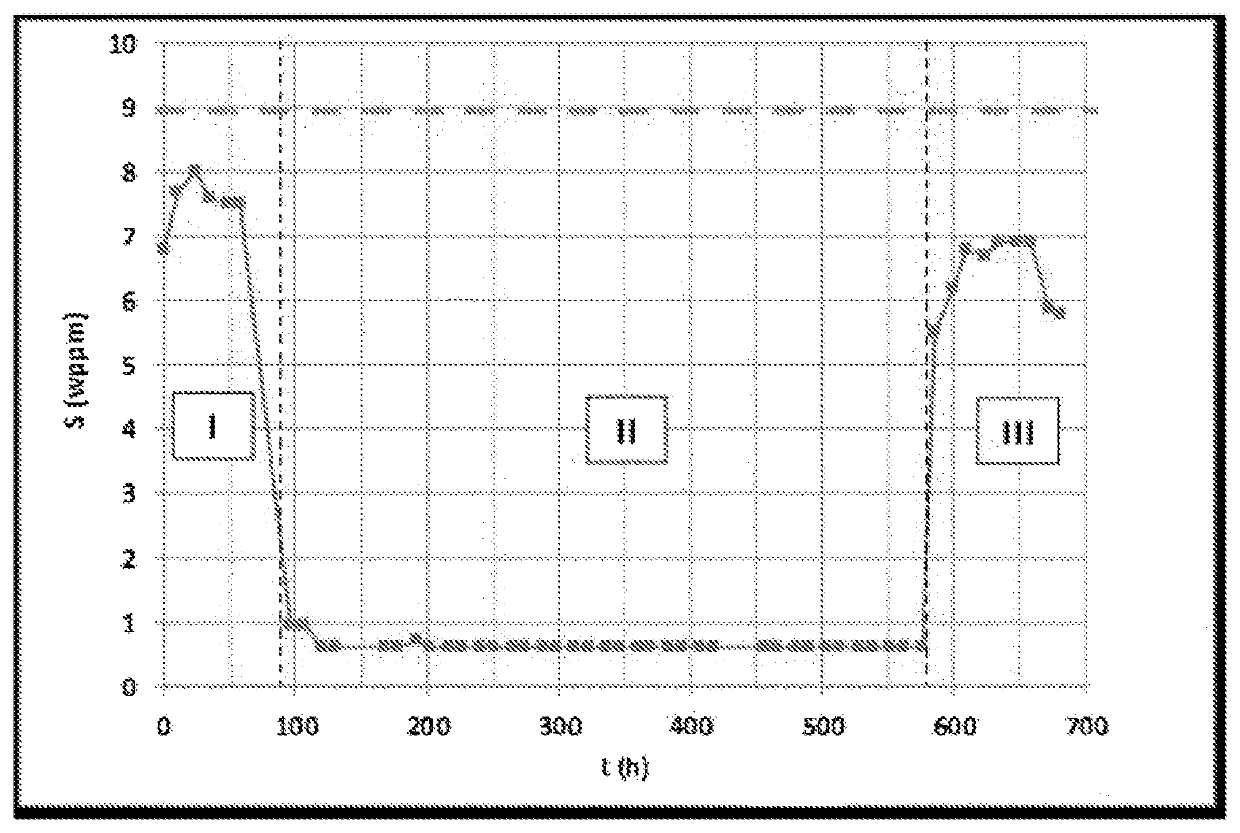

Deep desulphurization of low sulphur content feedstock

ActiveUS11492560B2Catalyst activation/preparationTreatment with hydrotreatment processesPhysical chemistryProcess engineering

The invention pertains to a process for deep desulphurization of low sulphur content feedstock comprising the steps of providing a low sulphur content hydrocarbon feedstock and contacting said hydrocarbon feedstock with a cobalt-molybdenum desulphurizing system or a nickel-molybdenum desulphurizing system in an oxide form in order to obtain a very low sulphur product comprising less than 5 ppm by weight sulphur.

Owner:TOTAL MARKETING SERVICES SA

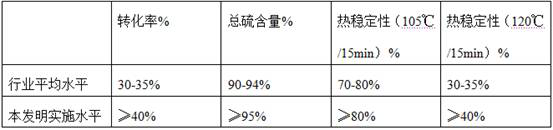

High stability sulphur product and production process thereof

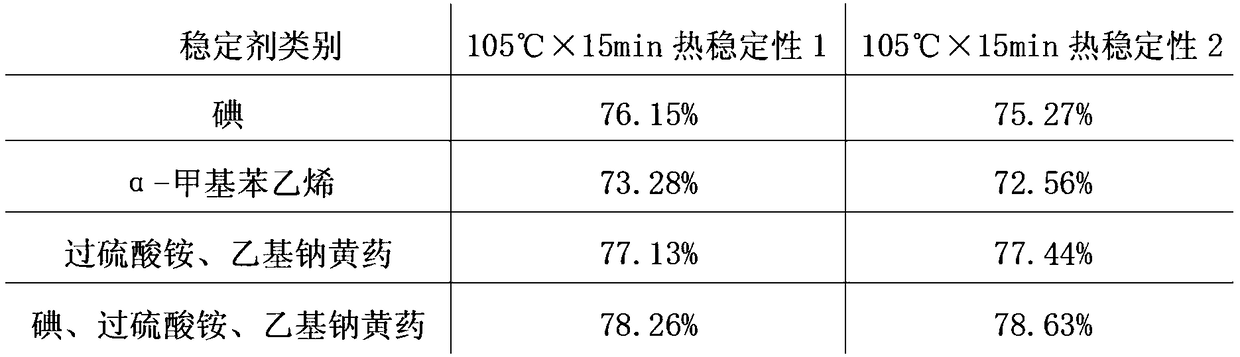

ActiveCN108394868AProtection against sulfur content effectsImprove thermal stabilitySulfur preparation/purificationSulfur productThermal stability

The invention discloses a high stability sulphur product and a production process thereof, and belongs to the technical field of sulfur production. The production process of high stability sulfur adopts a gasification-quenching method to produce insoluble sulfur, and comprises the procedures of raw material gasification, quenching treatment, tablet washing, drying, smashing and sieving, and finished product oil charging, wherein during second-time drying treatment, a product obtained after extracting and a special stabilizer are mixed and dried together, and the addition amount of the stabilizer accounts for 2-3 percent of the mass of an obtained insoluble sulfur product. The stabilizer of a special type is added in a sulfur production process, and the sulfur production process is optimized, so that the heat stability of the obtained insoluble sulfur can be effectively improved.

Owner:SHANGHAI JINGHAI ANHUI CHEM

Production method of high-dispersibility high-stability insoluble sulphur

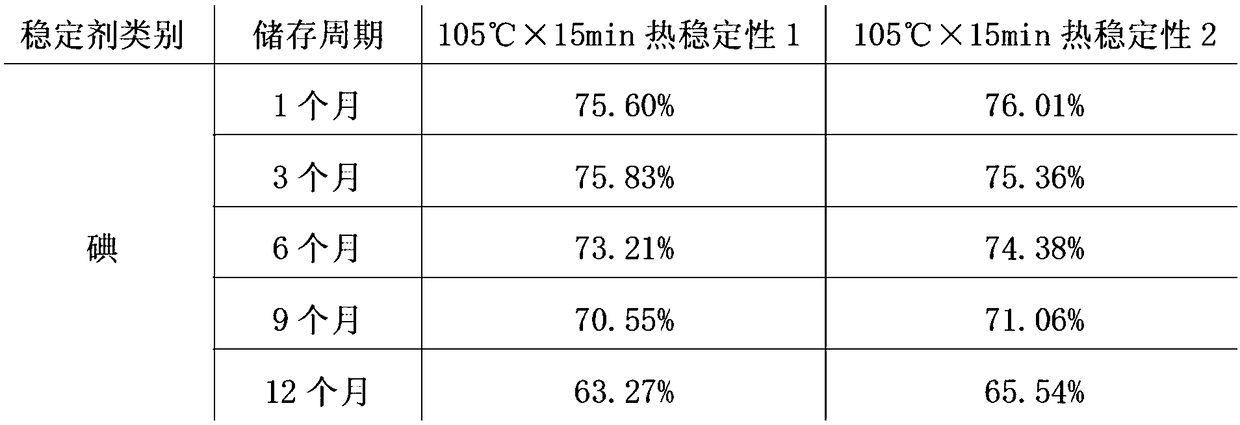

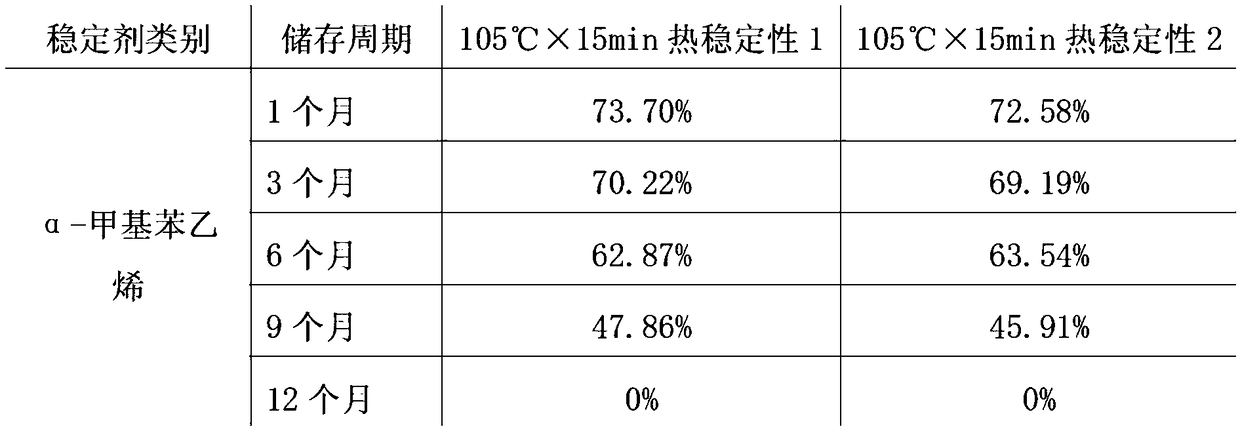

ActiveCN108329700AGuaranteed application effectImprove thermal stabilitySulfur preparation/purificationSodium ethyl xanthateIodine

The invention discloses a production method of high-dispersibility high-stability insoluble sulphur, and belongs to the technical field of sulphur production. The production method of high-dispersibility high-stability insoluble sulphur comprises the following steps that liquid sulphur is used as raw materials; a gasification-sharp cooling method is used for preparation to obtain middle-grade insoluble sulphur; then, the middle-grade insoluble sulphur is sequentially subjected to extraction, drying, sieving and oil filling treatment to obtain the insoluble sulphur product, wherein when the obtained middle-grade insoluble sulphur is subjected to drying treatment after the extraction, a proper amount of stabilizing agents are added; in addition, during oil filling treatment, a proper amountof fatty alcohol-polyoxyethylene ether is added; the stabilizing agents are prepared from ammonium persulfate, sodium ethyl xanthate and iodine. By using the production method provided by the invention, the thermal stability and dispersion performance of the insoluble sulphur can be effectively improved, so that the application effect is ensured.

Owner:SHANGHAI JINGHAI ANHUI CHEM

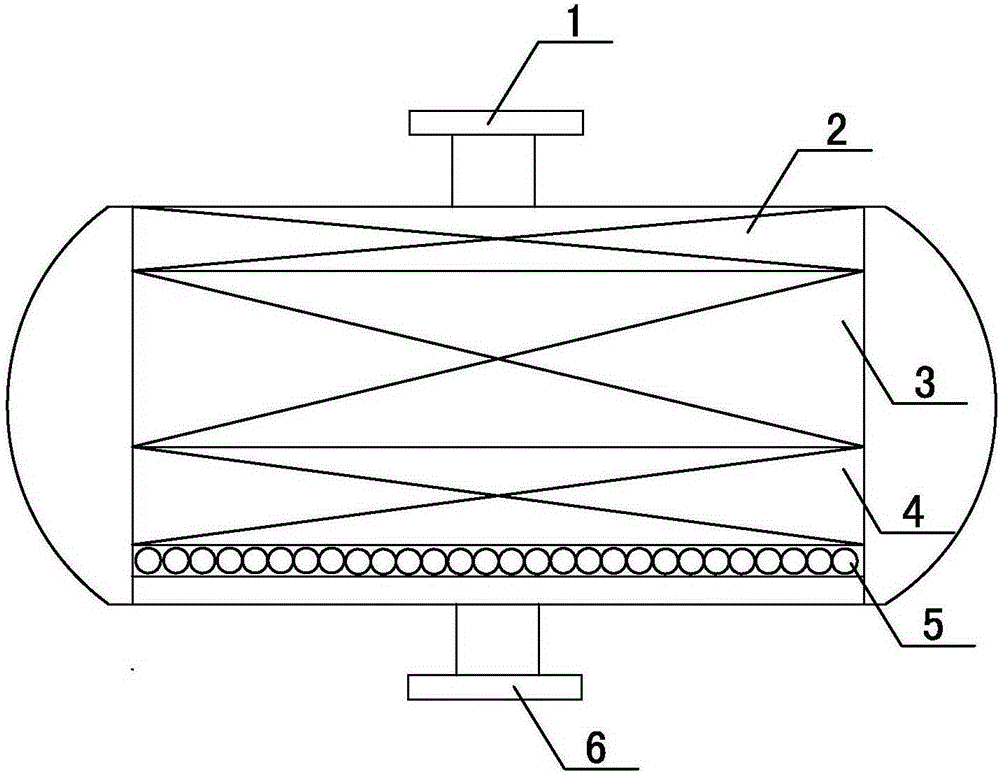

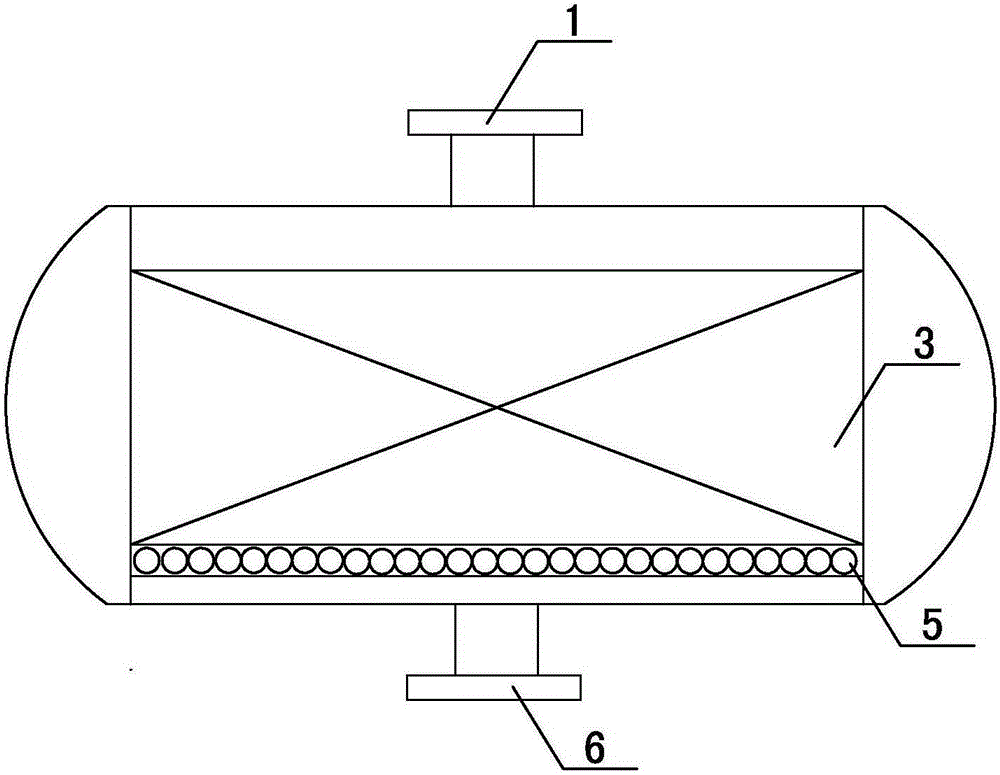

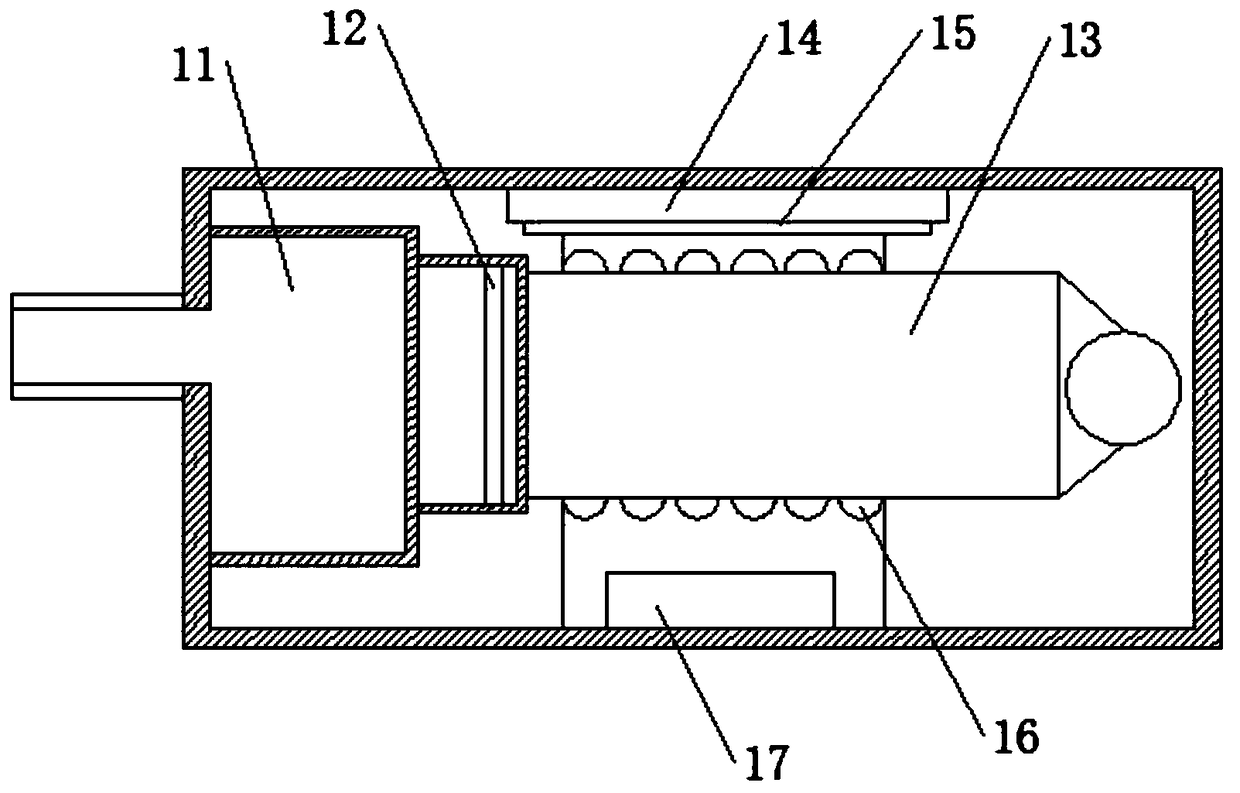

A kind of production method of insoluble sulfur

ActiveCN108101004BReduce the risk of contaminationIncrease productivitySulfur preparation/purificationSulfur productDistillation

The invention relates to a production method of insoluble sulfur. The production steps are composed of a series of production processes of melting sulfur, gasification, quenching, washing, drying, post-treatment, distillation and condensation. It is characterized in that a horizontal rotary reactor is used The processes of quenching, washing and drying are carried out; the production method of the present invention has the advantages of high production efficiency, high purity of produced products, complete recycling of materials, no discharge of toxic substances, etc., and is suitable for large-scale industrial production of insoluble sulfur products for radial tires.

Owner:广西联源机械化工有限公司

A kind of methanesulfonic acid system bismuth sulfide concentrate oxygen pressure leaching method

ActiveCN110396608BImprove leaching rateEffective dissolutionProcess efficiency improvementBismuth sulfideSulfur product

The invention discloses a method for oxygen pressure leaching of bismuth sulfide concentrate in methanesulfonic acid system, comprising the following steps: S1, material pretreatment: adding bismuth sulfide concentrate into a vertical mill, and using the vertical mill to sulfide The bismuth concentrate is finely ground, and then the screened material is dried for later use; S2, liquid preparation: according to the iron-containing phase and iron content in the material, appropriately add iron powder to the methanesulfonic acid solution, and then stir the solution , so that iron powder and methanesulfonic acid solution are fully mixed to obtain iron-containing methanesulfonic acid leaching agent. The present invention replaces the traditional oxidation-reduction roasting fire process by adopting oxygen pressure leaching technology, extracts bismuth efficiently, and also avoids the generation of low-concentration sulfur dioxide from the root. High yield, up to more than 93%, and simple process, the method is simple to operate, can efficiently dissolve bismuth, obtain sulfur products, and does not produce SO 2 , has the advantage of environmental protection.

Owner:CENT SOUTH UNIV +1

A method for reactive desulfurization of hydrogen sulfide and sulfur dioxide

ActiveCN109534297BIncrease acidityRapid responseDispersed particle separationSulfur preparation/purificationSolubilitySulfur product

A method for desulfurization by reaction of hydrogen sulfide and sulfur dioxide. Hydrogen sulfide and sulfur dioxide are reacted in a solution, the solution includes water and at least one organic basic compound soluble in water, and the initial pH value of the solution is ≥7.2. The mass fraction of the organic basic compound in the solution is 0.1% to 30%; in the above method, the selected organic basic compound is a compound with a solubility in water ≥ 0.1g / 100g water, preferably a solubility ≥ 1g / 100g water. The above reaction can be carried out at normal temperature and pressure, and the addition of organic basic compounds makes H 2 S and SO 2 The reaction time is greatly shortened, indicating that the dissolution rates of the two in water tend to be similar, so that the reaction is more likely to occur, and the sulfur product obtained by the reaction is high in purity, only liquid-solid separation is required without refining. The required reaction conditions of the method of the invention are mild, the equipment is simple and easy to process, the investment is low, and the operation is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

A comprehensive utilization method of zinc concentrate high pressure oxygen leaching sulfur residue

InactiveCN104120272BReduce pressure on environmental protectionReduce pollutionSulfur preparation/purificationProcess efficiency improvementSlagDistillation

The invention relates to a comprehensive utilization method of zinc concentrate high-pressure oxygen leaching sulfur residue, which belongs to the field of comprehensive utilization of industrial waste residue in the metallurgical industry. The method of the present invention is to add the sulfur residue into the leaching tank containing water and carbon disulfide, the water acts as a seal to prevent the volatilization of carbon disulfide during the leaching process, and after stirring and reacting, vacuum filtration and distillation are performed to obtain high-quality sulfur products, and the filter residue is washed, After drying, the enriched slag enriched with zinc and mercury is obtained; the sulfur product obtained by the above method contains more than 99.5% sulfur, Hg is less than 0.02mg / kg, the Zn content in the enriched slag reaches about 25%, Ag1600g / t is above, Hg0. About 5%; this technology can not only make full use of industrial waste sulfur slag, develop a new application way for the utilization of sulfur slag, turn waste into treasure, but also reduce the environmental protection pressure of smelters, reduce environmental pollution, and improve economic benefits of enterprises .

Owner:KUNMING UNIV OF SCI & TECH

Coking desulfurization liquid waste sulfur treatment device

The invention provides a coking desulfurization liquid waste sulfur treatment device, and belongs to the technical field of sulfur treatment. The coking desulfurization liquid waste sulfur treatment device comprises an oxidizing pot, a first conveying pump, a centrifugal machine, a mixing tank, a second conveying pump, a sulfur melting pot, a sulfur flaker and a chain scraper conveyor, wherein theoxidizing pot communicates with the centrifugal machine through a communicating pipeline, the centrifugal machine communicates with the mixing tank through a communicating pipeline, the mixing tank communicates with the sulfur melting pot through a communicating pipeline, the sulfur melting pot communicates with the sulfur flaker through a communicating pipeline, and the sulfur flaker communicates with the chain scraper conveyor through a communicating pipeline. The coking desulfurization liquid waste sulfur treatment device has the advantage that low-quality sulfur generated in an oxidationprocess of ammonium thiosulfate is conveyed to the sulfur melting pot to be subjected to sulfur melting treatment after being mixed with desulfurization liquid waste, generated high-quality sulfur issold after being treated through the sulfur flaker, and accordingly the problem that the original low-quality sulfur is hard to sell is solved. The coking desulfurization liquid waste sulfur treatmentdevice has the advantages of less investment, simple structure, convenience in use, good quality of sulfur products and the like.

Owner:BEIJING SHOUGANG INT ENG TECH

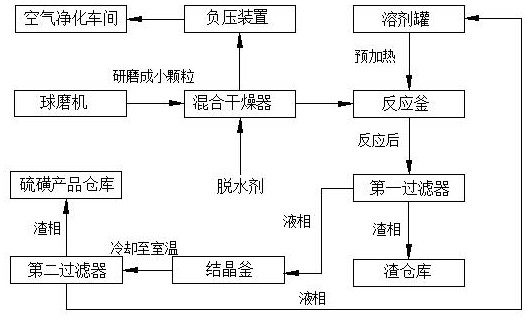

Wet circulation desulfurization process for high-sulfur anode slime

PendingCN114635034AHigh recovery rateImprove desulfurization effectSulfur compoundsSulfur productFluid phase

The invention discloses a wet circulating desulfurization process for high-sulfur anode slime. The wet circulating desulfurization process comprises the following steps: step 1, adding a dehydrating agent into the high-sulfur anode slime in a mixing dryer; 2, the dehydrated and dried high-sulfur anode slime is transferred into a reaction kettle, and a solvent is added into the reaction kettle through a solvent tank; step 3, transferring a product in the step 2 into a first filter, transferring a liquid phase filtered by the first filter into a crystallization kettle for cooling crystallization, cooling a crystallized product to room temperature, transferring the crystallized product into a second filter for filtering, and transferring a slag phase filtered by the first filter into a slag warehouse; and 4, conveying a liquid phase filtered by the second filter to a solvent tank for recycling, and conveying a slag phase filtered by the second filter to a sulfur product warehouse, wherein the slag phase is elemental sulfur. The method has the advantages of reasonable process flow, simplicity in operation, high desulfurization effect and high recycling rate.

Owner:NINGBO DADI CHEM ENG & ENVIRONMENTAL PROTECTION

Preparation method of wrapping sulphur vulcanizing agent capable of being used for production of rubber

The invention discloses a preparation method of a wrapping sulphur vulcanizing agent capable of being used for production of rubber. The preparation method comprises the step of preparing a wrapping sulphur product through a physical sedimentation method by taking common sulphur as a core material and taking rubber latex as a wall material. The process is simple, and the cost is low. The preparedwrapping sulphur product wraps a shell layer at a certain temperature, can melt and release sulphur, and can be used as a rubber vulcanizing agent.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

A kind of production method of high-grade insoluble sulfur and its production stabilizer

ActiveCN108394869BImprove thermal stabilityImprove conversion rateSulfur preparation/purificationSodium ethyl xanthateSulfur product

Owner:SHANGHAI JINGHAI ANHUI CHEM

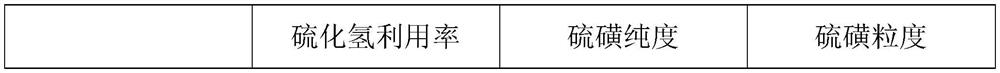

Method for preparing high-purity sulfur from tail gas containing hydrogen sulfide

ActiveCN112938905AAchieve high-value conversionNo secondary pollutionSulfur preparation/purificationSulfur productPhysical chemistry

The invention relates to a method for preparing high-purity sulfur from tail gas containing hydrogen sulfide. The method comprises the following step: carrying out contact reaction on the tail gas containing hydrogen sulfide and sulfuric acid through a contact device to obtain sulfur with the purity of more than or equal to 99.95%. The molar ratio of the sulfuric acid to the hydrogen sulfide is (0.1-1): 1; the concentration of the sulfuric acid is greater than or equal to 75%; and the high-purity superfine sulfur is obtained by controlling gas-liquid two-phase related parameters in the reaction process. The method is high in absorption reaction efficiency, mild in reaction process, free of secondary pollution and high in applicability. The purity of the sulfur product is greater than or equal to 99.5%, the particle size range is 10-30 [mu]m, and the sulfur product can be directly applied to industries such as medicine, agriculture and chemical engineering; and the treated absorption liquid can be directly sold or used as a by-product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

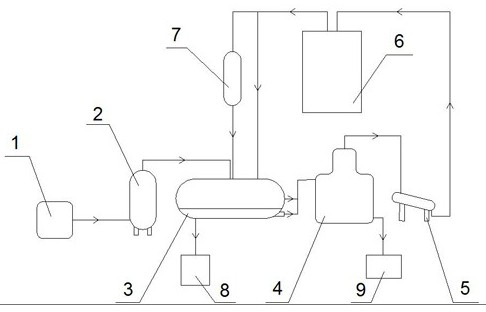

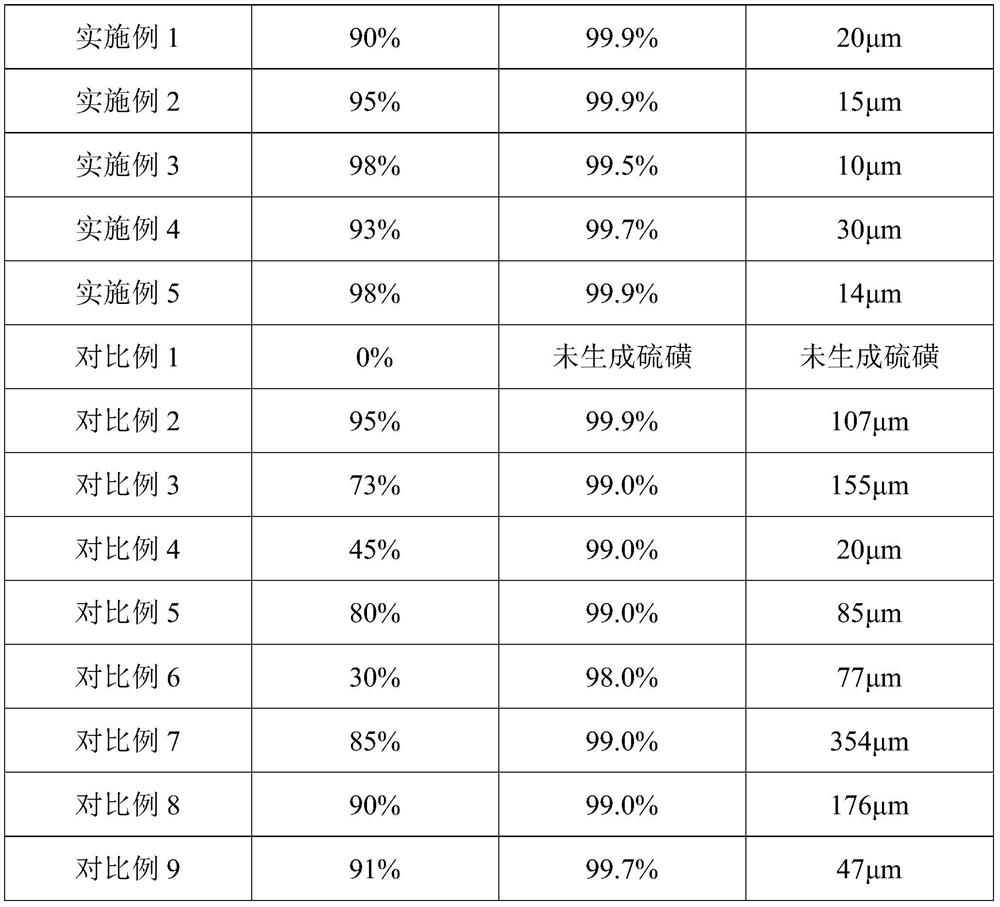

A production process for recovering sulfur dioxide from flue gas to produce sulfur

ActiveCN103879970BNo emissionsNo cloggingEnergy inputSulfur preparation/purificationSodium saltSodium sulphide

The invention provides a production process for preparing sulfur by recovering sulfur dioxide from flue gas. The production process comprises the following specific steps of: (A) carrying out desulfurization on the flue gas by sodium carbonate or sodium bicarbonate solution in an absorbing tower, concentrating and crystallizing absorbing solution after reacting with the flue gas, and separating out solid sodium salt; (B) feeding the solid sodium salt into a reducer, and under the action of a reducing agent, reducing the solid sodium salt into sodium sulfide; carrying out chilling, dissolving, filtering and washing on molten mixture from the reducer to obtain clean liquid which is aqueous solution of sodium sulfide; recovering the heat of gas with rich CO2 discharged by the reducer by a waste heat boiler to generate steam, and feeding the steam to next step for treatment; and (C) adding sodium bicarbonate into the aqueous solution of sodium sulfide obtained in the step (B), feeding H2S obtained by reaction into a claus furnace, and manufacturing a sulfur product; and feeding sodium carbonate solution obtained by reaction to react with the rich CO2 in the step (B), and obtaining sodium bicarbonate which can be recycled.

Owner:CHENGDU HUAXITANG INVESTMENT

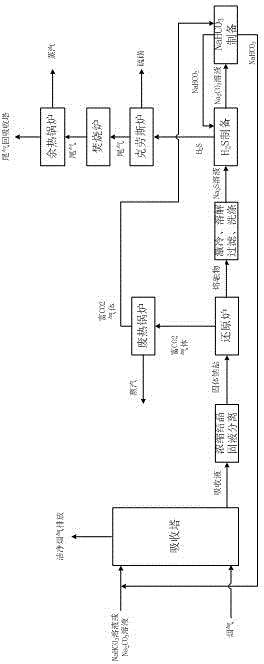

A kind of method for recovering sulfur and silver from zinc-oxygen pressure leaching residue

ActiveCN109734057BSolve the problem of high viscosity caused by iron contentHigh recovery rateSulfur compoundsProcess efficiency improvementSlagPolyacrylamide

The invention discloses a method for recovering sulfur and silver from zinc-oxygen pressure leaching slag, which belongs to the technical field of non-ferrous metal recovery. The method includes: (1) preliminary dehydration treatment; (2) adding flocculant for rough selection; (3) adding flocculant to Add a dispersant to the roughing concentrate for three-stage beneficiation; (4) sweep the roughing tailings for three stages; (5) combine the beneficiation I, II, and III tailings for middling treatment, and middling The rough concentrate and selected concentrate are combined into sulfur concentrate, and the tailings are silver-rich slag. The present invention aims at the problem that the sulfur particles are small and the precious metal Ag cannot be effectively recovered in the zinc oxygen pressure leaching process, and polyacrylamide is added as a flocculant to realize carrier flotation, and at the same time, the viscosity of the zinc oxygen pressure leaching slag solution containing iron is solved High problem, improve the recovery rate of sulfur and precious metal Ag. By adding a dispersant in the flotation process and carrying out microwave treatment, the dispersion of sulfur after flocculation is realized, the problem of difficult separation of sulfur and precious metals is solved, and the grade of sulfur products is improved.

Owner:CINF ENG CO LTD

Beneficiation method for separating zinc sulfide ores from sulphur in wet-method zinc smelting slag

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com