Comprehensive utilization method of sulfur slag generated in hyperbaric oxygen leaching of zinc concentrate

A high-pressure oxygen, zinc concentrate technology, applied in the fields of sulfur compounds, chemical instruments and methods, sulfur preparation/purification, etc., can solve the problems of difficult realization, ecological environment pollution, waste of sulfur resources and valuable metal elements, etc. Achieve the effect of improving enterprise economic benefits, reducing environmental pollution, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

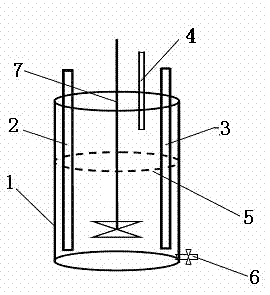

[0017] Example 1: Water is added to the leaching tank through the liquid feeding pipe, and an intermediate screen is set at 60% of the volume of the leaching tank, and then carbon disulfide is added to the lower part of the water, and 74.58% sulfur, 8.25% Zn, 527g / tAg and 0.17%Hg zinc concentrate high-pressure oxygen leaching sulfur slag, the mass ratio of zinc ore high-pressure oxygen leaching sulfur slag to carbon disulfide is 1:2. Stir and react at room temperature for 1.0h to leach sulfur from the sulfur slag material; the total volume of all added materials is 85% of the volume of the leaching tank, and the solid-liquid volume of zinc concentrate high-pressure oxygen leaching sulfur slag and carbon disulfide is 60% of the volume of the leaching tank ;

[0018] Then pass through the discharge pipe at the bottom of the leaching tank to the underwater bottom of the vacuum filter tank that has been added with water in advance, and carry out vacuum filtration (liquid-solid ...

Embodiment 2

[0020] Example 2: Water is added to the leaching tank through the liquid feeding pipe, and an intermediate screen is set at 60% of the volume of the leaching tank, and then carbon disulfide is added to the lower part of the water, and 74.58% sulfur, 8.25% Zn, 527g / tAg and 0.17%Hg zinc concentrate high-pressure oxygen leaching sulfur slag, the mass ratio of zinc ore high-pressure oxygen leaching sulfur slag to carbon disulfide is 1:4. Stir and react at room temperature for 0.5h to leach sulfur from the sulfur slag material; the total volume of all added materials is 80% of the volume of the leaching tank, and the solid-liquid volume of zinc concentrate high-pressure oxygen leaching sulfur slag and carbon disulfide is 55% of the volume of the leaching tank ;

[0021] Then pass through the discharge pipe at the bottom of the leaching tank to the underwater bottom of the vacuum filter tank that has been added with water in advance, and carry out vacuum filtration (liquid-solid ...

Embodiment 3

[0023] Example 3: Water is added to the leaching tank through the liquid feeding pipe, and an intermediate screen is set at 60% of the volume of the leaching tank, and then carbon disulfide is added to the lower part of the water, and 74.58% sulfur, 8.25% Zn, 527g / tAg and 0.17%Hg zinc concentrate high-pressure oxygen leaching sulfur slag, the mass ratio of zinc ore high-pressure oxygen leaching sulfur slag to carbon disulfide is 1:3, after the feeding is completed, increase the stirring speed to 300rpm, under the condition of water seal Stir and react at room temperature for 0.75h to leach sulfur from the sulfur slag material; the total volume of all added materials is 75% of the leaching tank volume, and the solid-liquid volume of zinc concentrate high-pressure oxygen leaching sulfur slag and carbon disulfide is 50% of the leaching tank volume ;

[0024] Then pass through the discharge pipe at the bottom of the leaching tank to the underwater bottom of the vacuum filter ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com