Closed circulation and zero emission processes for papermaking wastewater

A closed-cycle, paper-making wastewater technology, applied in processing process wastewater treatment, aerobic and anaerobic process treatment, flotation water/sewage treatment, etc., can solve secondary sticky copying and quality impact, organic pollutant concentration Accumulation, equipment corrosion and other problems can be achieved to reduce the processing burden, reduce fiber loss, and ensure the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

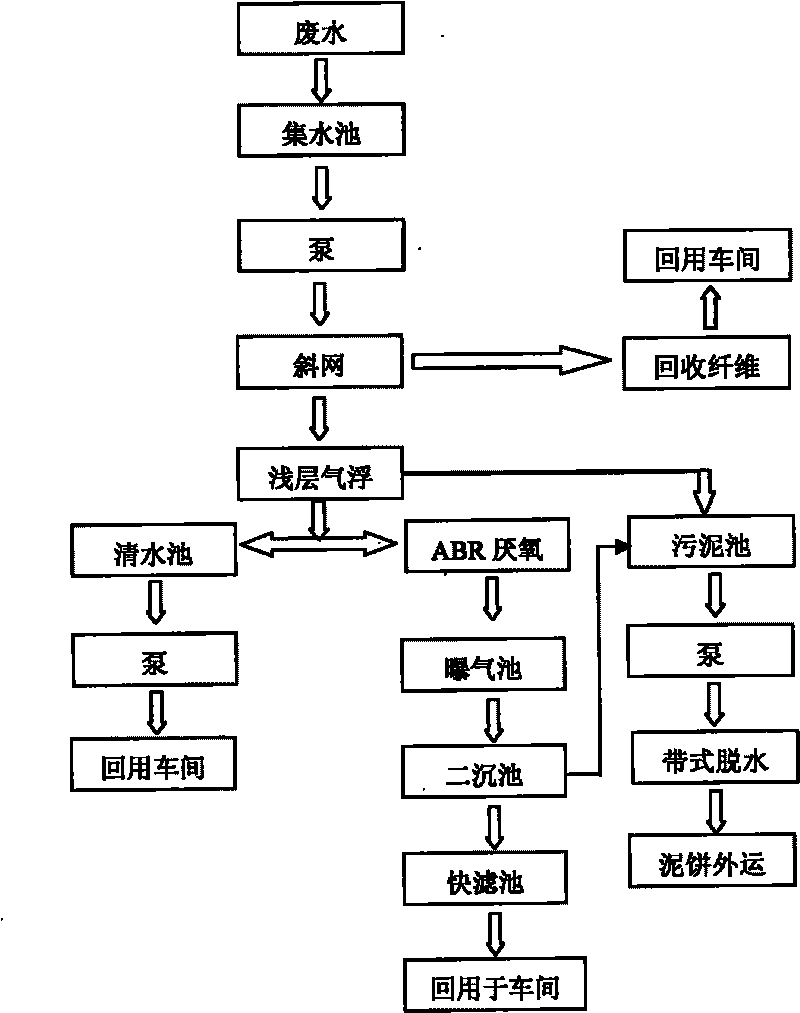

[0016] Referring to the drawings, the waste water first passes through the grid to cut off the paper scraps, foam paper, plastic paper and large particles in the water and enters the water collection adjustment tank to adjust the water volume and uniform water quality, and then use the pump to lift the water to the inclined screen for recycling After that, the waste water flows into the shallow air flotation tank for flocculation and air flotation reaction. It passes through the dynamic water outlet and the static water outlet, and the uplift distance is minimized, and it is not affected by the water outlet flow rate, so that the suspension floats vertically to the water surface in a relatively static environment. At the same time, according to a certain amount (depending on the water quality), add flocculant polyacrylamide (PAM) and polyaluminum chloride (PAC), the depth of the pool is only about 450mm, and the residence time of sewage in the air floatation is only 3-5min Trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com