Patents

Literature

413 results about "Germanium dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Germanium dioxide, also called germanium oxide, germania, and salt of germanium, is an inorganic compound with the chemical formula GeO₂. It is the main commercial source of germanium. It also forms as a passivation layer on pure germanium in contact with atmospheric oxygen.

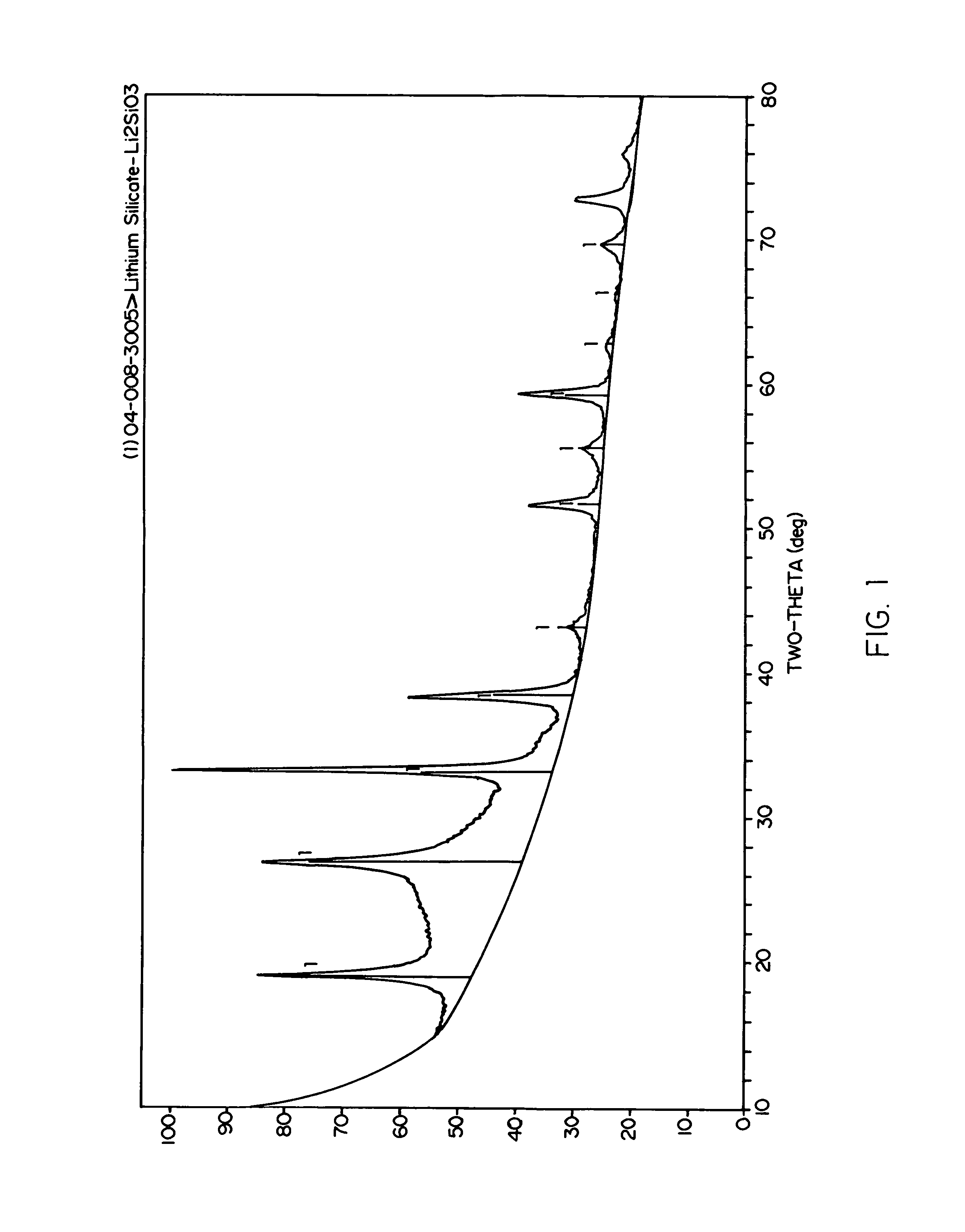

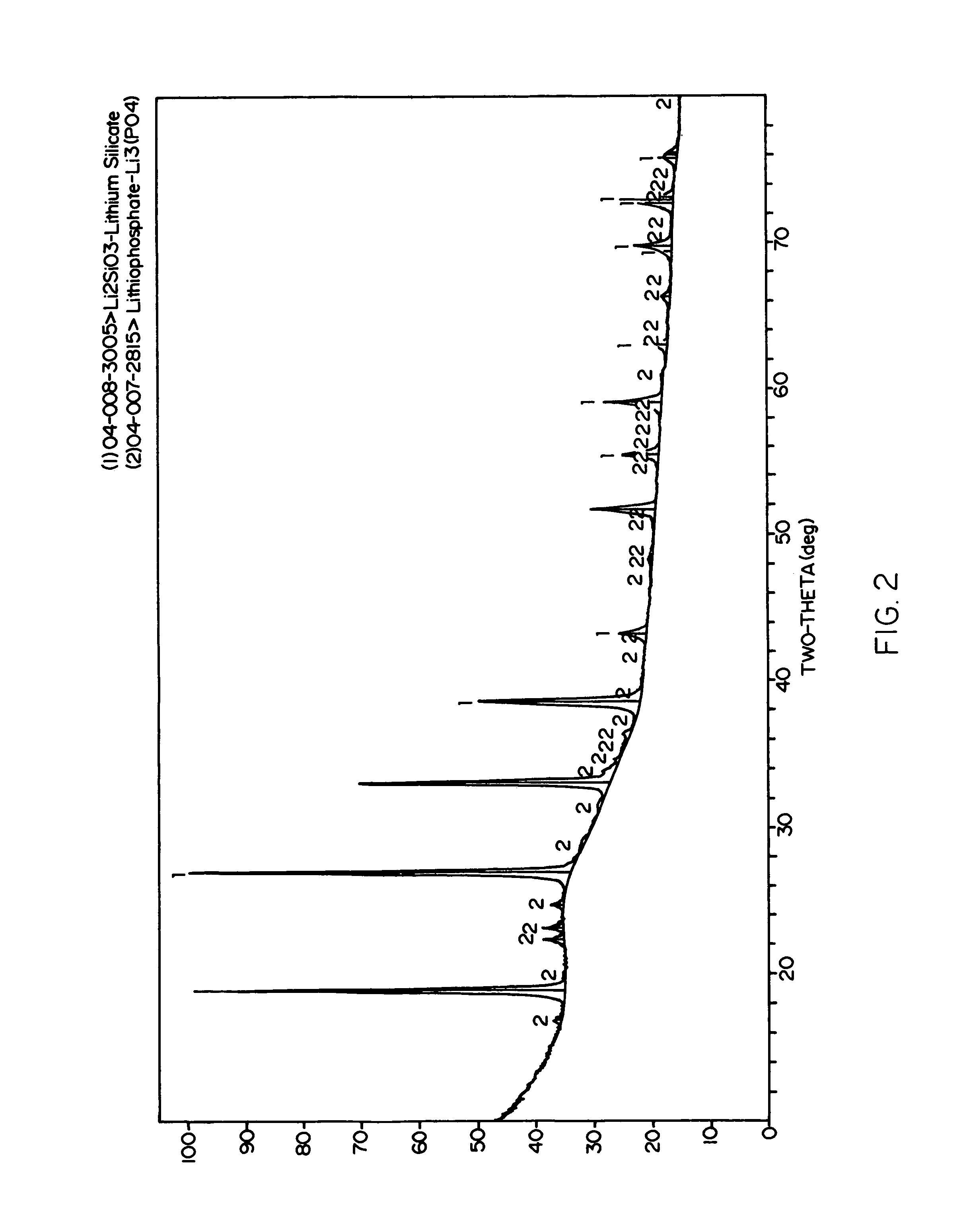

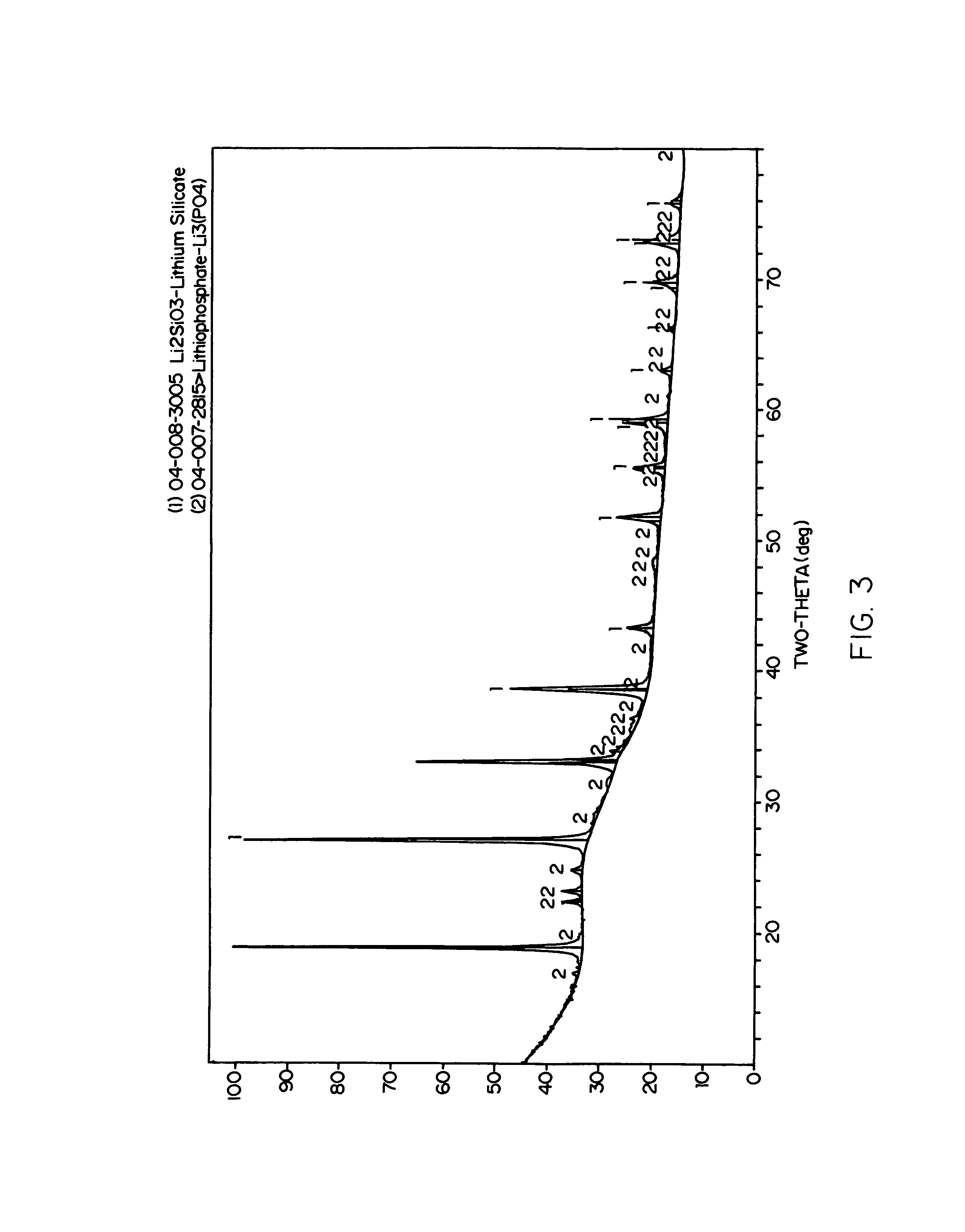

Lithium silicate glass ceramic for fabrication of dental appliances

ActiveUS20120094822A1Easy to controlGood physical propertiesGlass drawing apparatusGlass forming apparatusLithiumChemical composition

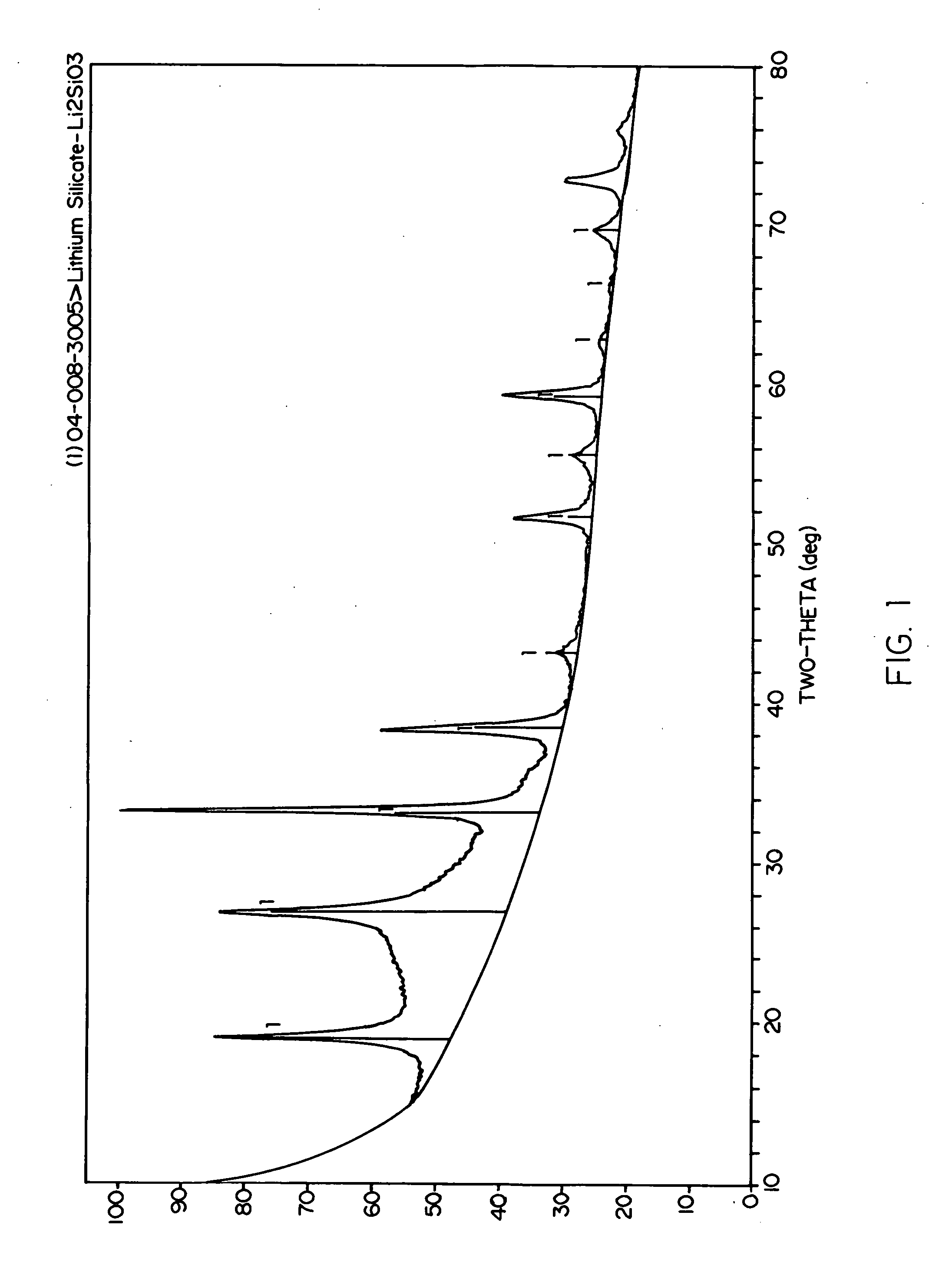

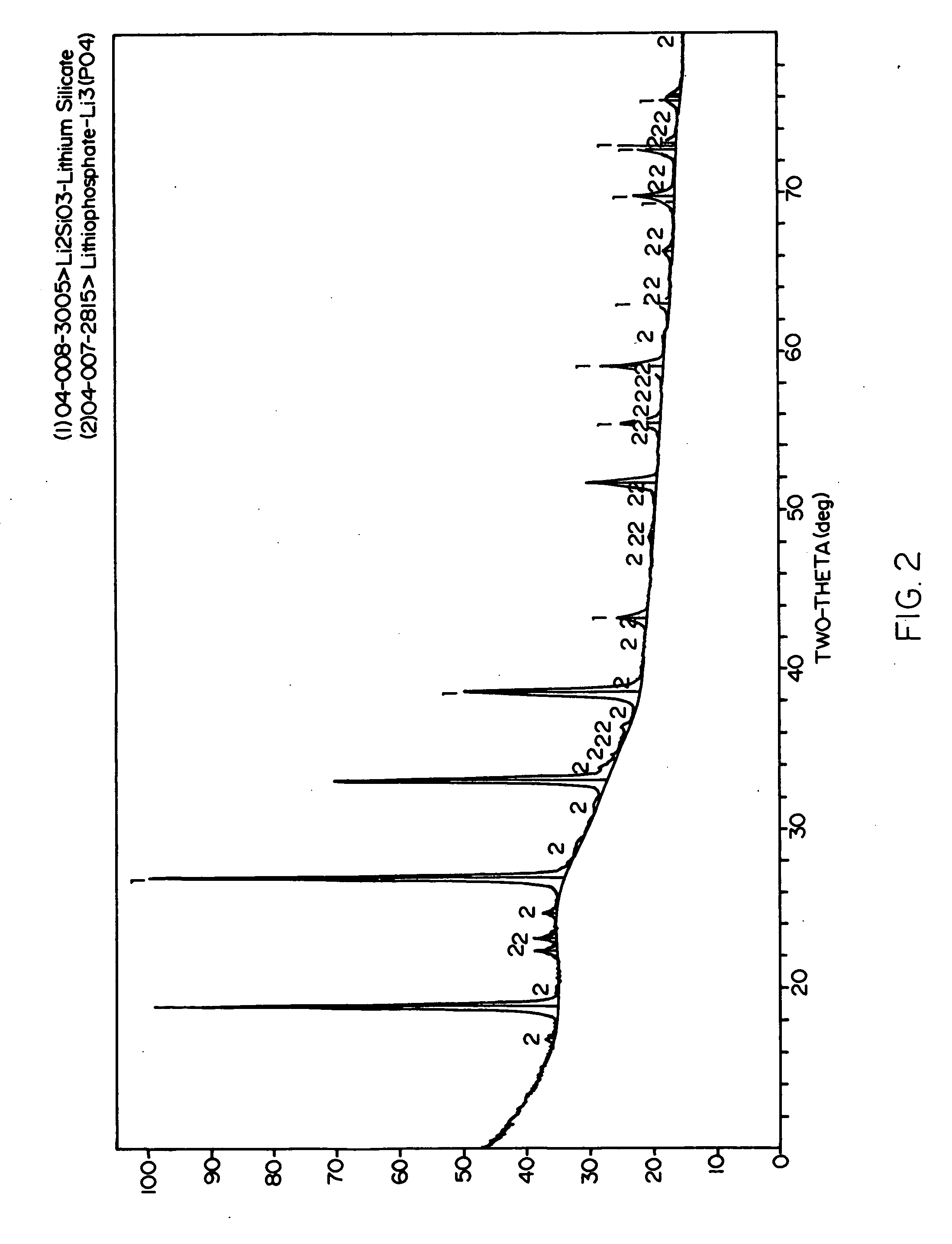

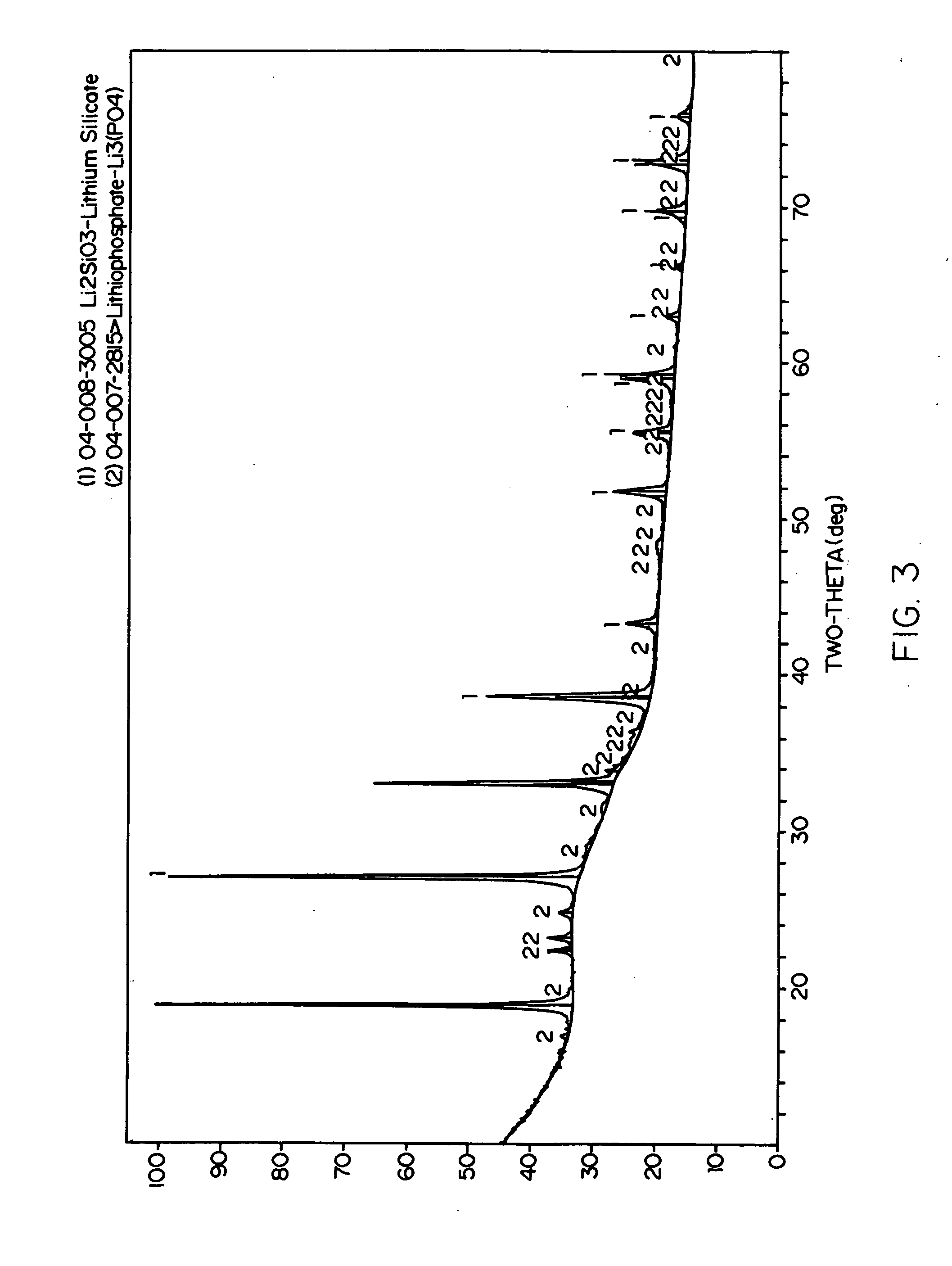

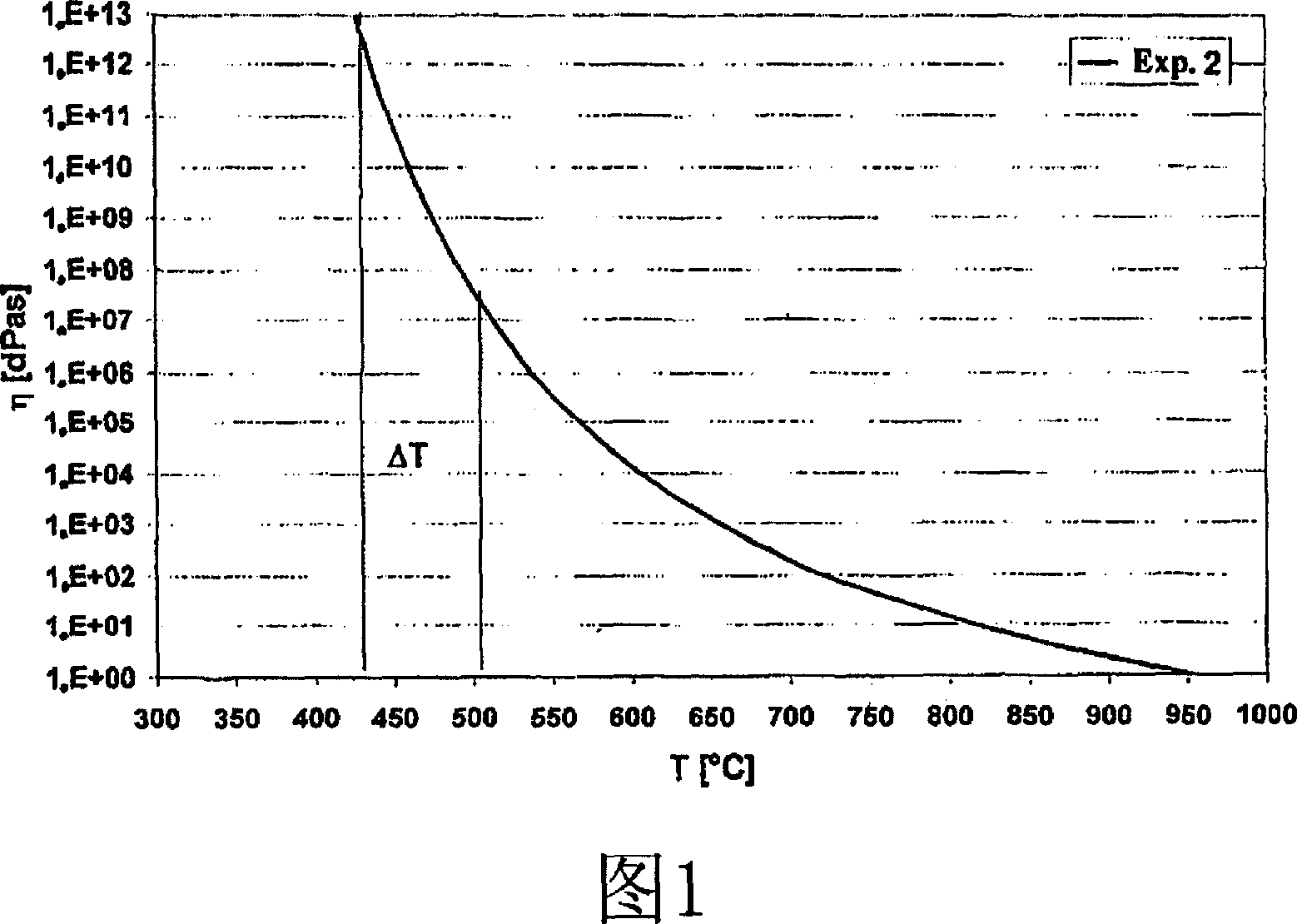

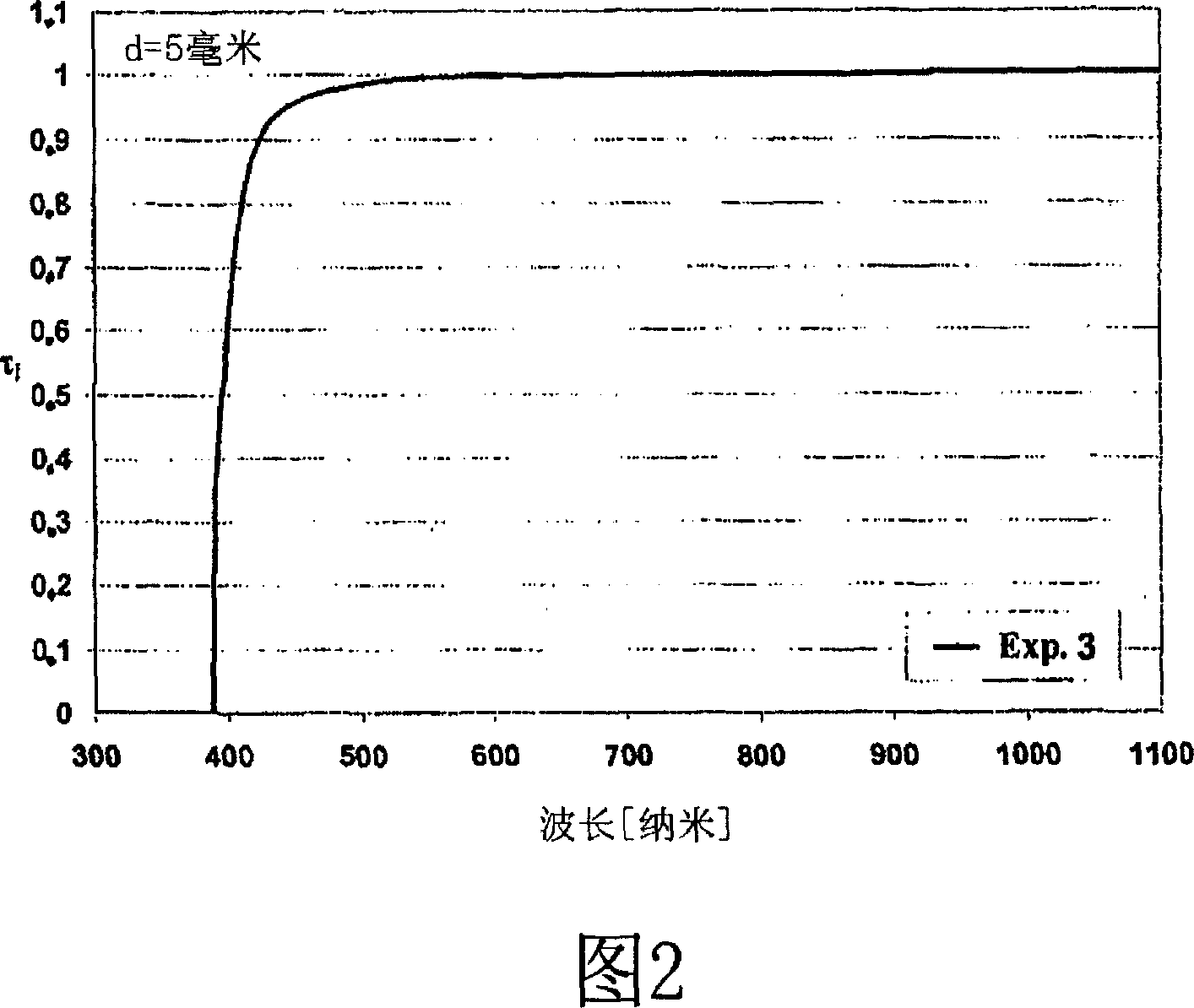

The present invention relates to a method of fabricating an improved lithium silicate glass ceramic and to that material for the manufacture of blocks for dental appliances using a CAD / CAM process and hot pressing system. The lithium silicate material has a chemical composition that is different from those reported in the prior art with 1 to 10% of germanium dioxide in final composition. The softening points are close to the crystallization final temperature of 800° C. indicating that the samples will support the temperature process without shape deformation.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

Ion nutritional liquid fertilizer and preparation method thereof

The invention discloses an ion nutritional liquid fertilizer and a preparation method thereof. The fertilizer comprises the following components by weight parts: 15-35 parts of potassium hydroxide, 5-15 parts of germanium dioxide, 1-5 parts of sodium selenite or sodium selenate, 5-15 parts of zinc acetate or zinc sulfate, 1-5 parts of chromic chloride, 2-8 parts of ammonium metavanadate, 15-40 parts of organic acid, 20-50 parts of amino acid, 10-20 parts of boric acid, 2-10 parts of urea and 500-900 parts of water, wherein the organic acid is citric acid or acetic acid and the amino acid is compound amino acid or monomer amino acid. The preparation method comprises the following steps of: taking the components of the fertilizer by weight parts; dissolving germanium dioxide into the potassium hydroxide; adding the organic acid, and then performing acidizing chelation reaction for 5-10 hours; adding the sodium selenite, zinc acetate, amino acid, boric acid, chromic chloride, ammonium metavanadate, urea and water; reacting for 5-10 hours; and filtering and removing slag, thereby obtaining the ion nutritional liquid fertilizer.

Owner:天津市星河系科技有限公司

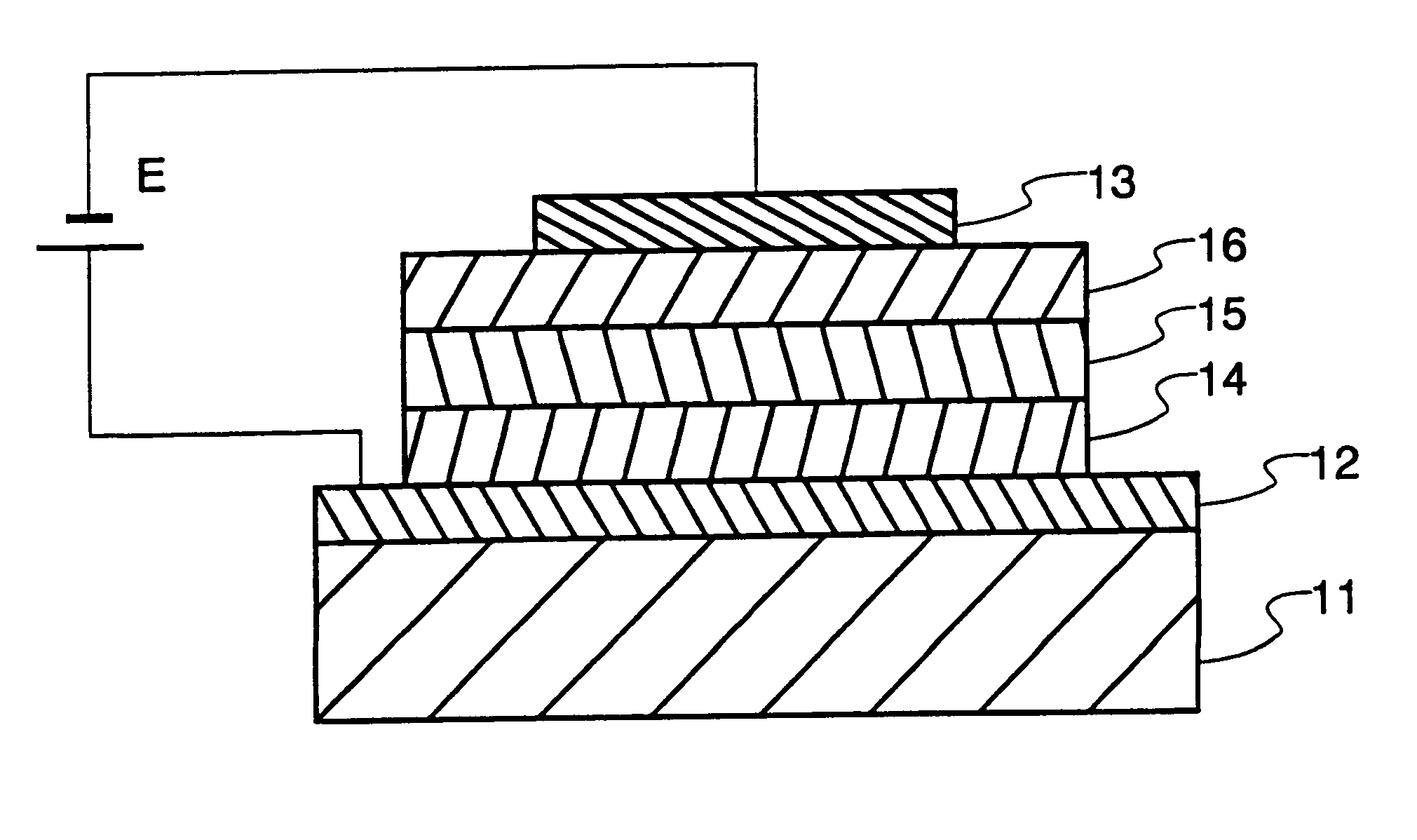

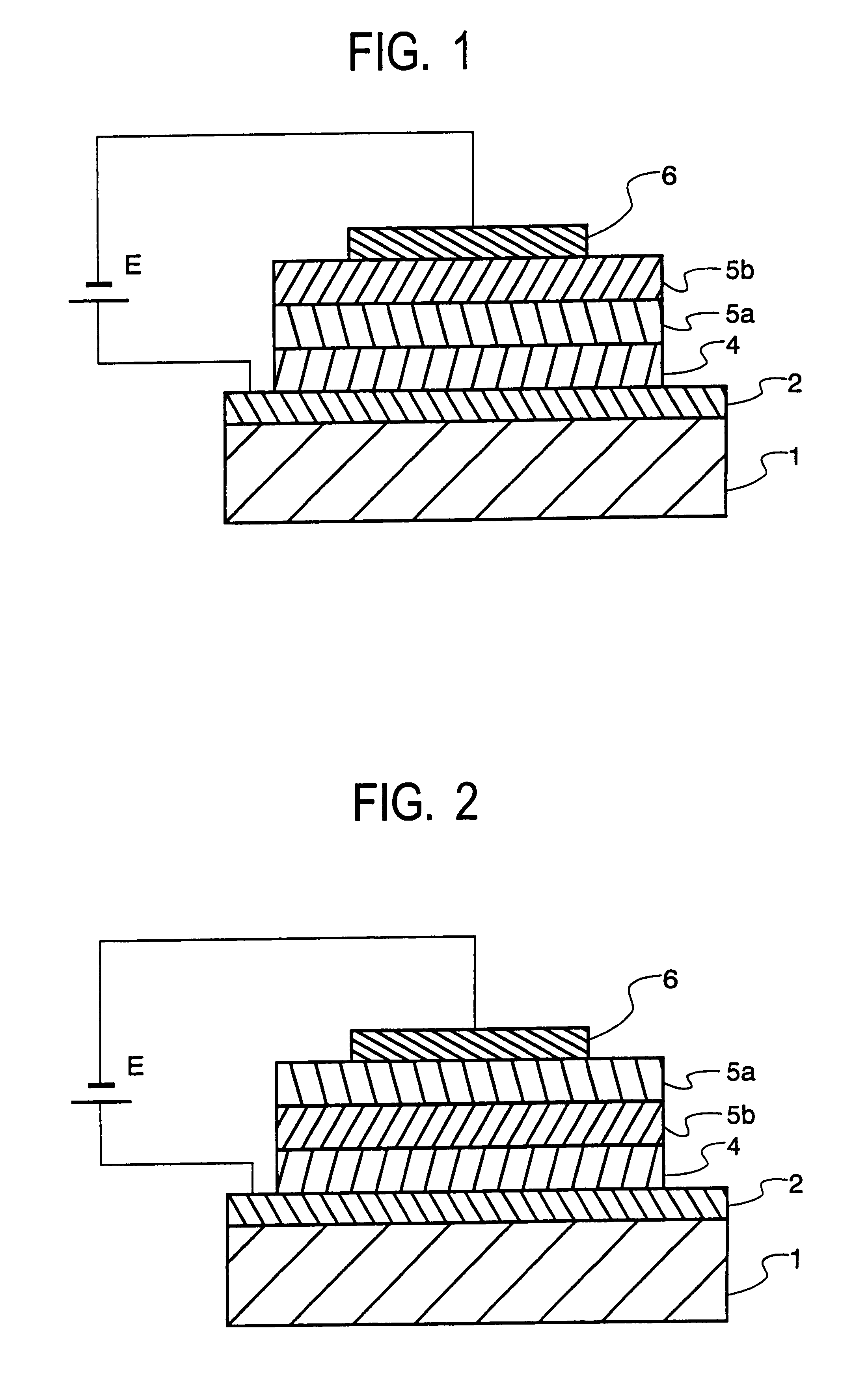

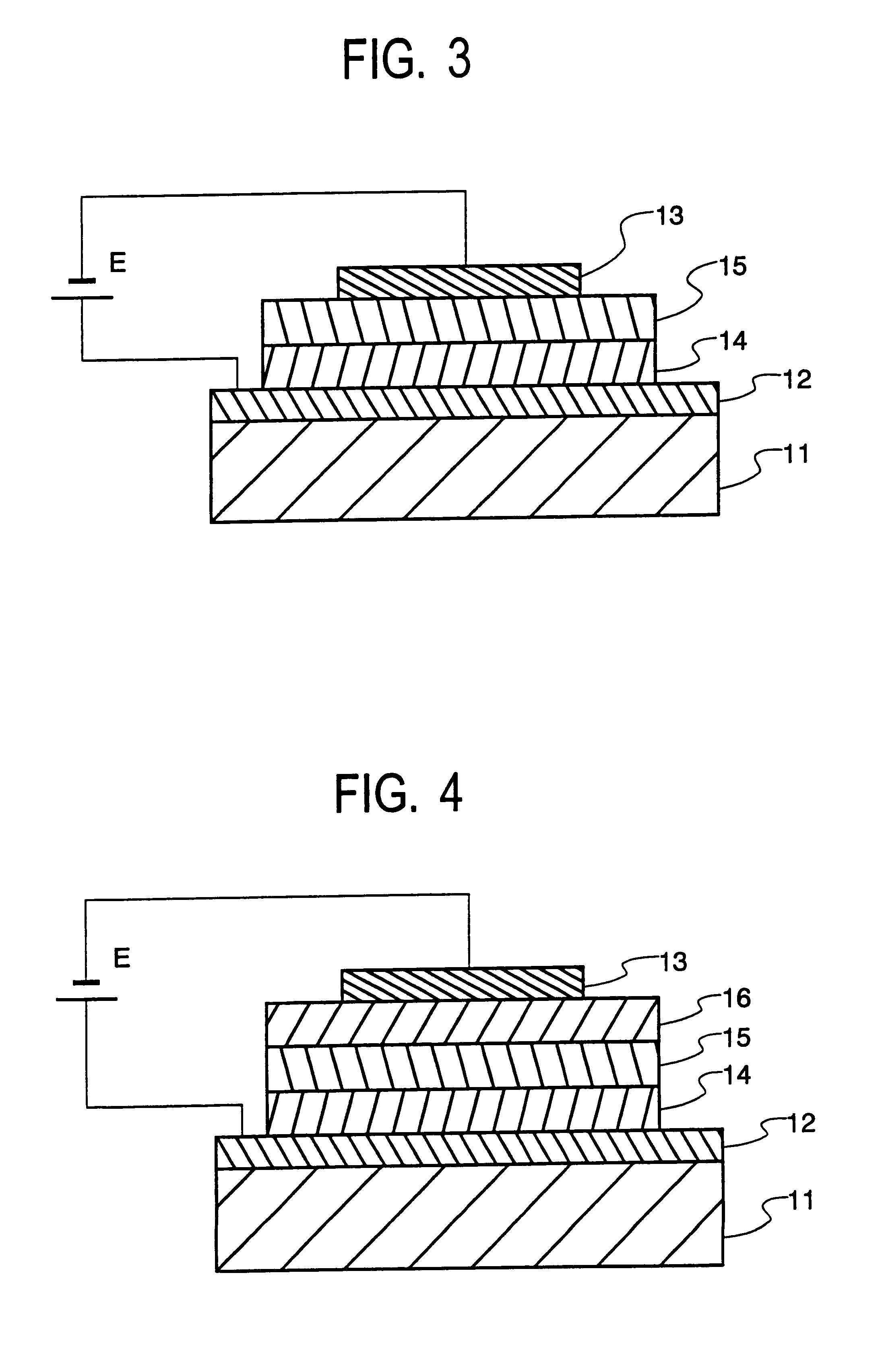

Organic electroluminescent device

InactiveUS6198219B1Improve performanceImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesLithium oxideRubidium oxide

The invention provides an organic EL device comprising a substrate, a hole injecting electrode and a negative electrode formed on the substrate, an organic layer containing an organic material between the electrodes, the organic layer including a light emitting layer having at least a light emitting function, and an electron injecting and transporting layer containing an electron transporting organic material and an inorganic insulative electron injecting and transporting layer formed of an inorganic material between the negative electrode and the light emitting layer. The inorganic insulative electron injecting and transporting layer contains at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, cesium oxide, strontium oxide, magnesium oxide, and calcium oxide as a main component, and silicon oxide, germanium oxide or a mixture of silicon oxide and germanium oxide as a stabilizer. This construction ensures better performance than prior art devices having electron injecting and transporting layers using organic materials, a high efficiency, long life, weather resistance, and high stability.

Owner:TDK CORPARATION

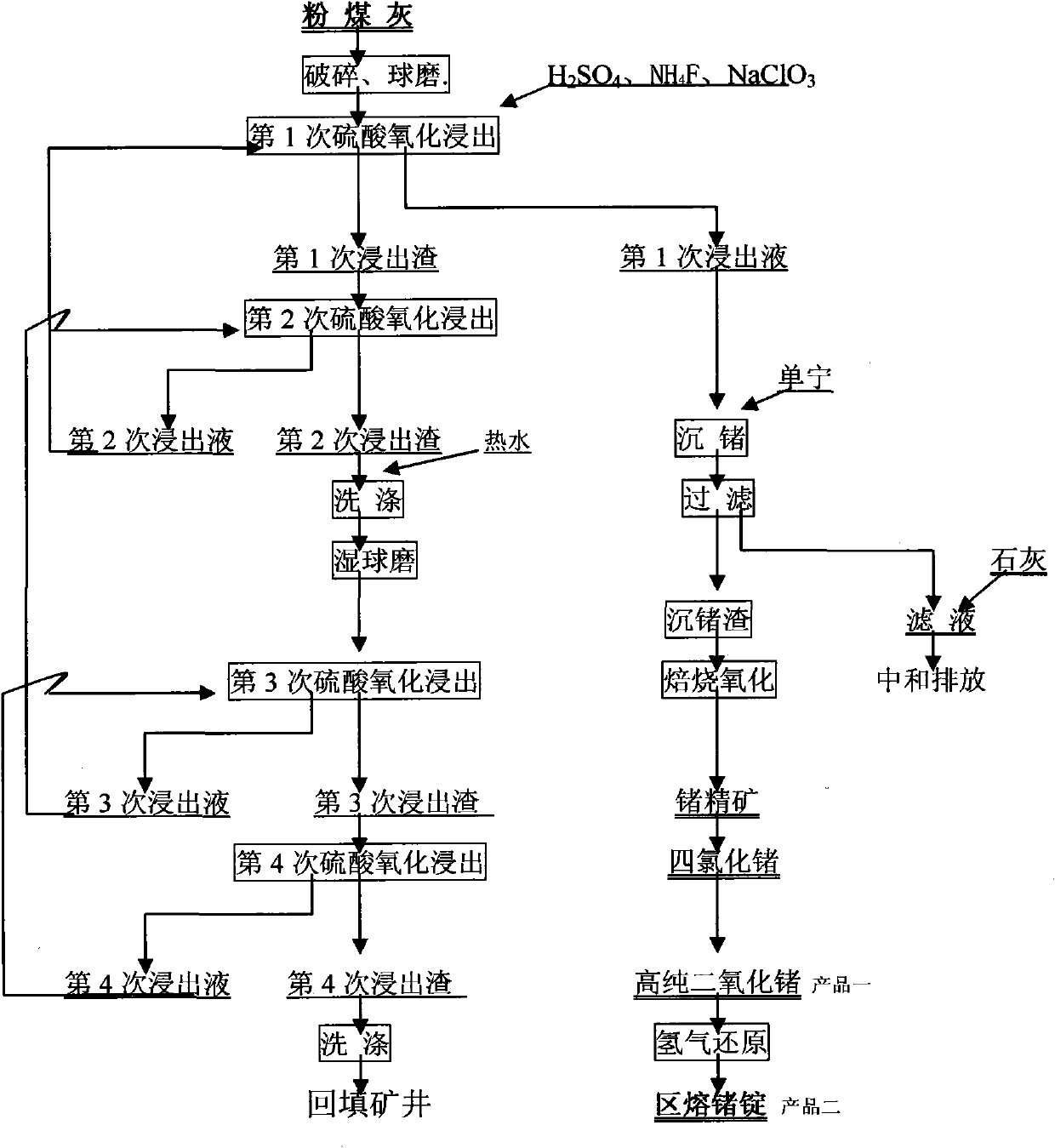

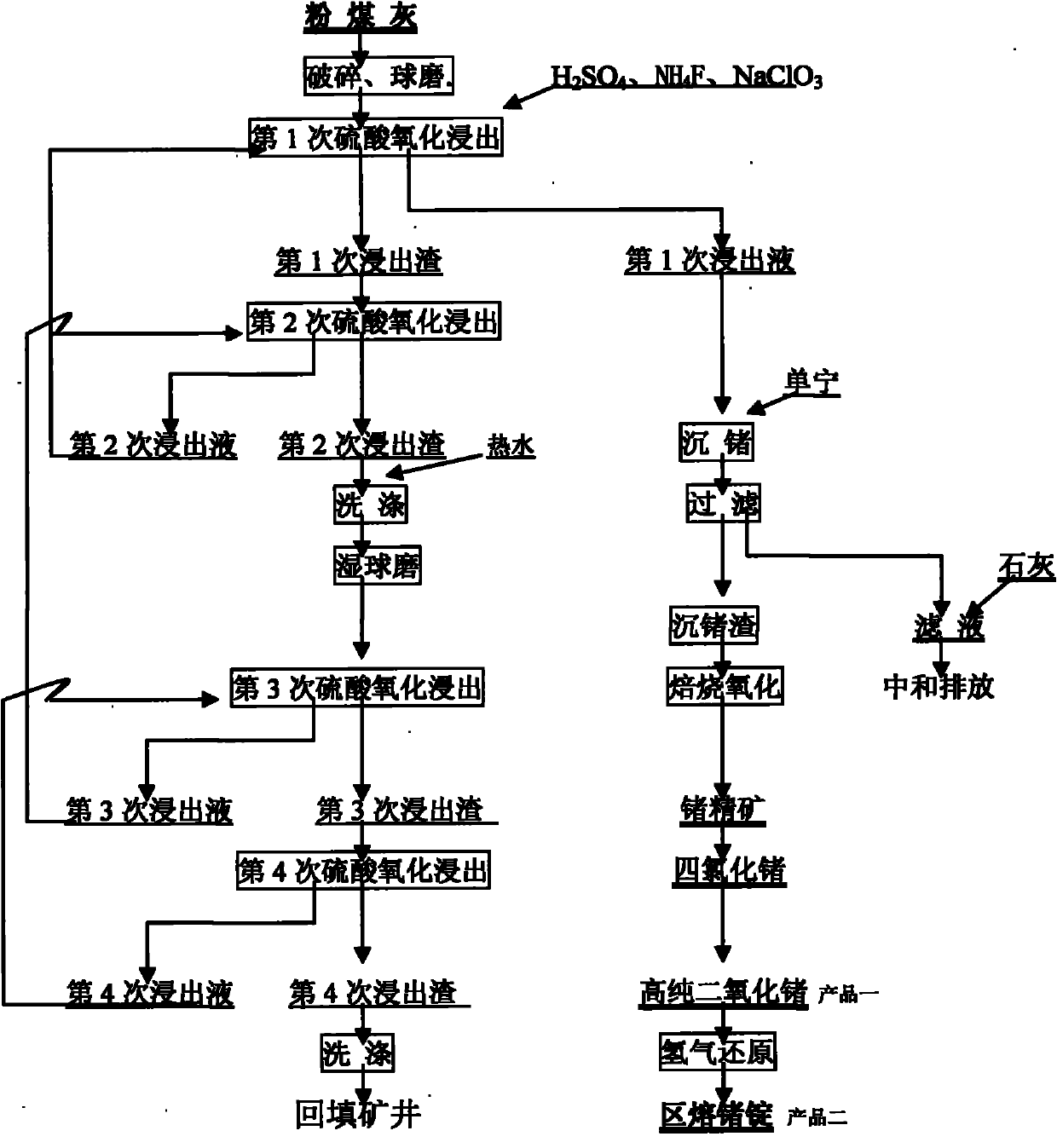

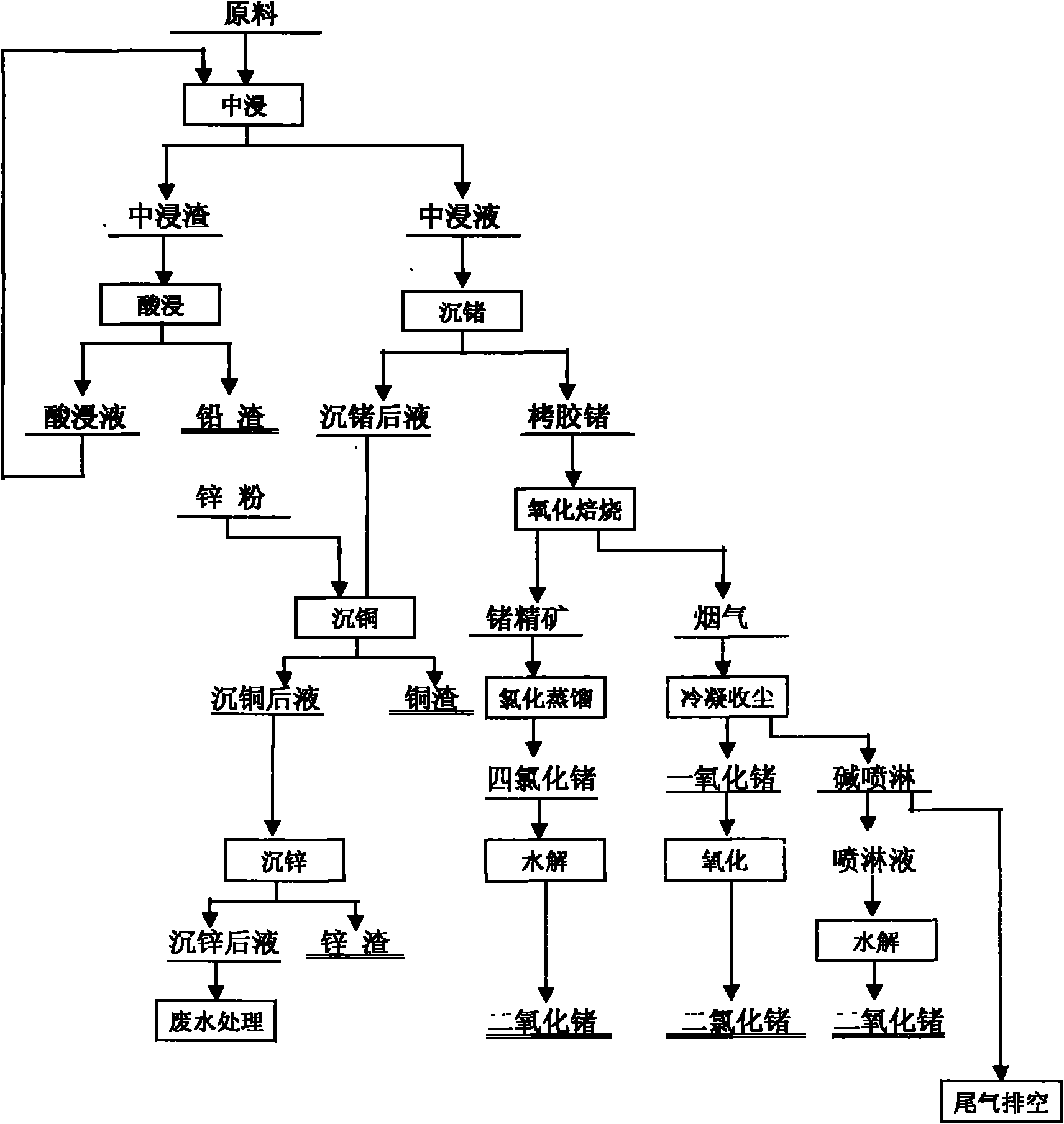

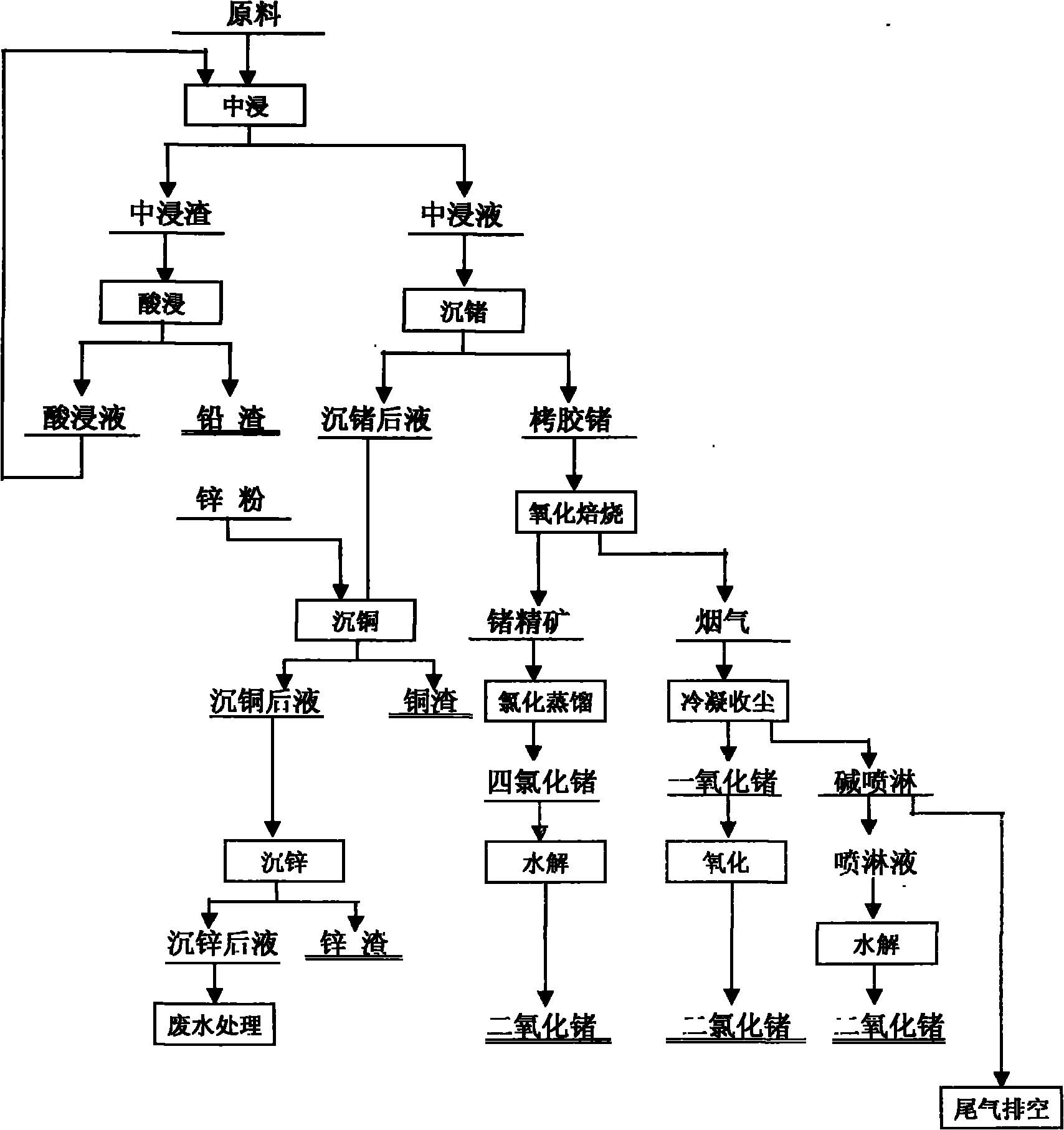

Method for recovering germanium from flyash by wet process

InactiveCN101906542ATake advantage ofReduce pollutionProcess efficiency improvementSodium chlorateHydrometallurgy

The invention relates to a method for recovering germanium from flyash by a wet process, belonging to the technical field of wet-process metallurgy. The method comprises the following steps of: (1) crushing flyash to more than 200 meshes by a wet process; (2) carrying out oxidizing leaching twice on wet flyash by using a sulfuric acid solution, sodium chlorate and ammonium fluoride; (3) crushing the flyash to 200-400 meshes for a second time; (4) leaching 3 or 4 times by using the same condition as that of the first leaching; (5) regulating the pH value of the first leached liquid to 2-2.5 by using ammonia water, and then precipitating and leaching out germanium in the liquid by using tannin with a weight percentage content of 80-99 percent; (6) drying and roasting the germanium precipitate to prepare a germanium concentrate; distilling the germanium concentrate with hydrochloric acid by using a conventional method to obtain germanium tetrachloride; and redistilling, rectifying, purifying and hydrolyzing to obtain high-purity germanium dioxide. The invention is used for flyash after recovering germanium by a fire process, sufficiently utilizes rare germanium metal, reduces the pollution of tailings to the environment, and has the advantages of low cost and high recovery rate.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

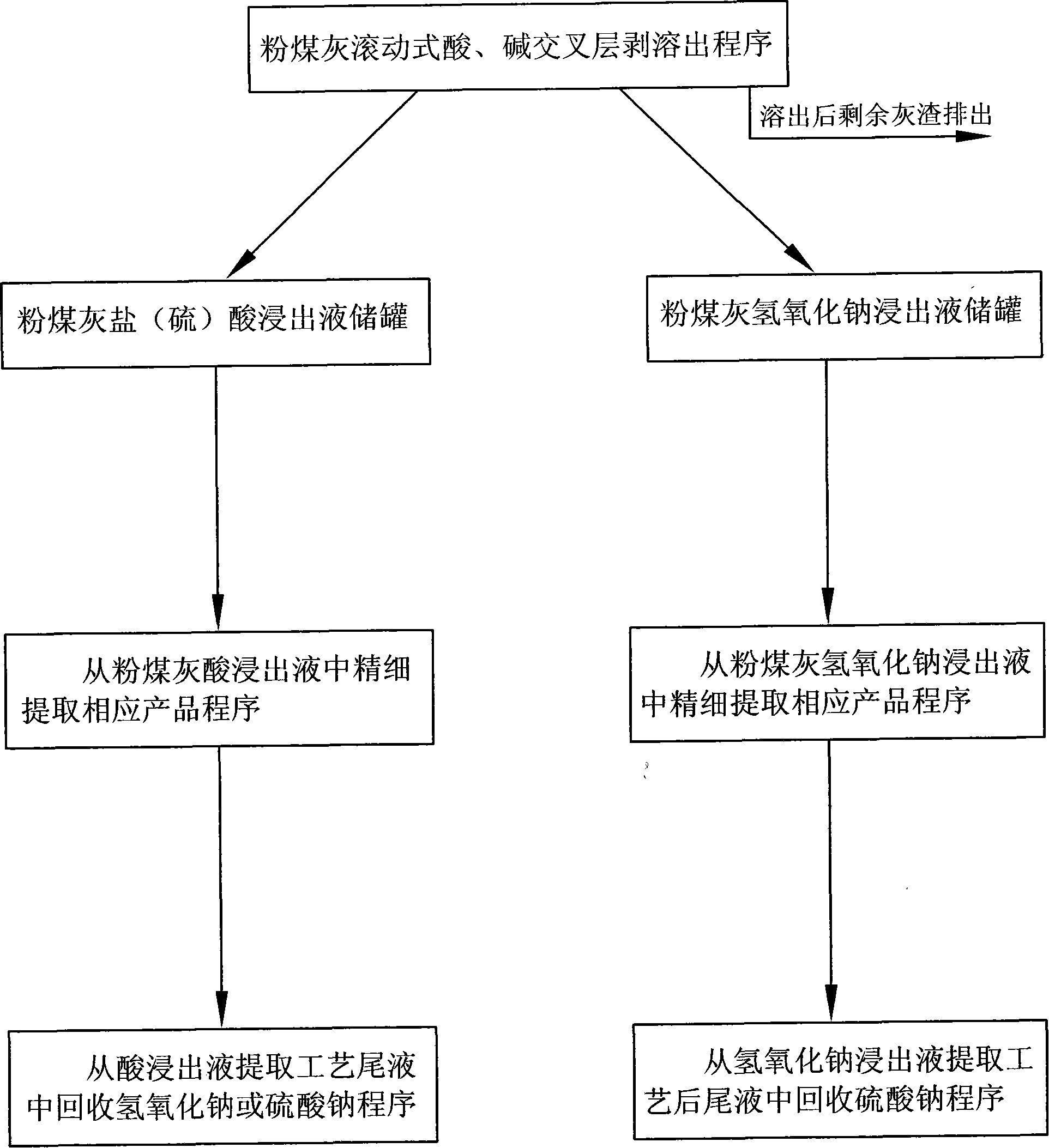

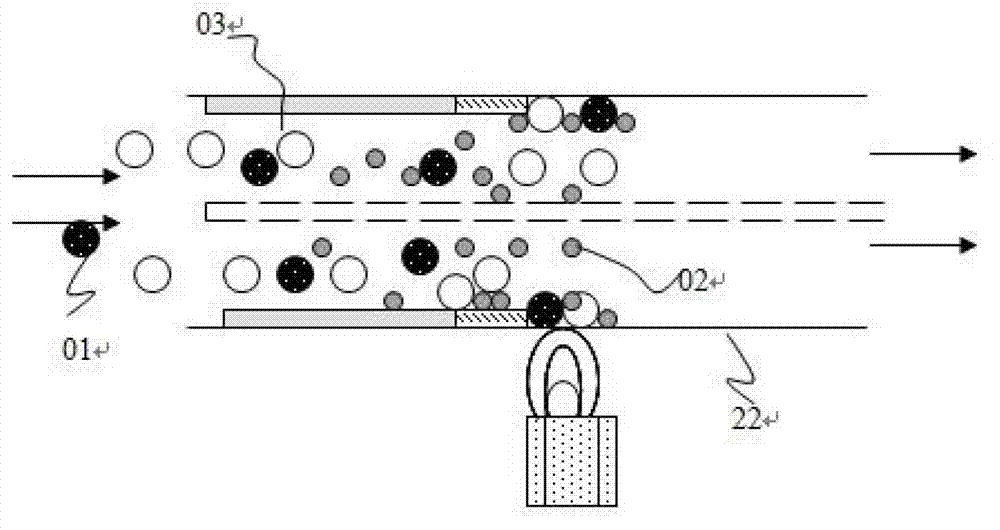

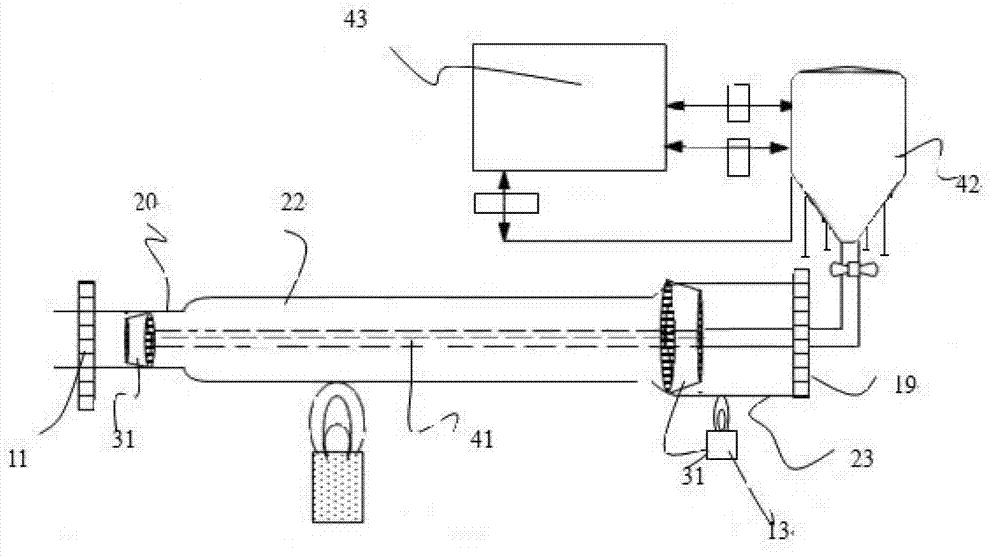

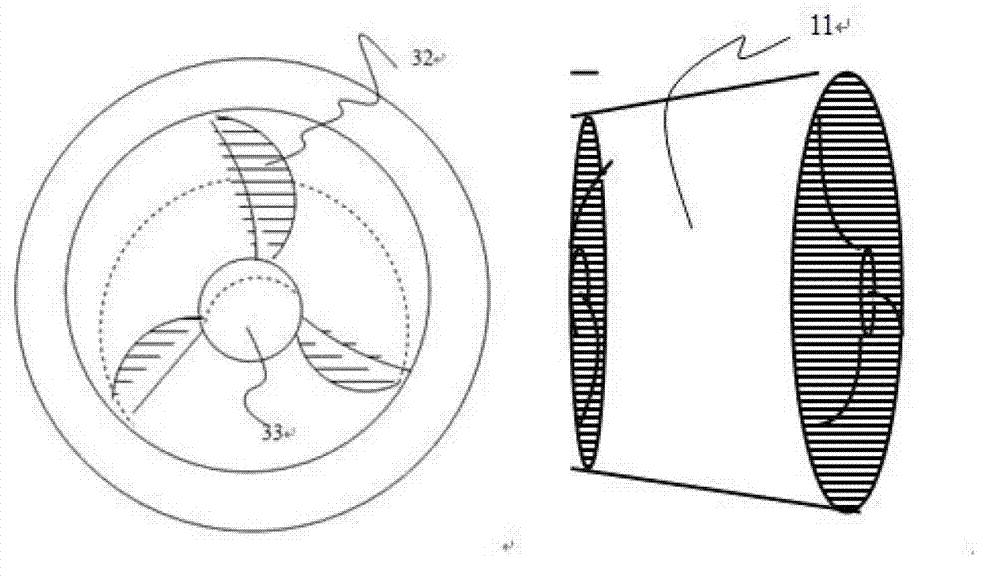

Coal ash roller type fine extractive technique

InactiveCN101200305ACompletely zero emissionsIron oxides/hydroxidesSolid waste disposalFerric hydroxideBrick

The invention relates to a powder coal ash rolling-type fine extraction method which can effectively peel and dissolve extractive, serially extract active silica, ferric hydroxide, iron oxide red, magnesium hydrate, calcium hydroxide, barium sulfate, lithium carbonate and lanthanide series and actinium series rare earth hydroxide with an enrichment amount >=0.01%, manganese, copper, zinc and gallium with an enrichment amount >=0.05%, and germanium dioxide, vanadium pentoxide, gold, silver, palladium and platinum metal with an enrichment amount >=0.0001% from the powder coal ash. The powder coal ash rolling-type fine extraction method has the advantages that the remainder ash of the powder coal ash after the treatment by the rolling-type fine extraction technique can be still comprehensively used for making brick and blending coagulation, thereby fully using the powder coal ash and realizing zero emission.

Owner:李文志 +1

Doping device for optical fiber preform

ActiveCN102815866AGuaranteed uniformityGuaranteed stabilityGlass making apparatusGas phaseRare earth

The invention provides a doping device for an optical fiber preform. On modified chemical vapor deposition equipment, a required clad material is deposited on an inner wall of a reaction tube by using an improved MCVD method; a gas phase and liquid phase composite doping device is employed to carry out uniform doping of active doping ions and a co-doped agent. For the gas phase doping, a simple-structured and low-cost heater is employed for direct heating; and a dopant is constantly heated by the heater, and is introduced by current-carrying oxygen for doping after vaporization. For the liquid phase doping, a micropore jet doping device is used to carry out direct online doping of a doping solution through an injection device. The composite doping device is used to carry out preparation of a rare earth doped preform, so as to realize synchronous deposition and vitrification of the rare earth doping ions, the co-doped agent and quartz base materials comprising silica and germanium dioxide, avoid dependence on the deposition loose pore structure layer, and increase flexibility of the concentration and the variety of the doping ions.

Owner:武汉长进光子技术股份有限公司

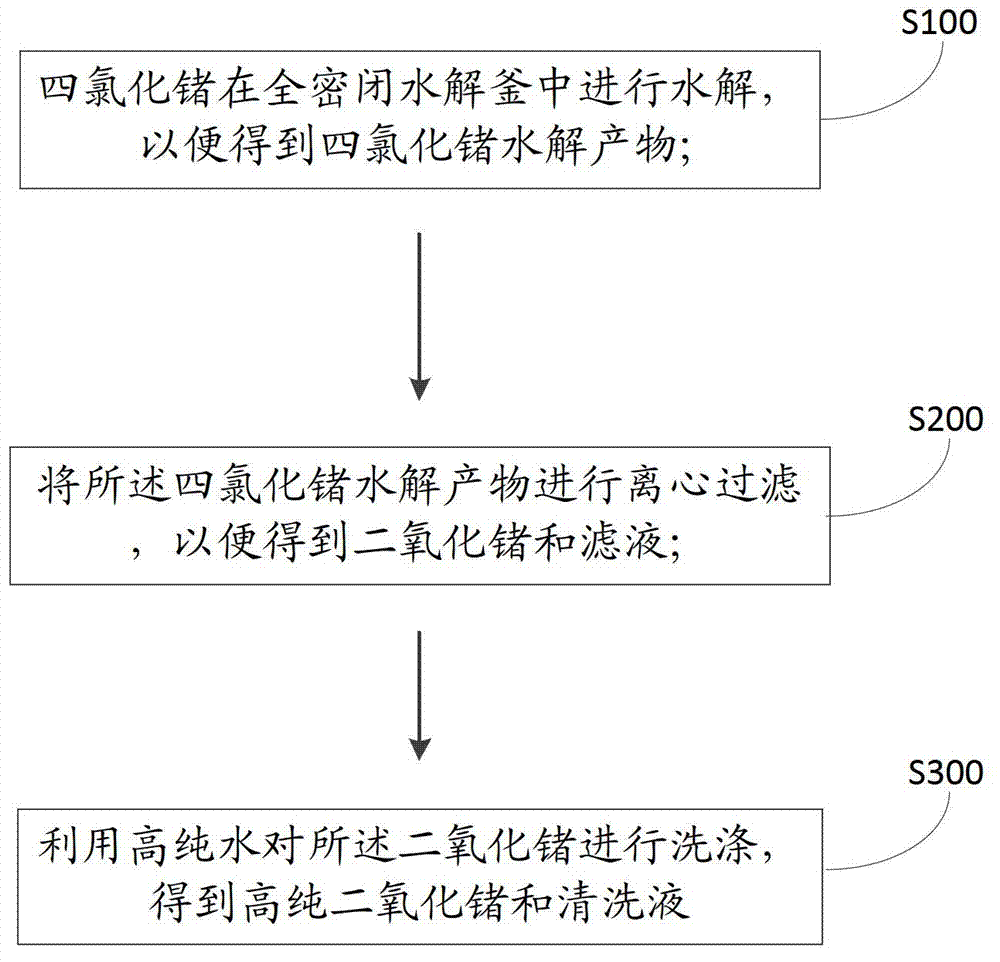

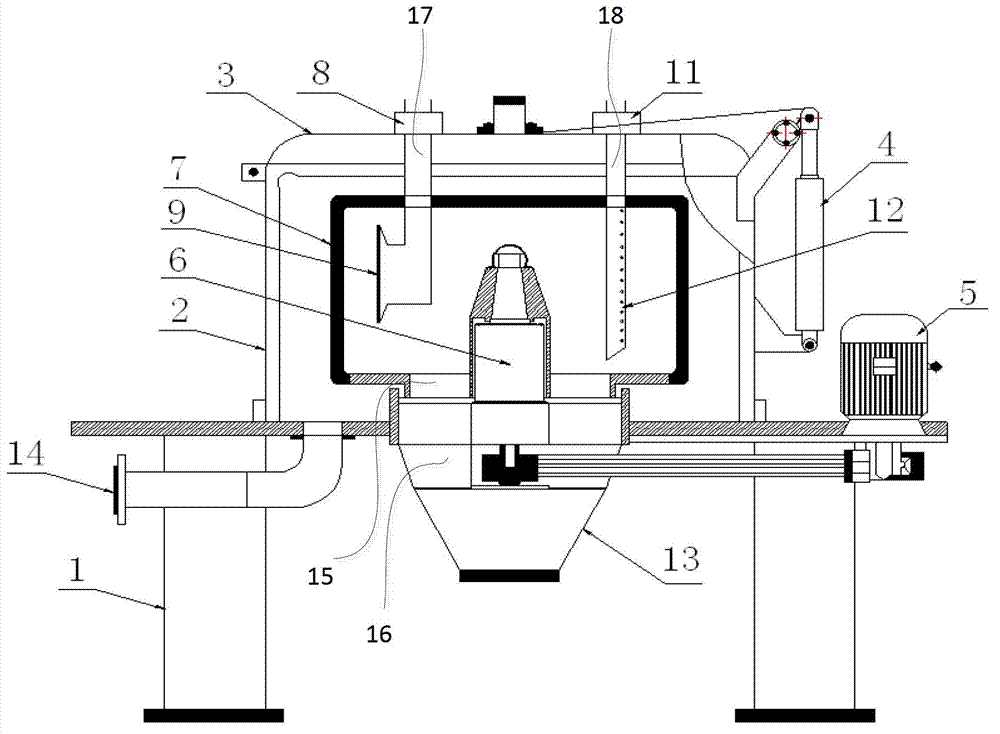

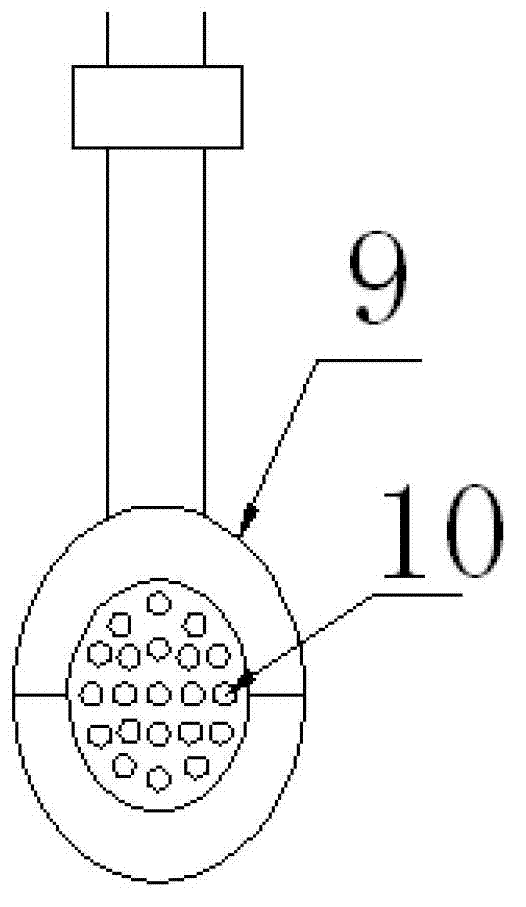

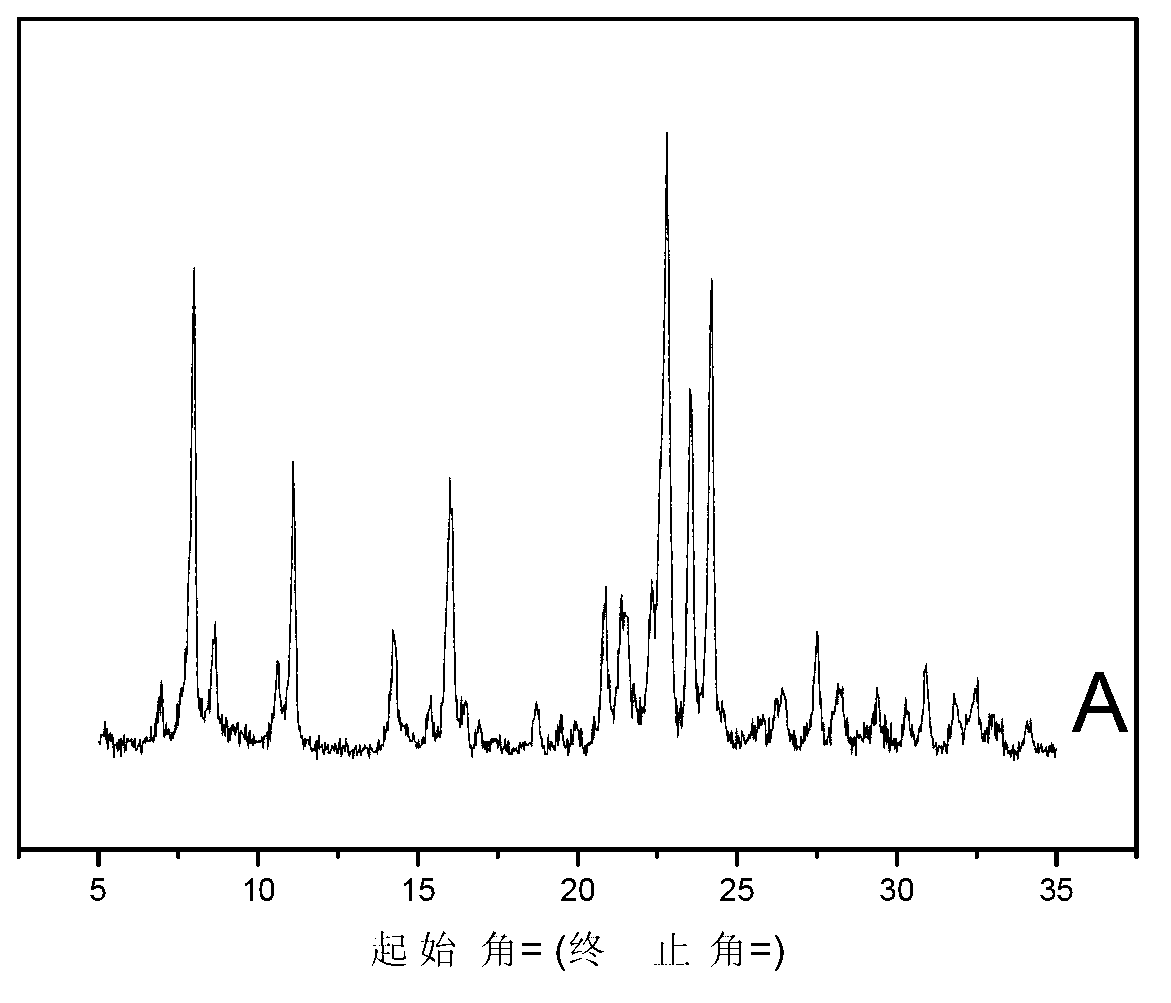

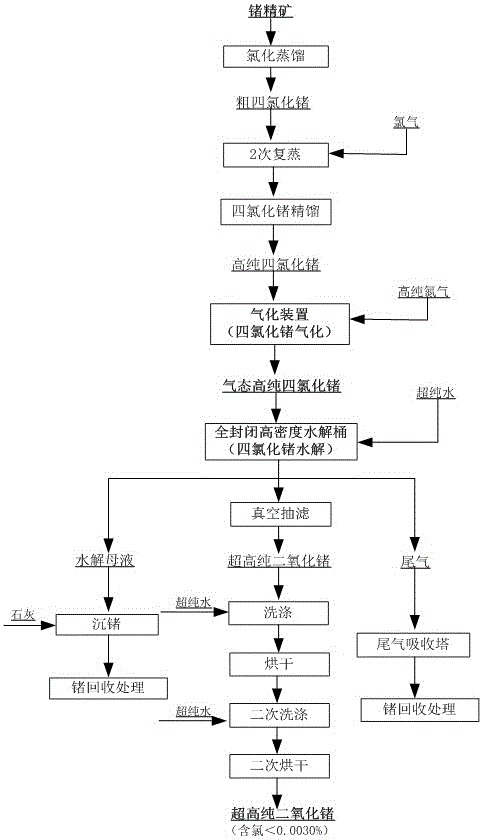

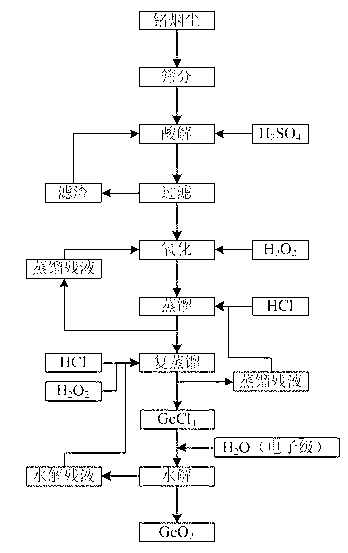

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

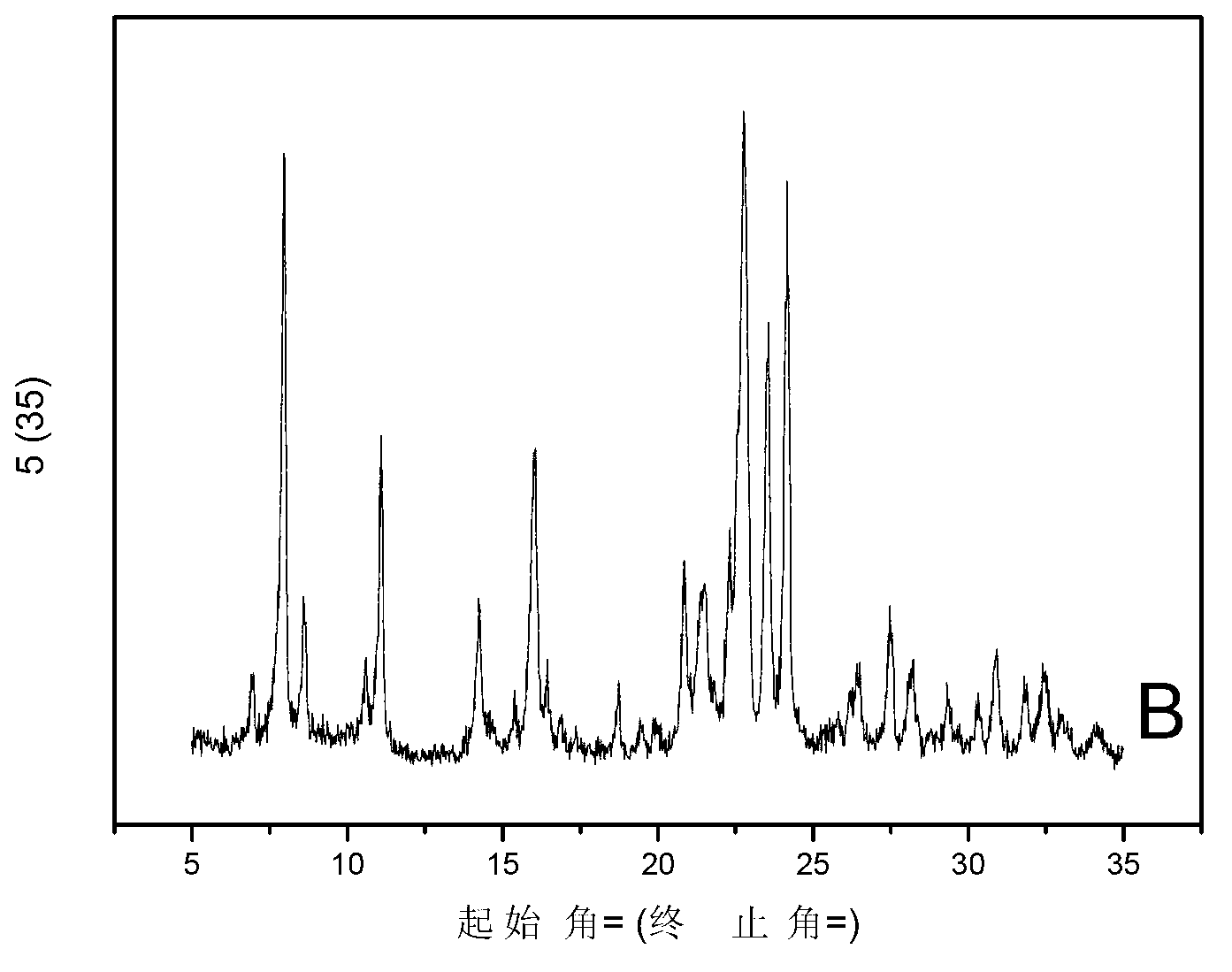

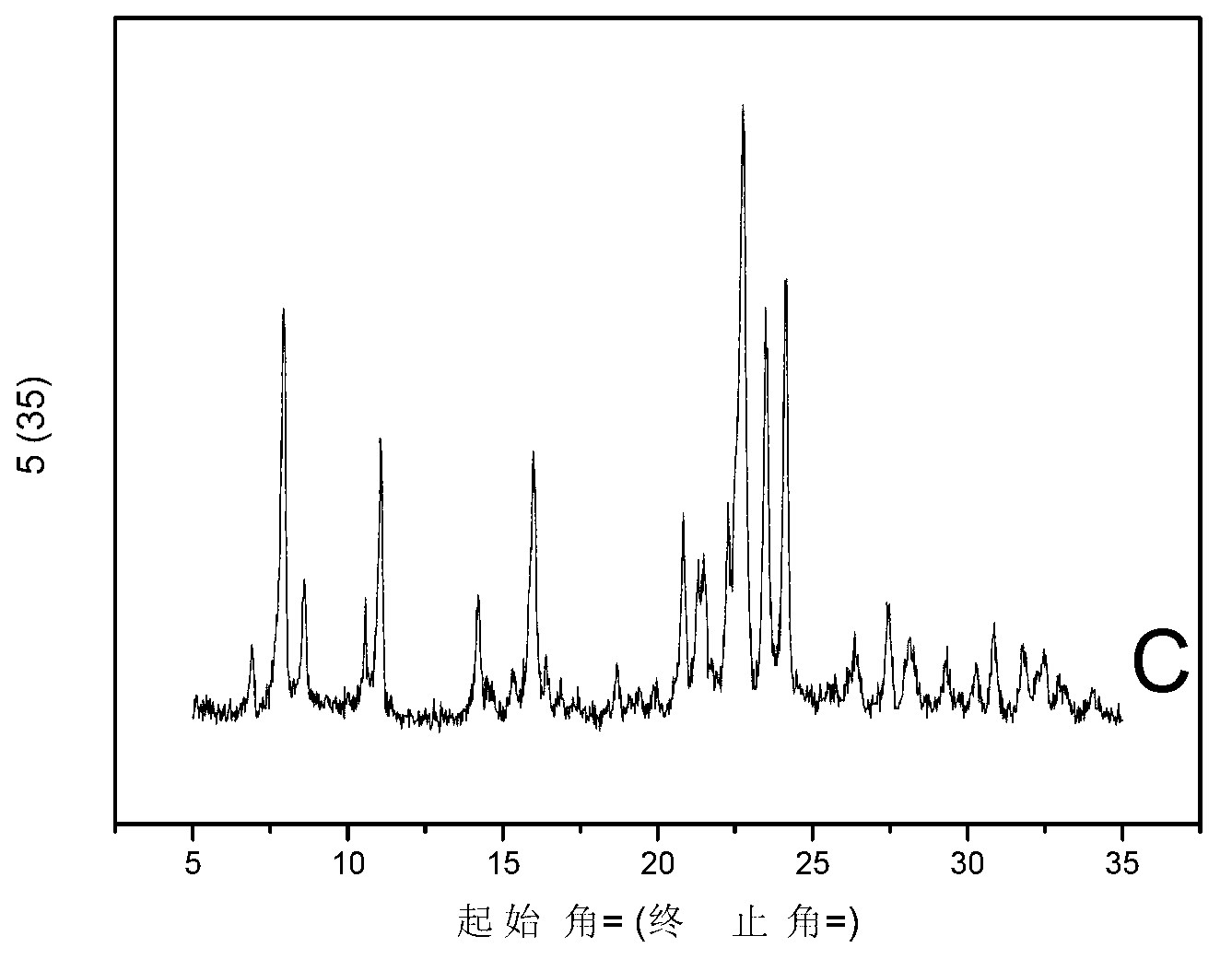

Low cost method for rapidly synthesizing ITQ-13 molecular sieve

ActiveCN103224242AShorten crystallization timeLower synthesis costSilicaMolecular-sieve and base-exchange compoundsMolecular sieveCrystallization temperature

The invention relates to a low cost method for rapidly synthesizing an ITQ-13 molecular sieve. The method comprises the steps of dissolving a template in deionized water; adding a promoter, an alkali source, germanium dioxide, an aluminium source and crystal seeds; adding a silicon source and a fluorine source successively when the above materials are dissolved; stirring to form a uniform gel; crystallizing for 0.5-8 days under self-generated pressure and at a crystallization temperature of 100-220 DEG C; shock cooling with cold water; fully washing a crystallization product with the deionized water; and drying to obtain molecular sieve raw powder. The synthetic method has the advantages of simpleness, rapidity, easiness and low cost.

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

Preparation method of low-chloride high-purity germanium dioxide

InactiveCN106564933ALow chlorine contentAvoid insufficient hydrolysisGermanium dioxideFiltrationNitrogen

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

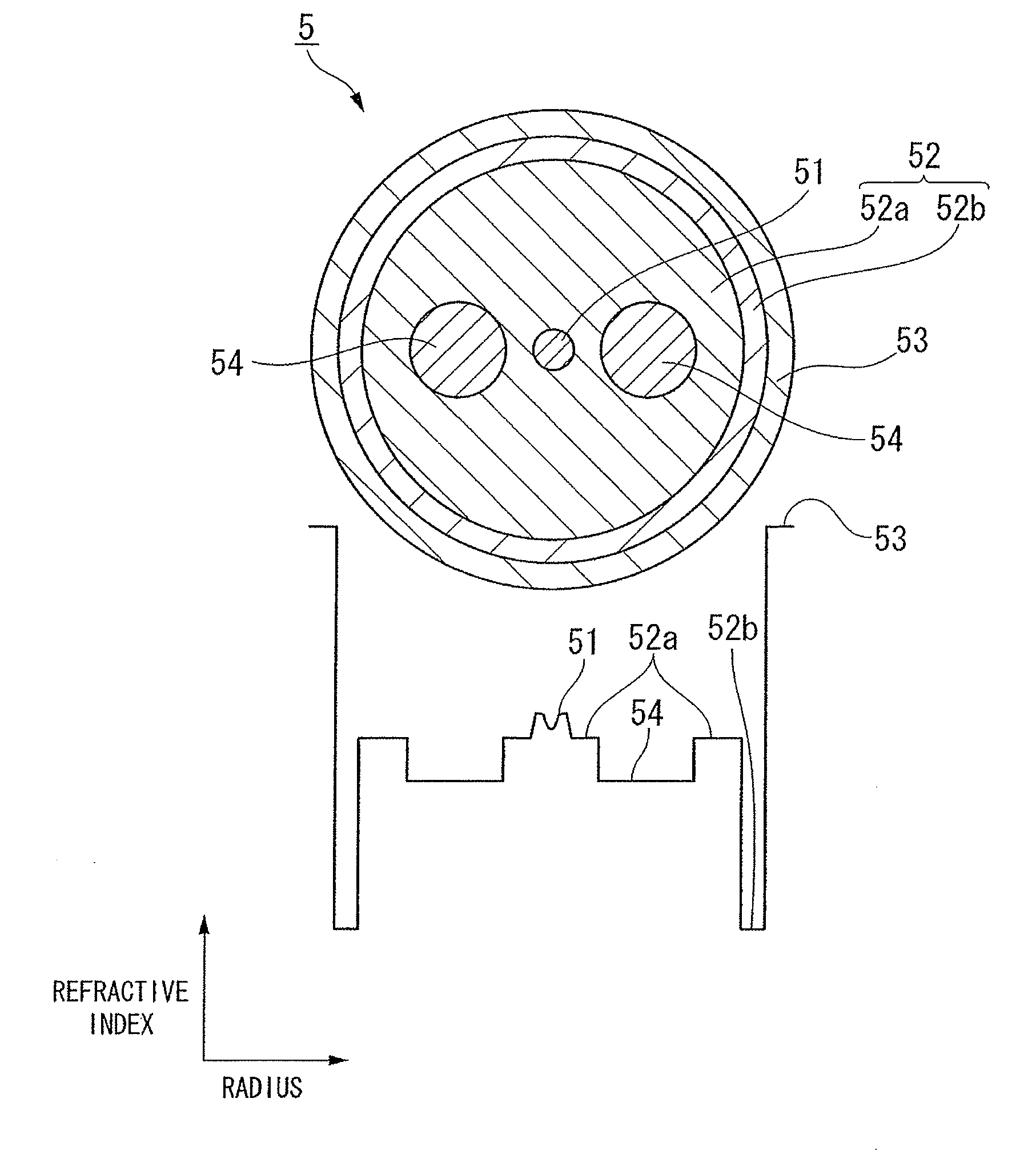

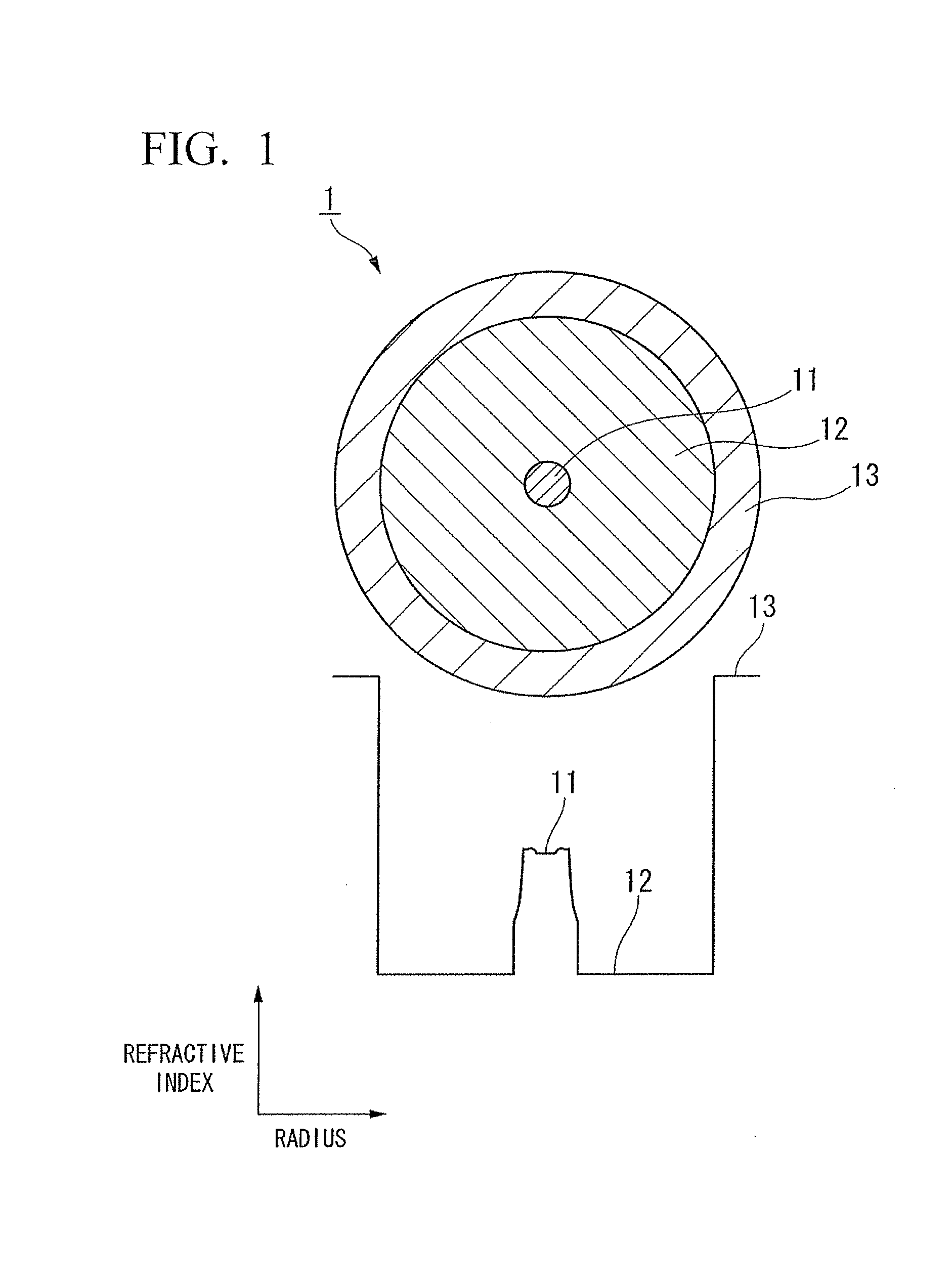

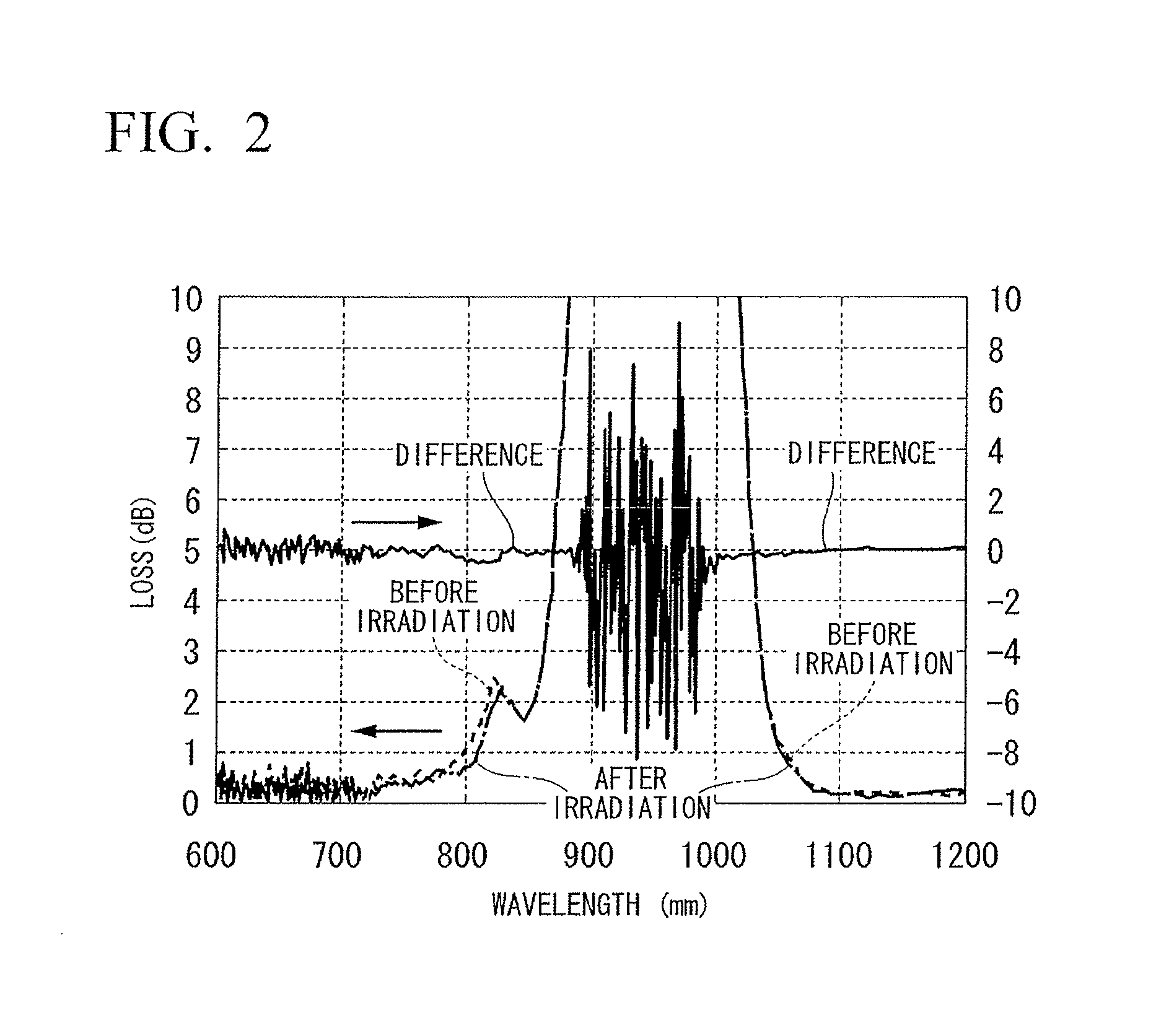

Ytterbium-doped optical fiber, fiber laser and fiber amplifier

ActiveUS20110142083A1Low costSuperior optical amplifying effectGlass optical fibreLaser using scattering effectsDiphosphorusGermanium dioxide

An ytterbium-doped optical fiber includes: a core which contains at least ytterbium, aluminum, and phosphorus; and a cladding which encircles the core, wherein an aluminum oxide equivalent concentration of the aluminum in the core is 0.2 mol % or more, a diphosphorus pentaoxide equivalent concentration of the phosphorus is higher than the aluminum oxide equivalent concentration, and the core either does not contain germanium or contains less than 1.1 mol % of germanium in a germanium dioxide equivalent concentration.

Owner:THE FUJIKURA CABLE WORKS LTD

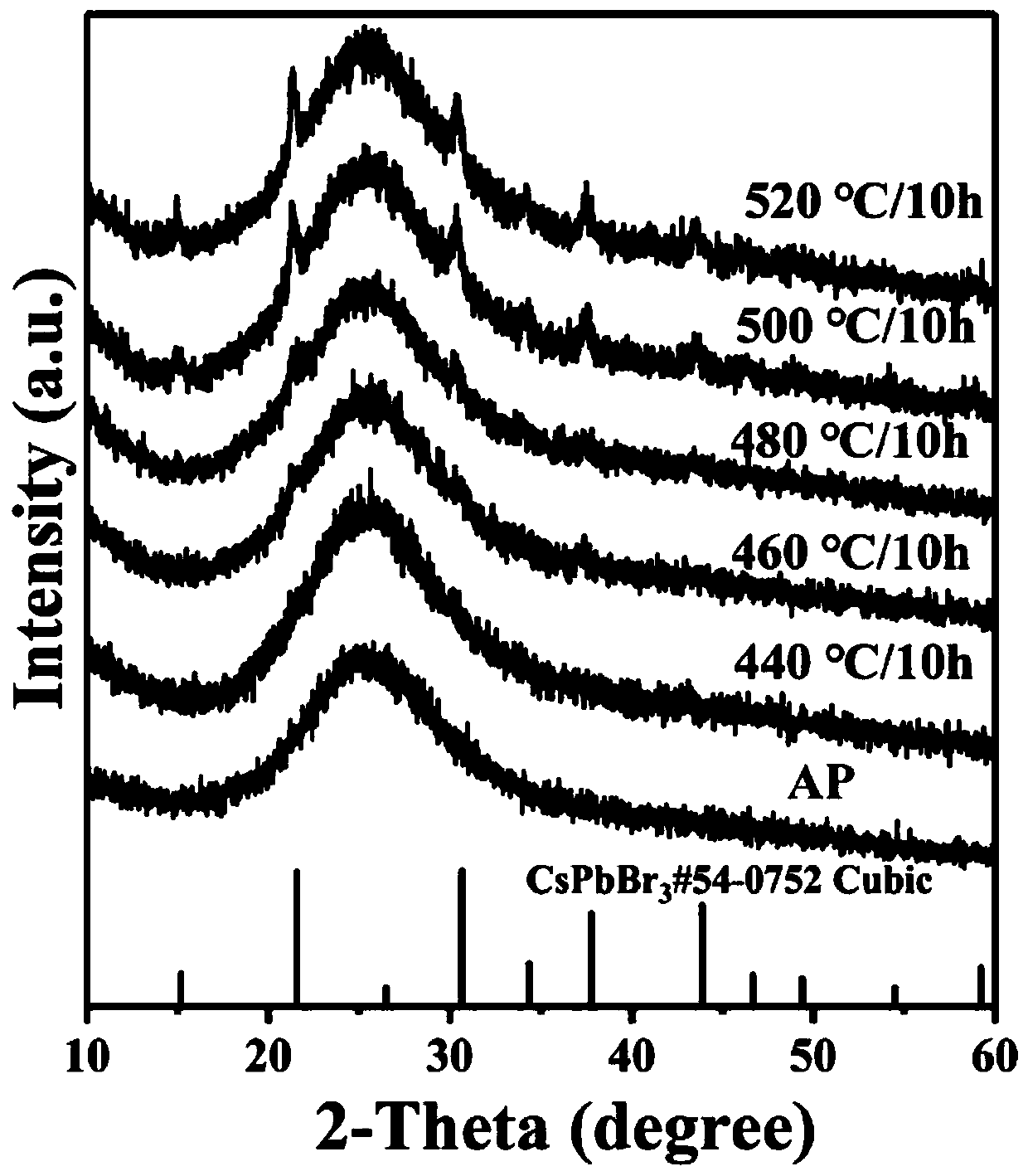

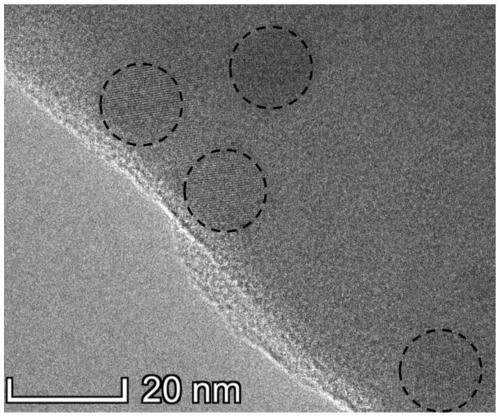

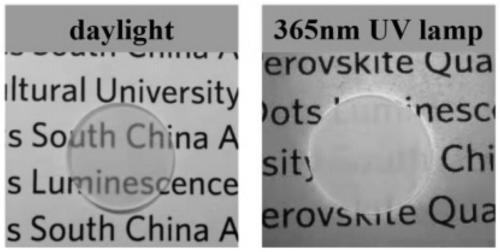

CsPbBr3 (cesium-lead-bromide) perovskite quantum dot fluorescent glass for display of wide color gamut and preparation method and application thereof

ActiveCN110294597AImprove internal quantum efficiencyImprove thermal stabilitySemiconductor devicesFluorescenceGermanium dioxide

The invention belongs to the technical field of display of fully-organic perovskite quantum dots, and discloses a CsPbBr3 (cesium-lead-bromide) perovskite quantum dot fluorescent glass for display ofwide color gamut and a preparation method and application thereof. The CsPbBr3 perovskite quantum dot fluorescent glass comprises the following components in percentage by mole: 0 to 45% of SiO2 (silicon dioxide), 0 to 45% of GeO2 (germanium dioxide), 30 to 40% of B2O3 (boron oxide), 2 to 8% of Al2O3 (aluminum oxide), 3 to 7% of MCO3 (metal carbonate), 1 to 5% of ZnO (zinc oxide), 5 to 15% of CsBr(cesium bromide) or Cs2CO3 (cesium carbonate), 2 to 10% of PbBr2 (lead bromide) or PbO (lead oxide), and 3 to 15% of NaBr (sodium bromide) or KBr (potassium-bromide), wherein M is Ca (calcium) or Sr(strontium); the sum of the components in percentage by mole is 100%. The CsPbBr3 perovskite quantum dot fluorescent glass has the advantages that the technology is simple, and the operation is easy;after in-situ crystallization, the quantum efficiency is higher, the light emitting stability is obviously improved, and the broad application prospect is realized.

Owner:SOUTH CHINA AGRI UNIV

Lithium silicate glass ceramic for fabrication of dental appliances

ActiveUS9241879B2Easy to controlGood physical propertiesImpression capsGlass drawing apparatusLithiumChemical composition

The present invention relates to a method of fabricating an improved lithium silicate glass ceramic and to that material for the manufacture of blocks for dental appliances using a CAD / CAM process and hot pressing system. The lithium silicate material has a chemical composition that is different from those reported in the prior art with 1 to 10% of germanium dioxide in final composition. The softening points are close to the crystallization final temperature of 800° C. indicating that the samples will support the temperature process without shape deformation.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

Lead and arsenic free optical glass with high refractive index

The invention relates to a lead- and arsenic-free, preferably gadolinium-free and more preferably fluorin-free optical glass, having a refractive index (nd) of 1.19-2.05, an Abbe number (vd) of 19-25, a low transition temperature of less than or equal to 470 DEG C, and preferably less than or equal to 450 DEG C, excellent productivity, excellent workability and excellent crystal stability, contains (by weight, on an oxide basis) more than 55% bismuth oxide (Bi2O3) and more than 13% germanium dioxide (GeO2) and has Bi2O3 to GeO2 ratio 5 or less. The inventive optical glass can be used for mapping, projection, telecom, optical communication engineering, shifting drivers, and laser technology and / or microlens array.

Owner:SCHOTT AG

Method for recovery germanium from germanium-containing flue dust

InactiveCN103173624ASimple technologyEasy to operateProcess efficiency improvementDistillationDistilled water

The invention provides a method for recovering germanium from germanium-containing flue dust. According to the invention, germanium flue dust is crushed and sieved, and is well mixed with water by stirring; industrial sulfuric acid is added, and continuous stirring is carried out under a temperature of 85-90 DEG C, until no more gas is produced in the material slurry; under stirring and under a temperature of 50-70 DEG C, H2O2 is added, until H2O2 is completely decomposed and no bubble appears; the obtained material slurry is filtered; industrial hydrochloric acid is added; heating is carried out, and distillation is carried out for 2-4h with distilled water as an absorbent, such that a distillate liquid I is obtained; re-distillation is carried out, such that a distillate liquid II is obtained; the distillate liquid II is hydrolyzed; and filtering and bake-drying are carried out, such that high-purity germanium dioxide powder is obtained. The flue dust processing method provided by the invention has the advantages of simple technology, easy operation, low investment, high recovery rate, and the like. The method has high comprehensive utilization rate upon germanium flue dust. Besides germanium, valuable metals such as zinc, lead, and silver can be recycled.

Owner:KUNMING UNIV OF SCI & TECH

Bright red underglaze color, overglaze and their prepn process

The present invention discloses one kind of bright red underglaze color, one kind of overglaze and their preparation process. The bright red underglaze color consists of stabilizer, 0.02-34 wt%, silica 11.3-56 wt%, lead oxide 2.4-27 wt%, cadmium sulfoselenide 2-20 wt%, Al2O3 1.7-27 wt%, B2O3 1.5-27 wt%, CrO2 0.3-32 wt%, GeO2 0.08-33 wt%, MgO 1.4-13 wt%, CaO 0.7-15 wt%, Li2O 0.7-13.2 wt%, K2O 1-7 wt% and NaO 1-5.3 wt%; and the overglaze consists of clinker 5-55 wt%, ZnO 3-12 wt%, albite 5-30 wt%, potash feldspar 7-35 wt%, baked talc 2-16 wt%, silica 2-18 wt%, and kaolin 2-26 wt%. The bright red underglaze color and the overglaze have pure color and very low Pb and Cd leaching amount.

Owner:胡天霏 +2

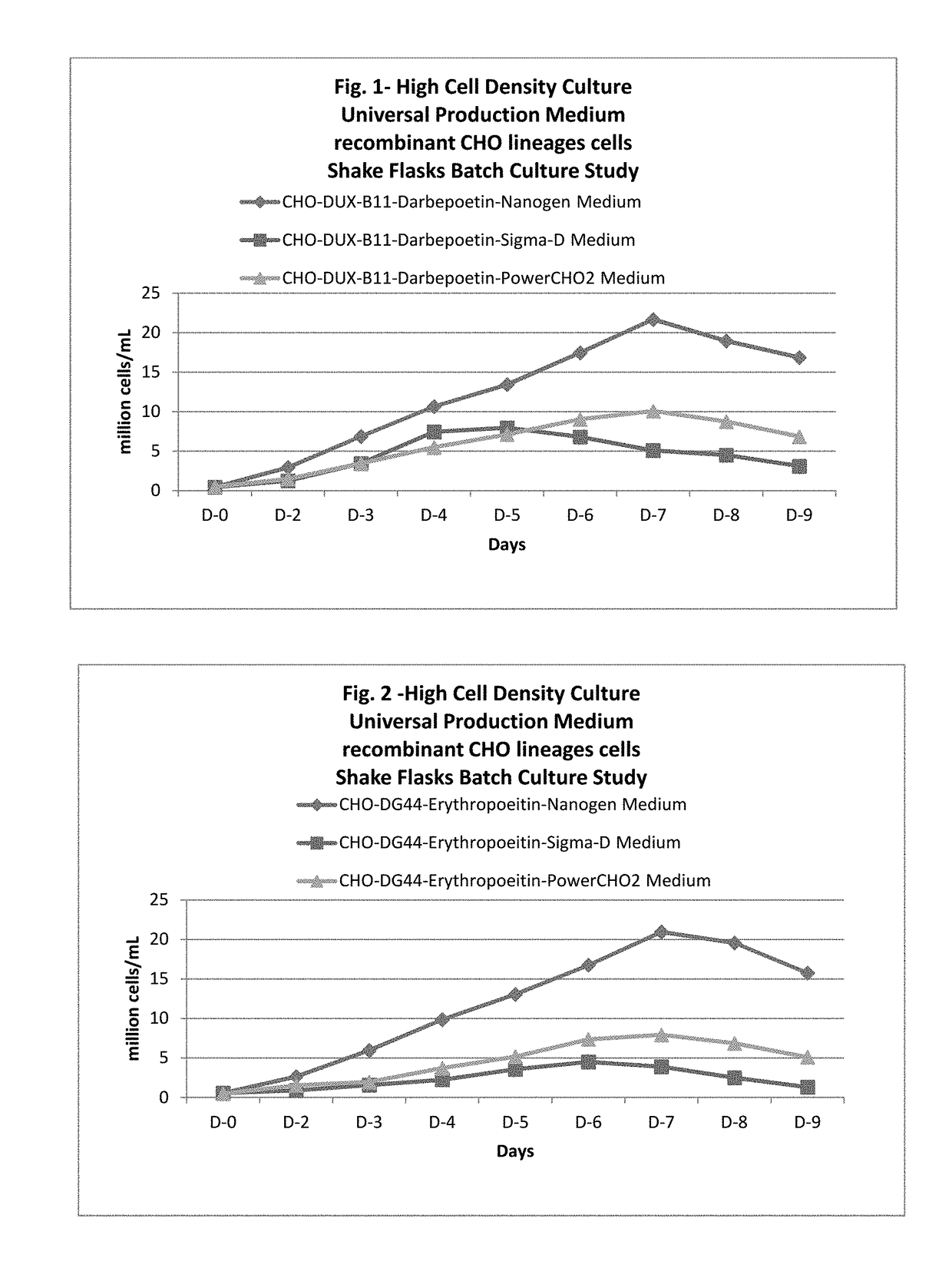

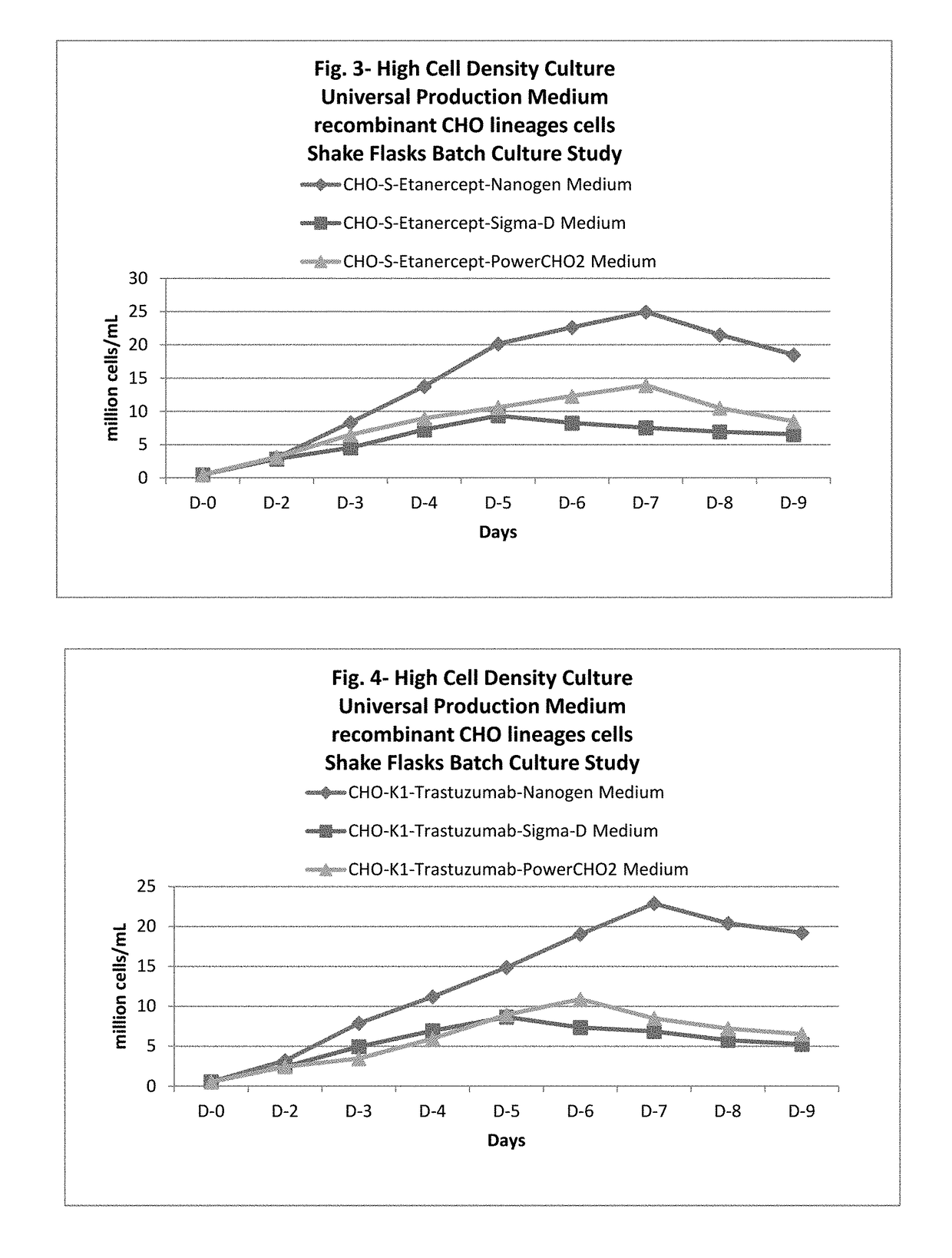

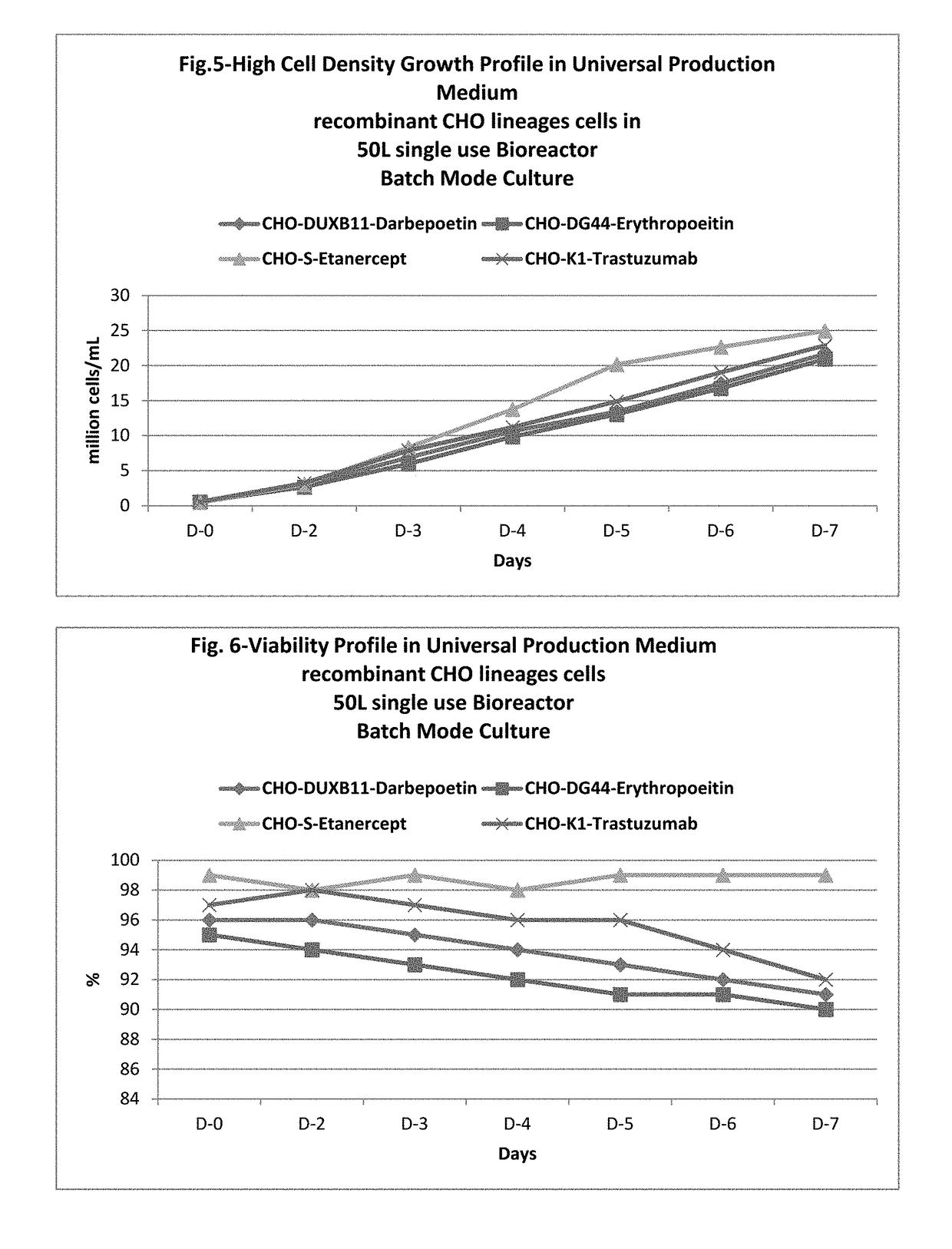

Universal, glycosylation enhancer, completely chemically defined medium formulation

ActiveUS20170218328A1Therapy is also rapidCulture processCell culture mediaSodium bicarbonateHydrolysate

In one embodiment, the present application discloses a cell culture medium for culturing cell lines suitable for producing a therapeutic protein, comprising an amino acid selected from a group consisting of L-arginine, L-asparagine, L-proline, L leucine and L hydroxyproline and a mixture thereof; a vitamin selected from a group consisting of ascorbic acid Mg2+ salt, biotin, pyridoxine HCL, folic acid, riboflavin and D-calcium pantothenate, and a mixture thereof; an element selected from a group consisting of ammonium meta vanadate, sodium meta vanadate, germanium dioxide, barium acetate, aluminum chloride, rubidium chloride, cadmium chloride, ammonium molybedate, stannous chloride, cobalt chloride, chromium sulfate, silver nitrate, sodium metasilicate, zinc sulfate, manganese sulfate H2O, manganous chloride, ferric nitrate 9H2O, ferrous sulfate 7H2O, ferric ammonium citrate, magnesium chloride anhydrous, and magnesium sulfate anhydrous, and a mixture thereof; a nucleoside selected from a group consisting of uridine and cystidine; a sugar selected from a group consisting of galactose, mannose and N-Acetyl-D-Mannosamine; and a triple buffering system comprising sodium carbonate, sodium bicarbonate and HEPES; wherein the cell culture medium is animal component-free, plant component-free, serum-free, growth factors-free, recombinant protein-free, lipid-free, steroid-free, and free of plant or animal hydrolysates and / or extracts.

Owner:NANOGEN PHARMA BIOTECH CO LTD

Use of germanium dioxide and/or alloys of GeO2 with silicon dioxide for semiconductor dielectric applications

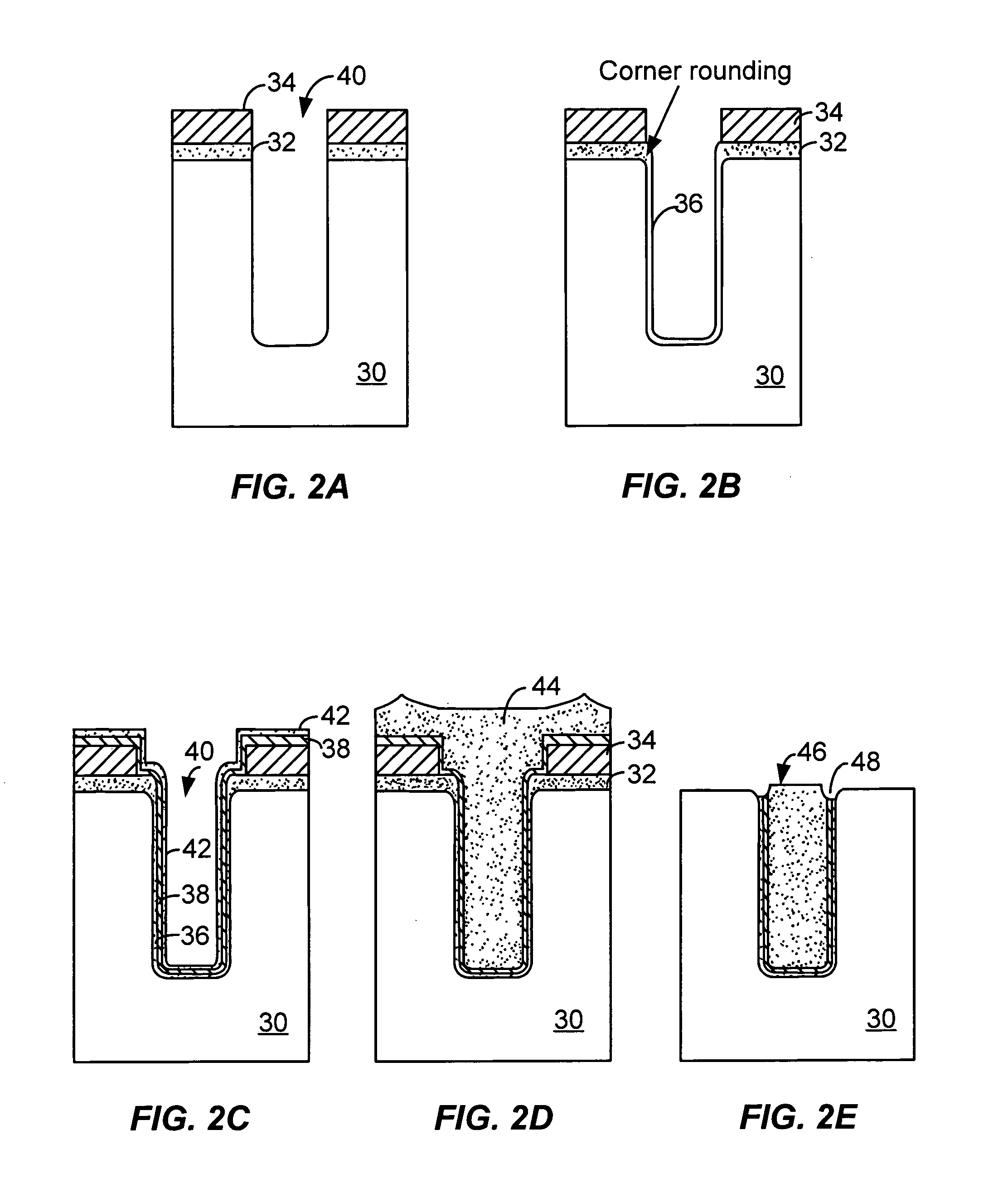

InactiveUS20060178003A1Increasing bias powerIncrease powerSemiconductor/solid-state device manufacturingDielectricVitrification

A method is disclosed for depositing a dielectric film on a substrate having a plurality of gaps formed between adjacent raised surfaces disposed in a high density plasma substrate processing chamber substrate. In one embodiment the method comprises flowing a process gas comprising a germanium source, a silicon source and an oxidizing agent into the substrate processing chamber; forming a high density plasma that has simultaneous deposition and sputtering components from the process gas to deposit a dielectric film comprising silicon, germanium and oxygen; and during the step of forming a high density plasma, maintaining a pressure within the substrate processing chamber of less than 100 mTorr while allowing the dielectric film to be heated above its glass transition temperature.

Owner:APPLIED MATERIALS INC

Condensed materials

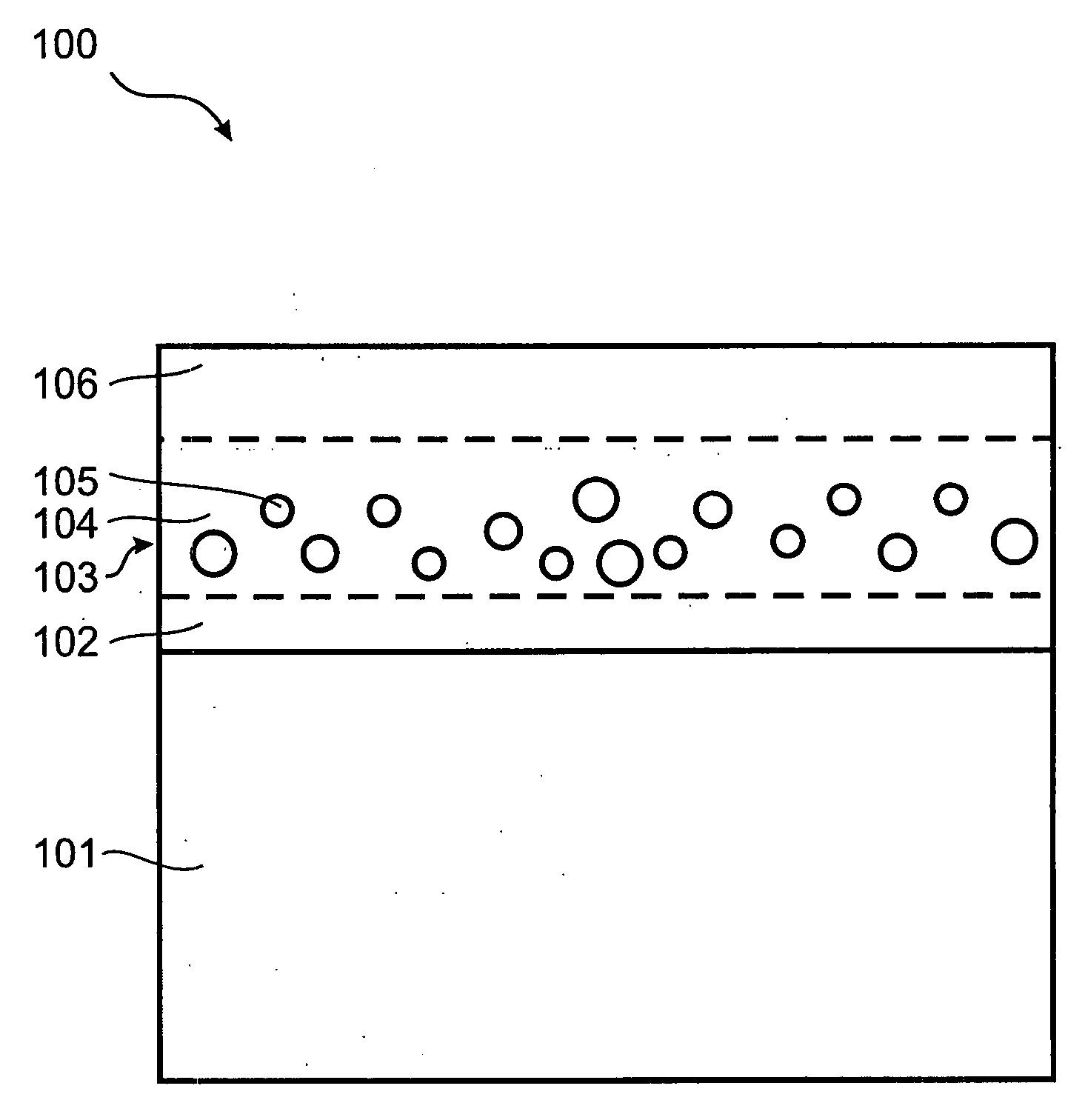

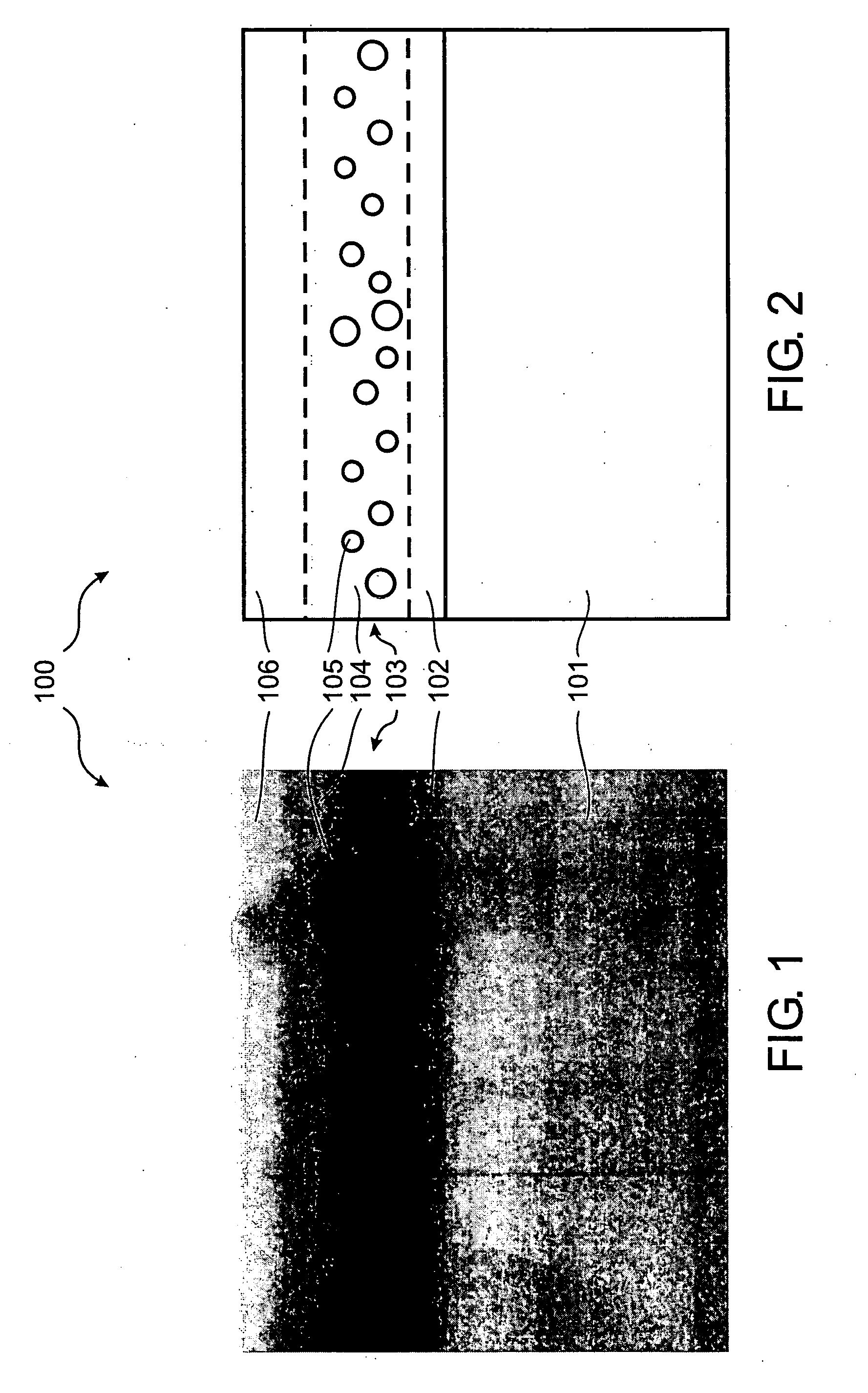

InactiveUS20100068505A1Prevents unwanted electron flowShorten the construction periodMaterial nanotechnologyLayered productsNanoparticleSilicon dioxide

A method for synthesis of germanium nanoparticles in thin SiO2 films comprising: preparing a solution comprising silicon esters, germaniumtetrachloride (GeCl4) or germanium esters, methyl- or higher alcohols, and water; applying the solution to a surface of a substrate; consolidating the solution on the surface of the substrate, thereby obtaining a glass comprising silicon dioxide and germanium dioxide; selectively reducing the germanium dioxide to form germanium nanoparticles.

Owner:WESTFALISCHE WILHELMS UNIV MUNSTER

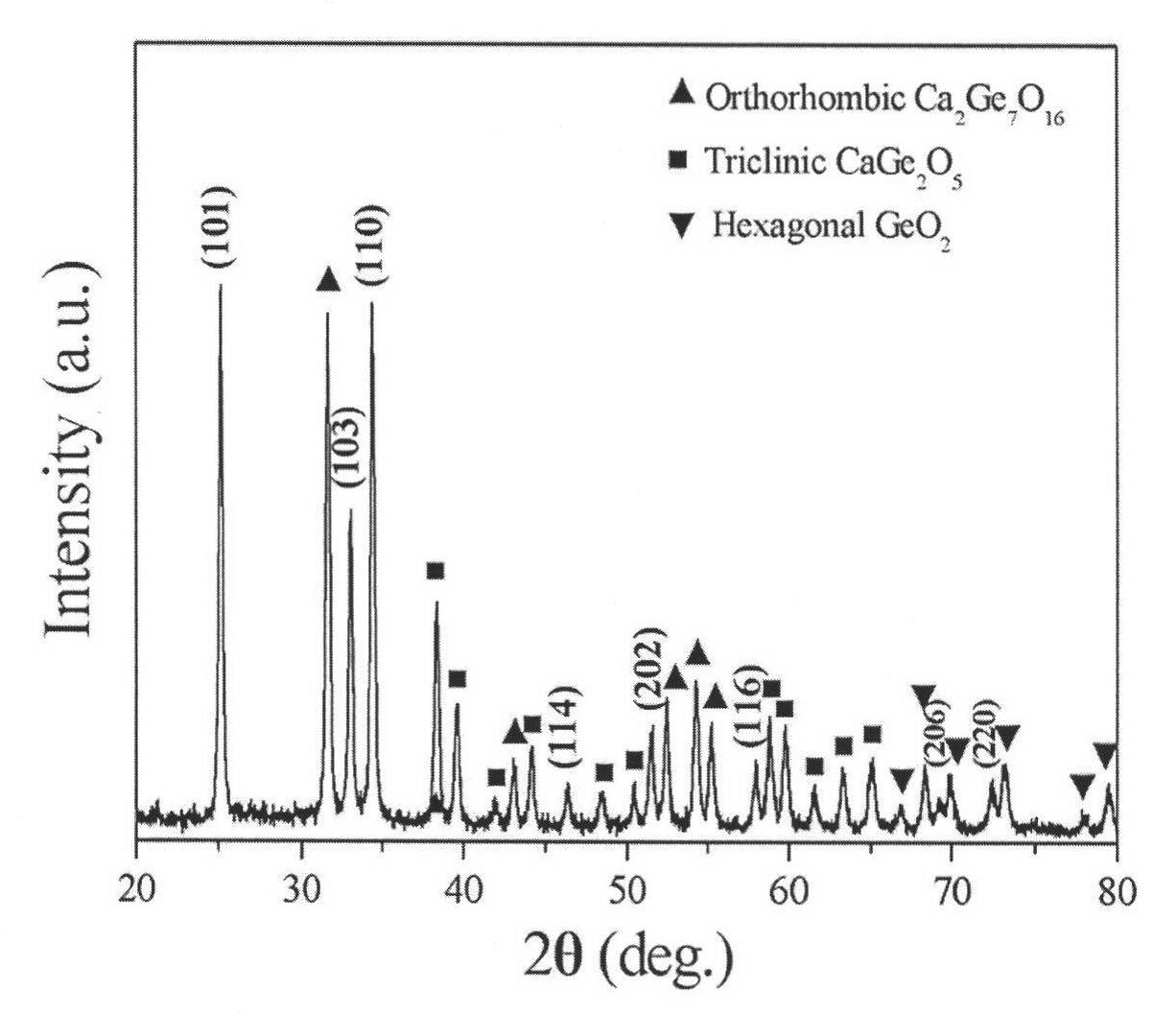

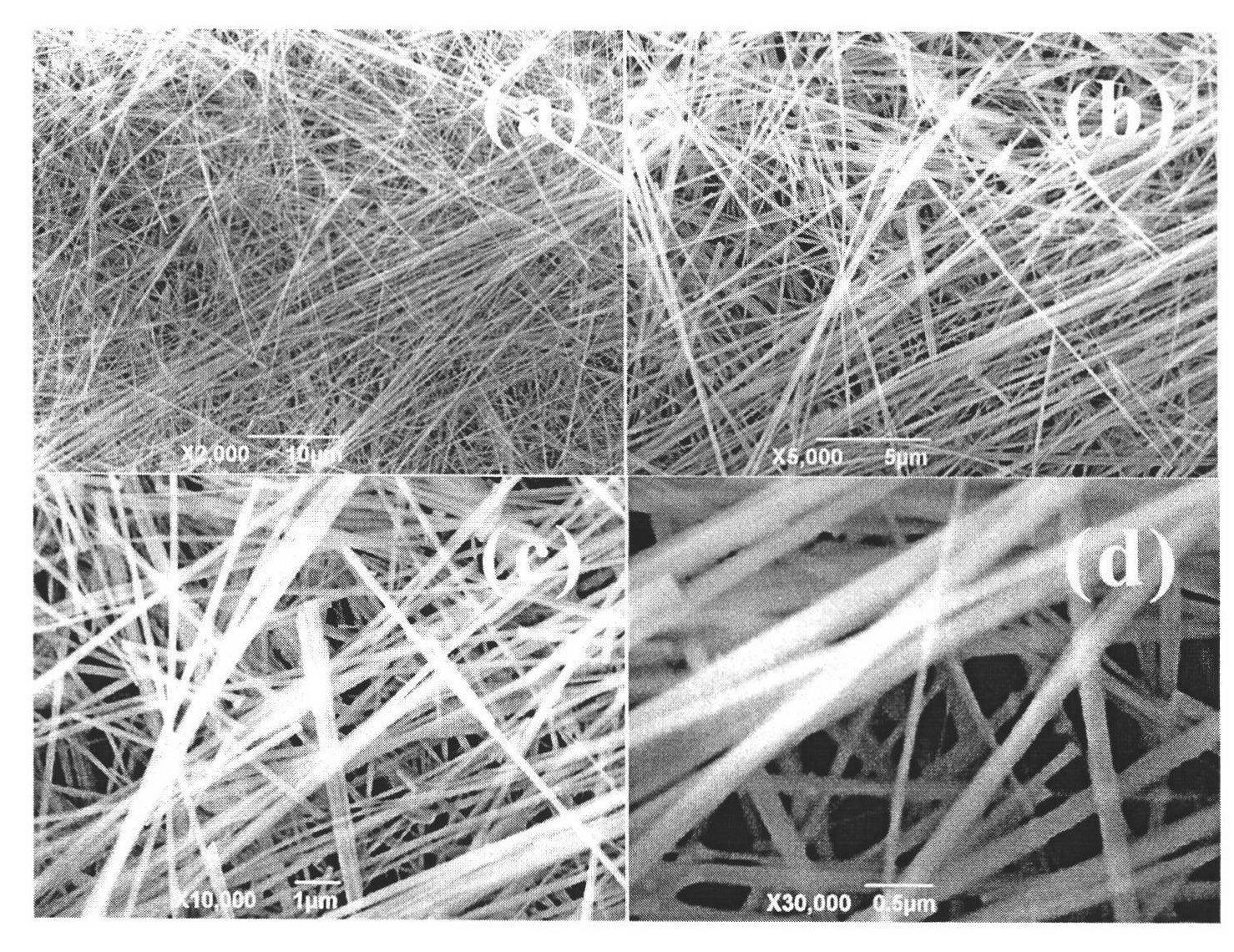

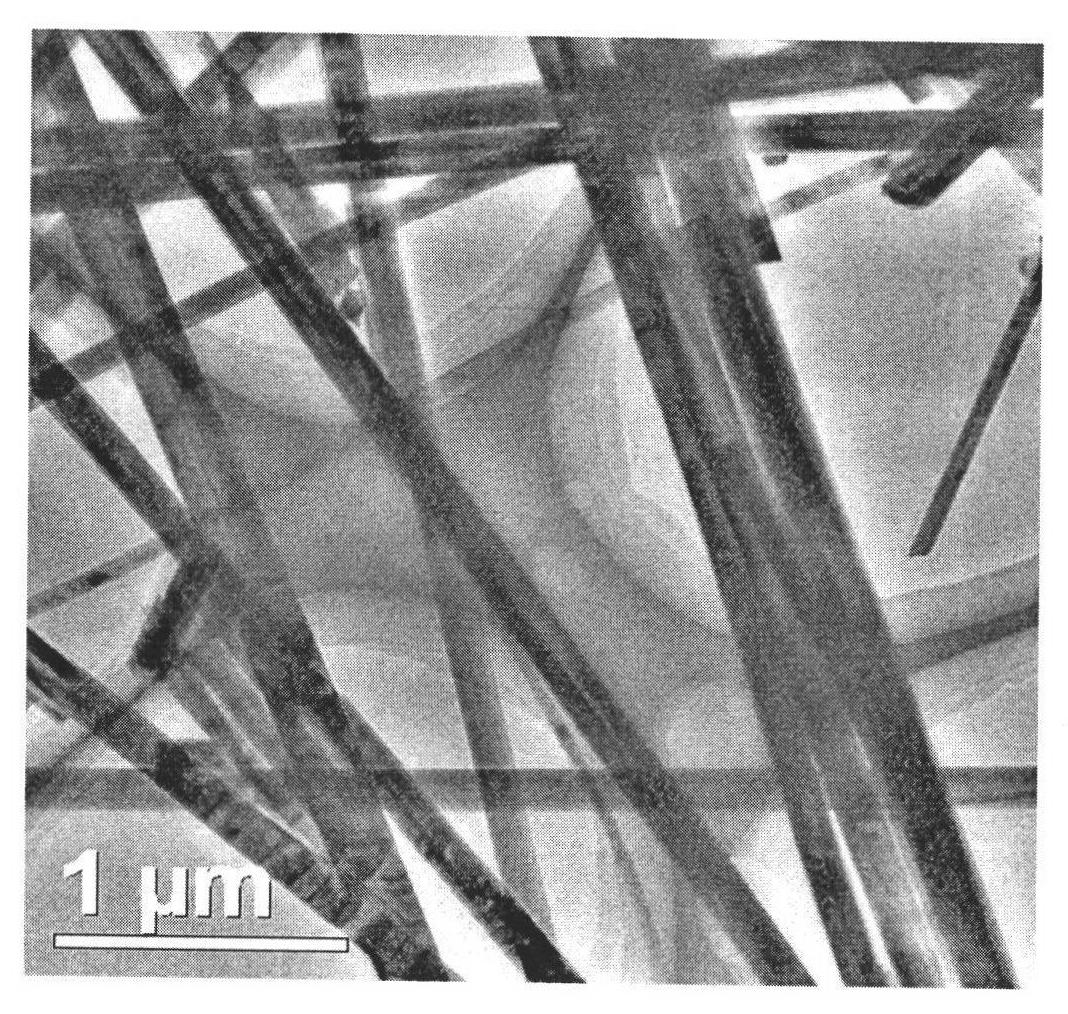

Calcium germinate nanowire and preparation method thereof

InactiveCN101956237AHigh purityLow purityPolycrystalline material growthFrom normal temperature solutionsEnvironmental resistanceNanowire

The invention provides a calcium germinate nanowire and a preparation method thereof, and belongs to the technical field of nano material preparation. The calcium germinate nanowire provided by the invention is prepared from monocrystalline calcium germinate with the diameter of between 20 to 100nm and the length of more than 100 mu m. In the preparation method, different calcium sources and germanium dioxide are taken as raw materials, and water is taken as a solvent, wherein the calcium sources are calcium acetate, calcium chloride or nitrate of lime; a molar ratio of calcium to germanium in the raw materials is 2:1; the preparation method comprises the following steps of: putting the germanium dioxide and the calcium-containing raw material into a stirrer, and adding the water and stirring; and placing mixed solution obtained after stirring into a sealed container, and then preserving the heat for 1 to 24 hours at the temperature of between 100 and 200 DEG C to obtain a white fluffy product, namely the calcium germinate nanowire. In the invention, the nontoxic germanium dioxide and the different calcium sources are used, and the water is taken as the solvent, so that the raw materials and the preparation process do not pollute the environment, and the preparation method accords with a development direction of the modern industry with the environmental-friendly requirement, and can realize environmental-friendly mass preparation for the calcium germinate nanowire.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for recovering germanium from germanium-containing materials

InactiveCN103952575AEfficient leachingImprove solubilityProcess efficiency improvementStrong acidsHydrometallurgy

The invention relates to a method for recovering germanium from germanium-containing materials, particularly relates to a method for recovering germanium from germanium-containing materials of non-ferrous smelting industry, and belongs to the technical field of hydrometallurgy. The method comprises the steps of leaching germanium-containing materials as raw materials of which the particle sizes are 100 meshes with inorganic strong acid as an leaching agent of which the concentration is 50-120g / L and an aid-leaching agent at 35-95 DEG C and filtering to obtain a germanium-containing leaching solution, adjusting the pH value of the germanium-containing leaching solution to be 6-9, stirring and carrying out liquid-solid separation to obtain germanium residues, and calcining the germanium residues at 350-500 DEG C to obtain a crude germanium dioxide product, wherein the aid-leaching agent is one of tartaric acid, water-soluble tartrate, citric acid, water-soluble citrate, oxalic acid and water-soluble oxalate. The method disclosed by the invention has the advantages of simple process, easiness in operation, high recovery ratio of germanium, large enrichment ratio, and convenience in industrial production and application.

Owner:CENT SOUTH UNIV

Method for comprehensively recovering various valuable metals from germanium-containing material by wet process

ActiveCN102094128AGood precipitation selectivityHigh recovery rateProcess efficiency improvementTanninZinc

The invention relates to a method for comprehensively recovering various valuable metals from a germanium-containing material by a wet process, belonging to the field of metallurgy of rare metals. The method comprises the following steps: leaching and separating lead slag in the circulation process, recovering germanium dioxide by tannin extract germanium participation, and recovering copper slag and zinc slag from the germanium participation waste liquor. The method provided by the invention can comprehensively and effectively recover valuable elements, such as lead, zinc, copper and germanium, and the technological process is stable and convenient to control; the invention effectively solves the problem of environmental pollution, and the recovery rate of germanium is up to 90% or above.

Owner:郴州雄风环保科技有限公司

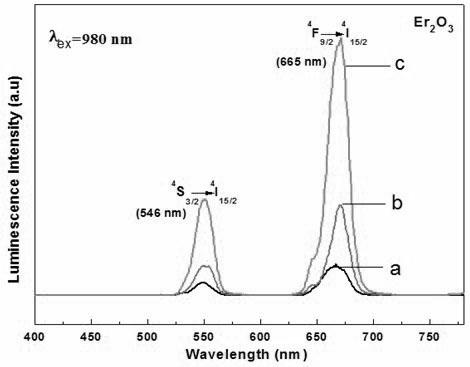

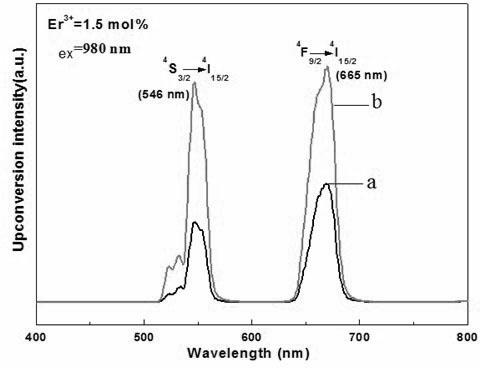

Preparation method of rare earth ion doped tungsten oxygen fluoride silicate up-converted luminescent glass

The invention discloses a preparation method of rare earth ion doped tungsten oxygen fluoride silicate up-converted luminescent glass. The preparation method comprises the steps of: firstly, uniformly mixing silicon dioxide, germanium dioxide, aluminum oxide, tungsten oxide, calcium fluoride, titanium dioxide and rare earth oxide in a mortar; and then preparing the Er<3+>-Yb<3+> rare earth ions doped tungsten oxygen fluoride silicate up-converted luminescent glass by adopting a high-temperature melting annealing method. The method disclosed by the invention is simple in preparation method, low in raw material cost and simple in required device without a special device; and the overall preparation process is carried out in air atmosphere. According to the invention, tungsten oxide is introduced into an oxygen fluoride silicate glass substrate for the first time, and the further solution of the problems that the oxygen fluoride silicate glass is poor in chemical stability and mechanical strength after tungsten oxide is introduced is facilitated, so that the glass product has the advantages of low phonon energy of fluoride and good crystallization stability of oxide, thereby obtaining strong up-converted red and green light output visible to naked eyes.

Owner:ZHEJIANG UNIV

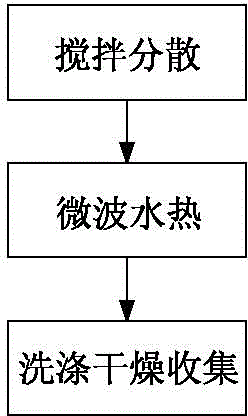

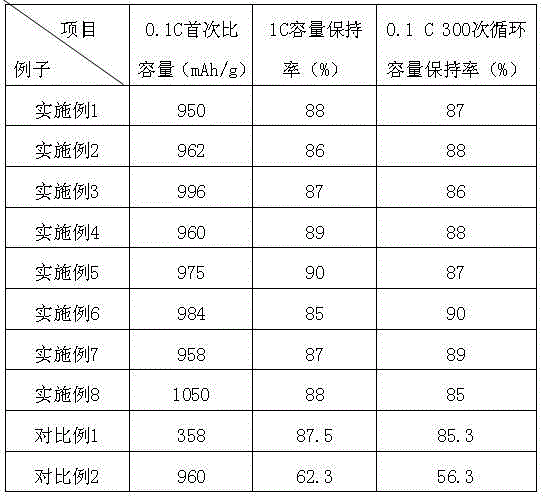

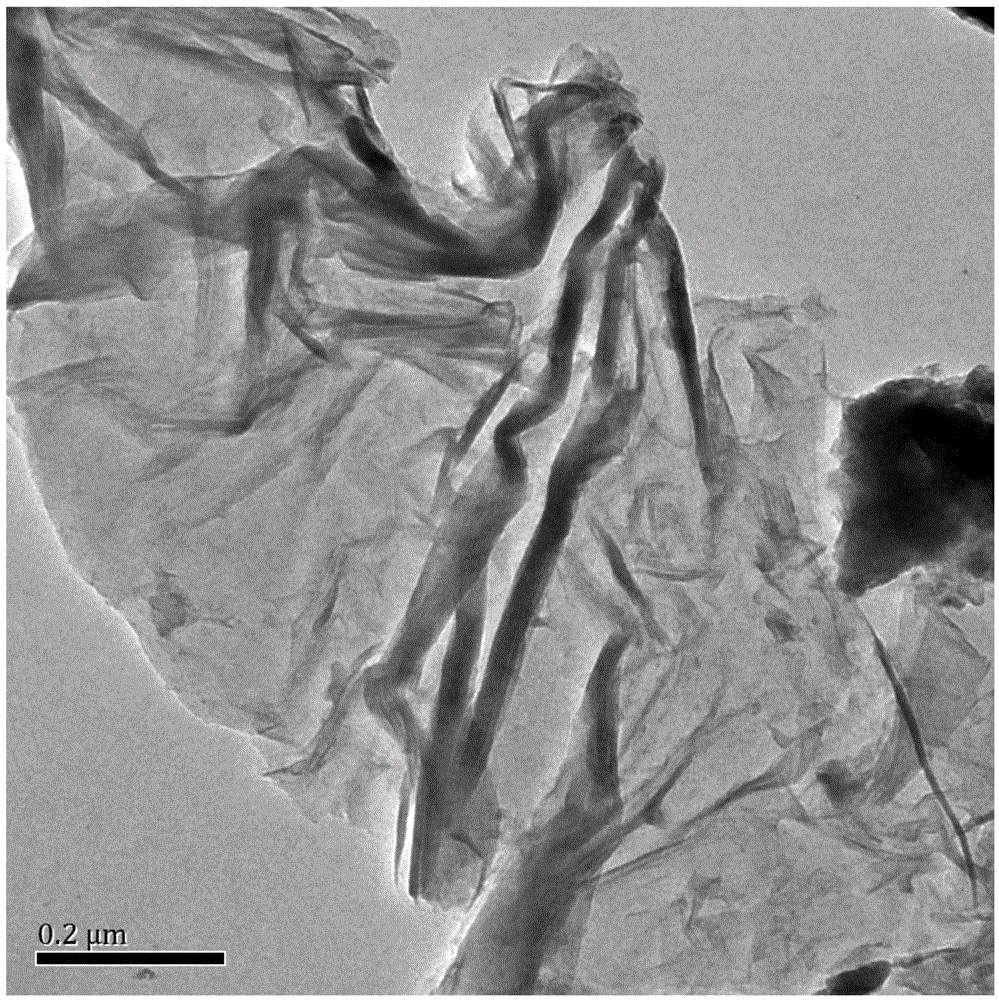

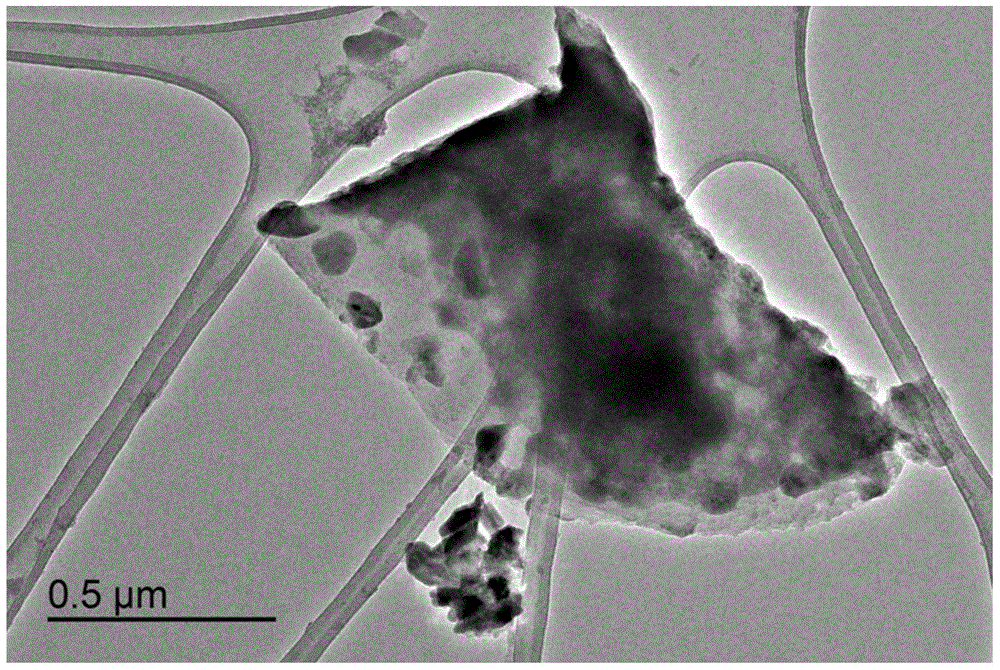

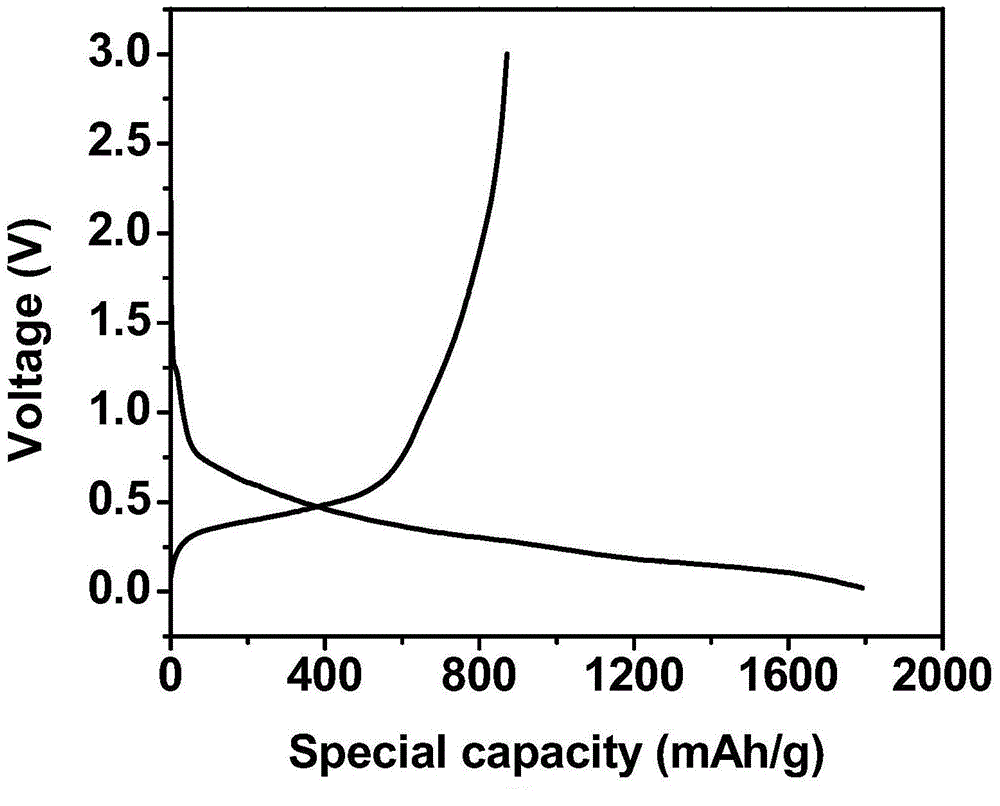

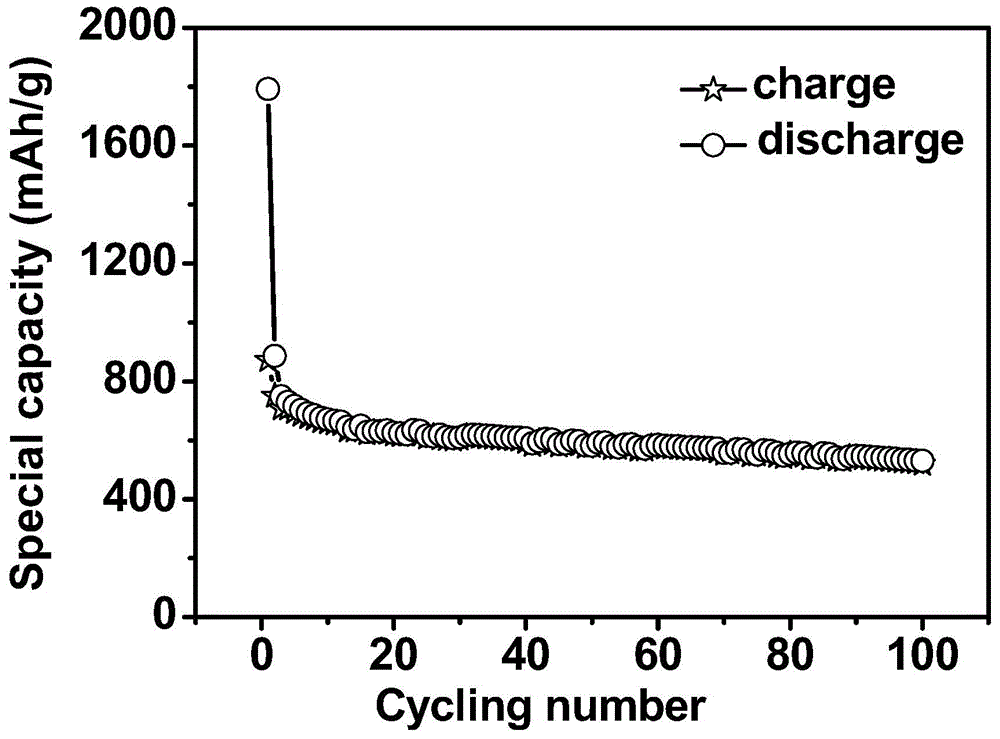

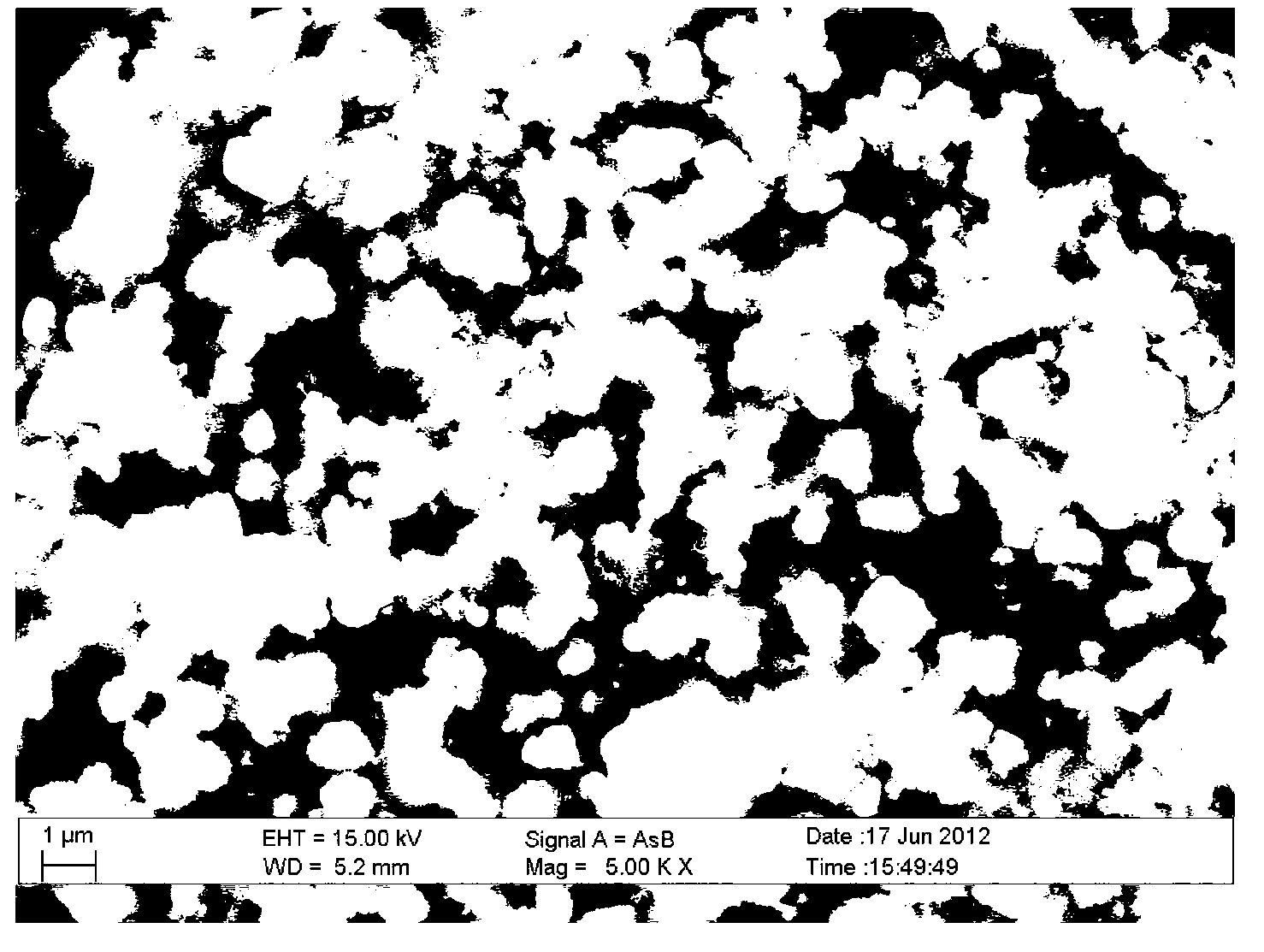

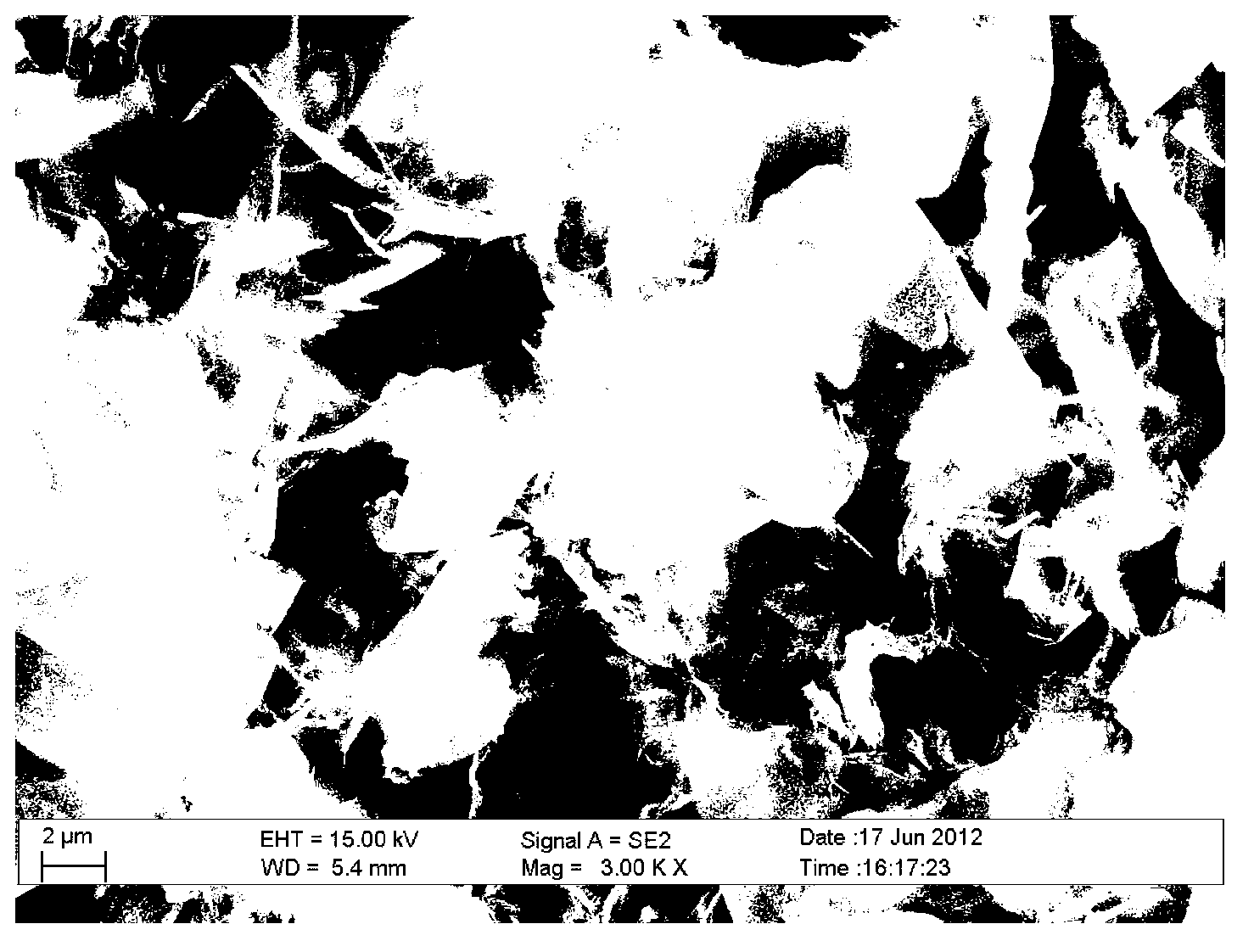

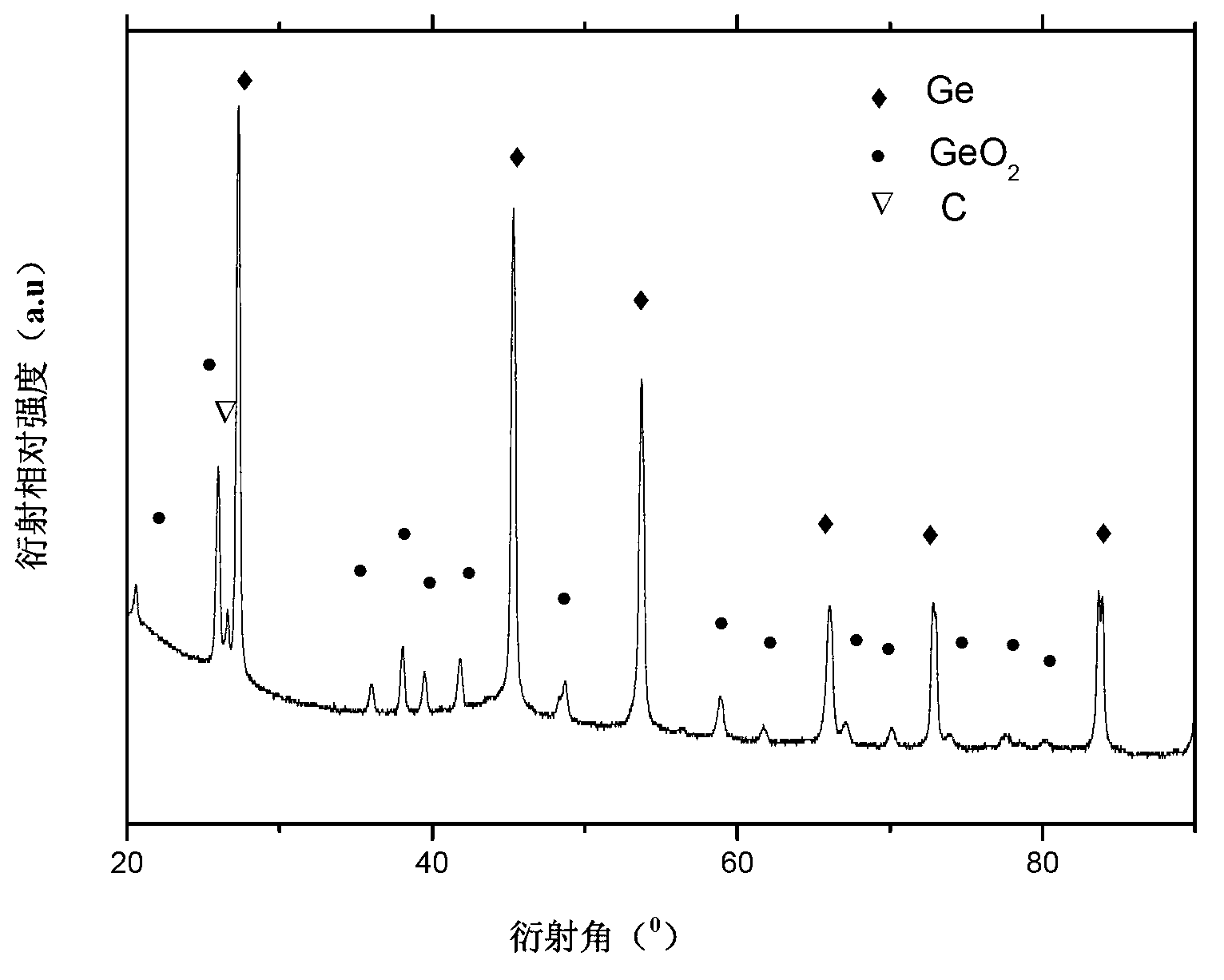

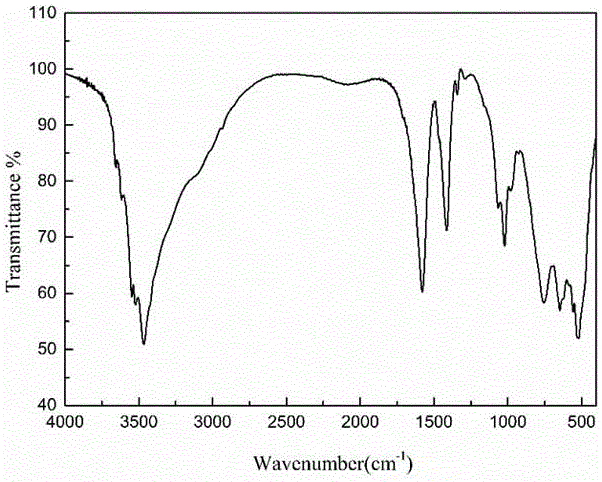

Germanium-graphene composite cathode material for lithium ion battery and preparation method thereof

InactiveCN104466104AHigh bonding strengthIncrease capacityCell electrodesElectrolytesSodium-ion batteryLithium-ion battery

The invention discloses a germanium-graphene composite cathode material for a lithium ion battery and a preparation method of the germanium-graphene composite cathode material. The composite cathode material is prepared from germanium particles and grapheme through compounding, wherein the nano germanium particles are uniformly distributed in a grapheme sheet layer to form a grapheme network cladded three-dimensional net structure. The preparation method comprises the following steps: (1) stirring and dispersing; (2) carrying out microwave hydrothermal; and (3) washing, drying and collecting. According to the germanium-graphene composite cathode material for the lithium ion battery and the preparation method of the germanium-graphene composite cathode material, germanium and germanium dioxide are re-crystallized and grow on the graphene in situ, the bonding strength of the germanium and the grapheme is higher than that of germanium-graphene composite material obtained through mixing simply, the electrical conductivity of the grapheme network is fully exerted, and the volume effect of the germanium is effectively inhibited. The germanium-graphene composite cathode material for the lithium ion battery has the characteristics of high capacity, high magnification and excellent cycling stability, the preparation process adopts simple and effective microwave hydrothermal reaction, the process is simple, the energy consumption is low, the yield is high, no pollution is caused, the germanium-graphene composite cathode material can be promoted and applied conveniently and is suitable for large-scale production.

Owner:东莞市翔丰华电池材料有限公司

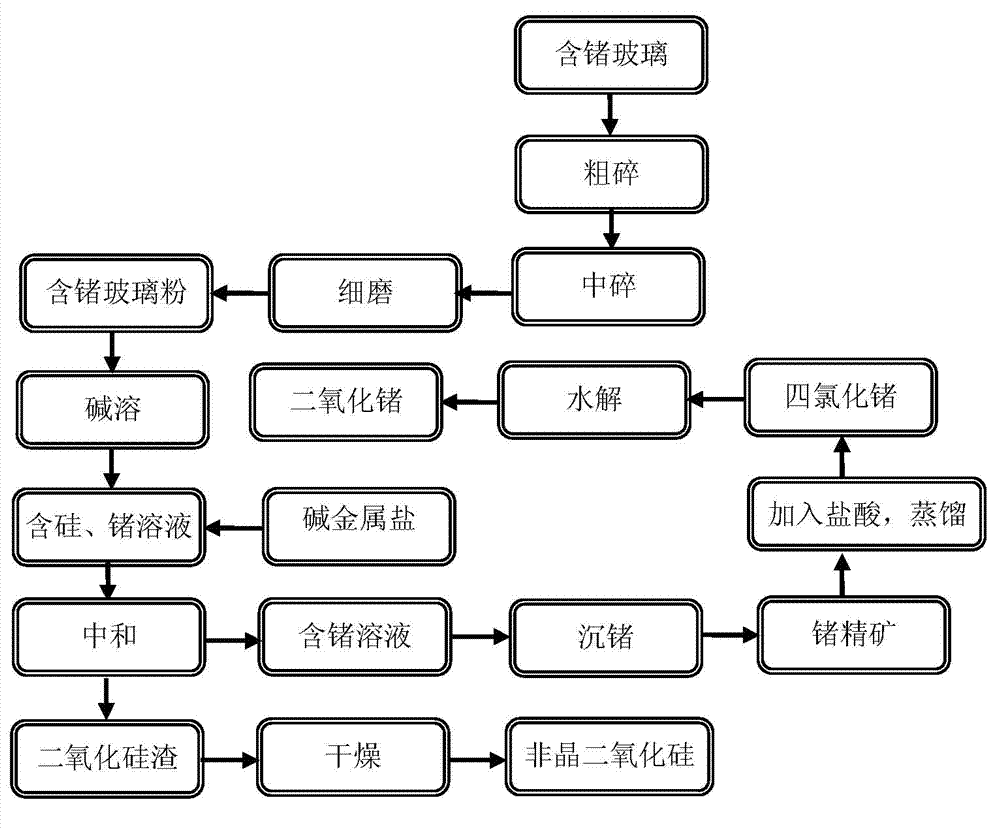

Method for recycling germanium from germanium-containing glass

The invention discloses a method for recycling germanium from germanium-containing glass, which comprises the following steps: 1) pulverizing germanium-containing glass into germanium-containing glass powder, adding an alkali solution into the germanium-containing glass powder, heating to 120-300 DEG C, and keeping the temperature for 1-10 hours to obtain a water solution containing sodium silicate and sodium germanate; 2) adding an alkali metal salt into the water solution containing sodium silicate and sodium germanate obtained in the step 1), regulating the pH value to 6-9, aging, carrying out solid-liquid separation, drying the solid to obtain amorphous silicon dioxide, and recycling; 3) adding magnesium chloride into the solution obtained by solid-liquid separation in the step 2) to obtain a precipitate containing magnesium germanate; and 4) mixing the precipitate containing magnesium germanate with hydrochloric acid, carrying out chlorination distillation, condensing to collect germanium tetrachloride, and hydrolyzing the germanium tetrachloride to obtain germanium dioxide. The method abandons the pyrogenic process for recycling high-silicon germanium-containing waste, lowers the energy consumption, reduces the environmental pollution, and has the advantages of simple technique, high germanium recycling rate and low recycling cost.

Owner:湖北拓材再生资源有限公司

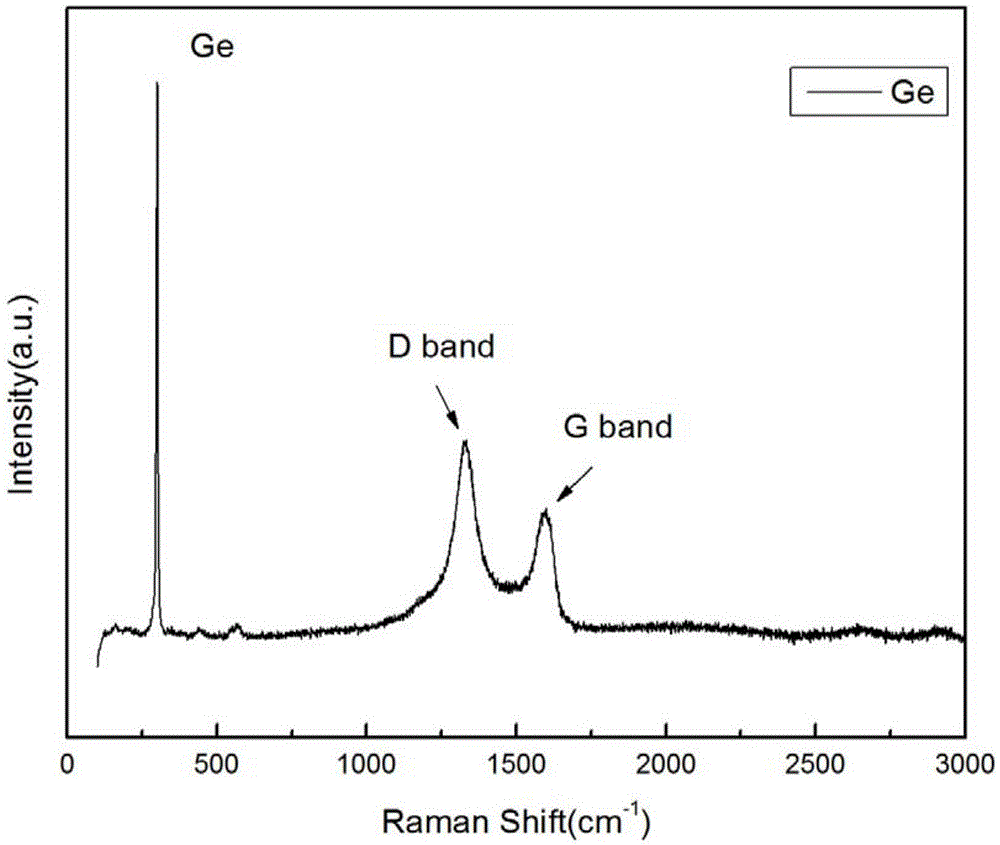

Preparation method of germanium nano-particle/multi-layer graphite compound-based high-performance anode material for lithium-ion battery

ActiveCN105529442AGood biocompatibilityEnables high-volume synthesisMaterial nanotechnologyCell electrodesElectric capacityChemical preparation

The invention provides a preparation method of a germanium nano-particle / multi-layer graphite compound-based high-performance anode material for a lithium-ion battery. By a common water solution method, germanium nano-particles are formed by reducing germanium dioxide, and are compounded with a multi-layer graphite material to prepare a nontoxic nano germanium / multi-layer graphite composite material, so that the nontoxic nano germanium / multi-layer graphite composite material is applied to the anode material for the lithium-ion battery and demonstrates excellent electrochemical properties. According to the preparation method provided by the invention, a high-quality germanium nano-particle / multi-layer graphite compound is obtained for the first time. Compared with other physical or chemical methods, the experimental operation is simpler and more convenient; a fussy chemical preparation process is not needed; meanwhile, the prepared composite material is high in purity and free of an oxidation layer; and the electric capacity of the lithium-ion battery can be greatly improved.

Owner:QUANZHOU NORMAL UNIV

Additive for mushroom rich in selenium

This invention relates to a selenium-rich additive for Lentinus edodes. The additive is rich in Se, Ge and K, and is prepared by mixing sodium selenite, germanium dioxide, potassium dihydrogen phosphate and water. The additive can promote Lentinus edodes growth, improve stress resistance, and increase Lentinus edodes yield and selenium content. The additive is good for health, and can prevent cancer, endemic goiter, diabetes, etc. Besides, the additive also has such advantages as no toxicity, no pollution, obvious yield increase effect, and convenient application.

Owner:FUHAI FARM PRODS LUOYANG

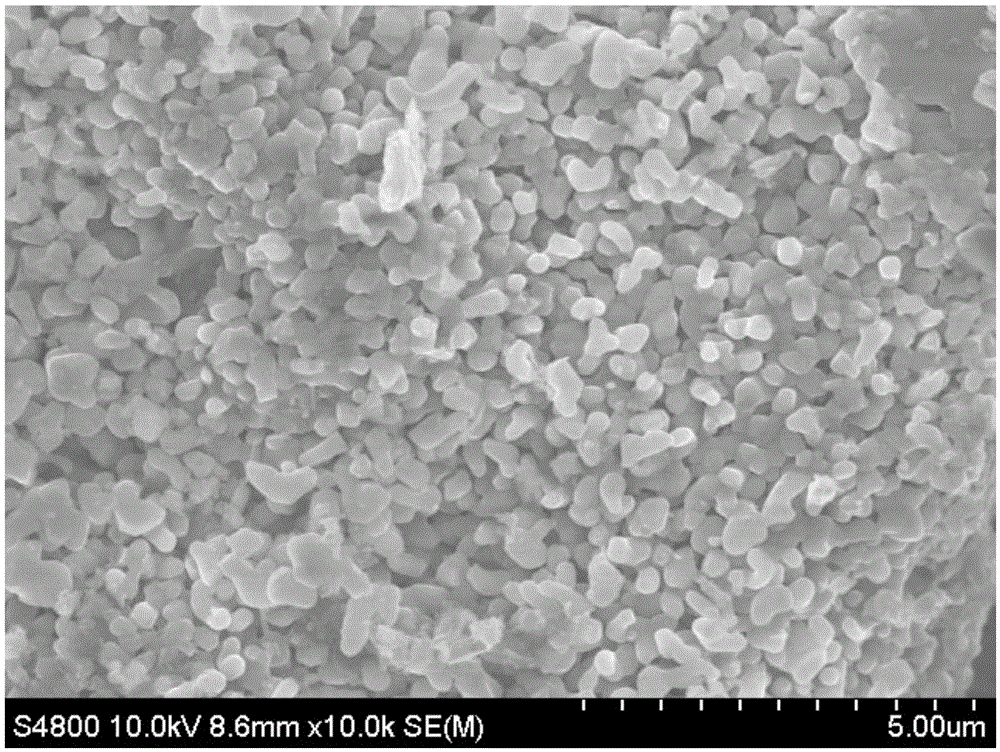

Germanium/carbon composite negative electrode material and preparation method thereof

InactiveCN104659346AImprove conductivityIncreased rate capacityNegative electrodesCarbon compositesHydrogen atmosphere

The invention discloses a germanium / carbon composite negative electrode material and a preparation method thereof. The preparation method comprises the steps of carrying out ball milling and mixing on germanium dioxide and polyvinylpyrrolidone, annealing at a hydrogen atmosphere in the presence of argon, so as to prepare the germanium / carbon composite negative electrode material. When being used as a negative electrode material of a lithium ion battery, the germanium / carbon composite negative electrode material has the characteristics of good cycling stability and high multiplying power capacity.

Owner:SHENZHEN CAPCHEM TECH

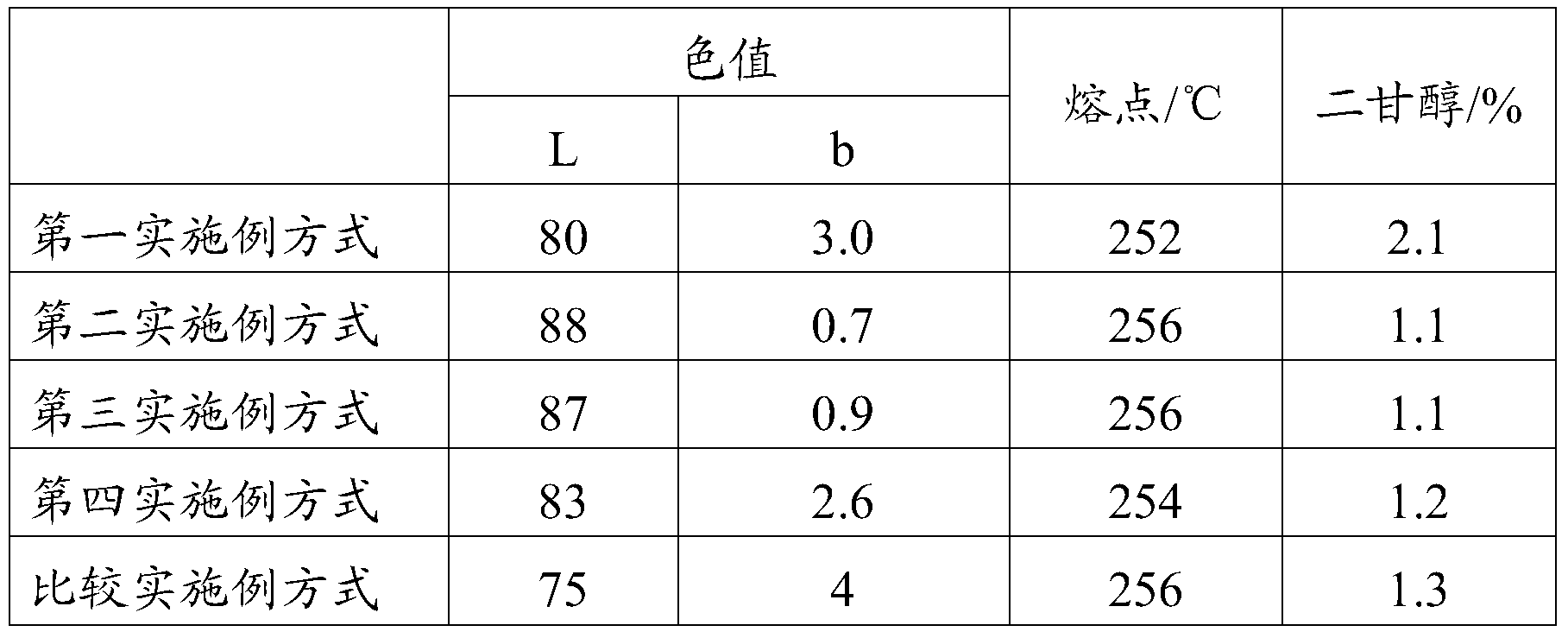

Preparation method of polyester substance, polyester substance, polyester chip and polyester film

The invention specifically discloses a preparation method of a polyester substance, the polyester substance, a polyester chip and a polyester film. The preparation method comprises the following operation steps of: a) mixing an acid component with an alcohol component, and performing esterification reaction or transesterification to obtain an ester; b) performing condensation polymerization to the ester obtained in the step a) under the effect of a catalytic system; and c) obtaining the polyester substance from the step b), wherein the catalytic system adopts a germanium dioxide catalyst, and the germanium dioxide is in form of a tetragonal crystal or a hexagonal crystal or is in an amorphous state. The polyester substance, polyester chip and polyester film prepared by the preparation method have low chromatic value b, high degree of purity and other outstanding characteristics, and are specifically suitable for being used for preparing an optical thin-film with high performance requirement.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Germanium-carbon-graphene composite material, and preparation method and application thereof

The invention discloses a germanium-carbon-graphene composite material which is compounded from nano germanium. germanium dioxide, flocculent carbon and reduction-oxidation graphene, wherein the germanium dioxide is coated on the surface layer of the germanium to form a core shell, thereby forming nano core-shell particles; and the nano core-shell particles are uniformly dispersed and distributed in the flocculent carbon, and coated by the reduction-oxidation graphene network. The invention also discloses a preparation method and application of the germanium-carbon-graphene composite material. The germanium-carbon-graphene composite material disclosed by the invention has the characteristics of high capacity, high ratio and high loop stability, and has the advantages of simple preparation technique, low energy consumption, high yield and no pollution.

Owner:SOUTH CHINA UNIV OF TECH

Special optical polyester synthesis catalyst and preparation method and application thereof

The invention discloses a special optical polyester synthesis catalyst. The special optical polyester synthesis catalyst is formed by gamma-A100H and a catalyst promoter by mass of 1:10-9:10 and is a combination of one or multiple of ethylene glycol antimony, antimonous oxide, antimony acetate, tetrabutyl titanate and germanium dioxide. The invention further discloses a preparation method and application of the catalyst. Polyester synthesized by the obtained special optical polyester synthesis catalyst is good in optical performance, low in diethylene glycol and carboxyl-terminated content and applicable to manufacture of optical polyester films.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com